Patents

Literature

135results about How to "Solve floating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

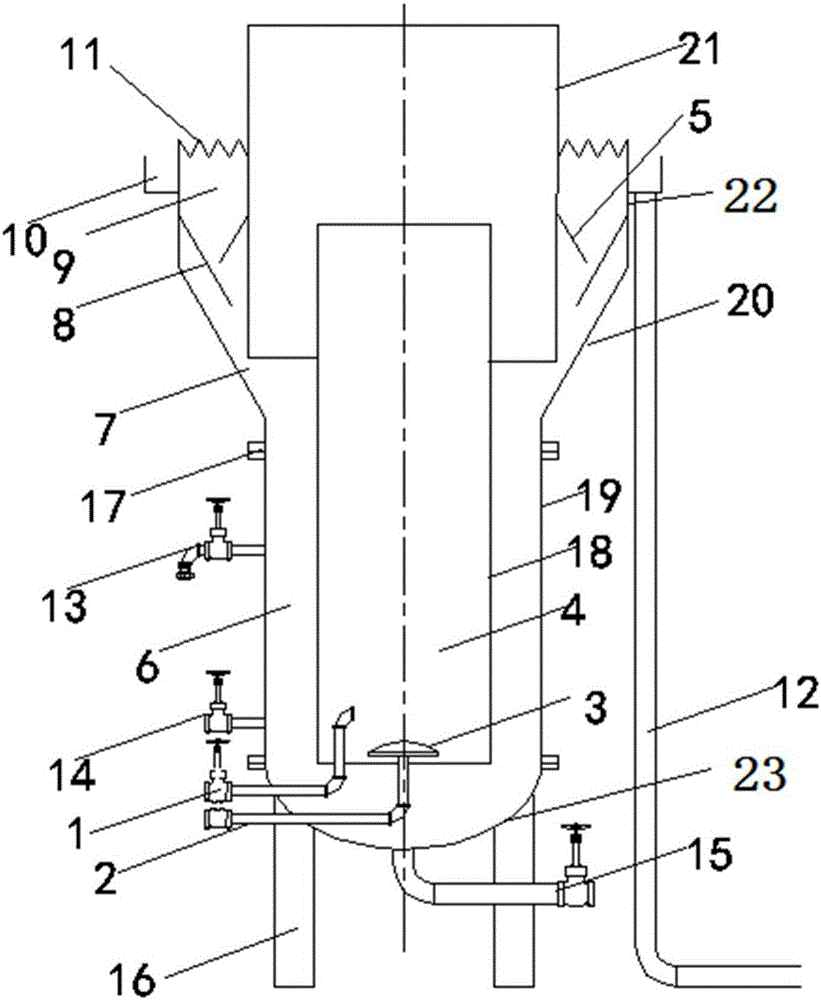

Method and device for recycling edible mushroom residues

ActiveCN102174586AImprove filtration efficiencyIncrease gas productionBioreactor/fermenter combinationsBiological substance pretreatmentsRed mudNew energy

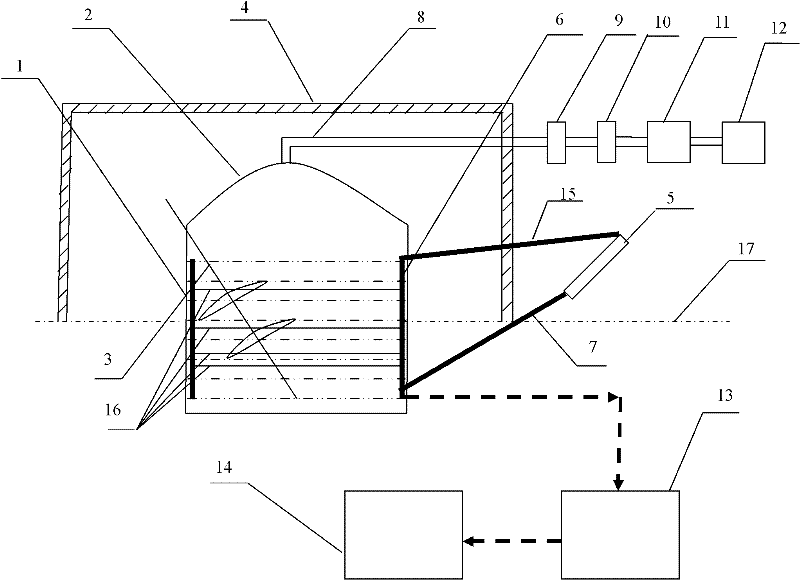

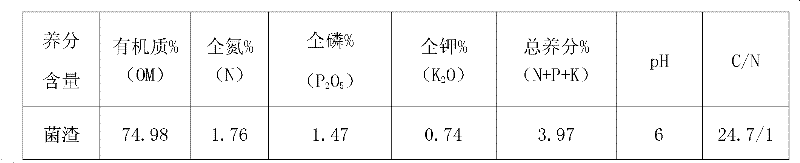

The invention relates to a method and device for recycling edible mushroom residues. The method mainly comprises the steps of placing waste mushroom residues and maize straws or excrements from a cattle farm into an anaerobic reactor for united fermentation to produce biogas, and covering a red-mud plastic head cover on the anaerobic reactor, wherein an inclined stirrer is arranged and is beneficial to feeding / discharging of mushroom residue raw materials and avoidance of crusting. The produced biogas is used for power generation and agriculture, biogas residues are used for manufacturing organic fertilizers, biogas slurry is prepared into foliar fertilizer for fruits or vegetables, and thus, new energy sources, namely the biogas and the organic fertilizers, are obtained while the mushroom residues are treated. The method and the device in the invention are mainly used in major edible mushroom producing areas, a solar-panel greenhouse and a solar heat supply device are assorted for the device, a composite microbial inoculum is assorted for the method, and the anaerobic reactor can be normally used all the year round.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

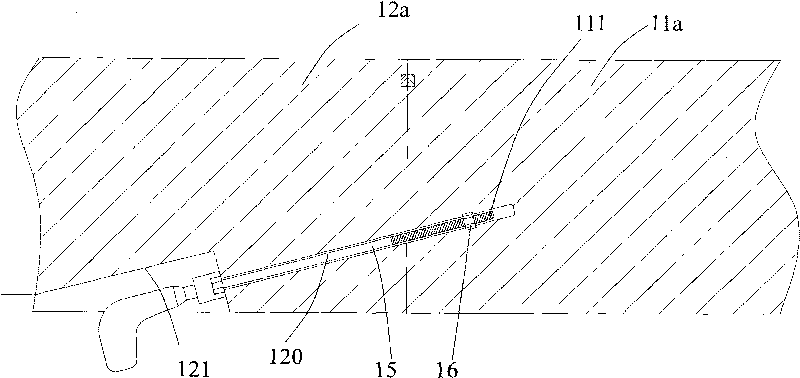

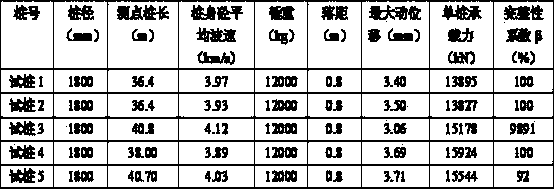

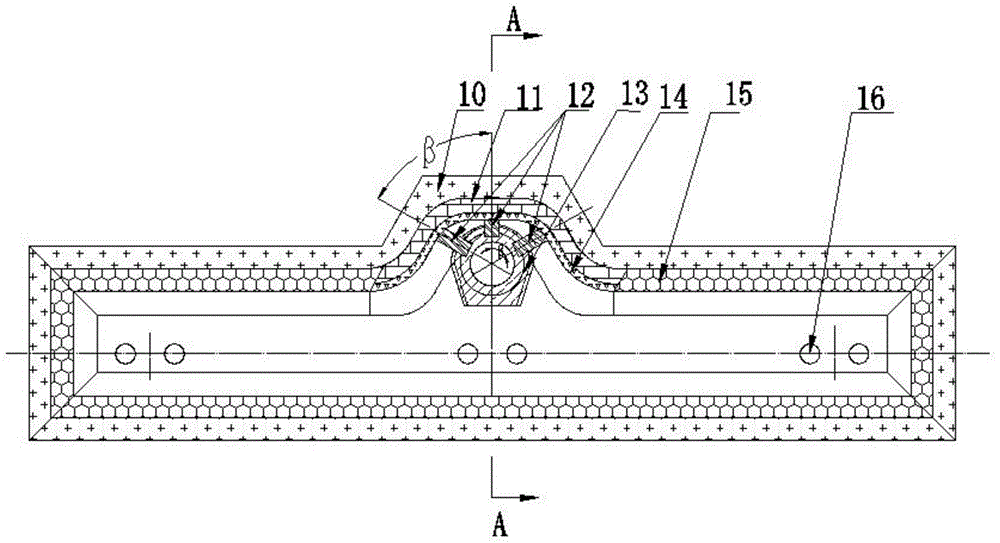

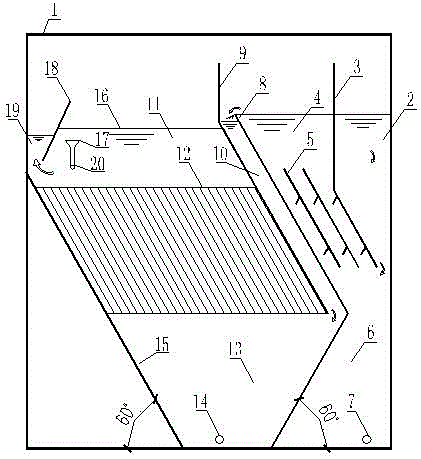

Method for controlling quality of tunnel pipe sheet built by using shield method and pipe sheet structure

ActiveCN101705829AHigh precisionImprove efficiencyUnderground chambersTunnel liningVehicle frameQuality control

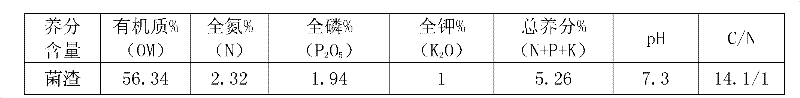

The invention provides a method for controlling the quality of a tunnel pipe sheet built by using a shield method, which comprises the steps of pipe sheet structure design, pipe sheet construction detection, pipe sheet assembling quality requirement and tunnel stability control, wherein in the pipe sheet structure design, the water prevention and the bonding strength are improved by the structural design of a connecting way, strength, water prevention, and the like of pipe sheets; in the pipe sheet construction detection, the eight-point measurement is carried out on the pipe sheets in the process of construction, the concentricity relation between the previous ring of pipe sheets and a shield shell is calculated, and the position of the next ring of pipe sheets is selected; in the pipe sheet assembling quality requirement, an assembled ring height difference and a longitudinal joint flare angle are controlled to confirm the assembling quality; and in the tunnel stability control, the floating of the pipe sheets is effectively prevented in a frame weight and synchronous slurry injection matching construction way after assembly. Accordingly, the quality of the pipe sheets is controlled in the whole course from structural design to construction, thereby ensuring the tunnel construction quality.

Owner:SHANGHAI TUNNEL ENG CO LTD

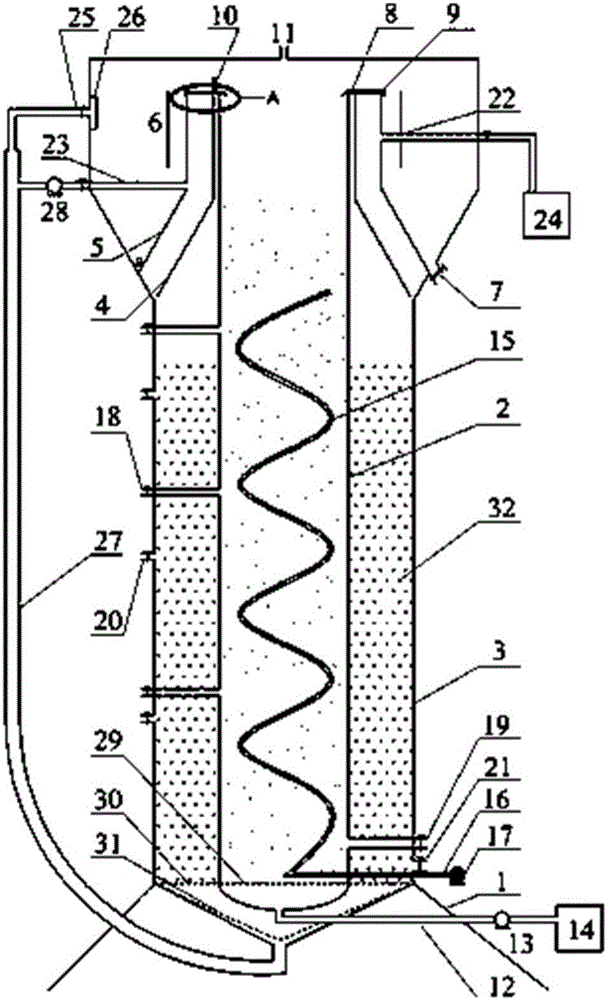

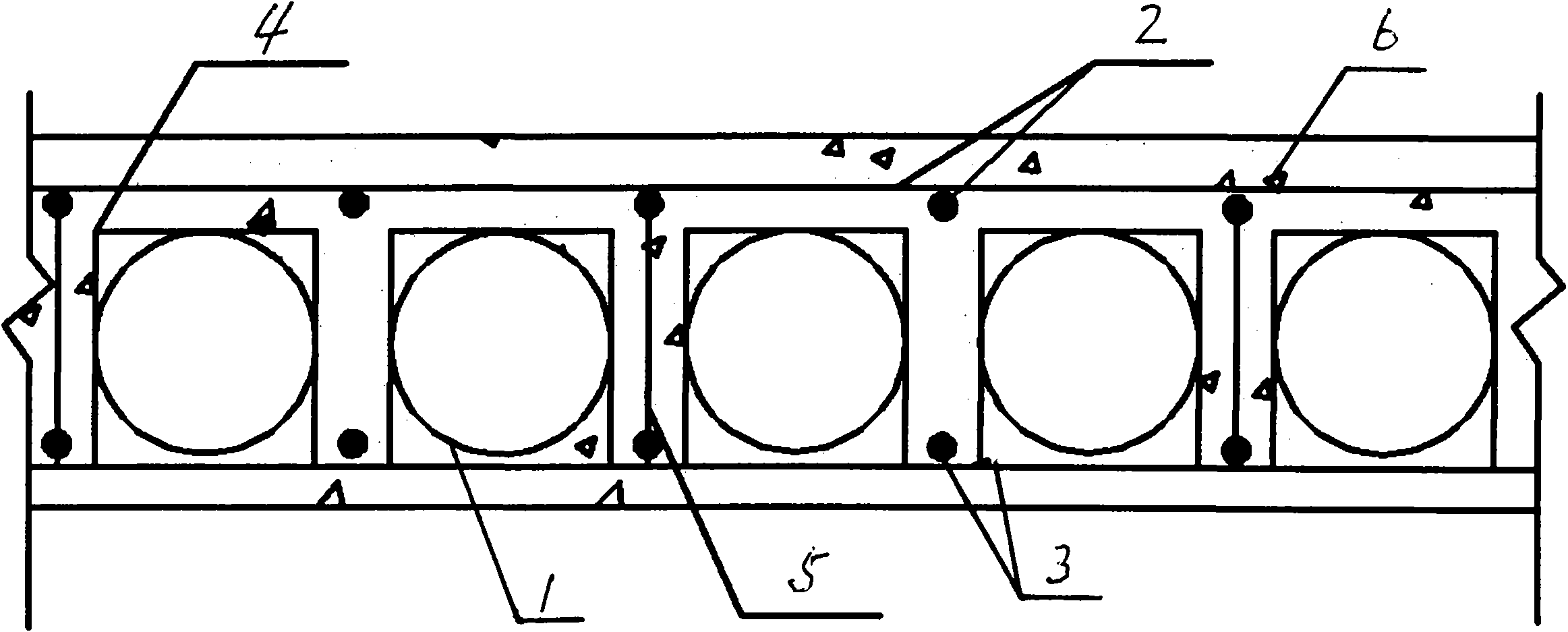

Integrated autotrophic synchronous biological denitrification granulation device

ActiveCN105800787AReduce the difficulty of application promotionPromote growthBiological treatment apparatusTreatment with aerobic and anaerobic processesSludgeEngineering

The invention discloses an integrated autotrophic synchronous biological denitrification granulation device which comprises an outer barrel arranged on a support.An inner barrel is arranged inside the outer barrel, both a water incoming pipe and an air incoming pipe penetrate the undersurface to extend into the inner barrel, the end of the air incoming pipe in the inner barrel is connected with an aeration head, the top of the outer barrel is connected with a sludge backflow slope, a sedimentation barrel is connected above the sludge backflow slope, an overflow weir is arranged at the upper edge of the sedimentation barrel, a water collection tank is arranged outside the sedimentation barrel, an isolation barrel is arranged at the top of the inner barrel in a sleeved manner, a sludge backflow gap is formed between the isolation barrel and the sludge backflow slope, the top of the isolation barrel is higher than the sedimentation barrel, a second gas-water separation annular baffle is connected on the inner wall of the sedimentation barrel, and a first gas-water separation annular baffle is arranged at a position above the second gas-water separation annular baffle and on the outer wall of the isolation barrel.A circulating device does not need to be added externally, so that energy conservation is realized; granular sludge can be cultured under action of self-circulation, and setting performance is good.

Owner:BIOGAS SCI RES INST MIN OF AGRI

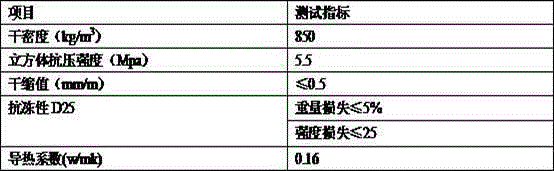

Lightweight wall special-purpose cell concrete, and production method thereof

InactiveCN105272352AReduce shrinkage cracksMaintain good performanceSolid waste managementCeramicwareFiberPolyvinyl alcohol

The invention discloses a lightweight wall special-purpose cell concrete, and a production method thereof. The production method comprises following steps: (1) rapid hardening sulphoaluminate cement, ordinary Portland cement, and dry discharge fly ash are delivered into a double helix conical mixer so as to obtain a composite cementing agent via premixing; (2) water, cold-water-soluble polyvinyl alcohol powder, polypropylene reinforcing fiber, calcium stearate water repellent, a silane coupling agent, expanded perlite, and polyphenyl foam particle are delivered into an agitator; (3) the composite cementing agent obtained via step (1) is delivered into the agitator, and micropore foam prepared from a micropore foaming agent via compressed air is sprayed into the agitator, an uniform slurry is obtained via mixing stirring, and slurry volume weight is controlled to be 1000 to 1200kg / m3; (4) the uniform slurry is pumped into lightweight wall products or cast-in-situ wall forming moulds; and (5) finished products are obtained via curing, hardening, moulding, and demoulding. The lightweight wall special-purpose cell concrete can be used for producing various lightweight wall products and cast-in-situ lightweight concrete walls, and is an ideal material used for producing energy-saving lightweight walls and products.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES +2

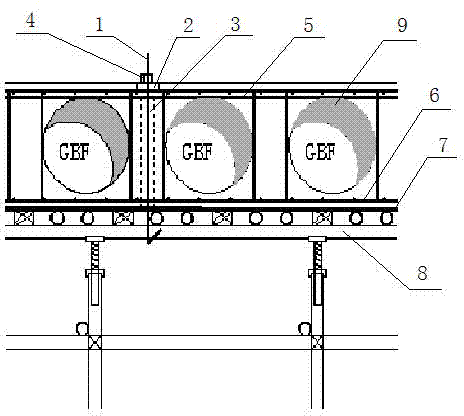

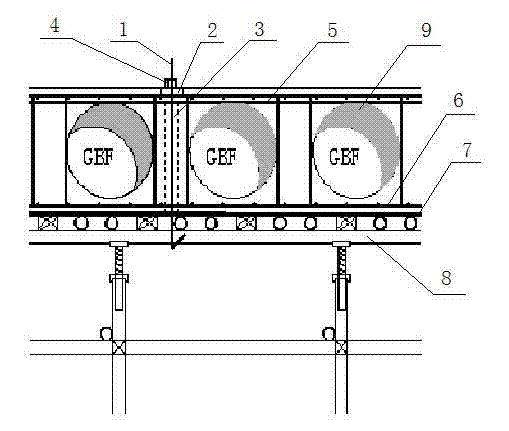

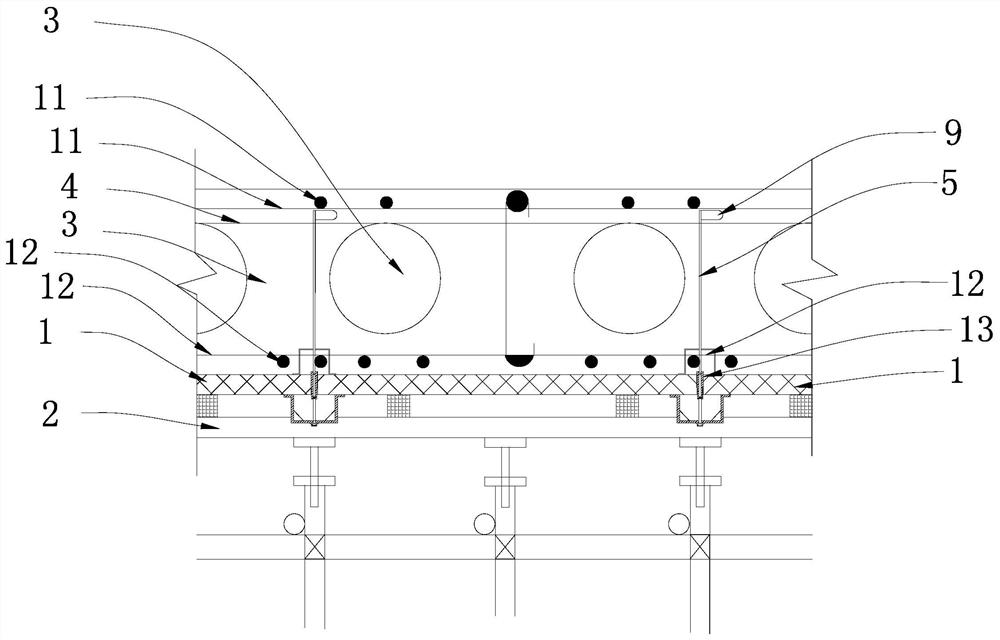

Anti-floating structure for cast-in-place concrete gbf hollow floor slab and method thereof

InactiveCN102296735ASolve the problem of consuming a large amount of iron wirePrevent rustFloorsBuilding material handlingHollow coreRebar

The invention discloses an anti-floating structure and a method thereof during construction of cast-in-situ concrete GBF hollow slabs. The anti-floating structure and method include installing a formwork on a formwork support; arranging GBF thin-walled pipes, punching holes in the formwork according to the vertical and horizontal intervals according to the position of the GBF thin-walled pipes; binding and installing the GBF thin-walled pipes with steel bars; installing PVC sleeves Pipes, hook bolts, and steel backing plates. Tighten the hook bolts and formwork brackets, and compress the steel backing plates and anti-floating steel bars through nuts. After various inspections and acceptances, the concrete is poured in place. Congeal; remove the steel backing plate and hook bolts, and fill the bolt holes with mortar. Adopting the structure and construction method of the present invention can effectively solve the problem of floating of GBF thin-walled pipes during cast-in-place concrete. After the formwork is removed, there is no need for post-processing of exposed wire heads, which saves a lot of wires and avoids easy Rust phenomenon occurs.

Owner:济南四建(集团)有限责任公司

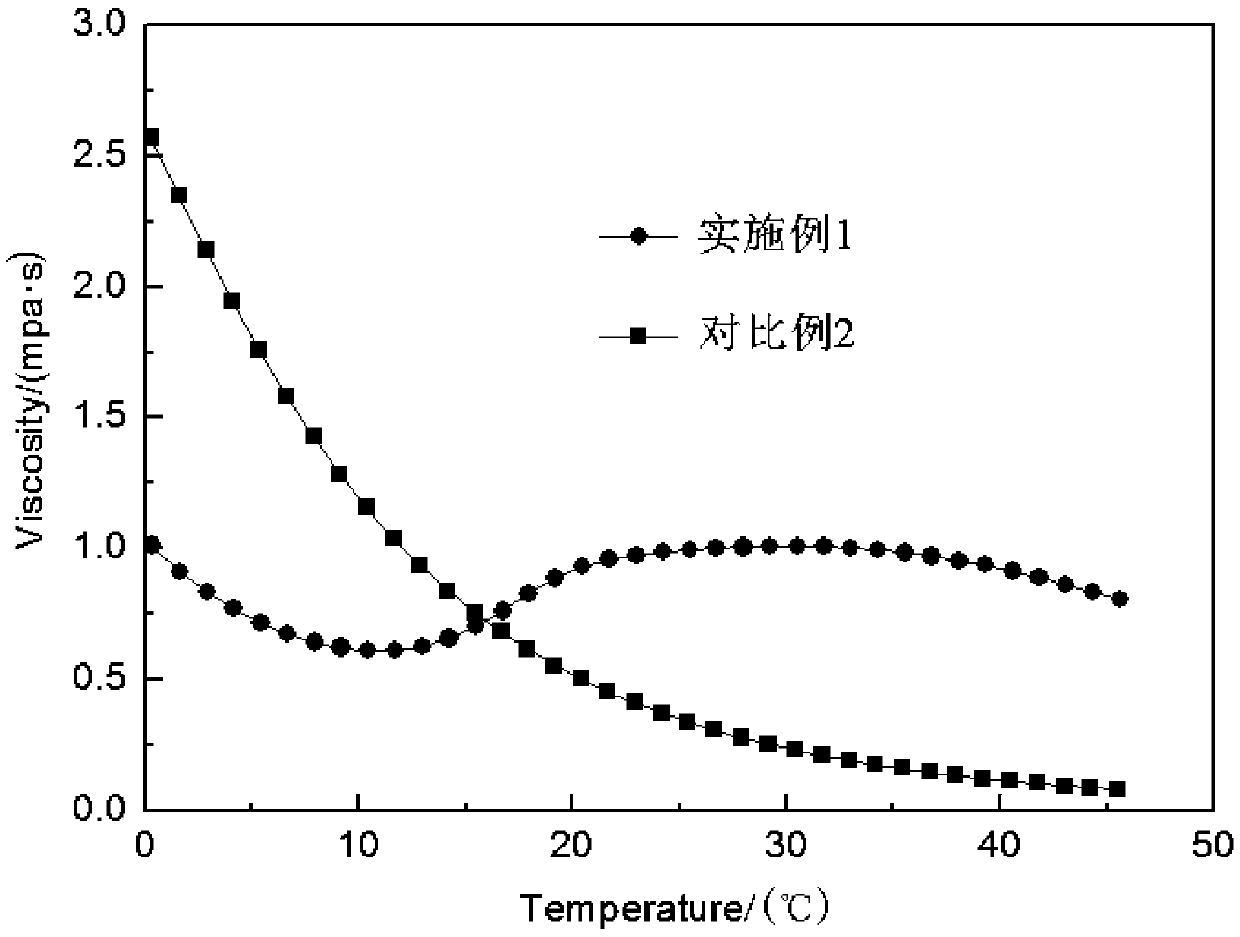

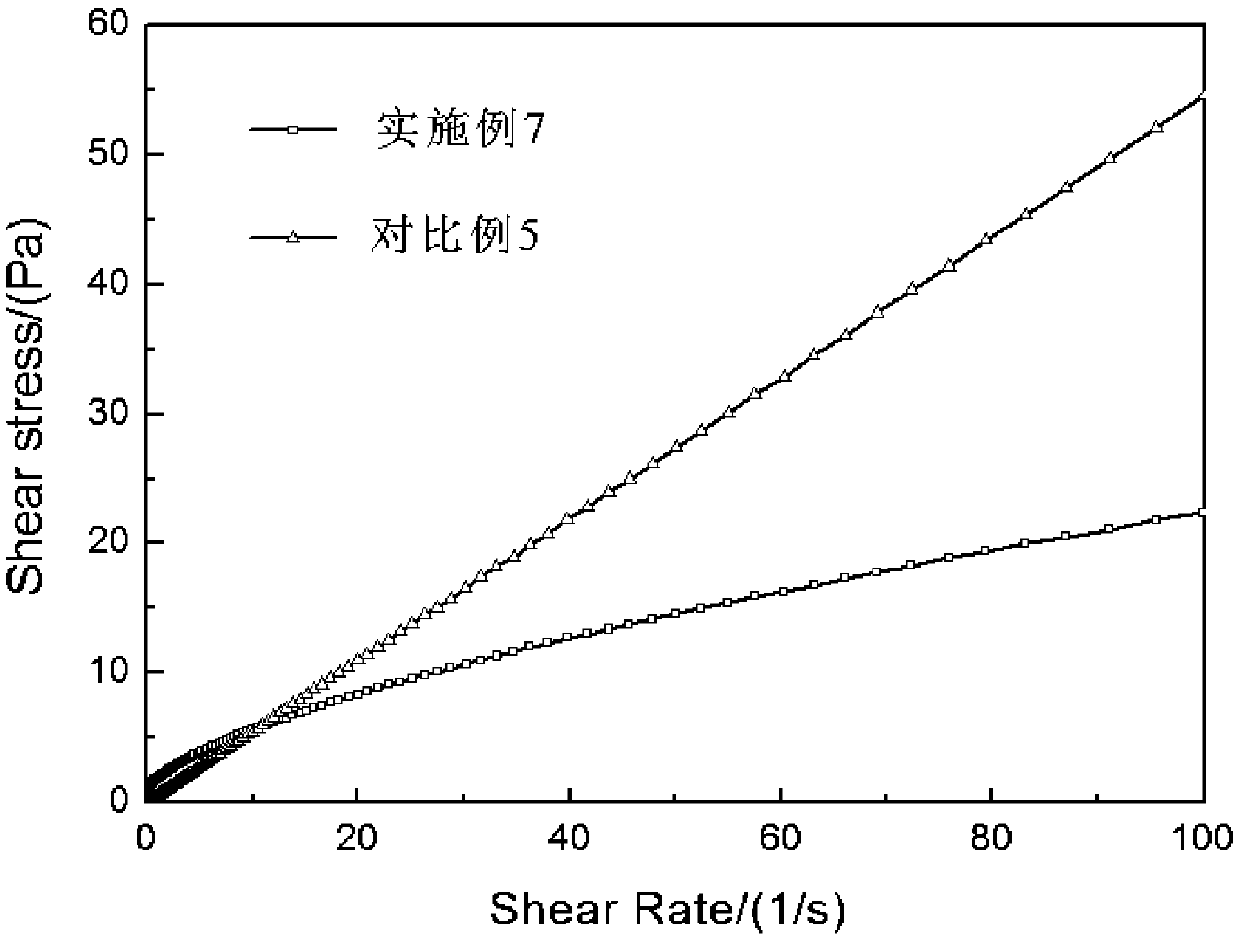

Concentrated liquid detergent composition

ActiveCN109576097AImprove suspension stabilityImprove stabilitySurface-active non-soap compounds and soap mixture detergentsTemperature resistanceViscosity

The invention relates to the technical field of daily washing products, in particular to a concentrated liquid detergent composition. A detergent system forms a compact lamellar liquid crystal structure by effectively compounding the surfactant, a certain rheological yield stress, excellent suspension stability and high-low temperature viscosity stability can be formed in the detergent system under the condition of a simple process, so that the detergent composition has the advantages of good stability, low viscosity, good washing performance, simple preparation process, low cost and the like,the problems of high cost, high viscosity and complicated preparation process of the detergent system caused by adding an external structuring agent to the detergent system in the prior art are avoided, and the problems of large viscosity change and poor temperature resistance of the existing concentrated liquid detergent under high and low temperature conditions are solved.

Owner:GUANGZHOU LIBY

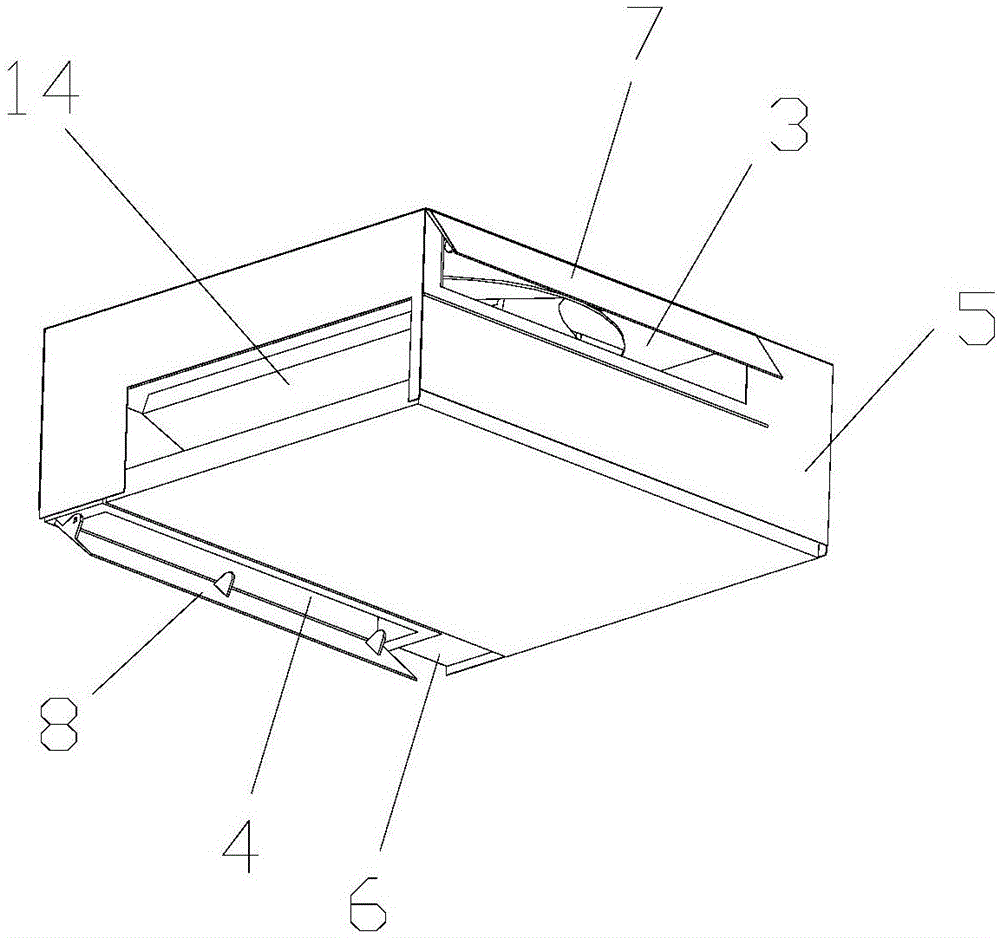

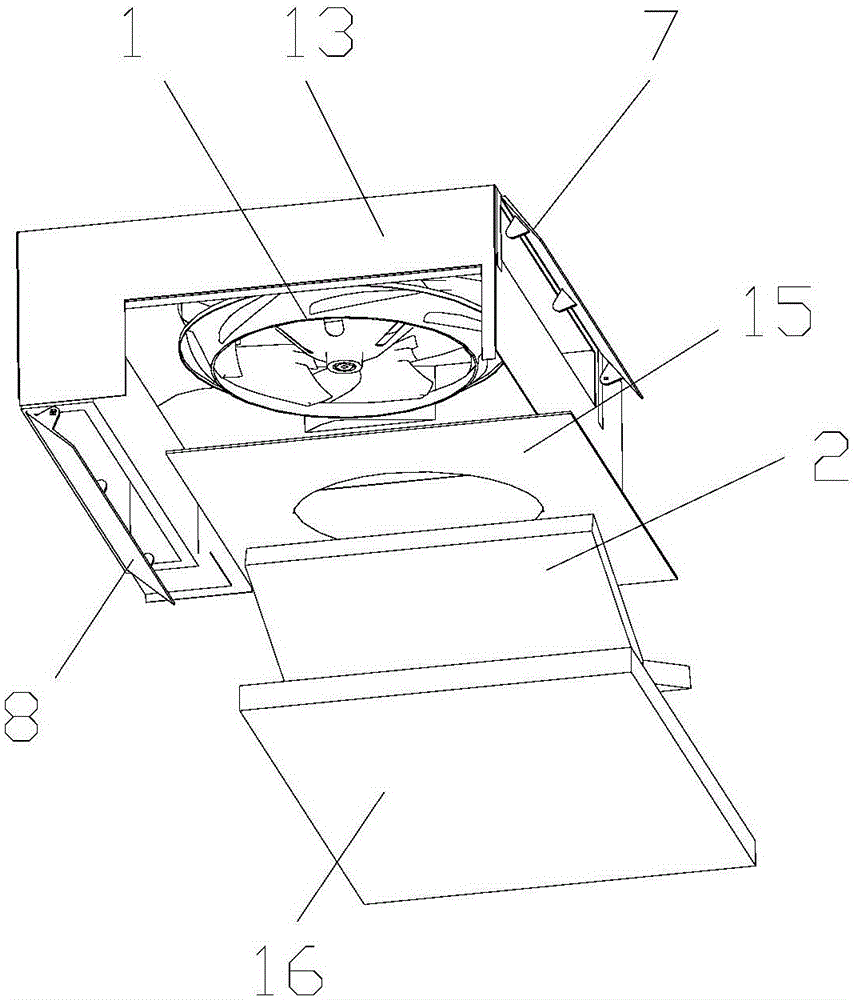

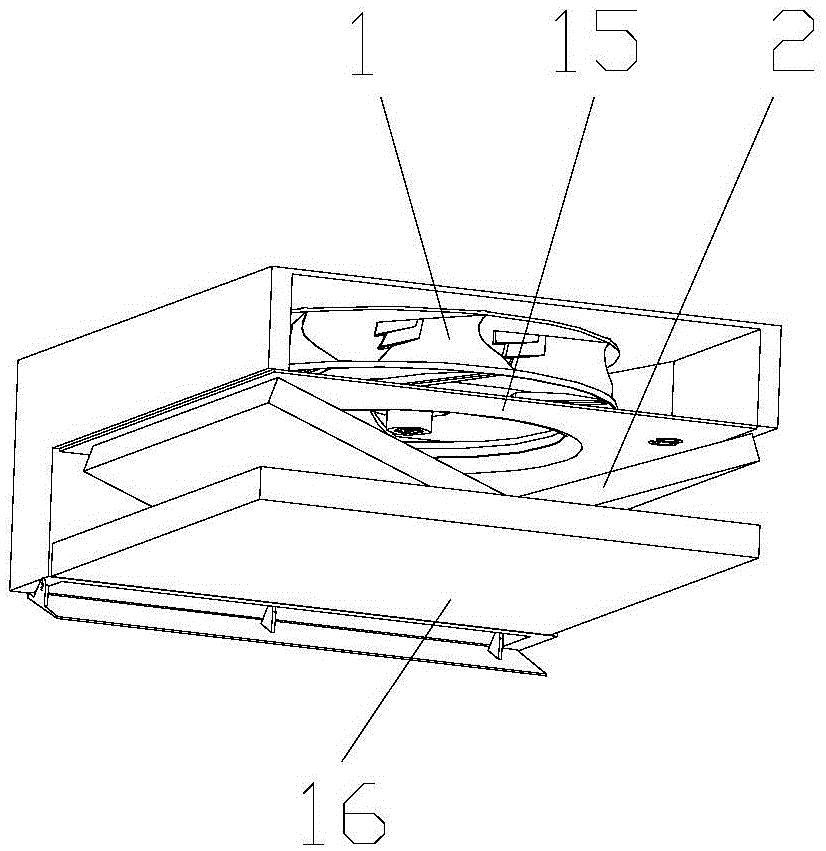

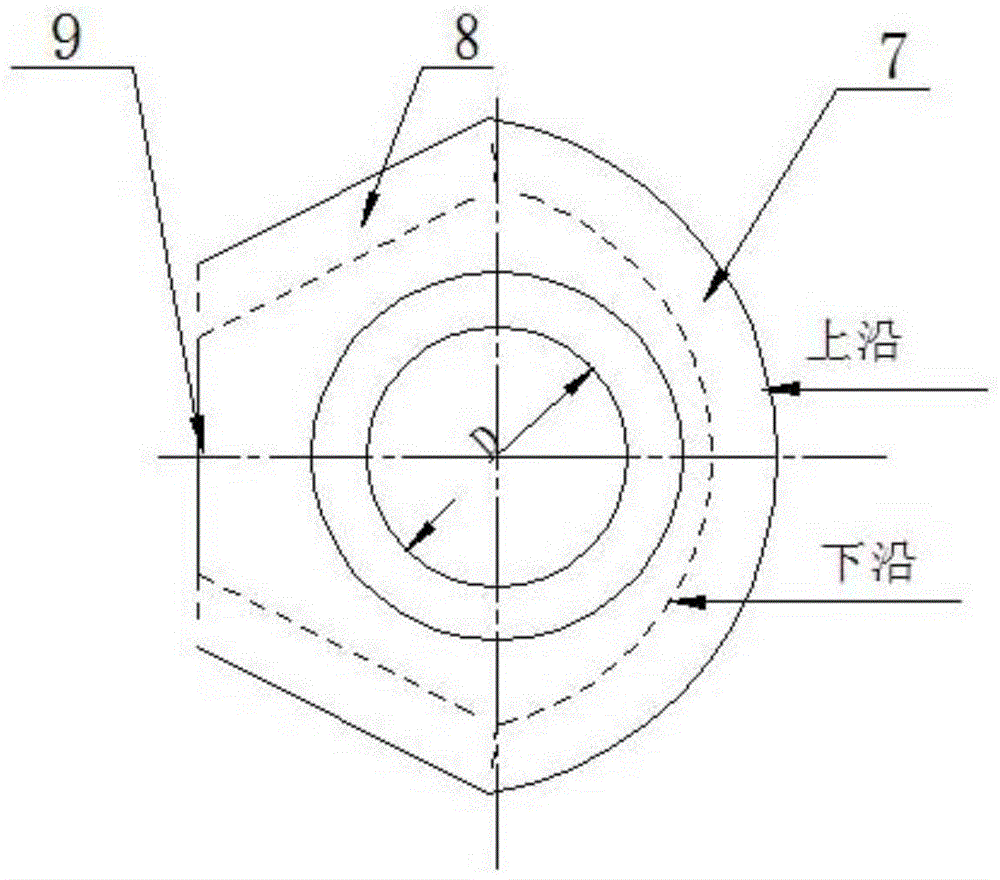

Air-pipe air conditioner indoor unit

InactiveCN105135534AImprove comfortSolve floatingLighting and heating apparatusAir conditioning systemsCold airFuselage

The invention relates to an air-pipe air conditioner indoor unit which comprises a unit body, wherein the air-pipe air conditioner indoor unit is provided with a first unit body air outlet and a second unit body air outlet with different air outlet directions; the first unit body air outlet is provided with an openable first air port baffle; and the second unit body air outlet is provided with an openable second air port baffle. The air-pipe air conditioner indoor unit can implement the air blast mode of cold air horizontal side blowing or hot air vertical down blowing, thereby solving the problems of up-floating of hot air and head blowing of cold air, and obviously enhancing the comfort of the human body.

Owner:GREE ELECTRIC APPLIANCES INC

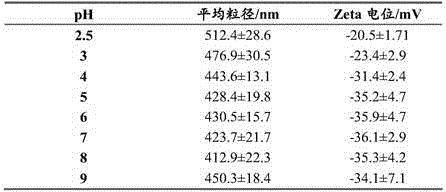

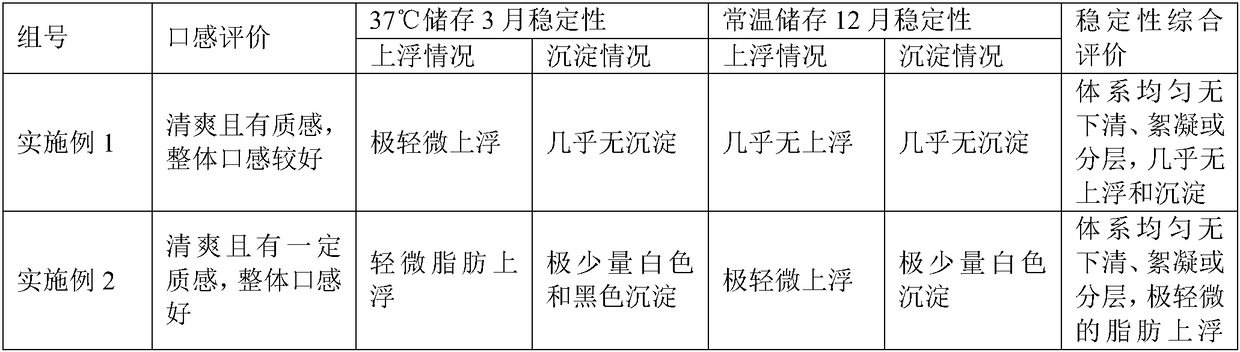

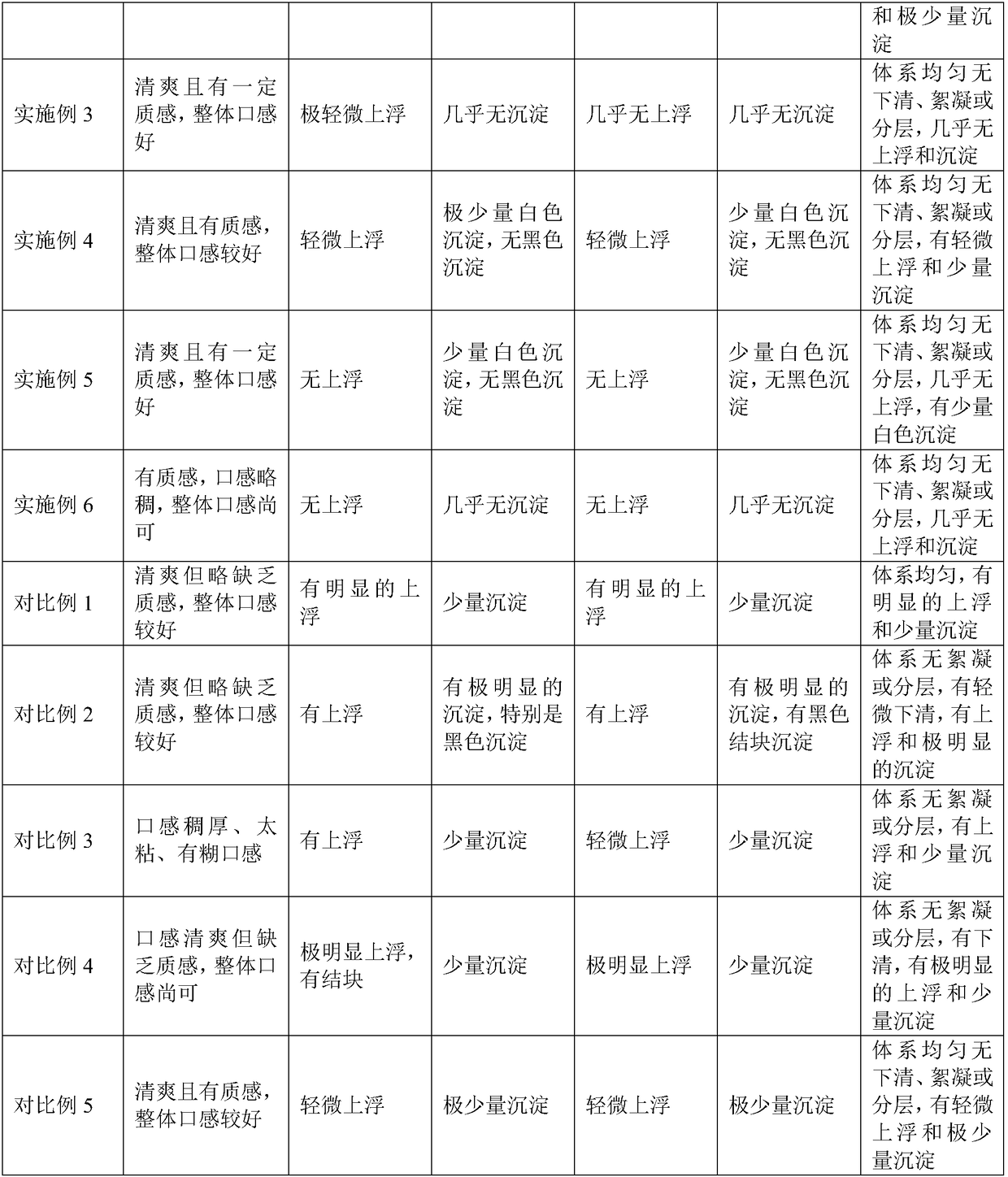

Milk beverage stabilizing agent, acid milk beverage using same and preparation method

The invention discloses a milk beverage stabilizing agent, an acid milk beverage using the same and a preparation method in the technical field of food. The milk beverage stabilizing agent comprises the following components in percentage by mass: 50%-70% of carboxymethyl curdlan, 10%-30% of Arabic gum, 10%-20% of propylene glycol alginate and 5%-10% of guar gum. The acid milk beverage comprises the following components in percentage by mass: 1%-8% of whole milk powder or defatted milk powder, 0.2%-1% of stabilizing agent, 10%-20% of white granulated sugar and the balance of water. The preparation method for the acid milk beverage comprises the following steps: taking 35 to 55 DEG C water, adding the white granulated sugar and the stabilizing agent into the water in turn, and stirring the mixture till the white granulated sugar and the stabilizing agent are dissolved to obtain solution A; taking the 35 to 55 DEG C water, adding the whole milk powder or the defatted milk powder into the water, and stirring the mixture till the whole milk powder or the defatted milk powder is dissolved to obtain solution B; and mixing the solution A and the solution B, cooling the solution to between 15 and 25 DEG C, adjusting pH to 4 by using citric acid solution, and heating, homogenizing and pasteurizing the solution to obtain the acid milk beverage. Because the carboxymethyl curdlan and the Arabic gum are introduced into the stabilizing agent, the stabilizing agent has good emulsifying effect and acid resistance, and can effectively improve the stability of a product.

Owner:SHANGHAI JIAO TONG UNIV

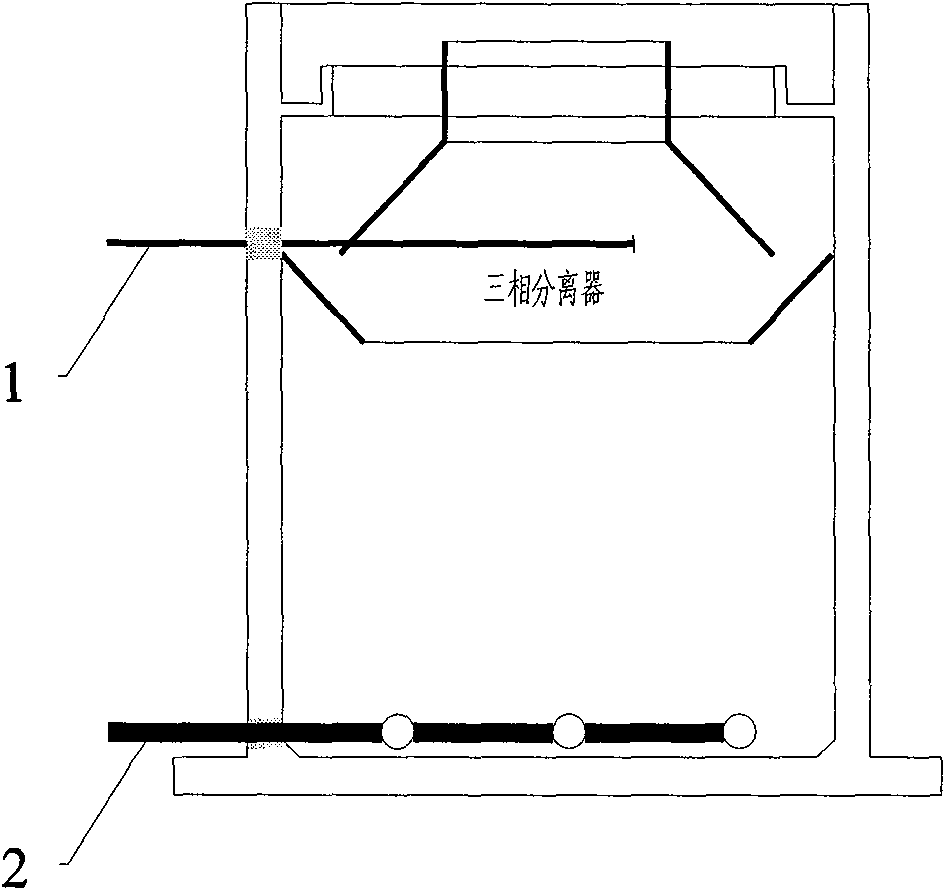

Method for rapidly culturing denitrifying granular sludge

ActiveCN101798142ASolve floatingSolve the problem of channel flow in sludge bedTreatment with anaerobic digestion processesSustainable biological treatmentStart timeSludge

The invention discloses a method for rapidly culturing denitrifying granular sludge with the technical features as follows: preprocessing inoculated aerobic or anaerobic flocculent sludge, speeding up formation of fine granular sludge, enabling the sludge to have certain activity, and inoculating the sludge on an up flow sludge blanket (USB) to obtain the granular sludge in a reactor in a short time with less floater and channels in a sludge bed. The invention has the advantages of shortening USB start time, rapidly culturing denitrifying granular sludge, simple and effective method, strong operability, low cost and easy popularization, and is especially suitable for starting a large-scale USB reactor.

Owner:内蒙古金河环保科技有限公司

Method of optimizing and returning to field of straw of cold region rice field

InactiveCN107484454ASolve floatingOvercoming the problem of easy hardeningSoil-working methodsEnvironment effectEcological safety

The invention discloses a method of optimizing and returning to field of straw of a cold region rice field, and relates to the field of returning to fields of straw of the rice fields. The method aims to solve the technical problems that according to a traditional method of returning to a field of straw, the effect of returning to the field is poor, during a process of returning to the field of the straw, the labor input of a farmer is increased, and the rice transplanting quality is affected. The method comprises the steps of (1) harvesting, wherein the straw is evenly dispersed in the field during harvesting; (2) land preparation and stubble burying, (3) irrigation for field steeping, stubble burying and land leveling and (4) rice transplanting and fertilizer application. Through the method, not only can returning to the field of the straw be achieved in the cold region rice field to achieve a purpose of land fertility betterment, but also negative environment effects caused by mass burning of the straw are alleviated, and fertilizer saving, the high yield, the high quality, the high efficiency and the ecological safety of the rice field are achieved; the method is used for returning to the field of the straw in a cold region.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Method of producing rice fertilizer

InactiveCN101033163AThe amount of adsorption is easy to controlReduce lossFertiliser formsUrea compound fertilisersFertilizerUrea

This invention discloses a production method for rice fertilizers , namely a production method for SCU, in which, large grains of urea pass through flowing melt sulfur to realize coating to urea, then melt olefin is sprayed to it to be cooled to room temperature , then a conditioner is added to the rice fertilizer, and the conditioner is dolomite powder or diatomite adsorbed on the surface of the rice fertilizer grain in the 1.5-2.5% volume of the weight of the rice fertilizer, the conditioner is added in a roller screen, in which, substances on the screen are finished products and conditioners below the screen is fed back to the feeding port by a screw feed machine, the rice fertilizer processed by this method alters surface structure of SCU grains and increases spreading speed of water on the grain surface.

Owner:汉枫缓释肥料(江苏)有限公司

Preparation method of carbon nano tube enhanced zinc-aluminum alloy-base composite material

The invention relates to a preparation method of a zinc-aluminum alloy-base composite material, in particular to a preparation method of a carbon nano tube enhanced zinc-aluminum alloy-base compositematerial. The aim is to solve the problems that according to an existing method, when carbon nano tubes are added into zinc-aluminum alloy melt, carbon nano tubes are not uniform in dispersion, and the mechanical properties of the prepared carbon nano tube enhanced zinc-aluminum alloy-base composite material are poor. The method includes the steps that 1, CNTs-Zn composite powder is prepared; 2, aCNTs-Zn intermediate material is prepared; 3, smelting is conducted, so that the carbon nano tube enhanced zinc-aluminum alloy-base composite material is obtained. The carbon nano tube enhanced zinc-aluminum alloy-base composite material can be obtained.

Owner:XIANGTAN UNIV +1

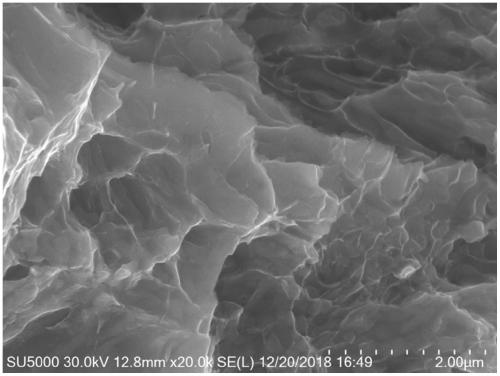

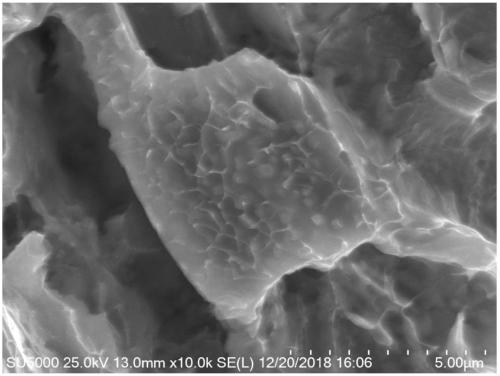

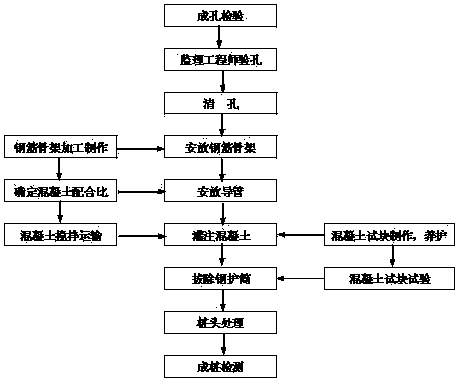

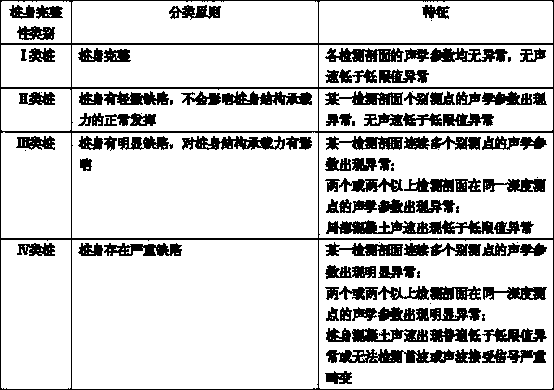

Grouting pile construction method for dry operation drilling and waterless pouring of concrete

ActiveCN104110028AReduce temporary land occupationReduce consumptionBulkheads/pilesMud systemsWater resources

The invention relates to a grouting pile construction method for dry operation drilling and waterless pouring of concrete. According to the method, hole drilling and cleaning are carried out in a rotary drilling dry operating method, and the concrete is poured through a waterless method. The operating steps of waterless pouring of the concrete include that when first batch of concrete is poured, the distance between a lower port of a conduit and the hole bottom ranges from 25 cm to 40 cm, and the depth, buried into the concrete, of the conduit is not less than 1 m; in the process of pouring the concrete, the buried depth of the conduit is controlled to be not less than 3 m; when the poured concrete is close to the top of a pile, the height of a funnel is increased so as to ensure that the elevation between the funnel and the top of the pile is not less than 4 m. By the adoption of the method, a mud system is completely omitted, consumption of mud raw materials and water resources is reduced, and the engineering construction cost is obviously lowered; moreover, the cost for transporting excavated muck is far lower than the cost for transporting and processing the mud, so considerable expenses for discharging and processing the mud are saved, the temporarily occupied land of the mud system is omitted, and the effect is obvious especially when construction is carried out on the condition that an urban site is narrow.

Owner:河北省水利工程局集团有限公司

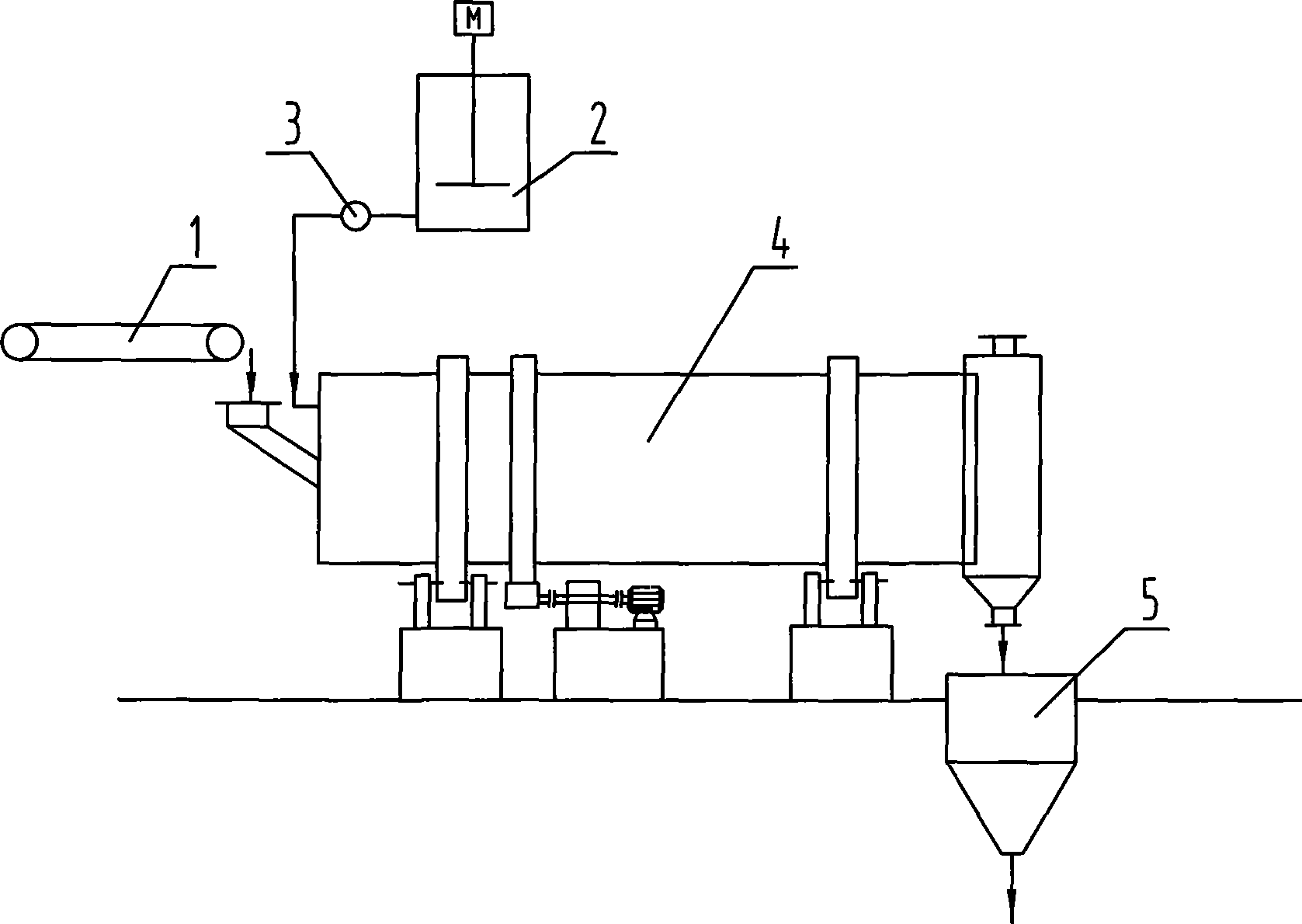

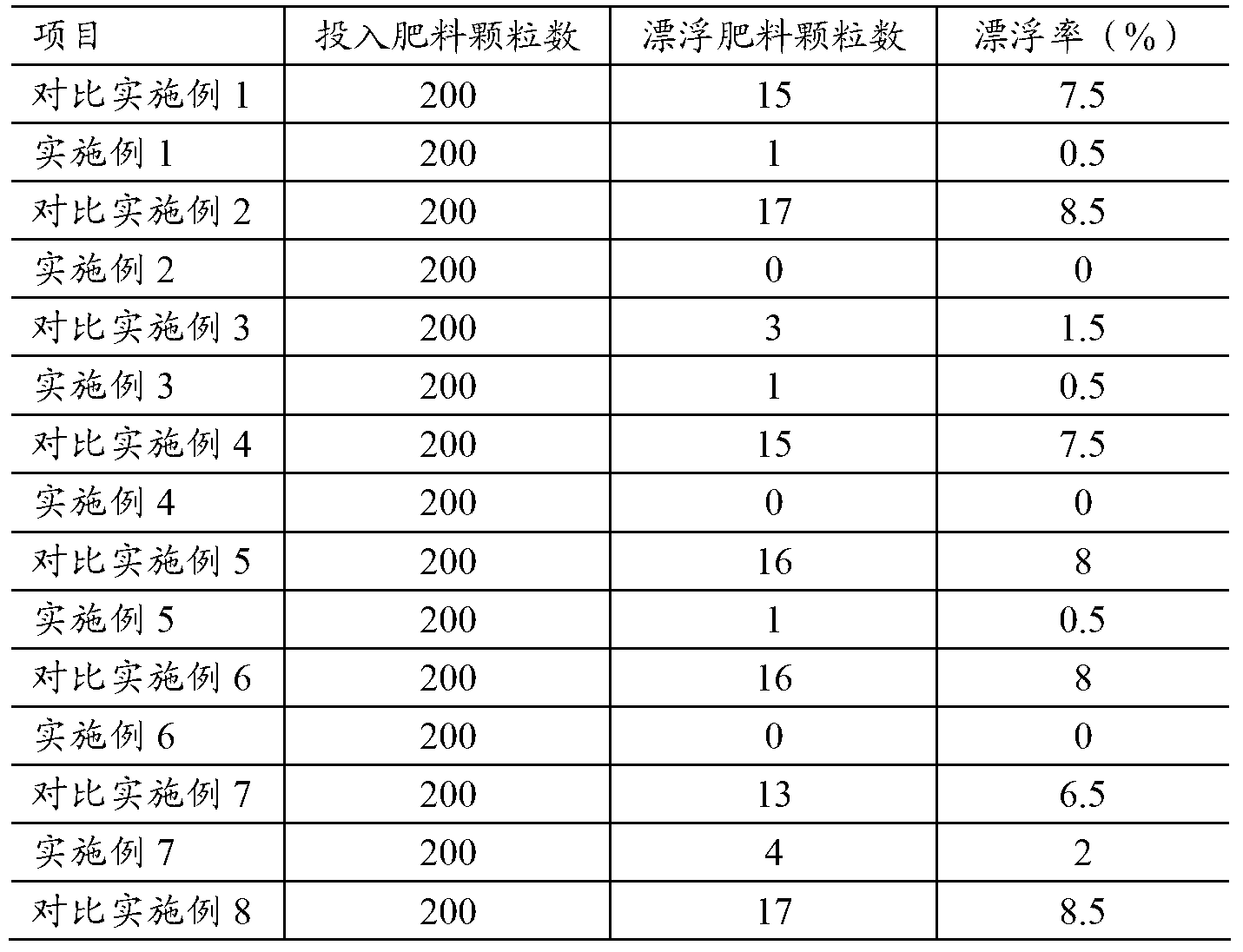

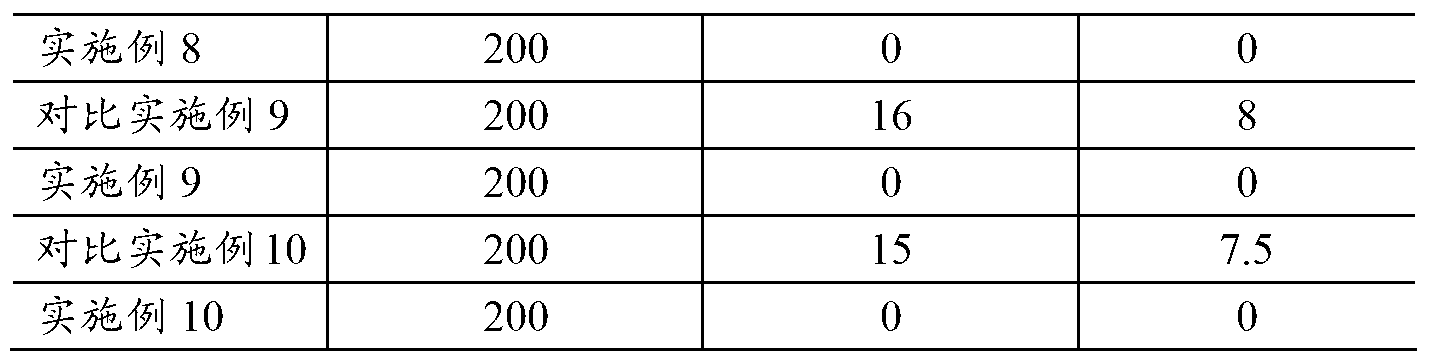

Anti-floating processing method and apparatus of coated controlled release fertilizer

The invention discloses a method for anti-floating treatment of coated controlled-release fertilizer and a device thereof. The method comprises the following steps: anti-floating agent is coated on the surfaces of coated controlled-release fertilizer granules, so as to realize the effect that the coated controlled-release fertilizer does not float in water. The method can perfectly solve the problem of floating of the controlled-release fertilizer in water and the problems of uneven fertilization and nutrient loss which are caused by the floating of the fertilizer; in addition, the original process of the method for the controlled-release fertilizer is not required to be changed. Therefore, the equipment is simple, and the operation is convenient.

Owner:KINGENTA ECOLOGICAL ENG GRP

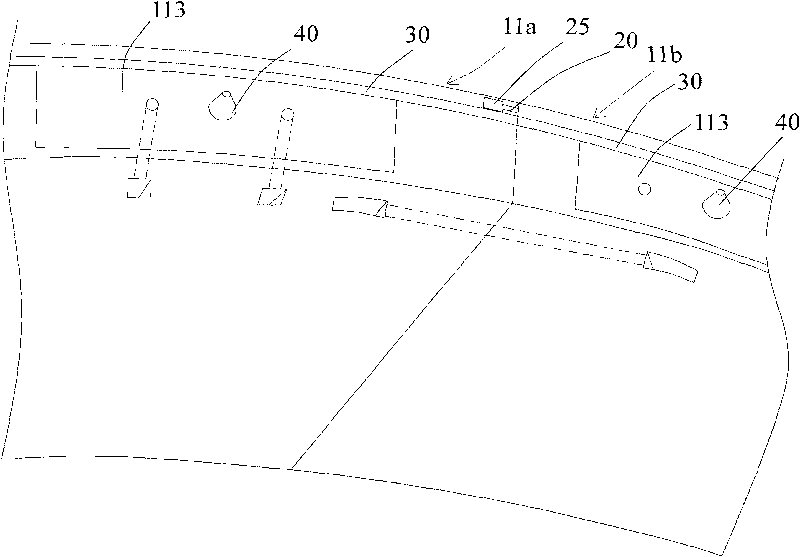

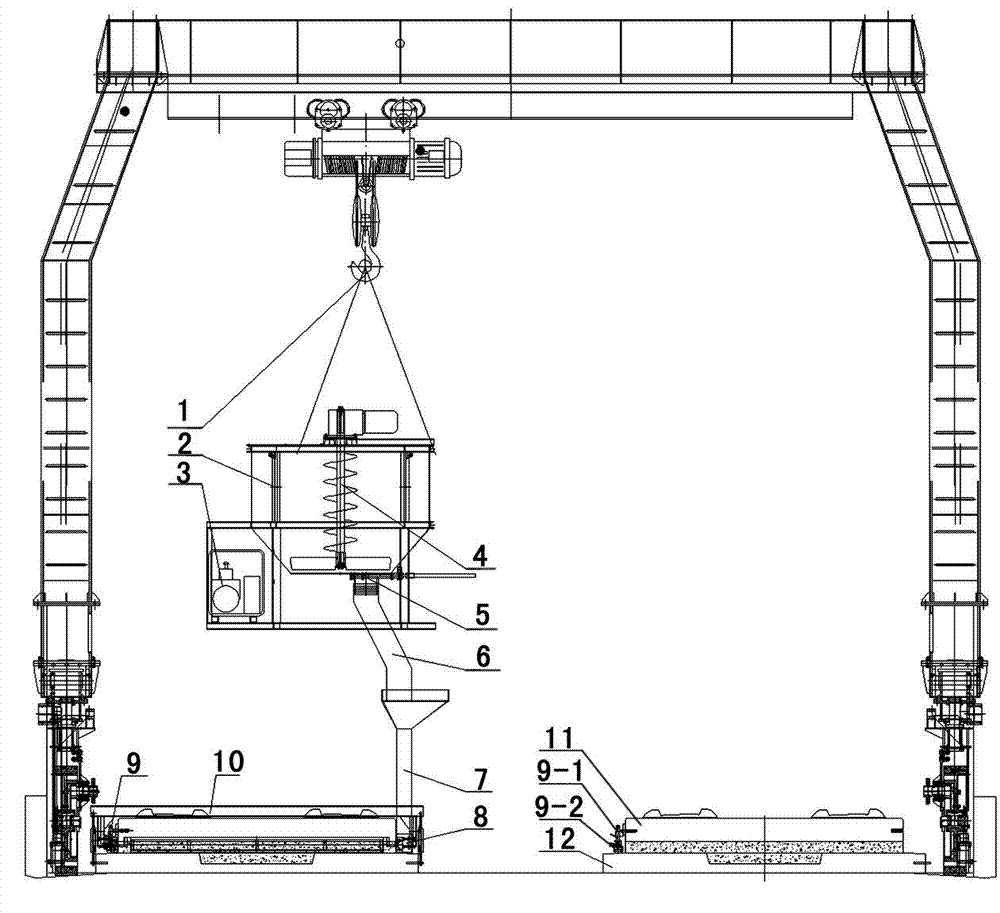

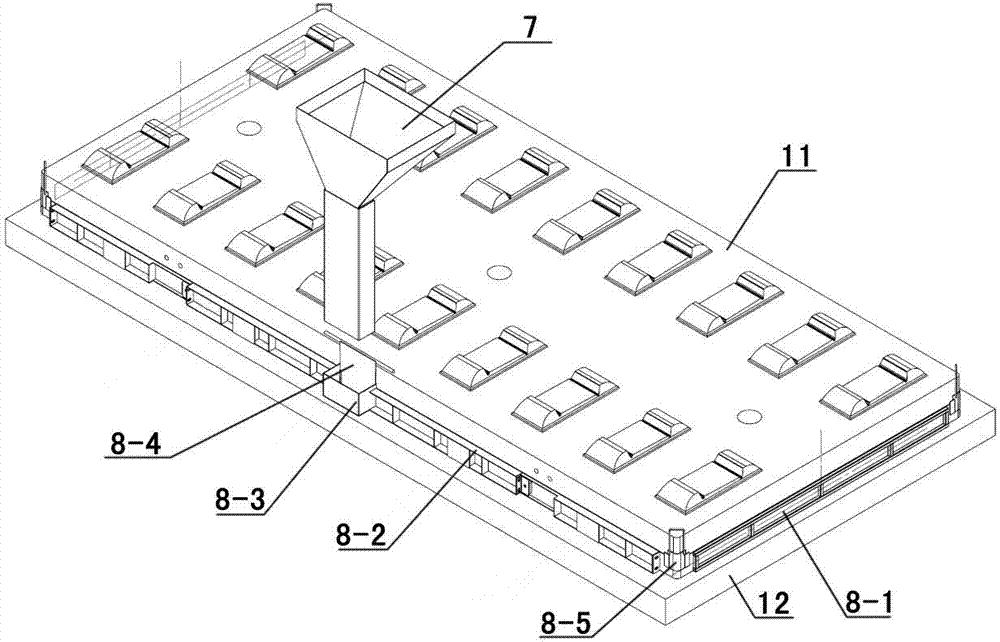

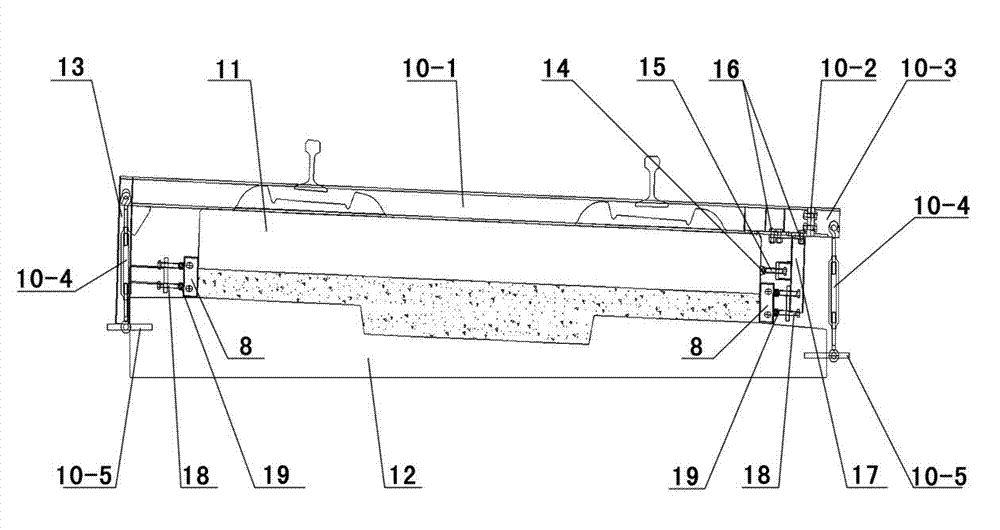

CRTS III type slab ballastless track self-compacting concrete casting tooling and method

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

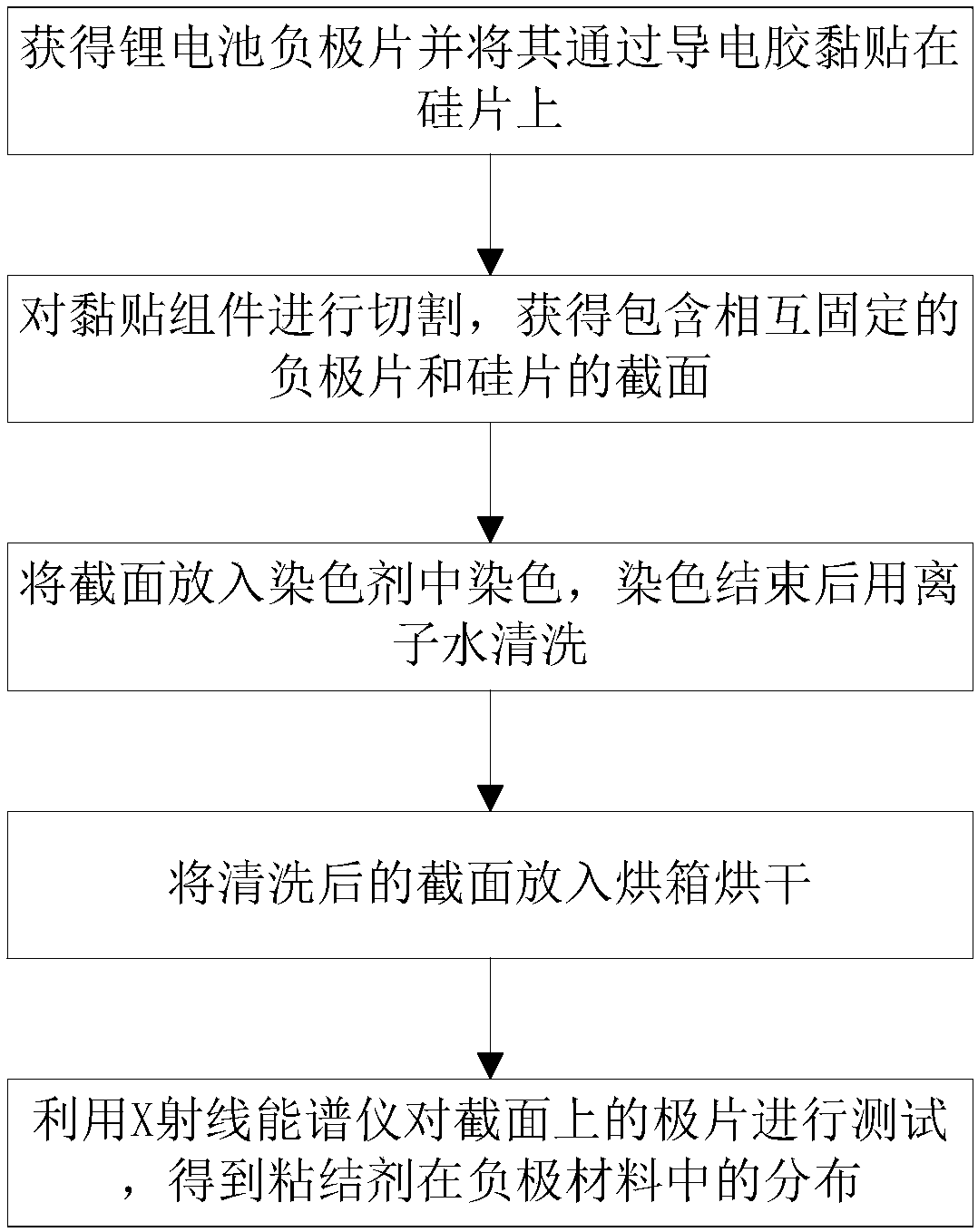

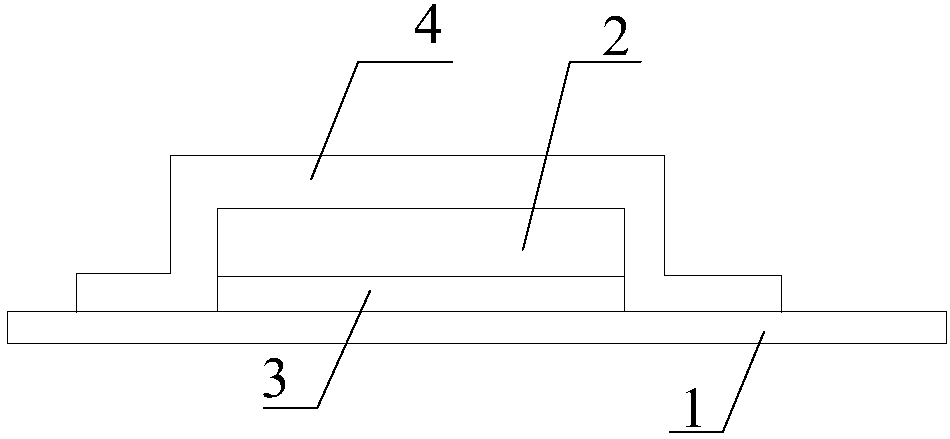

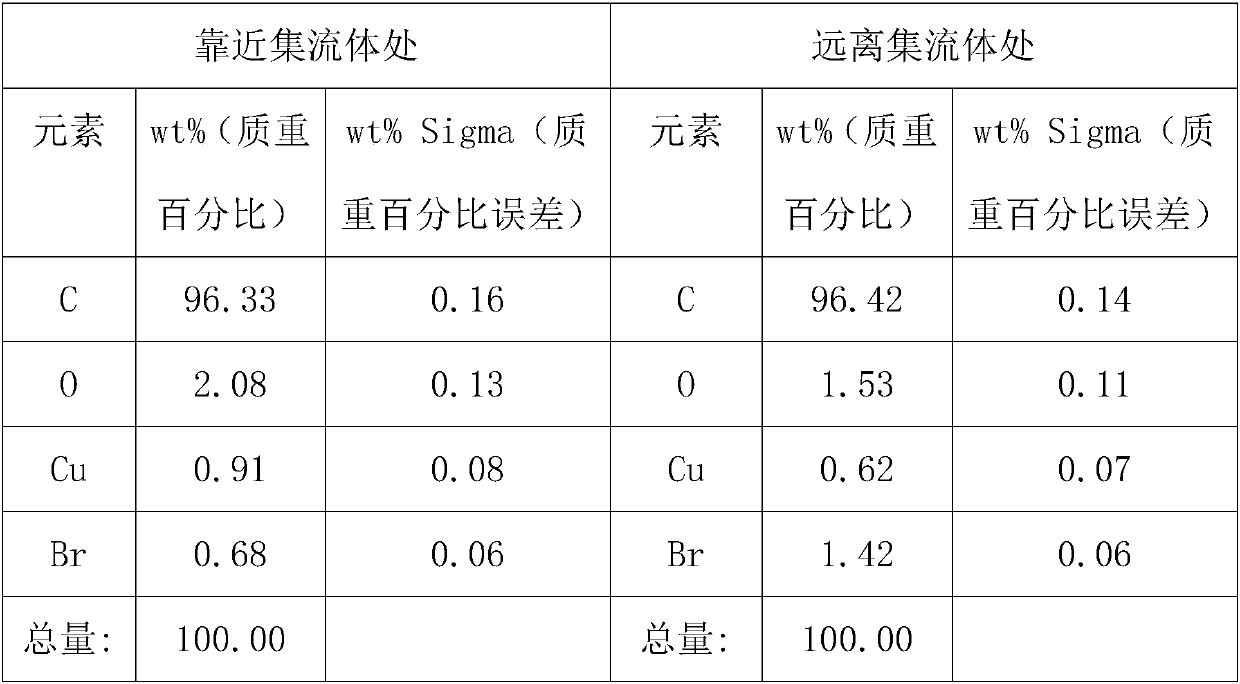

Method for detecting distribution of lithium ion battery negative electrode binder in electrode sheet

InactiveCN107831178AEffective distributionSolve floatingMaterial analysis using wave/particle radiationPreparing sample for investigationElement analysisMaterials science

The invention discloses a method for detecting the distribution of a lithium ion battery negative electrode binder in an electrode sheet. The binder on a cross section is dyed, and the distribution ofthe binder on the cross section is obtained through element analysis.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

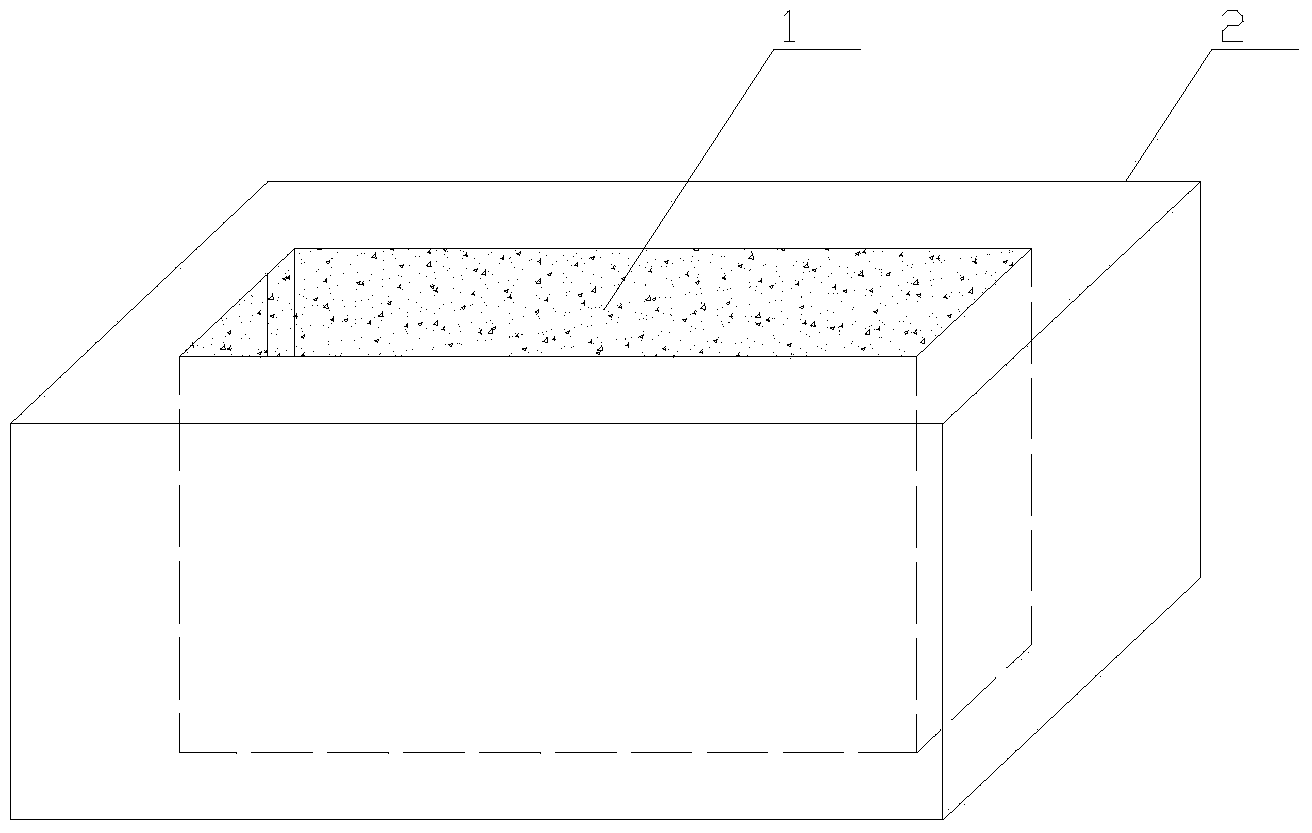

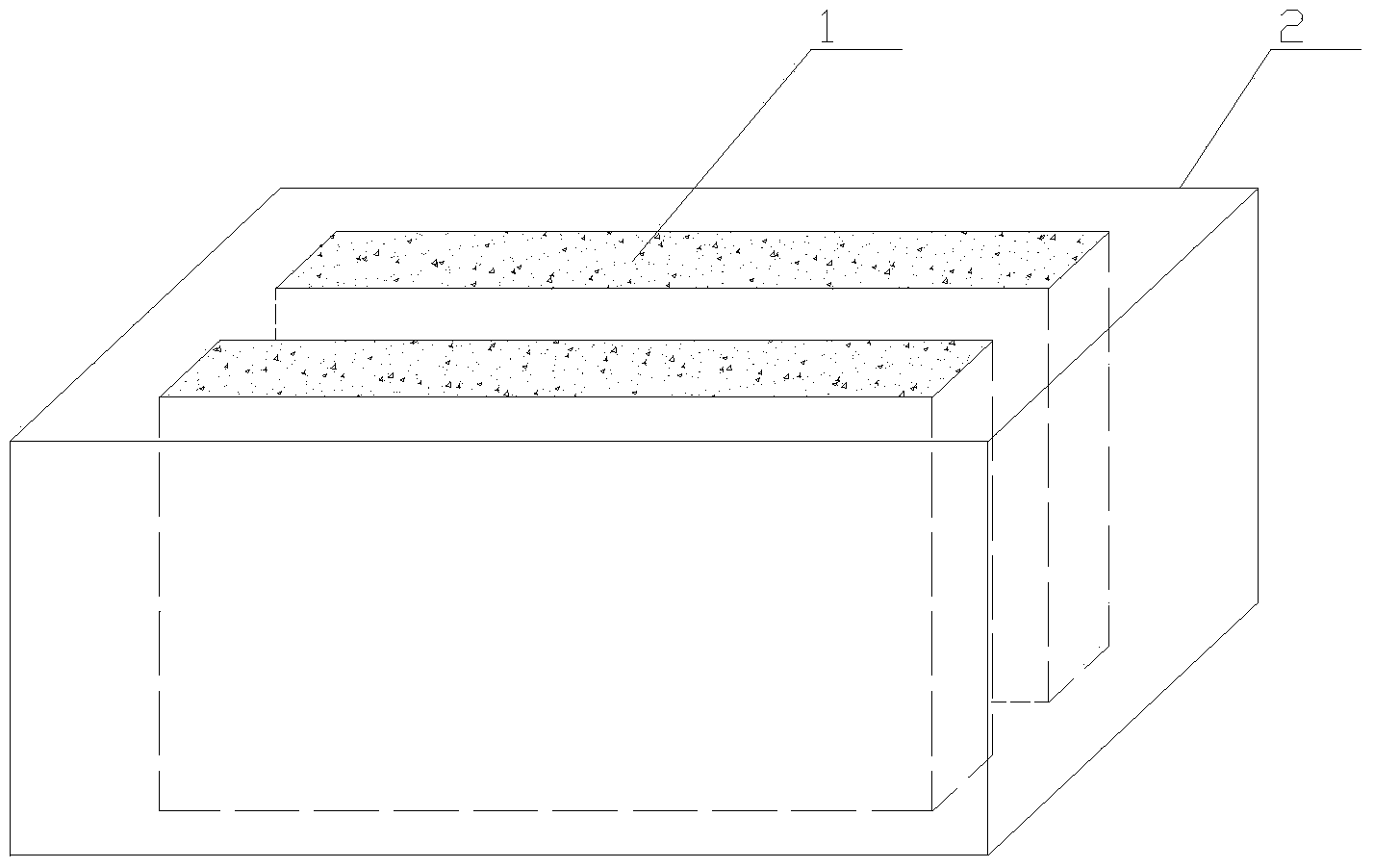

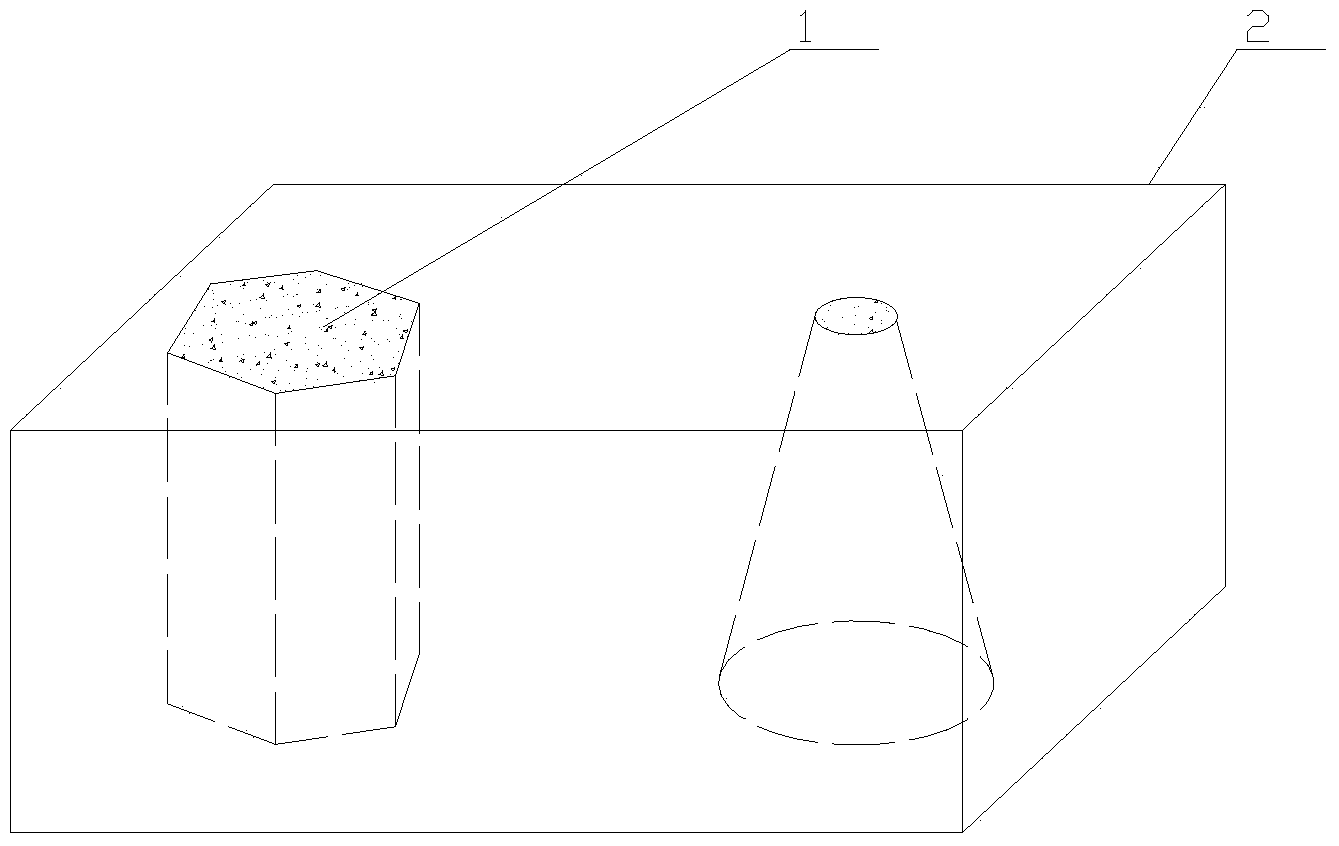

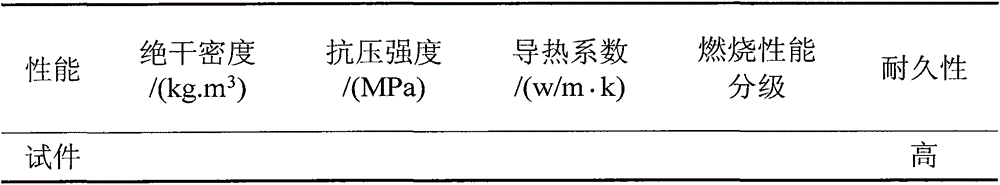

Composite building block as well as production mold and production method thereof

ActiveCN103833281ASolve floatingResolve offsetConstruction materialSolid waste managementCombustionUltimate tensile strength

The invention discloses a composite building block as well as a production mold and a production method thereof. The invention provides the composite building block which is stable in structure, high in specific strength, low in water absorption, good in size stability, high in combustion grade, good in heat preservation property and low in cost, and the production mold and the production method of the composite building block. The composite building block comprises a bearing base body and at least one heat preservation body, wherein the heat preservation body is prepared from the following components in percentage by weight: 40-60% of cement, 8-15% of silica fume, 3-5% of hydrogen peroxide, 0.5-1% of a modifying agent and 31-38% of water; the bearing base body is prepared from the following components in percentage by weight: 20-40% of cement, 0-40% of tailing sand, 25-65% of a construction waste raw material, 10-40% of coal ash, 3-5% of a fiber bar-shaped material, 0.10-0.40% of hydrogen peroxide, 0.7-1.6% of an additive and 20-36% of water; at least one accommodation hole is formed in the bearing base body; the heat preservation body is arranged inside the accommodation hole and is combined with the inner wall of the accommodation hole. The invention provides the composite building block which is stable in structure, high in specific strength, low in water absorption, good in size stability, high in combustion grade, good in heat preservation property and low in cost on the whole.

Owner:CHINA BUILDING MATERIALS ACAD

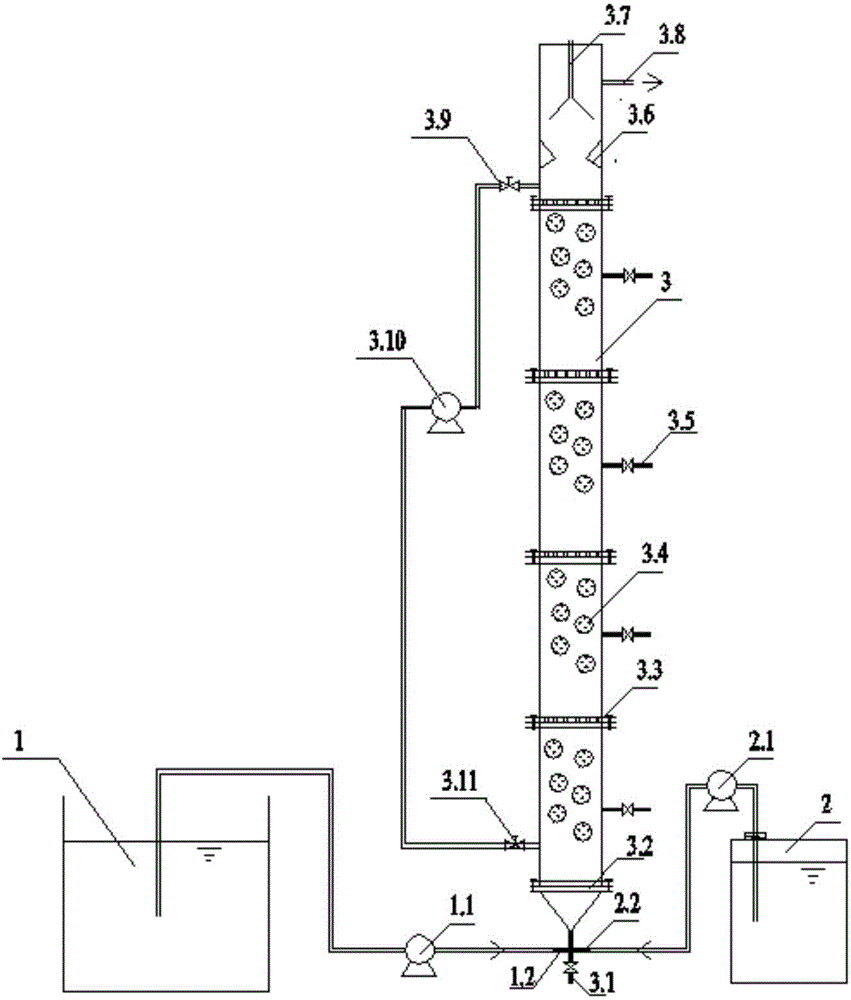

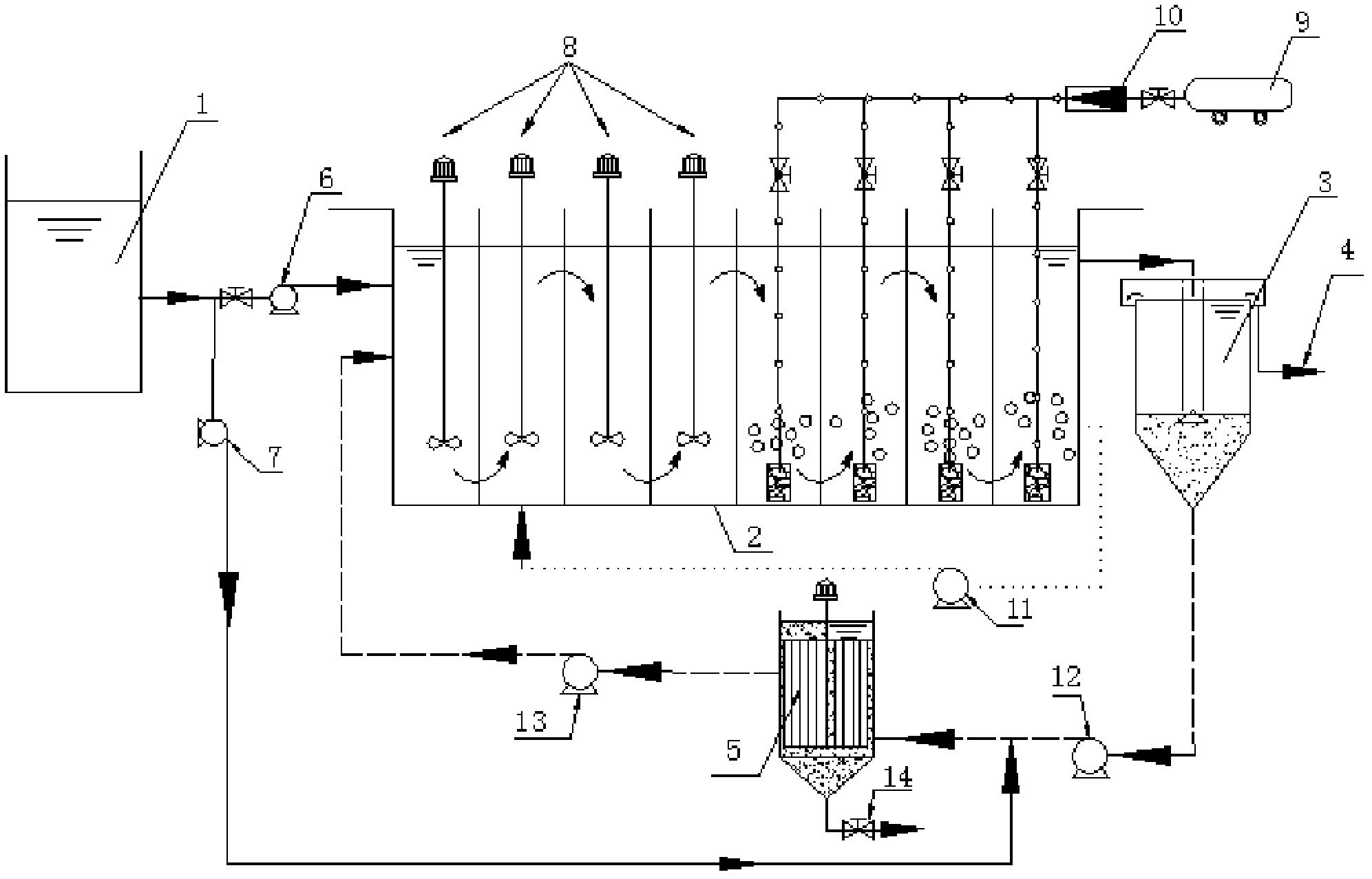

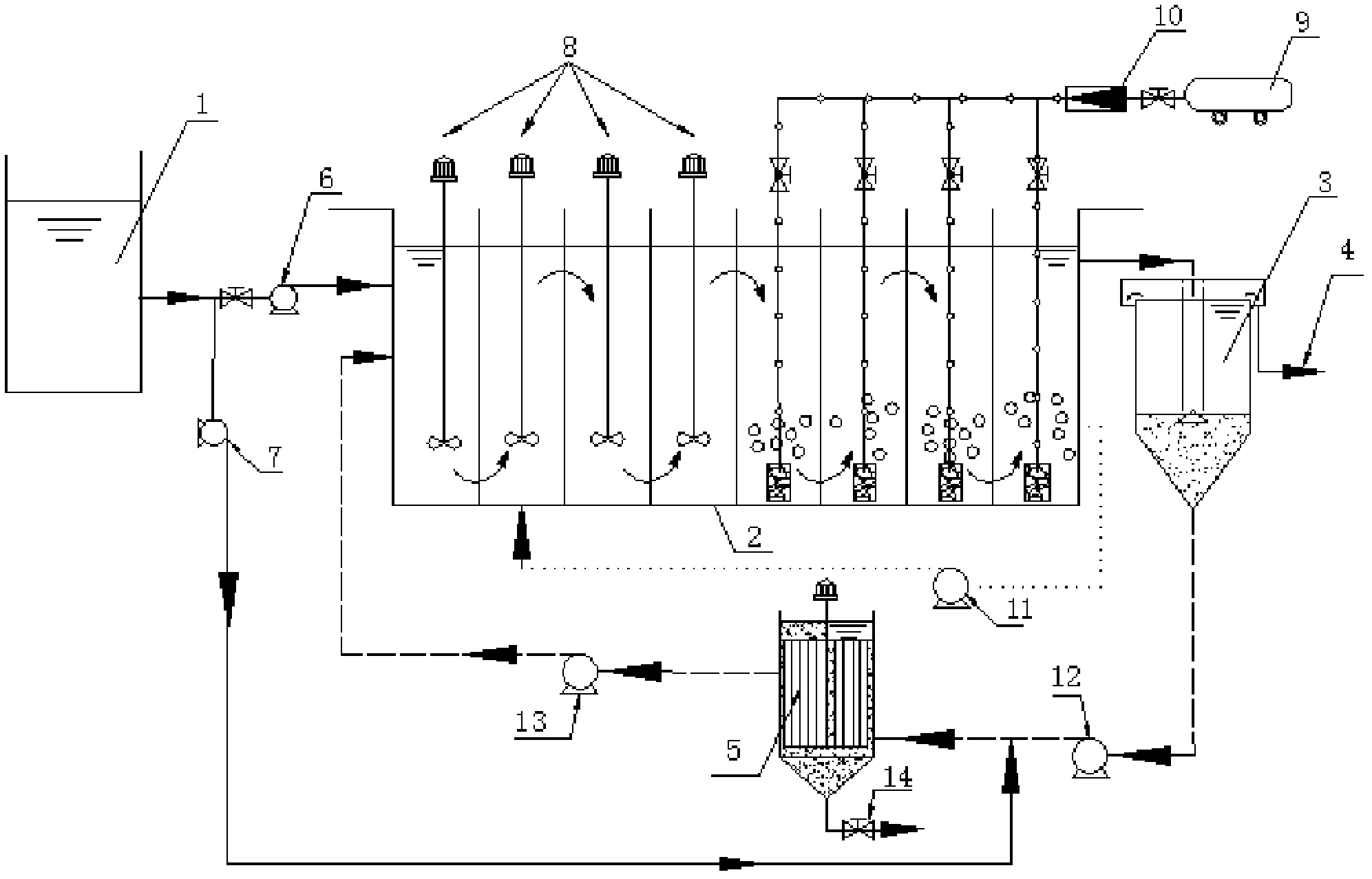

Production device and method for achieving stable denitrification of nitrite in continuous flow

InactiveCN104628131AProduce efficientlyEfficiently implemented generationWater contaminantsTreatment with anaerobic digestion processesNitriteSludge

The invention discloses a production device and a production method for achieving stable denitrification of nitrite in continuous flow, and belongs to the technical field of biological sewage treatment. The method comprises the following steps: with lightweight suspended filler as a carrier, attaching short-range denitrifying sludge on the surface of the filler; and with an organic carbon source in inflow water as an electron donor, continuously reducing nitrate in inflow water into nitrite. According to the production device and method, the electron donor can be lastingly provided for an anaerobic ammonia oxidation technology; the problems of sludge flotation and loss in an upflow denitrification reactor are effectively solved; in addition, the reactor disclosed by the invention is simple in structure, small in floor area, low in cost and beneficial to popularization.

Owner:BEIJING UNIV OF TECH +1

Device and method for strengthening A2/O denitrification

ActiveCN102583897AGuaranteed uptimeSolve floatingMultistage water/sewage treatmentMunicipal sewagePhysics

The invention discloses a device for strengthening A2 / O denitrification. The anaerobic region of the AAO device and a sludge denitrification pond are connected, the aerobic region of the AAO device is connected with a settling pond, and the sludge denitrification pond is connected with the anaerobic region of the AAO device. The settling and sludge storage functions of the settling pond are separated through technological adjustment, the functions of the original sludge concentration pond are expanded, the original sludge concentration pond is upgraded into the sludge denitrification pond, the overall performance of the sewage treatment system is enhanced, the energy-saving stable and efficient denitrification and dephosphorization of the combined system are realized under the condition of not adding structures, and a theoretical basis and technical support are provided for the upgrading and reconstruction of a municipal sewage treatment plant.

Owner:BEIJING UNIV OF TECH

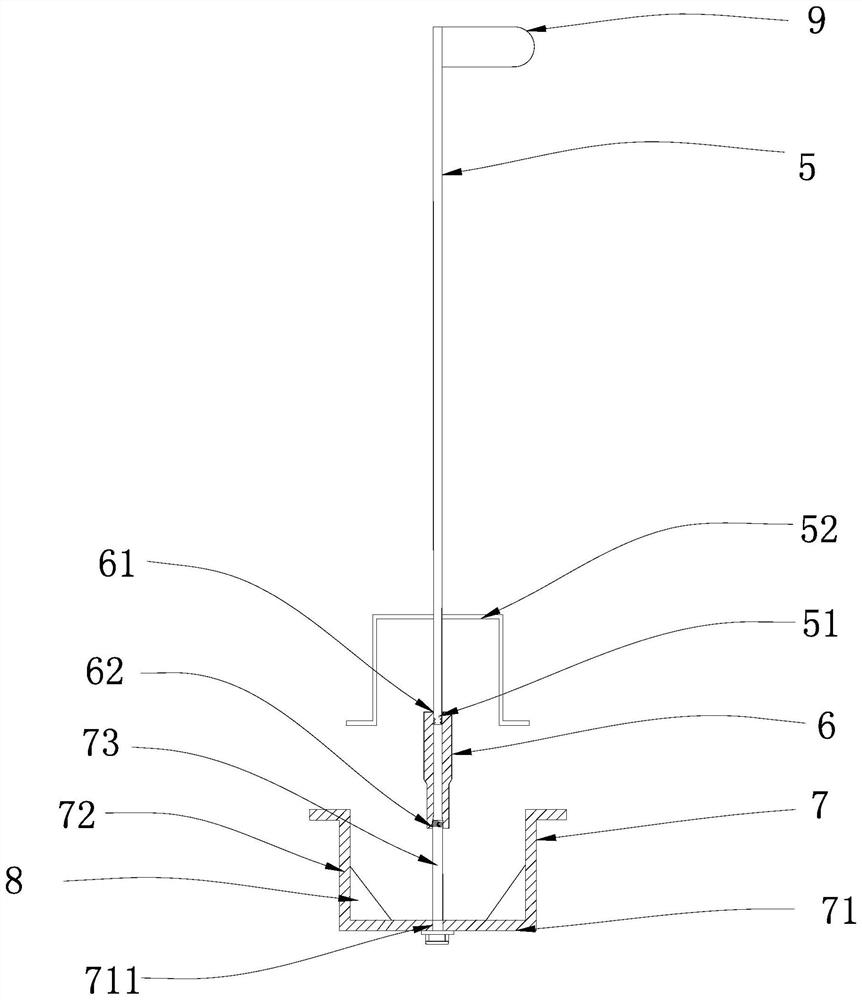

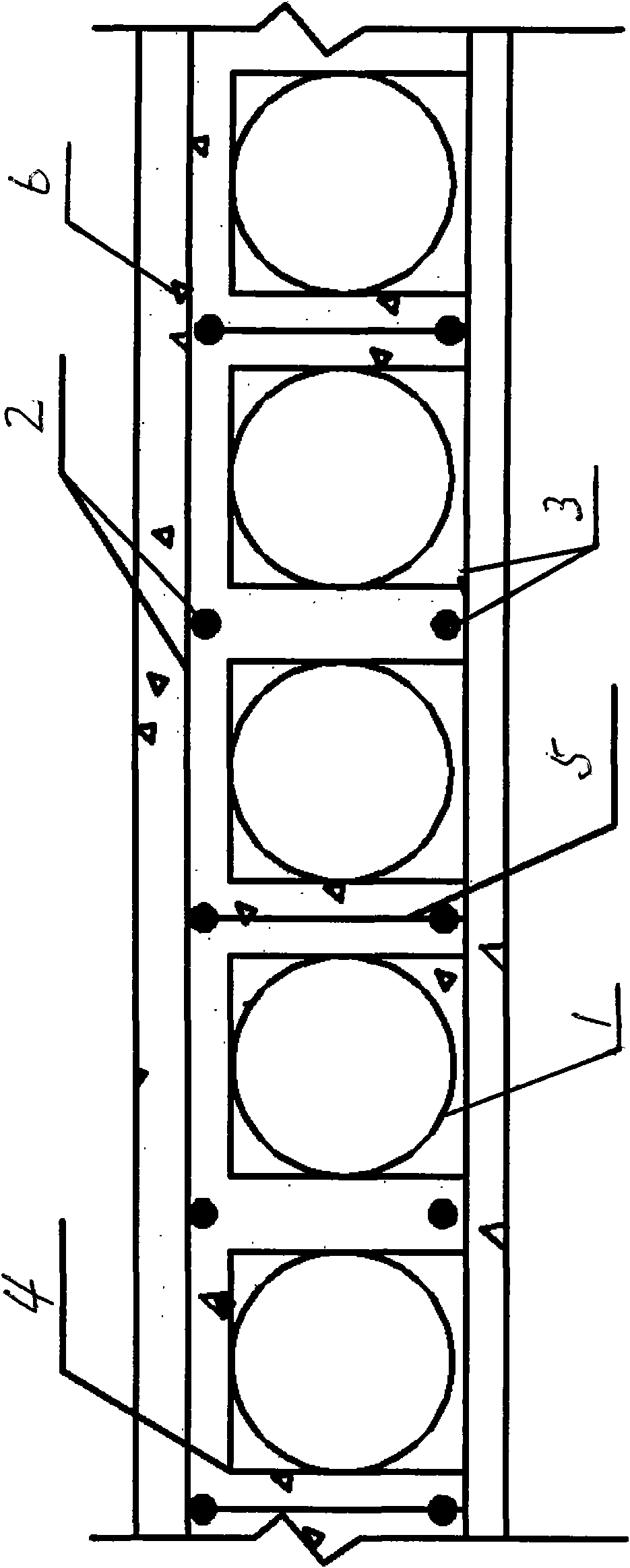

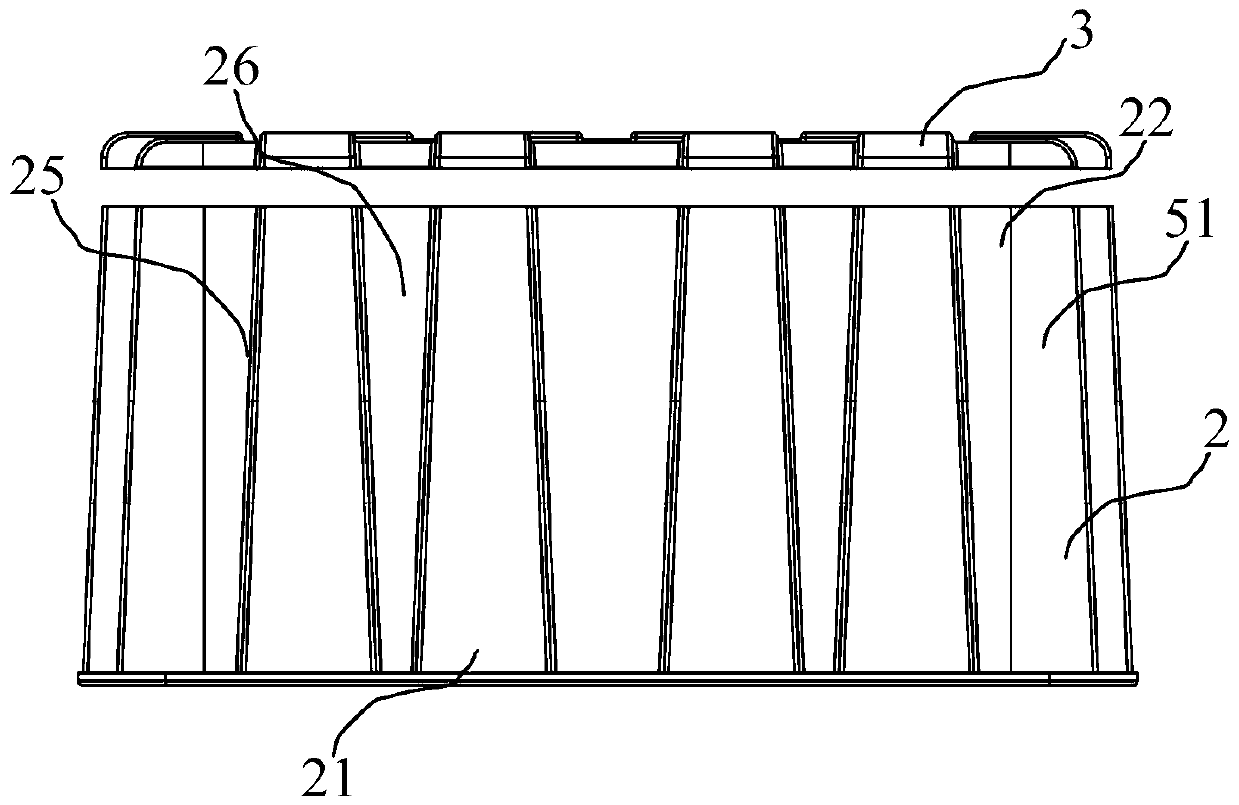

Thin-wall internal-mould large-thickness hollow floor plate

The invention discloses a thin-wall internal-mould large-thickness hollow floor plate comprising a layer of totally-closed core pipes in circular pipe shapes, reinforcing meshes and pouring concrete, wherein the reinforcing meshes are respectively arranged above and below the layer of core pipes; a pressure pipe reinforcing bar is tightly close to and surrounds each core pipe, and a row of vertical anti-floating reinforcing bars are arranged at intervals of every 2-4 core pipes; and the pouring concrete is filled among the core pipes, the reinforcing meshes and the pressure pipe reinforcing bars and on the upper surface of the upper reinforcing mesh. The thin-wall internal-mould large-thickness hollow floor plate is in a double-layer reinforcing bar structure, the core pipes are positioned in the middle of the pouring concrete to form a hollow structure so as to become a permanent core mould, and the problems of fixation and floating of the core pipes in the concrete pouring process are solved through the structure. The invention has the advantages of fast construction, convenient installation, heat insulation and good sound insulation performance, can effectively reduce the self weight, correspondingly decreases girders, columns and walls which support the floor plate and foundation loads and greatly reduces the quantity of reinforcing bars as structural members.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Dressing process of gold ores

InactiveCN101898167ASolve the floating speed problemSolve the problem that the sulfide particles with large specific gravity cannot be floatedFlotationWet separationAutomatic controlAutomated control system

A dressing process of gold ores comprises the step of pulp particle size grading. The difference lies in that the dressing process also comprises the steps of ore dressing and pulp washing, dispensing and stirring at fixed time for reaction, ore floating at fixed time, tailing discharging at fixed time, etc, therefore, in the ore floating procedure, the pulp viscosity does not affect the floating upward speed of the sulfides, the sulfide particles with high proportion do not exist, the floatation concentrate pulp does not flow back in the opposite direction, the heavy metals and the valuable elements can be maximally recovered and the discharged tailings do not contain sulfides and heavy metals. The single floatation ore groove circulating linkage mechanism is adopted and is automatically monitored and regulated by an automatic control system, thus greatly shortening the ore floating process. Compared with the prior art, the dressing process can save energy by more than 50% and is especially suitable for the gold mine industry.

Owner:孙宝海

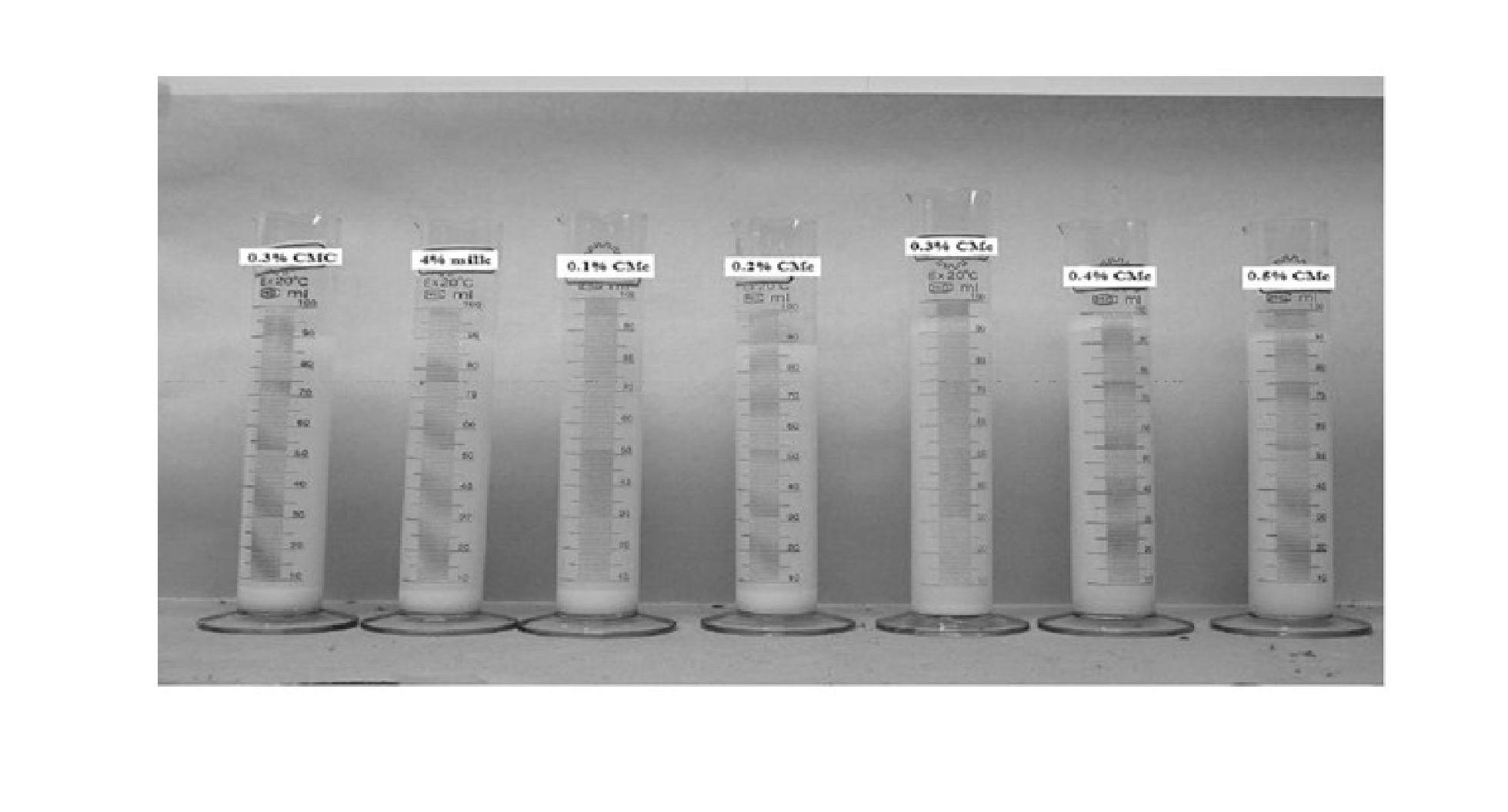

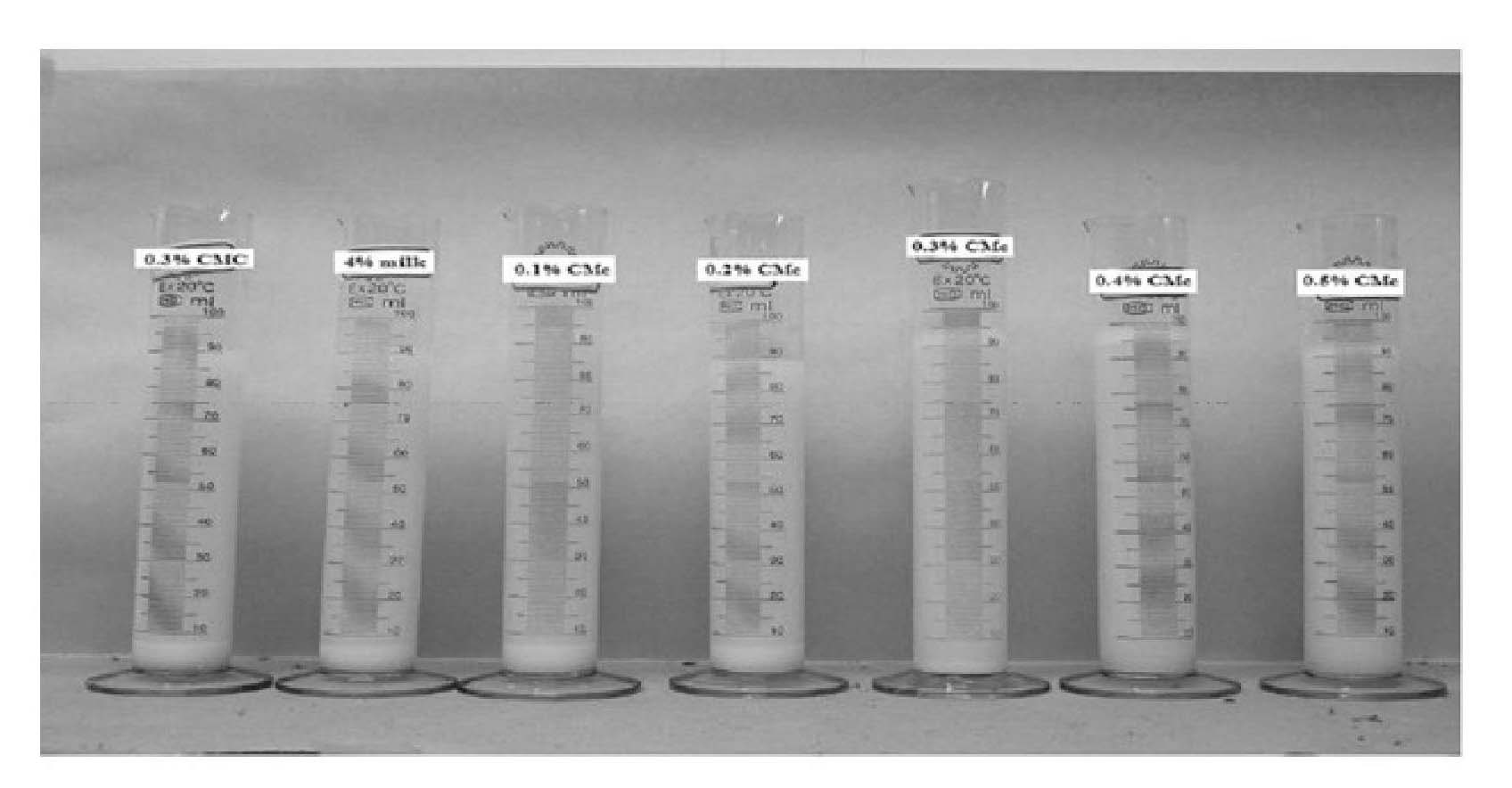

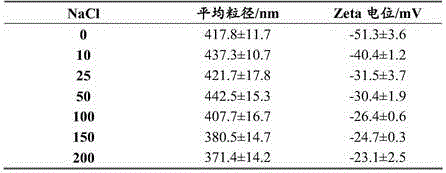

Milk protein-anionic polysaccharide emulsification stabilizer and application thereof

The invention discloses a preparation method of a milk protein-anionic polysaccharide emulsification stabilizer, and solves the problems that the conventional emulsification stabilizer is poor in stabilizing effect and short in shelf life. According to the technical scheme, the milk protein-anionic polysaccharide emulsification stabilizer comprises the following raw materials in parts by weight: 0.3-0.6 part of milk protein, 0.3-0.6 part of anionic polysaccharide and 75.7-87.3 parts of water; the preparation method comprises the following steps: dissolving the milk protein into water, adjusting pH to 7, then denaturing at the high temperature of 65-95 DEG C, cooling to 15-25 DEG C, then adjusting pH to 4-8, adding the anionic polysaccharide, stirring till the anionic polysaccharide is dissolved, and obtaining the milk protein-anionic polysaccharide emulsification stabilizer. The milk protein-anionic polysaccharide emulsification stabilizer is good in mouth feel; the raw materials are easy to obtain; the milk protein-anionic polysaccharide emulsification stabilizer is safe and healthy, has a good emulsifying effect, and can effectively improve the stability of milk beverage to prolong the shelf life of a product.

Owner:WUHAN POLYTECHNIC UNIVERSITY

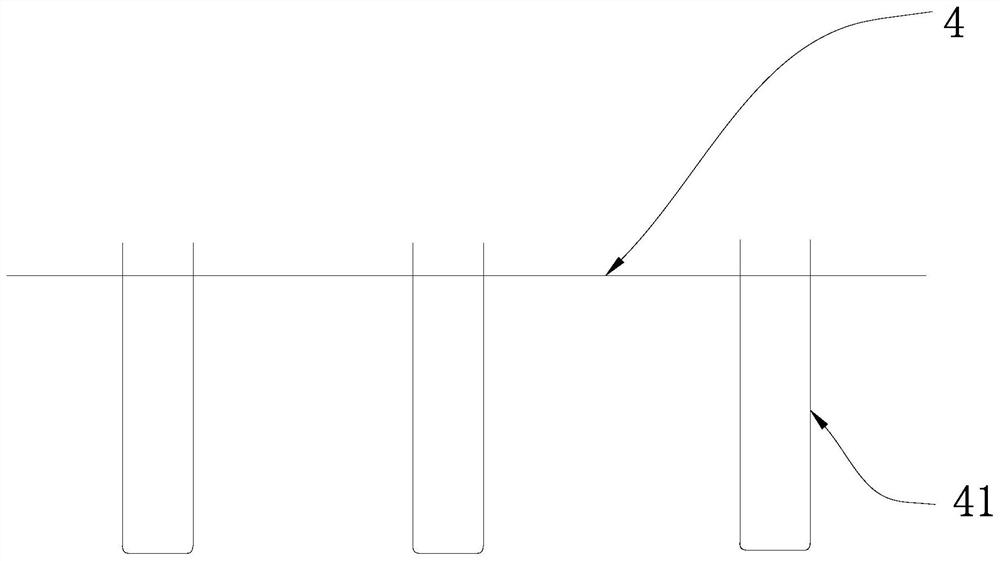

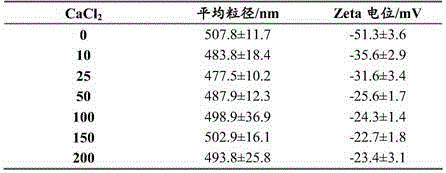

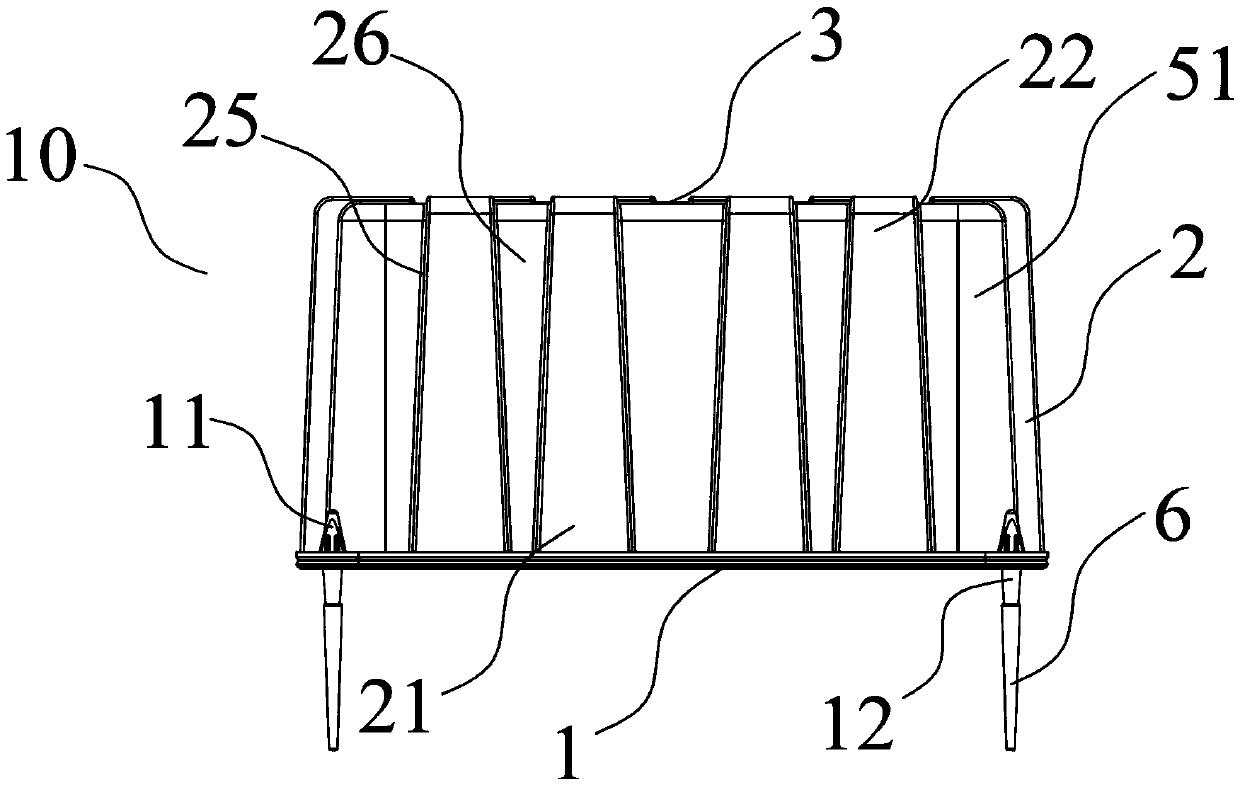

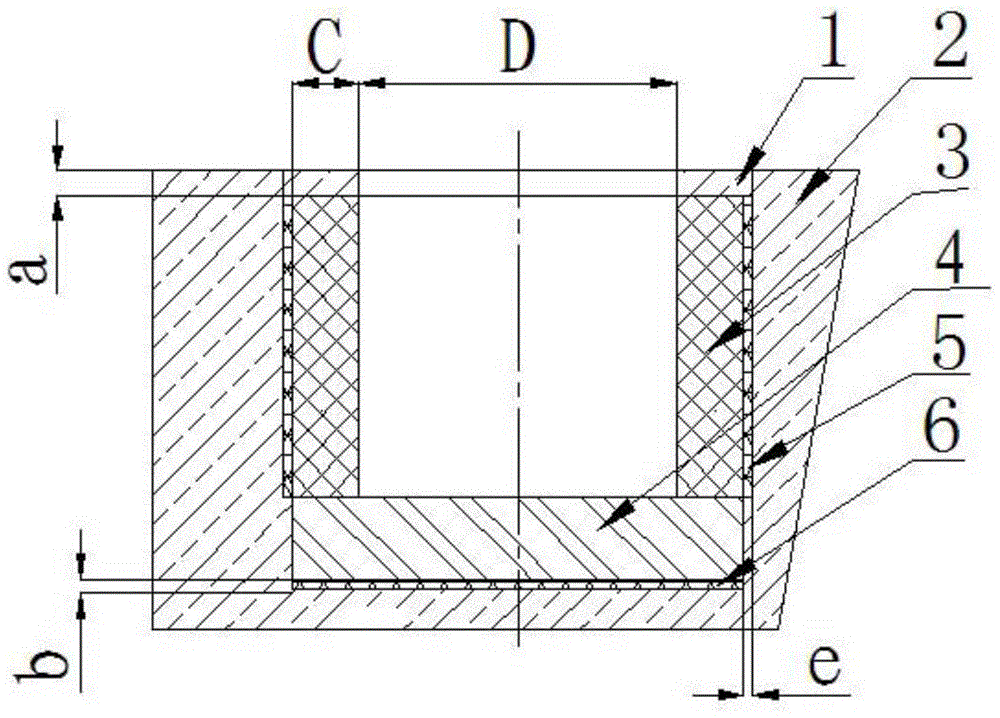

Hollow body, hollow floor and manufacturing method of hollow floor

The invention provides a hollow body. The hollow body is characterized in that a lower cover detachably covers the lower end of an annular lateral wall, an upper cover covers the upper end of the annular lateral wall, and an inner cavity is formed among the lower cover, the annular lateral wall and the upper cover. Preferably, the upper cover detachably covers the upper end of the annular lateral wall. The annular lateral wall is formed by folding a foldable part in a surrounding manner. A through hole is formed in the annular lateral wall. A plurality of vertical folding lines are vertically arranged on the annular lateral wall at intervals. The invention further provides a related hollow floor and a manufacturing and construction method of the hollow floor. The hollow body has the advantages that the hollow body is ingenious in design, simple in structure, convenient to store and transport, capable of increasing prefabricating rate, time saving, labor saving, capable of lowering cost and shortening construction period, safe, economical, environmental friendly, and suitable for large-scale popularization and application; the hollow body does not float in concrete which is not cured, the hollow body can be removed after being combined with a cured concrete base plate, water accumulation in the cavity is avoided, the related hollow floor can be prefabricated, and in-situ reinforcing steel bar laying and hollow floor pouring can be reduced.

Owner:周梅艳

Method for preparing foam cement by utilizing fly ash ceramsite as lightweight aggregate

InactiveCN103951459ASolve floatingImprove weak areasSolid waste managementCeramicwareCarboxymethyl cellulosePolyvinyl alcohol

The invention relates to a method for preparing foam cement by utilizing fly ash ceramsite as lightweight aggregate. The specific process is as follows: step a), adding sodium carboxymethyl cellulose into water and dissolving to obtain sodium carboxymethyl cellulose water solution; step b), adding polyvinyl alcohol solution into the solution, uniformly stirring, then sequentially adding fly ash ceramsite and mixture while stirring, uniformly stirring, finally adding hydrogen peroxide into slurry which is mixed uniformly, fast stirring, placing into a mold, hardening and molding, performing final setting, demolding and performing indoor moisturizing spray or covering a film for curing till a testing period so as to obtain fly ash ceramsite foam cement. According to the method, by adding sodium carboxymethyl cellulose, a weak area between aggregate and cement slurry is improved, the bonding strength is improved, the mechanical properties and the durability of foam cement are significantly improved and the floating problem of ceramsite is solved.

Owner:SHAANXI UNIV OF SCI & TECH

A turbulent flow controller for profiled billet continuous casting tundish and its installation method

The invention relates to a beam blank continuous casting tundish turbulence controller and an installation method thereof. The turbulence controller comprises a shell, a bottom plate, a sleeve core and a pressing ring, wherein the shell is of a cavity structure with the upper opening open, the bottom plate is located at the bottom of the cavity of the shell, the bottom end of the sleeve core is located on the bottom plate, the pressing ring is arranged at the upper end of the sleeve core and located in the cavity of the shell, the longitudinal center line of the pressing ring and the sleeve core coincides with the longitudinal center line of the inner cavity of the shell, and an expansion seam is arranged between the bottom of the inner cavity of the shell and the bottom plate as well as between the inner wall of the shell and the sleeve core. According to the turbulence controller, because the pressing ring is arranged on the sleeve core, the problem that upper layer magnesia carbon bricks on the side wall of the sleeve core fall off is solved; when the turbulence controller is installed, a plurality of pressing bricks are arranged on the same circumference in the same plane above the pressing ring so that the overall floatation problem of the turbulence controller can be solved, the quality stability of the turbulence controller is improved, and the unexpected technological effect is achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Novel combined sedimentation tank

InactiveCN106039776AImprove sedimentation efficiencyGuaranteed treatment effectSedimentation tanksSettling tanks feed/dischargeParticulatesWater discharge

The invention discloses a novel combined sedimentation tank, which comprises a water distribution ditch, a pre-sedimentation zone, a water distribution zone, a fine sedimentation zone and a water discharging ditch. The pre-sedimentation zone is internally equipped with an inclined plate settler and a sludge thickening cone. The fine sedimentation zone is equipped with an inclined tube settler, a sludge thickening cone, a floating sludge baffle and a floating sludge discharging hopper. The pre-sedimentation zone is used for sedimentation of large flocculent particles and the fine sedimentation zone is used for sedimentation of small flocculent particles. The distance between inclined plates of the inclined plate settler is larger the distance between inclined tubes of inclined tube settler. Through the floating sludge discharging hopper, floating sludge inside the floating sludge baffle is discharged outside the sedimentation tank at a fixed period. The novel combined sedimentation tank provides partition sedimentation for large and small flocculent particles, the advantage of a dual settler is utilized, and distance arrangement of inclined plates and inclined tubes enables the problem of blocking of the inclined plates or the inclined plates to be avoided, thereby achieving a high sedimentation efficiency. Through arrangement of the floating sludge discharging hopper and the floating sludge baffle, the content of floating sludge and suspended matters in discharged water is obviously decreased.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

Treatment method for preventing resin-coated controlled-release fertilizer from floating

The invention relates to a treatment method for preventing a resin-coated controlled-release fertilizer from floating. According to the method, a water-retaining agent, talcum powder and water are uniformly mixed, so that an anti-floating agent is obtained; then, the anti-floating agent is added to the resin-coated controlled-release fertilizer, and the mixture is uniformly stirred, so that the surface of the controlled-release fertilizer is uniformly coated with the anti-floating agent; and the controlled-release fertilizer is dried in the shade and then applied. When particles of the fertilizer are applied to the water, the particles absorb water and sink into the water rapidly, so that problem that the resin-coated controlled-release fertilizer floats in the water is solved, problems of nutrient loss and nonuniform fertilization are avoided.

Owner:领先生物农业股份有限公司

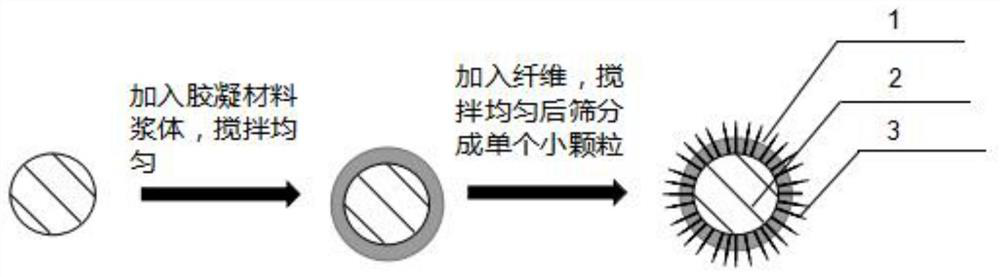

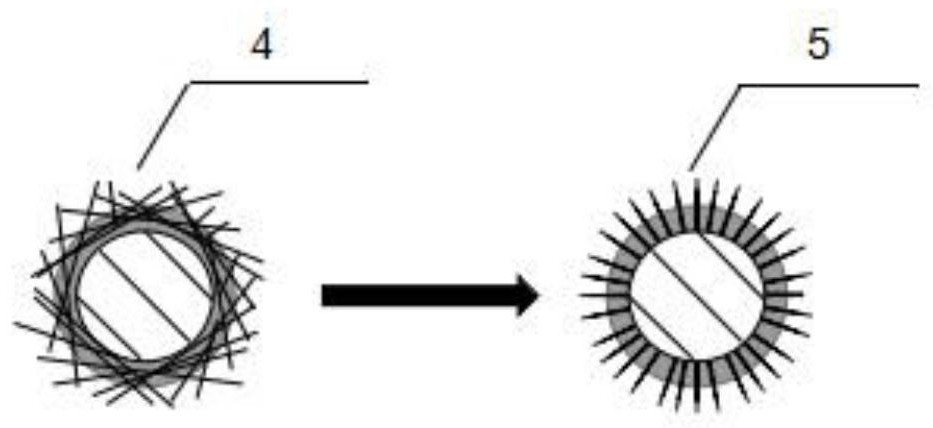

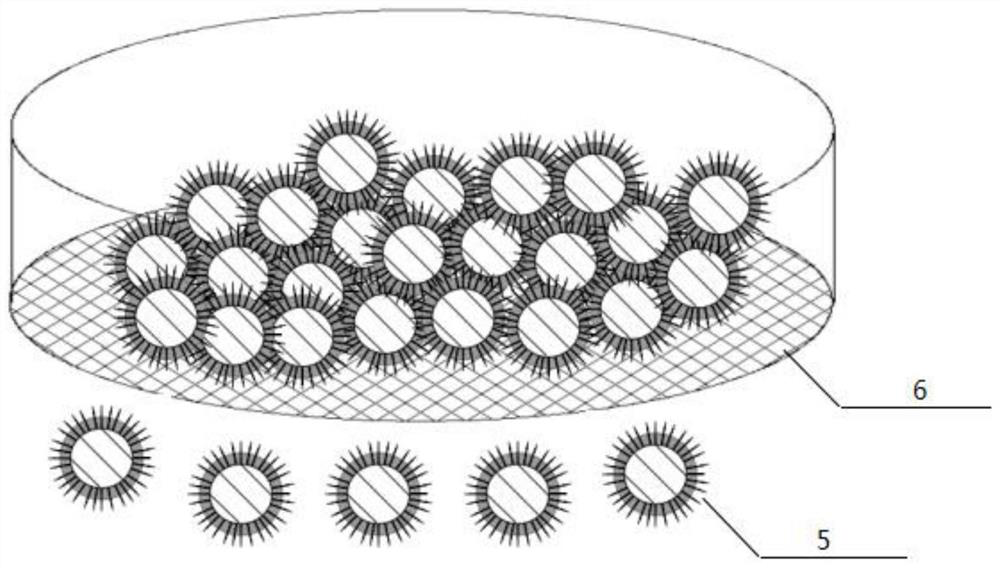

Fiber-wrapped lightweight aggregateand method for inhibiting floating of lightweight aggregate

The invention discloses a fiber-wrapped lightweight aggregate and a method for inhibiting floating of the lightweight aggregate. Pre-wetted lightweight aggregate and fiber are connected into a whole through a small amount of cementing material slurry, a cementing material slurry thin layer with the fiber is formed on the surface of the lightweight aggregate, and the hair-like lightweight aggregate with the fiber is prepared after coagulation and hardening. The lightweight aggregate is used as a novel coarse aggregate to prepare lightweight concrete. Therefore, the floating problem of the lightweight aggregate is effectively solved, and the homogeneity of a test piece is ensured; one end of the fiber on the surface of the lightweight aggregate is embedded and fixed in the thin layer of the cementing material coating the surface of the aggregate, and the other end of the fiber on the surface of the lightweight aggregate is embedded and fixed in concrete slurry, so that the contact area between the aggregate and the cement slurry is increased. Compared with a method of directly adding fibers, the method has the advantages that prepared concrete has larger tensile strength and larger interface bonding strength with the aggregate and cement paste, so that the lightweight aggregate is more effectively prevented from floating upwards.

Owner:BEIJING UNIV OF TECH

Stabilizing agent for coconut milk beverage and method for preparing coconut milk beverage by using stabilizing agent

The invention relates to the field of beverages, and discloses a stabilizing agent for a coconut milk beverage and a method for preparing the coconut milk beverage by using the stabilizing agent. Eachof 100g of the stabilizing agent comprises 0.5-80g of an emulsifying agent, 0.2-15g of an emulsifying agent, 0.1-10g of an acidity regulator, and 0-50g of white granulated sugar. The emulsifying agent is stable multilayer emulsion particles which are prepared by compounding a micromolecule emulsifying agent with a protein macromolecule emulsifying agent, performing emulsifying through combinationof titanium dioxide or hydrophilicity gas phase silicon dioxide superfine solid particles, and finally, performing embedding with sodium starch octenyl succinate. The coconut milk beverage product prepared by using the compound stabilizing agent has the advantages that little fat goes up, the precipitate content is low, obvious black precipitate does not exist, and the mouth feel is refreshing.

Owner:HANGZHOU WAHAHA TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com