Mold manufacturing method and preparation method of ultra-large type composite carbon fiber tube

A technology of composite materials and carbon fiber tubes, which can be used in household appliances, tubular objects, and other household appliances. It can solve the problems of complex molding process and heavy pipe fittings, and achieve the effects of simple curing process, high strength and high quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

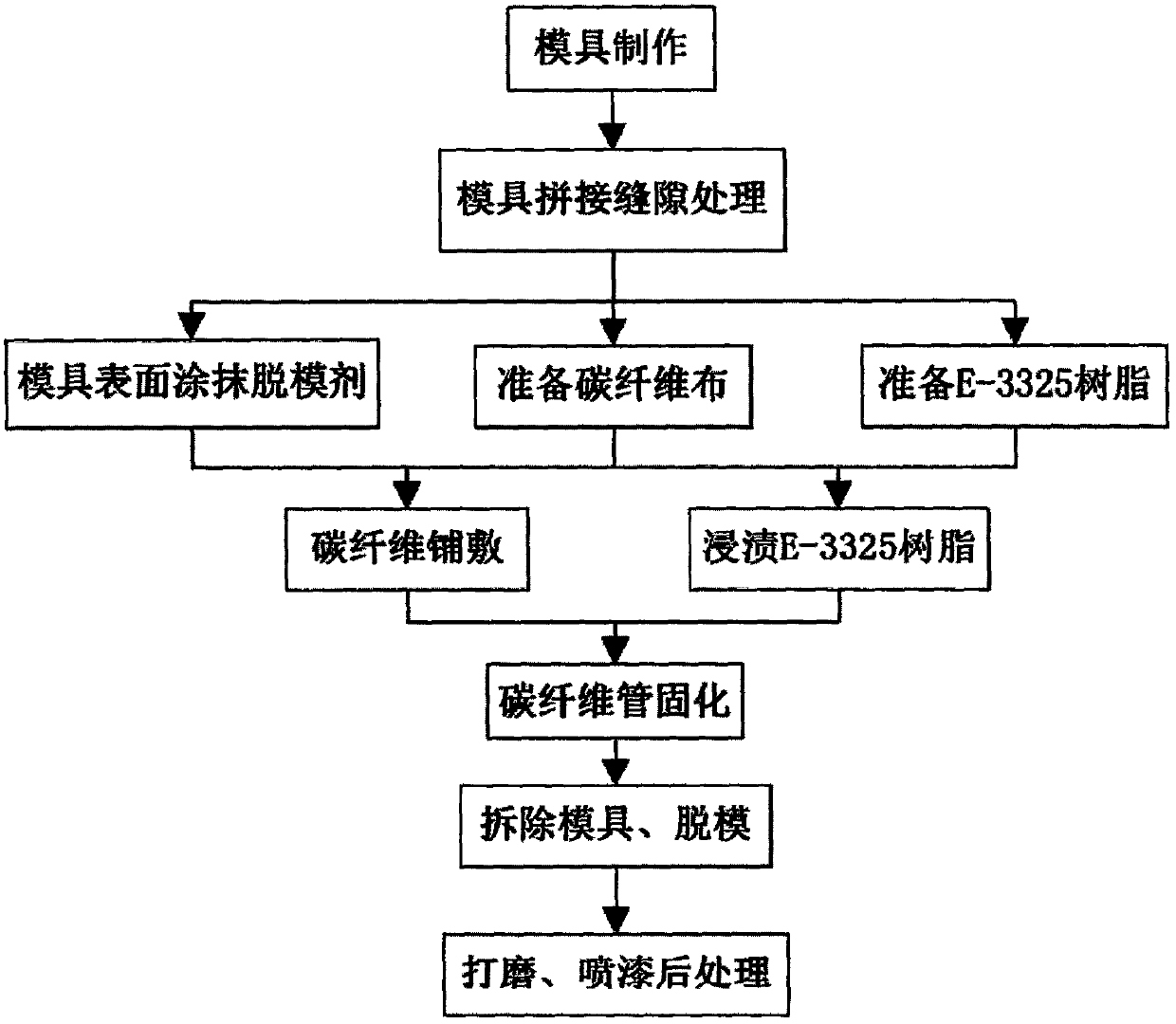

[0027] Such as figure 1 Shown, the present invention relates to a kind of preparation method of ultra-large composite carbon fiber tube comprising the following steps:

[0028] Step 1: Make the mold.

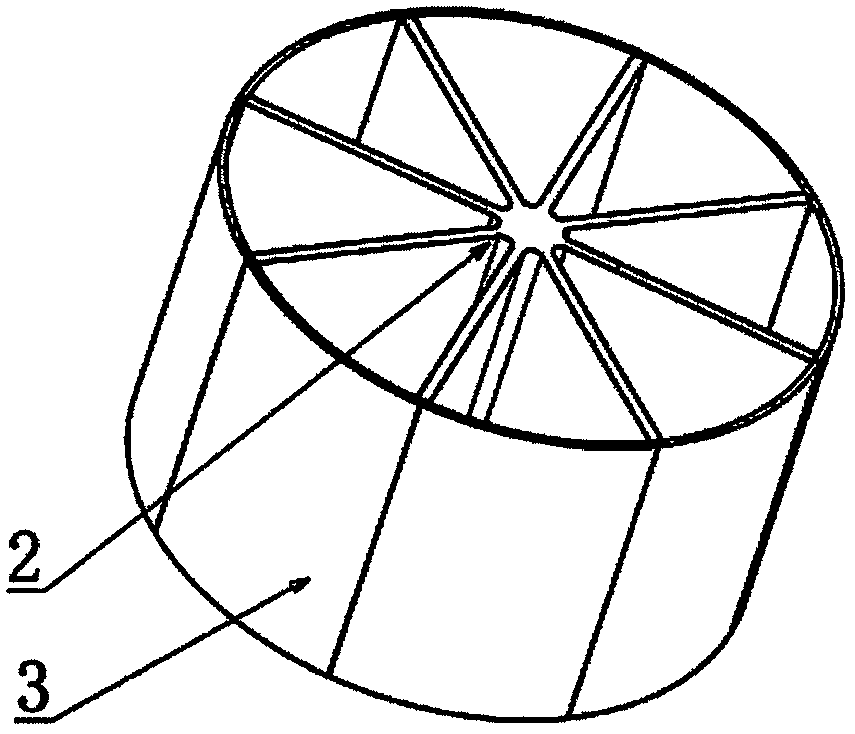

[0029] Such as image 3 As shown, the mold is composed of a mold skeleton 2 and a mold skin 3 . The mold skeleton 2 is welded and spliced by the metal skeleton, which is simple in forming and high in strength, and can meet the requirements of making carbon fiber tubes of any diameter. The mold skin 3 is fixed on the mold skeleton 2, and the mold skin 3 is riveted with the metal skeleton 2.

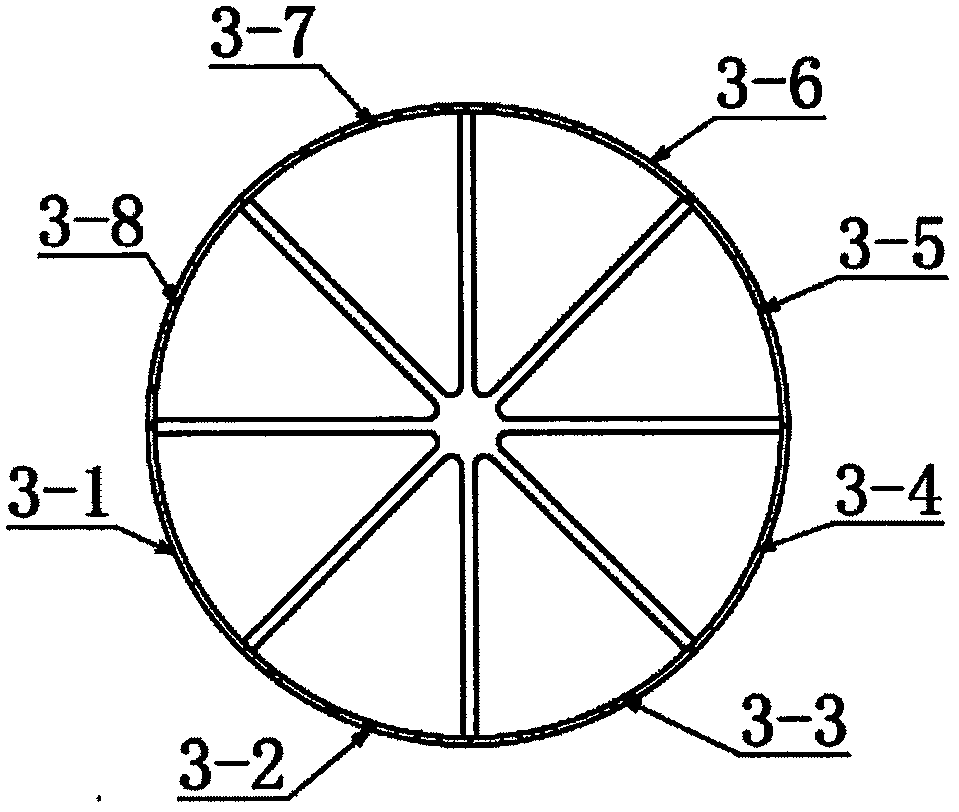

[0030] Apply mold release agent on the outer surface of the mold skin, fill the splicing gap of the mold skin with unsaturated resin putty, and polish to ensure the surface of the mold skin is smooth. The mold skin is made of rolled steel plate, and the mold skin is composed of 6-10 modules, which are spliced together along the circumferential direction, such as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com