Patents

Literature

147results about How to "Improve axial strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

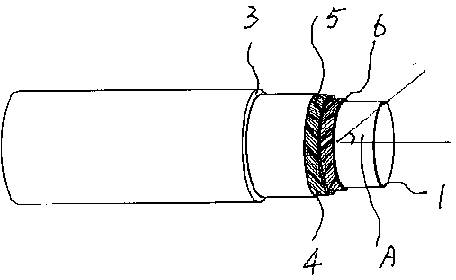

Catheter with an expandable end portion

InactiveUS7094243B2Improve axial strengthImprove scalabilityStentsEar treatmentMedical deviceBiomedical engineering

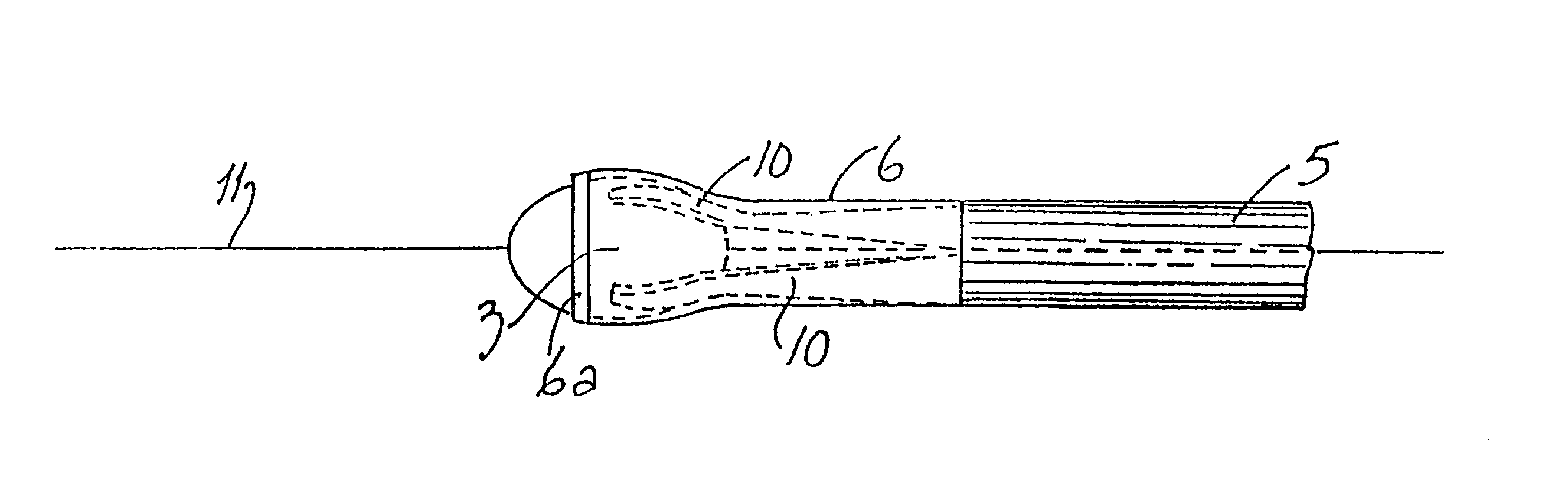

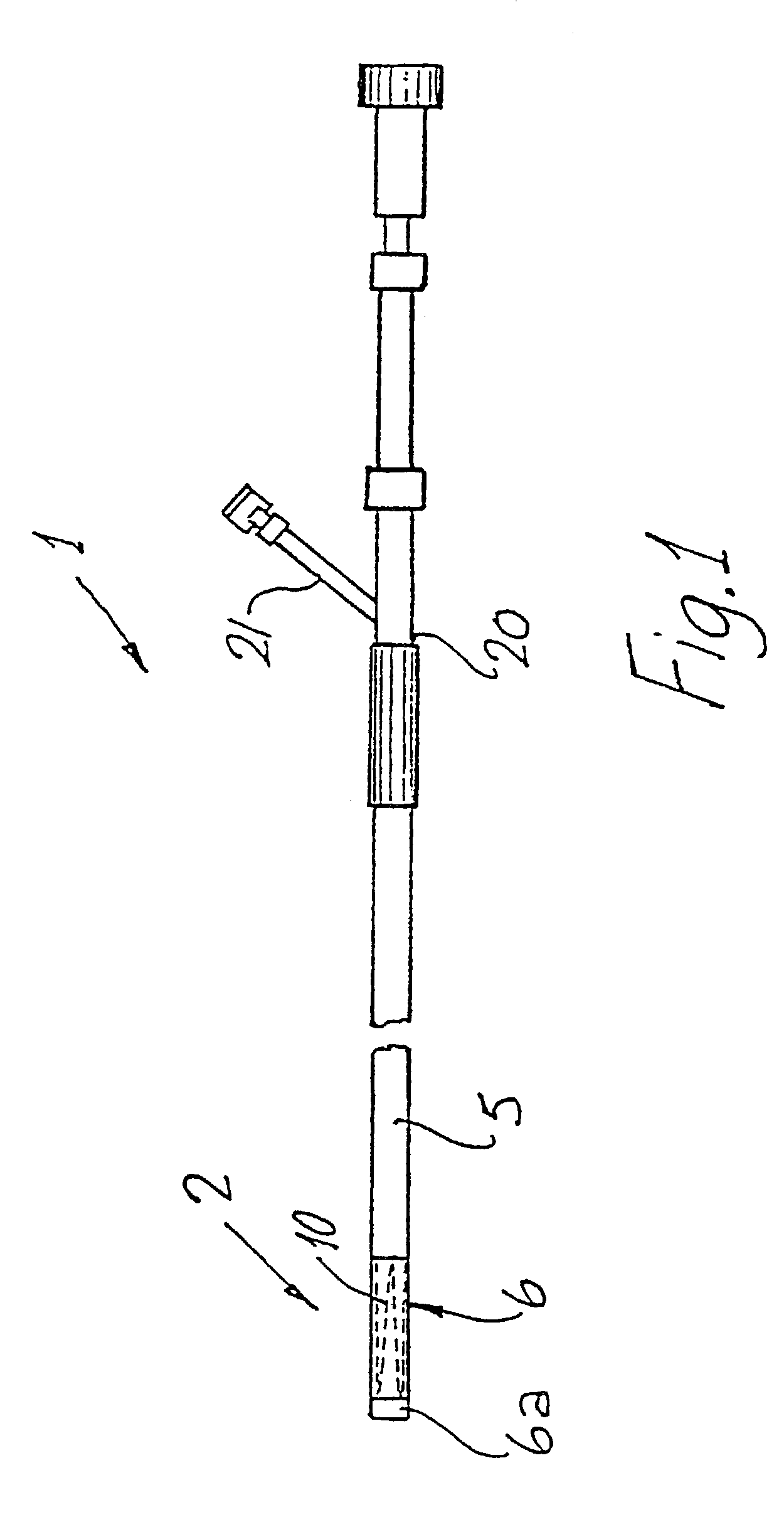

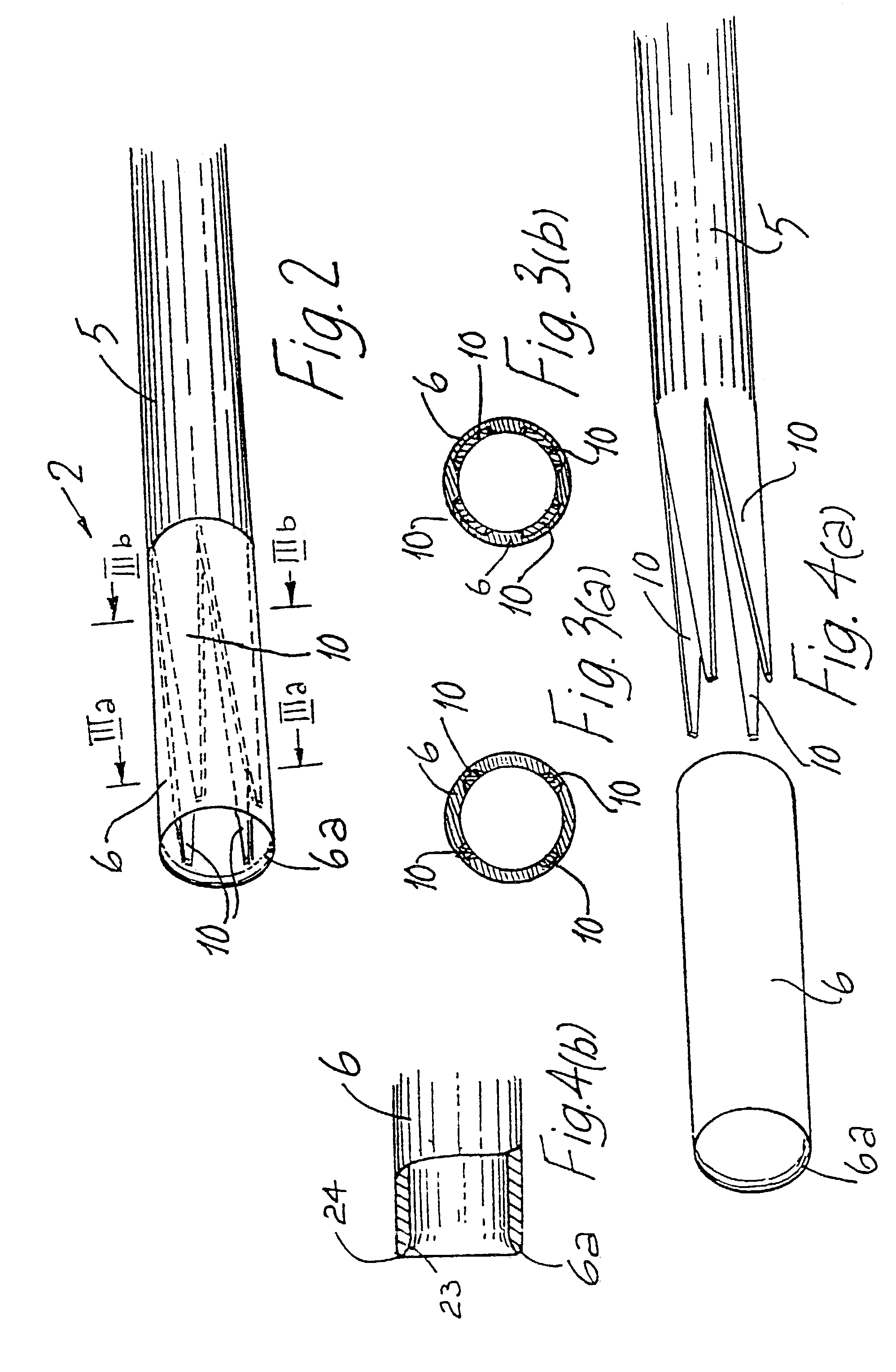

A catheter (2) is used in medical applications, for example for the retrieval of a sample from a patient or the insertion or retrieval of medical devices such as filters, stents (3) to and from the patient. The catheter (2) includes an expandable tip (6) at a leading portion of a catheter tube portion (5). This expandable tip (6) can retrieve or deliver samples, medical devices, etc. (3), which are slightly larger than the dimensions of a main catheter tube (5) inserted into the patient. The expandable tip (6) can also include extension members (10) which provide axial support to the expandable tip (6) but which still allow expansion in the radial direction.

Owner:SALVIAC

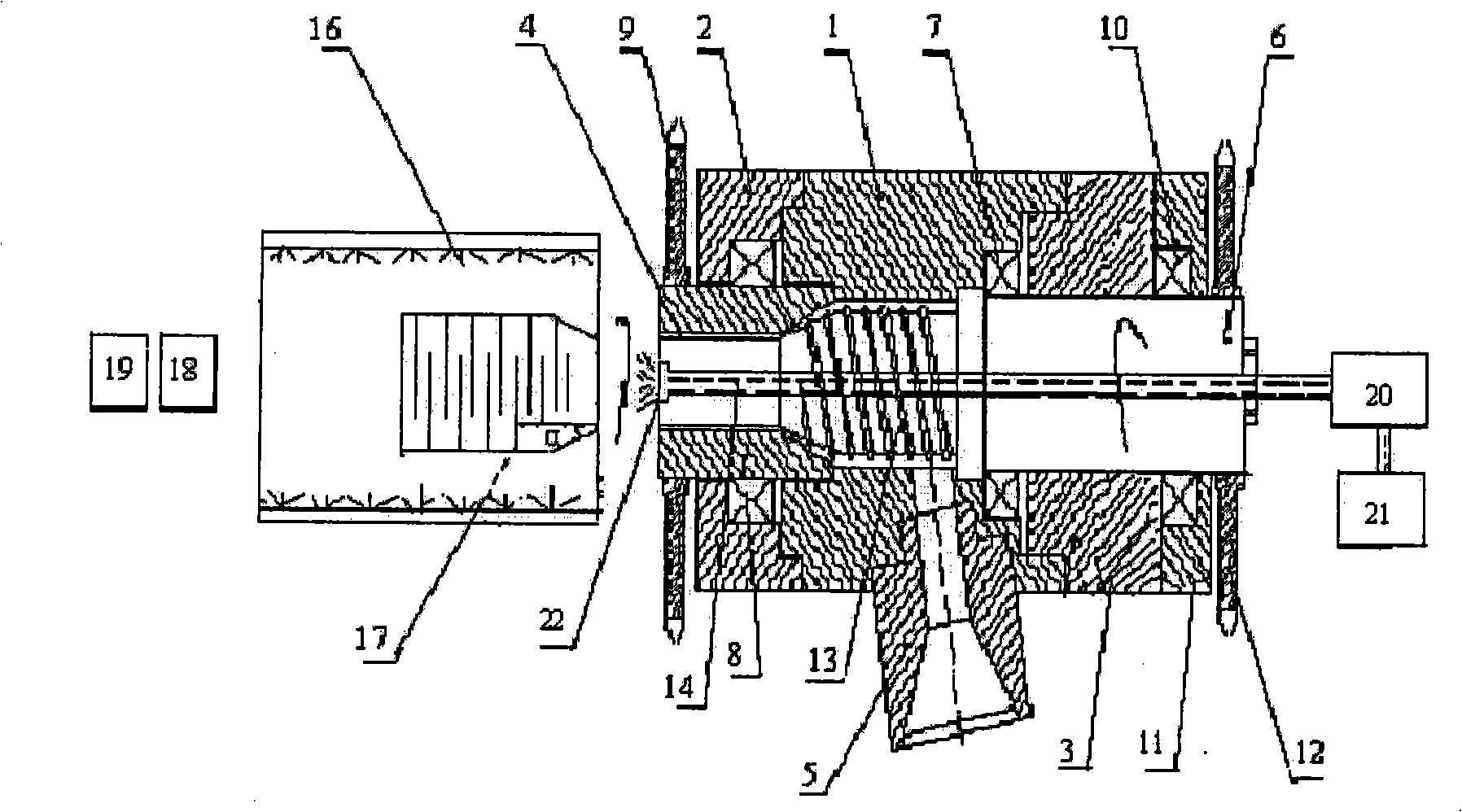

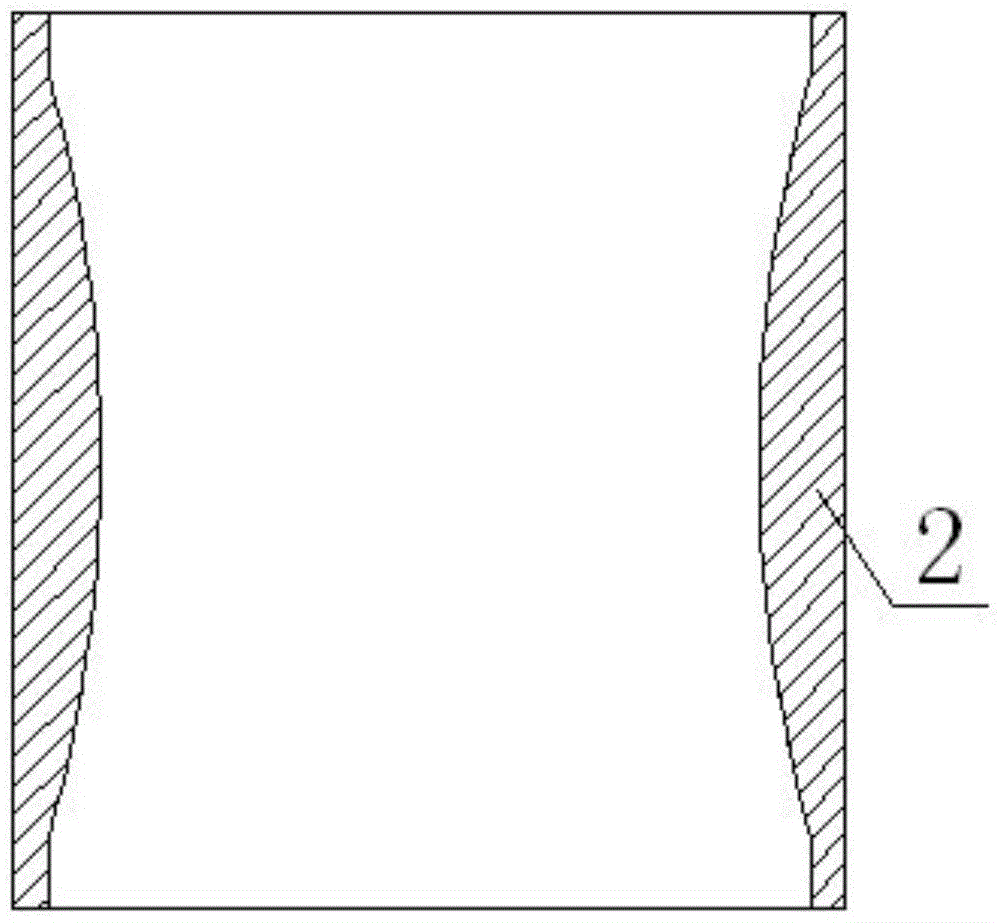

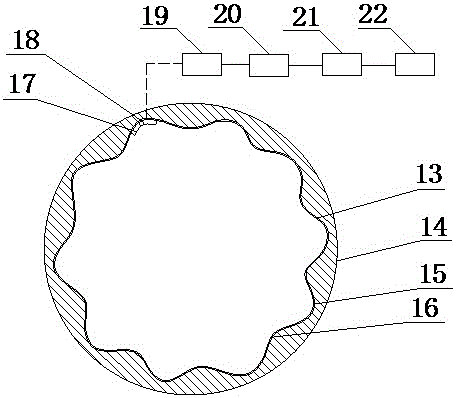

Preparation method and device of high performance polymers pipes

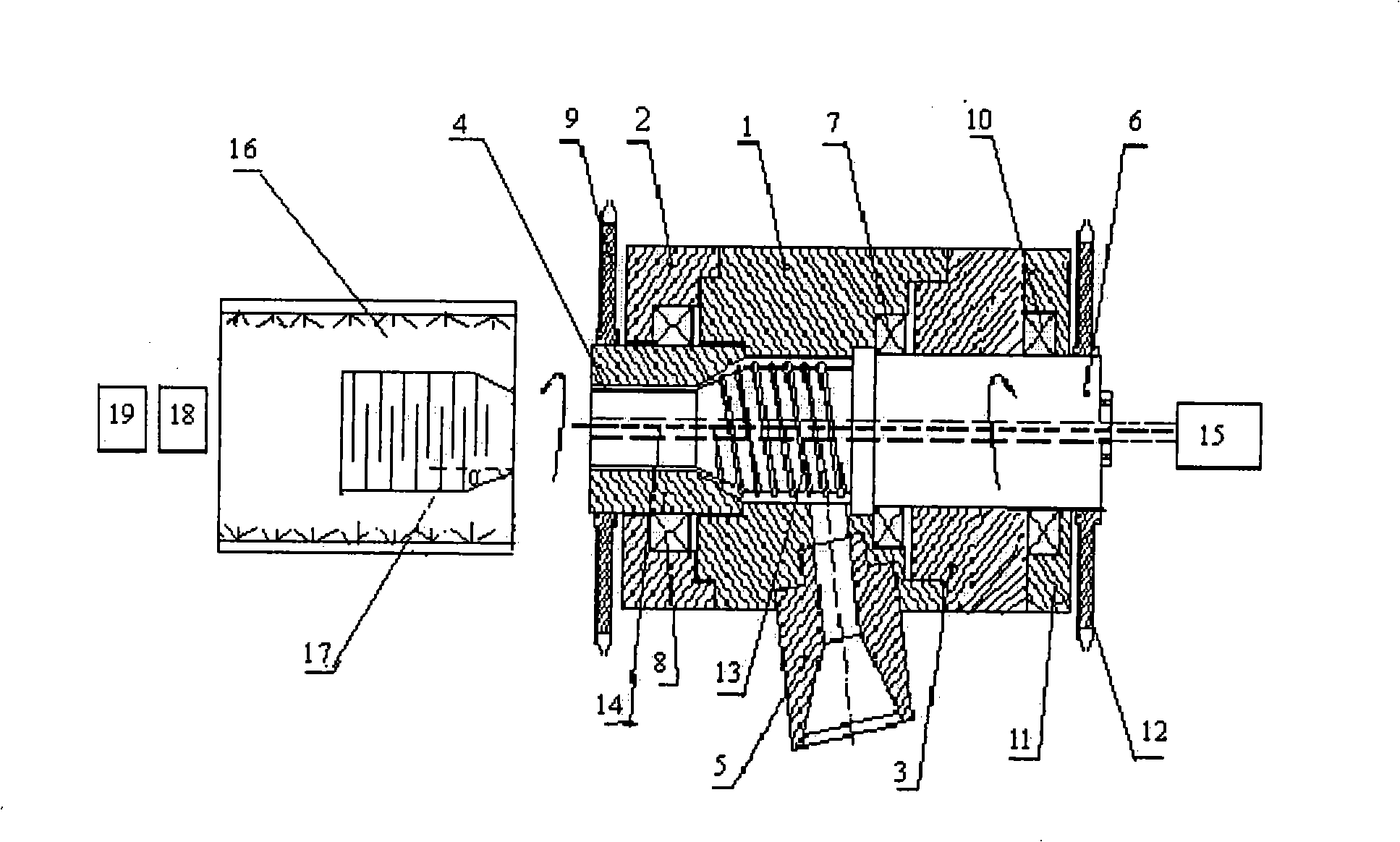

The invention discloses a method for preparing a high-performance polymer pipe. The method adopts the steps that during the extrusion molding process of the pipe, the crystallization, the orientation or the dispersed phase morphological structure of the polymer pipe can be adjusted, controlled and fixed through the shearing action generated by the rotation of a core rod in a machine head relative to an orifice die, or the rotation of the orifice die in the machine head relative to the core rod, or the rotation of the core rod and the orifice die in the identical or opposite direction simultaneously, and by cooling and shaping the inner wall and the outer wall of the extruded pipe simultaneously, and adjusting and controlling the temperature field, the cooling rate and the temperature gradient during the extrusion molding process of the pipe. The invention further discloses a device designed according to the method. The method has the advantages that the macromolecular orientation, the crystallization or the dispersed phase morphological structure which are generated through induction can be retained in the plastic pipe, so that deorientation can be avoided, the internal stress of the pipe can be reduced, and the performance of the pipe is improved.

Owner:SICHUAN UNIV

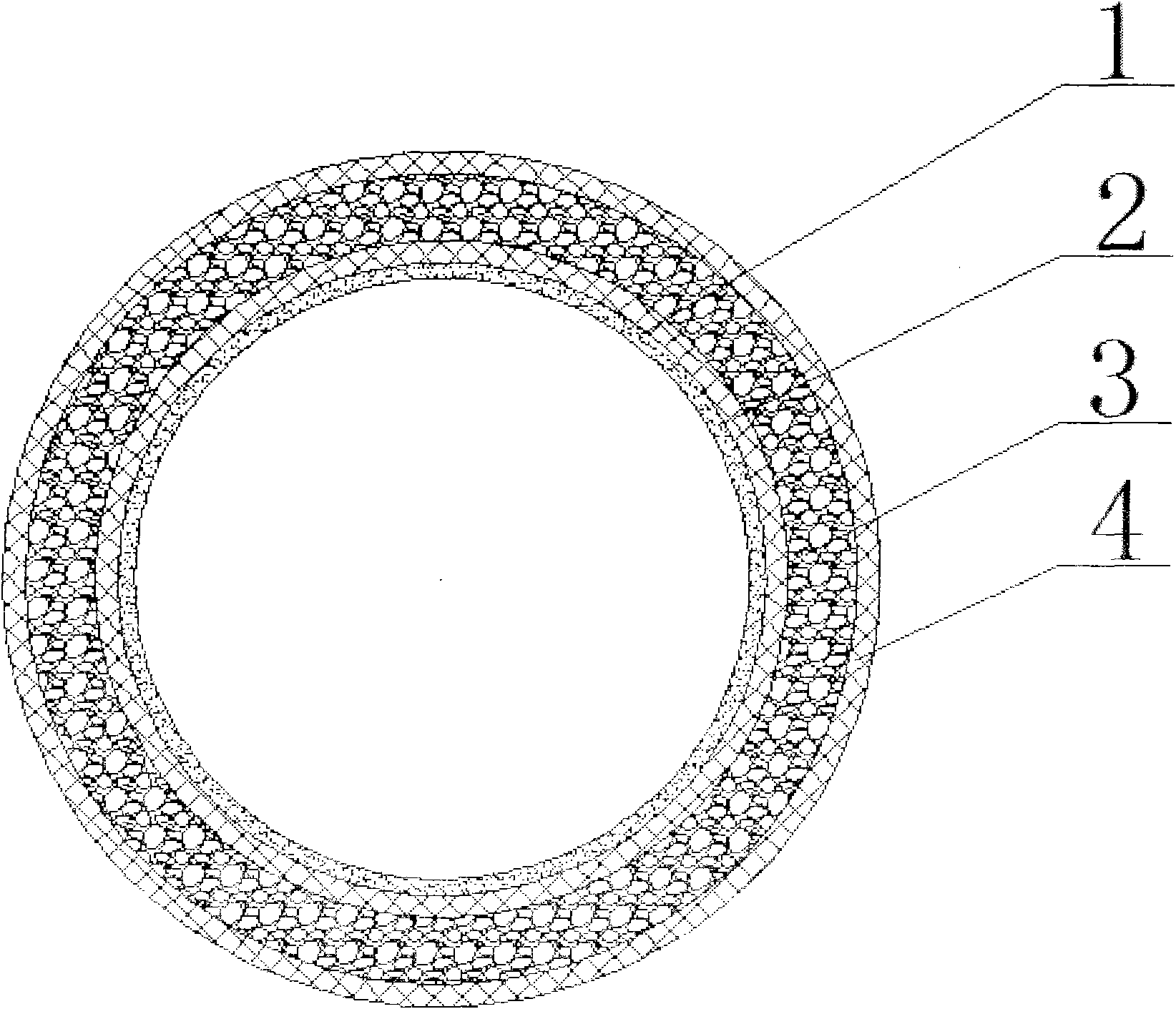

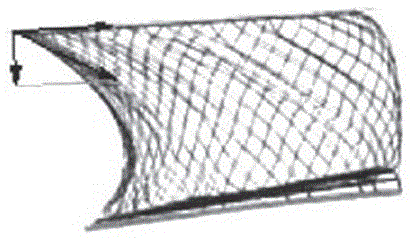

Ultra-large-diameter bamboo winding composite tube and manufacturing method thereof

ActiveCN105715881AImprove axial strengthEnhanced bending and impact resistanceRigid pipesTubular articlesStress distributionFiber

The invention belongs to the related field of composite tubes, and discloses an ultra-large-diameter bamboo winding composite tube. The bamboo winding composite tube comprises a lining layer, a composite strengthening layer and an outer protection layer from inside to outside, and the lining layer is made of fiber blankets or non-woven fabrics with anticorrosive resin in an adhesion manner; the composite strengthening layer is formed in a manner that two different types of bamboo skin curtains are wound outside the lining layer in a layer-by-layer manner according to the proper layer number and the thickness proportion wholly in the ring direction, the bamboo skin curtains are sprayed with the resin in a liquid-leaching manner while winding is carried out, and then bonding curing is carried out; and the outer protection layer is cured on the outer surface of the strengthening layer in a coating manner, and the effects of water prevention, corrosion prevention, radiation prevention and the like are achieved. The invention further discloses a corresponding manufacturing method. Through the ultra-large-diameter bamboo winding composite tube and the manufacturing method, even under the tube diameter obvious expanding condition, the characteristic that the whole structure of the bamboo winding composite tube is free of stress distribution defect can be well kept, and meanwhile comprehensive properties of pressure resistance, ring stiffness, long-term use quality stability and the like can be obviously improved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

Manufacturing method for glass steel pipeline in zero-degree winding manner

The invention discloses a manufacturing method for a glass steel pipeline in a zero-degree winding manner. The method sequentially comprises the steps that winding yarn immersed in resin is used for hoop winding, then, a wire guiding head drives the winding yarn to pass multi-tooth comb rings buckled at the two ends of a core die to be axially wound, finally, winding yarn immersed in resin is in hoop winding again to stabilize an axial winding layer, hoop and axial winding is repeated, and pipeline winding with different strength requirements is achieved. Continuous winding of the axial zero degree of the winding yarn and pipelines is achieved, the axial mechanical performance of the pipelines is optimal, and then the high requirement of industrial fields for the axial performance can be met. The required axial strength is achieved, the production cost is reduced to the maximum degree, meanwhile, the pipeline thickness is reduced, and the pipelines are convenient to transport and use.

Owner:HEBEI HAOZHENG NON METALLIC MATERIALS TESTING SERVICES CO LTD

Reinforced compound sheathing canal, preparation method and application thereof

InactiveCN105105894AReduce surgical riskPrevent extensionStentsSurgeryTransport systemInvasive treatments

The invention discloses a reinforced compound sheathing canal, a preparation method and application thereof. The reinforced compound sheathing canal sequentially comprises an inner layer, a reinforced layer and an outer layer from interior to exterior, wherein the reinforced layer comprises axial reinforcing elements and a spiral reinforcing element, the spiral reinforcing element is a single spiral element or is formed by combining two or more spiral elements, the axial reinforcing elements are disposed on the inner side or outer side of the spiral element, or are inserted between the spiral elements, and various axial reinforcing elements are uniformly arranged in the circumference direction of the sheathing canal. The reinforced compound sheathing canal provided by the invention has the advantages of thin wall, high axial strength, high radial strength, high torque transitivity and the like, can be applied to a transport system for transporting medical device implants needed in a minimally invasive treatment and can reduce the outer diameter of the transport system, so that the medical device implants are easy to arrive at lesion positions, damage to the blood vessel of a patient is reduced, and sufficient technical support is provided for reliable, successful and safe transport and implantation of the medical device implants by the transport system.

Owner:NINGBO LINSTANT POLYMER MATERIALS CO LTD

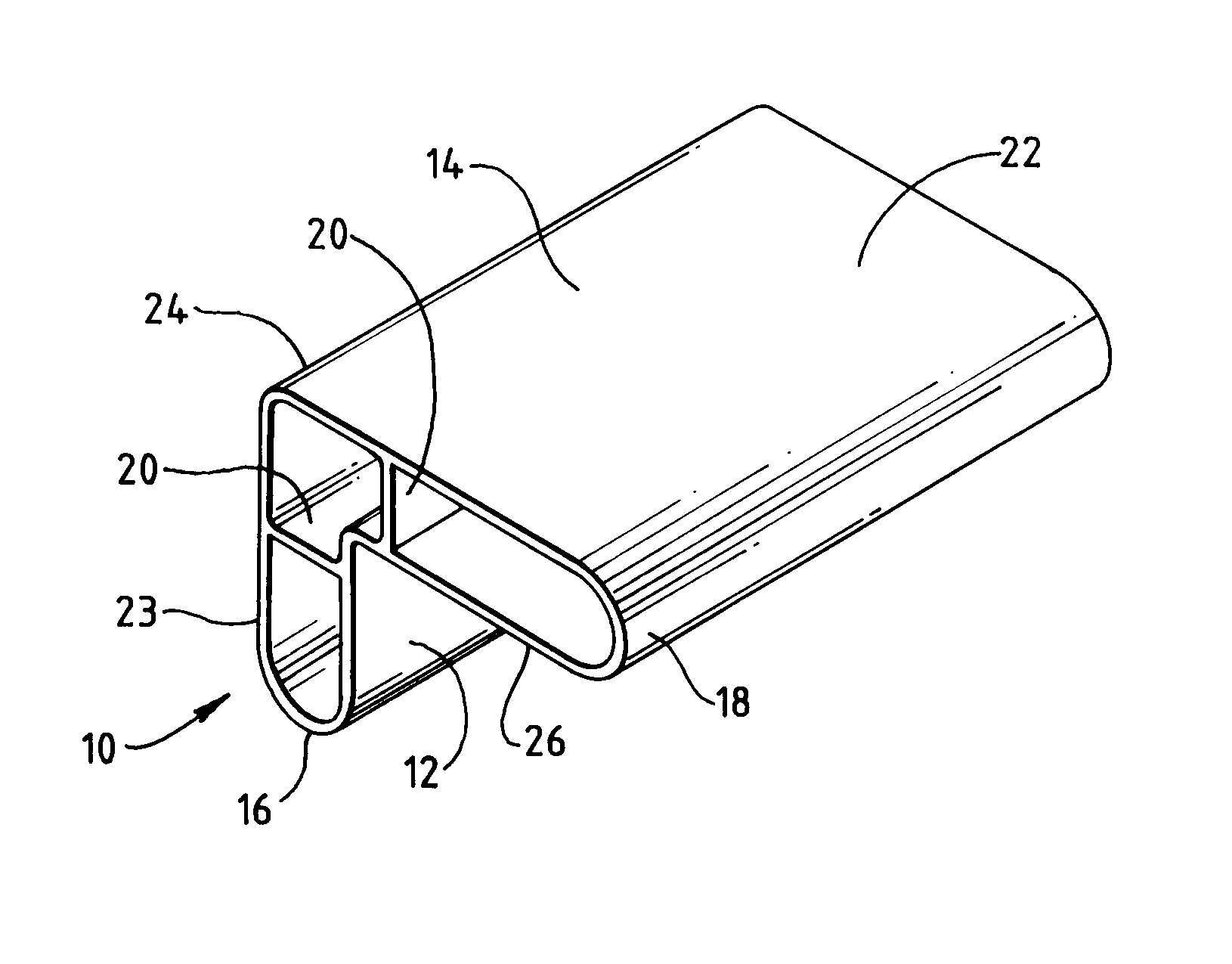

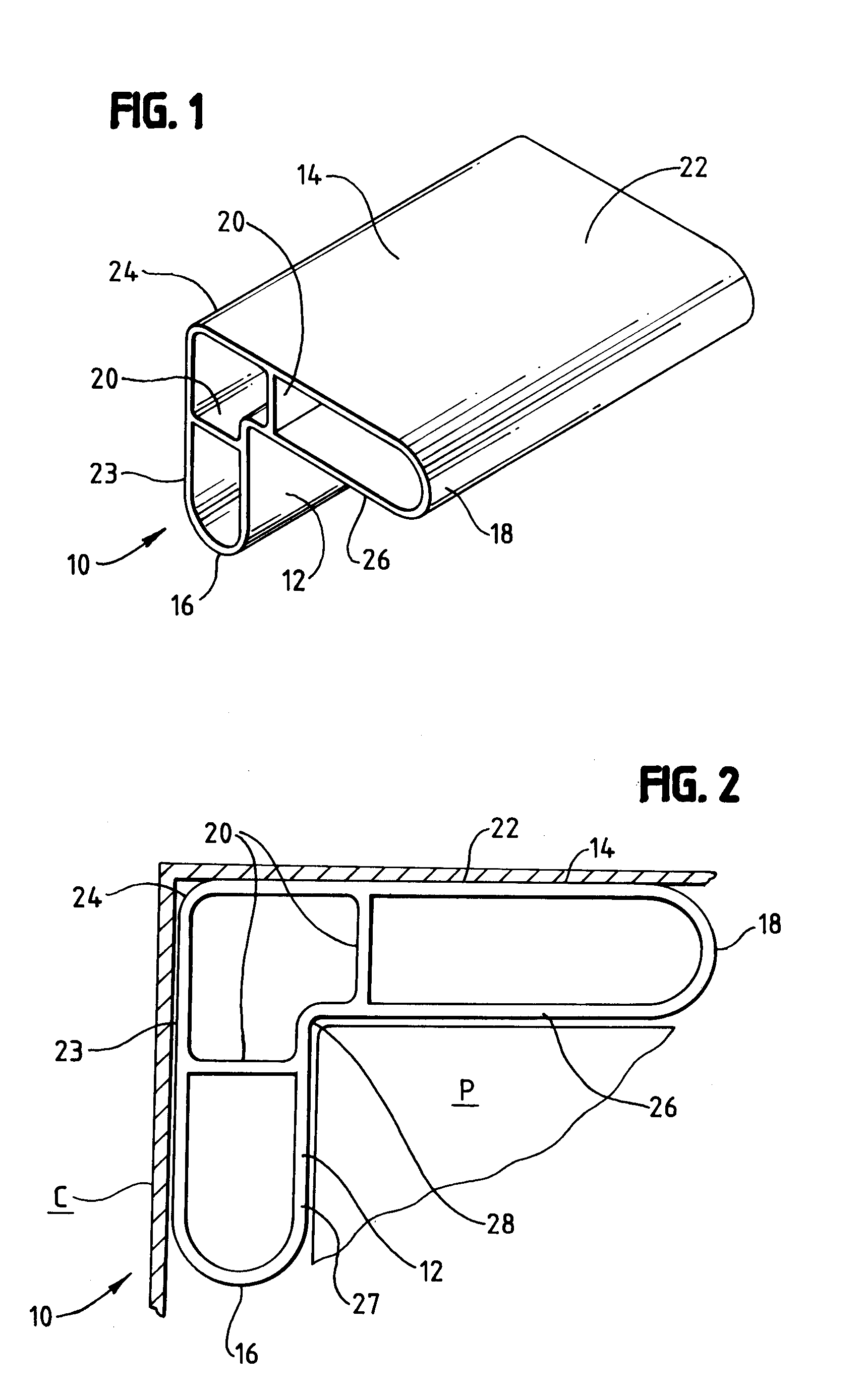

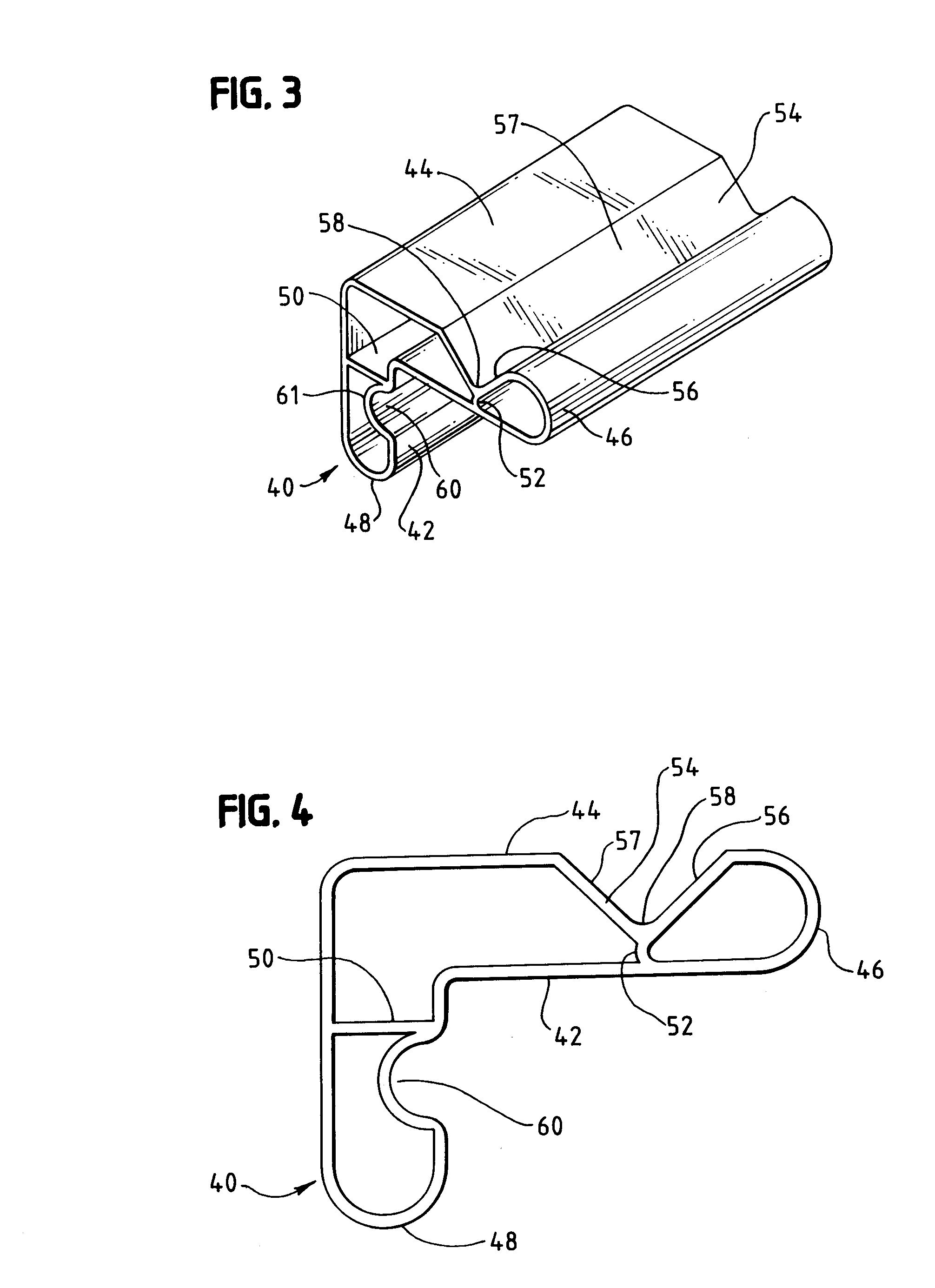

Extruded Corner Post For Vertical and Lateral Protection

Owner:SONOCO DEV INC

Automobile leaf spring bushing

InactiveCN104149570AImprove axial strengthImprove radial strengthResilient suspensionsAlloyEngineering

The invention discloses an automobile leaf spring bushing and belongs to automobile suspension elastic elements. The bushing comprising an inner sleeve, an outer sleeve, filling rubber layers and retaining rings. The outer surface of the inner sleeve is in an arc shape protruded outwardly on the axial section of a bushing body, the inner surface of the outer sleeve is in an arc shape protruded inwardly on the axial section of the bushing body, a high damping alloy layer is arranged between the inner sleeve and the outer sleeve, and the filling rubber layers fill between the inner sleeve and the high damping alloy layer and between the outer sleeve and the high damping alloy layer; the inner sleeve is in a hollow cylindrical structure with two ends with steps, the diameters of two ends are smaller than the diameter of the middle of the inner sleeve, and two ends of the inner sleeve are provided with the retaining rings respectively through the steps of the inner sleeve. Owing to the unique shapes of the inner sleeve and outer sleeve, the radial strength of the leaf spring bushing is increased; the high damping alloy layer is arranged between the inner sleeve and the outer sleeve, the axial strength of the filling rubber layers is increased, and the fine damping performance is provided.

Owner:宁国天运橡塑制品有限公司

Coiled plastic composite pipe reinforced with fibre

ActiveCN103062528ASmall bending radiusEasy to transportFibre treatmentFlexible pipesPolyesterGlass fiber

The invention belongs to the technical field of a plastic composite pipe, and discloses a coiled plastic composite pipe reinforced with fibre. The technical scheme includes that an inner tube layer is made of polymer materials, the outer wall of the inner tube layer is wound or braided a wear-resistant fibrous layer constituted by polyester industrial fibers, aramid fibers and glass fibers, the outer surface of the fibrous layer is coated with a modified polymer corrosion protection layer, and the inner tube layer, the fibrous layer and the protective layer composite into one integral structure. The coiled plastic composite pipe reinforced with fibre has the advantages of small bending radius, high pressure resistance and high temperature resistance.

Owner:河北宇通特种胶管有限公司

Mortar-filled glass fiber reinforced plastic pipe

InactiveCN102080743AImprove axial strengthHigh tensile strengthRigid pipesGlass fiberFlexural strength

The invention discloses a mortar-filled glass fiber reinforced plastic pipe, which comprises a lining layer, an inner reinforcing layer, a mortar filler layer and an outer reinforcing layer, wherein the inner reinforcing layer is between the lining layer and the mortar filler layer, and the mortar filler layer comprises quartz sand impregnated with unsaturated polyester resin and ground calcium carbonate. The mortar-filled glass fiber reinforced plastic pipe is characterized in that: in the quartz sand impregnated with unsaturated polyester resin and ground calcium carbonate, the percentage mixing ratio of the unsaturated polyester resin to the quartz sand to the ground calcium carbonate is (9-15):(74-90):(8-14). Compared with the prior art, the mortar-filled glass fiber reinforced plastic pipe has the advantages that: the unsaturated polyester resin content in the mortar filler layer is as low as 9 to 15 percent; the quality of the product is stable and the product is in strict accordance with the requirements of the national GB / T21238-2007standards of glass fiber reinforced plastic mortar-filled pipes on mechanical properties including pipe axial tension, circumferential tension, bending strength, ring stiffness, deflection A and deflection B; and the manufacturing cost of the pipe is reduced by 5 to 30 percent.

Owner:奉玉贞

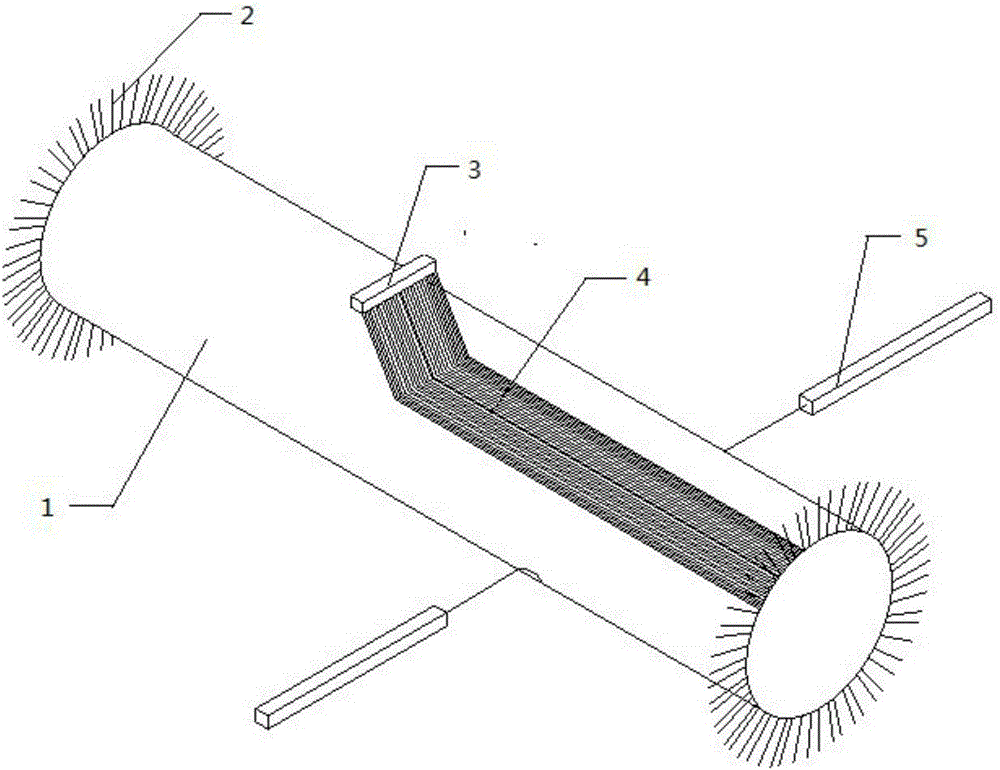

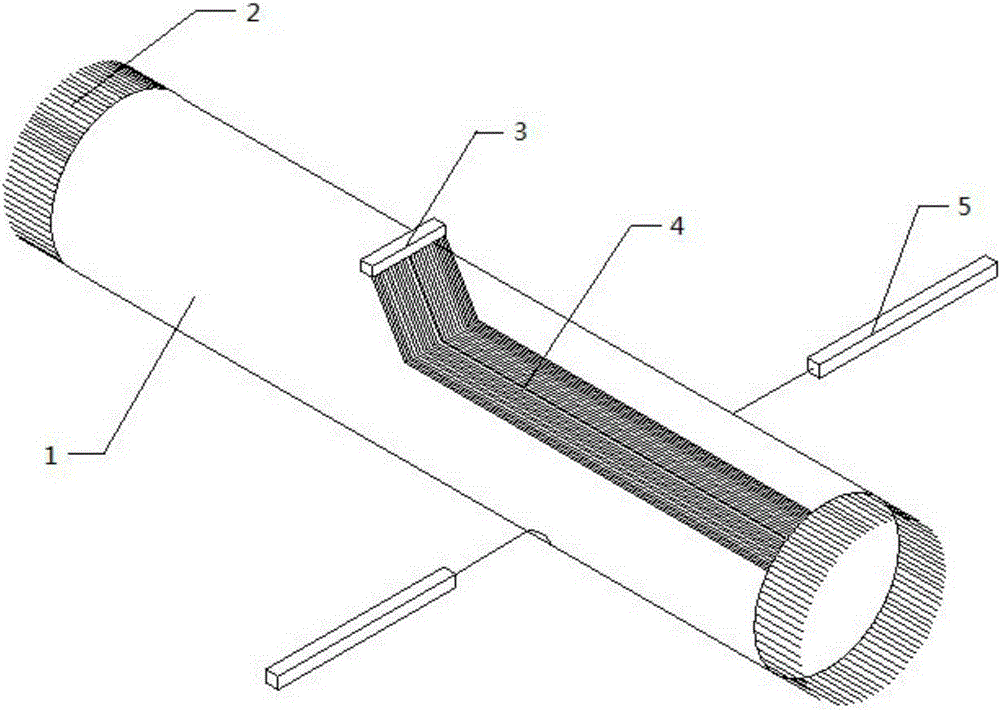

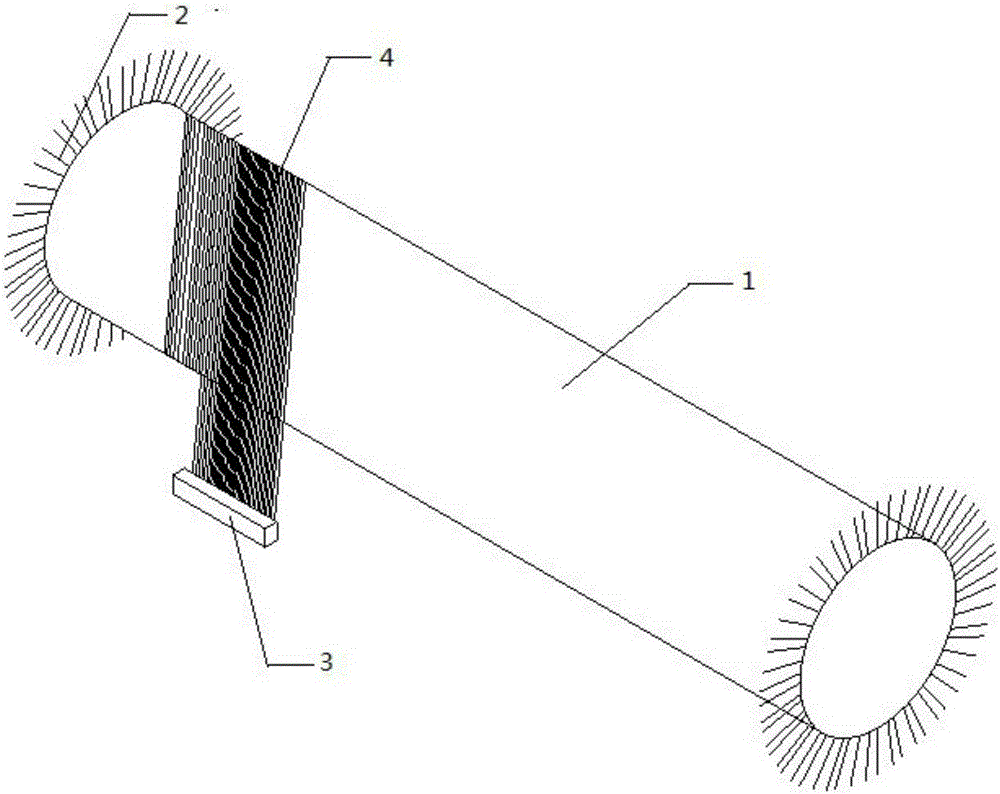

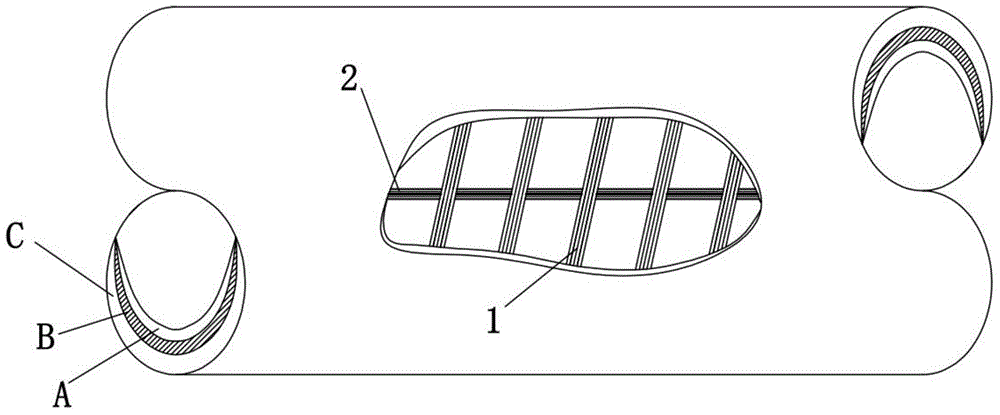

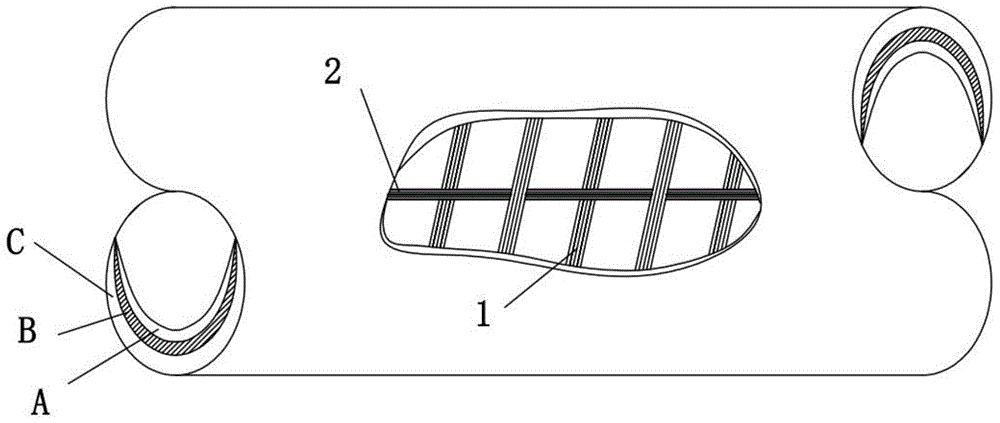

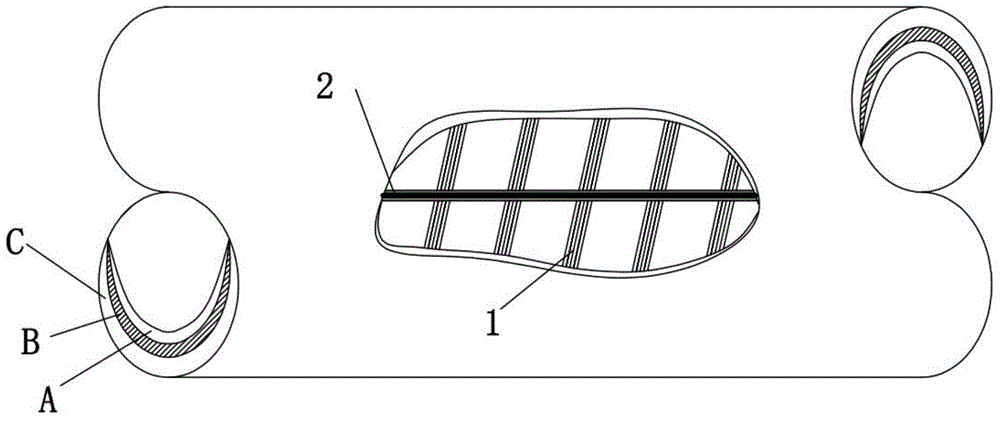

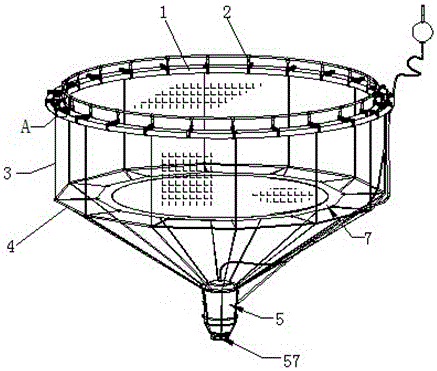

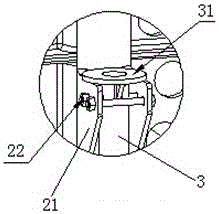

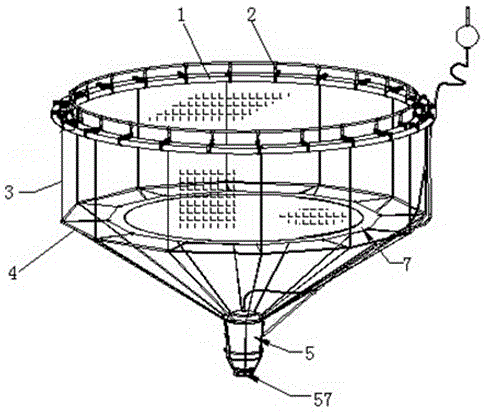

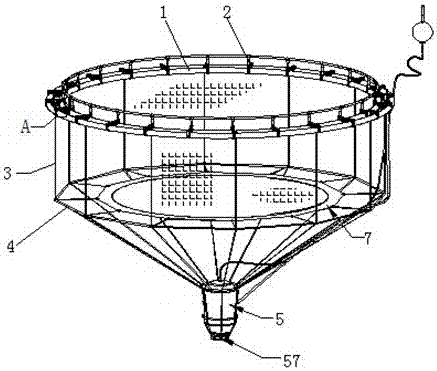

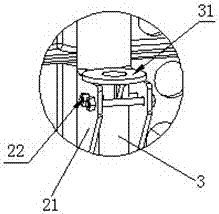

Lift-type aquaculture net cage

ActiveCN105028270ASimple structureSimple and reliable operation control systemClimate change adaptationPisciculture and aquariaEngineeringPipe support

The invention belongs to the technical field of aquaculture net cages, in particular to a lift-type aquaculture net cage. The lift-type aquaculture net cage comprises two floating pipes (1) and a floating pipe support (2); the floating pipes (1) are connected together through the floating pipe support (2). The lift-type aquaculture net cage is characterized by also comprising a plurality of vertical rigid hanging beams (3), a plurality of horizontal rigid hanging beams (4) and a gravity regulating device (5); the top ends of the vertical rigid hanging beams (3) are connected onto the floating pipe support (2), and the bottom ends of the adjacent vertical rigid hanging beams (3) are respectively connected with two ends of the corresponding horizontal rigid hanging beam (4); the gravity regulating device (5) is connected with the bottom ends of the vertical rigid hanging beams (3) through underframe nylon mooring ropes (6). The lift-type aquaculture net cage provided by the invention has the advantages that the structure is simpler, the operation control system is simpler and more reliable, netting is low in deformation; lift is safe and reliable by anti-swing cloth, and the function of the net cage is more complete and humanized.

Owner:广东联塑农业设施科技有限公司

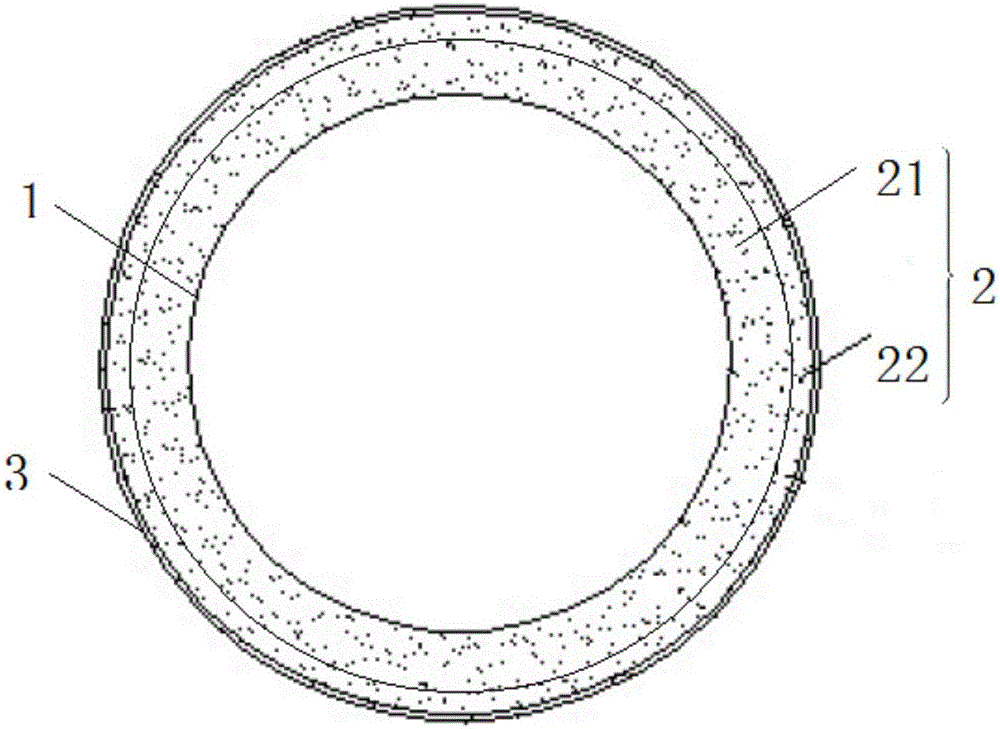

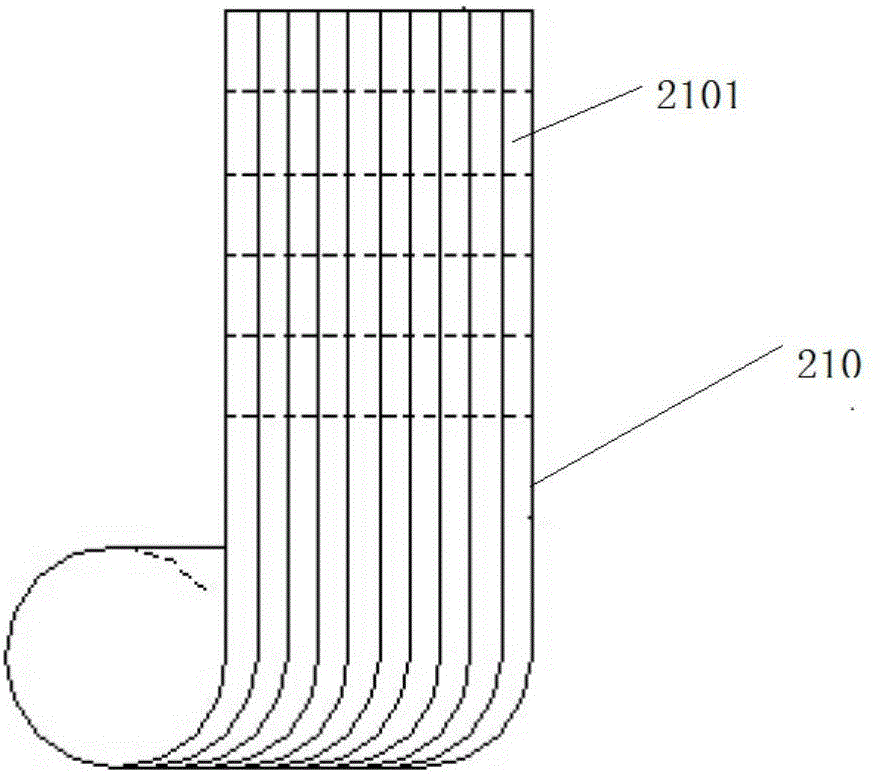

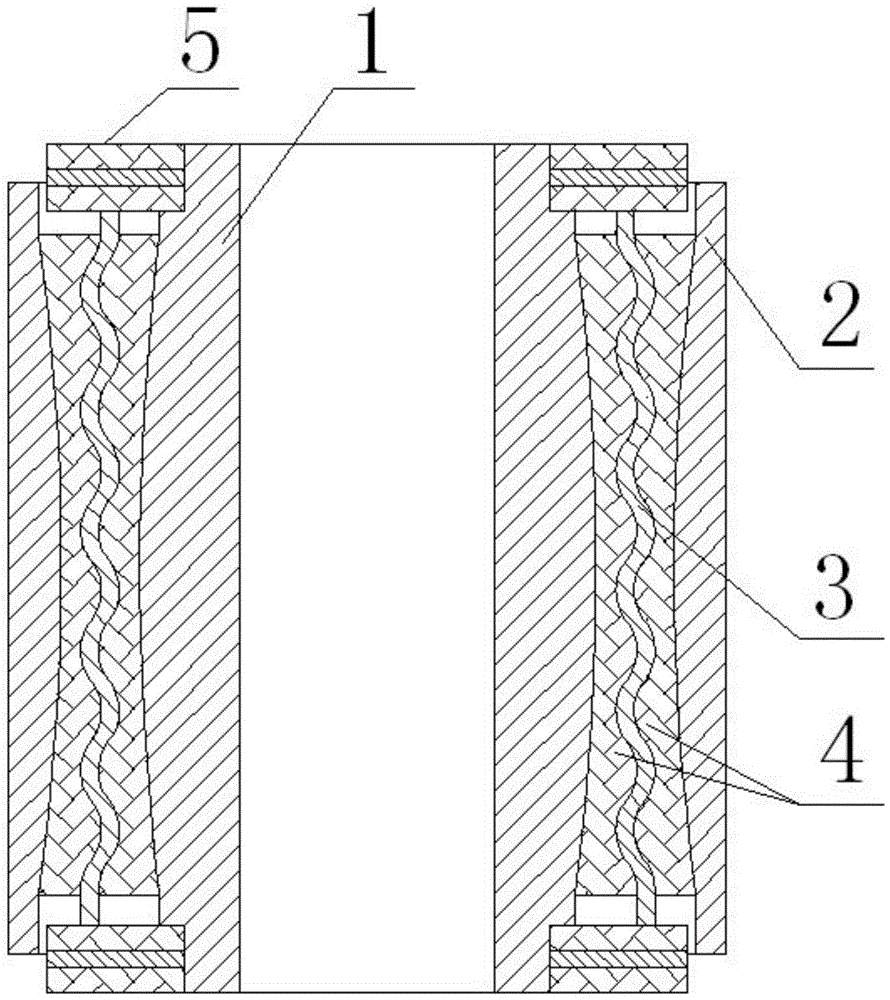

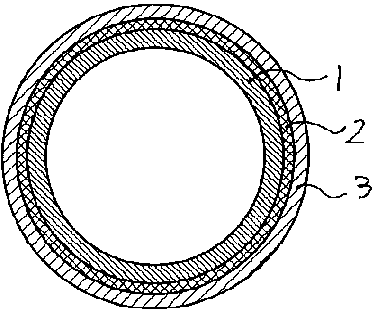

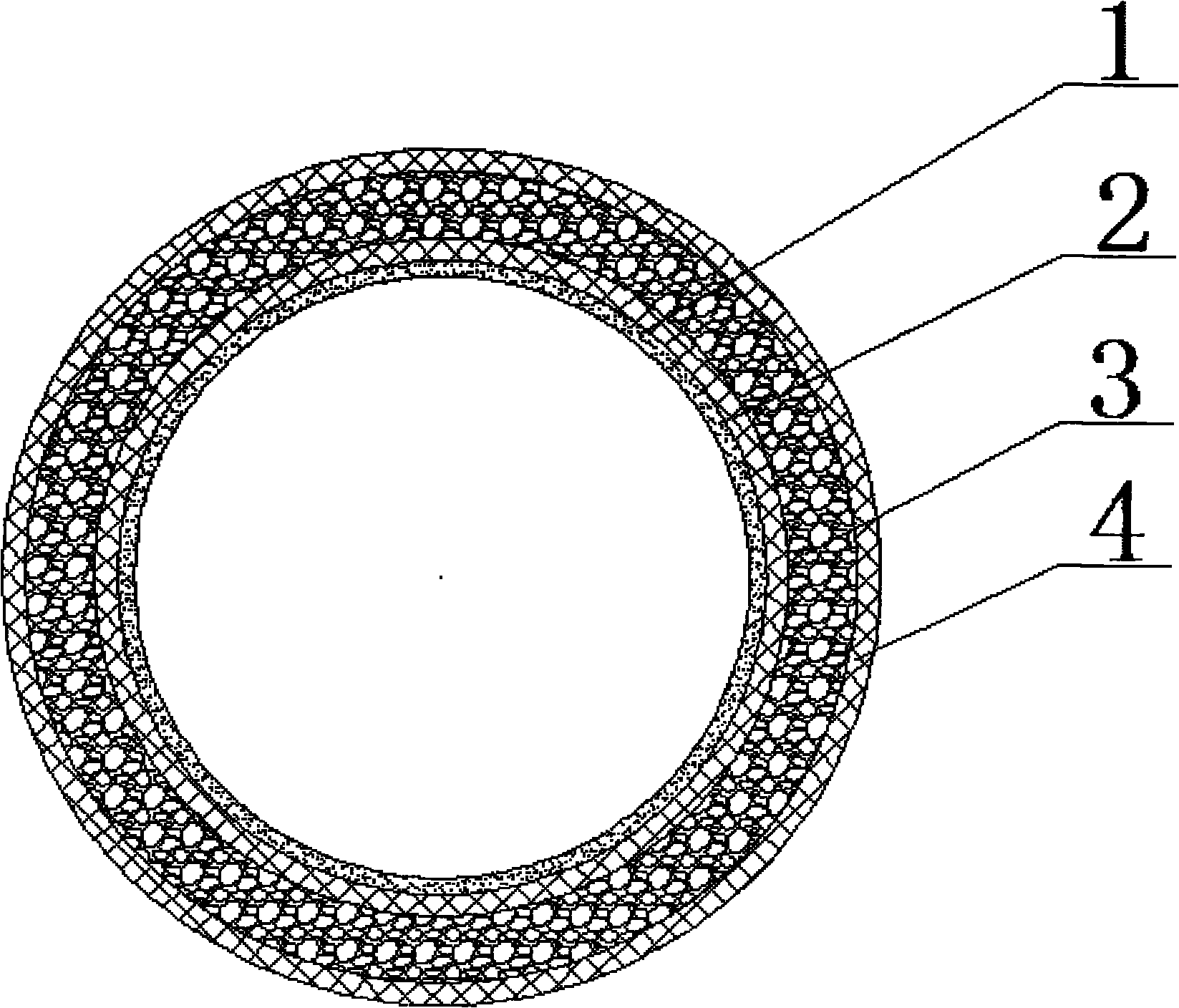

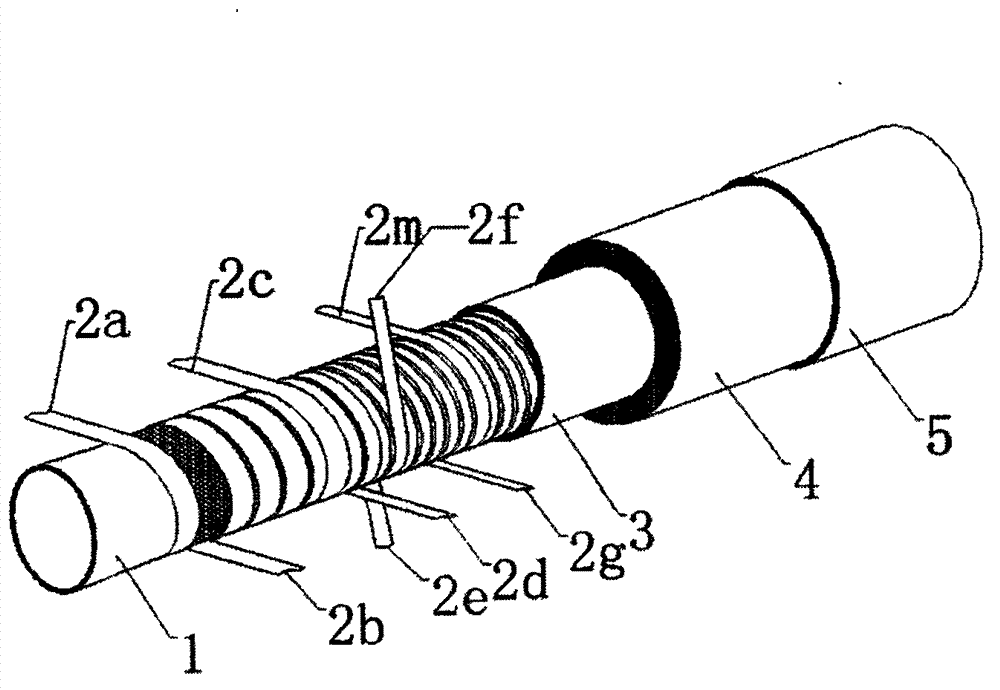

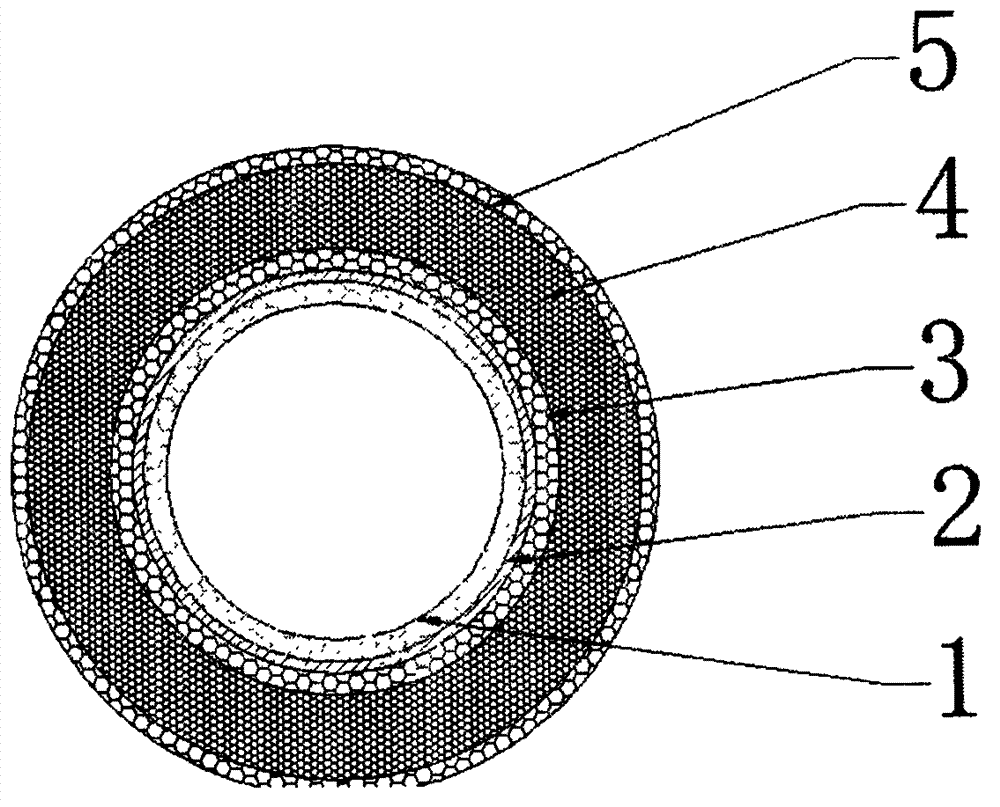

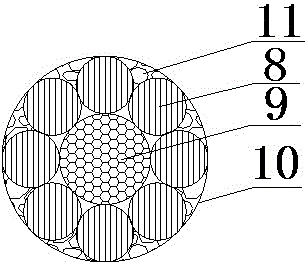

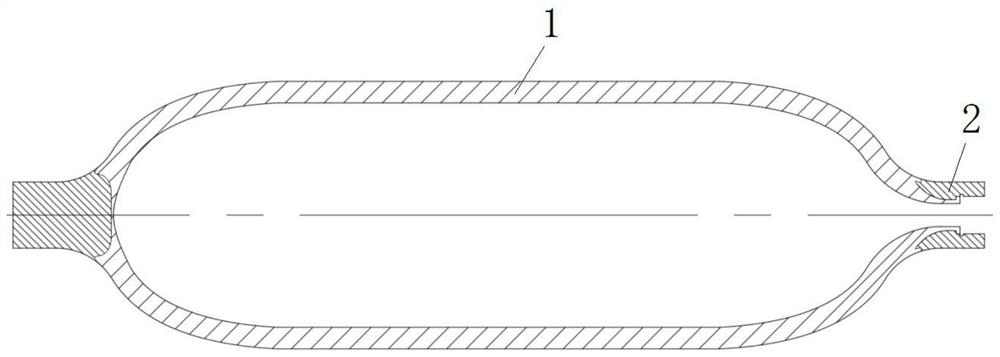

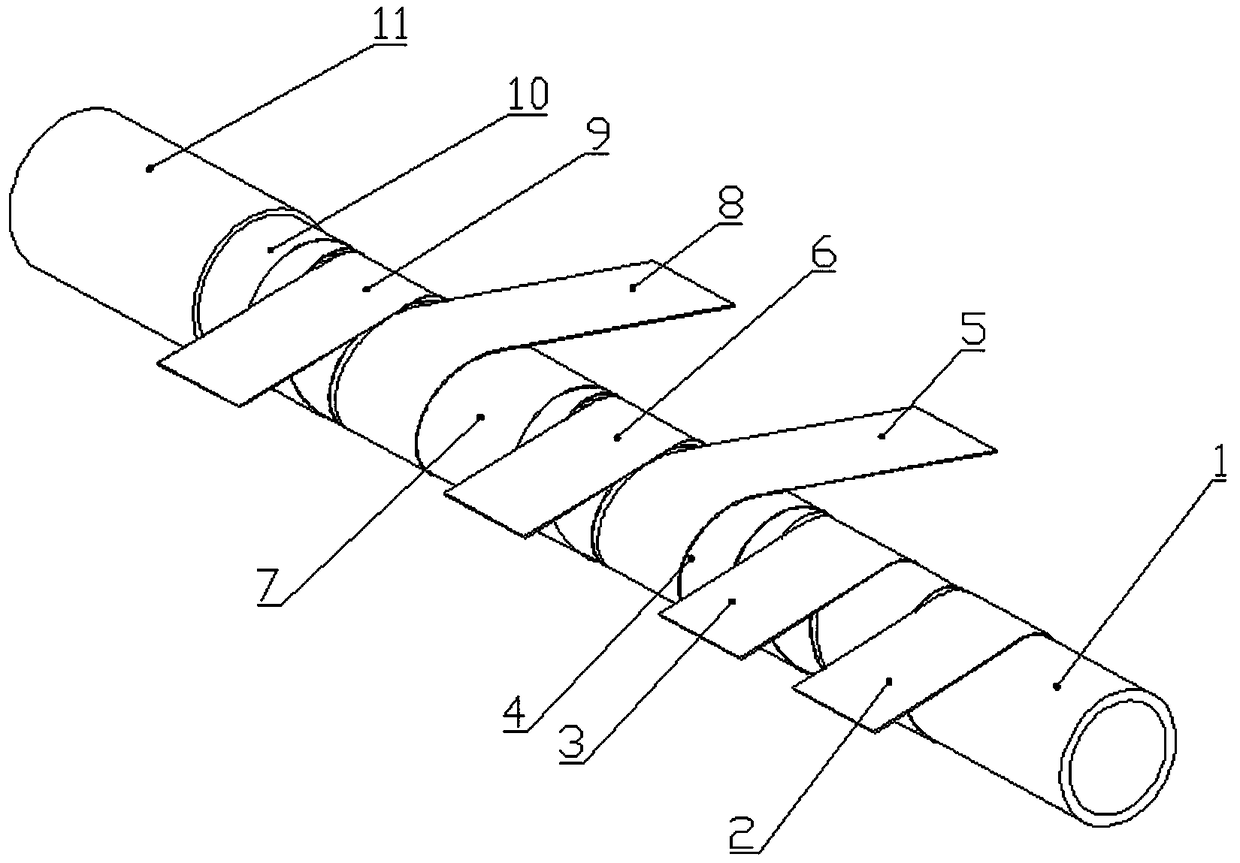

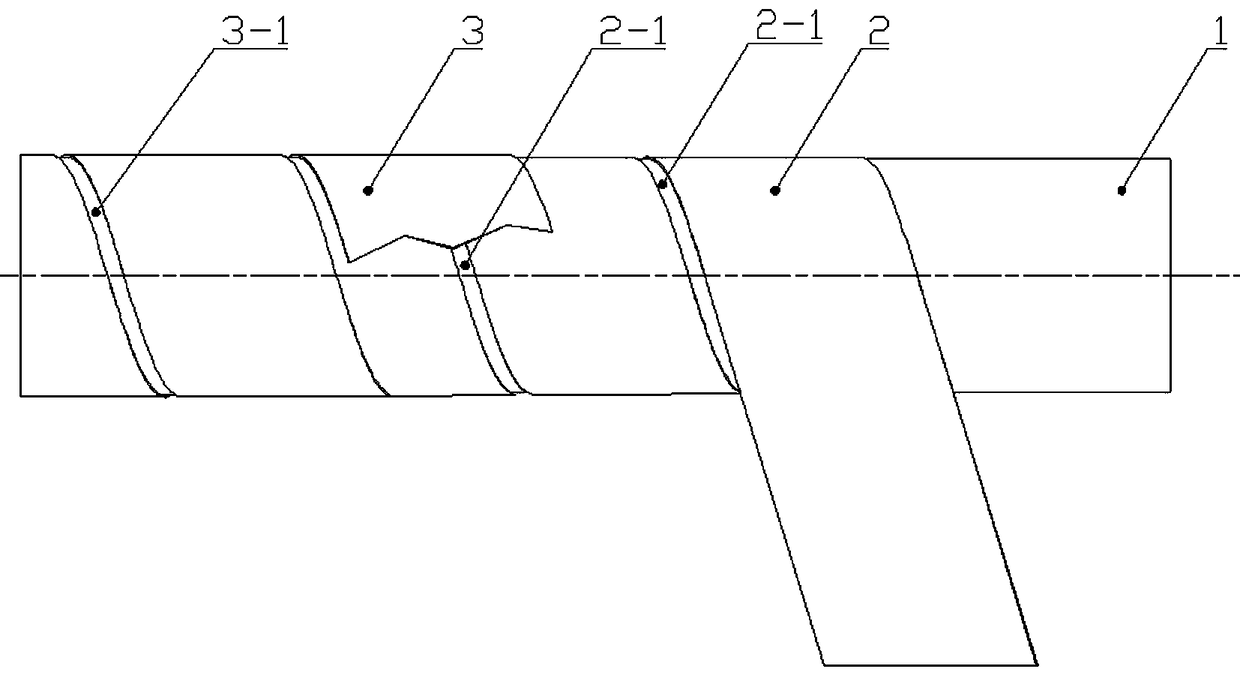

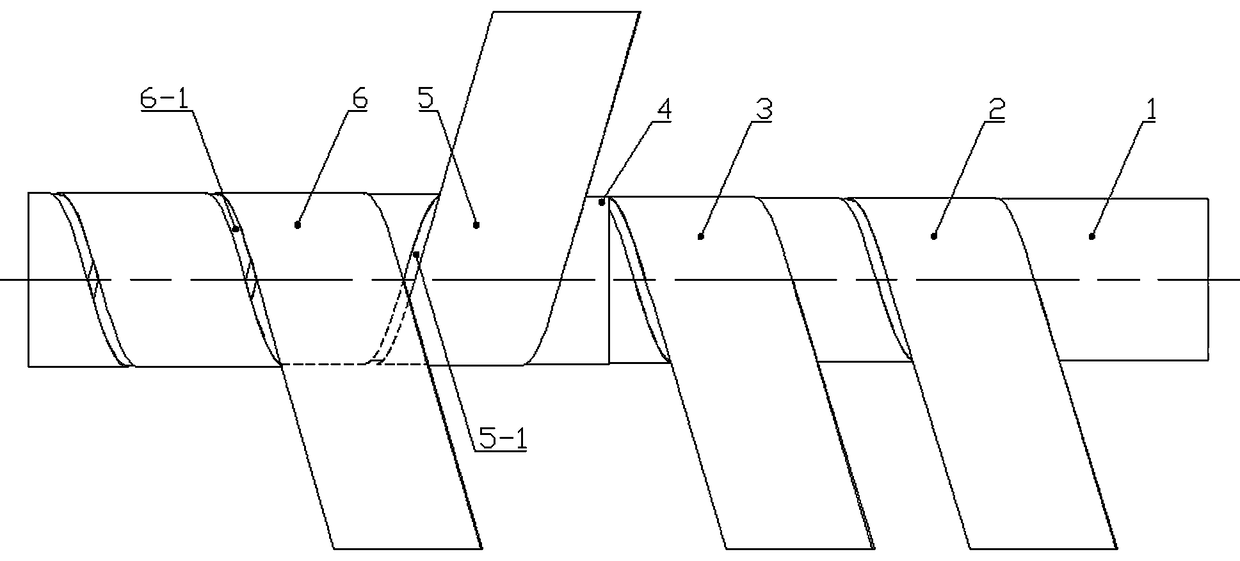

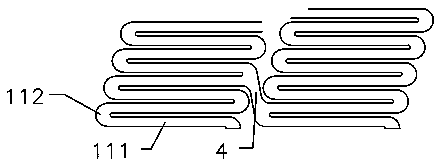

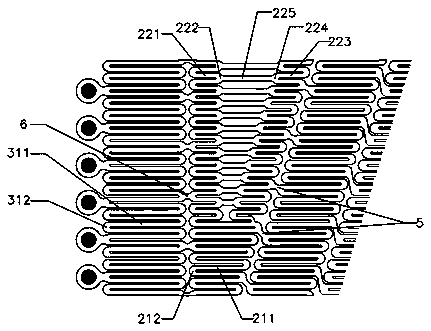

Continuously reinforced composite tube winded by glass fiber resin band and preparation method

InactiveCN102788199AHigh strengthImprove axial strengthThermal insulationPipe protection by thermal insulationGlass fiberChemical composition

The invention provides a continuously reinforced composite tube winded by a glass fiber resin band and a preparation method. The continuously reinforced composite tube winded by the glass fiber resin band comprises an inner tube 1, a glass fiber resin band spiral reinforced layer 2, a coating layer 3, an improved closed cell thin film layer 4 and an outer tube 5 from inside to outside sequentially. The glass fiber resin band spiral reinforced layer 2 is of more than one glass fiber resin band winding layers. Different angles are formed between axial directions of each of the resin bands and the inner tube 1. Gaps are reserved between bands of each glass fiber resin band. The invention further discloses a method for preparing the continuously reinforced composite tube. According to the invention, the circumferential strength and axial strength of the tube are increased by high strength of glass fiber. The glass fiber resin band is thin and the chemical components have good corrosion resisting effects. The manufacturing process is simple and convenient, so that the weight of the tube body is greatly reduced, the corrosion problem can be effectively solved, and the weight of the tube body is reduced.

Owner:长春高祥特种管道有限公司

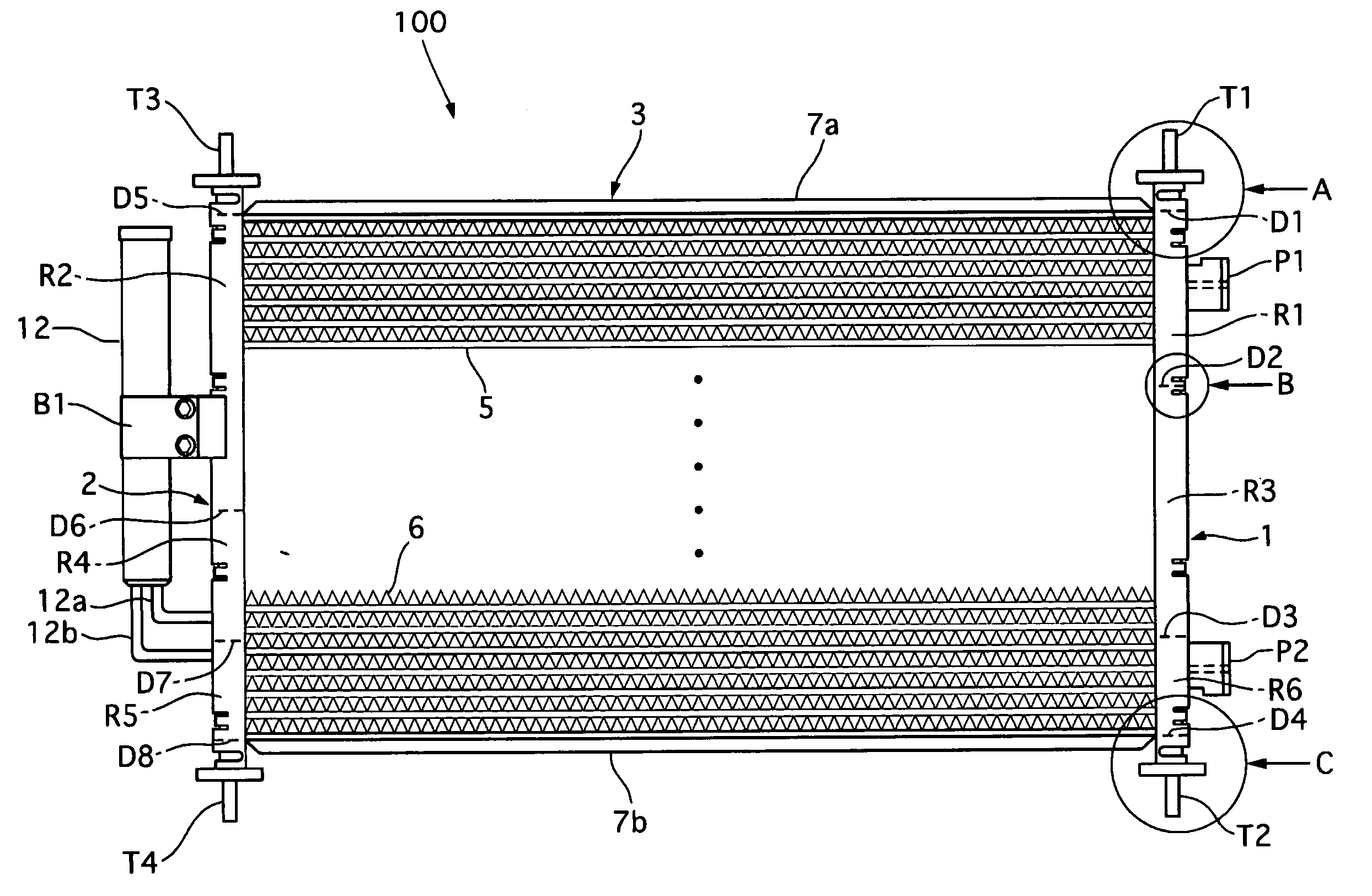

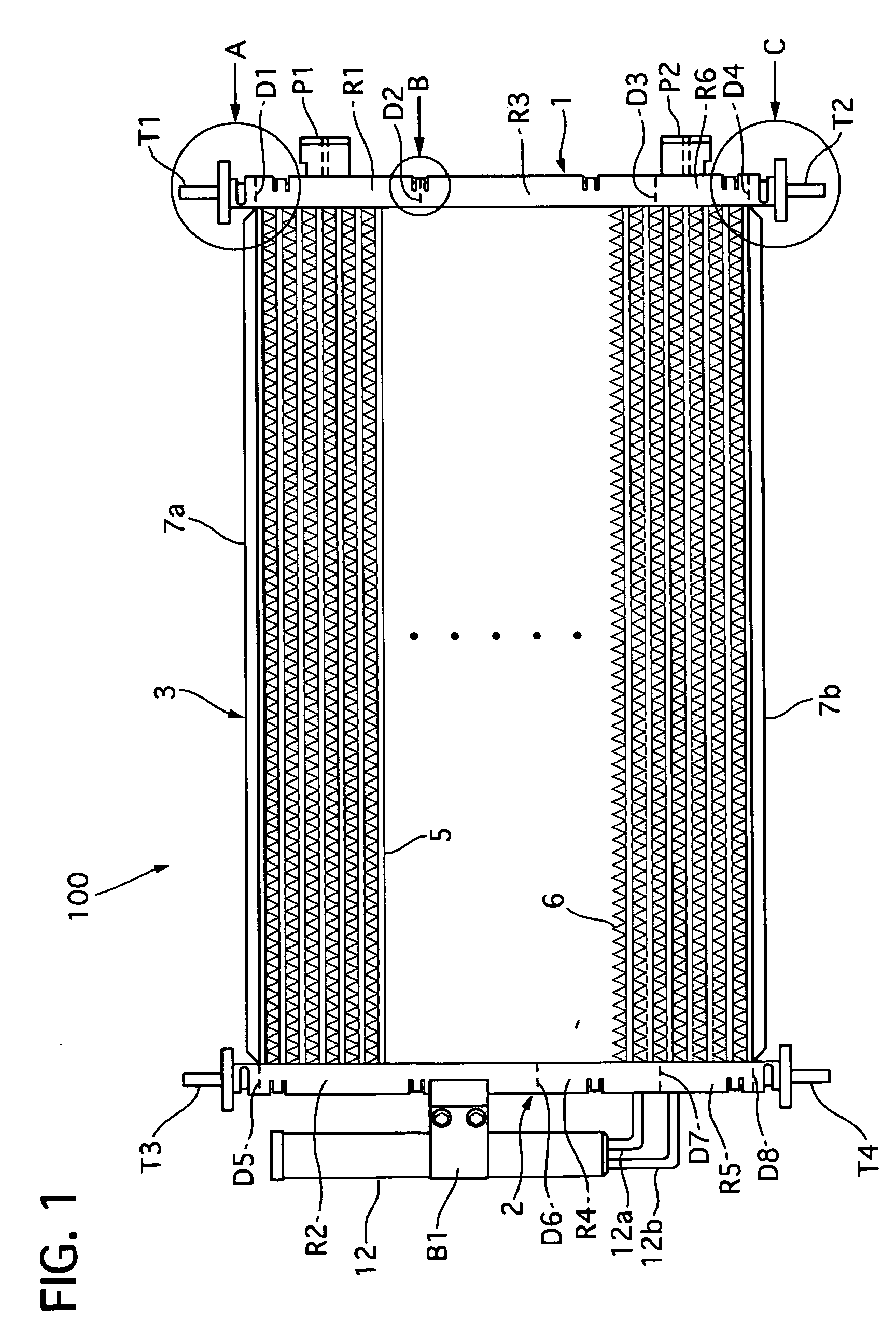

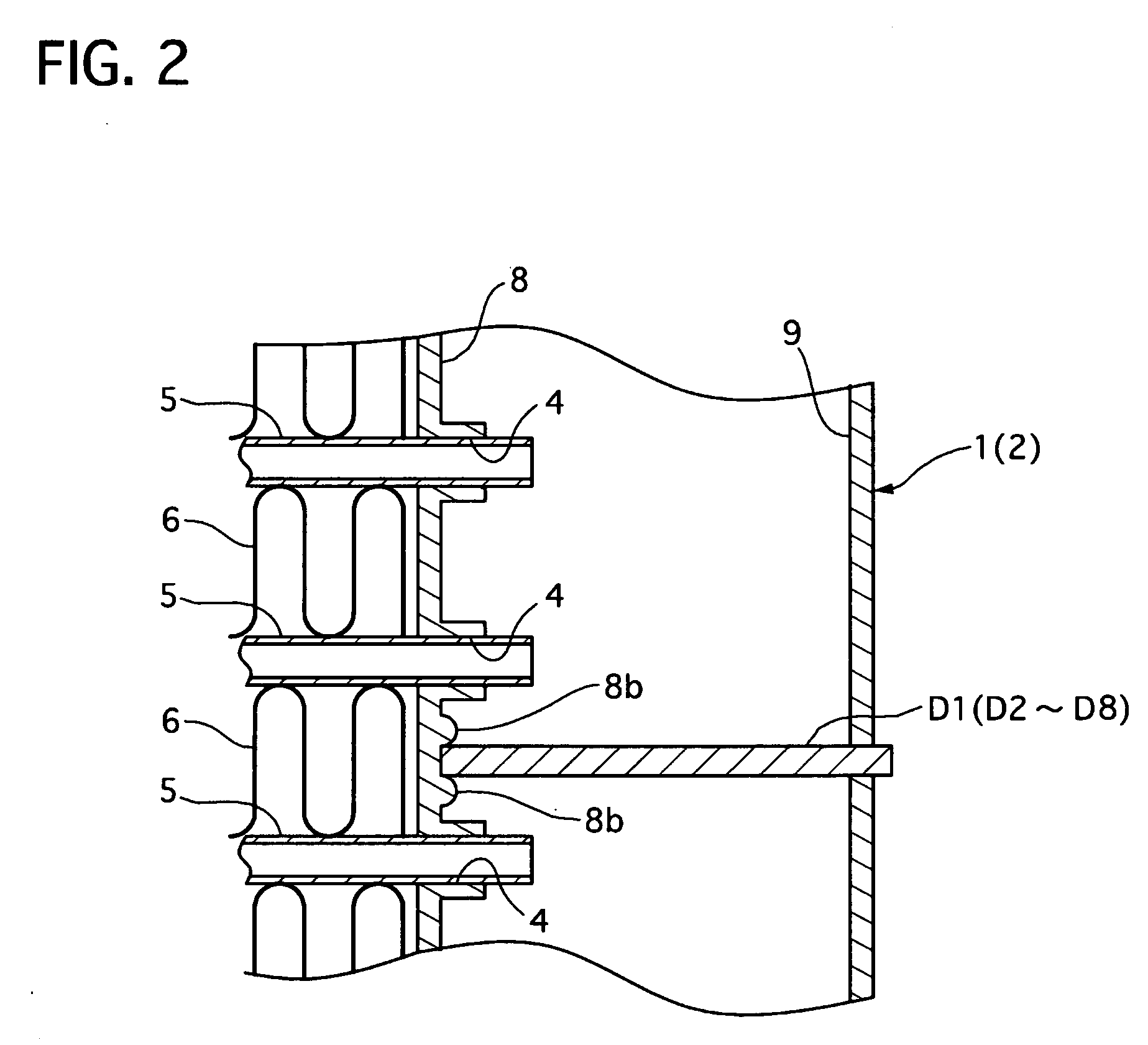

Condenser

InactiveUS20070062215A1Avoid stress concentrationImprove axial strengthEvaporators/condensersMetal-working apparatusElectrical and Electronics engineering

A condenser includes a pair of tanks, at least one of the tanks having a communicating hole, a condenser core arranged between the tanks and having fins and tubes fluidically connected with the tanks, and a connector having a connecting hole. A peripheral portion of the communicating hole is pressed into the connecting hole to form a burring portion which is caulked on an inner face forming the connecting hole so that the connector and the tank are temporarily fixed with each other, and facing portions of the tank and the connector are integrally fixed with each other by blazing. The inner surface of the connecting hole is provided with a holding groove to receive an inserted projecting portion formed on a part of an outer surface of the burring portion for holding the connector to the tank.

Owner:CALSONIC KANSEI CORP

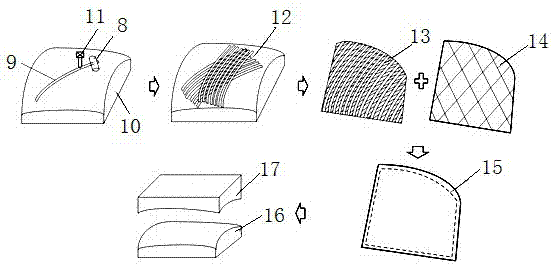

Forming method for composite blade of aircraft engine

The invention discloses a forming method for a composite blade of an aircraft engine. The forming method includes the following steps that carbon fiber bundles are unfolded, the unfolded carbon fiber bundles are soaked with thermoplastic resin slurry, and intermediate bundles are obtained; the intermediate bundles are dried; the intermediate bundles are heated in an ultrasonic vibration heating mode, the heated intermediate bundles are laid layer by layer in a dry laying mode, and a blade preform is formed after laying; the blade preform is sleeved with a carbon fiber fabric sleeve, and the carbon fiber fabric sleeve and the internal blade preform are subjected to edge sewing through a three-dimensional sewing method; and the sewn blade preform and carbon fiber fabric sleeve are put into an RTM mold and are subjected to mold closing and curing molding through the RTM technology, and the composite blade is obtained. According to the forming method, the proportion and accurate positioning of axial fibers are guaranteed, and thus the integrality and impact resistance of the composite blade are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

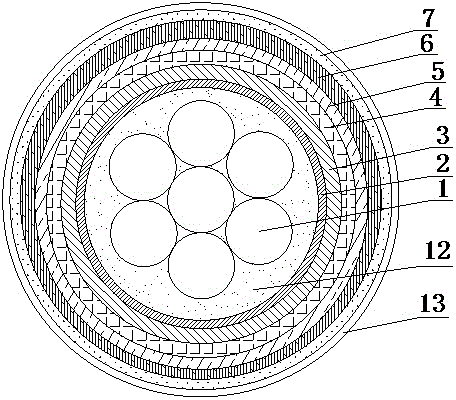

Moistureproof underground cable protection device

ActiveCN106057327AAvoid corrosion damageImprove water resistanceInsulated cablesAnti-corrosive paintsFiberCarbon fibers

The invention provides a moistureproof underground cable protection device, and belongs to the technical field of a cable. The device comprises a moistureproof underground cable and a protection sleeve. The moistureproof underground cable comprises a cable body. The cable body comprises conduction cores, an insulation layer I, a lining layer, a first waterproof layer, a metal sheath, a second waterproof layer and a jacket layer, from the inside to the outside. There are multiple conduction cores. An insulation layer II is wrapped out of the conduction cores. Cross-linking polyolefin is filled among the conduction cores. Carbon fibers are doped in the cross-linking polyolefin. The protection sleeve is sleeved out of the moistureproof underground cable. The protection sleeve comprises a protection sleeve body. The shape of the protection sleeve body matches the shape of the moistureproof underground cable. The inner surface of the protection sleeve body is a structure that concave surfaces and convex surfaces are alternated. An anticorrosive material is coated on the inner surface. According to the device, the structure of an existing underground cable protection device is improved and optimized; the comprehensive performance of the cable is improved; in particular, the corrosion resistance is remarkably improved; and the waterproof performance is excellent; and the stability is high.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Lifting-type cultivation net cage

ActiveCN105010189ASimple structureSimple and reliable operation control systemClimate change adaptationPisciculture and aquariaEngineeringSpherical form

The invention belongs to the technical field of cultivation net cages, and more specifically relates to a lifting-type cultivation net cage. The net cage comprises two floating tubes and a floating tube support. The floating tubes are connected together through the floating tube support. The net cage is characterized in that the net cage comprises a plurality of vertical grid suspension beams, a plurality of horizontal rigid cross beams, and a gravity adjustment device. The tops of the vertical grid suspension beams are provided with a spherical or semispherical suspension block, and the floating tube support is provided with installation holes. The bottom of the installation hole is an arc-shaped surface which is matched with the spherical or semispherical suspension block. The vertical grid suspension beams pass through installation holes. The bottoms of the adjacent vertical grid suspension beams are respectively connected with two ends of the horizontal rigid cross beams. The gravity adjustment device is connected with the bottoms of the vertical grid suspension beams through bottom frame nylon mooring ropes. The net cage is simpler in structure, is simpler and more reliable in operation control system, is small in net deformation, is resistant to cloth swinging, enables the lifting to be safe and reliable, and is more complete and humanized in cage functions.

Owner:广东联塑农业设施科技有限公司

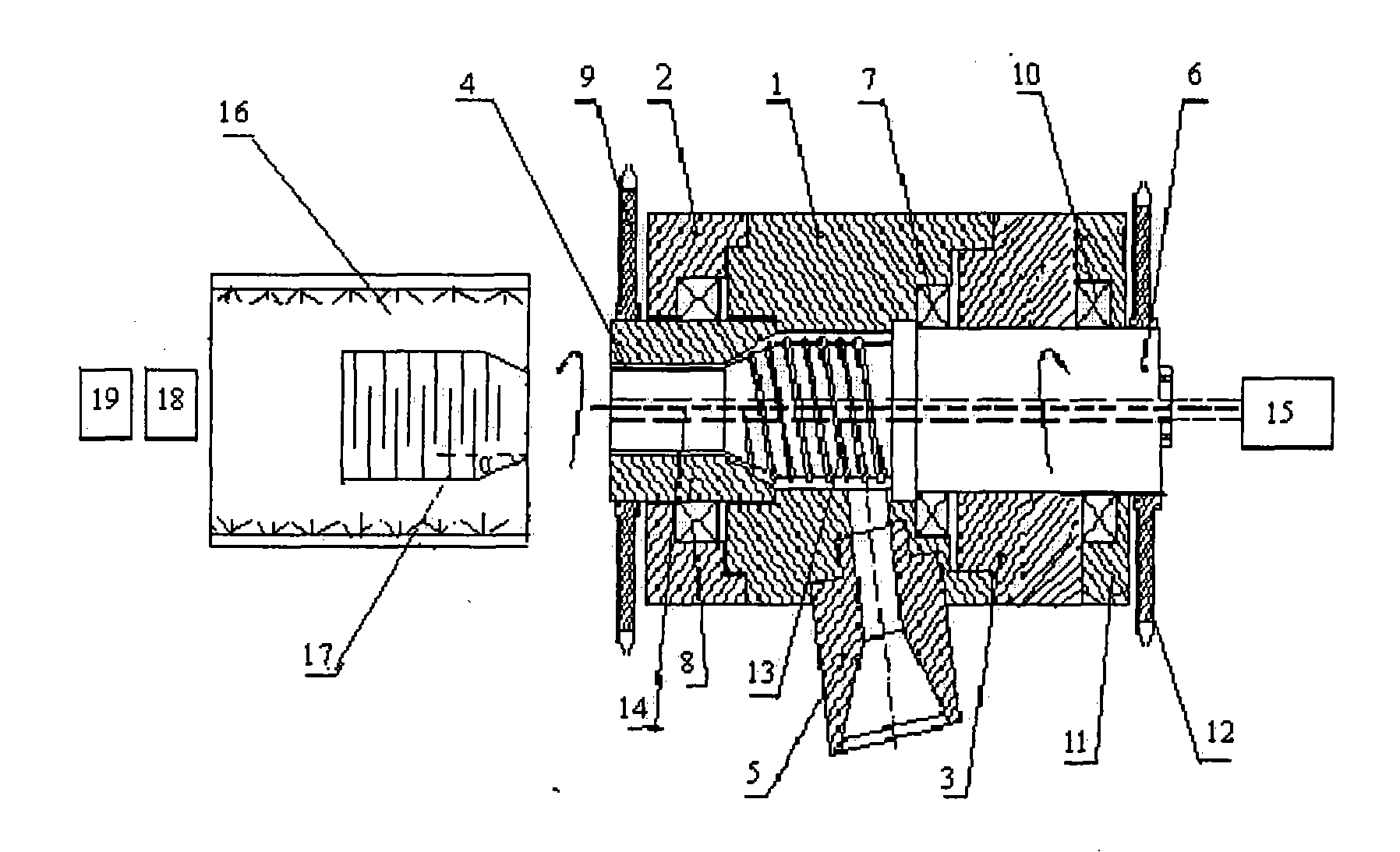

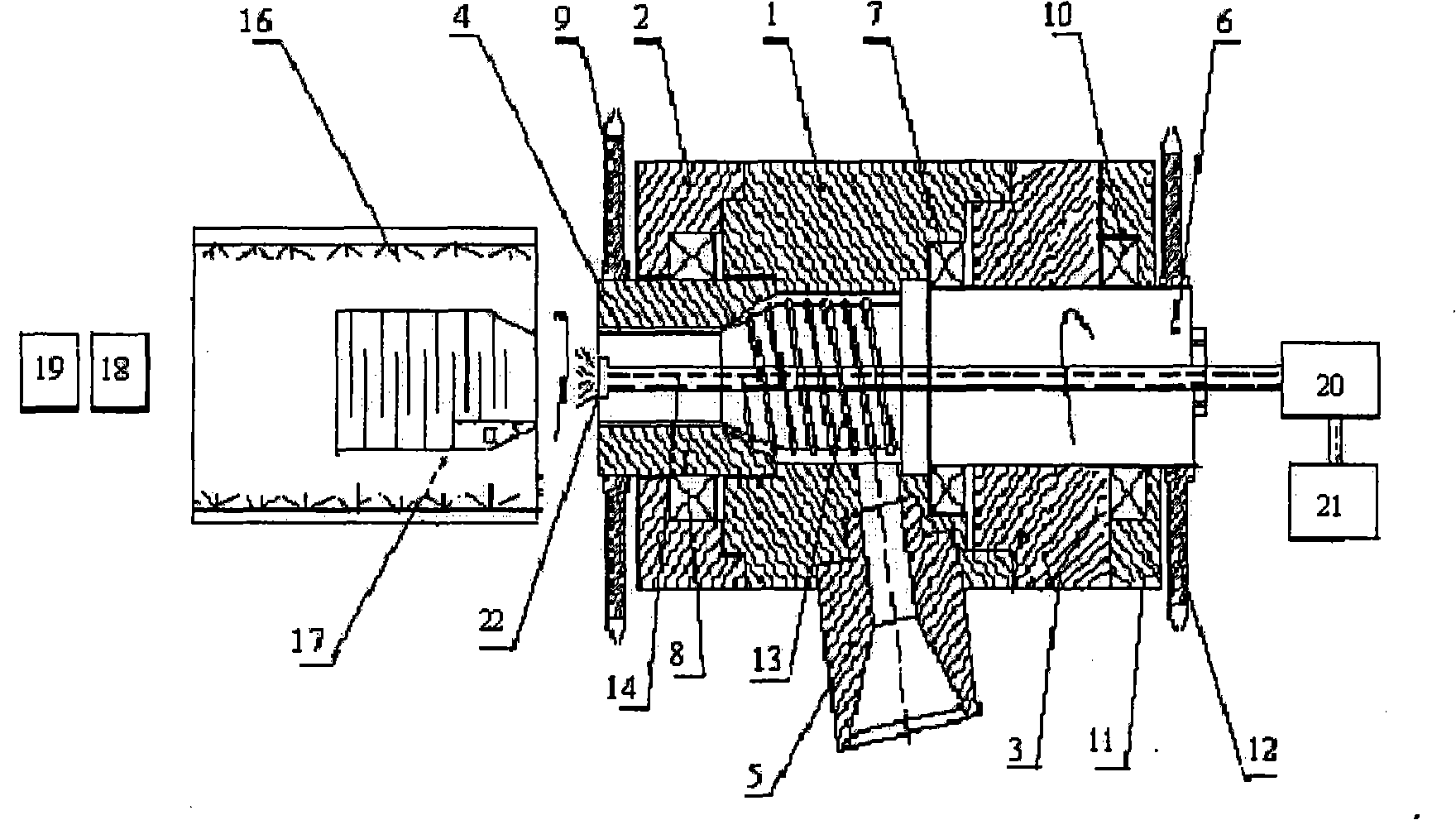

Preparation method and device of high performance polymers pipes

The invention discloses a method for preparing a high-performance polymer pipe. The method adopts the steps that during the extrusion molding process of the pipe, the crystallization, the orientation or the dispersed phase morphological structure of the polymer pipe can be adjusted, controlled and fixed through the shearing action generated by the rotation of a core rod in a machine head relativeto an orifice die, or the rotation of the orifice die in the machine head relative to the core rod, or the rotation of the core rod and the orifice die in the identical or opposite direction simultaneously, and by cooling and shaping the inner wall and the outer wall of the extruded pipe simultaneously, and adjusting and controlling the temperature field, the cooling rate and the temperature gradient during the extrusion molding process of the pipe. The invention further discloses a device designed according to the method. The method has the advantages that the macromolecular orientation, thecrystallization or the dispersed phase morphological structure which are generated through induction can be retained in the plastic pipe, so that deorientation can be avoided, the internal stress of the pipe can be reduced, and the performance of the pipe is improved.

Owner:SICHUAN UNIV

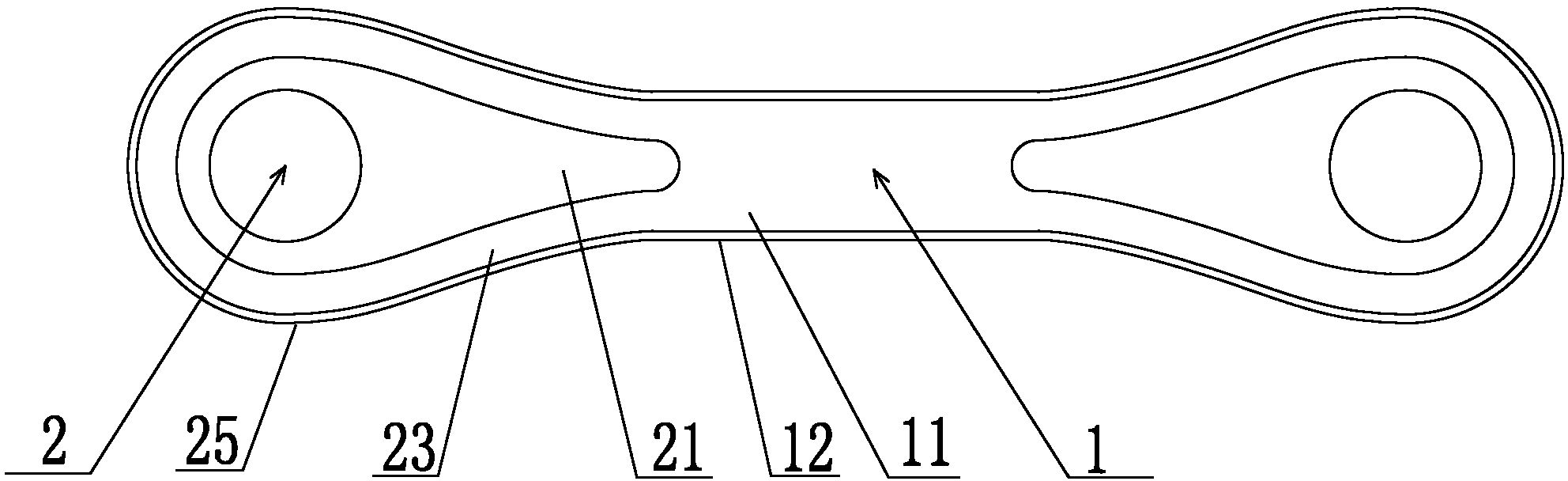

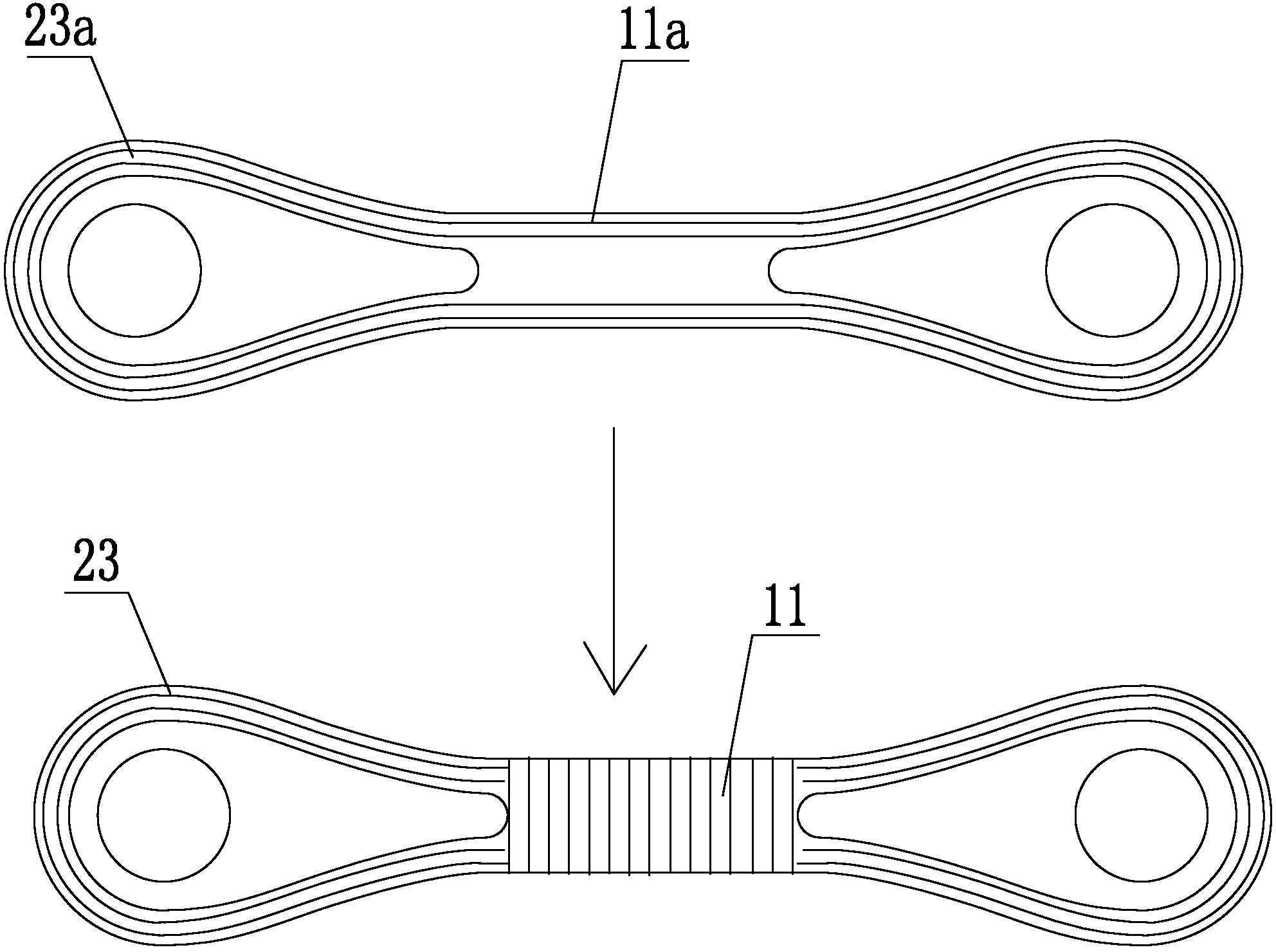

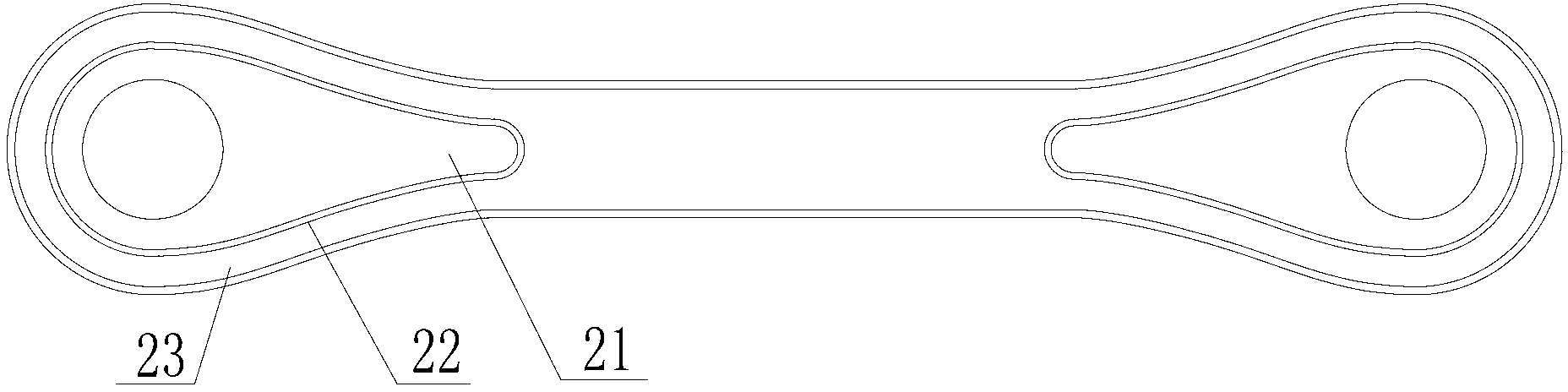

Tension member and preparation method and engineering machinery thereof

InactiveCN102837453AReduce weightHigh tensile strengthConnecting rodsSynthetic resin layered productsTension memberUltimate tensile strength

The invention discloses a tension member and the preparation method and the engineering machinery of the tension member. The tension member comprises a middle part and connecting parts, wherein the middle part comprises a carbon fiber composite material body, the connecting parts are arranged at two ends of the middle part, and each connecting part comprises a core part and a carbon fiber carbon fiber layer covering the surface of the core part. The tension member is mainly made of carbon fiber composite materials. The carbon fiber composite materials have the advantages of being low in density, high in axial strength and modulus, and good in fatigue durability. Therefore, weight of the tension member is lowered, and tensile strength and load-carrying property of the tension member are improved at the same time. The tension member has the advantages of being light in weight, and convenient to detach, install and transport. When the tension member is applied to a crane, hoisting capacity of the crane in large radius working conditions can be guaranteed. Besides, the tension member is high in strength and modulus, and the load-carrying property of the tension member is higher than that of an existing steel wire rope or a steel plate or steel tube.

Owner:SANY HEAVY IND CO LTD (CN)

A lifting type breeding cage

ActiveCN105028270BSimple structureSimple and reliable operation control systemClimate change adaptationPisciculture and aquariaEngineeringPipe support

Owner:广东联塑农业设施科技有限公司

Fiber-reinforced thermal insulation board and preparation method thereof

InactiveCN107311604AImprove stress resistanceAvoid crackingCeramicwareThermal insulationCement slurry

The invention discloses a fiber-reinforced thermal insulation board and a preparation method thereof, and relates to the technical field of thermal insulation boards.The fiber-reinforced thermal insulation board is prepared from the following raw materials in parts by weight: 65 to 75 parts of modified magnesium oxysulfate cement slurry, 35 to 45 parts of desulfuration gypsum, 30 to 31 parts of modified expanded perlite, 29 to 30 parts of modified diatomite, 24 to 26 parts of fly ash, 24 to 26 parts of waste glass powder, 15 to 16 parts of auxiliary agents and 75 to 85 parts of water. The fiber-reinforced thermal insulation board has a better compressive property and is not easy to crack, the preparation method is simple and the cost is relatively low.

Owner:HEFEI HUAGAI PHOTOVOLTIAC TECH CO LTD

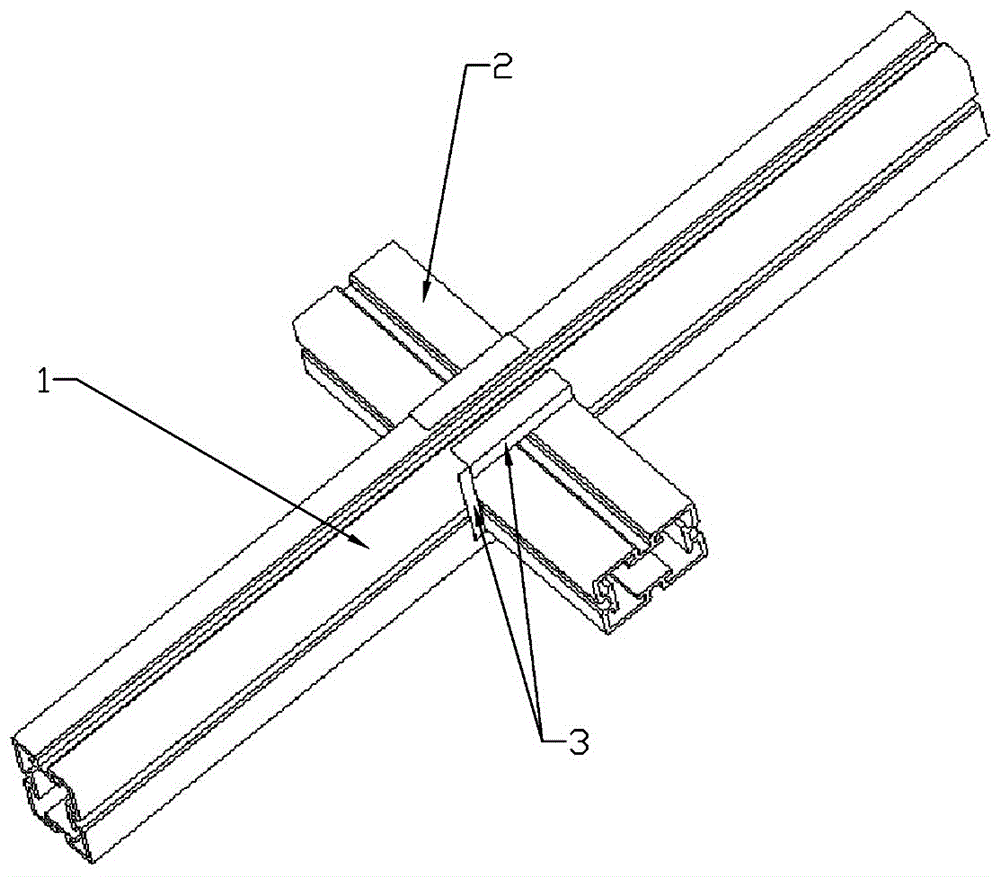

Carbon fiber reinforcement aluminum alloy mortise and tenon structure and preparation method thereof

The invention discloses a carbon fiber reinforcement aluminum alloy mortise and tenon structure which comprises a mortise piece and a tenon piece, wherein the mortise piece is provided with a mortise; a tenon connection part of the tenon piece is inserted into the mortise; at least one inner surface of the mortise is coated with carbon fiber composite cloth; and the tenon connection part is in interference fit with the mortise coated with the carbon fiber composite cloth. The carbon fiber is high in axial strength and module, low in density, high in specific performance, good in fatigue resistance, low in thermal expansion coefficient and good in corrosion resistance, has no creep deformation, has superhigh temperature resistance at the non-oxidizing environment and has anisotropism, and the specific heat and conductivity of the carbon fiber is between the specific heat and conductivity of nonmetal and the specific heat and conductivity of metal. With the utilization of the carbon fiber composite cloth to reinforce the mortise and tenon structure, a tenon pulling phenomenon of the mortise and tenon structure can be retarded effectively. The carbon fiber reinforcement aluminum alloy mortise and tenon structure has the characteristics of high strength and rigidity, reduction in energy consumption ability, and the like, and can be widely applied to the fields of automotive industry, sports equipment, fire protection, and the like.

Owner:SUN YAT SEN UNIV

Method for preparing steel lining washing rollers

The invention provides a method for preparing steel lining washing rollers, which includes the following steps: firstly preparing a steel lining roller; then winding the steel lining roller with a carbon fiber layer, wherein during the winding process, frictioning is performed manually while winding to increase the content of carbon fiber; placing the steel lining roller wound with the carbon fiber layer in a curing box for heating and curing; performing the skim coating on the roller surface subjected to curing; finally preparing the finished steel lining composite carbon fiber washing roller. The finished steel lining composite carbon fiber washing roller prepared through adopting the method provided by the invention has the advantages of light weight, antifatigue, excellent rigidity, corrosion resistance and long service life.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

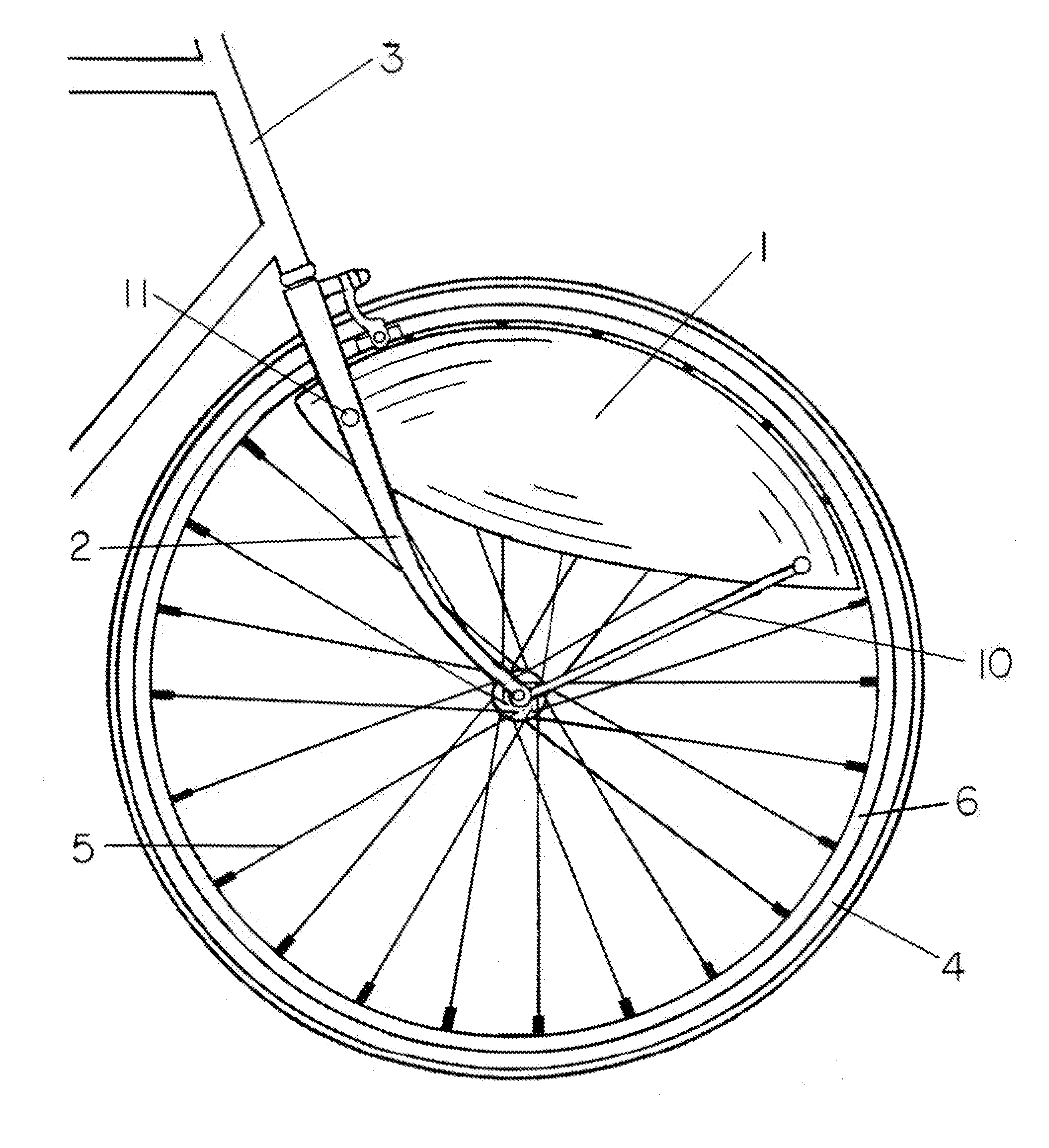

METHOD and APPARATUS for MINIMIZING DRAG-INDUCED FORCES on a WHEELED VEHICLE

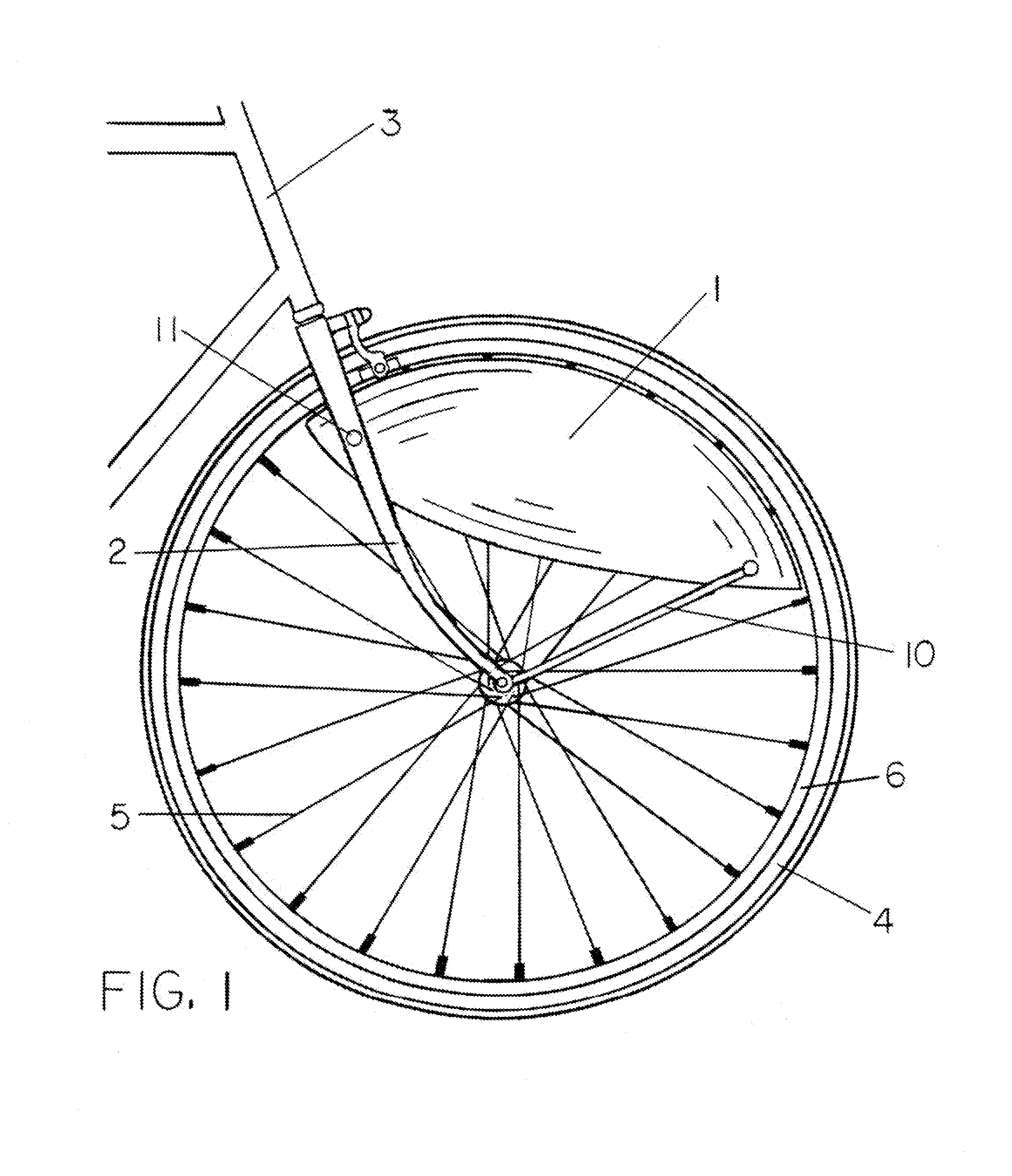

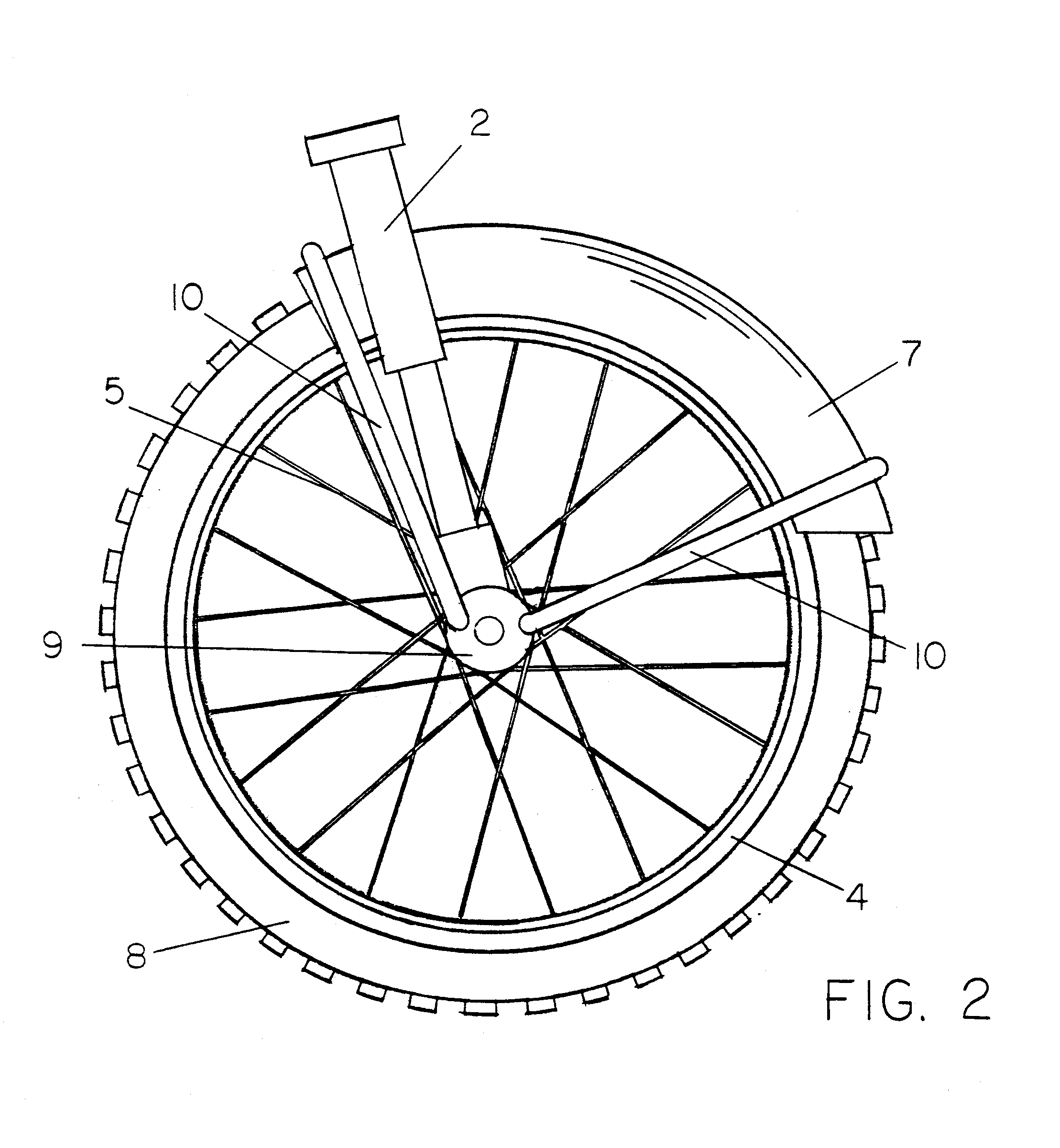

ActiveUS20140265431A1Reduce resistanceImprove rolling resistanceVehicle seatsVehicle body stabilisationGround contactDrag torque

An aerodynamically optimized drag-reduction means and method for optimal minimization of the drag-induced resistive forces upon a terrestrial vehicle wheel, where the drag-induced resistive moments on wheel surfaces pivoting about the point of ground contact are reduced, and the vehicle propulsive forces needed to countervail the resistive forces on the wheel are reduced. The drag reduction means includes: a streamlined wheel cover positioned on a vehicle to shield the faster moving upper wheel surfaces from headwinds; a streamlined wind-deflecting fairing positioned on a vehicle to shield the faster moving upper wheel surfaces from headwinds; an engine exhaust pipe diposed on a vehicle whereby exhaust gases deflect headwinds to shield the faster moving upper wheel surfaces of an automotive wheel; an automotive spoked wheel having streamlined oval-shaped wheel spokes arranged in one or more rows for greater axial strength; a streamlined tailfin rotatably attached to a wheel spoke, which thereby may pivot about the spoke in response to varying crosswinds; and a tire having streamlined tread blocks arranged in an aerodynamic pattern.

Owner:MAGEE GARTH L

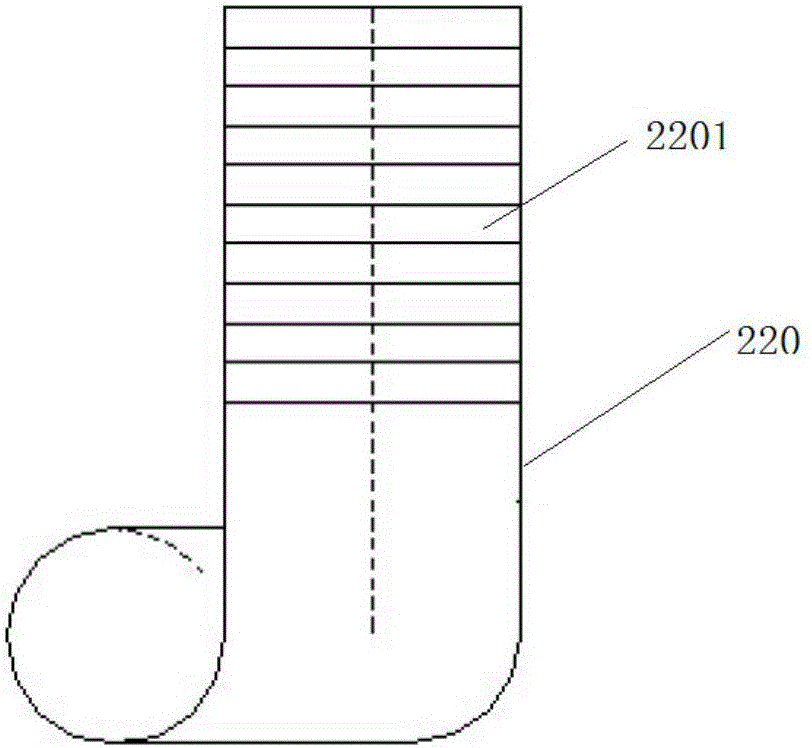

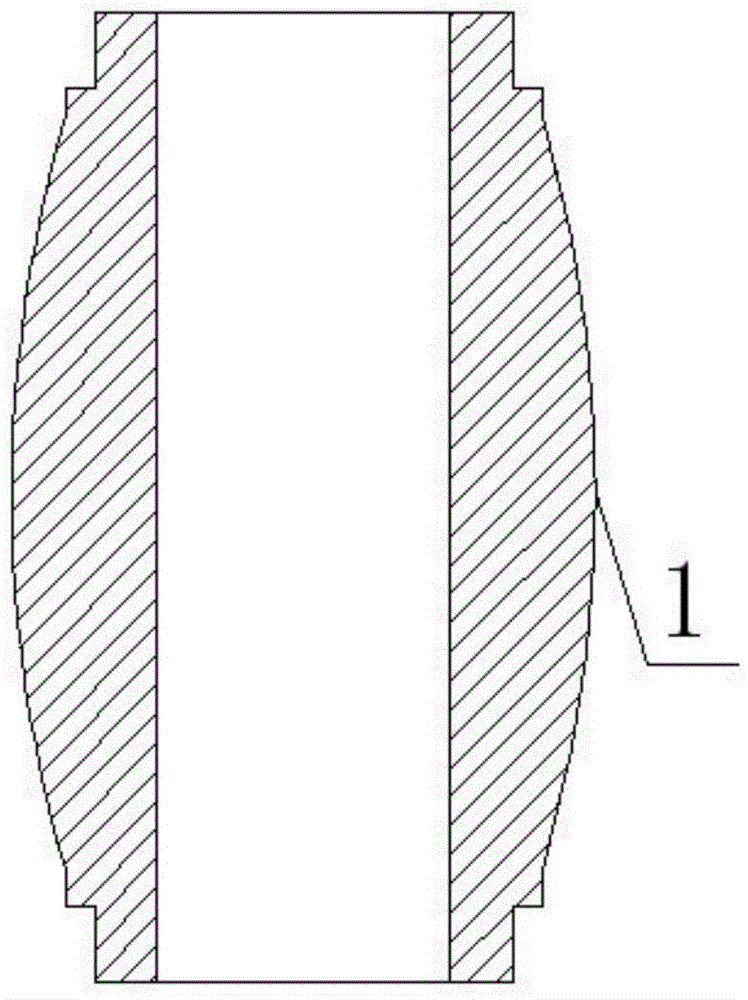

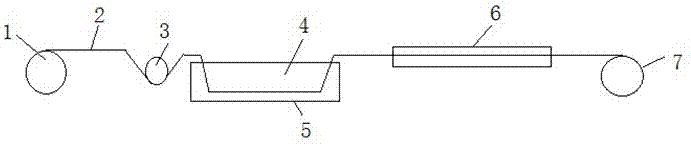

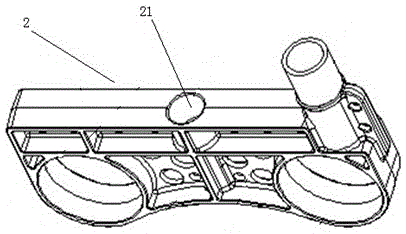

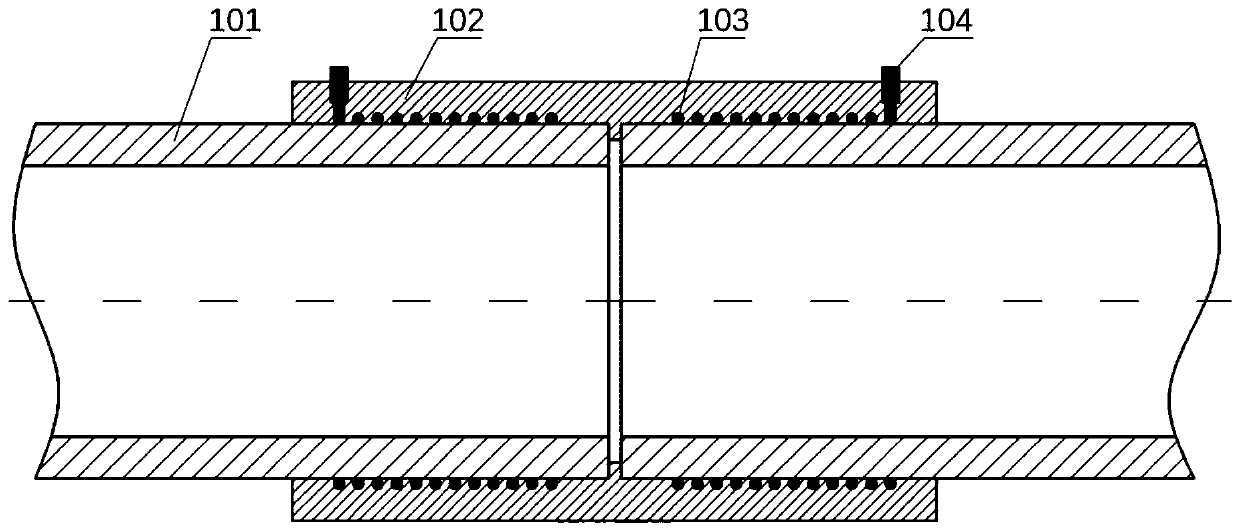

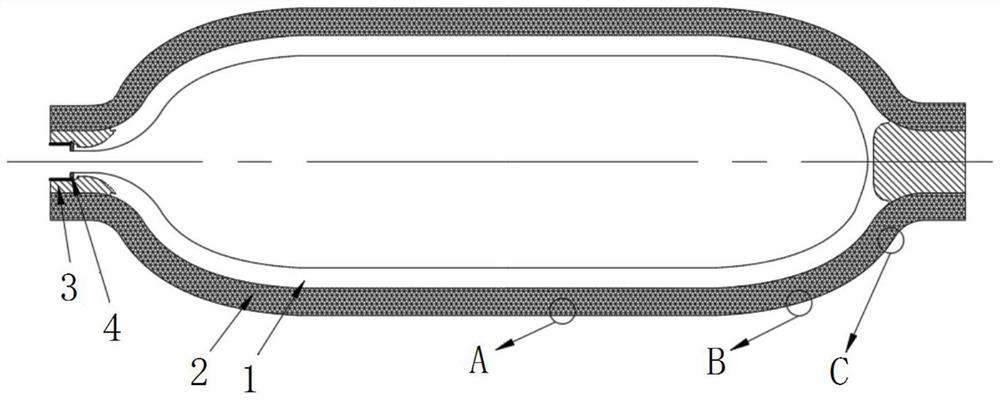

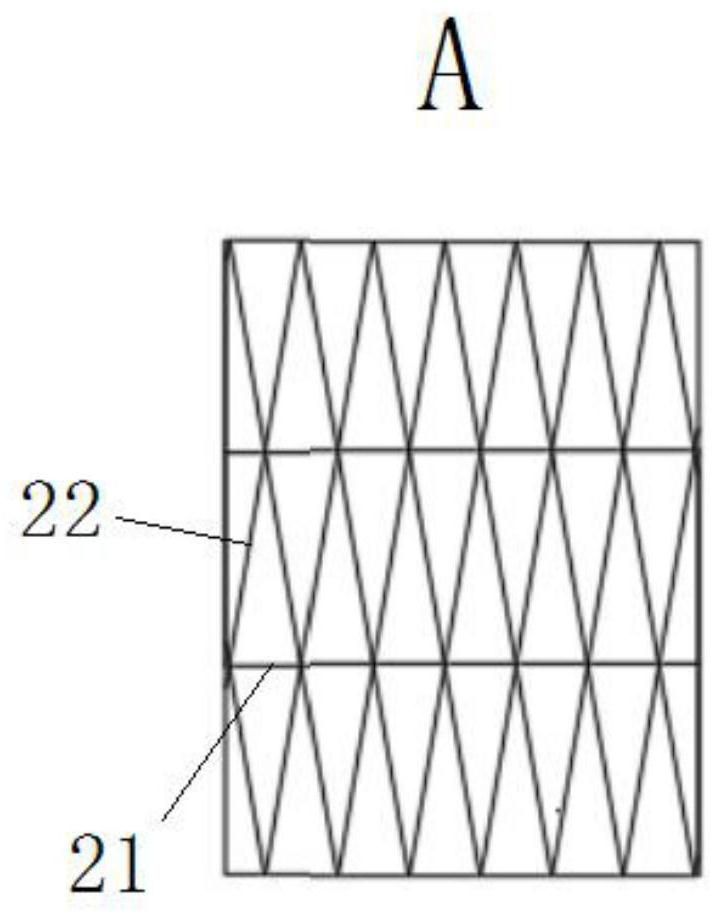

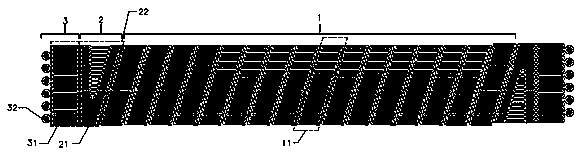

Short fiber reinforced plastic electric melting pipe with optimized injection position and injection mold thereof

ActiveCN111089212AIncreased degree of axial orientationImprove axial strengthPipe connection arrangementsThermoplasticPolymer science

The invention relates to the field of thermoplastic electric melting pipes, and aims to provide a short fiber reinforced plastic electric melting pipe with an optimized injection position and an injection mold thereof. The pipe comprises an electric melting pipe body embedded with a resistance wire, wherein two binding posts which are respectively connected to the two ends of the resistance wire are arranged on the electric melting pipe body; the electric melting pipe body is made of thermoplastic plastic filled with short fibers; and the injection position is arranged on any end face of the electric melting pipe, so that the injection molding direction is parallel to the axial direction of the pipe. According to the short fiber reinforced plastic electric melting pipe, the axial orientation degree of the fibers in the electric melting pipe is improved, the problem that the fiber orientation is not ideal in the short fiber reinforced thermoplastic plastic electric melting pipe which isinjected by the electric melting pipe injection mold is solved, and the axial strength of the short fiber reinforced plastic electric melting pipe is improved. The pipe is formed in one step by an injection molding method, and an additional steel plate or a fiber reinforced layer is not needed, so that the manufacturing process is simple, the stability is good, the process cost is reduced, and the defects of bonding in the prior art, ring-only enhancement and the like are overcome.

Owner:ZHEJIANG UNIV +1

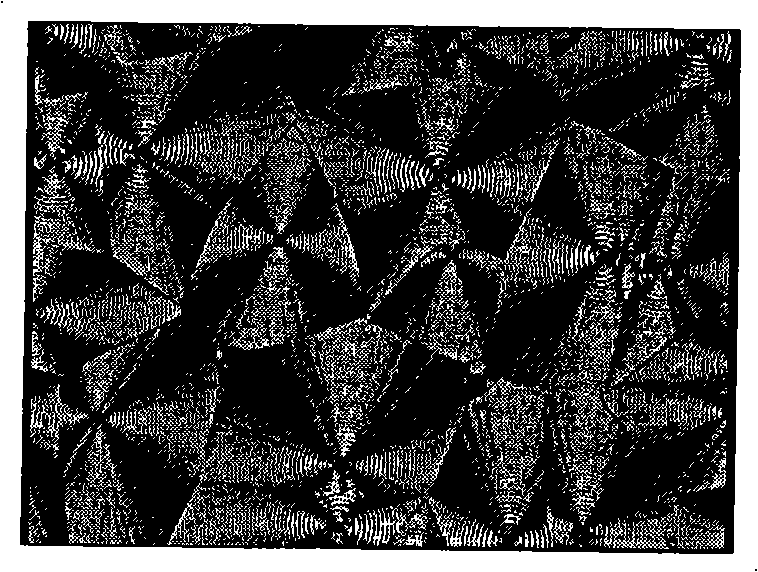

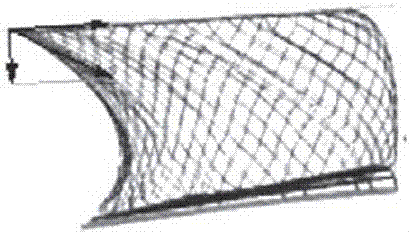

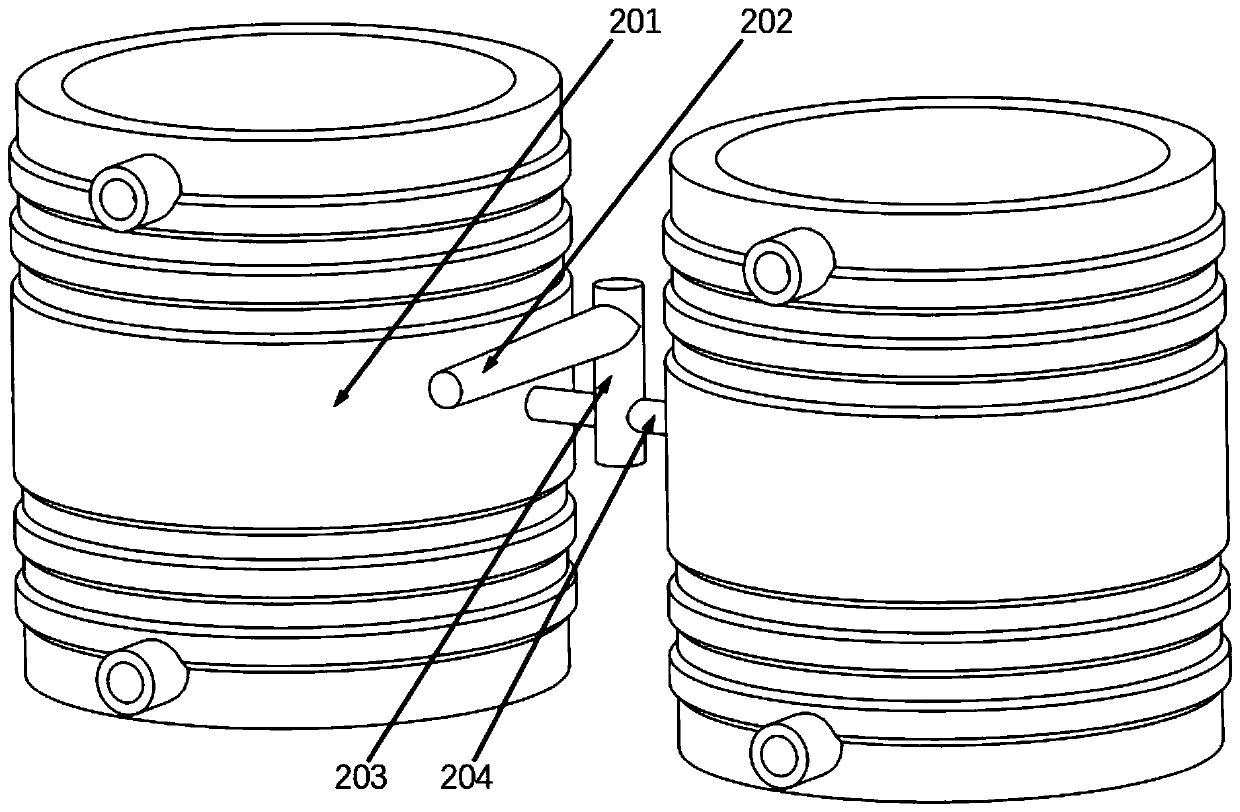

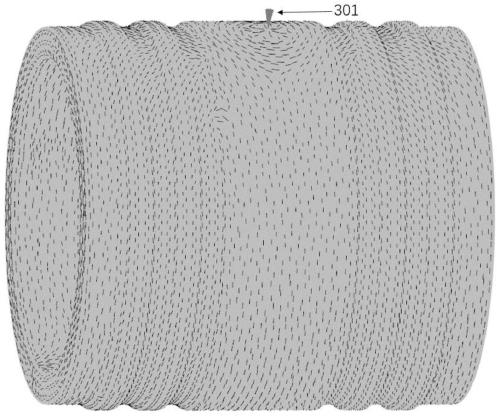

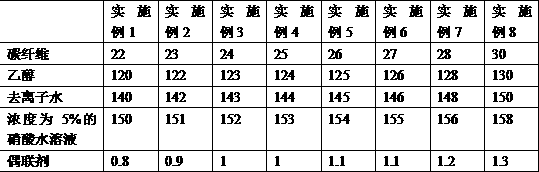

Preparation method of woven gas cylinder and woven gas cylinder

ActiveCN113478791AImprove axial strengthIncrease fiber densityVessel manufacturingVessel wallsFiberCeramic materials

The invention discloses a preparation method of a woven gas cylinder and the woven gas cylinder. The preparation method comprises the following steps that S1, an inner container with a gentle radian at an end socket is prepared; S2, a plurality of fiber layers are woven on the outer surface of the inner container, the fiber layers are evenly distributed on the outer surface of the inner container, the smooth sand phenomenon is avoided, the weaving angle of the fiber layers changes along with the radius change of the weaving portion, at the polar hole, the weaving angle is a small angle, and the distance between the axial fibers is reduced by weaving at the small angle, so that the condition that the radius at the polar hole is small is adapted, at the end socket section, the weaving angle is increased along with the increase of the radius of the weaving part, and in the cylinder body section, the weaving angle of the cylinder body section under the same fiber layer is maximum and is kept unchanged; S3, resin is poured, cured and formed; and S4, air tightness detection, grinding and polishing treatment are carried out. According to the preparation method, the weaving angle is changed along with the radius change of the weaving part, so that the fiber layers can be uniformly distributed on the outer surface of the inner container, the sand slipping phenomenon is avoided, and the gas cylinder is ensured to have enough strength and strength uniformity.

Owner:HEFEI UNIV OF TECH

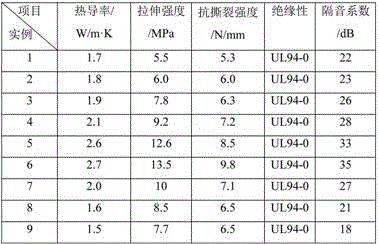

Material of noise-reducing and radiating shell of transformer

The invention belongs to the technical field of high polymer material, specifically relates to a material of a noise-reducing and radiating shell of a transformer. The shell material comprises the following raw materials by weight parts: 30-40 parts of polyurethane resin, 15-26 parts of methyl vinyl silicone rubber, 20-35 parts of carbon fiber, 10-20 parts of aluminium oxide,7-12 parts of kieselguhr, 2-8 parts of silicone oil, 0.5-1.5 parts of antioxidant,2-5 parts of 2,5-dimethyl-2,5-dual (tert butyl peroxy)hexane. The noise-reducing and radiating shell material of the transformer provided in the invention has lightweight, high hardness, shock resistance, wearing resistance, ageing resistance and good effects of sound absorption and radiating.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Continuous reinforced thermoplastic pipe wound around by metal strip

ActiveCN108930846AHigh strengthImprove axial strengthGeneral water supply conservationTransportation and packagingMetal stripsManufacturing cost reduction

The invention discloses a continuous reinforced thermoplastic pipe wound around by a metal strip. According to the pipe, a method of group division designing of the winding metal strip is adopted, thewinding metal strip is reasonably distributed, and meanwhile, the high strength of the metal strip is utilized to increase the circumferential strength and the axial strength of a pipe, so that the anti-pressure ability of the pipe is improved, metal belt reinforcing layers are not bonded, the flexibility of the composite pipe is improved, and the relative slippage amount among the metal belt layers is reduced; and the manufacturing process is simple and convenient, the equipment investment requirement is small, so that the manufacturing cost is greatly reduced, and the flexibility and the seismic resistance of the pipeline are guaranteed.

Owner:NINGBO OPR OFFSHORE ENG EQUIP CO LTD

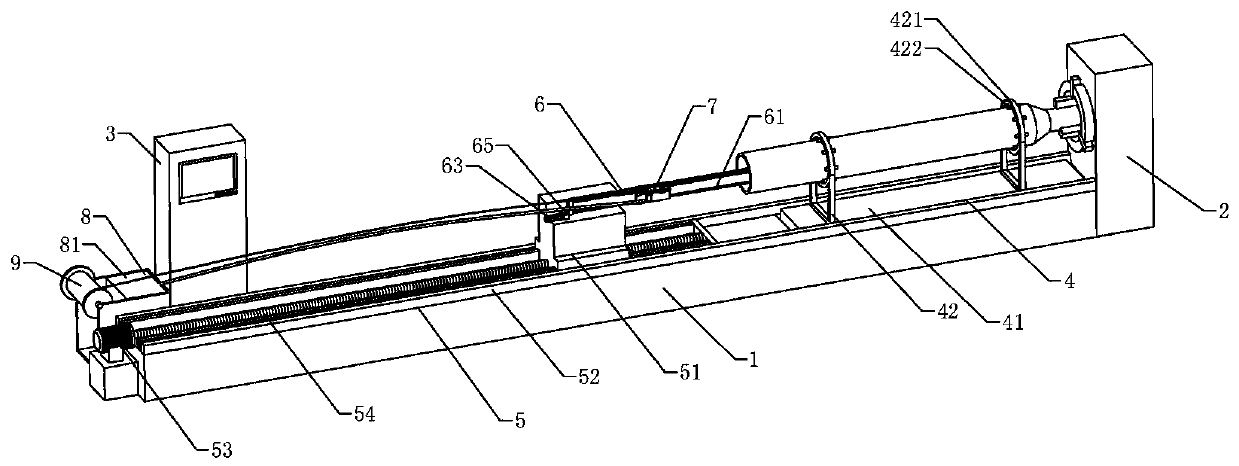

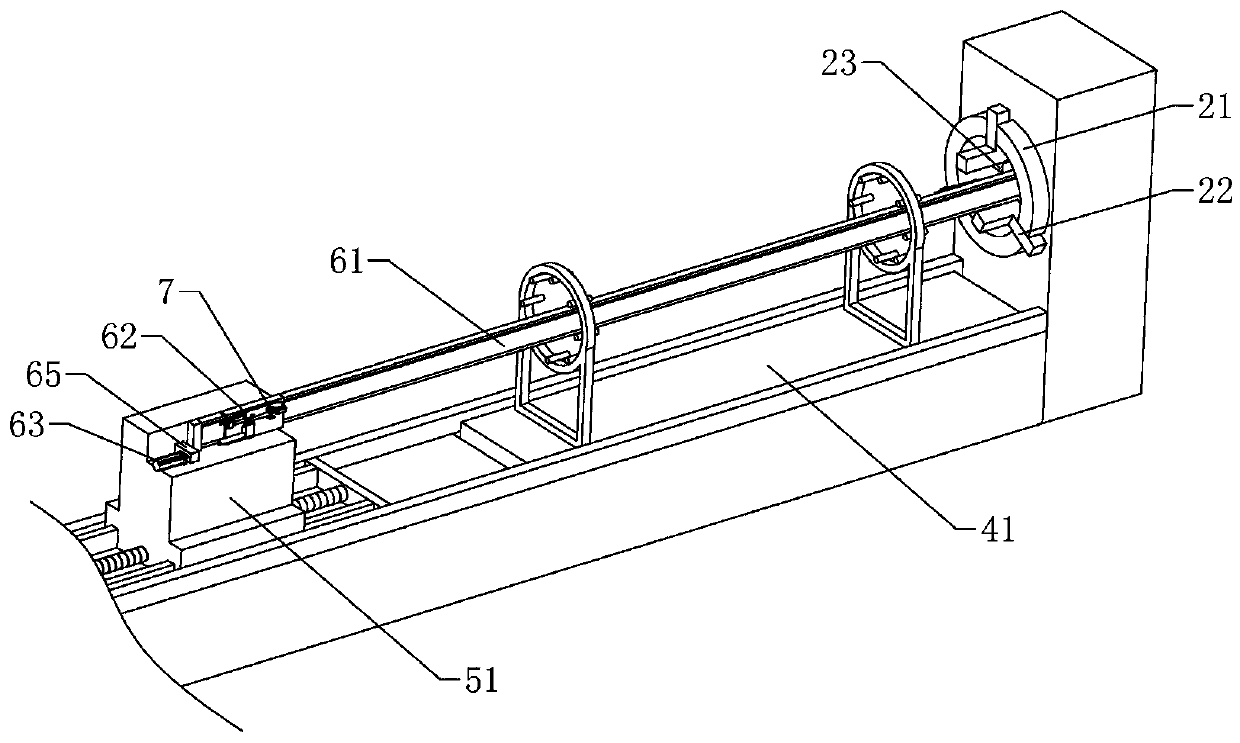

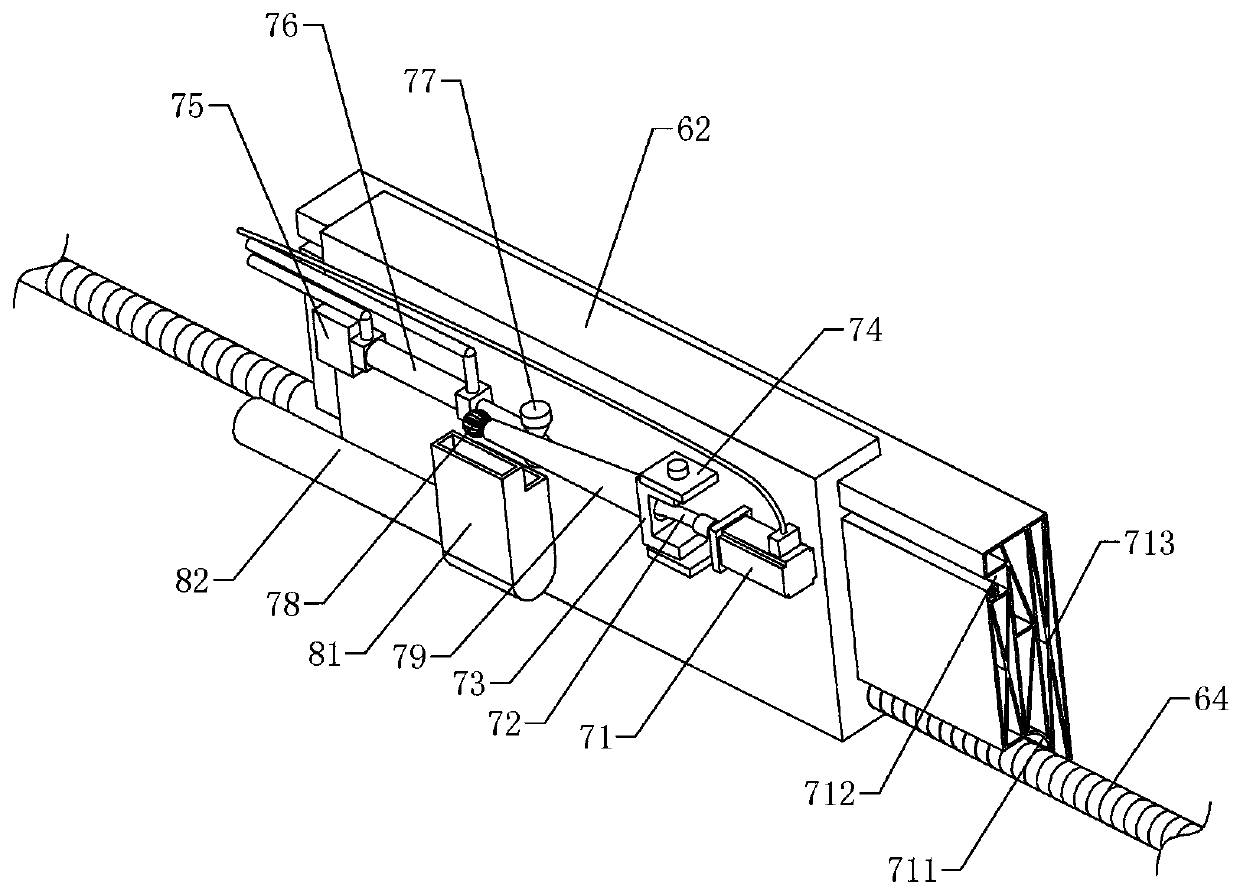

Device and method for grinding inner surface of elongated cylindrical shell

PendingCN109940469AImprove axial strengthSmall axial variableGrinding carriagesRevolution surface grinding machinesEngineeringAlloy

The invention relates to the field of machining, in particular to a device and a method for grinding the inner surface of an elongated cylindrical shell. The grinding device comprises a machining table, a shell rotating mechanism and a numerical control system, wherein the machining table is provided with a shell supporting mechanism, a first supporting plate mechanism and a second supporting plate mechanism, the shell rotating mechanism comprises a driving rotating disc, a clamping claw and a supporting plate clamp, the supporting plate clamp is arranged on the inner side of the driving rotating disc, the first supporting plate mechanism comprises a sliding supporting table, a guide rail, a first servo motor and a first positioning screw rod, the second supporting plate mechanism is arranged at the upper end of the sliding supporting table, the second supporting plate mechanism comprises an alloy sliding rail, a grinding side sliding plate, a second servo motor, a second positioning screw rod and a gear speed regulation box, the section height of the alloy sliding rail is larger than the section width of the alloy sliding rail, the grinding side sliding plate is arranged on the side surface of the alloy sliding rail, and a grinding cutter position-adjusting mechanism is arranged on the grinding side sliding plate.

Owner:HUZHOU TEACHERS COLLEGE

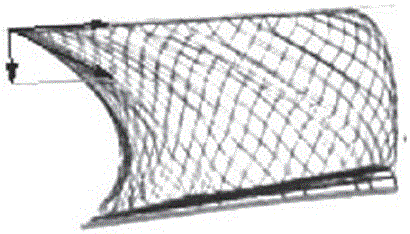

Medical self-expanding support

The invention provides a medical self-expanding support. The medical self-expanding support comprises a body and a transition region. The body comprises multiple sets of first circumferential winding lines connected into a whole. Each first circumferential winding line is provided with multiple first sawtooth waveform objects spirally arranged in the circumferential direction. The adjacent first circumferential winding lines are connected through first connecting bridges. Each first sawtooth waveform object comprises two adjacent equal-length first struts and a first top section for connecting the adjacent first struts. The first connecting bridges are connected between the first top sections. The transition region is arranged at the end of the body and comprises a first transition section and a second transition section which are adjacently connected, and the first transition section and the second transition section are connected with the body through second connecting bridges. The support is of a tubular structure and has the shrinking diameter through which the support is arranged in the blood vessel and the expansion diameter through which the support abuts and expands in the blood vessel. The medical self-expanding support is reasonable in structure, convenient to use, high in flexibility and radial and axial strength and good and durable in use effect.

Owner:ZHEJIANG BARTY MEDICAL TECH CO LTD

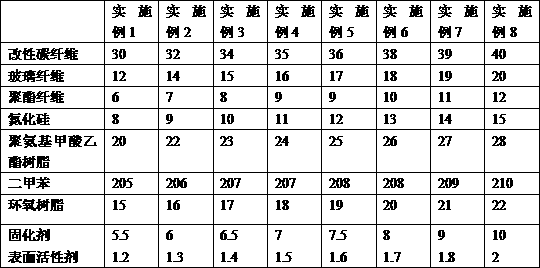

Power transmission line carbon fiber composite core lead core rod

ActiveCN110517820AImprove axial strengthHigh modulusInsulated cablesInsulated conductorsPolyesterEpoxy

The invention discloses a power transmission line carbon fiber composite core lead core rod, and belongs to the technical field of power transmission line leads. The power transmission line carbon fiber composite core lead core rod is prepared from the following raw materials in parts by weight: 30-40 parts of modified carbon fibers, 12-20 parts of glass fibers, 6-12 parts of polyester fibers, 8-15 parts of silicon nitride, 20-28 parts of polyurethane resin, 205-210 parts of xylene, 15-22 parts of epoxy resin, 5.5-10 parts of curing agent and 1.2-2 parts of surfactant. The surface of the corerod is round, clean and smooth and consistent in color and luster without defect, the tensile strength is over 2663MPa and the elastic modulus is over 130GPa. The core rod can be wound on a 55D-diameter cylinder at a winding speed of not more than 3r / min for one circle and the core rod does not crack or break, the withstand pressure of not less than 30KN in the radial pressure resistance test andthe end part does not crack or peel. The tensile strength of the surface layer is over 2511MPa after the torsion test for 360 degrees, and the surface layer does not crack.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

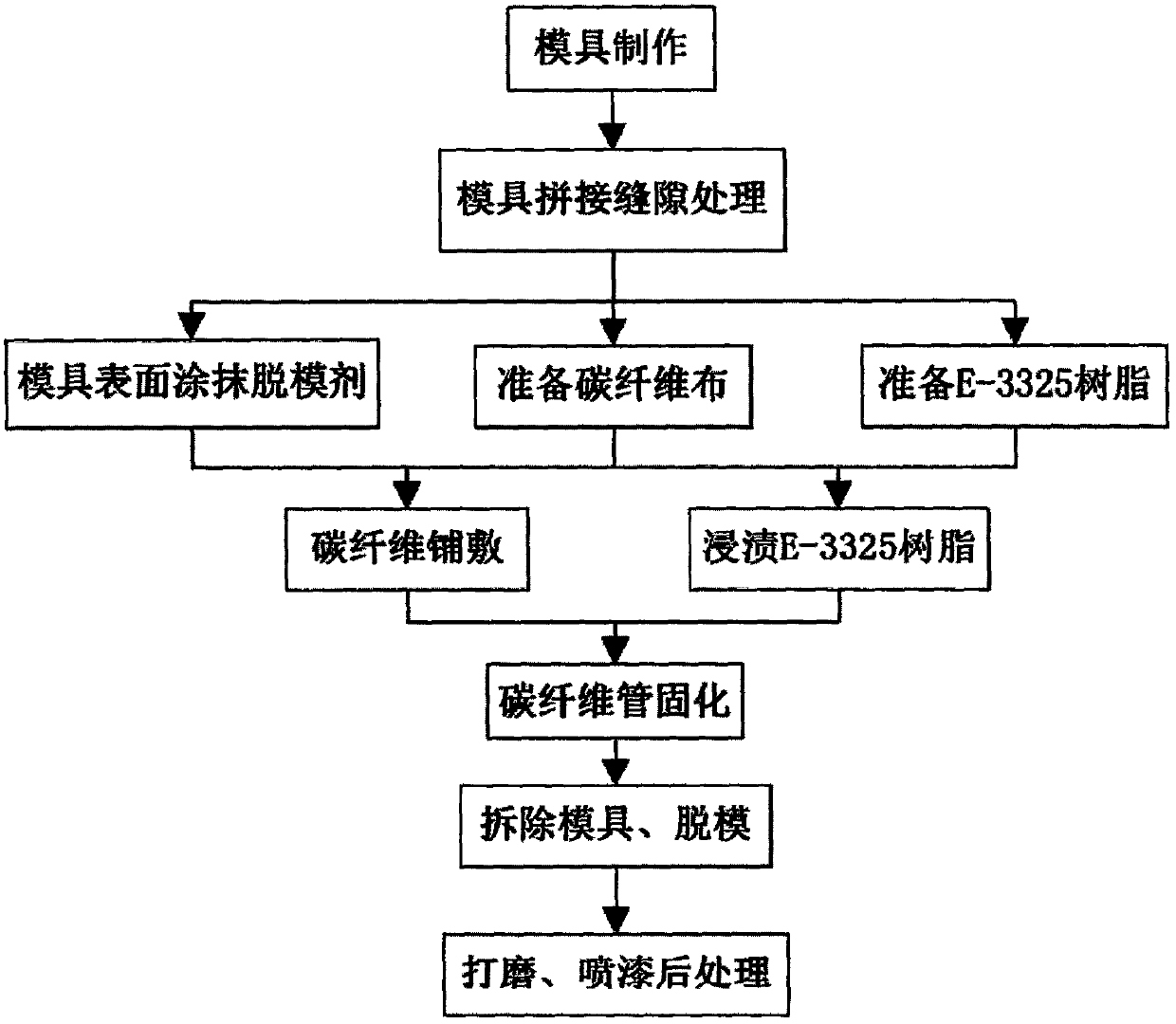

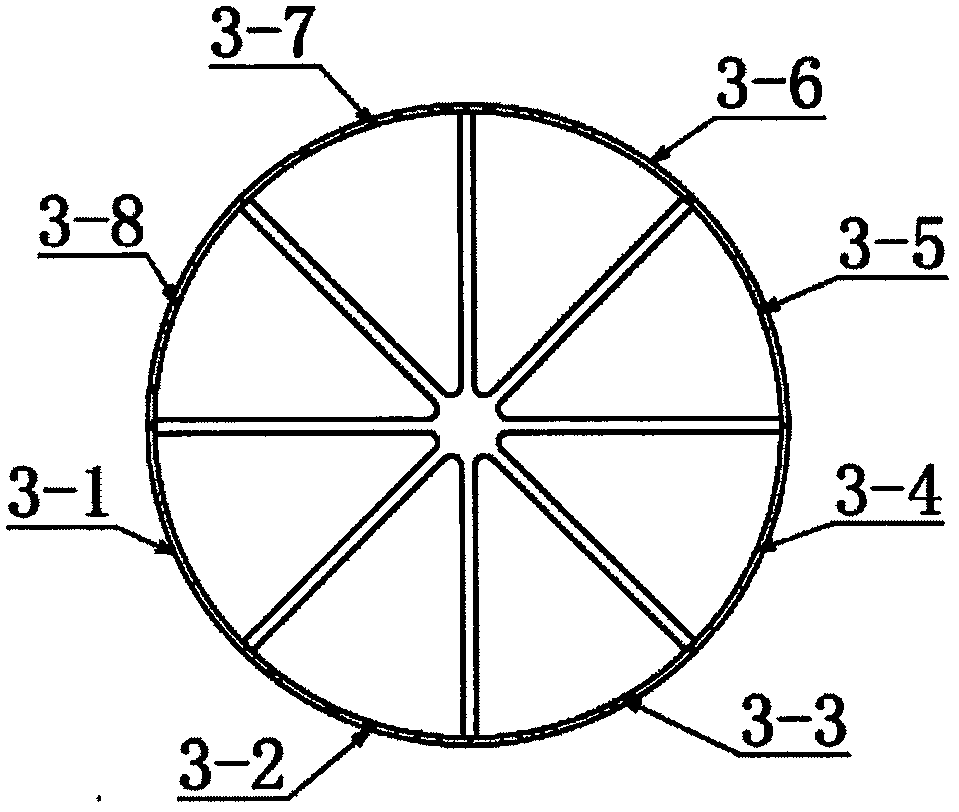

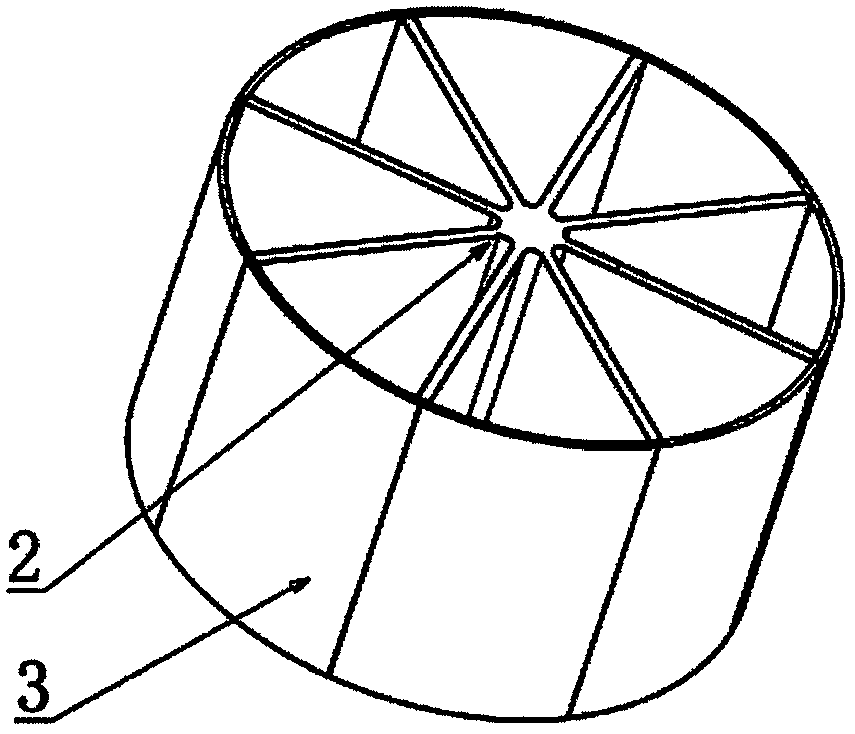

Mold manufacturing method and preparation method of ultra-large type composite carbon fiber tube

The invention relates to a preparation method of an ultra-large type composite carbon fiber tube. The preparation method of the ultra-large type composite carbon fiber tube is characterized by comprising the following steps that firstly, a mold is manufactured, a mold framework is formed by splicing metal frameworks, a mold skin is fixed to the mold framework, and the outer surface of the mold skin is coated with a mold release agent; secondly, carbon fiber fabric is laid on the outer surface of the mold skin; and thirdly, after standing and solidifying, demolding treatment is conducted.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com