Continuous reinforced thermoplastic pipe wound around by metal strip

A technology of enhancing thermoplastic and winding reinforcement, which is applied to rigid pipes, metal layered products, hoses, etc., can solve the problems of coiled tubing winding diameter equipment conditions are relatively limited, uniform reinforcement of pipes cannot be guaranteed, and production equipment is expensive. Reduce relative slippage, improve flexibility, and reduce equipment investment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by specific embodiment, in conjunction with accompanying drawing, the technical solution of the present invention is described in further detail:

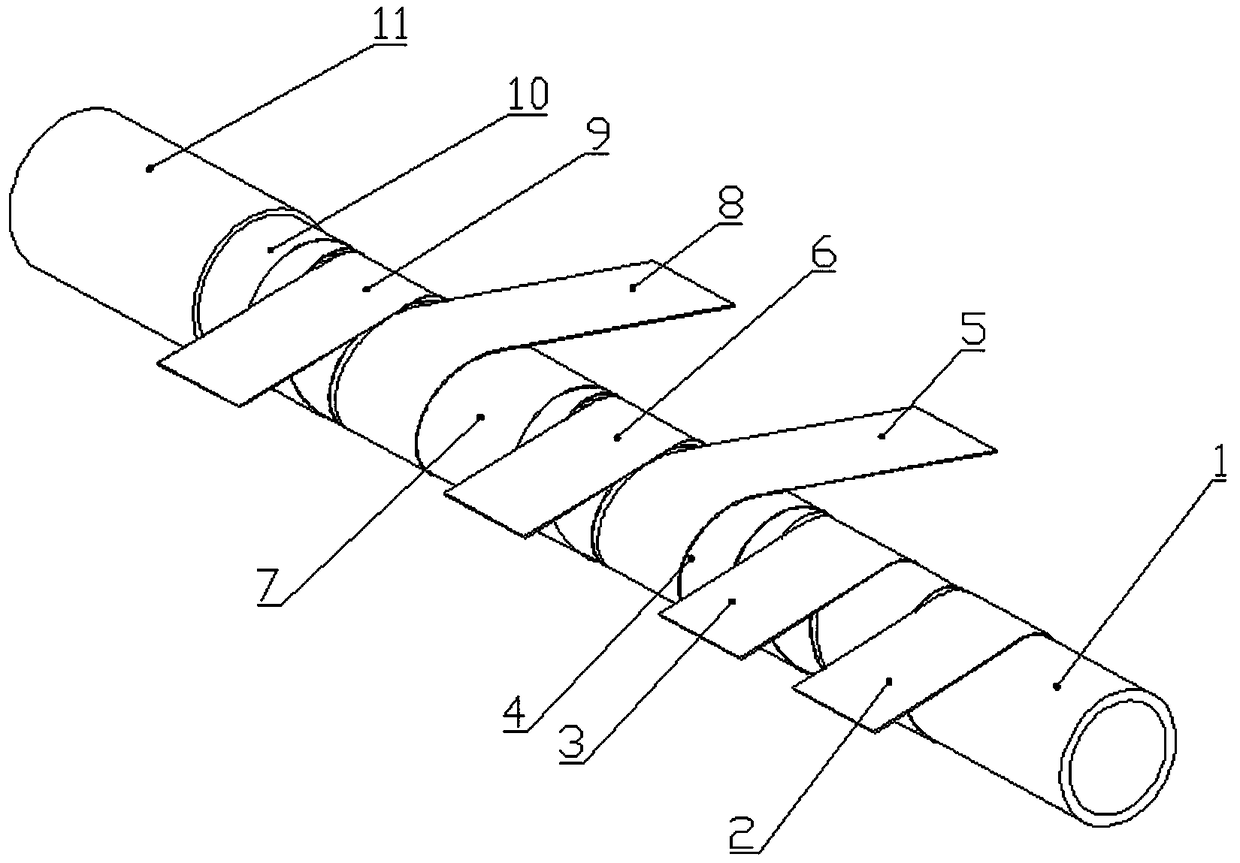

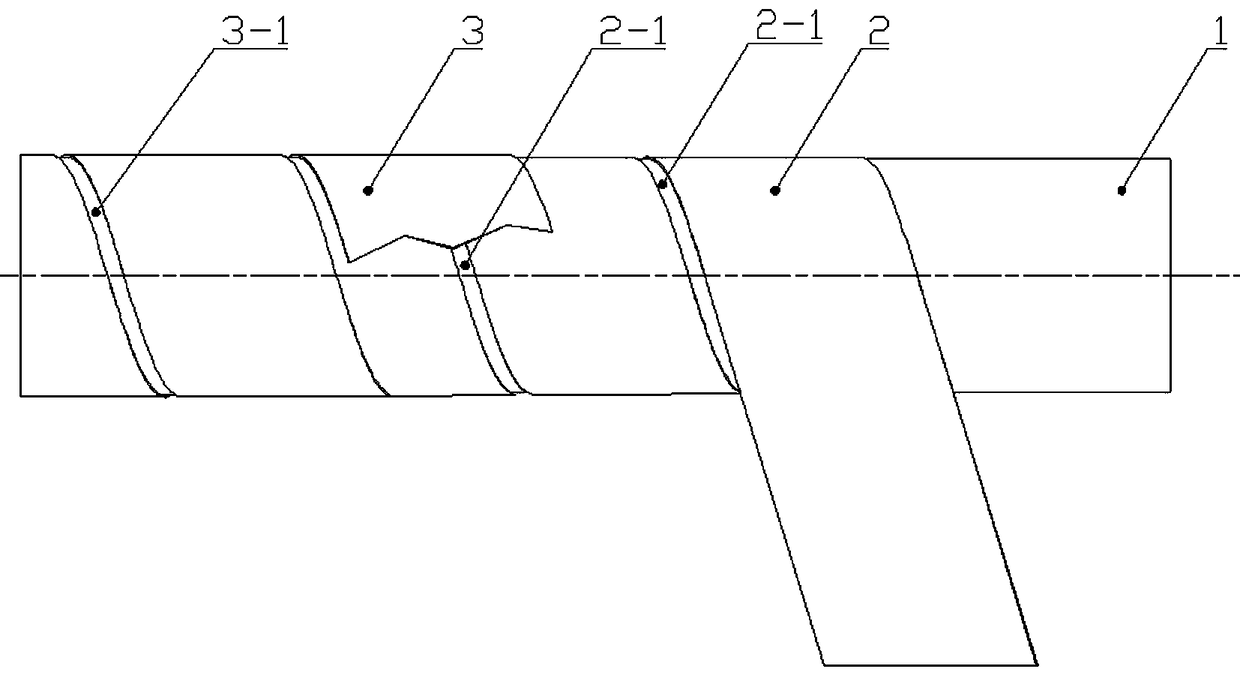

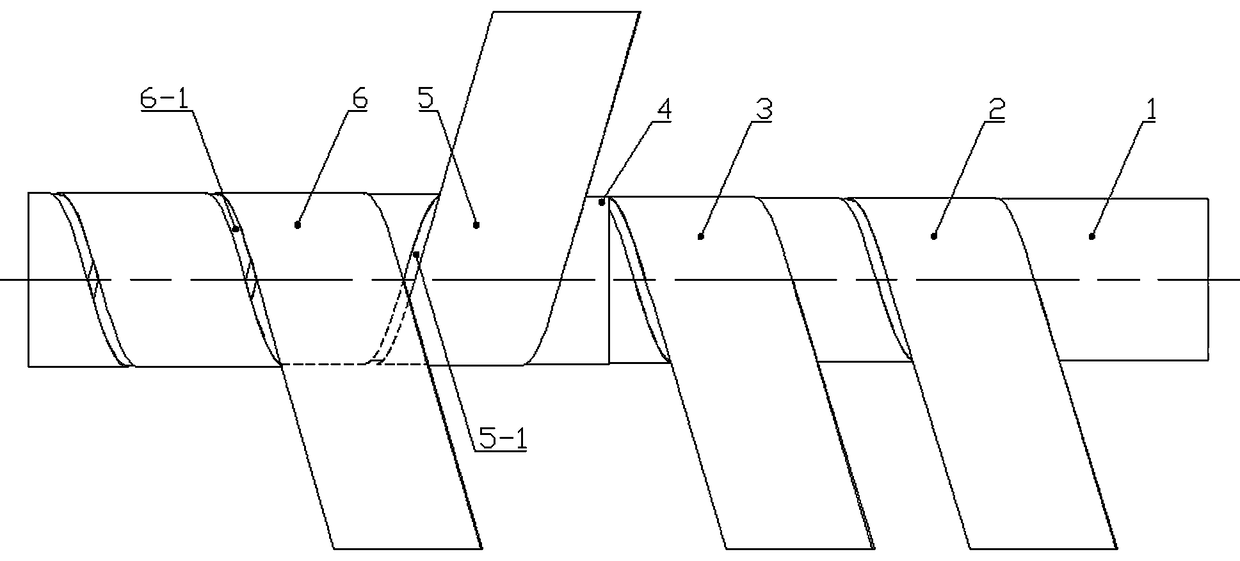

[0022] Example: as attached Figure 1-4 As shown in Fig. 1, a metal belt wound continuous reinforced thermoplastic composite pipe, the metal belt adopts steel belt, which is a six-layer steel belt wound continuous reinforced thermoplastic composite pipe, and the composite pipe is the innermost inner pipe from the inside to the outside. 1. The metal belt winding reinforcement layer in the middle layer and the outermost outer cladding tube 11; the metal belt winding reinforcement layer consists of multi-layer steel belts 2, 3, 5, 6, 8, 9 and polyester functional layers 4, 7 , 10 helically wound and formed. The inner tube and the outer cladding tube are high-density polyethylene (HDPE) plastic tubes, which not only have strong flexibility, but also have functions such as corrosion resistance, wear resistance, scratch res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com