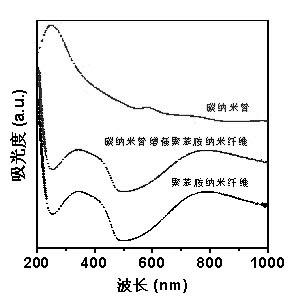

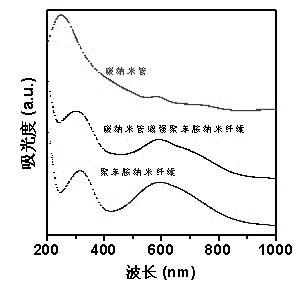

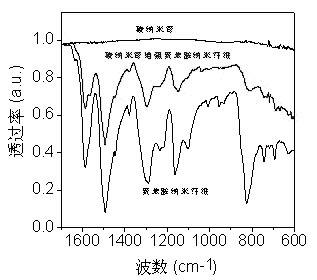

Carbon nano tube reinforced polyaniline nano-fiber and preparing method thereof

A carbon nanotube and nanofiber technology, applied in the field of carbon nanotube reinforced polyaniline nanofibers and their preparation, can solve the problems of low electrical conductivity and poor processing performance, and achieve controllable electrical conductivity, efficient dispersion or dissolution, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] A method for preparing polyaniline nanofibers that do not contain carbon nanotubes, without adding carbon nanotubes, that is, the concentration of carbon nanotubes is 0%, with 0.1mol / L hydrochloric acid as the reaction medium, ammonium persulfate as the oxidant, and N -Phenylphenylenediamine is an initiator, and its preparation method specifically comprises the following steps:

[0089] (1) Dissolve 750mg of aniline monomer in 100mL of 0.1mol / L hydrochloric acid to form an aniline monomer solution;

[0090] (2) Dissolve 37.5mg of initiator in 2mL of ethanol to form an initiator solution;

[0091] (3) Dissolve 450mg of oxidizing agent in 100mL of 0.1mol / L hydrochloric acid to form an oxidizing agent solution;

[0092] Described oxidizing agent is ammonium persulfate;

[0093] (4) Add the initiator alcohol solution obtained in step (2) to the aniline monomer solution obtained in step (1) and mix quickly, then add the oxidant solution obtained in step (3) immediate...

Embodiment 2

[0100] A method for preparing carbon nanotube-reinforced polyaniline nanofibers, comprising using carbon nanotubes with a concentration of 0.5% as an additive, 0.1mol / L hydrochloric acid as a reaction medium, ammonium persulfate as an oxidant, and N -Phenylphenylenediamine is initiator, and its preparation method specifically comprises the following steps:

[0101] (1) Disperse 750mg of aniline monomer and 4mg of carbon nanotubes in 100mL of 0.1mol / L hydrochloric acid to form a blend of aniline monomer and carbon nanotubes;

[0102] (2) Dissolve 37.5mg of initiator in 2mL of ethanol to form an initiator solution;

[0103] (3) Dissolve 450mg of oxidizing agent in 100mL of 0.1mol / L hydrochloric acid to form an oxidizing agent solution;

[0104] Described oxidizing agent is ammonium persulfate;

[0105] (4) Add the initiator alcohol solution obtained in step (2) to the blend of aniline monomer and carbon nanotubes obtained in step (1) and mix quickly, then immediately...

Embodiment 3

[0112] A method for preparing carbon nanotube-reinforced polyaniline nanofibers, that is, a carbon nanotube with a concentration of 1% is used as an additive, 0.1mol / L hydrochloric acid is used as a reaction medium, ammonium persulfate is used as an oxidant, and N -Phenylphenylenediamine is initiator, and its preparation method specifically comprises the following steps:

[0113] (1) Disperse 750mg of aniline monomer and 8mg of carbon nanotubes in 100mL of 0.1mol / L hydrochloric acid to form a blend of aniline monomer and carbon nanotubes;

[0114] (2) Dissolve 37.5mg of initiator in 2mL of ethanol to form an initiator solution;

[0115] (3) Dissolve 450mg of oxidizing agent in 100mL of 0.1mol / L hydrochloric acid to form an oxidizing agent solution;

[0116] Described oxidizing agent is ammonium persulfate;

[0117] (4) Add the initiator alcohol solution obtained in step (2) to the blend of aniline monomer and carbon nanotubes obtained in step (1) and mix quickly, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com