Light slurry for shield synchronous grouting

A synchronous grouting, lightweight technology, applied in the field of materials, can solve problems such as safety accidents, segment floating, loss, etc., to ensure the quality of the project, reduce the loss and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In terms of parts by weight, the light grout for shield grouting includes 250kg 42.5 grade ordinary silicon cement, 750kg first grade fly ash, 50kg 20 mesh expanded perlite particles (true density less than 0.60), 1.0kg polycarboxylate powder Body water reducing agent, 20kg coagulation agent, 10kg UWB-II type high resistance to dispersion polysaccharide flocculant and 650kg water.

[0026] The bulk density of light grout for shield grouting is 1400kg / m 3 , the initial setting time is 640min, and the final setting time is 800min; it does not disperse or segregate in water; the fluidity of 3h can still maintain 195mm and above; the 3d strength is 0.7MPa, and the 28d is greater than 2.5MPa. When constructing in the hard rock water-rich section , which can effectively prevent the floating phenomenon of segments caused by a large amount of slurry loss.

Embodiment 2~12

[0028] Examples 2-12 are basically the same as Example 1, except that the components of each substance are different, and the specific parameters and performance results are shown in Table 1 and Table 2.

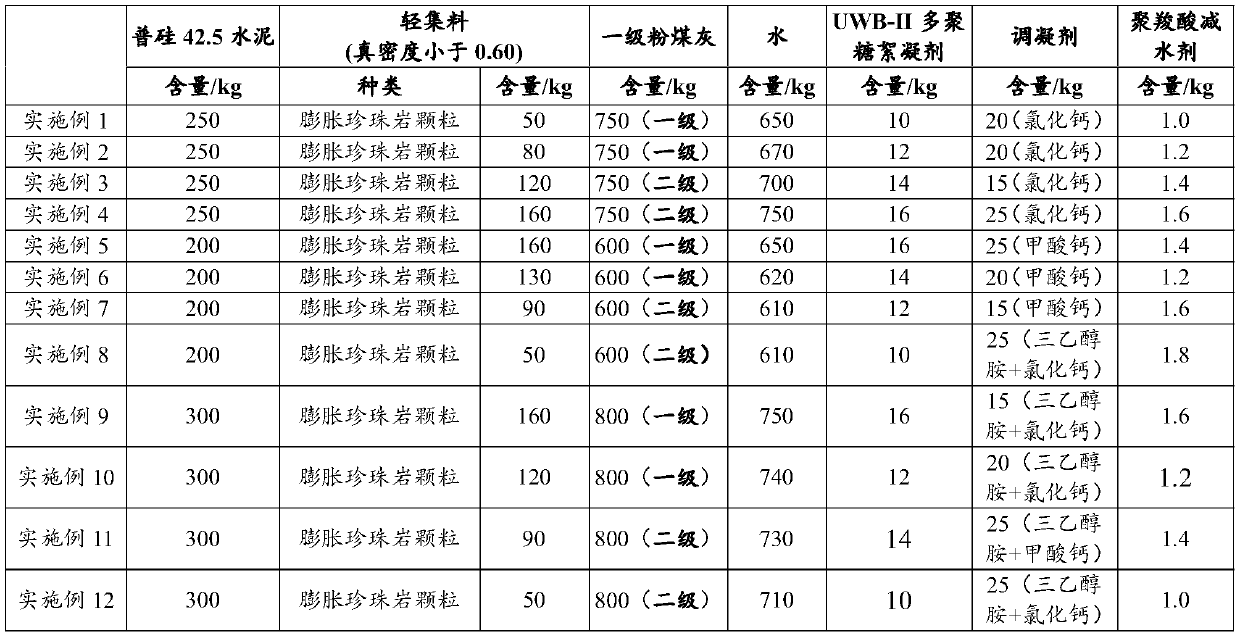

[0029] The composition of each embodiment of light grout for shield tunneling grouting in table 1

[0030]

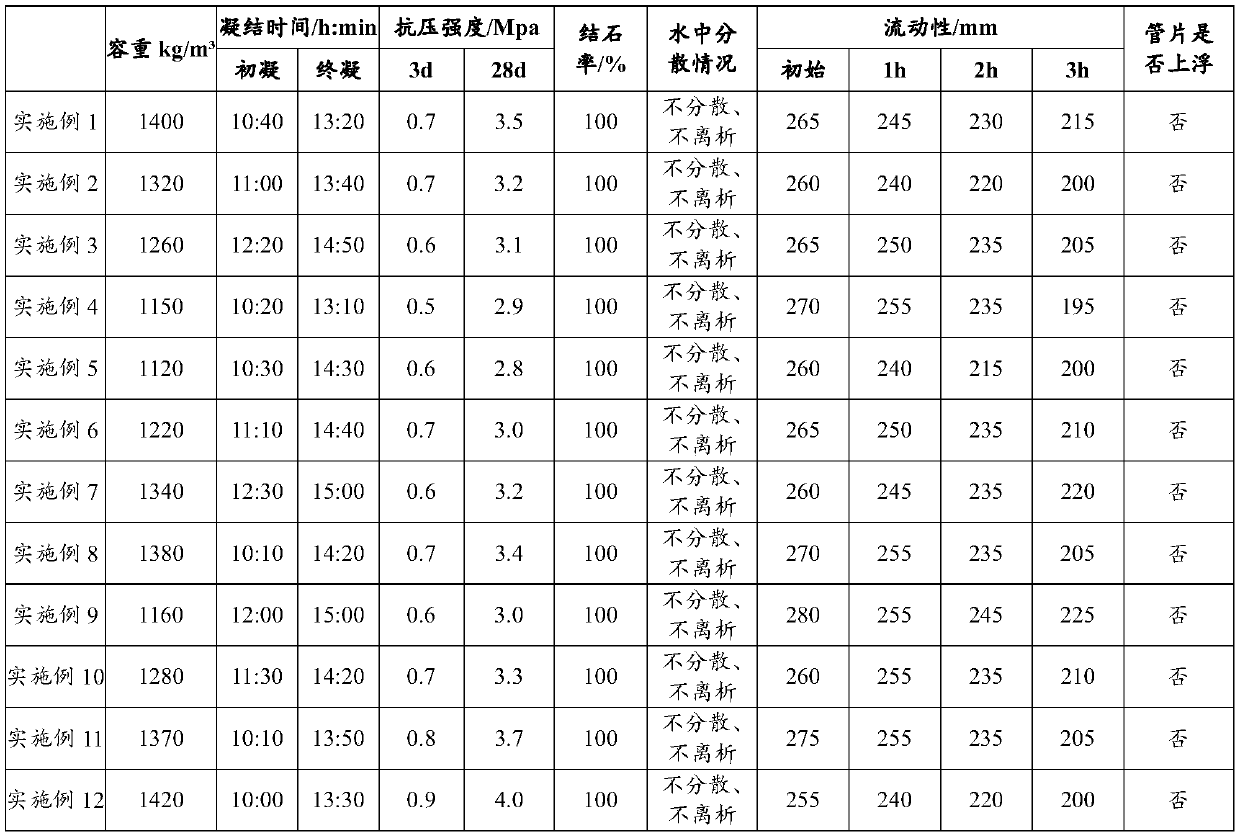

[0031] Table 2 The performance parameters of each embodiment of light grout for shield tunneling grouting

[0032]

[0033] As can be seen from Table 2, the 3d compressive strength of the lightweight slurry in water for shield tunneling grouting of the present invention can reach more than 0.5MPa, and the bulk density is 1120kg / m 3 ~1420kg / m 3 , The 3h flow performance remains above 195mm, which can meet the requirements of the synchronous grouting pump for the fluidity of the slurry. At the same time, it does not disperse, segregate, and bleed in water, and the stone rate is 100%.

[0034] Compared with the prior art, the lightweight grout for shield grouting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com