Patents

Literature

122results about How to "Test coherence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

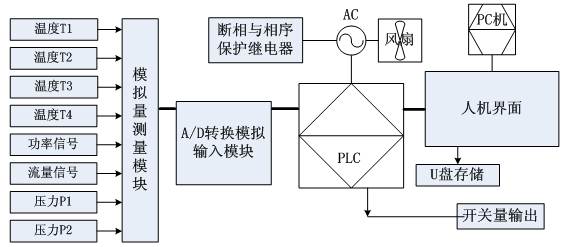

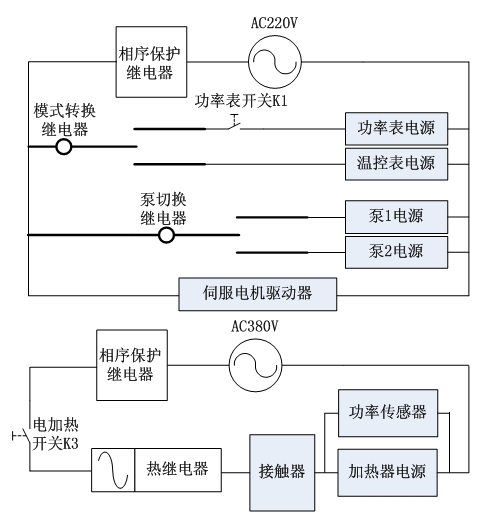

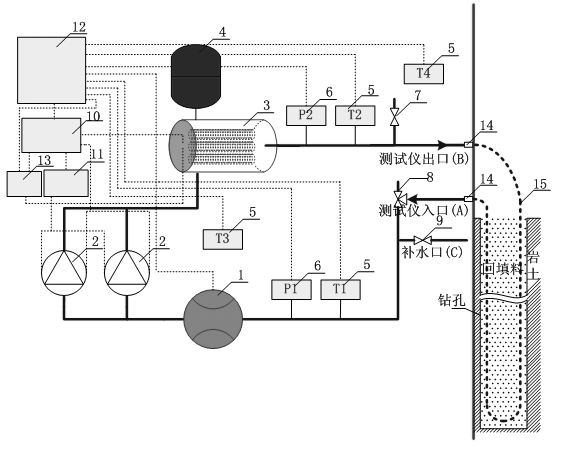

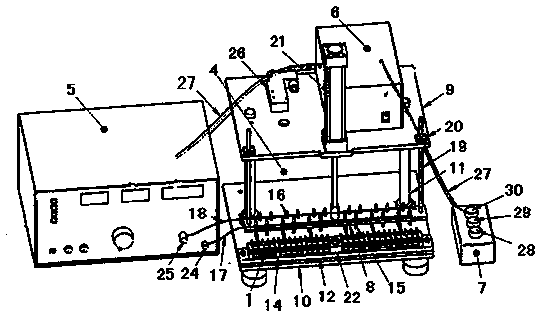

Instrument and method for testing stratum in-situ thermal property of ground source heat pump and heat exchange quantity of buried pipe

InactiveCN102033079ACompact structureEasy to carryMaterial heat developmentPower sensorFlow transducer

The invention discloses an instrument for testing the stratum in-situ thermal property of a ground source heat pump and the heat exchange quantity of a buried pipe, comprising a pipeline circulating system, a testing system and a monitoring system, wherein the pipeline circulating system is a circuit which is formed by connecting a flow sensor, a circulating water pump, an electric heater, an expanding tank, an exhausting valve, a three-way valve and a water supplying valve with a U-shaped buried pipe through connectors; and the testing system comprises a flow sensor, a temperature sensor, a pressure sensor and a power sensor, which are respectively connected with the monitoring system. In the invention, the testing instrument has compact structure and is convenient for carrying; two testing modes of testing the stratum in-situ thermal property and the heat exchange quantity can be economically and conveniently realized at the same time by utilizing one machine; two circulating pumps are alternately used to prolong the service life of the circulating pumps; the test and the adjustment are more convenient; and the testing data is accurate.

Owner:NANJING UNIV +1

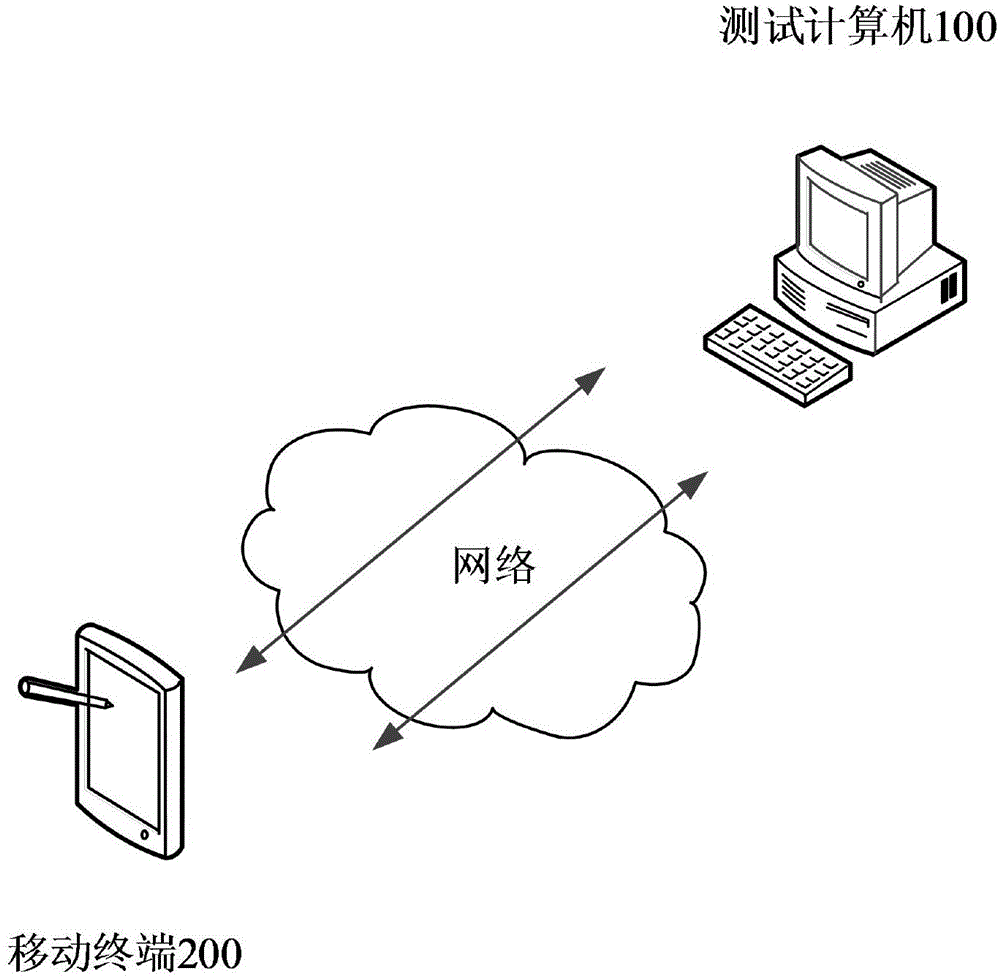

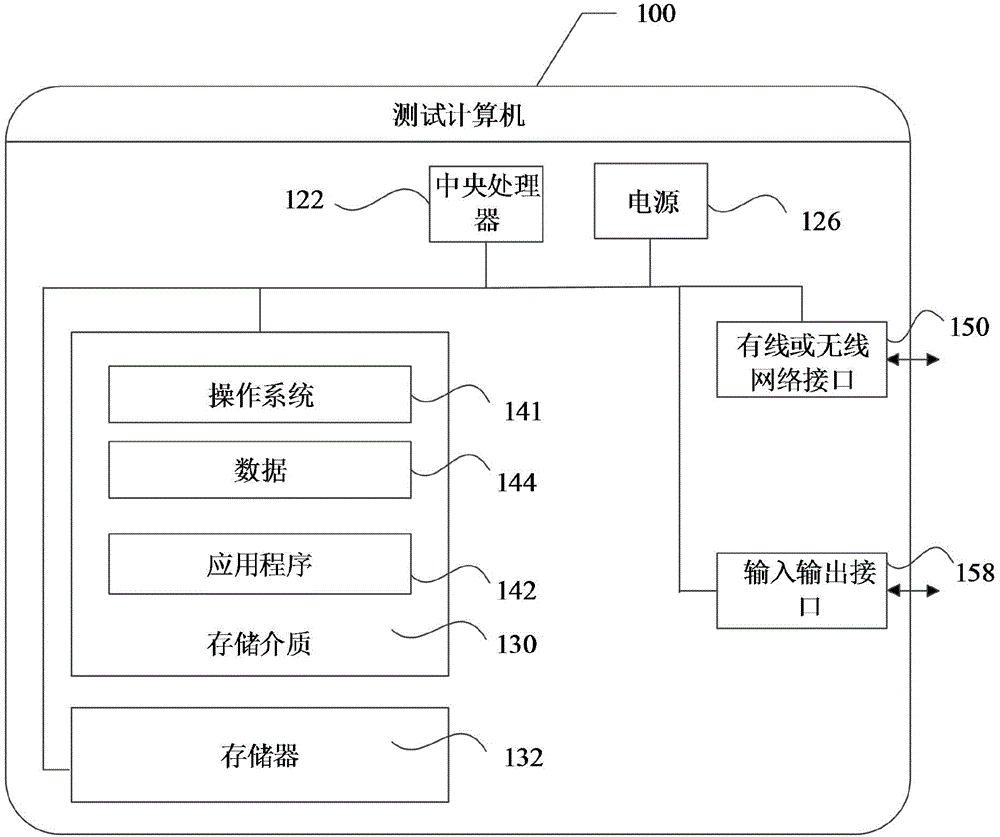

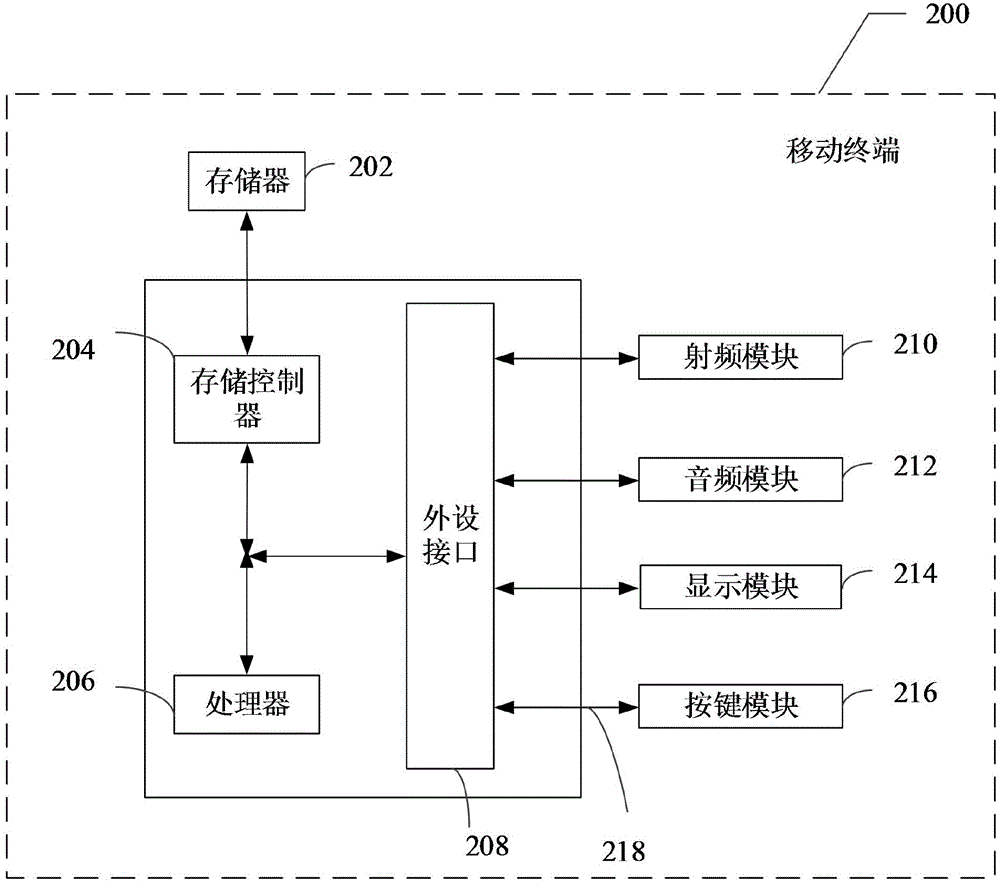

Program testing method, device and system

ActiveCN105487966AImprove test efficiencyTest coherenceSoftware testing/debuggingEnergy efficient computingProgram testingComputer science

The invention provides a program testing method, which comprises the following steps of extracting a plurality of test cases from a test program and executing the test cases at a mobile terminal one by one in order to test a to-be-tested program; obtaining test result data, and re-executing the test case corresponding to the test result data when the test result data shows that the to-be-tested program has program crash or unexpected exit; and executing the next test case if re-execution is carried out for the preset times and the test result data still shows that the to-be-tested program has program crash or unexpected exit. The invention also provides a program testing device and system. According to the program testing method, device and system, the subsequent test can be continued to finish when the tested program has program crash or unexpected exit in the test, so that the whole test process is guaranteed to go well, and thus the program testing efficiency is improved.

Owner:深圳市雅阅科技有限公司

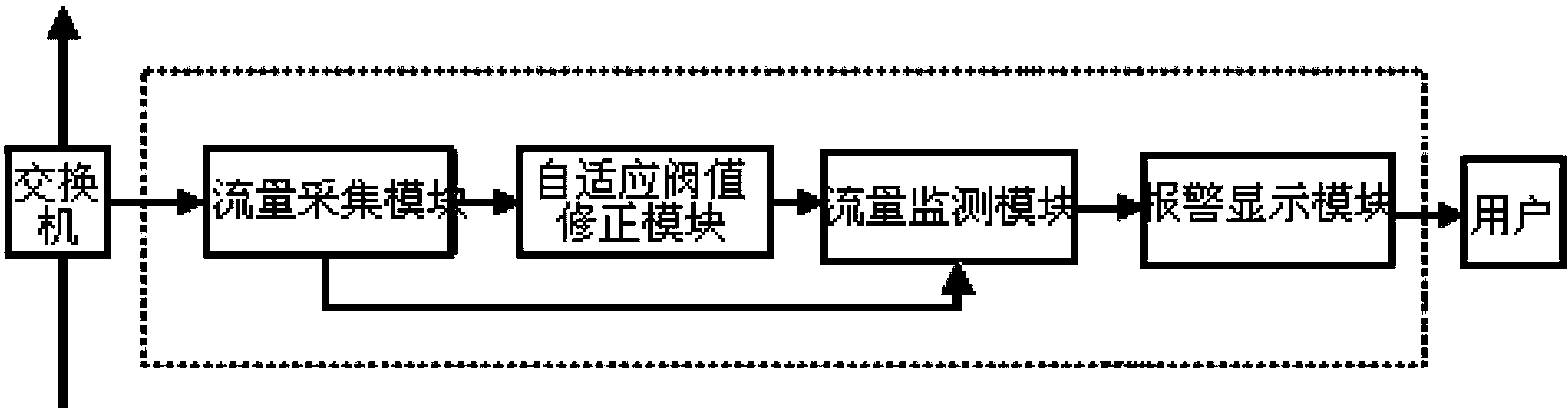

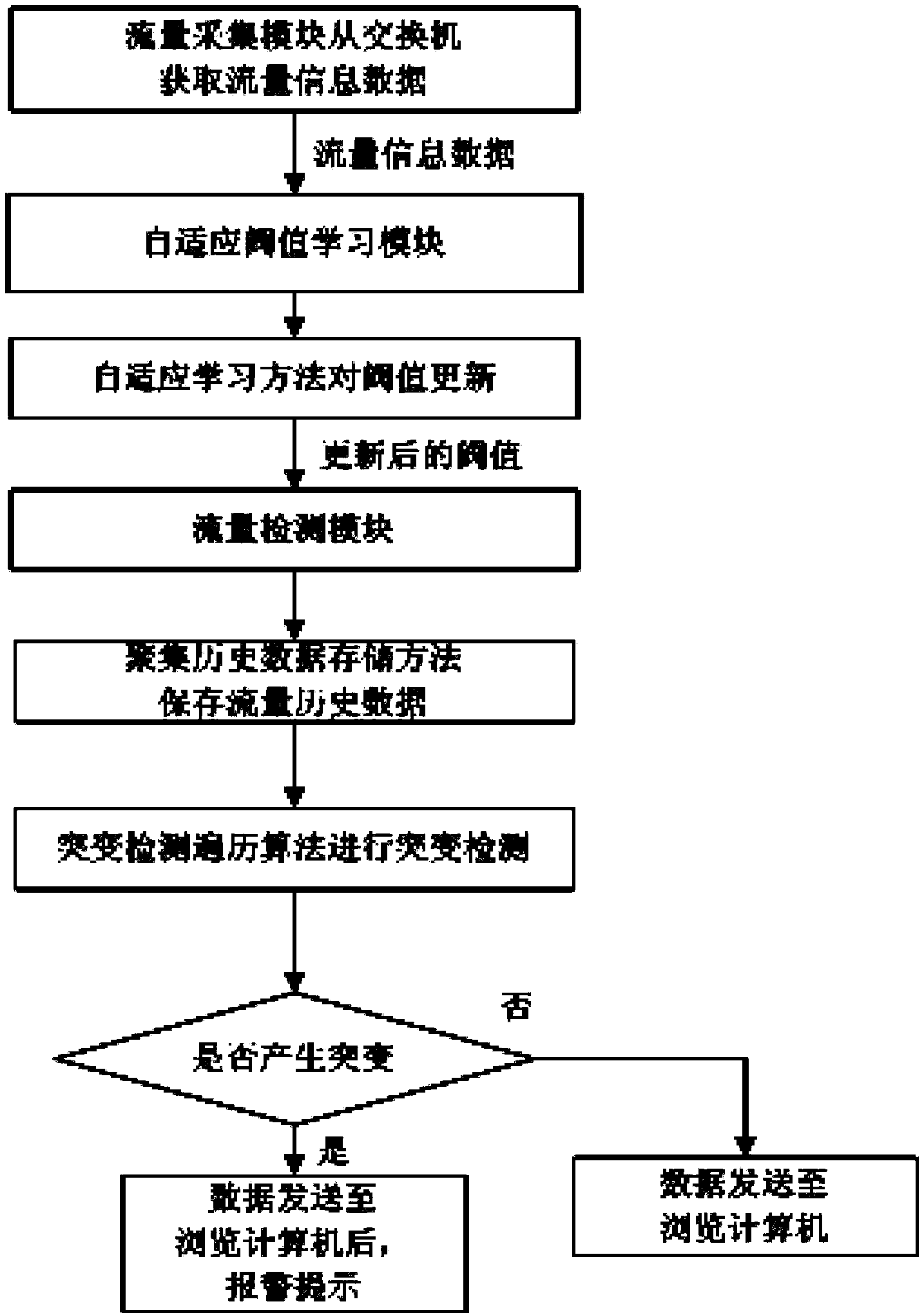

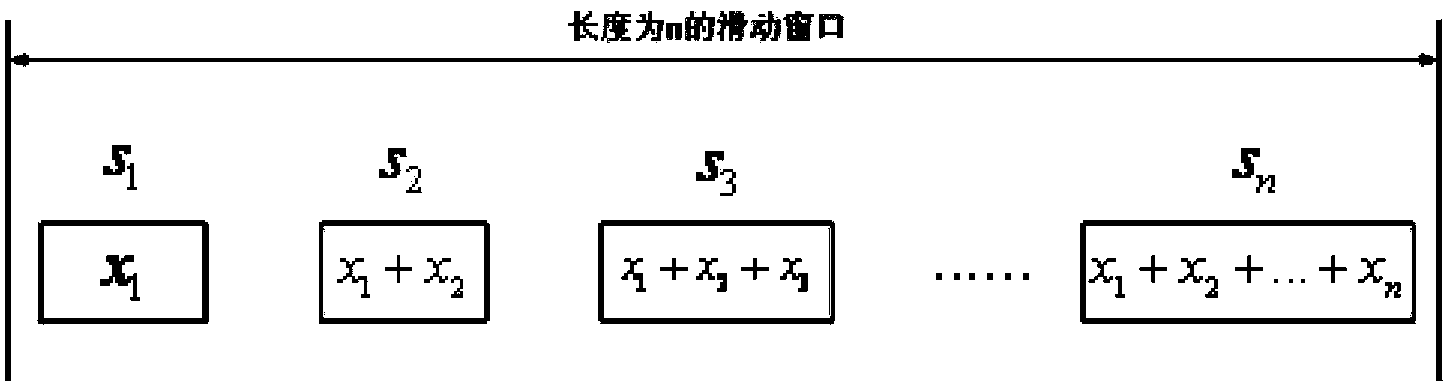

Threshold-self-adaptive-correcting network flow monitoring system and method

ActiveCN103780445AGuaranteed correctnessGuaranteed adaptabilityData switching networksSelf adaptiveHuman–computer interaction

The invention provides a threshold-self-adaptive-correcting network flow monitoring system and method. The system includes a flow acquisition module, a self-adaptive threshold correction module, a flow monitoring module and an alarm display module. The flow acquisition module obtains flow information data from a switch and transmits the flow information data to the self-adaptive threshold correction module and the flow monitoring module. The self-adaptive threshold correction module confirms a threshold parameter initial value and updates the threshold parameter and transmits the updated threshold parameter to the flow monitoring module. The flow monitoring module compares current flow and historical flow conditions and judges whether accumulated-flow mutation happens in a network and uses the current flow as historical flow which is then saved as flow historical data after the judgment is completed and transmits the judgment result to the alarm display module. The alarm display module performs displaying through a man-machine interaction interface according to a calculation result transmitted by a flow detection module.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

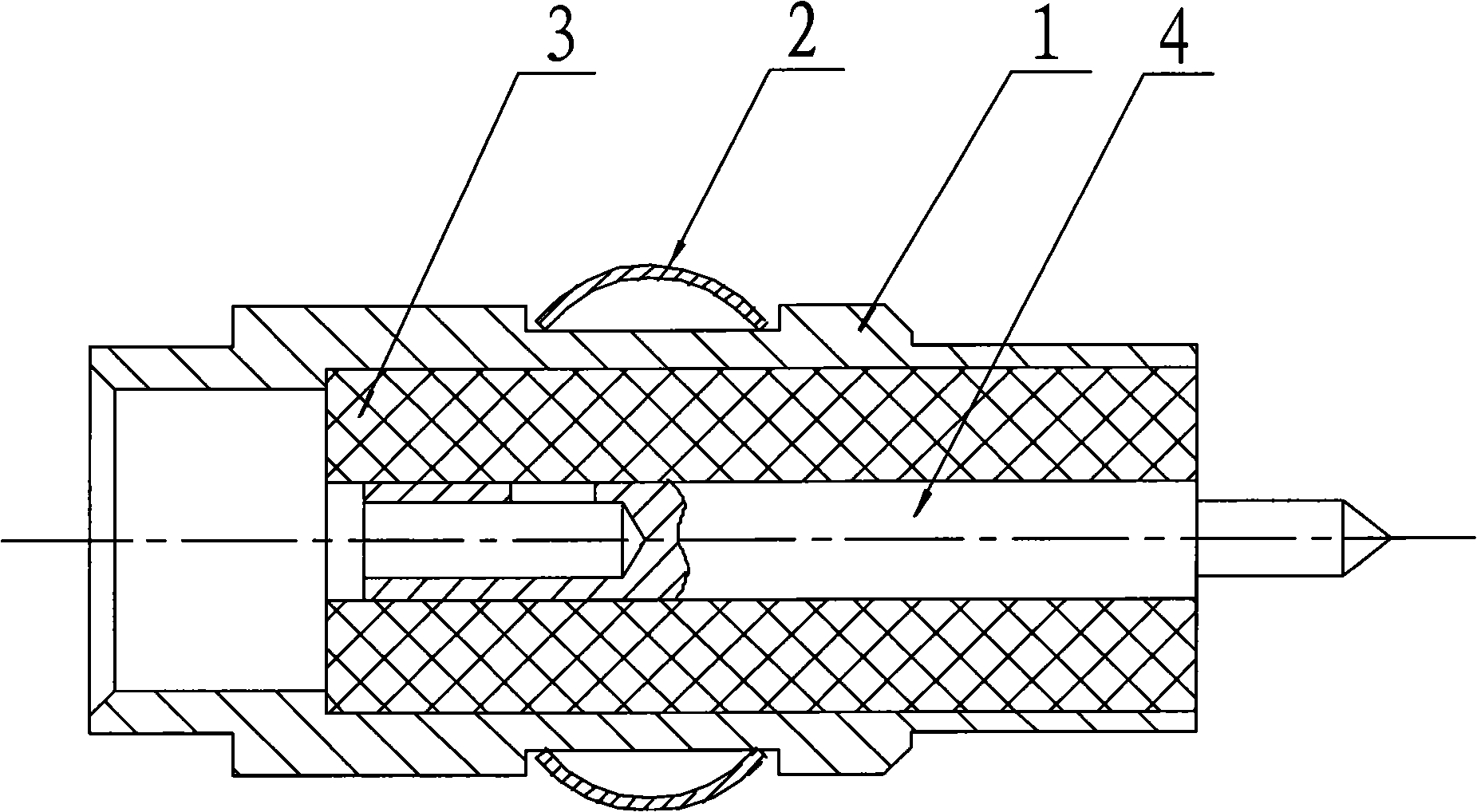

Quick-speed plug connector assembly for testing

InactiveCN101562303AAvoid interferenceFirmly connectedElectrical measurement instrument detailsElectrical testingTest efficiencyElectrical conductor

The invention discloses a quick-speed plug connector assembly for testing, which comprises a plug and a connecting sleeve for connecting the plug with a socket, wherein a connecting through hole is formed in the connecting sleeve, the front end hole wall of the connecting through hole is provided with connecting threads for connecting the socket, and a clip and a structure for fixing the plug are also arranged in the connecting through hole; the plug comprises a shell made up of conductors, a contact pin is inserted axially in the shell, an insulator is filled between the shell y and the plug, the plug extends axially and protrudes out of the front end face of the connecting sleeve, and the outer surface of the shell is provided with an elastic contact in block fit with the connecting sleeve. By adopting the structure, the quick-speed plug connector assembly has a simple structure and convenient connection, can save the testing time and accelerate the testing, and improve the testing efficiency.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

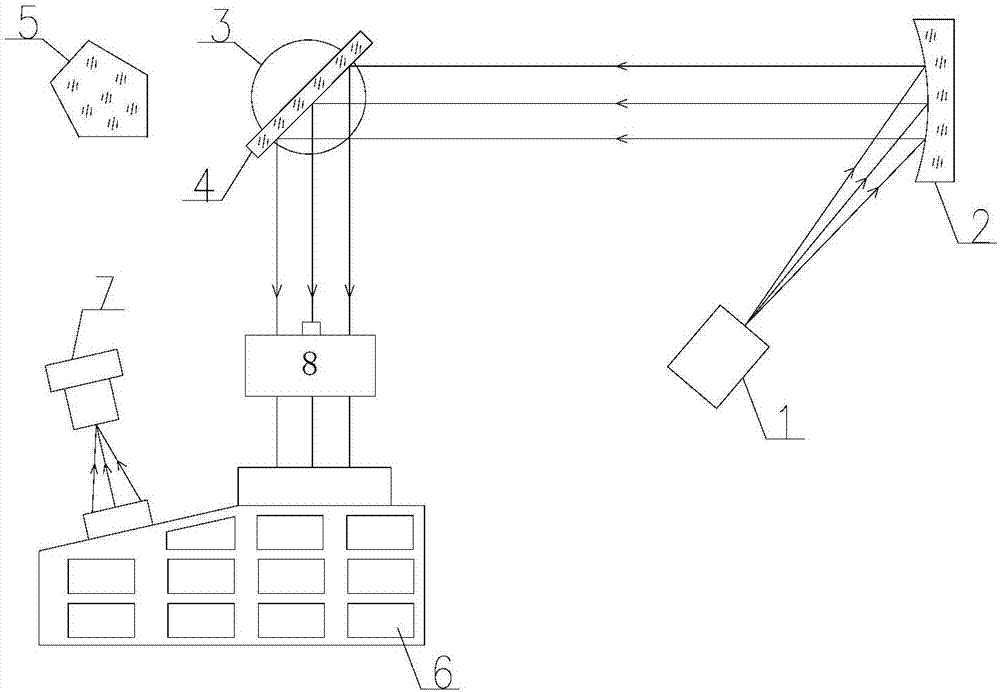

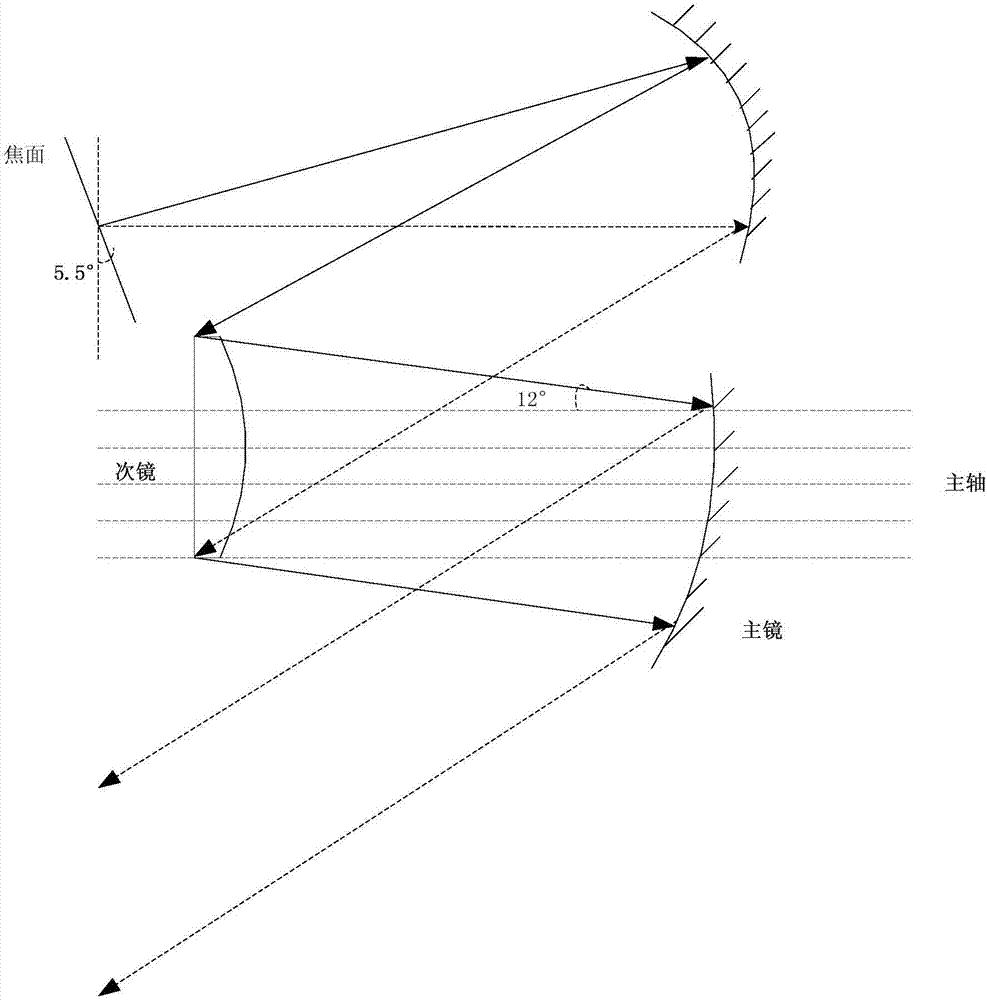

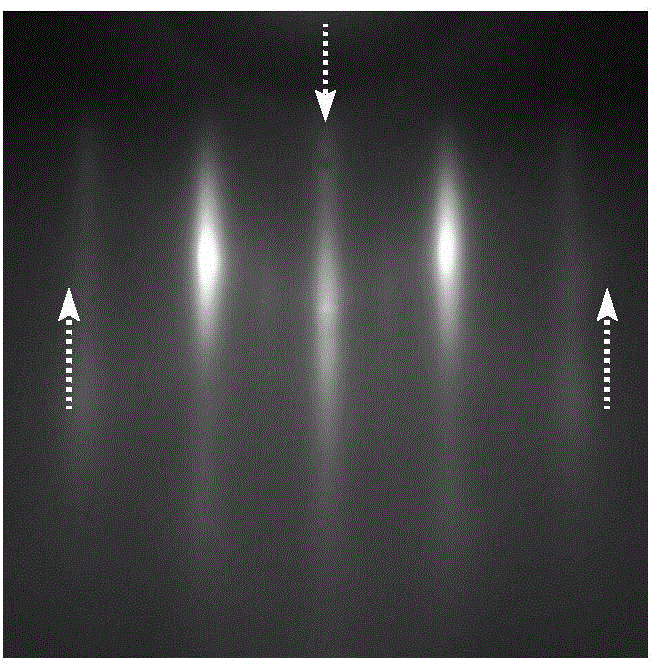

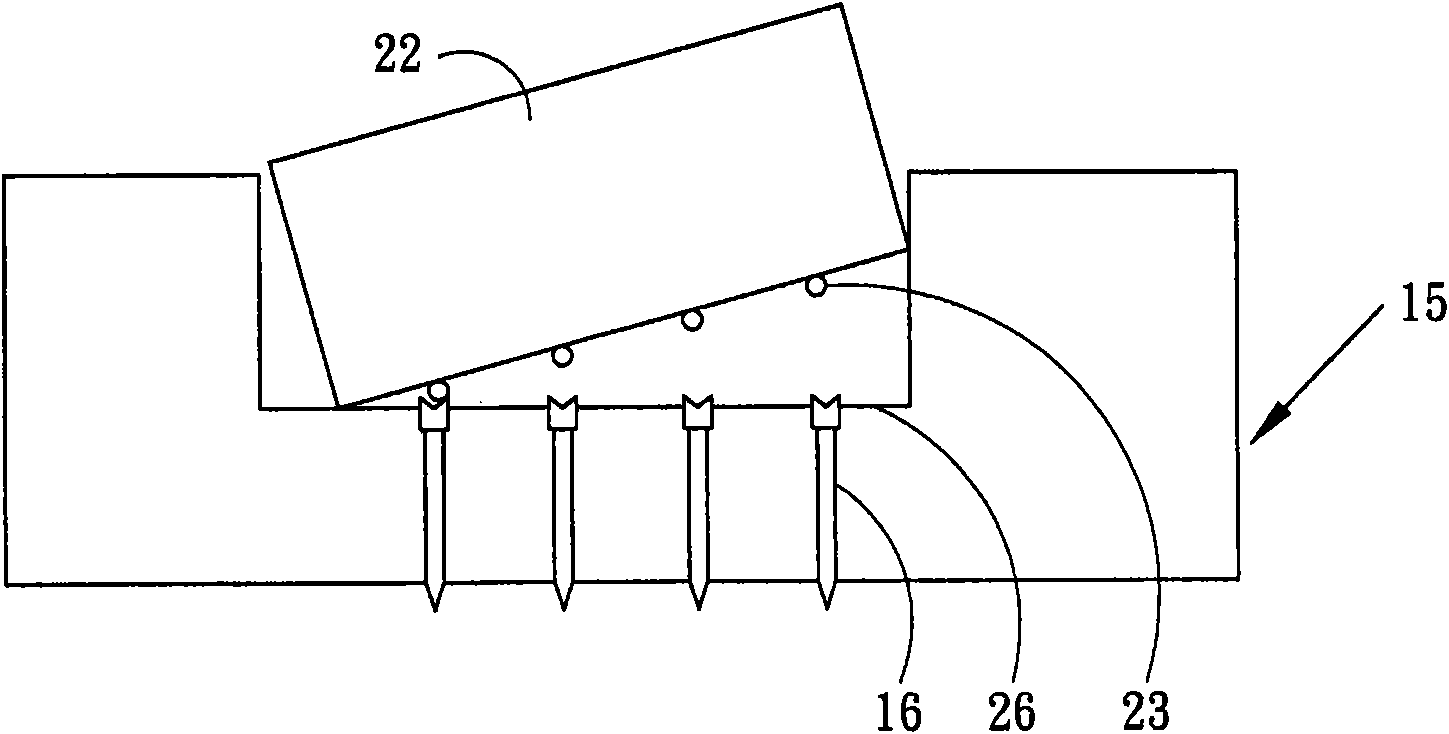

MTF test device and test method for off-axis three-mirror optical system with large field of view

ActiveCN107132028AWide range of applicationsQuick fixTesting optical propertiesPentaprismOptical path

The invention provides an MTF test device and test method for an off-axis three-mirror optical system with a large field of view, which are easy to operate and easy to realize. The test method includes the steps of firstly determining the specific position of a plane mirror using a pentaprism and an autocollimation theodolite to ensure that the plane mirror reflects an optical path for 90 degrees so that the reflected optical path by the plane mirror enters a field of view of an off-axis three-mirror optical system under test completely; secondly, deflecting a detector of an MTF measurement system; and thirdly, finding out an exact image plane position and measuring a transfer function by the MTF measurement system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

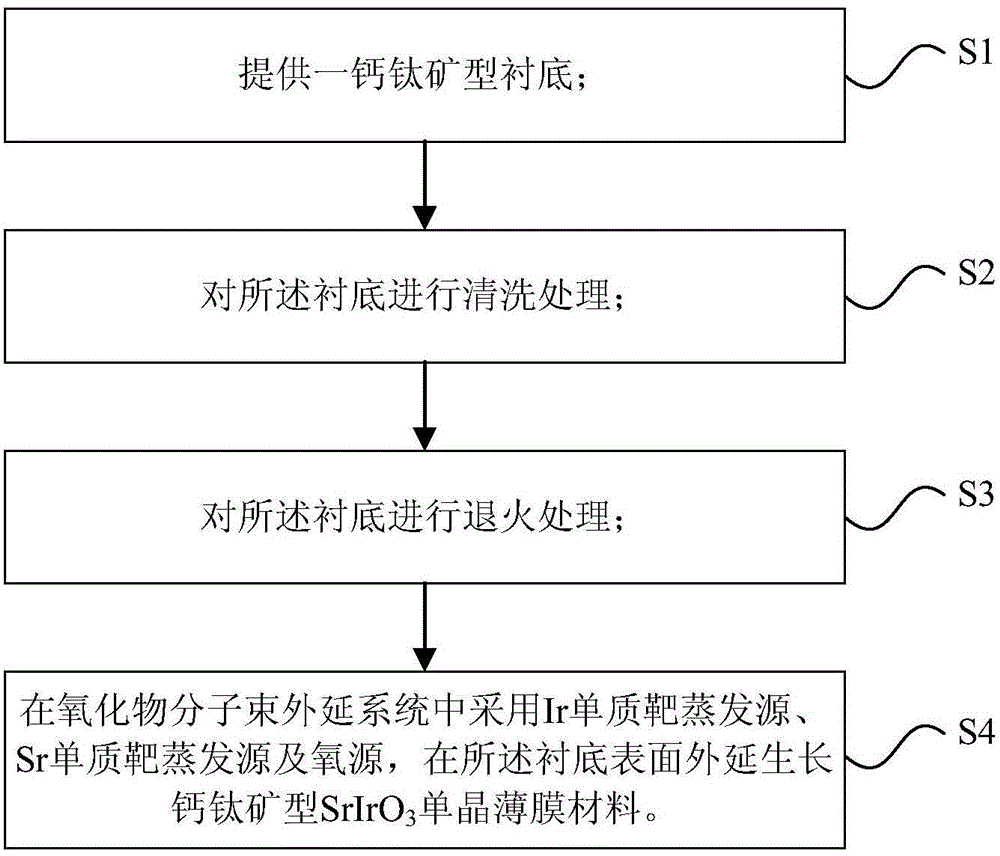

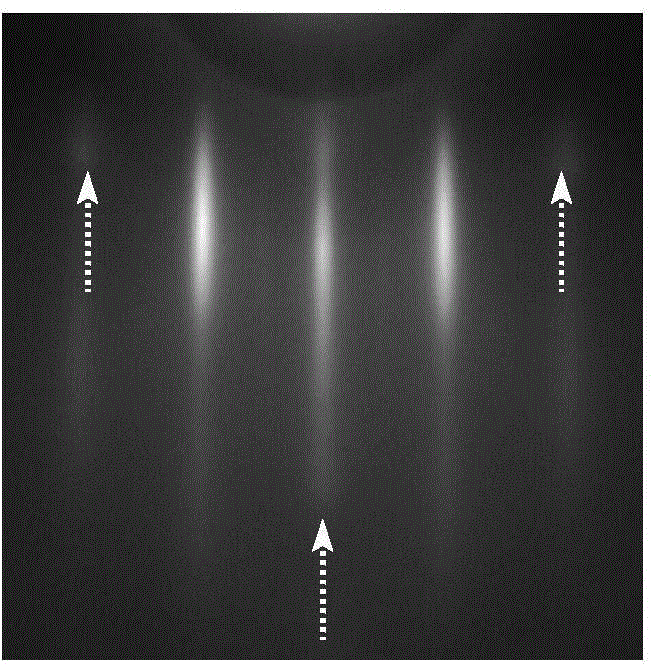

Preparation method of perovskite type SrIrO3 single crystal film material

InactiveCN104947192AQuality improvementGood for implementing testsPolycrystalline material growthFrom chemically reactive gasesElectronic structureStable state

The invention provides a preparation method of a perovskite type SrIrO3 single crystal film material. The preparation method of the perovskite type SrIrO3 single crystal film material comprises the following steps: S1, providing a perovskite type substrate; S2, cleaning the perovskite type substrate; S3, annealing the perovskite type substrate; S4, adopting a Ir simple substance target evaporator source, a Sr simple substance target evaporator source and an oxygen source in an oxide molecular beam epitaxy system, and growing the perovskite type SrIrO3 single crystal film material at epitaxy of the surface of the perovskite type substrate. The preparation method of the perovskite type SrIrO3 single crystal film material is characterized in that an oxide molecular beam epitaxy technology is utilized, ultrahigh vacuum equipment hardware and a simple substance evaporator source are selected, an evaporator source beam flow is stably controlled, the substrate is selected and treated, and thin film synthesis parameters are stably controlled, so that a high-quality perovskite type SrIrO3 single crystal film material is prepared. Compared with a bulk material, the single crystal film material has great advantages and is of a stable-state perovskite type structure, an epitaxial film surface is a natural smooth cleavage surface, testing of an electronic structure can be facilitated, and testing can be carried out more smoothly due to high cleanliness of sample surface.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

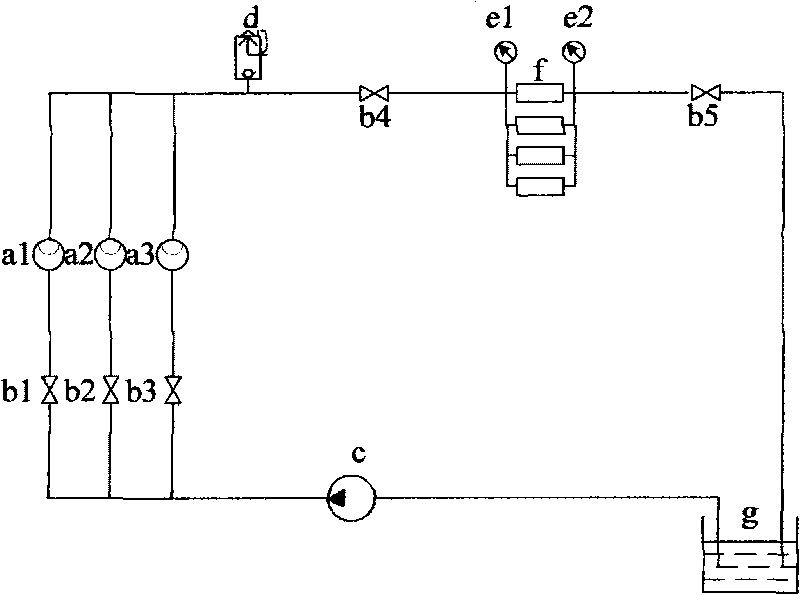

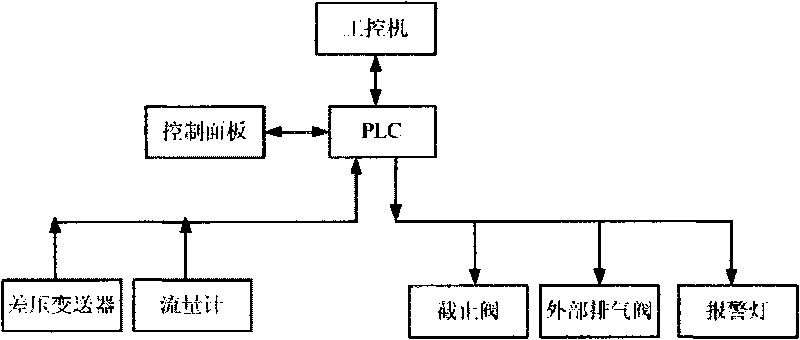

Test platform of balance valve

ActiveCN101738312ARealize automatic controlReduce labor intensityMachine part testingAutomatic controlPressure difference

The invention relates to a test platform of a balance valve, which comprises a test loop, wherein the test loop mainly comprises a water tank, a pressure stabilizing water pump, a flow detecting pipeline and a balance valve interface unit which are connected in series by water pipes; the balance valve interface unit comprises one or more balance valve interface branches; each balance valve interface branch is provided with a balance valve interface and a pressure detecting instrument for detecting a pressure difference at both ends of the balance valve interface; the balance valve interface branches are connected in parallel; and all the balance valve interfaces have same or different connecting structures. The platform realizes a detecting test of the balance valves with different diameters, is convenient for the detection of the balance valve and can also carry out automatic control by a control device, have stable detecting result and small offset and improve the detecting efficiency.

Owner:IDC PLUMBING & HEATING TECH BEIJING

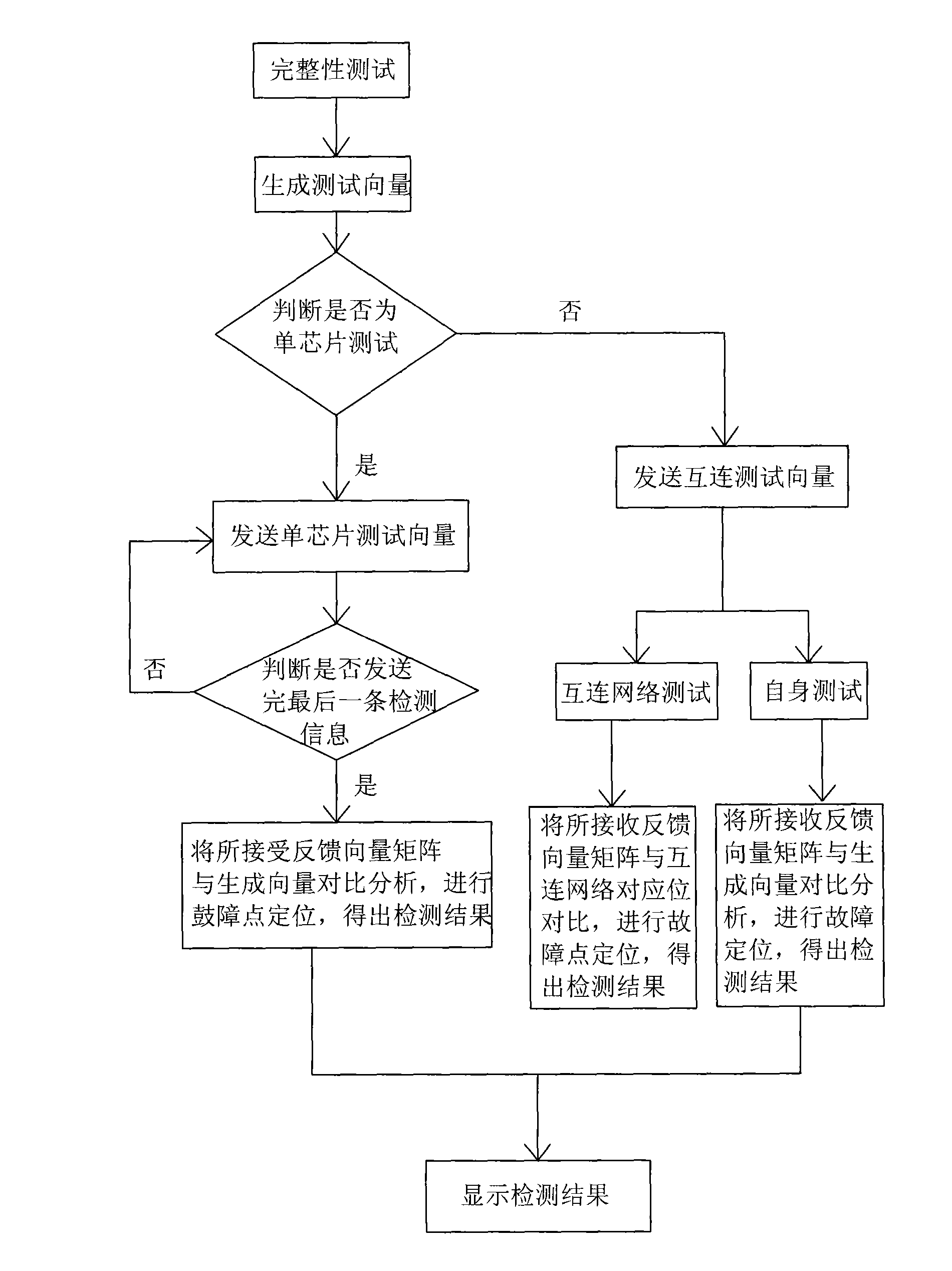

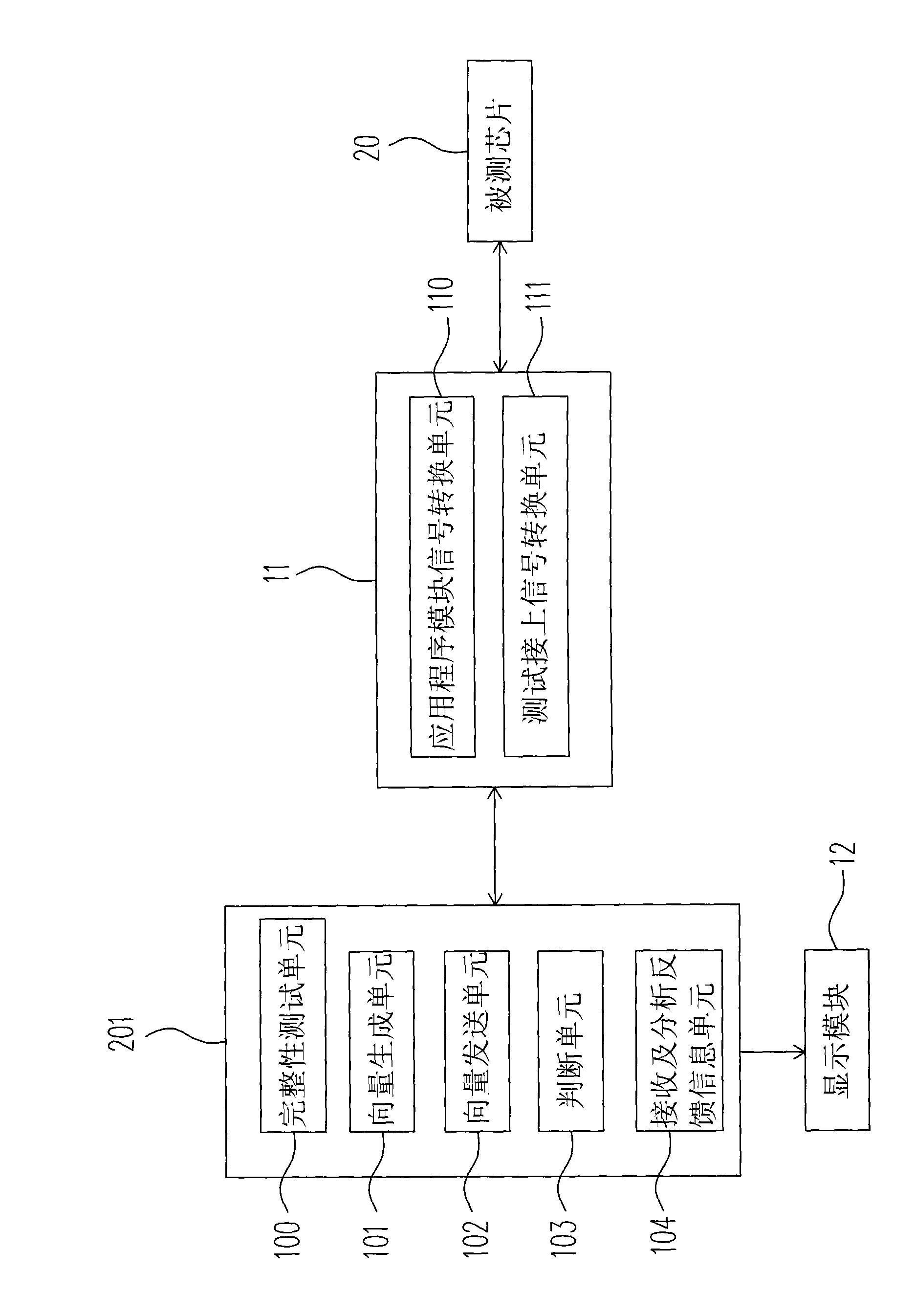

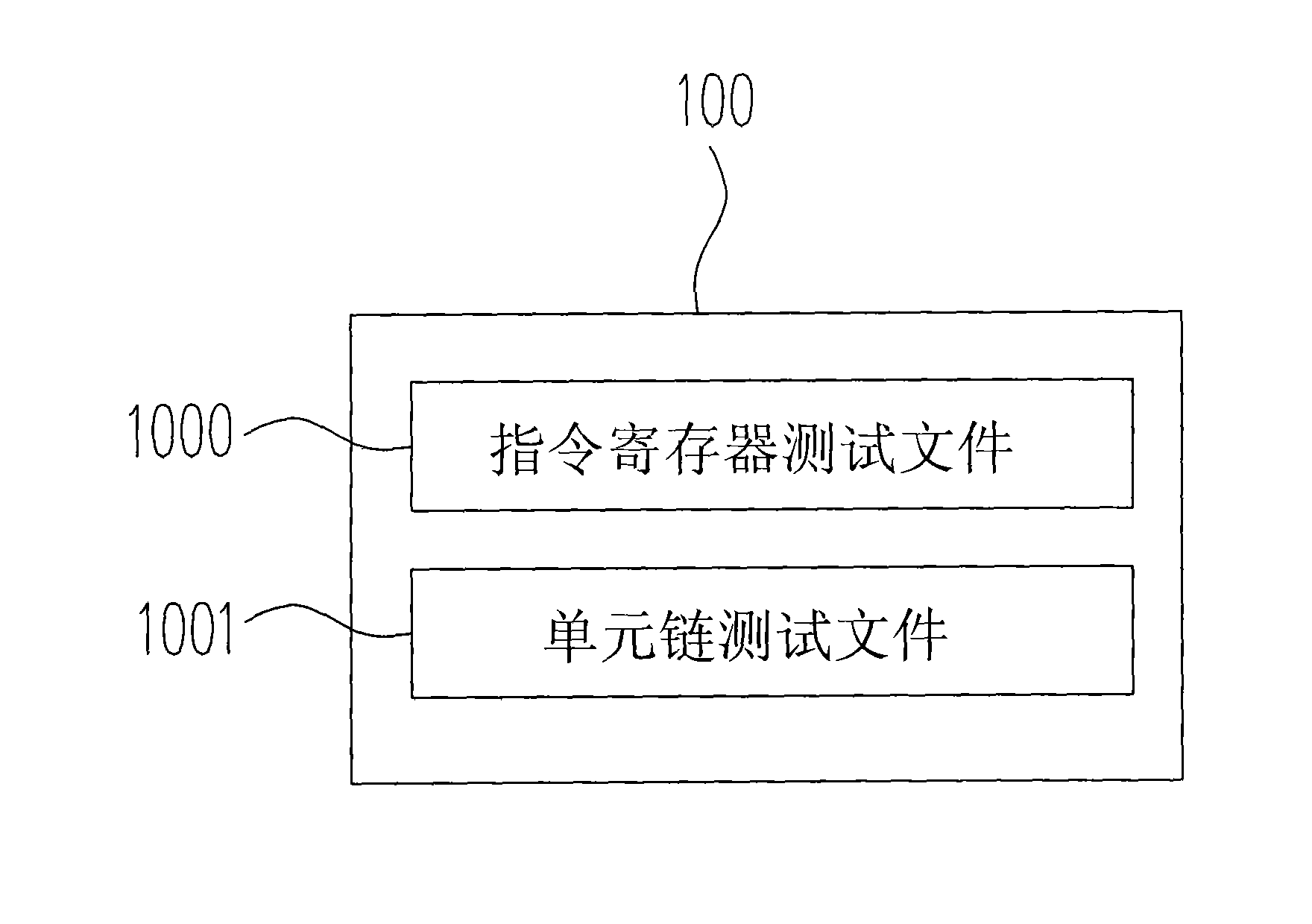

Boundary scanning chip failure detection device and method

InactiveCN101526581ARealize communicationTest coherenceElectronic circuit testingApplication moduleEmbedded system

The invention discloses a boundary scanning chip failure detection device and a method. A test interface connected to a detected chip by an application program fully detects the detected chip. The device comprises an application program module, a receiving and analyzing feedback information unit and a display module, wherein the application program module is provided with a vector sending unit which can send a test vector to the detected chip and detect a detected main board; the receiving and analyzing feedback information unit receives the feedback information of the detected chip and acquires the detection results through analyzing the feedback information; and the display module displays the detection results acquired by analyzing the feedback information through the application program module. The method comprises the following steps: a, sending the test vector to the detected chip; b, receiving and analyzing the feedback information of the detected chip; and c, displaying the detection results acquired by analyzing the feedback information. The device and the method achieve full detection of the detected chip, and can successfully detect question points of the detected chip and accurately position; and the test is more convenient.

Owner:MITAC COMP (SHUN DE) LTD

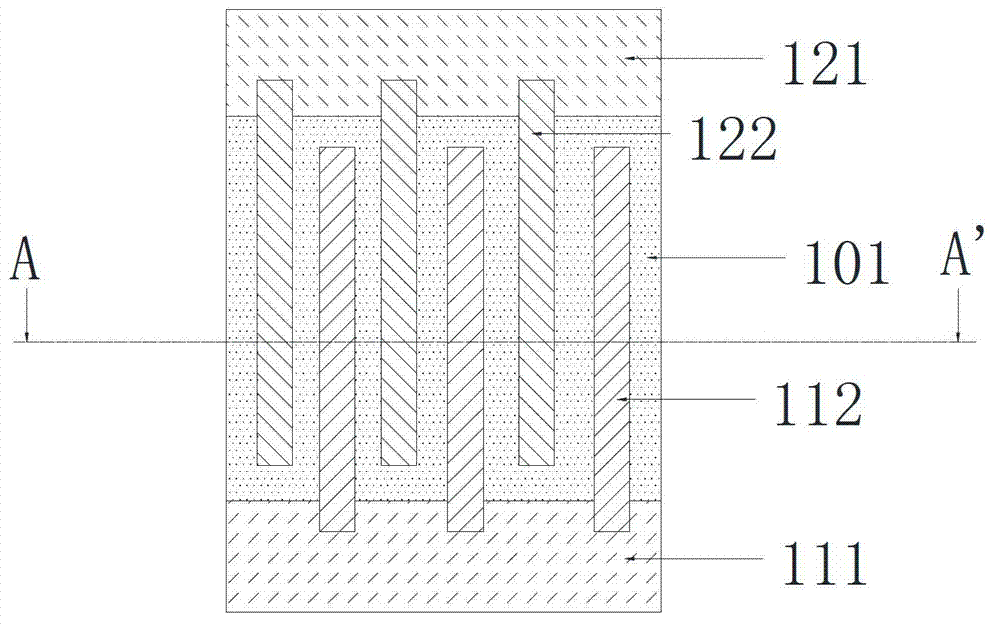

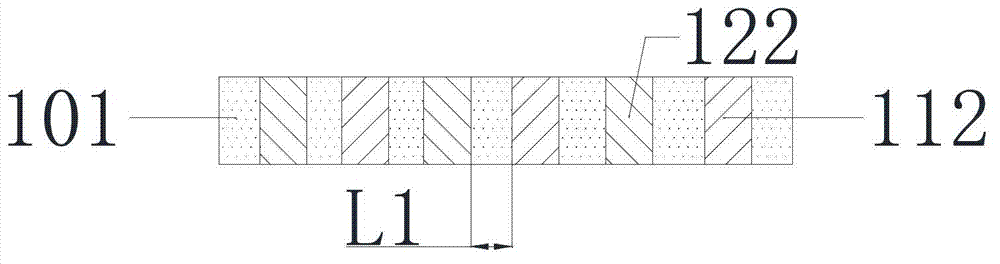

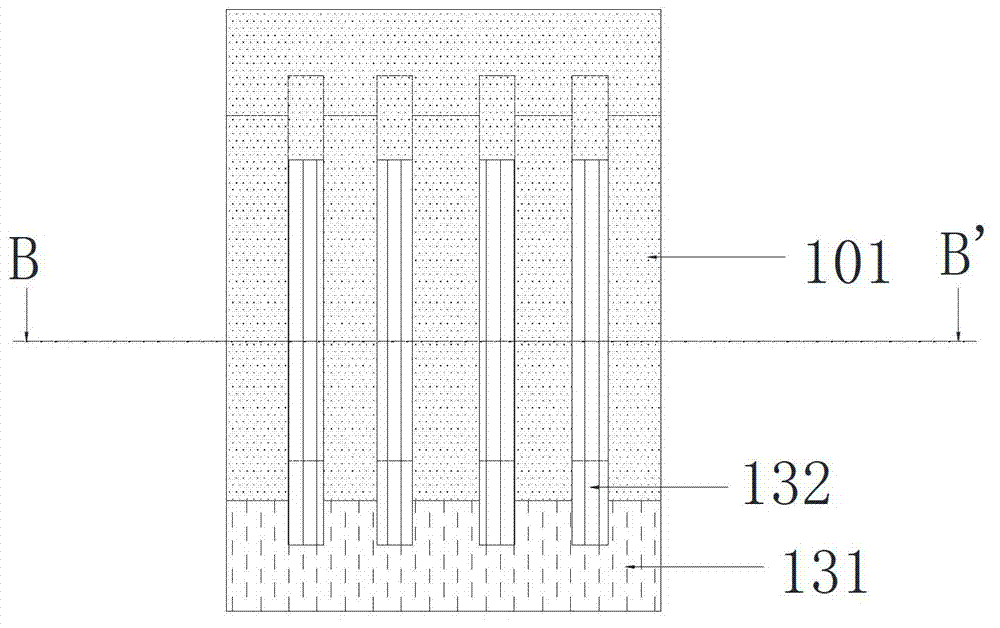

Test structure for dielectric breakdown reliability analysis in integrated circuit and test method thereof

ActiveCN103594453AGuaranteed accuracyAccurate assessmentTesting dielectric strengthSemiconductor/solid-state device detailsElectricityEngineering

The invention discloses a test structure of dielectric breakdown reliability analysis in an integrated circuit. The test structure comprises a lower layer metal wire structure, an upper layer metal wire structure, a through hole structure and a dielectric medium, wherein the lower layer metal wire structure comprises a first metal wire structure and a second metal wire structure which are arranged at intervals. The invention further discloses a test method of the test structure. The test method comprises the steps of providing a substrate, and forming an actual structure to be tested on the substrate according to the test structure; and measuring the dielectric breakdown reliability between adjacent metal wires of the lower layer metal wire structure in the actual structure to be tested, the dielectric breakdown reliability between the upper layer metal wire structure and the upper layer metal wire structure in the actual structure to be tested, and the dielectric breakdown reliability between a through hole and the adjacent second metal wire structure in the actual structure to be tested. The test structure disclosed by the invention can accurately evaluate places which require to be evaluated in dielectric medium voltage resistance of an actual circuit, thereby ensuring the accuracy of interconnecting wire reliability analysis.

Owner:SEMICON MFG INT (SHANGHAI) CORP

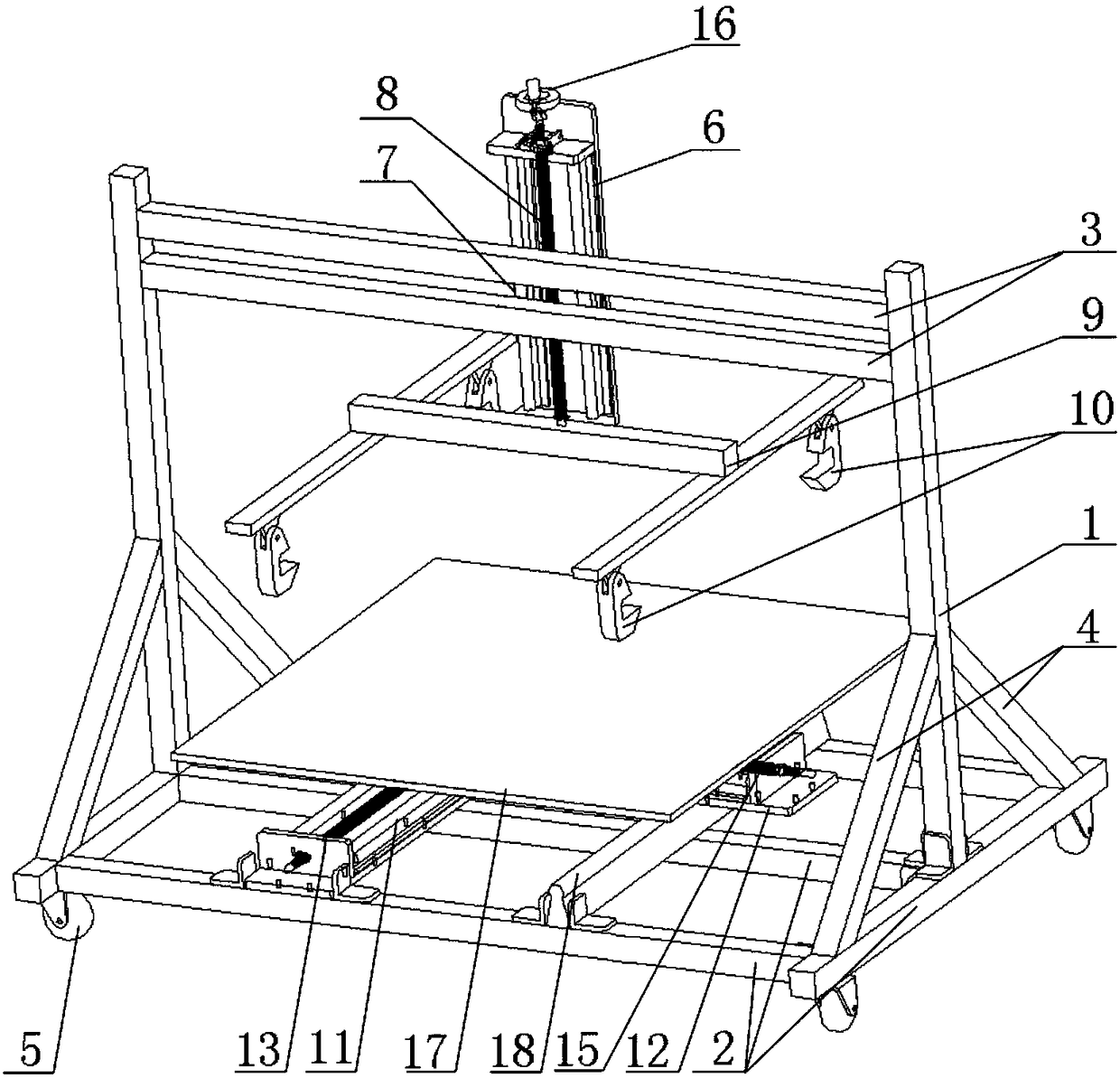

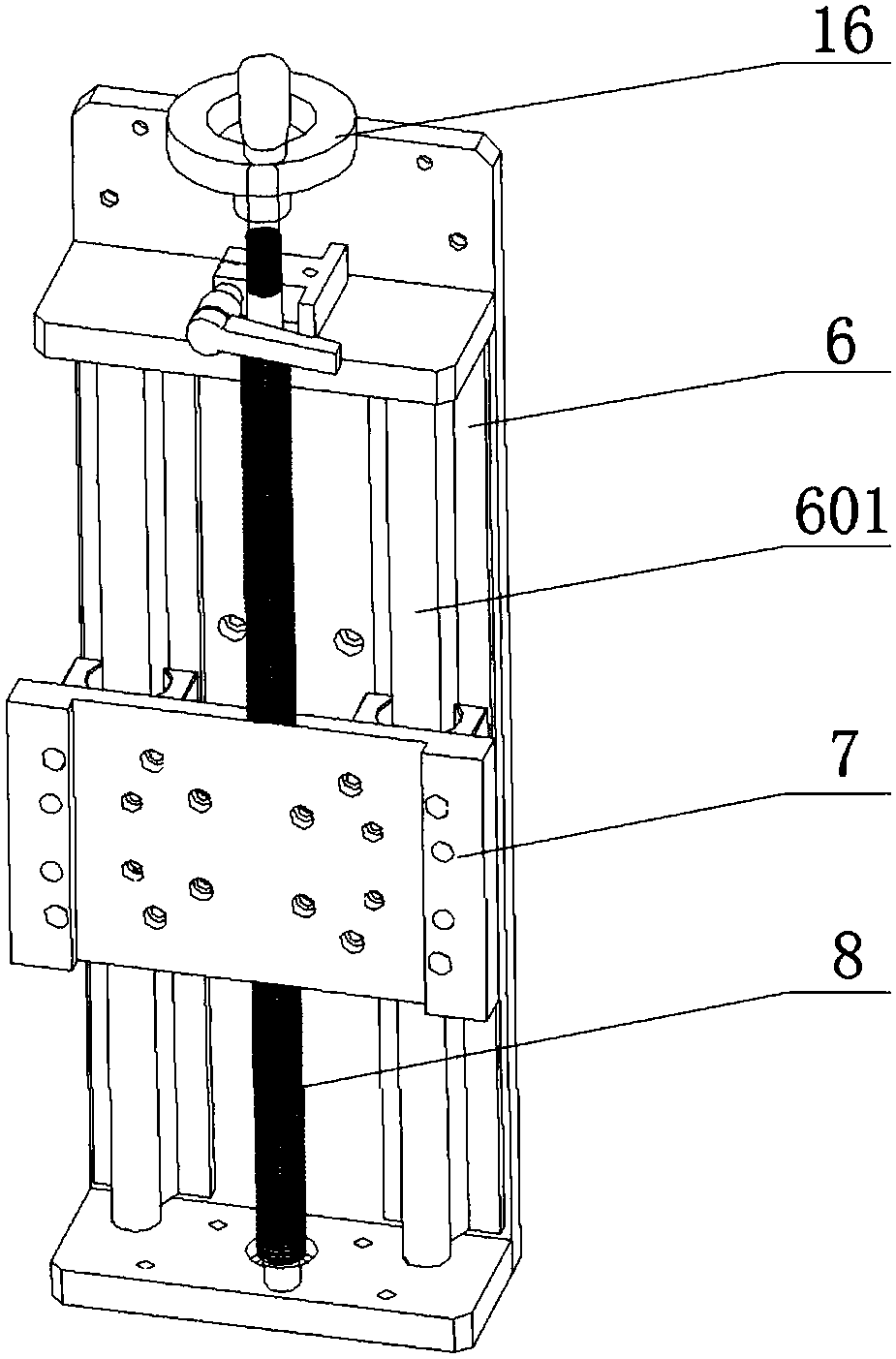

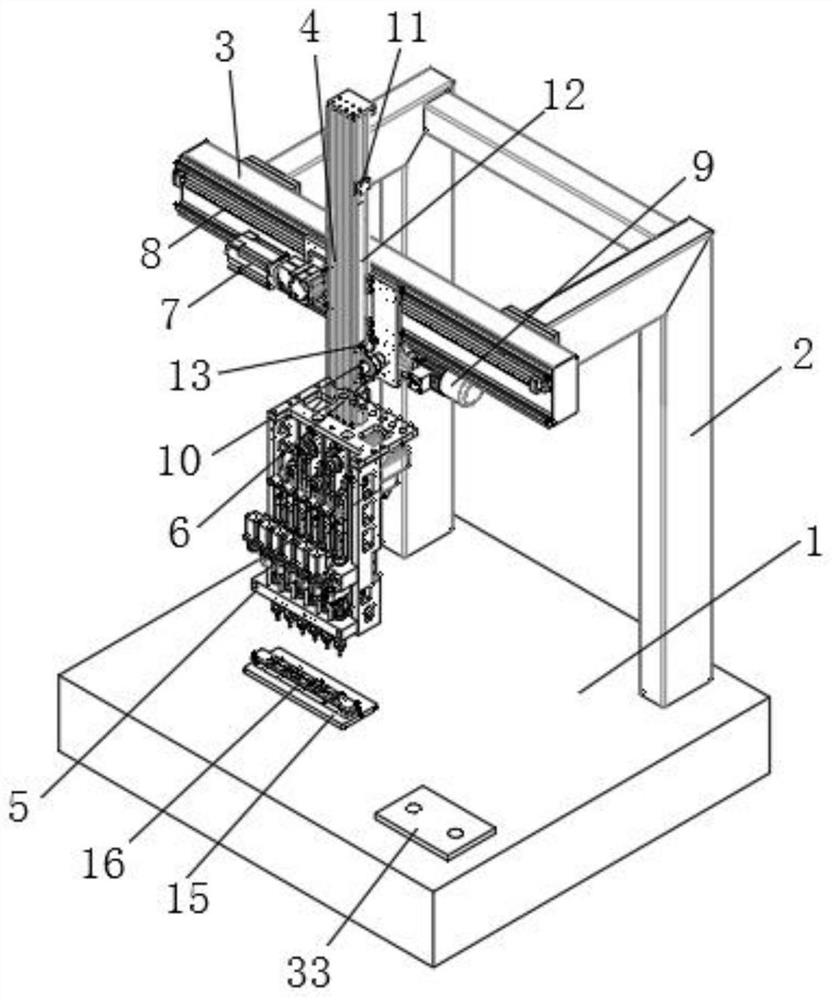

Automatic startup and shutdown device of mobile phone

ActiveCN103905591AReduce labor costsSolve the problem that the mobile phone cannot be controlled to switch on and offSubstation equipmentKey pressingEngineering

The invention provides an automatic startup and shutdown device of a mobile phone. The device comprises a base (1), a transverse sliding rail (2), a longitudinal sliding rail (8) and a key control device, wherein the transverse sliding rail (2) is parallel with the longitudinal sliding rail (8), so that a sliding block (6) of a fixture freely moves in the X direction and the Y direction; the key control device comprises the longitudinal sliding rail (8), a lifting guide rail (11) and a horizontal guide rail (14). Because of the structure, a horizontal key (16) can move in the X direction and the Z direction, a vertical key (17) can move in the X direction, the Y direction and the Z direction, the device is matched with the fixture of the mobile phone to move in the X direction and the Y direction, and startup motion testing is completed. The fixture is flexible to modulate according to the size and applicable to mobile phones of various sizes (including ultrathin large sizes) and types (flip phones and bar phones), and the mobile phone can be placed horizontally and vertically. A manipulator moves in the X direction, the Y direction and the Z direction through an electromagnet, and the requirements for mobile phone sizes and key positions are met.

Owner:CHINA ACADEMY OF INFORMATION & COMM +1

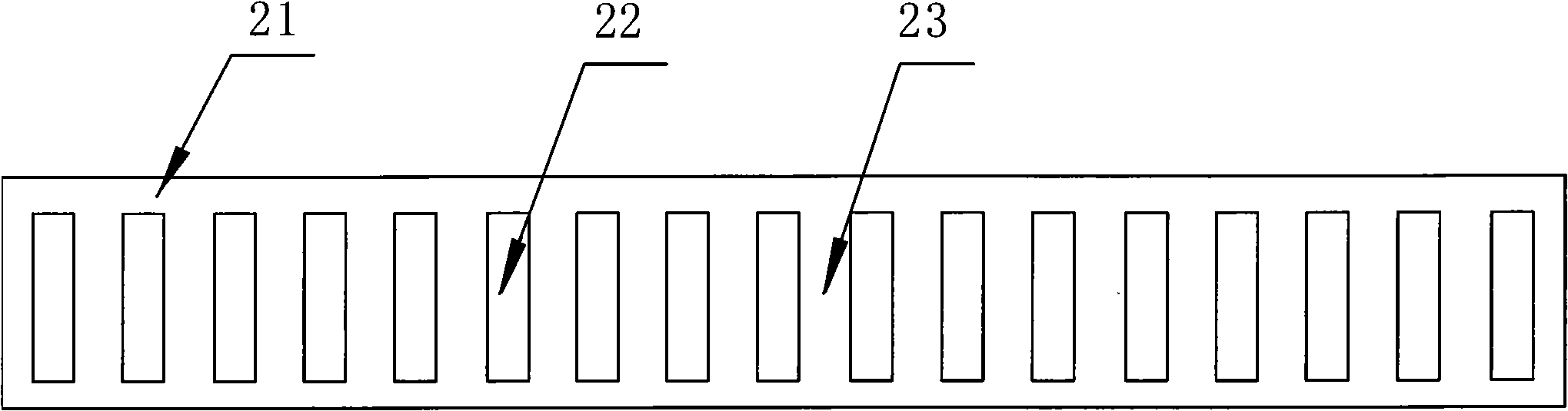

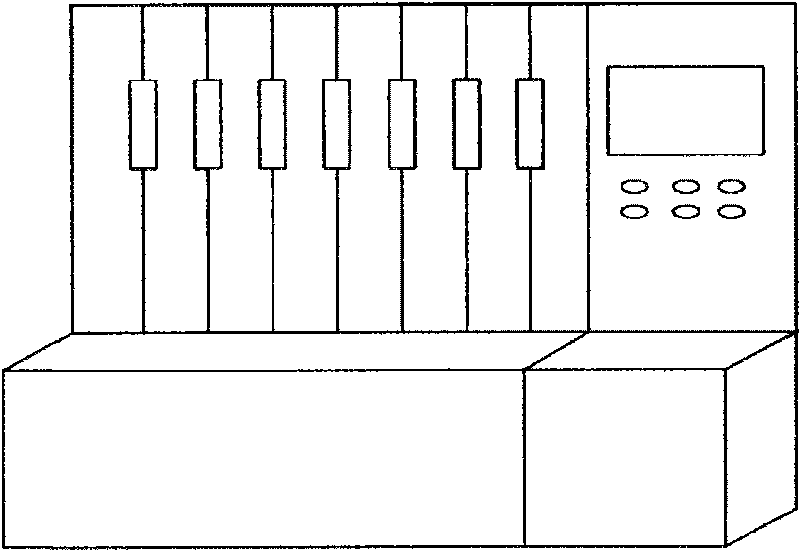

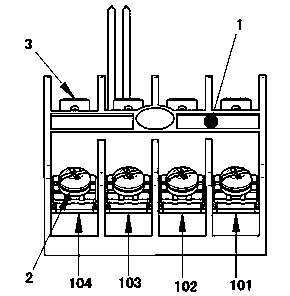

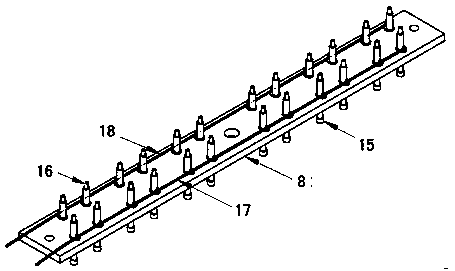

Automatic terminal voltage resistance and insulation test system and control method

ActiveCN104297650AImprove test efficiencyReduce labor costsTesting dielectric strengthMeasurement instrument housingTest efficiencyTerminal voltage

The invention relates to an automatic terminal voltage resistance and insulation test system. The automatic terminal voltage resistance and insulation test system comprises a test device. The test device comprises a machine frame, wherein the machine frame is composed of an upper supporting plate, a lower supporting plate and an unthreaded shaft supporting pillar, the upper supporting plate and the lower supporting plate are arranged in parallel with the upper supporting plate above the lower supporting plate, the unthreaded supporting pillar is connected between the upper supporting plate and the lower supporting plate, a terminal installing plate is installed on the upper end face of the lower supporting plate, a plurality of terminal sleeving rods are distributed on the upper end face of the terminal installing plate side by side in the long axis direction of the terminal installing plate, every two adjacent terminal sleeving rods are separated by a separating plate, a probe plate which can move vertically is movably hung below the upper supporting plate, and a plurality of probe sets are distributed on the probe plate in the long axis direction of the probe plate. The automatic terminal voltage resistance and insulation test system has the advantages that the test device is simple in structure and sequentially tests a plurality of terminals automatically at the same time, the test efficiency of the terminals is improved, and labor cost is reduced.

Owner:NAN TONG HUAGUAN ELECTRIC CO LTD

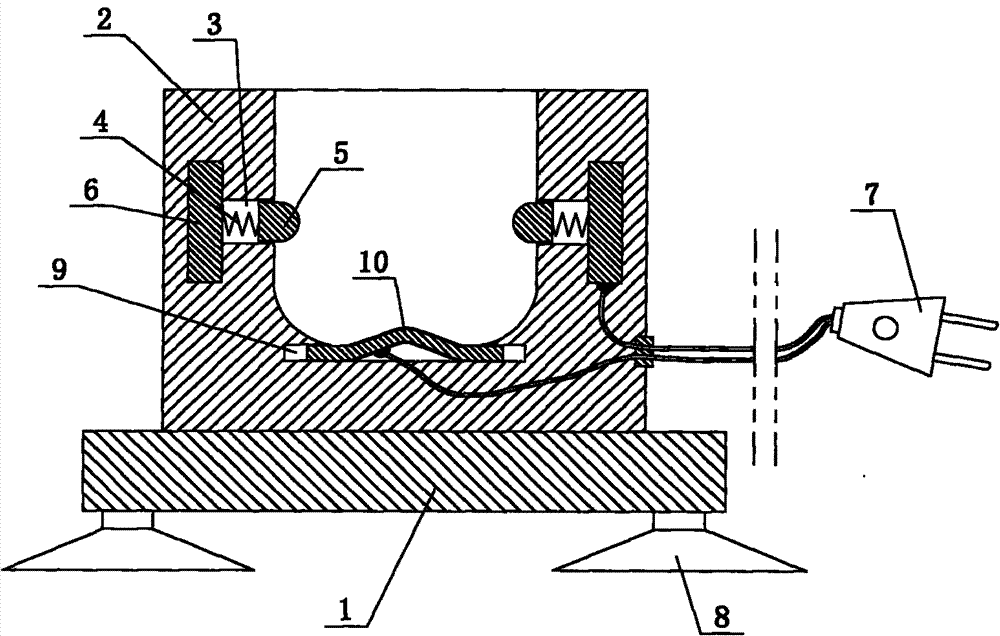

Lamp holder for bulb test

The invention relates to a lamp holder for a bulb test. The lamp holder comprises a base and a lamp cap sleeve installed on the base. The lamp holder is structurally characterized in that at least one counter bored hole is formed in the inner side wall of the lamp cap sleeve, a positioning pin with the front end stretching out of the counter bored hole is installed in the counter bored hole through a spring, and a metal ring electrically connected with the positioning pin is arranged in the lamp cap sleeve. An elastic metal piece is arranged on the inner bottom wall of the lamp cap sleeve, and the metal ring and the elastic metal piece are respectively connected with a power source plug through conductive lines. The front end portion of the positioning pin is in the shape of a semi sphere. A plurality of packing cup type suction discs are installed on the base. An annular inserting groove is formed in the bottom of the inner side wall of the lamp cap sleeve, the middle of the elastic metal piece protrudes outwards, and the two ends of the elastic metal piece are arranged in the annular inserting groove in an inserted mode. The lamp holder for the bulb test has the advantages of being simple in structure, convenient to use and high in testing efficiency.

Owner:高密市佰邦家政保洁服务有限公司

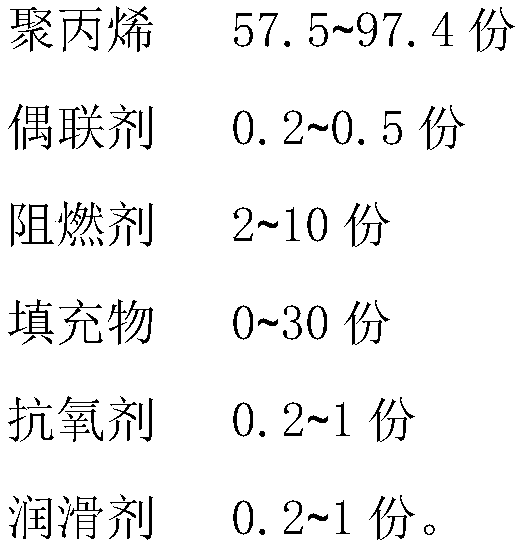

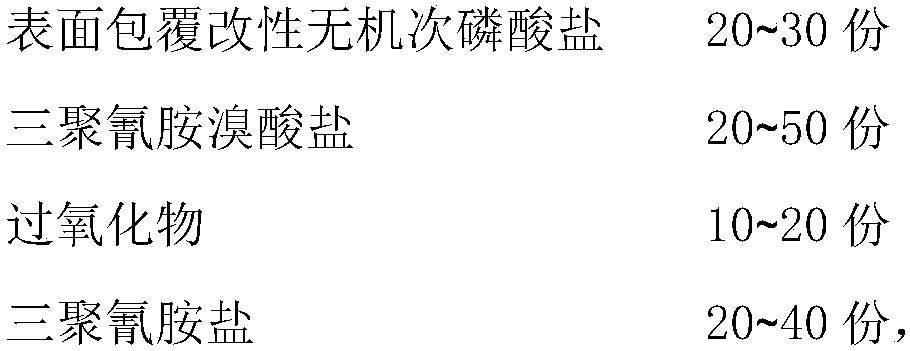

Low-smell flame retardant polypropylene material having needle flame property and preparation method of retardant polypropylene material

ActiveCN107903496AImprove heat resistanceImprove poor friction resistancePolypropyleneFire retardant

The invention relates to a flame retardant material, and particularly relates to a low-smell flame retardant polypropylene material having a needle flame property and a preparation method of the retardant polypropylene material. The preparation method of the retardant polypropylene material comprises the following various substances by weight: 57.5-97.4 parts of polypropylene, 0.2-0.5 part of a coupling agent, 2-10 parts of a flame retardant, 0-30 parts of filler, 0.2-1 part of an antioxidant, and 0.2-1 part of a lubricant. The flame retardant polypropylene material can effectively meet the requirements on low smell and needle flame.

Owner:广东顺德同程新材料科技有限公司

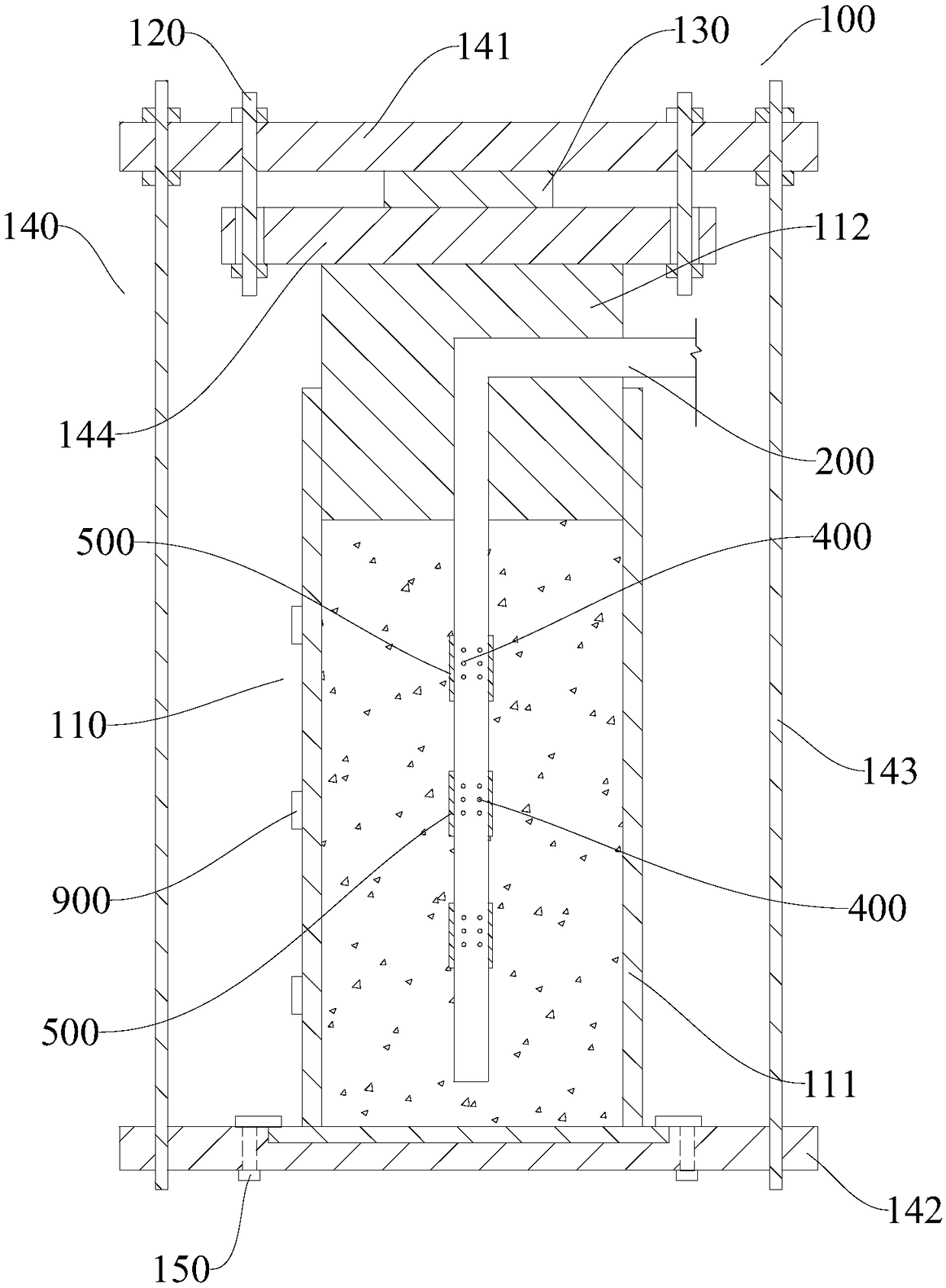

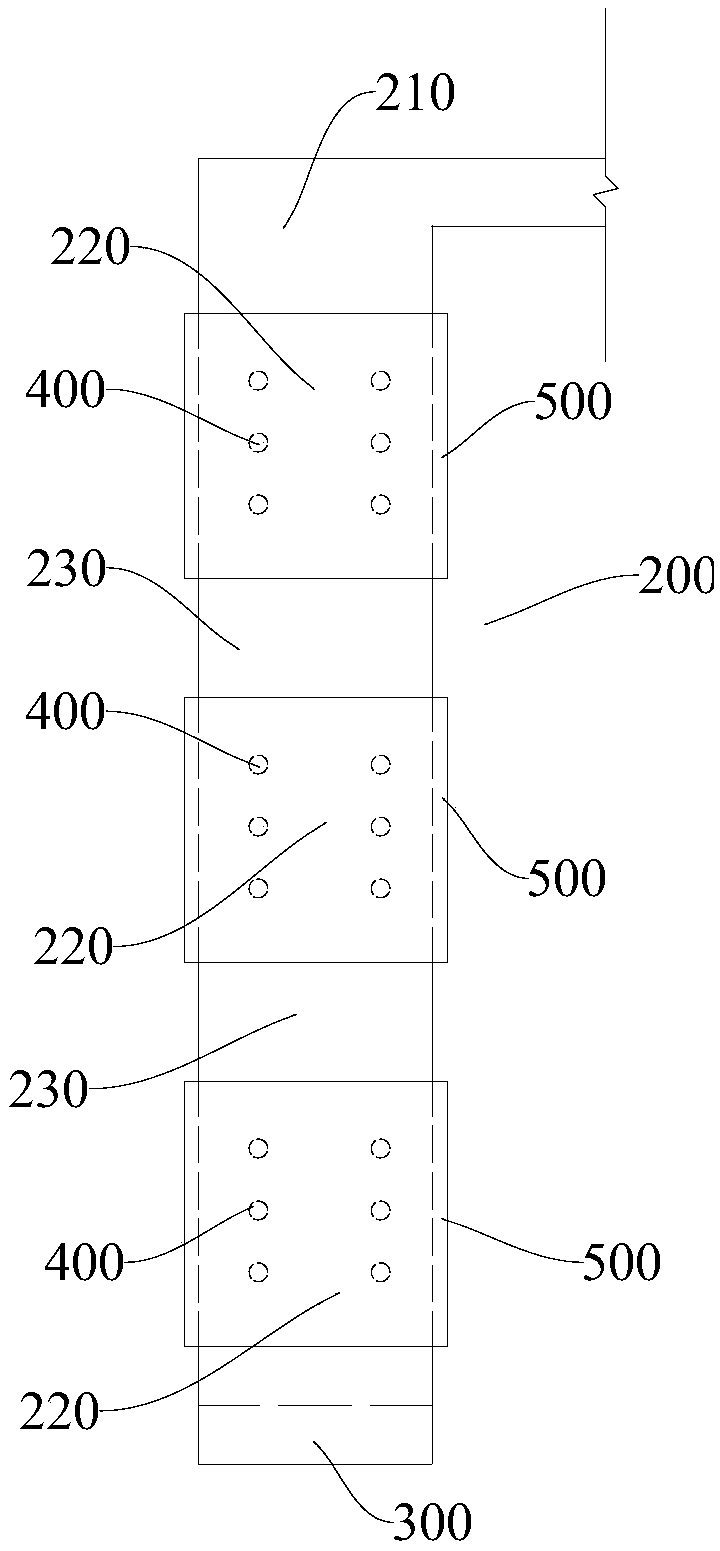

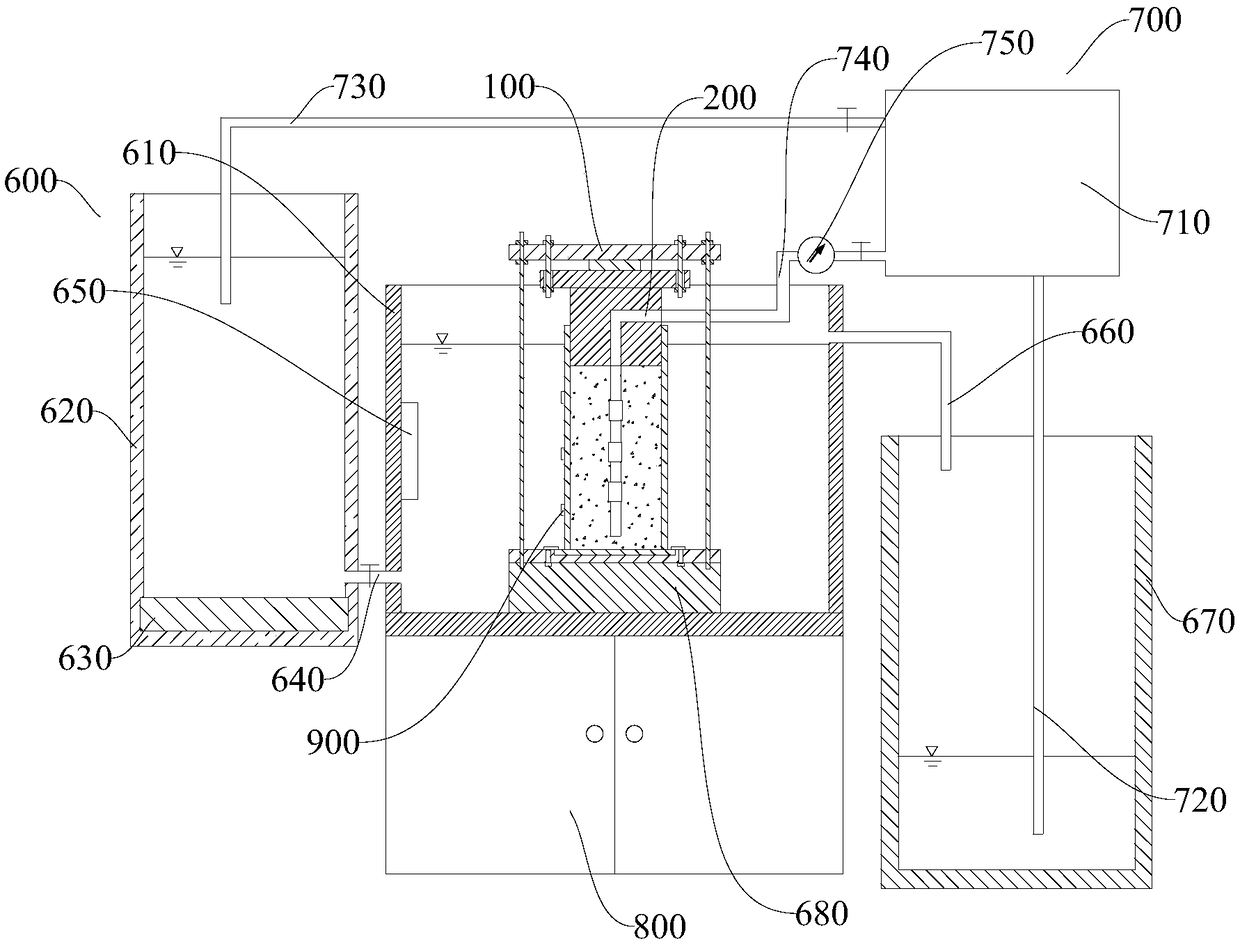

Bending and anti-cracking performance testing device and testing method

PendingCN109490096AAvoid breakageReduces the effects of bending fracturesMaterial strength using steady bending forcesTest fixtureTraining set

The invention discloses a bending and anti-cracking performance testing device and a testing method. The testing device comprises a base, clamping mechanisms, force application mechanisms and a bending guiding mechanism, wherein the clamping mechanism is used for clamping a test piece; the force application mechanisms are used for supporting and driving the clamping mechanism; when one pair of theforce application mechanisms get close to each other, the test piece is bent and the clamping mechanisms located at the end parts of the force application mechanisms are driven to rotate in the forceapplication mechanisms; and the bending guiding mechanism is used for limiting the test piece to be bent in the direction of the bending guiding mechanism. According to the bending and anti-crackingperformance testing device, the clamping mechanisms rotate in the force application mechanisms so as to prevent the test piece from being subjected to a counter force to crack a clamping position; theforce application mechanisms get close to each other to drive the test piece to bend, and influences, caused by stress concentration, on bending and cracking of the test piece, are reduced, so that the accuracy of testing results is improved; and the bending guiding mechanism is arranged and the bending direction is controllable when the test piece is bent, so that photographing equipment is fixed at a certain part when operation including photographing, collection and the like needs to be carried out and other positions do not need to be adjusted, and a test is carried out smoothly.

Owner:NANJING COMM INST OF TECH

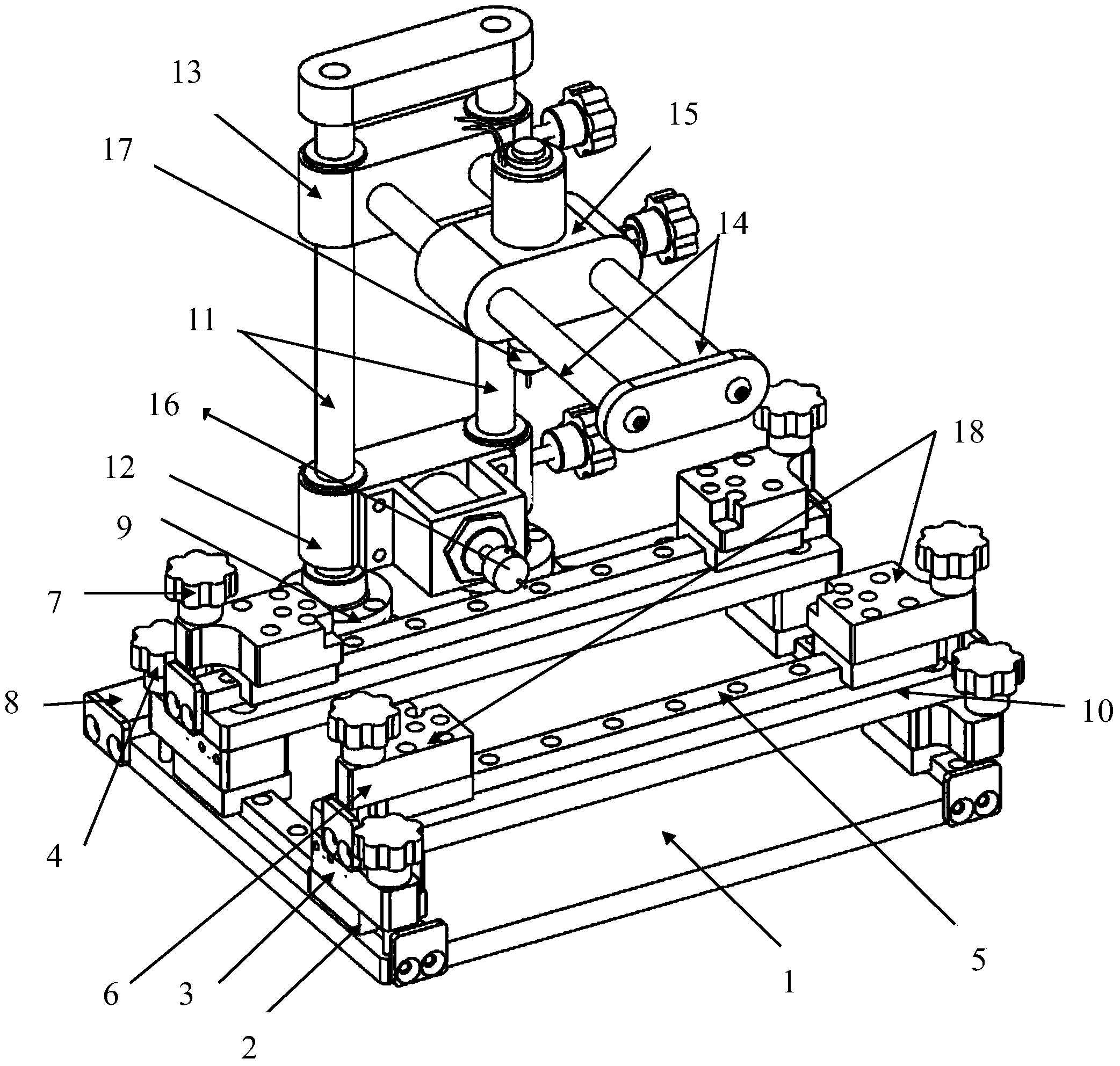

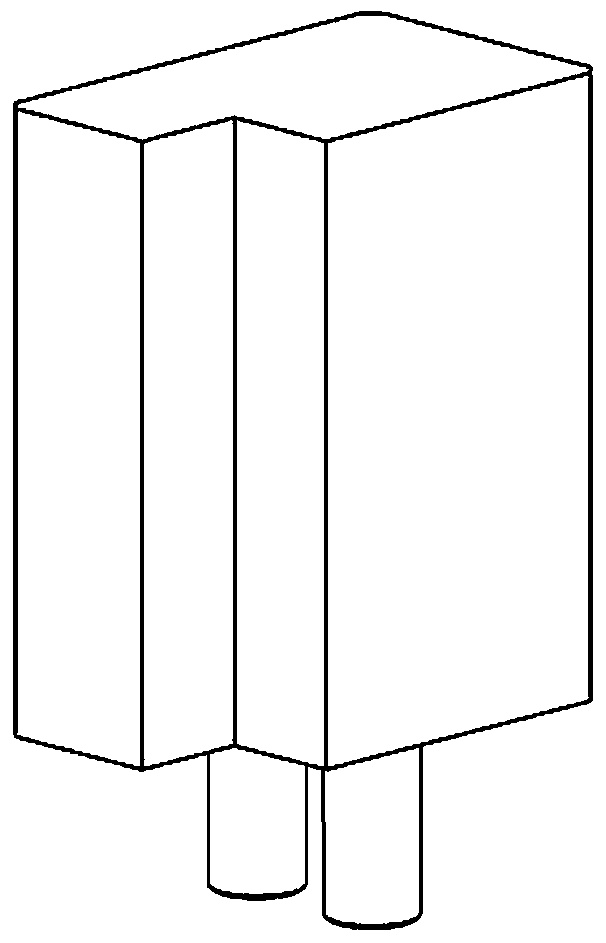

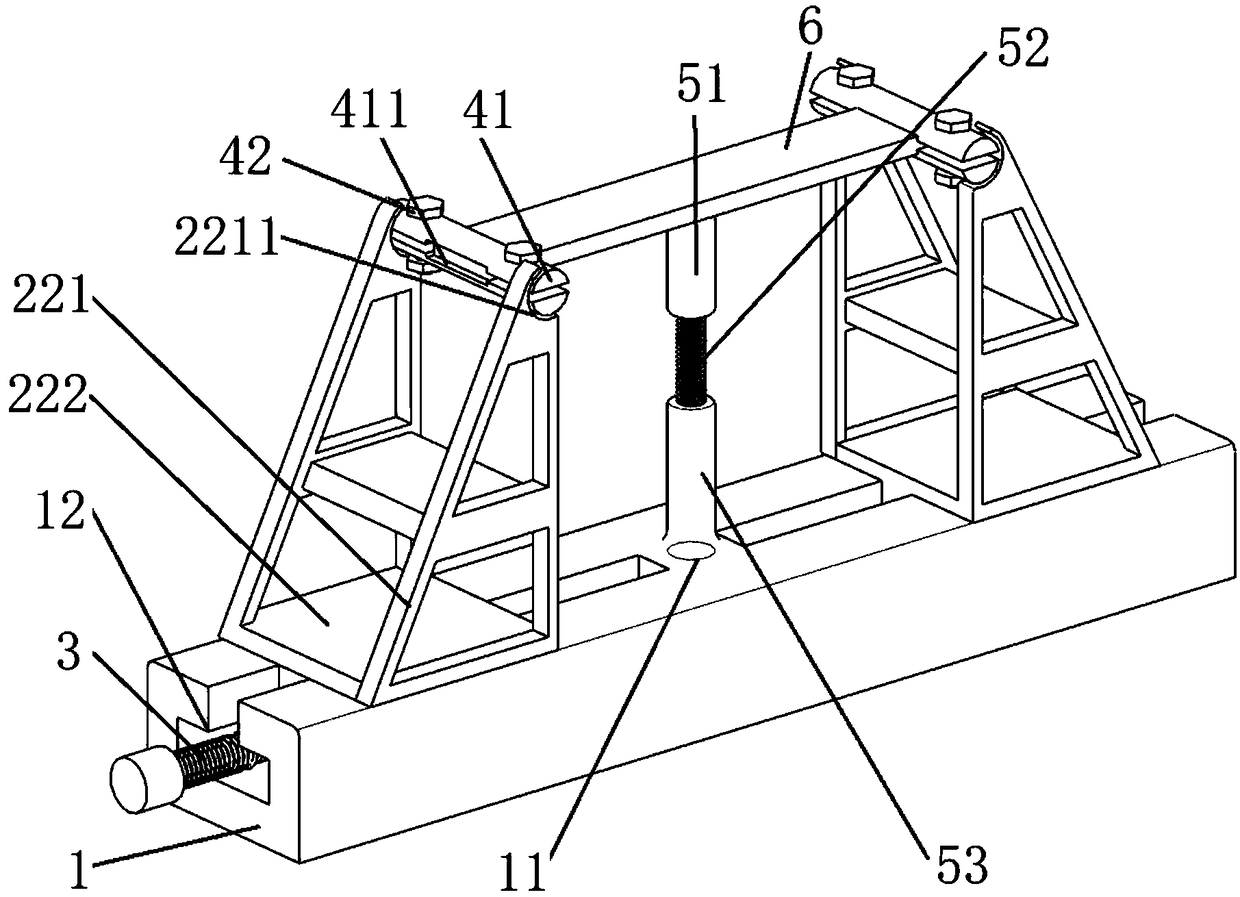

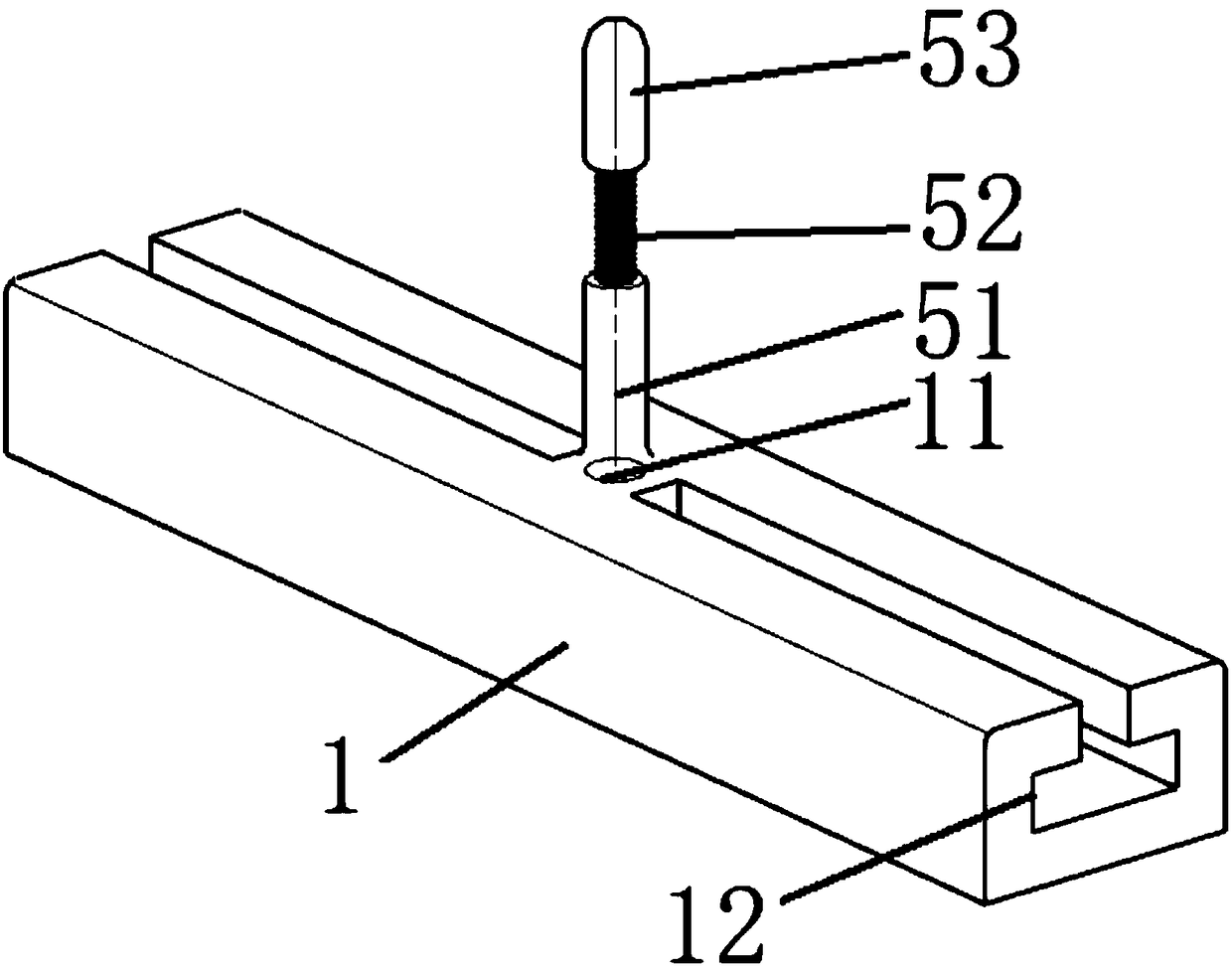

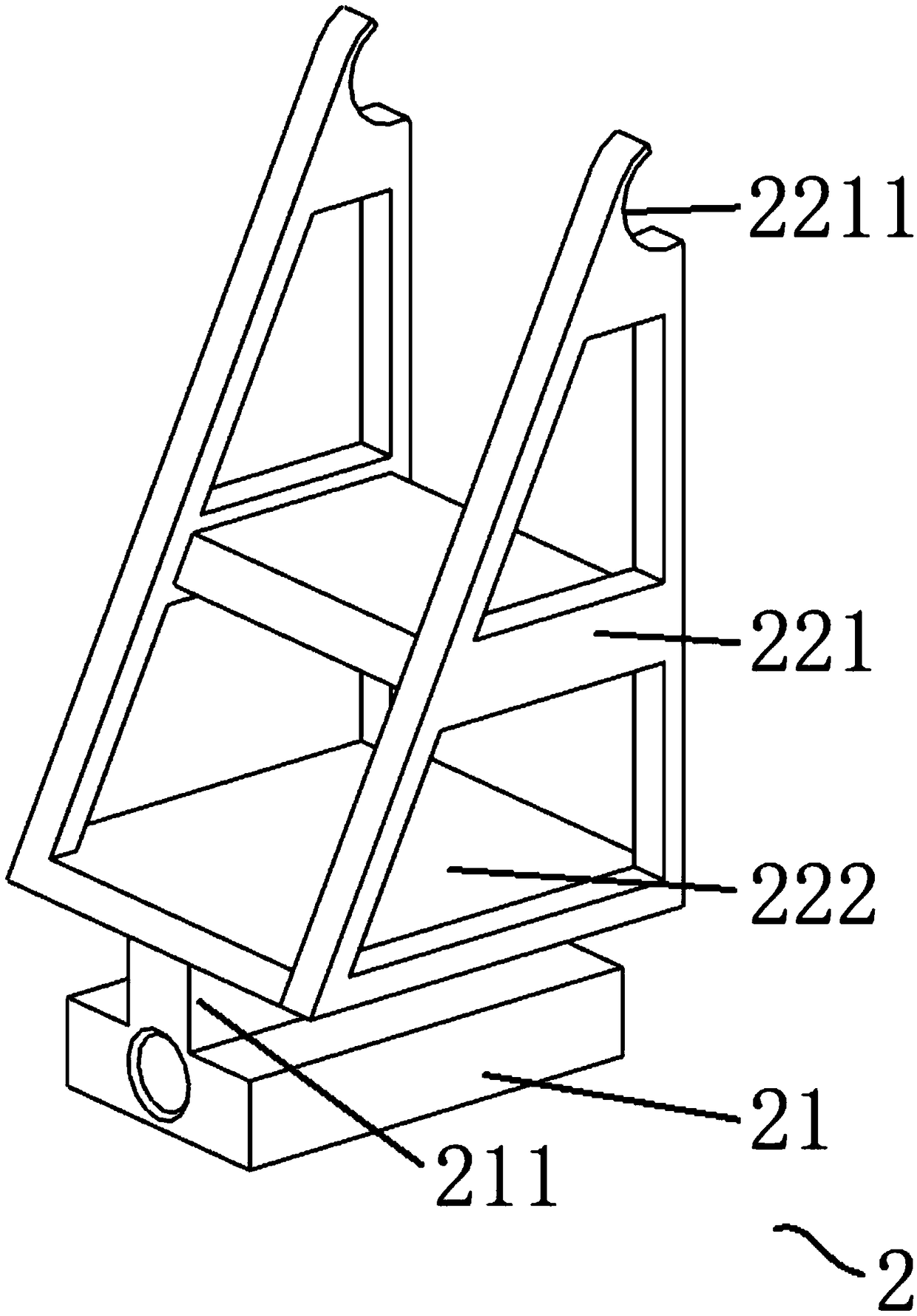

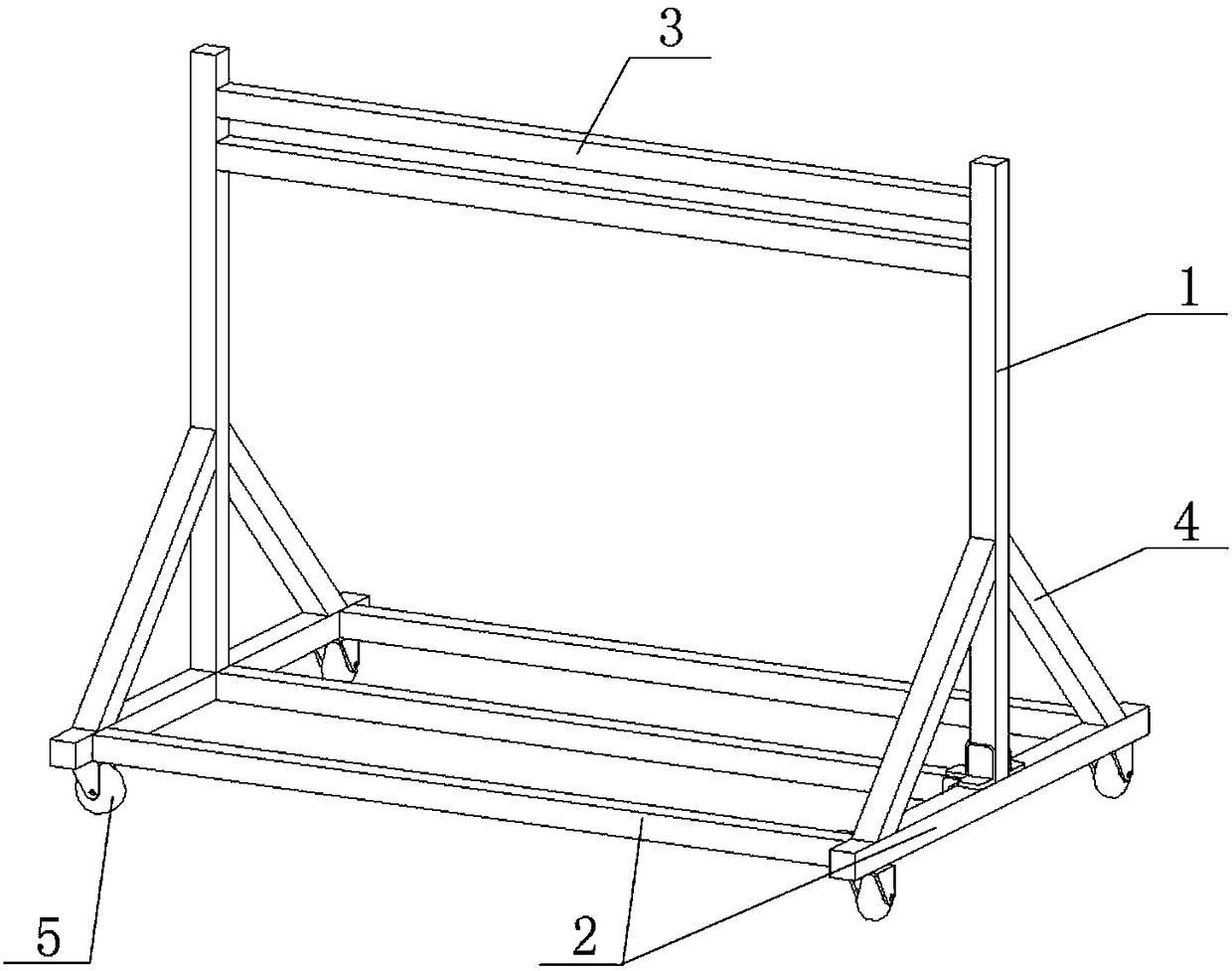

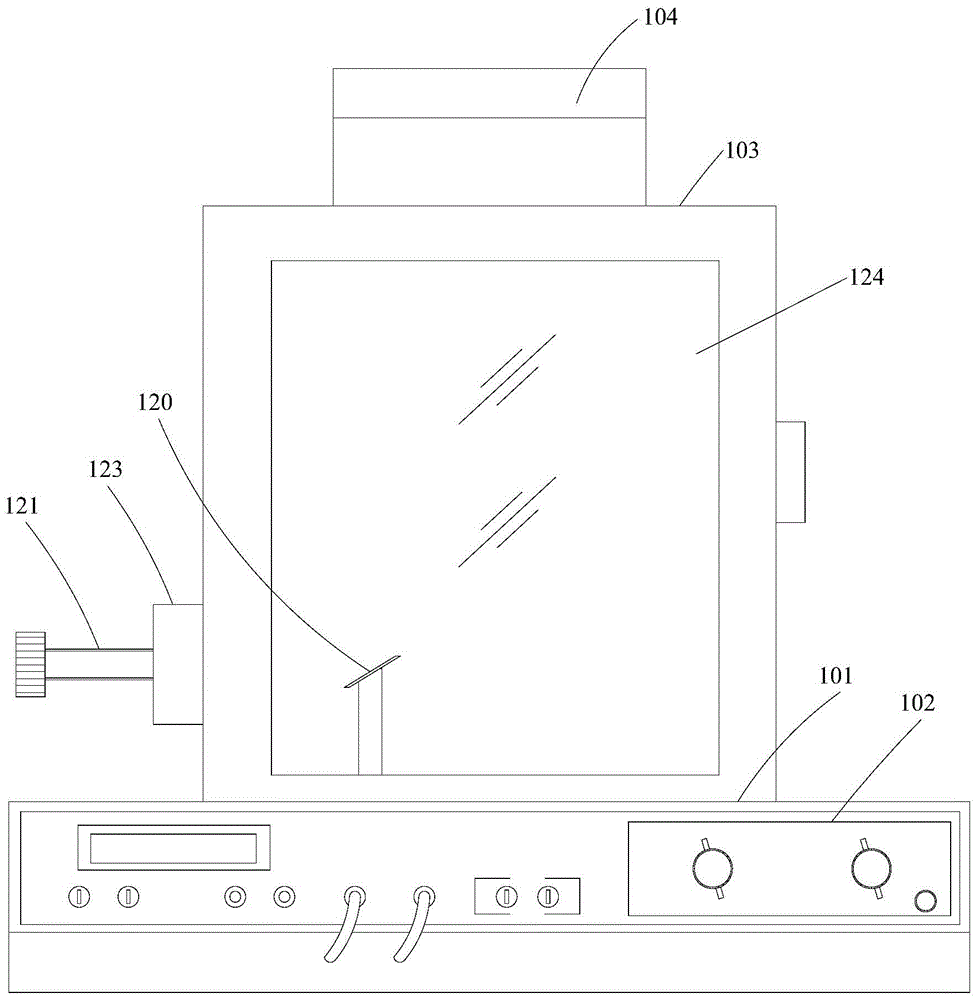

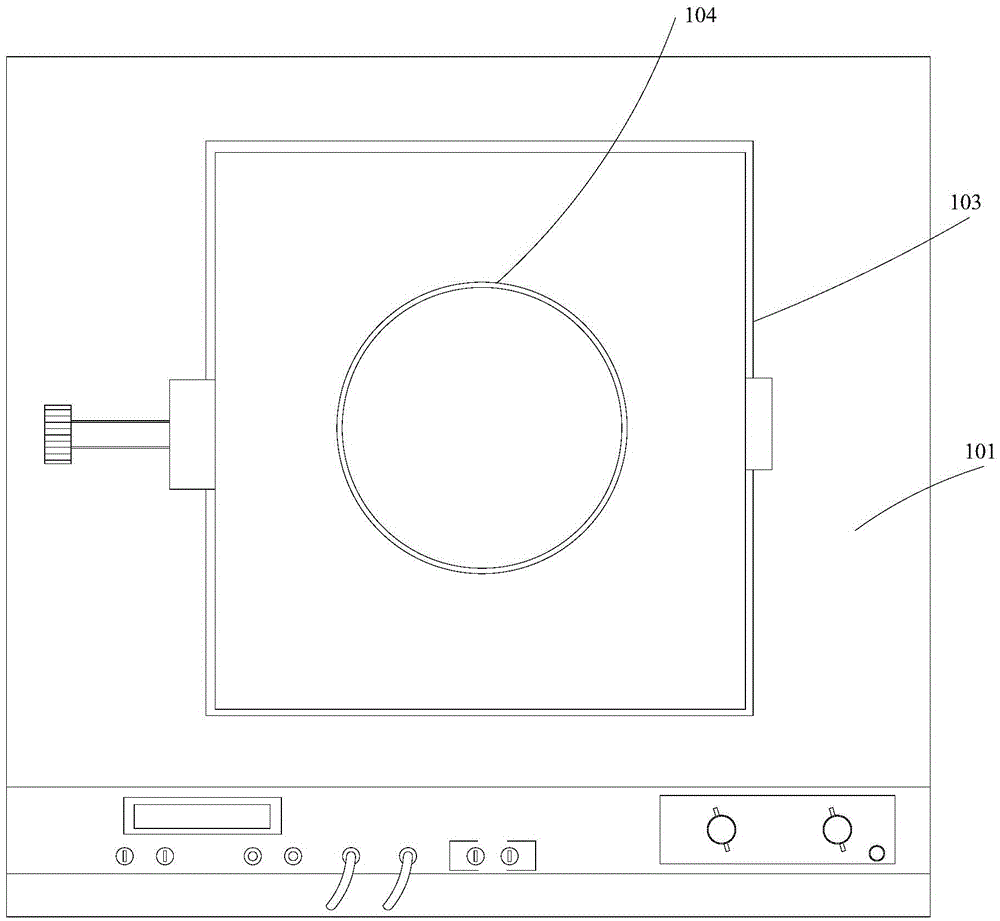

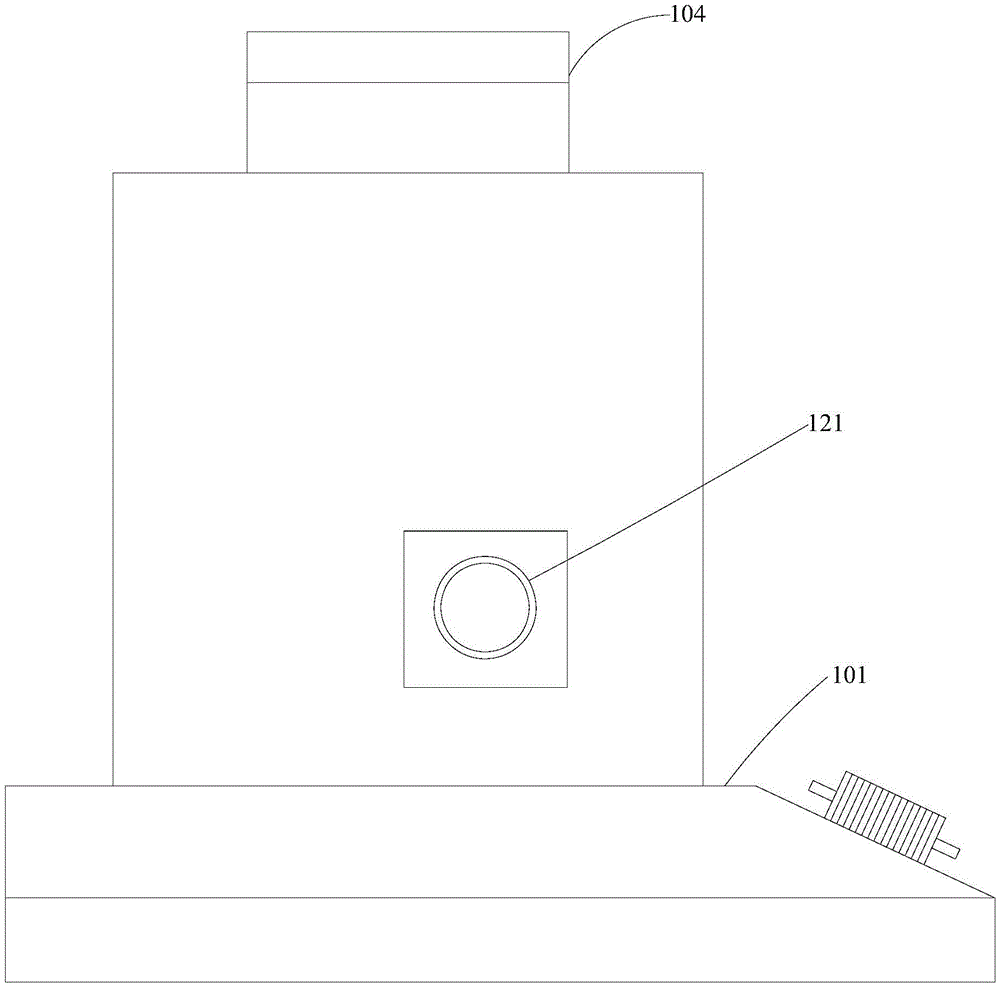

Test bracket for wireless charging device

ActiveCN108692756ATest coherenceImprove reliabilityMeasurement apparatus componentsEngineeringInductive charging

The invention discloses a test bracket for a wireless charging device. The test bracket includes a vertical motion mechanism which is used for mounting a receiving coil and driving the receiving coilto perform vertical motion, a horizontal motion mechanism which is used for mounting a transmitting coil and driving the transmitting coil to perform horizontal motion, and a supporting mechanism which is used for mounting the vertical motion mechanism and the horizontal motion mechanism. When testing is performed, a distance between the receiving coil and the transmitting coil can be changed by operating the vertical motion mechanism; the relative offset of the receiving coil and the transmitting coil can be changed by operating the horizontal motion mechanism; and at the same time, under thejoint action of the vertical motion mechanism and the horizontal motion mechanism, the test of the charging coil of a wireless charging pile device can be successfully completed; and since manual movement operation of the receiving coil and the transmitting coil is abandoned, instead, the movement operation of the receiving coil and the transmitting coil is realized through the mechanical movement of the vertical motion mechanism and the horizontal motion mechanism, the motion adjustment of the receiving coil and the transmitting coil has greater precision and accuracy, and at the same time,test accuracy and the reliability of test results are improved.

Owner:ZONECHARGE (SHENZHEN) WIRELESS POWER TECH CO LTD

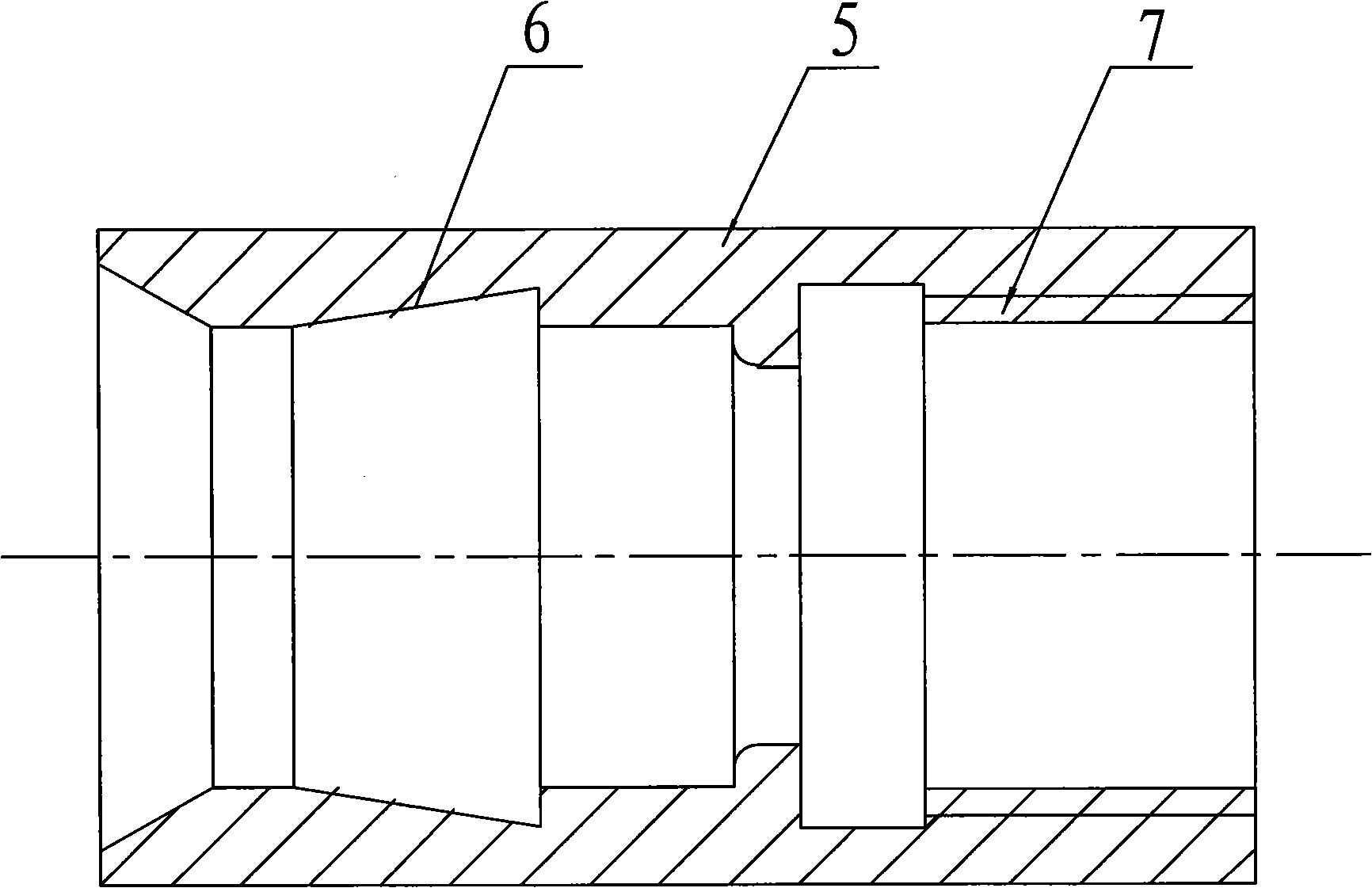

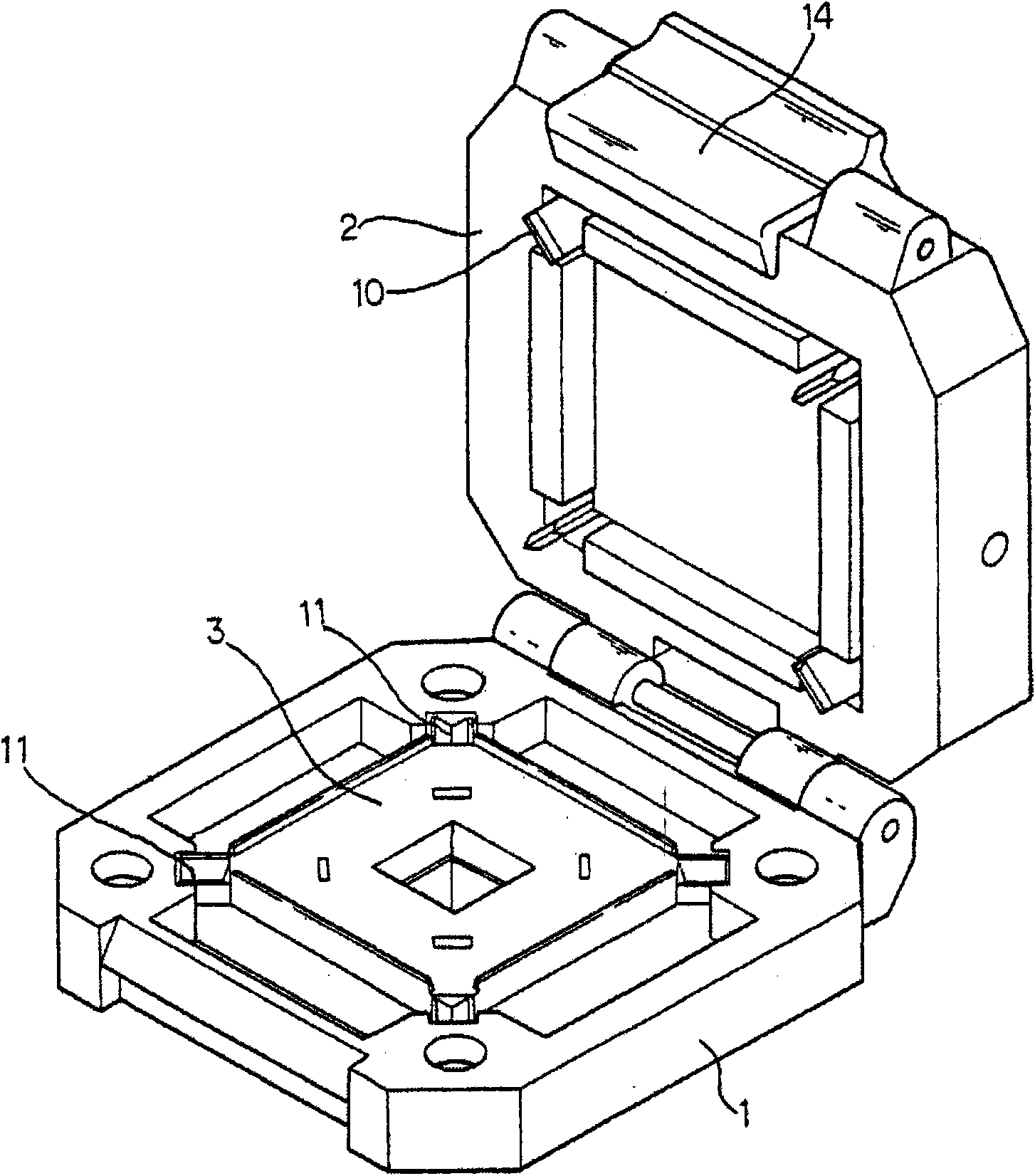

Wafer socket and method for detecting horizontal positioning of wafer

InactiveCN101577393AAvoid damageTest coherenceElectric discharge tubesCoupling contact membersEngineeringInductor

The invention relates to a wafer socket and a method for detecting horizontal positioning of wafer. The wafer socket comprises a base and an assembly, wherein the base is provided with a positioning surface for accommodating the wafer and two pairs of optical inductors are respectively arranged in the assembly and are close to regions of two diagonal lines so as to detect whether the wafer is horizontally positioned. The invention aims at ensuring that the wafer is placed at the right place so as to prevent the wafer from being damaged during the test and ensure that the test can be smoothly performed.

Owner:KING YUAN ELECTRONICS

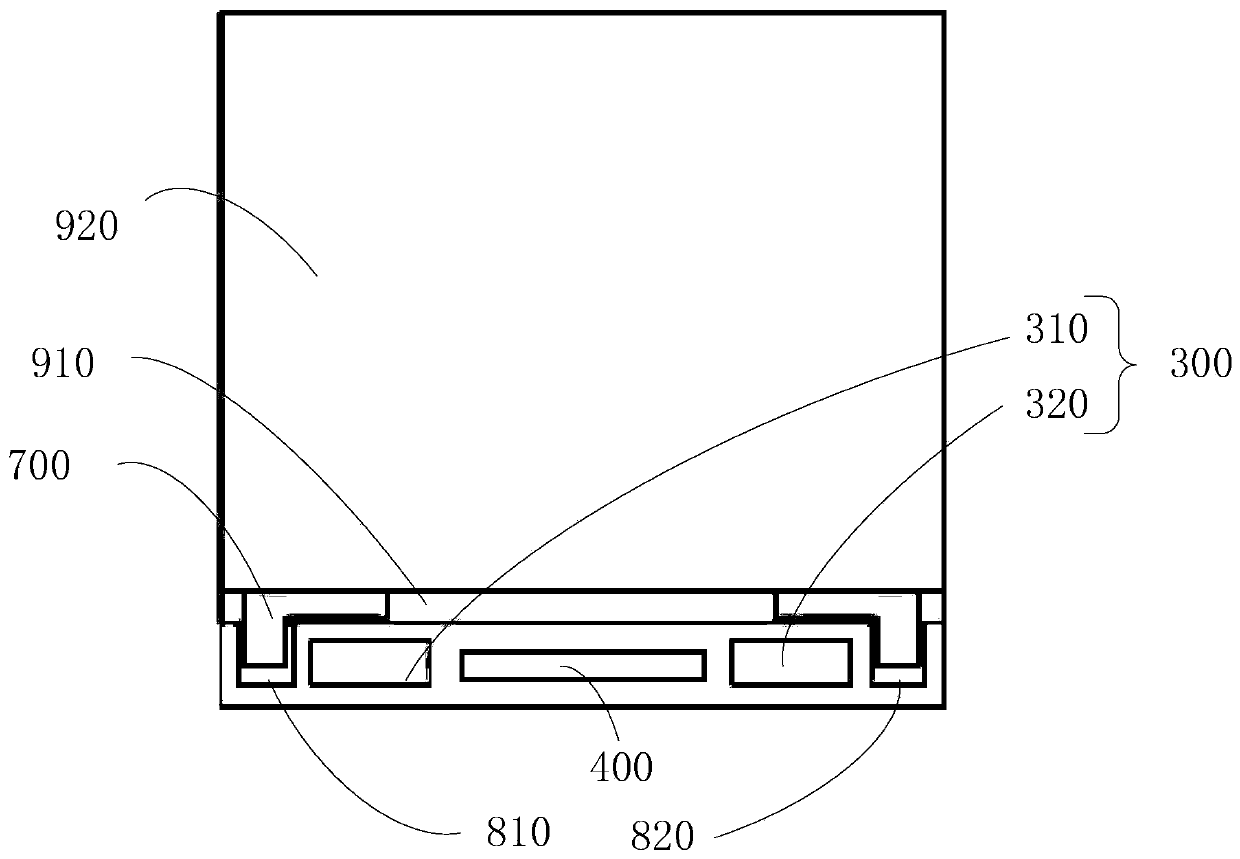

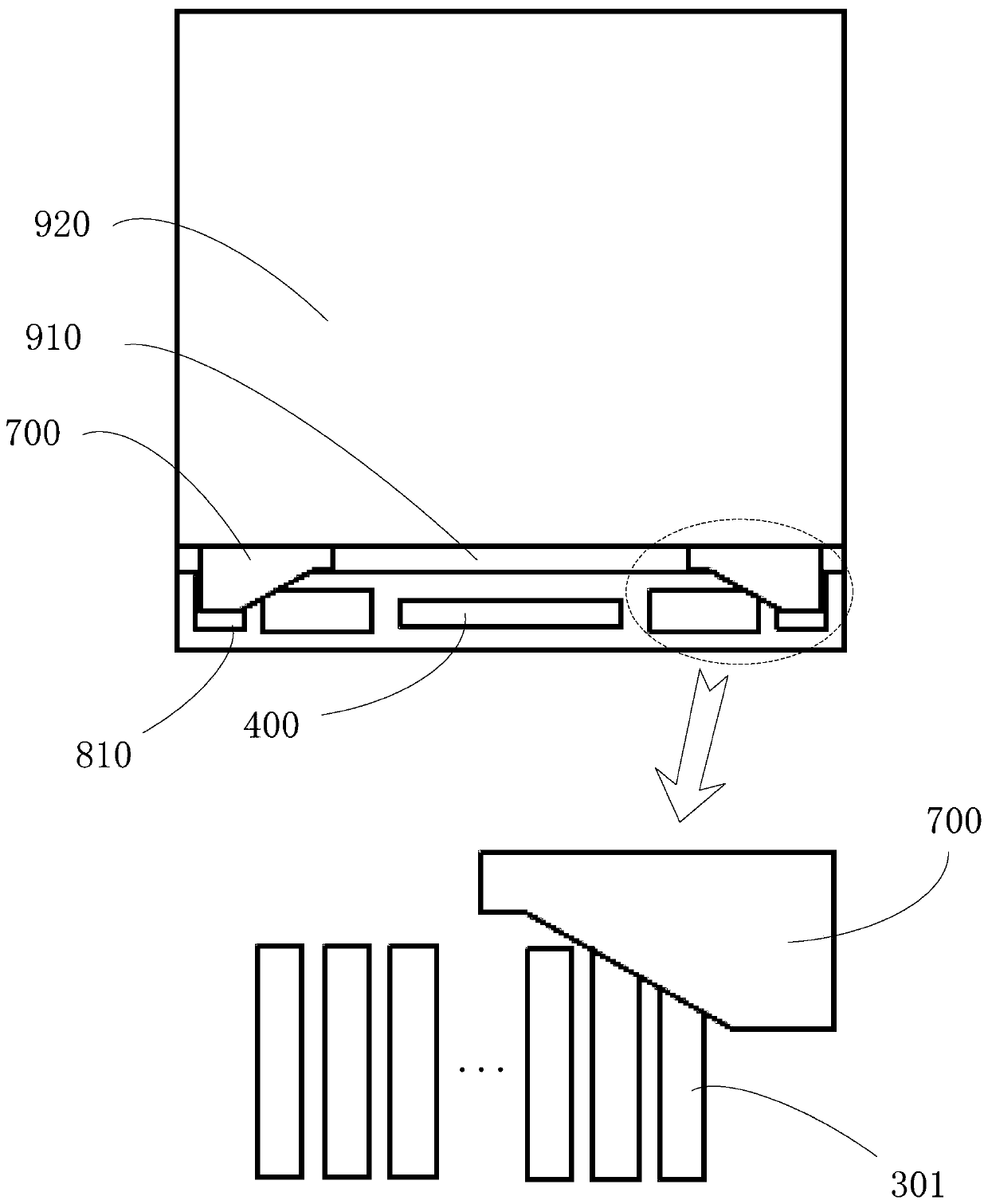

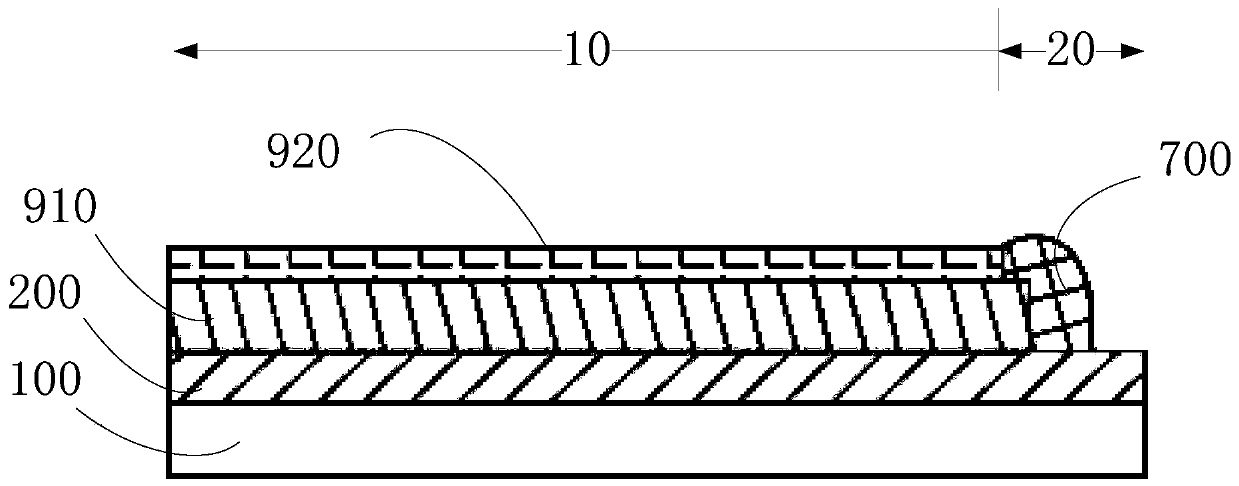

Display panel and test method thereof

ActiveCN110927999AAvoid short circuit problemsAvoid damageNon-linear opticsComputer hardwareControl switch

The invention discloses a display panel and a test method thereof. According to the display panel, a control switch is arranged between a test connection pad and a signal circuit; when a module lighting test is carried out, the control switch is controlled to be switched off, so that the problem of short circuit of a signal circuit during the module lighting test caused by short circuit of two ormore test connection pads due to the fact that a conductive adhesive is coated on the test connection pads is avoided, and the damage to the circuit due to large current caused by the short circuit isalso avoided; besides, a switch connection pad connected with the control end of the control switch is further arranged, so that when the jig is used for CT testing, the jig is connected with the control end to control the control switch to be connected, a signal circuit is connected with the test connection pad, and smooth CT testing is guaranteed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

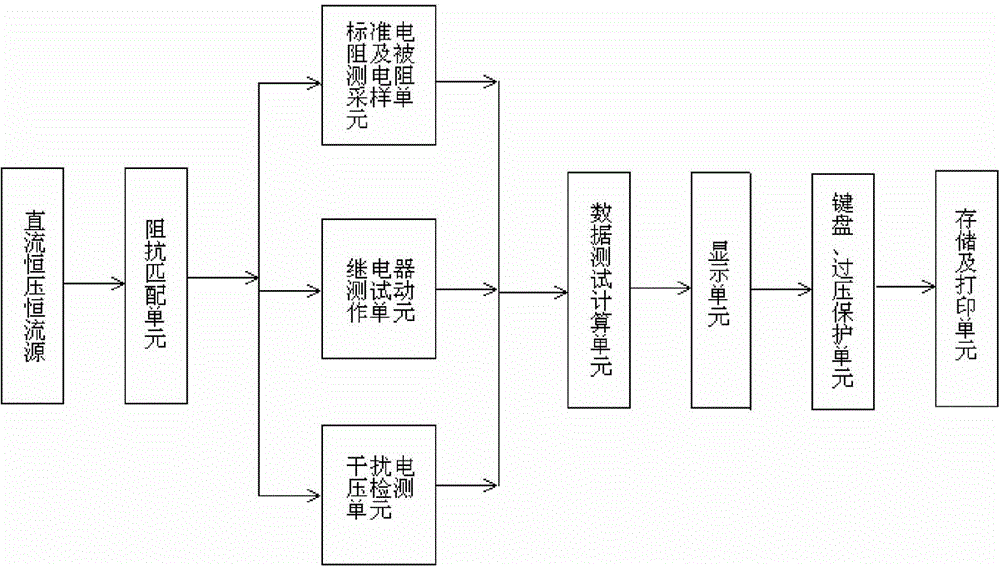

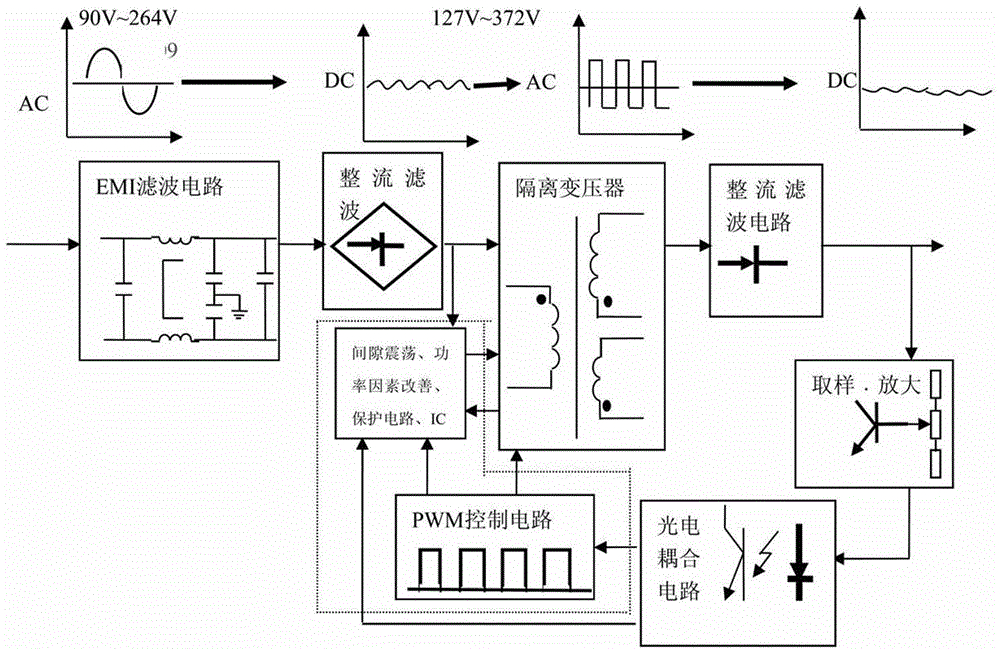

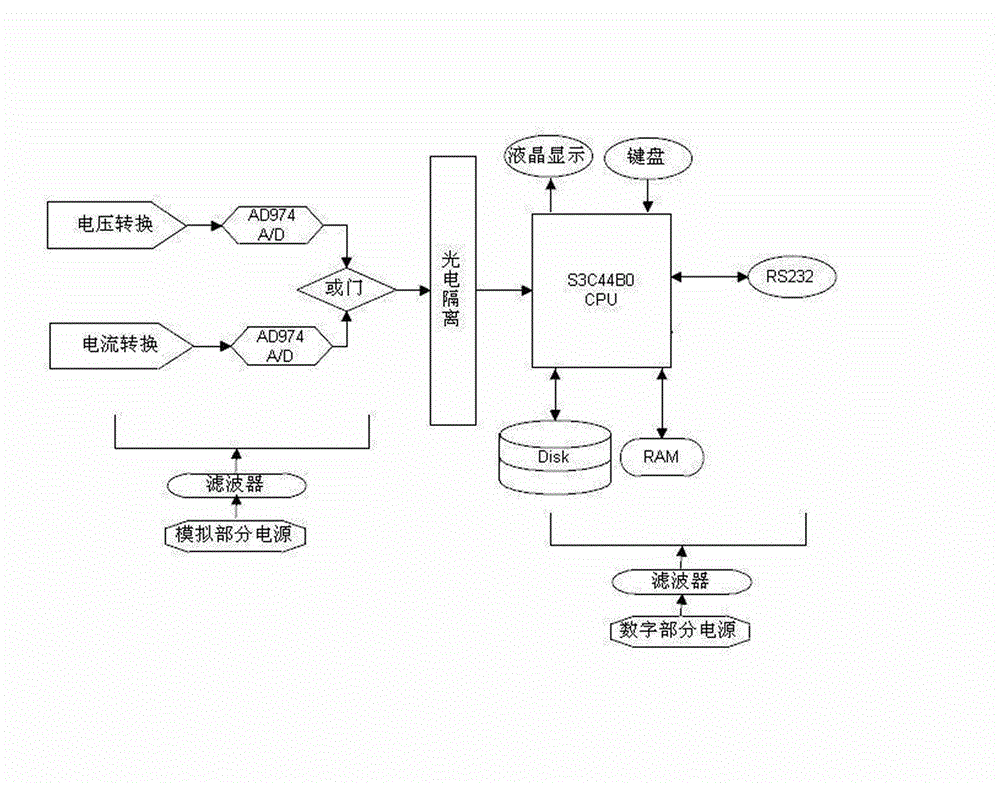

Anti-interference direct current resistance testing device

ActiveCN102981058AInnovative ideasStrong field applicabilityResistance/reactance/impedenceElectrical measurement instrument detailsConstant current sourceDc resistance

The invention relates to an anti-interference direct current resistance testing device, which adopts the structure that a direct current, constant voltage and constant current source is connected with an impedance matching unit; the impedance matching unit and a data testing and calculating unit are respectively connected with a standard resistance and measured resistance sampling unit, a relay test action unit and an interference voltage detecting unit; the data test calculating unit is connected with a display unit; the display unit is connected with a keyboard and an over-voltage protection unit; and the keyboard and the over-voltage protection unit are connected with a storage and printing unit. The device can meet the requirements of achieving smooth and accurate test of direct current resistance under the condition of a 350V relative interference voltage or a 100V interphase interference voltage.

Owner:FUSHUN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

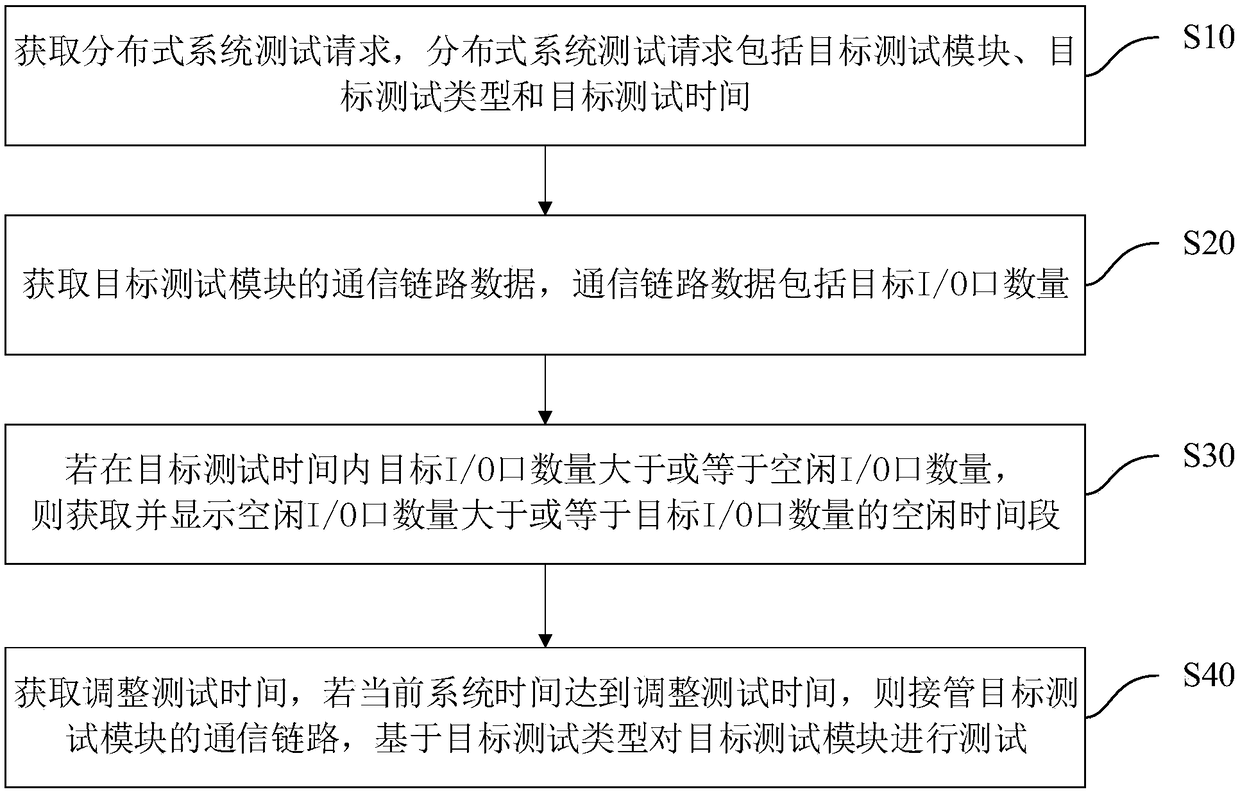

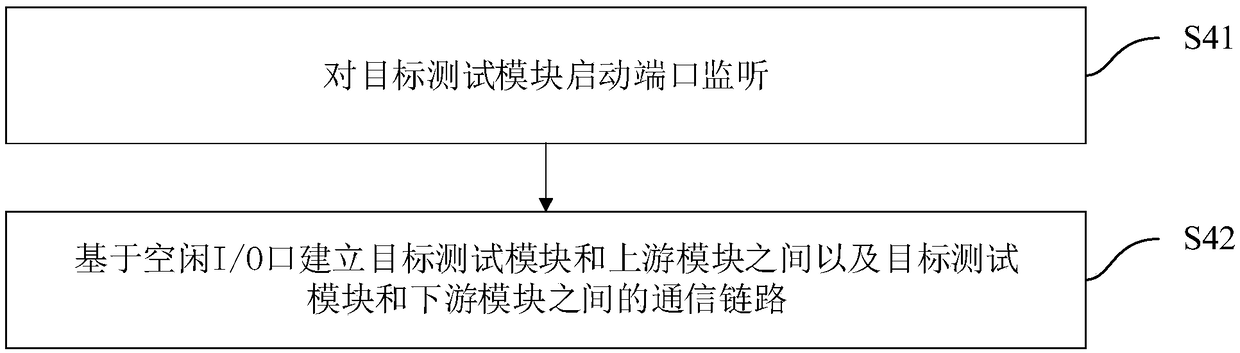

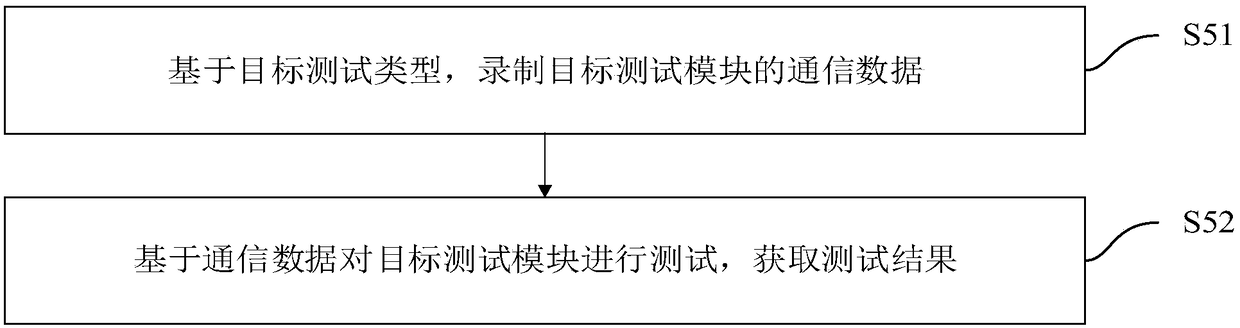

Distributed system test method and device, computer equipment and storage medium

InactiveCN108563562ATest coherenceImprove convenienceSoftware testing/debuggingTransmissionTest efficiencyIdle time

The invention discloses a distributed system test method and device, computer equipment and a storage medium. The distributed system test method comprises the following steps of: obtaining a distributed system test request, wherein the distributed system test request comprises a target test module, a target test type and a target test time; obtaining communication link data of the target test module, wherein the communication link data comprises a target I / O interface quantity; if the target I / O interface quantity is greater than an idle I / O interface quantity in the target test time, obtaining and displaying an idle time period in which the idle I / O interface quantity is greater than or equal to the target I / O interface quantity; and obtaining an adjusted test time, and if the current system time arrives the adjusted test time, taking over a communication link of the target test module, and testing the target test module on the basis of the target test type. The distributed system test method is capable of ensuring the distributed system test convenience and improving the distributed system test efficiency.

Owner:PING AN TECH (SHENZHEN) CO LTD

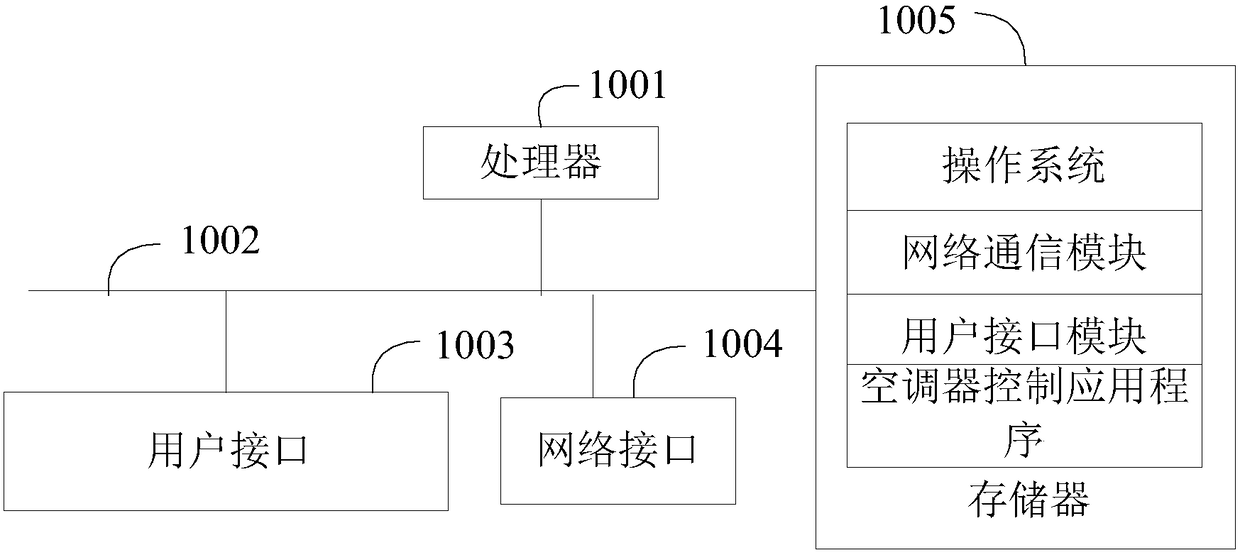

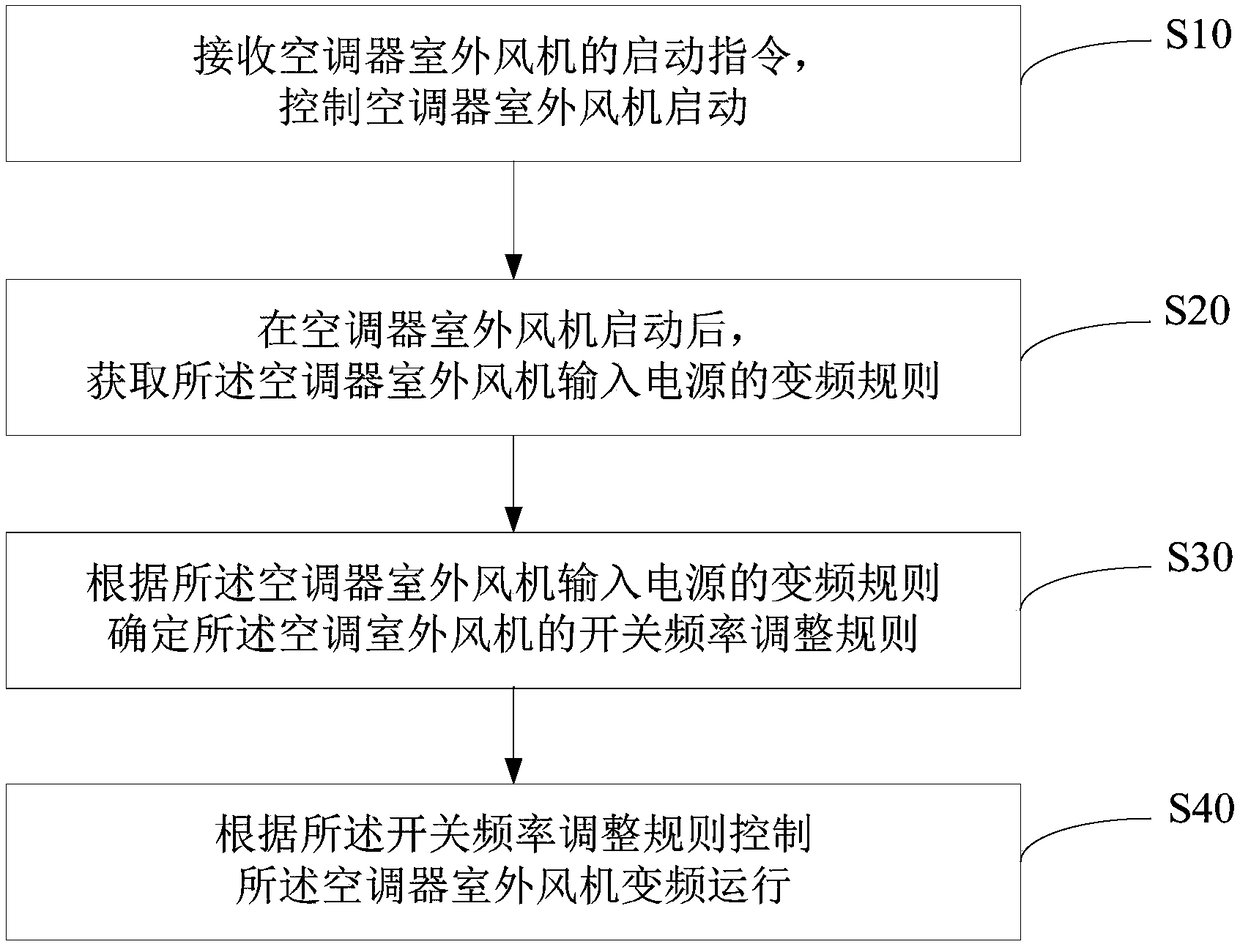

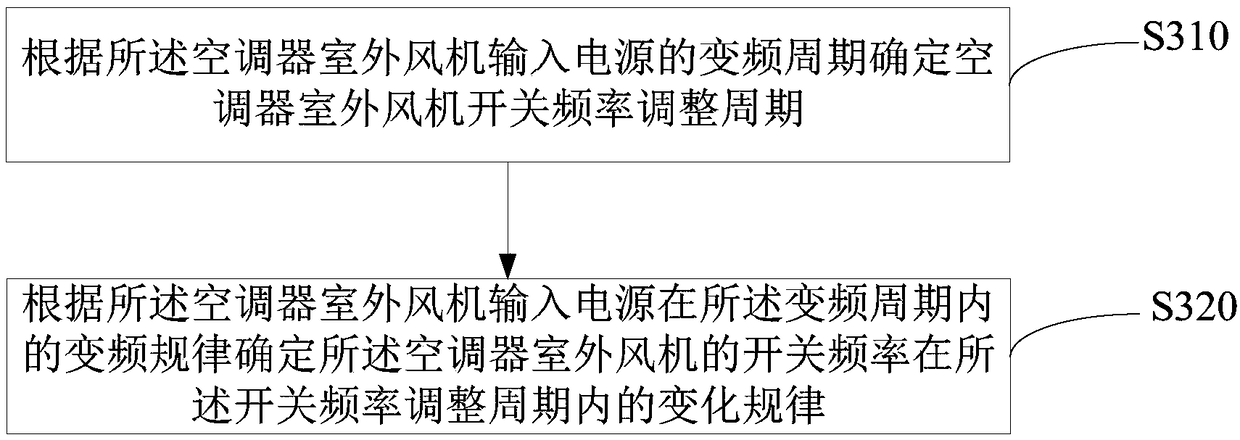

Control method and device of air conditioner and compute readable storage medium

ActiveCN108317696AStagger EMISmooth EMI testMechanical apparatusSpace heating and ventilation safety systemsElectromagnetic interferenceSwitching frequency

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

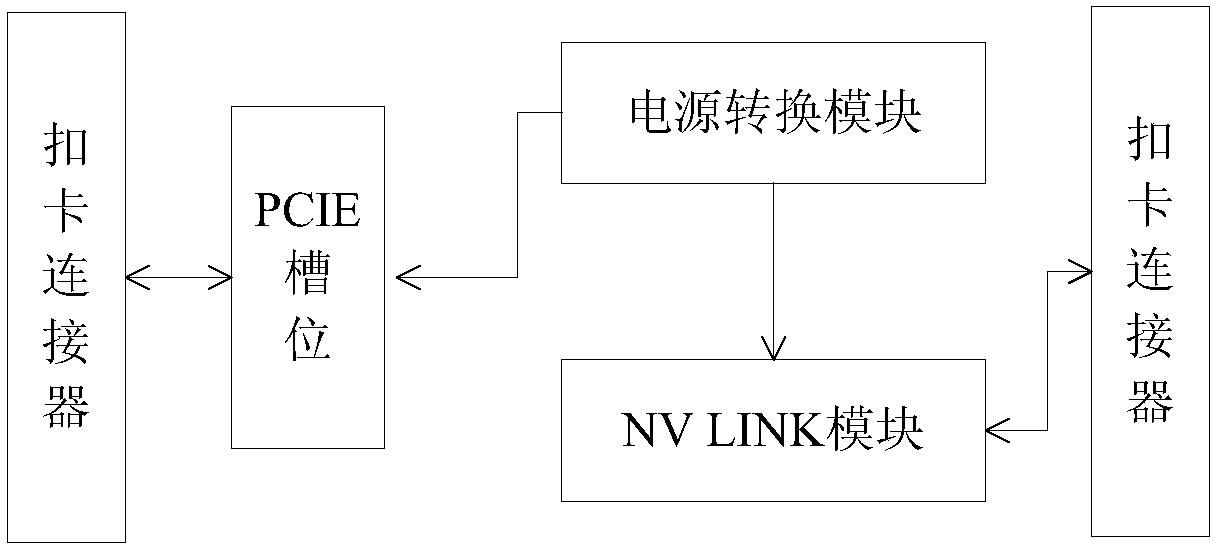

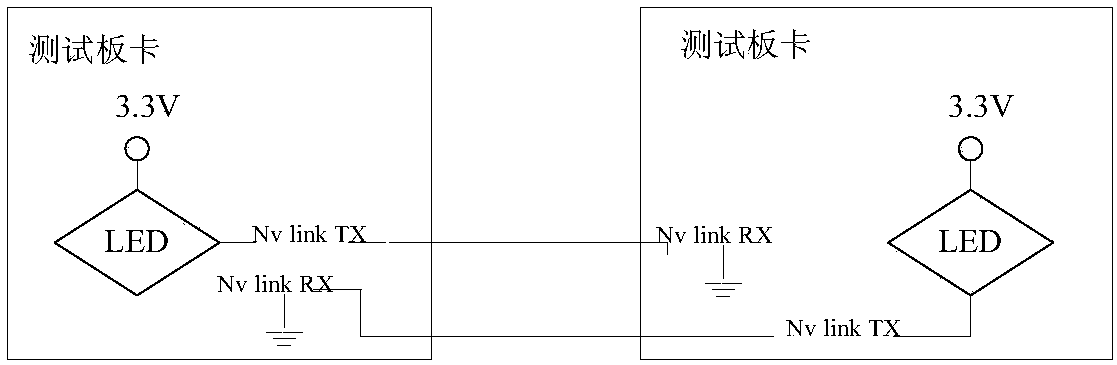

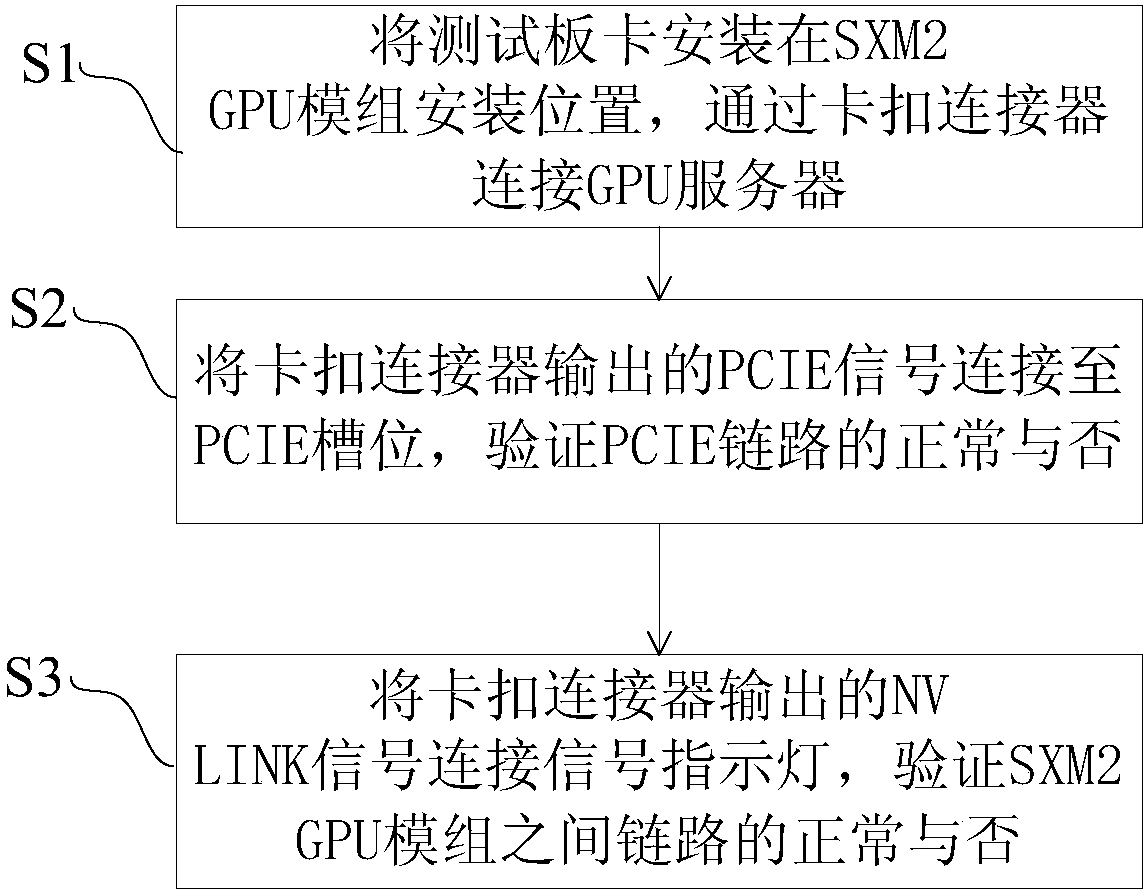

SXM2 GPU link test board card and method

ActiveCN108280004AAvoid damageReduce testing costsFaulty hardware testing methodsEngineeringTest board

The embodiment of the invention discloses an SXM2 GPU link test board card and method. The test board card comprises a card buckle connector, a power supply changeover module, a PCIE slot and an NV LINK module, wherein the card buckle connector is used for being connected with a GPU server, the power supply changeover module is used for supplying power to the test board card, the PCIE slot where aPCIE GPU card is installed is used for verifying whether or not a PCIE link connected with SXM2 GPUs is normal or not, and the NV LINK module is used for testing whether or not the link between the SXM2 GPUs is normal or not. When the SXM2 GPU link test board card and method are used for testing the reliability of the SXM2 GPU module link, it is unnecessary to use real SXM2 GPU modules for testing, damage caused to SXM2 GPU modules in the link test process is avoided, and the test cost is greatly reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

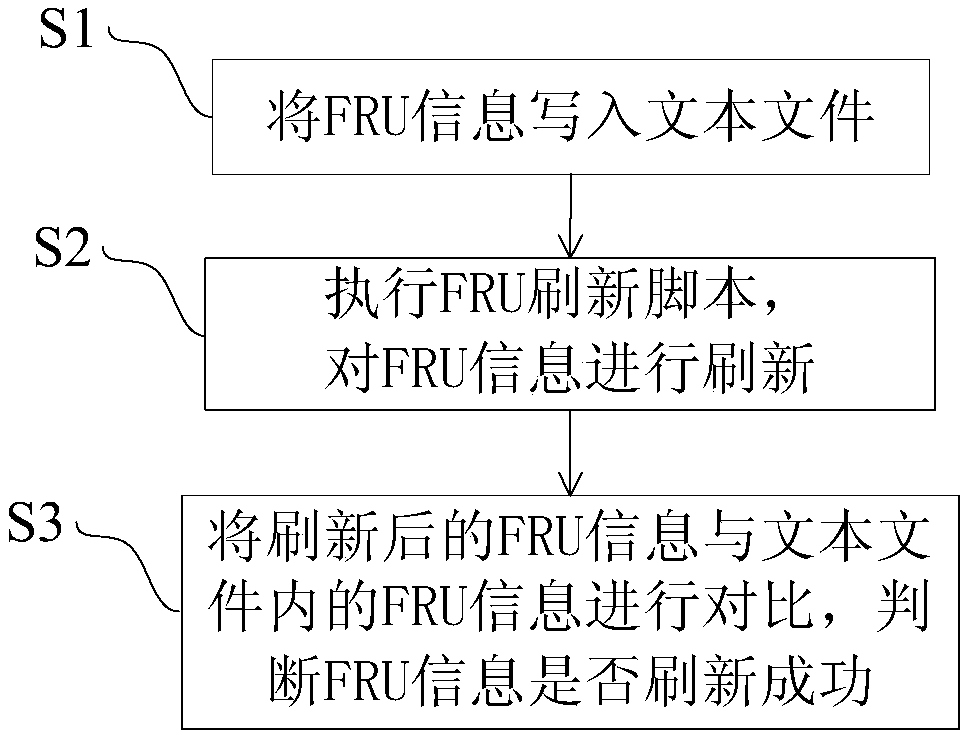

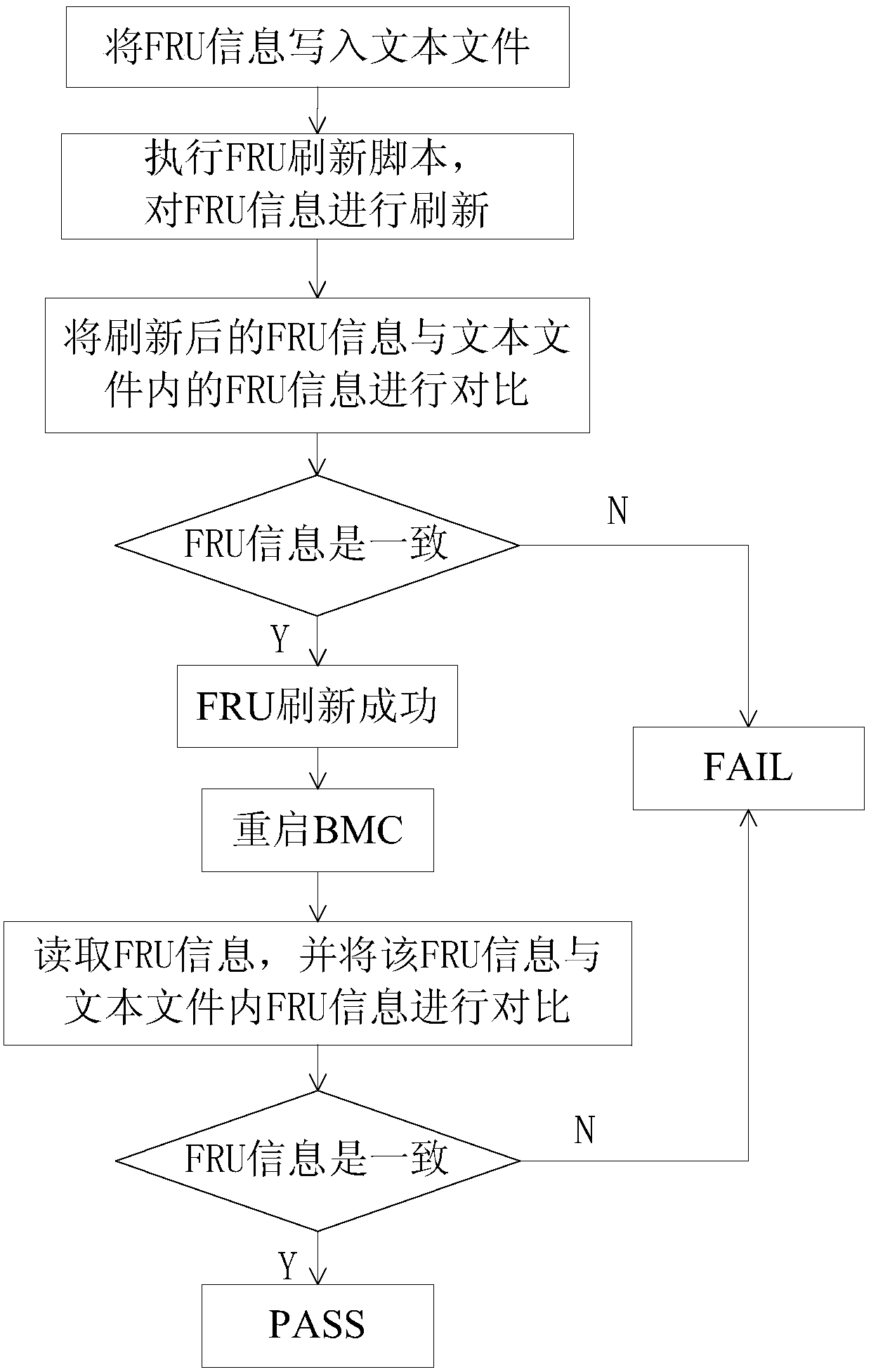

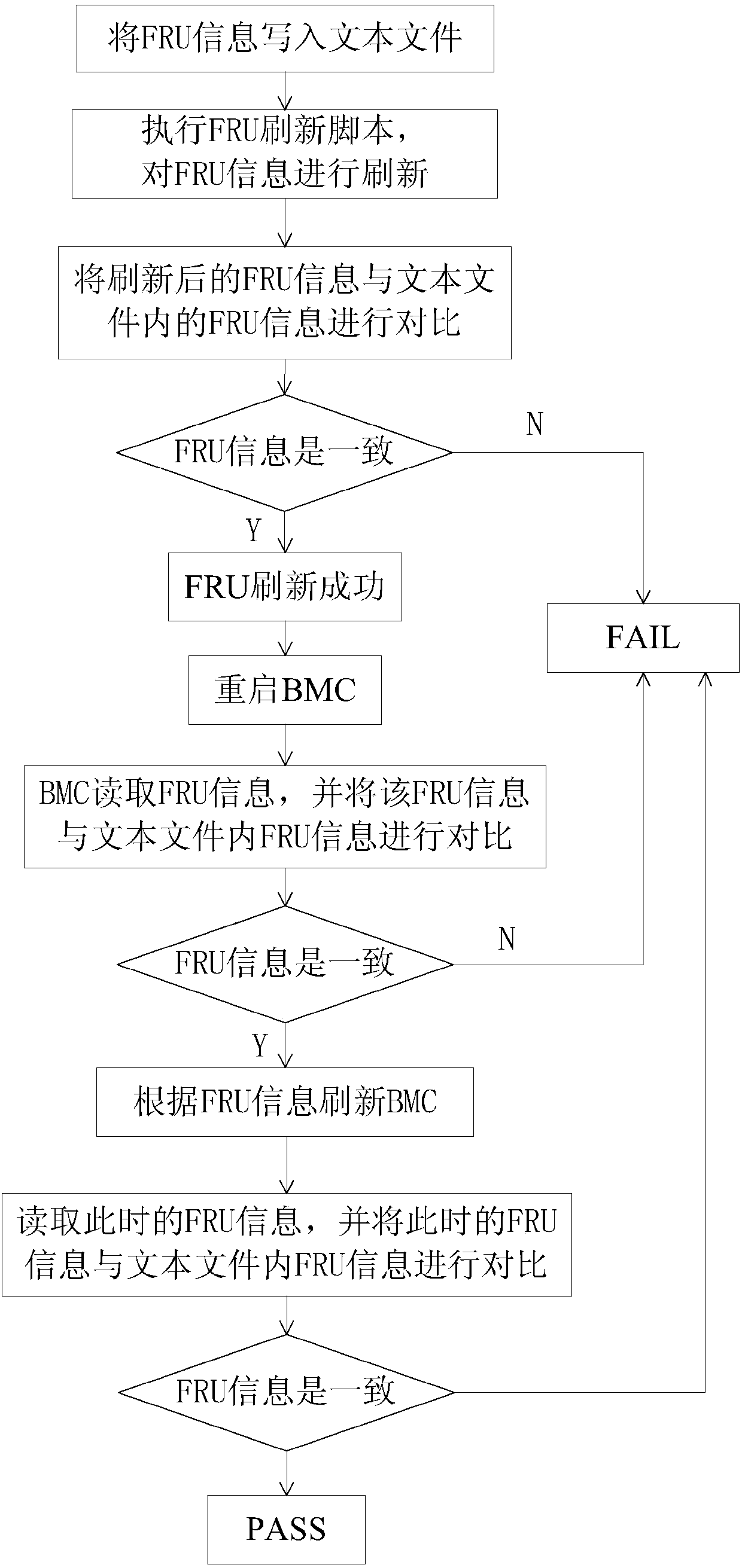

Method for testing consistency of FRU information

InactiveCN107704390AAvoid Manual InspectionImprove work efficiencySoftware testing/debuggingProgramming languageSoftware engineering

The invention discloses a method for testing consistency of FRU information. The method comprises the steps that the FRU information is written into a text file, and an FRU refreshing script is executed to refresh the FRU information; the refreshed FRU information is compared with the FRU information in the text file, and whether the FRU information is successfully refreshed is judged. According to the method, whether the FRU information is consistent can be judged by directly checking text file content, manual checking is avoided, and working efficiency and accuracy are improved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

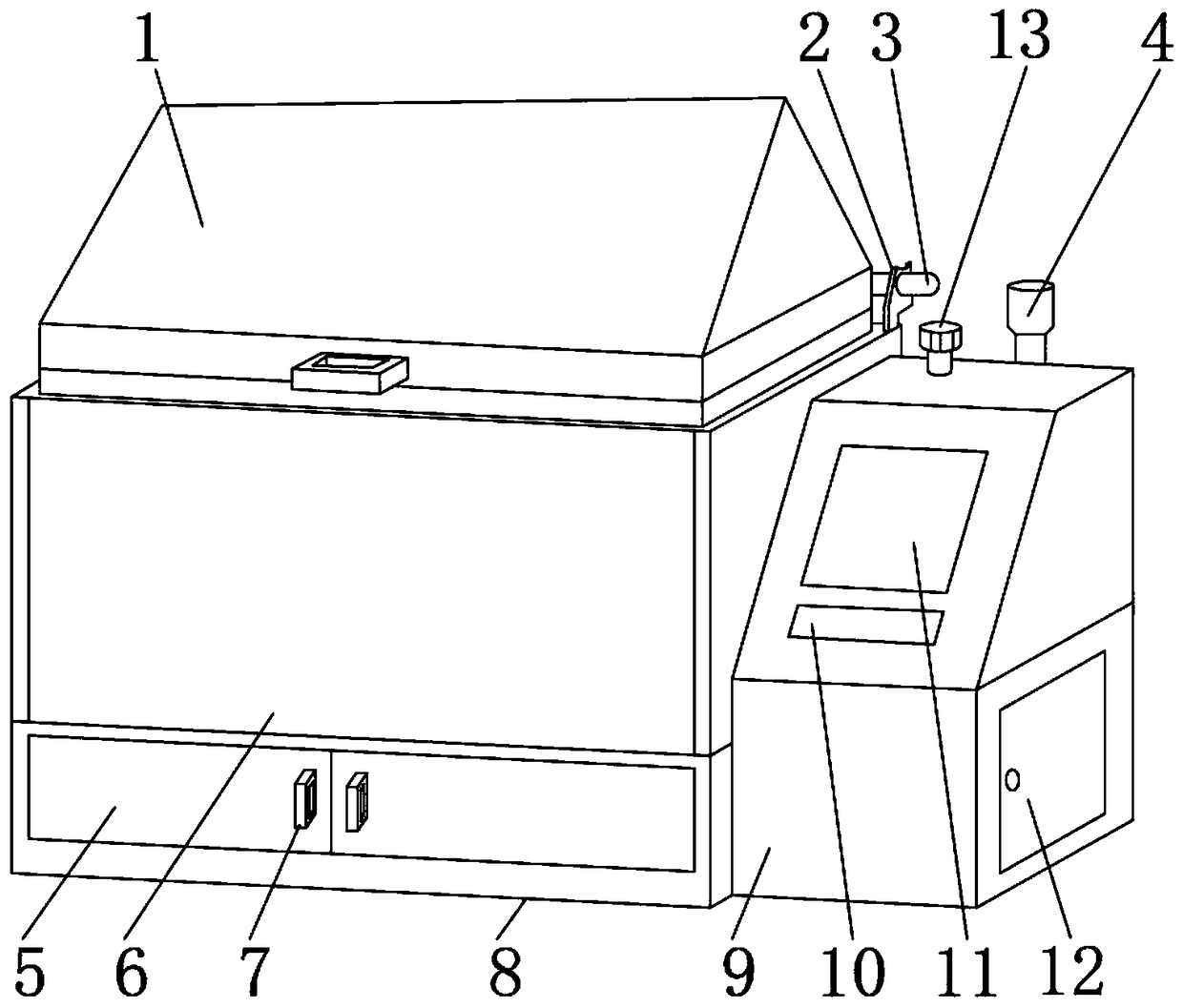

Automobile door hinge corrosion resistance detecting device

InactiveCN108918401AComprehensive detection effectEasy to fixWeather/light/corrosion resistanceTherapeutic effectEngineering

The invention discloses an automobile door hinge corrosion resistance detecting device comprising a main body casing and a control cabinet, wherein the outer surface of the upper end of the main bodycasing is movably provided with a visible box cover, a connecting shaft is fixedly connected to the outer surface of the rear end of the visible box cover, the outer surface of the connecting shaft iscovered with a fixed iron piece, and a test box is fixedly mounted on the outer surface of the lower end of the visible box cover. The automobile door hinge corrosion resistance detecting device hasa relatively-comprehensive detection effect, and can ensure that the outer surface of a hinge is evenly heated and receives a uniform liquid during detection, so that test results are more accurate, the automobile door hinge corrosion resistance detecting device has a better waste liquid treatment effect to ensure the inside of the automobile door hinge corrosion resistance detecting device may not be corroded by an acidic liquid, the automobile door hinge corrosion resistance detecting device can better carry out centralized treatment and movement of waste liquid, has a better fixing effect,can better fix the hinge, and can adjust the length of a clamp according to the size of the hinge. The scope of use of the device is enlarged.

Owner:安徽双红机械制造有限公司

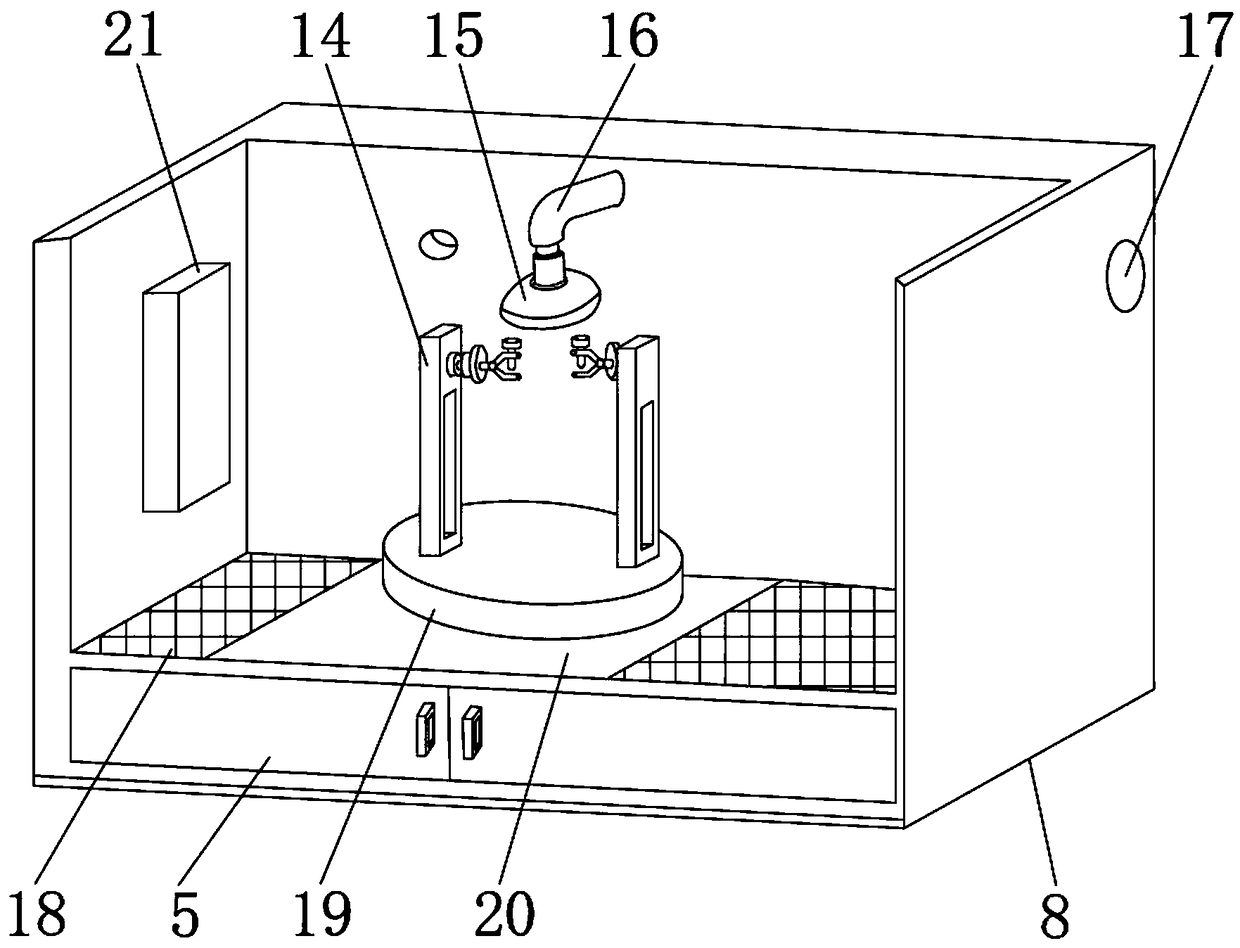

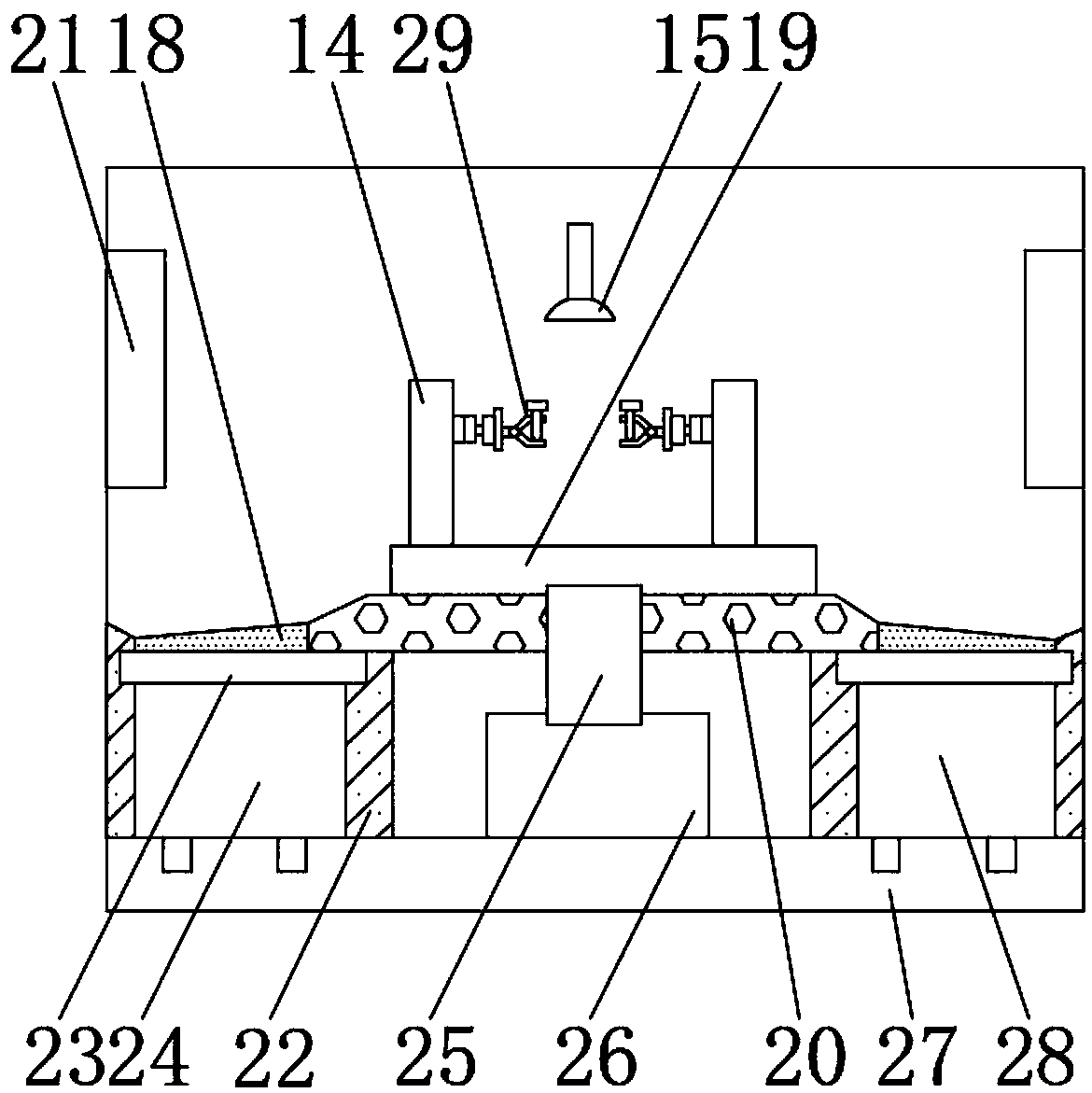

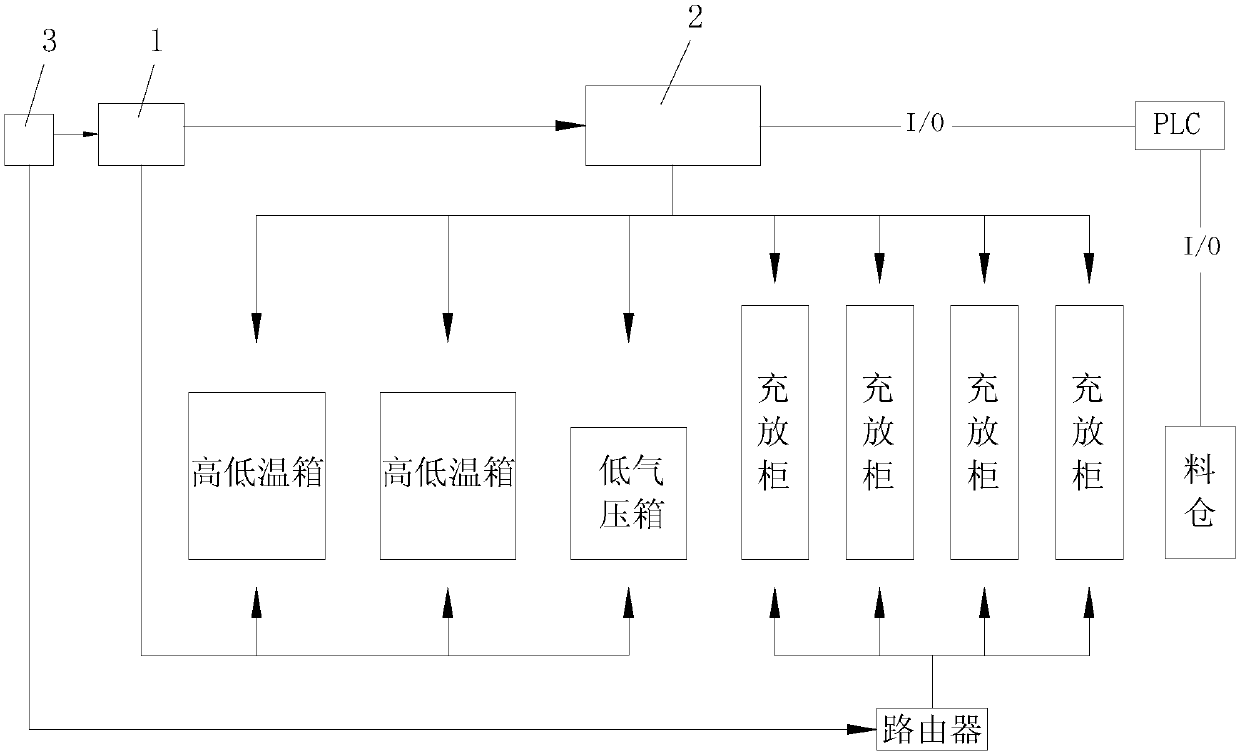

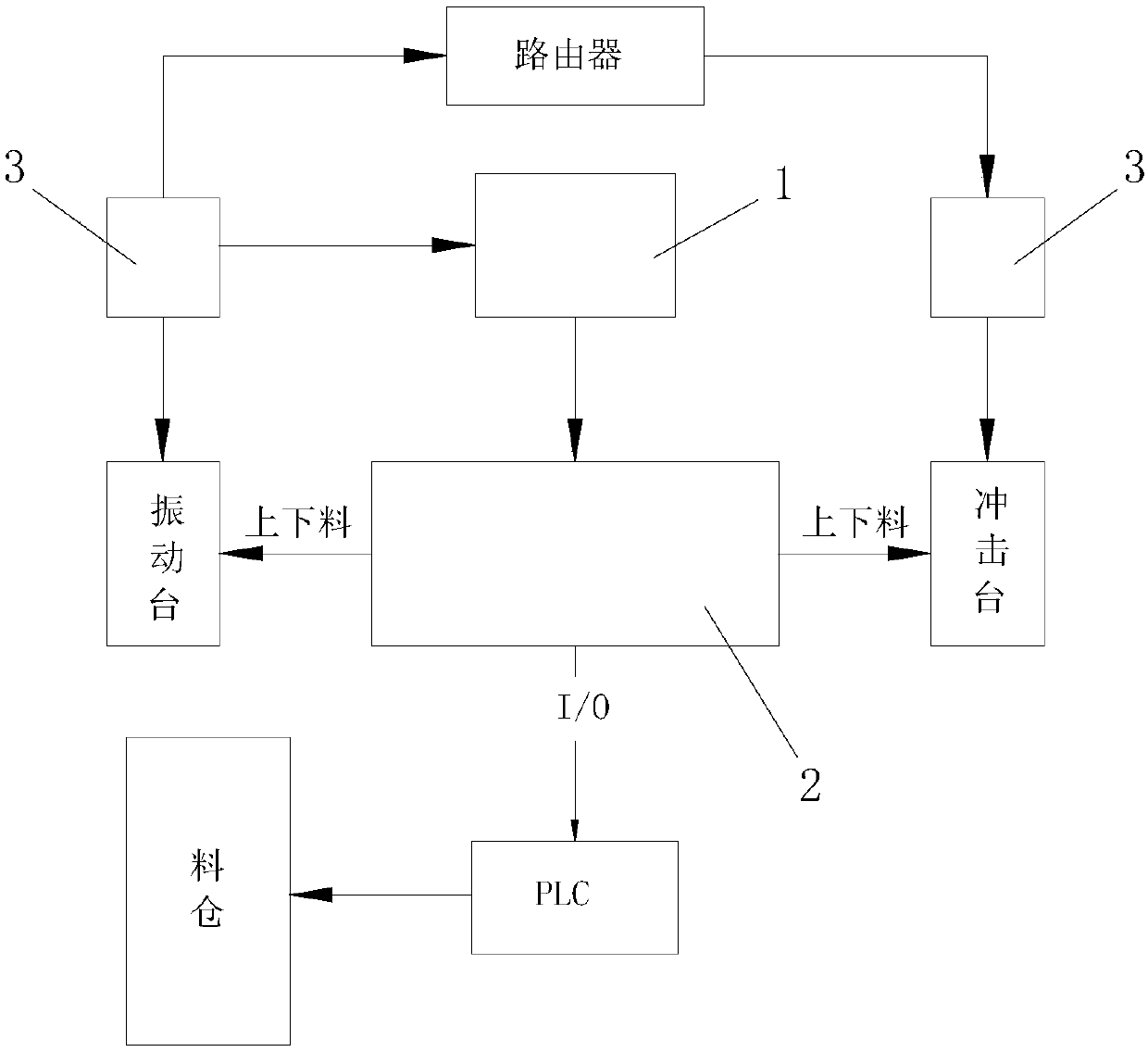

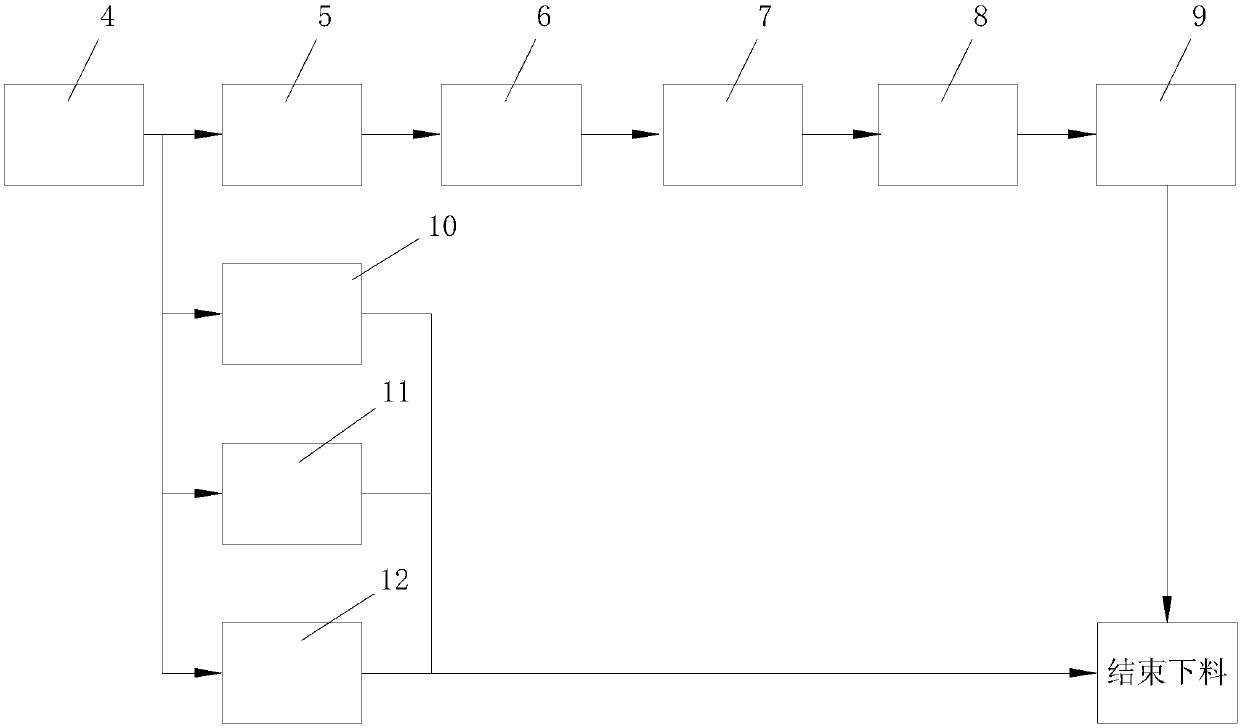

Automatic battery test system based on robot

PendingCN107727351AReduce dependenceReduce work stressElectrical testingManipulatorTest efficiencyWorking pressure

The invention relates to an automatic battery test system based on a robot. The automatic battery test system comprises a controller, a power supply system, a mechanical arm, a test device, a sample to be tested and a PC. The sample to be tested is a battery; the power supply system is connected with the controller, and the controller provides a needed supply voltage frequency for the mechanical arm, the test device, the sample to be tested and the PC through the power supply system; the mechanical arm is used for grabbing the sample to be tested, the input end of the mechanical arm is connected with the controller, and the controller controls the mechanical arm to grab or carry objects or operate tools by sending instructions; the test device is connected with the controller, the PC and the mechanical arm separately, the controller provides a needed state for the sample to be tested through the test device, and the PC is connected with the controller. Compared with the prior art, theautomatic battery test system can reduce the dependence on test personnel, relieve the working pressure of test personnel, make the test coherent, greatly improve the test quality and the test efficiency and reduce the test cost.

Owner:SGS STANDARD TECHNICAL SERVICES SHANGHAI CO LTD

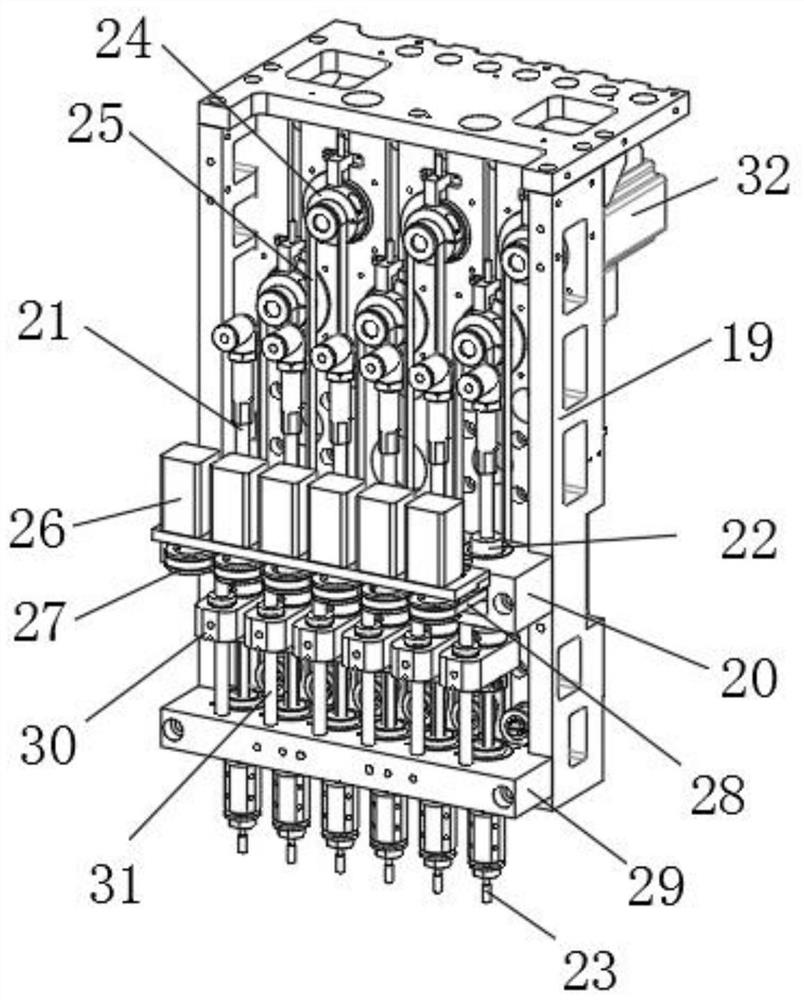

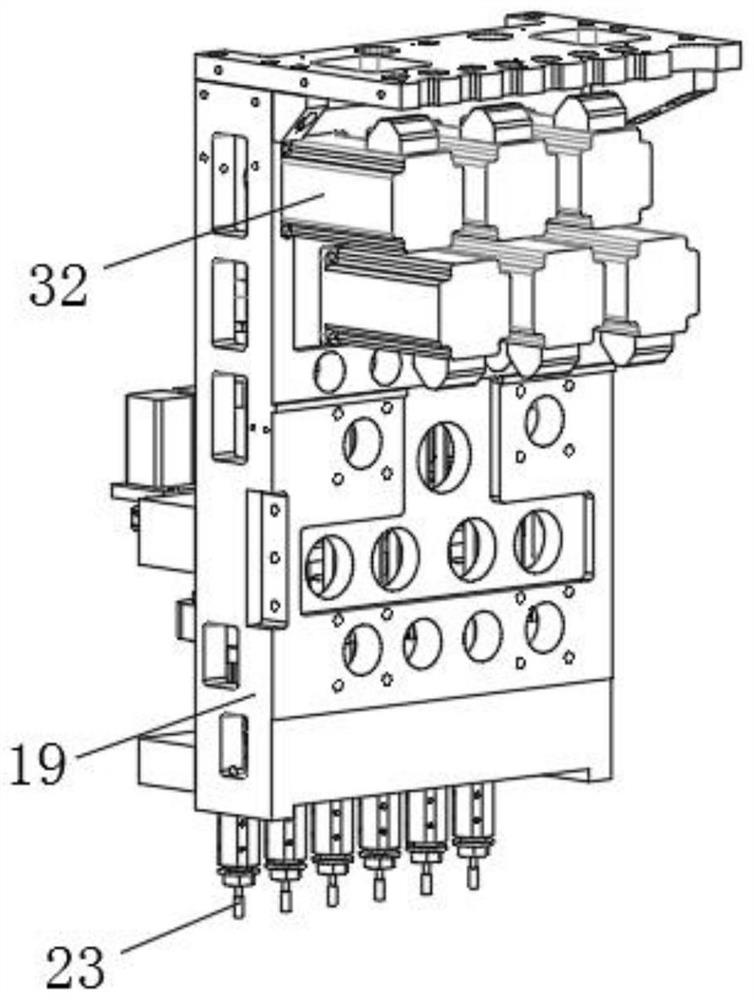

Semiconductor element sorting and testing all-in-one machine

InactiveCN111715542AFast installationImprove work efficiencySortingStructural engineeringMechanical engineering

The invention discloses a semiconductor element sorting and testing all-in-one machine. The semiconductor element sorting and testing all-in-one machine comprises a base, wherein a supporting frame isfixedly mounted on the upper surface of the base; a transverse beam is fixedly mounted at the top of the supporting frame through a bolt; a movable plate is movably mounted at one side of the transverse beam; a hoisting arm is movably mounted at one side of the movable plate; a grasping mechanism is fixedly mounted at the bottom end of the hoisting arm; a socket plate is mounted on the upper surface of the base; a testing socket is mounted on the socket plate; a plurality of mounting grooves are formed in the testing socket; the grasping mechanism comprises a mounting plate; a plurality of outer splines are rotatably mounted on a supporting seat I; a ventilation pipe is movably mounted at the inner sides of the outer splines along the vertical direction; and a suction nozzle is fixedly mounted at the bottom of the ventilation pipe. The semiconductor element sorting and testing all-in-one machine disclosed by the invention can be used for testing a plurality of semiconductor elements in one time and the working efficiency is high; and angles of the semiconductor elements are convenient to adjust so that the semiconductor elements are accurately put into the mounting grooves and themounting speed of the semiconductor elements is rapid.

Owner:安徽富信半导体科技有限公司

Five-point recognition method for CCDs (Charge Coupled Devices)

ActiveCN107525477AStability analysis calculationAnalysis and calculation are accurateOptically investigating flaws/contaminationUsing optical meansEngineeringPrinted circuit board

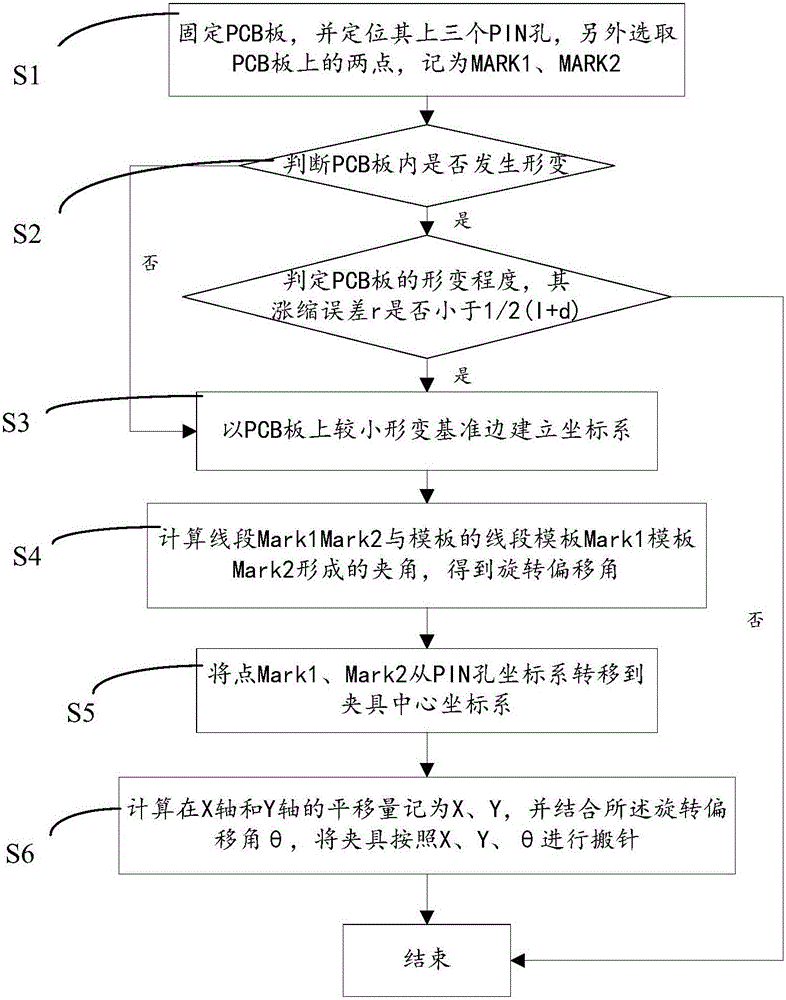

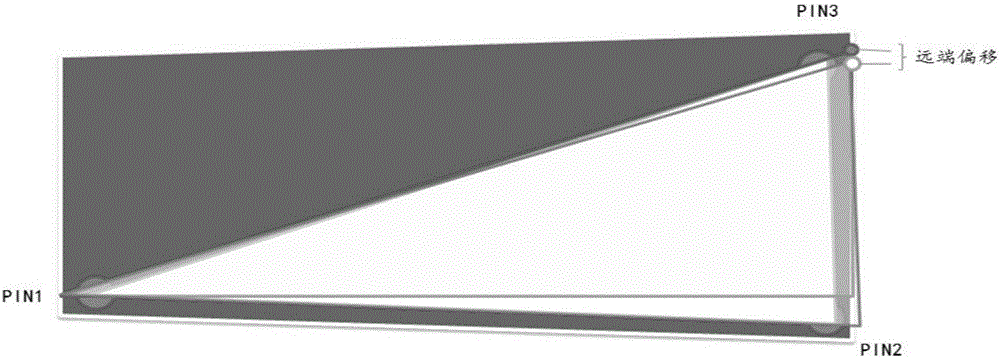

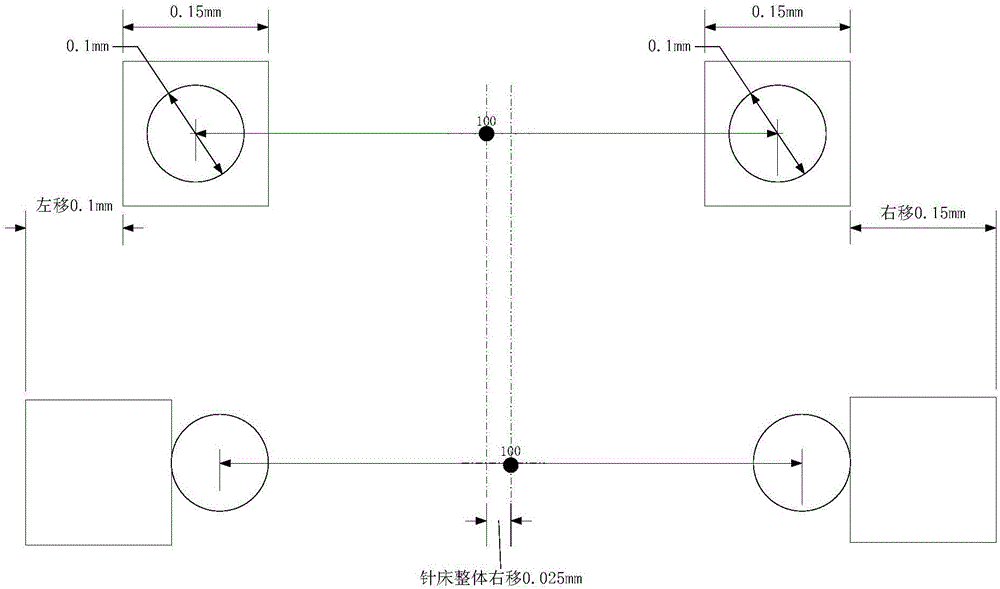

The invention discloses a five-point recognition method for CCDs (Charge Coupled Devices). The method includes the following steps that: a PCB (printed circuit board) is fixed, three PIN holes on the PCB are positioned, two addition points are selected from the PCB and marked as MARK1 and MARK2 respectively; whether deformation occurs in the PCB is judged through judging whether the triangle of the PIN holes of the PCB is totally equal to the triangle of the PIN holes of a template, if no deformation occurs in the PCB or the expansion and shrinkage error r of the PCB is smaller than 1 / 2 (l+d), a coordinate system is built with a small-deformation reference edge of the PCB, namely, the opposite side of the smallest-deformation angle of the PCB is adopted as an X axis, and a PIN hole coordinate system is built with one endpoint or the middle point of the side adopted as an origin point; an included angle between a ling segment Mark1Mark2 and a line segment template Mark1 and template Mark2 is calculated, so that a rotation shift angle is obtained; the point Mark1 and point Mark2 are shifted to a fixture center coordinate system from the PIN hole coordinate system; and the translation quantities of the PCB on an X axis and a Y axis are recorded as X and Y respectively, and a fixture (or the PCB) is made to move according to X, Y and Theta (or -X,-Y and -Theta) on the basis of the rotation shift angle. The recognition method of the present invention is more accurate and more stable.

Owner:SHENZHEN MASONE ELECTRONICS

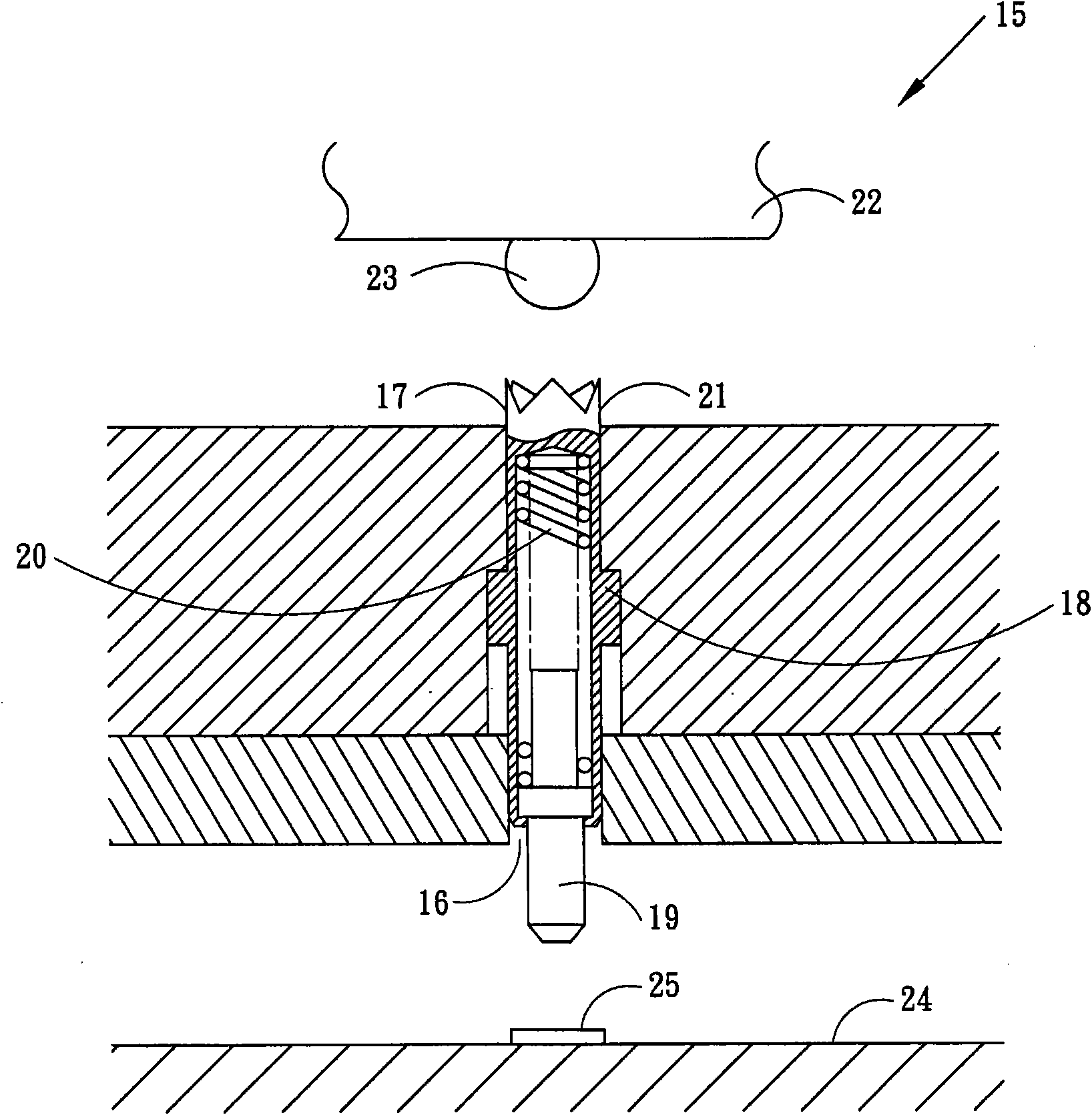

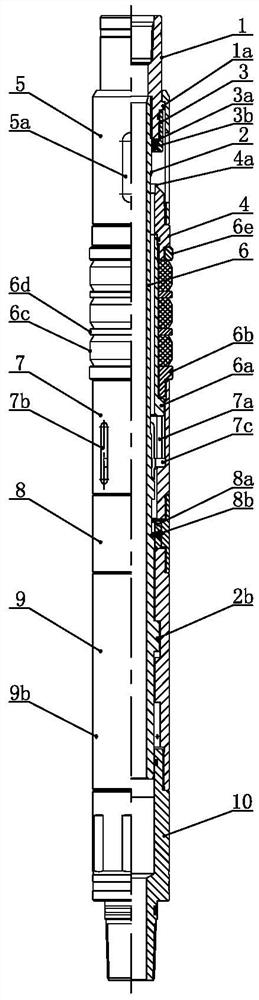

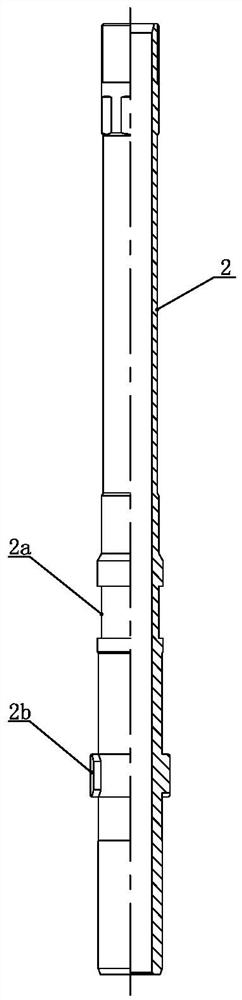

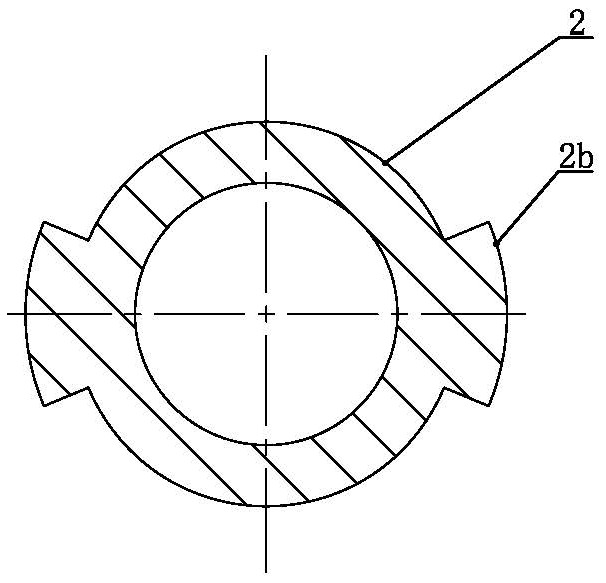

Packer for formation testing and method for performing formation testing by adopting packer

ActiveCN111911110APrevent pre-settingGood for walkingWell/borehole valve arrangementsSealing/packingUpper jointEngineering

The invention relates to a packer for formation testing and a method for performing formation testing by adopting the packer. The packer comprises an upper joint, wherein a conical female thread is formed in the upper end of the upper joint, a core pipe extending downwards is screwed in an internal thread in the lower end of the upper joint, and the lower end of the core pipe is inserted into an upper port of a lower joint and is sealed through an O-shaped ring; a conical male thread is formed in the lower end of the lower joint; and a bypass mechanism capable of communicating upper liquid flow and lower liquid flow of the packer is arranged on the periphery of the core pipe and below the upper joint, a setting mechanism is arranged below the bypass mechanism, a shear pin mechanism is arranged below the setting mechanism, and a transposition mechanism for controlling bypass and setting is arranged below the shear pin mechanism. During well descending, the bypass is opened to communicate upper and lower annuluses, after in place, the core pipe is rotated, the bypass is closed, setting is performed, stratum fluid enters a string, then the bypass is opened, unsetting is performed, andthe string is lifted. In the drilling process, it is ensured that the straddle packer cannot be set in advance, so that packer rubber sleeves are effectively protected, and the straddle test successrate is practically increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

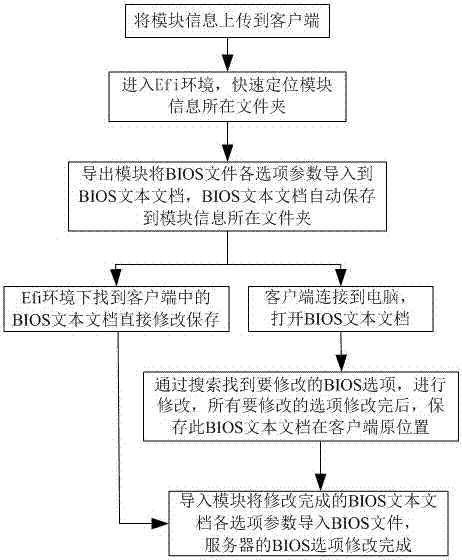

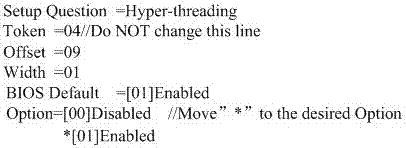

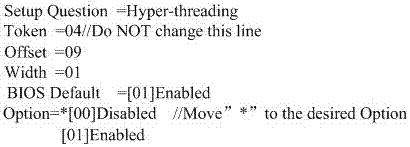

Method for extracting and modifying BIOS in Efi environment

The invention relates to a method for extracting and modifying BIOS in an Efi environment. The method is characterized by comprising the following steps that step1: module information is uploaded to a client; step2: a server is started to get into the Efi environment, to locate a folder where the module information is stored; step3: an export module imports optional parameters of a BIOS text document into the BIOS text document, the BIOS text document is automatically saved to the folder where the module information is stored, and that exporting file succeeds is prompted if saving succeeds; step4: the client is connected to a computer and the BIOS text document is opened; step5: BIOS options needing to be modified are searched for and then modified, and after modification of all the BIOS options needing to be modified is completed, the BIOS text document is saved at the original location of the client; step6: an import module imports optional parameters of the modified BIOS text document into the BIOS text document, that importing file succeeds is prompted if importing is completed, and then modifying the BIOS options of the server is completed.

Owner:GUANGDONG INSPUR BIG DATA RES CO LTD

Static cracking agent expansion force testing device and method

PendingCN109459174APrevent overflowTest coherenceApparatus for force/torque/work measurementTemperature controlRock engineering

The invention provides a static cracking agent expansion force testing device and belongs to the technical field of rock engineering. The static cracking agent expansion force testing device comprisesa testing device body internally provided with a reaction cavity, a water injection pipe and a rubber sleeve, wherein the reaction cavity is formed in a temperature control system, the water inlet end of the water injection pipe is arranged outside the reaction cavity, the water outlet end of the water injection pipe extends into the reaction cavity, the end portion of the water outlet end is provided with a baffle for plugging an outlet of the water injection pipe, the side wall of the portion, extending into the reaction cavity, of the water injection pipe is provided with a water injectionhole enabling the inner cavity of the water injection pipe to be communicated with the reaction cavity, the rubber sleeve sleeves the side wall, provided with the water injection hole, of the water injection pipe and is used for plugging an outlet of the water injection hole. The invention also provides a static cracking agent expansion force testing method. By adopting the static cracking agentexpansion force testing device and the static cracking agent expansion force testing method, the technical problems are solved that at present, an expansion force testing device cannot measure the change of an expansion force of a static cracking agent during water injection and cannot achieve temperature control.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

Polymer material density testing equipment

InactiveCN105424552APlay the effect of saving electricityComprehensive dataSpecific gravity measurementVolumetric Mass DensityEngineering

The invention provides polymer material density testing equipment and belongs to the field of testing equipment. The equipment comprises an equipment body, the equipment body comprises a weight testing instrument, the top of the equipment body is provided with a vacuum cover, which is detachably connected to the top of the equipment body; the top of the vacuum cover is provided with a cover body, which is connected to the top of the vacuum cover through screw joint; the lateral wall of the vacuum cover is provided with an exhaust opening; the top of the equipment body is provided with a plug-in mechanism, the plug-in mechanism comprises a slot, the external side of the slot is provided with a circular first boss, the top of the first boss is provided with a sealing ring; the bottom of the external side of the vacuum cover is provided with a circular second boss, the height of the second boss is lower than that of the first boss, a gap exists between the first boss and the second boss; and the edge of the sealing ring stretch out the first boss and extends to the space above the second boss. The provided density testing equipment can measure the weight of a polymer material in a vacuum state and then calculate the density of the polymer material, and thus more precise data can be obtained.

Owner:佛山市顺德区特丰塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com