Mortar-filled glass fiber reinforced plastic pipe

A technology of glass fiber reinforced plastic with sand and sand layer, applied in the field of pipeline, can solve the problems of affecting market competitiveness and high cost, and achieve the effect of stable product quality and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

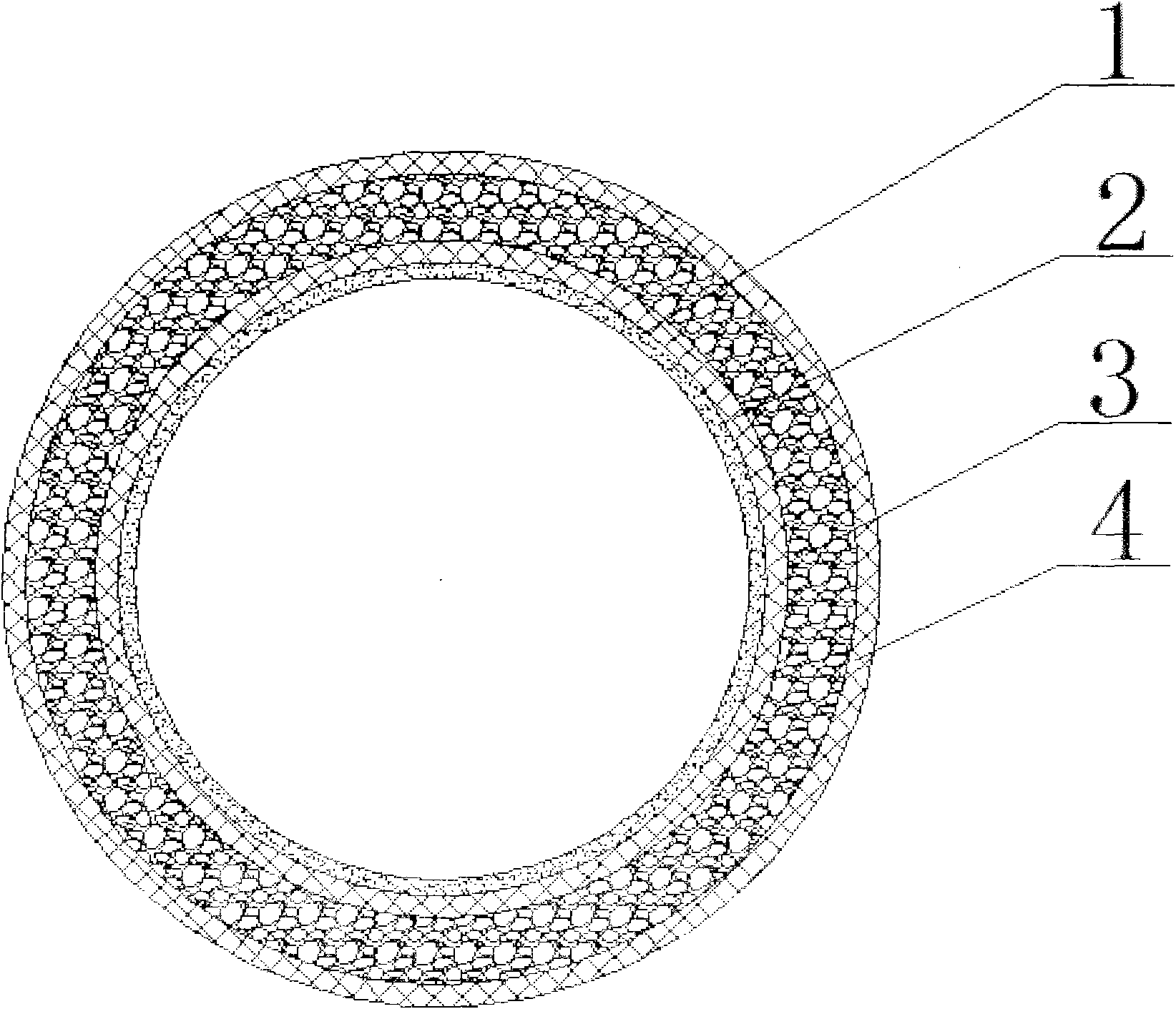

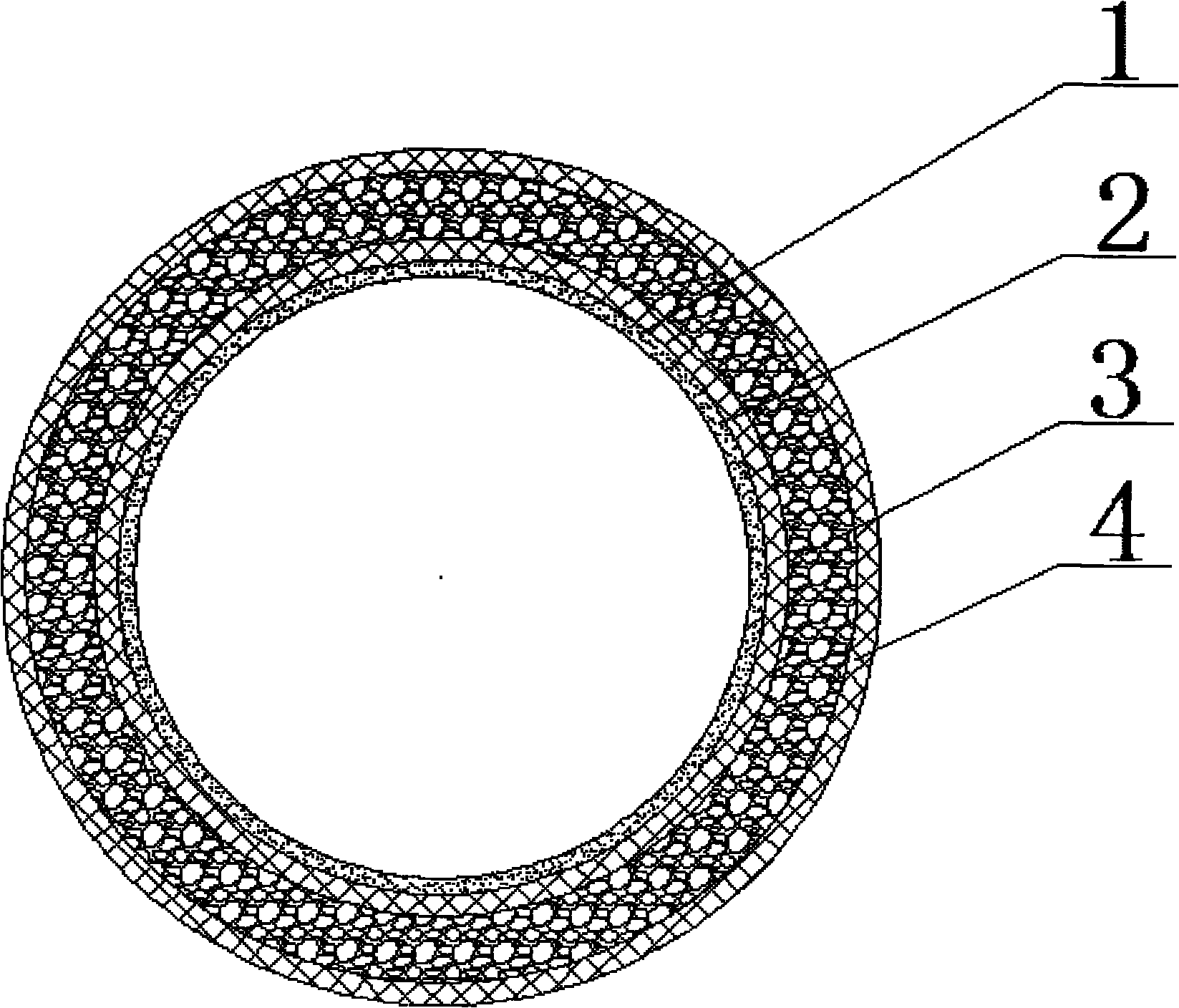

[0028] A glass-steel sand-filled pipe as shown in the accompanying drawings, from the inside to the outside is an inner lining layer 1, an inner reinforcement layer 2, a low-resin-content sand-inclusion layer 3 and an outer reinforcement layer 4.

[0029] The inner lining layer 1 is formed by winding resin and glass fiber fabric to form the inner wall of the pipe, which is used to transport medium and prevent corrosion and leakage. The manufacturing method is the same as that of ordinary sand-filled pipes.

[0030] The inner reinforcement layer 2 and the outer reinforcement layer 4 are formed by winding resin and glass fiber fabrics, which are used to improve the axial strength and hoop strength of the pipe wall, including tensile strength, bending strength and impact strength. The manufacturing method is the same as that of ordinary sand-filled pipes. .

[0031] The sand layer 3 with low resin content includes quartz sand and natural calcite impregnated with o-phthalic unsatu...

specific Embodiment approach 2

[0037] A low-resin-content FRP sand-filled pipe, the structure and manufacturing method of which are basically the same as those of Embodiment 1, the difference being that the ratio of o-phthalic unsaturated polyester resin, quartz sand and natural calcite is 12%:77% : 11%. Quartz sand includes 15% of 16-20 mesh, 13% of 20-24 mesh, 15% of 24-30 mesh, 12% of 30-40 mesh, 18% of 40-50 mesh, and 18% of 50-60 mesh And 9% of 60-80 mesh quartz sand.

specific Embodiment approach 3

[0038] A FRP sand-filled pipe with low resin content, the structure and its manufacturing method are basically the same as those of Embodiment 1, the difference is that the ratio of o-phthalic unsaturated polyester resin, quartz sand and natural calcite is 15%:71% : 14%. Quartz sand includes 13% of 16-20 mesh, 15% of 20-24 mesh, 15% of 24-30 mesh, 12% of 30-40 mesh, 18% of 40-50 mesh, and 18% of 50-60 mesh And 9% of 60-80 mesh quartz sand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com