Drill bit performance testing device

A technology of testing device and drill bit, applied in the field of drill bit, can solve the problems of inability to ensure the quality of the drill bit, single test effect, unsatisfactory and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

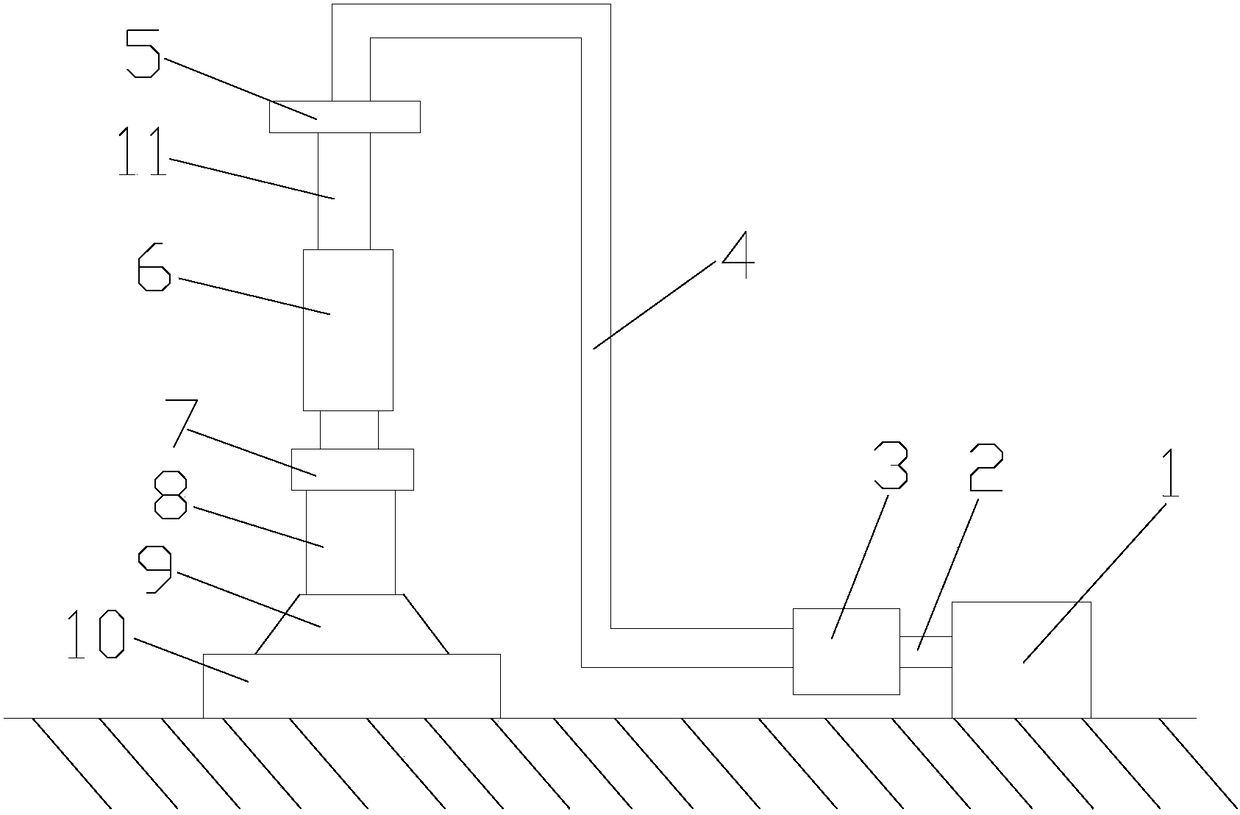

[0012] like figure 1 Shown is a performance test device for a drill bit, including a pump 1, a circulation joint 2, a flow meter 3, a pipeline 4, a power head 5, a drill bit 6, a drill mandrel 7, a drill bit conversion joint 8, a tester 9 and a rock sample 10. The pump 1 is connected to the flowmeter 3 through the circulation joint 2, and the other end of the flowmeter 3 is connected to the power head 5, the drill bit 6, the drill mandrel 7, the drill bit conversion joint 8, the tester 9 and the rock sample 10 through the pipeline 4 in sequence.

[0013] Wherein, a short drill rod 11 is also arranged between the power head 5 and the drill bit 6 . Pipeline 4 is a hose.

[0014] Although the specific embodiments of the present invention have been described above, those skilled in the art should understand that these are only examples, and various changes or modifications can be made to the embodiments without departing from the principle and essence of the present invention. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com