Quick-speed plug connector assembly for testing

A connector component, a fast technology, applied to the parts of the connecting device, the parts of the electrical measuring instrument, the connection, etc., can solve the problem of cumbersome connection between the test instrument and the equipment under test, so as to save the time of debugging or testing, Accelerate the test speed and ensure the effect of close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

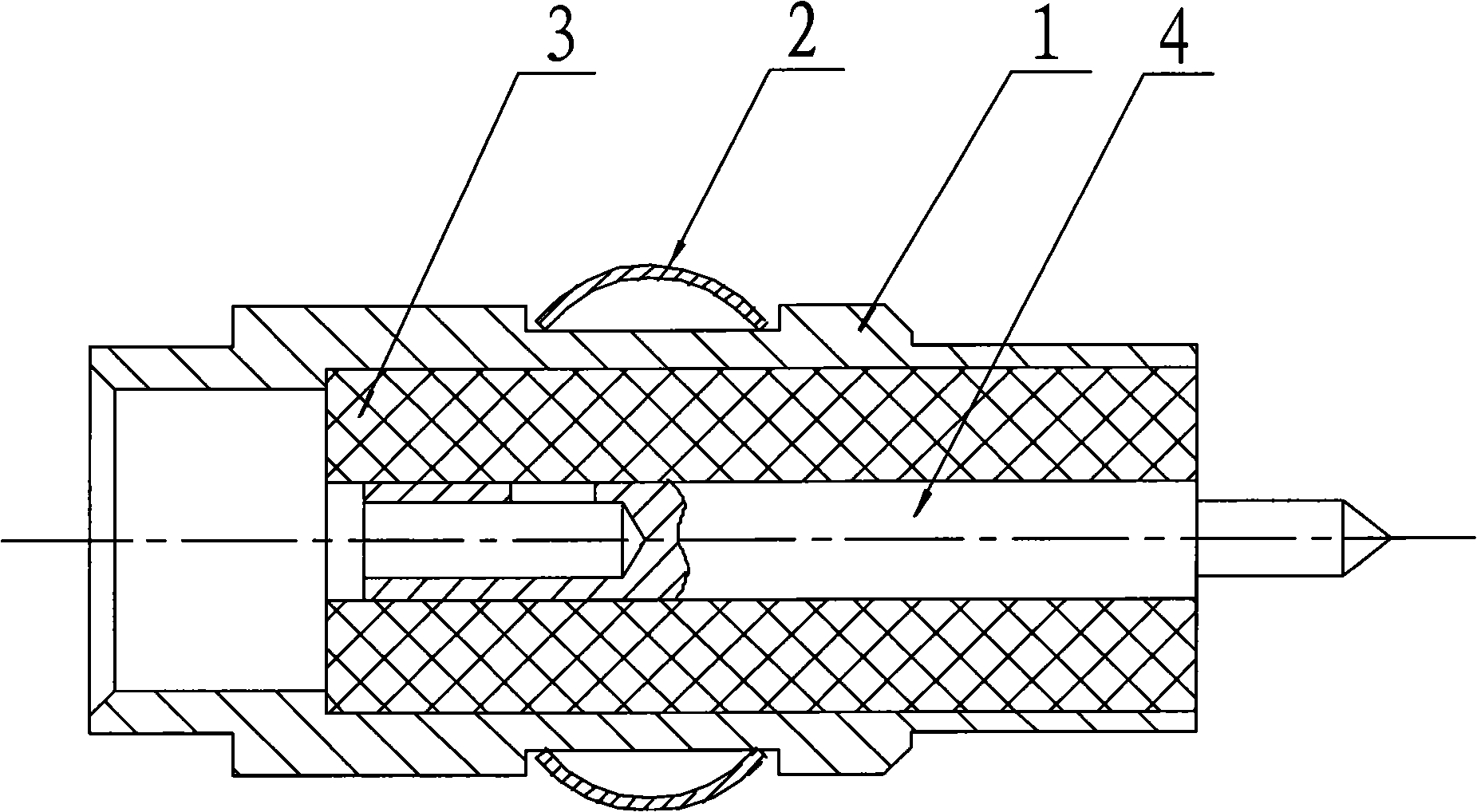

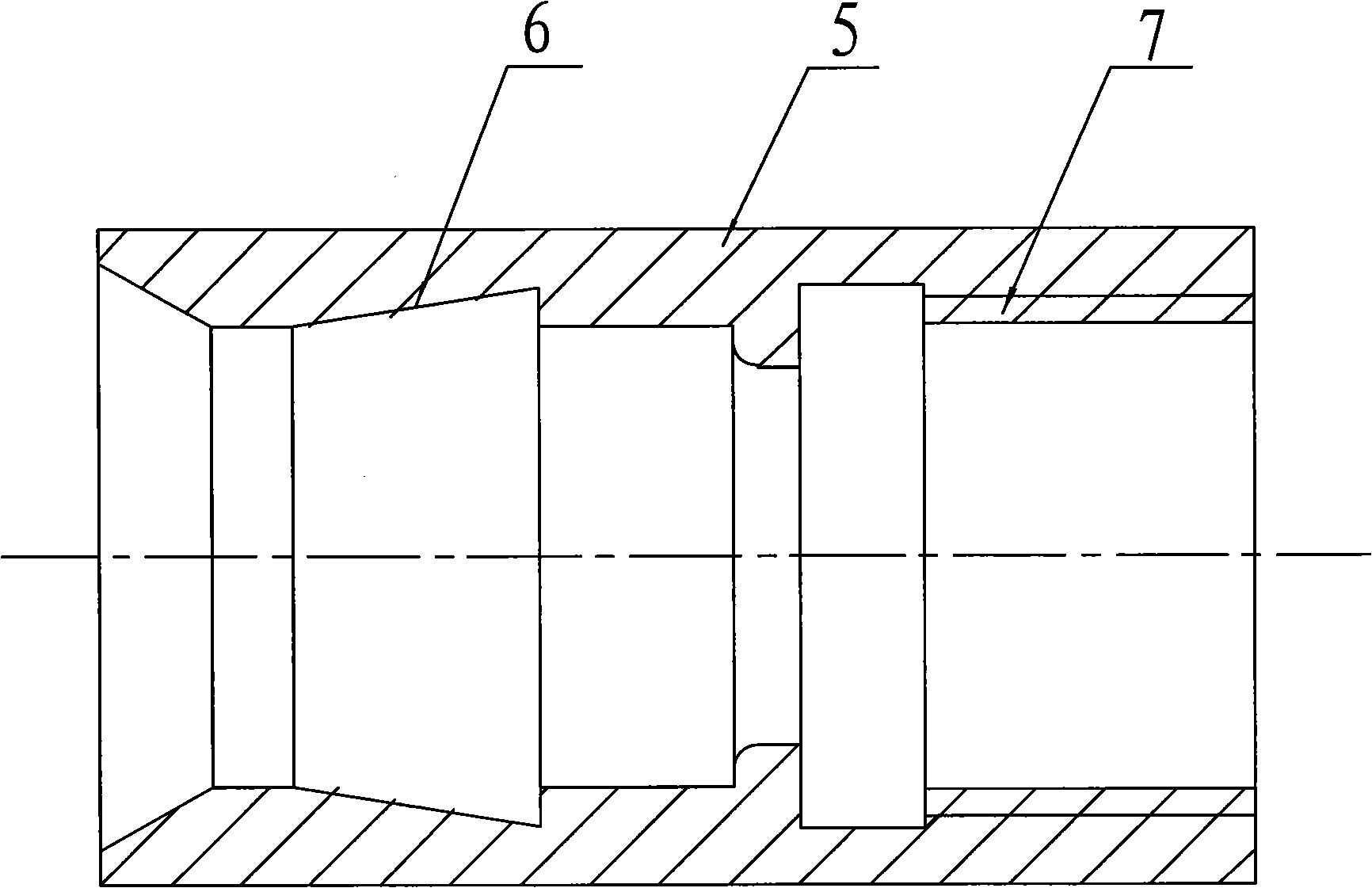

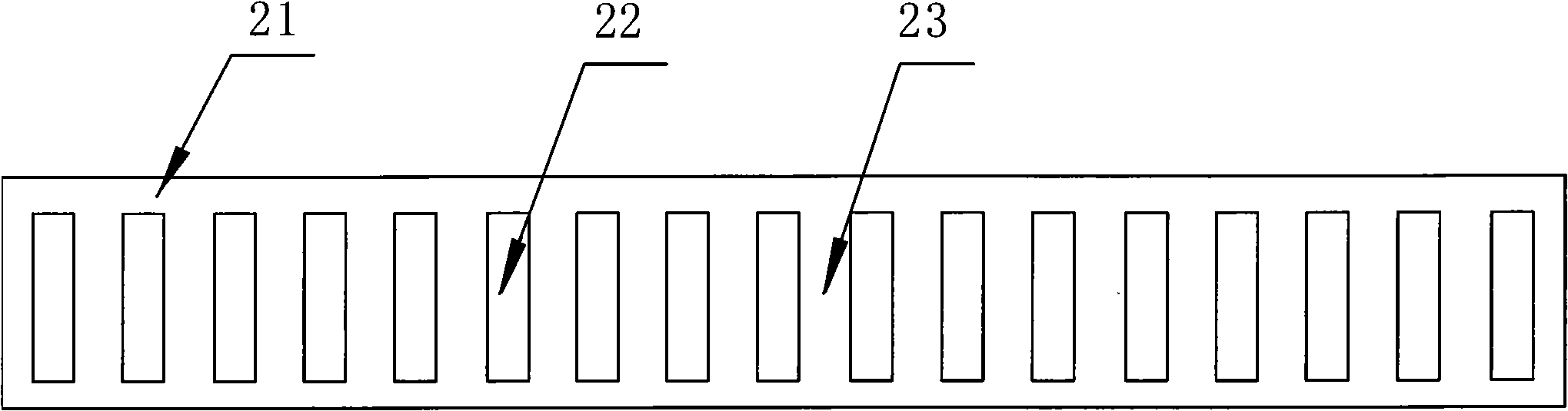

[0021] Such as figure 1 , figure 2 , image 3 As shown, the quick plug-in connector of the present invention is composed of a plug and a special connection sleeve 5 for mating with it. The plug includes a housing composed of an outer conductor 1. The outer surface of the housing is provided with steps, and the steps face the insertion direction. Set with chamfers. The outer conductor 1 is axially pierced with a pin 4 that is plugged into the socket. The pin 4 extends axially along the outer conductor and protrudes from the front end of the outer conductor. On the rear end of the outer conductor 1, there is a socket for connecting the test cable. The connection part 9 is filled with an insulator 3 between the outer conductor 1 and the contact pin 4, and an annular groove is formed on the outer surface of the outer conductor 1 in the circumferential direction, and an annular elastic contact piece 2 is installed in the annular groove. The elastic contact piece 2 includes a me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com