Patents

Literature

159 results about "Polyaniline nanofibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

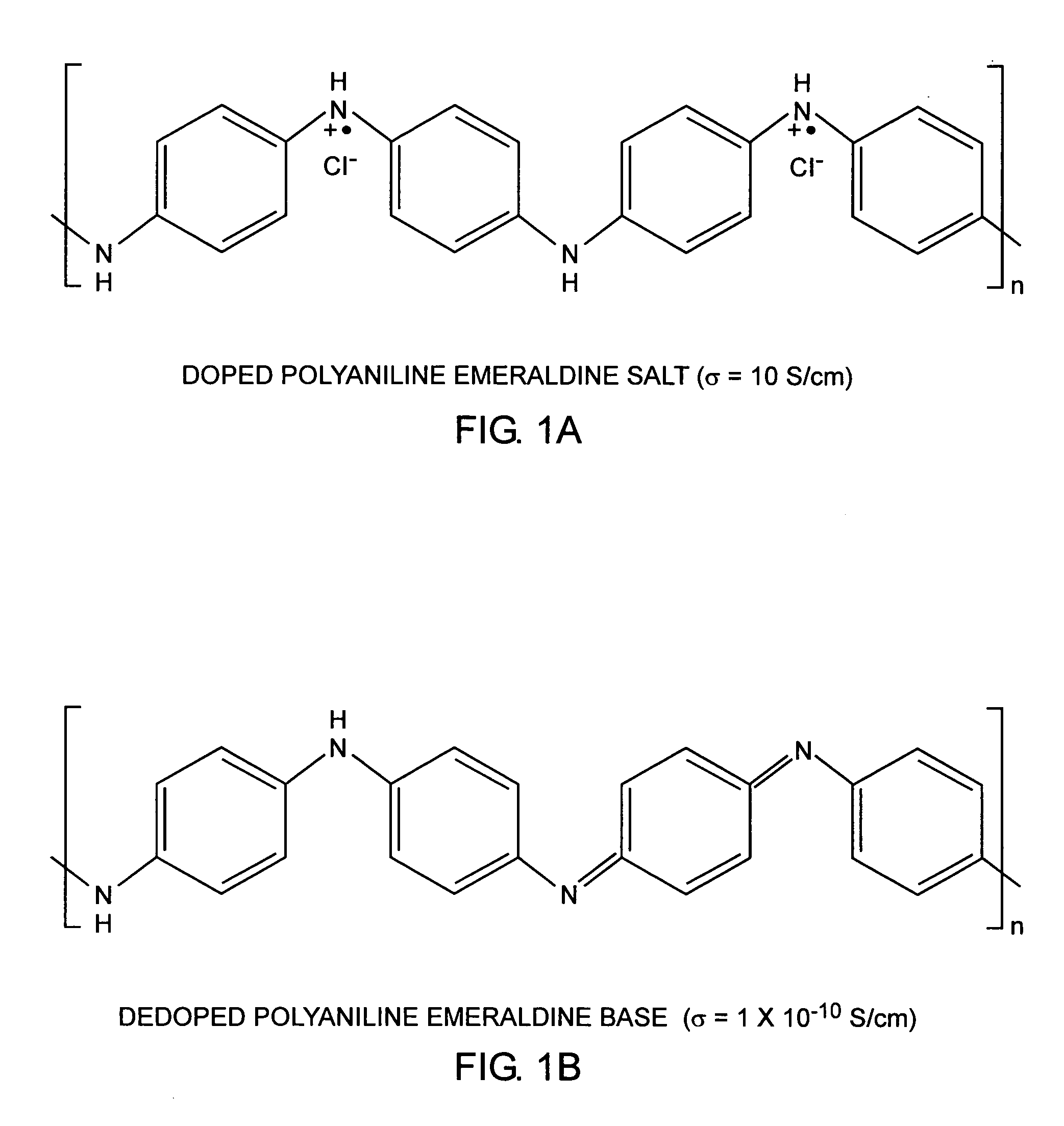

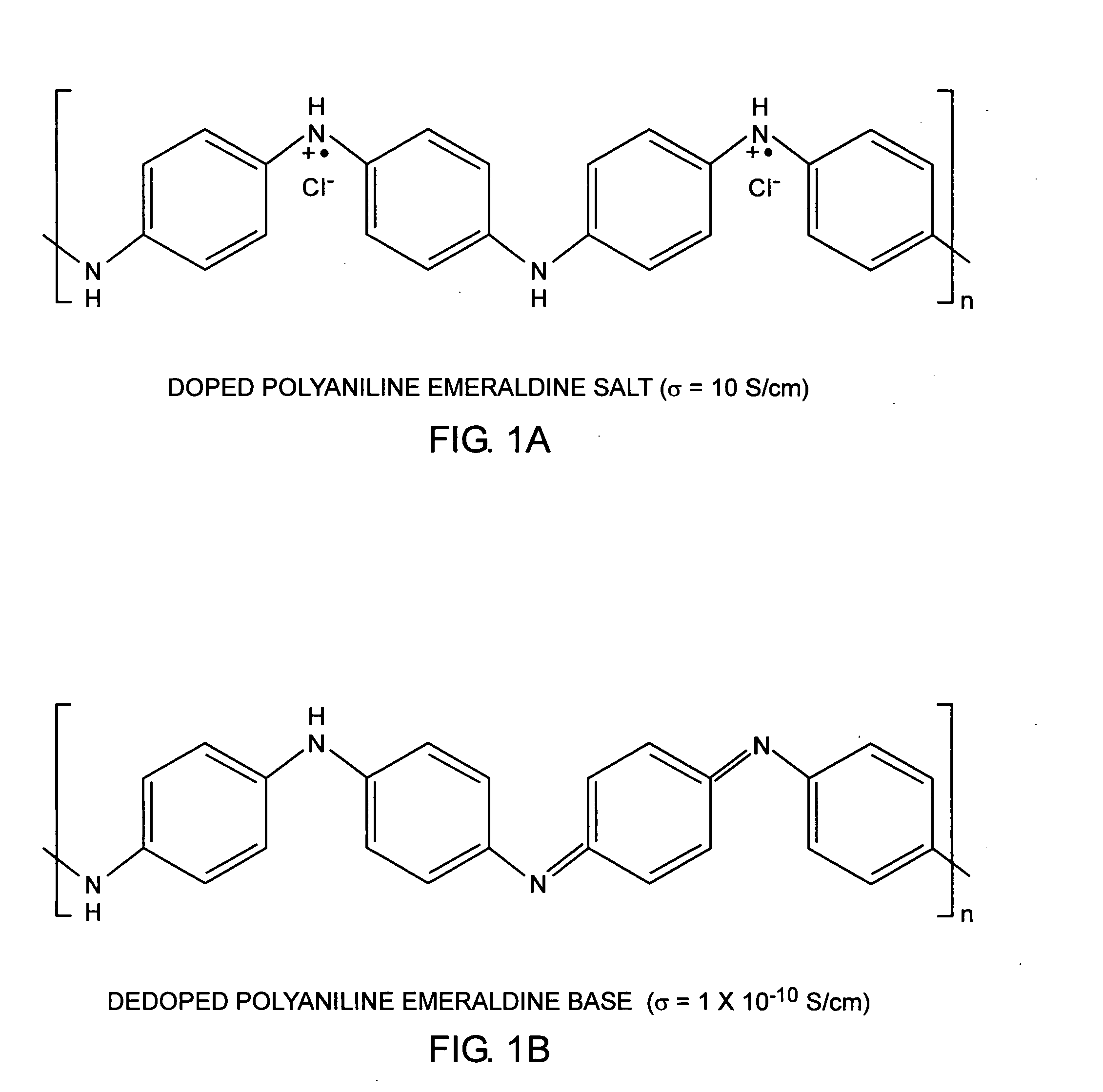

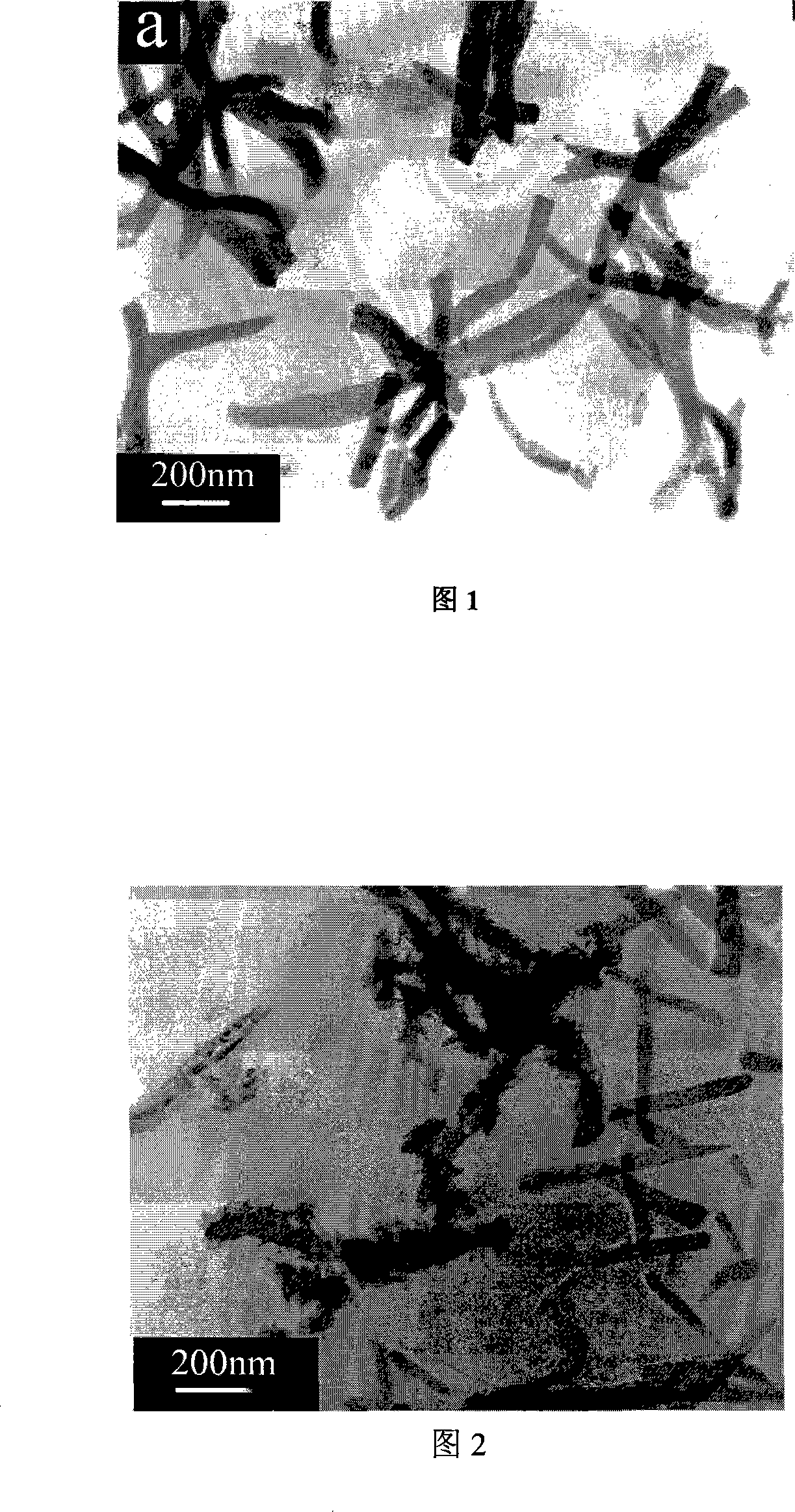

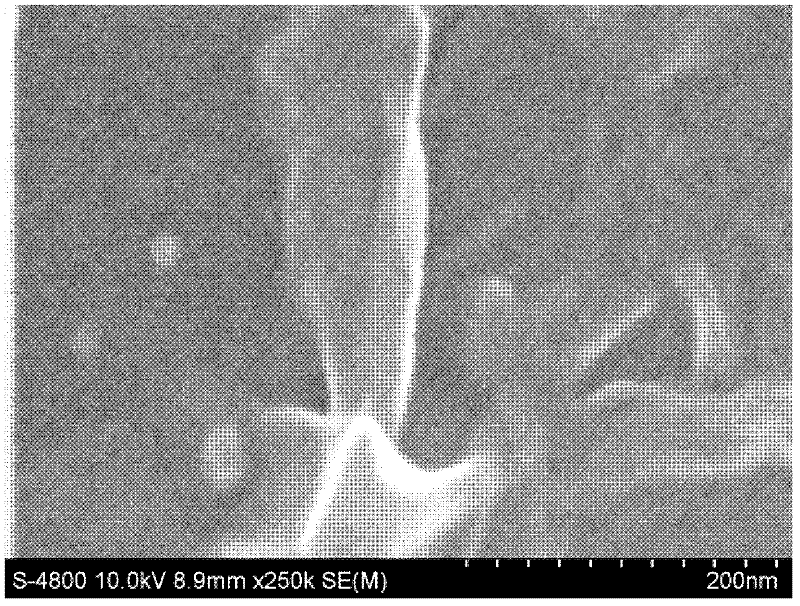

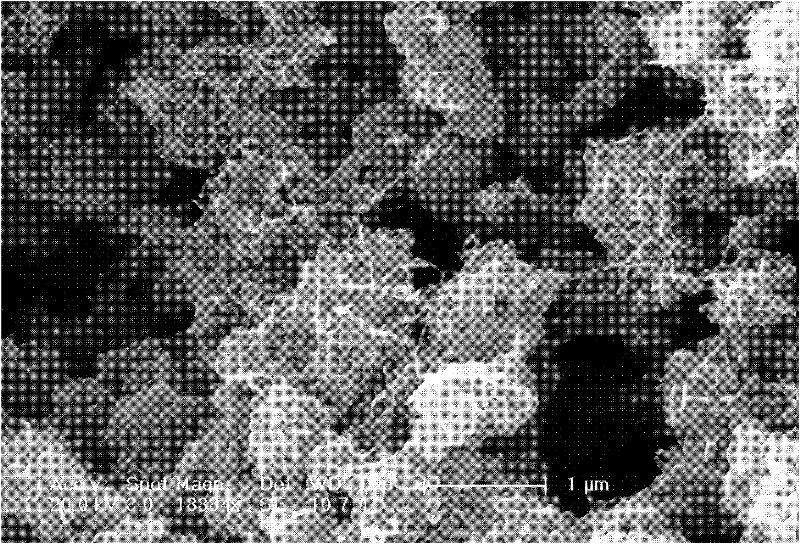

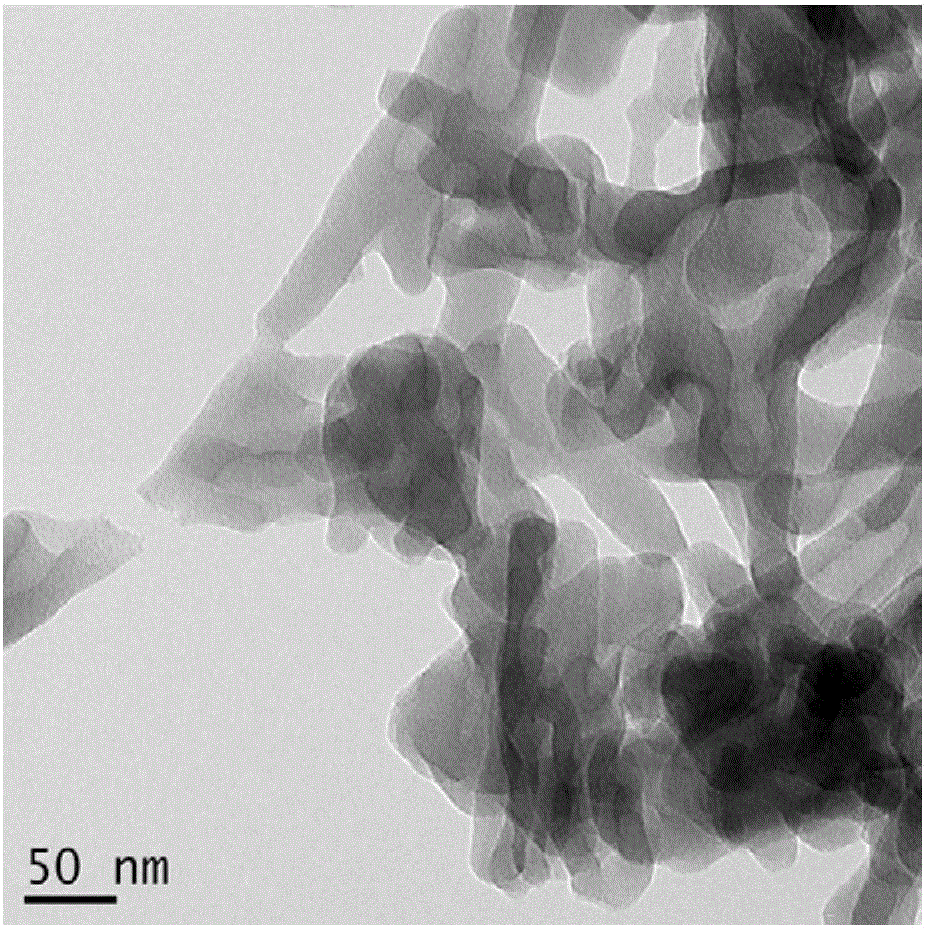

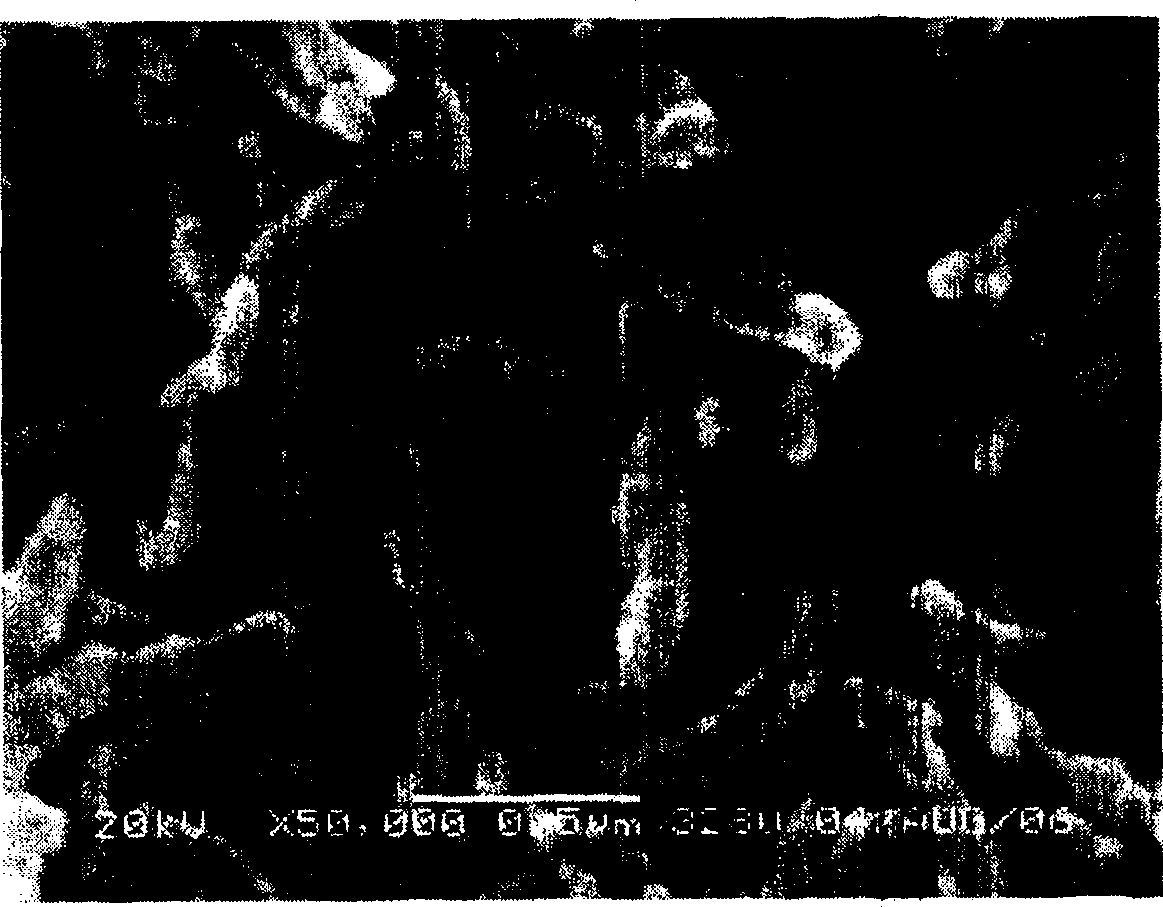

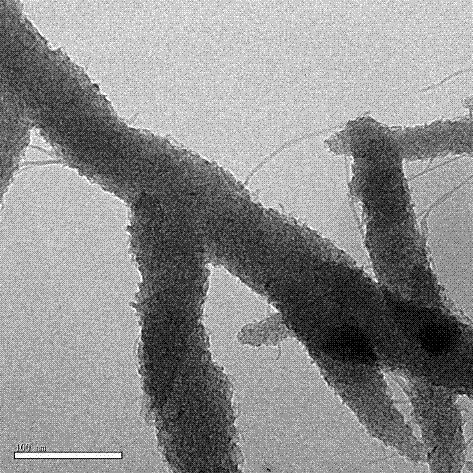

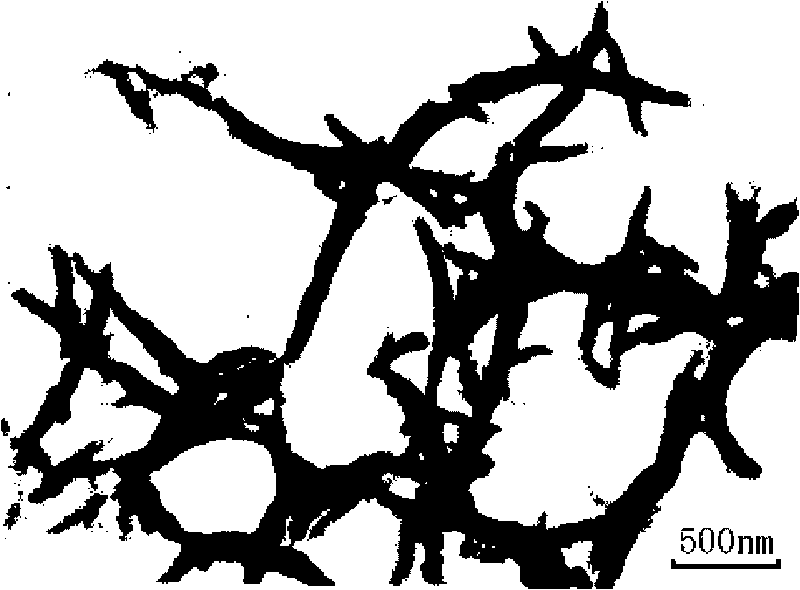

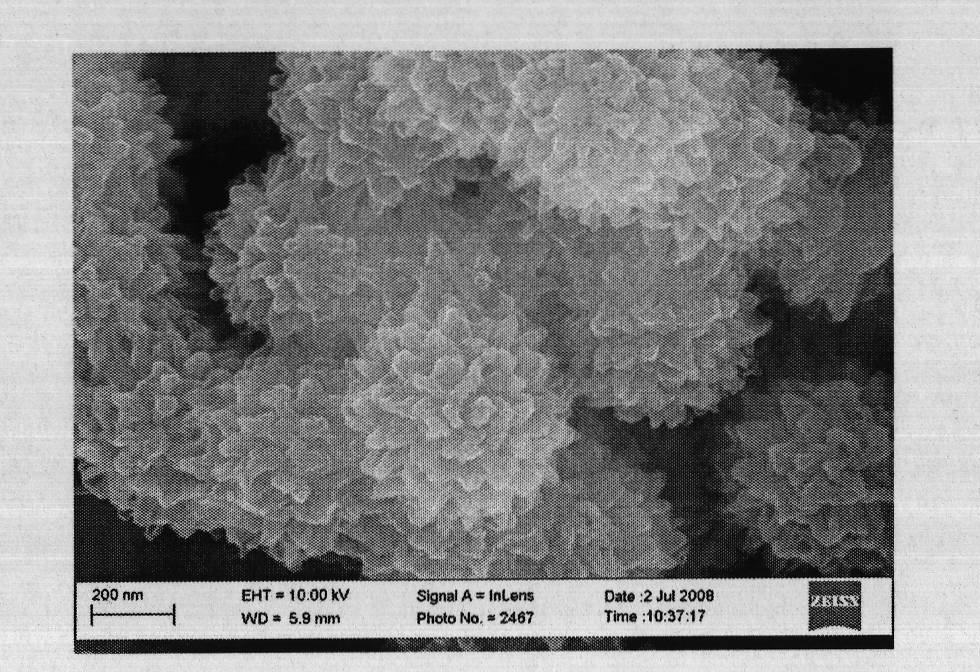

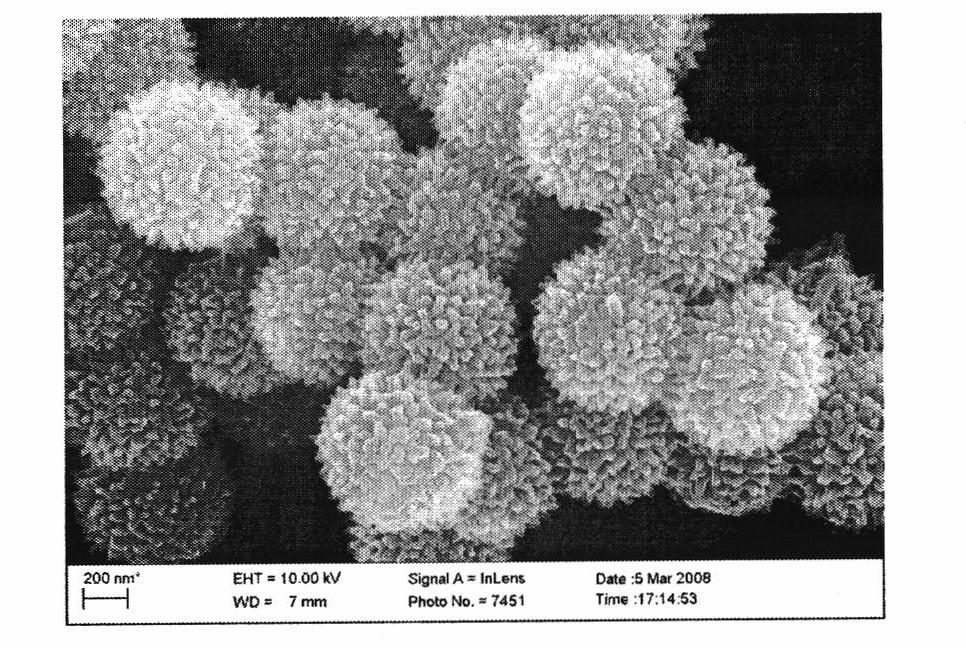

Polyaniline nanofibers are a high aspect form of polyaniline, a polymer consisting of aniline monomers, which appears as discrete long threads with an average diameter between 30 nm and 100 nm. Polyaniline is one of the oldest known conducting polymers, being known for over 150 years. Polyaniline nanofibers are often studied for their potential to enhance the properties of polyaniline or have additional beneficial properties due to the addition of a nanostructure to the polymer. Properties that make polyaniline useful can be seen in the nanofiber form as well, such as facile synthesis, environmental stability, and simple acid/base doping/dedoping chemistry. These and other properties have led to the formation of various applications for polyaniline nanofibers as actuators, memory devices, and sensors.

Preparation method of conductive polymer polyanilinc nano fiber

InactiveCN1786304AEasy to getEasy to manufactureMonocomponent synthetic polymer artificial filamentFiberSolubility

The invention relates to a conduction macromolecule polyaniline nanometer fiber manufacturing method. It includes the following steps: respectively dissolving aniline and oxidant in acid with water medium; mixing them with action of ultrasonic wave, and controlling temperature at¿C5-30 centigrade degree to do aniline polyreaction; gaining doping state polyaniline nanometer fiber when it finishes; removing the water and solubility impurity; drying; using ammonia liquor to neutralize the doping state; filtering; washing; drying; gaining eigenstate polyaniline nanometer fiber; processing it by dopant to gain conduct state; drying to gain powdery purpose. The invention adopts ultrasonic wave in polyreaction to gain polyaniline fiber with 20-100nm diameter, 500-5000nm length. The method has simple operation, and high yield.

Owner:XI AN JIAOTONG UNIV

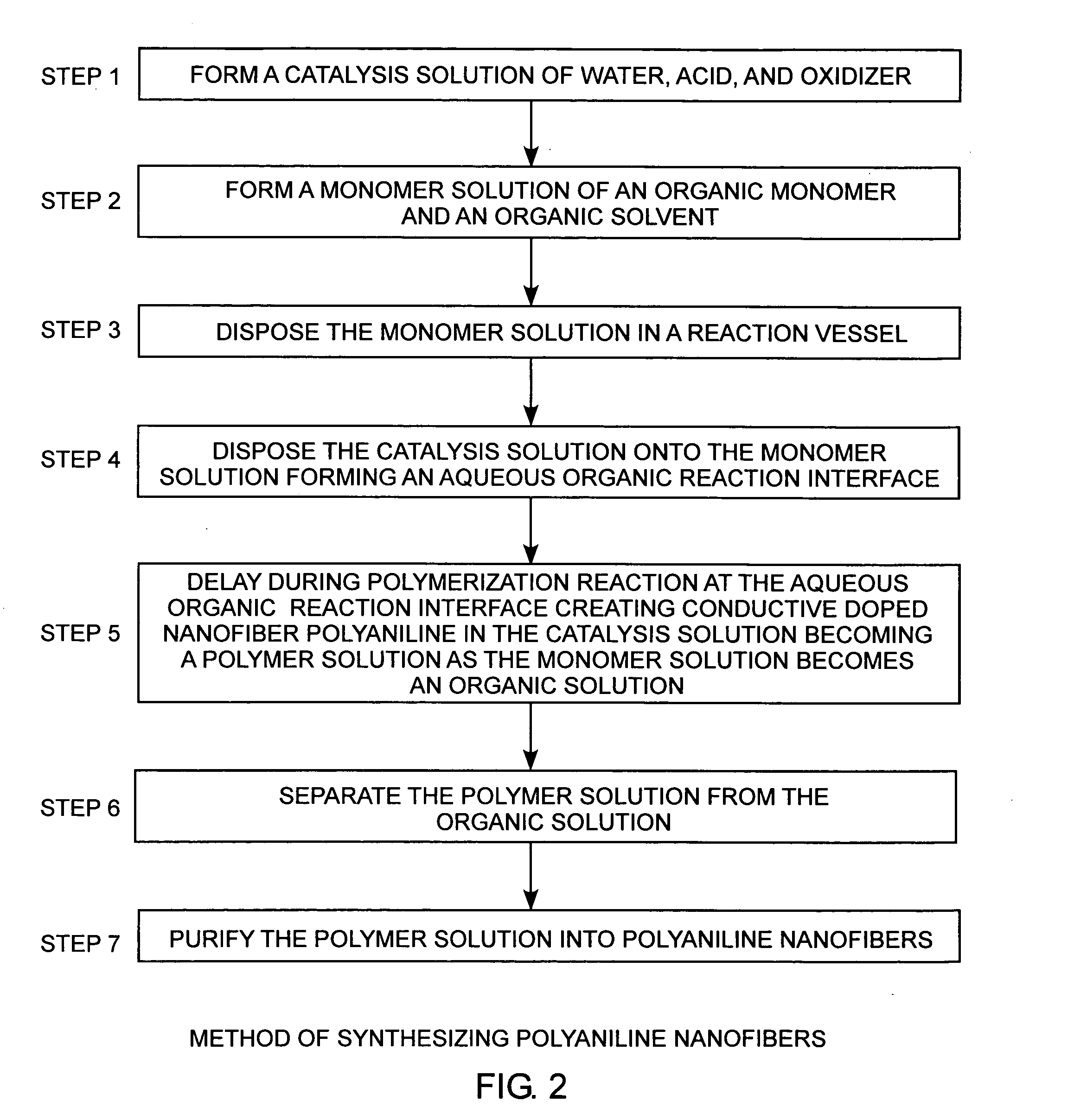

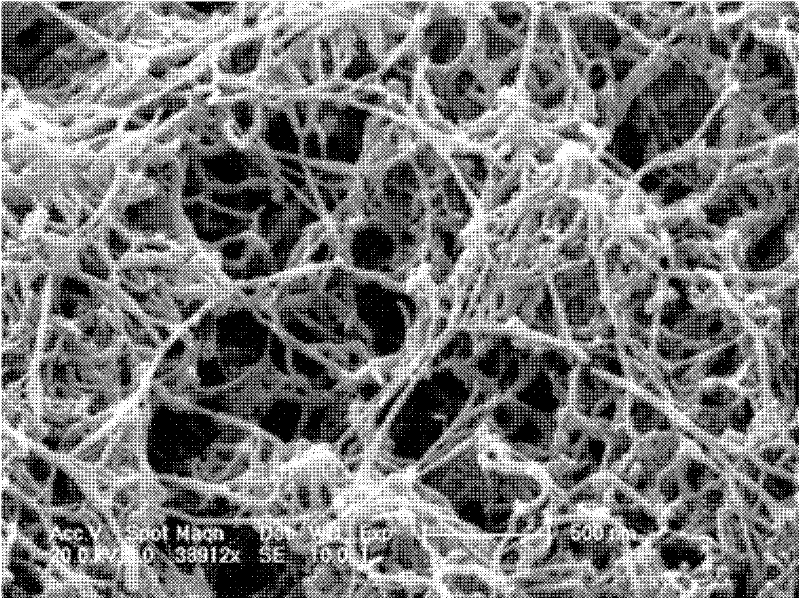

Synthetic method for conducting polymer nanofibers

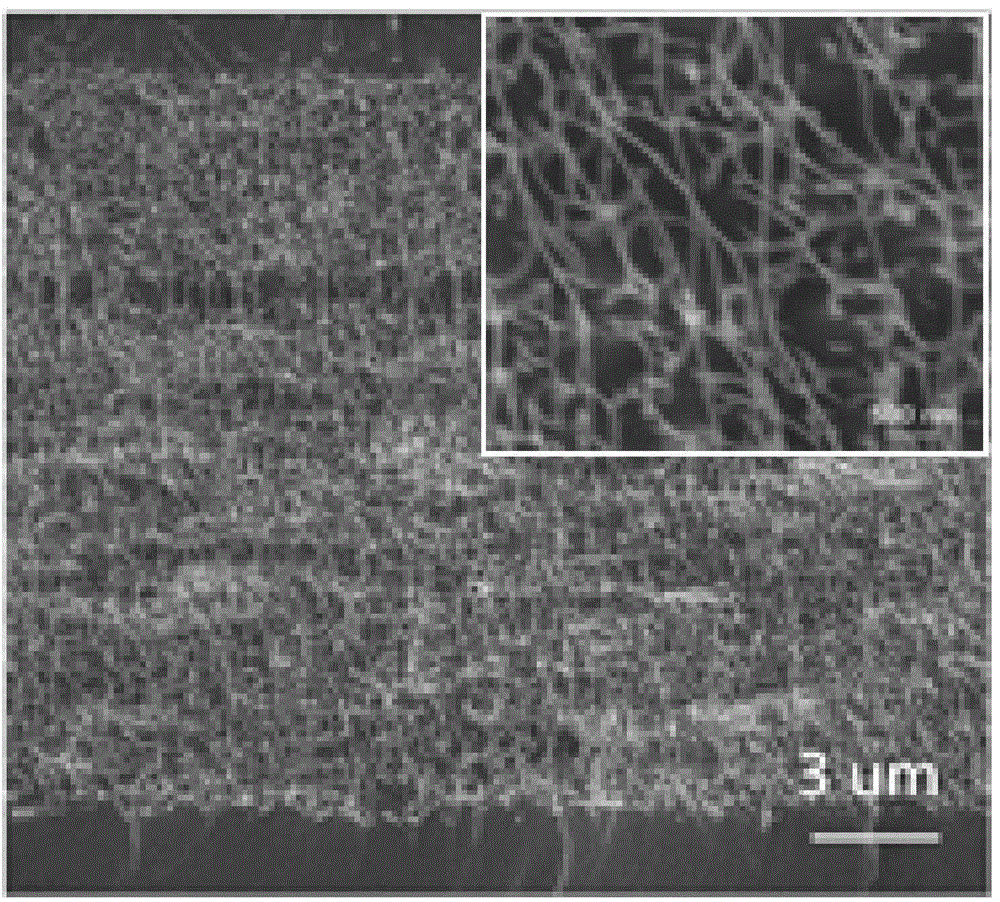

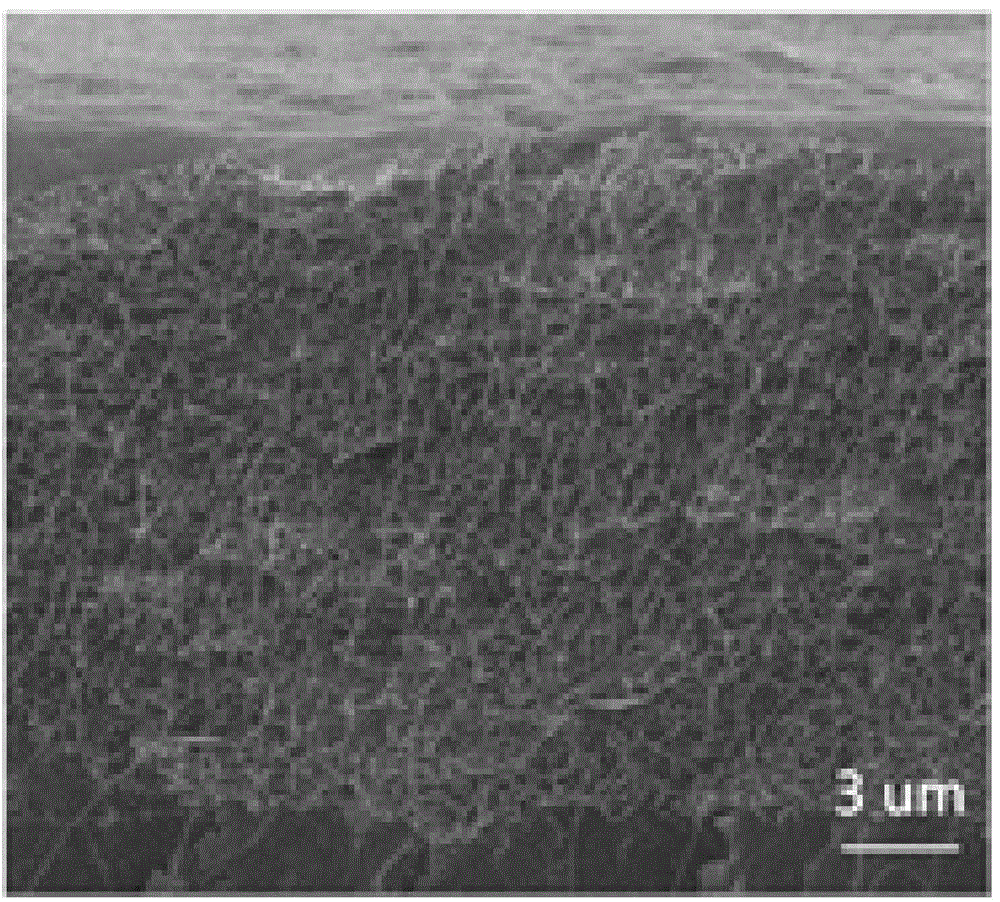

ActiveUS20050131139A1High sensitivityFaster chemical time responseMaterial nanotechnologySynthetic resin layered productsFiberTime response

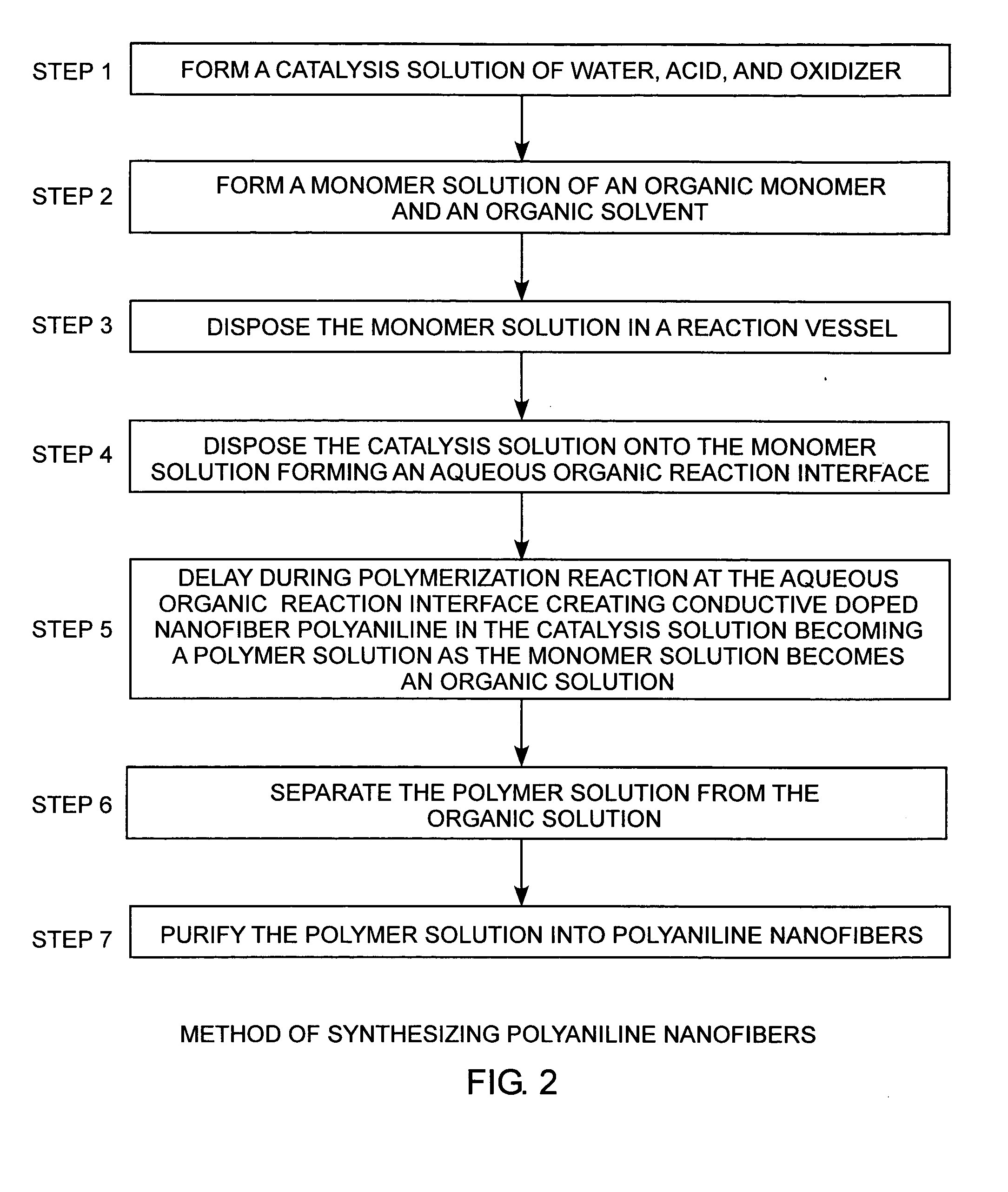

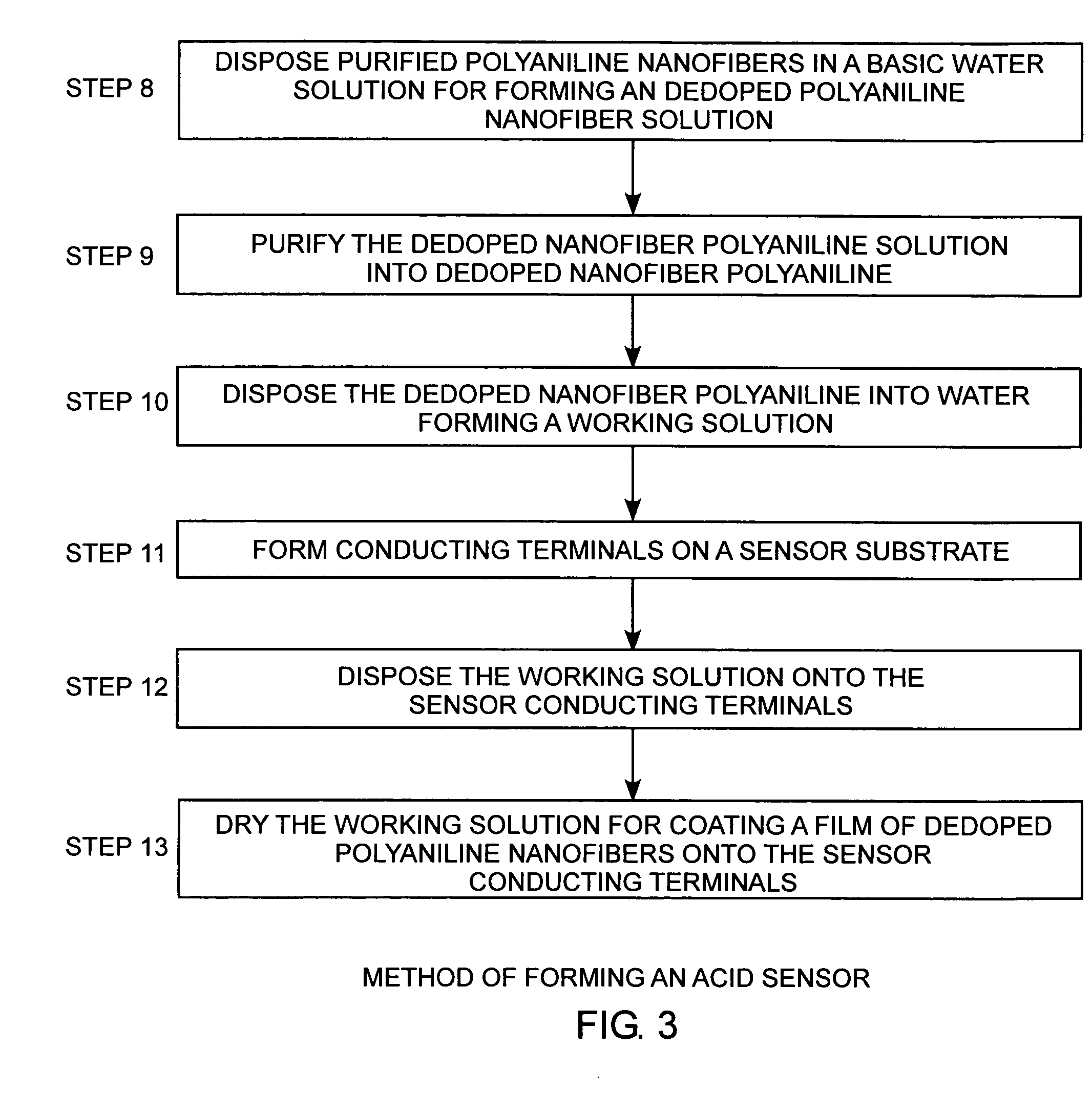

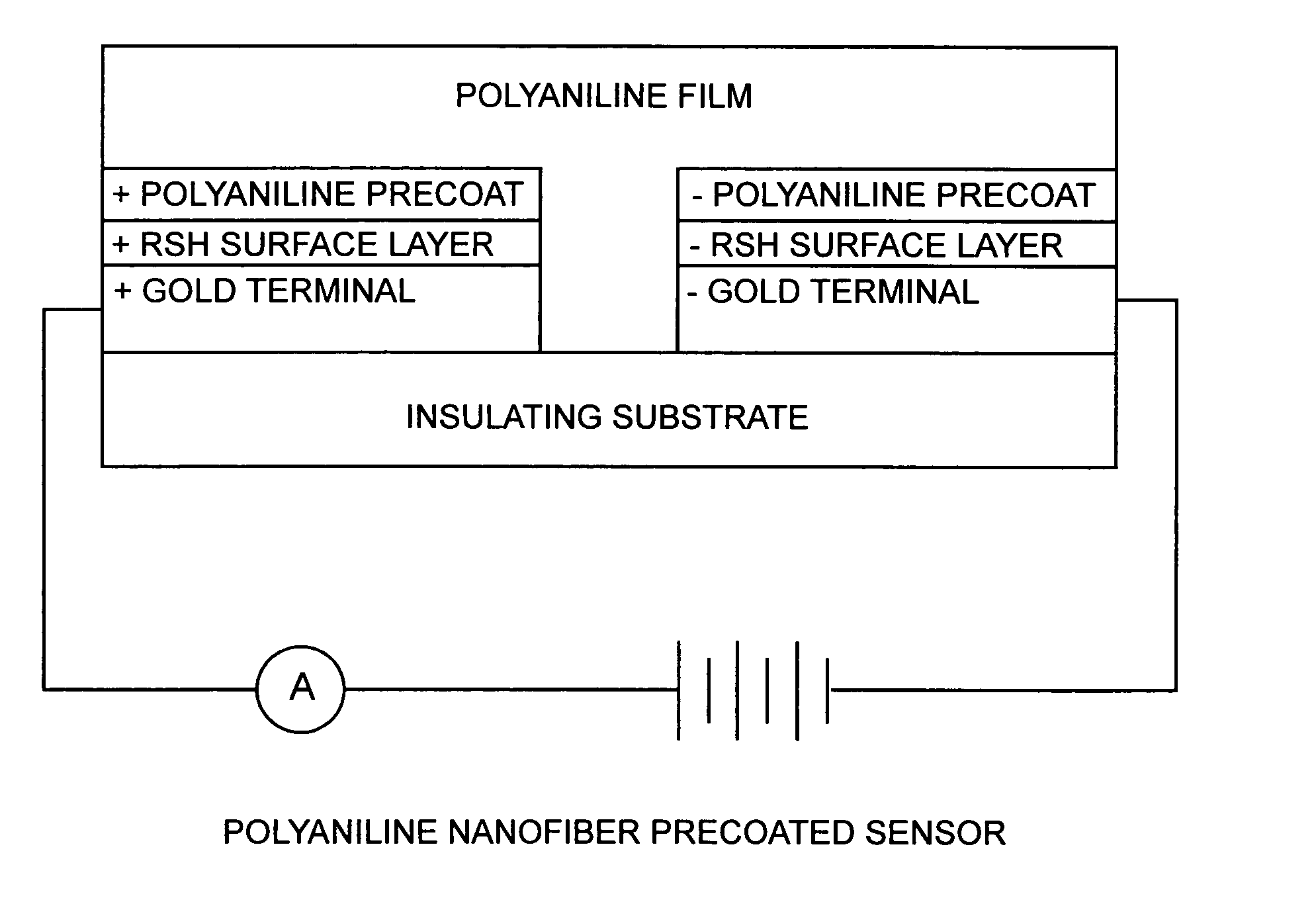

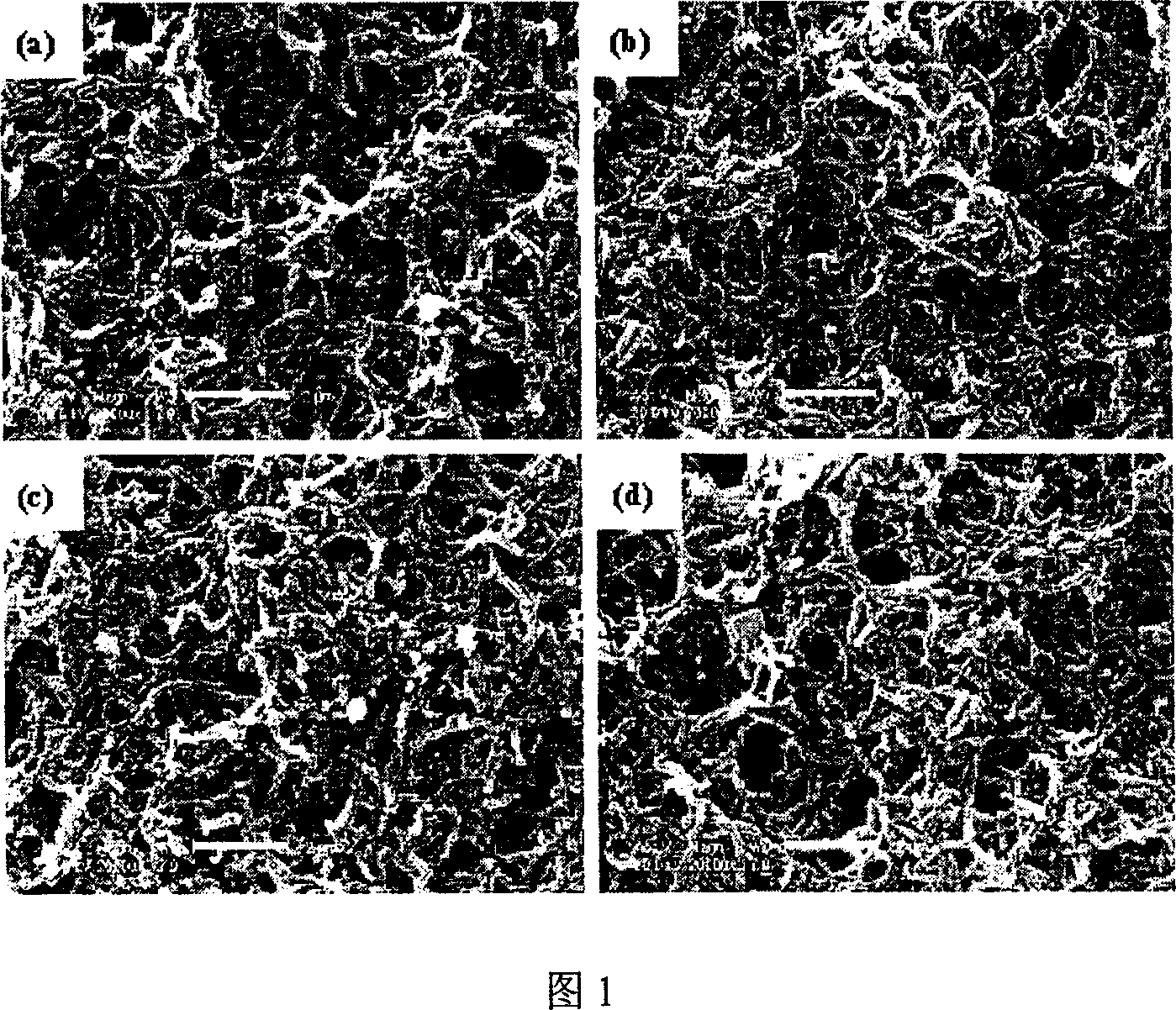

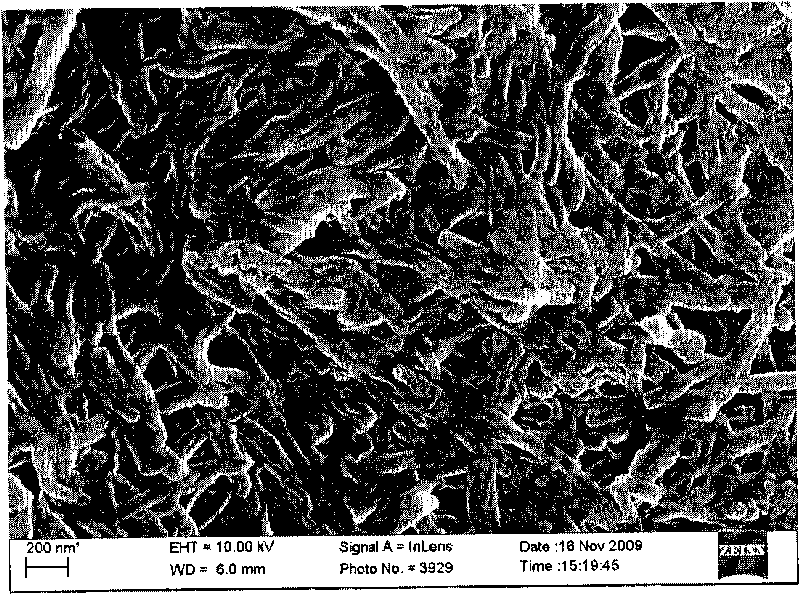

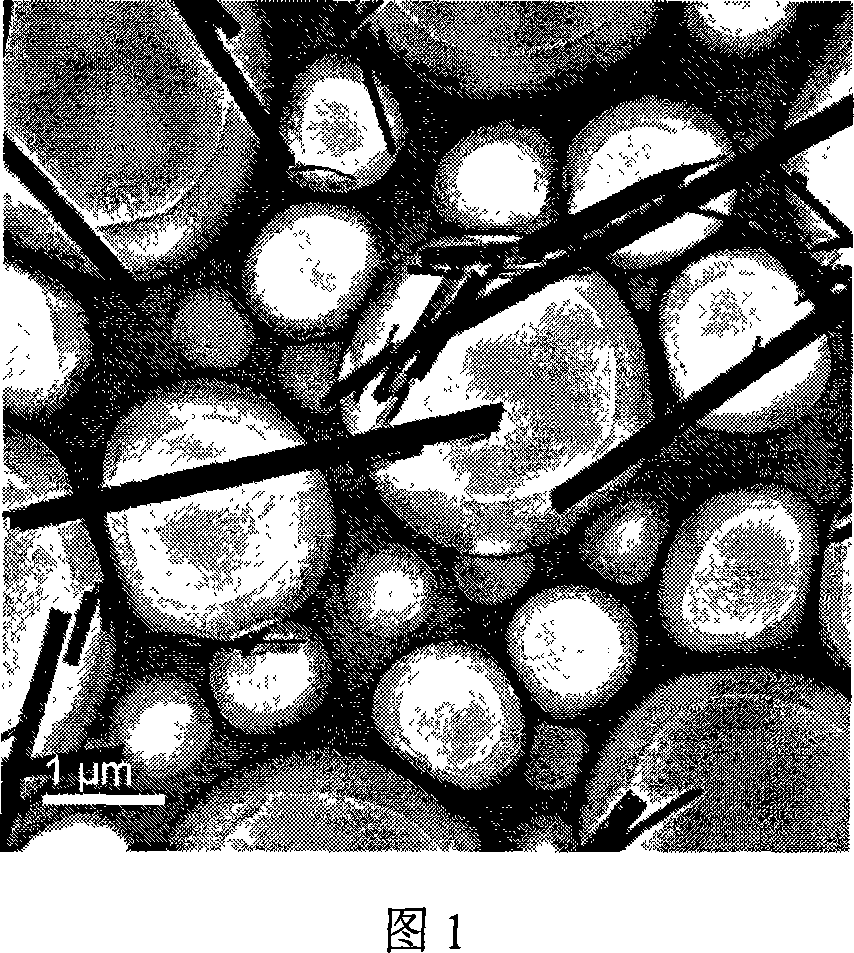

Polymer nanofibers, such as polyaniline nanofibers, with uniform diameters less than 500 nm can be made in bulk quantities through a facile aqueous and organic interfacial polymerization method at ambient conditions. The nanofibers have lengths varying from 500 nm to 10 μm and form interconnected networks in a thin film. Thin film nanofiber sensors can be made of the polyaniline nanofibers having superior performance in both sensitivity and time response to a variety of gas vapors including, acids, bases, redox active vapors, alcohols and volatile organic chemicals.

Owner:THE AEROSPACE CORPORATION +1

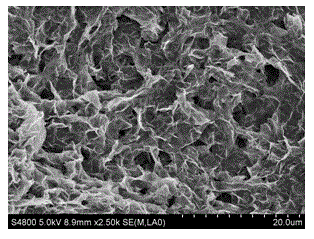

Preparation method for high-concentration graphene-polyaniline nanofiber composite dispersion liquid and high-concentration graphene-polyaniline nanofiber composite film

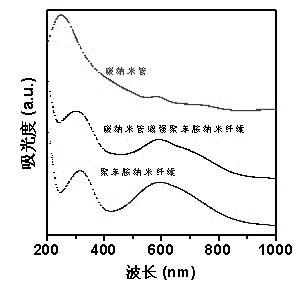

The invention relates to a preparation method for a high-concentration graphene-polyaniline nanofiber composite dispersion liquid and a high-concentration graphene-polyaniline nanofiber composite film. The method comprises: respectively adding graphite oxide and polyaniline nanofiber to two parts of distilled water to carry out ultrasonic dispersion to obtain a graphene oxide dispersion liquid and a polyaniline nanofiber dispersion liquid; adding the polyaniline nanofiber dispersion liquid to the graphene oxide dispersion liquid in a dropwise manner, then carrying out ultrasonic dispersion toform a composite dispersion liquid; mixing the composite dispersion liquid and a reducing agent, then carrying out the reaction under conditions of a constant temperature and ultrasonic wave to obtain the graphene-polyaniline nanofiber composite dispersion liquid; carrying out vacuum filtration for the graphene-polyaniline nanofiber composite dispersion liquid to prepare the composite film; adopting dilute acid leaching to prepare the self-supporting composite film with high conductivity. According to the method, the polyaniline nanofiber is adopted as the dispersion stabilizer for the graphene to prepare the high-concentration composite dispersion liquid, such that the problem of difficult removal of the traditional dispersing agent is solved, the synergistic effect of the composite material is easily provided. In addition, the prepared self-supporting composite film has good flexibility and high conductivity.

Owner:XI AN JIAOTONG UNIV

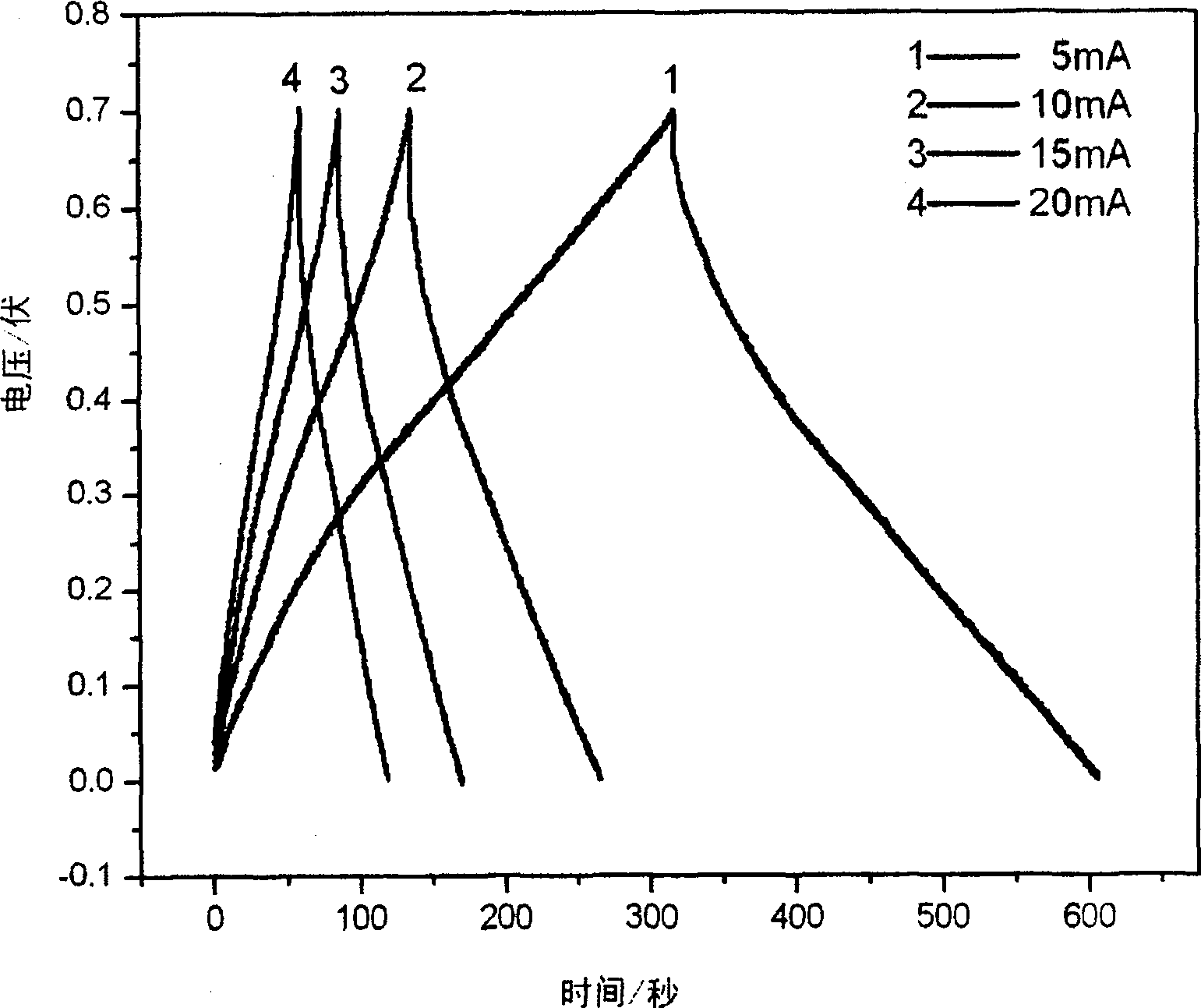

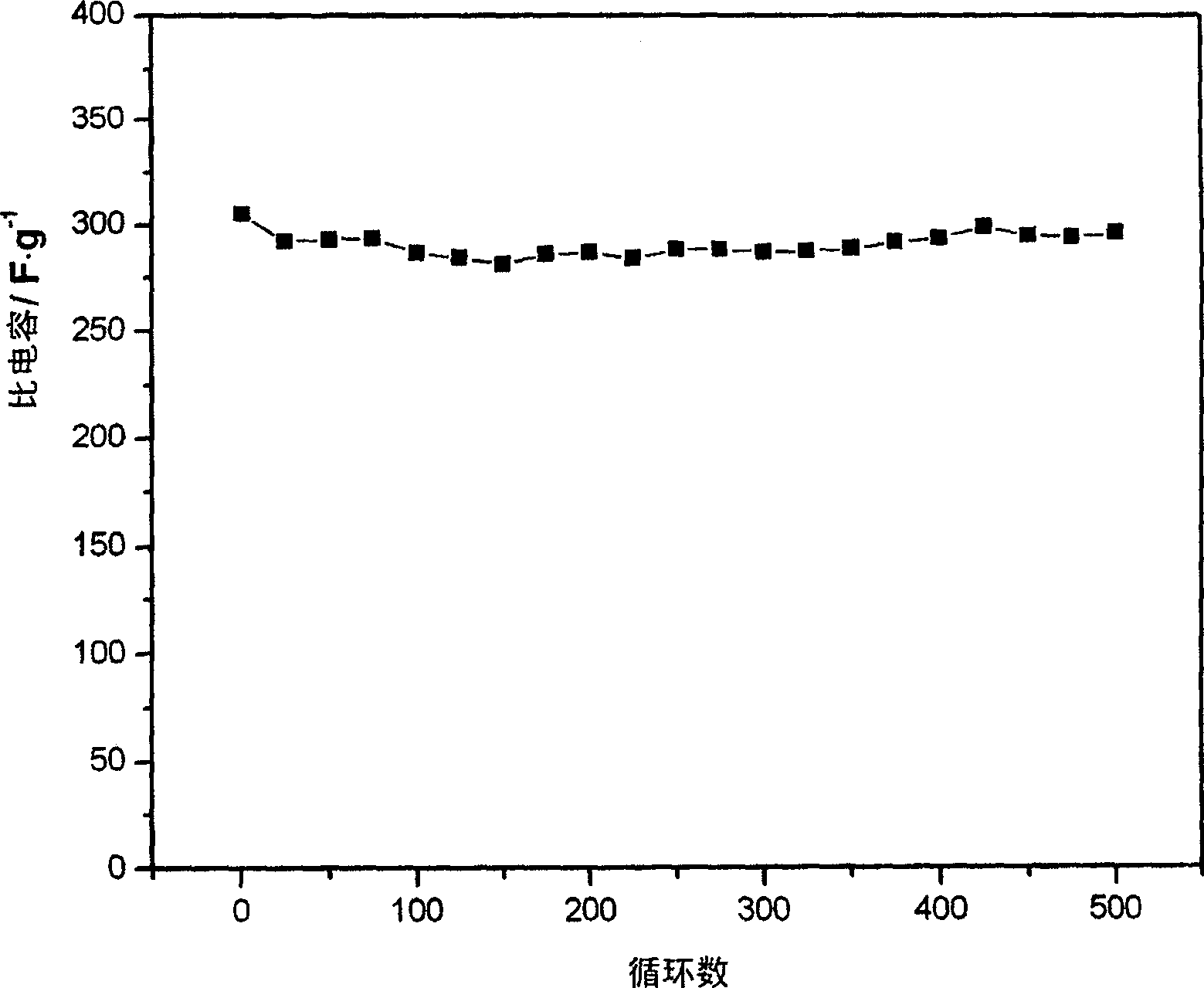

Method of preparing super capacitor electrode material polyaniline nano fiber

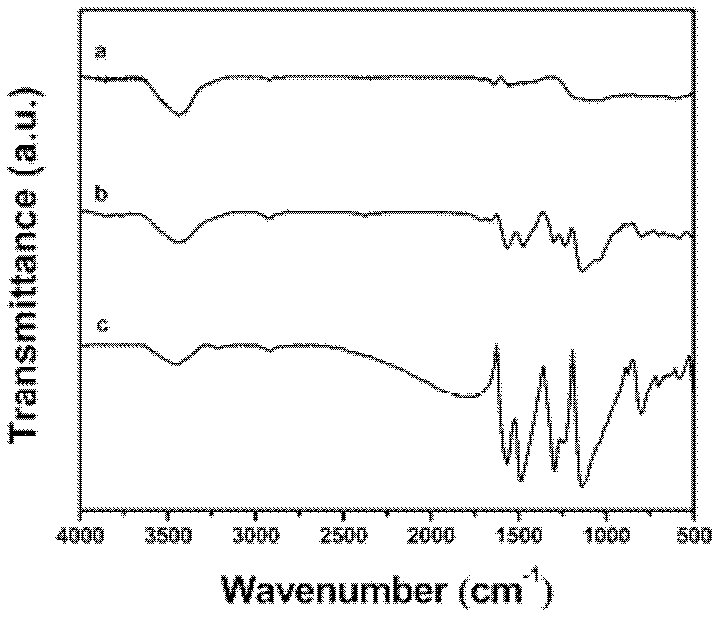

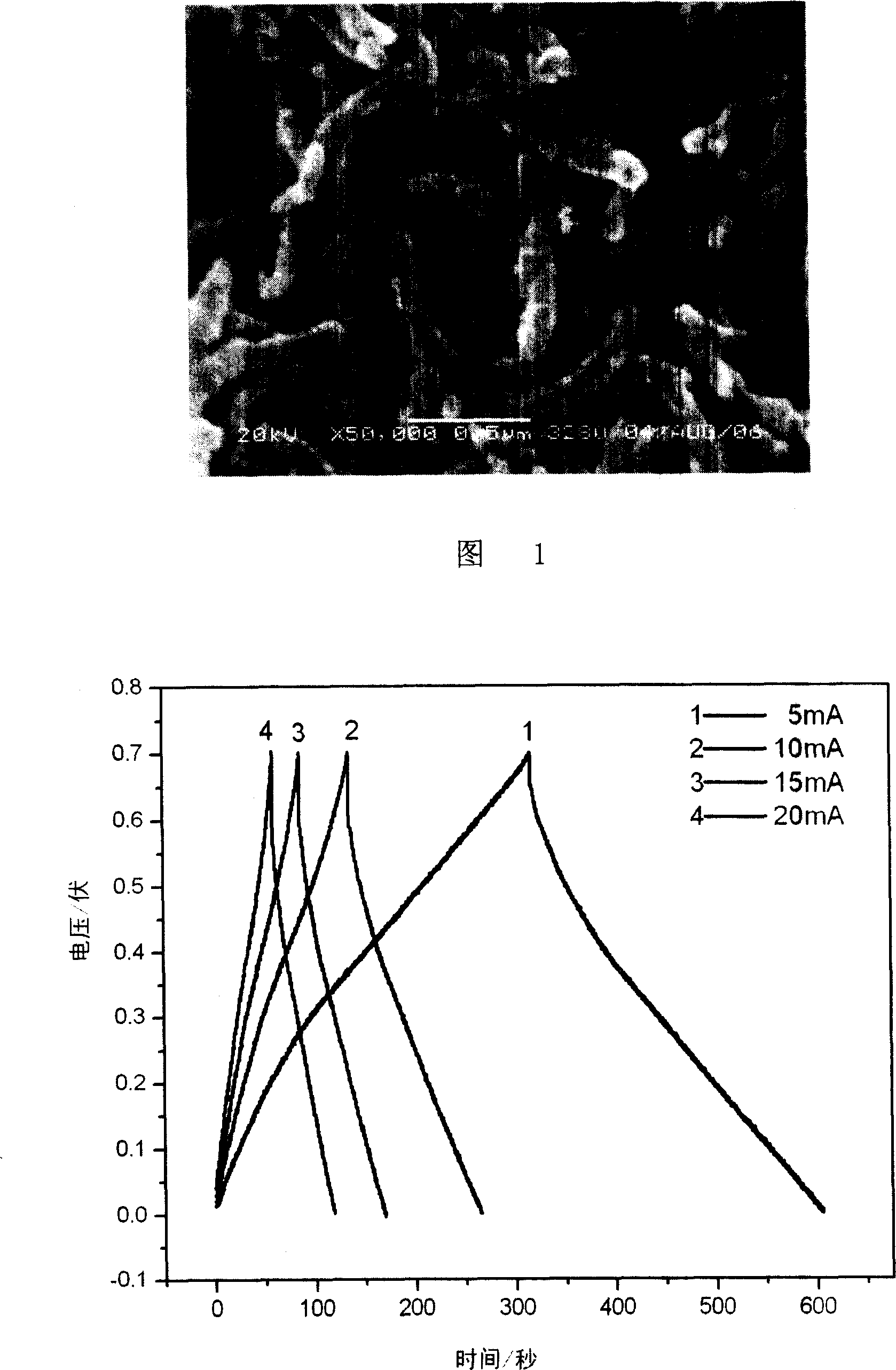

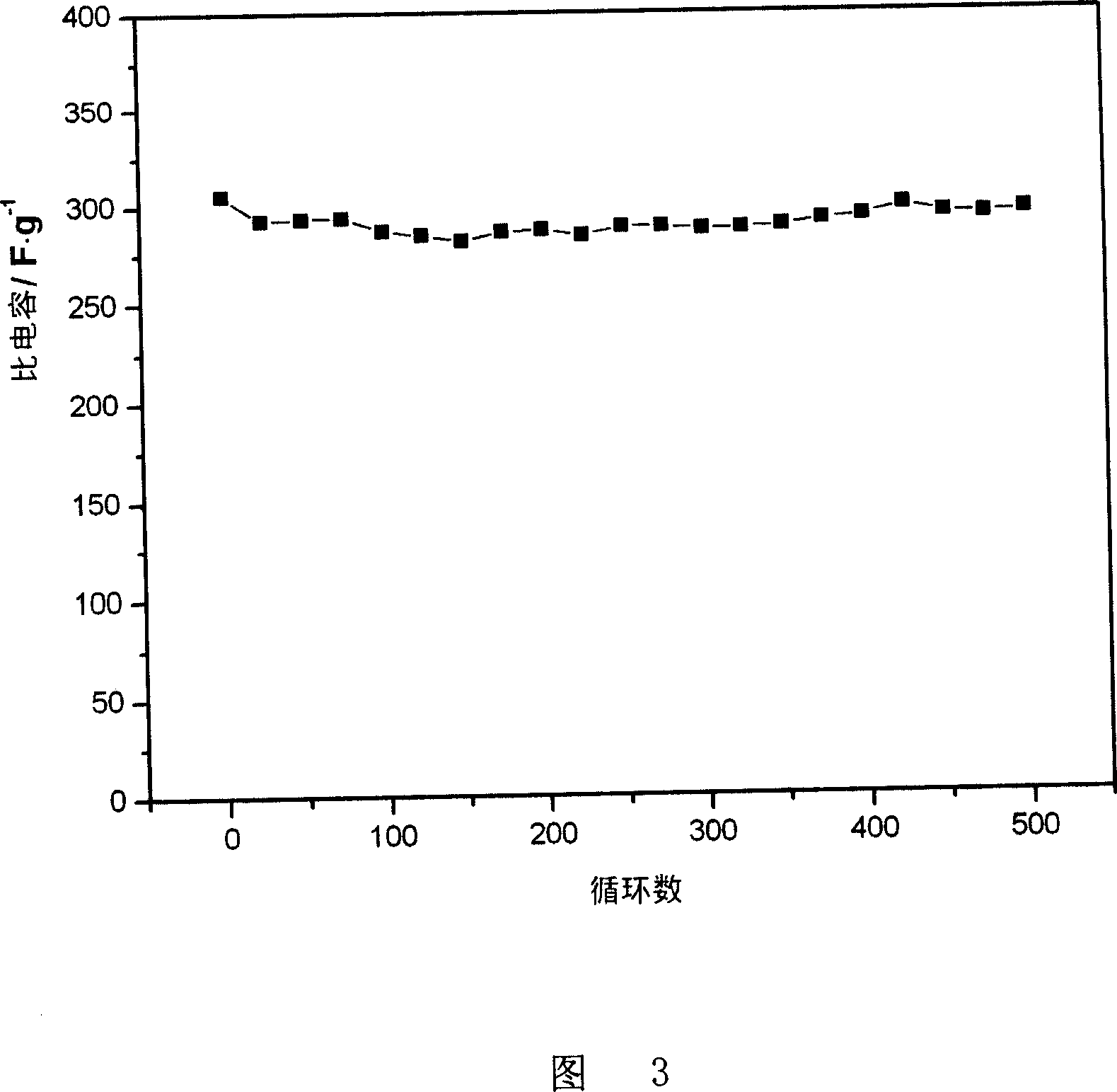

InactiveCN101016660AHigh specific capacitanceImprove cycle lifeMonocomponent synthetic polymer artificial filamentFiberCapacitance

The invention discloses a method for preparing polyaniline nanometer fiber used as the electrode material of super capacitor, which uses monomer aniline and oxidant ammonium persulphate as materials, using the aggregate reaction at oil / water interface to prepare polyaniline material, and optimizes and controls the interface aggregate technique to prepare the polyaniline nanometer fiber whose diameter is between 30-120nm and length is between 500nm and some micrometers. When in use, the inventive material can hold high capacitance per unit volume and obtain long service life, while the capacitance attenuation after 500 times of discharge-charge circles is under 5%, to improve the electrode circle property. Compared with present technique, the invention has simple process, simple operation and low cost, while it can prepare much nanometer fiber polyaniline material via one process, to support batch production.

Owner:CENT SOUTH UNIV

Polymethyl methacrylate/polyaniline nano fibre composite resistor type film gas sensor and preparation method thereof

InactiveCN101226161ALarge specific surface areaQuick responseMaterial resistanceResponse sensitivityFiber

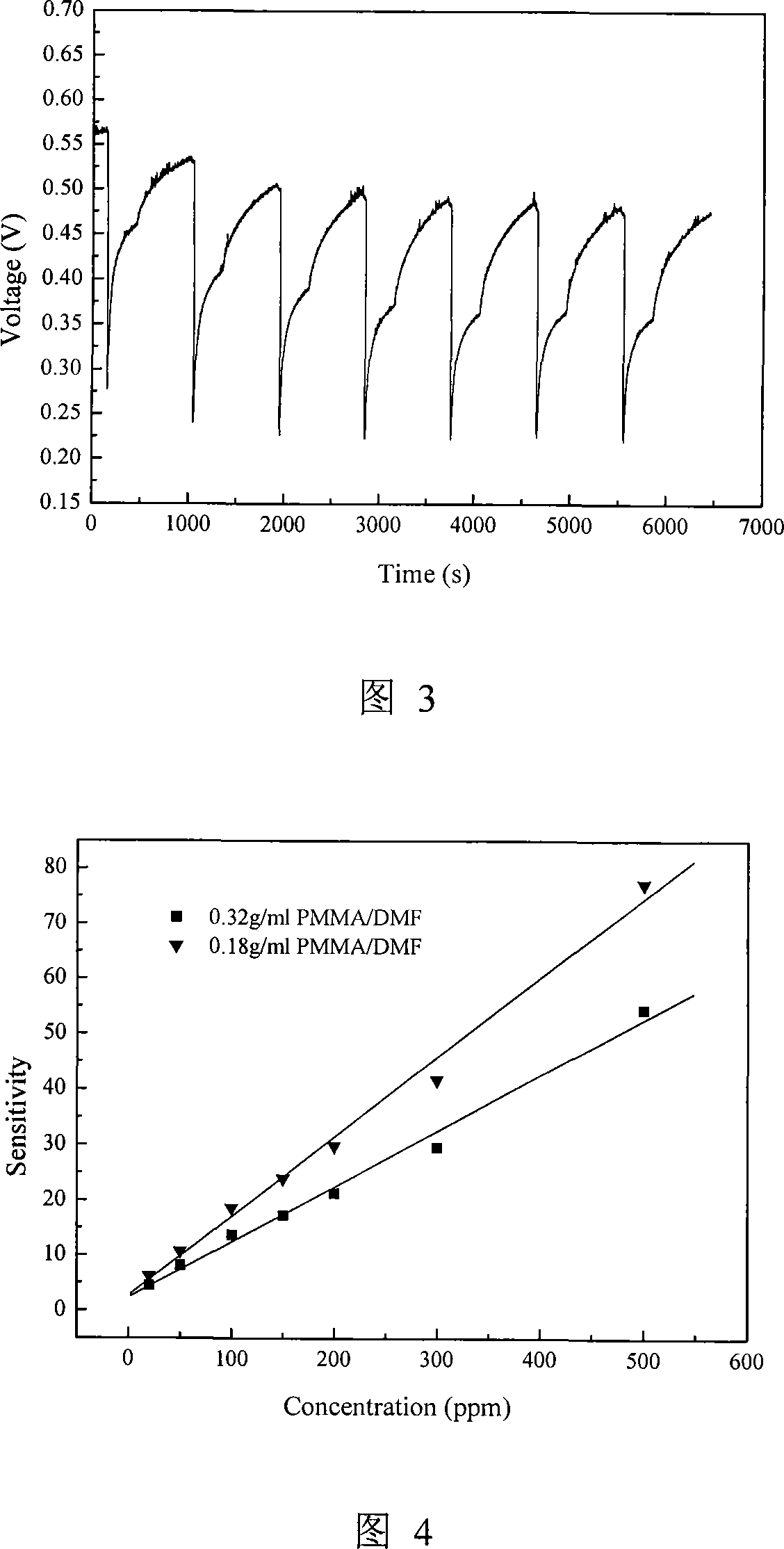

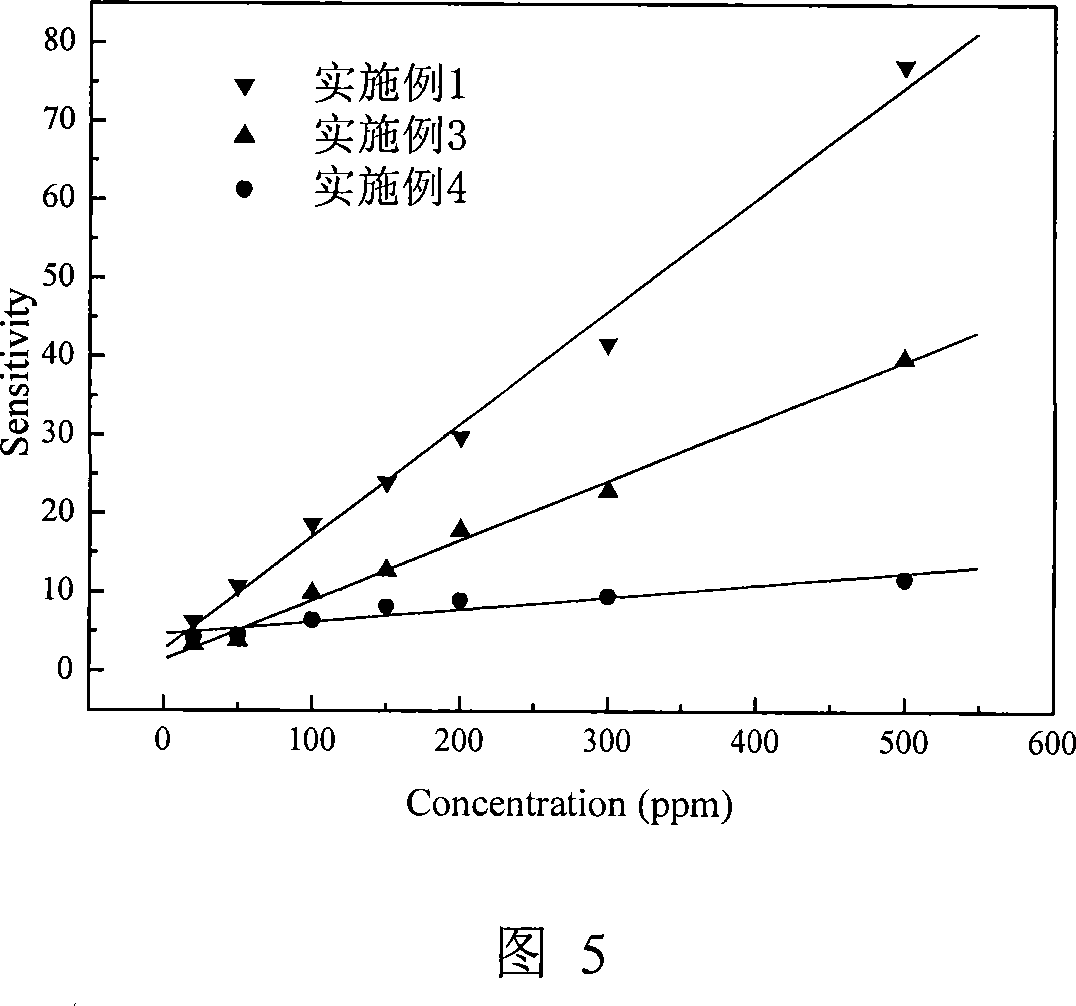

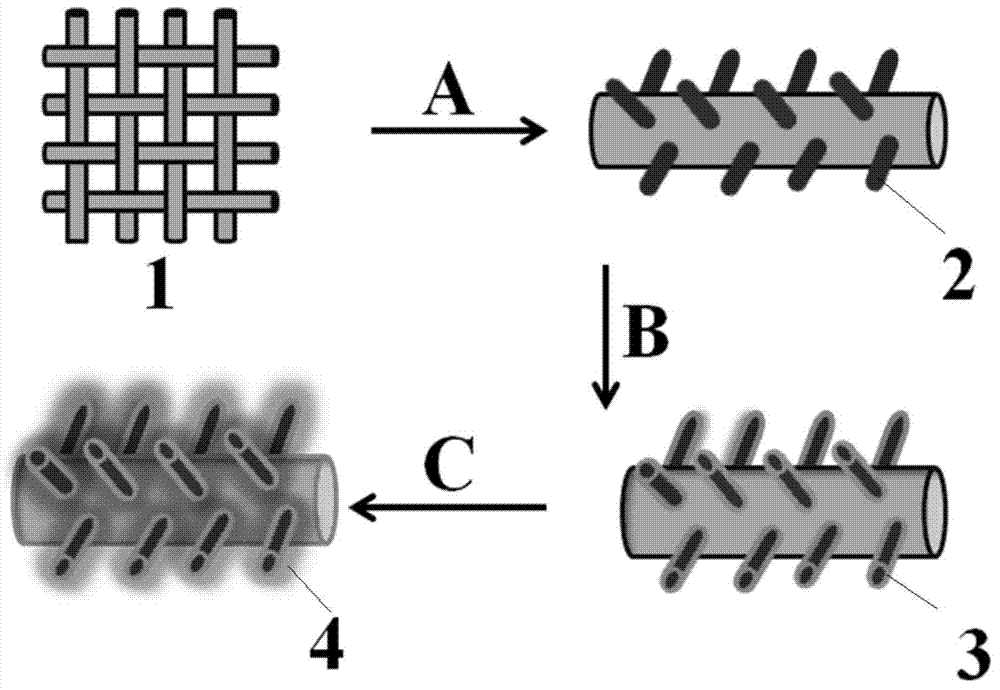

The invention discloses a polymethyl methacryate / polyaniline nanometer fiber composite resistance membrane gas sensor and a relative preparation method. The invention uses electrostatic spinning method to prepare polymethyl methacryate (PMMA) nanometer fiber, uses solution original aggregation method to compose polyaniline (PAN) to obtain the PMMA / PANI nanometer fiber composite membrane, and covers the composite film on the an Au interdigital ceramic substrate electrode. The invention has simple preparation, low cost and batch production application, while the prepared gas sensor has wide measurement range, high response sensitivity, better linearity, better resilience and room-temperature detection on triethylamine gas. The invention has wide application for online accurate measurement of triethylamine gas density under room temperature in industrial and agricultural production and atmosphere.

Owner:ZHEJIANG UNIV

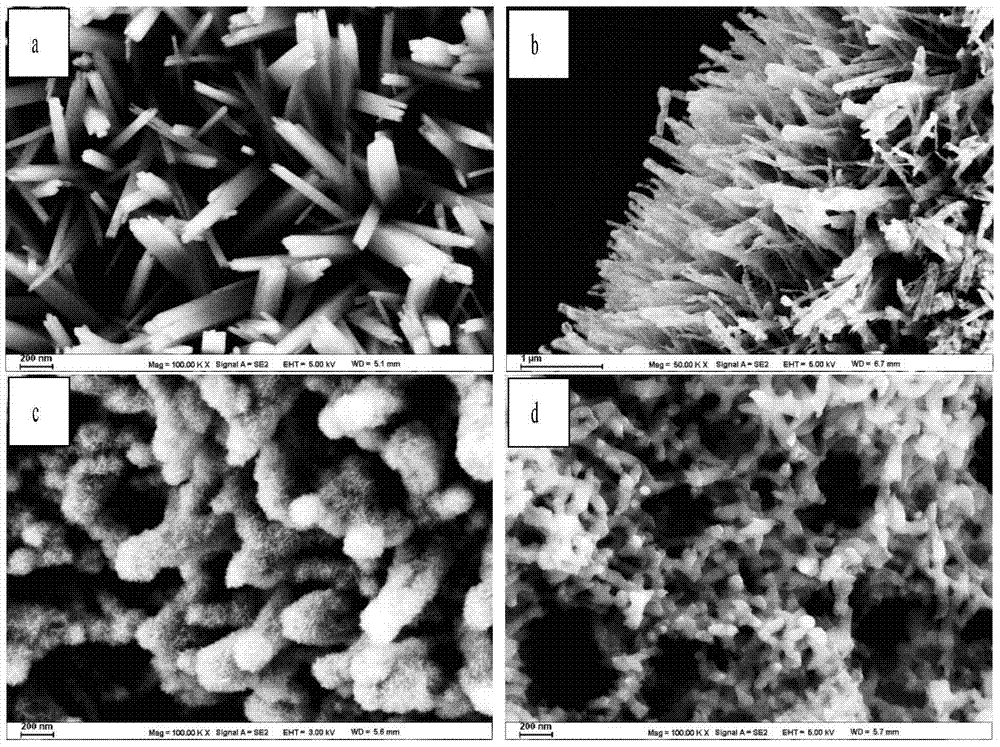

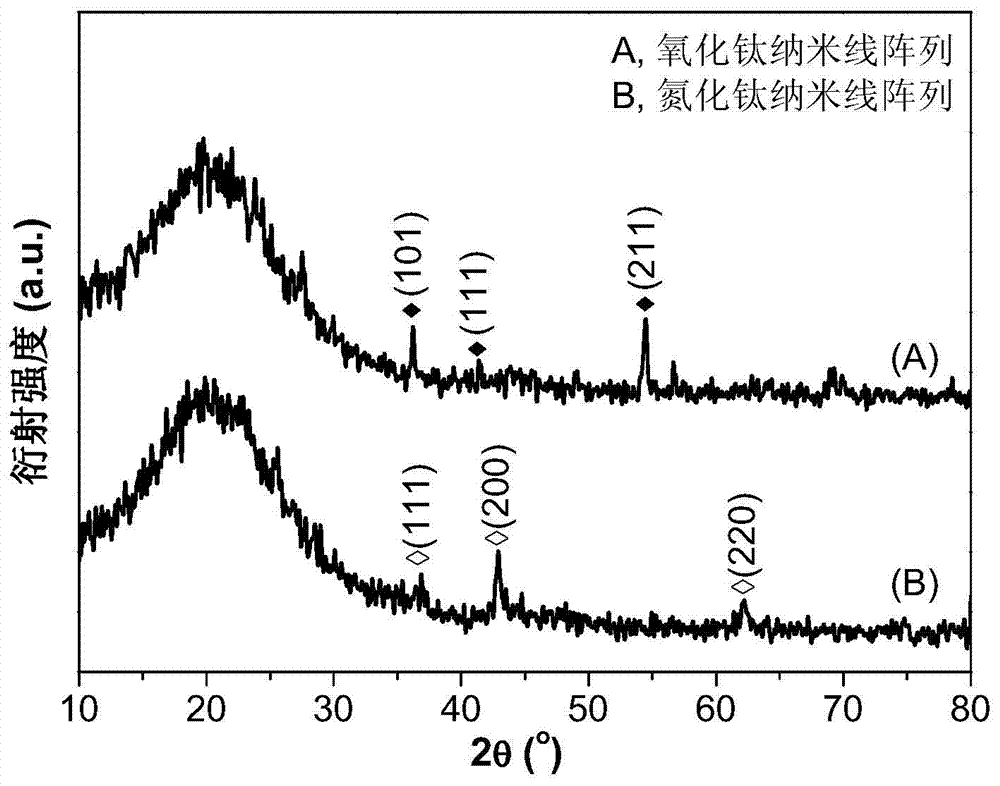

Polyaniline-manganese dioxide-titanium nitride nanowire array composite material and preparation method and application thereof

InactiveCN104240967AExtensive practical application valueExtensive productivityHybrid capacitor electrodesHybrid/EDL manufactureTitanium nitrideSupercapacitor

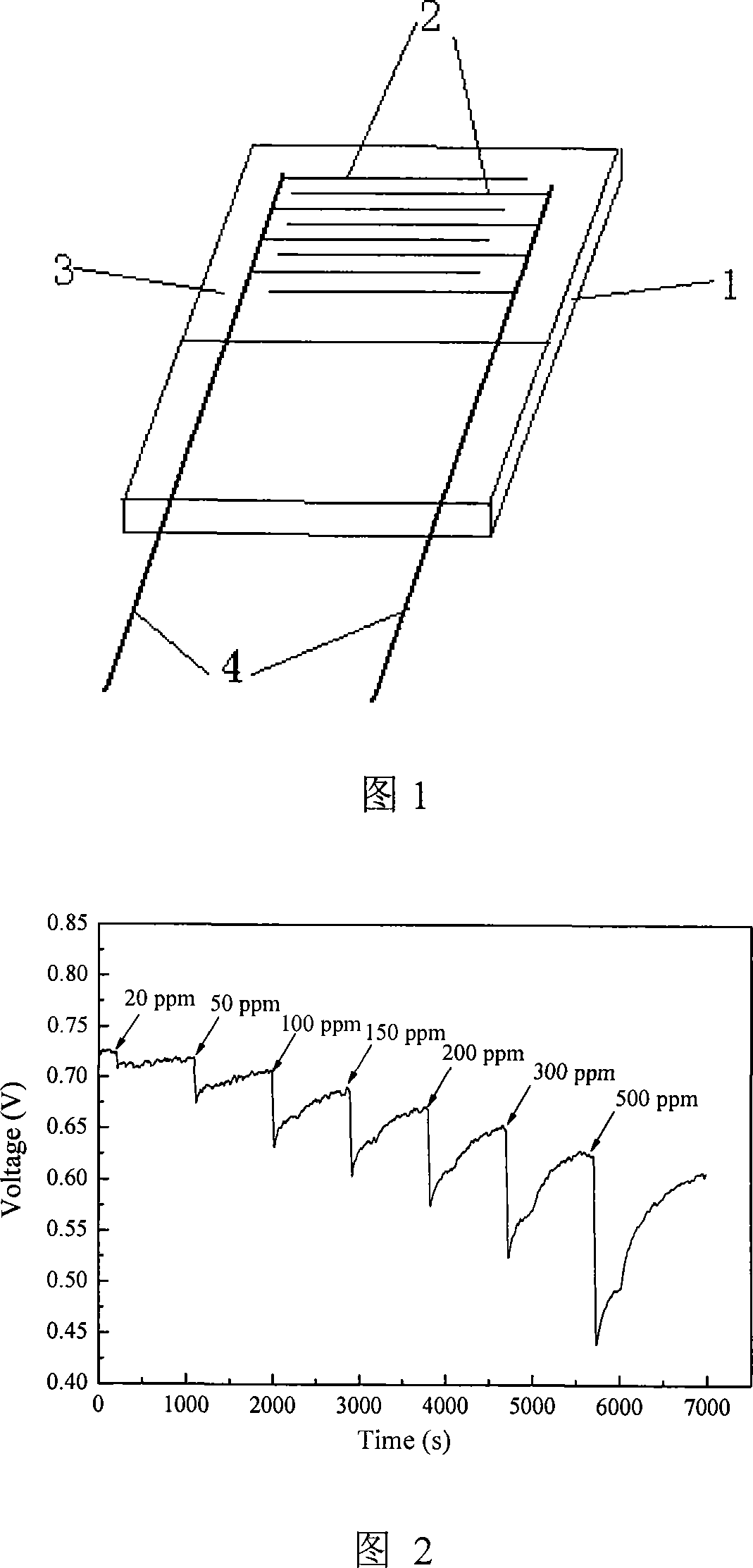

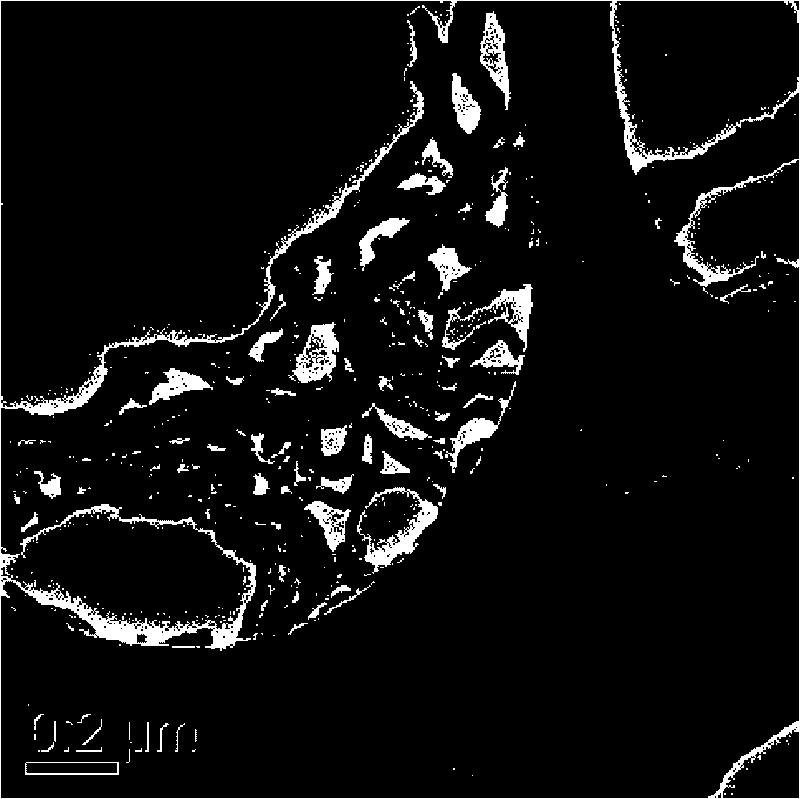

The invention provides a polyaniline-manganese dioxide-titanium nitride nanowire array composite material which comprises a carbon substrate (1), a titanium nitride nanowire array (2), a villiform manganese dioxide nano-film (3) and a coralliform polyaniline nanofiber (4). The titanium nitride nanowire array (2) is perpendicularly arranged on the surface of the carbon substrate (1) and connected with the carbon substrate (1) to form an integral structure, the manganese dioxide nano-film (3) coats the surface of the titanium nitride nanowire array (2), and the coralliform polyaniline nanofiber (4) is adhered on the surface of the manganese dioxide nano-film (3). The invention further provides a preparation method of the composite material and application of the composite material in a supercapacitor. The polyaniline-manganese dioxide-titanium nitride nanowire array composite material has features of an orderly-arranged porous structure, is regular and controllable in shape and appearance, can be directly applied to an electrode material of the supercapacitor and has wide actual application value and industrial production prospect.

Owner:SOUTHEAST UNIV

Conducting polymer nanofiber sensors

InactiveUS20050126909A1High sensitivityFaster chemical time responseNanotechMaterial resistanceFiberTime response

Polymer nanofibers, such as polyaniline nanofibers, with uniform diameters less than 500 nm can be made in bulk quantities through a facile aqueous and organic interfacial polymerization method at ambient conditions. The nanofibers have lengths varying from 500 nm to 10 μm and form interconnected networks in a thin film. Thin film nanofiber sensors can be made of the polyaniline nanofibers having superior performance in both sensitivity and time response to a variety of gas vapors including, acids, bases, redox active vapors, alcohols and volatile organic chemicals.

Owner:RGT UNIV OF CALIFORNIA +1

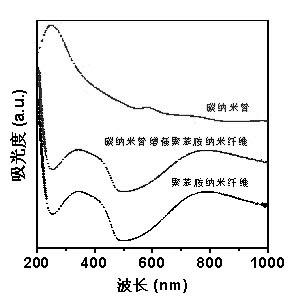

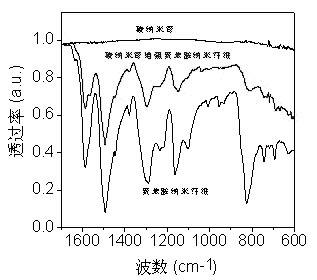

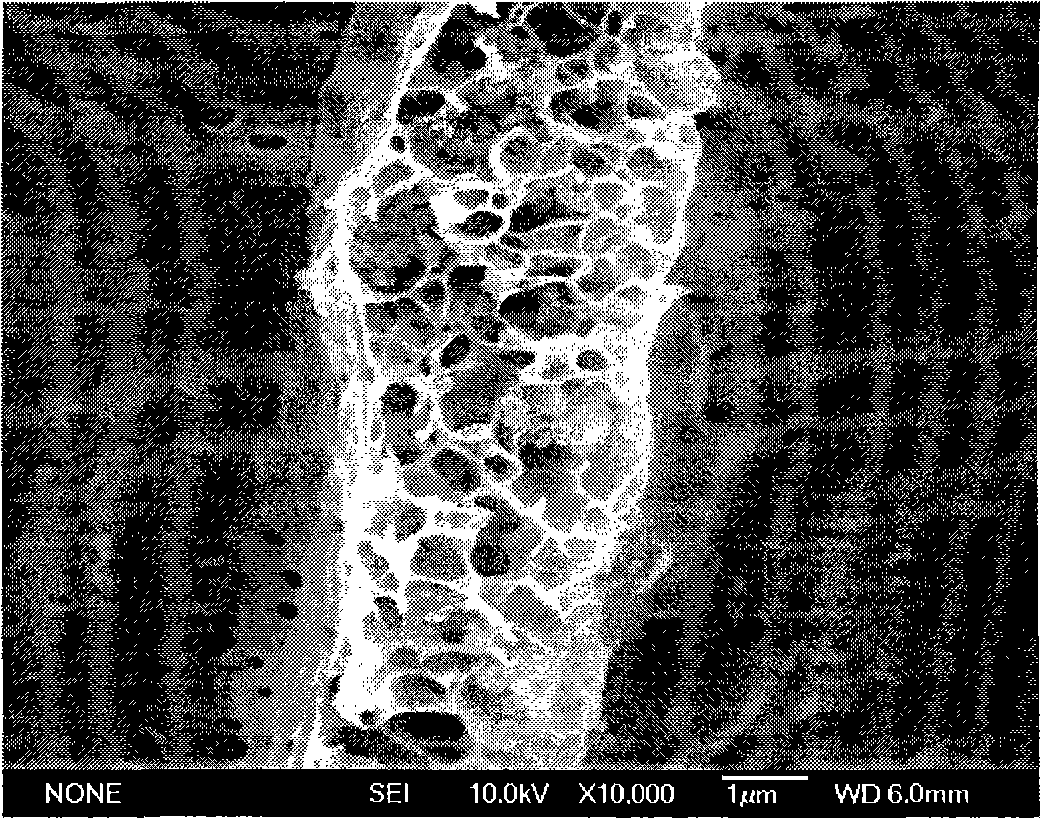

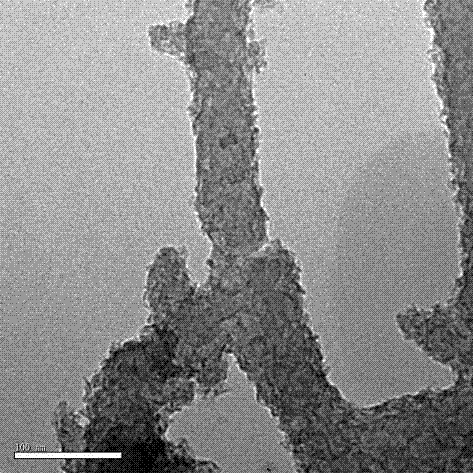

Method for preparing carbon nano-tube modified polyaniline nano fiber composite material

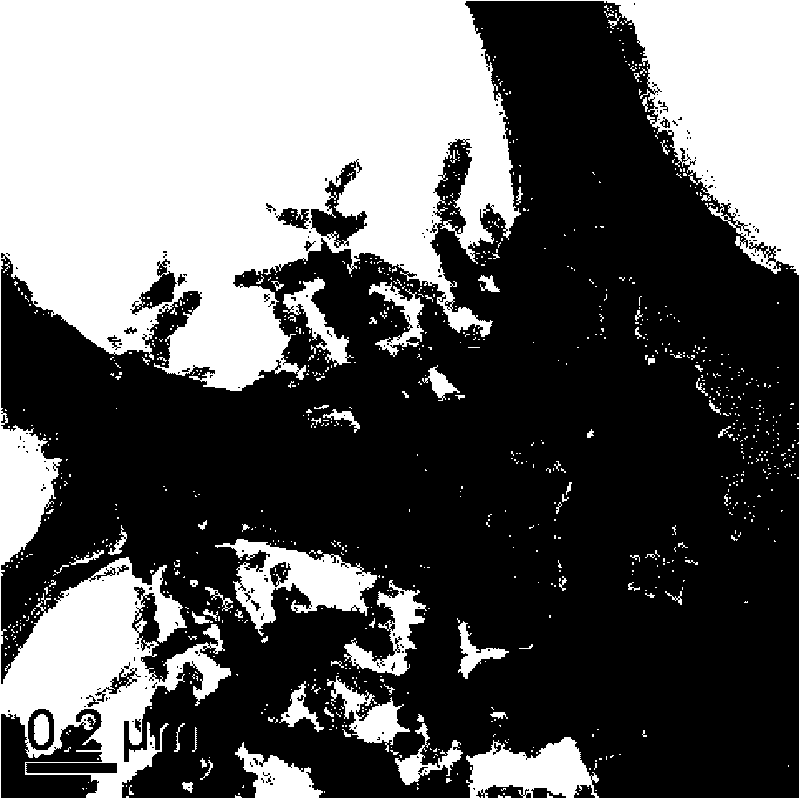

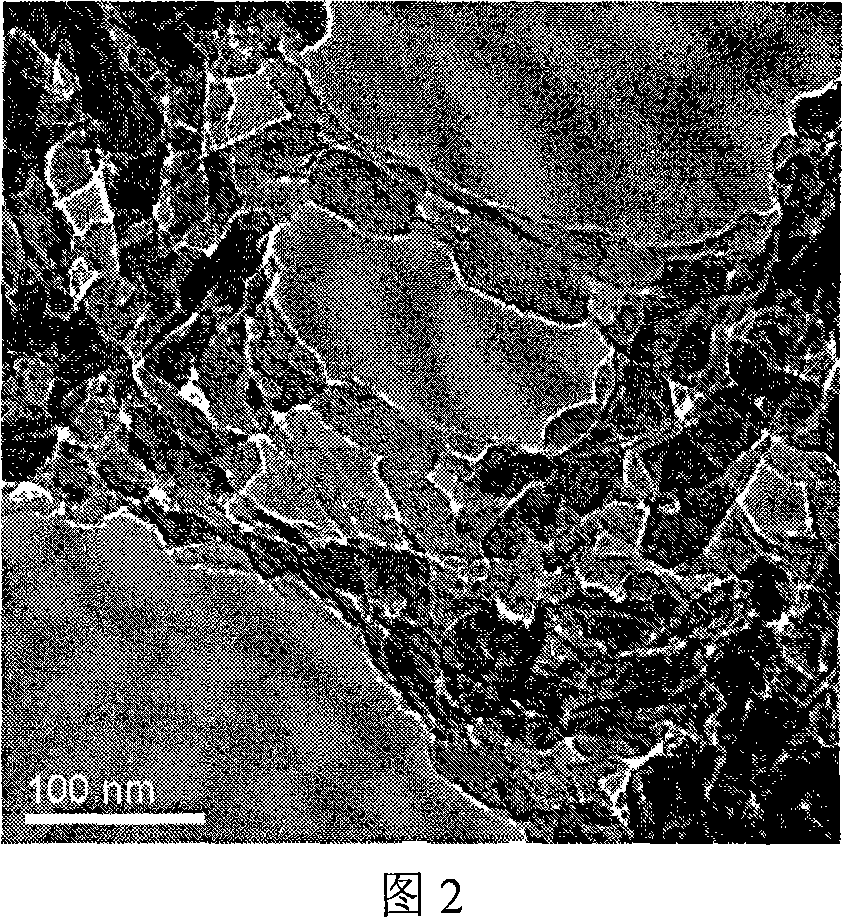

InactiveCN101235199ALarger than surfaceImprove conductivityNon-conductive material with dispersed conductive materialFiberCarbon nanotube

The invention discloses a preparation process of carbon nano-tube modification polyaniline nano fiber conductivity composite material. The characteristics of the invention are that conducting acid treatment for carbon nano-tube with concentrated mixed acid, adding carbon nano-tube which is treated with acid and aniline monomer into perchloric acid water solution according to the weight ratio of 1:6-1-32, and evenly dispersing through ultrasonic processing, using ammonium persulphate as oxidation agent, controlling the molar ratio of ammonium persulphate and aniline monomer within 1:2-1:8, and reacting under the ambient temperature to obtain polyaniline nano fiber / conductivity composite material of polyaniline coating carbon nano-tube coexisting structure. The process has simple art, and is easy to be controlled. The composite material which is prepared has the characteristics of high electricity conductivity ratio and small influence by system pH valve, large specific surface and excellent electrochemistry property and the like, which is expected to be used on electrode material such as second lithium ion cell and super capacitor and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Electrochemical method for synthesizing Nano fiber of polyaniline

InactiveCN1958854AUniform particle sizeArrangement rulesElectrolysis componentsElectrolytic organic productionFiberElectrolysis

This invention relates to an electrochemical method for synthesizing polyaniline nanofibers. The method comprises: uniformly mixing 0.5-1.5 mol / dm3 proton acid dopant, 0.1-0.4 mol / dm3 aniline monomer, and 0.5-2 mol / dm3 alcohol dopant in a three-electrode system, pouring into a reactor, electrolyzing at 10-30 deg.C under constant electrical potential for 10-30 min to obtain polyaniline nanofibers adsorbed on the working electrodes. The obtained polyaniline nanofibers have uniform particle sizes (50-150 nm) and ordered arrangement, and can be widely used in photoelectronic devices, information, sensors, molecular leads and molecular devices.

Owner:YANGZHOU UNIV

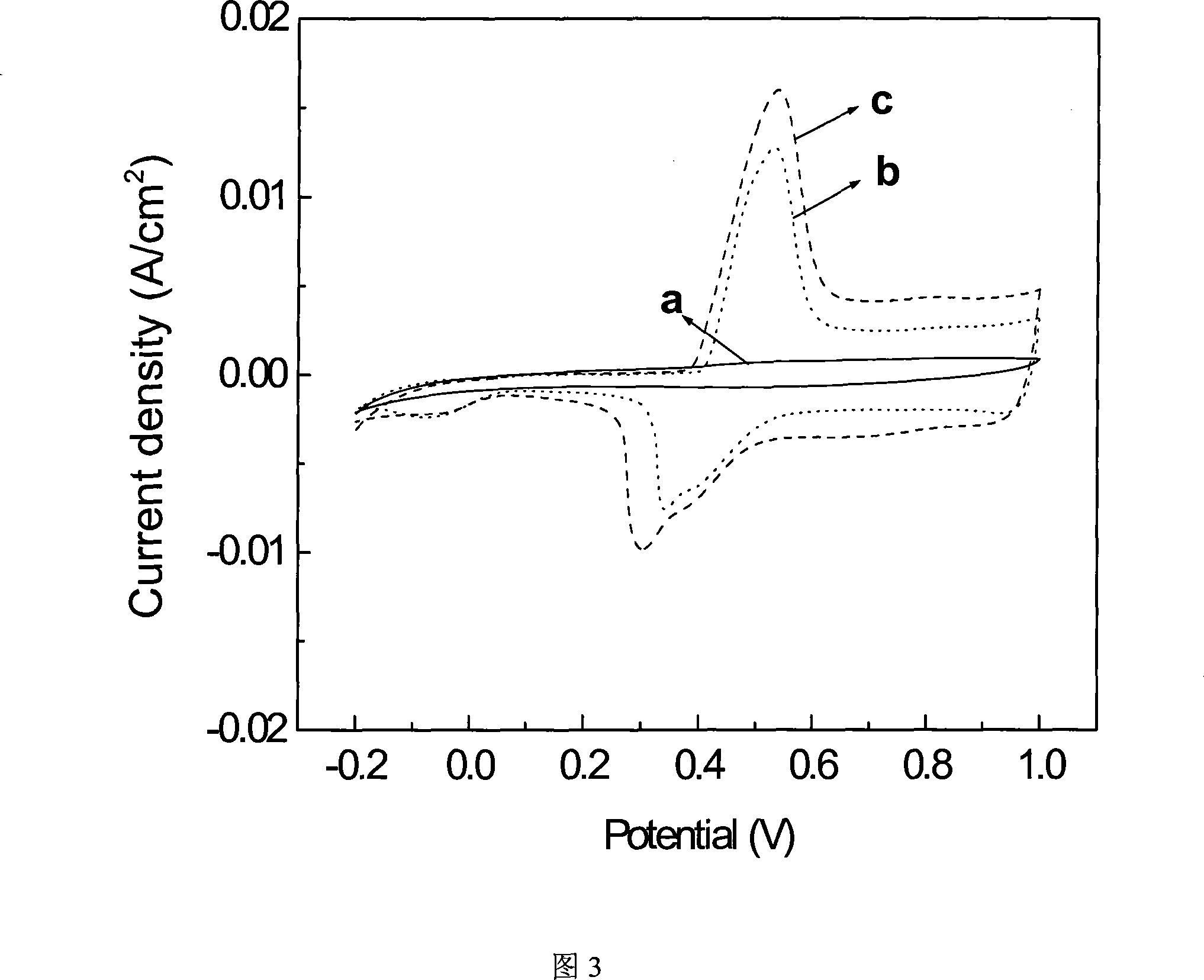

Polyaniline nano-fiber electrode material for super capacitor and preparation method thereof

InactiveCN101710541AInhibition of agglomerationInhibition of secondary growthElectrolytic capacitorsHybrid/EDL manufactureCapacitanceFiber

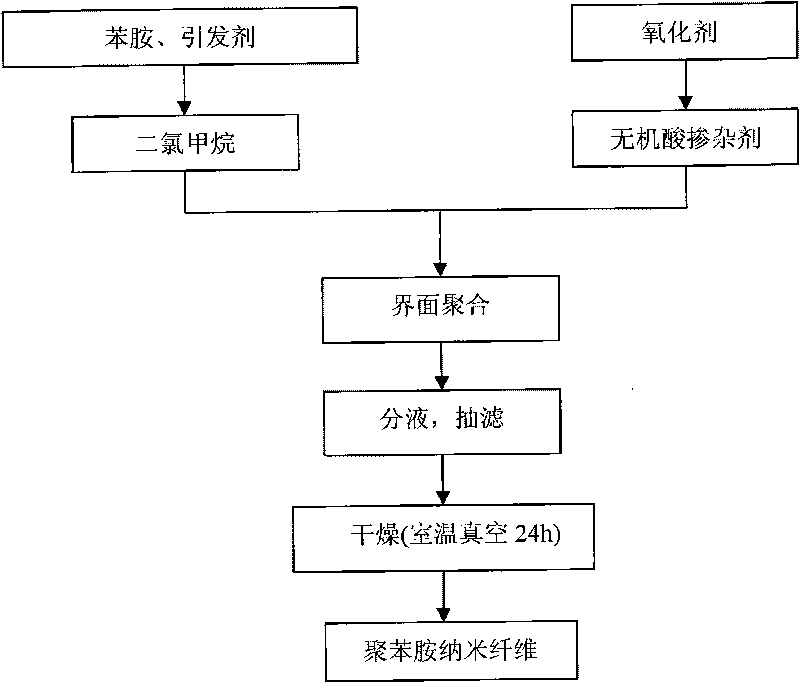

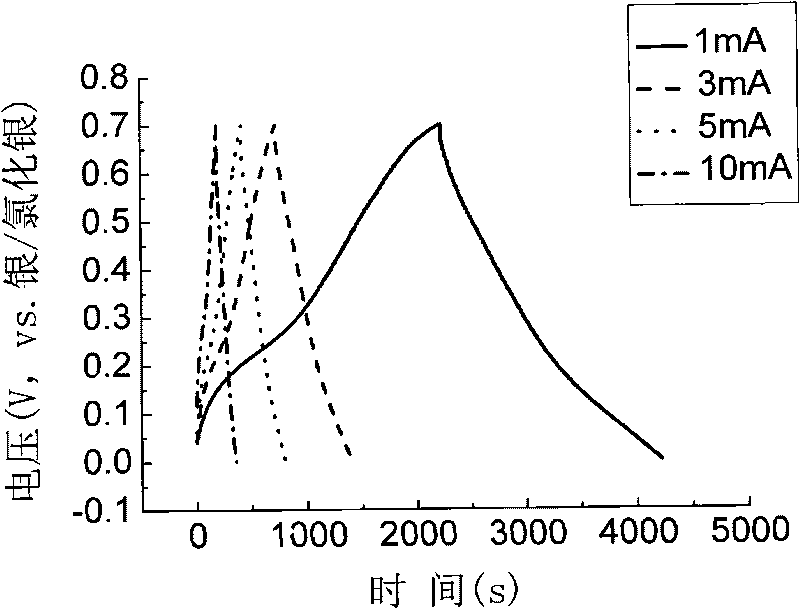

The invention discloses a polyaniline nano-fiber electrode material for a super capacitor and a preparation method thereof, belonging to the field of electrochemistry and new energy material. The method is characterized by comprising the steps of: dissolving aniline and initiating agent into dichloromethane organic phase, dissolving oxidizing agent into inorganic acid dope additive water phase, carrying out interfacial polymerization at the temperature of 0-30 DEG C, and obtaining the polyaniline nano-fiber electrode material by separating liquid, washing and drying; wherein the volume ratio between the dichloromethane organic phase and the inorganic acid dope additive water phase is 1:1, the concentration range of the aniline is 0.02-1mol / L, the concentration range of the initiating agent is 0.02-0.002mol / L, and the molar ratio range between the aniline and the oxidizing agent is 1:1-8:1. The polyaniline nano-fiber is controllable in structure as well as good in one-dimensional directivity, electrical conductivity and electrochemical properties. The electrode material has the specific capacitance of 549Fg-1 and the advantage of simple preparing technique.

Owner:UNIV OF SCI & TECH BEIJING

Carbon nano tube reinforced polyaniline nano-fiber and preparing method thereof

InactiveCN102558554AConductivity controllableOvercome the technical problem of not being able to conduct electricity under alkaline conditionsFiberPolymer science

The invention discloses carbon nano tube reinforced polyaniline nano-fiber and a preparing method thereof. The preparing method includes steps of: adding aniline monomers and carbon nano tubes into dilute acid for ultrasound treatment to obtain carbon nano tube and aniline monomer blend solution; dissolving initiators into ethanol to form initiator solution and dissolving oxidants in dilute acid to form oxidant solution; and adding the initiator solution into the carbon nano tube and aniline monomer blend solution, then adding the oxidant solution, severely swinging for a moment, performing centrifugation, washing, redispersion and the like after standing reaction is complete so as to finally obtain the carbon nano tube reinforced polyaniline nano-fiber. The preparing method is simple, efficient and high in controllability. The carbon nano tubes can be uniformly dispersed on a polyaniline matrix. The mean diameter of the obtained carbon nano tube reinforced polyaniline nano-fiber is 30-60 nm, the length is 1-2 mu m, and electric conductivity is 10(-8)-10(2) S / cm, and the carbon nano tube reinforced polyaniline nano-fiber can be used in the application fields such as sensors, actuating devices, ultra-capacitors, electrochromatic windows, functional coatings and ultrafiltration membranes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

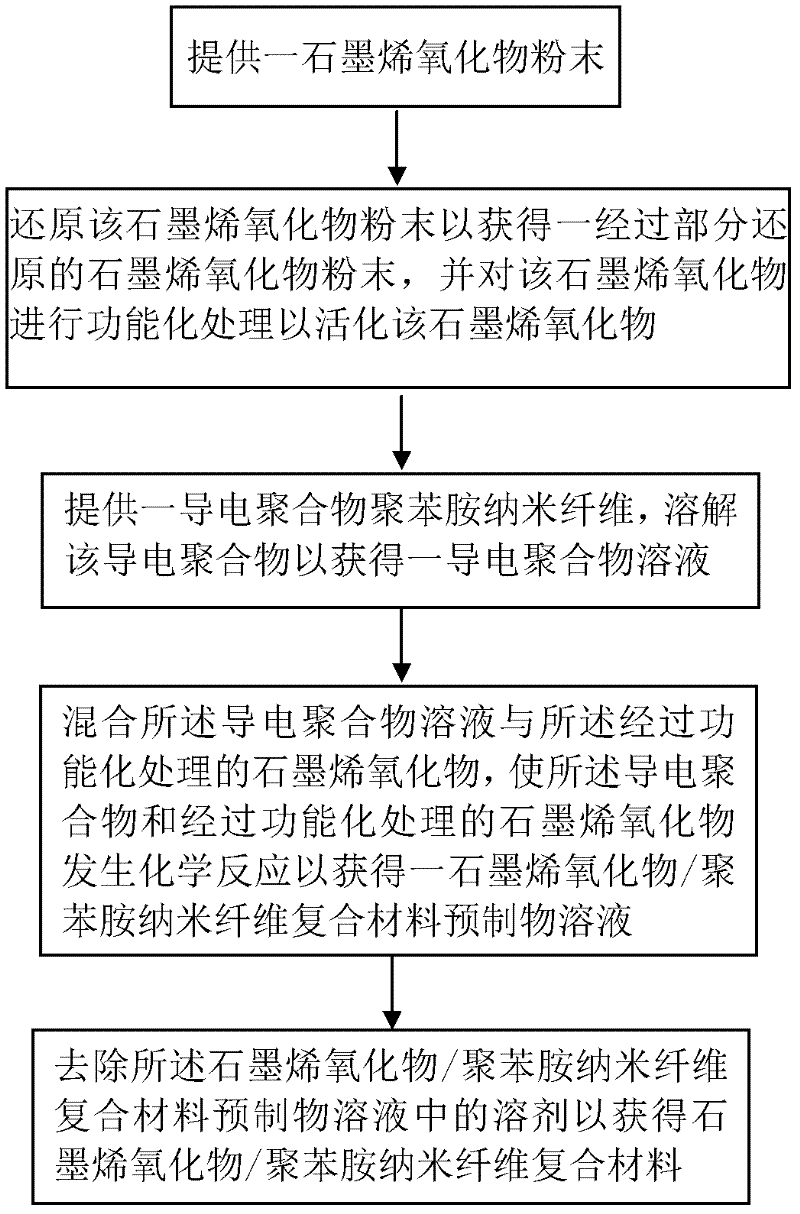

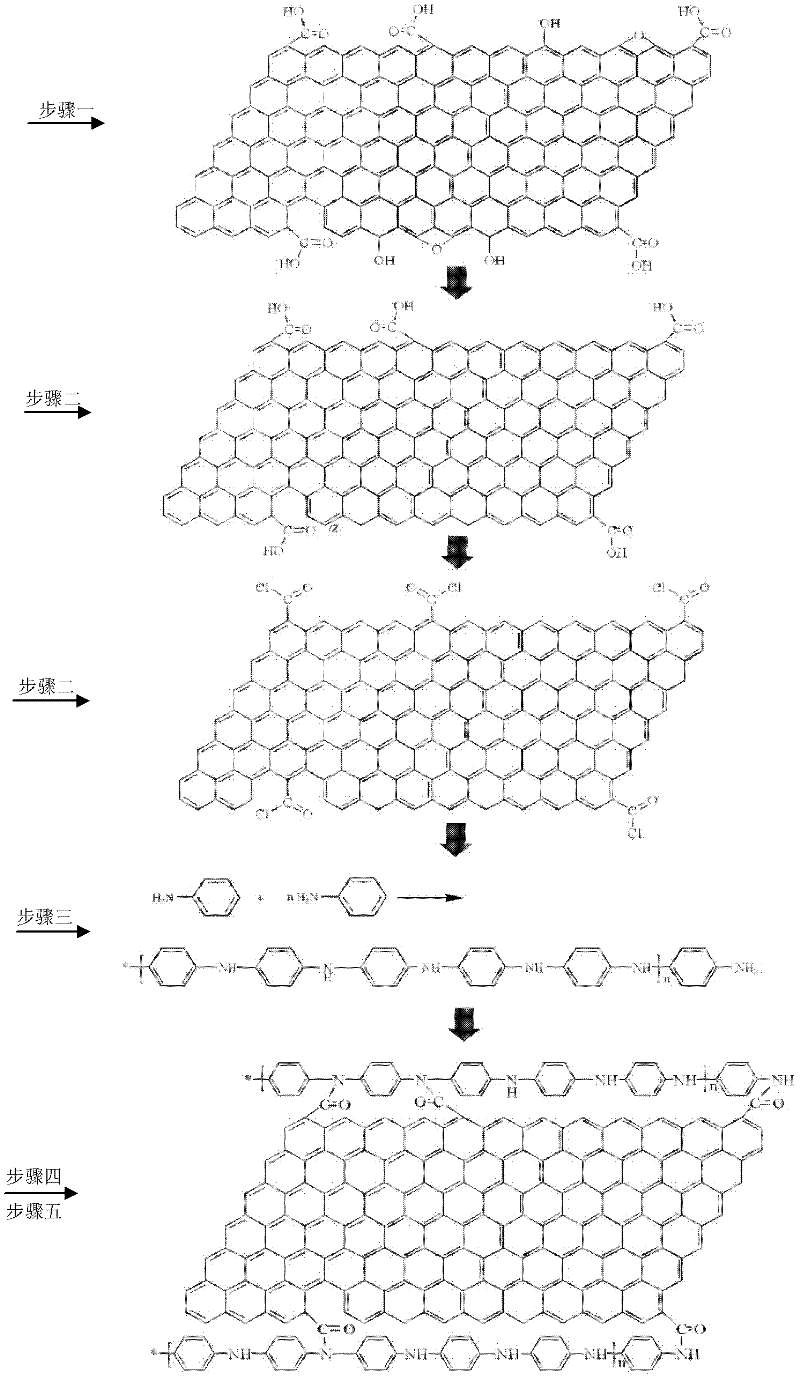

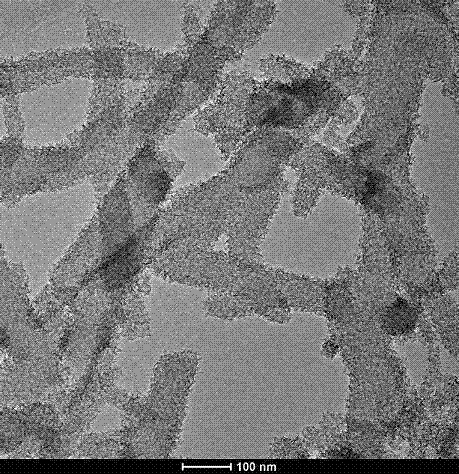

Graphene/polyaniline nano-fiber composite material and preparation method and application in super capacitor thereof

InactiveCN102532891AIncrease capacityHigh capacity retentionElectrolytic capacitorsPigment treatment with non-polymer organic compoundsFiberElectric capacity

The invention relates to a graphene / polyaniline nano-fiber composite material and a preparation method; an application of the composite material as an electrode material in a super capacitor; and a preparation method of the super capacitor. The composite material is obtained by chemical bond connection of functionally-treated graphene oxides with conductive polymer through amido groups; through reduction of the composite material, the conductivity is increased; combined with its inherent characteristic of structure stability, the composite material has higher electric capacity. The invention also relates to a super capacitor, which comprises a first electrode, a second electrode, a first current collector, a second current collector, a diaphragm, and an electrolytic solution; the first electrode and the second electrode are composed of the graphene oxide / polyaniline composite material, wherein the graphene / polyaniline nano-fiber composite material comprises graphene and conductive polymer which are in chemical bond connection through amido groups.

Owner:BEIHANG UNIV

Preparation method of conductive polymer polyanilinc nano fiber

InactiveCN1323199CEasy to getEasy to manufactureMonocomponent synthetic polymer artificial filamentFiberSolubility

The invention relates to a conduction macromolecule polyaniline nanometer fiber manufacturing method. It includes the following steps: respectively dissolving aniline and oxidant in acid with water medium; mixing them with action of ultrasonic wave, and controlling temperature at-5 to 30 centigrade degree to do aniline polyreaction; gaining doping state polyaniline nanometer fiber when it finishes; removing the water and solubility impurity; drying; using ammonia liquor to neutralize the doping state; filtering; washing; drying; gaining eigenstate polyaniline nanometer fiber; processing it by dopant to gain conduct state; drying to gain powdery purpose. The invention adopts ultrasonic wave in polyreaction to gain polyaniline fiber with 20-100nm diameter, 500-5000nm length. The method has simple operation, and high yield.

Owner:XI AN JIAOTONG UNIV

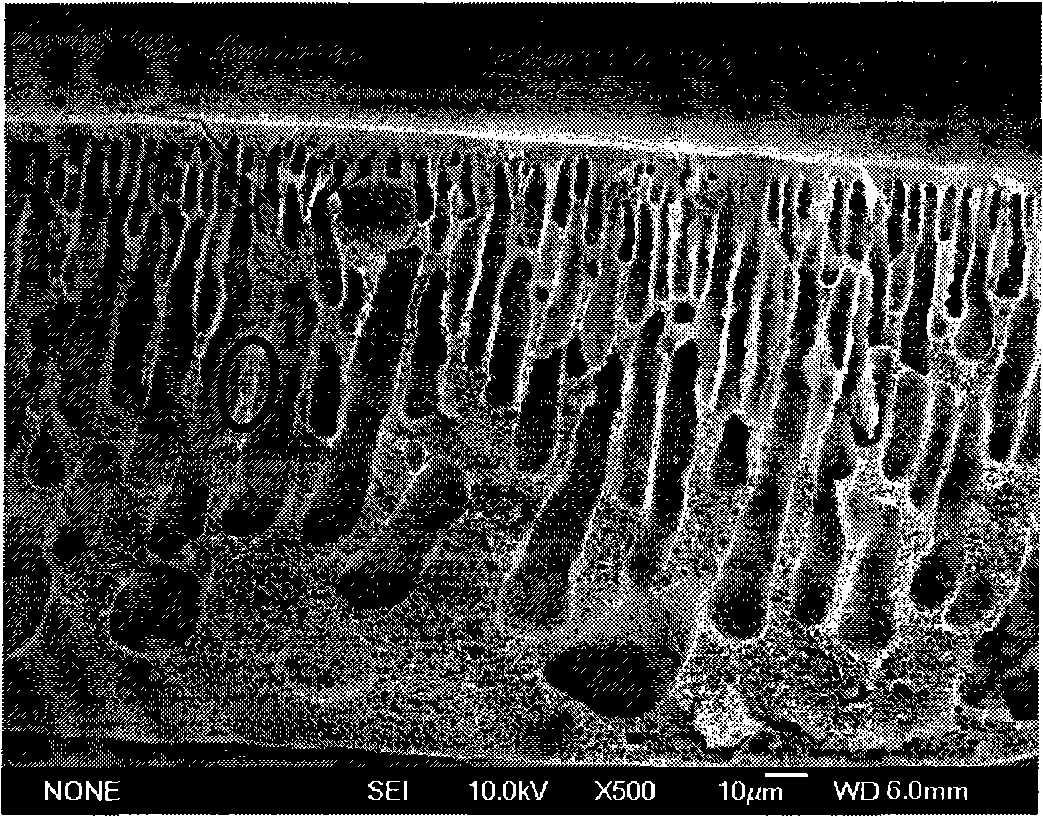

Method for preparing polyaniline and nano-fibre blend composite film

InactiveCN101274220AImprove hydrophilicityImproved ability to resist membrane foulingSemi-permeable membranesProtein solutionComposite film

The invention discloses a preparation method of poly-aniline nano-fibre co-mixing composite film, belonging to the preparation technique of ultra-filter composite film. The method process comprises that poly-aniline nano-fibre is dispersed to one or more out of solvent N, N-dimethylacetamide, dimethylformamide, N-cymene-2-pyrazolidinone or dimethyl sulfoxide; film-forming polymer material polysulfone is uniformly dissolved into the dispersion of the poly-aniline nano-fibre-solvent to gain casting solution; the casting solution is scraped on a glass plate and the film is formed by using water as coagulation bath, so as to gain the poly-aniline nano-fibre co-mixing composite film of the invention with high throughput and high pollution resistance. The preparation method of the poly-aniline nano-fibre co-mixing composite film has simple method, easy operation and low cost; the pure water throughput of the prepared poly-aniline nano-fibre co-mixing composite film is 1.6 to 2.3 times of that of pure polysulfone membrane and the throughput preservation rate of the poly-aniline nano-fibre co-mixing composite film on protein solution is 1.2 to1.5 times of that of the pure polysulfone membrane.

Owner:TIANJIN UNIV

Preparation method of polyaniline nanofibers

The invention provides a preparation method of polyaniline nanofibers, which comprises the following steps of: (a) mixing a phenylamine monomer and an inorganic acid to obtain a first mixed liquid, wherein the concentration of the phenylamine monomer in the first mixed liquid is 1 -3 mol / L; (b) mixing an oxidizing agent and the first mixed liquid to obtain a second mixed liquid, and polymerizing the phenylamine monomer in the second mixed liquor to obtain a first reaction product, wherein the oxidation-reduction potential Eox of the oxidizing agent is less than or equal to 0.8V and larger than or equal to 0.5V; and (c) cleaning, washing with alkali and drying the first reaction product to obtain the polyaniline nanofibers. Compared with the prior art, the preparation method provided by the invention has the advantages that the prepared polyaniline nanofibers have uniform diameter and high purity and are suitable for large-scale industrial production, and the production efficiency is increased.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Hexagonal boron nitride epoxy compound anticorrosion coating and preparation method and application thereof

ActiveCN106752673AGood storage stabilityNot easy to sinkAnti-corrosive paintsEpoxy resin coatingsEpoxyDispersed media

The invention discloses a hexagonal boron nitride epoxy compound anticorrosion coating and a preparation method and application thereof. The anticorrosion coating is mainly composed of hexagonal boron nitride, polyaniline nanofiber, epoxy resin, a disperse medium, a coating additive, an epoxy resin curing agent, a solvent, etc. The hexagonal boron nitride epoxy compound anticorrosion coating provided by the invention has good storage stability, is not easy to sink to the bottom, has simple preparation process, is low-cost, and is suitable for large-scale production. A coating layer formed by the coating has excellent barrier property and lasting corrosion resistance. The product has a good application prospect in the industries of chemical engineering, petroleum, electric power, ship, light textile, storage, transportation, spaceflight, etc.

Owner:XINHE NEW MATERIALS CO LTD

Method of preparing super capacitor electrode material polyaniline nano fiber

InactiveCN100480443CHigh specific capacitanceImprove cycle lifeMonocomponent synthetic polymer artificial filamentCapacitanceFiber

The invention discloses a method for preparing polyaniline nanometer fiber used as the electrode material of super capacitor, which uses monomer aniline and oxidant ammonium persulphate as materials, using the aggregate reaction at oil / water interface to prepare polyaniline material, and optimizes and controls the interface aggregate technique to prepare the polyaniline nanometer fiber whose diameter is between 30-120nm and length is between 500nm and some micrometers. When in use, the inventive material can hold high capacitance per unit volume and obtain long service life, while the capacitance attenuation after 500 times of discharge-charge circles is under 5%, to improve the electrode circle property. Compared with present technique, the invention has simple process, simple operation and low cost, while it can prepare much nanometer fiber polyaniline material via one process, to support batch production.

Owner:CENT SOUTH UNIV

Polyaniline nanofiber/manganese dioxide nanorod composite material and preparation method thereof

The invention provides a polyaniline nanofiber / manganese dioxide nanorod composite material and a preparation method thereof. In the polyaniline nanofiber / manganese dioxide nanorod composite material, the particle diameter of polyaniline nanofibers is 40-60 nanometers, and the particle diameter of manganese dioxide nanorods is 3.0-5.0 nanometers; and the manganese dioxide nanorods are uniformly loaded on the surfaces of the polyaniline nanofibers. The preparation method comprises the following steps: uniformly dispersing the polyaniline nanofibers in water; thoroughly mixing, and then adding a potassium permanganate water solution in one step; and thoroughly mixing at 25 DEG C for 10 minutes while keeping the polyaniline concentration at 0.4 g / L and controlling the potassium permanganate concentration at 3.6-21.5 mmol / L, thus obtaining the polyaniline nanofiber / manganese dioxide nanorod composite material. The composite material has the advantages of simple and convenient preparation process, high stability and good reproducibility.

Owner:YANGZHOU UNIV

Static synthesis method of aniline-sulfoacid aniline copolymer nano-fiber

The invention provides a static synthesis method of aniline-sulfoacid aniline copolymer nano-fiber, belonging to the technical field of conducting polymer material. The invention solves the problems that the traditional polymerization method of preparing the conducting polyaniline nano-fiber needs an additional template, has complicated after-treatment processes, pollutes the environment by the used solvent, produce less polymers, is not suitable for mass production, and the like. In the invention, the aniline and the sulfoacid aniline are used as monomers, and the static chemical oxidation polymerization implementation method is used for preparing the polyaniline nano-fiber. The method can be used for preparing the polyaniline nano-fiber which is 30-95nm in diameter and 1.6 micrometers in length. The method of the invention has the characteristics of simple operation, high yield and low cost, belongs to the aqueous system and does not relate to organic solvents, is an environment-friendly method of synthesizing the polyaniline nano-fiber, and provides a new way for synthesizing the polyaniline nano-fiber.

Owner:FUZHOU UNIV

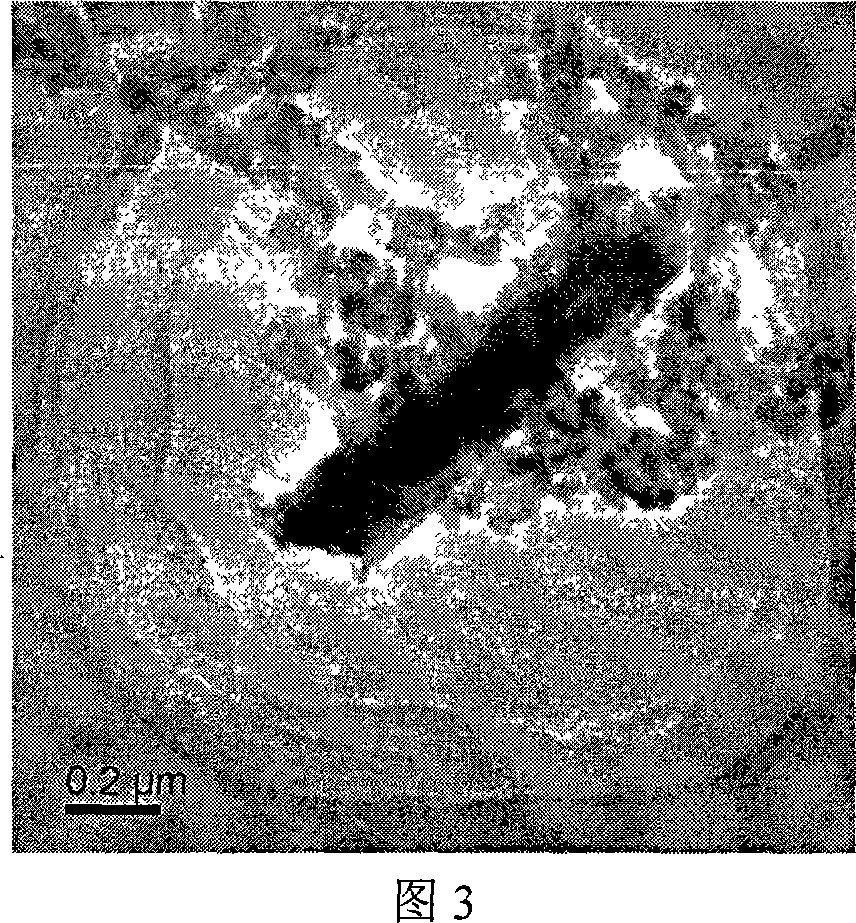

Preparation of polystyrene/polyaniline composite microsphere supported catalyst

InactiveCN101844092AHigh catalytic efficiencyNo safety hazardOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsIron saltsMicrosphere

The invention relates to a preparation of a polystyrene / polyaniline composite microsphere supported molybdenum catalyst, which belongs to the technical field of preparation of the macromolecule supported metal catalytic material. In the preparation, a polystyrene microsphere is used as a hard template and is added into deionized water with a dispersed aniline monomer, and an oxidant of water-soluble iron salt is added at a time, thereby obtaining a sea urchin-shaped polystyrene / polyaniline composite microsphere through assembly of one-dimensional polyaniline nanofibers. In the preparation of the supported catalyst, MoO(O2)2(DMF)2 is used as a catalyst-supporting active central precursor and is supported on a polystyrene / polyaniline microsphere substrate of a special nano-structure for synthesis of a supported solid catalytic material, wherein the synthesized supported catalyst is a super-hydrophilic supported catalyst. The supported catalyst can be doped with PFOS at the room temperature to prepare a super-hydrophobic supported catalyst, so that the polystyrene / polyaniline composite microsphere supported catalyst can be applied in various substrates and oxygen sources. Moreover, the polystyrene / polyaniline composite microsphere supported catalyst has high catalytic activity.

Owner:UNIV OF SCI & TECH BEIJING

Three-dimensional graphene, polyaniline and cobaltosic oxide composite material and preparation method and application

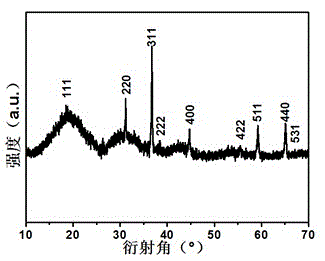

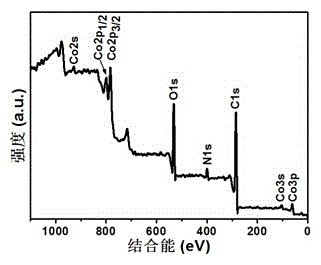

InactiveCN104987715ASolve sheddingSolution to short lifeHybrid capacitor electrodesCobalt oxides/hydroxidesPolyaniline nanofibersGraphite oxide

The invention discloses a three-dimensional graphene, polyaniline and cobaltosic oxide composite material and preparation method. The graphene, polyaniline and cobaltosic oxide composite material is of a three-dimensional micron or nano porous structure and is composed of the graphene, polyaniline nano fibers and the cobaltosic oxide, wherein the cobaltosic oxide grows on the polyaniline nano fibers to form polyaniline and cobaltosic oxide nanoparticles with the particle size 10-50 nm, and the polyaniline and cobaltosic oxide nanoparticles are evenly distributed on the graphene surface; the preparation method of the three-dimensional graphene, polyaniline and cobaltosic oxide composite material comprises the steps that in-suit polymerization is conducted on graphene oxide and aniline to obtain a graphene oxide and polyaniline crude product, bivalent cobalt salt and the graphene oxide are added, and washing and freeze-drying are sequentially conducted on the obtained product under the hydrothermal condition to obtain the three-dimensional graphene, polyaniline and cobaltosic oxide composite material which has the specific capacity capable of reaching 1021 F / g to the maximum and excellent circulation and rate performance and serves as a supercapacitor. The preparation method is simple, low in cost and environmentally friendly.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

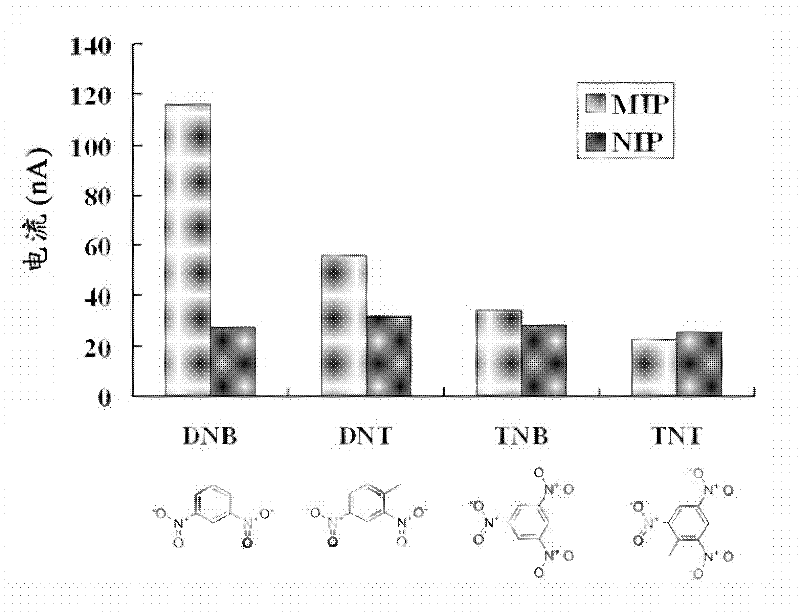

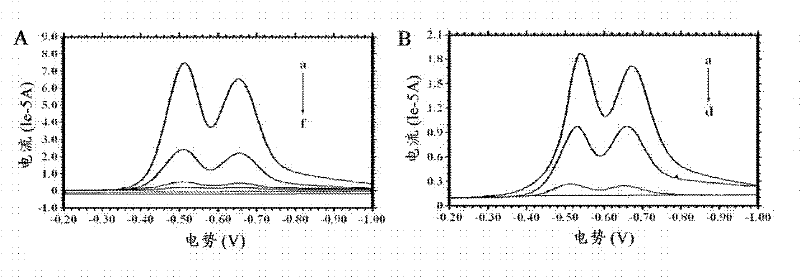

Functionalized polyaniline nanometer material, molecular imprinted polymers (MIP) composite, molecular imprinted sensor, electrochemical testing equipment and preparation method of MIP composite

The invention provides a functionalized polyaniline nanometer material which comprises an olefinic function monomer or an olefinic function monomer layer combined on the surface of the nanometer material; further, imprint polymerization selectivity is induced so as to generate the polyaniline-molecular imprinted polymers (MIP) composite with a shell-core structure through an olefinic link which is decorated on the surface of polyaniline nanometer fibre and is in the olefinic function monomer layer; and specially, a nitrobenzene compound or an insecticide is used, 1,3-dinitro benzene (DNB) or ethyl parathion is preferentially utilized as a template molecule, thereby obtaining the polyaniline-MIP composite used for detecting the nitrobenzene compound or the insecticide. The invention also relates to a molecular imprinted sensor prepared from the MIP composite and an electrochemistry testing equipment and preparation method of the MIP composite.

Owner:SONY CORP +1

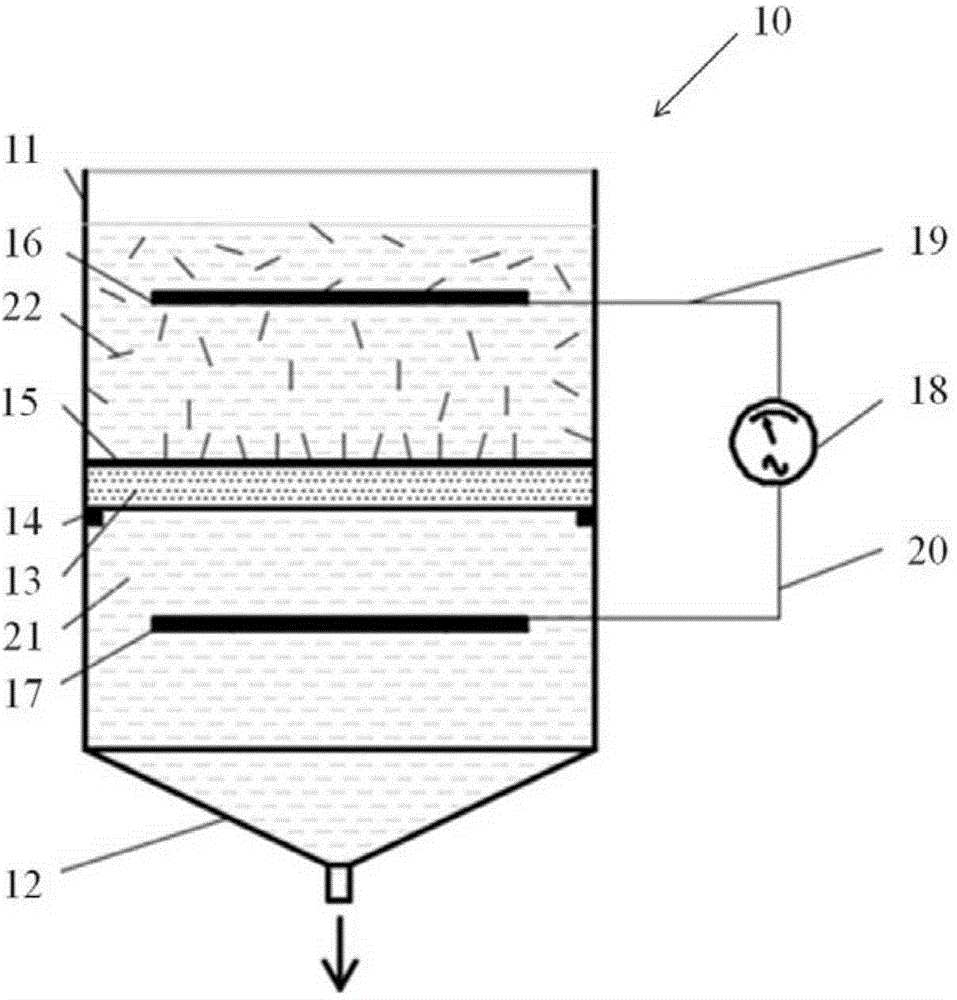

Method and device for preparing vertical orderly carbon nano tube/polyaniline composite membrane

The invention provides a method of preparing a vertical orderly carbon nano tube / polyaniline composite membrane. The method is characterized by comprising the following steps: a step of preparing a mixed aqueous dispersion liquid, namely, preparing a carbon nano tube subjected to the acidification treatment into a carbon nano tube aqueous dispersion liquid, preparing a polyaniline nano fiber aqueous dispersion liquid, then mixing the carbon nano tube aqueous dispersion liquid with the polyaniline nano fiber aqueous dispersion liquid to perform ultrasonic treatment for 4 hours and mechanical stirring for 30 minutes to obtain the mixed aqueous dispersion liquid; a step of preparing a carbon nano tube / polyaniline composite membrane by cooperating suction filtration with electric fields, namely pouring the mixed aqueous dispersion liquid into a suction filtration-electric field device, applying voltage of 100-250V to filter paper vertically, regulating the suction filtration power to 180W, applying the synergistic effect of the electric fields and the suction filtration to the mixed aqueous dispersion liquid, continuously applying voltage for 24 hours after the suction filtration is ended, then, taking out the filter paper and naturally drying the filter paper in the air to obtain the carbon nano tube / polyaniline composite membrane, wherein a mass ratio of the carbon nano tube to the polyaniline nano fiber in the mixed aqueous dispersion liquid is 5 to 1.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Polyaniline nano fiber and its preparing process

InactiveCN1995096AShape is easy to controlSimple processMonocomponent synthetic polymer artificial filamentFiberOrganic solvent

The invention discloses a polyaniline nanometer fiber and making method, which comprises the following steps: blending inorganic solution of vanadic anhydride and inorganic acid solution of phenylamine with molar rate at 1 1-14 completely; controlling the molar density of inorganic acid at 0.1-2mol / L; reacting at 0-5 deg. c for 1-24h; obtaining the polymer product; centrifuging; washing; drying to obtain the product.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of polyaniline nanofiber array

InactiveCN101845148ALarge specific surface areaGood hydrophobic/hydrophilic transition performanceMonocomponent synthetic polymer artificial filamentPolymer scienceAniline

The invention relates to a preparation method of a polyaniline nanofiber array, which belongs to the technical field of the conductive polymer. The preparation method comprises the following process steps: using a polymer substrate or a prepared composite polymer substrate to prepare aniline emulsion of a certain concentration, placing the slide into the aniline emulsion, taking out the slide after swelling for a certain period, then placing the slide into oxidant solution of a certain concentration, reaction and assembly, thereby preparing the polyaniline nanofiber array. The method has the advantages that: (1) the large-area polyaniline nanofiber array can be obtained; and (2) the utilization rate of aniline is high, thereby saving the cost. The obtained polyaniline nanofiber array has the advantages of large surface area, high conductivity and the like, and has broad application prospects in sensors, energy storage and the like.

Owner:UNIV OF SCI & TECH BEIJING

Hybridization material of Nano fiber of titanium oxide / polyaniline, and preparation method

This invention relates to a method for preparing TiO2 / polyaniline nanofiber hybrid material. The hybrid material is composite nanoparticles composed of 20-70 wt. % one-dimensional TiO2 nanorods and polyaniline nanofibers. The hybrid material is prepared by combination of template-induced polymerization and hydrothermal method from TiO2 and aniline with HCl as the dopant, ammonium persulfate as the initiator, and poly (vinyl pyrrolidone) as the surfactant. The ratio of polyaniline to ammonium persulfate is 4:1. The hybrid material has such advantages as high thermal stability, good mechanical properties, low cost, abundant and cheap raw materials, no toxicity, no harm, simple process, and controllable composition and properties.

Owner:DALIAN UNIV OF TECH

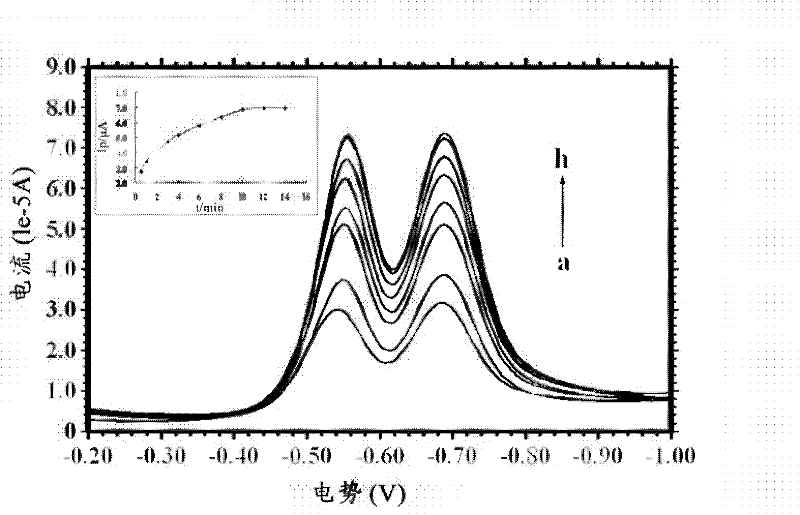

Preparation method of electrochemical sensor based on polyaniline nanofiber

InactiveCN102645461AImprove electrocatalytic activityHigh sensitivityMaterial electrochemical variablesNitrite ionNanofiber

The invention relates to a preparation method of an electrochemical sensor based on polyaniline nanofiber. The preparation method comprises the following steps of: firstly, preparing polyaniline nanofiber; then, dispersing the purified polyaniline nanofiber under ultrasonic oscillation into deionized water to form green suspension; and coating 10uL of water solution of the polyaniline nanofiber on the surface of a glass carbon electrode, and drying to obtain a modified electrode so as to prepare the electrochemical sensor based on polyaniline nanofiber. The sensor prepared by the invention shows high electro-catalysis activity to the reduction of nitrite ion, has high sensitivity, wide linear range, low detection limit and good stability, and provides a new way for monitoring the reaction process of ascorbic acid and nitrite ion.

Owner:WUXI BAILING SENSING TECH

A polyaniline/carbon mixed super capacitor

InactiveCN101017736AImprove pore structureLarge specific surface areaHybrid capacitor electrolytesElectrolytic capacitorsFiberHigh energy

The disclosed polyaniline / charcoal mixed super capacitor comprises: an anode as Li-doped nano polyaniline fiber or composite with charcoal, the organic electrolyte, and a charcoal-made cathode. Compared with prior art, this invention holds same performance and higher energy density.

Owner:CENT SOUTH UNIV

Method of preparing lithium salt doping state polyaniline electrode material for super capacitor

InactiveCN101016412AImprove pore structureLarge specific surface areaElectrolytic capacitorsFiberCapacitance

The invention discloses a preparing method of lithium salt doping state polyaniline electrode material to produce super capacitor, which comprises the following steps: adopting interfacial polymerization method; preparing acid doping state polyaniline nanometer fiber with diameter between 30 nm and 120 nm and length at 500nm to several micrometer; contra-doping with alkali liquor; getting Eigen state; doping with lithium salt solution under the protection of inert gas; getting the product. This electric pole material possesses bigger than 120 F / g ratio capacitance value in organic electrolytic solution, which can resolve the problem of low ratio capacitance value in the organic electrolytic solution.

Owner:CENT SOUTH UNIV

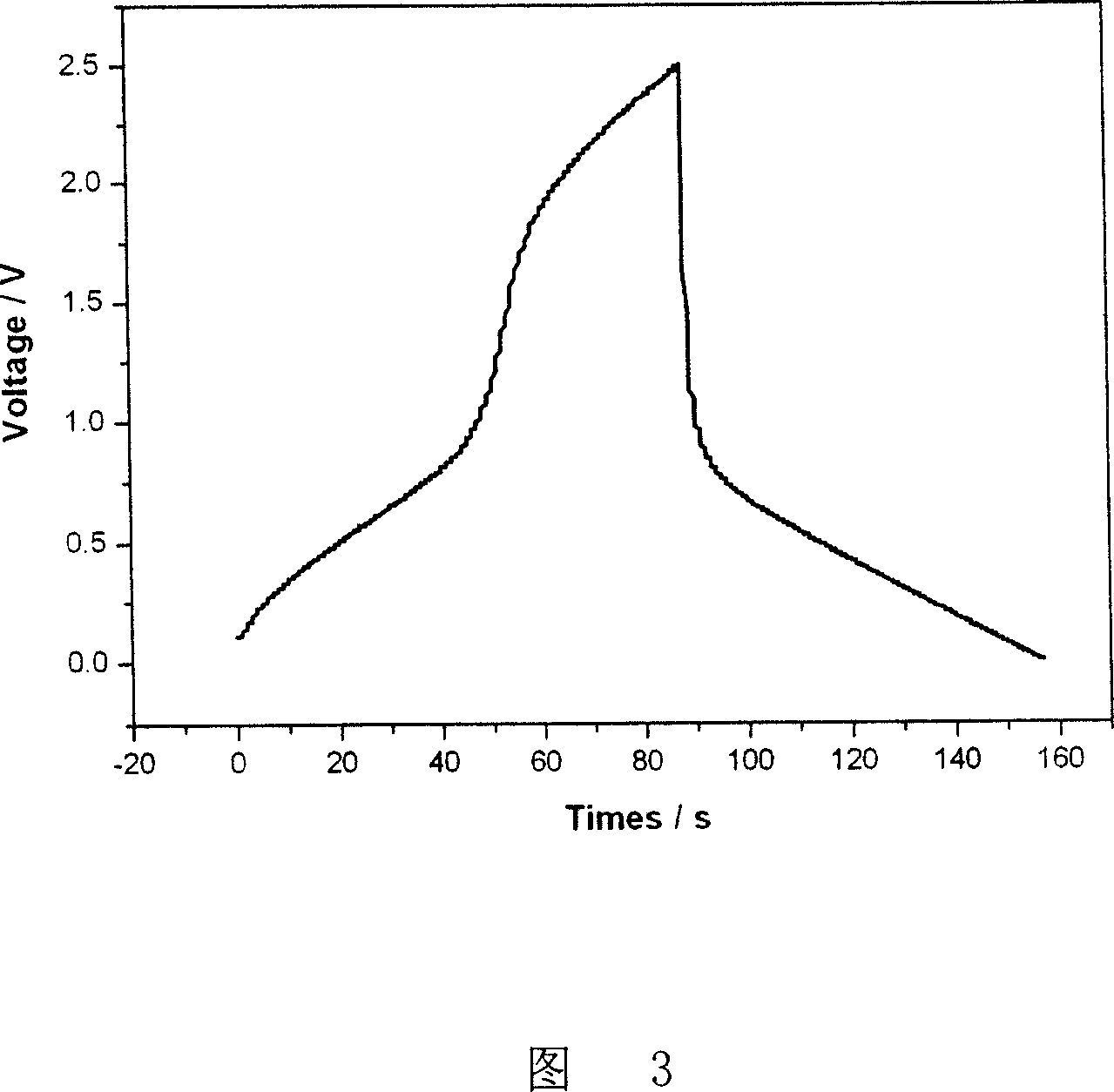

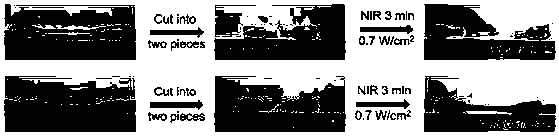

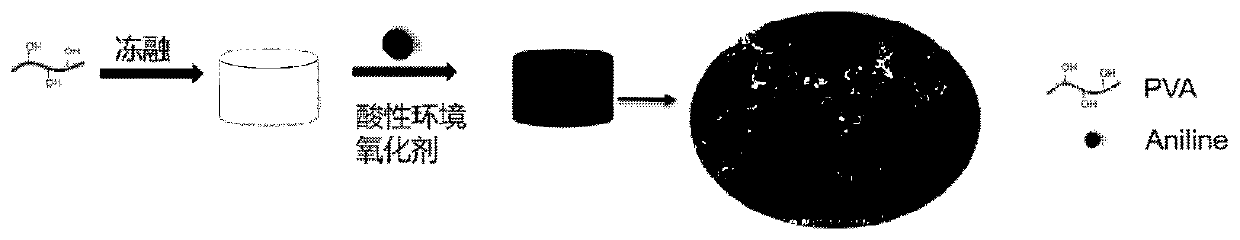

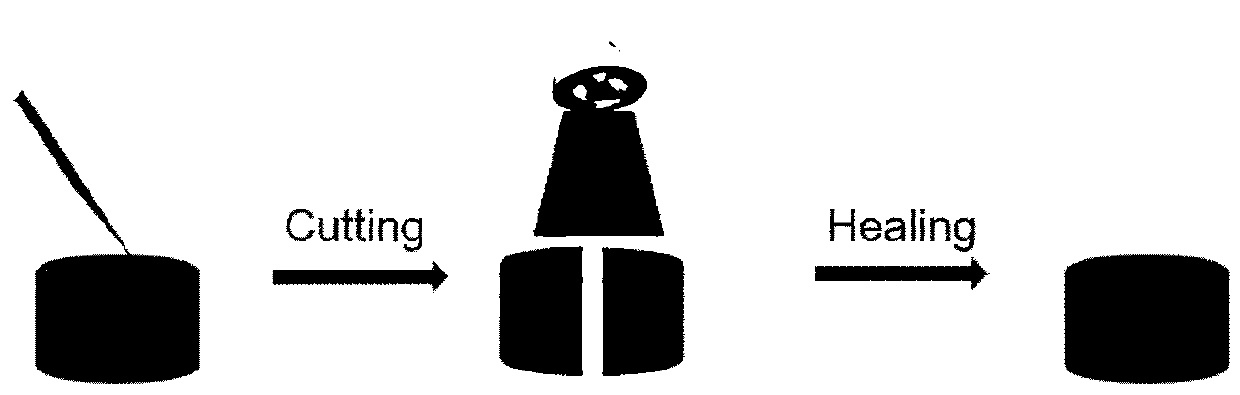

Polyvinyl alcohol-polyaniline composite hydrogel, and preparation method and application thereof

The invention discloses a polyvinyl alcohol-polyaniline composite hydrogel, and a preparation method and an application thereof. The composite hydrogel comprises a polyvinyl alcohol hydrogel and polyaniline nanofiber, wherein the polyaniline nanofiber is compounded in the three-dimensional network structure of the polyvinyl alcohol hydrogel through a manner of in-situ polymerization; the method ofin-situ polymerization is as follows: an aniline monomer is induced by an oxidant to the surface of the three-dimensional network structure of the polyvinyl alcohol hydrogel to form a nanofiber structure with a diameter in a range of 10 to 40 nm through a nucleation grafting process in an acidic environment; the composite hydrogel can utilize the photothermal conversion characteristic of polyaniline fiber to raise a temperature to 50 DEG C or above by conversion of light energy into heat energy; and a polyvinyl alcohol chain segment moves to realize intermolecular hydrogen bond recombinationand realize self-healing of induction through remote control of near-infrared light. The composite hydrogel provided by the invention has simple design, simple and convenient operation, uniform and stable system, good biological compatibility, and great potential when being used as a biomedical material.

Owner:NANJING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com