Patents

Literature

38 results about "Reinforced thermoplastic pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

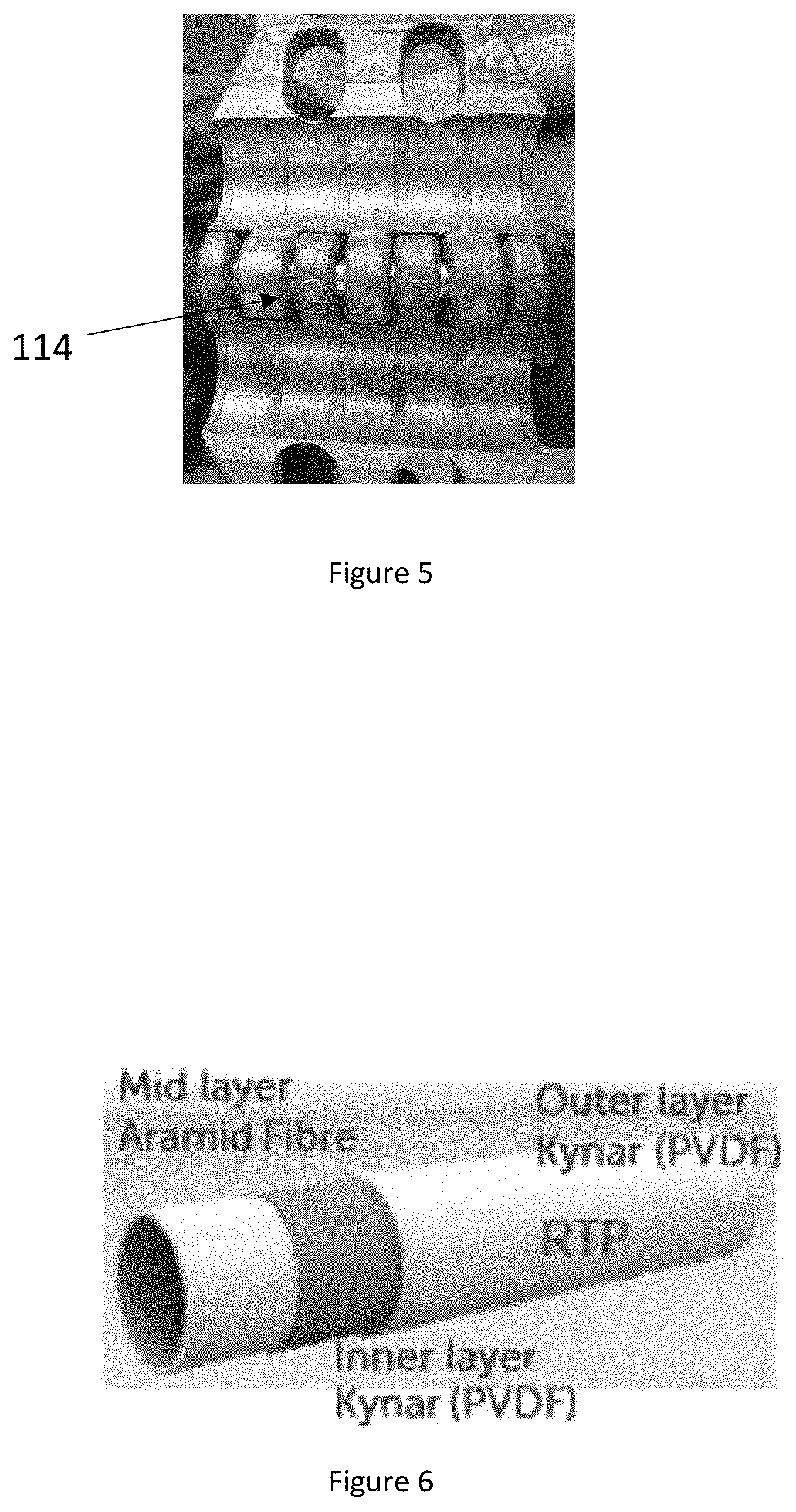

Reinforced thermoplastic pipe (RTP, also known as flexible composite pipe or FCP) is a generic term referring to a reliable high strength synthetic fibre (such as glass, aramid or carbon) or high strength steel wire reinforced pipe system. Initially developed in the early 1990s by Wavin Repox, Akzo Nobel and by Tubes d'Aquitaine from France, who developed the first pipes reinforced with synthetic fibre to replace medium pressure steel pipes in response to growing demand for non-corrosive conduits for application in the onshore oil and gas industry, particularly from Shell in the Middle East. Because of its expertise in producing pipes, Pipelife Netherlands was involved in the project to develop long length RTP in 1998. The resulting system is marketed today under the name SoluForce. More recently the technology of producing such pipe, including the marketing, rests with a few key companies.

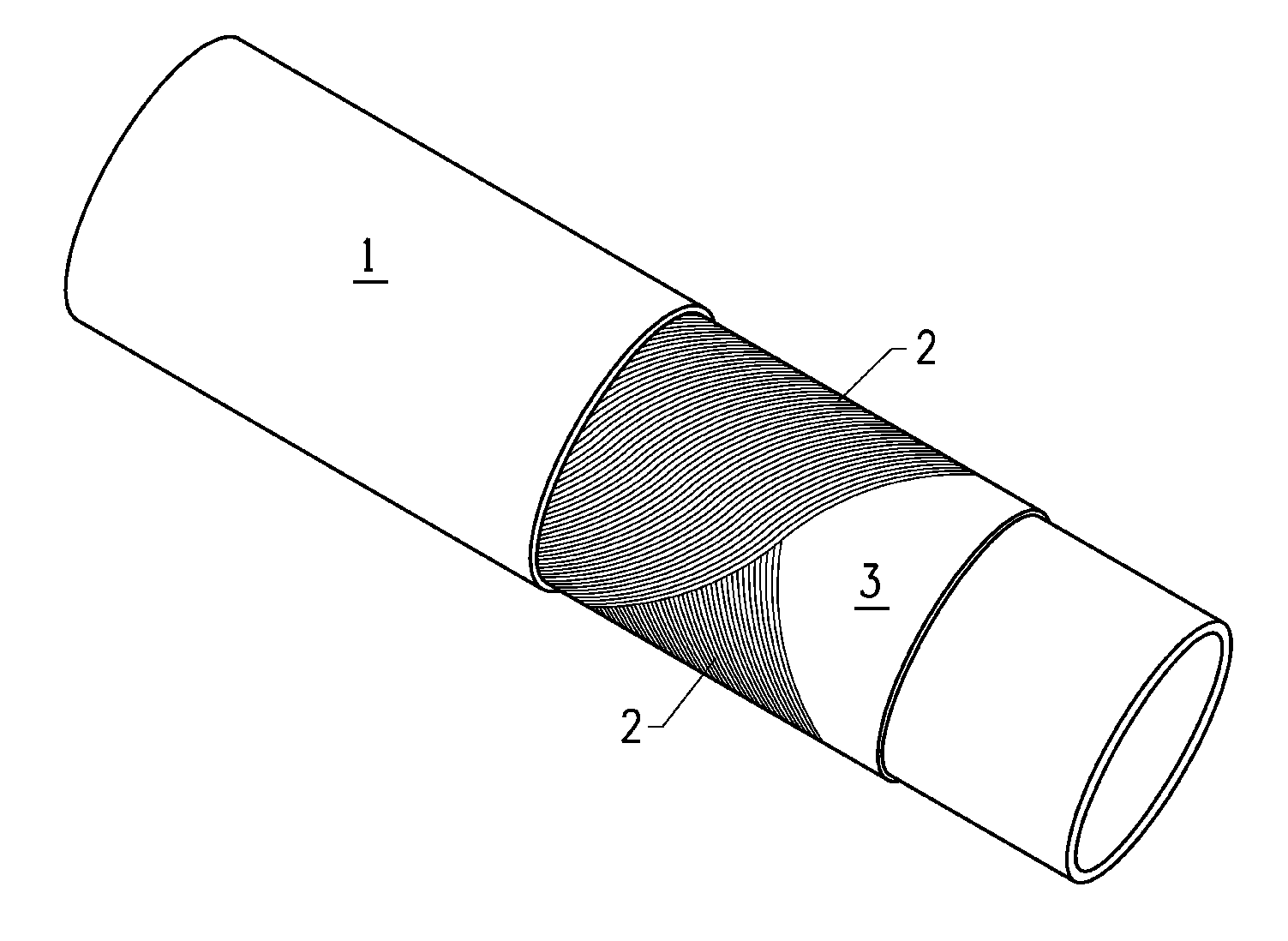

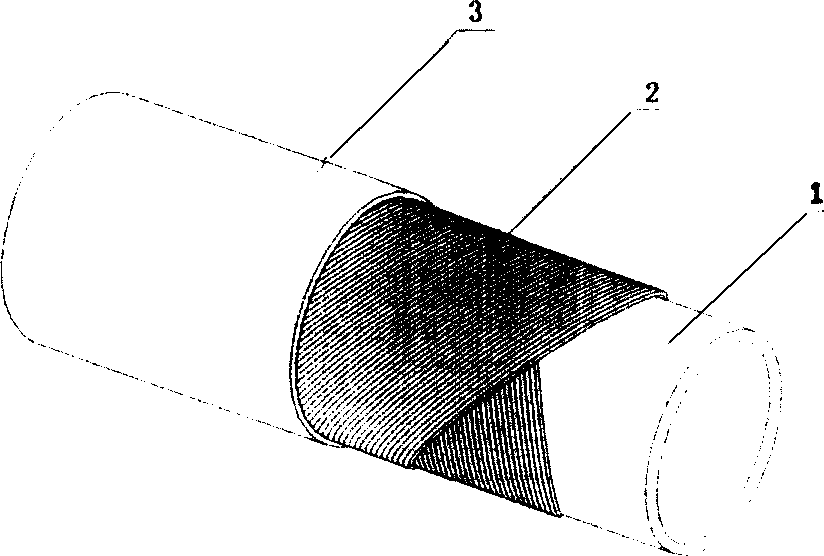

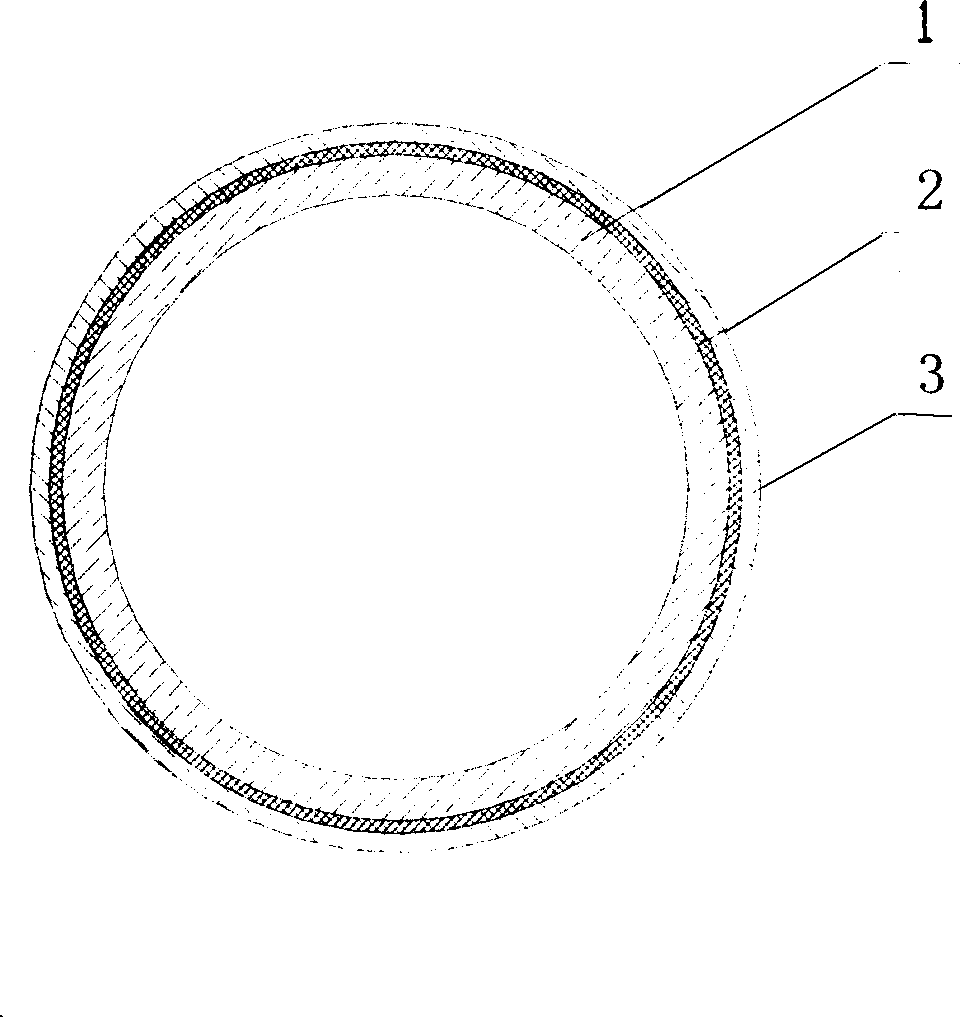

Continuous filament wound and reinforced thermoplastic pipe and manufacturing process thereof

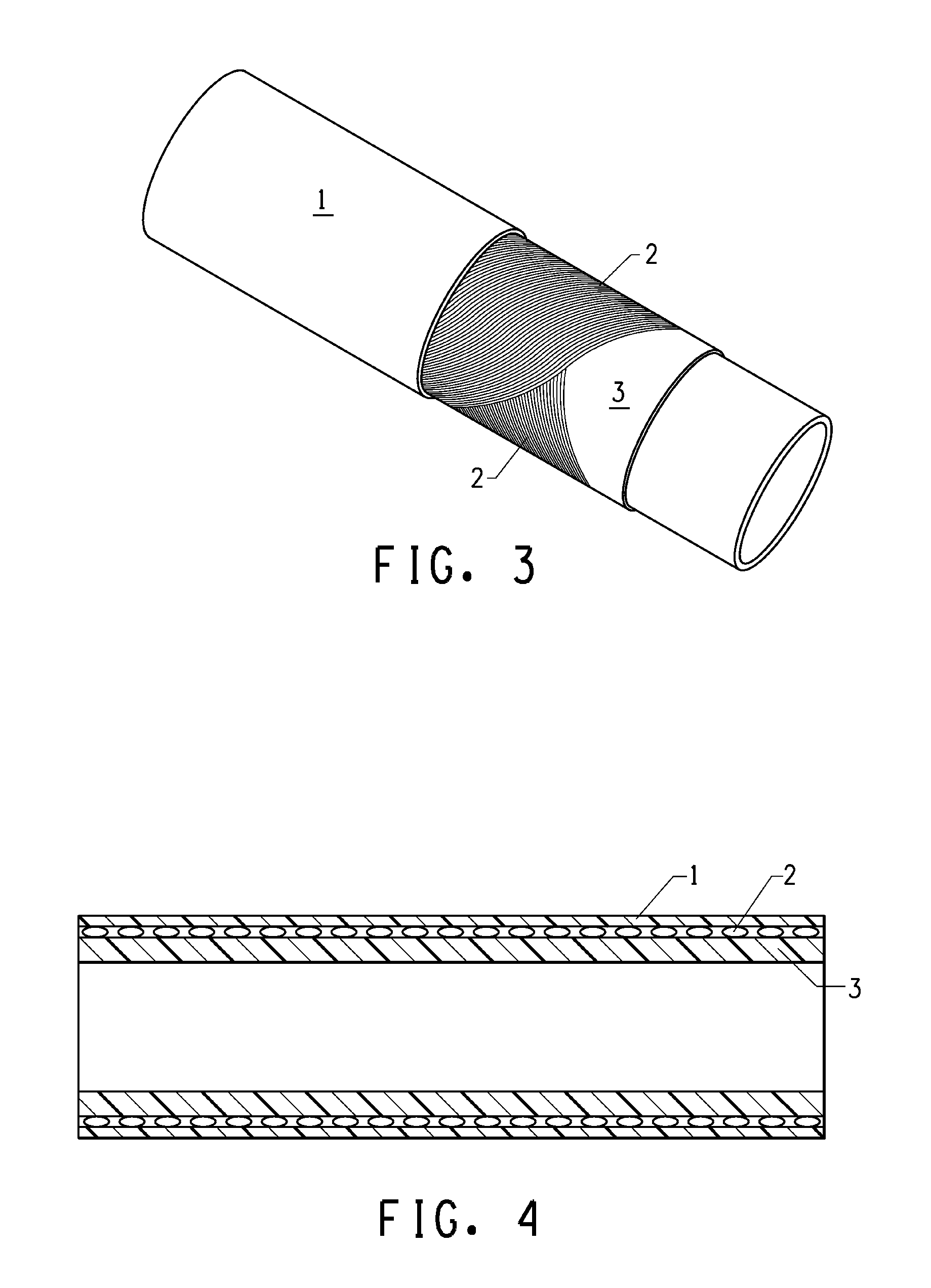

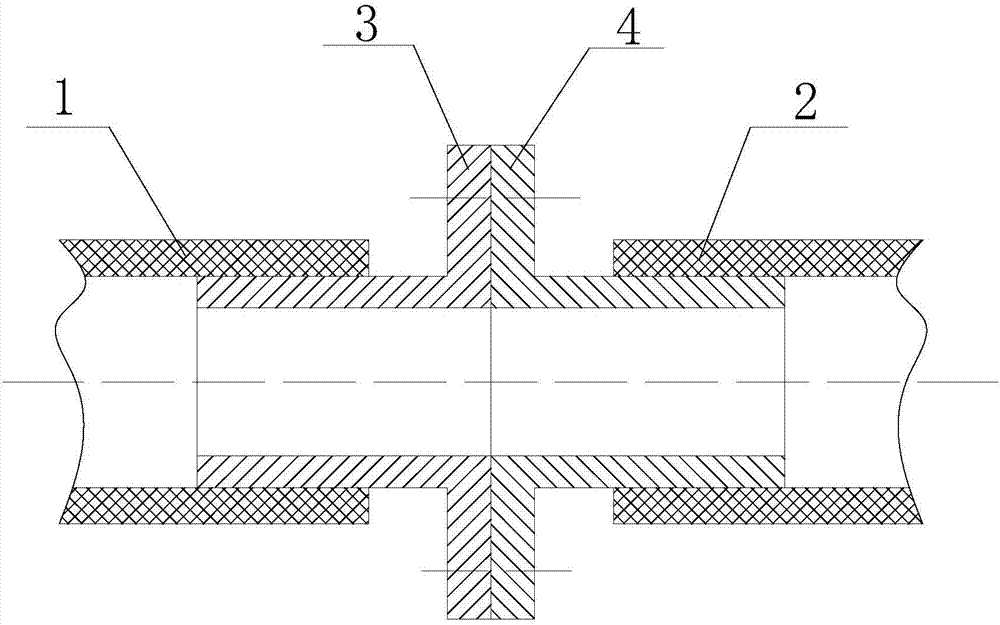

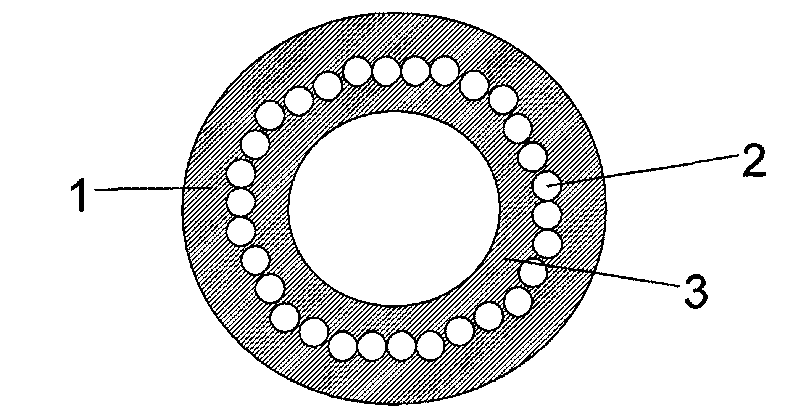

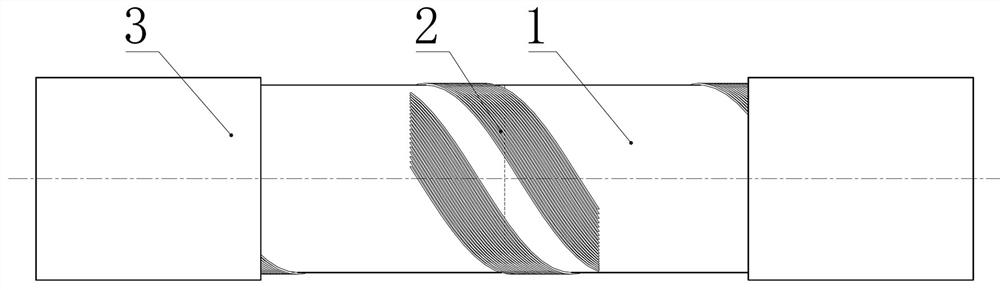

The invention relates to a pipeline structure used for transporting different media such as solid, liquid and gases and a manufacturing process thereof. A continuous filament wound and reinforced thermoplastic pipe is characterized in that a tubular pipeline liner layer, a pipeline structural layer and a pipeline outer protective layer are wound to manufacture a whole structure; the pipeline structural layer is positioned between the pipeline liner layer and the pipeline outer protective layer; the pipeline liner layer and the pipeline outer protective layer are made of thermoplastic plastics; and the pipeline structural layer is made of continuous filaments. The pipeline provided by the invention has better strength, rigidity, shock resistance, fracture toughness, temperature and corrosion resistance, seepage resistance and the like than the traditional thermoplastic or thermosetting pipelines, can be widely applied in the fields such as water supply and sewerage works, petrochemical industry, coal gas and natural gas transportation, seawater desalination and nuclear power and can be suitable for special environments and requirements such as heavy calibre, high rigidity, high strength and high corrosivity.

Owner:CHANGSHA XINSHI PIPELINE

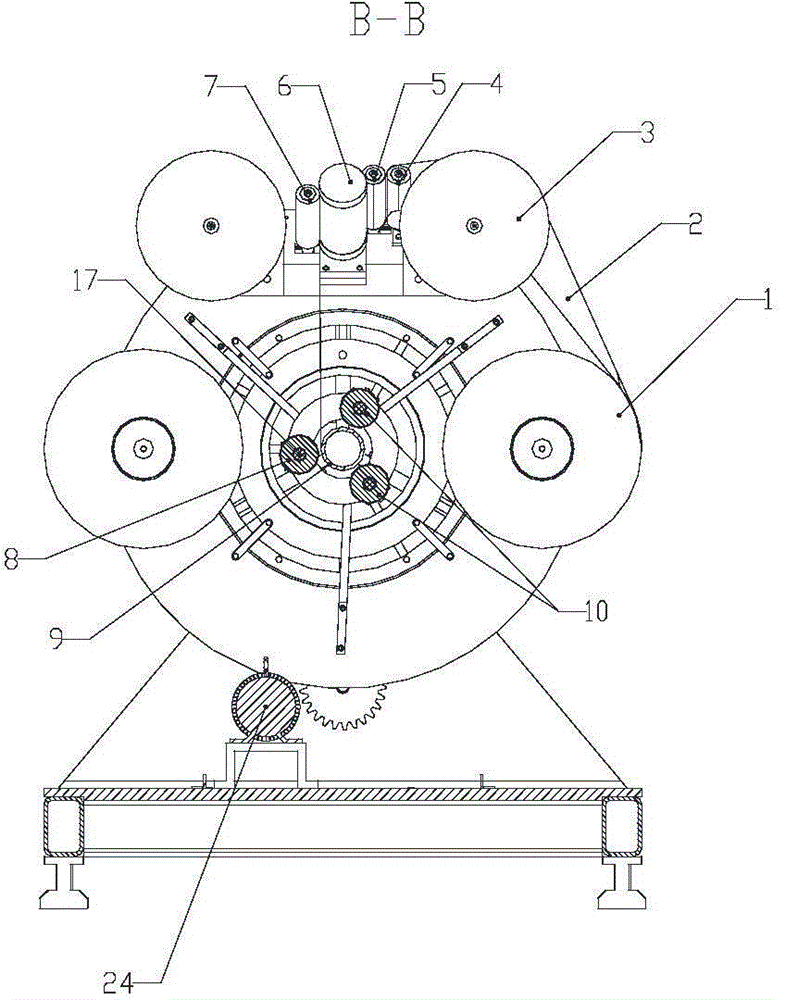

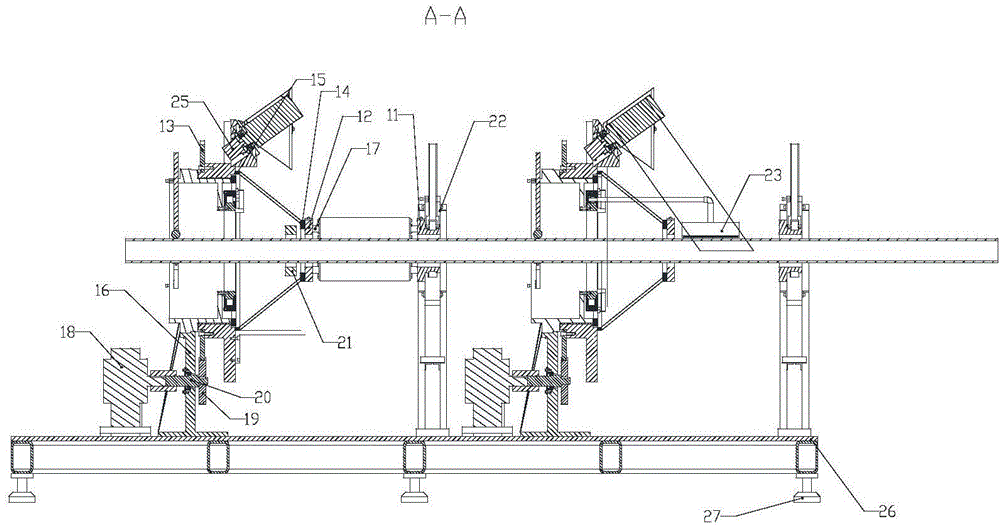

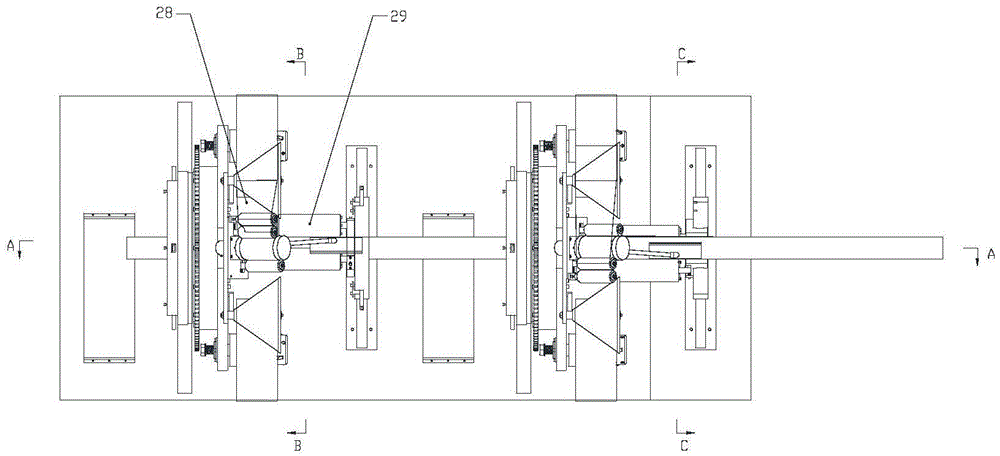

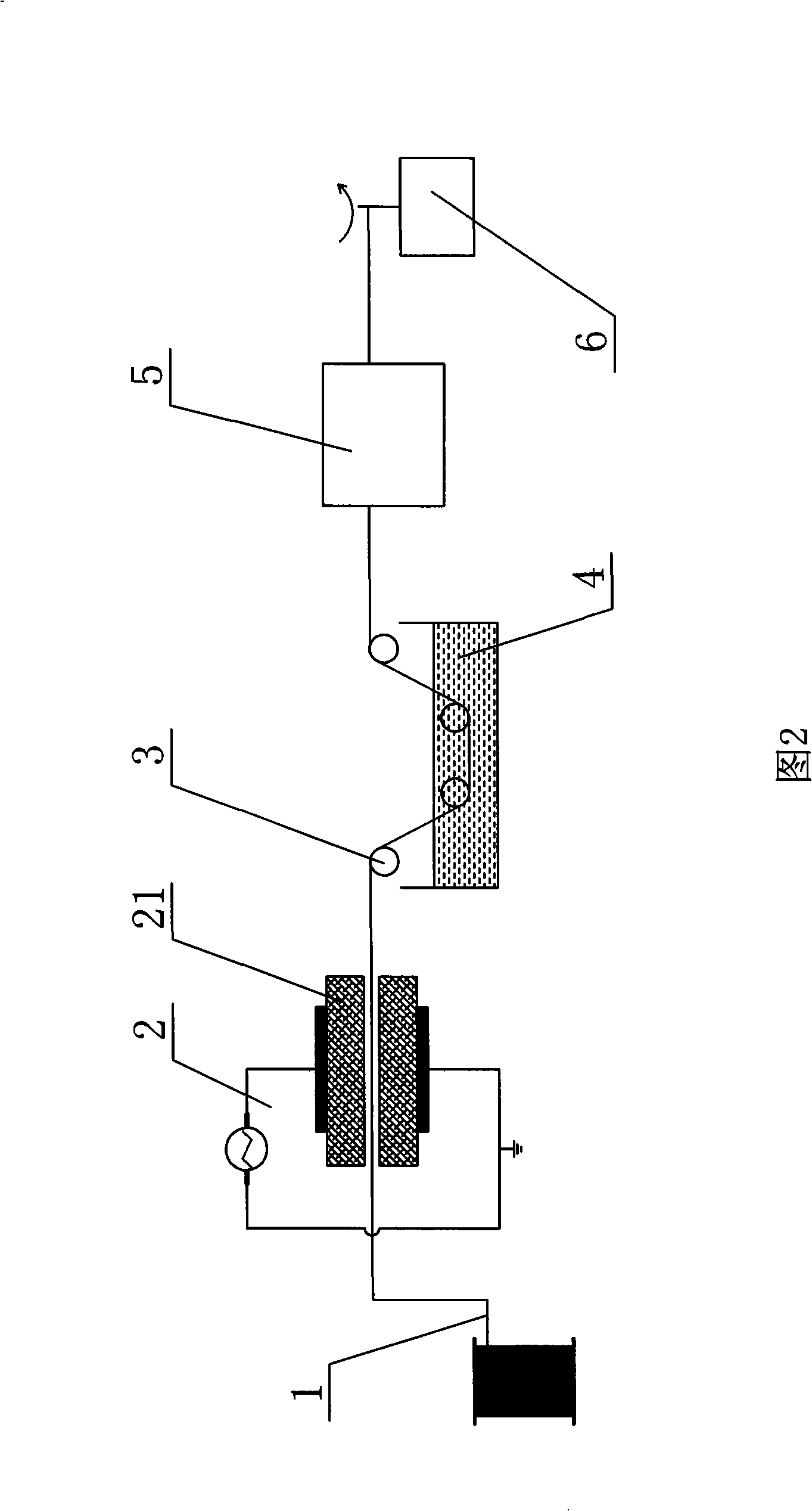

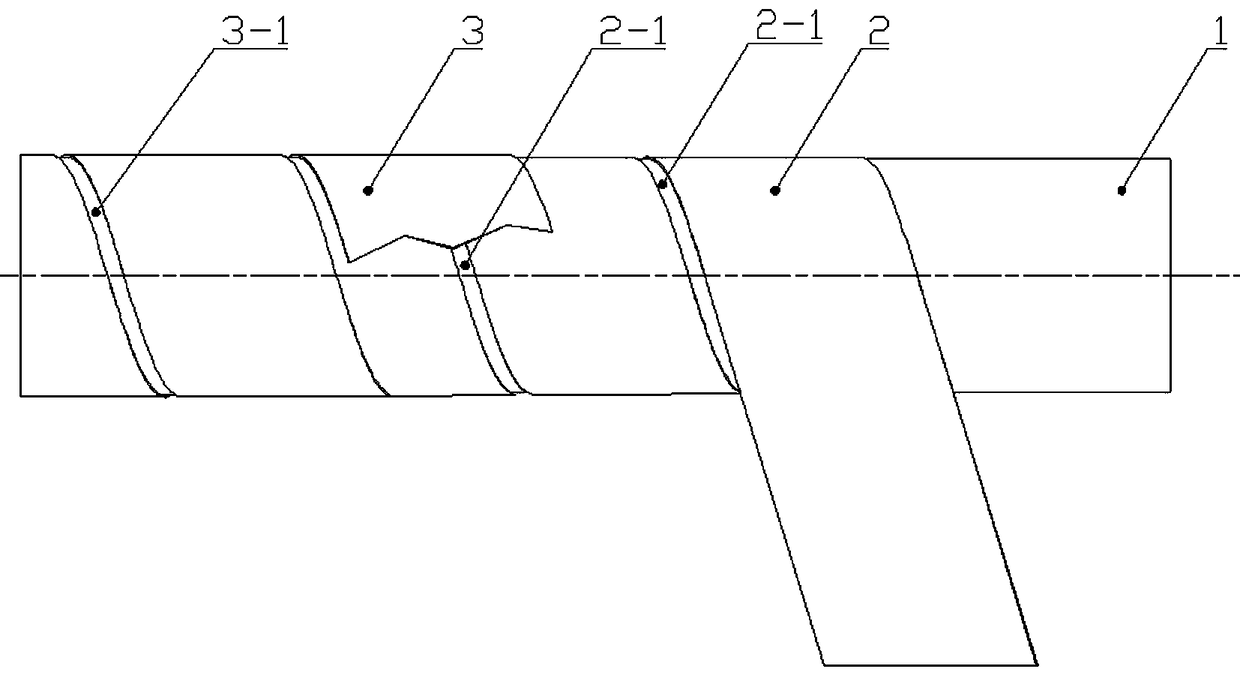

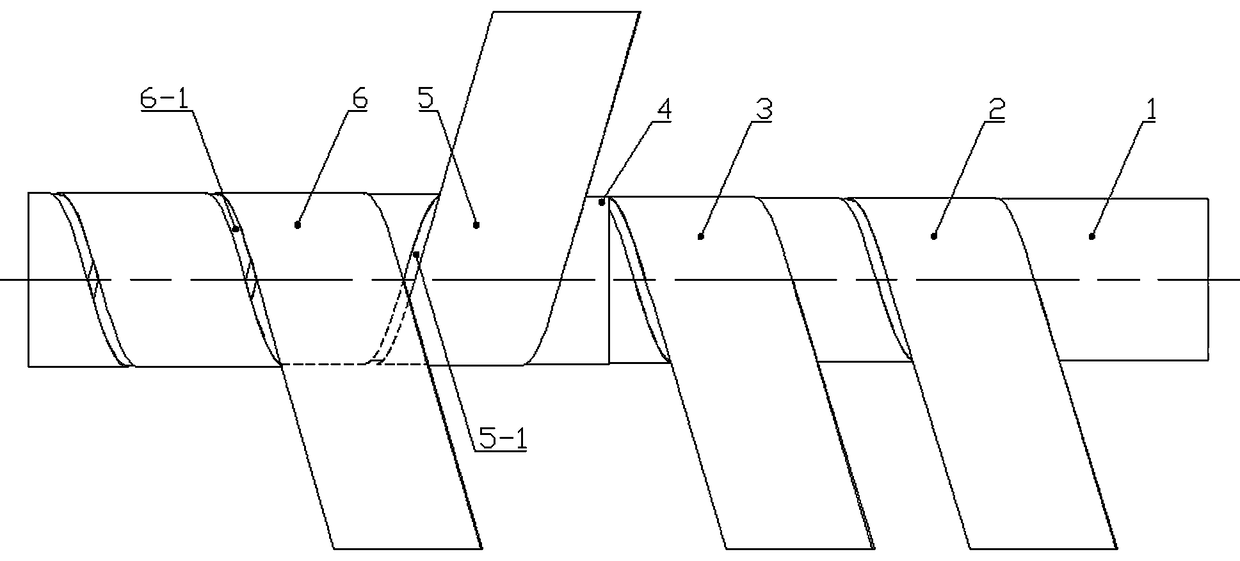

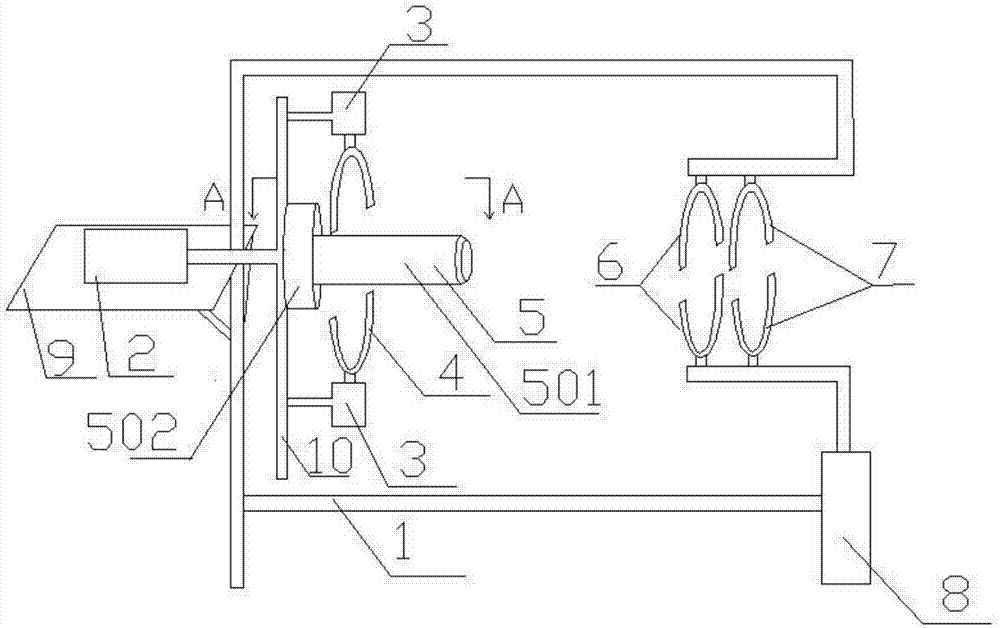

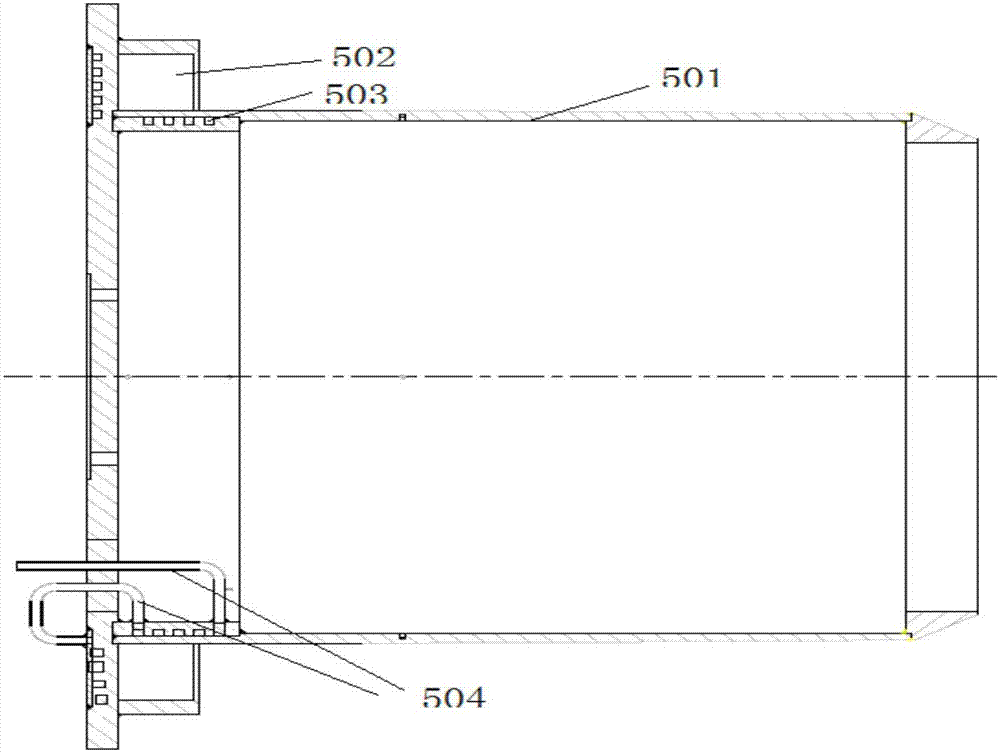

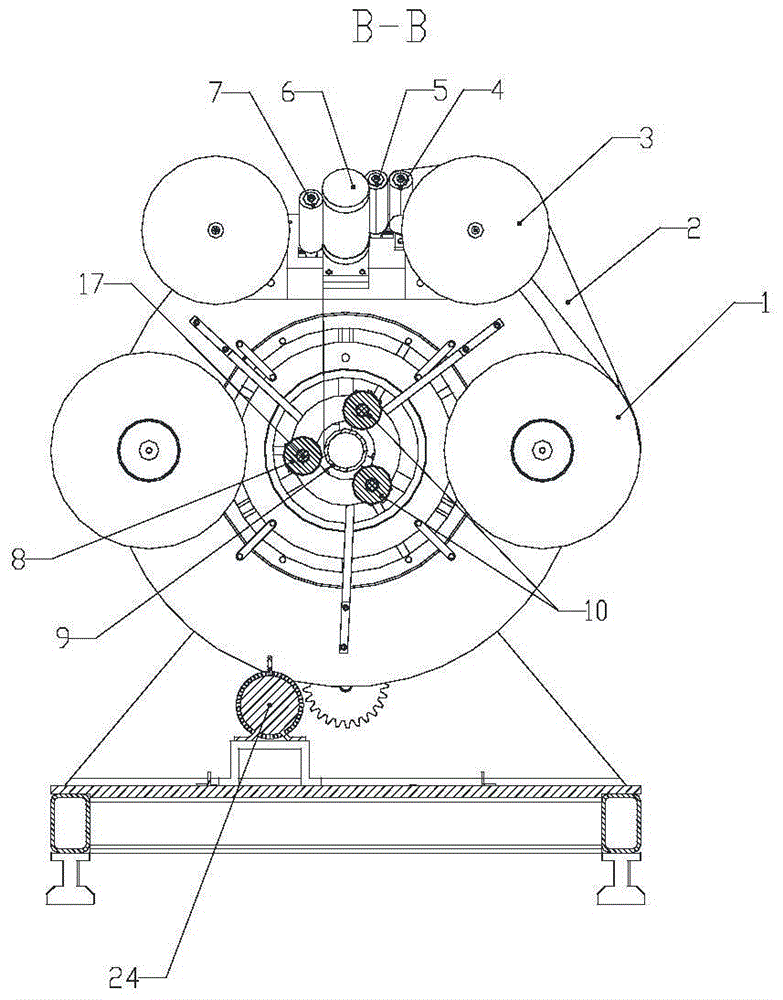

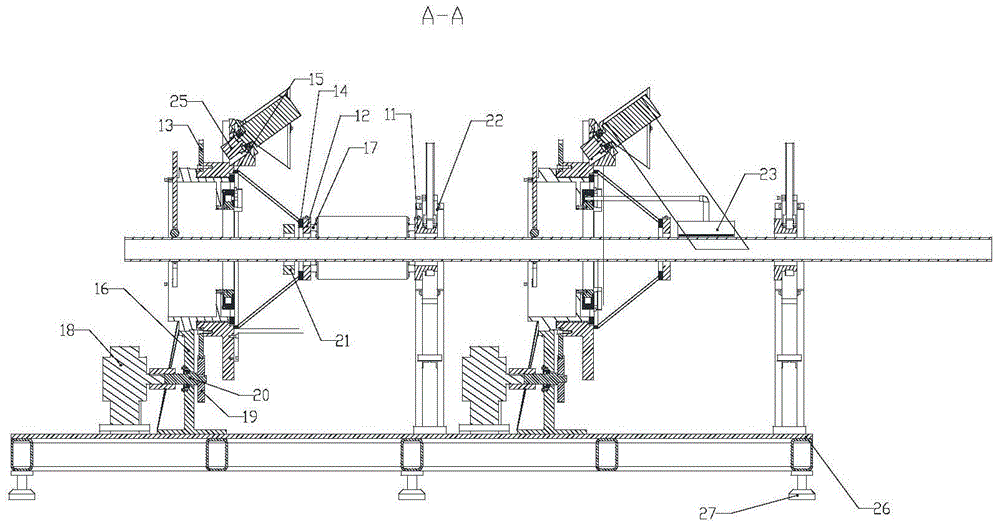

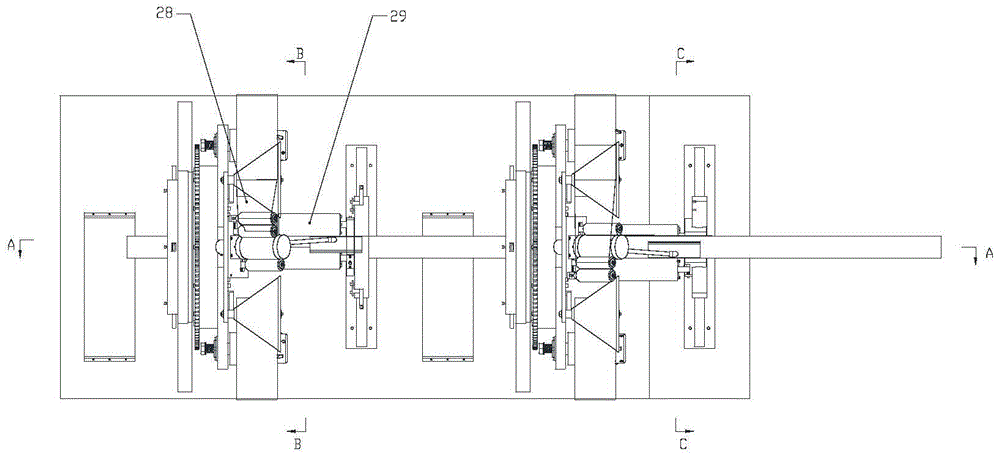

Whole combination type enhanced thermoplastic pipe composite tape winder and winding method thereof

The invention discloses a whole combination type enhanced thermoplastic pipe composite tape winder and a winding method thereof. In the provided composite tape winder, the functions of composite tape delivering, tension force controlling, and winding angle controlling are integrated into a big gear; during the winding process among a matrix pipe straightening device, a matrix pipe preheating device, and a composite tape, the heating or preheating device of the contact surface between the matrix pipe and composite tape is connected to the large gear so as to drive the devices synchronously, thus during the operation process, the synchronism among rotation parts, stability, and uniformity are greatly improved; moreover, the mechanical structure of the winder is simplified, the complicated electric-control device is saved, and the fault rate during the operation process and maintenance cost are both reduced therefore. The provided wing method of the composite tape winder has the advantages of good continuity and stability, high automation degree, and good quality of composite tape winding, and thus has a good market promotion and application prospect.

Owner:青岛海聚新材料科技有限公司

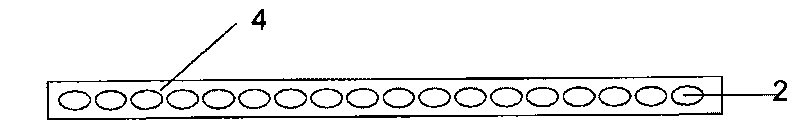

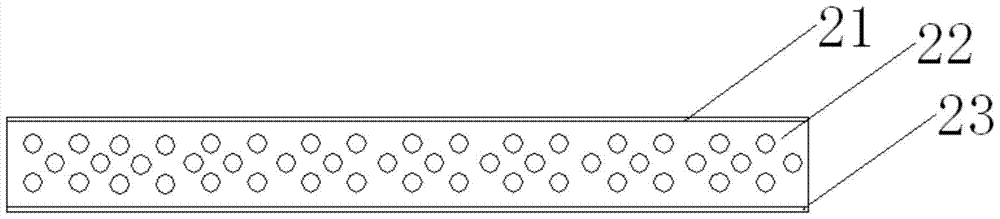

Fiber-reinforced thermoplastic pipe

Disclosed is a reinforced thermoplastic pipe, comprising a thermoplastic polymer inner tube, a thermoplastic polymer outer tube and a reinforcing fabric between the thermoplastic polymer inner tube and the thermoplastic polymer outer tube. The reinforcing fabric comprises thermosettable thermoplastic polymer weft yarns and unidirectionally woven warp yarns. The warp yarns are twisted into twisted cords. Disclosed is also a process of making the reinforced thermoplastic pipe.

Owner:EI DU PONT DE NEMOURS & CO

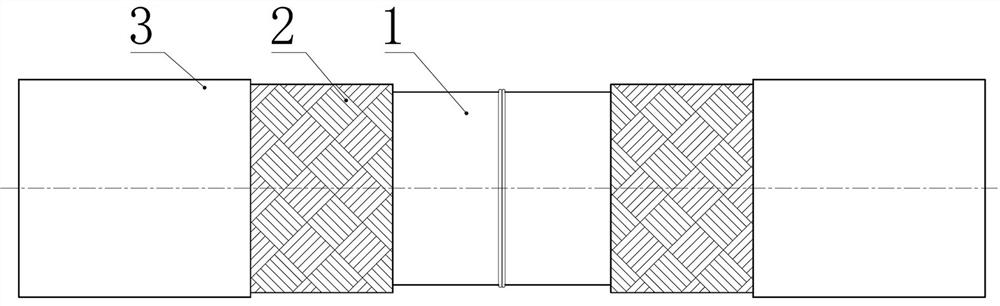

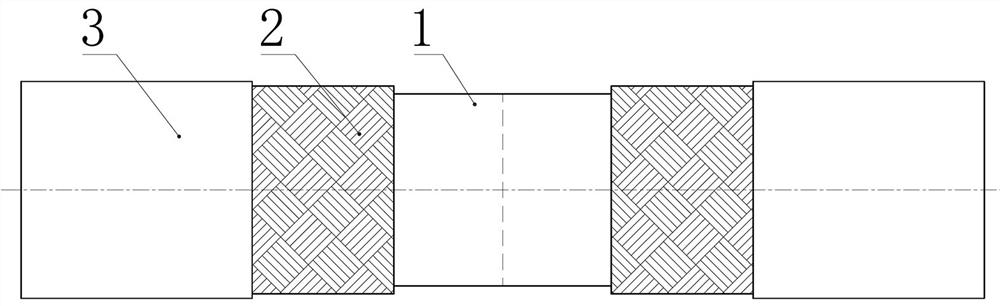

Reinforced thermoplastic pipe (RTP) joint structure and connection method thereof

PendingCN107228248AEffective protectionImprove pressure resistancePipe connection arrangementsButt jointHigh pressure

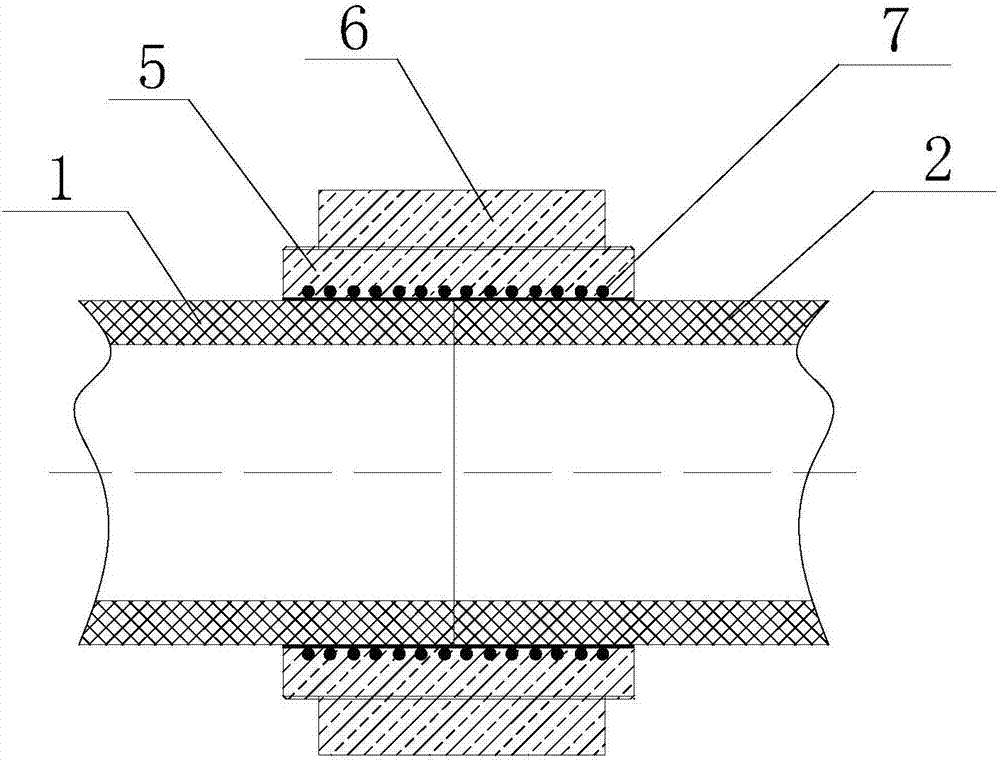

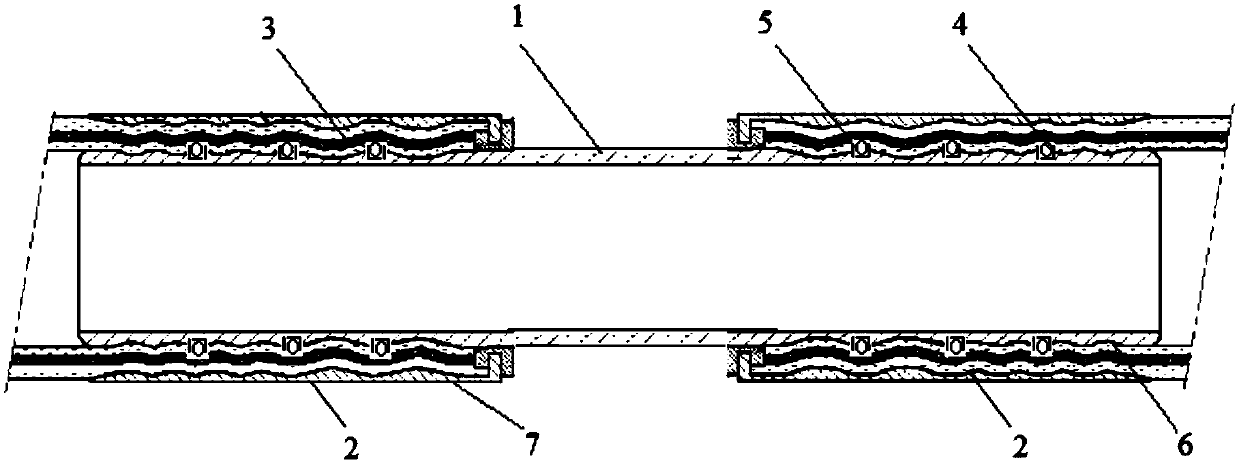

The invention provides a reinforced thermoplastic pipe (RTP) joint structure and a connection method thereof. The RTP joint structure comprises a first RTP, a second RTP, a PE electric melting joint and a GRE reinforced pipe hoop. The first RTP and the second RTP have the same external diameter, and the butt joint end faces of the first RTP and the second RTP are subjected to thermofusion welding. The internal diameter of the PE electric melting joint is matched with the external diameter of the first RTP, and a heating wire is preset and wound inside the PE electric melting joint. The outer wall of the PE electric melting joint is provided with an external thread. The PE electric melting joint simultaneously sleeves the first RTP and the second RTP and is subjected to electric fusion welding to the first RTP and the second RTP through the heating wire, the inner wall of the GRE reinforced pipe hoop is provided with an internal thread matched with the external thread of the PE electric melting joint, and the GRE reinforced pipe hoop is screwed on the external thread of the PE electric melting joint. According to the RTP joint structure, problems that in the prior art, an RTP connection part corrodes easily, is low in high pressure resistance and is subjected to wax deposition and blockage easily can be effectively solved.

Owner:曹如锋

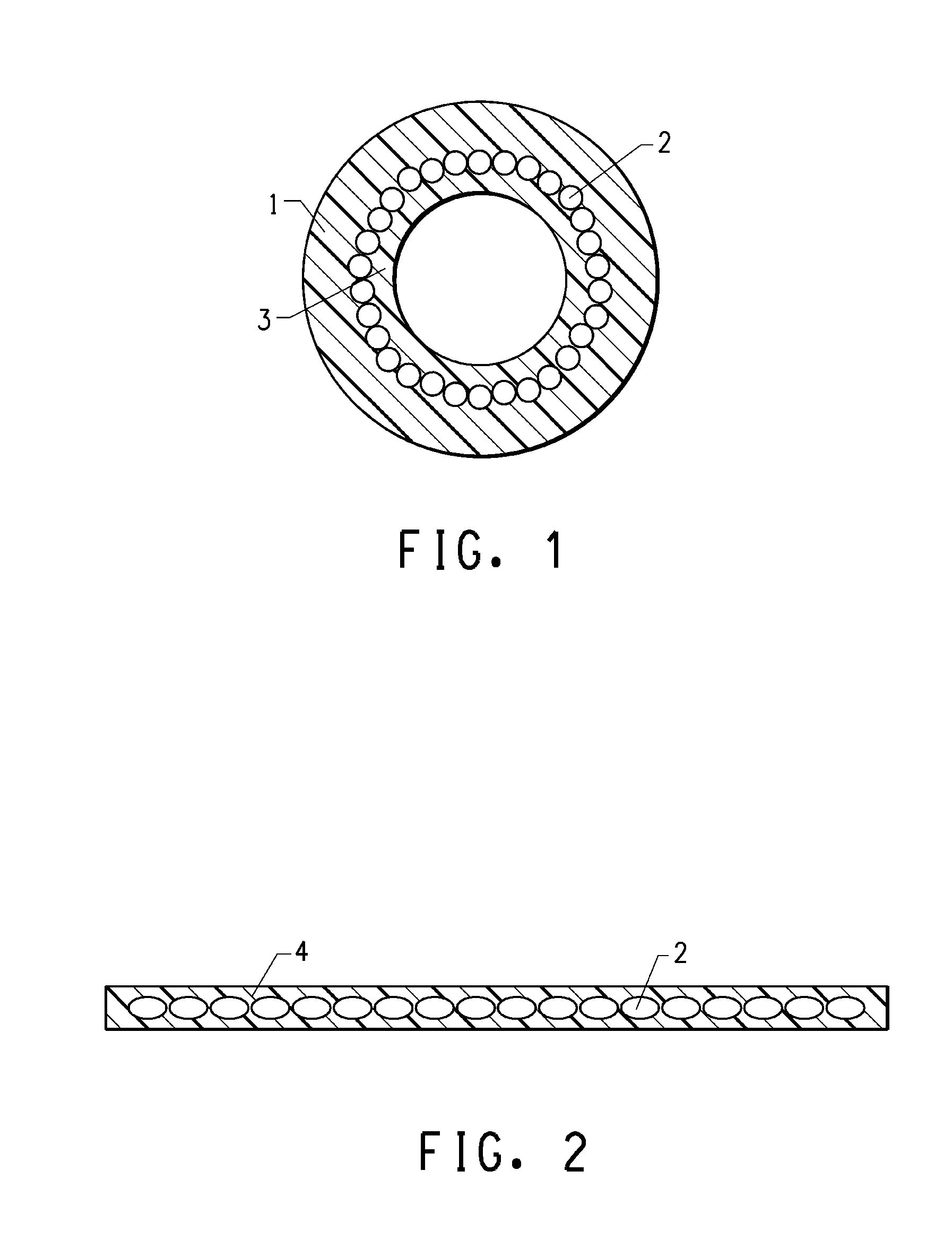

Plastic pipe for reinforcing thermal plasticity

InactiveCN101349367AImprove corrosion resistanceImprove pressure resistanceRigid pipesEngineeringBasalt fiber

The invention discloses a reinforced thermoplastic plastic pipe which is relatively light in weight and is largely increased by pressure resistant performance, which comprises an inner layer pipe and an outer layer pipe. The reinforced thermoplastic plastic pipe is characterized in that a reinforced layer is further arranged between the inner layer pipe and the outer layer pipe, and the reinforced layer is wound by at least two layers of basalt fibers which are treated by plasma. The weight of the reinforced thermoplastic plastic pipe is only the one-quarter of a steel pipe, pressure resistant performance is greatly increased, the pipe can bear 800 Pa pressures, and is long in service life and strong in erosion resistance, besides, the plastic pipe can be processed into a pony roll in hundreds of meters, and is more convenient in paving and less in connector. The plastic pipe can be widely applied to conveying crude oil, acid natural gas and the like.

Owner:ZHANGJIAGANG ZHONGLIAN TECH +1

Fiber band reinforced thermoplastic pipe

The invention discloses a thermoplastic reinforced pipe, which comprises a thermoplastic polymer internal pipe, a thermoplastic polymer external pipe, and a reinforcing textile between the thermoplastic polymer internal pipe and the thermoplastic polymer external pipe, wherein the reinforcing textile comprises a warp which is obtained by performing heat setting on a thermoplastic polymer weft and is woven unidirectionally, and the polymer warp is prepared from a twisted rope. The invention also discloses a method for manufacturing the thermoplastic reinforced pipe, which comprises the following steps of: a) providing the thermoplastic polymer internal pipe; b) twisting fibers for manufacturing the warp to have the twist multiplier of between 0.1 and 6.5 so as to obtain twisted fibers, stranding and performing back twisting on 2 to 20 strands of the twisted fibers to have the twist multiplier of between 0.1 and 6.5 so as to obtain the twisted rope; c) using the twisted rope as a warp thread and a single strand of a polymer yarn as a weft thread to weave the twisted rope into a unidirectional reinforcing textile on a loom, and then performing heat setting on the weft thread to prepare the reinforcing textile; d) enwinding the reinforcing textile on the polymer internal pipe at an included angle of 50 to 60 degrees; and e) coating the polymer external pipe through an external pipe extruder.

Owner:EI DU PONT DE NEMOURS & CO

Reinforced thermoplastic plastic pipe and its production method

InactiveCN1869492AIncrease forceEnhancement effect is goodLaminationLamination apparatusPolyesterLow-density polyethylene

The invention relates to thermal plasticity plastic tubing and the manufacture method. It includes three layers structure that the inner layer is nanometer material modified high density polyethylene tubing, the middle layer is compound polyester fiber, and the outside layer is nanometer modified high density polyethylene layer. The manufacture method includes the following steps: making nanometer material modified high density polyethylene agglomerate; extruding inner layer; twisting middle compound polyester fiber layer; hot shaping and bonding middle layer compound polyester fiber layer; extruding out layer. The invention is low cost, simple method, and low energy consumption.

Owner:常州市生富公路材料有限公司

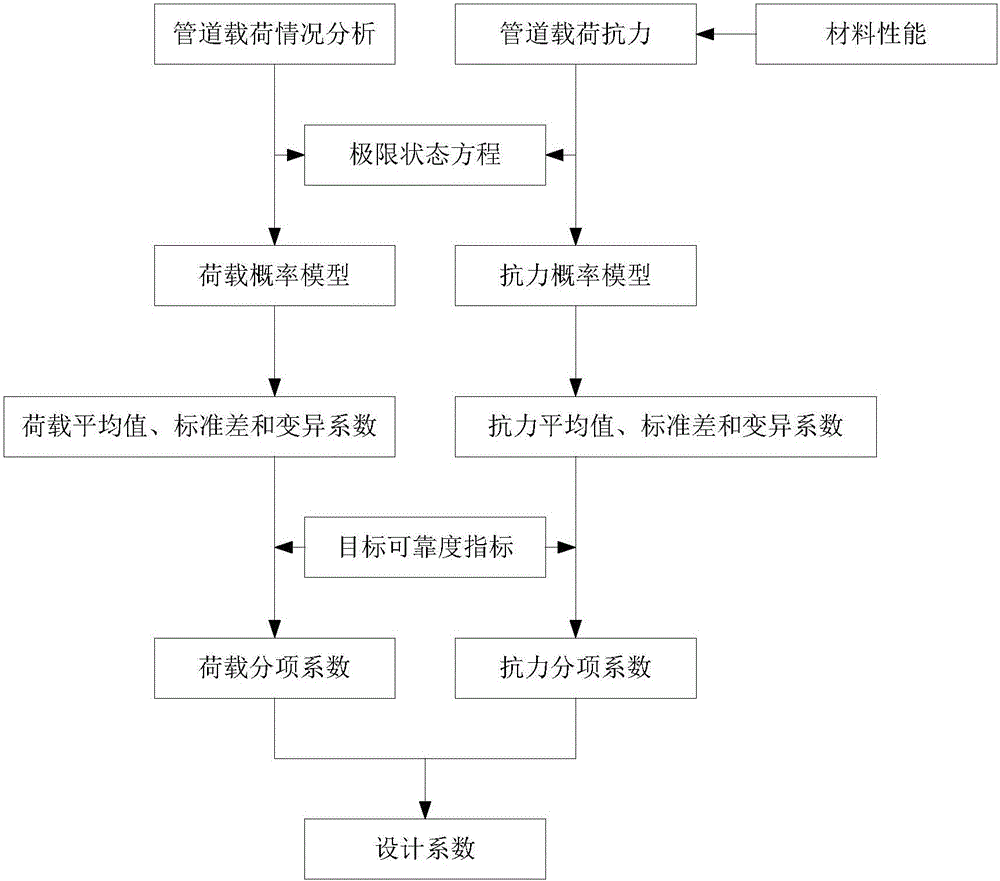

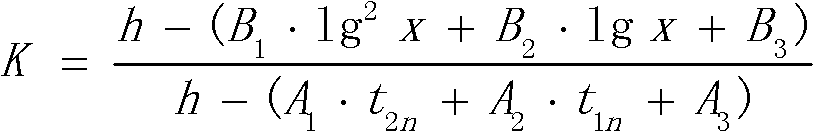

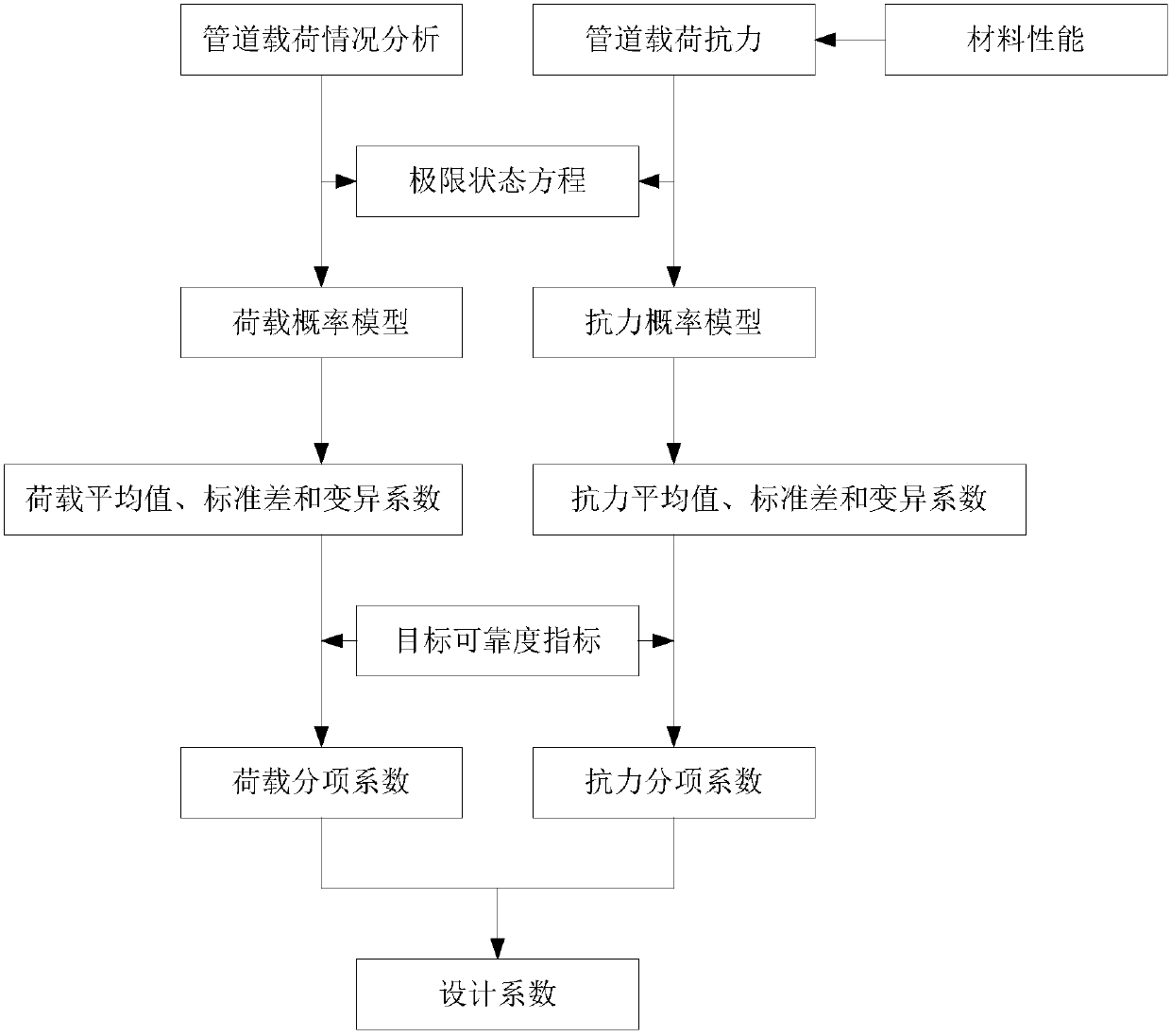

Method for determining design coefficient of reinforced thermoplastic pipe (RTP)

The invention discloses a method for determining a design coefficient of a reinforced thermoplastic pipe (RTP). The method comprises the following steps: analyzing an internal pressure load, bending load, external pressure load, axial tension load, temperature difference load and combined load of the RTP, and analyzing the load resistance of the RTP; establishing a limit state function, load probability model and resistance probability model under different load conditions; determining an average value, standard difference and variation coefficient of the loads and the resistance; giving a target reliability index, and determining a partial load coefficient and partial resistance coefficient by virtue of a FORM method; determining the design coefficient by virtue of an LRFD method. The method has the beneficial effects that the loads of the RTP are classified into the internal pressure load, the bending load, the external pressure load, the axial tension load, the temperature difference load and the combined load; the target reliability index is combined to form a calculation method for the design coefficient by establishing a limit state equation and establishing the probability models, so that a foundation is laid for the future engineering application of the RTP to an oil and gas transmission pipeline.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Continuous reinforced thermoplastic pipe wound around by metal strip

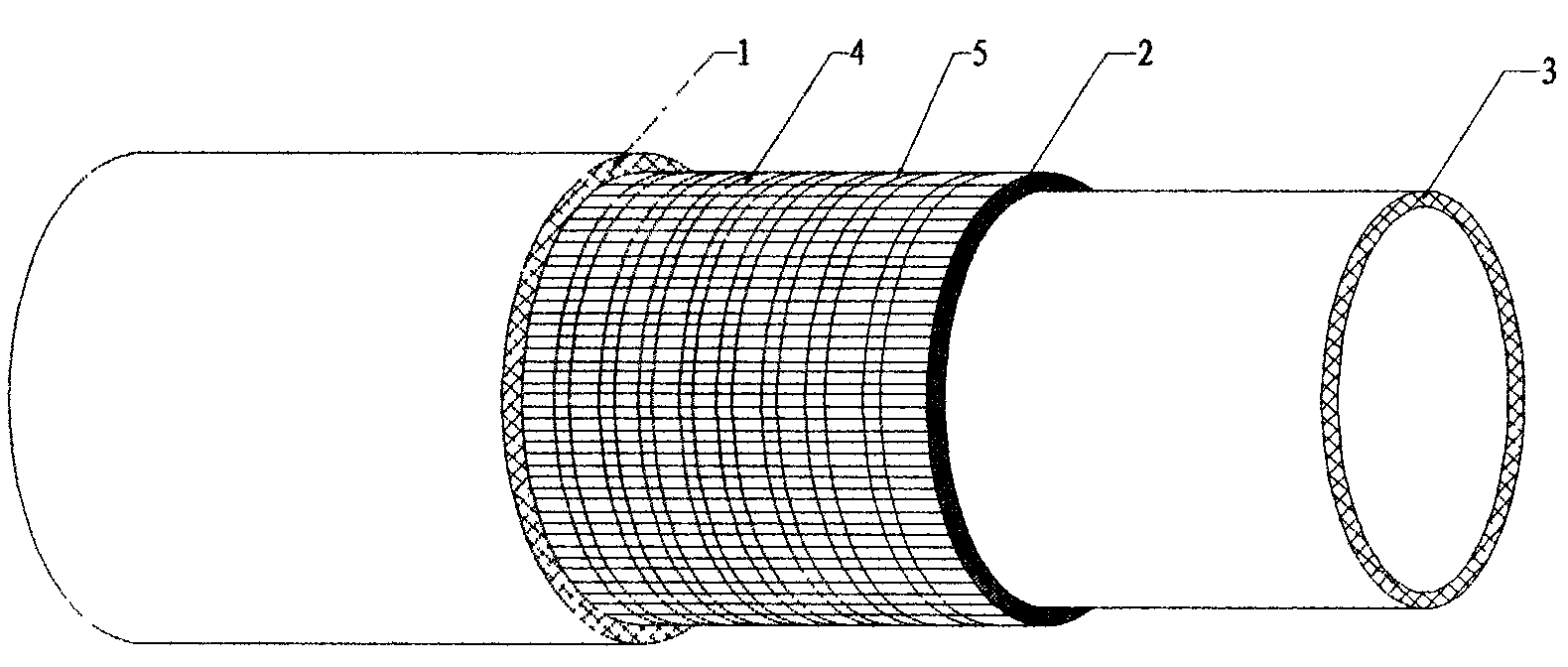

ActiveCN108930846AHigh strengthImprove axial strengthGeneral water supply conservationTransportation and packagingMetal stripsManufacturing cost reduction

The invention discloses a continuous reinforced thermoplastic pipe wound around by a metal strip. According to the pipe, a method of group division designing of the winding metal strip is adopted, thewinding metal strip is reasonably distributed, and meanwhile, the high strength of the metal strip is utilized to increase the circumferential strength and the axial strength of a pipe, so that the anti-pressure ability of the pipe is improved, metal belt reinforcing layers are not bonded, the flexibility of the composite pipe is improved, and the relative slippage amount among the metal belt layers is reduced; and the manufacturing process is simple and convenient, the equipment investment requirement is small, so that the manufacturing cost is greatly reduced, and the flexibility and the seismic resistance of the pipeline are guaranteed.

Owner:NINGBO OPR OFFSHORE ENG EQUIP CO LTD

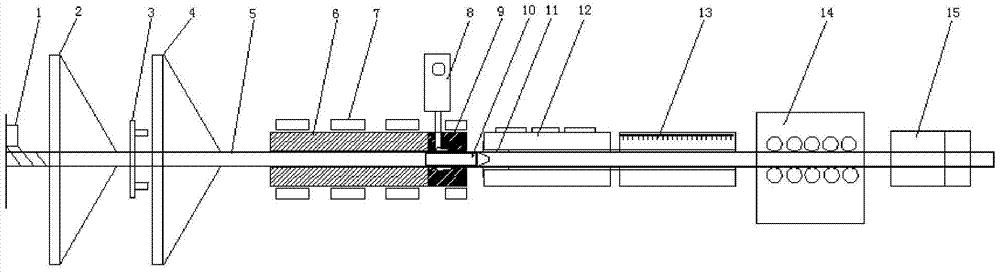

Roll Forming Technology of Fiber Reinforced Thermoplastic Pipes

InactiveCN102259427AImproved vertical and horizontal performanceIncrease productivityTubular articlesEngineeringPlastic film

Fiber-reinforced thermoplastic pipe rolling molding technology, the technical route is to first clean and dry the fiber-woven net, and perform coupling treatment; the thermoplastic is prefabricated into a strip-shaped sheet; The plastic sheet is calendered and stacked to form a strip-shaped composite sheet, and then the strip-shaped thermoplastic sheet and the strip-shaped composite sheet are stacked on the heated and rotating inner mold of the pipe, wound and rolled again, and cooled to form a fiber-reinforced thermoplastic. Plastic tubing. The invention has the advantages of simple process, low equipment investment cost, high production efficiency, and easy large-scale products. The longitudinal and transverse fibers of the fiber net improve the longitudinal and transverse properties of the pipe; adjusting the ratio of the longitudinal and transverse fibers of the fiber net can produce Pipes to meet different engineering requirements.

Owner:HEFEI HUAYU RUBBER EQUIP

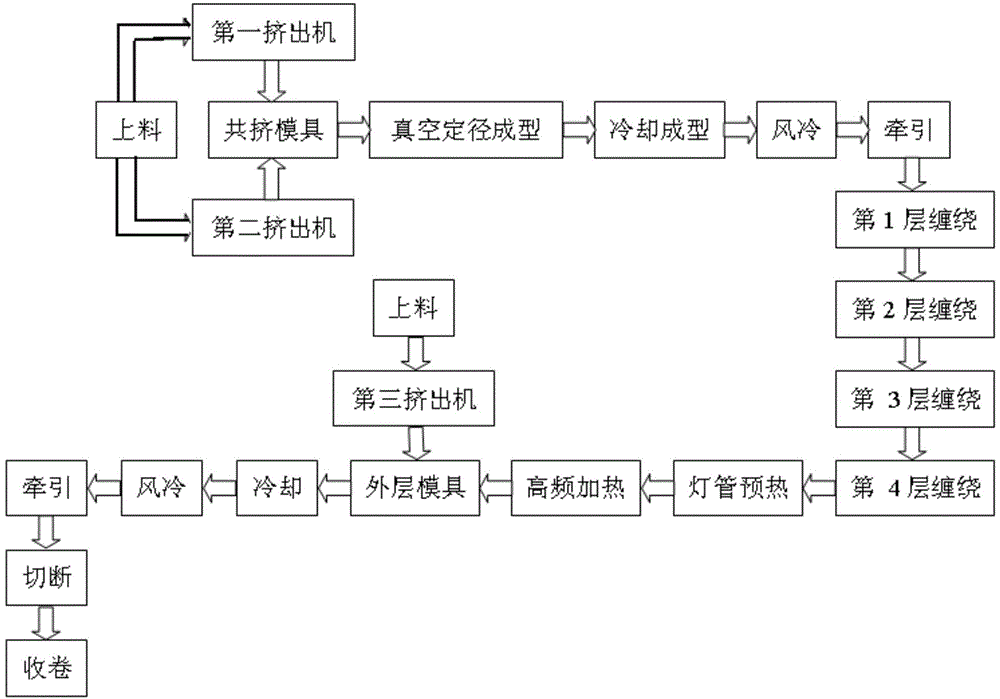

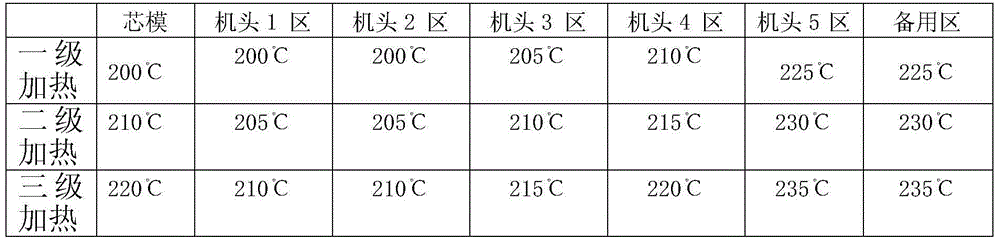

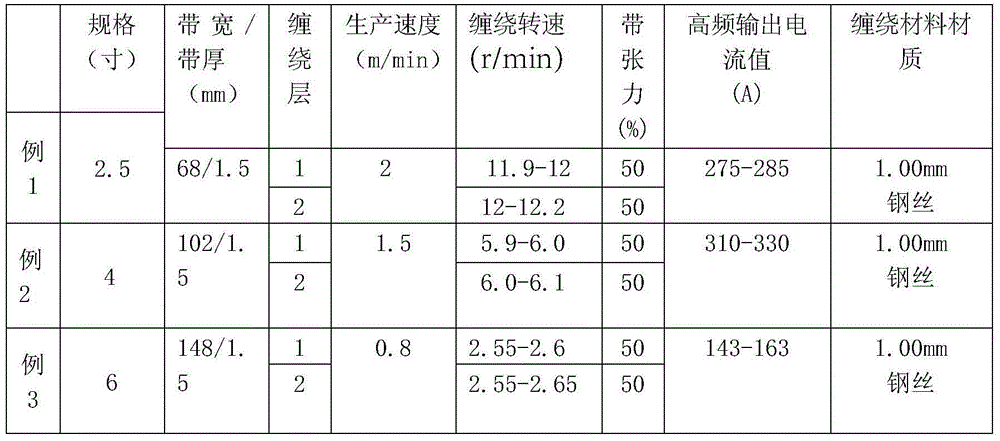

Thermoplasticity reinforcing plastic pipe preparation process

The present invention discloses a thermoplasticity reinforcing plastic pipe preparation process, which comprises inner pipe layer preparation, reinforcing layer preparation and protection layer preparation and specifically comprises steps of material feeding, heating, extruding, traction, winding, wrapping, code spraying, marking, cutting, coiling, and packing, wherein the screw extruder barrel heating and the mold heating are completed through the three-stage six-zone heating stage, the winding axis center line and the inner pipe axis center line form the angle of 50-60 DEG, and the strip-like material bidirection cross winding structure is formed and comprises the left spiral winding later and the right spiral winding layer. The preparation process is the thermoplasticity reinforcing plastic pipe preparation process with characteristics of high production efficiency and low cost, wherein the pressure bearing capacity can achieve 32 MPa, and the impact resistance can achieve 130 KJ / m<2>.

Owner:JIANGSU SHENSHI NEW MATERIAL TECH

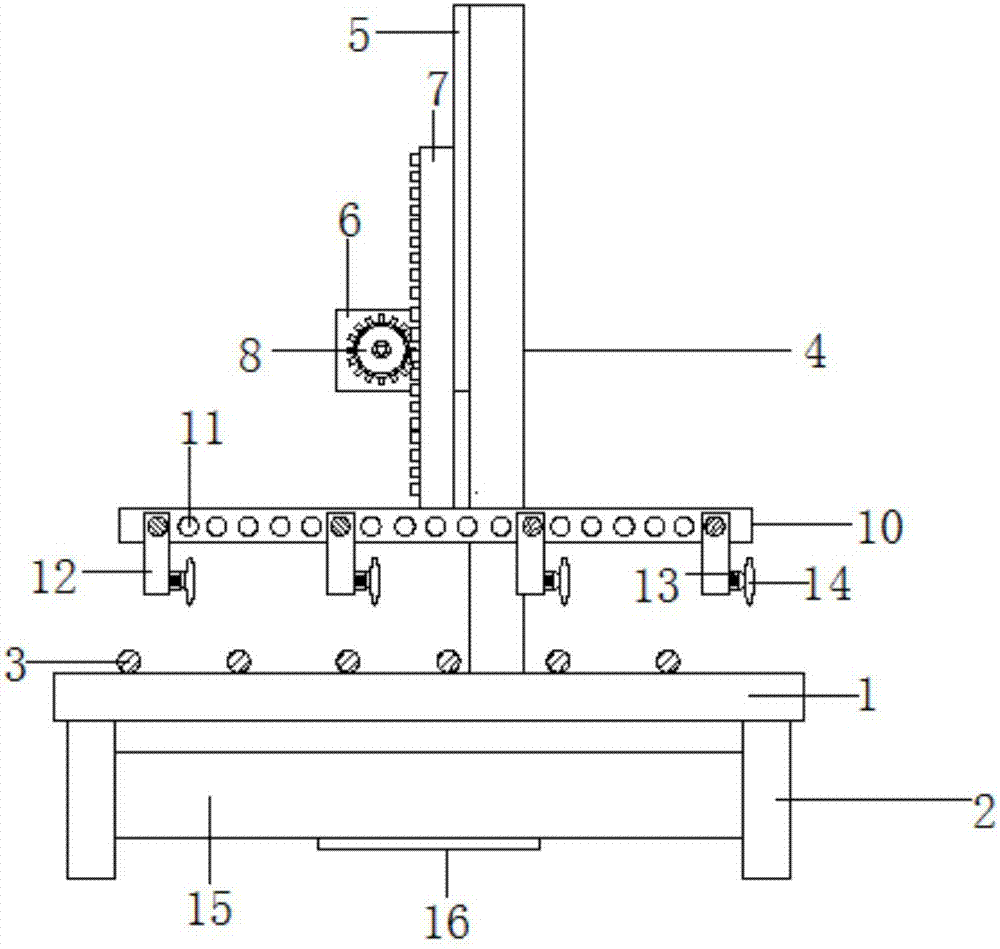

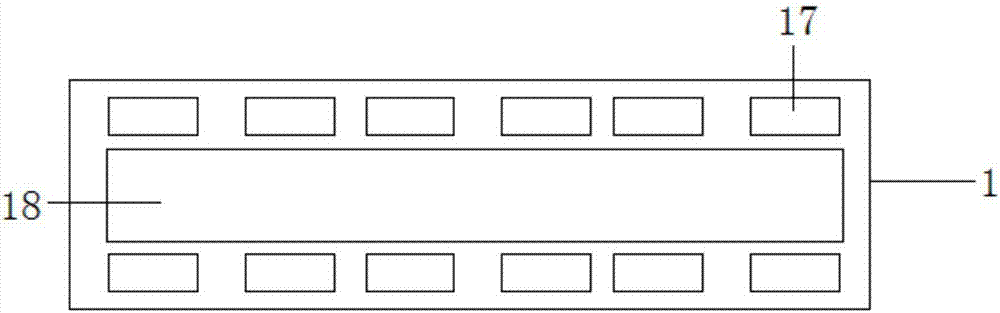

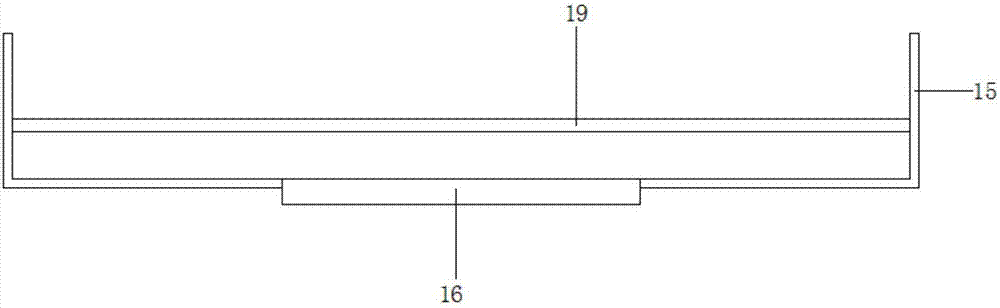

Environmental-friendly continuous glass fiber reinforced thermoplastic pipe segmentation device

InactiveCN107263576AFast cutting speedIncrease productivityMetal working apparatusGlass fiberEngineering

The invention discloses an environment-friendly continuous glass fiber-reinforced thermoplastic pipe cutting device in the technical field of thermoplastic pipe cutting. The top is evenly provided with conveying rollers, the rear surface of the frame body is provided with a pillar, the left outer wall of the pillar is provided with a slide rail, the left side of the slide rail is slidably connected to a rack, and the left side of the rack is The teeth are connected with gears, the rear surface of the pillar is provided with a support plate, the left side of the front surface of the support plate is provided with a driving device, the bottom of the front surface of the rack is provided with a support rod, and the outer wall of the support rod is uniform Threaded holes are provided, four sets of connecting rods are arranged on the front surface of the support rod, a motor is arranged on the bottom of the right outer wall of the connecting rod, and a cutter is connected to the right power output end of the motor, and the structure of the present invention is reasonably used Convenient, fast cutting speed for reinforced thermoplastic pipes, effectively improving the production efficiency of the factory.

Owner:江苏赛尔超高压特种管业有限公司

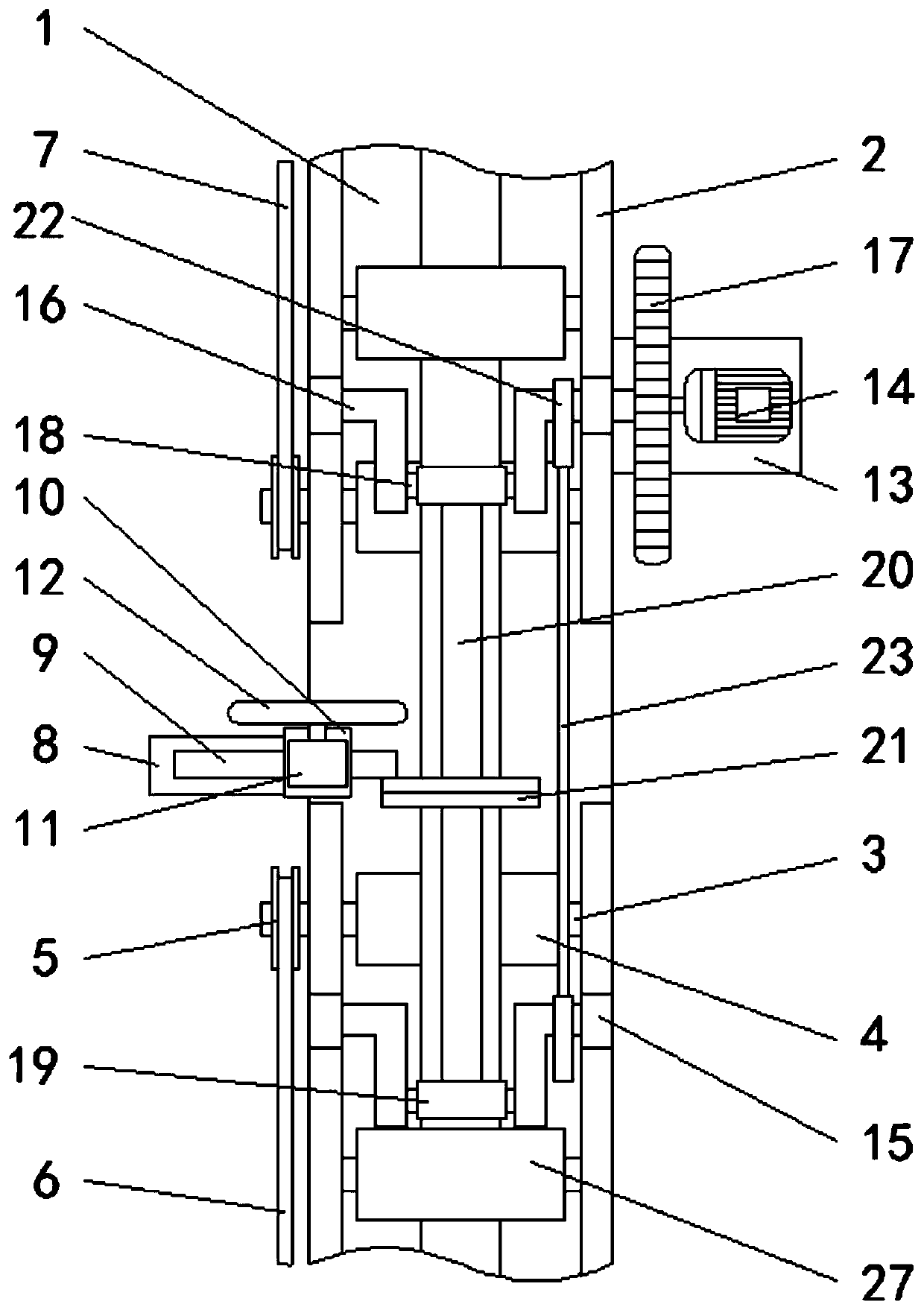

Reinforced thermoplastic pipe end forming device and method

The invention belongs to the technical field of mechanical equipment, and relates to a pipe end forming device and a pipe end forming method, in particular to a reinforced thermoplastic pipe (RTP) end forming device and a reinforced thermoplastic pipe end forming method. The reinforced thermoplastic pipe end forming device and the reinforced thermoplastic pipe end forming method are applied to the pipe machining and manufacturing industry and are used in pipe port manufacturing occasions; the problems that the connection is difficult and the service life of a RTP is shortened since a middle reinforcement layer is exposed to the air are solved, the butting efficiency can be improved effectively and the service life of the RTP can be prolonged; a chamfer is formed at the end part of an internal mould of the reinforced thermoplastic pipe end forming device, so that RTP penetration is facilitated; the diameter of the internal mould is greater than the internal diameter of the RTP, so that during pipe end forming, an expanding effect is exerted on the RTP, and pipe welding is facilitated; hot oil is added to an oil duct, so that an internal layer of the RTP can be heated; the flanging height L is 1.5-2 times of the thickness of the pipe wall of a solid wall at the same pressure rating, so that the pipe end welding safety is guaranteed; and the reinforced thermoplastic pipe end forming device is simple in overall structure, reliable in principle, good in pipe end forming effect, easy and simple to operate, and has good economic benefits and broad market prospects.

Owner:王庆昭

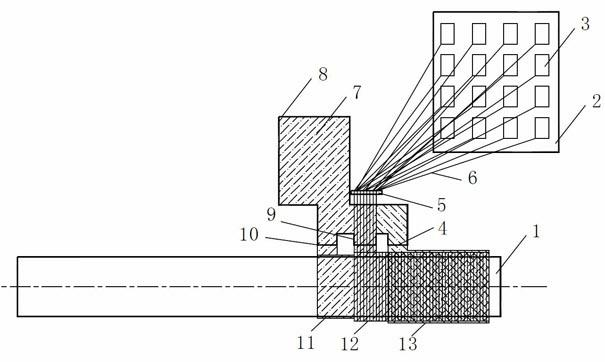

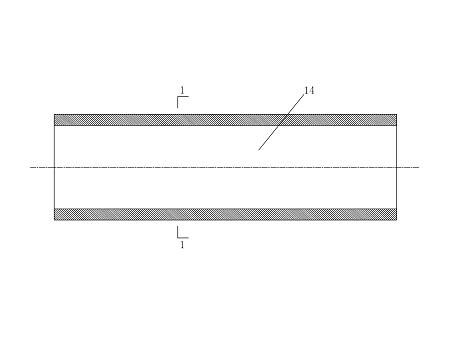

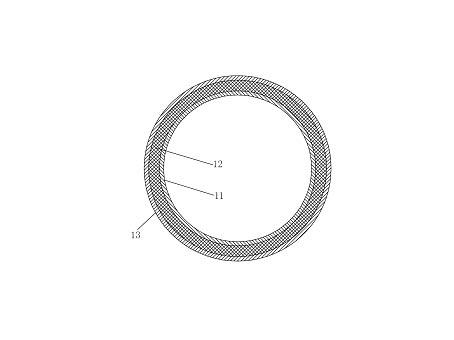

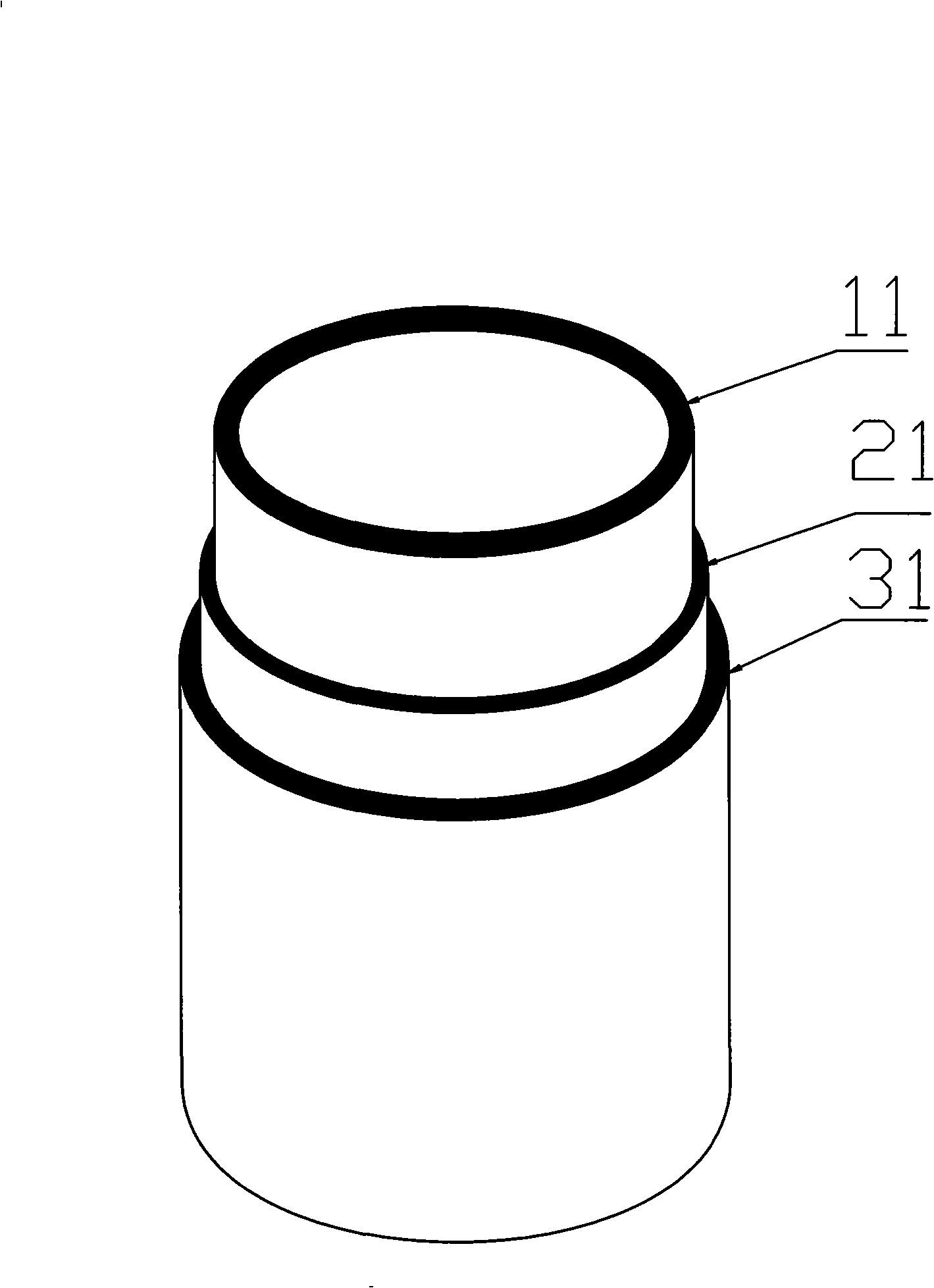

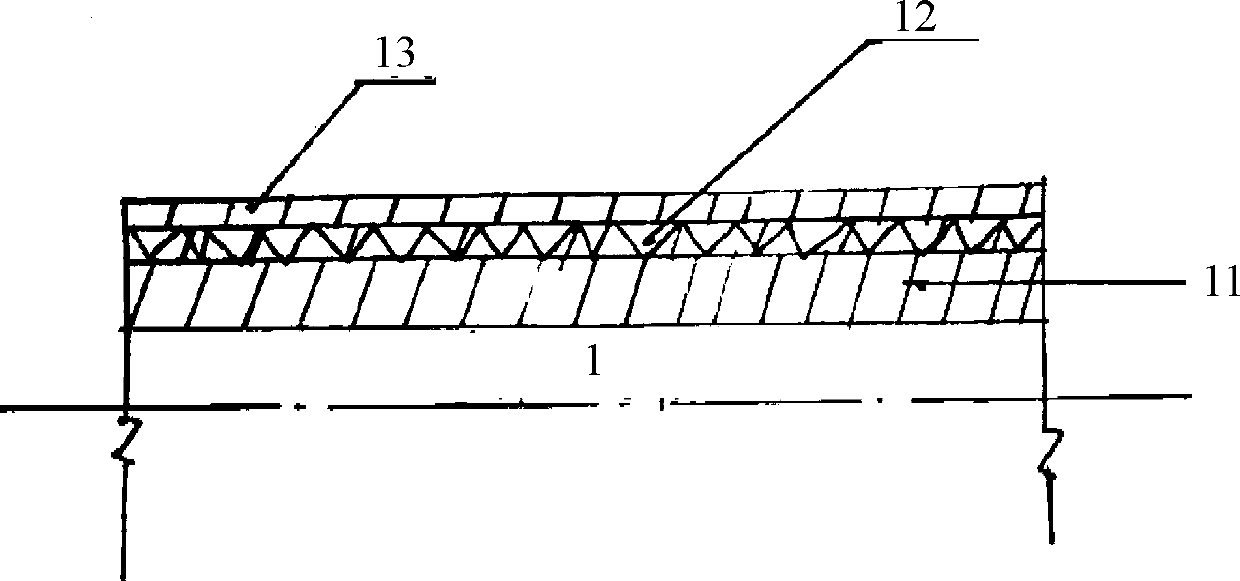

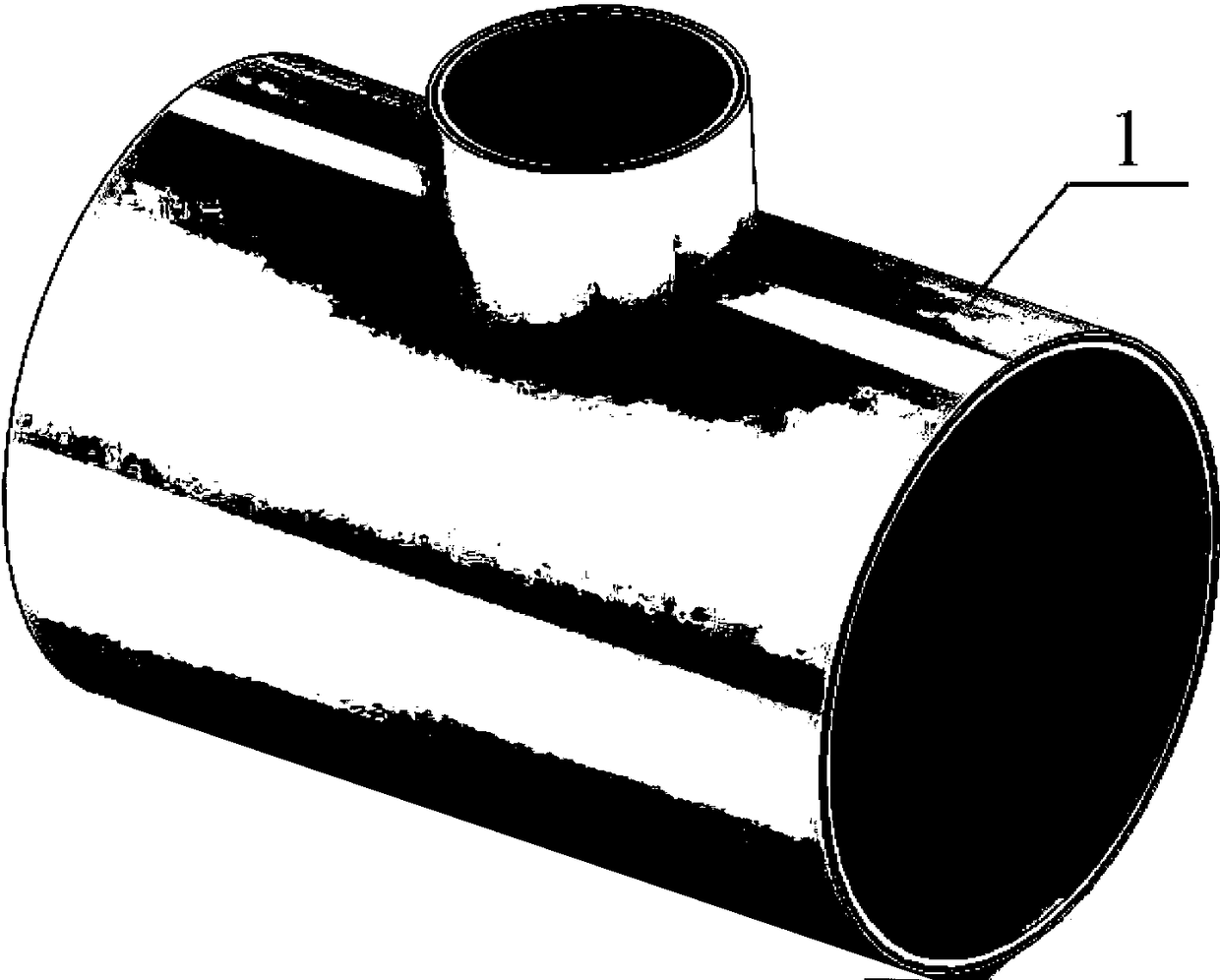

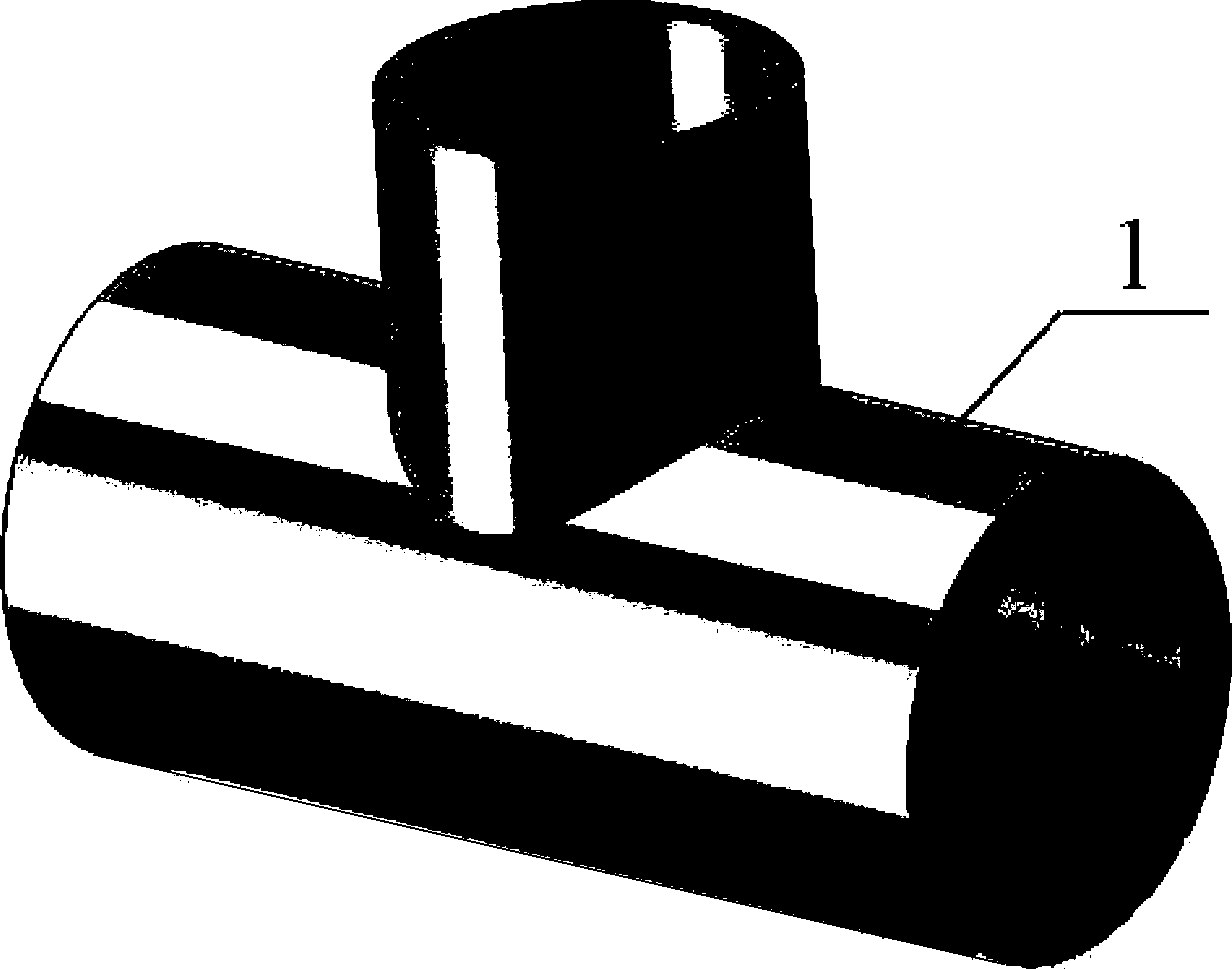

Pipe special for manufacturing continuous fiber reinforced thermoplastic pipe fitting, and manufacturing method thereof

The invention relates to the field of reinforcing high-molecular compounds through loose or adherent fibrous materials, in particular to a pipe special for manufacturing a continuous fiber reinforcedthermoplastic pipe fitting, and a manufacturing method thereof. The pipe special for manufacturing the continuous fiber reinforced thermoplastic pipe fitting is characterized in that a continuous fiber reinforced thermoplastic pipe fitting pipe (1) is an interlayer hot-melting combined special three-layer structure continuous fiber reinforced composite pipe which is composed of a particularly thickened pure plastic inner layer pipe (11), a reinforced core layer pipe (12) with the particularly-increased continuous fiber prepreg tape winding layer number and a pure plastic protective layer outerlayer pipe (13). The pipe special for manufacturing the continuous fiber reinforced thermoplastic pipe fitting is convenient to manufacture, high in mechanical strength and long in service life.

Owner:上海英泰塑胶股份有限公司

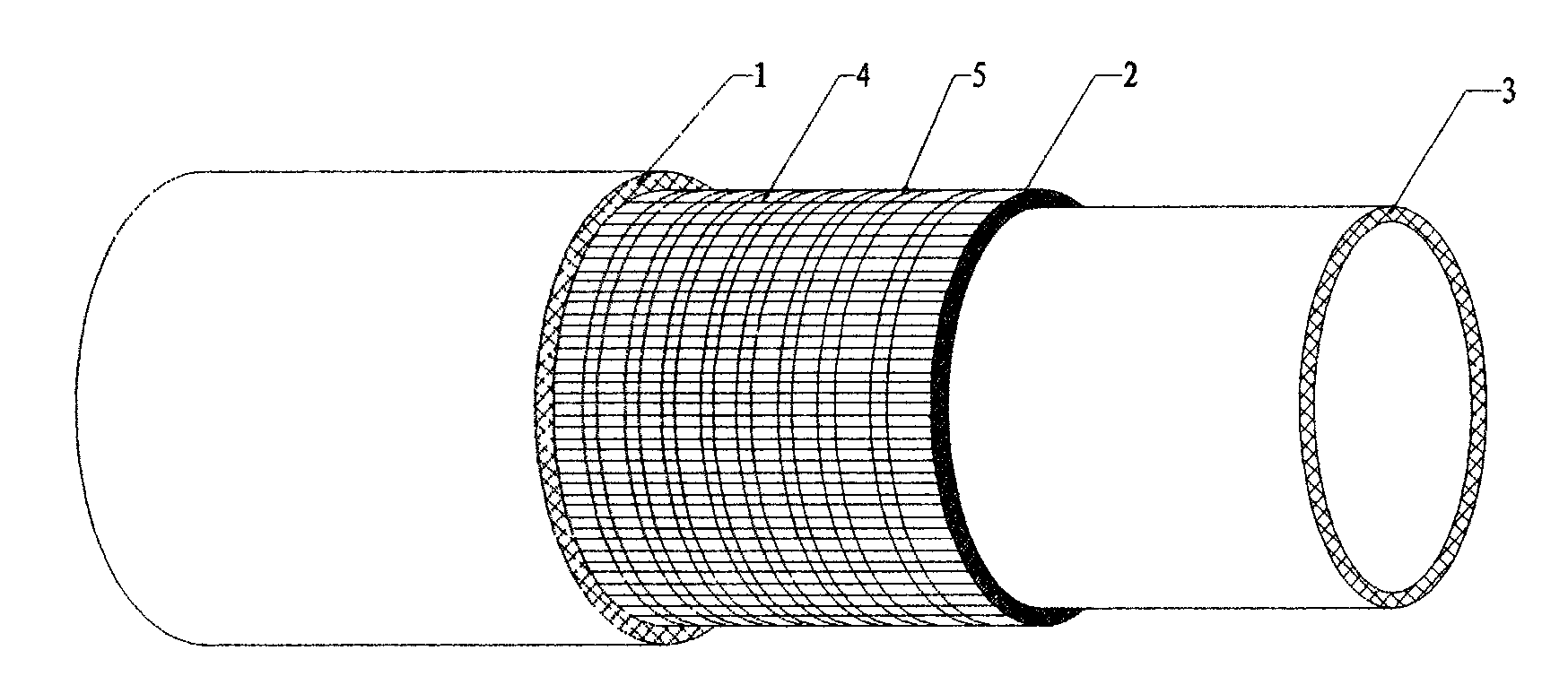

Related to continuous fiber reinforced thermoplastic pipe and production method

ActiveCN105003753BShorten the lengthReasonable process designFlexible pipesRigid pipesYarnWhole body

The invention relates to the technical field of glass fiber and pipeline forming, particularly to a thermoplastic pipeline related to continuous fiber reinforcement and a producing method. The pipeline comprises an inner layer, a weaving enhancement structure layer on the inner layer and an outer thermoplastic protective layer on the inner layer and the enhancement structure layer, wherein the three-layer structure is integrally formed; the inner layer adopts thermoplastic membranes or sheets; the enhancement layer is prepared through weaving, twining and longitudinally configurating preimpregnated thermoplastic fiber yarns; the outer layer is extruded with an extruder on the inner layer and the enhancement layer through the adoption of a thermoplastic material, so that the three-layer structure is integrated into a whole body, wherein the pipeline specification is below D1000 mm; the working pressure is 1-15 MPa. According to the thermoplastic pipeline and the producing method, the conventional RTP pipe three-layer structure is reserved, and the conventional multistep shaping method is changed to one-step shaping, so that the production line length is shortened by a half, and the equipment input is greatly decreased; the novel product is more stable in quality, higher in internal pressure strength and applicable to continuous production.

Owner:深圳鑫宝通材料科技有限公司

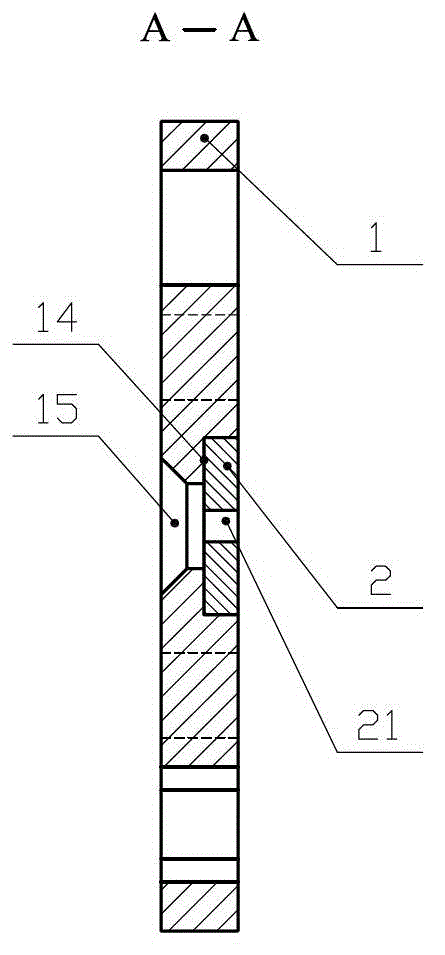

Continuous fiber reinforced thermoplastic pipe high-pressure resistant joint pipe fitting group and manufacturing method thereof

InactiveCN108621434AHigh strengthEasy to manufactureBranching pipesDomestic articlesPolymer sciencePipe fitting

The invention relates to the field of loose or adhesive fibrous material reinforced high-molecular compounds and particularly relates to a continuous fiber reinforced thermoplastic pipe high-pressureresistant joint pipe fitting group and a manufacturing method thereof. The continuous fiber reinforced thermoplastic pipe high-pressure resistant joint pipe fitting group comprises pipe fittings and connecting pieces, wherein the pipe fittings and connecting pieces are composed of pipes (1); the pipe fitting group is characterized in that the pipes (1) comprise three layers from inside out, namelyan inner pipe layer (11), a reinforcing layer (12) and an outer pipe layer (13) respectively; stepped holes (14) of two-stage steps are formed in two ends of the inner pipe layer (11); larger round holes of the stepped holes (14) are formed in the outer end; smaller round holes of the stepped holes (14) are formed in the inner end. The continuous fiber reinforced thermoplastic pipe high-pressureresistant joint pipe fitting group disclosed by the invention is high in strength, convenient to manufacture and wide in application range.

Owner:上海英泰塑胶股份有限公司

Reinforced thermoplastic plastic pipe

The invention discloses a reinforced thermoplastic plastic pipe which is characterized by consisting of the following raw materials in parts by weight: 90-97 parts of PE80, 2-3 parts of zinc phosphate, 3-5 parts of carbon fiber, 2-3 parts of polyisobutene, 0.2-1 part of pyromellitic dianhydride, 1-2 parts of linoleic acid, 1-2 parts of octyl-4-isothiazolin-3-one, 2-3 parts of biimidazoline-ammonium-salt corrosion inhibitor, 2-4 parts of nano fluorite powder, 2-3 parts of glass powder, 0.8-1 part of octyl tin mercaptan OTM-17N, 0.8-2 parts of 2-mercapto benzimidazole and 10-13 parts of composite filler. The pipe is particularly suitable for long-distance transport pipes and offshore oil and gas fields, is high in corrosion resistance and has high damage resistance, and a leakage phenomenon is avoided.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

Method for inspecting reinforced thermoplastic pipe based on designed life

ActiveCN102183407BReduce manufacturing costImprove reliabilityMaterial strength using tensile/compressive forcesUltimate tensile strengthMaterials science

The invention relates to the field of design and inspection of reinforced thermoplastic pipes (RTP) and aims at providing a method for inspecting the reinforced thermoplastic pipe based on the designed life. The method comprises the following steps of: performing bursting test on the RTP; performing puncture test on the RTP; performing tensile test on a reinforcement material of the RTP and a base body material of the RTP; obtaining a long-time burning pressure Plife of the RTP based on the designed life; and finally comparing a relation between the long-time burning pressure Plife and a designed pressure Pdesign, if Plife is greater than or equal to K'Pdesign, determining that the product is qualified. By the method, the burning pressure under long-time service life of the RTP can be forecast and inspected by short-time test, so the working procedure of performing a large amount of long-time hydrostatic test in the conventional long-time hydrostatic intensity measurement method basedon an extrapolation method, so the RTP production cost is saved, the production period is shortened, and the reliability and the product competitiveness of the RTP are enhanced.

Owner:ZHEJIANG UNIV

On-spot connection joint and method for reinforced thermoplastic plastic pipes

InactiveCN109595410AImprove corrosion resistanceEasy connection processSleeve/socket jointsCorrosion resistant alloyHot melt

The invention discloses an on-spot connection joint and method for reinforced thermoplastic plastic pipes. The on-spot connection joint comprises a connection pipe with the two ends being connected inside the RTP pipes in a sleeved manner, the two ends of the connection pipe are provided with ring-shaped teeth and provided with a plurality of seal ring grooves, the parts, connected on the connection pipe in a sleeving manner, of the RTP pipes are provided with outer sleeve tubes in a sleeved manner, and the outer sleeve tubes perform sealing through seal rings arranged inside the seal ring grooves and hot melt glue layers coated on the ring-shaped tooth portions at the two ends of the connection pipe. According to the on-spot connection joint and method for the reinforced thermoplastic plastic pipes, by means of the method that parts in contact with a fluid medium adopt stainless steel, corrosion resistant alloy or bimetallic steel pipes, the corrosion resistant performance of traditional carbon steel coupler joint core pipes is improved; the single connection pipe is adopted as an inner pipe for connecting the two RTP pipes, connection procedures are reduced, the connection process between the pipes is optimized, and the connection reliability and the construction efficiency are improved; and by means of the additions of the seal rings and the hot melt glue layers in the structure, internal small molecular medium escape passages are obstructed, and the connection tightness is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Section cutting equipment with section processing mechanism for glass fiber reinforced thermoplastic pipe

InactiveCN111531620AAvoid displacementEdge grinding machinesMetal working apparatusGlass fiberGear wheel

The invention relates to the technical field of thermoplastic pipes, and discloses section cutting equipment with a section processing mechanism for a glass fiber reinforced thermoplastic pipe. The section cutting equipment comprises a fixed bottom plate, wherein support legs are fixedly connected to the front surface of the fixed bottom plate; lower support frames are fixedly connected to one ends, away from the fixed bottom plate, of the support legs; and movable rods are movably connected to the interiors of the lower support frames. According to the section cutting equipment with the section processing mechanism for the glass fiber reinforced thermoplastic pipe, the movable rods are rotated by starting two reduction motors installed on the fixed bottom plate, a second driving motor isstarted to drive connecting arms to rotate, and two transmission gears are engaged, so that the connecting arms in upper support frames are made to rotate, then cutters outside positioning rods cut off the plastic pipe, and the automatic high-efficiency cutting is achieved; and the cross section of the plastic pipe can be processed to be smoother by a grinding wheel, and the two reduction motors are started to continuously push the plastic pipe at the same time.

Owner:江苏赛尔超高压特种管业有限公司

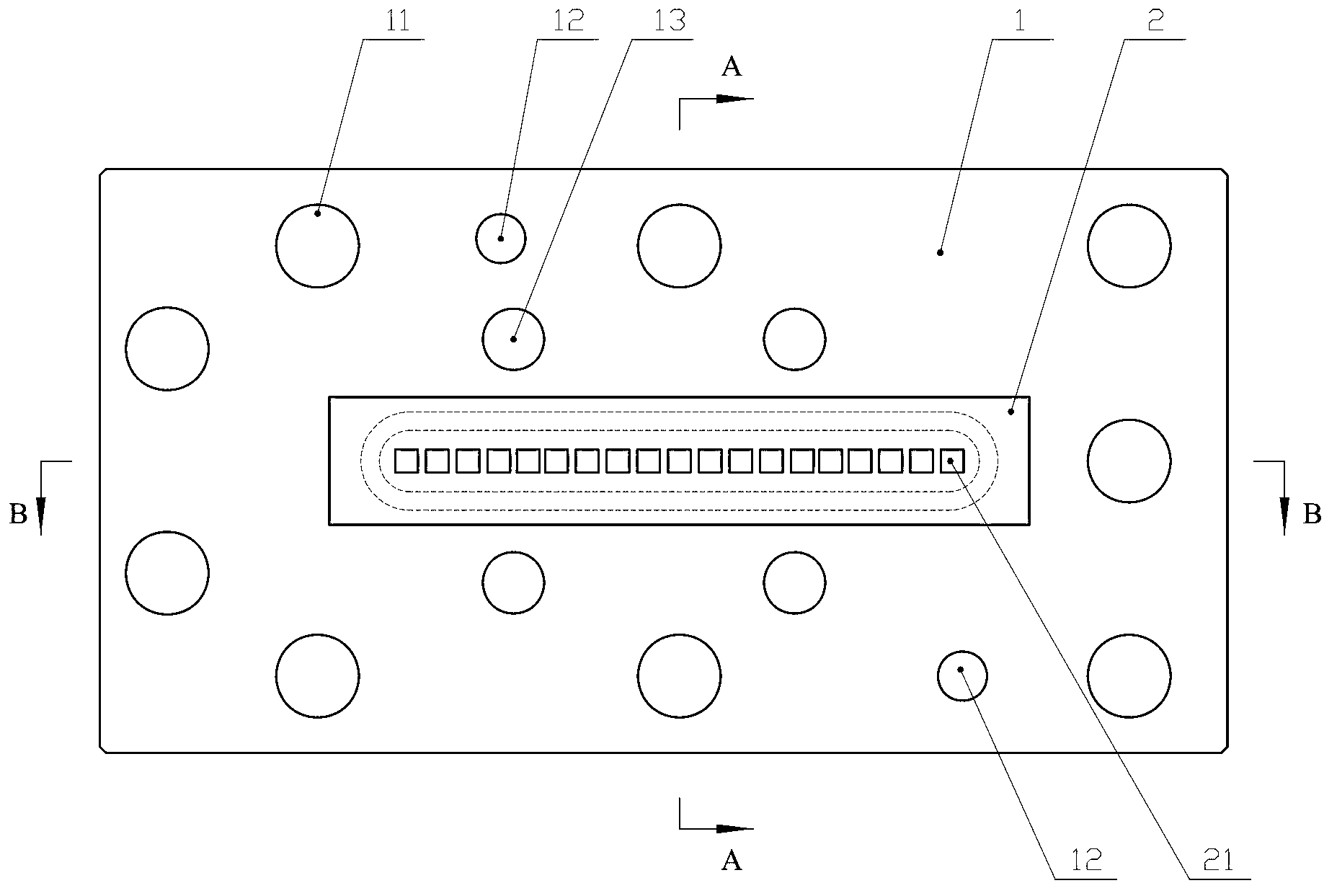

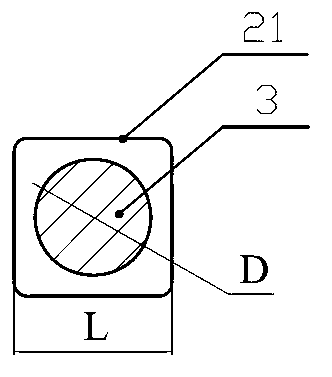

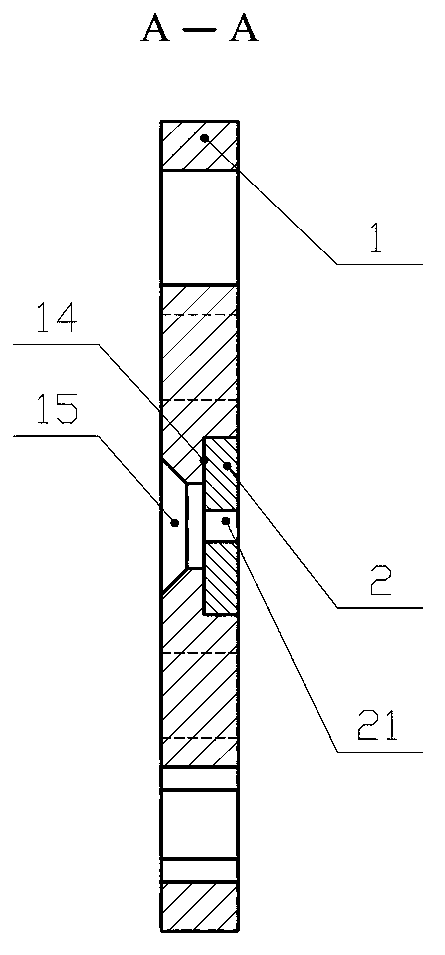

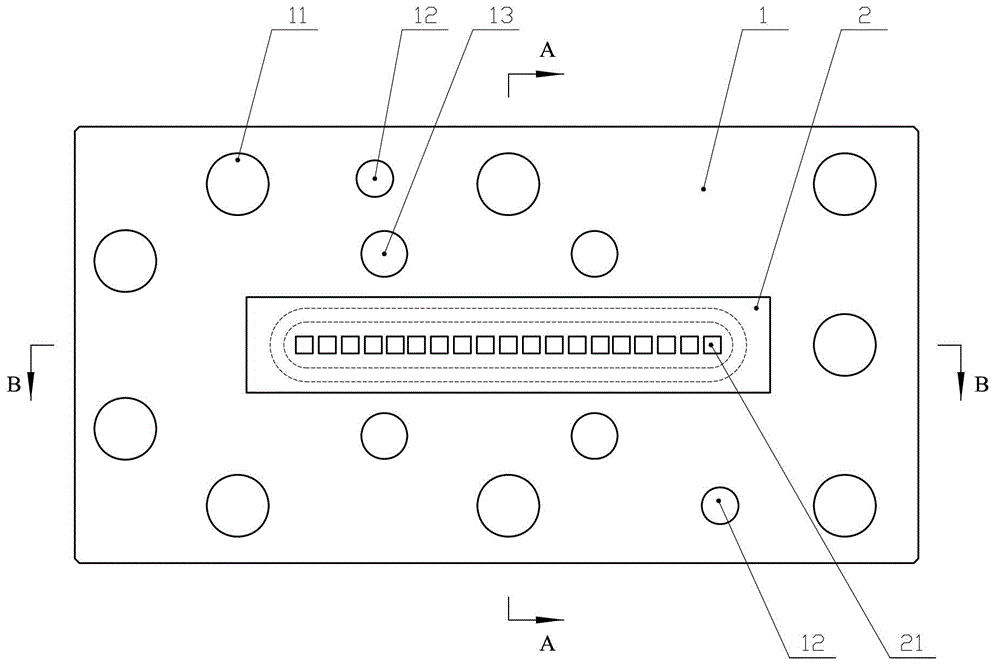

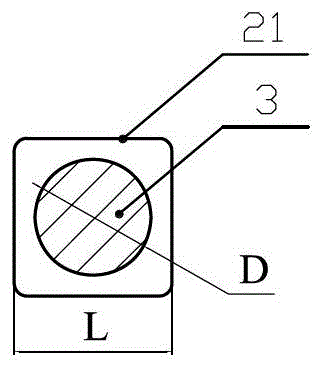

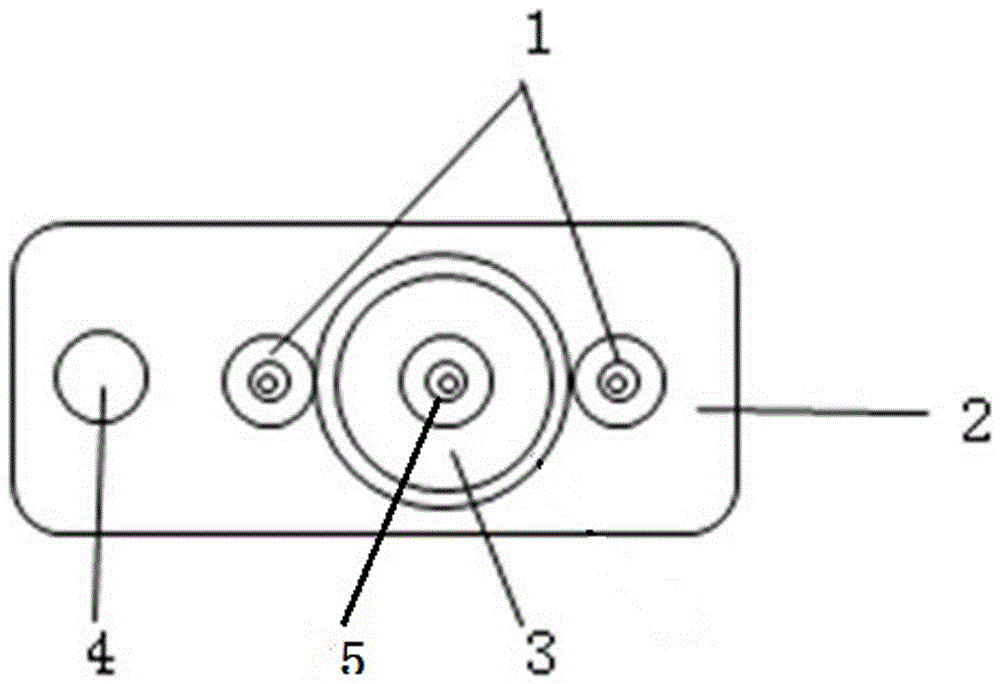

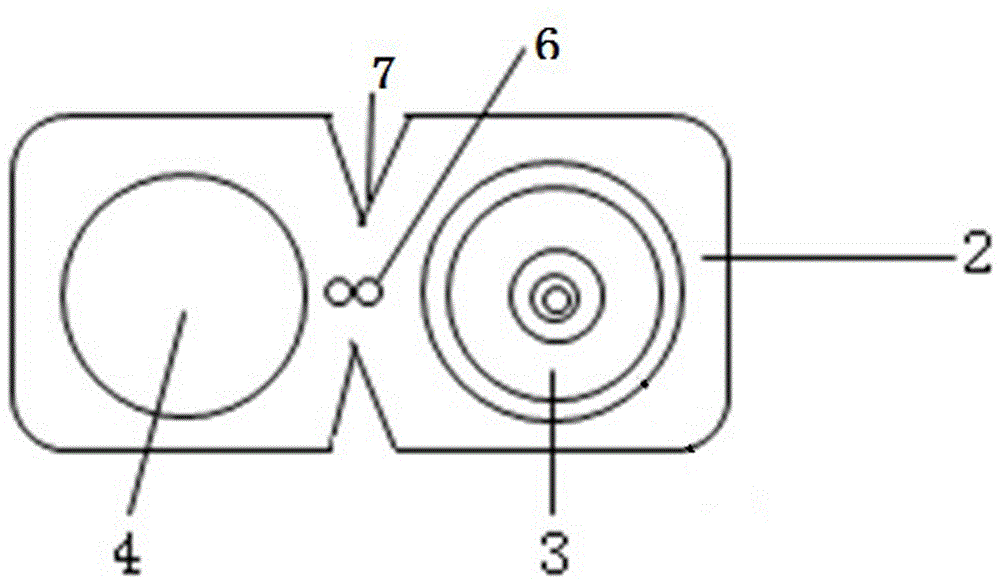

Threading mold for producing reinforcing band for strengthening thermoplastic plastic pipe

InactiveCN102935712AReduce wearAvoid jammingTubular articlesEngineeringReinforced thermoplastic pipe

The invention discloses a threading mold for producing a reinforcing band for strengthening a thermoplastic plastic pipe. The threading mold comprises a base body and a threading hole plate, wherein threading holes are arranged on the threading hole plate side by side. The threading holes are square structures. The threading mold effectively solves the problem that silk ropes / cotton ropes are easily abraded and broken in the manufacturing process of the interlayer reinforcing band, effectively improves the rate of finished reinforcing band products manufactured by the silk ropes / cotton ropes, guarantees stable and continuous production and remarkably improved the production efficiency.

Owner:GUANGZHOU ADVANCE TECH

Threading mold for producing reinforcing band for strengthening thermoplastic plastic pipe

InactiveCN102935712BAvoid jammingAvoid cloggingTubular articlesEngineeringReinforced thermoplastic pipe

The invention discloses a threading mold for producing a reinforcing band for strengthening a thermoplastic plastic pipe. The threading mold comprises a base body and a threading hole plate, wherein threading holes are arranged on the threading hole plate side by side. The threading holes are square structures. The threading mold effectively solves the problem that silk ropes / cotton ropes are easily abraded and broken in the manufacturing process of the interlayer reinforcing band, effectively improves the rate of finished reinforcing band products manufactured by the silk ropes / cotton ropes, guarantees stable and continuous production and remarkably improved the production efficiency.

Owner:GUANGZHOU ADVANCE TECH

A Method for Determining Design Coefficients of Thermoplastic Reinforced Composite Pipelines

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

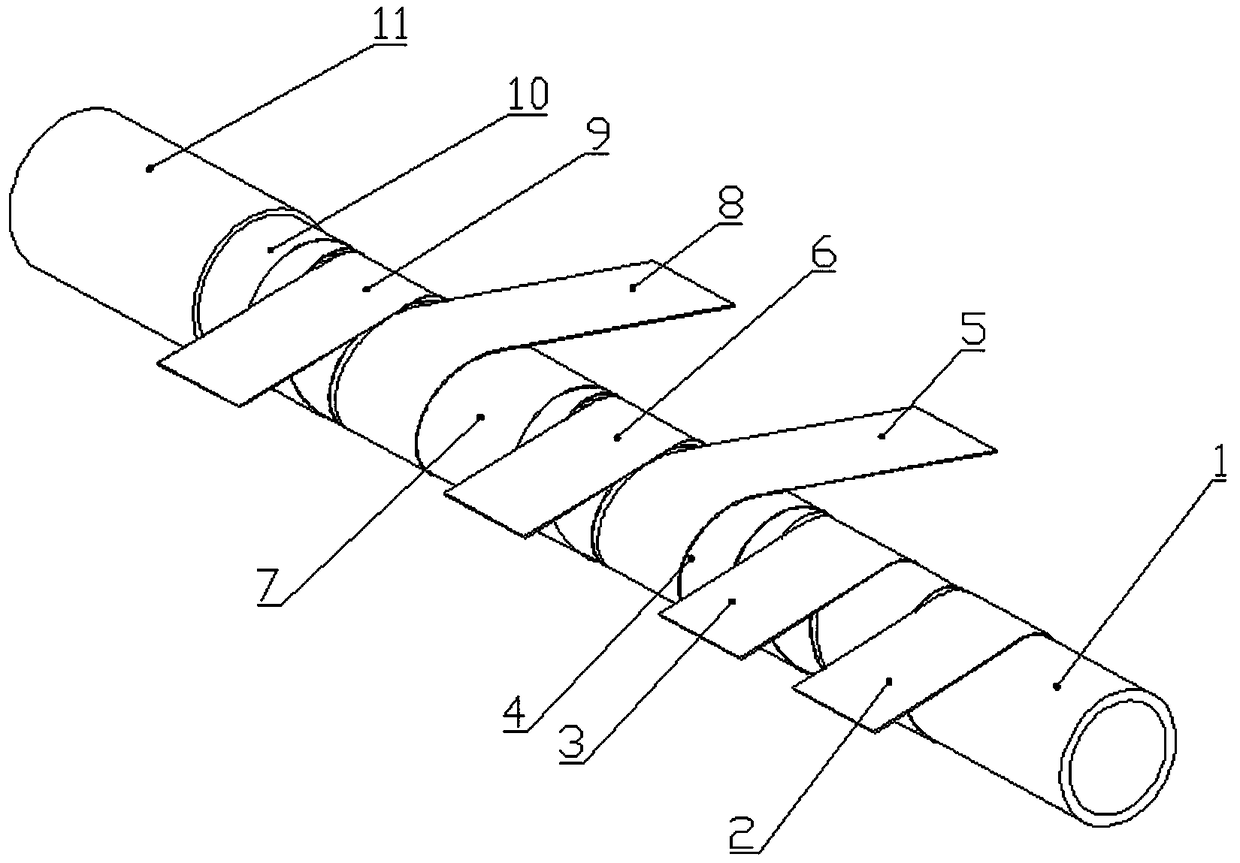

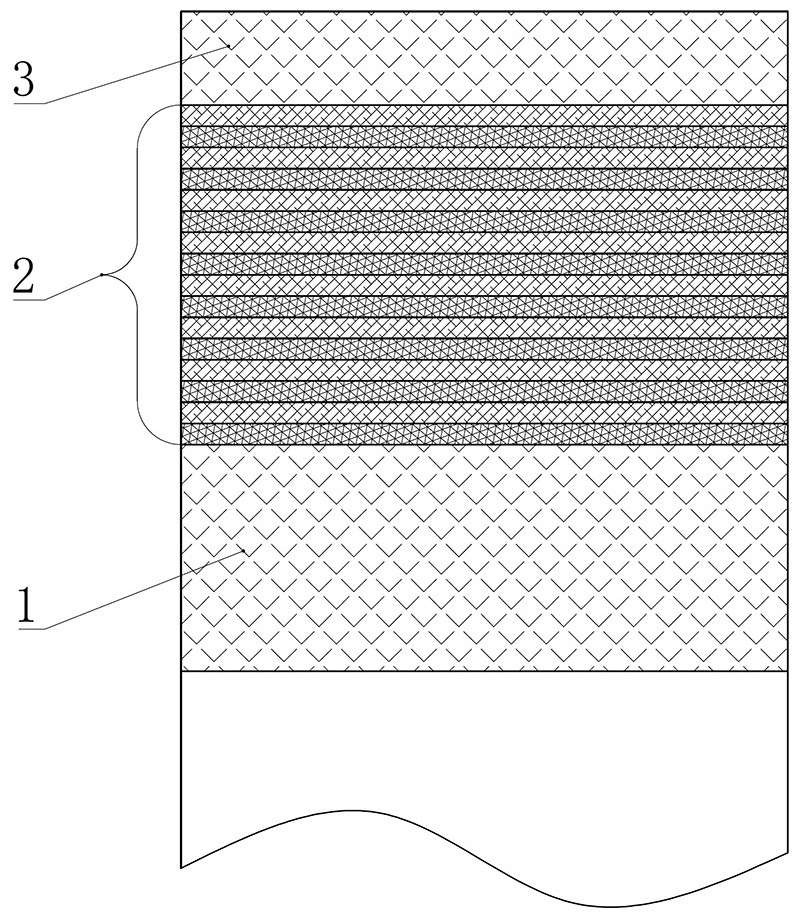

Connection method of large-diameter high-pressure fiber-reinforced flexible composite pipe

ActiveCN113400696BHigh strengthEnhanced flexible constraintsHose connectionsPipe connection arrangementsStress concentrationUltimate tensile strength

The invention relates to a connection method for large-diameter high-pressure fiber-reinforced flexible composite pipes, and belongs to the field of fiber-reinforced thermoplastic pipes. Its technical solution: welding the inner lining layer, then overlapping and winding the reinforcing layer according to the direction of rotation of each layer, and finally setting a protective layer on the outside of the joint. The invention can avoid the problem of stress concentration of the reinforcing layer caused by the metal joint, and at the same time solve the problem of insufficient strength of the welded joint. The technical scheme of the present invention can effectively and high-strengthly connect large-diameter high-pressure fiber-reinforced flexible composite pipes to meet the needs of oil and gas pipeline transportation and other application occasions.

Owner:YIBIN UNIV

Composite tape winding machine for fully integrated reinforced thermoplastic pipe and its winding method

The invention discloses a whole combination type enhanced thermoplastic pipe composite tape winder and a winding method thereof. In the provided composite tape winder, the functions of composite tape delivering, tension force controlling, and winding angle controlling are integrated into a big gear; during the winding process among a matrix pipe straightening device, a matrix pipe preheating device, and a composite tape, the heating or preheating device of the contact surface between the matrix pipe and composite tape is connected to the large gear so as to drive the devices synchronously, thus during the operation process, the synchronism among rotation parts, stability, and uniformity are greatly improved; moreover, the mechanical structure of the winder is simplified, the complicated electric-control device is saved, and the fault rate during the operation process and maintenance cost are both reduced therefore. The provided wing method of the composite tape winder has the advantages of good continuity and stability, high automation degree, and good quality of composite tape winding, and thus has a good market promotion and application prospect.

Owner:青岛海聚新材料科技有限公司

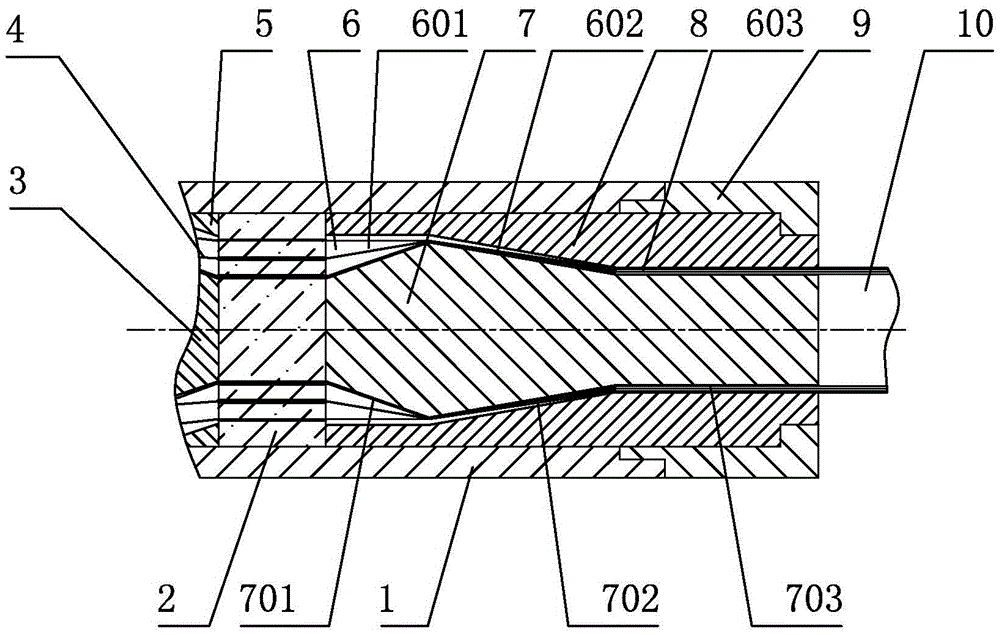

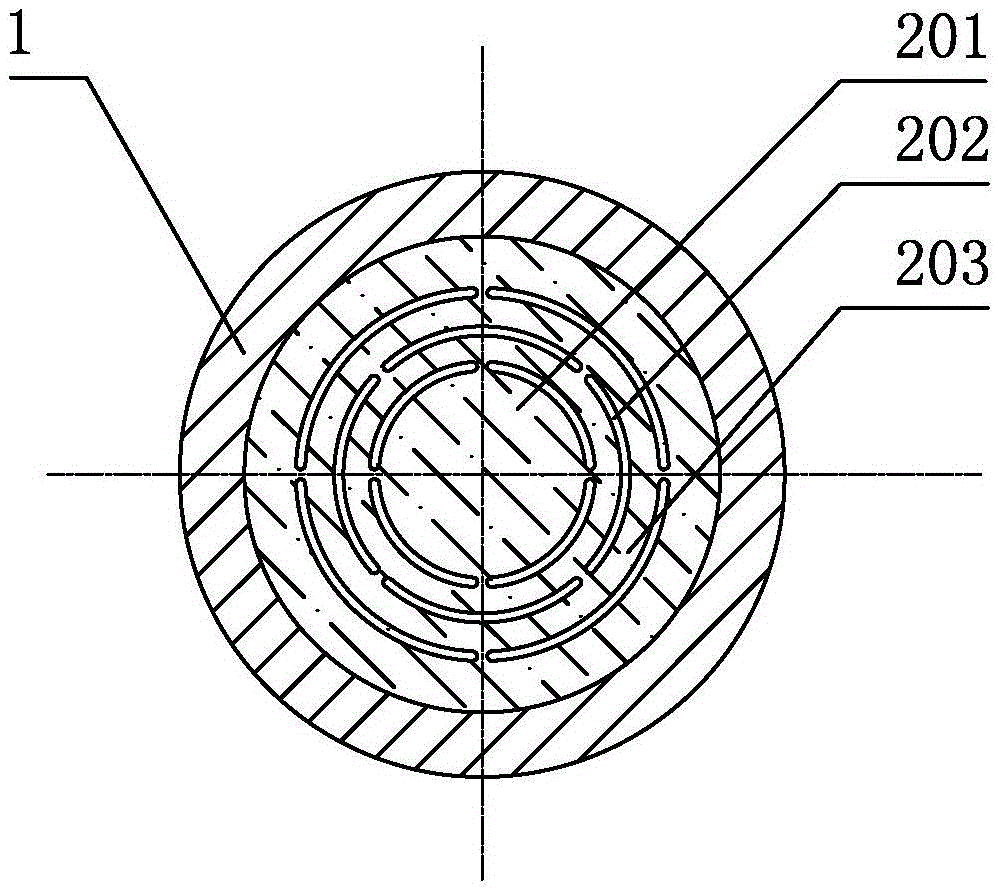

Forming mold and forming method of continuous fiber reinforced thermoplastic pipe

The invention relates to a forming die of a continuous fiber-reinforced thermoplastic plastic pipe and a forming method of the forming die. The forming die comprises a machine body, wherein a shaft sleeve, a beam splitting block and a mouth die are sequentially arranged in the machine body along the axial direction; the beam splitting block is fixed by the mouth die on the rear side and the shaft sleeve on the front side, and arc-shaped beam-splitting slits are formed in the beam splitting block; the rear end of the mouth die is locked through a locking nut connected with the machine body; the front end of the beam splitting block is fixedly connected with a spindle. The forming method comprises the following steps: (1) segmenting a molten continuous fiber-reinforced thermoplastic resin-based impregnation tape into multiple arc sections; (2) superposing various layers of segmented impregnation tape; (3) adhering the various layers of impregnation tape; (4) fusing each layer of the impregnation tape to form a tube billet; and (5) sizing the pipe, cooling through a cooling device, cutting through a cutting device, and forming the pipe. The axial bearing capacity of the pipe is greatly improved, so that the axial stiffness of the pipe is greatly improved.

Owner:SHANDONG UNIV OF TECH

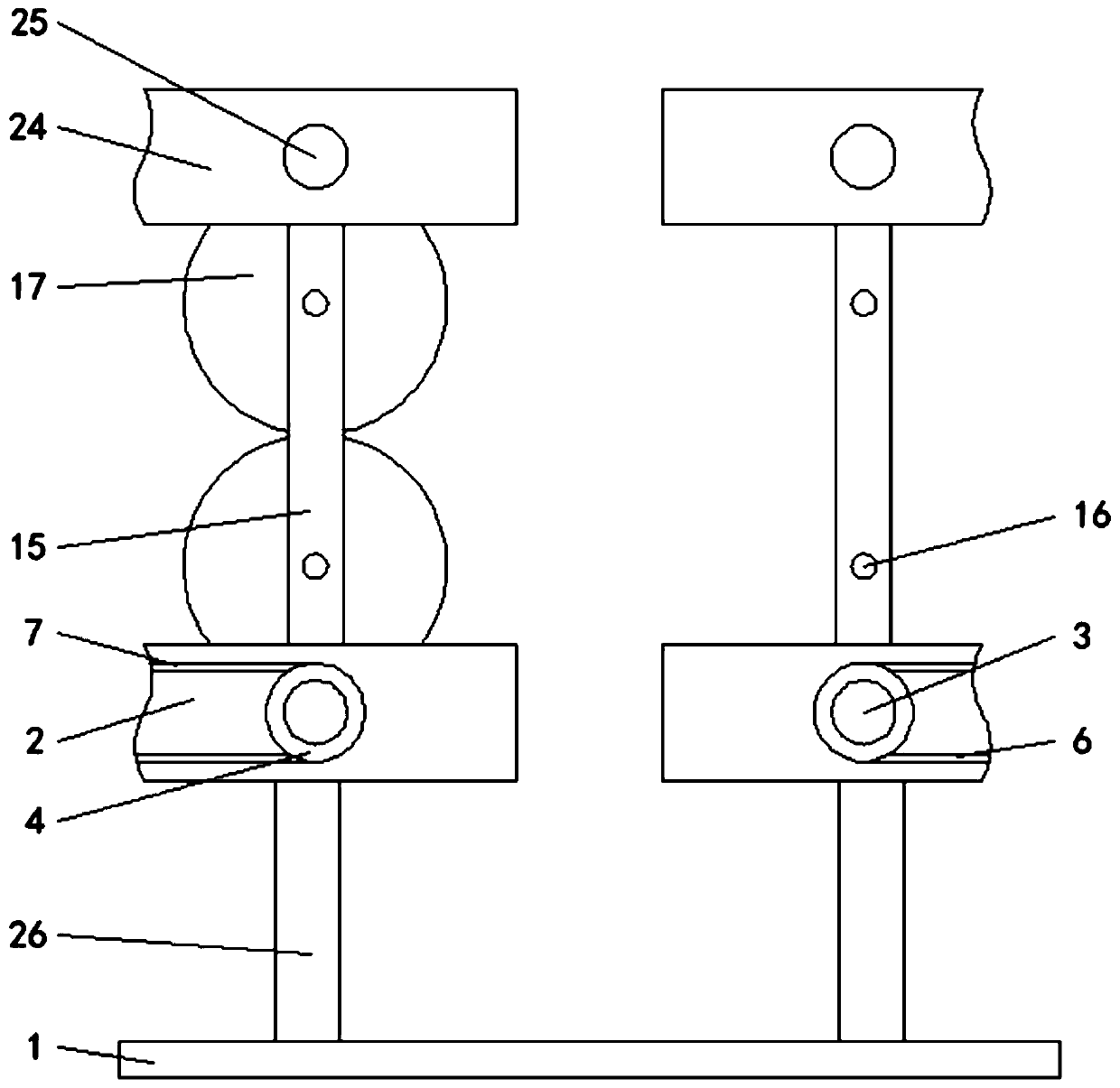

Roundness correcting method for continuous fiber reinforced thermoplastic pipe port

PendingCN108544743AMeet the requirements of socket welding processHigh strengthPolymer chemistryFiber reinforcement

The invention relates to the field of reinforcing high molecular compounds with incompact or adhered fibrous materials, in particular to a roundness correcting method for a continuous fiber reinforcedthermoplastic pipe port. The roundness correcting method for the continuous fiber reinforced thermoplastic pipe port is characterized by comprising the following steps in sequence: A, equipment preparing; and B, port roundness correcting. The roundness correcting method is high in strength, is convenient in manufacturing, and is wide in scope of application.

Owner:上海英泰塑胶股份有限公司

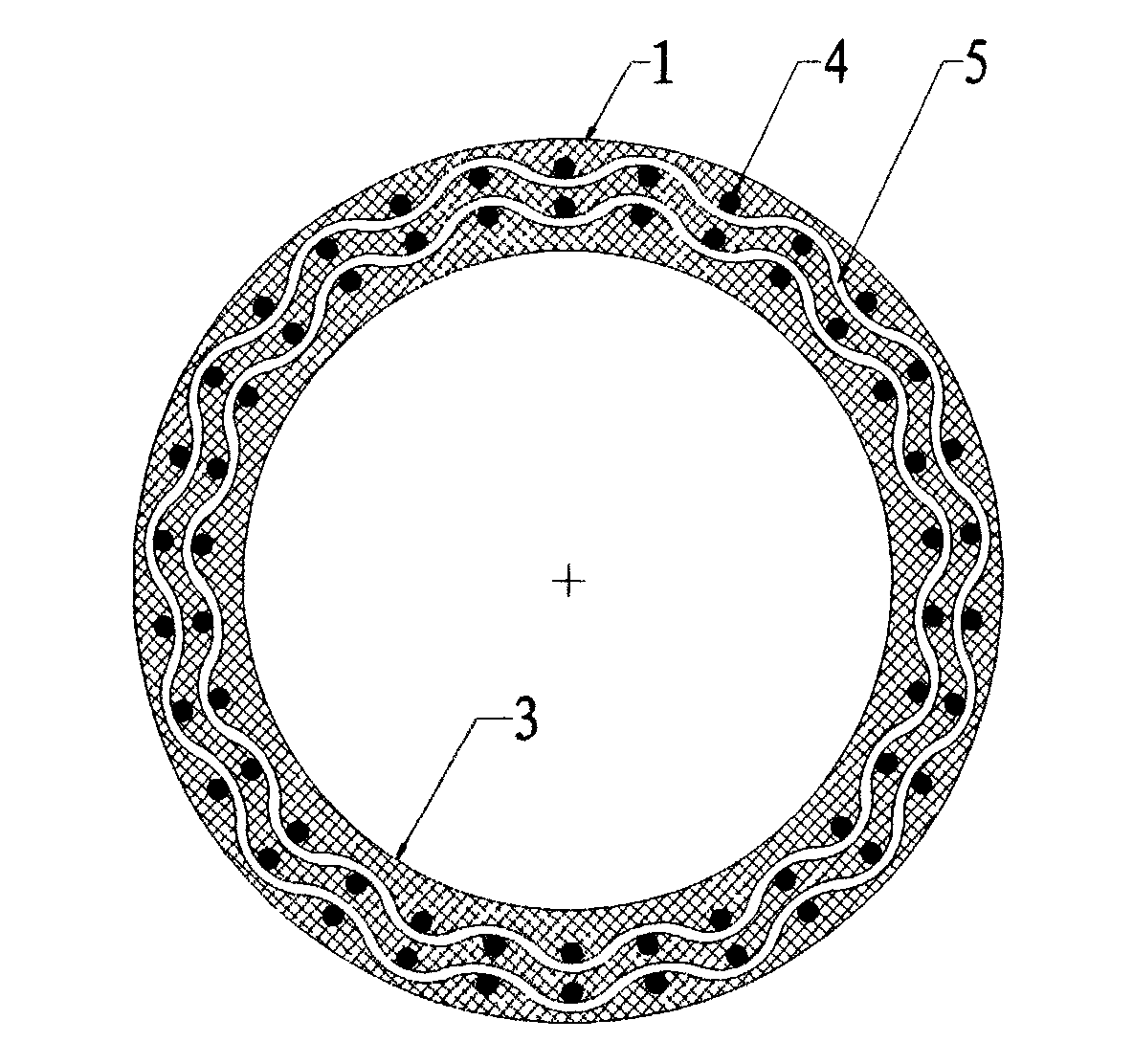

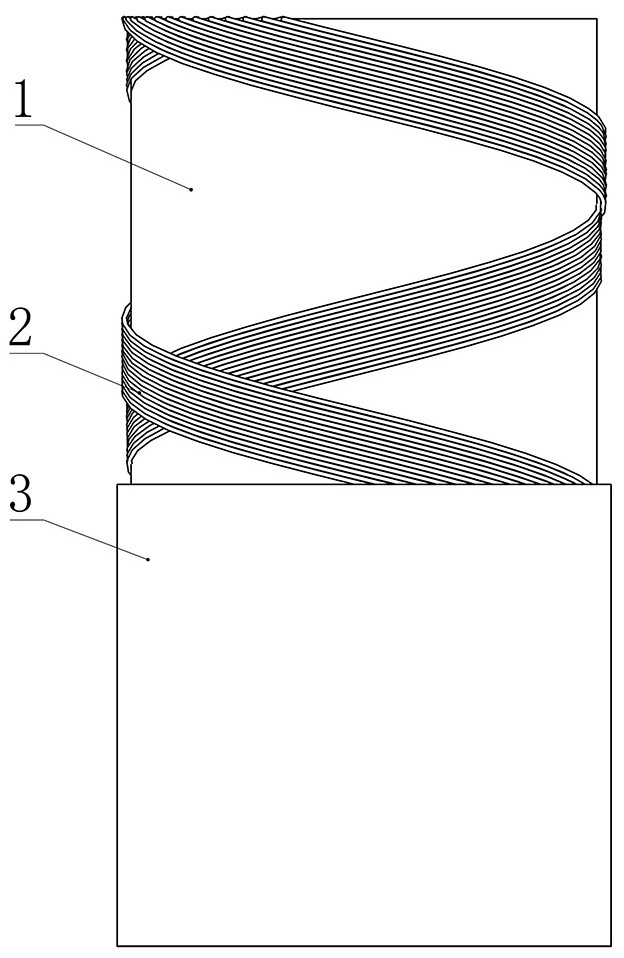

Winding wire for large-diameter high-pressure flexible composite pipe and using method thereof

ActiveCN113306125BAvoid the impact of pressure capacityEasy to processFiber bundleMechanical engineering

The invention relates to a large-diameter high-pressure flexible composite pipe winding and a use method thereof, belonging to the field of fiber-reinforced thermoplastic pipes. Its technical scheme: the fiber bundle is wound on the inner core of the flexible material, and then wound to form a multi-layer reinforcing layer; and by changing the angle between the winding direction of the fiber bundle and the axis of the inner core, the fiber bundle The slack degree of each layer of winding is adjusted according to the volume ratio of the inner core, the angle between the winding direction and the axis of the pipeline, the twist of the fiber bundle, etc., so that the winding of each layer is uniformly stressed, and finally the pressure bearing of the fiber-reinforced flexible composite pipeline is improved. ability. The invention solves the problem that the inner layer fibers of the existing flexible composite pipes bear large force and the outer layer fibers bear little force, and can be used for large-diameter and high-pressure flexible composite pipes.

Owner:YIBIN UNIV

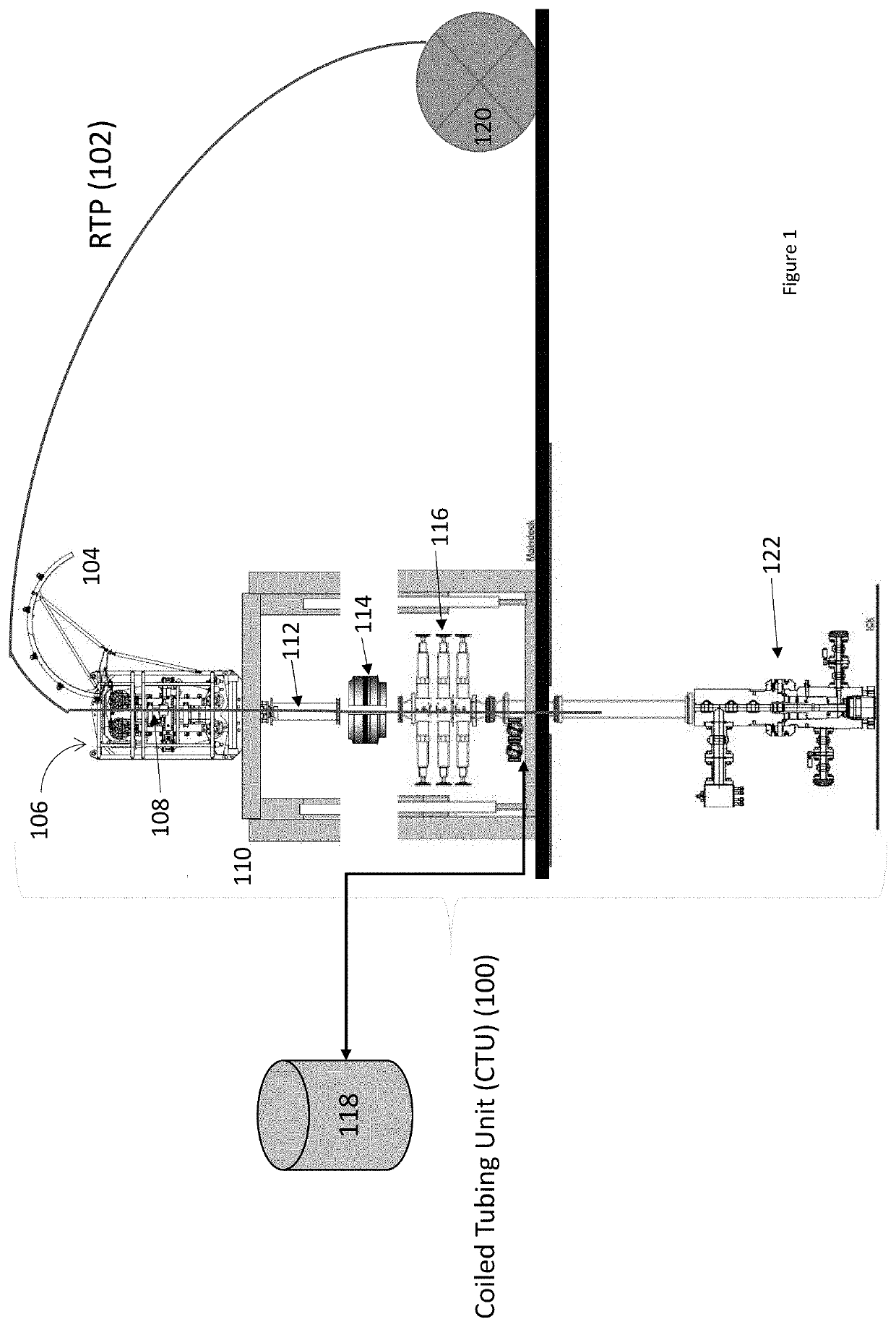

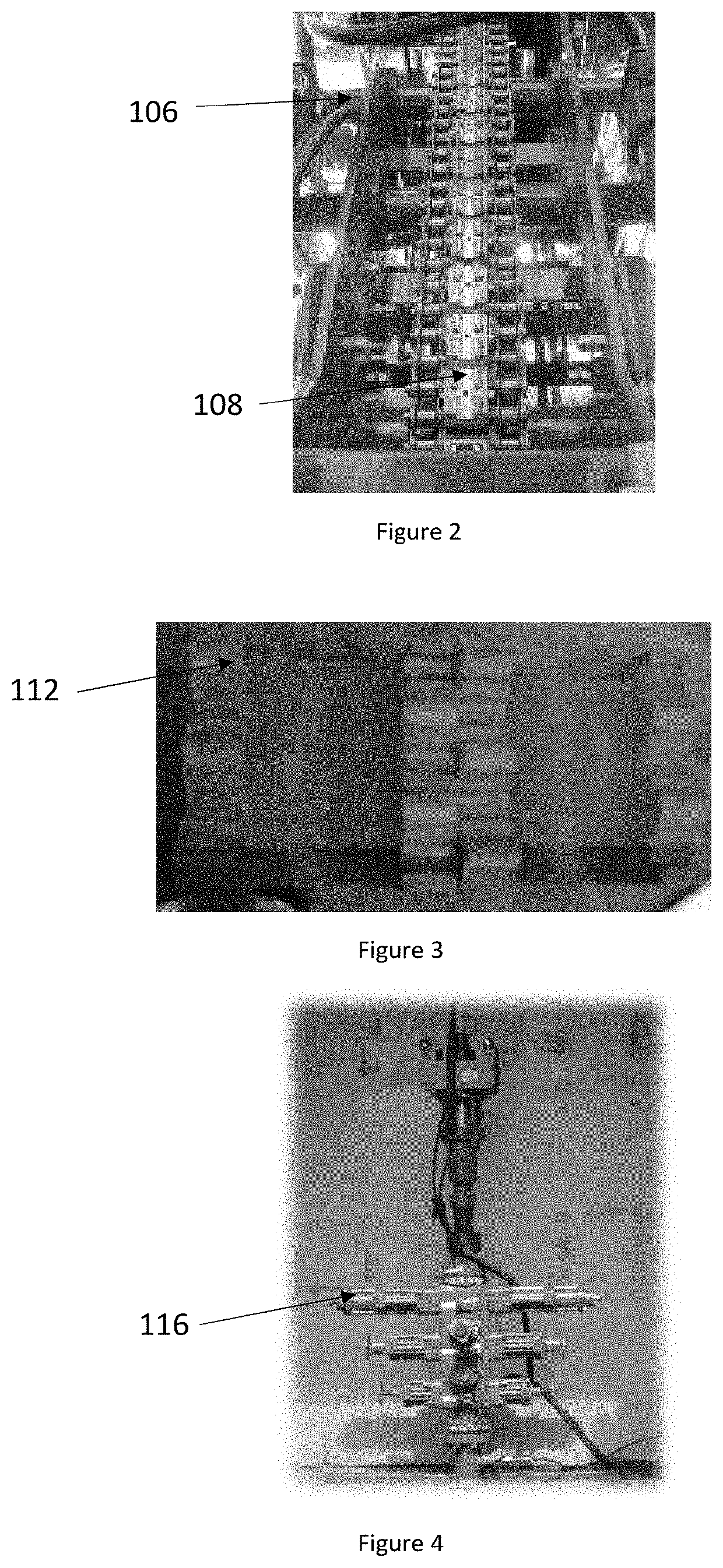

A method of installing a reinforced thermoplastic pipe (RTP)

InactiveUS20210062591A1Relieve stressMinimize damagePipe supportsDrilling rodsBlowout preventerComposite material

A method of installing a reinforced thermoplastic pipe (RTP) (102) in a production tube is provided, the method includes the steps of preparing a bottom assembly (703) in a production well, swaging connectors (707, 709) onto both ends of the RTP (102),and connecting respective ends of the RTP (102) with connectors (707, 709) to top and bottom assemblies (701, 703), characterized in that, the connectors (707, 709) further include metal collars that maintain shape of the RTP (102) and prevents pressure from escaping the RTP (102) and a blowout preventer (BOP) (116) is provided to cut off the RTP (102) when displacement is detected by the trip tank (118).

Owner:GASOLINEIAM NASIONAL BERHAD

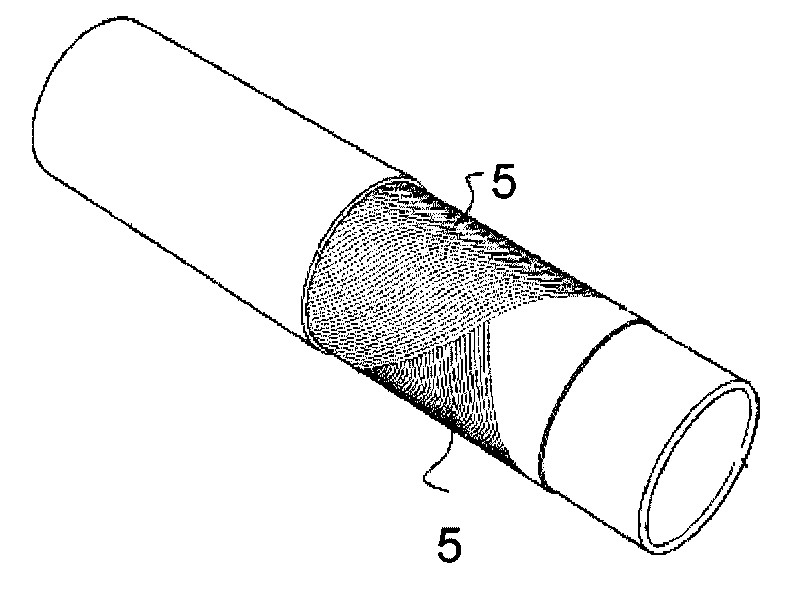

Stress and temperature sensing optical cable pre-embedded in RTP

InactiveCN106094146AThe force and heat feedback signal is accurate and stableConducive to pre-buried layingMeasurement devicesFibre mechanical structuresRounded RectangleEngineering

The invention discloses a stress and temperature sensing optical cable pre-embedded in a Reinforced Thermoplastic Pipe (RTP). The stress and temperature sensing optical cable comprises an optical fiber assembly, a tensile element, and an outer sheath, and is characterized by also comprising an optical unit. The optical unit comprises a loose tube and a tight coated optical fiber I. The cross section of the outer sheath is a rounded rectangle structure. The optical unit employs the loose tube structure and the built-in tight coated optical fiber I structure. The diameter of the tight coated optical fiber is 0.6mm. The one-tight and one-loose structure design accurately senses an outside stress and the temperature, reduces the overall external diameter of the cable, and facilitates the pre-embedding.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com