Power transmission line carbon fiber composite core lead core rod

A transmission line, carbon fiber technology, applied in the direction of circuits, conductors, electrical components, etc., can solve the problem of easy fracture of carbon fiber composite core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

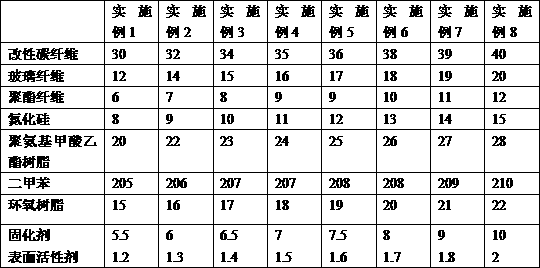

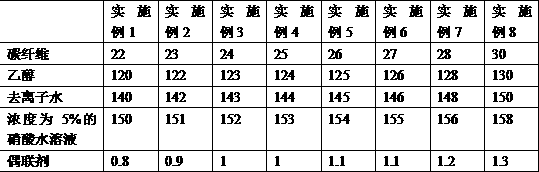

[0031] This embodiment provides a carbon fiber composite core conductor mandrel for a power transmission line, which is made of the weight parts of each raw material as described in Table 1 and Table 2. Wherein, the coupling agent is KH550. The curing agent is curing agent 703. The surfactant is nonylphenol polyoxyethylene ether phosphate.

[0032] A method for preparing a carbon fiber composite core conductor mandrel for a power transmission line, comprising the following steps:

[0033] S1: Add S-twist to modified carbon fiber, glass fiber and polyester fiber, 100 twist / m, then take 1 fiber and combine them, add Z-twist, 100 twist / m to make composite fiber yarn;

[0034] S2: After mixing epoxy resin, polyurethane resin and curing agent, stir at room temperature at a speed of 200r / min for 60s, then add silicon nitride, xylene, and surfactant, keep stirring at a constant speed for 5 minutes, get mixed solution;

[0035] S3: adding the composite fiber thread obtained in ste...

Embodiment 2

[0038] This embodiment provides a carbon fiber composite core conductor mandrel for a power transmission line, which is made of the weight parts of each raw material as described in Table 1 and Table 2. Wherein, the coupling agent is KH550. The curing agent is curing agent 704 . The surfactant is potassium lauryl ether phosphate.

[0039] A method for preparing a carbon fiber composite core conductor mandrel for a power transmission line, comprising the following steps:

[0040] S1: Add S-twist to modified carbon fiber, glass fiber and polyester fiber, 100 twist / m, then take 1 fiber and combine them, add Z-twist, 100 twist / m to make composite fiber yarn;

[0041] S2: After mixing epoxy resin, polyurethane resin and curing agent, stir at room temperature at a speed of 250r / min for 45s, then add silicon nitride, xylene, and surfactant, and keep stirring at a constant speed for 4 minutes. get mixed solution;

[0042] S3: adding the composite fiber thread obtained in step S1 i...

Embodiment 3

[0045] This embodiment provides a carbon fiber composite core conductor mandrel for a power transmission line, which is made of the weight parts of each raw material as described in Table 1 and Table 2. Wherein, the coupling agent is KH551. The curing agent is curing agent 703. The surfactant is nonylphenol polyoxyethylene ether phosphate.

[0046] A method for preparing a carbon fiber composite core conductor mandrel for a power transmission line, comprising the following steps:

[0047] S1: Add S-twist to modified carbon fiber, glass fiber and polyester fiber, 100 twist / m, then take 1 fiber and combine them, add Z-twist, 100 twist / m to make composite fiber yarn;

[0048] S2: After mixing epoxy resin, polyurethane resin and curing agent, stir at room temperature at a speed of 300r / min for 30s, then add silicon nitride, xylene and surfactant, keep the speed constant and continue stirring for 3min. get mixed solution;

[0049] S3: adding the composite fiber thread obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com