A turbulent flow controller for profiled billet continuous casting tundish and its installation method

A technology of turbulence controller and profiled billet continuous casting, which is applied in the field of continuous casting tundish technology, can solve the problems of affecting the service life, unplanned shutdown of profiled billet continuous casting machine, and failure to solve the turbulence controller, etc., so as to improve the safety of use Reliability, solution to unplanned outage accidents, and the effect of solving the overall floating problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

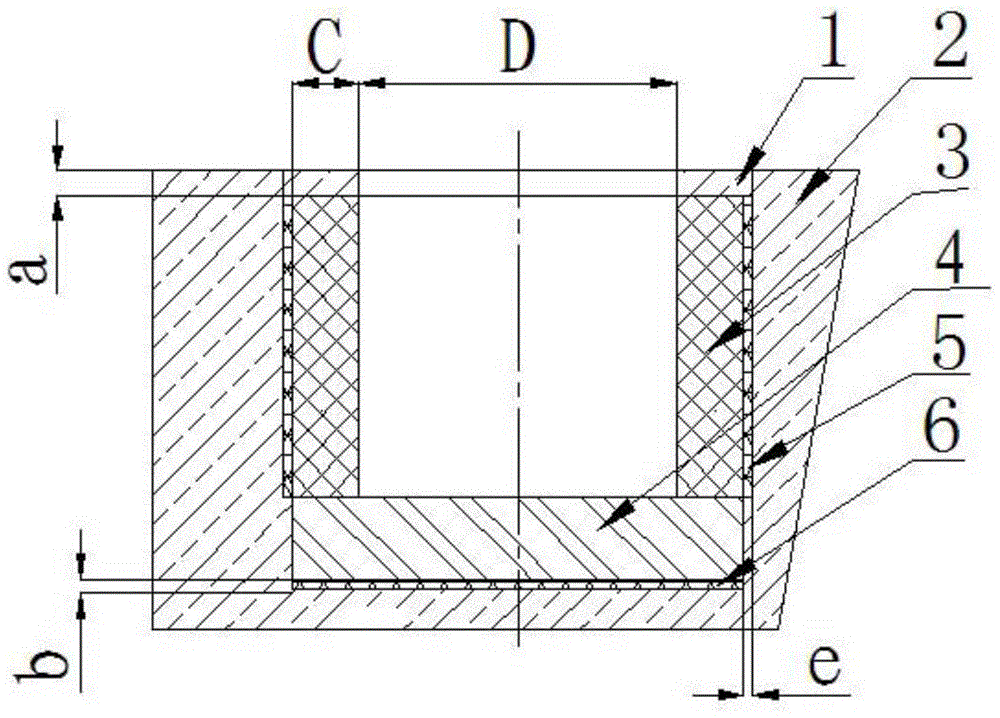

[0042]This embodiment provides a turbulent flow controller 13 for a profiled billet continuous casting tundish, such as figure 1 with figure 2 As shown, the turbulence controller 13 includes a casing 2, a bottom plate 4, a sleeve core 3 and a pressure ring 1. The casing 2 is a cavity structure with an open upper end, the bottom plate 4 is located on the bottom of the cavity of the casing, and the bottom end of the sleeve core 3 is located on the bottom of the bottom plate. 4, the pressure ring 1 is arranged on the upper end of the sleeve core 3 and is located in the housing cavity, the longitudinal centerline of the pressure ring 1 and the sleeve core 3 coincides with the longitudinal centerline of the inner cavity of the housing, and the bottom of the inner cavity of the housing and the bottom plate 4, An expansion joint is set between the inner wall of the shell and the sleeve core 3, and an anti-oxidation coating is applied on the exposed surface of the sleeve core and the...

Embodiment 2

[0050] This embodiment provides a tundish turbulence controller for profiled billet continuous casting, the structure is as described in Embodiment 1, the difference is that the bottom plate 4 is made of magnesia carbon bricks and the length, width, and thickness are 230×115×65mm. The thickness of the expansion joint A5 between the inner wall of the shell and the sleeve core 3 is 1.5 mm; the thickness of the expansion joint B6 between the bottom of the shell cavity and the bottom plate 4 is 2.5 mm.

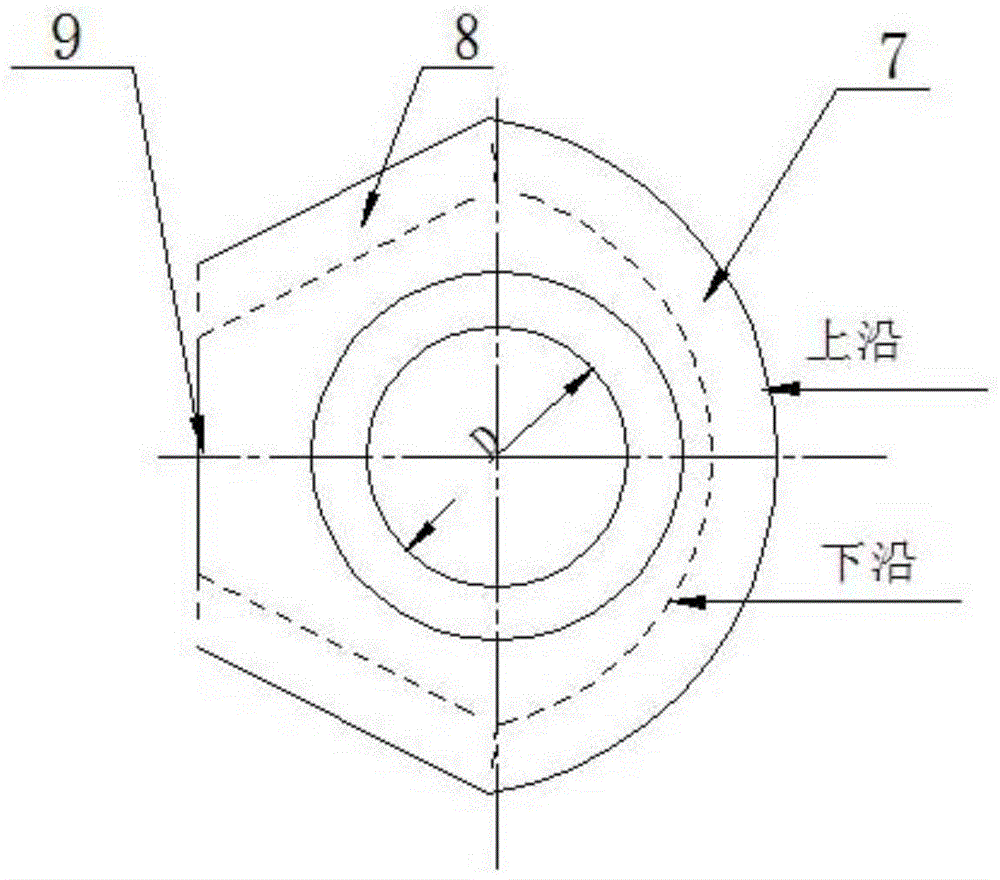

[0051] The sleeve core 3 and the pressure ring 1 are both designed as circular cylindrical bodies, the ring inner diameter D of the sleeve core 3 and the pressure ring 1 is 420mm, the ring thickness C of the sleeve core 3 is 115mm, and the ring thickness of the pressure ring 1 is the sum of the ring thickness C of the sleeve core and the thickness e of the expansion joint A5, the ring height a of the pressure ring 1 is 35mm, and the pressure ring 1 is casted with magnesium spinel c...

Embodiment 3

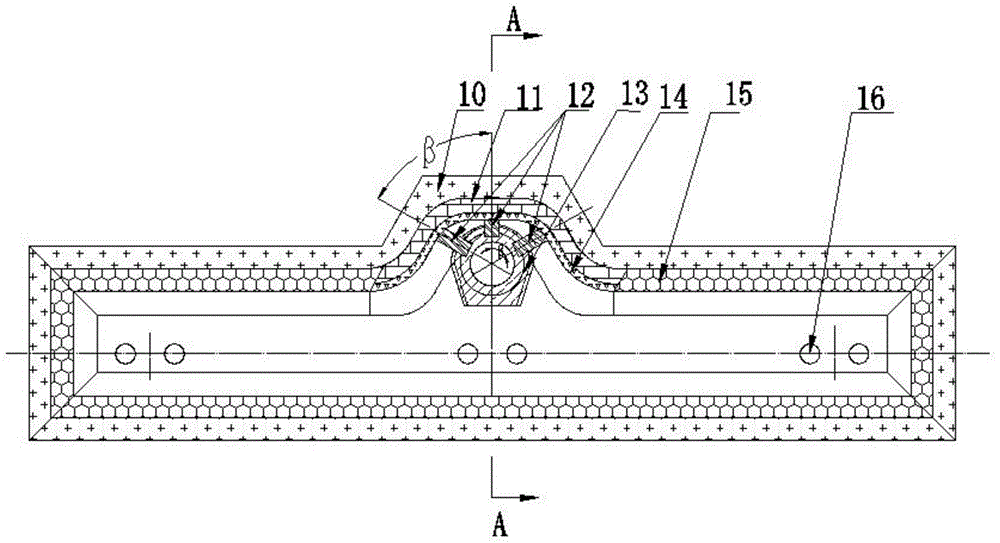

[0053] Such as image 3 with Figure 4 As shown, this embodiment provides a method for installing a turbulence controller in a profiled billet continuous casting tundish, including the following steps,

[0054] (1) Using the existing technology, first construct the bottom-wrapping working lining dry material 17, with a thickness h of 80 mm; then construct the wall-wrapping working lining dry material 15 other than the impact zone working lining, with a thickness z of 80 mm, and then bake and form ;

[0055] (2) Position the turbulence controller 13 so that its longitudinal centerline coincides with the centerline of the ladle shroud 18, and fill the space between the turbulence controller 13 and the tundish permanent lining 10 with a spread;

[0056] (3) Fix the turbulence controller 13, use the used magnesia-carbon brick wet method to build the working lining 11 in the impact area, and when the masonry reaches the upper edge of the turbulence controller 13, place three pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com