Method for inspecting reinforced thermoplastic pipe based on designed life

A technology that enhances thermoplasticity and design life. It is applied in the direction of strength characteristics, using stable tension/pressure to test material strength, and analyzing materials. The effects of production cost, shortened production cycle, increased reliability and product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

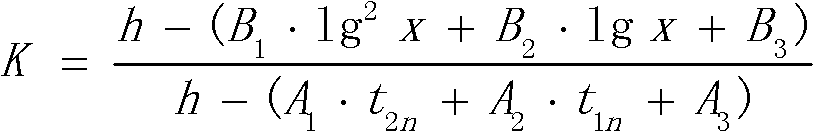

Image

Examples

Embodiment 1

[0094] Taking steel wire-wound reinforced plastic composite pipe (PSP for short) as an example, the burst pressure at which the PSP design life is 50 years is predicted by the method mentioned in this patent. PSP specifications are shown in Table 3:

[0095] Table 3 PSP Specifications

[0096] Nominal diameter / mm

Steel wire diameter / mm

Total number of steel wires

Wall thickness / mm

Winding angle θ / °

110

0.8

36

8.5

35.3

[0097] 1. PSP rapid blasting test

[0098] Test temperature T a The temperature is 20°C, and the inner medium of the sample is water. The results of the rapid burst test are shown in Table 4.

[0099] Table 4 The relationship between rapid burst pressure and burst time

[0100]

test 1

test 2

Test 3

Burst pressure / MPa

6.4

6.6

6.2

Blasting time / s

135

122

129

[0101] According to the experimental results, the average value ...

Embodiment 2

[0141] Taking aramid fiber reinforced composite pipe (AFRP for short) as an example, use the method mentioned in this patent to predict the burst pressure of AFRP with a design life of 50 years. AFRP specifications are shown in Table 9:

[0142] Table 9 AFRP Specifications

[0143]

[0144] 1. AFRP rapid burst test

[0145] Test temperature T a The temperature is 20°C, and the inner medium of the sample is water. The results of the AFRP rapid burst test are shown in Table 10.

[0146] Table 10 The relationship between rapid burst pressure and burst time

[0147]

test 1

test 2

Test 3

Burst pressure / MPa

12.1

11.7

12.2

Blasting time / s

61

63

55

[0148] According to the experimental results, the average value of the burst pressure is:

[0149] P b = 1 n Σ i = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com