Anode material of electric/high pressure coupling elastic press and its installation and use method

A technology of anode materials and presses, applied in chemical instruments and methods, electrochemical sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as sludge pollution and corrosion, achieve long life and reduce loss costs , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The anode material of an electric / high-voltage coupling elastic press machine of the present invention is a braid obtained by mixing and weaving 40% carbon fiber and 60% polypropylene fiber, that is, a carbon fiber composite material cloth; wherein, the carbon fiber is selected with a resistivity of 144 ohms Carbon fiber with a tensile strength of 4410Mpa, a fineness of 700g / 1000m, a flammability of UL94V-0, and a halogen content of Cl2 , the thickness is 0.30mm.

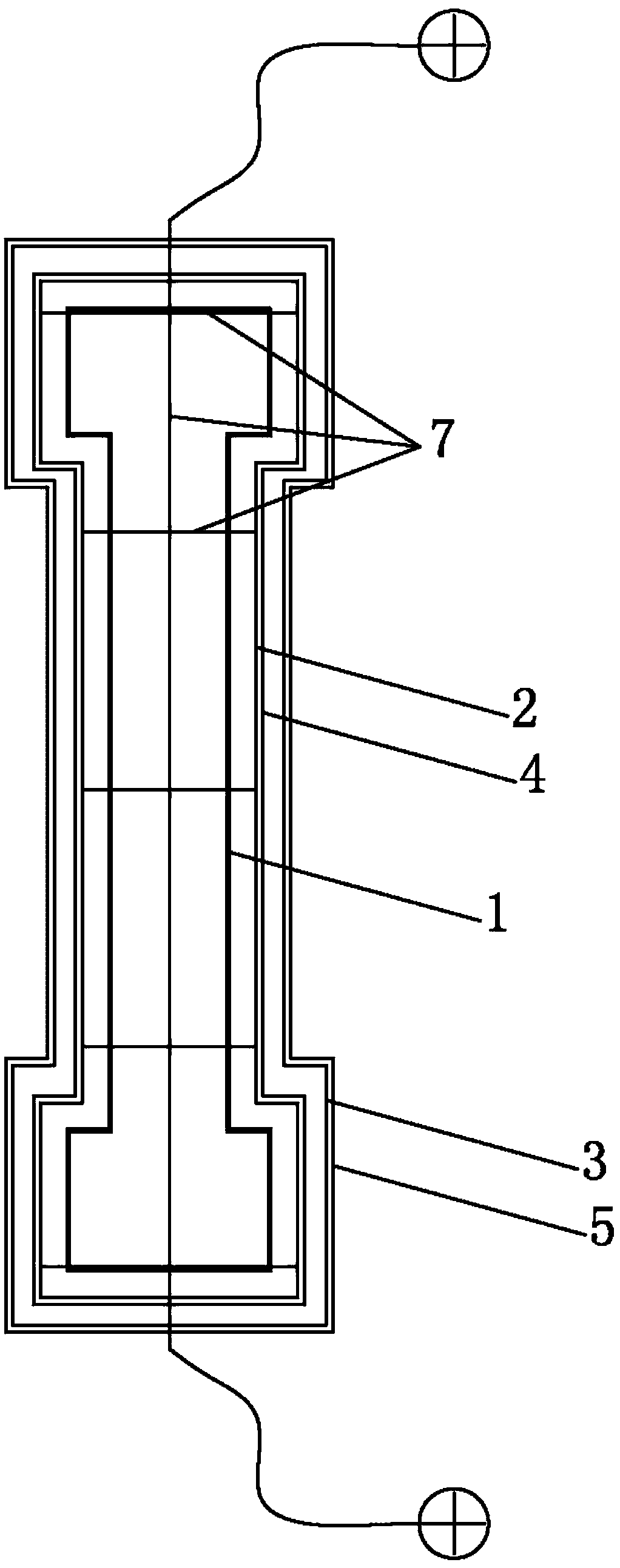

[0039] Such as figure 1 As shown, the carbon fiber composite material cloth 2 of the present invention is installed behind the common filter cloth 3 on the anode filter frame 1 of the conventional electric / high pressure coupling elastic press; Connect and use as anode. A circle of epoxy resin insulating layer 4 with a thickness of 3mm is provided at the periphery of the outer surface of the carbon fiber composite material cloth 2; a circle of rubber insulation layer 5 with a thickness of 3mm is provided at t...

Embodiment 2

[0041]The anode material of an electric / high-voltage coupling elastic press machine of the present invention is a braid obtained by mixing and weaving 30% carbon fiber and 70% polypropylene fiber, that is, a carbon fiber composite material cloth; wherein, the carbon fiber is selected with a resistivity of 36 Ohm meter, the tensile strength is 3530Mpa, the denier is 400g / 1000m, the flammability is UL94V-0, and the halogen content is Cl2 , the thickness is 0.30mm.

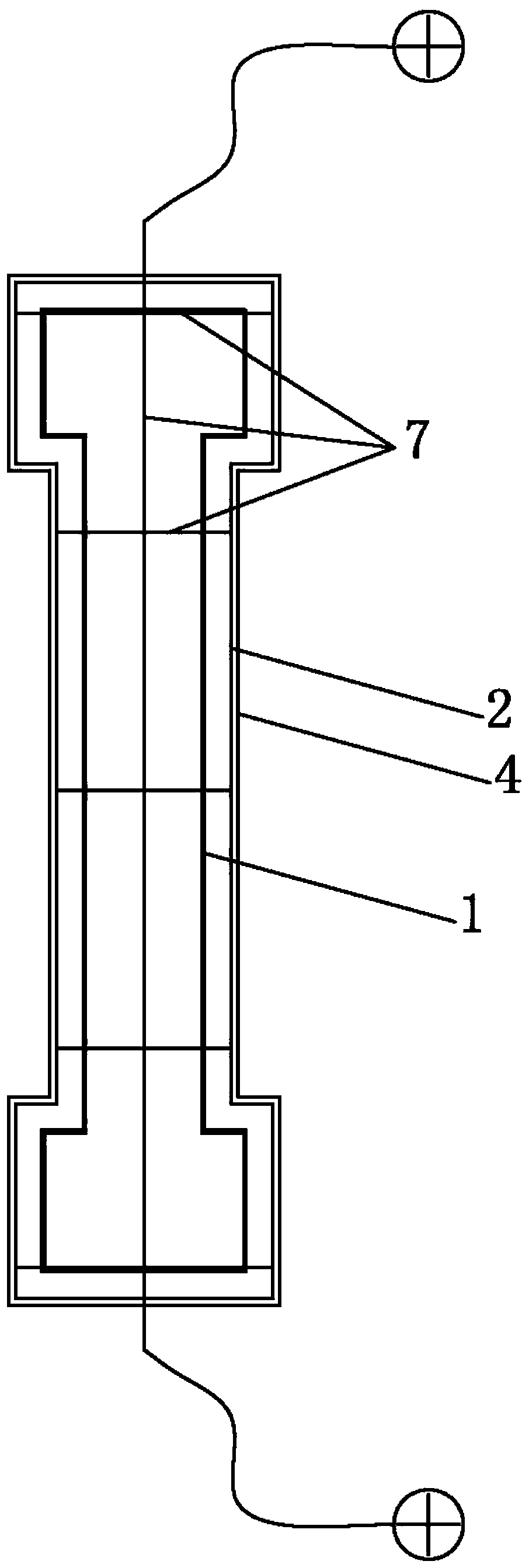

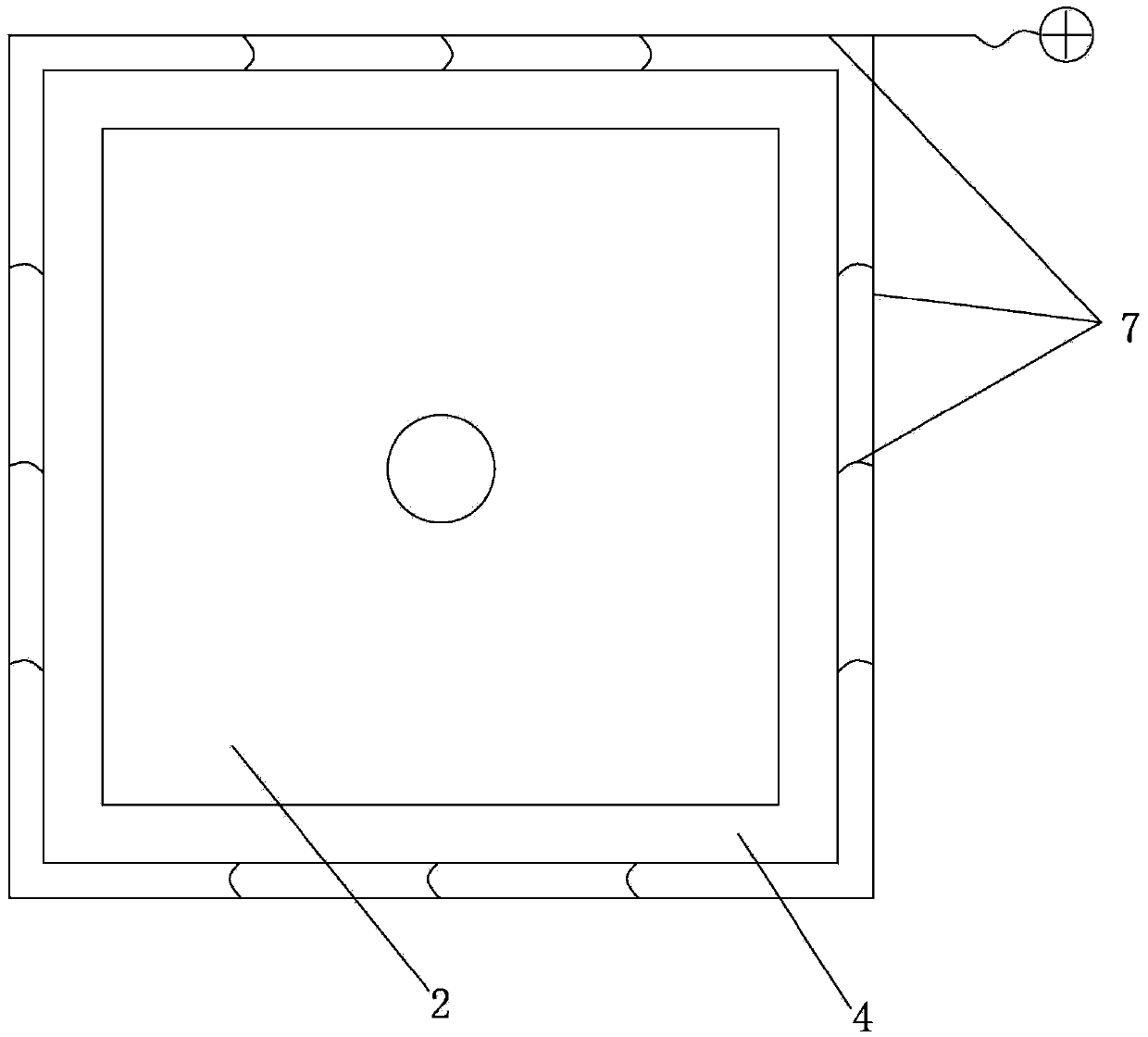

[0042] Such as figure 2 As shown, the carbon fiber composite material cloth 2 of the present invention replaces the common filter cloth on the anode filter frame 1 of the conventional electric / high pressure coupling elastic press, directly as the filter cloth of the anode filter frame 1; the carbon fiber composite material cloth 2 passes through the metal Wire 7 is connected with the positive pole of the power supply and used as an anode. Such as figure 2 , image 3 As shown, an epoxy resin insulating layer 4 wi...

Embodiment 3

[0044] The anode material of an electric / high-voltage coupling elastic press machine of the present invention is a braid obtained by mixing and weaving 45% carbon fiber and 55% polypropylene fiber, that is, carbon fiber composite material cloth; wherein, the resistivity of carbon fiber is 100 ohms carbon fiber with a tensile strength of 3800Mpa, a denier of 600g / 1000m, a flammability of UL94V-0, and a halogen content of Cl2 , the thickness is 0.30mm.

[0045] In the present invention, the carbon fiber composite material filter cloth 2 is installed behind the common filter cloth 3 of the anode filter frame 1 of the conventional electric / high pressure coupled elastic press; the carbon fiber composite material filter cloth 2 is connected to the positive pole of the power supply through a metal wire 7 , used as anode. The outer surface of the carbon fiber composite material filter cloth 2 is provided with a rubber insulating layer with a thickness of 2 mm; the outer surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com