Patents

Literature

100results about How to "Anisotropic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

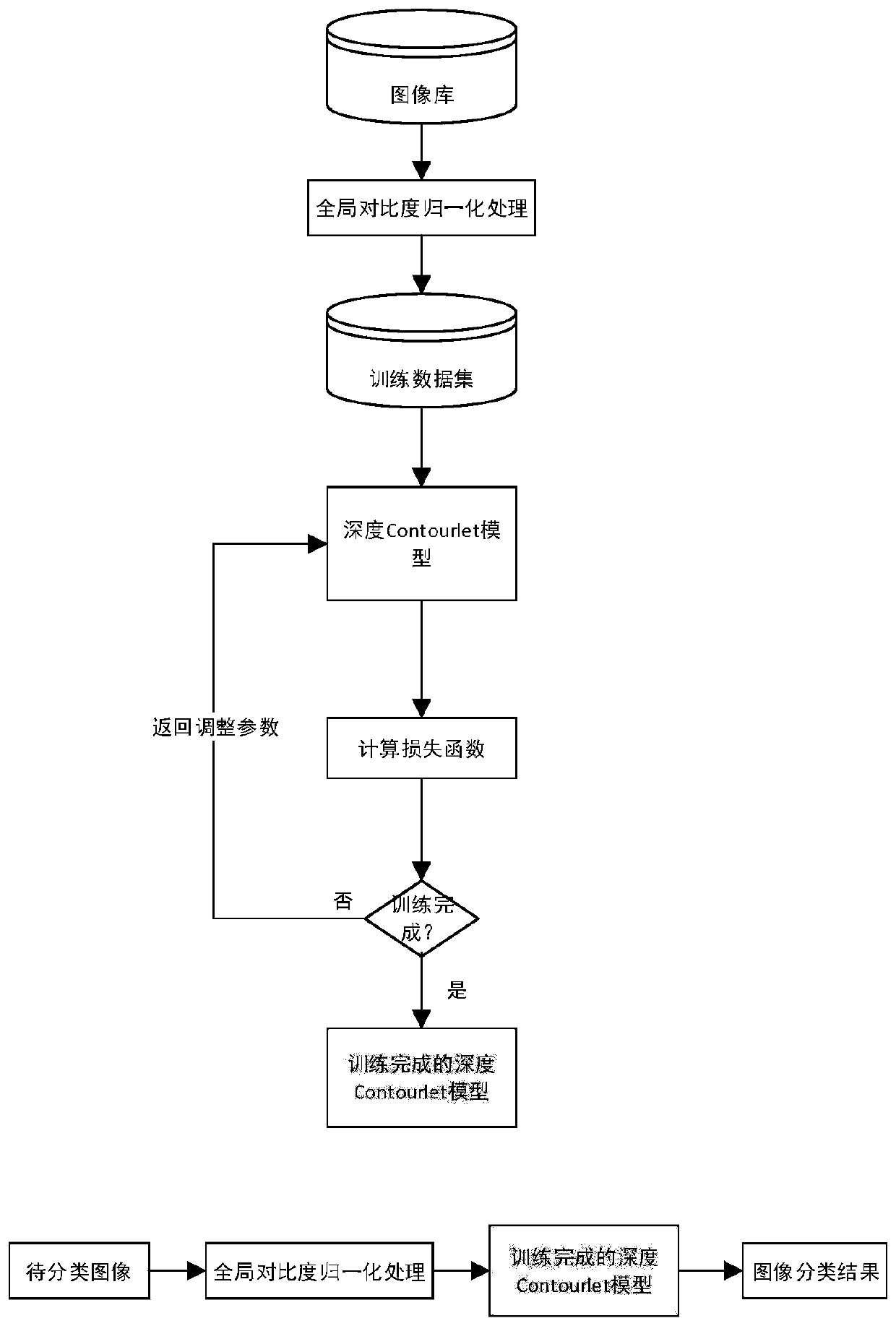

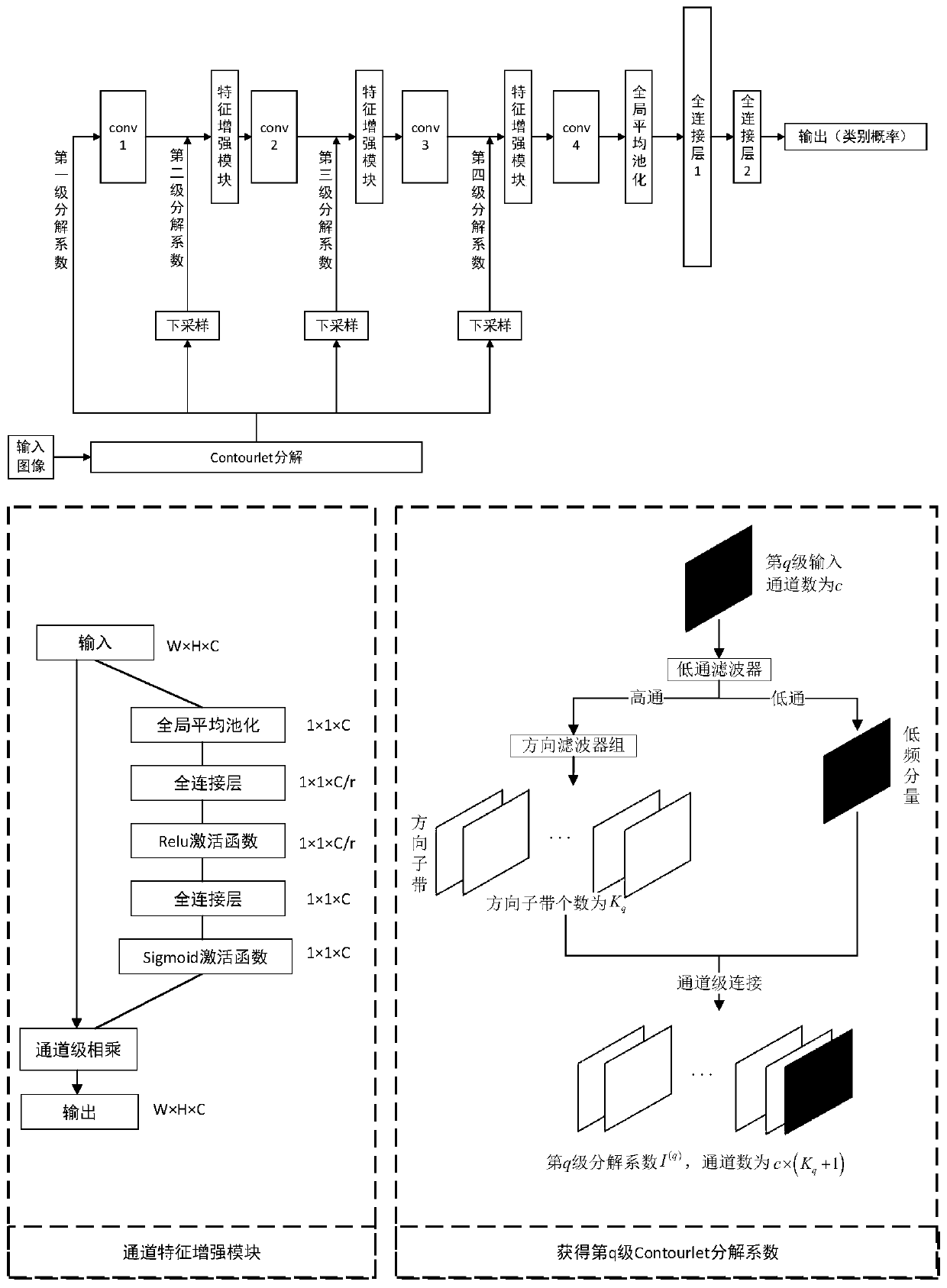

Remote sensing image classification method based on attention mechanism deep Contourlet network

ActiveCN110728224AApproximation effect is goodGood rotation invarianceScene recognitionNeural architecturesTest sampleNetwork output

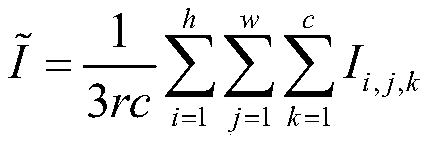

The invention discloses a remote sensing image classification method based on an attention mechanism deep Contourlet network, and the method comprises the steps: building a remote sensing image library, and obtaining a training sample set and a test sample set; then, setting a Contourlet decomposition module, building a convolutional neural network model, grouping convolution layers in the model in pairs to form a convolution module, using an attention mechanism, and performing data enhancement on the merged feature map through a channel attention module; carrying out iterative training; performing global contrast normalization processing on the remote sensing images to be classified to obtain the average intensity of the whole remote sensing images, and then performing normalization to obtain the remote sensing images to be classified after normalization processing; and inputting the normalized unknown remote sensing image into the trained convolutional neural network model, and classifying the unknown remote sensing image to obtain a network output classification result. According to the method, a Contourlet decomposition method and a deep convolutional network method are combined, a channel attention mechanism is introduced, and the advantages of deep learning and Contourlet transformation can be brought into play at the same time.

Owner:XIDIAN UNIV

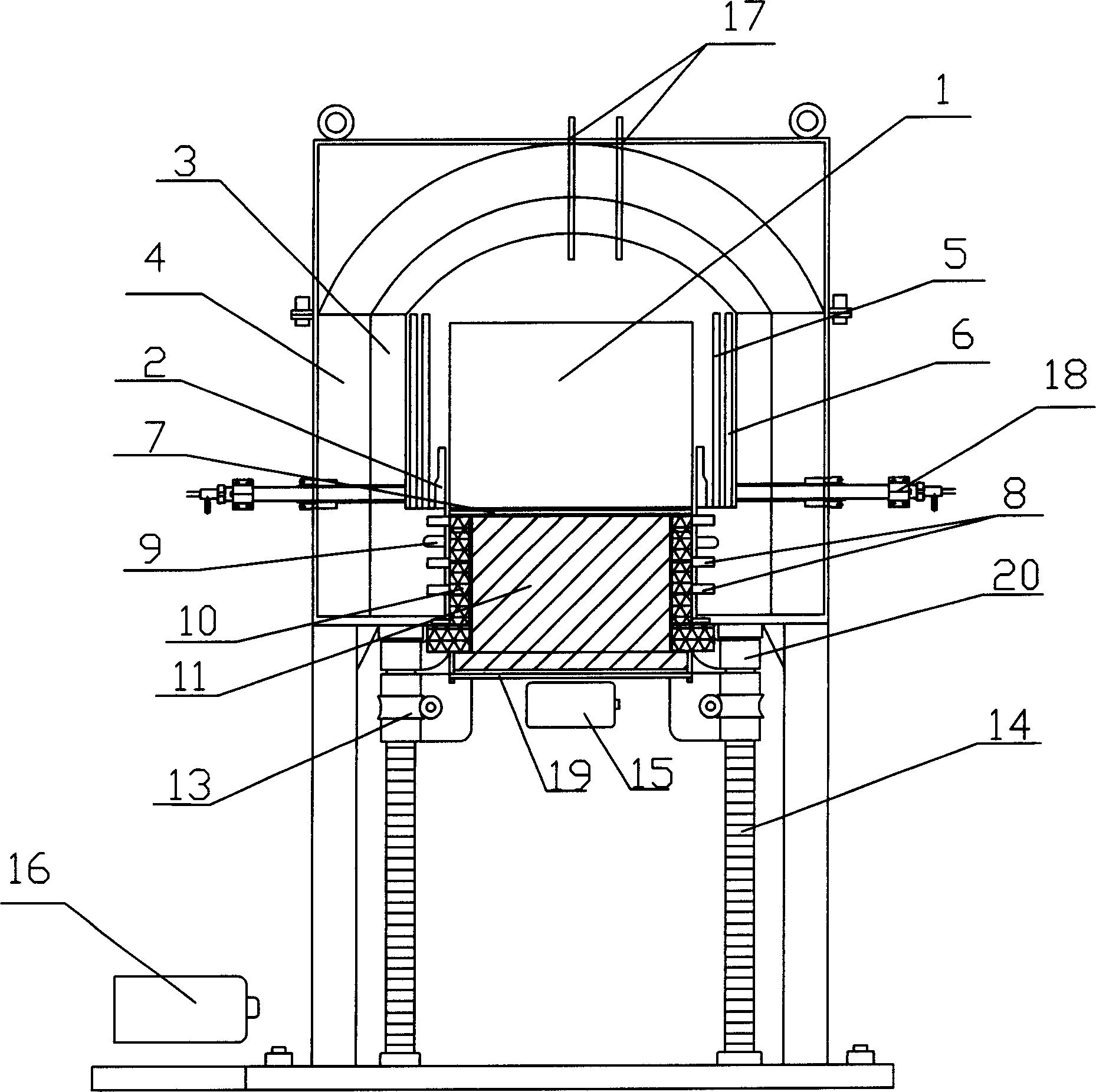

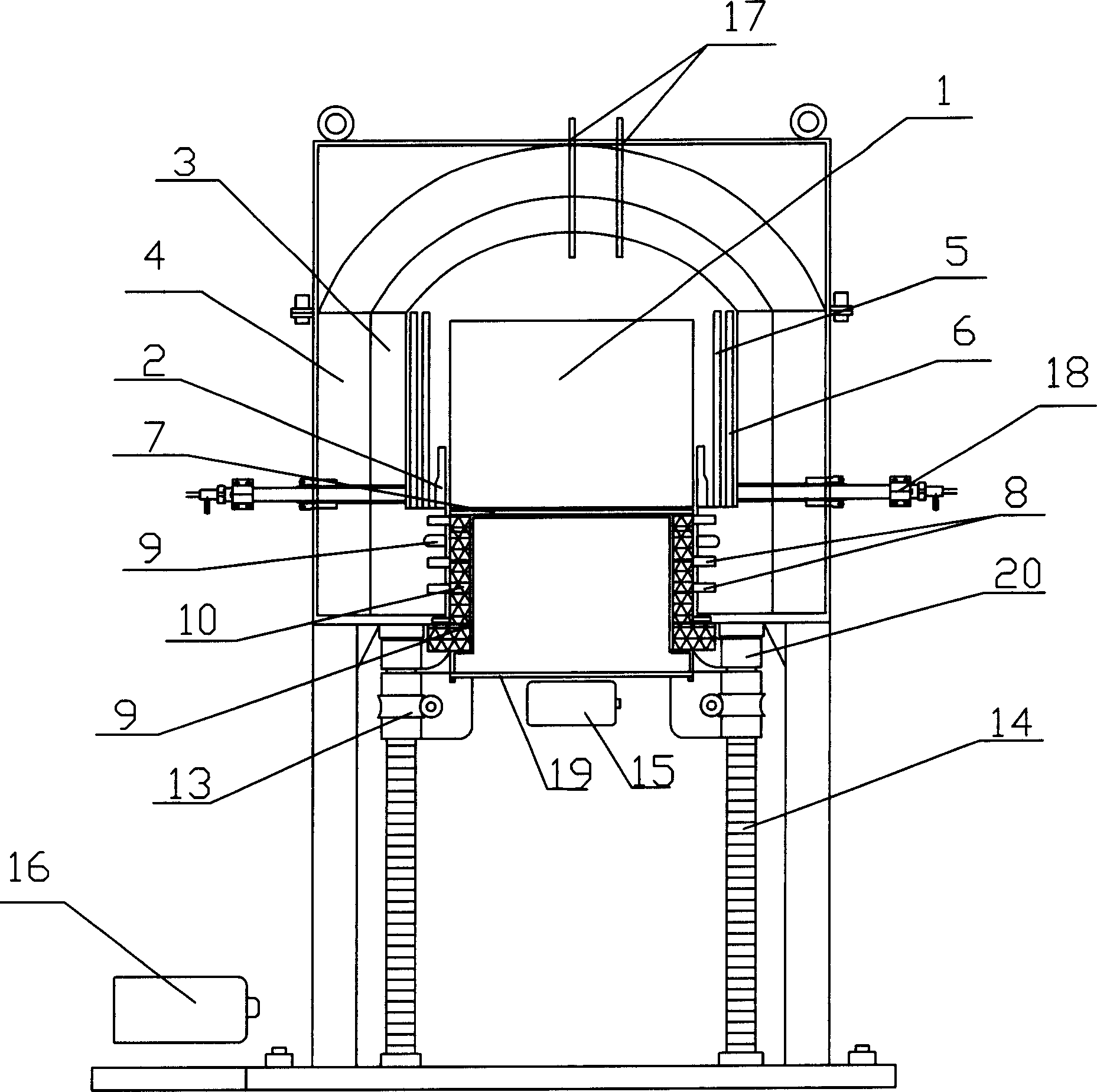

Directional solidifying smelter

InactiveCN1862201ASimple structureReduce the number of vacuum stagesCrucible furnacesCrucibleSmall footprint

The present invention discloses a kind of unidirectional solidification smelting furnace. It includes the following main several portions: crucible, refractory external heat-insulating stool with hollow structure, internal heat-insulating stool, radiation bearing plate, lifting hoop, circular recessed groove and elastic sealing ring, lifting screw rod, water cooler and lifting worm, sliding supporting plate, lifting servo motor and speed-reducing control device. Said invention also provides the connection mode of all the above-mentioned portions and concrete operation method of said smelting furnace.

Owner:高文林

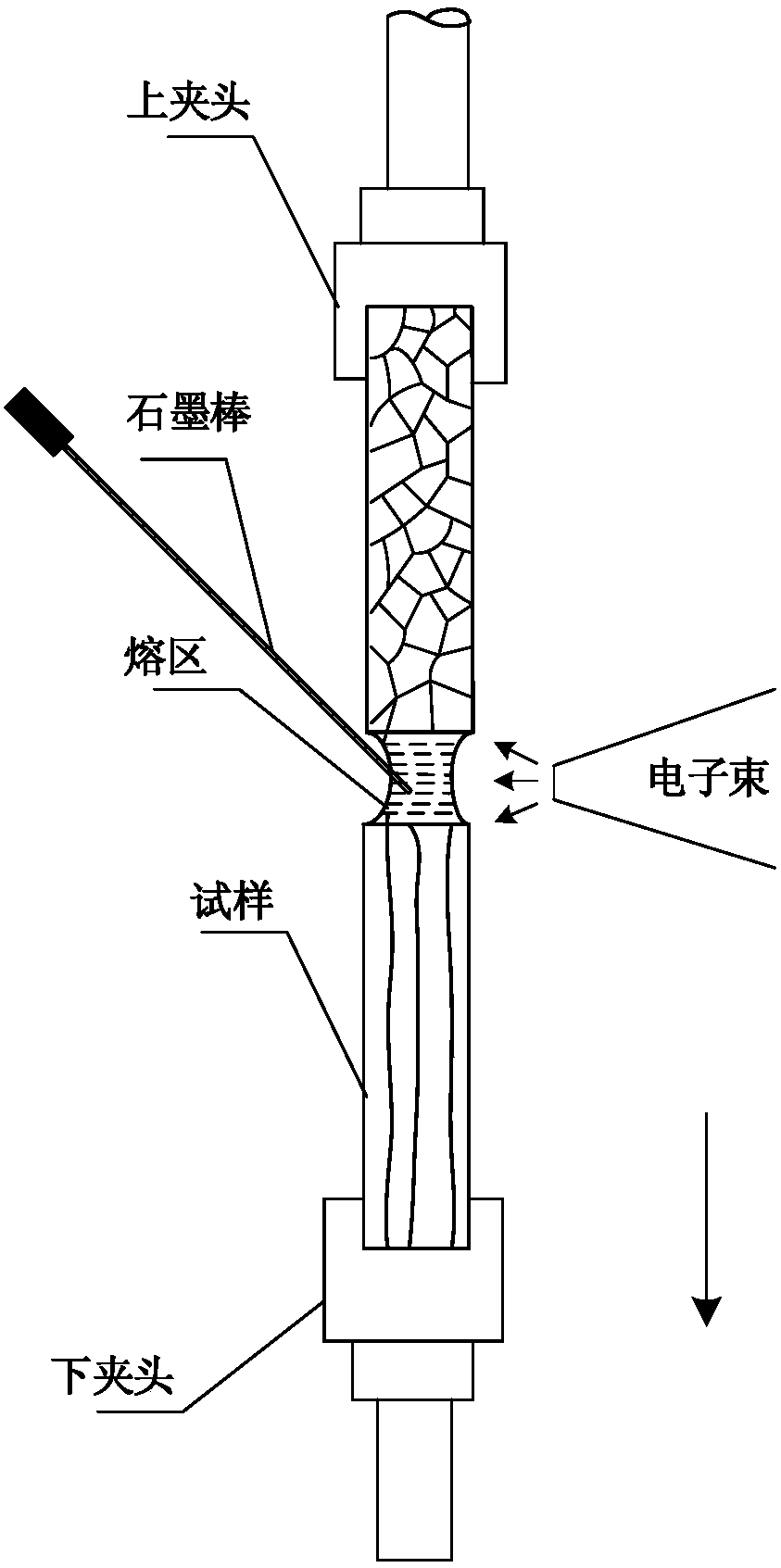

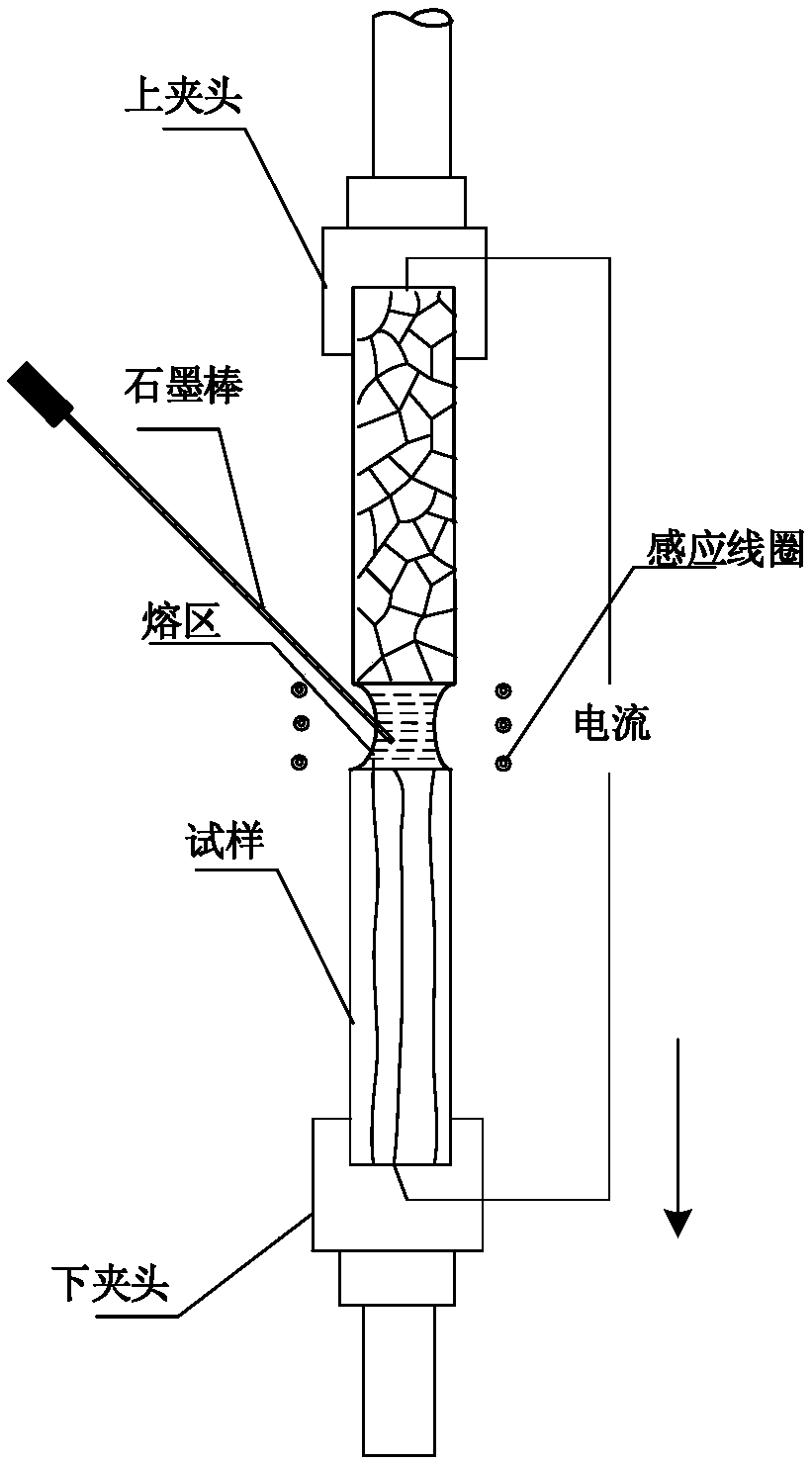

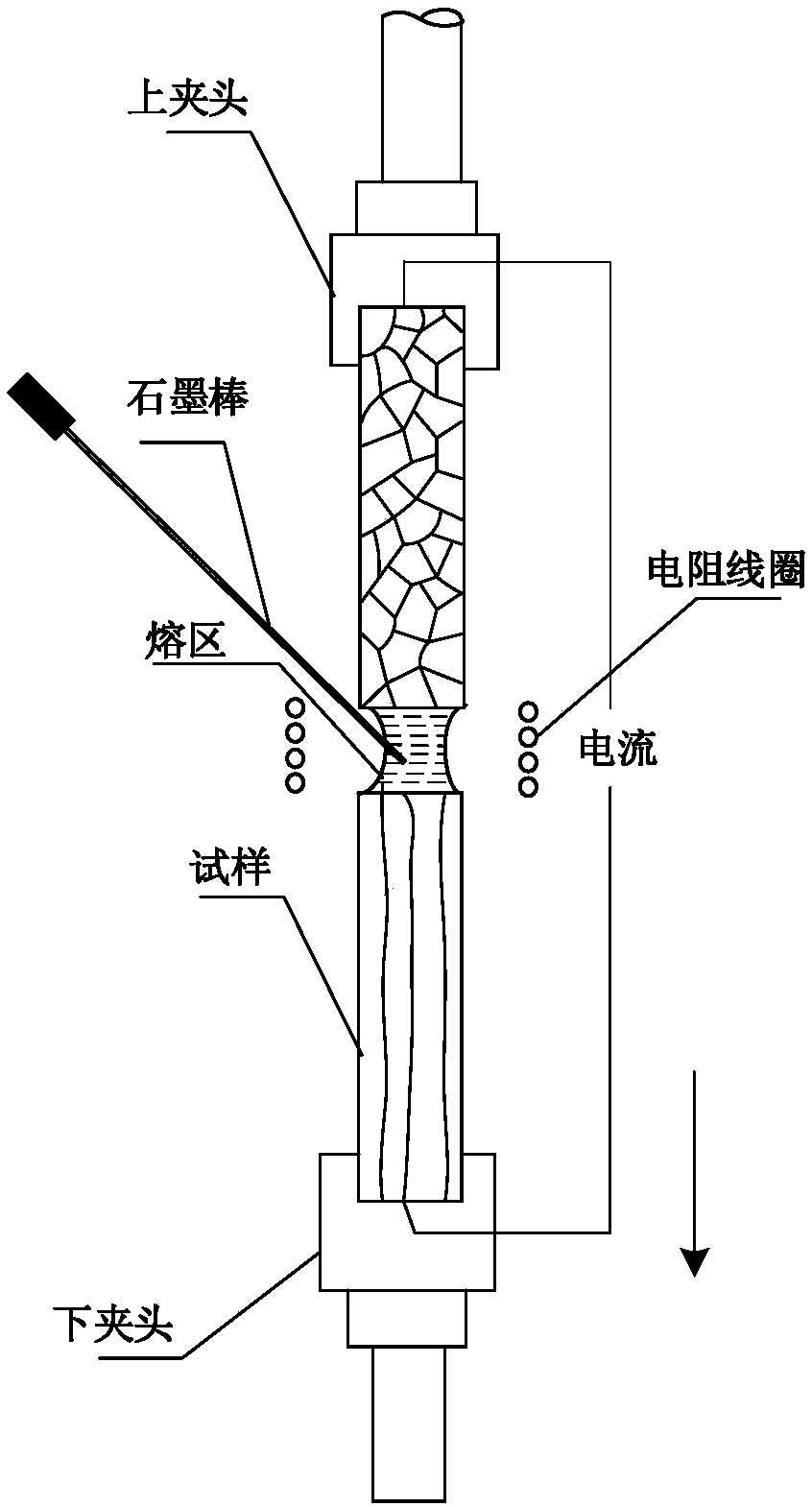

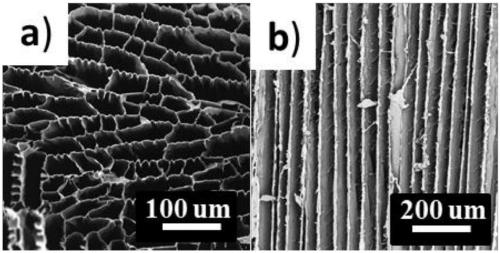

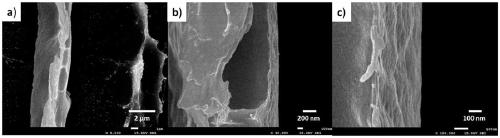

Graphene/metal composite material and preparation method thereof

The invention discloses a graphene / metal composite material and a preparation method thereof. The method comprises the following steps of: (1) weighing a metal rod and a high-purity carbon rod in percentage by mass, wherein the high-purity carbon rod accounts for 1%-30%; (2) clamping the cleaned metal rod on an upper chuck and a lower chuck of a withdrawing system of a directional solidification furnace adopting a floating zone method, clamping the high-purity carbon rod on a clamp beside the withdrawing system, and enabling the bottom end of the high-purity carbon rod to be in contact with amelting zone of the metal rod; and (3) performing vacuum-pumping on the directional solidification furnace adopting the floating zone method, performing directional solidification on the metal rod, controlling length of a melting zone to be 1-50 mm, moving the metal rod from top to bottom at a rate of 1-5000 [mu]m / s, and rotating along the axis of the withdrawing system; and enabling the bottom end of the high-purity carbon rod to be within the melting zone of the metal rod all the time. According to the graphene / metal composite material obtained by the method disclosed by the invention, carbon exists in a metal lattice in the form of graphene, and the two-phase interface is good in combination, so that conductivity of the material is favorably improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

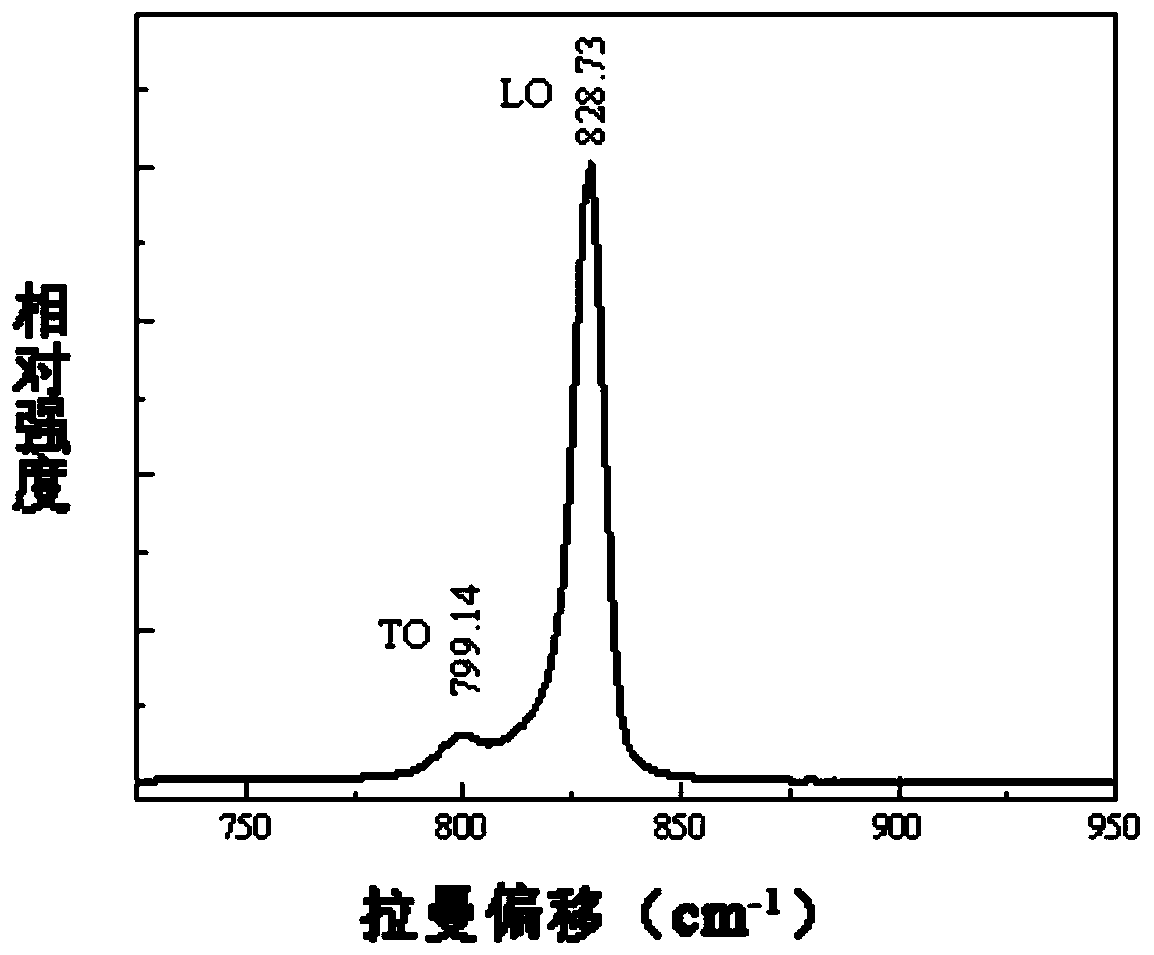

Production method for nanocrystalline anisotropic rare earth permanent magnetic powder

InactiveCN101174499AAnisotropicImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureRare earthQuenching

The invention belongs to the technical field of rare-earth permanent magnetic material, aiming to solve the problem of weak magnetic property of nano-sized rare-earth permanent magnet powder produced according to prior art. The invention is characterized in that the rare earth-transition metal permanent magnet alloys are processed by vacuum induction melting and vacuum rapid quenching; then the quenched flakes must be hot-rolled at least one time with hot rolling temperature from 500DEG C to 1000DEG C; and the linear velocity of hot roller reaches 0.5to 55.0m / s; compared with the temperature before hot rolling, the final thickness of the flakes after hot rolling is reduced by 10 to 95%; the flakes is made into magnetic texture by controlling the thickness reduction of the flakes with the direction of the magnetic texture parallel with the direction of hot rolling power; the crystalline grain of the flakes are nano-grains; then the hot-rolling flakes are broken; the average particle size of the magnetic powder is 3to 30Mu m. Each particle has magnetic texture; then the magnetic power is graded according to size; finally, the graded magnetic powder is packed by following methods respectively: non-vacuum package, vacuum package or package by charging protective air under the condition of vacuum. The magnetic powder is of anisotropic and high magnetic properties.

Owner:NINGBO UNIV

Negative ion ceramic product, and manufacturing method thereof

InactiveCN110194654AHigh temperature and corrosion resistanceImprove crack resistance and abrasion resistanceCeramic materials productionClaywaresCeramic glazePorous starch

The invention discloses a negative ion ceramic product, and a manufacturing method thereof, and belongs to the technical field of ceramic. The blank body raw materials of the negative ion ceramic product comprise, by mass, 30-40 parts of bone meal, 10-15 parts feldspar, 5-6 parts calcite, 20-30 parts kaolin, 10-15 parts clay, 3-5 parts water glass, 3-6 parts carbon fiber powder, 3-6 parts porous starch, 5-10 parts of tourmaline powder and 3-8 parts of Chongguang stone powder; a glaze raw material comprises following components, by mass, 10-20 parts agate stone, 10-50 parts feldspar, 5-10 partsquartz, 5-8 parts of sintered talc, 3-10 parts of zirconia, 5-15 parts of a fluxing agent, 3-8 parts of energy mineral powder, 5-10 parts of tourmaline powder and 2-5 parts of monazite powder. The negative ion ceramic product is excellent in negative ion release performance, flat in ceramic glaze surface, fine in texture, bright and smooth in glaze color, and high in strength and wear resistance.

Owner:DEHUA HENGHAN ARTS

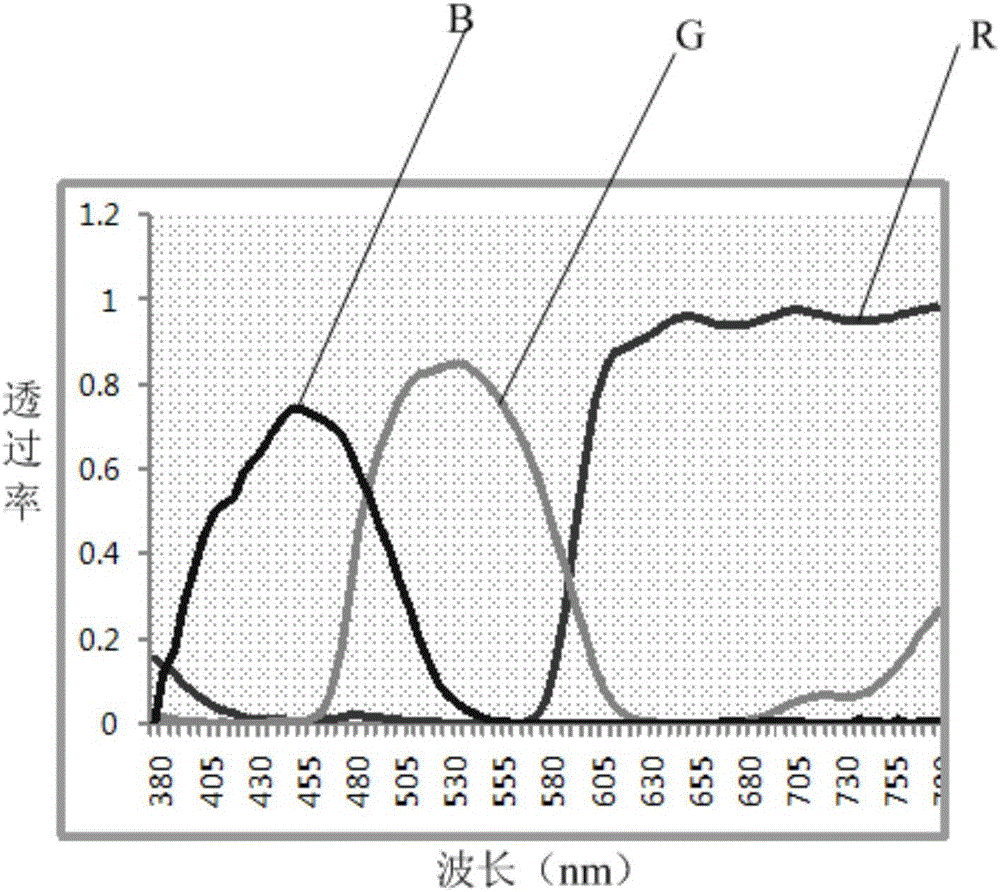

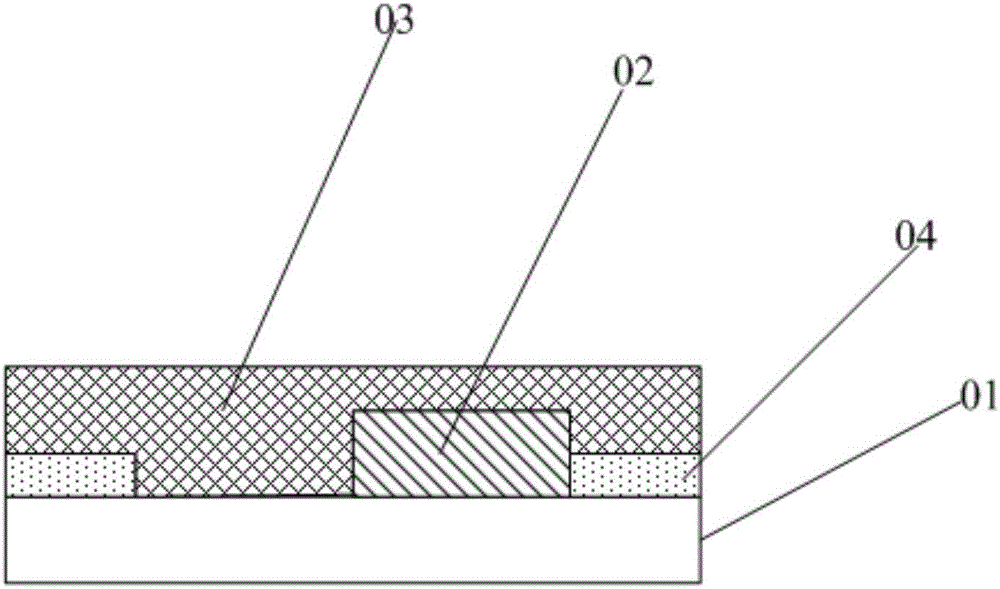

Color film substrate and manufacturing method thereof

InactiveCN106094322AAnisotropicReduce widthStatic indicating devicesNon-linear opticsPhase differenceColor film

The invention discloses a color film substrate and a manufacturing method thereof. The color film substrate comprises: an optical film layer which is in each pixel region on a substrate base plate and does not completely cover the pixel region, a black matrix surrounding each pixel region, and a protective layer covering the black matrix and each pixel region. The optical film layer and the protective layer are used to change phase of light. Thus, the optical film layer is covered but not completely covered on the pixel region, light rays emitting from the pixel region have different optical distances. When light in certain wavelength passes through the color film substrate, the part passing through the optical film layer and the part not passing through the optical film layer have phase difference, that is, light rays passing through the two regions have different phase changes, and thus light rays are overlaid to reinforce or overlaid to cancel, so that light rays in certain wavelengths cannot pass through the color film substrate. Through adjusting the thickness of the optical film layer, red light, green light, and blue light passing through the color film substrate can be respectively realized.

Owner:BOE TECH GRP CO LTD +1

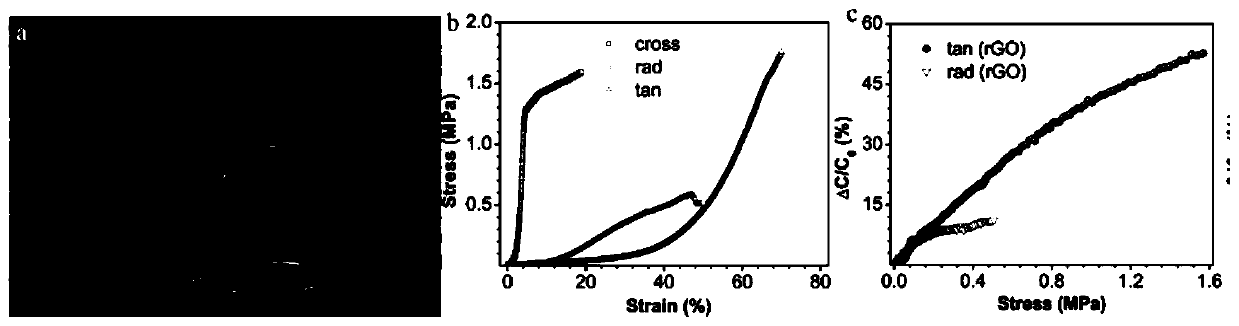

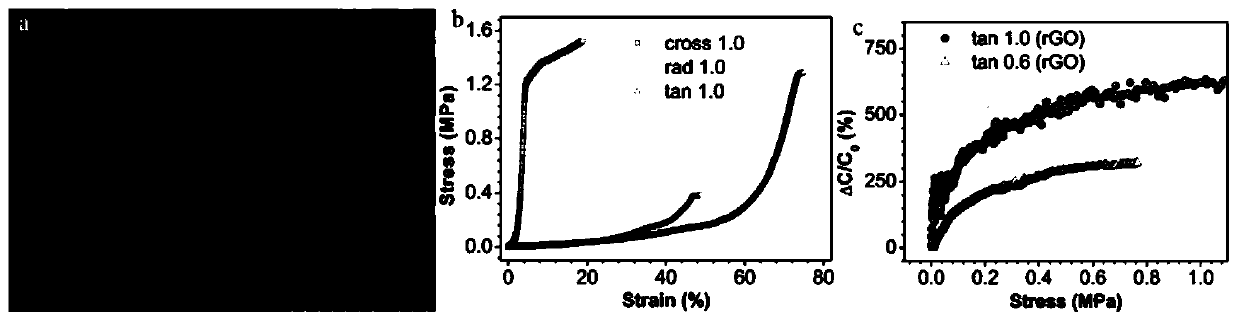

Capacitive sensor material, and preparation method and application thereof

The invention provides a preparation method of a capacitive sensor material. The preparation method comprises the following steps: processing wood with an acidic and alkaline solution, fully washing the wood with water, soaking the wood in tert-butyl alcohol to replace deionized water in the wood, freeze-drying the wood soaked in the tert-butyl alcohol to obtain wood aerogel, and polymerizing thewood aerogel with an aqueous solution containing a polyelectrolyte monomer, a cross-linking agent, an initiator and a catalyst to obtain the capacitive sensor material. The invention further disclosesa capacitive sensor containing the sensor material, and a preparation method thereof. The sensor material prepared by the method has excellent mechanical properties and an excellent ionic conductivity, and the further prepared flexible capacitive mechanical sensor has a very high sensitivity and a very wide sensing range.

Owner:ZHEJIANG FORESTRY UNIVERSITY

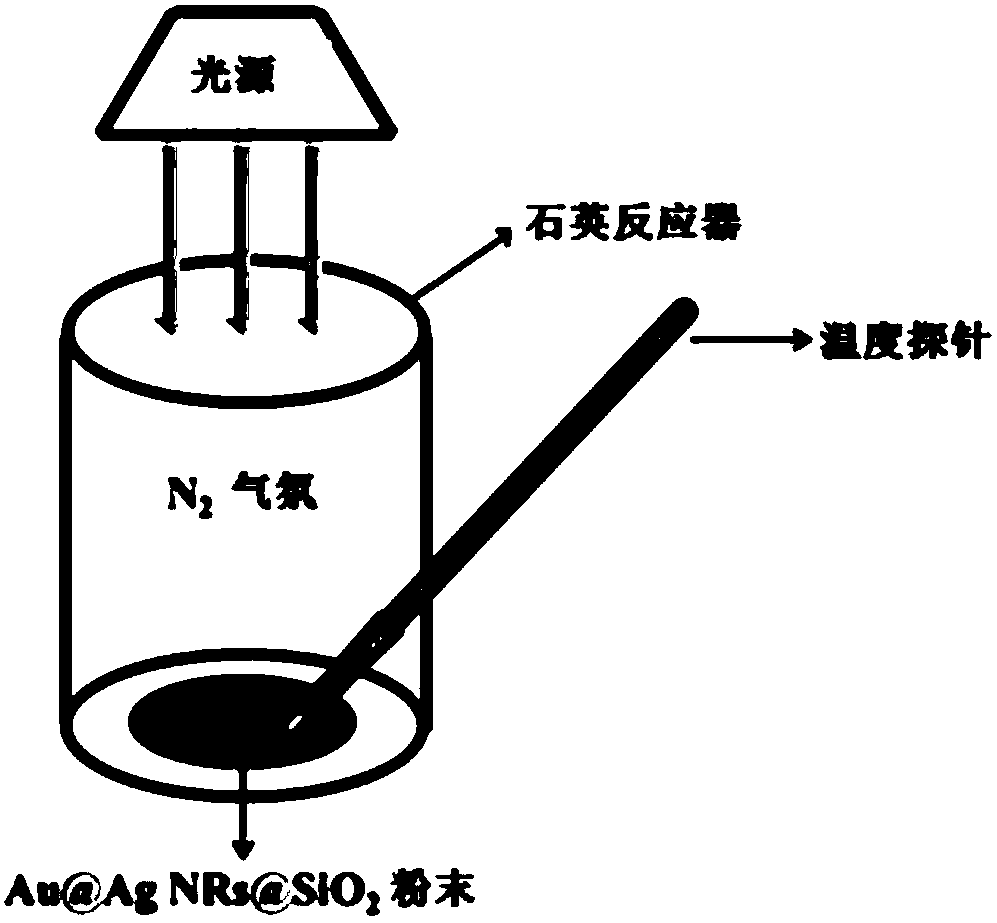

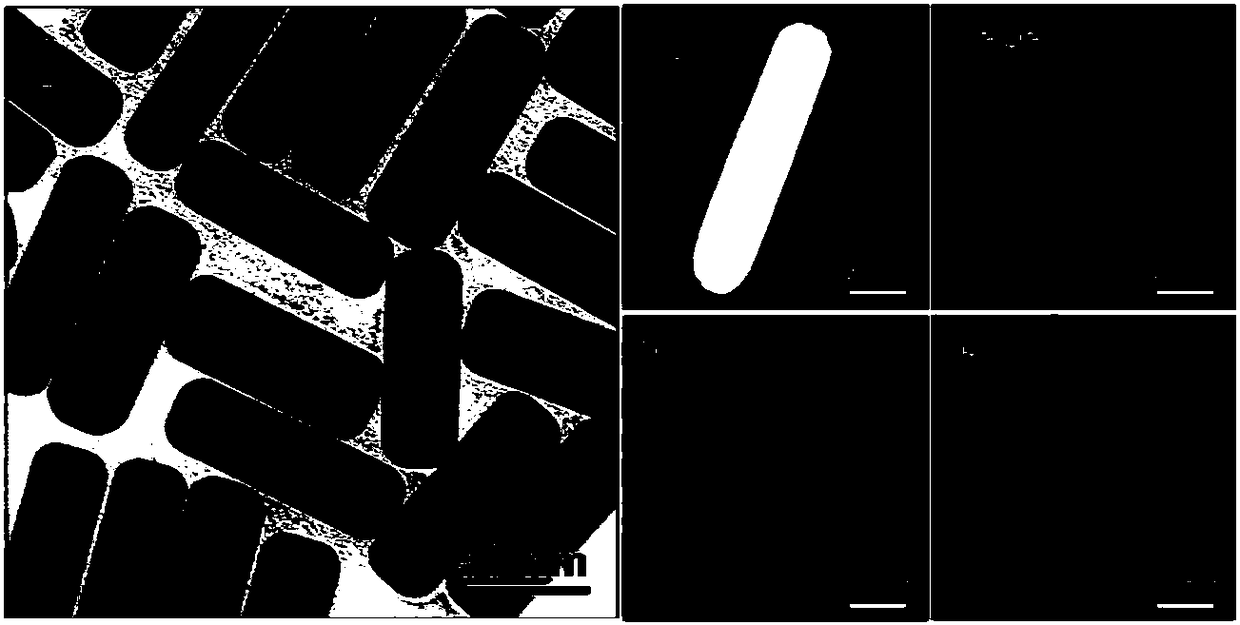

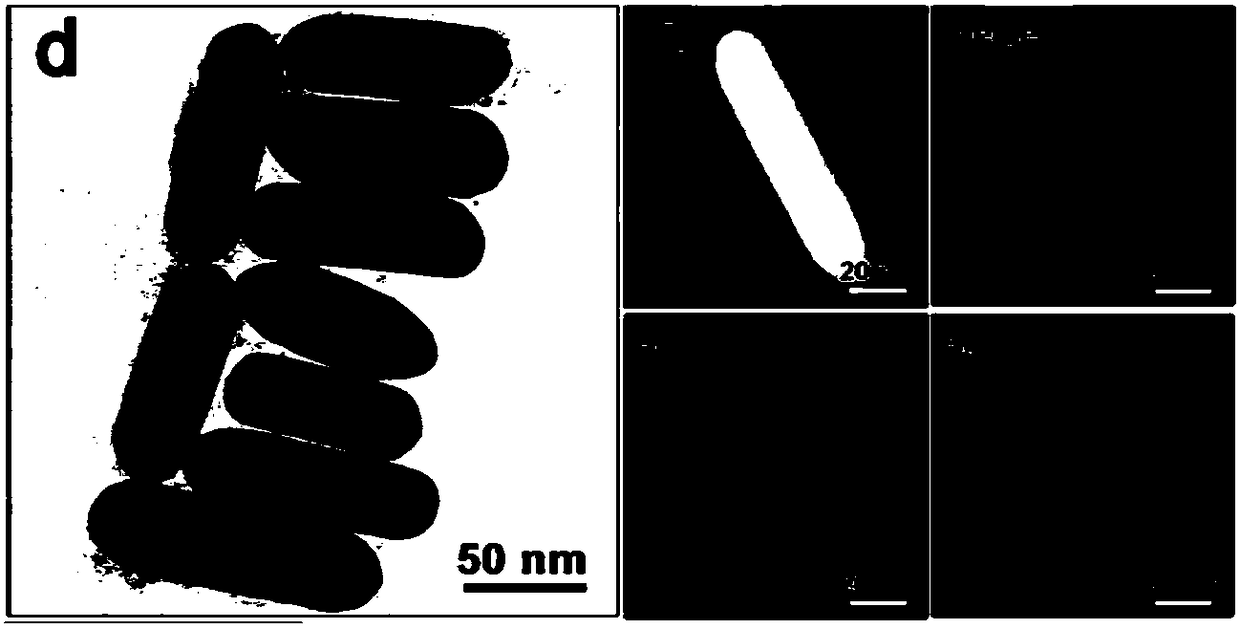

Method for preparing alloy nanoparticle

ActiveCN108568518AEasy to operateMild conditionsTransportation and packagingMetal-working apparatusMetal alloyCore shell

The invention provides a method for preparing an alloy nanoparticle. The method utilizes good SPR properties and local heating ability of precious metal materials and heat insulation and original shape maintaining functions of SiO2 nano layers, so that different metal atoms in a multi-metal structure of a core-shell structure migrate to form the multi-metal alloy nanoparticle with constant morphology. The method uses sunlight or simulated sunlight as a light source without the need for other energy sources, the method is green, environmentally friendly and simple and quick to operate, completely alloyed nanoparticles of various morphologies can be prepared, and the prepared alloy nanoparticle has good dispersion performance, uniform size and excellent stability.

Owner:SUZHOU UNIV

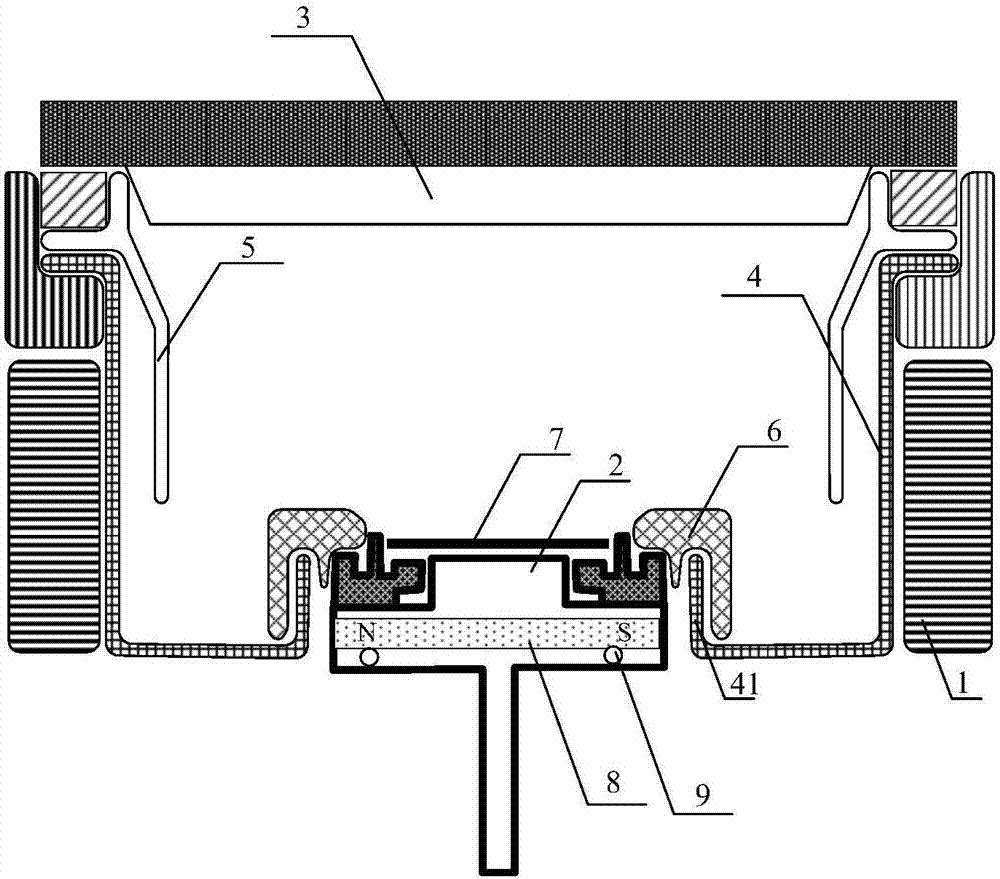

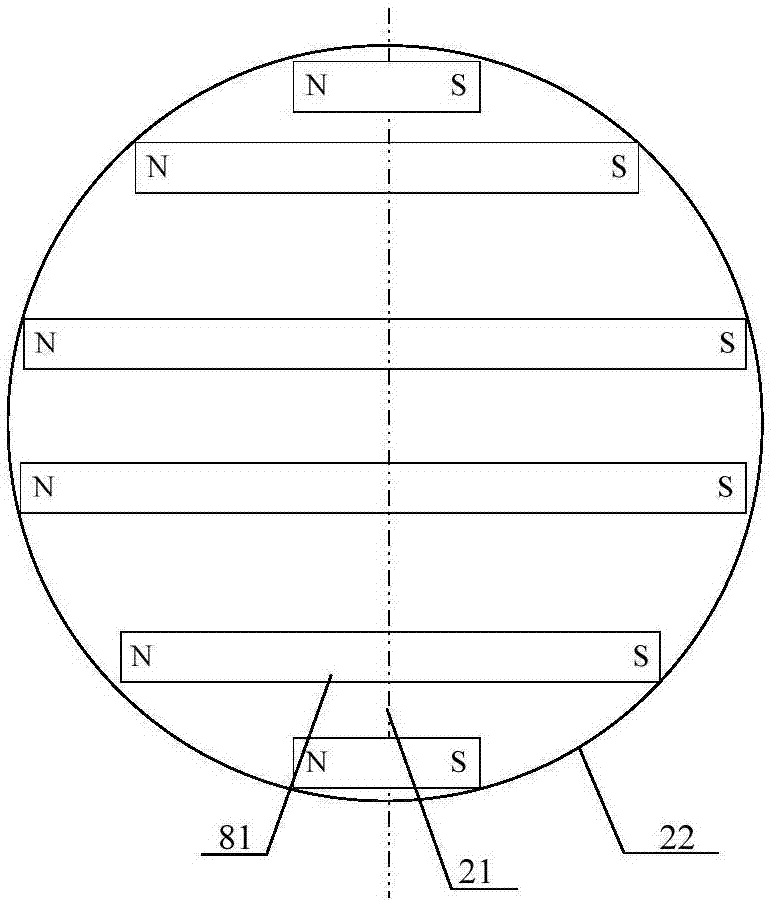

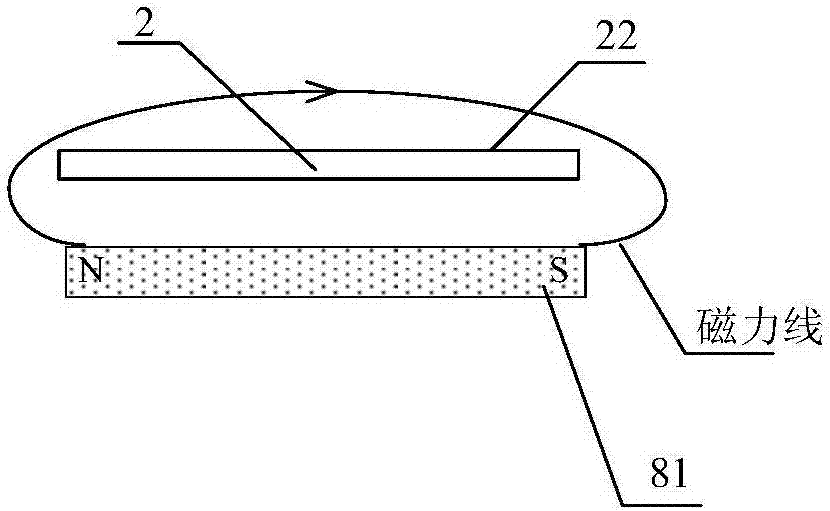

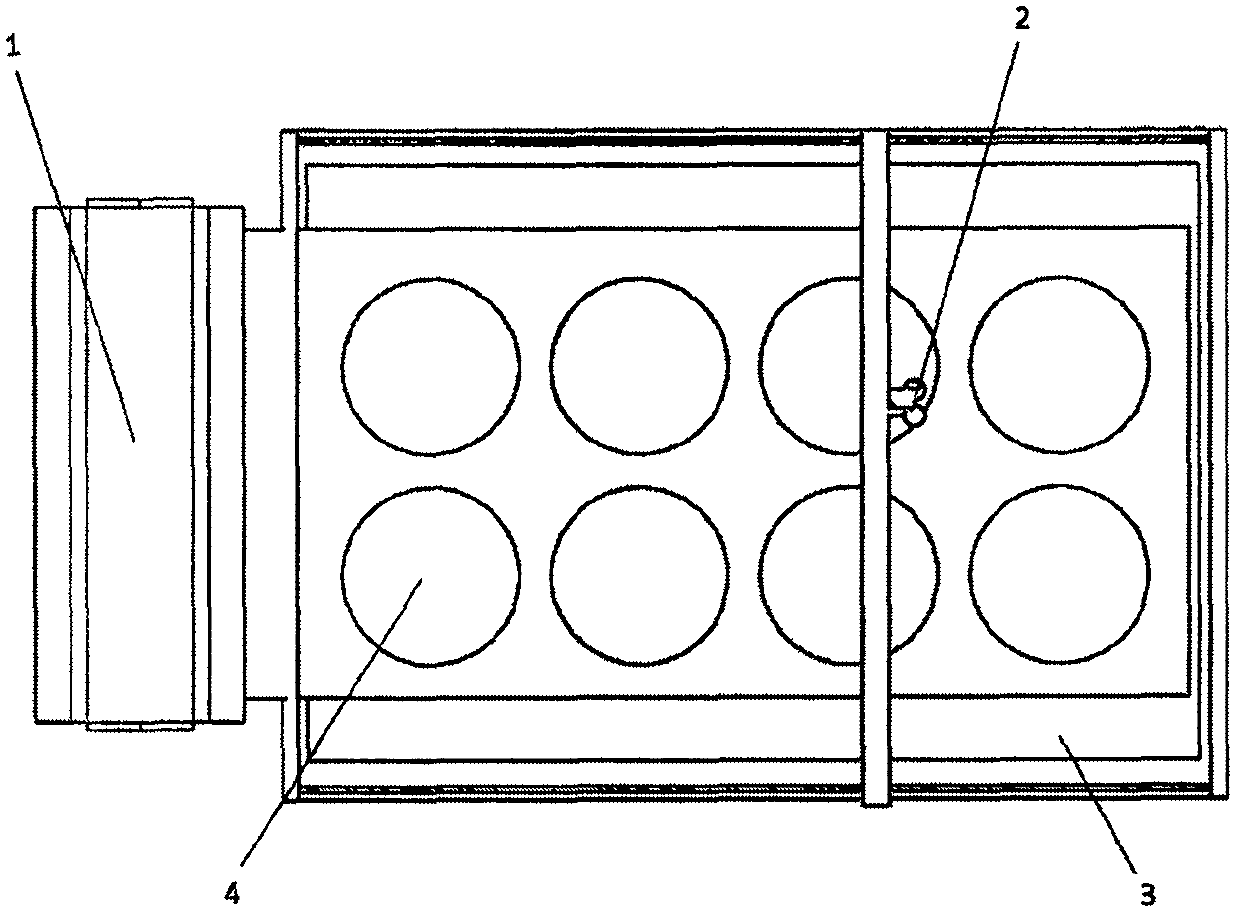

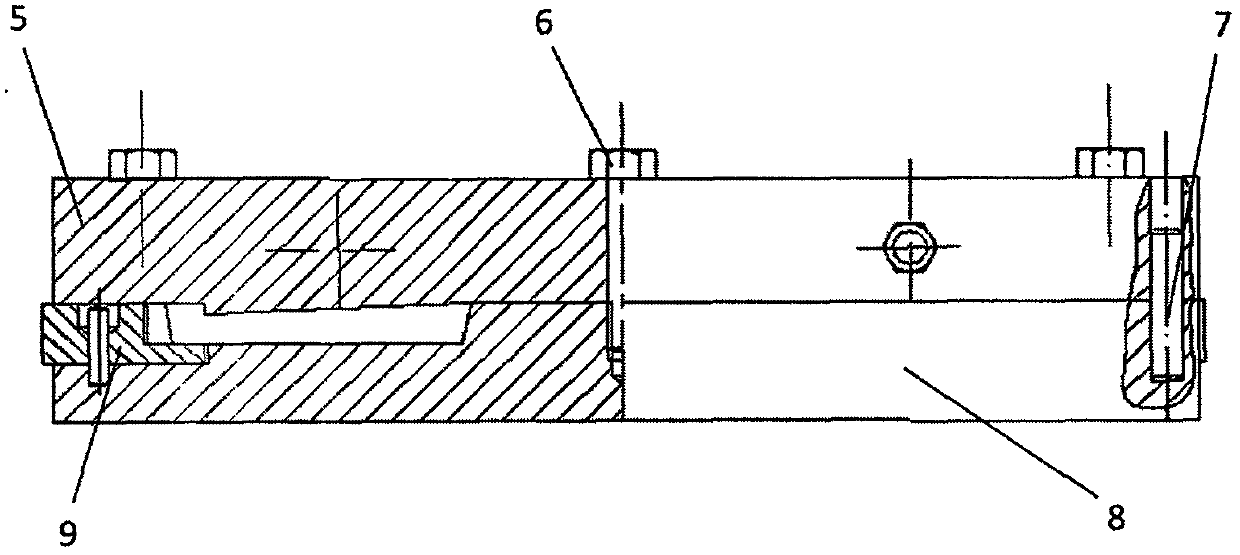

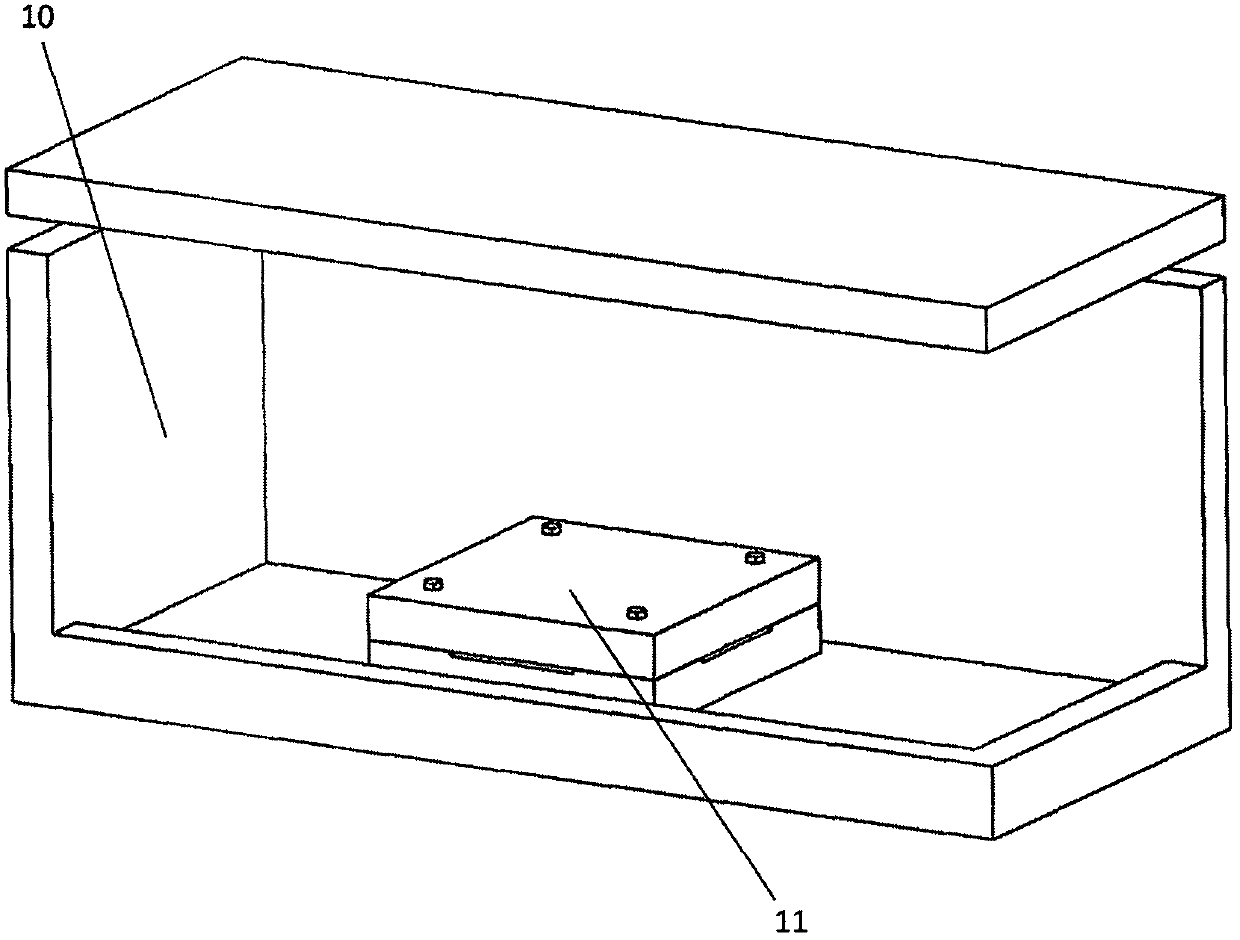

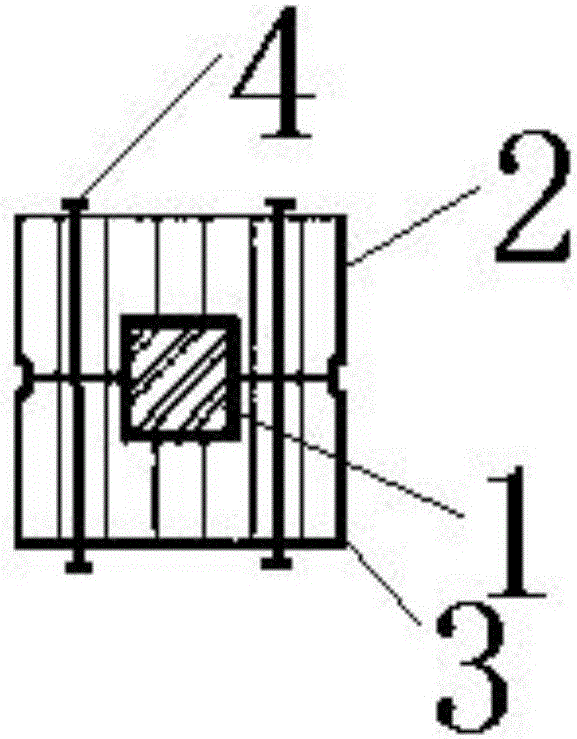

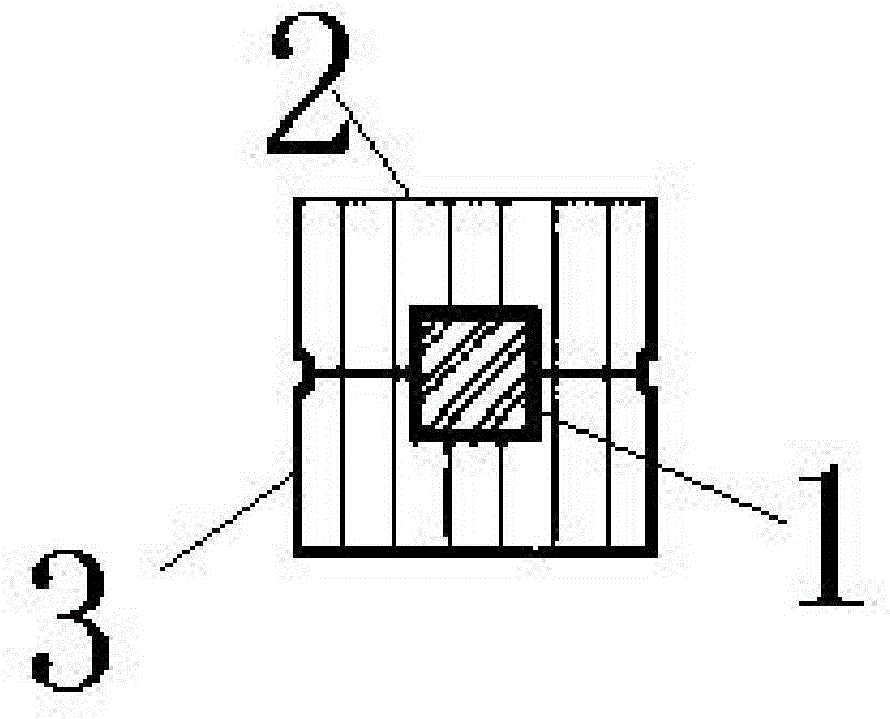

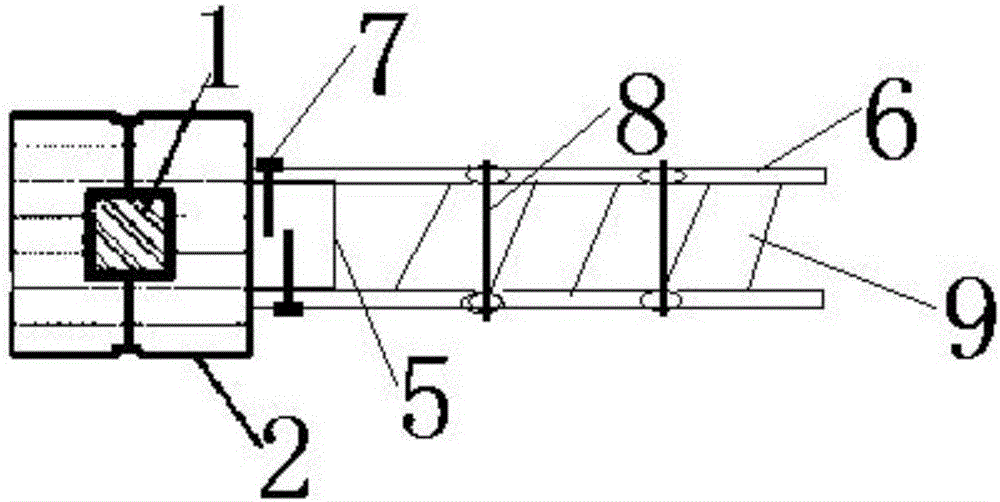

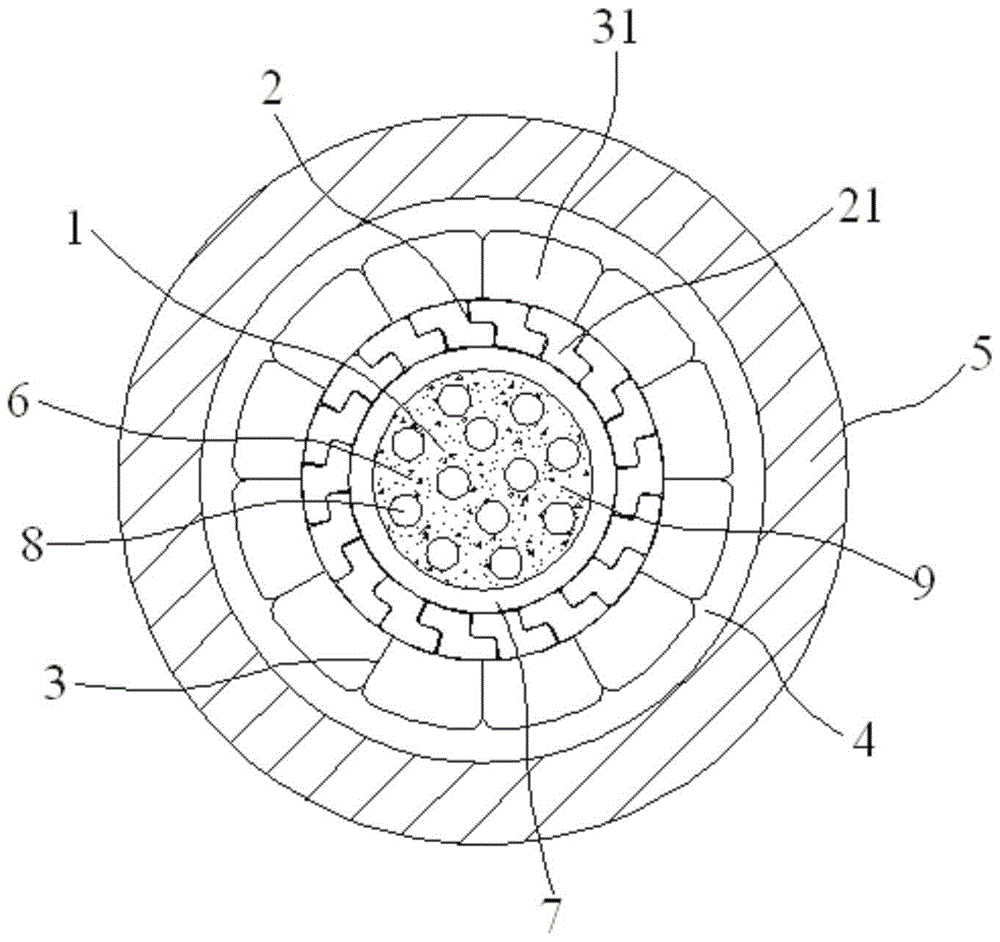

Magnetic film deposition chamber and film deposition device

ActiveCN107313019AAchieve in-plane anisotropyHas in-plane anisotropyVacuum evaporation coatingSputtering coatingBearing surfacePhysics

The invention provides a magnetic film deposition chamber and a film deposition device. The magnetic film deposition chamber comprises a cavity body. The cavity body is internally provided with a base. The base comprises a bearing surface used for bearing a workpiece to be machined. The magnetic film deposition chamber further comprises a bias magnetic field device. The bias magnetic field device comprises a first magnet set. The first magnet set is arranged below the base and used for forming a first horizontal magnetic field above the base. The first horizontal magnetic field is used for enabling a magnetic film deposited on the workpiece to be machined to have in-plane anisotropy. By adopting the magnetic film deposition chamber provided by the invention, the horizontal magnetic field which is enough to induce the in-plane anisotropy can be formed on the base. The requirements for preparing magnetic films with the in-plane anisotropy on large-size workpieces to be machined by production equipment are met.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Manufacturing process for carbon fiber composite forming membrane disk

The invention discloses a manufacturing process for a carbon fiber composite forming membrane disk. The manufacturing process comprises the steps that a prepreg is slit into a prepreg body in a certain shape and angle; a mold is cleaned and coated with a mold releasing agent; a heating platform is used for carrying out preheating treatment on the cut prepreg body; the prepreg body is laid to forma carbon fiber composite layer in a regular shape; a vacuum membrane bag is used for carrying out sealing treatment, and vacuumizing is carried out to form negative pressure; an oven is used for heating and solidifying the carbon fiber composite layer; the cooled carbon fiber composite layer is separated from the mold; the carbon fiber composite layer is cut and polished, and a finished product ofthe carbon fiber composite forming membrane disk is obtained. The membrane disk manufactured through the method has high-content fiber, the surface is bright without bubbles, the interlayer bonding intensity achieves an effect of a compression molding process, and the requirement for carbon fiber composite product production in the fields of aerospace and navigation.

Owner:刘长喜

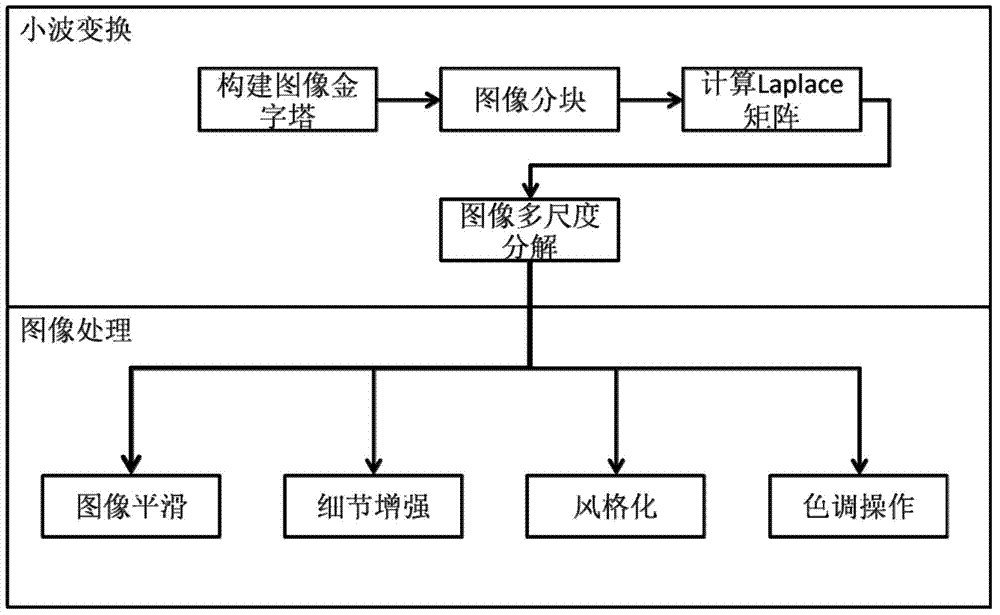

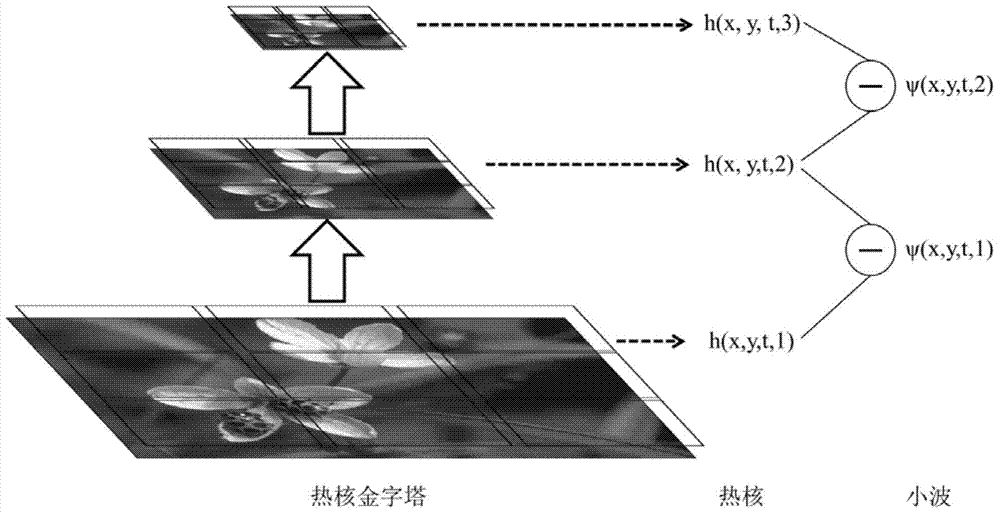

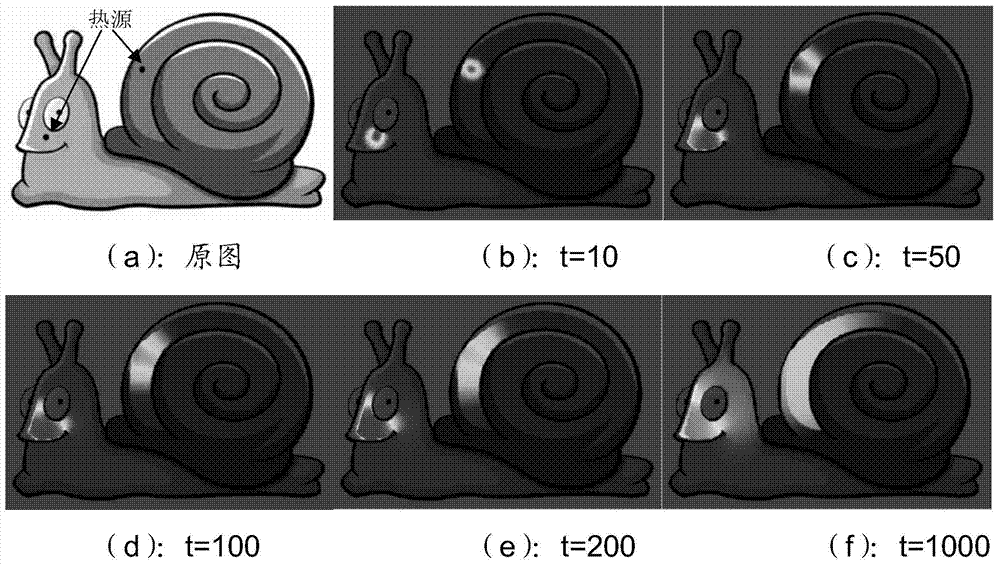

Anisotropism wavelet image processing method based on thermonuclear pyramid

InactiveCN103700064AImage smoothingMulti-scale conceptImage enhancementMultiscale decompositionPartial differential equation

The invention provides an anisotropism wavelet image processing method based on a thermonuclear pyramid. According to the method, at the theoretical part, wavelets are obtained through thermonuclear difference between adjacent layers of an image pyramid, and are equal to negative one order derivation of a thermal diffusion partial differential equation, relative to time; at an implementation part that: 1), mapping images to be a weight undirected graph, coding structural characteristics into a Laplacian matrix, and achieving anisotropism thermal diffusion; 2), dividing the images into image subblocks with overlaps, calculating wavelets of all image blocks in a parallel mode, reducing calculated amount by using a block overlapping method and effectively eliminating blocking effects after recombination; 3), adopting Krylov subspace technology to accelerate image block wavelet transform calculation, and avoiding time-consuming matrix spectral factorization. At the application part, the method is applied to image processing with structural protecting function. The data related anisotropism wavelet system provided by the invention achieves structure protection multiscale decomposition for the images, and shows excellent performance in various image processing applications.

Owner:BEIHANG UNIV

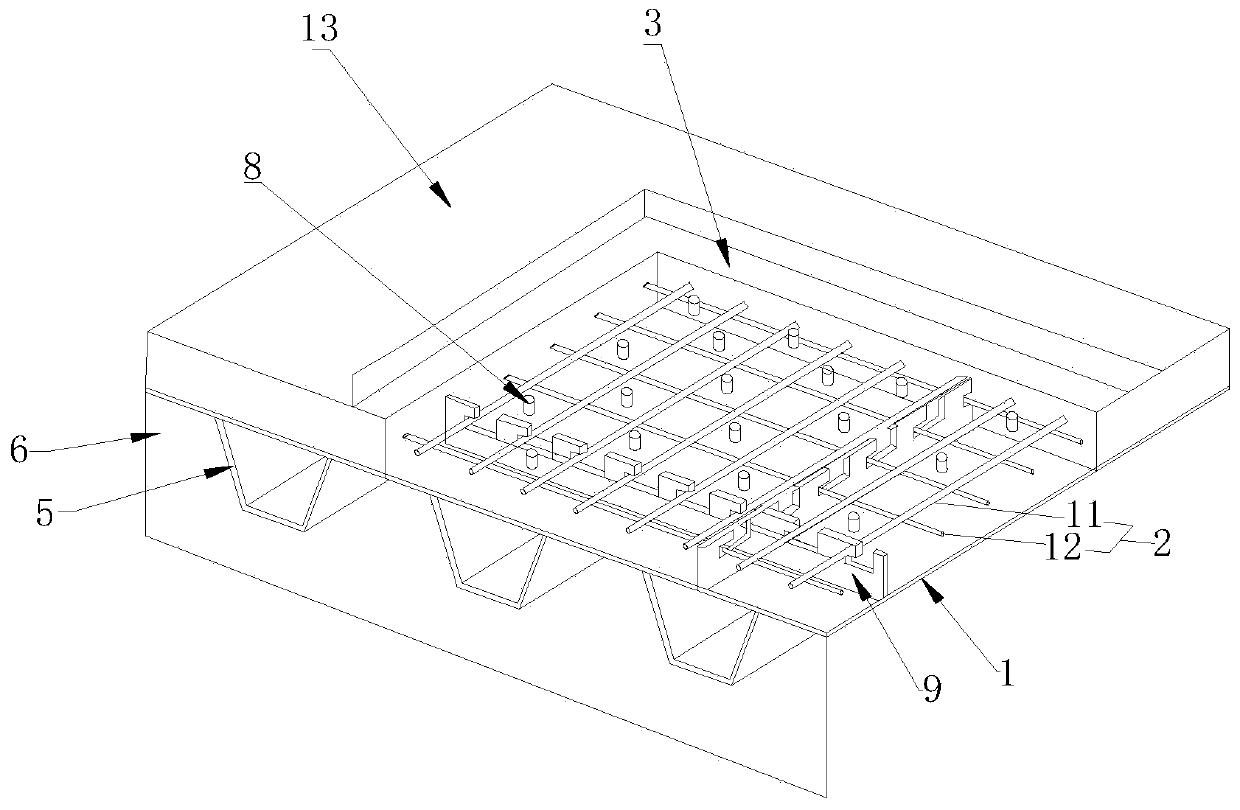

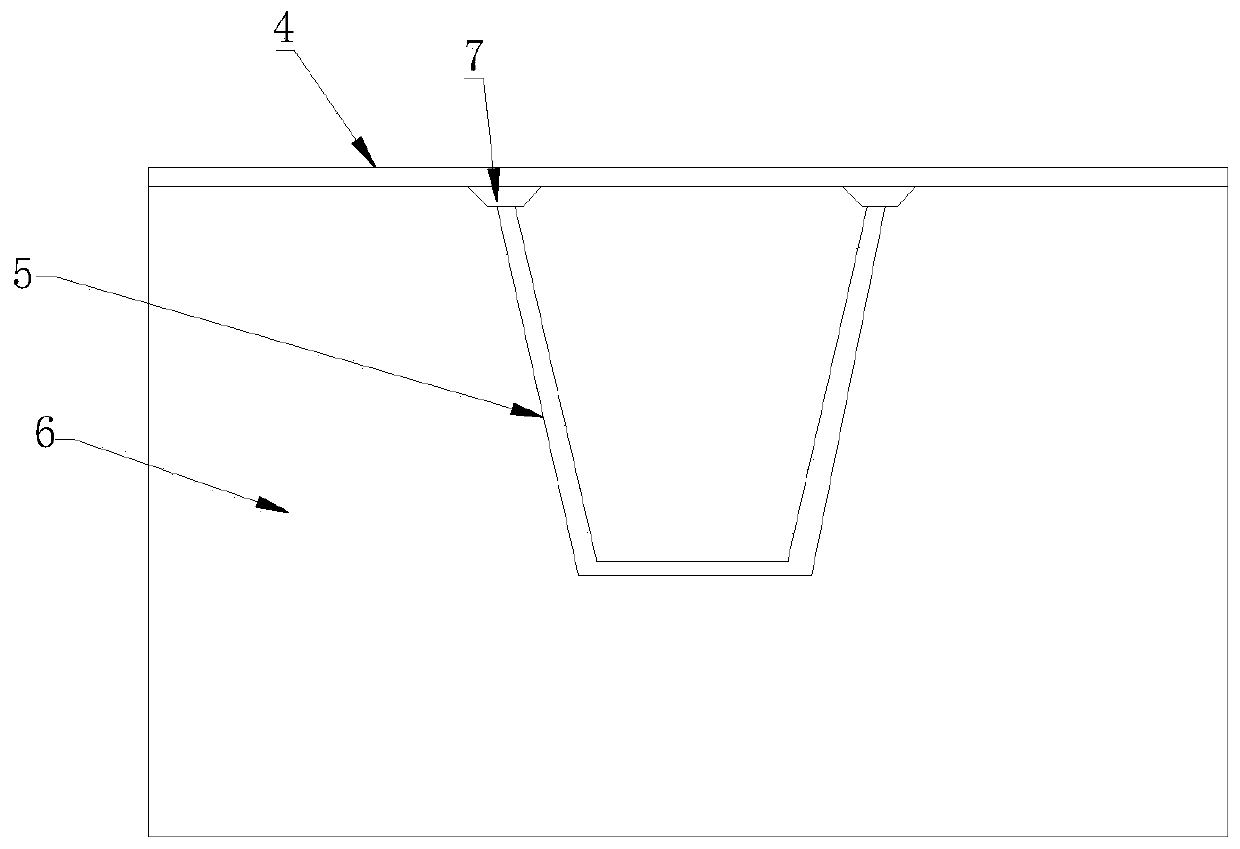

Orthotropic steel bridge deck ductile concrete composite structure and construction method

PendingCN111485491AIncrease stiffnessImprove mechanical performanceBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses an orthotropic steel bridge deck ductile concrete composite structure and a construction method, and relates to the technical field of bridge engineering. The key points of thetechnical scheme are as follows: the orthotropic steel bridge deck ductile concrete composite structure comprises an orthotropic steel bridge deck, a grid mesh and a tough concrete layer; a pluralityof longitudinal ribs are transversely arranged on the bottom surface of the steel bridge deck at intervals; shear nails are arranged on the top surface of the steel bridge deck; a plurality of criss-cross erecting rib perforated plates are arranged on the top surface of the steel bridge deck at equal intervals; and an SBS modified asphalt SMA pavement layer is paved on the top surface of the tough concrete layer. The combined structure can improve the overall rigidity of the steel bridge deck and improve the fatigue problem of the steel bridge deck system and has the advantages of light self-weight, high bearing capacity and simple structure, and can ensure that the steel bridge deck has a wide application range and good stress performance under various conditions; bridge construction cost is saved, and benefits are remarkable. The national key research and development plan subsidy is obtained, the subject name is the key technical research of the efficient construction of the combined structure urban bridge, and the subject number is 2017YFC070348.

Owner:中交三公局第一工程有限公司

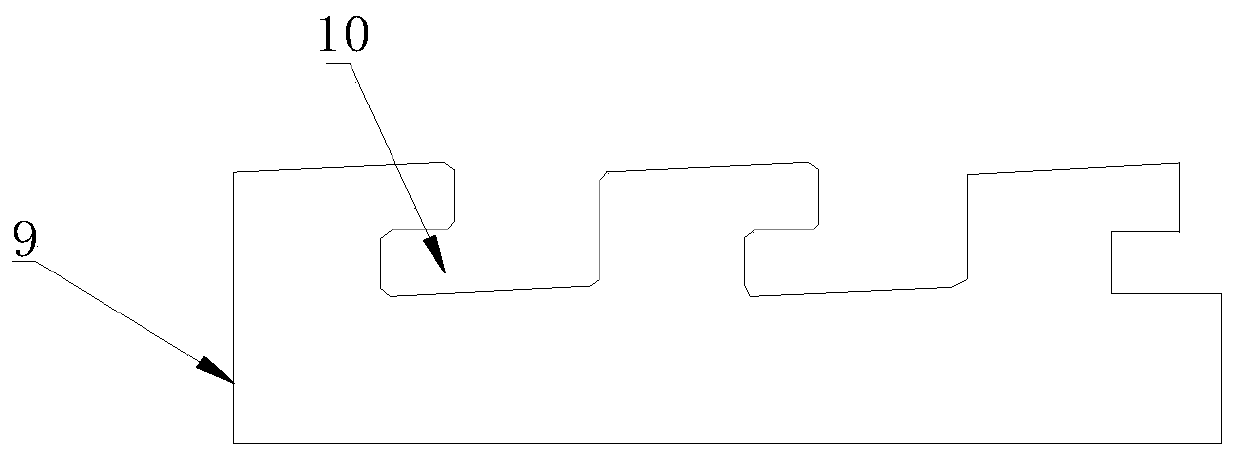

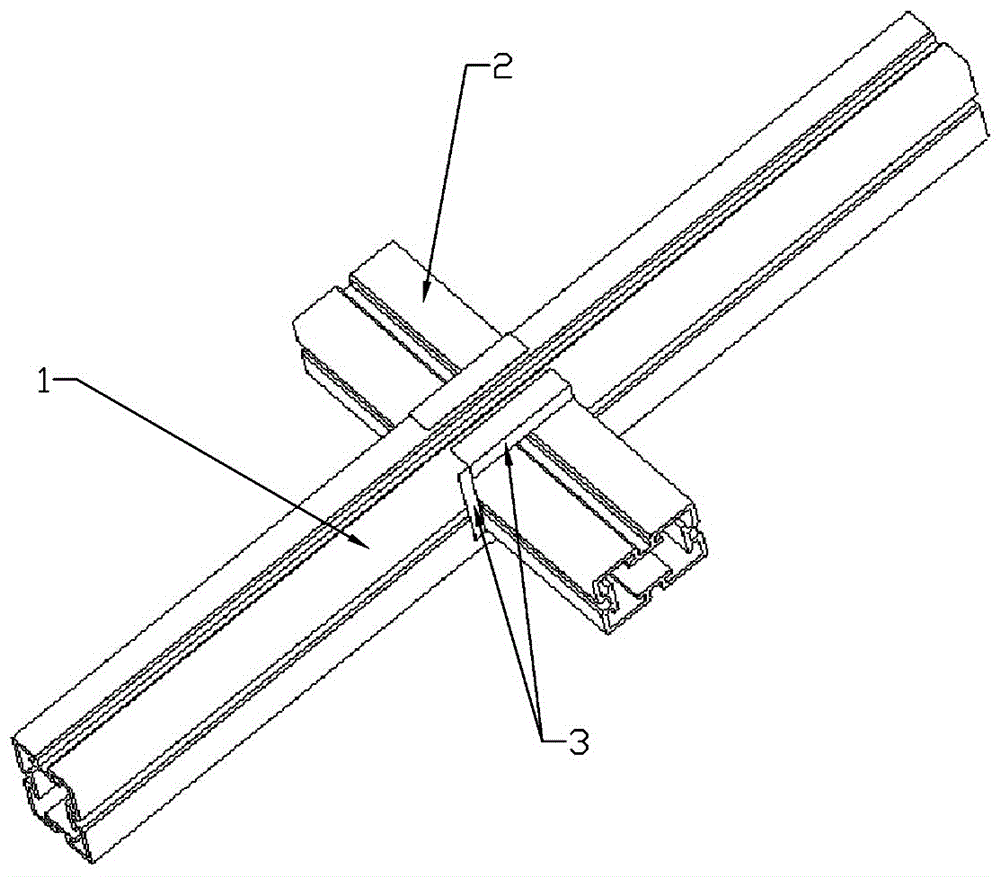

Carbon fiber reinforcement aluminum alloy mortise and tenon structure and preparation method thereof

The invention discloses a carbon fiber reinforcement aluminum alloy mortise and tenon structure which comprises a mortise piece and a tenon piece, wherein the mortise piece is provided with a mortise; a tenon connection part of the tenon piece is inserted into the mortise; at least one inner surface of the mortise is coated with carbon fiber composite cloth; and the tenon connection part is in interference fit with the mortise coated with the carbon fiber composite cloth. The carbon fiber is high in axial strength and module, low in density, high in specific performance, good in fatigue resistance, low in thermal expansion coefficient and good in corrosion resistance, has no creep deformation, has superhigh temperature resistance at the non-oxidizing environment and has anisotropism, and the specific heat and conductivity of the carbon fiber is between the specific heat and conductivity of nonmetal and the specific heat and conductivity of metal. With the utilization of the carbon fiber composite cloth to reinforce the mortise and tenon structure, a tenon pulling phenomenon of the mortise and tenon structure can be retarded effectively. The carbon fiber reinforcement aluminum alloy mortise and tenon structure has the characteristics of high strength and rigidity, reduction in energy consumption ability, and the like, and can be widely applied to the fields of automotive industry, sports equipment, fire protection, and the like.

Owner:SUN YAT SEN UNIV

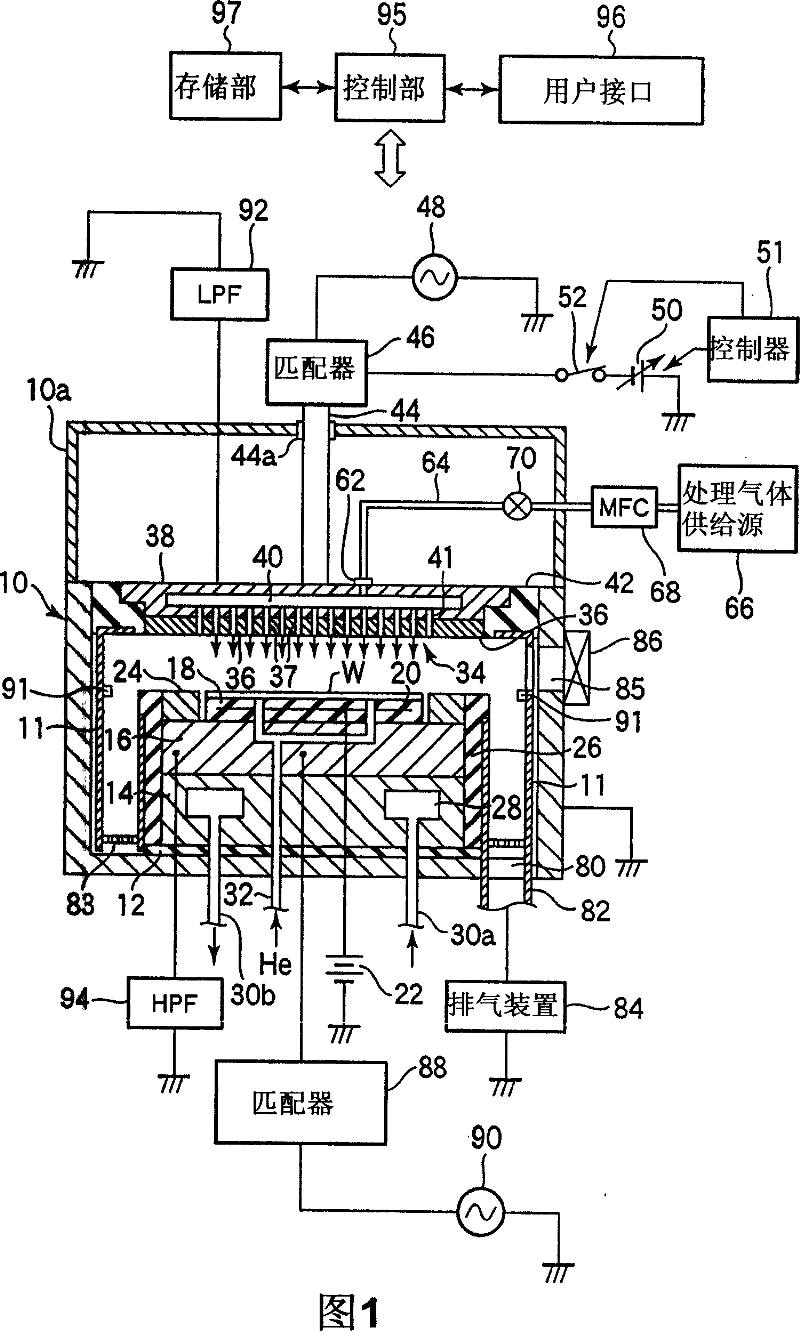

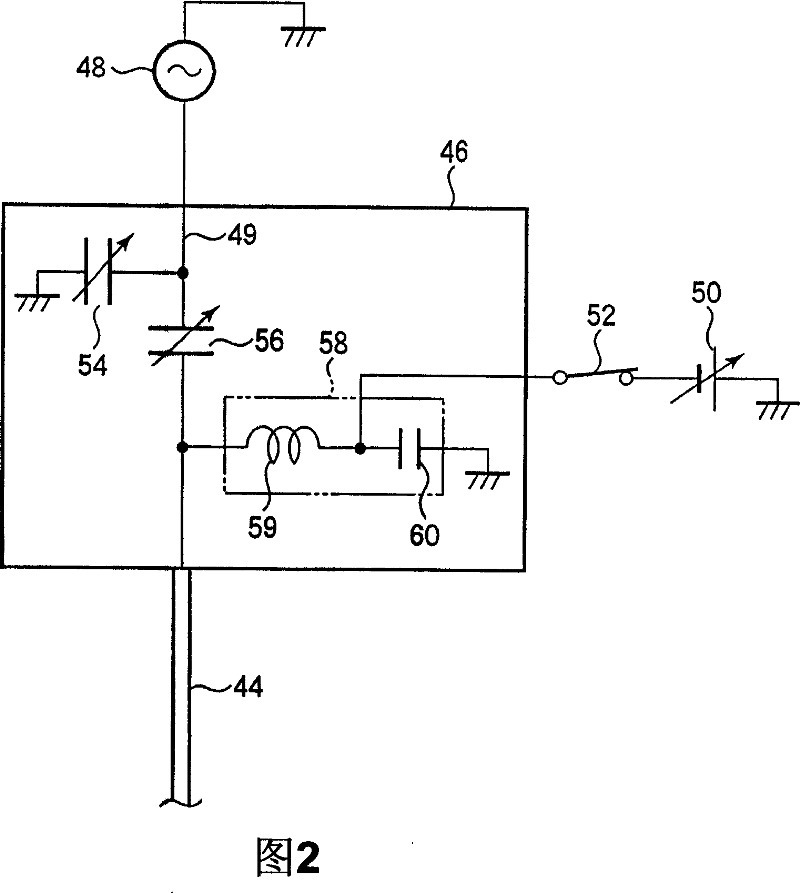

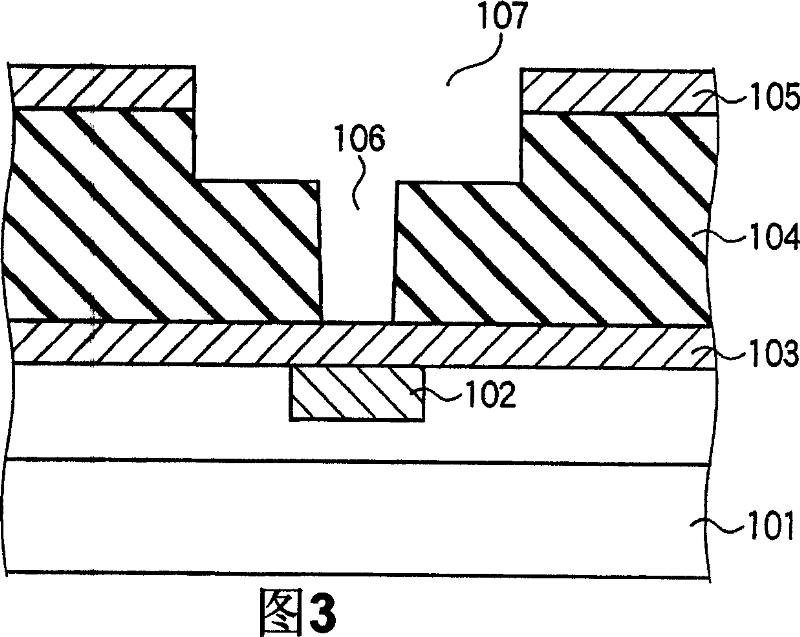

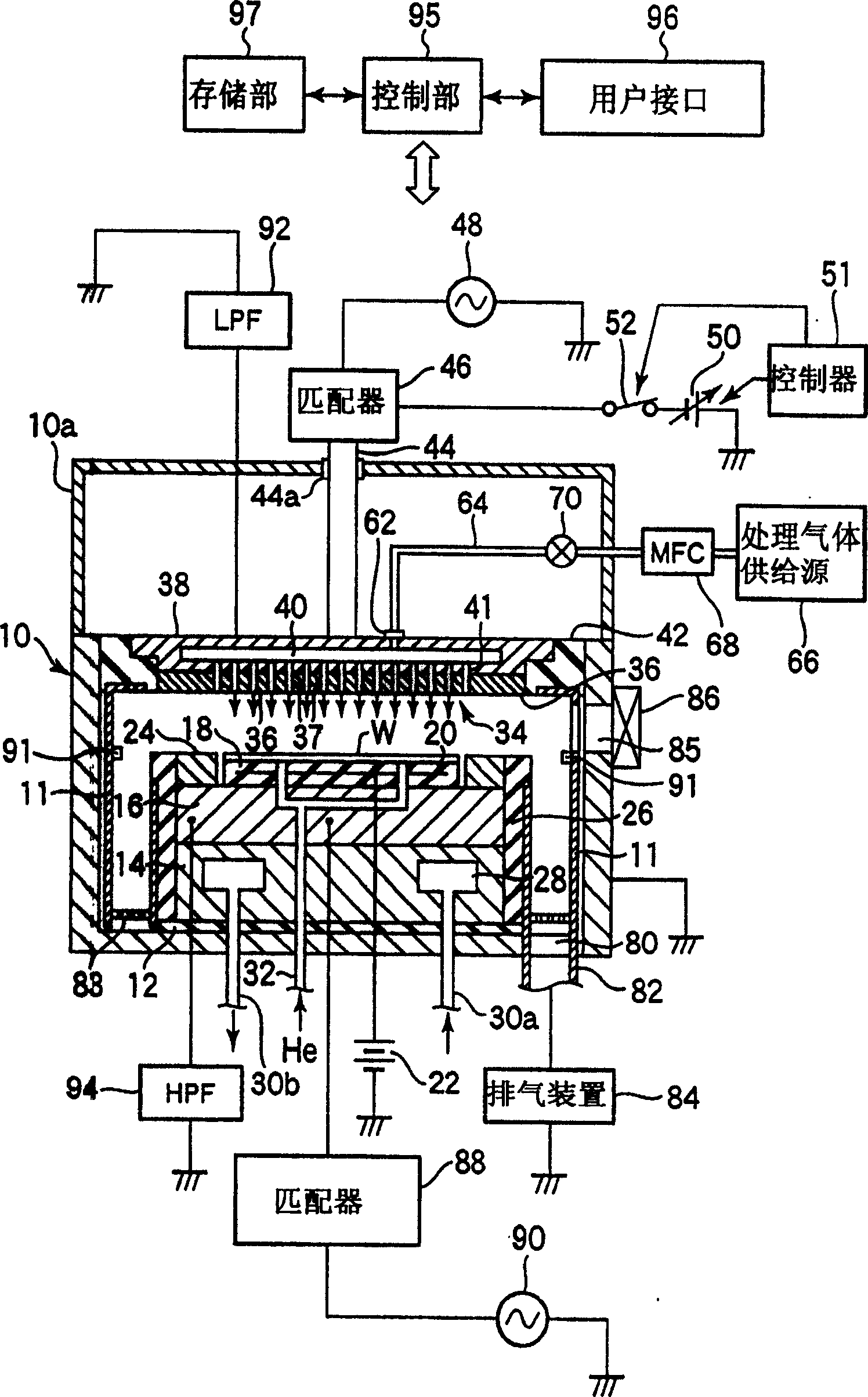

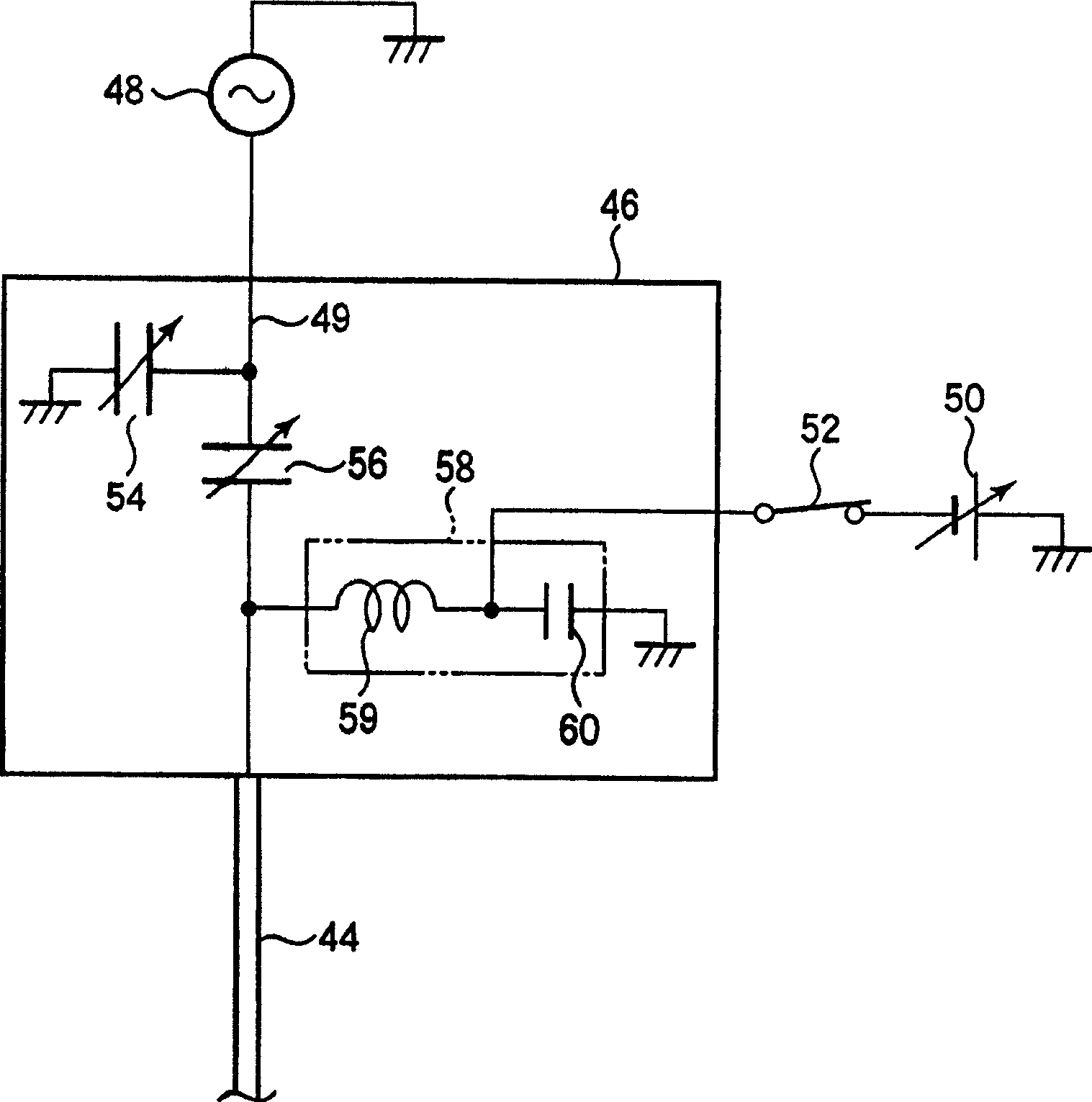

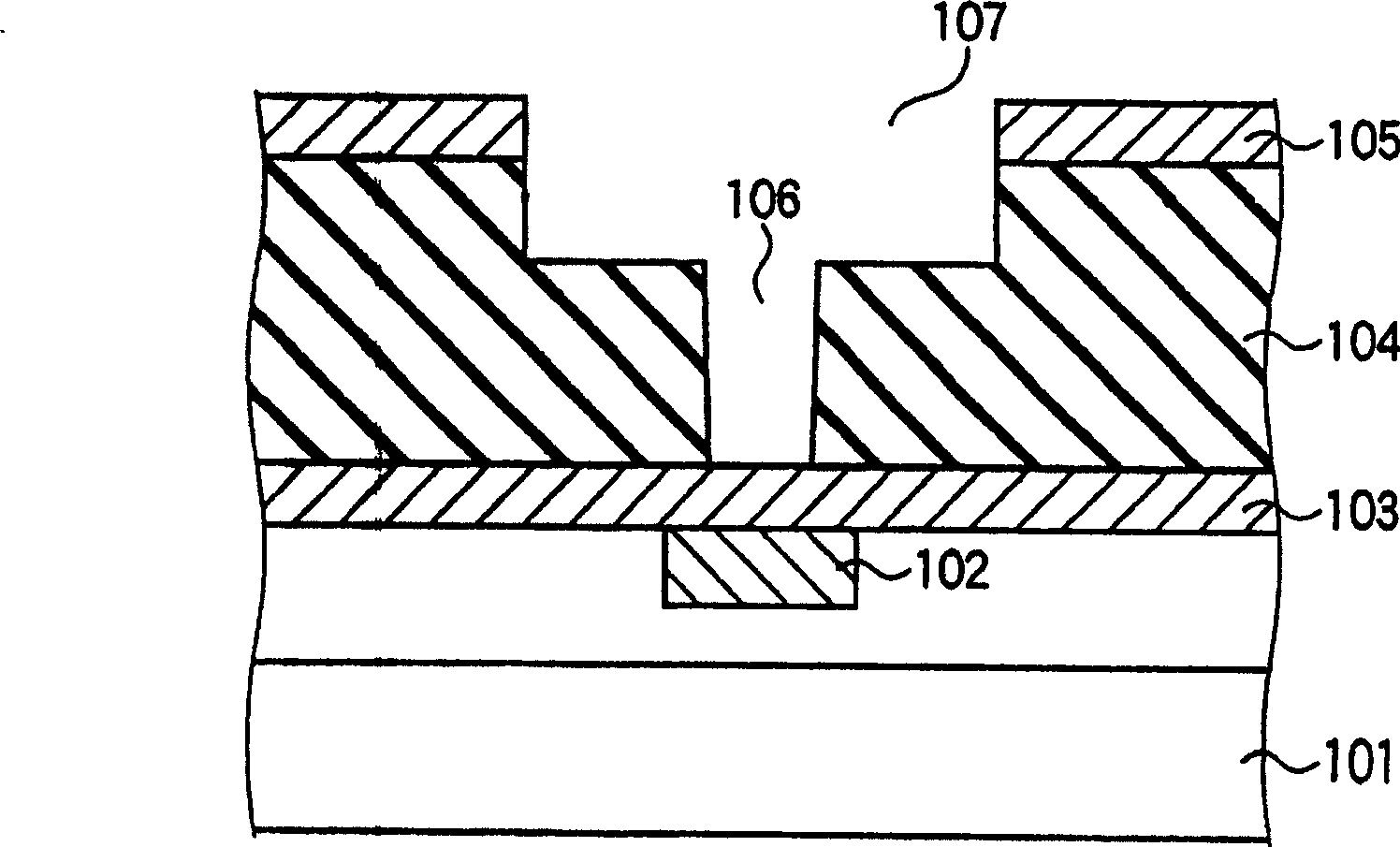

Plasma etching method and computer-readable storage medium

ActiveCN101038872AReduce etch rateAnisotropicSemiconductor/solid-state device manufacturingEtching selectivityLow-k dielectric

In a plasma etching method for plasma-etching an etching stop film after plasma-etching a low-k film in a structure in which a wiring layer, the etching stop film made of an SiC-based material, the low-k film and an etching mask are formed in that order on a substrate, the method includes the step of arranging the structure having the plasma-etched low-k film in a processing chamber in which a first and a second electrode are provided to face each other at vertically separated locations. The plasma etching method further includes the steps of introducing a processing gas containing NF3 into the processing chamber; generating a plasma by applying a high frequency power to one of the first and the second electrode; and applying a DC voltage to said one of the electrodes.

Owner:TOKYO ELECTRON LTD

Bionic dermis as well as preparation method and application thereof

The invention discloses bionic dermis. An implant is a three-dimensional braided fabric of biocompatible fiber, and the fiber adsorbs, absorbs or is wrapped with protein substance favorable for skin or dermis restoration. The invention also discloses a preparation method for the bionic dermis and application thereof.

Owner:RUIJIN HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Surface insulation coated carbon fiber and preparation method thereof as well as heat-conducting gasket and preparation method thereof

InactiveCN110230187AImprove insulation performanceAnisotropicCarbon fibresHeat-exchange elementsThermal transmittanceFiber

The invention discloses carbon fiber subjected to insulation treatment. The carbon fiber comprises a carbon fiber base material and an insulating coating formed on the surface of the carbon fiber basematerial. The carbon fiber provided by the invention has high insulating property and can effectively avoid the bad influence of the carbon fiber in application of electronic components. The invention also discloses a preparation method of the surface insulation coated carbon fiber, a heat-conducting gasket comprising the carbon fiber as well as a preparation method of the heat-conducting gasket.The heat-conducting gasket provided by the invention performs directional flocking on the carbon fiber with insulating effect in the manufacturing process, so the heat-conducting gasket has the effects of anisotropy, high heat conductivity, high insulating property and the like.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

Flexible high flame retardant biologic aerogel material and preparation method thereof

ActiveCN109485910AAnisotropicImprove mechanical propertiesCoatingsPolymer scienceLimiting oxygen index

The invention discloses a preparation method of a flexible high flame retardant biologic aerogel material. The preparation method comprises the following steps: preparing a biomass macromolecular solution; uniformly mixing the biomass macromolecular solution with a synthesized resin precursor solution to obtain a mixed solution, then quickly placing the mixed solution at -20 to -200 DEG C to be cooled in a single direction and freezing the mixed solution to a solid; and finally, freezing and drying the solid in a freeze dryer to obtain a biologic aerogel and crosslinking the biologic aerogel in a dried vacuum environment or a dried alkaline vacuum environment at 150-200 DEG C for 0.5-50 h to obtain the flexible high flame retardant biologic aerogel material. The material has anisotropic mechanical property, has high axial strength and has rebound resilience radially. The pore wall of the material has a porous structure, and the aerogel prepared by the porous material has an ultralow heat conductivity coefficient which is 0.002-0.02W / (m.K). The density of the material is 16-181 kg / m<3>, the extreme oxygen index is 24.0-39.0%, the peak heat release rate is 55.6-245.6 kW / m<2>, and thecontact angle of the aerogel is 60-148 degrees.

Owner:SICHUAN UNIV

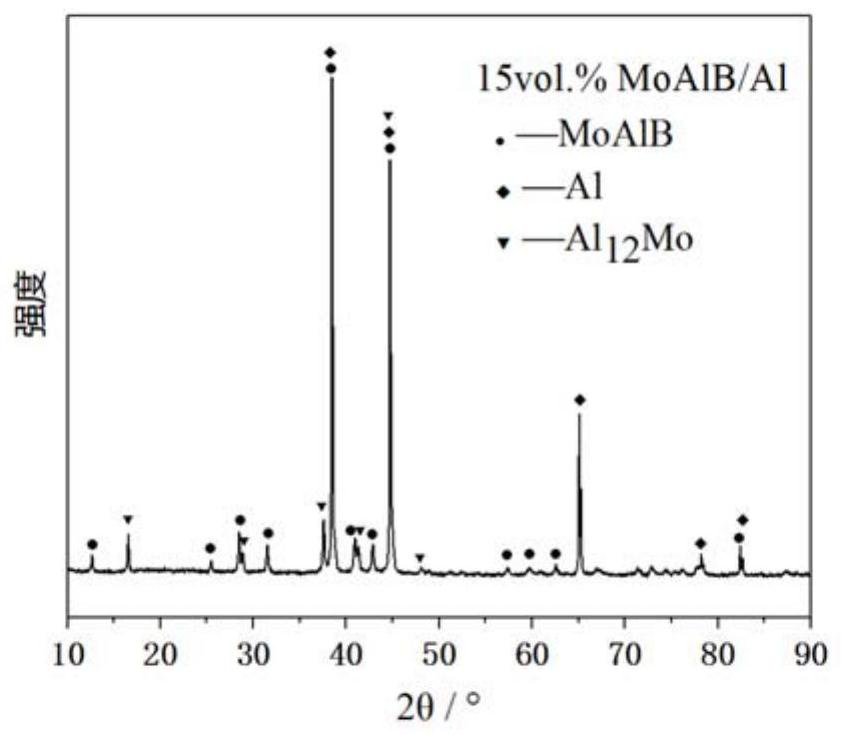

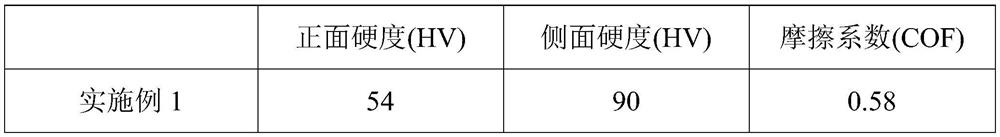

MAB phase ceramic-metal layered composite material as well as preparation method and application thereof

ActiveCN111873570AImprove antioxidant capacityThere will be no shortened lifespanLaminationLamination apparatusSlurryCeramic metal

The invention provides an MAB phase ceramic metal layered composite material and a preparation method and application thereof. The composite material comprises metal layers and MAB phase layers whichare alternately stacked, wherein the MAB phase layers are attached to the metal layers; the preparation method of the composite material comprises the following steps: preparing MAB phase slurry; coating the MAB phase slurry on the surface of a metal substrate; drying and curing the metal base material coated with the MAB phase slurry, and then performing lamination to obtain a laminated blank; preprocessing the laminated blank to obtain a pre-product; and sintering the pre-product, and cooling the sintered product along with the furnace to obtain the MAB-phase ceramic metal layered compositematerial. The composite material has the advantages of high interface strength, light weight, high strength, wear resistance and corrosion resistance, and can meet the application requirements in thefields of carrying tools, power transmission and transformation or military materials.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

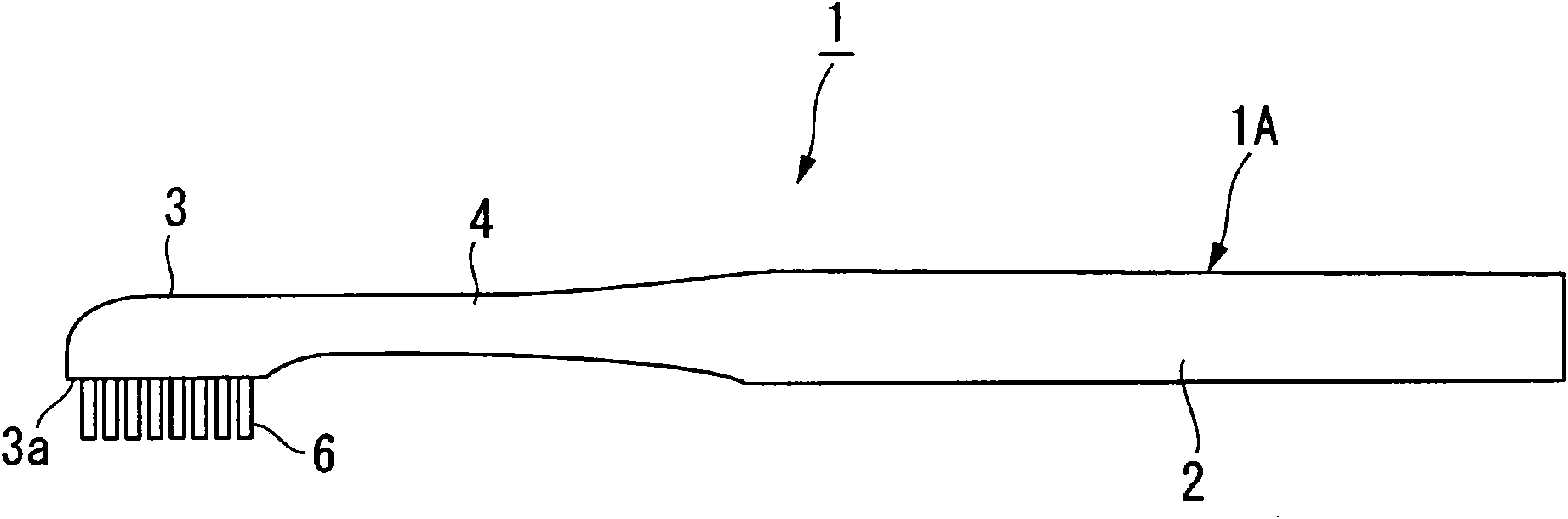

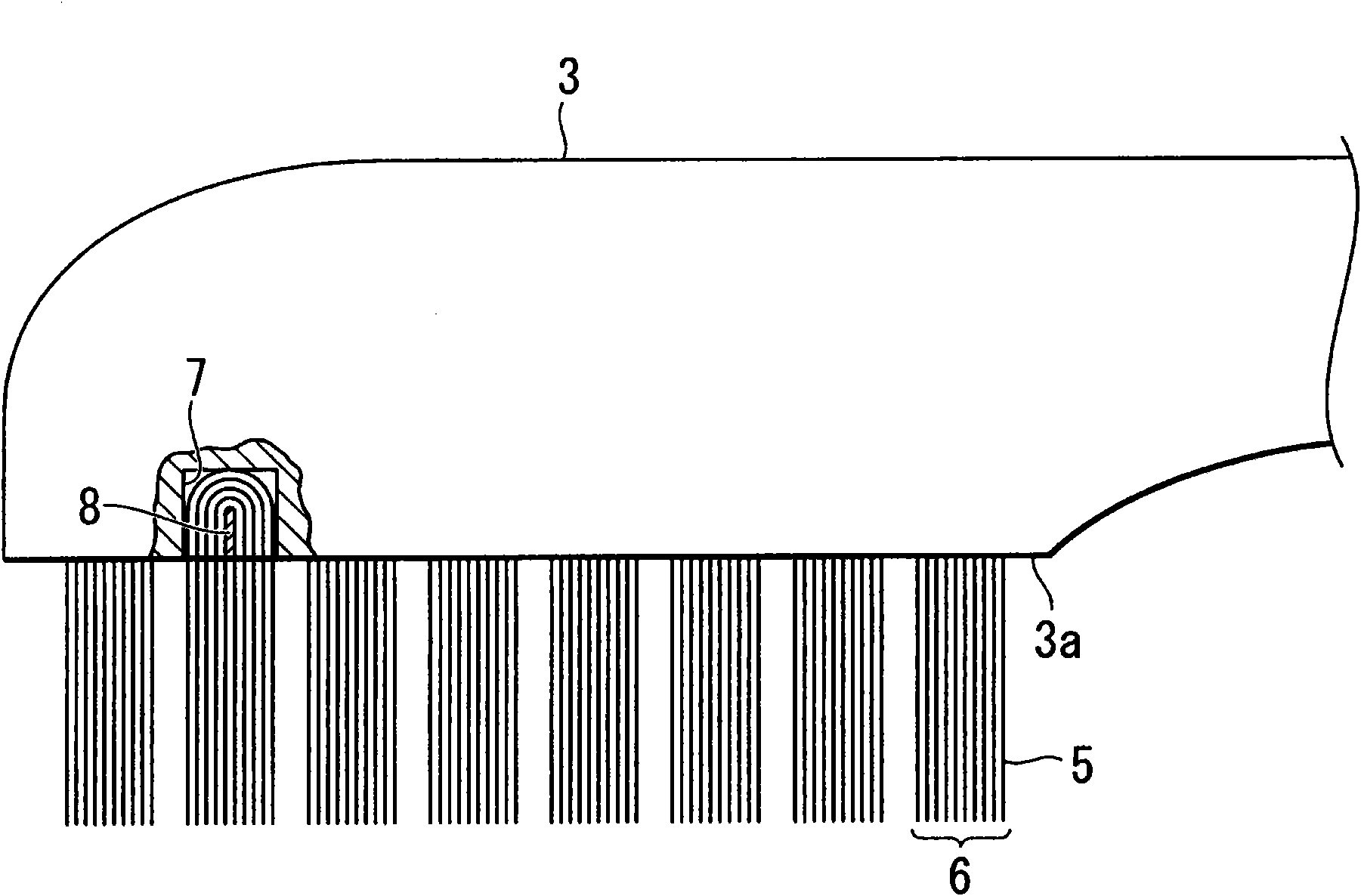

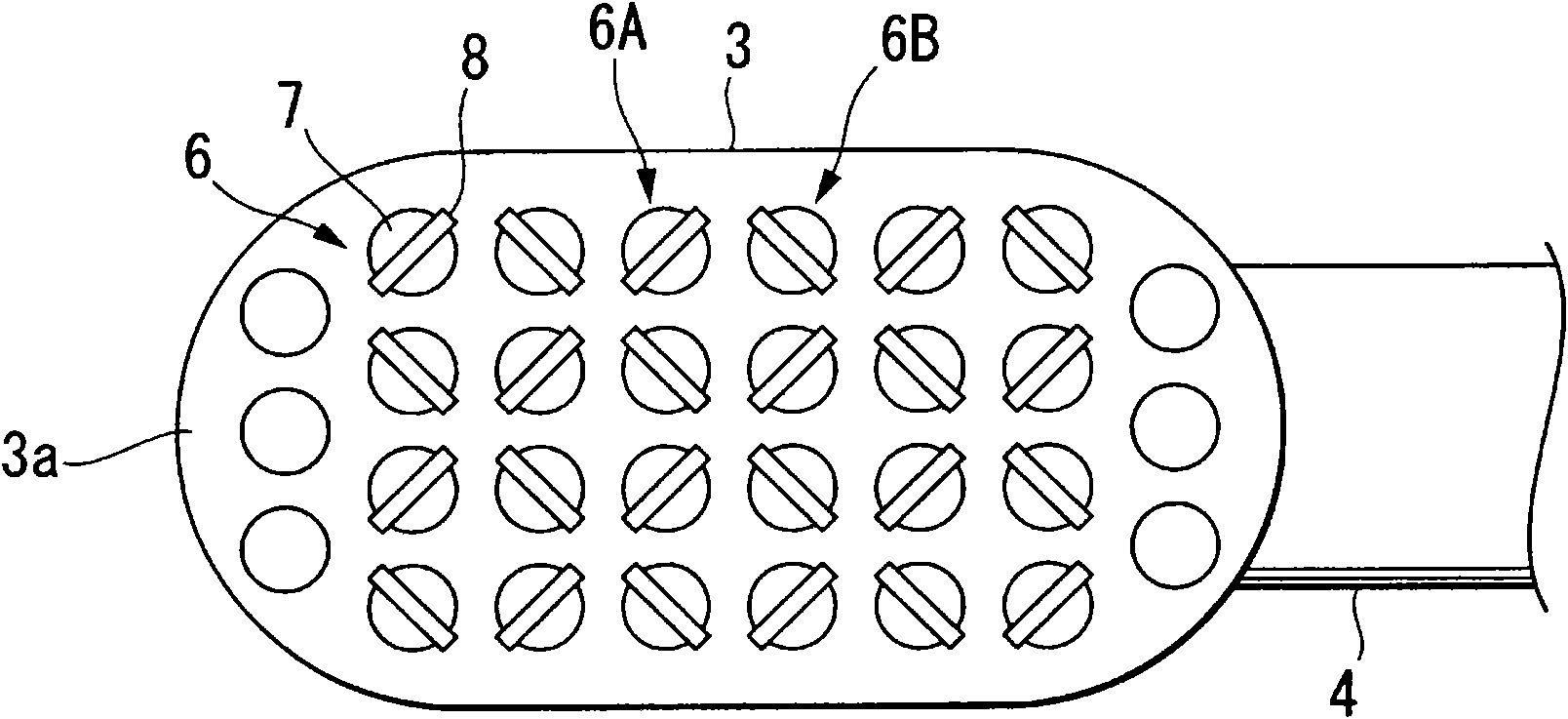

Toothbrush

InactiveCN101932264AAnisotropicGuaranteed cleanlinessBristleTooth cleaningBiomedical engineeringHair implant

A toothbrush in which a plurality of hair implant holes (7) are arranged on the hair implant surface (3a) of a head portion (3) at a predetermined interval in the length direction and the width direction of the head portion, and a bundle of brush flexible in one direction is implanted in each hair implant hole (7). Out of hair bundles (6A, 6B) adjoining in the length direction and the width direction of the head portion (3), the flat line (8) of one hair bundle (6A) and the flat line (8) of the other hair bundle (6B) are arranged obliquely with respect to the arrangement direction of the hair bundle (6) and the inclining direction of the flat lines (8) is set reverse so that one hair bundle (6A) and the other hair bundle (6B) are arranged alternately in the length direction and the width direction of the head portion (3).

Owner:LION CORP

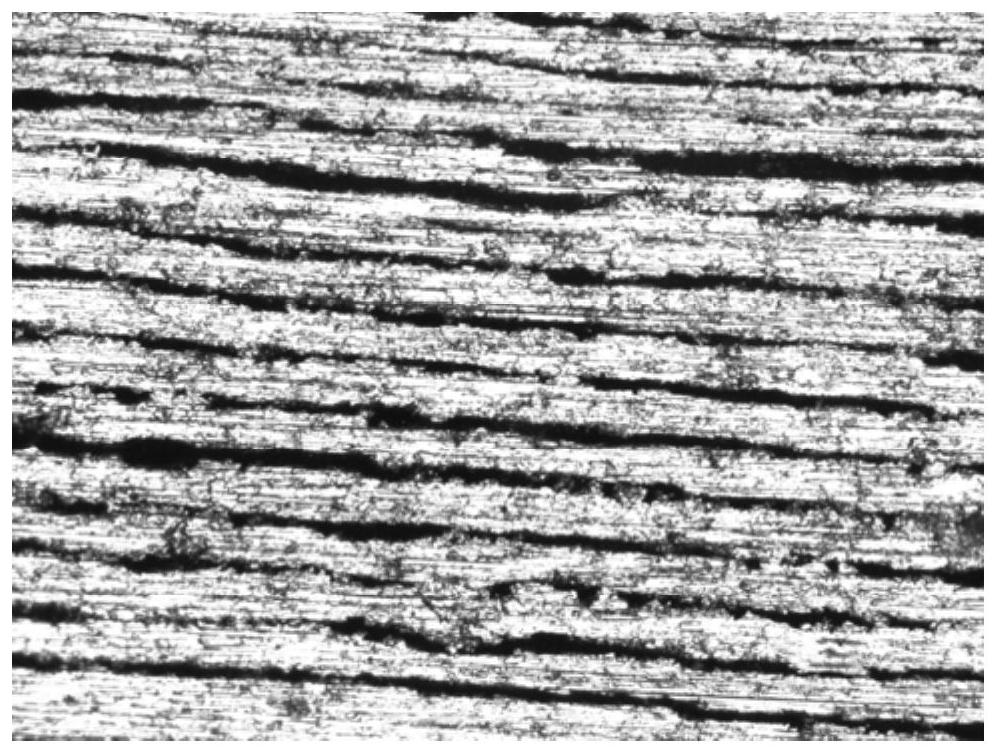

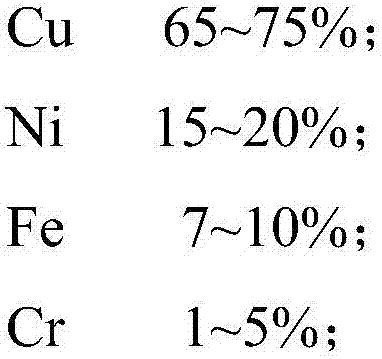

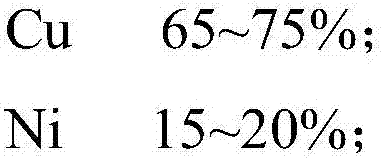

Deformable permanent magnet alloy, deformable permanent magnet alloy thin strip and preparation method thereof

ActiveCN107099695AImprove antioxidant capacityImprove coercive forceMagnetic materialsVacuum induction meltingNickel

The invention provides deformable permanent magnet alloy, a deformable permanent magnet alloy thin strip and a preparation method thereof. The deformable permanent magnet alloy comprises the following components in percentage by weight: 65-75 percent of Cu, 15-20 percent of Ni, 7-10 percent of Fe and 1-5 percent of Cr. The preparation method of the deformable permanent magnet alloy thin strip comprises the following steps: weighing the alloy components according to the weight ratio, performing vacuum induction melting on raw materials and casting into a copper-nickel-iron-chromium alloy ingot; forging the alloy ingot; hot-rolling the cast alloy ingot at a temperature of 600-900 DEG C and preparing into the alloy thin strip of 0.1-0.3 mm; tempering the alloy thin strip for 0.5-2 hours at a temperature of 500-650 DEG C. Through the design of the alloy components, a small quantity of Cr is added, so that the oxidation resistance of a permanent magnet material is increased, and meanwhile, the coercive force is increased to a certain degree; the thin strip is prepared through the forging, hot-rolling and tempering processes, so that the processes are simplified, the implantation is easy, and the preparation cost is low.

Owner:山东麦格智芯机电科技有限公司

Novel super heat conduction ceramic film composite material and preparation method thereof

The invention discloses a novel super heat conduction ceramic film composite material and a preparation method thereof, and belongs to the technical field of wave absorption function materials. The composite material is prepared from the following raw materials in parts by weight: 20 to 25 parts of fast soluble sodium silicate, 28 to 32 parts of crystal silicon, 4 to 8 parts of nanometer magnesia,13 to 17 parts of carbon fiber, 2 to 5 parts of boron fiber, 2 to 5 parts of silicic acid fiber, 8 to 12 parts of aluminum oxide powder and 23 to 28 parts of deionized water. The obtained material covers the surface of metal to isolate the metal from external media so as to block external high-temperature oxygen and corrosive substances; the metal pipe wall is effectively protected; the wave absorption performance is obvious; infrared radiation is generated; a good energy saving effect is achieved; the material is applied to the field of boilers; the energy is saved; the environment is protected; the operation of the boiler is safe; the boiler friction pipe blasting is reduced; the boiler hearth coking is reduced; the service life of the boiler is prolonged.

Owner:上海欧尔塔特种印刷科技有限公司

Polyolefin microporous film and method for manufacturing same, separator for nonaqueous electrolyte secondary cell, and nonaqueous electrolyte secondary cell

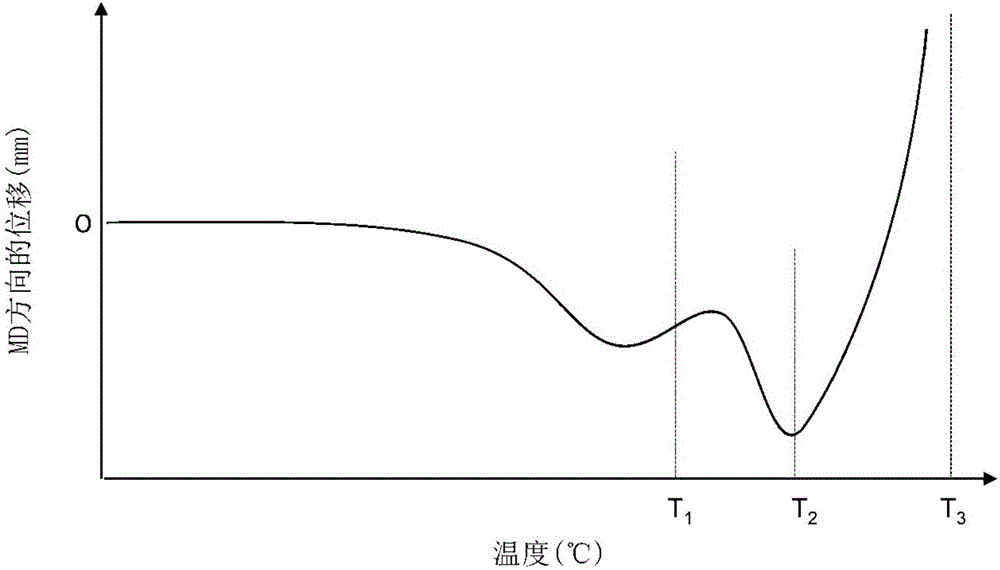

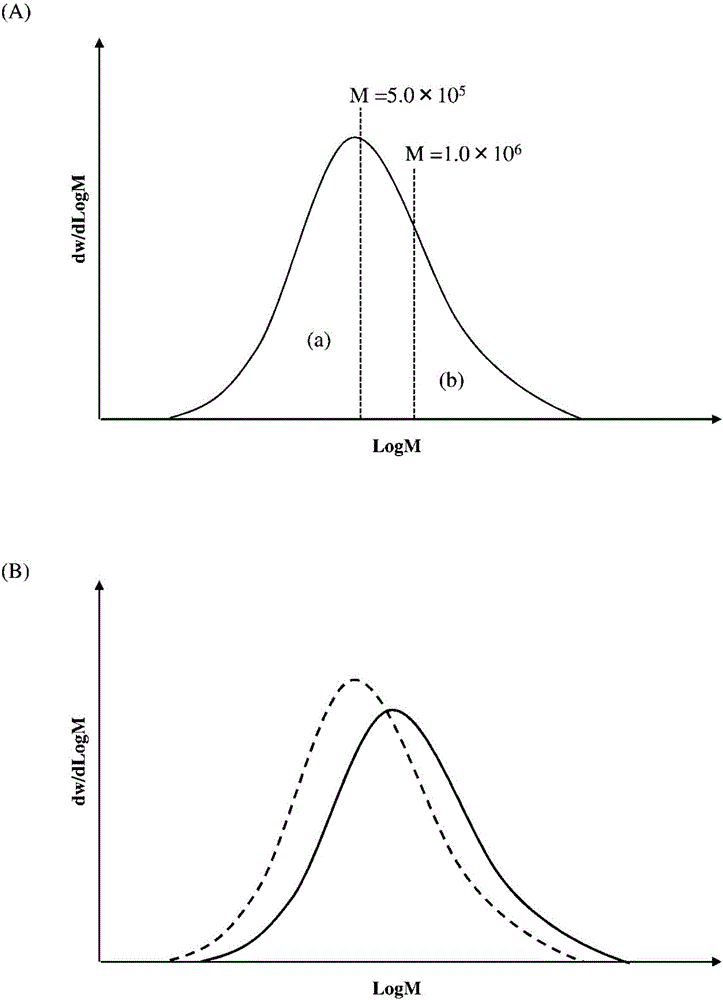

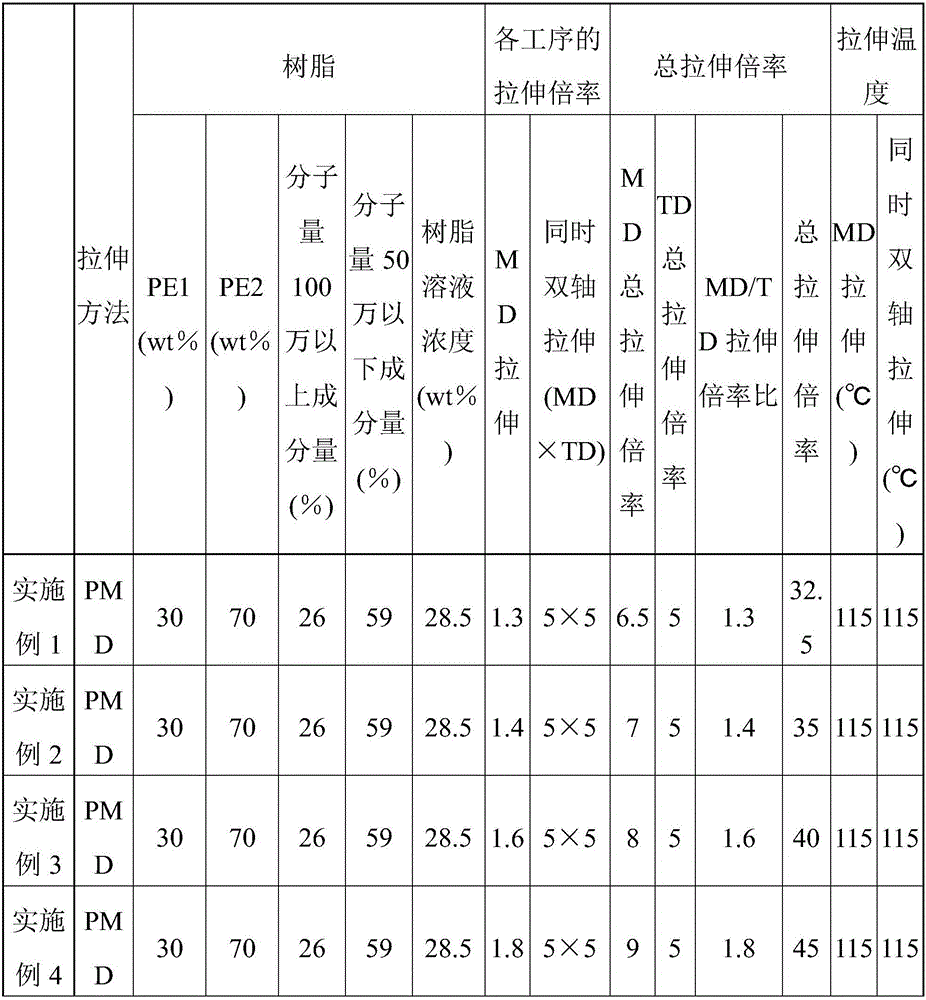

InactiveCN106661264ASmall apertureSuppress generationFinal product manufactureSecondary cellsPolymer sciencePolyolefin

Provided is a polyolefin microporous film having pores with small diameters and excellent shutdown characteristics, and which is suitable for a separator for a nonaqueous electrolyte secondary cell. The polyolefin microporous film is characterized in that the difference between the shutdown start temperature in the MD direction and the temperature at maximum shrinkage in the MD direction is 8.6 DEG C or greater, and the maximum pore diameter thereof is less than 0.036 [Mu]m. Also provided is a method for manufacturing the polyolefin microporous film, characterized by comprising melt-kneading and molding into a sheet shape a plasticizer and a polyolefin resin including an ultrahigh-molecular-weight polyolefin, stretching the resultant sheet in the MD direction and performing simultaneous biaxial stretching thereof, and then drying the stretched sheet.

Owner:TORAY IND INC

Boron phosphide single crystals and preparation method and application thereof

ActiveCN110284195AReduce defectsExcellent performancePolycrystalline material growthFrom frozen solutionsHydrogen phosphideSingle crystal

The invention provides boron phosphide single crystal and a preparation method and application thereof. The method comprises the following steps: (1) mixing a boron source, a phosphorus source and a catalyst, placing in a container and vacuumizing, and then sealing; (2) placing the sealed container in step (1) in a reactor, raising the temperature to a first reaction temperature to carry out a reaction, and then lowering the temperature to a second reaction temperature at a rate of temperature fall of 0.06 DEG C / min or below to obtain the boron phosphide single crystal. The preparation method of the boron phosphide single crystal provided by the invention avoids the use of hazardous gases such as hydrogen phosphide; the interaction among the catalyst and the boron source and the phosphorus source is utilized, and high-temperature reaction is first performed and then the temperature is slowly lowered for reaction, so that the separation by crystallization of boron phosphide is gradually realized to obtain the single crystal; the preparation method is a relatively convenient and feasible synthesis method.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Co-Cr-Mo-N alloy and preparation method thereof

The invention relates to the field of material processing and discloses a preparation method of Co-Cr-Mo-N alloy. The preparation method comprises the steps of vacuum melting - vacuum casting - heat treatment - rolling - cutting. The Co-Cr-Mo-N alloy is vacuum melted and cast, heated to the temperature of 1,150-1,350 DEG C and rolled into a star shape, wherein the single rolling amount is 10%-18%,and the finish-rolling diameter is 8-10mm. According to the preparation method, a rolling method is used for processing the Co-Cr-Mo-N alloy to form a slender rod, the processing technology is simple, processing efficiency is effectively improved, a product is fine in structure, a bulky phase is crushed, density is improved, and the mechanical properties of the material are improved.

Owner:江苏应用元素科技有限公司

Etching solution

PendingCN113981447AFinely craftedSlow etch rateConductive material chemical/electrolytical removalBenzeneIntegrated circuit manufacturing

The invention discloses an etching solution formula, and relates to the field of printed circuit board manufacturing and the field of integrated circuit manufacturing. According to the invention, the etching solution can be provided for reducing the copper thickness and forming the circuit, can improve the poor pinholes in the copper surface and optimize the rectangular circuit section, and meanwhile, improves the etching speed and improves the efficiency. The etching solution is characterized by being composed of sulfuric acid, hydrogen peroxide, an alcohol accelerant and a benzene ring stabilizer, the mass ratio of hydrogen peroxide to sulfuric acid in unit volume is larger than 8: 1, the hydrogen peroxide accounts for 8-30% by mass, the sulfuric acid accounts for 0.3-15% by mass, the alcohol accelerant accounts for 5-20% by mass, and the benzene ring stabilizer accounts for 0-2% by mass.

Owner:纳然电子技术(苏州)有限公司

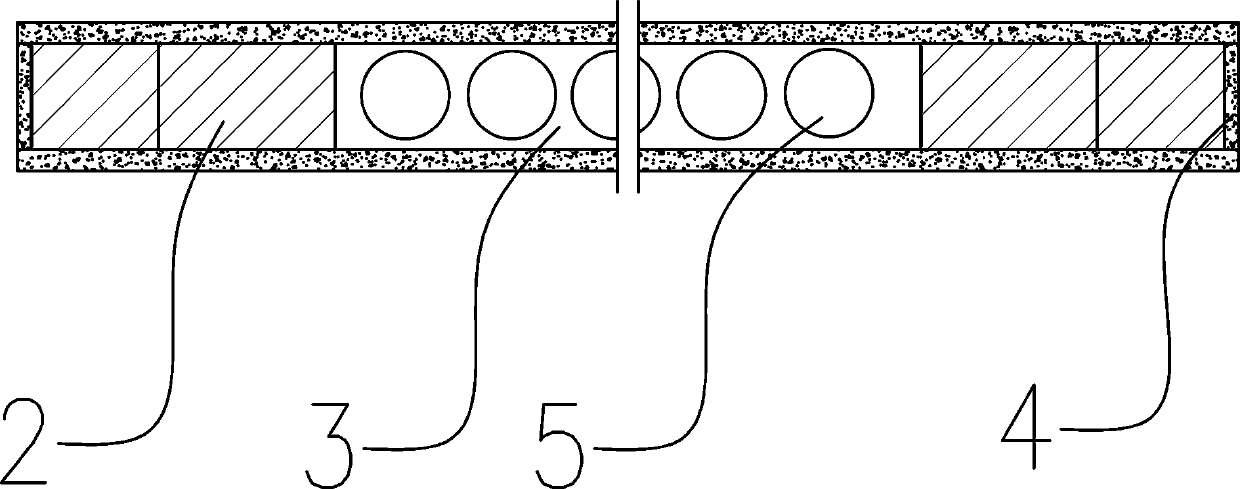

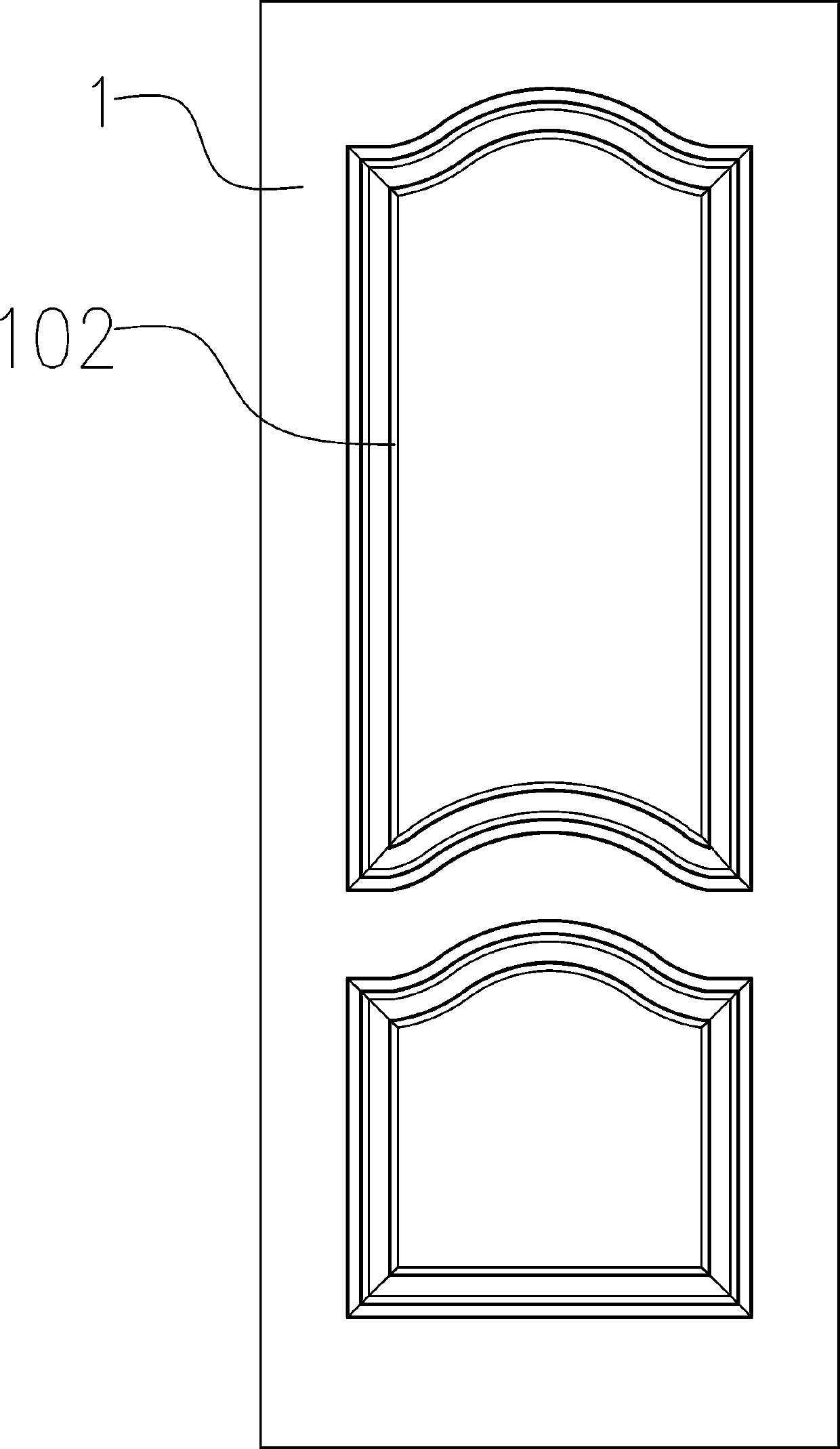

Lacquered wood press-attaching door and preparation method

PendingCN107553677AEasy to processGuaranteed appearanceWood working apparatusDoor leavesAssembly lineEnvironmentally friendly

The invention provides a lacquered wood press-attaching door and a preparation method. According to the lacquered wood press-attaching door, a door leaf comprises a lacquered faceplate, a door leaf core plate and a homochromous veneer edgeband. The lacquered faceplate and the door leaf core plate are in splicing connection. The homochromous veneer edgeband and the periphery of the door leaf are insplicing connection. The lacquered faceplate refers to a finished product plate with the surface being provided with an overcoating and UV paint. The preparation method includes the following steps that the blanked lacquered faceplate is prepared; a bridge hole plate and wood beams are blanked, and density boards are pressed onto the two surfaces of the bridge hole plate and the wood beams with glue to be made into the door leaf core plate after drying; the lacquered faceplate is spliced onto the surface of the door leaf core plate, and the four edges of a door leaf semi-finished product areclosed with the edgeband; and a door leaf finished product of the lacquered wood press-attaching door can be obtained through the steps. According to the lacquered wood press-attaching door and the preparation method, the lacquered faceplate and the door leaf core plate are combined and then edge banding is conducted, so that the manufacturing process steps are simplified, the painting technologyis omitted particularly, the production technology is more environmentally friendly, production time is greatly shortened, and assembly line processing can be better achieved.

Owner:北京爱构筑家居科技有限公司

Plasma etching method and computer-readable storage medium

ActiveCN100474524CReduce etch rateAnisotropicSemiconductor/solid-state device manufacturingHigh frequency powerDc voltage

In a plasma etching method for plasma-etching an etching stop film after plasma-etching a low-k film in a structure in which a wiring layer, the etching stop film made of an SiC-based material, the low-k film and an etching mask are formed in that order on a substrate, the method includes the step of arranging the structure having the plasma-etched low-k film in a processing chamber in which a first and a second electrode are provided to face each other at vertically separated locations. The plasma etching method further includes the steps of introducing a processing gas containing NF3 into the processing chamber; generating a plasma by applying a high frequency power to one of the first and the second electrode; and applying a DC voltage to said one of the electrodes.

Owner:TOKYO ELECTRON LTD

Wood-coated steel-steel and wood composite column

The invention discloses a wood-coated steel-steel and wood composite column which comprises a square steel pipe. An upper wood plate and a lower wood plate are coated on the outside of the square steel pipe; the upper wood plate and the lower wood plate are connected with each other by fasteners or are adhered and connected with each other by adhesive. The wood-coated steel-steel and wood composite column has the advantages that wood for the wood-coated steel-steel and wood composite column is light, environmentally friendly, renewable and reusable and is high in strength, and energy can be saved by the wood; steel for the wood-coated steel-steel and wood composite column is light and isotropic and is high in strength, convenient to construct, uniform in texture and excellent in energy dissipation capacity, and construction can be industrialized by the aid of the steel; merits of the wood and the steel can be sufficiently utilized by steel and wood composite structures of the wood-coated steel-steel and wood composite column, the shortcomings of the wood and the steel can be overcome by the aid of the merits, energy can be saved, the wood-coated steel-steel and wood composite column is environmentally friendly, green buildings are excellent in seismic performance, and the like.

Owner:YANCHENG INST OF TECH

Bionic dermis and preparation method and application thereof

The invention discloses a bionic dermis. An implant is a three-dimensional braided fabric of biocompatible fiber, and the fiber is adsorbed, absorbed or enwrapped with an extracellular matrix component substance of normal skins and / or dermis tissues which is advantageous for repairing skins or dermises. The invention also discloses a preparation method and application of the bionic dermis.

Owner:RUIJIN HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Flexible cable for communication power supply

InactiveCN105047263AExtended service lifePrevent defects caused by smoothnessNon-insulated conductorsFlexible cablesIsooctyl acrylateFiber

The invention discloses a flexible cable for a communication power supply. The flexible cable comprises a circular high-intensity carbon fiber core, Z-shaped conductors are twisted at the external surface of the circular high-intensity carbon fiber core and form an inner conducting layer, trapezoidal conductors are twisted at the external surface of the inner conducting layer and form an outer conducting layer, a polyethylene insulating tape wraps the external surface of the outer conducting layer, a halogen-free polyolefin elastomer insulating layer wraps the external surface of the polyethylene insulating tape, and an adhesive filling portion is arranged in an aluminum alloy layer and placed among carbon fibers. The adhesive filling portion is composed of 100 parts of maleic anhydride, 15-20 parts of butyl acrylate monomer, 20-30 parts of isooctyl acrylate, 8-10 parts of n butanol, 2-3 parts of dibenzoyl peroxide, 1.5-2.5 parts of triethylene tetramine, 1-3 parts of graphite particles, 3-5 parts of aluminum powder and 8-12 parts of diatomite by weight. The flexible cable is high in tensile intensity, current carrying capacity and flexibility, easy to bend, and tight in structure; and the minimal bending radius is reduced to 3 times of the cable diameter.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com