Three-dimensional graphene, polyaniline and cobaltosic oxide composite material and preparation method and application

A technology of tricobalt tetroxide and composite materials, which is applied in the directions of cobalt oxide/cobalt hydroxide, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc. , the effect of increasing the specific surface area and improving the electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

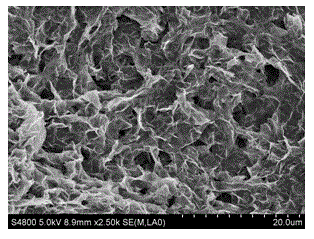

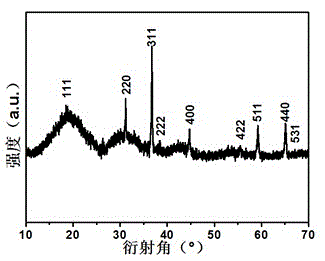

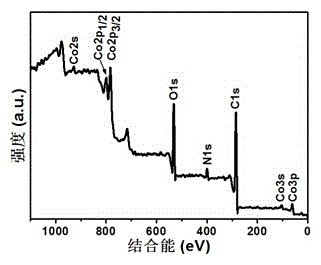

[0047] A three-dimensional graphene / polyaniline / cobalt tetroxide composite material, composed of graphene, polyaniline and cobalt tetroxide, has a three-dimensional micron or nanometer porous structure, wherein cobalt tetroxide grows on the nanofibers of polyaniline to form polyaniline / cobalt tetroxide nanoparticles, The polyaniline / cobalt trioxide nanoparticles are evenly distributed on the graphene surface.

[0048] The above-mentioned preparation method of a kind of three-dimensional graphene / polyaniline / cobalt tetroxide composite material specifically comprises the following steps:

[0049] (1) Add 1 mg of graphene oxide to 1 ml of dispersant 1, and control the ultrasonic power to 300-400w at room temperature for 30-90 minutes to disperse evenly to obtain a graphene oxide dispersion;

[0050] Described dispersant 1 is deionized water, and its consumption is by graphene oxide: dispersant 1 is 1mg: 1mL;

[0051] (2) Add 60ml of aniline monomer into 1mg of dispersant 2, and ...

Embodiment 2

[0068] A three-dimensional graphene / polyaniline / cobalt tetroxide composite material, composed of graphene, polyaniline and cobalt tetroxide, has a three-dimensional micron or nanometer porous structure, wherein cobalt tetroxide grows on the nanofibers of polyaniline to form polyaniline / cobalt tetroxide nanoparticles, The polyaniline / cobalt trioxide nanoparticles are evenly distributed on the graphene surface.

[0069] The above-mentioned preparation method of a kind of three-dimensional graphene / polyaniline / cobalt tetroxide composite material specifically comprises the following steps:

[0070] (1) Add 1mg of graphene oxide into 3ml of dispersant 1, control the ultrasonic power at room temperature to 300-400w for 30-90min to disperse evenly, and obtain the graphene oxide dispersion;

[0071] Described dispersant 1 is deionized water, and its consumption is by graphene oxide: dispersant 1 is 1mg: 3mL;

[0072] (2) Add 30ml of aniline monomer to 1mg of dispersant 2, control the...

Embodiment 3

[0088] A three-dimensional graphene / polyaniline / cobalt tetroxide composite material, composed of graphene, polyaniline and cobalt tetroxide, has a three-dimensional micron or nanometer porous structure, wherein cobalt tetroxide grows on the nanofibers of polyaniline to form polyaniline / cobalt tetroxide nanoparticles, The polyaniline / cobalt trioxide nanoparticles are evenly distributed on the graphene surface.

[0089] The above-mentioned preparation method of a kind of three-dimensional graphene / polyaniline / cobalt tetroxide composite material specifically comprises the following steps:

[0090] (1) Add 1 mg of graphene oxide to 5 ml of dispersant 1, and control the ultrasonic power to 300-400w at room temperature for 30-90 minutes to disperse evenly to obtain a graphene oxide dispersion;

[0091] Described dispersant 1 is deionized water, and its consumption is by graphene oxide: dispersant 1 is 1mg: 5mL;

[0092] (2) Add 50ml of aniline monomer into 1mg of dispersant 2, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com