Clamp for extension test of glass fiber tape for optical cable and testing method

A glass fiber tape and tensile testing technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the glass fiber tape cannot be stretched and tested, and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

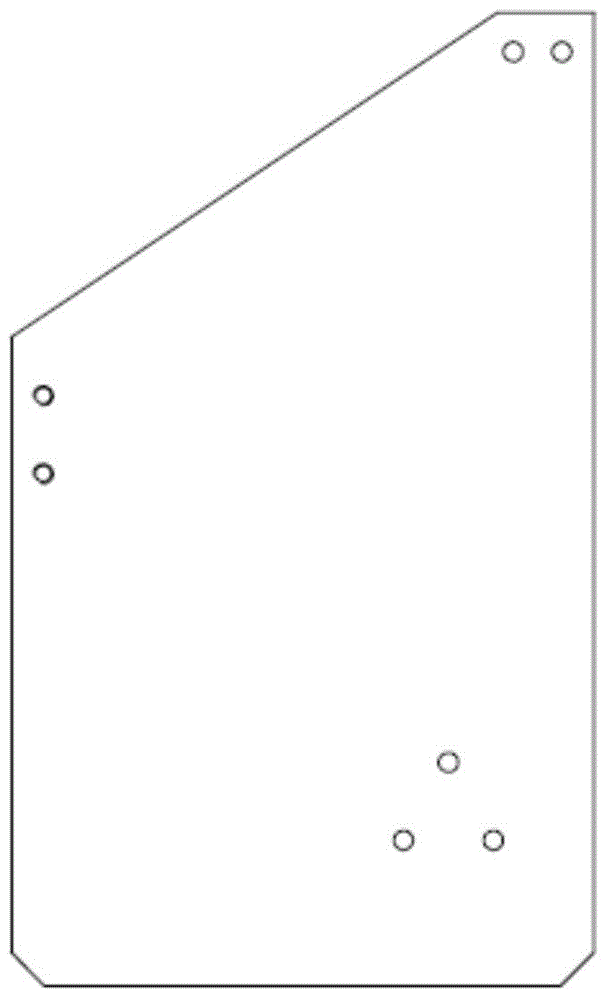

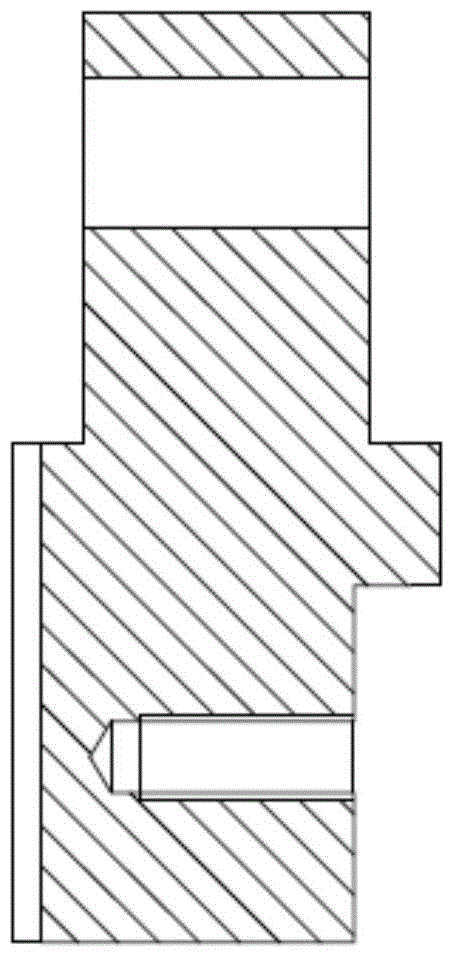

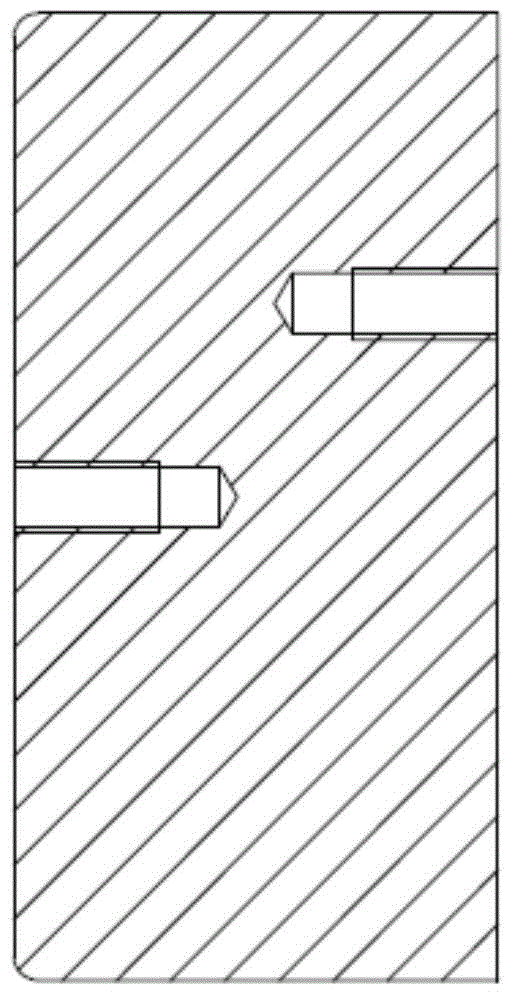

[0036] The present invention is a kind of jig for tensile test of glass fiber ribbon for optical cable, refer to Figure 1 to Figure 7 , which specifically includes a base plate 1, the upper side of the base plate 1 is fixedly equipped with a cylindrical hole fixing head 2, and the lower side is fixedly equipped with a ring 3 and a fixed disc 4, and it is also fixedly installed on the edge of the middle plate. Clamping fixture 5 and I-type clamping device 6.

[0037] Among them, the bottom plate 1 is made of No. 45 steel material, and has been quenched and tempered and surface quenched. There are several fixing holes on it. The position and size of the fixing holes must be accurate. Roughness needs to reach 1.6.

[0038] The fixed head 2 with a cylindrical hole is made of No. 45 steel material, and after quenching and tempering treatment, all acute angles are inverted into obtuse angles, deburred, and the surface roughness must reach 1.6. For the cylindrical head fixed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com