Pressure bursting test system and method for low-temperature deep-cooling pressure vessels and pipelines

A low-temperature cryogenic and blasting test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve the problems that it is difficult to characterize ultimate strength, container strength and air tightness cannot be directly reflected, etc. , to achieve the effect of reducing the test cost, risk and destructive weakening, and reducing the dosage

Active Publication Date: 2016-04-20

HEFEI GENERAL MACHINERY RES INST +1

View PDF7 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The national standard stipulates that the pressure test should be carried out after the container is manufactured and before leaving the factory. Some pressure equipment also requires a burst test, but it is usually carried out at room temperature. When calculating the pressure test pressure, it must be multiplied by the test temperature a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

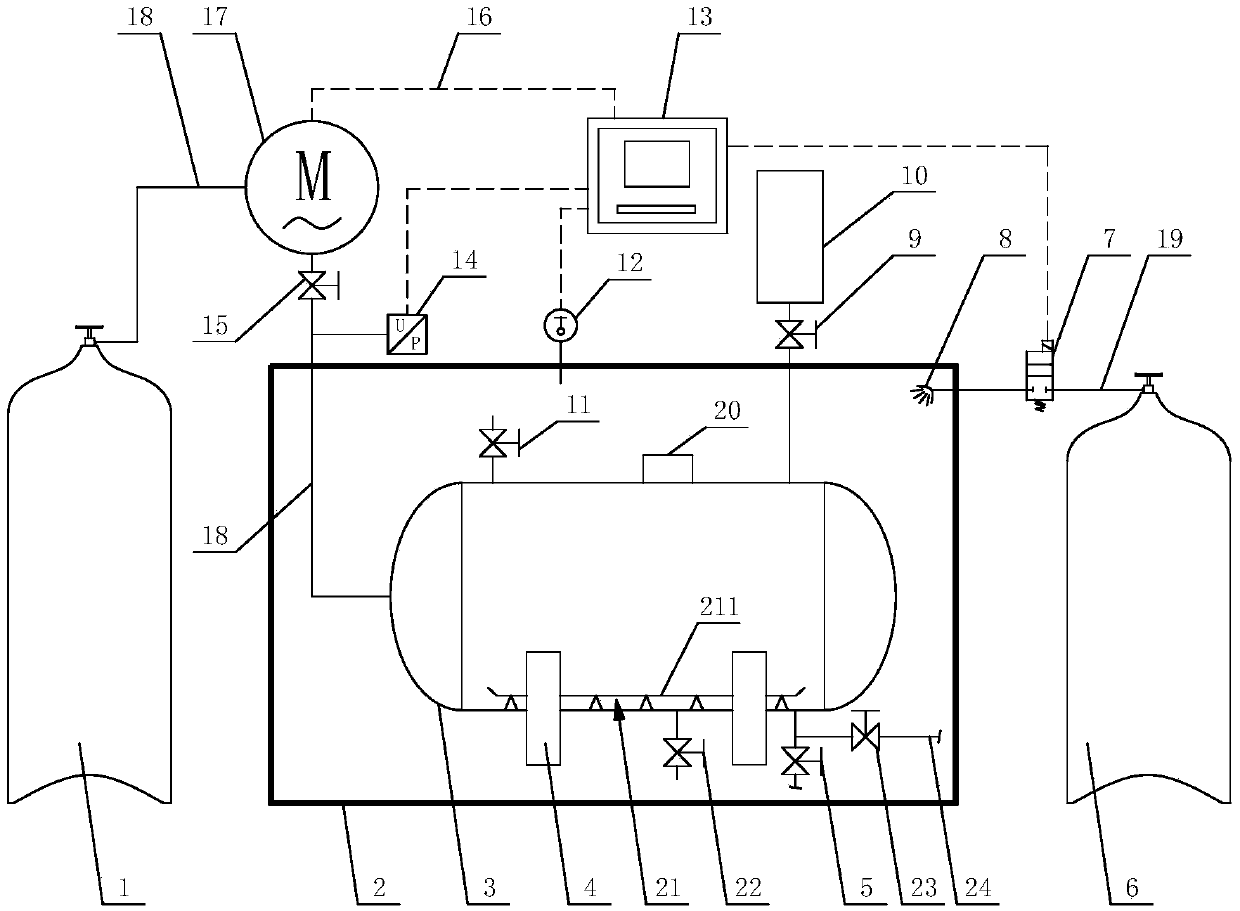

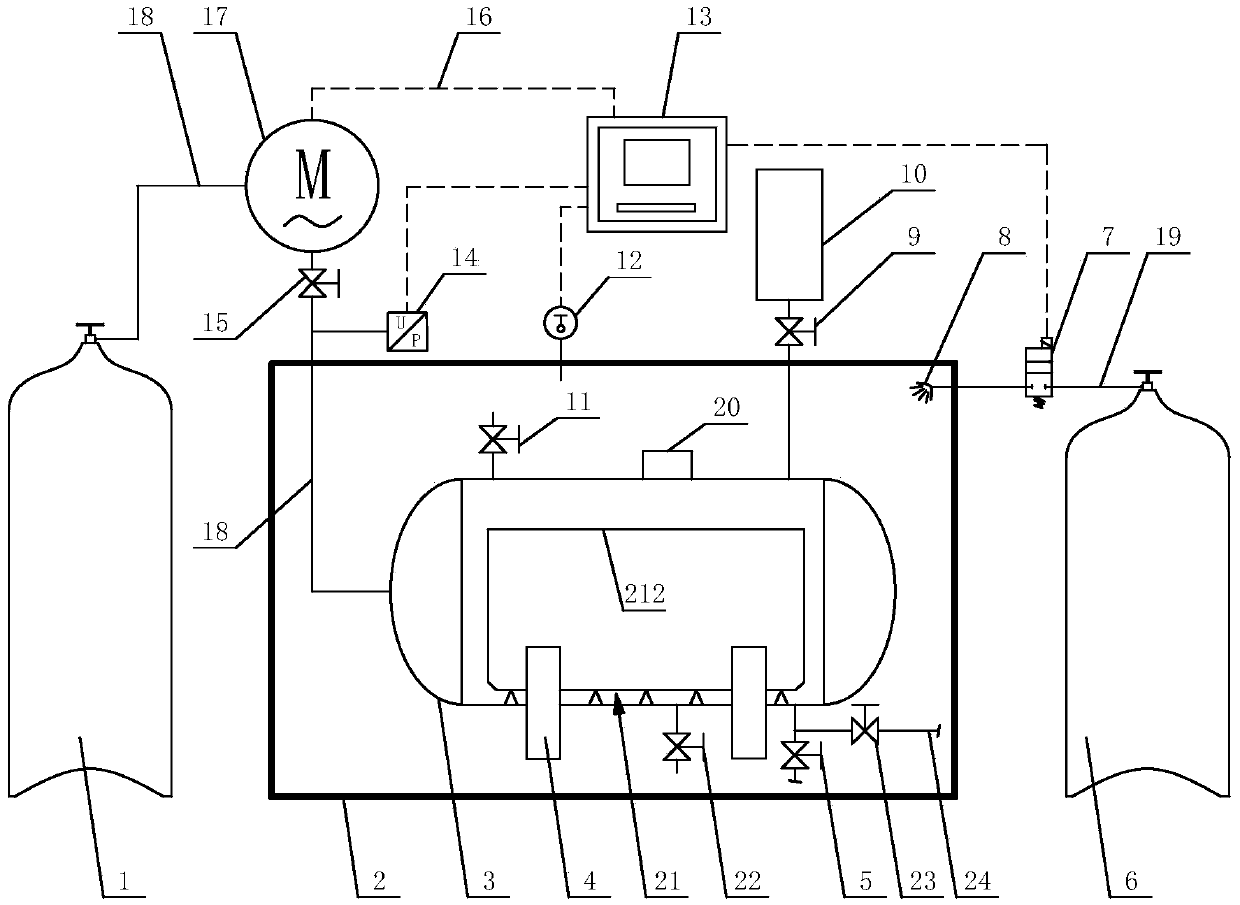

The invention relates to a pressure bursting test system and method for low-temperature deep-cooling pressure vessels and pipelines. The pressure bursting test system comprises a pressure bursting subsystem, a low-temperature deep-cooling environment subsystem, a vessel filling subsystem and a control subsystem, wherein the pressure bursting subsystem comprises a test medium storage device and a to-be-tested vessel which are mutually communicated, and the to-be-tested vessel is fixedly arranged in the low-temperature deep-cooling environmental box; a supporting device is arranged on the inner side of the to-be-tested vessel; the low-temperature deep-cooling environment subsystem comprises a low-temperature deep-cooling environmental box and a refrigerant storage tank which are mutually communicated; the vessel filling subsystem comprises an oil tank used for supplying oil for the to-be-tested vessel. The test system and method can conduct pressure test and bursting test of the pressure vessels in the low-temperature deep-cooling environment (from 269 DEG C below zero to zero DEG C) and test the strength, the airtightness and the bursting pressure of the pressure vessel in the low-temperature deep-cooling environment; by virtue of the measures of adding a filler into the vessel, recycling of both a refrigerant and a pressure medium and the like, the energy consumption is reduced to the utmost extent and the test cost is reduced.

Description

technical field [0001] The invention relates to a pressure-resistant blasting test system and method, in particular to a low-energy consumption test system and method for pressure-resistant blasting of pressure vessels and pipelines in a low-temperature and cryogenic environment. Background technique [0002] With the development of industry, the application of low-temperature cryogenic pressure vessels is becoming more and more extensive. Since low-temperature cryogenic vessels generally contain flammable and explosive media such as liquefied natural gas, and the cryogenic environment has a great influence on the mechanical properties of materials, once the Leakage or rupture will lead to serious consequences, so the strength and safe use of such containers are more stringent than general containers. The national standard stipulates that the pressure test should be carried out after the container is manufactured and before leaving the factory. Some pressure equipment also r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/12

CPCG01N3/12G01N2203/0019G01N2203/0044G01N2203/0067

Inventor 危书涛范志超陈学东聂德福汪睿

Owner HEFEI GENERAL MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com