Patents

Literature

190 results about "Burst test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A burst test is a destructive test and performed to determine the pressure overload capacity of pressure containing parts. The tests are performed with a fluid. This test is often performed as a pre-production test to meet safety and quality standards.

Fibrous structures

ActiveUS7687140B2Non-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

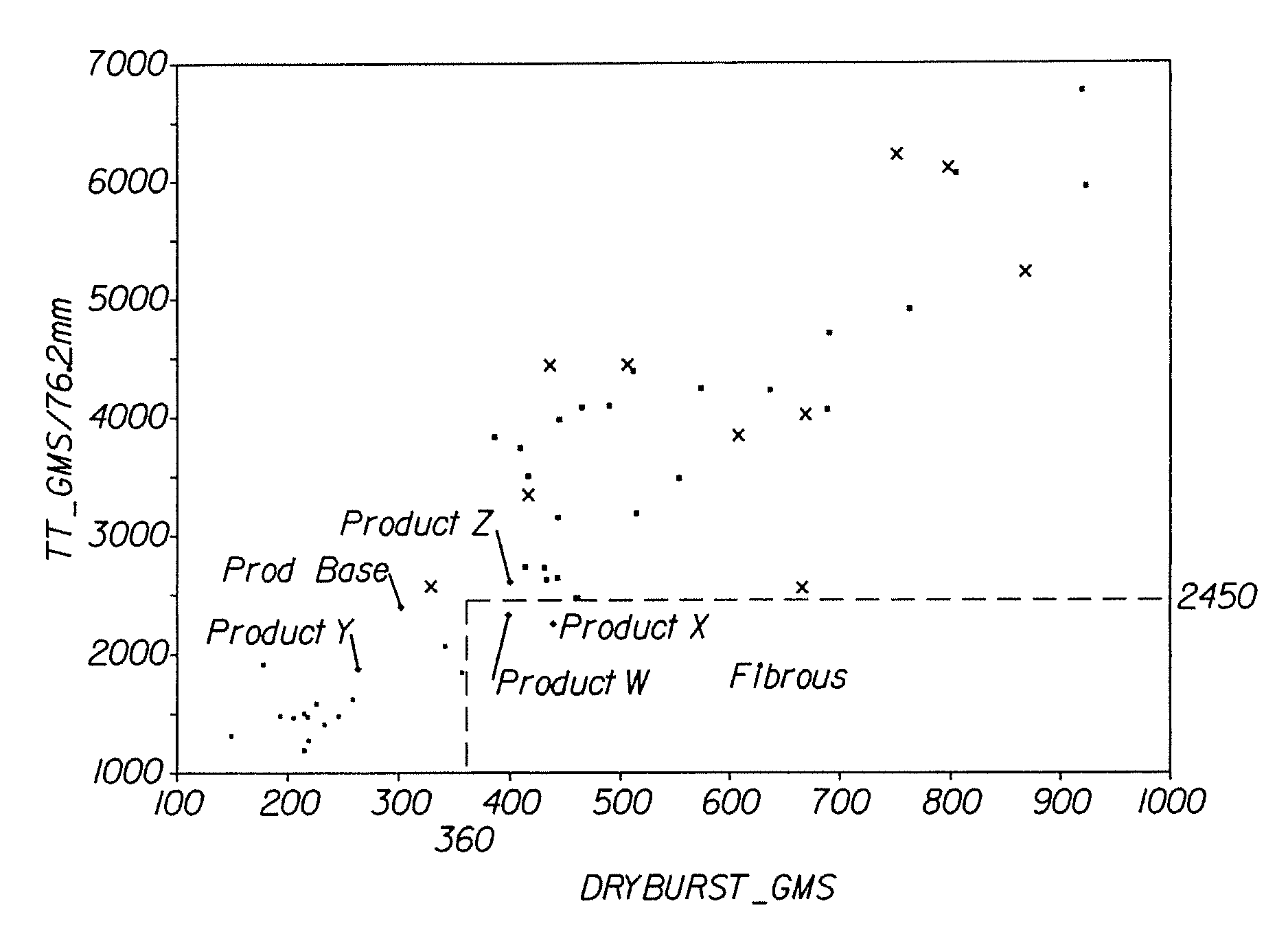

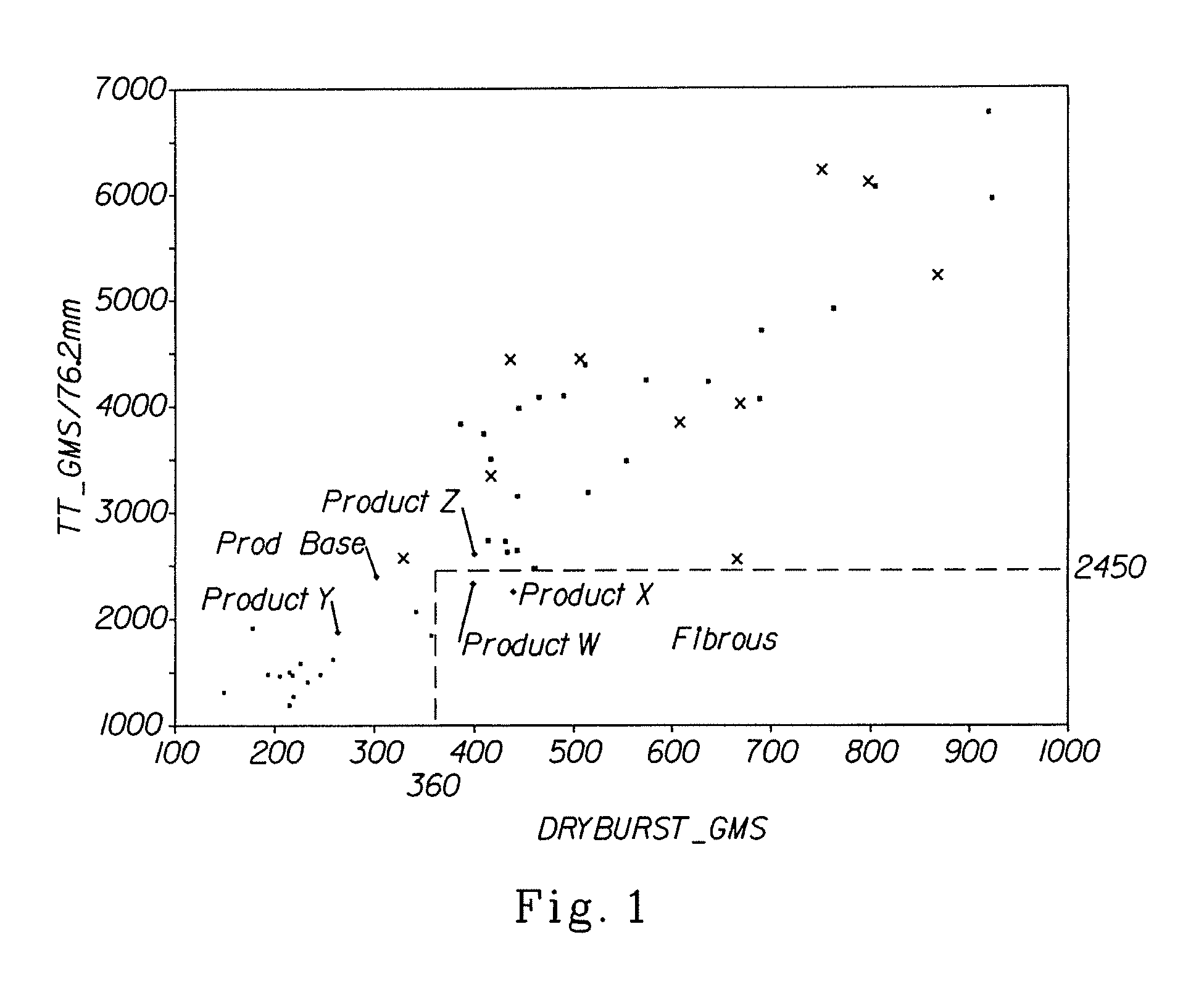

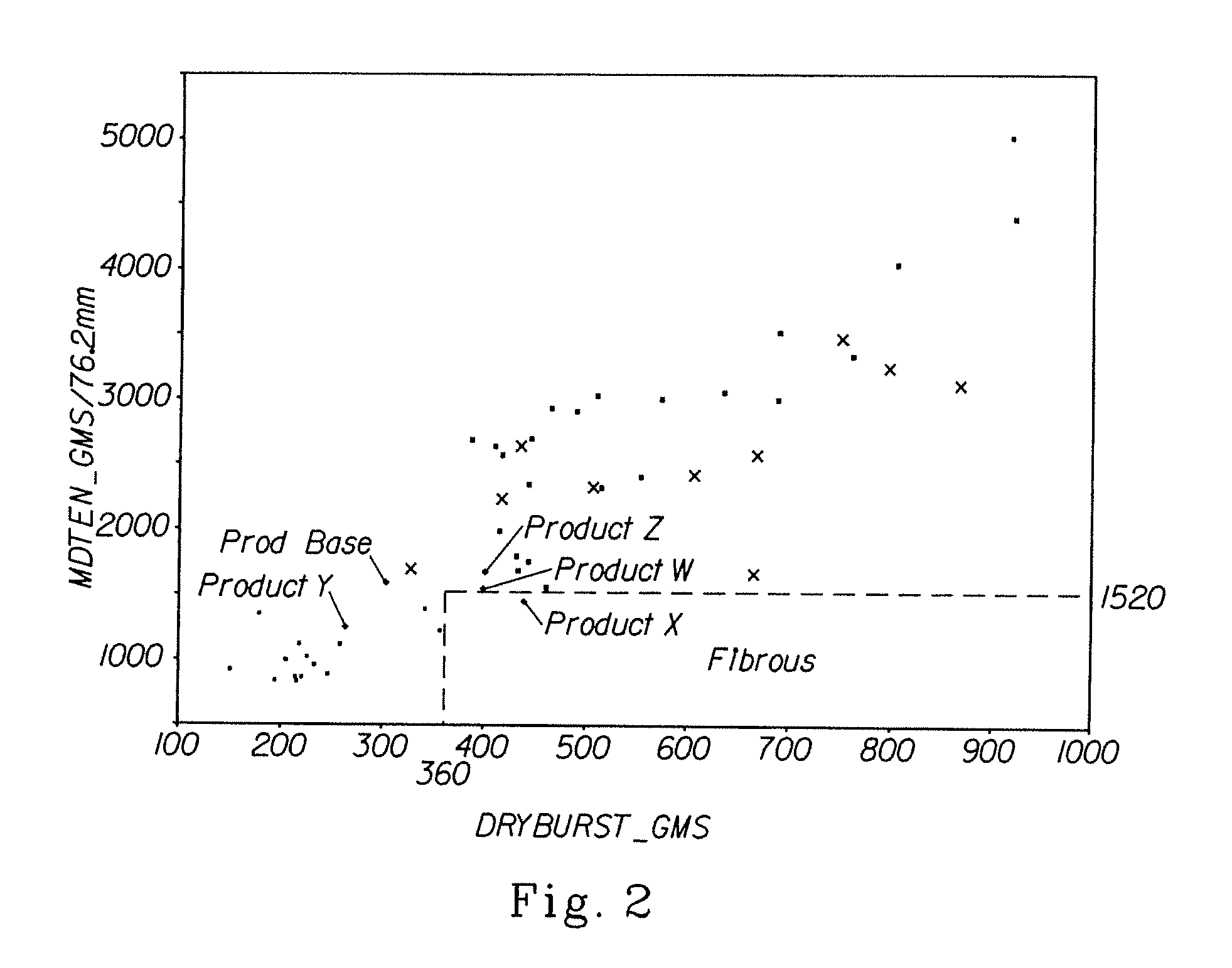

Fibrous structures that exhibit a Dry Burst of greater than 360 g as measured according to the Dry Burst Test Method and optionally, a Total Dry Tensile of less than 2450 g / 76.2 mm and / or a Machine Direction (MD) Dry Tensile of less than 1520 g / 76.2 mm and / or a Geometric Mean GM) Total Dry Tensile of less than 1180 g / 76.2 mm as measured according to the Tensile Strength Test Method are provided.

Owner:PROCTER & GAMBLE CO

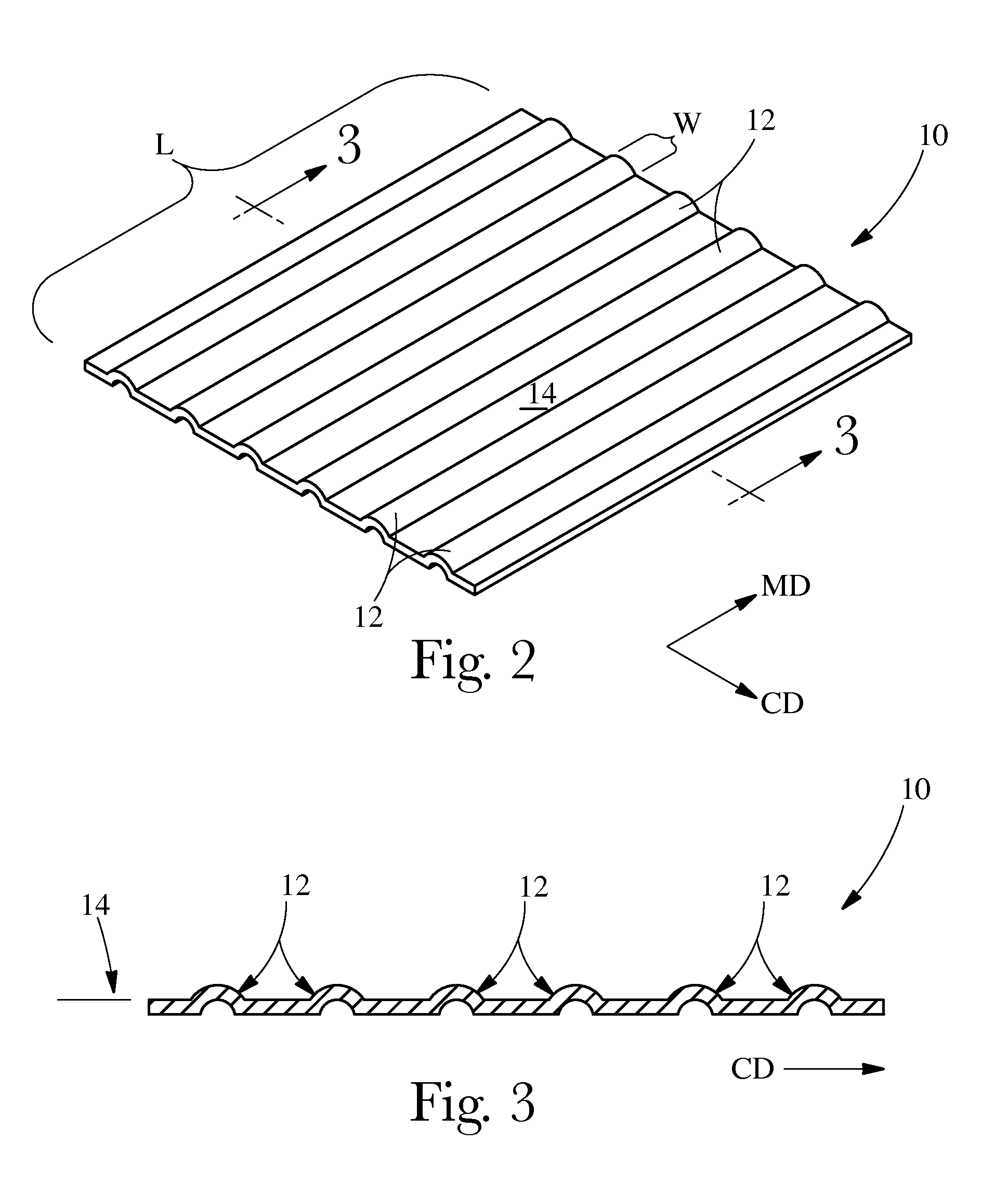

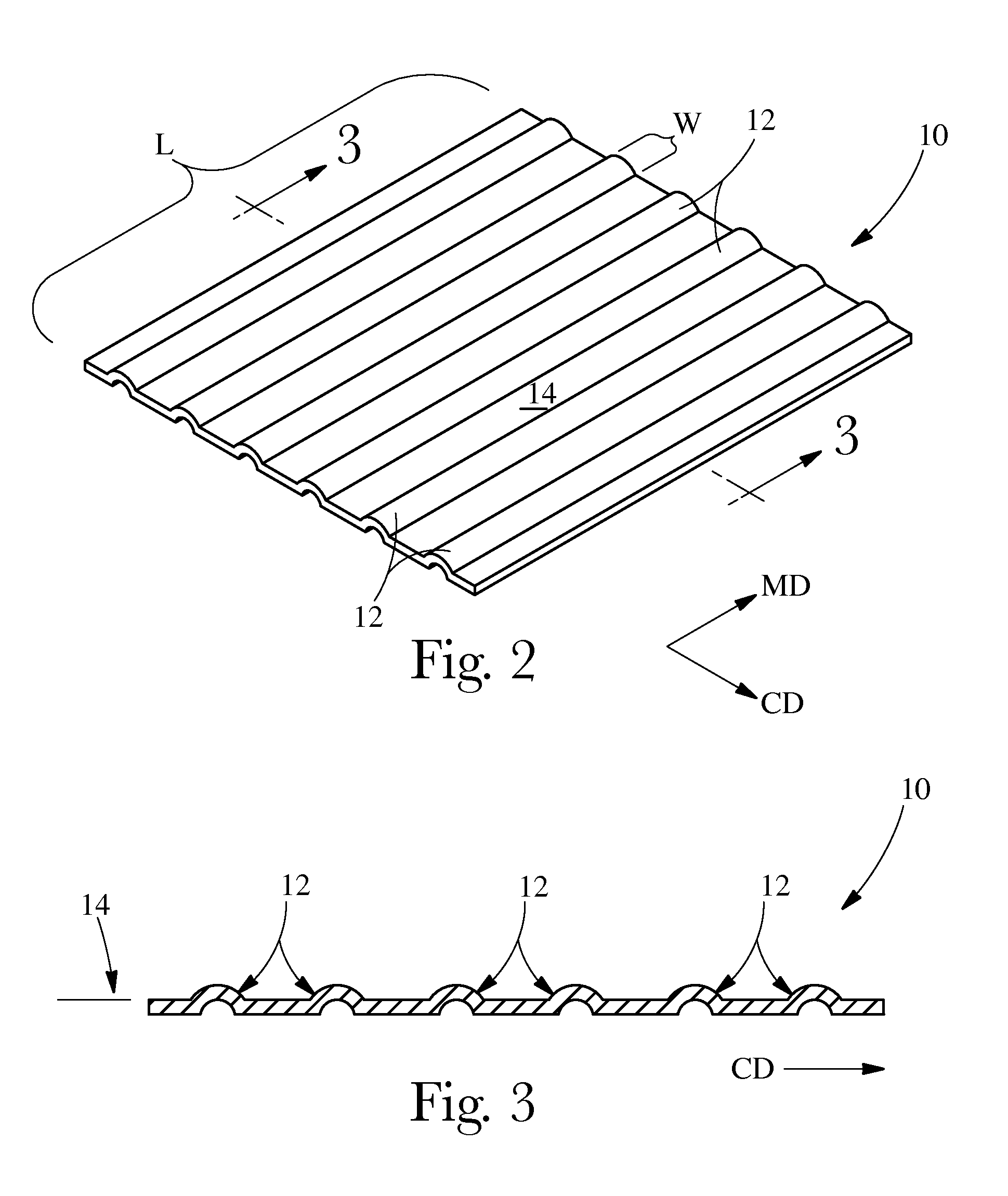

Embossed fibrous structures

ActiveUS7811665B2Non-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

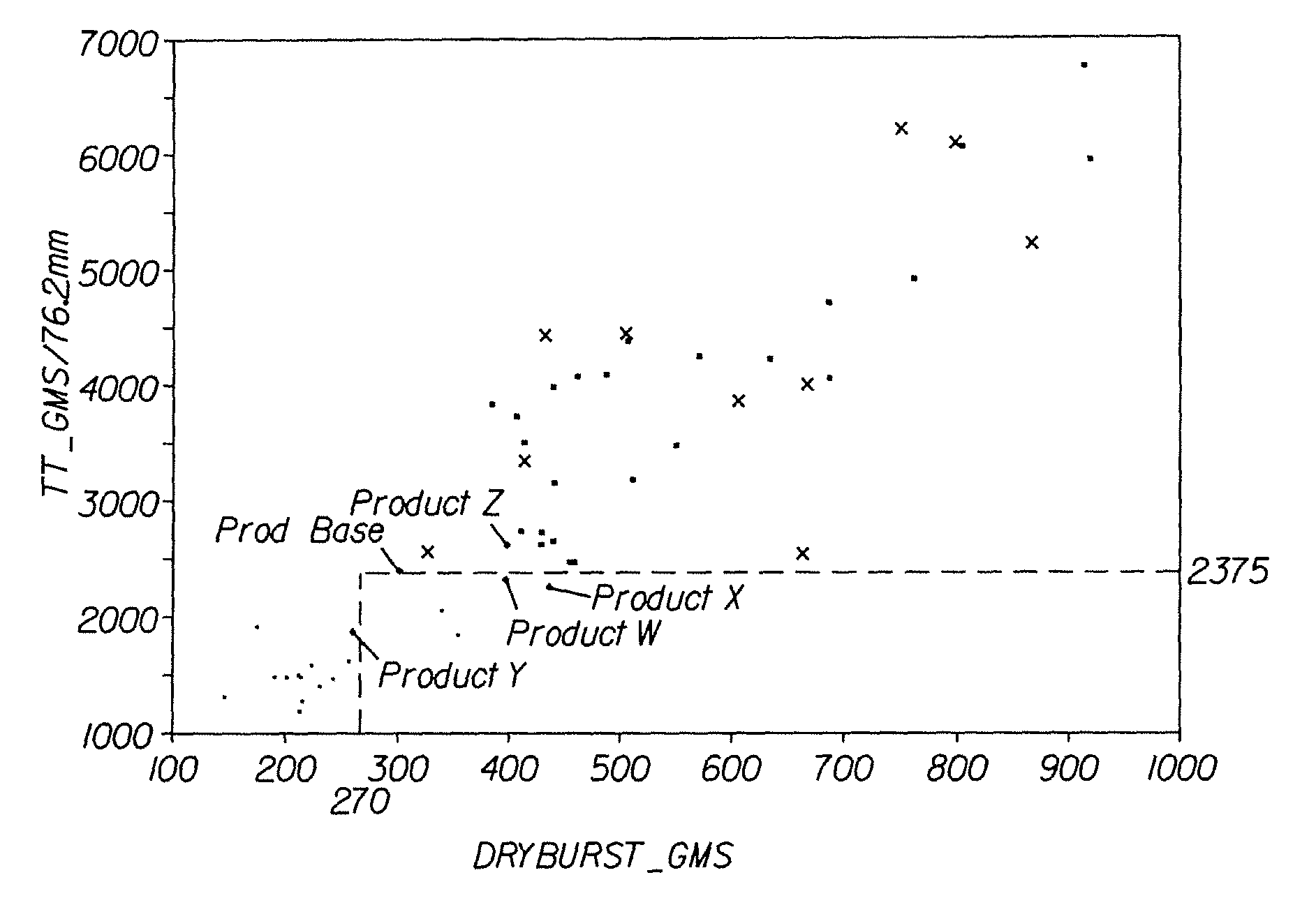

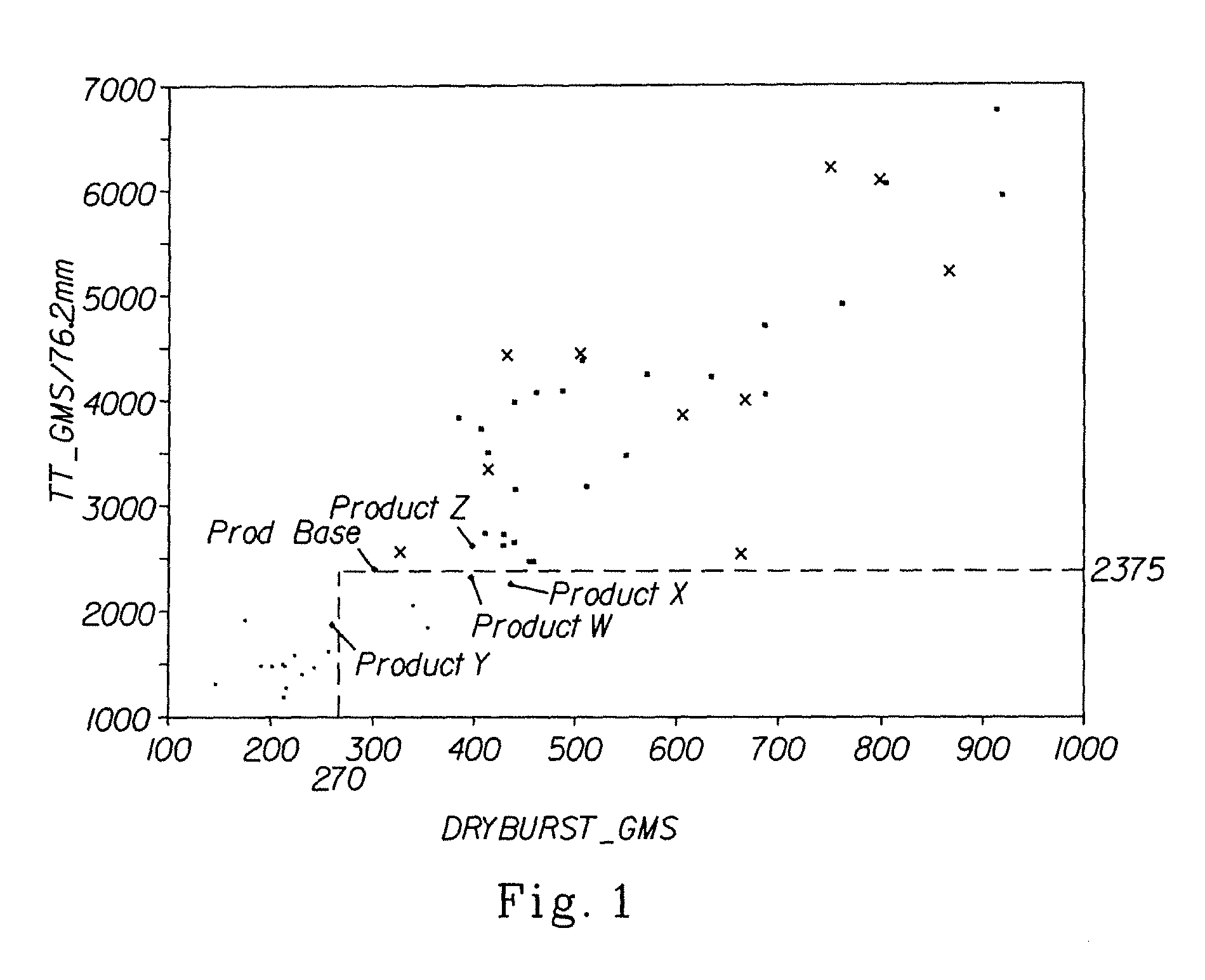

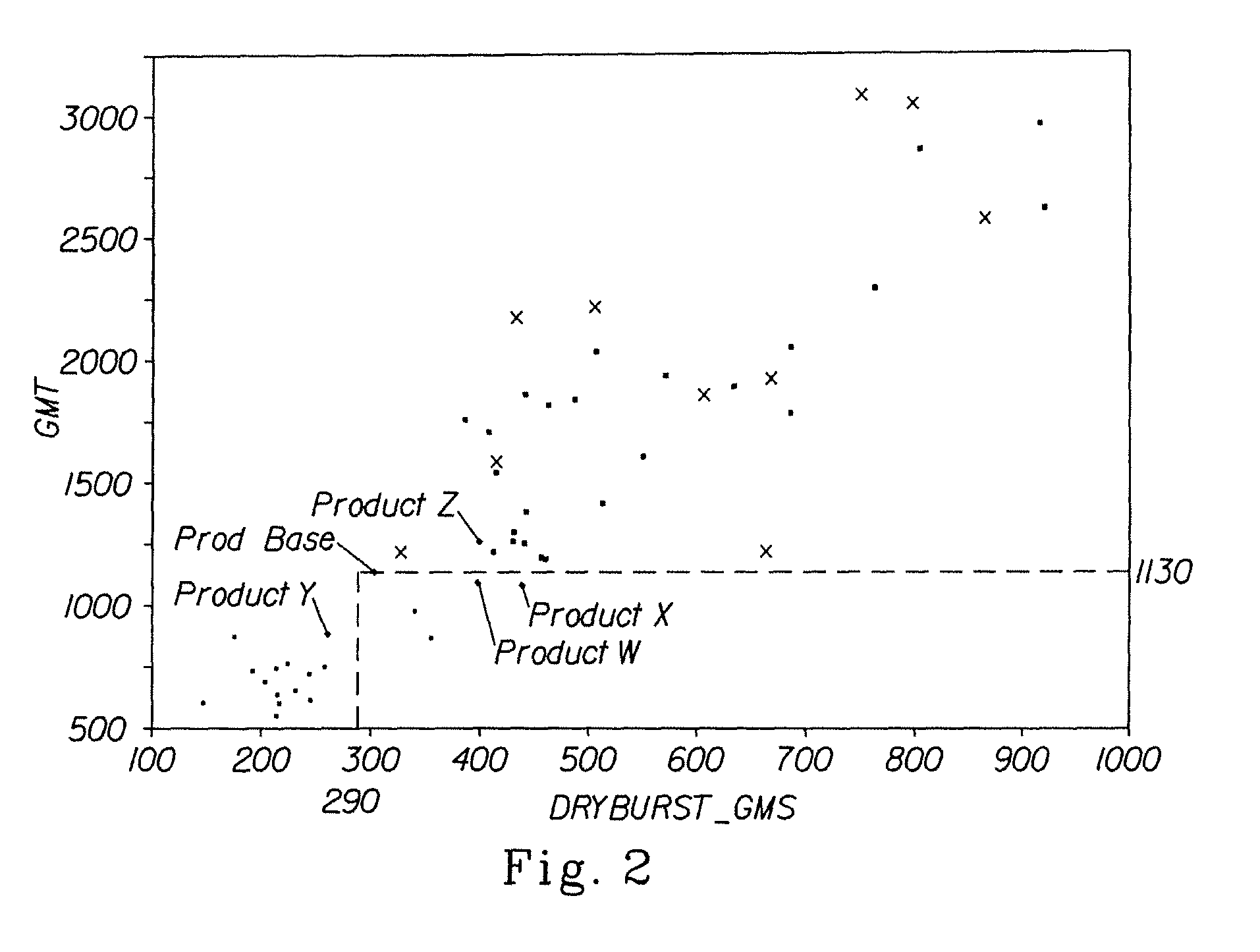

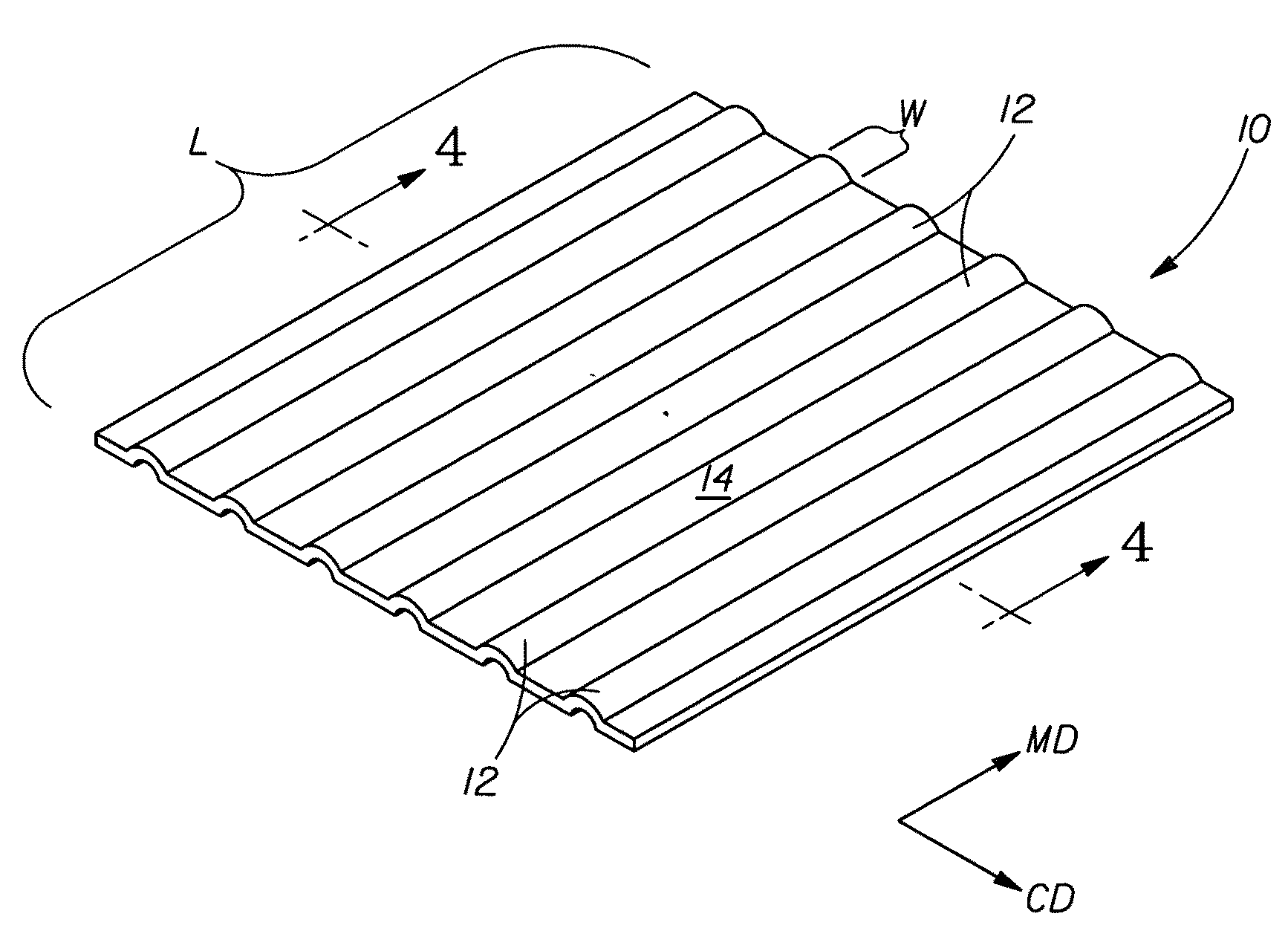

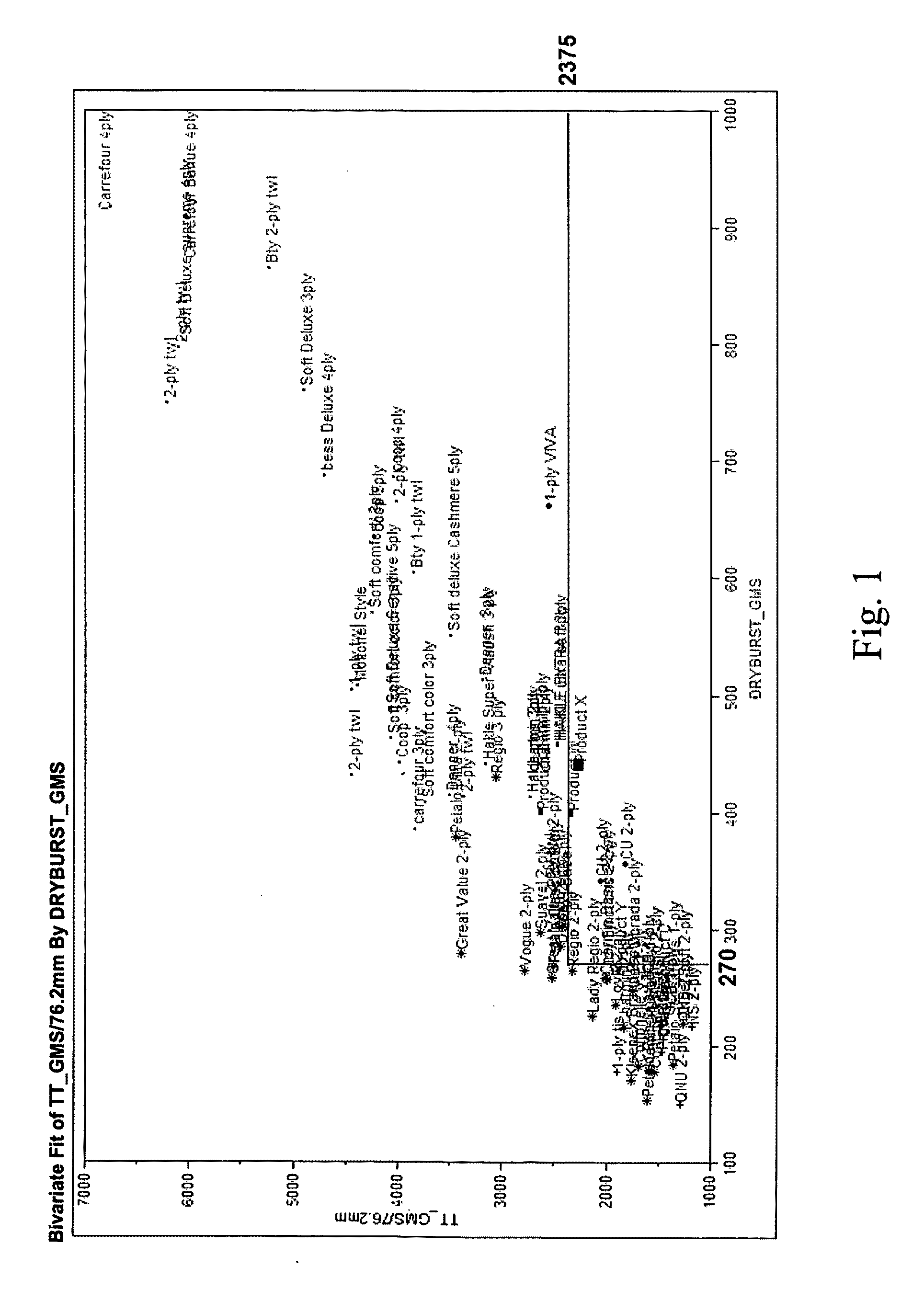

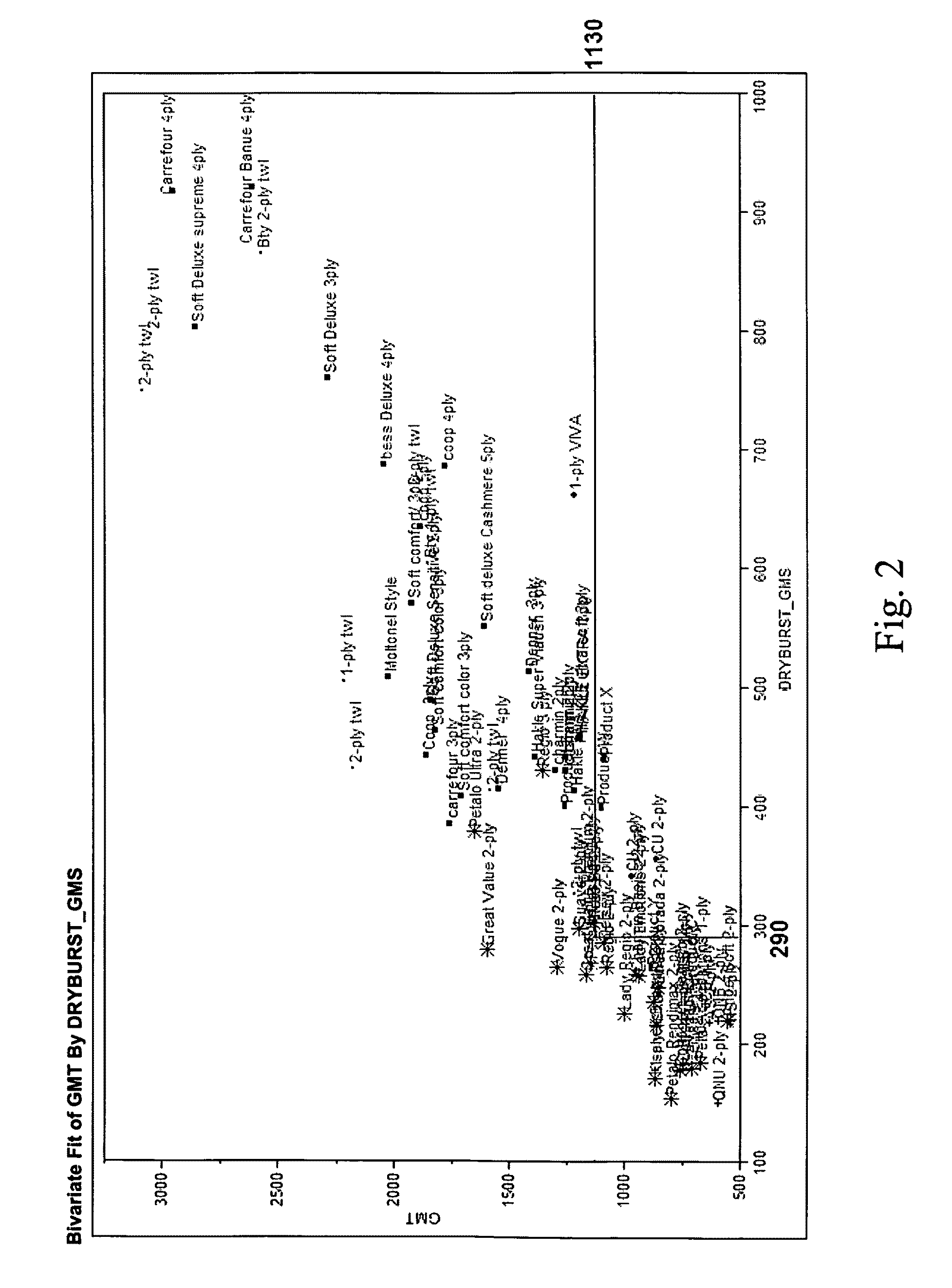

Embossed fibrous structures that exhibit a Dry Burst of greater than 270 g as measured according to the Dry Burst Test Method and more particularly to embossed fibrous structures that exhibit a Dry Burst of greater than 270 g as measured according to the Dry Burst Test Method and a Total Dry Tensile of less than 2375 g / 76.2 mm and / or a Geometric Mean Total Dry Tensile of less than 1130 g / 76.2 mm as measured according to the Tensile Strength Test Method are provided.

Owner:PROCTER & GAMBLE CO

Embossed fibrous structures

ActiveUS20090218056A1Non-fibrous pulp additionNatural cellulose pulp/paperUltimate tensile strengthFiber structure

Embossed fibrous structures that exhibit a Dry Burst of greater than 270 g as measured according to the Dry Burst Test Method and more particularly to embossed fibrous structures that exhibit a Dry Burst of greater than 270 g as measured according to the Dry Burst Test Method and a Total Dry Tensile of less than 2375 g / 76.2 mm and / or a Geometric Mean Total Dry Tensile of less than 1130 g / 76.2 mm as measured according to the Tensile Strength Test Method are provided.

Owner:THE PROCTER & GAMBLE COMPANY

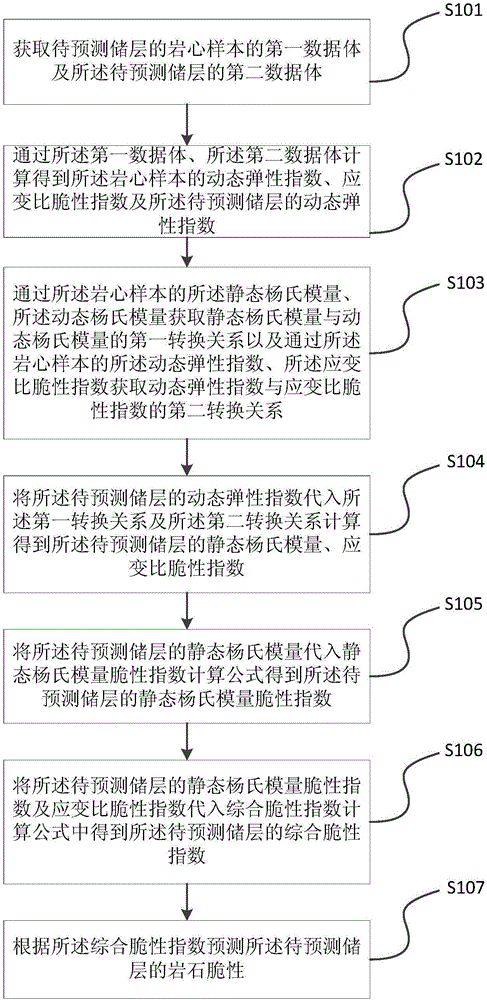

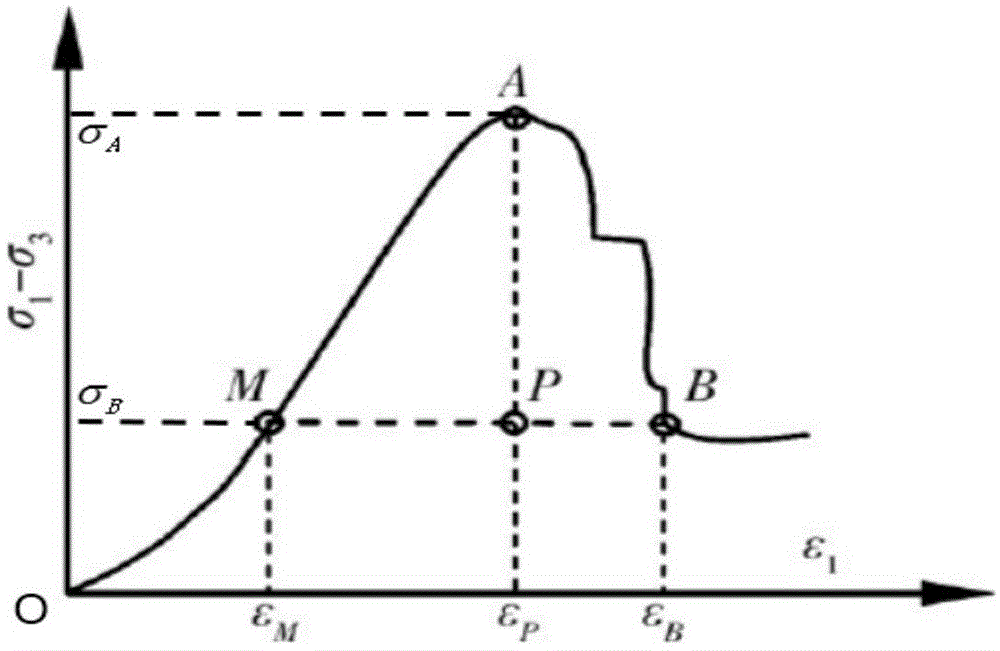

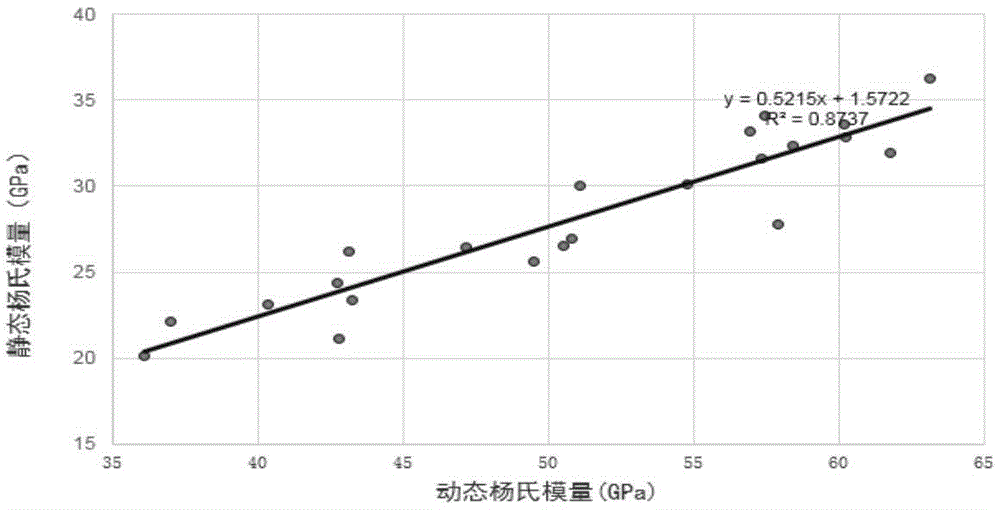

Prediction method and device for brittleness of reservoir rock

ActiveCN104406849APredict brittlenessMaterial strength using tensile/compressive forcesSeismic signal processingGeomorphologyBurst test

The invention discloses a prediction method and device for brittleness of reservoir rock. The prediction method comprises the following steps: firstly, obtaining dynamic and static elastic parameters of core samples of the reservoir to be predicted and the mechanical parameters of the rocks through a static mechanical test, an ultrasonic test and a core bursting test, calculating the dynamic elastic parameters of the reservoir to be predicted according to prestack seismic inversion results, and further calculating the static elastic parameters of the reservoir to be predicted and the mechanical parameters of the rocks; then, building the relationship among the dynamic and static elastic parameters and the mechanical parameters of the rocks through a linear fitting method, further calculating the comprehensive brittleness indexes of the rocks, and predicting the brittleness of rock of the reservoir to be predicted through the comprehensive brittleness indexes. By adopting the prediction method and the device provided by the invention, rock brittleness of the tight reservoir can be described relatively truly.

Owner:PETROCHINA CO LTD

Testing upstream cable channels

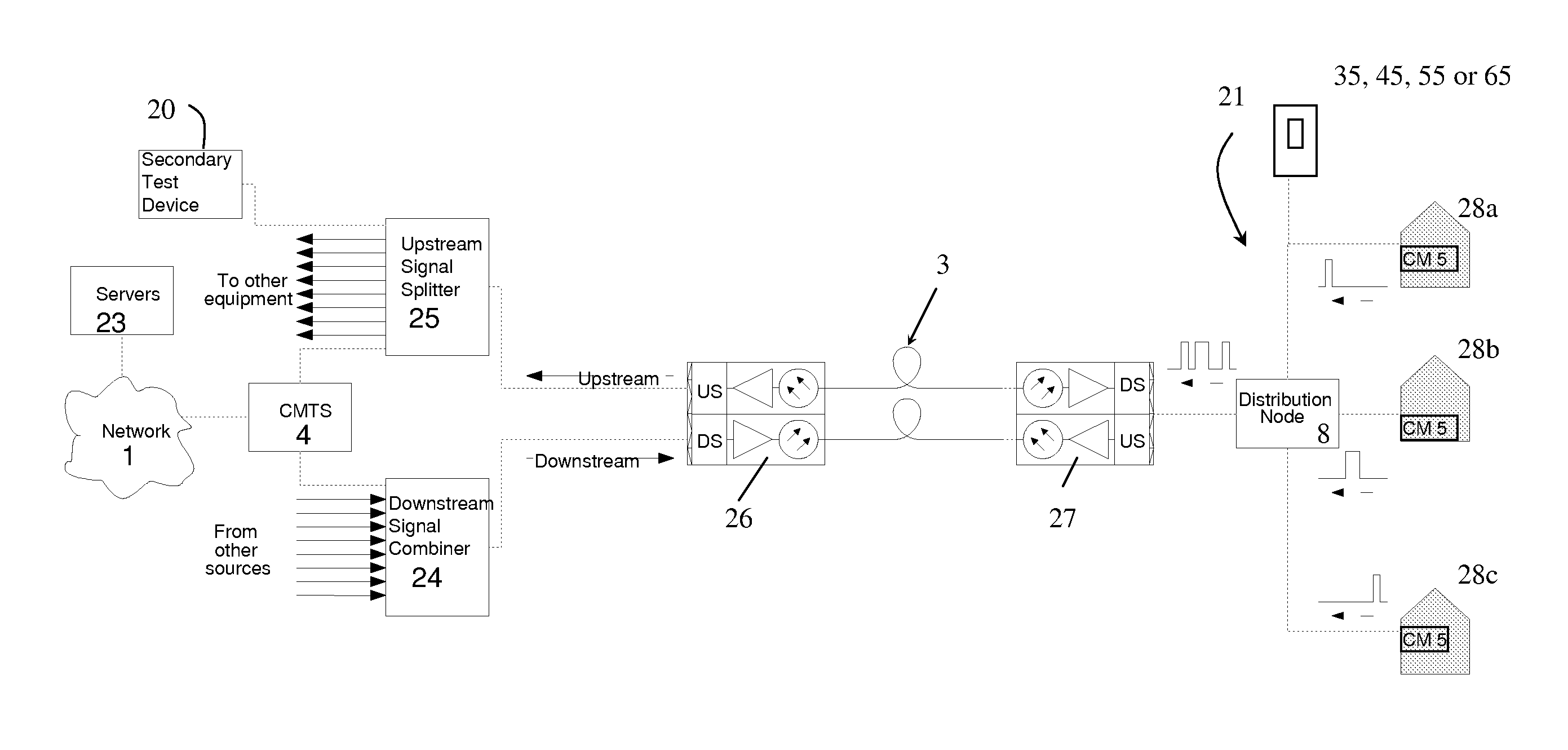

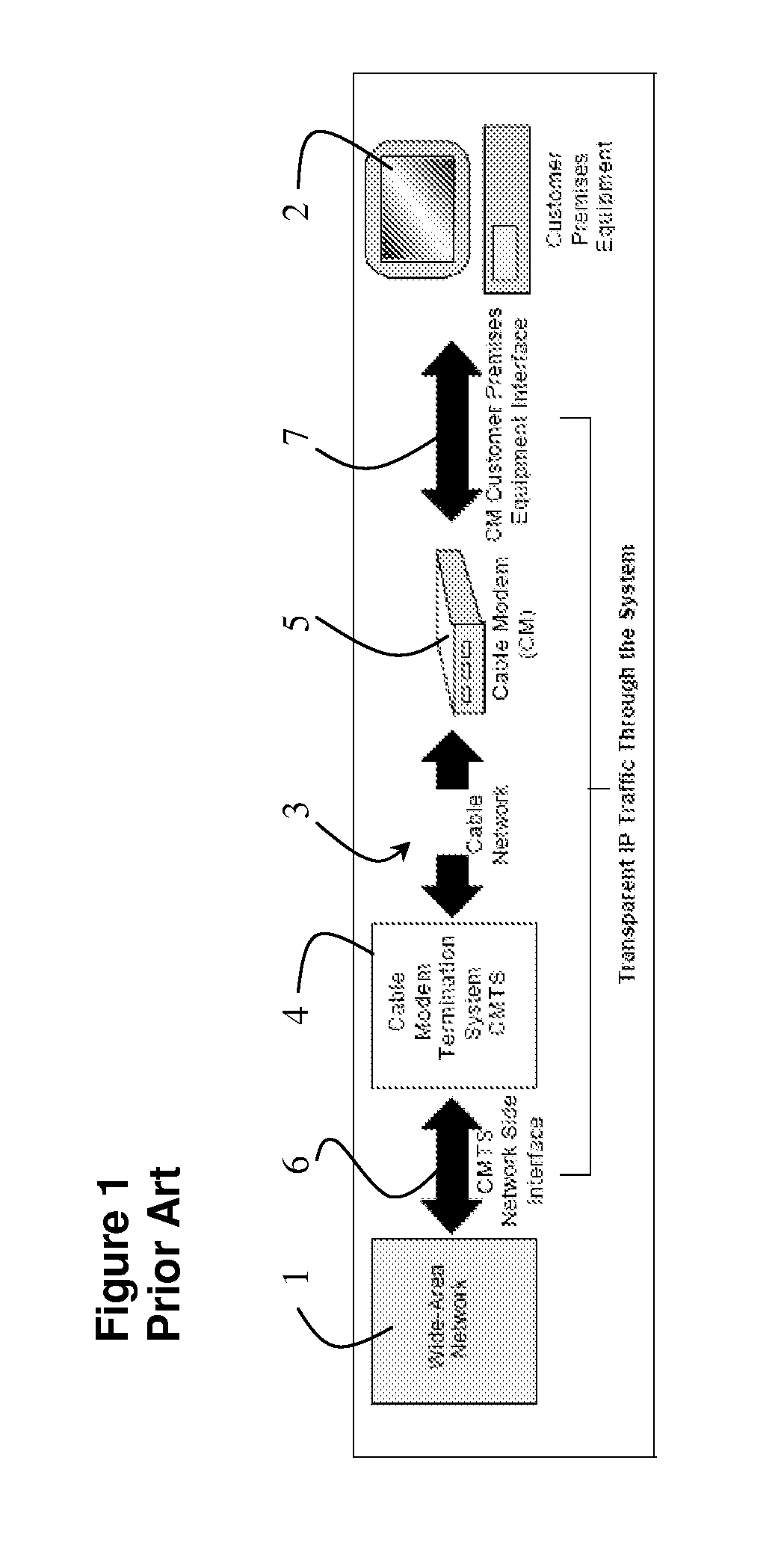

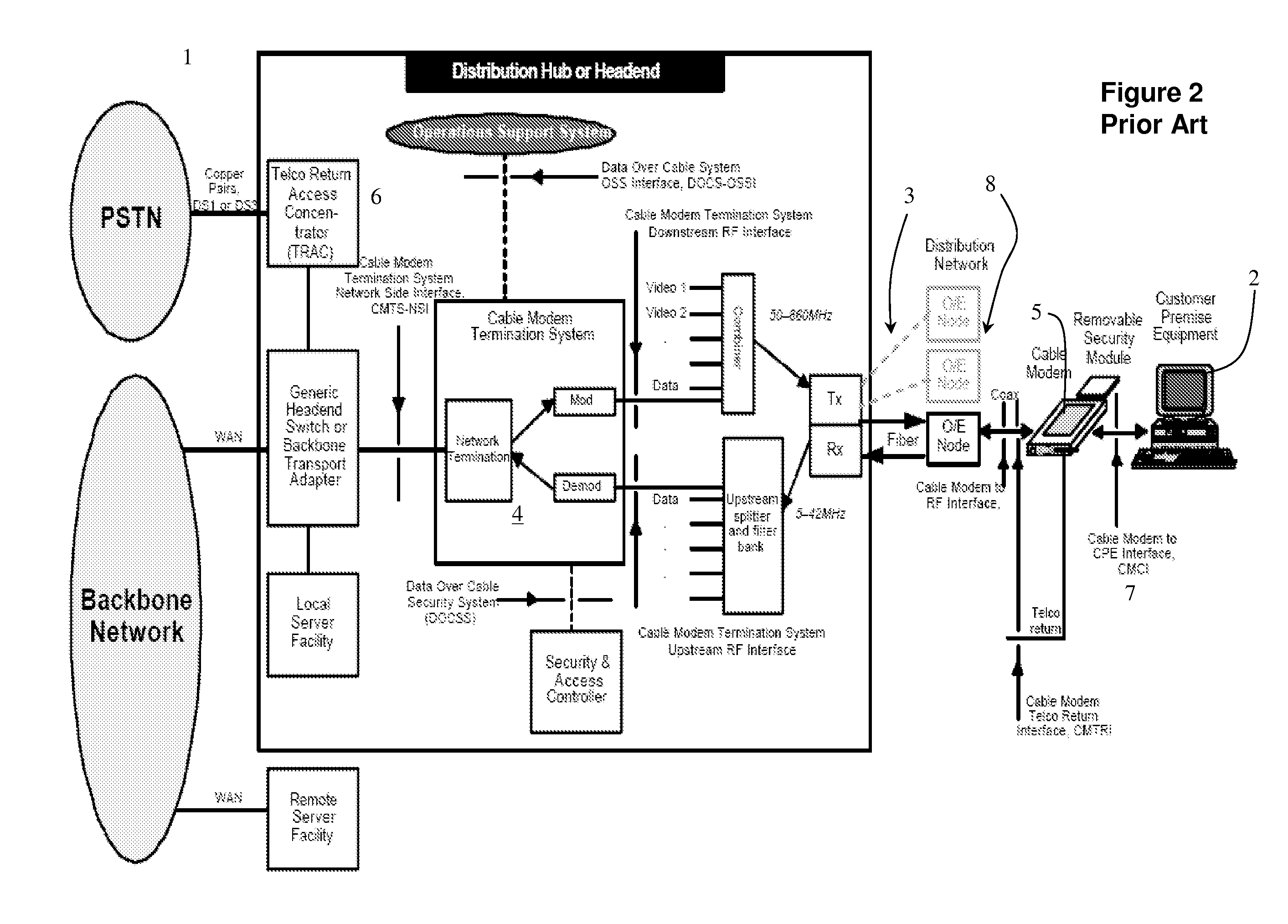

In order to measure the performance of a DOCSIS upstream channel as well as to locate impairments, a special test signal is transmitted in a time slot of the upstream channel by a test instrument positioned anywhere within the CATV plant. A second test instrument, located at the termination point of the upstream plant, then detects, recovers, and processes the test signal in order to complete the measurement. The typical methods used to detect and recover bursted signals within a DOCSIS upstream channel use precise timing information transmitted in a corresponding DOCSIS downstream channel. Unfortunately, the downstream channel and thus the precise timing information are not always available to the secondary test instrument. The present invention also describes an apparatus and method for detecting a bursted test signal without the use of the DOCSIS upstream channel timing.

Owner:VIAVI SOLUTIONS INC

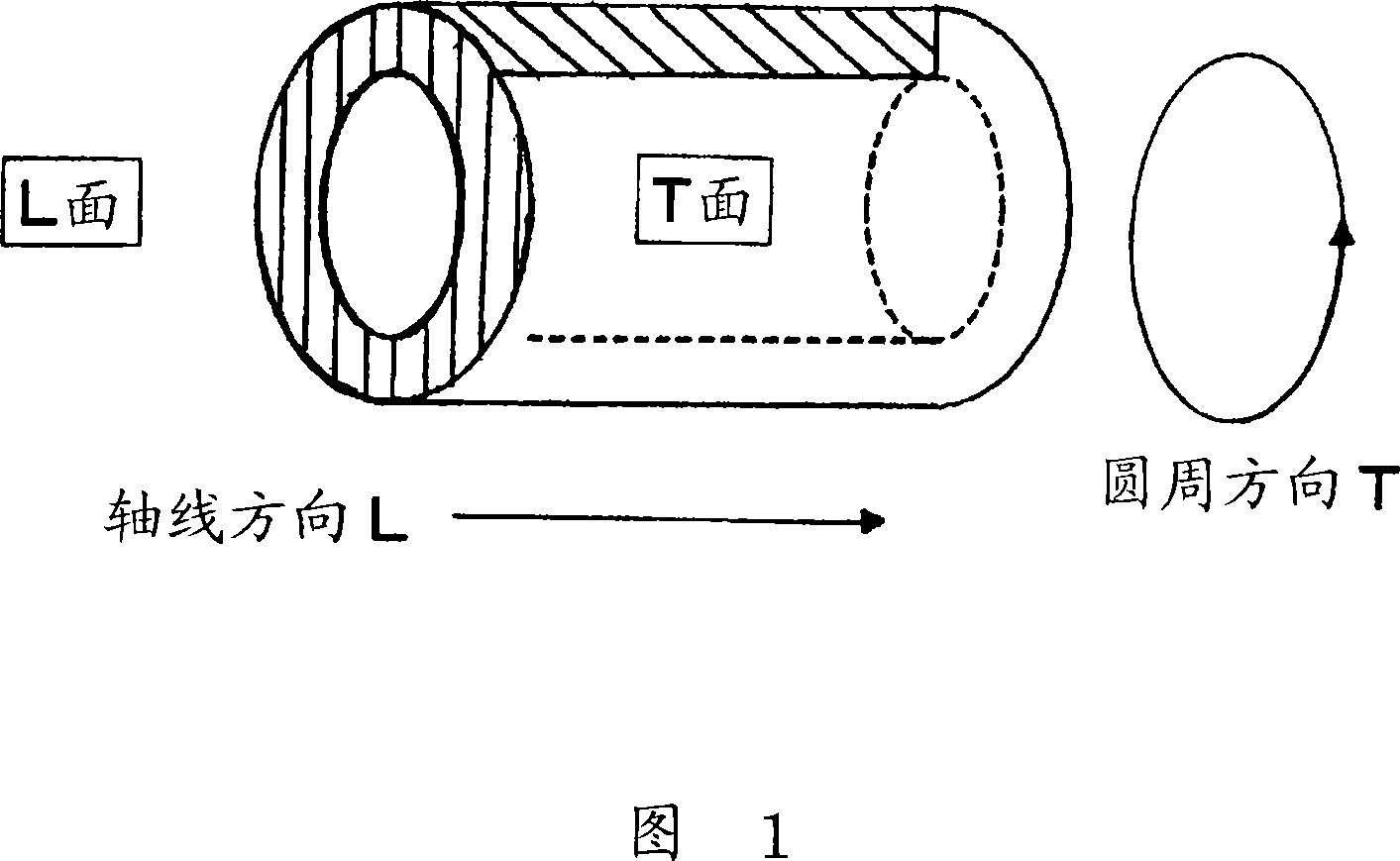

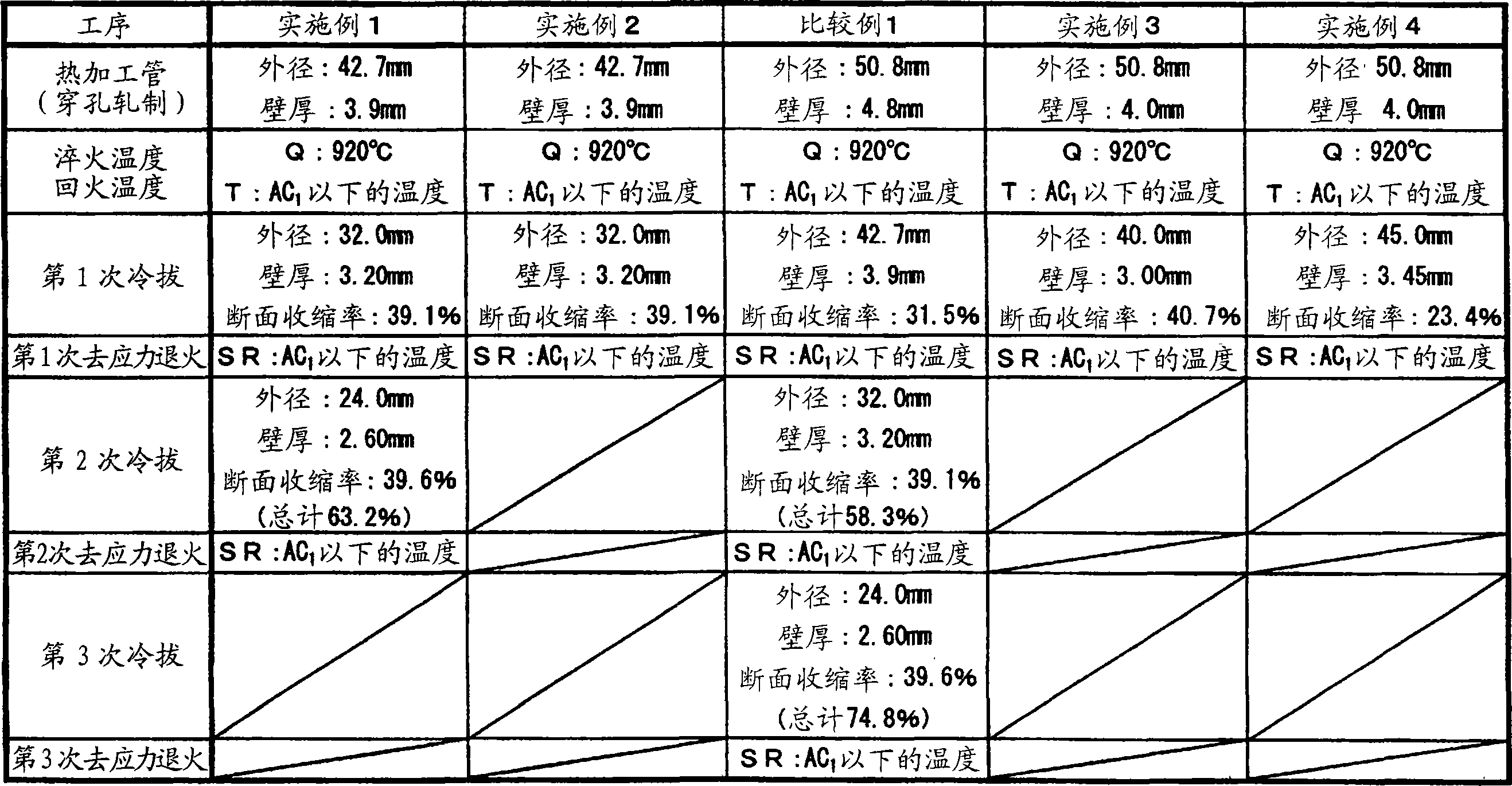

Steel pipe for an airbag inflator and a process for its manufacture

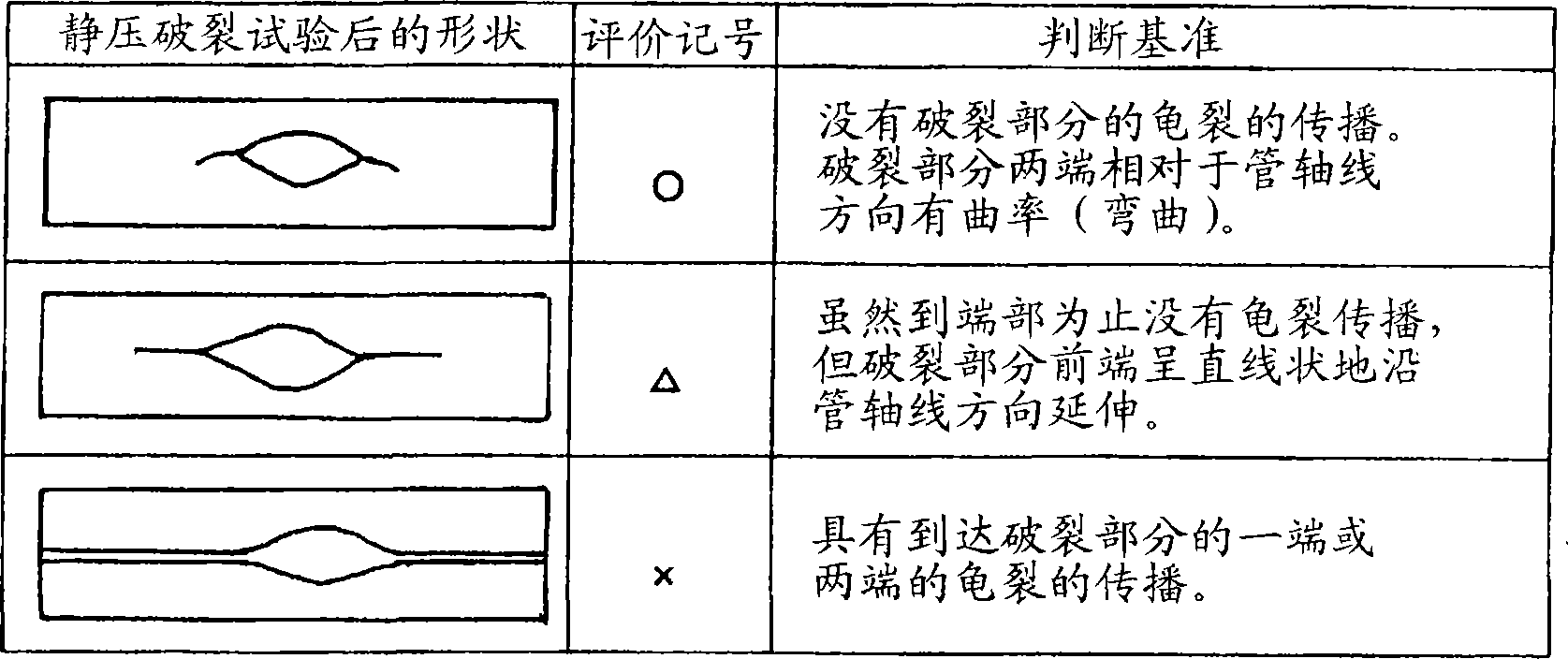

InactiveUS20060124211A1High dimensional accuracySmall sizePedestrian/occupant safety arrangementFurnace typesX-rayStress relief

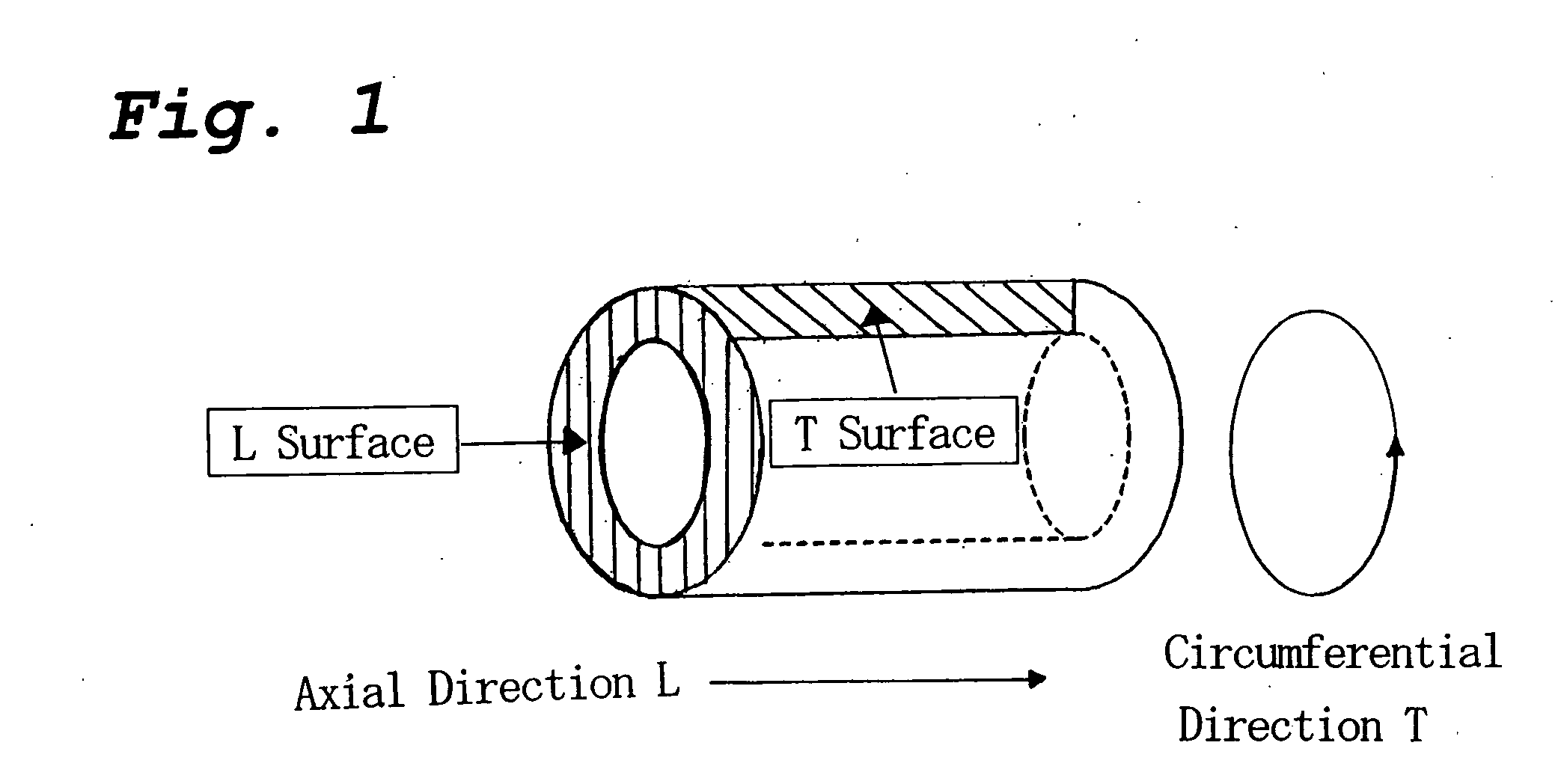

A steel pipe for an airbag inflator having a high strength of at least 900 MPa and preferably at least 1000 MPa in tensile strength along with a high toughness and exhibiting good resistance to bursting such that it has no propagation of cracks in a burst test at −40° C. or below is manufactured by quenching a pipe of a steel comprising, in mass %, C: 0.05-0.20 %, Si: 0.1-1.0 %, P: at most 0.025 %, S: at most 0.010 %, Cr: 0.05-1.45 %, Al: at most 0.10 %, and one or both of Ti and Mn satisfying Ti<0.02% and 0.4%≦Mn+40Ti≦1.2% from a temperature of at least the Ac1 transformation point of the steel, tempering the pipe at a temperature lower than the Ac1 transformation point, applying cold working to it with a reduction of area of at most 65%, and subjecting it to stress relief annealing at a temperature lower than the Ac1 transformation point. The ratio L / T of the X-ray integrated intensity ratio of the {110} plane measured for the cross section perpendicular to the axial direction L of the steel pipe to that measured for the cross section perpendicular to the circumferential direction T is at most 50.

Owner:NIPPON STEEL CORP

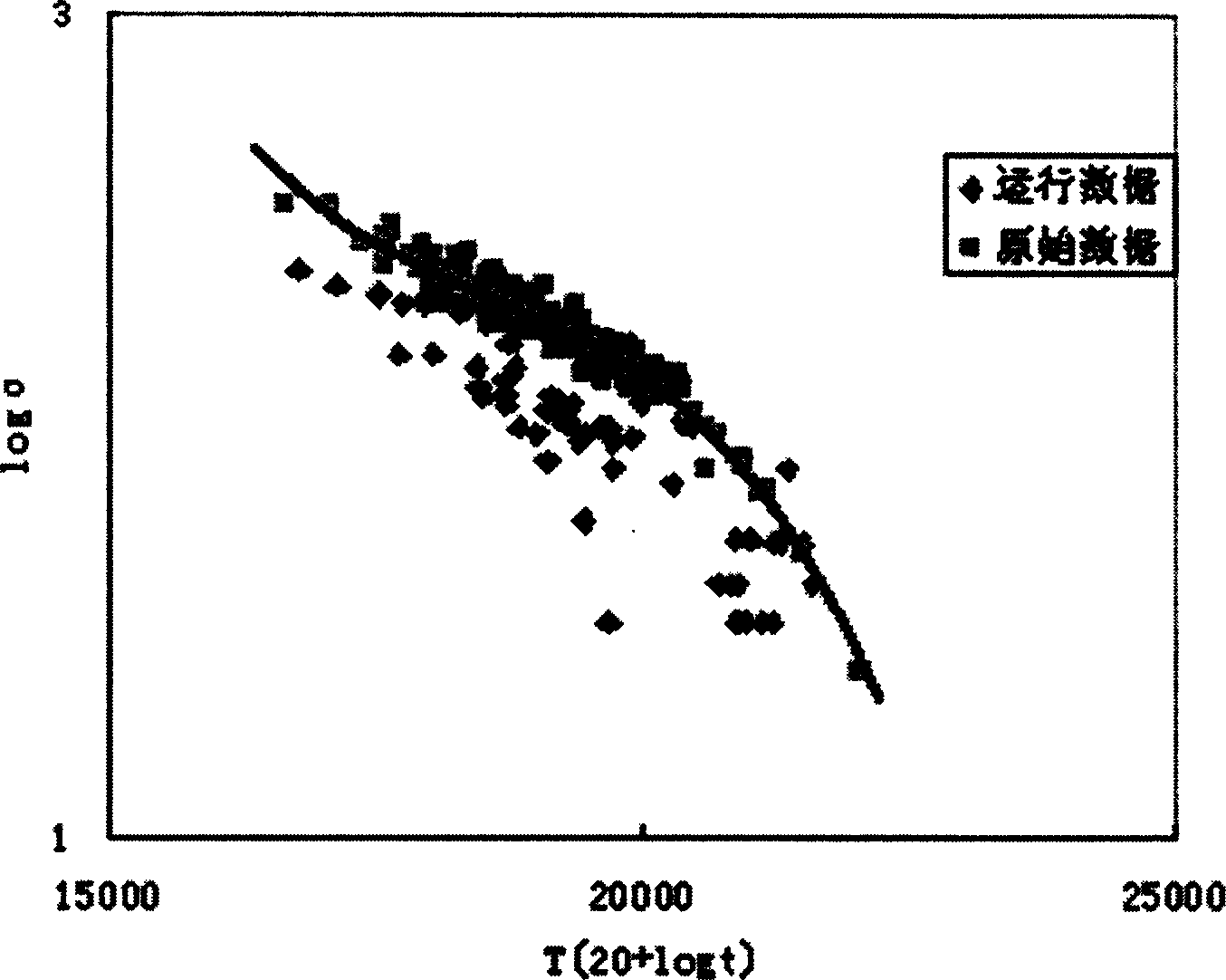

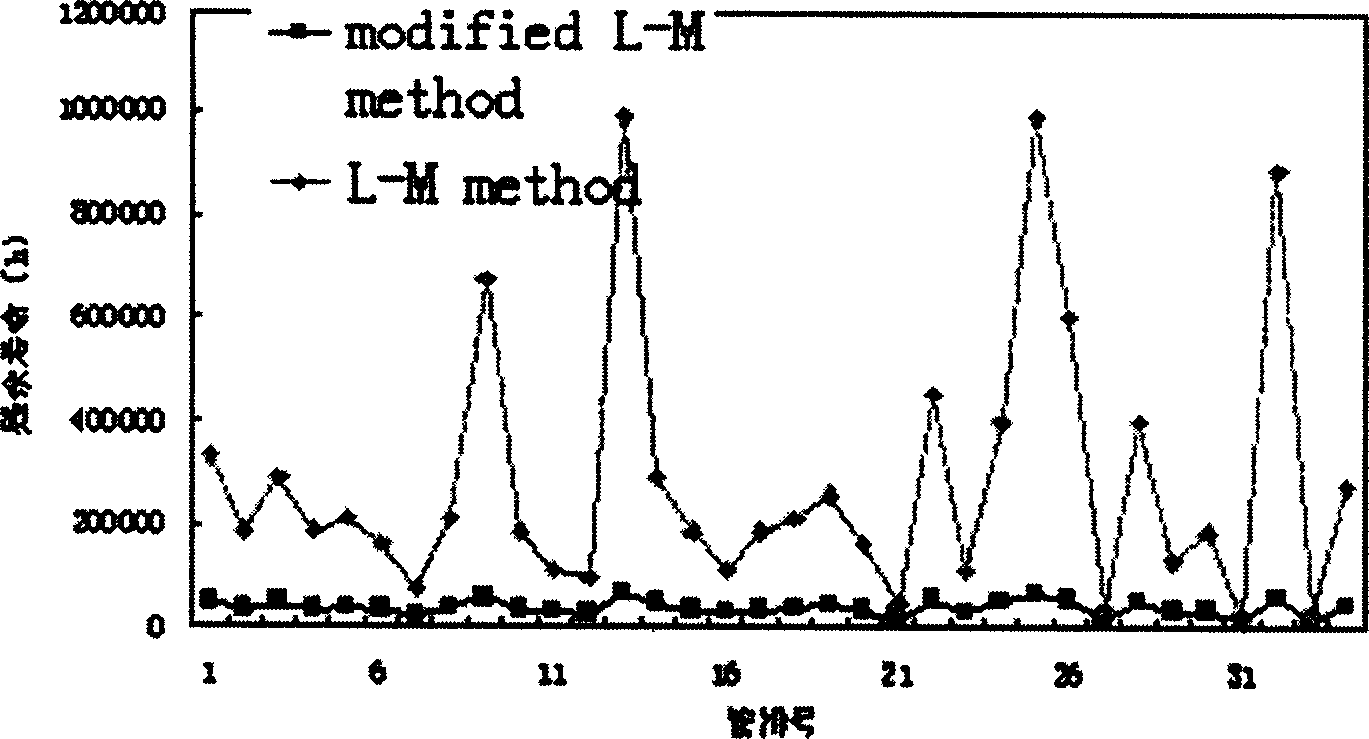

Test method of high-temp, component creep life

The testing method of high-temp. component creep life adopts the simulation pipe-bursting test machine or durable strength testing machine to make creep rupture acceleration simulation test of new materials which have different ageing extents and are not aged under the condition of a series of temp. and stresses. It adopts polynomical regressive analysis method to process data, and obtain the relationship formula of non-aged material between ageing factor, temp. and life time. By utilizing test, data processing and formula operation the material creep service life can be obtained.

Owner:XIAN THERMAL POWER RES INST CO LTD

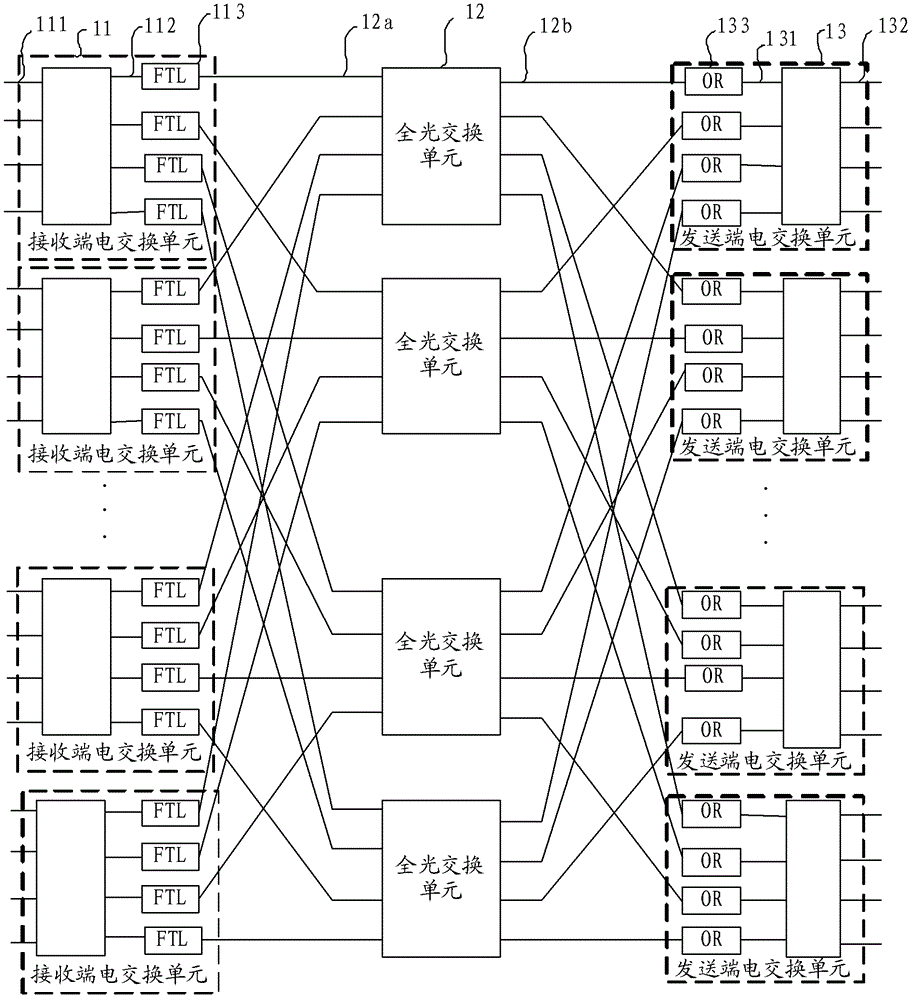

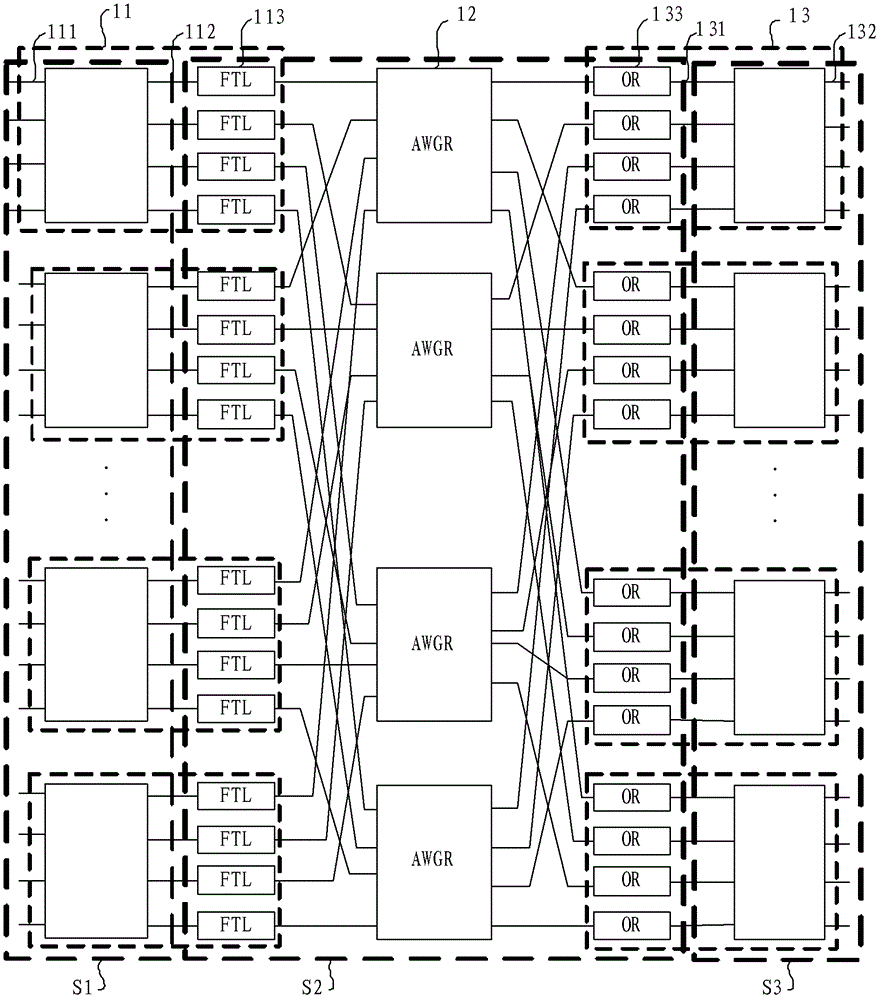

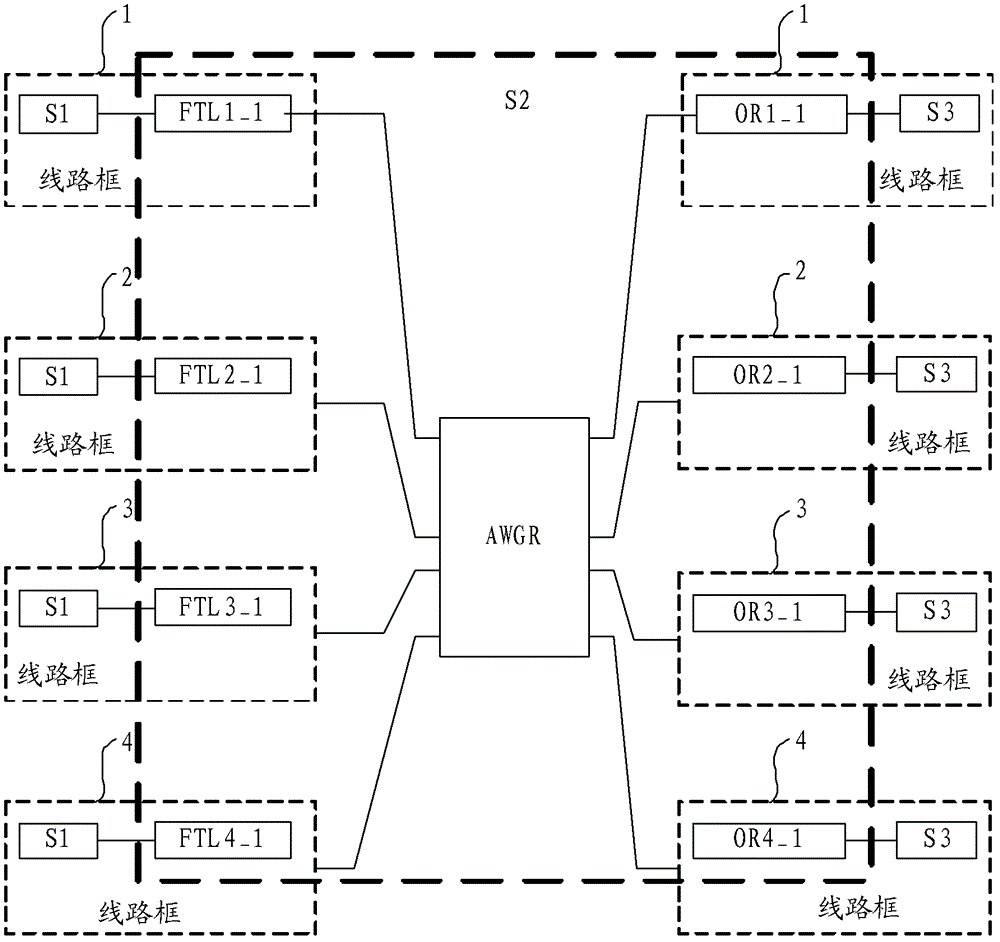

Optical network switching nodes, optical burst synchronization method and circuit frame of multi-frame cluster

ActiveCN102726058ALarge capacityImprove bandwidth utilizationMultiplex system selection arrangementsSynchronisation by photonic/optical meansSystem capacityPhase difference

Embodiments of the present invention provide optical network switching nodes, an optical burst synchronization method and circuit frames of a multi-frame cluster. The synchronization method comprises that: a reference frame is selected, wherein output ports in which the FTLs (fast tunable lasers) in the reference frame are positioned transmit optical burst test signals to receiving ports in which the ORs (optical receivers) in other circuit frames are positioned, and the optical burst test signals carry transmission time slot numbers; and the receiving ports in which the ORs in other circuit frames are positioned, according to optical path difference between the receiving ports to the output ports which the FTLs in the reference frame are positioned, the timing that the receiving ports receive the optical burst test signals and the transmission time slot numbers, obtain the time phase difference between the receiving ports and the reference frame, and then local clock phase calibration is conducted on the basis of time difference phase. With the technical schemes, the problem of optical burst synchronization is solved, an OTN-based multi-frame cluster system is realized, system capacity is increased and power consumption is reduced.

Owner:HUAWEI TECH CO LTD

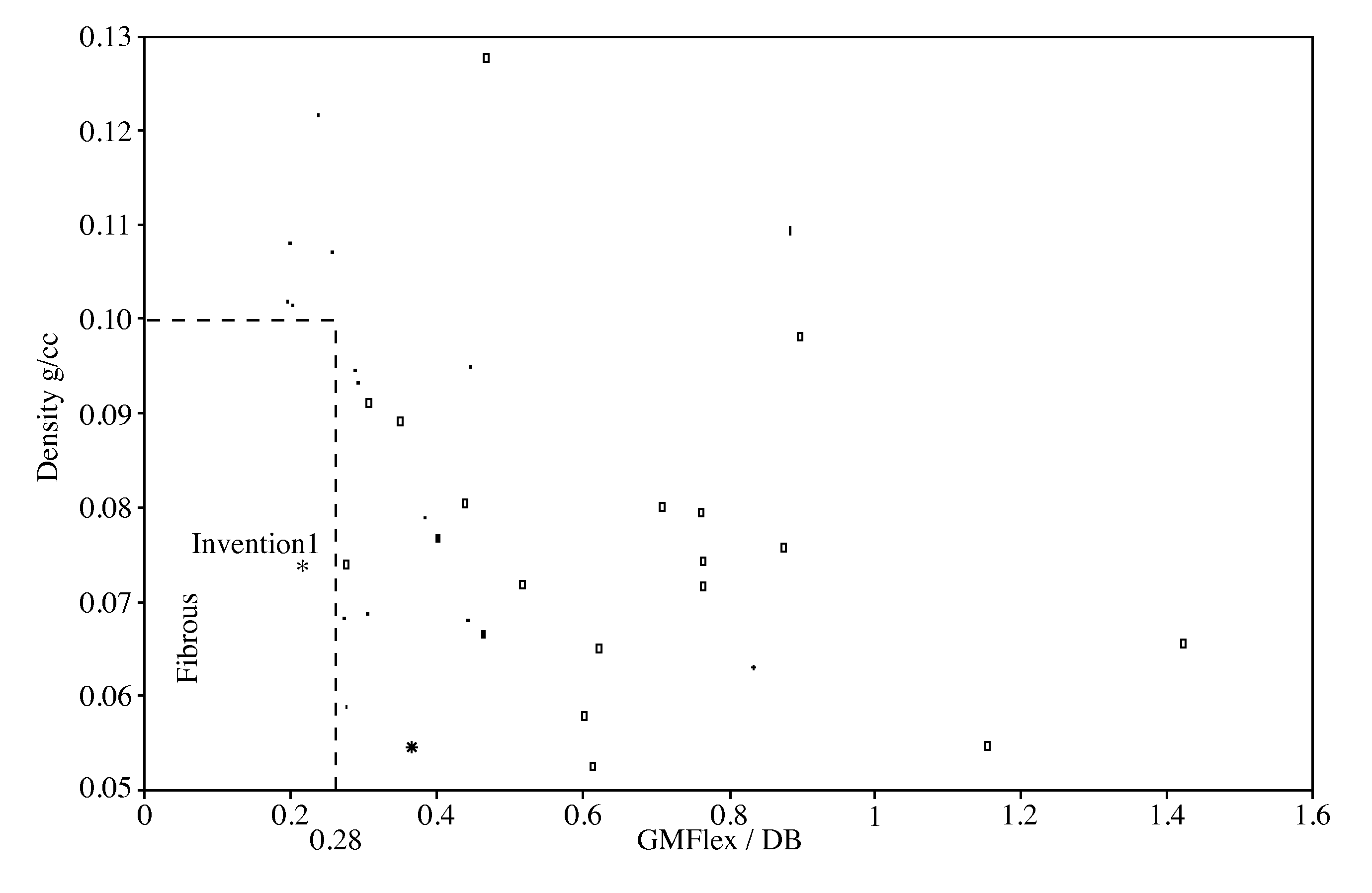

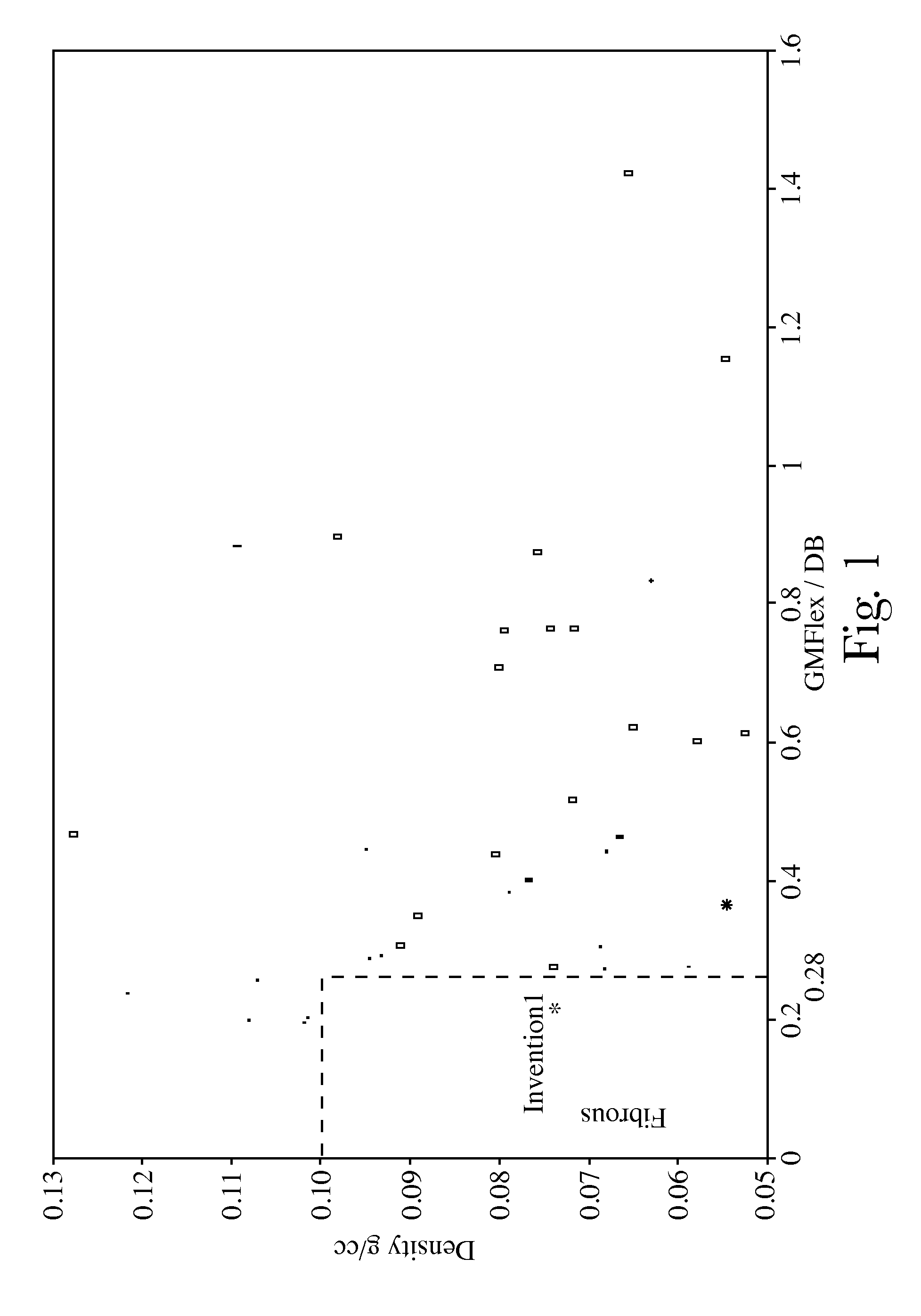

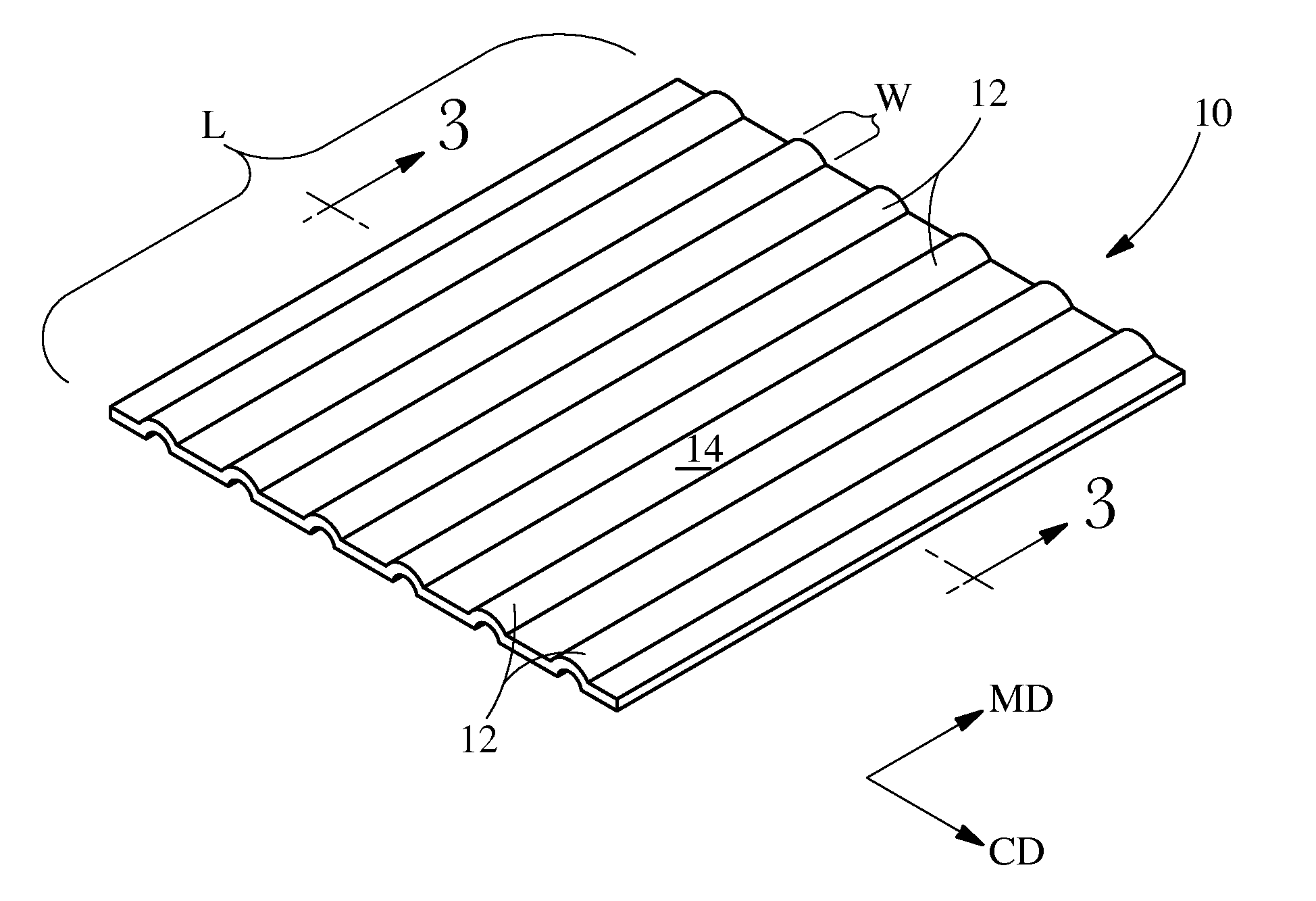

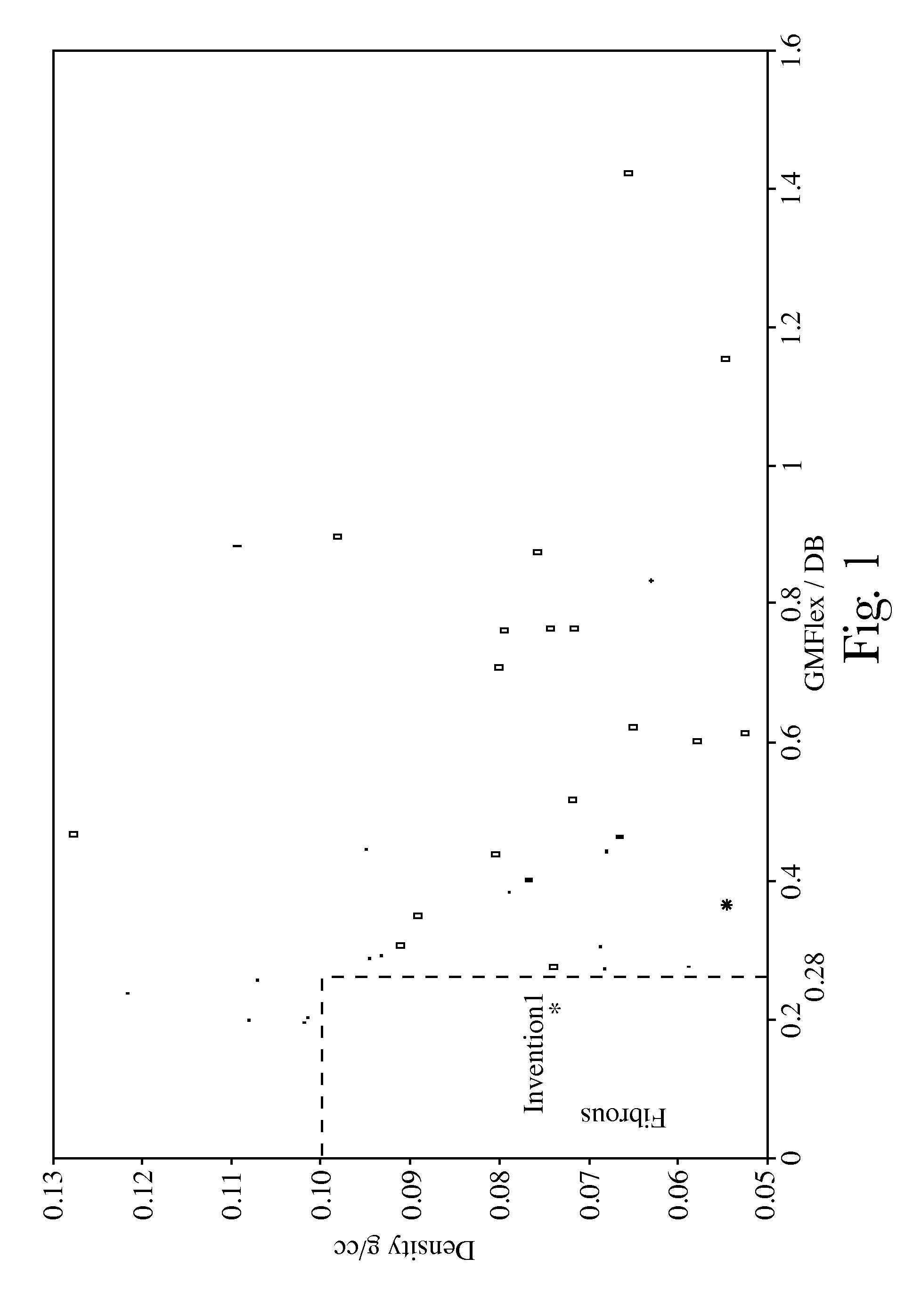

Fibrous structures

Fibrous structures that exhibit a Geometric Mean Flexural Rigidity (GM Flexural Rigidity or GMFlex) as measured according to the Flexural Rigidity Test Method described herein to Dry Burst (DB) as measured according to the Dry Burst Test Method described herein ratio (GMFlex / DB ratio) of less than 0.26 and a Density of less than 0.10 g / cm3 as measured according to the Test Methods described herein are provided.

Owner:PROCTER & GAMBLE CO

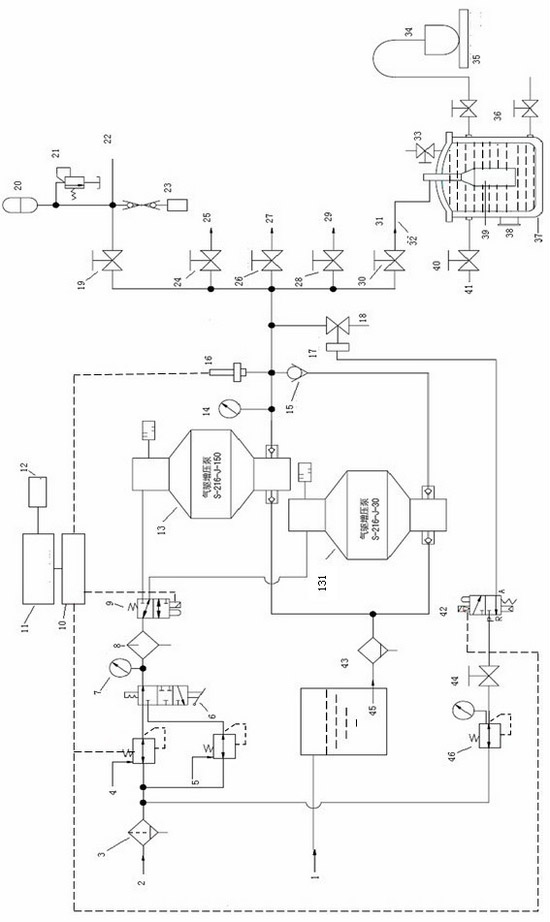

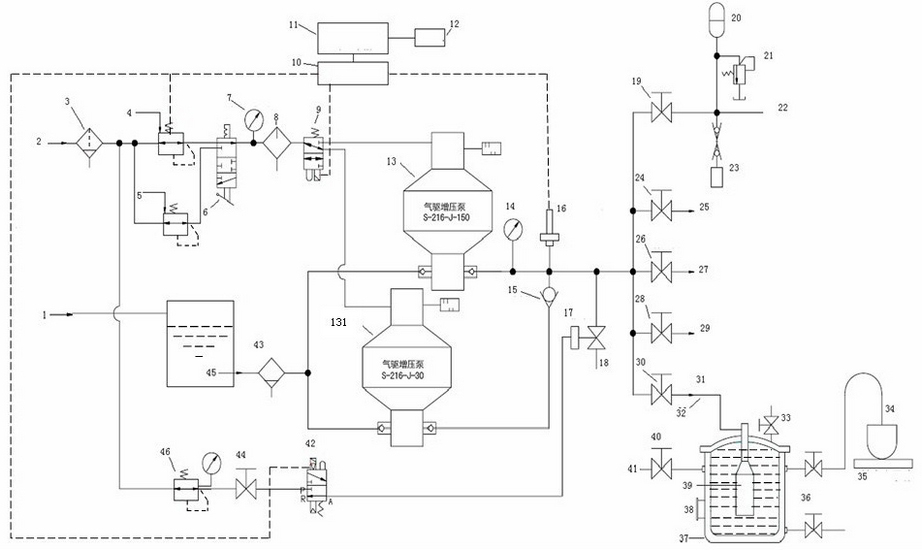

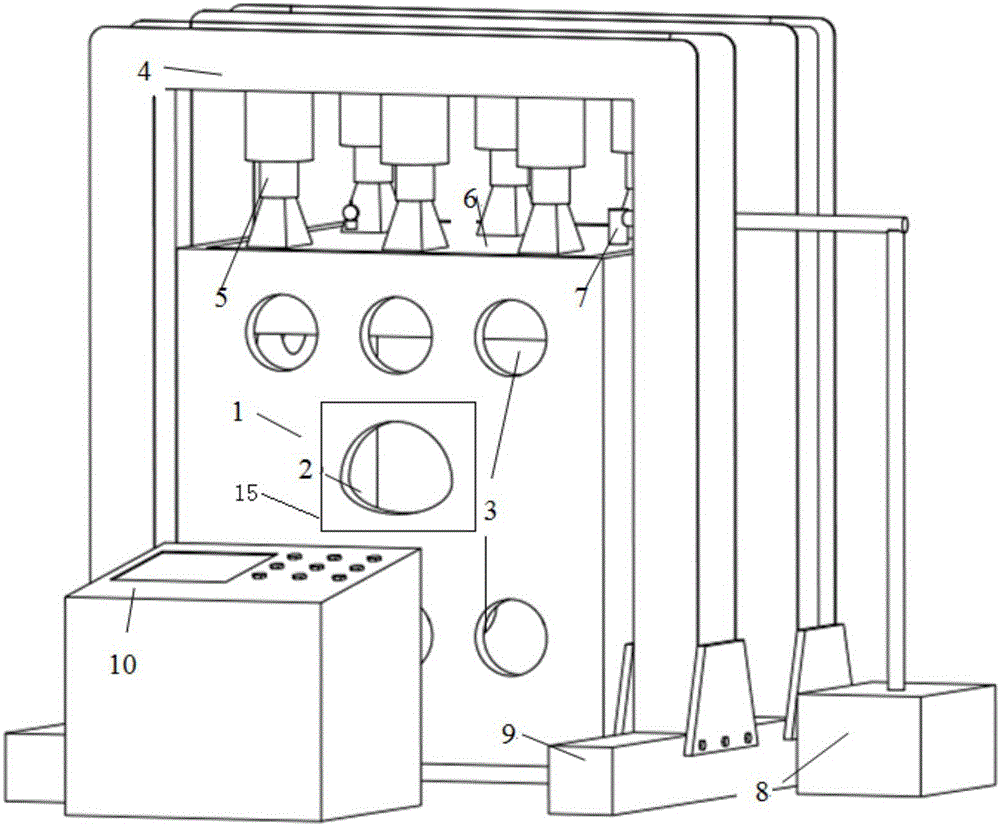

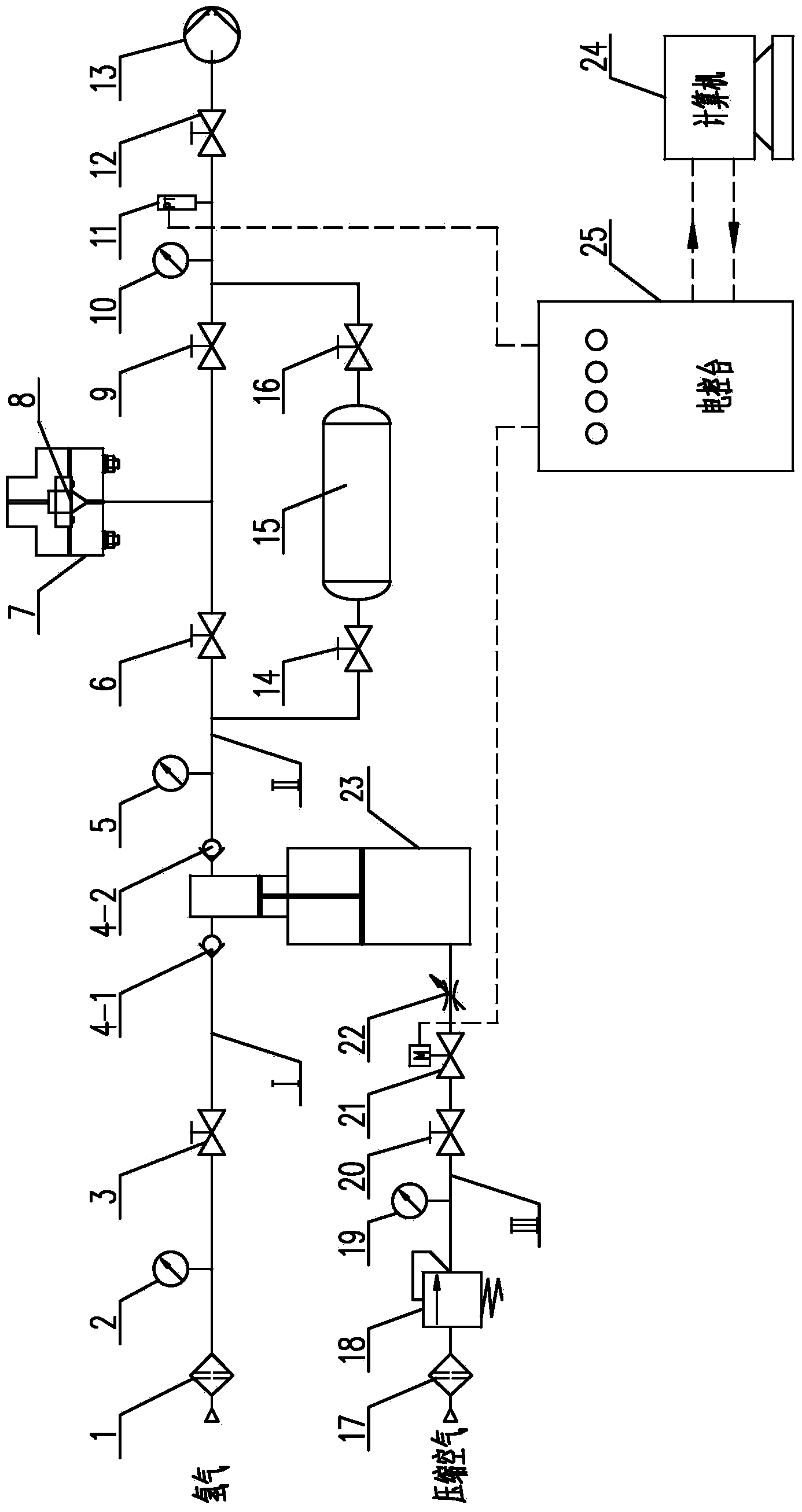

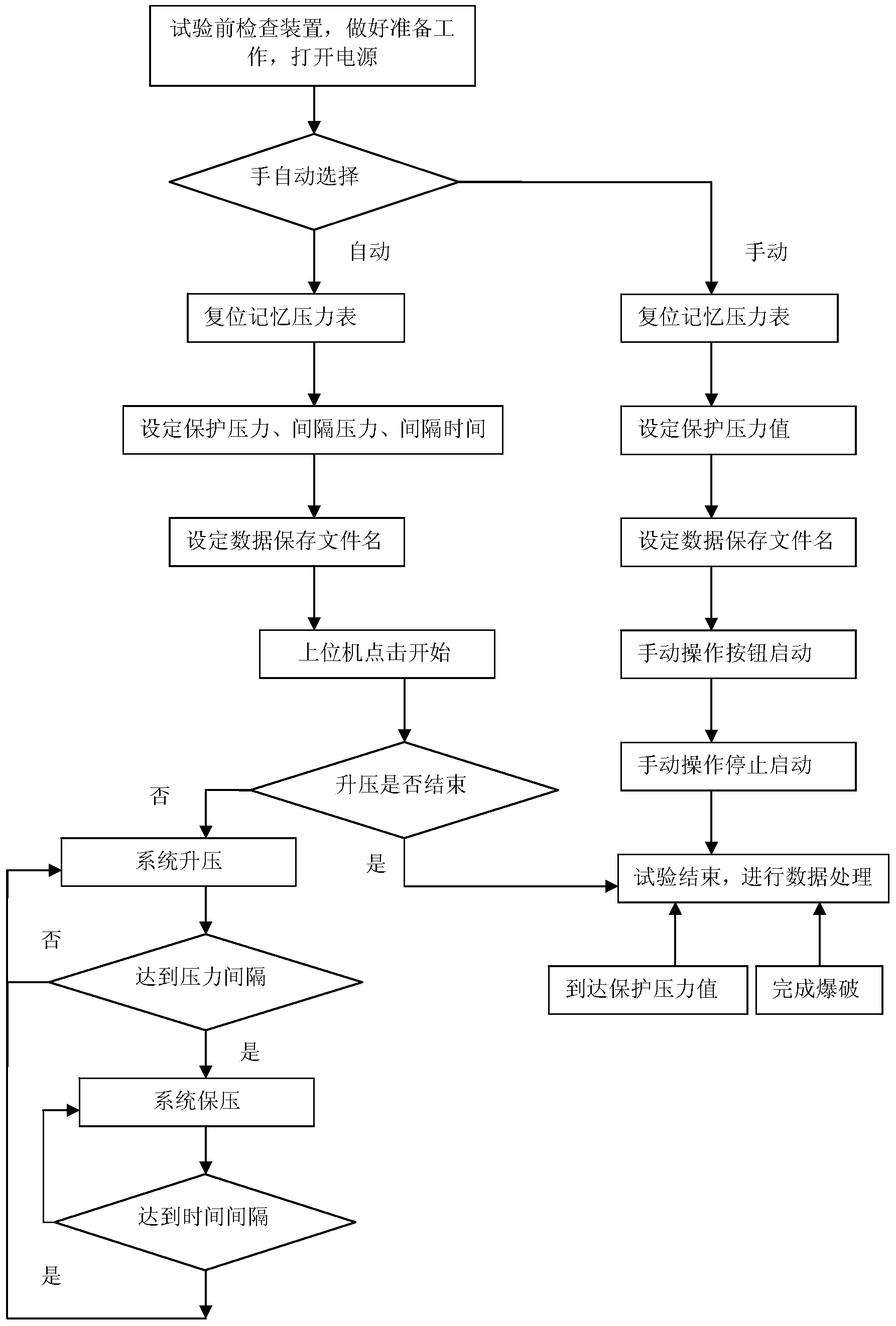

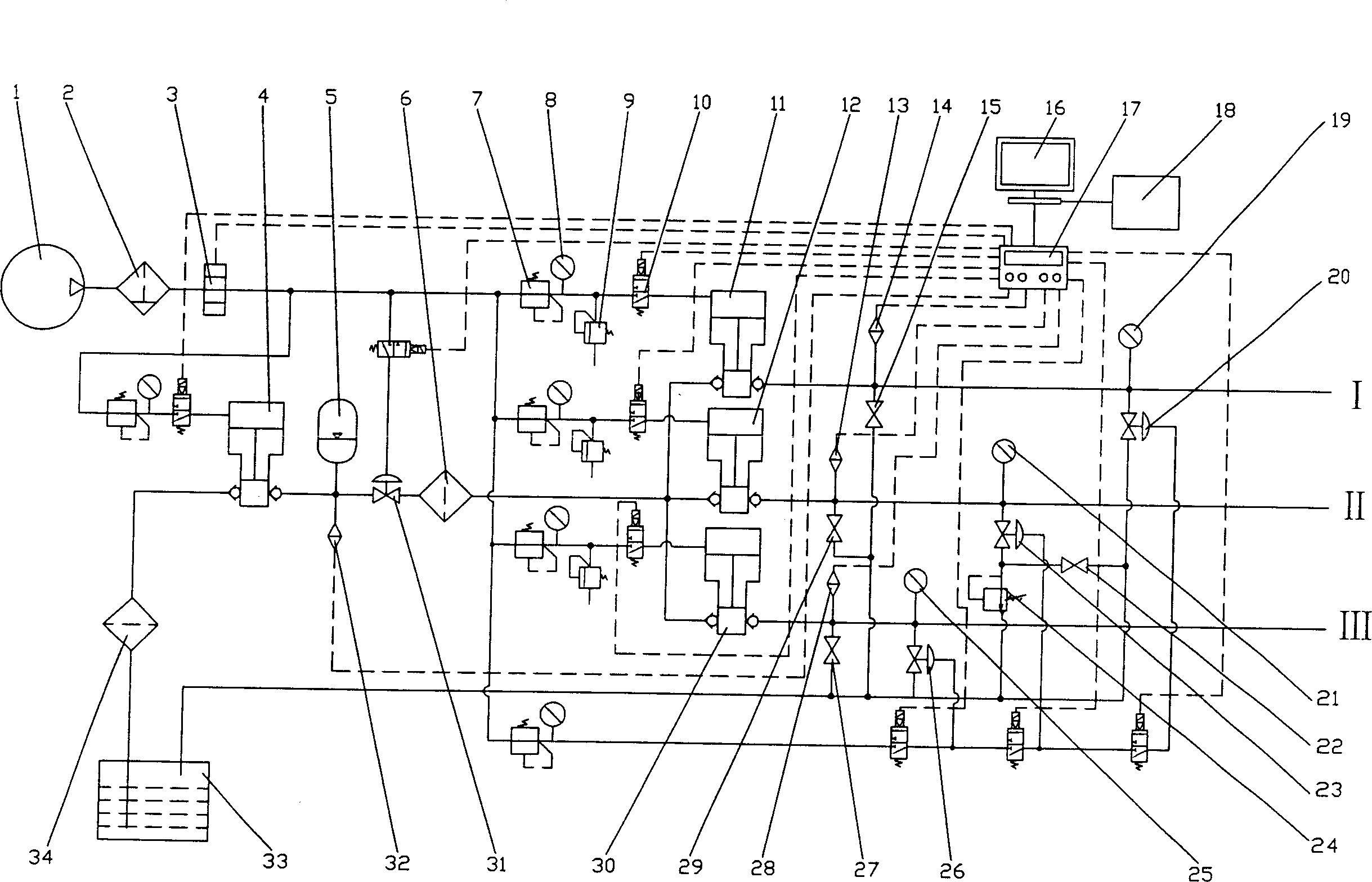

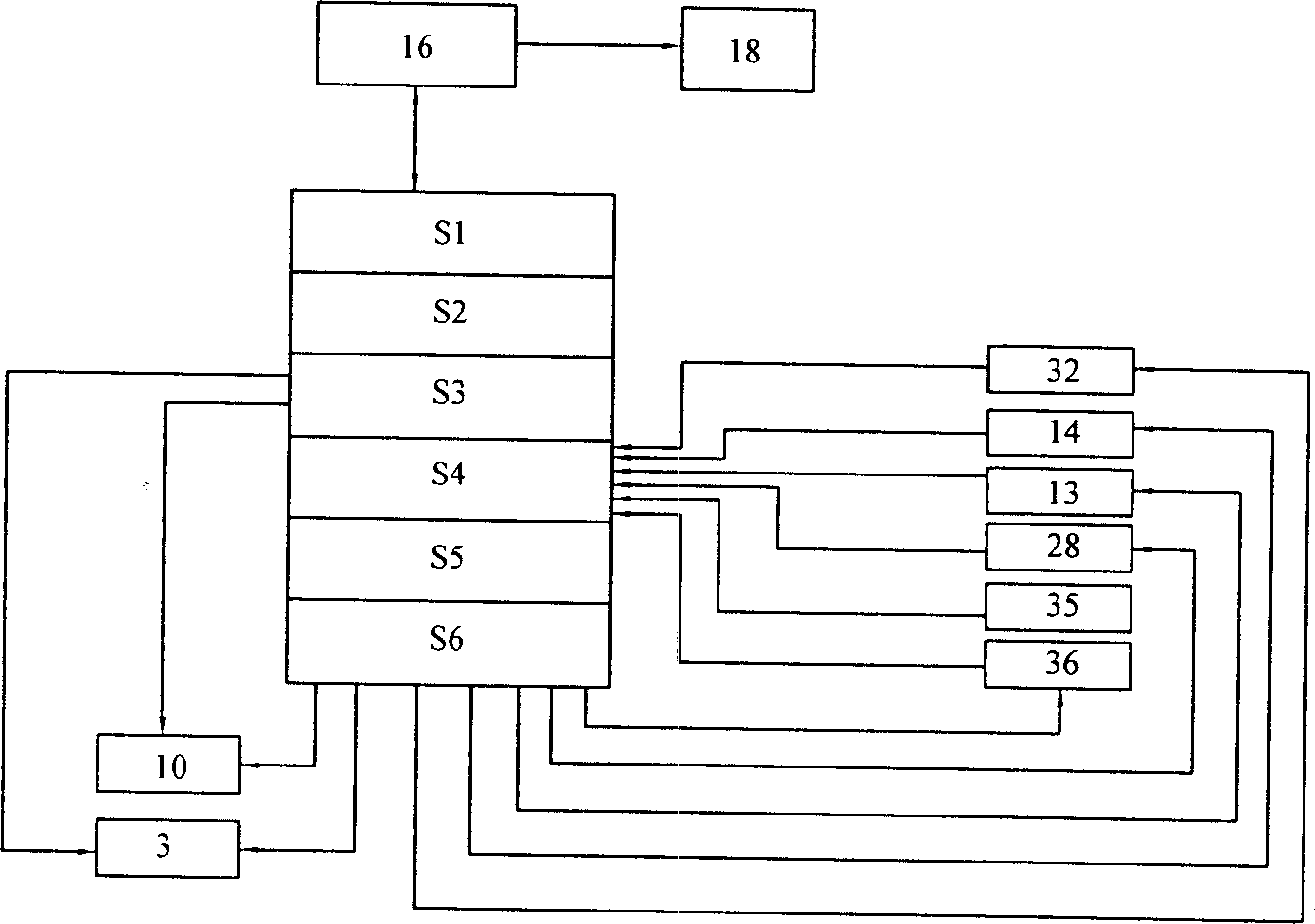

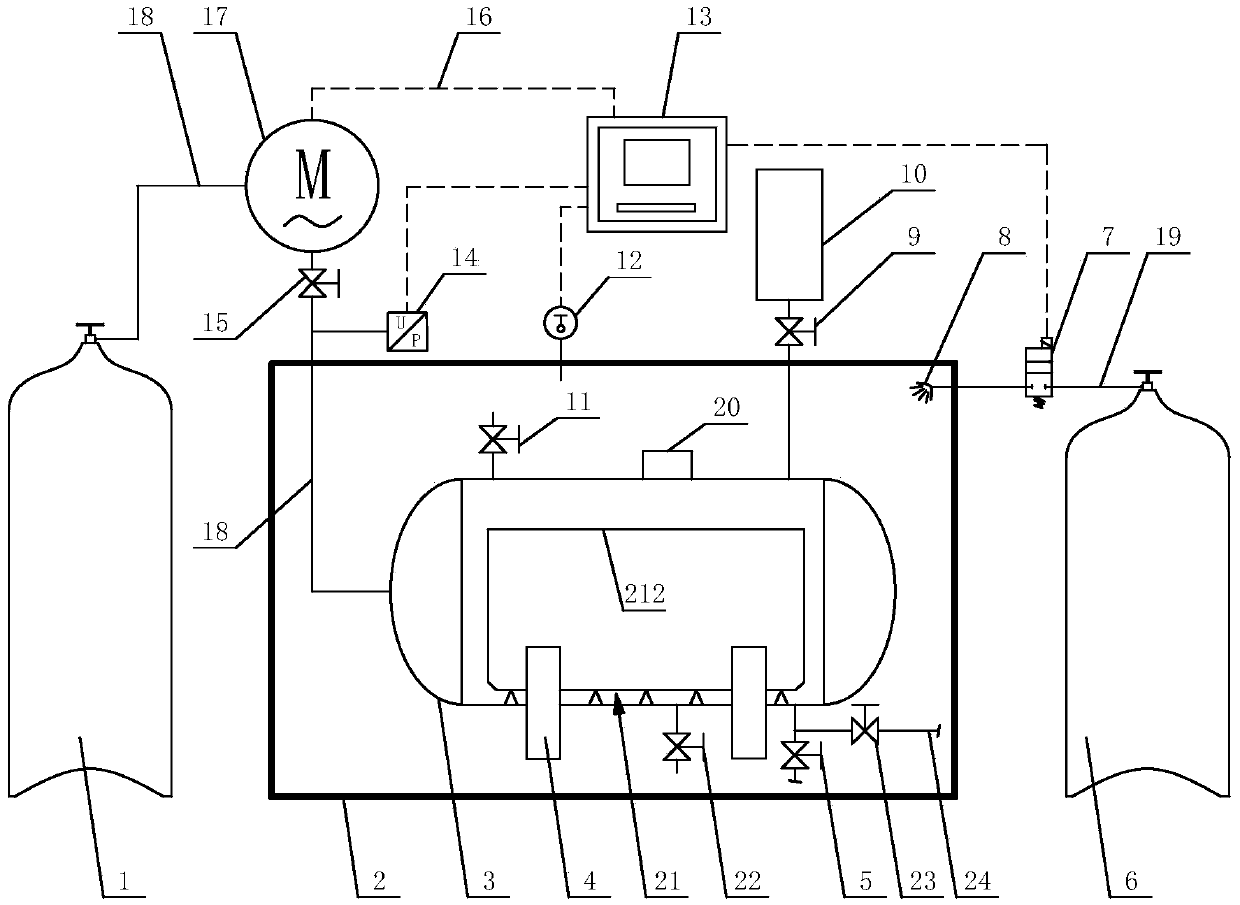

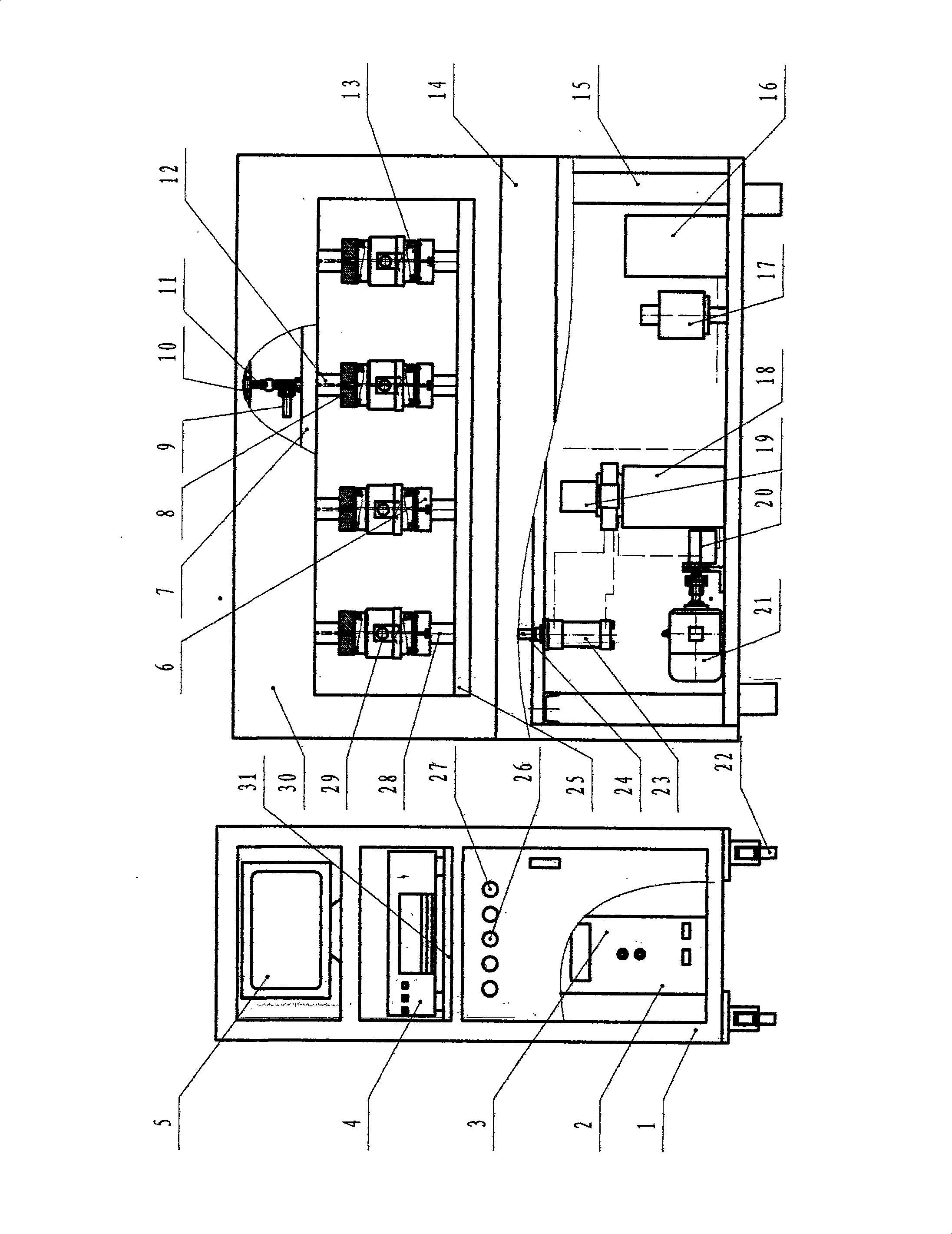

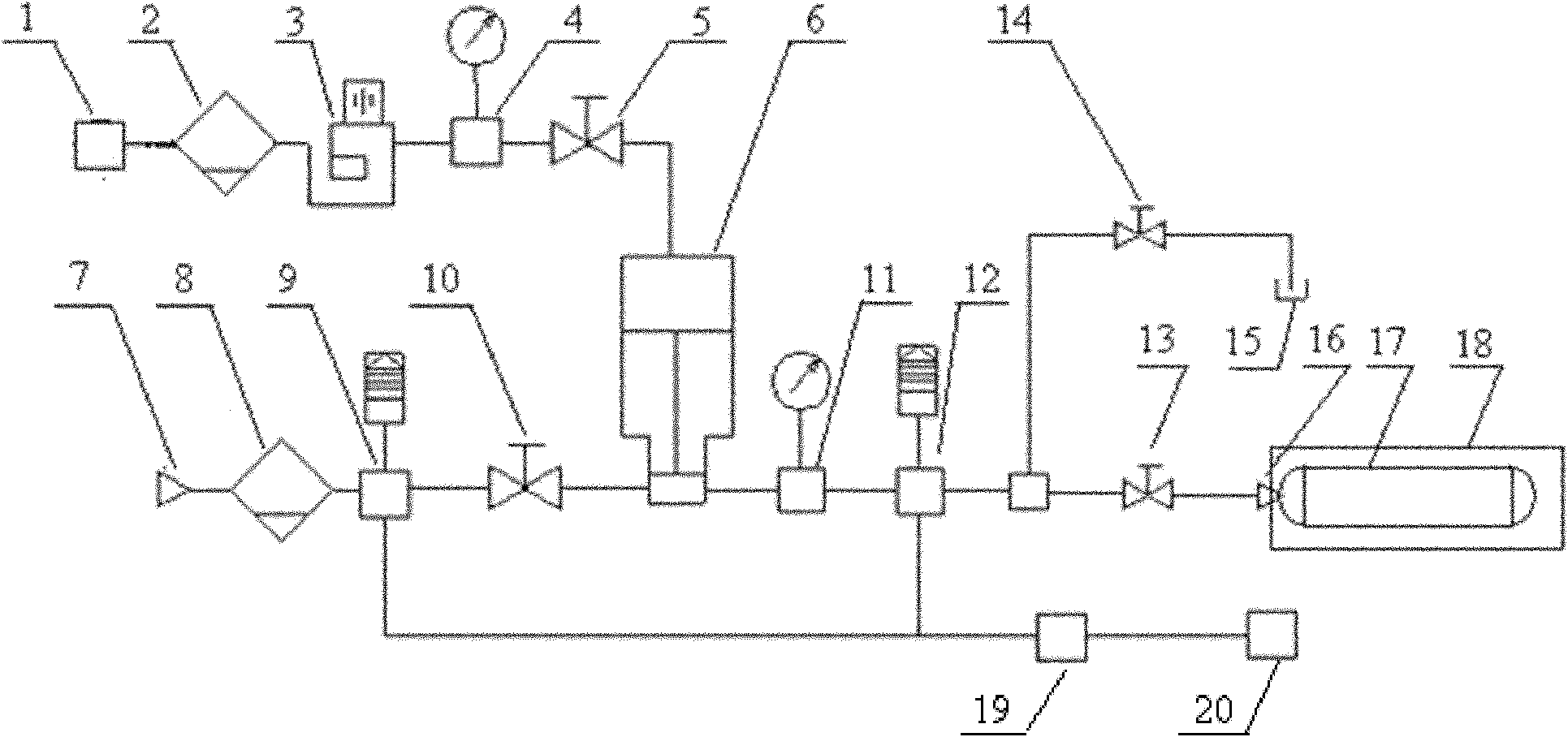

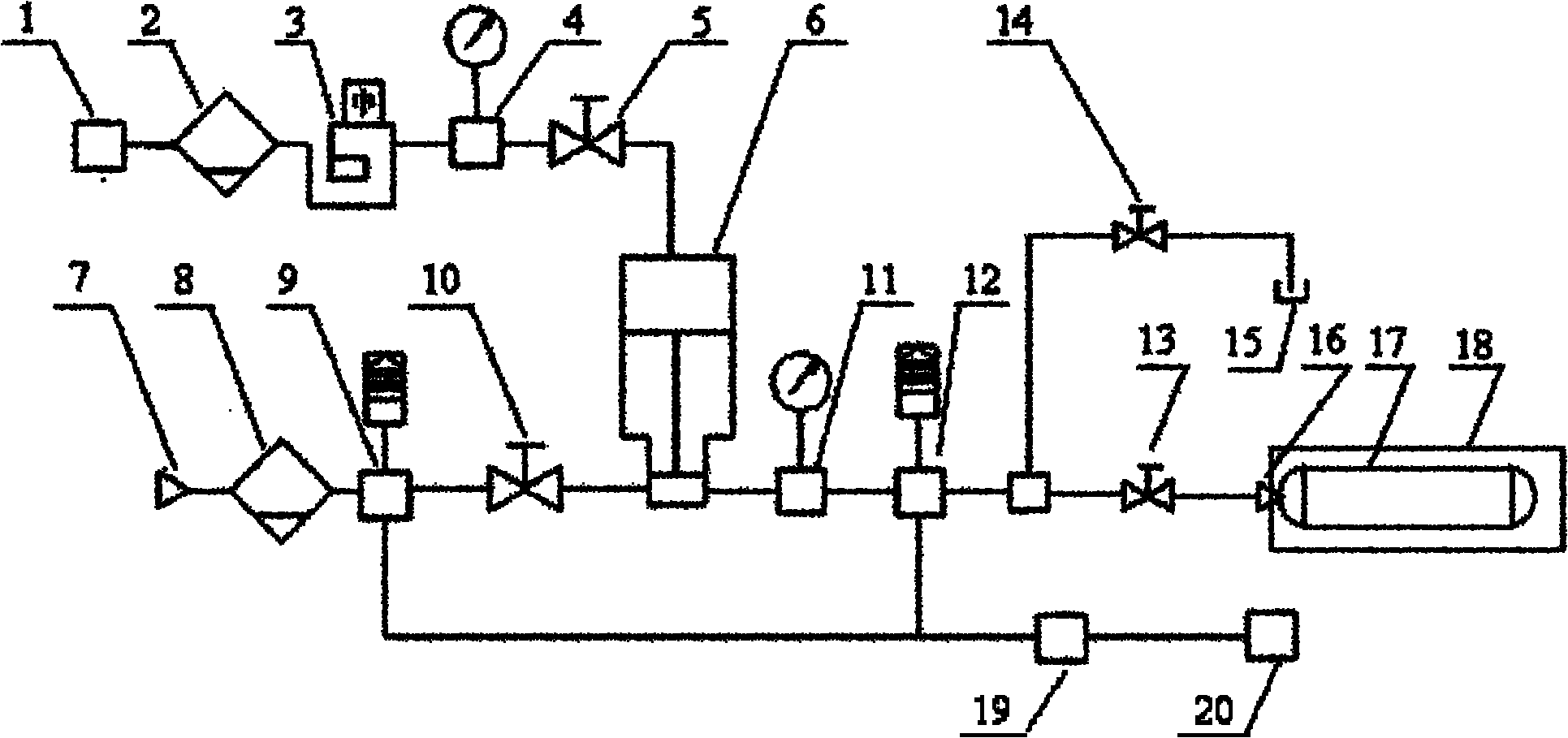

Measurement and control system for hydraulic test

ActiveCN102607960ABoost rate adjustableReal-time detection of pressure changesMaterial strength using tensile/compressive forcesSimultaneous control of multiple variablesAutomatic controlControl signal

The invention relates to a measurement and control system for a hydraulic test. A system control part is composed of a PLC (programmable logic controller) control cabinet, an industrial personal computer and a printer, a PLC is included in the PLC control cabinet, and the industrial personal computer is used as an upper computer of the PLC and connected with the PLC via a communication cable; a measurement and control pipeline part comprises a gas source supply pipeline, a gas-driving booster pump A, a gas-driving booster pump B, a liquid source supply pipeline, a high hydraulic output pipeline and a liquid unloading pipeline; and the PLC outputs a current control signal to the output end of an electric proportional valve, and the electric proportional valve controls gas pressure and gas flow rate by adjusting the position of a gas inlet valve according to the current control signal and a gas pressure signal which is output in proportion. The measurement and control system can performvarious pressure tests including an intensity test, a burst test for a safety relief device of a container, and a test for the residual deformation rate of the container; automatic control and manualcontrol in the hydraulic test for a fire-fighting product are independent from each other and can be used independently; pressure-boosting speed is adjustable, pressure change and dynamic curve output are detected in time; the measurement and control system is high in pressure control accuracy, small in volume, light in weight and low in energy consumption; multi-level pressure-boosting can be realized; and the measurement and control system has the characteristics of being high in reliability, high in accuracy, easy in operation etc.

Owner:应急管理部天津消防研究所

Crack initiation steel pipe for full-scale gas bursting test of large-diameter high-grade steel gas pipeline and preparation method thereof

The invention discloses a crack initiation steel pipe for a full-scale gas bursting test of a large-diameter high-grade steel gas pipeline and a preparation method thereof, belonging to the field of a petroleum pipeline breakage control test. The steel pipe comprises the following components by weight percent: 0.07%-0.12% of C, 1.50%-1.75% of Mn, 0.15%-0.35% of Si, less than or equal to 0.015% of P, 0.010%-0.020% of S, 0.005%-0.030% of Al, less than or equal to 0.002% of O, less than or equal to 0.00015% of H, less than or equal to 0.005% of N and the balance of Fe; and carbon equivalent is less than or equal to 0.55%, and the cold cracking sensitive coefficient is less than or equal to 0.28%. The preparation method comprises the following steps: smelting and continuously casting the raw materials so as to form a thick slab; carrying out rough rolling and precise rolling so as to obtain a hot rolled steel plate; and forming the hot rolled steel plate, then welding, and then expanding diameter so as to prepare the steel pipe, wherein the yield strength of the steel pipe is 550MPa-840MPa, the tensile strength of the steel pipe is 625MPa-990MPa, the charpy impact toughness of the steel pipe at the temperature of 0 DEG C is controlled between 100J-200J, and the fracture shearing area in a drop test is larger than or equal to 85%. The prepared steel pipe is used as the crack initiation steel pipe for the full-scale gas bursting test; and after crack initiation is carried out, the fracture is of ductile fracture topography and has no obvious fracture separation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Fibrous structures

Fibrous structures that exhibit a Geometric Mean Flexural Rigidity (GM Flexural Rigidity or GMFlex) as measured according to the Flexural Rigidity Test Method described herein to Dry Burst (DB) as measured according to the Dry Burst Test Method described herein ratio (GMFlex / DB ratio) of less than 0.26 and a Density of less than 0.10 g / cm3 as measured according to the Test Methods described herein are provided.

Owner:THE PROCTER & GAMBLE COMPANY

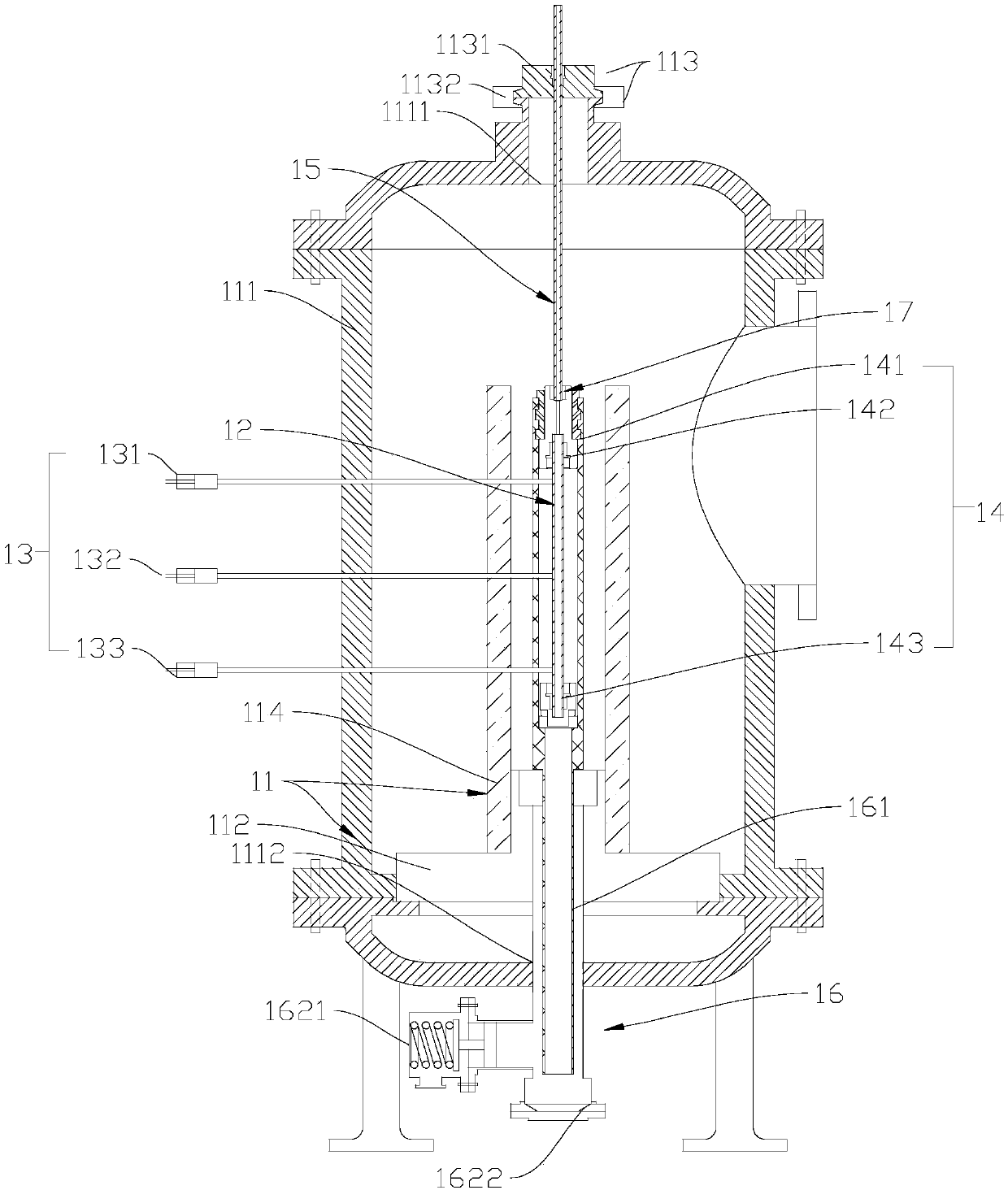

System and method for tunnel water-bursting test under high crustal stress-osmotic pressure

ActiveCN105738216AIncrease stiffnessAvoid lossMaterial strength using tensile/compressive forcesControl systemEngineering

The invention relates to a system and method for tunnel water-bursting test under high crustal stress-osmotic pressure. The system comprises a main box used for simulating excavation of a tunnel model, the main box is of integrated structure and placed on a base, two opposite sides of the base are fixed on two slide rails, and an n-shaped counter-force frame is arranged between the two slide rails. The bottom ends of two support legs of the counter-force frame are fixed detachably on the slide rails. The top beam of the counter-force frame is fixedly connected with the top end of a loading system. An information monitoring element is arranged in the main box, the loading system and the information monitoring element are connected with a monitoring and controlling system. The monitoring and controlling system controls the loading system to apply crustal stress and osmotic pressure to the model material in the main box.Research on tunnel water bursting under the condition of high crustal stress-osmotic pressure engineering excavation turbulence is realized, and actual needs of the engineering are met.Further, fully automatic control of operation is realized and experiment operation is greatly facilitated.

Owner:SHANDONG UNIV

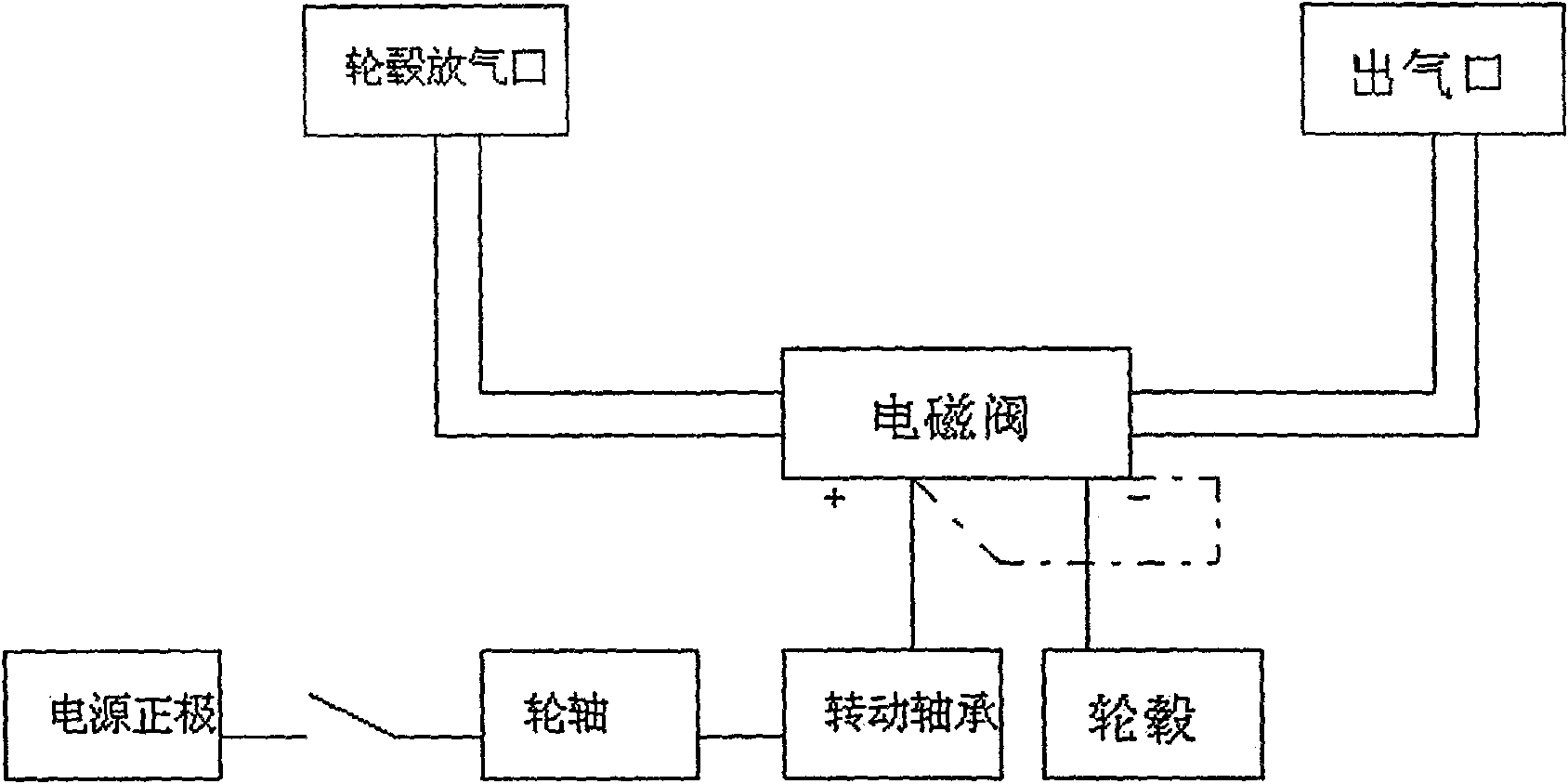

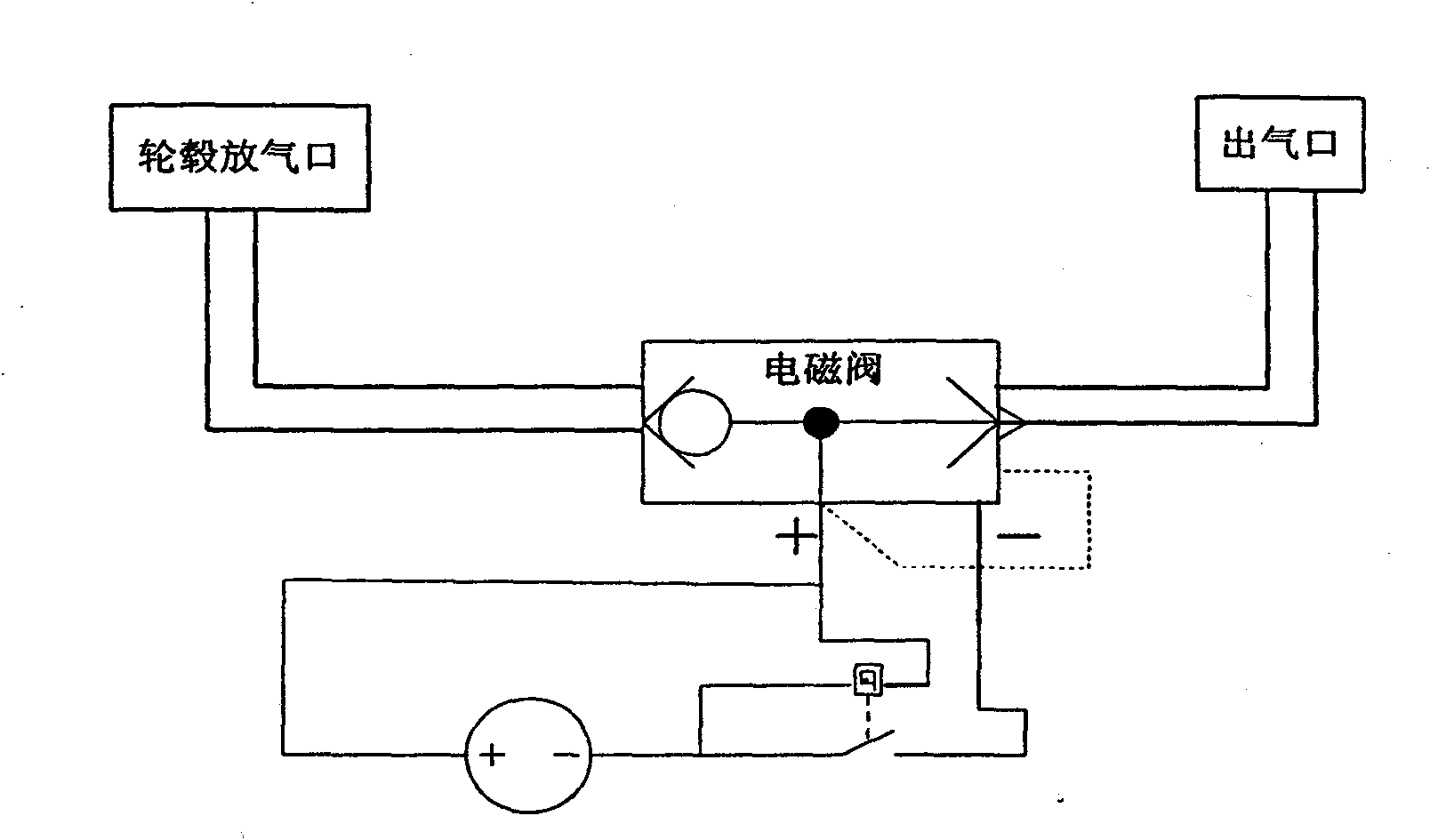

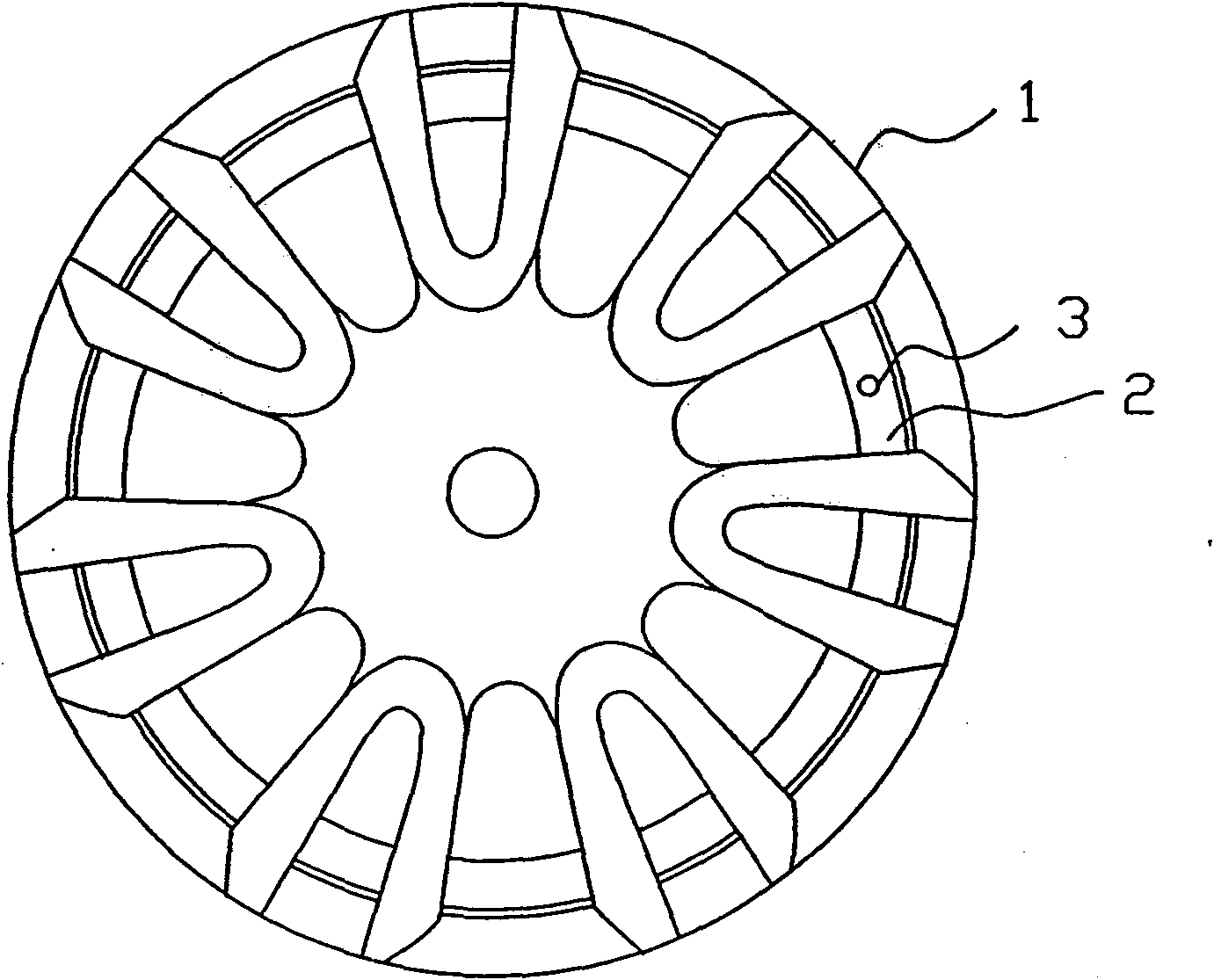

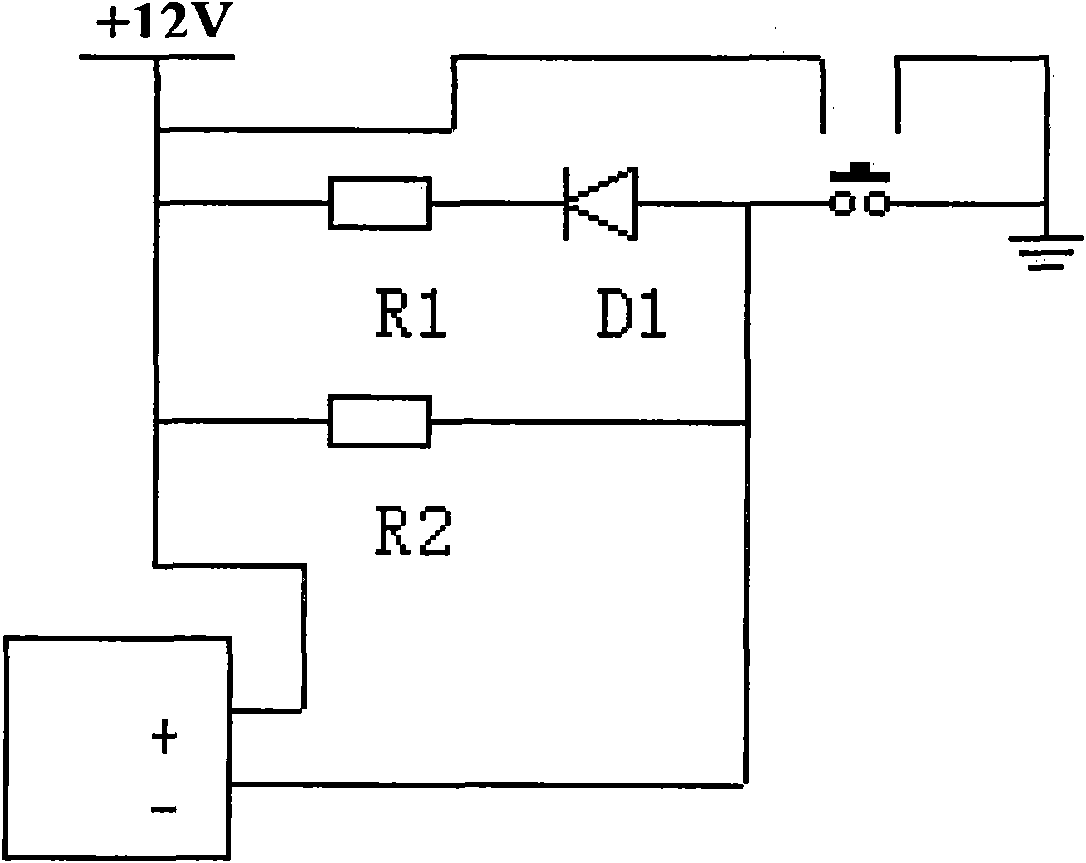

Device for tire burst test

InactiveCN101620029AEasy to operateMeet the requirements of rapid deflationVehicle tyre testingEngineeringMechanical engineering

The invention discloses a device for a tire burst test, comprising a wheel. A wheel hub is provided with a deflation port, a deflation tube is welded at the deflation port, and the deflation tube is provided with an electromagnetic valve; a rotating bearing is arranged outside a wheel shaft, and an insulating layer is arranged outside the rotating bearing; the wheel shaft and the anode a vehicle power source are connected through a switch circuit, the anode of the electromagnetic valve is connected with a circuit of the rotating bearing, and the cathode of the electromagnetic valve is connected with a circuit of the wheel hub. The device is additionally provided with an accessory device on a tire wheel hub of a conventional automobile and uses the electromagnetic valve as a control unit to deflate the tire so as to achieve the test effect same as the tire burst without damaging the tire, thereby saving the cost and being favorable for repeated tests.

Owner:ZHEJIANG UNIV

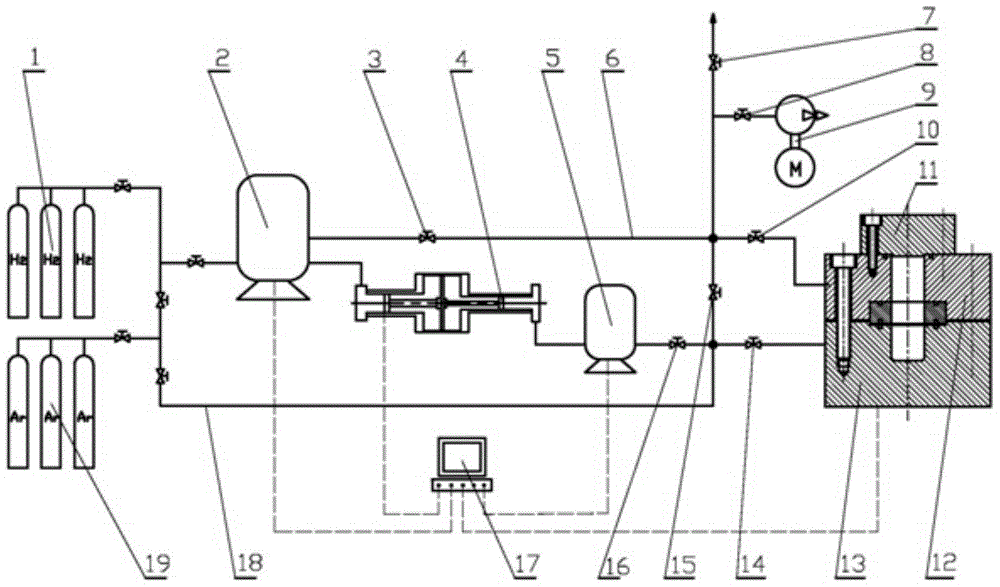

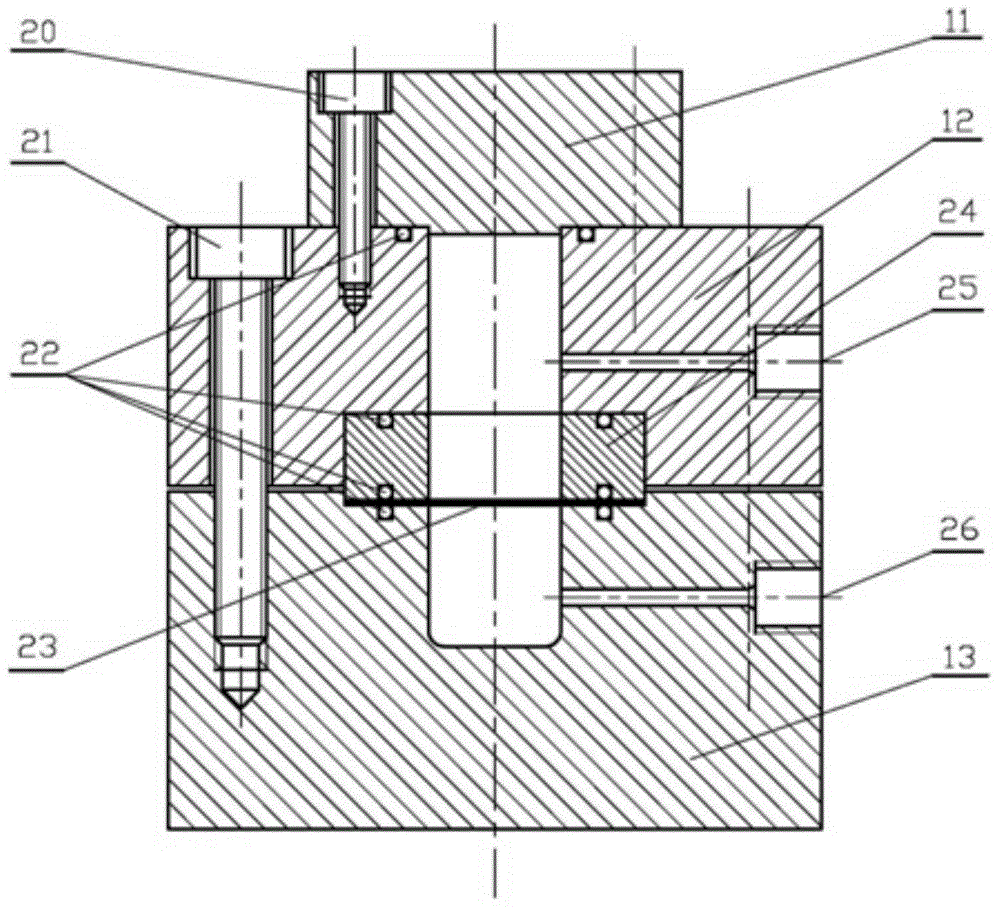

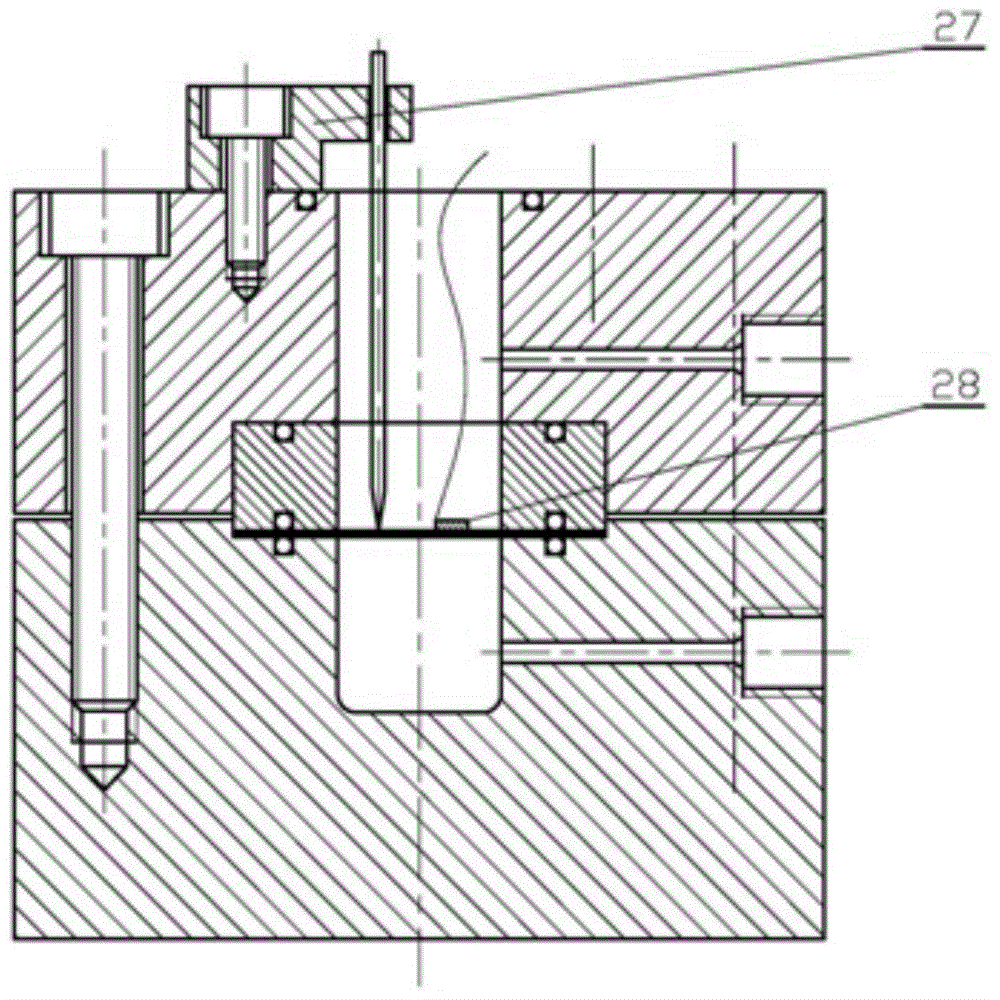

High-pressure hydrogen embrittlement structure test apparatus and test method thereof

ActiveCN104215513AVersatileWith test functionMaterial strength using tensile/compressive forcesHigh pressure hydrogenBurst test

The invention relates to a high pressure hydrogen embrittlement structure test apparatus and a test method thereof. The test apparatus comprises a compressed air system, a hydrogen pipeline system and a data acquisition and control system, compressed air is used as a driving gas source to drive a gas booster, hydrogen is pressurized by the gas booster, the pressurized hydrogen is respectively conveyed to a test container or a clamping device through a pipeline, pressure-tight test is carried out after a predetermined test pressure is reached, or boosting is continuously carried out until a sample is exploded to realize the explosion test and determine its explosion pressure. The anti-hydrogen embrittlement performance test of a metal material can be completed through disc test, and the hydrogen embrittlement damage test of a structural member can also be completed through an object or a simulated container; and the high pressure hydrogen test environment with the highest pressure of 80MPa can be realized, unit operation can be adjusted and controlled by the test pressure, the dwelling time and other key test parameters, and the large range adjustment and the stable control of the boosting rate can completely meet hydrogen embrittlement related test requirements.

Owner:HEFEI GENERAL MACHINERY RES INST

Multifunctional high voltage apparatus safe property checking device

InactiveCN1828257AWith overpressure protection functionWide output pressure rangeStructural/machines measurementHigh pressureProtection system

The disclosed device comprises: a gas dynamic system, a water-filling exhausting system to fill the pressure media into the high-pressure device rapidly and exhaust gas, a pressure up-down system for compression, holding and release; a detection control system to monitor and control whole process and output data, and a security protection system to protect when over pressure. This invention fit to different test and analysis with stable pressure and well reliability.

Owner:ZHEJIANG UNIV

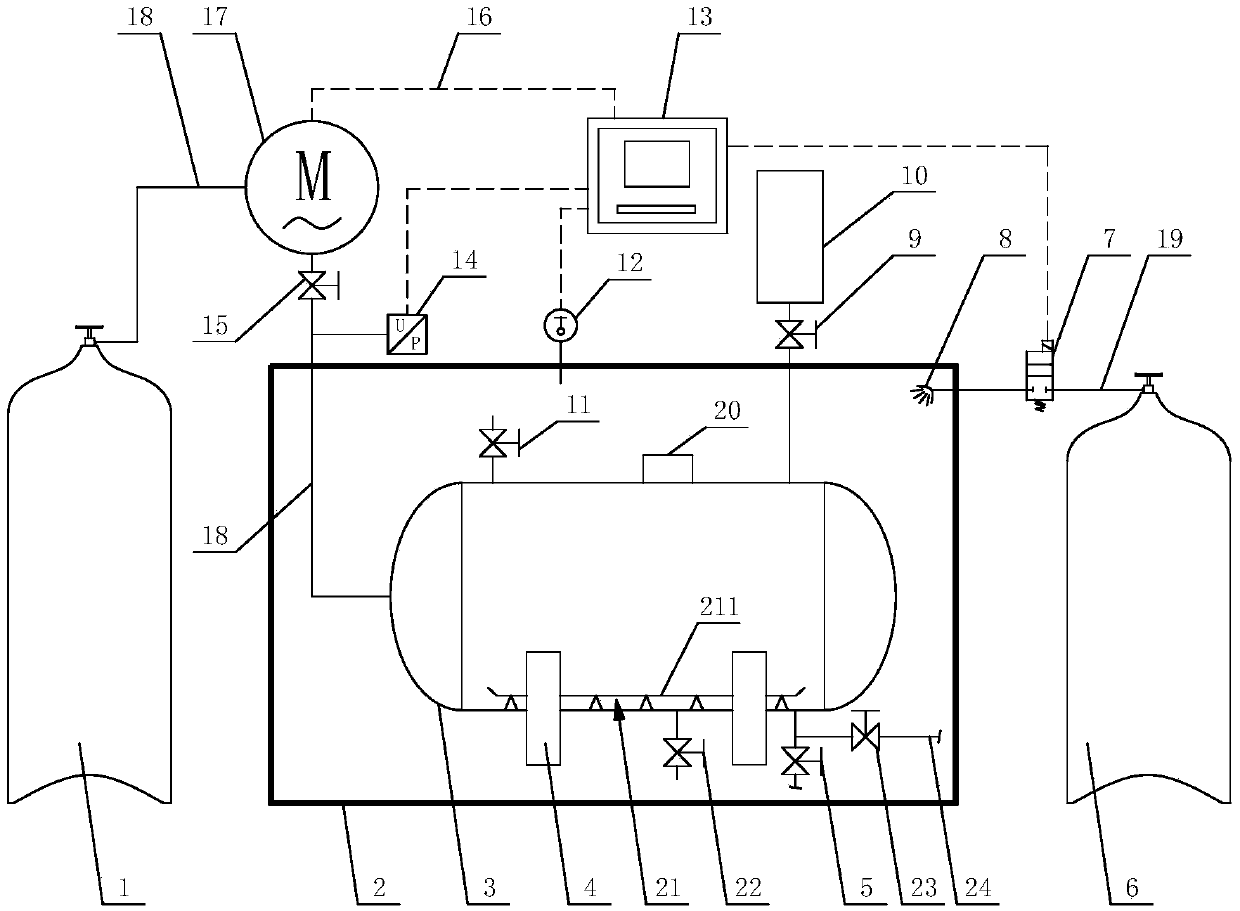

Pressure bursting test system and method for low-temperature deep-cooling pressure vessels and pipelines

ActiveCN105510140ATest strengthTest air tightnessMaterial strength using tensile/compressive forcesEngineeringAir tightness

Owner:HEFEI GENERAL MACHINERY RES INST +1

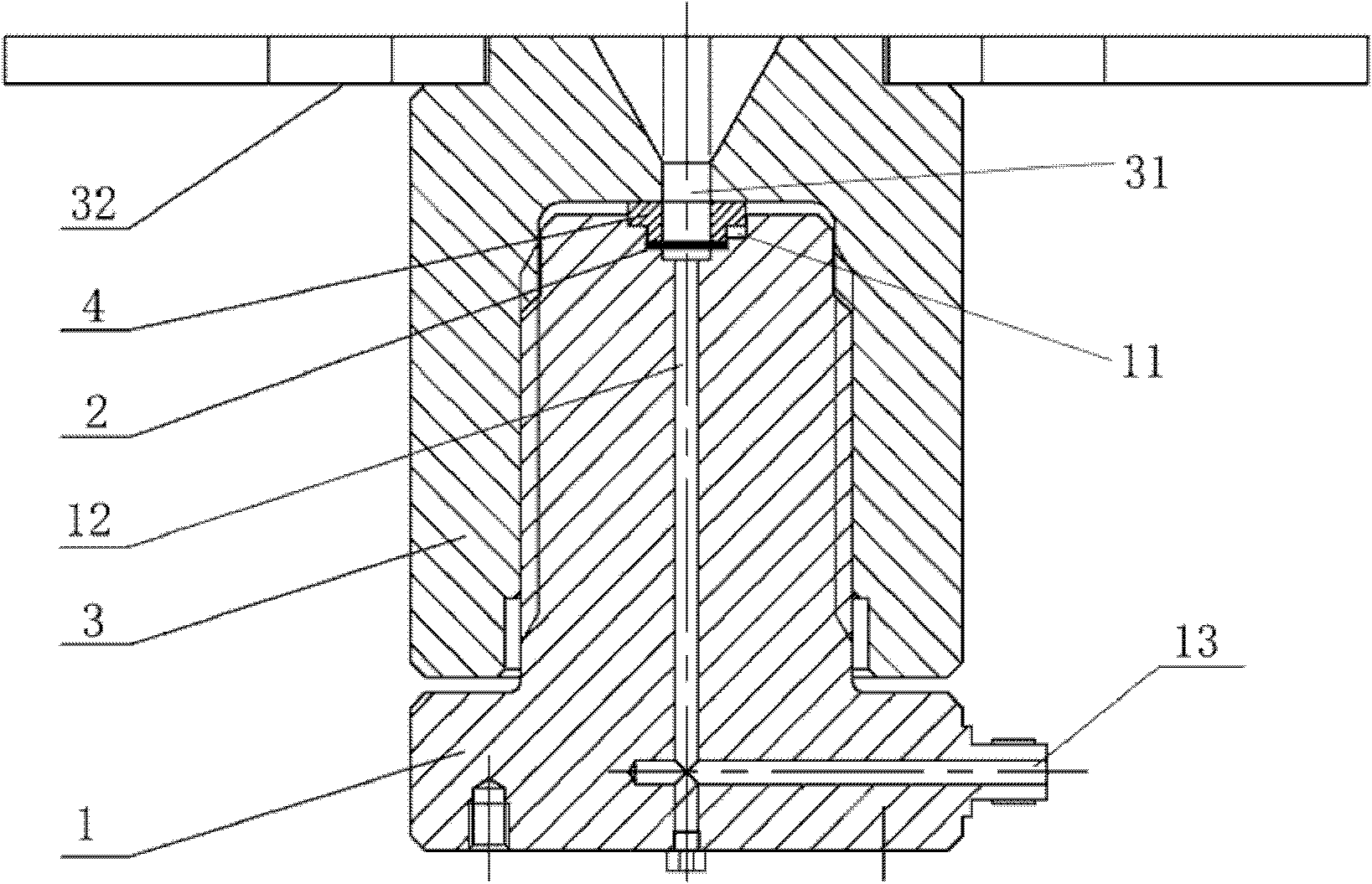

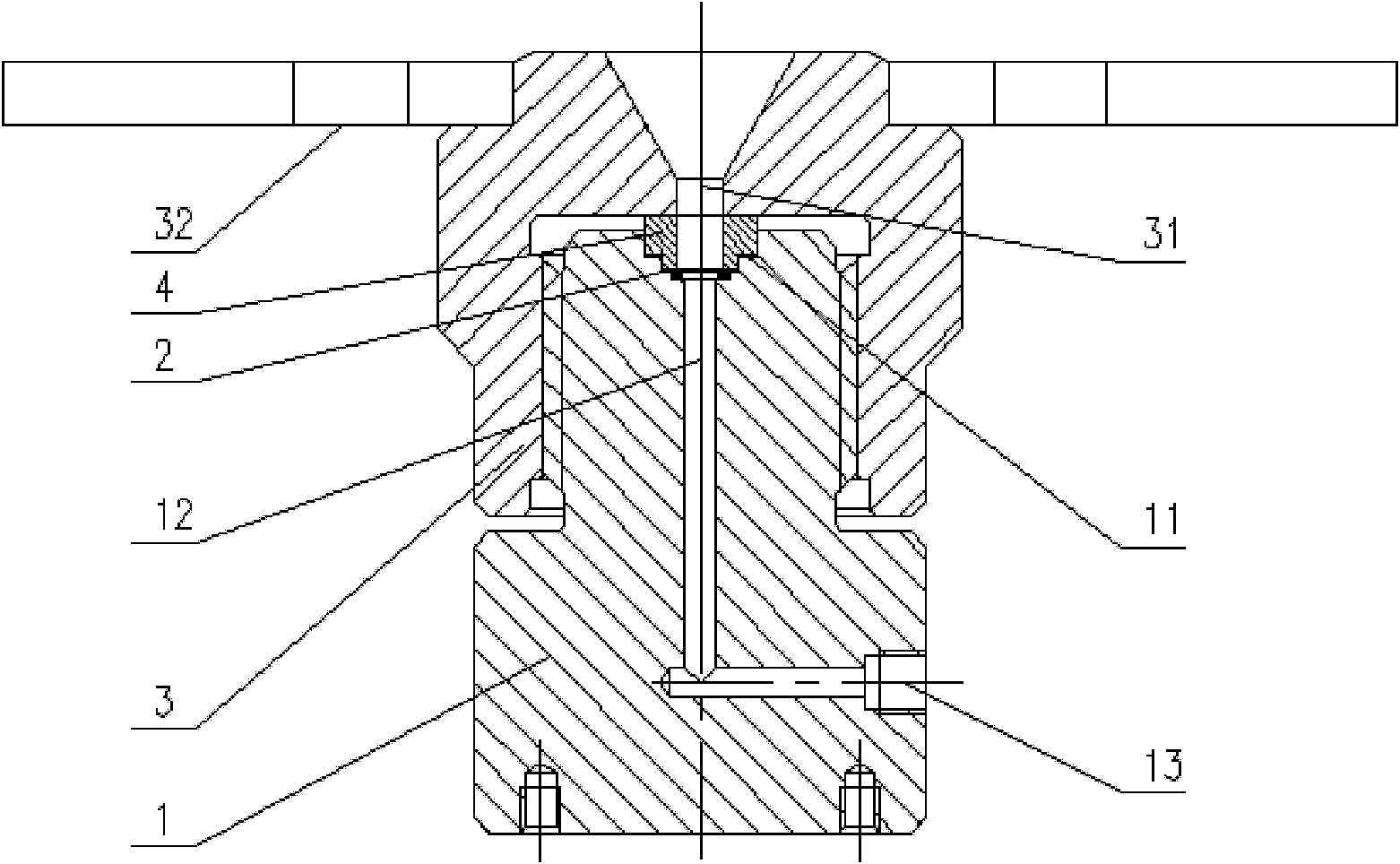

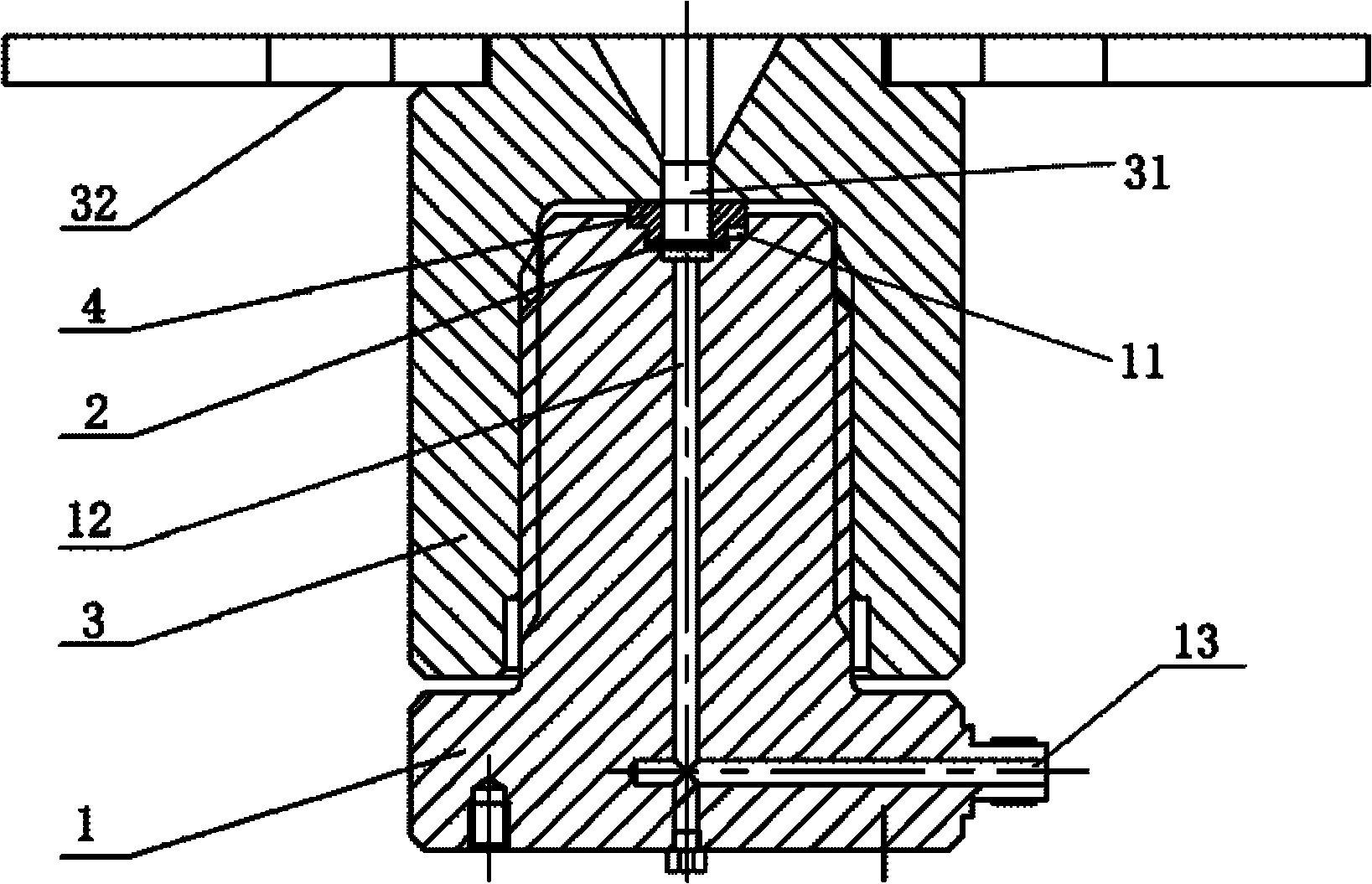

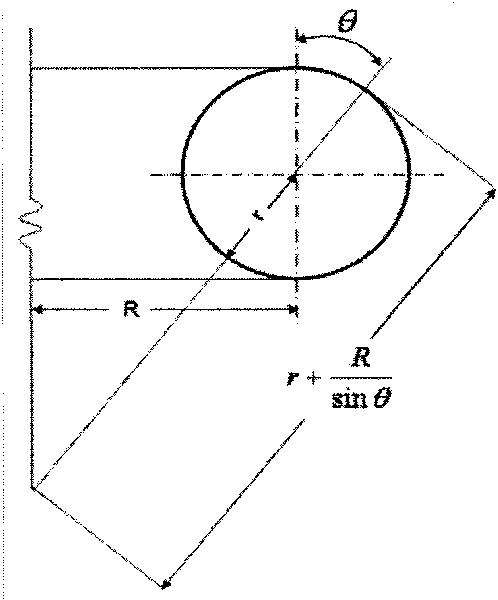

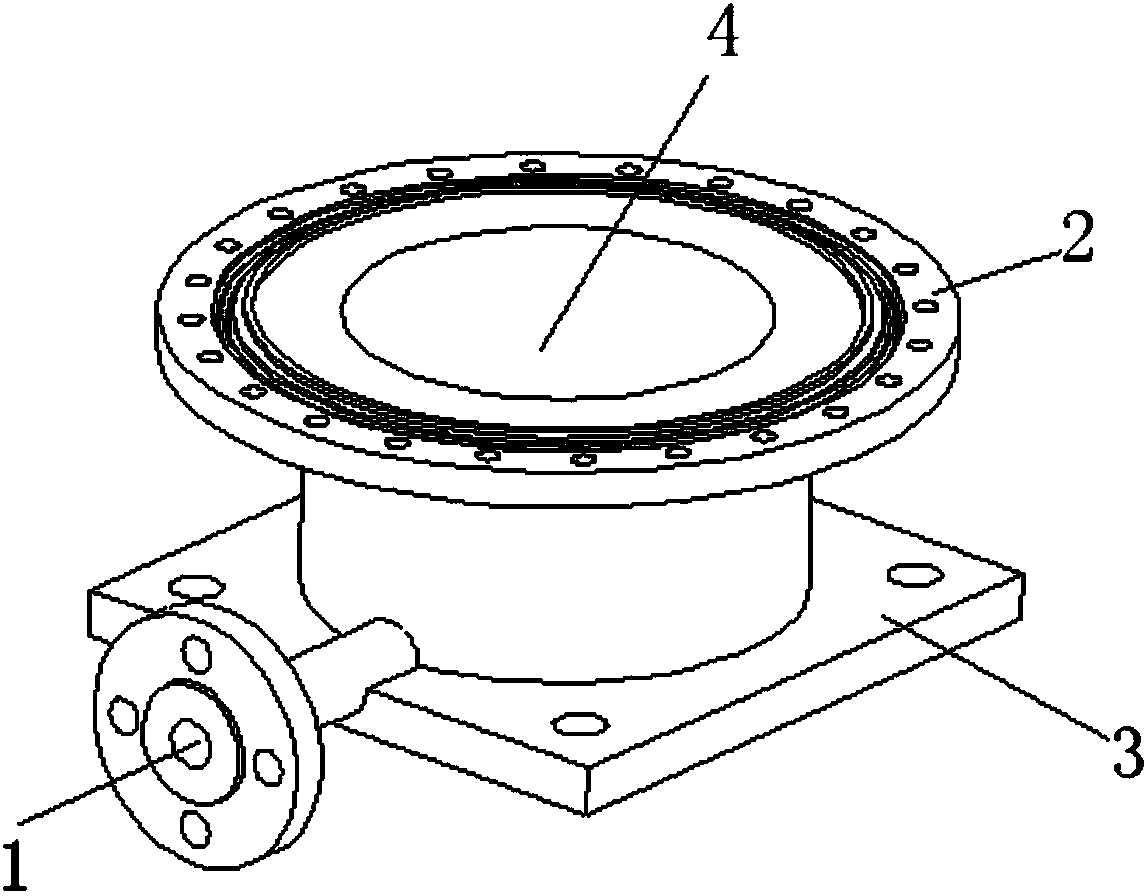

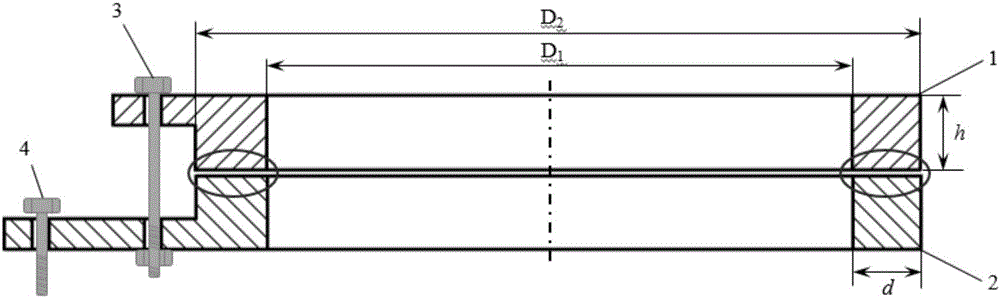

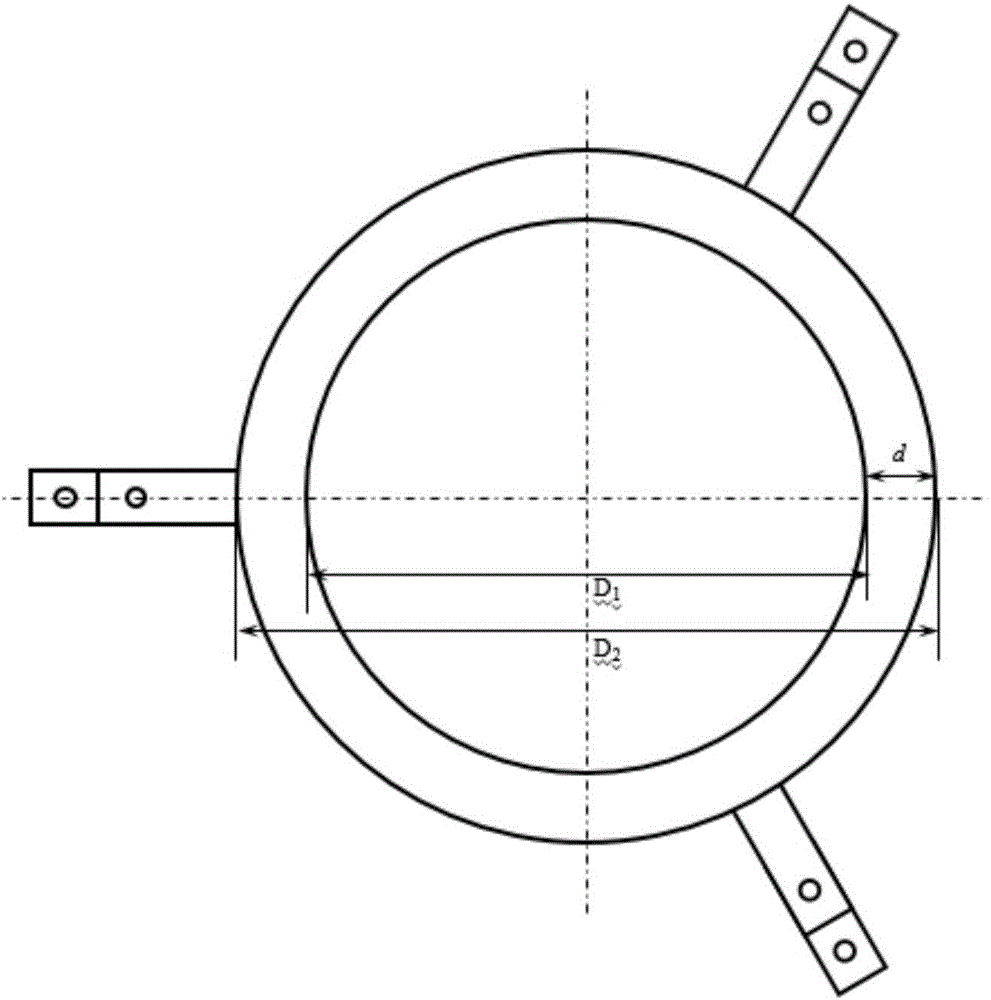

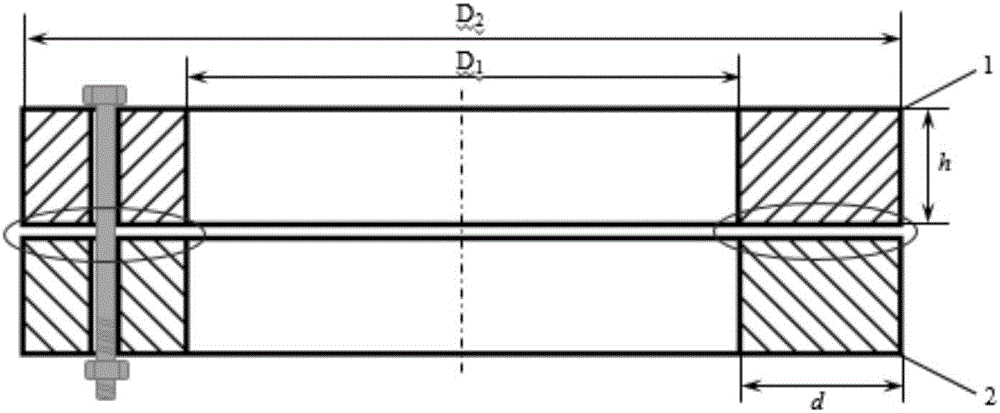

Small sample hydraulic burst test method and device for material property test

InactiveCN102183415AThe overall stress situation is simplifiedSimplify loading uncertaintyMaterial strength using tensile/compressive forcesSmall sampleEngineering

The invention discloses a sample hydraulic burst test method and loading and clamping device. The method comprises the steps of: providing a base, wherein the upper end of the base is provided with a sample accommodating groove, a liquid cavity is arranged in the base, one end of the liquid cavity is communicated with the bottom of the sample accommodating groove, and the other end of the liquid cavity is a liquid inlet end which is positioned at the lower part of the base; filling liquid in the liquid cavity to evacuate air in the liquid cavity; placing a sample in the sample accommodating groove; sheathing and securing a clamping part at the upper part of the base, and remaining the edge of the sample under a clamped condition, wherein the clamping part is provided with a measuring hole communicated with the sample accommodating groove; filling high-pressure liquid from the liquid inlet end to ensure that the sample can be dilated and deformed under the action of the high-pressure liquid till burst, and measuring test data from the measuring holes; and analyzing the test data to obtain material properties.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST +1

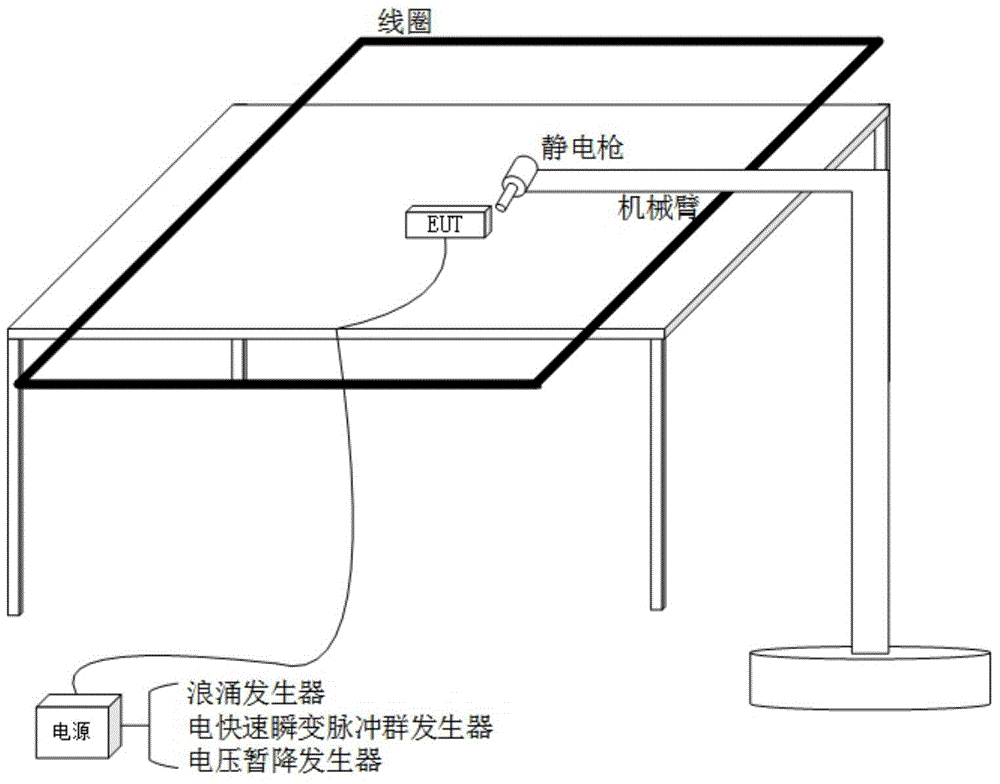

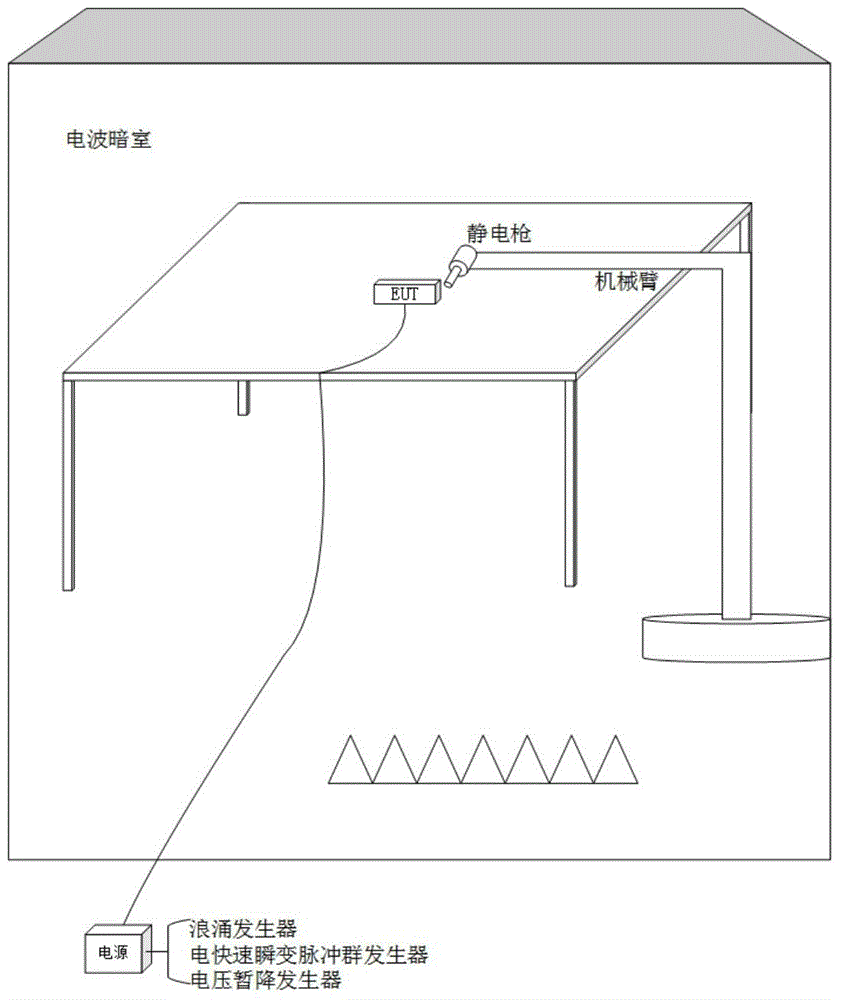

Transformer station intelligent electronic device multi-source anti-interference degree characteristic testing method

The invention provides a transformer station intelligent electronic device multi-source anti-interference characteristic testing method. The testing method comprises a mixed power frequency magnetic field testing method and a mixed radio frequency radiation anti-interference degree testing method. The mixed power frequency magnetic testing method is characterized in that during the power frequency magnetic field test, the surge test and the static test can be carried out; during the power frequency magnetic field test, the electrical fast transient burst test and the static test can be carried out; during the power frequency magnetic field test, the voltage dip test and the static test can be carried out. The mixed radio frequency radiation anti-interference degree testing method is characterized in that during the radio frequency anti-interference degree test, the surge test and the static test can be carried out; during the radio frequency radiation anti-interference degree test, the electrical fast transient burst test and the static test can be carried out; during the radio frequency anti-interference degree test, the voltage dip test and the static test can be carried out. The method provided by the invention is capable of simulating a plurality of interference ways, which are applied to the intelligent electronic devices at the same time, and then the anti-interference degree can be tested, and the acquired testing result can be used to reflect the actual condition, and therefore the credibility and the authority of the anti-interference degree test can be improved greatly.

Owner:STATE GRID CORP OF CHINA +3

Steel pipe for air bag inflator and method for production thereof

ActiveCN101048524AHigh strengthPredictive rupture resistancePedestrian/occupant safety arrangementFurnace typesX-rayStress relief

A steel pipe for an air bag inflator which has a high strength of a tensile strength of 900 MPa or more, preferably 1000 MPa or more, together with high toughness, and exhibits good burst resistance wherein no cracks develop in a burst test at -40 DEG C or lower is produced by a method comprising providing a raw steel pipe containing, in mass %, 0.05 to 0.20 % of C, 0.1 to 1.0 % of Si, 0.025 % or lower of P, 0.010 % or lower of S, 0.05 to 1.45 % of Cr, 0.10 % or less of Al, 0.02 % or less of Ti, and one or both of Ti and Mn satisfying 0.4 = Mn + 40 X Ti = 1.2, rapidly cooling the raw steel pipe from a temperature of Ac1 transformation temperature or higher, tempering the resultant steel pipe at a temperature lower than Ac1 transformation temperature, subjecting the tempered steel pipe to a cold working wherein a reduction of area is 65 % or less, and then subjecting the worked steel pipe to a stress relief annealing at a temperature lower than Ac1 transformation temperature. The L / T ratio of X ray integral intensity ratios of {110} face measured in the cross section perpendicular to the axis direction (L) and the cross section perpendicular to the periphery direction (T) of the above steel pipe is 50 or lass.

Owner:NIPPON STEEL CORP

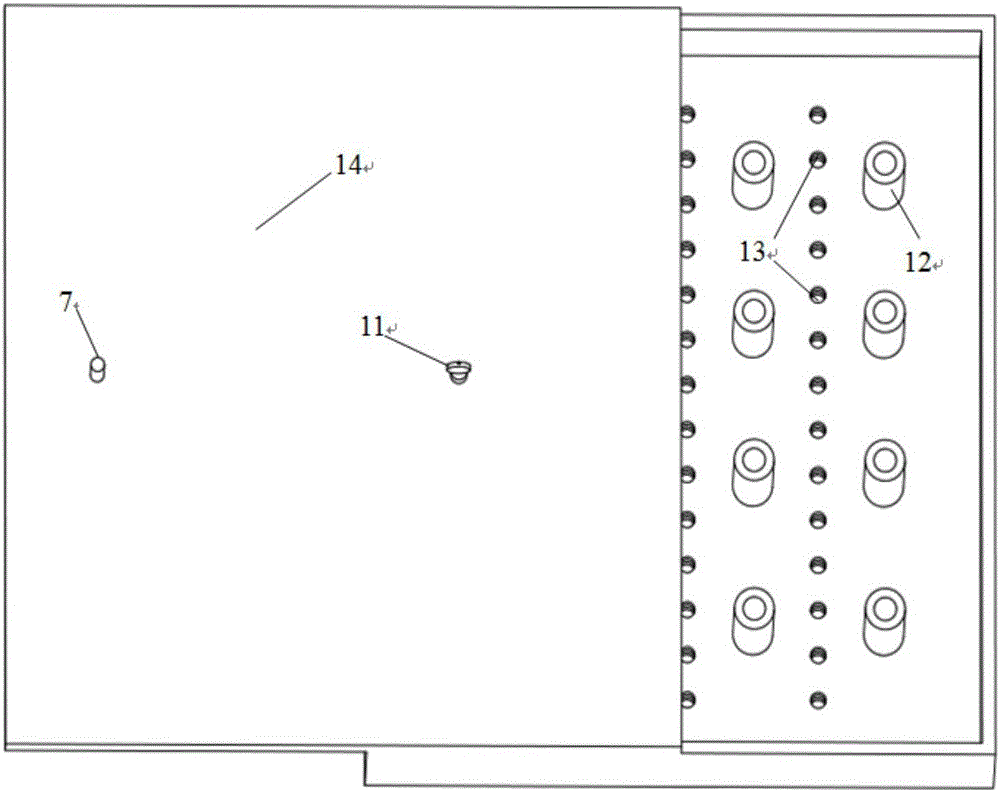

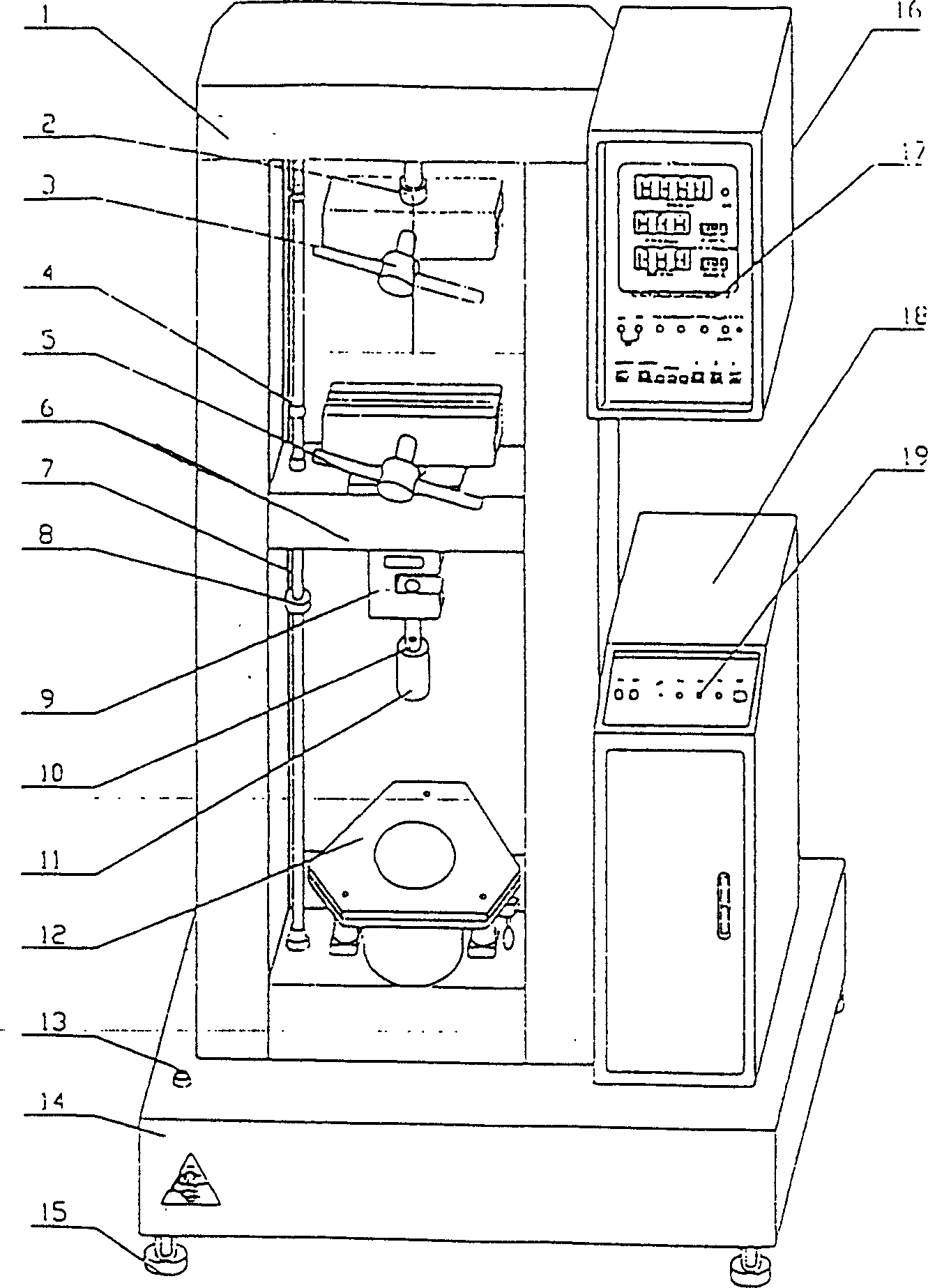

Multi-station ball-valve bursting test machine

InactiveCN101339111AVersatileImprove work efficiencyFluid-tightness measurement using fluid/vacuumStrength propertiesAutomatic controlUltimate tensile strength

The invention discloses a multi-work station ball valve blasting testing machine which belongs to the field of testing device. The testing machine comprises a testing host and a control cabinet. The testing host is divided into two layers; a testing table is arranged on the upper layer and a machine base is arranged on the lower layers. The testing table is provided with 3 to 10 testing work stations which are arranged in parallel and which can simultaneously test the pressure and blasting performance of 1 to 10 ball valves. In the test, hydraulic oil uses a solenoid directional control valve to push each piston; the compression rod of each piston can rise simultaneously; a special sealing fixture is used for sealing and clamping two ends of the ball valve. A hydraulic test pump is used for pouring the testing medium into the tested ball valve and boosting the pressure of the tested ball valve so as to test the ball valve. The testing machine can simultaneously seal, clamp, pour the testing medium into and test a plurality of ball valves. In the whole test process, a computer is used for automatically controlling the test through a PLC controller. And the testing machine has the advantages of stable performance, high work efficiency, low labor intensity, simple structure, high security, and so on.

Owner:于常友 +1

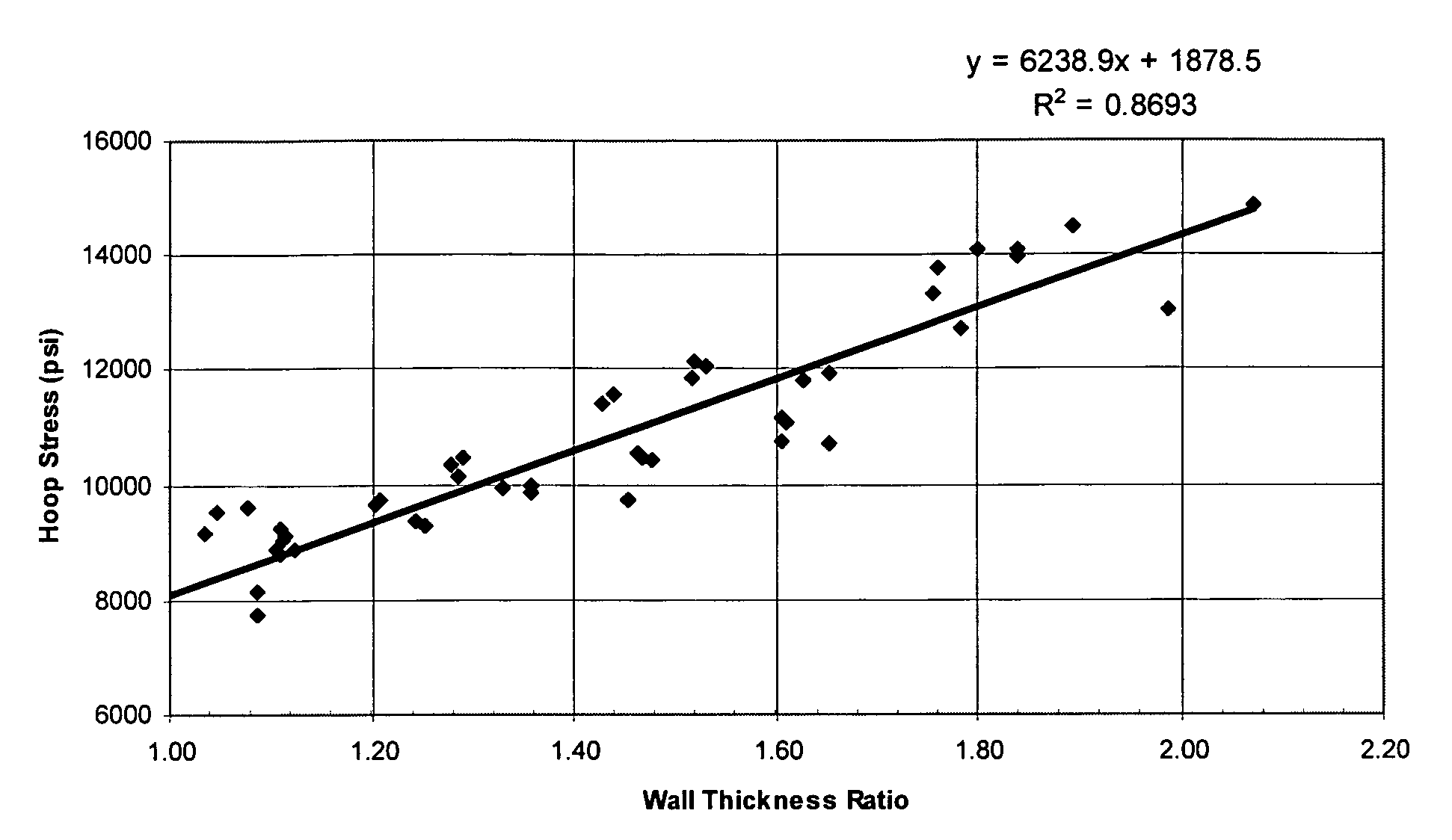

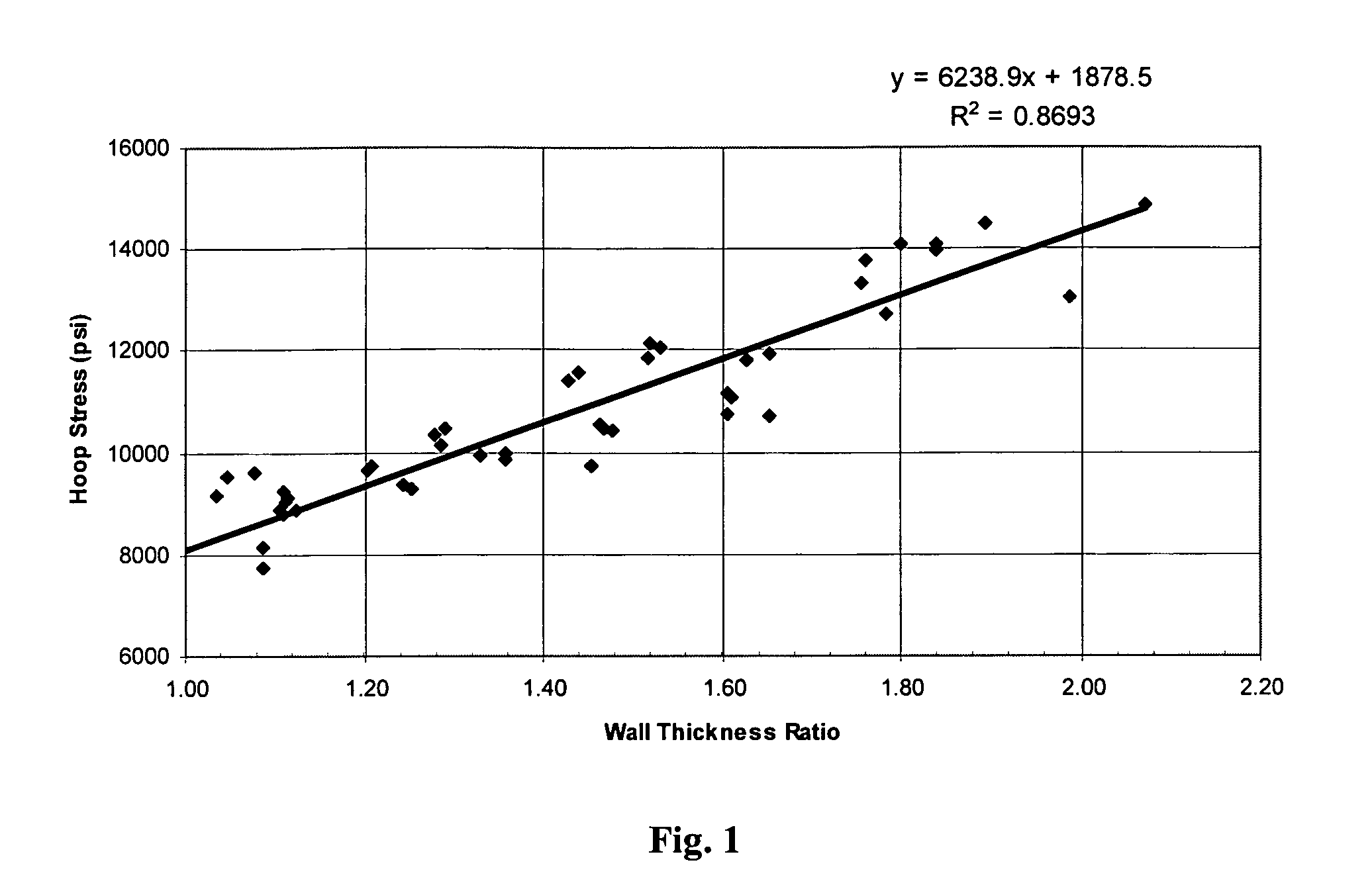

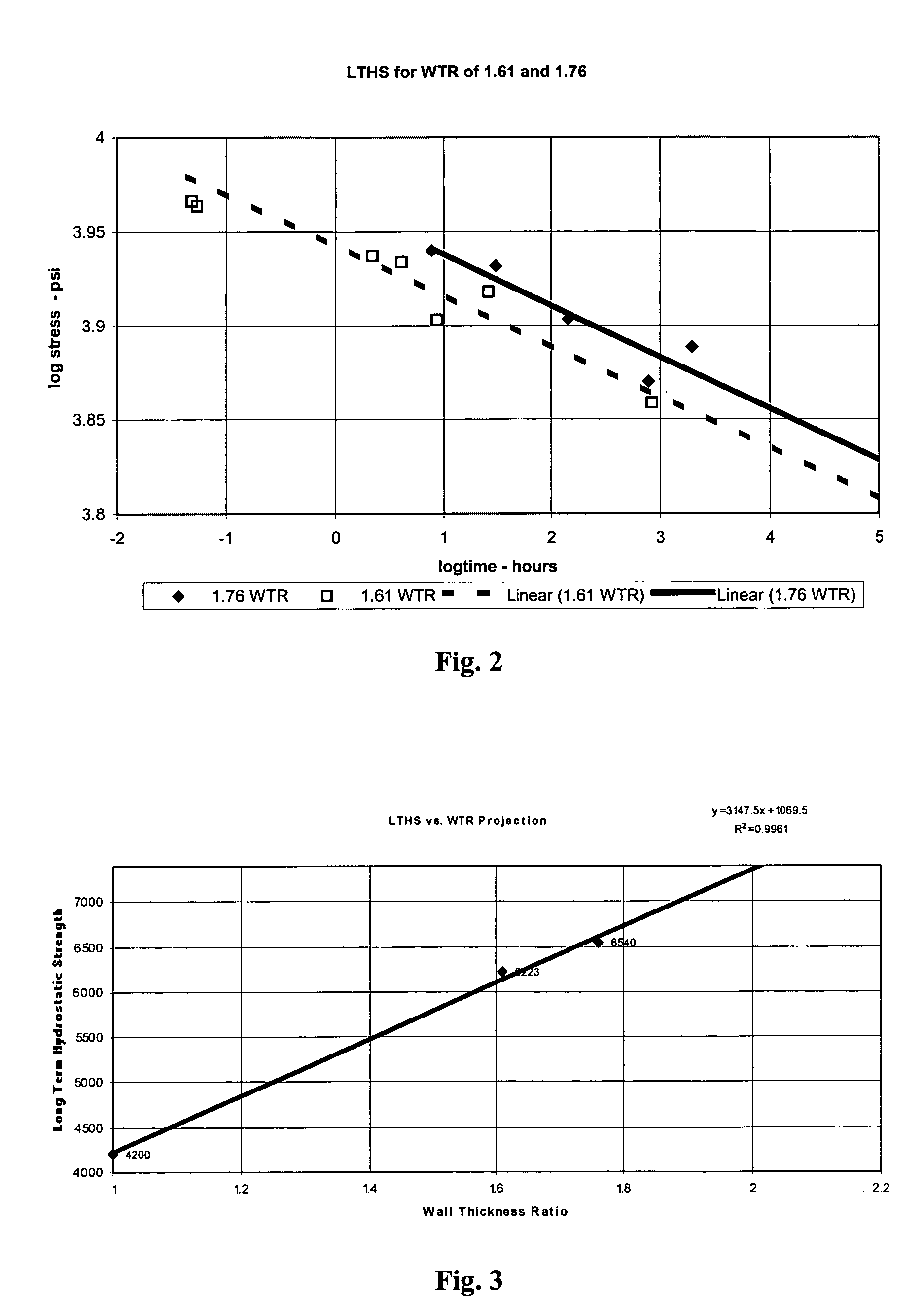

Method for determining pressure capability in conduit

InactiveUS7269520B2Detection of fluid at leakage pointForce measurementRegression analysisEngineering

Disclosed is a method that provides for the calculation and prediction of hoop strength of an expanded pipe, preferably a PVC pipe or conduit. The method includes the steps of: (a) determining hoop strength as a function of relative wall thickness; (b) determining Wall Thickness Ratio (WTR) by dividing a nominal wall thickness of the original conduit by the minimum wall thickness of the expanded conduit; (c) determining long-term hydrostatic strength by at least one of hoop testing and burst testing; and (d) applying an accelerated regression analysis to the results in step (c), yielding a Hydrostatic Design Basis (HDB). The resulting HDB may be plotted against WTR to provide the user with graphical data for use in making design decisions and choosing specific conduit for specific applications.

Owner:UNDERGROUND SOLUTIONS INC

Multifunctional high power machine for earthworker's cloth testing and use thereof

InactiveCN1542430AWide range of test itemsPracticalMaterial strength using tensile/compressive forcesUltimate tensile strengthBurst test

The present invention relates to material test machine technology and is one geotextile strength test machine and its application. The test machine includes crossbeam, driving mechanism, test head, sensor module, microcomputerized controller, display, portal and pedestal. The upper holder for testing tensile strength and tear strength is set on the portal, and the lower holder is set on the crossbeam. The crossbeam with ends connected to the driving mechanism may be shifted inside the portal, and the test head and the sensor module are set on the crossbeam and connected together. There is elevated clamping unit set on the pedestal. The test head may be one of the CBR bursting test head, spherical bursting test head, piercing test head, plate material pressing test head and plate material breaking test head. The present invention may be used in complete various test jobs.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

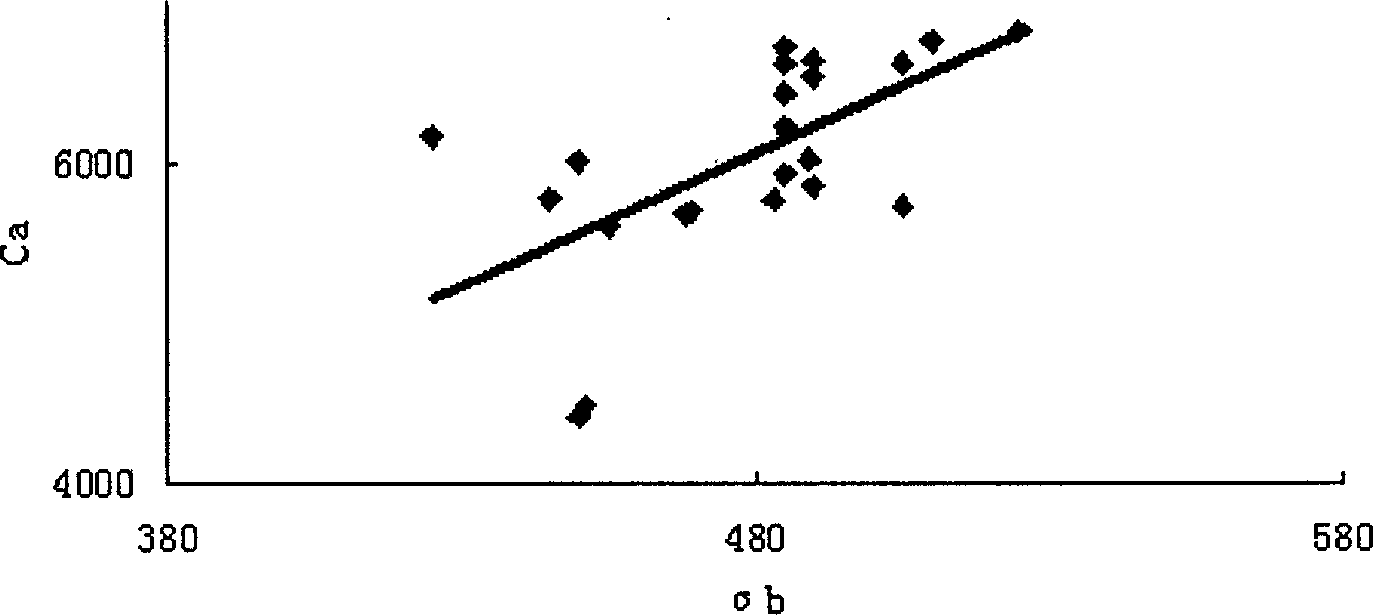

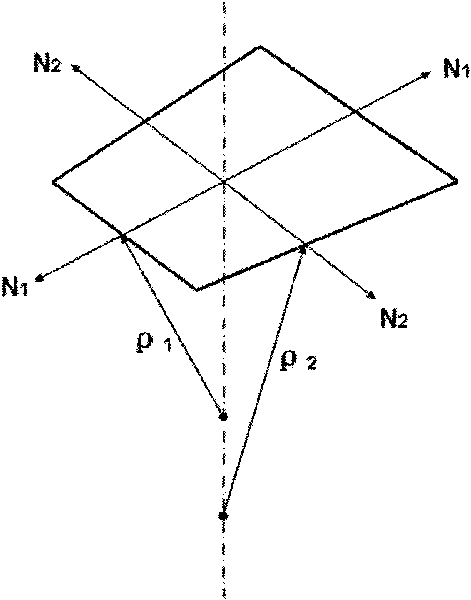

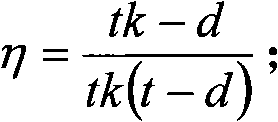

Residual intensity evaluation method of corrosion defect contained steam injection pipeline compensator bent pipe

ActiveCN101726456AAvoid stress concentrationHigh engineering practical valueMaterial strength using tensile/compressive forcesUsing mechanical meansMean diameterFlow stress

The invention relates to a residual intensity evaluation method of a corrosion defect contained steam injection pipeline compensator bent pipe, which comprises the following steps of: computing the bearing capacity of the bent pipe through a formula plimit=Sigma f / (r Eta+3r2 Alpha Eta 2), wherein plimit in the formula is the ultimate bearing capacity of the bent pipe, Sigma f is the flow stress of a pipe, r is the mean radius of the bent pipe, alpha is the ellipticity of the bent pipe, Eta is an intermediate variable, t in the formula is the wall thickness of a pipeline, d is a defect depth, k is an intermediate variable, L in the formula is a defect length and Dm is the mean diameter of the bent pipe; carrying out full-size hydrostatic bursting test verification by utilizing the compensator bent pipe with corrosion defects, and comparing a measured value with a theoretical value, wherein the theoretical value is smaller, and an error is 24.7 percent. A result indicates that the method has higher engineering utility value and reasonable safe reliability.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-pressure bursting test system for pressure vessels

InactiveCN102419285AImprove securitySimple structureMaterial strength using tensile/compressive forcesEngineeringYield pressure

The invention discloses a high-pressure bursting test system for pressure vessels. The high-pressure bursting test system comprises a high-pressure bursting sample vessel, a high-pressure power source module, a vessel installing and sealing protection device module, a pressure relief device module, and a pressure / flow signal measuring and displaying module, wherein the high-pressure power source module is hermetically connected with the high-pressure bursting sample vessel by the vessel installing and sealing protection device module, the pressure / flow signal measuring and displaying module is arranged on an airflow path / liquid flow path of the high-pressure power source module, and the pressure relief device module is connected between the high-pressure power source module and the high-pressure bursting sample vessel. By using the high-pressure bursting test system for pressure vessels disclosed by the invention, a pressure-liquid feed amount change curve can be measured and recorded in real time, and through analysis on the curve, the volume expansibility, yield pressure, ultimate load, bursting pressure and safety margin of the vessel can be obtained; and the high-pressure bursting test system is high in measurement accuracy and comprehensive in data and can provide more useful information for scientific researches.

Owner:EAST CHINA UNIV OF SCI & TECH +2

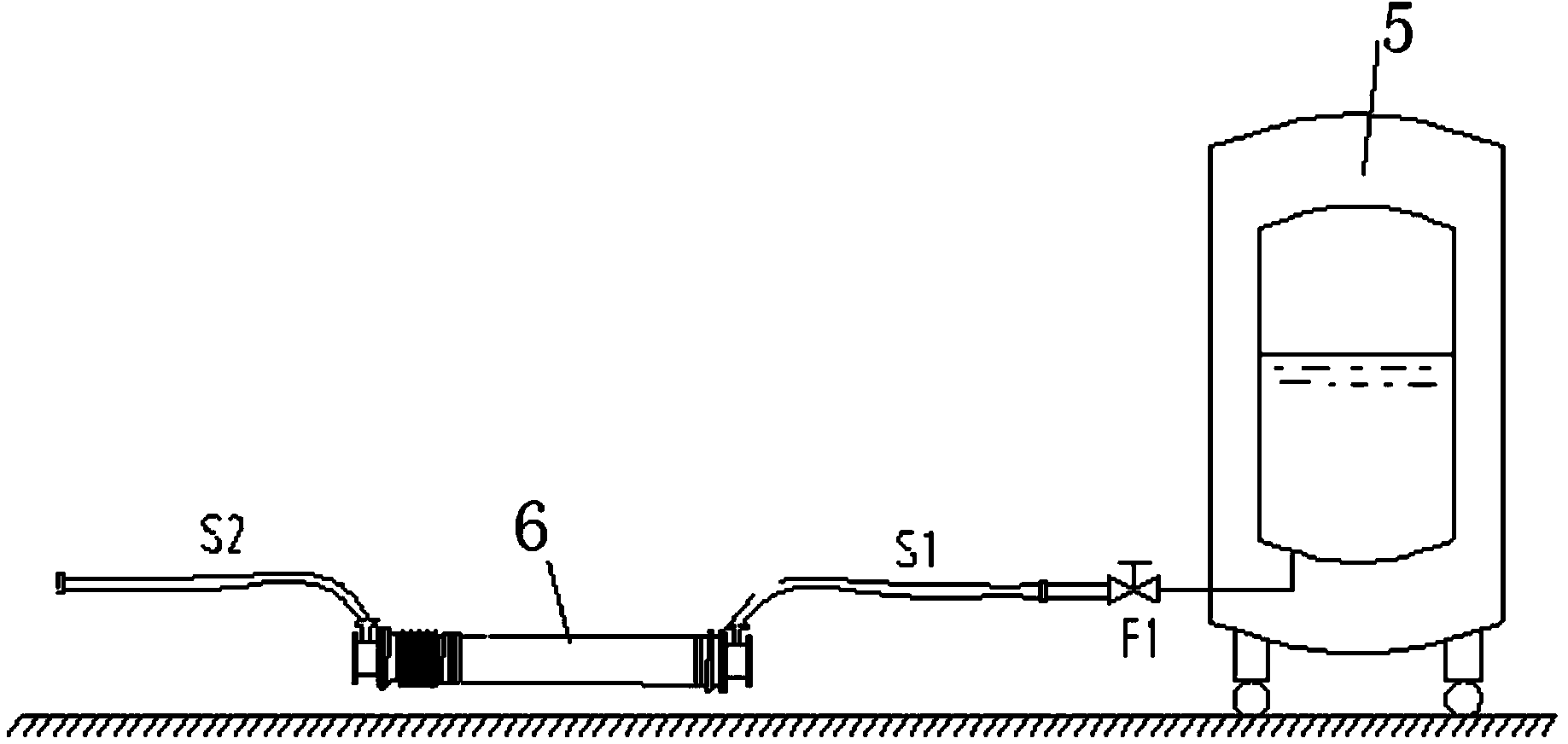

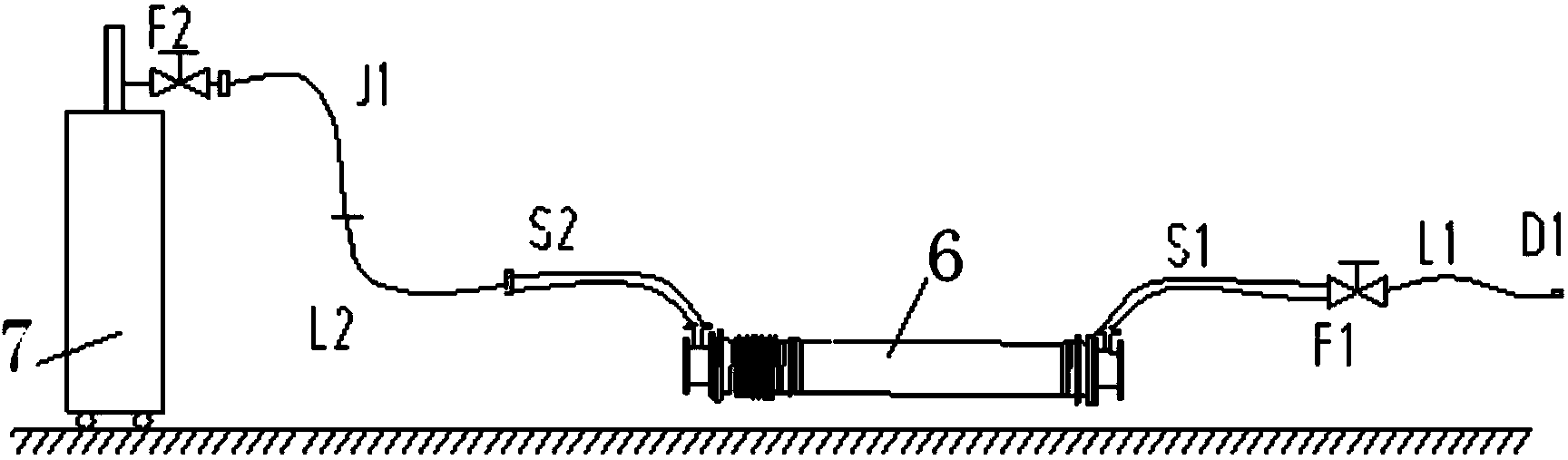

Low-temperature pipeline high-pressure burst testing device

ActiveCN104237020AEasy to operateReduce powerMaterial strength using tensile/compressive forcesAviationNitrogen

The invention belongs to the technical field of structural strength of aviation and aerospace and specifically relates to a low-temperature pipeline high-pressure burst testing device. The device comprises a filling system and a pressurizing system, wherein the filling system comprises a stainless steel flexible pipe S2 with the through diameter of 20mm, a low-temperature pipeline, a stainless steel flexible pipe S1 with the through diameter of 20mm, a manual valve F1 and a liquid nitrogen tank which are connected with one another sequentially, S1 is a filling pipe and S2 is an exhaust pipe; the pressurizing system comprises a pressure sensor D1, a stainless steel flexible pipe L1 with the through diameter of 10mm, the manual valve F1, the stainless steel flexible pipe S1 with the through diameter of 20mm, the low-temperature pipeline, the stainless steel flexible pipe S2 with the through diameter of 20mm, a stainless steel flexible pipe L2 with the through diameter of 10mm, a rubber flexible pipe J1 with the through diameter of 10mm, a manual valve F2 and a nitrogen bottle which are connected with one another sequentially. The low-temperature pipeline high-pressure burst testing device provided by the invention can apply a high-pressure load to the pipeline filled with a low-temperature medium, thereby obtaining a real stress state and a carrying limit of the low-temperature pipeline through a testing means.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

Device for wireless remote control tire burst test

InactiveCN101620030ASimple structureReduce testing costsVehicle tyre testingDriver/operatorMagnetic valve

The invention discloses a device for a wireless remote control tire burst test, comprising a wheel. A wheel hub is provided with a deflation port, a deflation tube is welded at the deflation port, and the deflation tube is provided with an electromagnetic valve; and the electromagnetic valve supplies power through a direct current power source, and the on-off of the magnetic valve is controlled through a wireless remote control switch. The device is additionally provided with an accessory device on a tire wheel hub of a conventional automobile and uses the electromagnetic valve as a control unit to deflate the tire so as to achieve the test effect same as the tire burst without damaging the tire, thereby saving the cost and being favorable for repeated tests. Because the wireless remote control switch remotely controls the electromagnetic valve, the burstiness of the test is increased so that the device is particularly suitable for training drivers in special industries.

Owner:ZHEJIANG UNIV

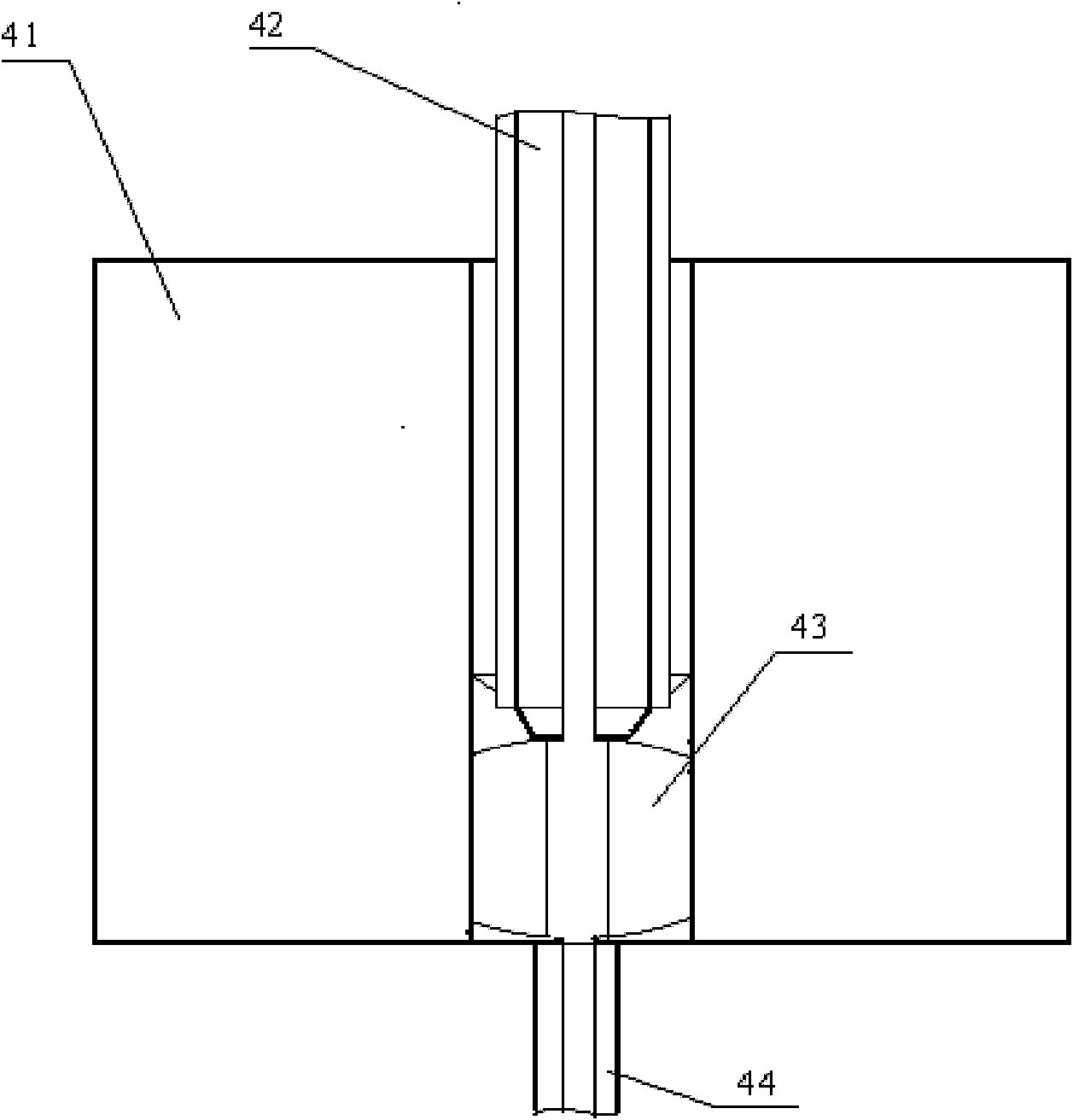

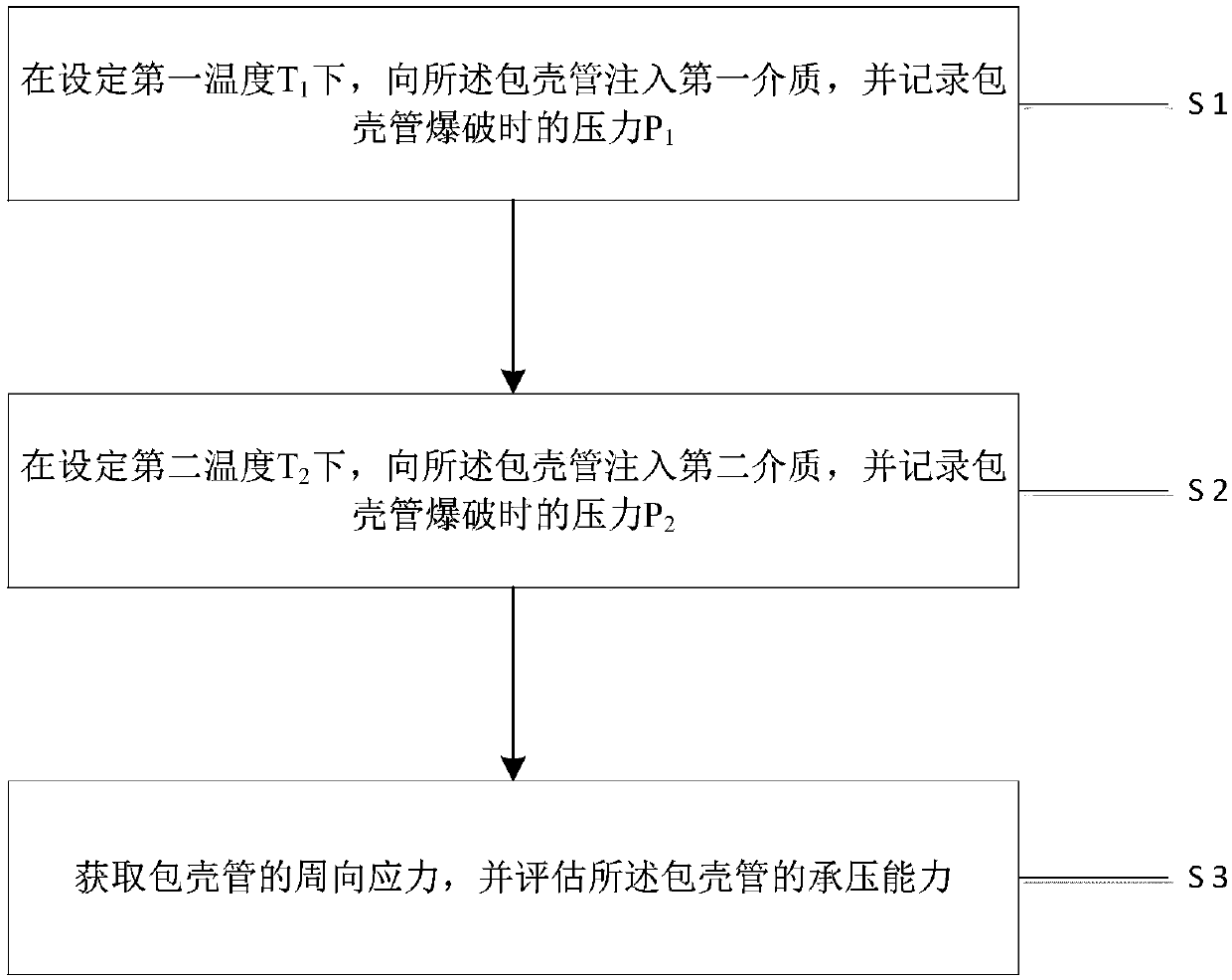

Cladding tube internal pressure bursting test device and method

ActiveCN108051321AReal-time detection of temperatureFacilitated releaseNuclear energy generationStrength propertiesInternal pressureEngineering

The invention relates to a cladding tube internal pressure bursting test device. The device comprises a first medium source, a second medium source, a vacuum heating device, a cladding tube arranged in the vacuum heating device, a pressure medium conveying pipeline, at least one temperature probe which is arranged on the vacuum heating device and detects the cladding tube temperature, a pressure release device arranged on the vacuum heating device and a control device, wherein the pressure medium conveying pipeline is connected with the first medium source and the second medium source and communicated with the cladding tube and conveys pressure media to the cladding tube, and the control device is connected with the vacuum heating device and the pressure medium conveying pipeline and controls the vacuum heating device to heat and controls the pressure medium conveying pipeline to convey the media; the control device comprises a first mode of controlling the pressure medium conveying pipeline to convey the first media at first temperature and a second mode of controlling the pressure conveying pipeline to convey the second media. The cladding tube internal pressure bursting test device can be used for simulating and measuring the loading capacity of the cladding tube in the working condition that a nuclear power plant has an accident in the high temperature and high pressure environment.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +3

Bursting device

The invention provides a bursting device. The bursting device comprises a test table, a support arranged on the test table and a base arranged on the test table. The bursting device further comprises a bursting clamping head, a stress and strain sensor connected with the bursting clamping head, a high speed photometer, a hydraulic servo motor, a stabbing cone and a jig. The hydraulic servo motor is connected with the bursting clamping head, and the bursting clamping head is connected with the stabbing cone. Such design significantly improves the fastness of clamping of textile / textile structure reinforced flexible composite material to be tested, reduces the relative slippage between a sample to be tested and the jip, reduces pulling-out of yarn from the textile structure, and improves the accuracy and reliability of a bursting test.

Owner:SUZHOU UNIV

Multifunctional pressure difference type method for testing compatibility of high-pressure hydrogen and materials

ActiveCN104880368AReduce volumeReduce investmentMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesTest efficiencyDifferential pressure

The invention relates to the field of development of material mechanical property testing devices, and aims at providing a multifunctional pressure difference type method for testing the compatibility of high-pressure hydrogen and materials. The method includes a bursting test method, a variable-hydrogen-pressure fatigue test method and a constant-hydrogen-pressure fatigue test method. By means of the method for applying loads on a disc sample through the pressure difference of the upper surface and the lower surface of the disc sample, complex servo test mechanisms are avoided, the device size is greatly reduced, the device input is reduced, operation is easy and convenient, and the test efficiency is improved; in the test process, parameters such as strain and displacement of the disc sample can be conveniently measured, and corresponding tested elements are not influenced by high-pressure hydrogen.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com