Automatic terminal voltage resistance and insulation test system and control method

An automatic test system, voltage-resistant insulation technology, applied in the direction of testing dielectric strength, electrical program control, program control in sequence/logic controller, etc., can solve the problems of high labor intensity and low test efficiency, and reduce labor cost, improve test efficiency, and improve the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

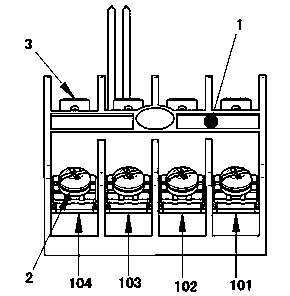

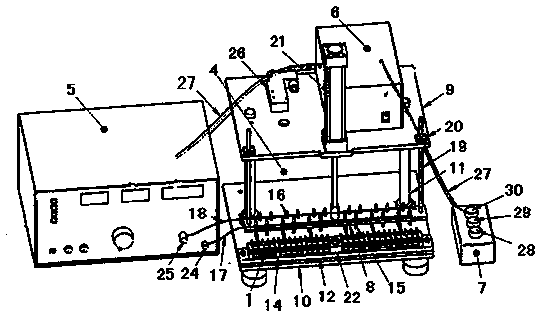

[0036] Such as Figure 2-Figure 4 As shown, the present invention discloses a terminal withstand voltage insulation automatic test system, including a test device 4, a withstand voltage insulation tester 5, a control device 6 and a start-stop controller 7,

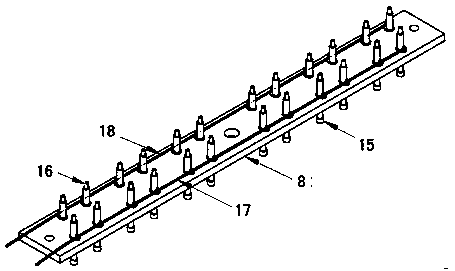

[0037] Above-mentioned test device 4 comprises frame, and frame is made up of upper support plate 9 and lower support plate 10 that are arranged in parallel up and down and the optical axis support column 11 that is connected between upper support plate 9 and lower support plate 10; A terminal mounting plate 12 is installed on the upper end surface of the terminal mounting plate 12, and six terminal mounting rods 13 are arranged side by side along the long axis direction of the terminal mounting plate 12, and a partition is used between each two adjacent terminal mounting rods 13 14 apart, so that each terminal 1 is separated; a probe board 8 that can move up and down is hoisted under the upper support plate 9, and six gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com