A kind of preparation method of the water-based coating that adjusts high insulation surface resistance

A technology for insulating surfaces and water-based coatings, applied in the direction of conductive coatings, coatings, etc., can solve the problems of electrical insulators that cannot be electrostatically sprayed, ambient humidity, high temperature requirements, and lack of timeliness, so as to achieve environmental protection and sustainability The effect of development, low cost, wide application value and industrial prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method for adjusting a water-based coating with high insulating surface resistance, the steps are as follows:

[0037] (1) Preparation of solution A: Add 0.90 g of polyvinylpyrrolidone into 10.0 g of pure water, and keep the temperature at 40°C for 30 hours to completely dissolve the polyvinylpyrrolidone. Add 0.20 mL of aniline monomer and 0.40 g of p-toluenesulfonic acid into the above aqueous solution of polyvinylpyrrolidone, and stir evenly to obtain A solution.

[0038] (2) Preparation of solution B: add 0.61 g of ammonium persulfate into 4.0 g of pure water, and stir until completely dissolved to obtain solution B.

[0039](3) Put the two solutions of A and B in a constant temperature tank, and when the temperature is adjusted to -5°C, quickly mix and stir the A and B solutions until uniform, and polymerize at a constant temperature of -10°C for 16 hours.

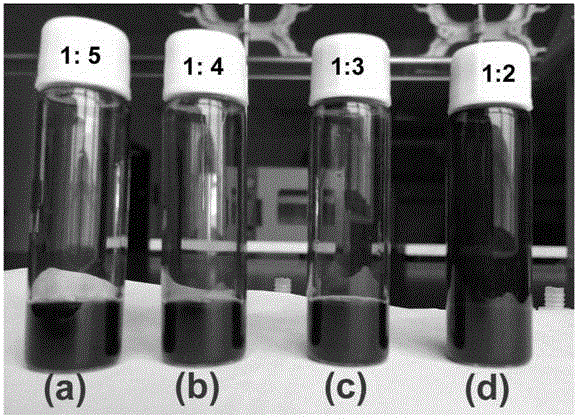

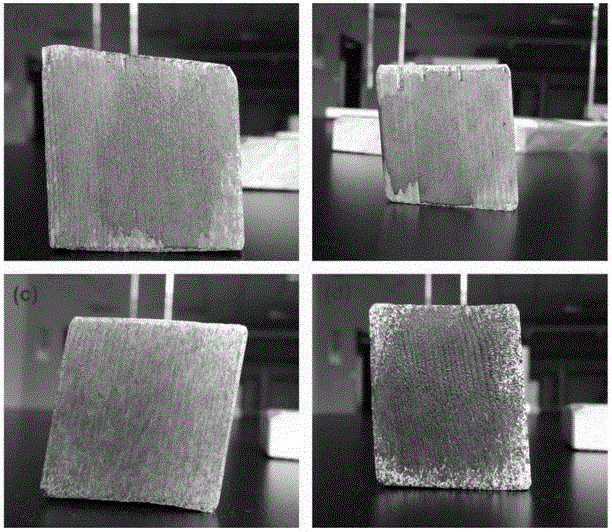

[0040] (4) Mix the above-mentioned mixed solution and pure water according to the mass ratio o...

Embodiment 2

[0044] A preparation method for adjusting a water-based coating with high insulating surface resistance, the steps are as follows:

[0045] (1) Preparation of solution A: Add 1.0 g of polyvinyl alcohol into 10.0 g of pure water, and keep the temperature at 70°C for 30 hours to completely dissolve the polyvinyl alcohol. Add 0.20 mL of aniline monomer and 0.40 g of p-toluenesulfonic acid into the above aqueous solution of polyvinyl alcohol, and stir evenly to obtain A solution.

[0046] (2) Preparation of solution B: add 0.61 g of ammonium persulfate into 4.0 g of pure water, and stir until completely dissolved to obtain solution B.

[0047] (3) Put the two solutions of A and B in a constant temperature tank, and when the temperature is adjusted to -10°C, quickly mix and stir the A and B solutions until uniform, and polymerize at a constant temperature of -10°C for 16 hours.

[0048] (4) Mix the mixed solution obtained above with pure water at a weight ratio of mixed solution: ...

Embodiment 3

[0052] A preparation method for adjusting a water-based coating with high insulating surface resistance, the steps are as follows:

[0053] (1) Preparation of solution A: Add 0.90 g of polyvinylpyrrolidone into 10.0 g of pure water, and keep the temperature at 40°C for 30 hours to completely dissolve the polyvinylpyrrolidone. Add 0.20 mL of aniline monomer and 0.49 g of naphthalenesulfonic acid into the above aqueous solution of polyvinylpyrrolidone, and stir evenly to obtain A solution.

[0054] (2) Preparation of solution B: add 0.61 g of ammonium persulfate into 4.0 g of pure water, and stir until completely dissolved to obtain solution B.

[0055] (3) Put the two solutions of A and B in a constant temperature tank, and when the temperature is adjusted to -5°C, quickly mix and stir the A and B solutions until uniform, and polymerize at a constant temperature of -10°C for 16 hours.

[0056] (4) Mix the mixture obtained above with pure water at a mass ratio of 1:3, and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com