Apparatus for realizing surplus sludge disposal and membrane filtration through coupled single-chamber inclined-plate multi-positive-electrode microbial fuel cell

A fuel cell and excess sludge technology, applied in the field of environmental engineering, can solve the problems of reducing water production efficiency, unsatisfactory water quality, increasing operation complexity, etc., to reduce membrane pollution, high application potential and practical value, and solve the problem of water The effect of poor water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

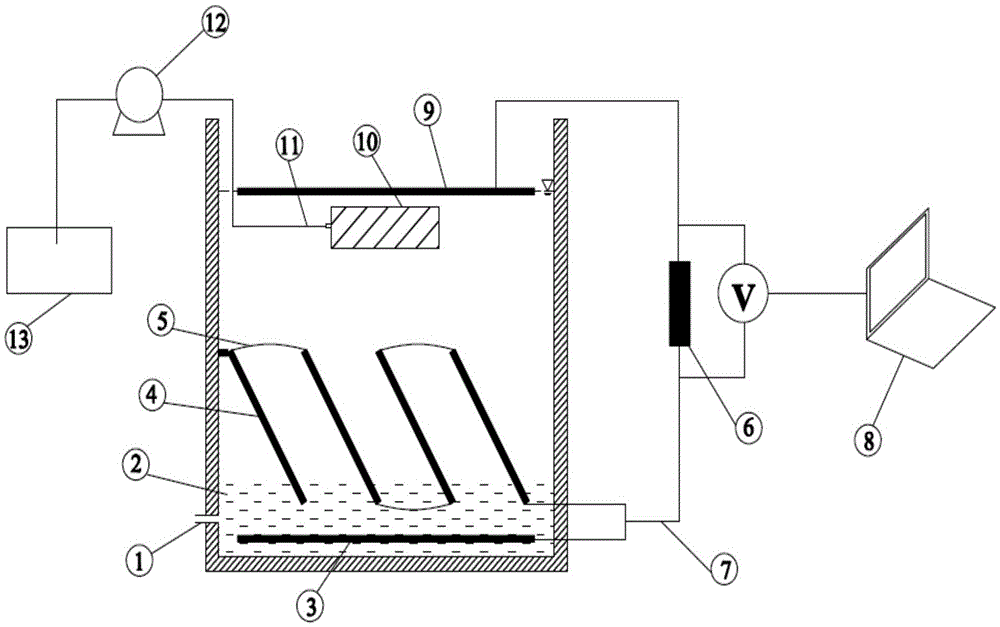

[0022] A membrane separation coupled single-chamber inclined plate multi-anode residual sludge microbial fuel cell. The simulation device is 226mm long, 200mm wide, and 250mm high. There is anaerobic sludge in the anaerobic zone at the bottom, and the top is directly exposed to the air. The anode carbon felt is placed In the sludge in the anaerobic zone, the length is 200mm, the width is 180mm, and the area is 360cm 2 . Inclined plate anode carbon felt, length 200mm, width 100mm, a total of four inclined plates are placed in the middle of the device at 60°, the horizontal spacing is 50mm, and the vertical spacing is 43mm. The hollow fiber membrane module is placed in the supernatant liquid. Above the membrane module, a carbon felt cathode is placed on the liquid surface, which is exposed to the air as an air cathode. The length is 200mm, the width is 90mm, and the effective area is 180cm. 2 .

[0023] Activated sludge enters the sludge 2 in the anaerobic zone from the bottom slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com