Gating system sprue combined device for full mold casting and using method of gating system sprue combined device

A pouring system and solid casting technology, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of increased energy consumption of sprues, sand flushing on the bottom of castings, and cumbersome operation process, so as to improve production efficiency, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

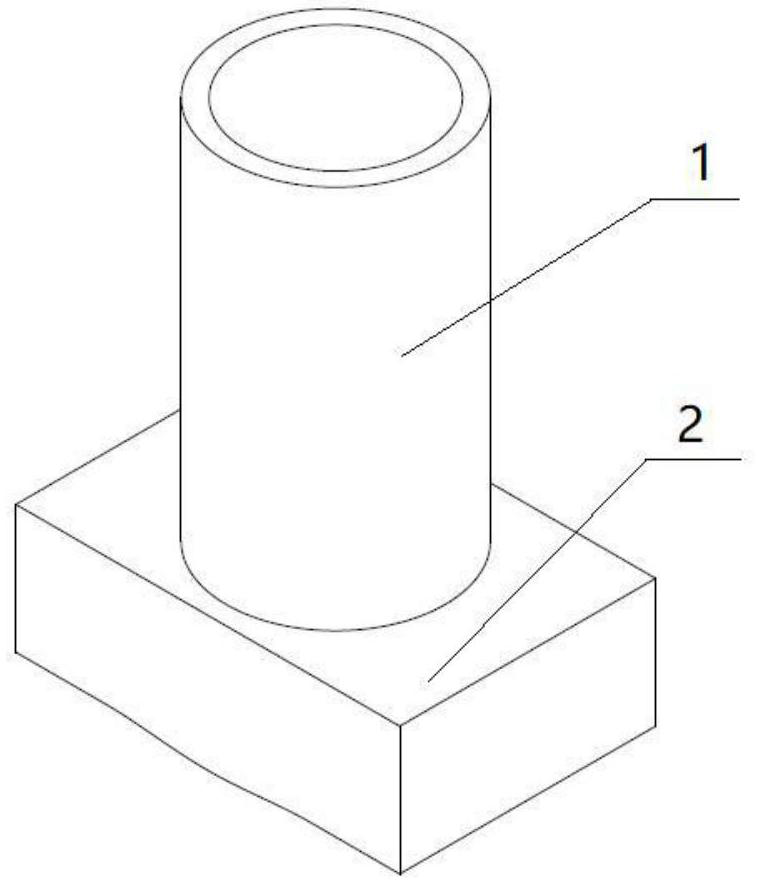

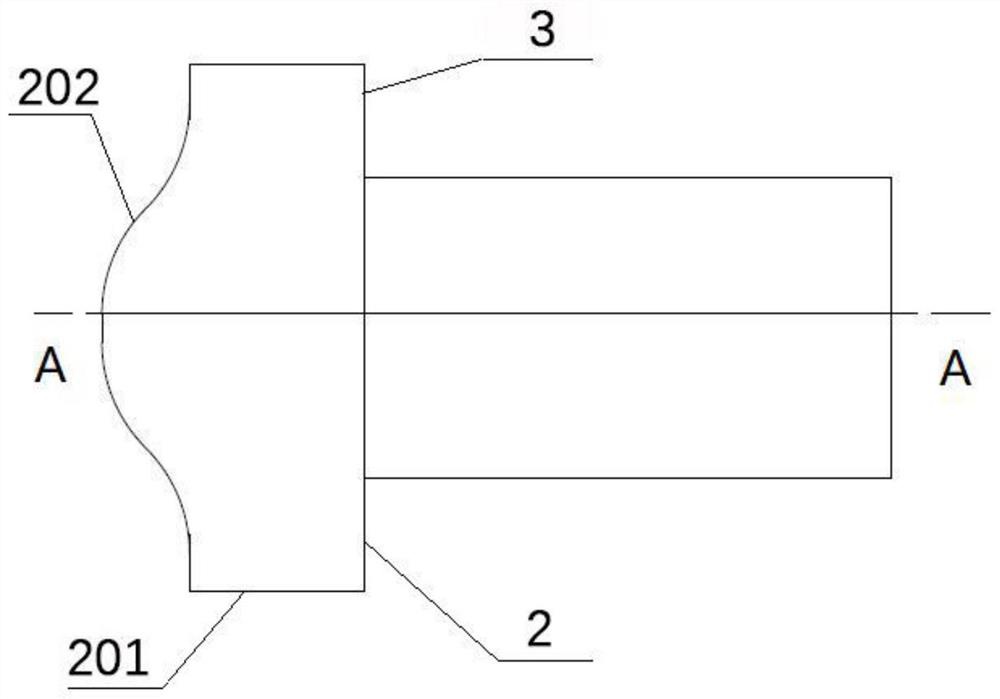

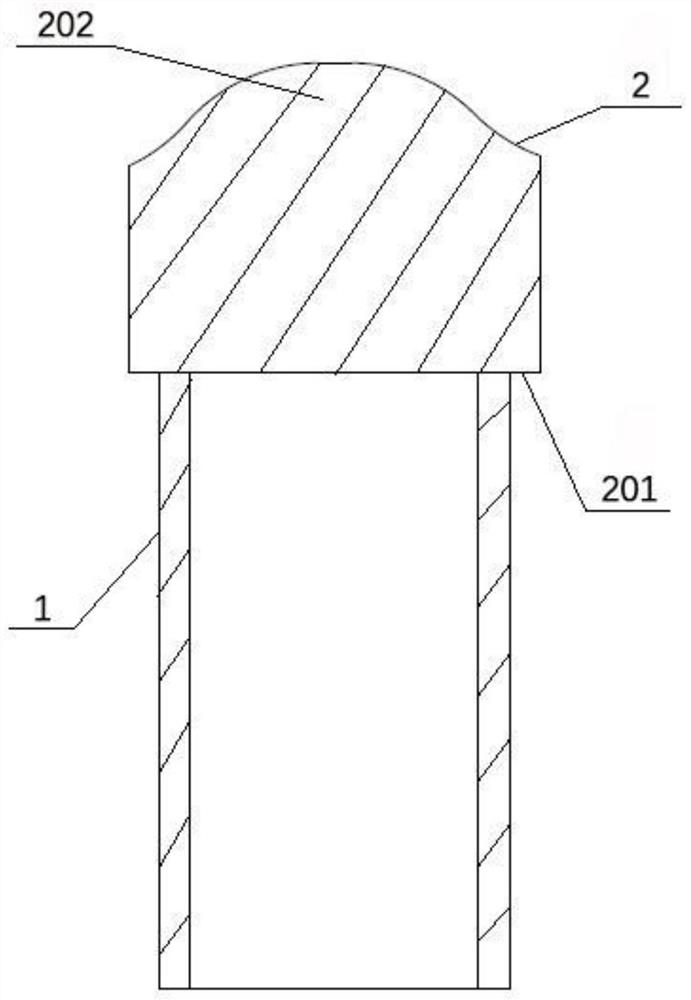

[0028] A sprue combination device for a pouring system for full mold casting, characterized in that it includes a sprue 1, a sprue seat 2 and a paint layer 3;

[0029] The sprue 1 is a circular tubular structure of high-temperature refractory ceramics, and the size of the sprue is selected according to the process requirements during use;

[0030] The sprue seat 2 is integrally formed, including a base 201 and a buffer protrusion 202;

[0031] Wherein the base body 201 is in the shape of a cuboid, and the buffer protrusion 202 is arranged on the base body 201;

[0032] The sprue 1 is connected to the sprue seat 2, and the connection surface is opposite to the surface provided with the buffer protrusion 202;

[0033] Wherein the sprue 1 and the sprue seat 2 are connected by a paint layer 3 on the outer wall;

[0034] The sprue seat 2 is made of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com