Carbon fiber reinforcement aluminum alloy mortise and tenon structure and preparation method thereof

A carbon fiber reinforcement, aluminum alloy technology, applied in the connection of connecting components, mechanical equipment, rods, etc., can solve the problems of reduced strength and increased aluminum alloy defects, and achieve the effect of reducing energy dissipation capacity, small thermal expansion coefficient, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

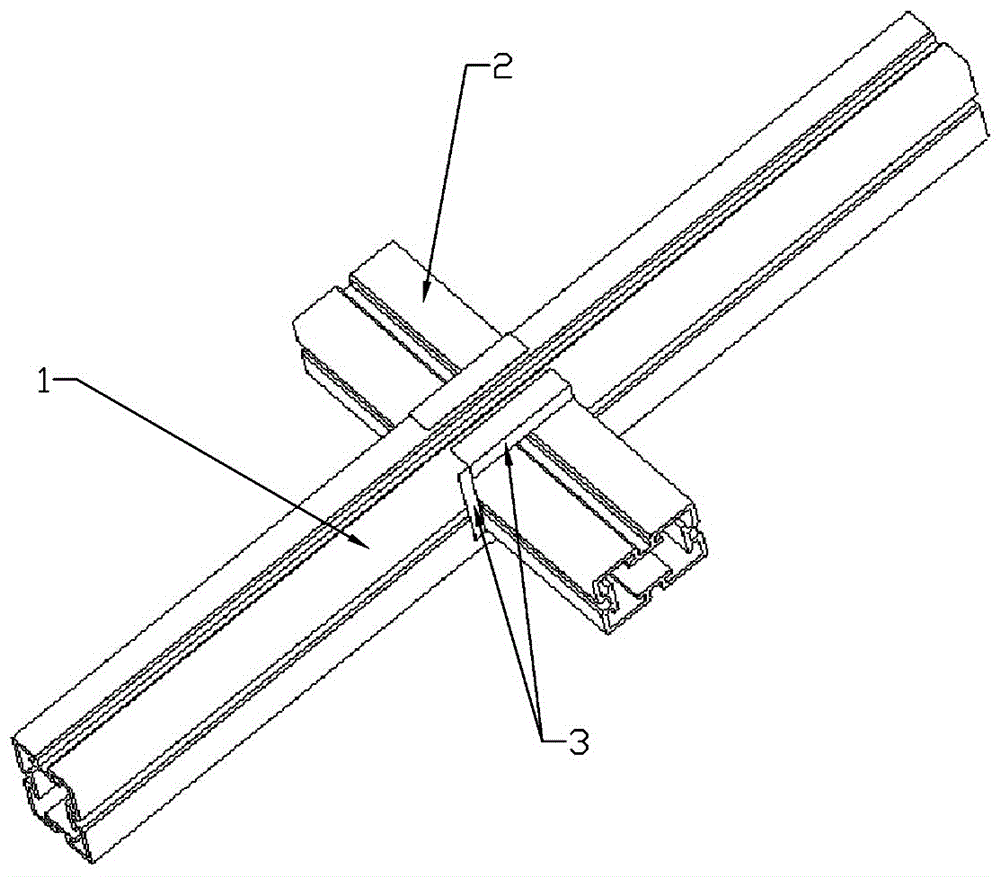

[0017] refer to figure 1 , a carbon fiber reinforced aluminum alloy mortise and tenon structure, including a mortise piece 1 and a mortise piece 2, the mortise piece 1 is provided with a mortise hole, the mortise joint part of the mortise piece 2 is inserted into the mortise hole for connection, and at least one inner surface of the mortise eye is covered with carbon fiber The composite cloth 3, the mortise and tenon joint parts are in interference fit with the mortise eyes covered with the carbon fiber composite cloth 3, and the interference fit of the mortise and tenon structure complies with the GB / T5371-2004 standard. Carbon fiber has high axial strength and modulus, low density, high specific performance, no creep, ultra-high temperature resistance in non-oxidizing environment, good fatigue resistance, specific heat and electrical conductivity between non-metal and metal, thermal expansion coefficient Small and anisotropic, good corrosion resistance. Using carbon fiber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com