Low-temperature pipeline high-pressure burst testing device

A low-temperature pipeline and blasting test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems that cannot meet the requirements of pipeline blasting tests, and the real state cannot be known, so as to achieve simple operation and guarantee safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

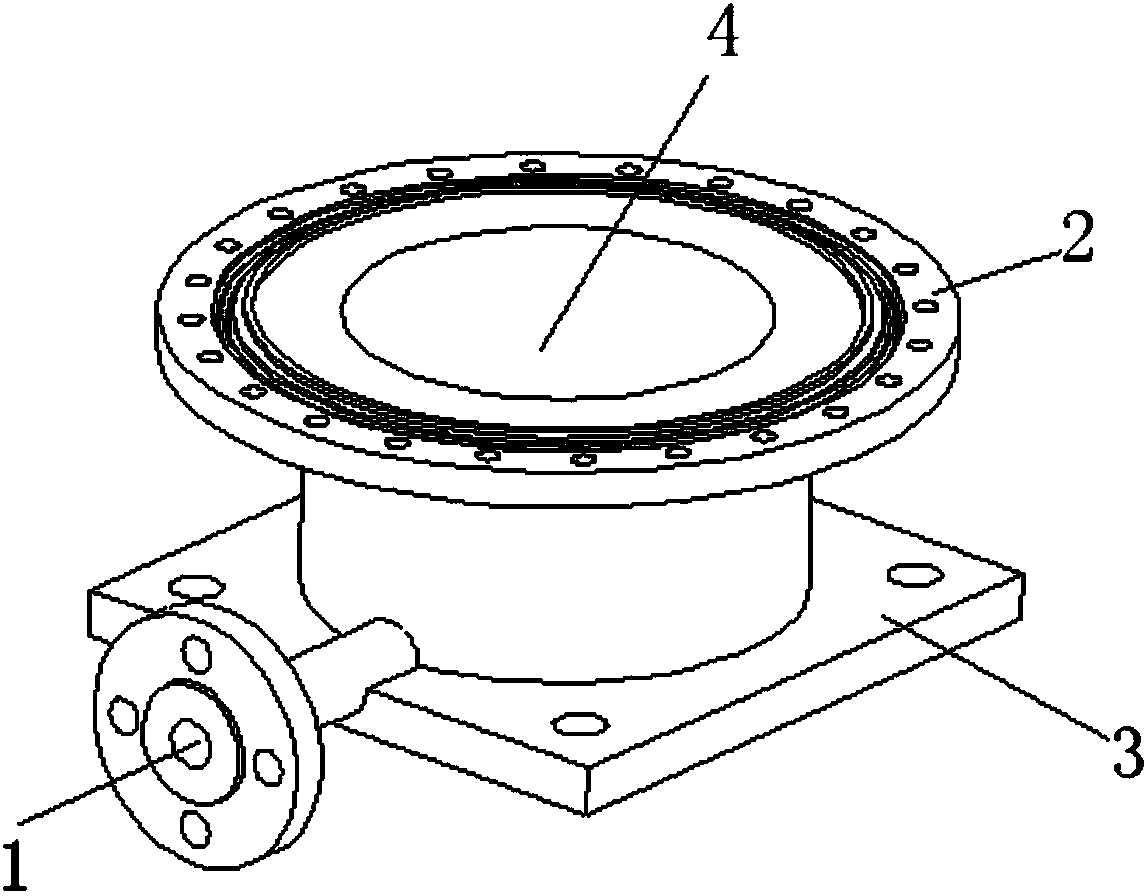

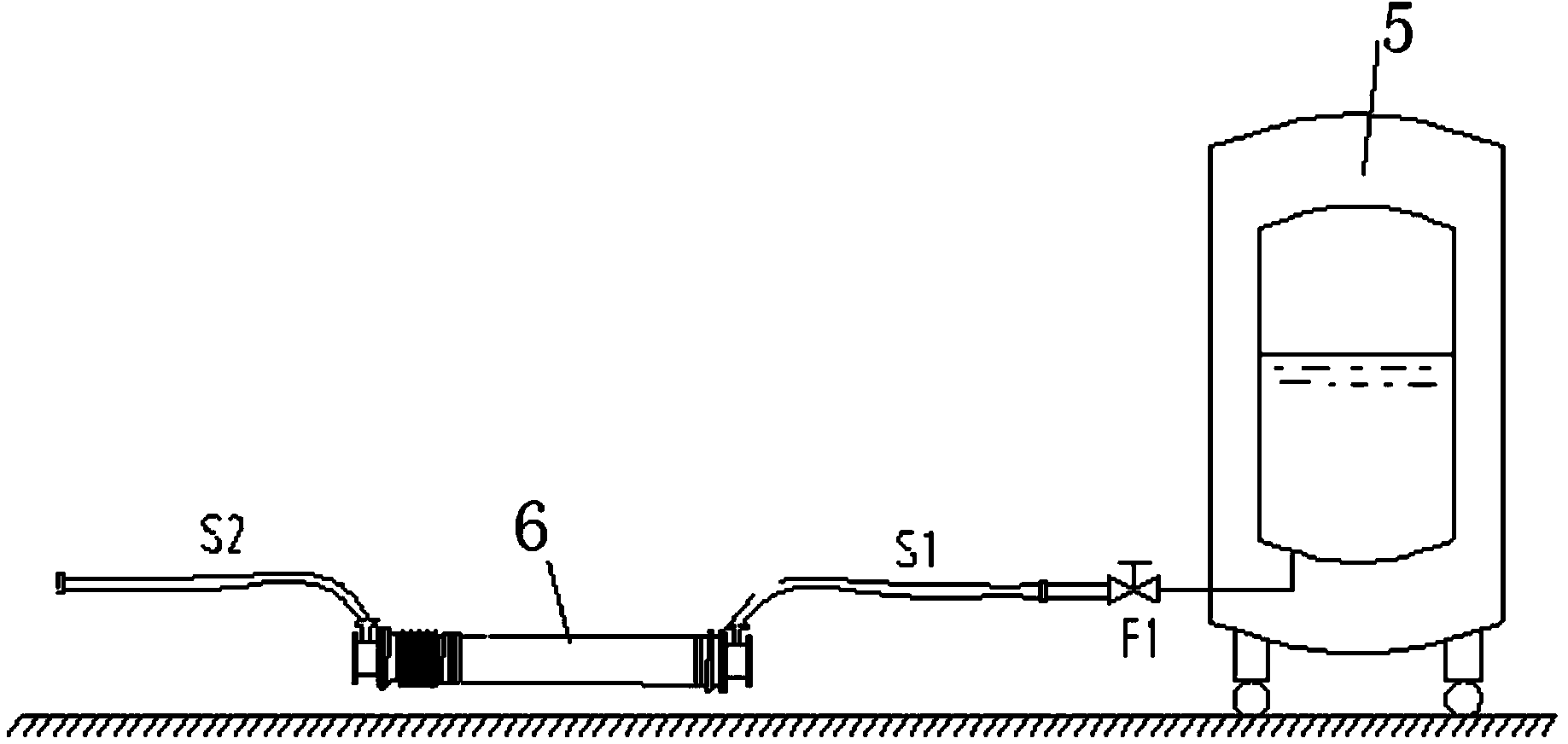

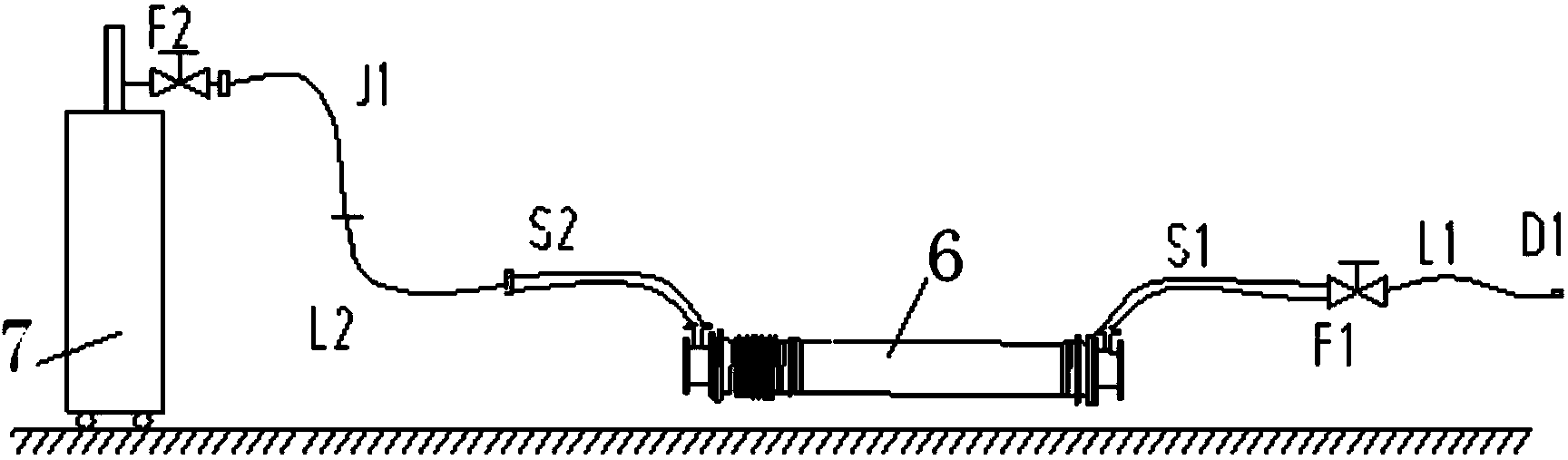

[0026] First solve the problem of pipeline installation and fixing. Usually, two ends of the cryogenic pipeline 6 are respectively provided with an open flange, such as figure 1 As shown, the open flange includes a sealing surface 2 at the upper end, a cavity body 4 and a fixed support end 3 at the lower end thereof, and a filling port 1 is provided on the side of the cavity body 4, and the filling port 1 and the bottom surface of the cavity body 4 , that is, the upper surface of the fixed support end 3 is flush, the cavity 4 communicates with the filling port 1, and the water flows out through the filling port 1 by its own weight when draining water. The open flange simultaneously has three functions of sealing, filling pressurization and fixing. In order to ensure its performance at low temperature, the stainless steel material 0Cr18Ni9 is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com