Automatic battery test system based on robot

A technology of automated testing and robotics, applied in the testing of machines/structural components, vibration testing, impact testing, etc., can solve problems such as small battery testing market share, improve testing quality and testing efficiency, reduce working pressure, and reduce testing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

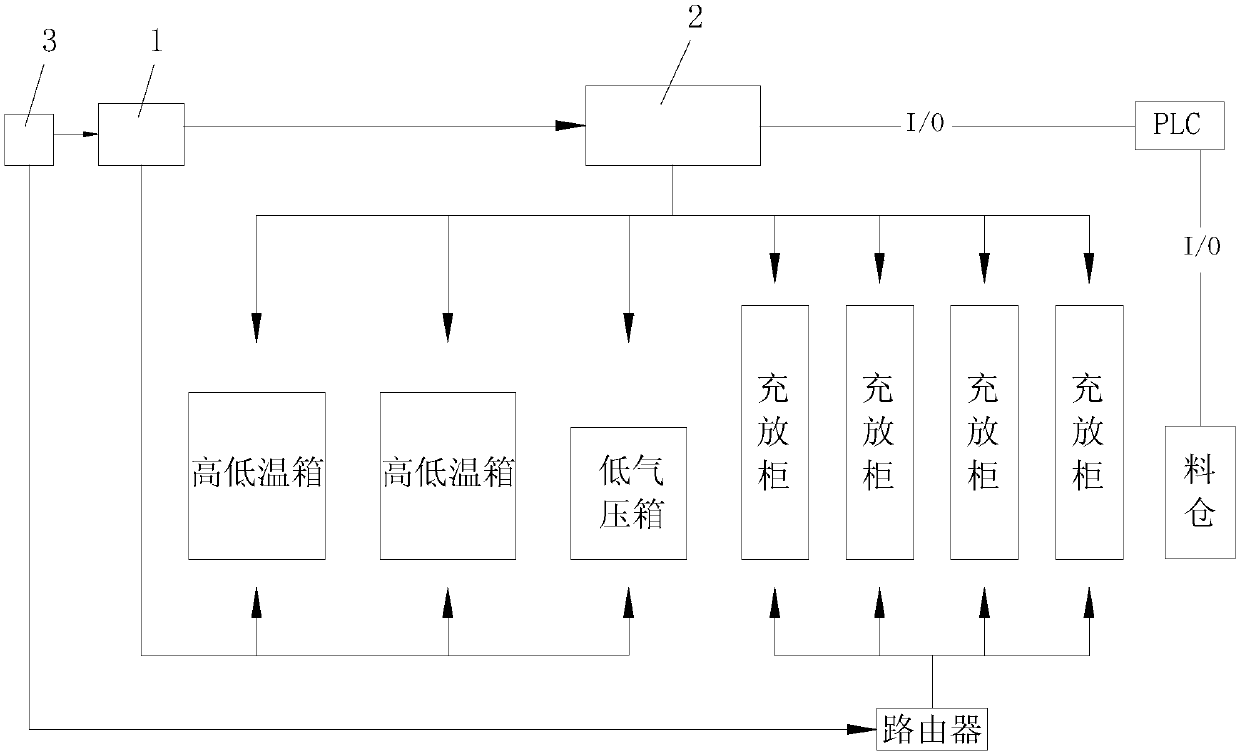

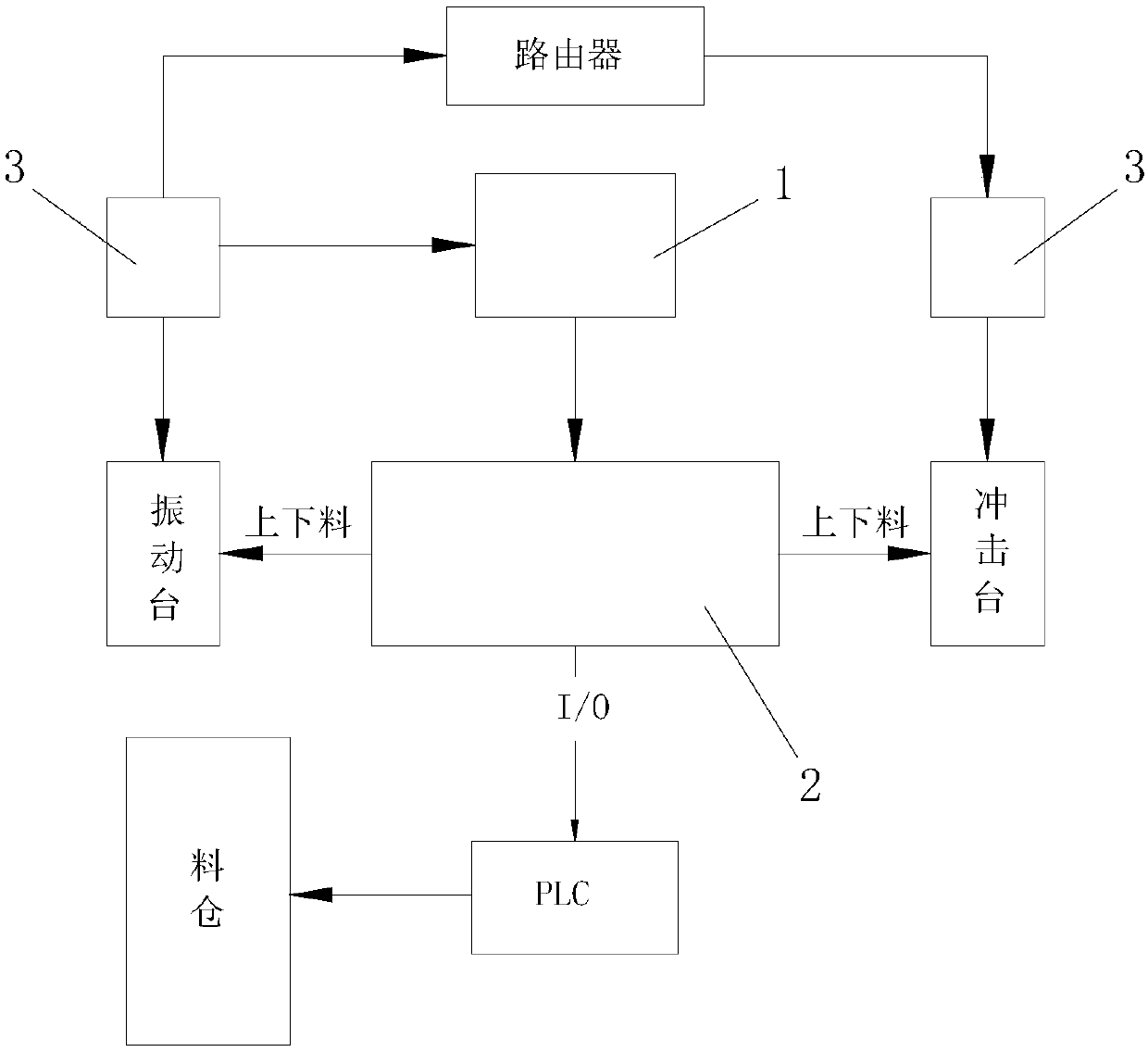

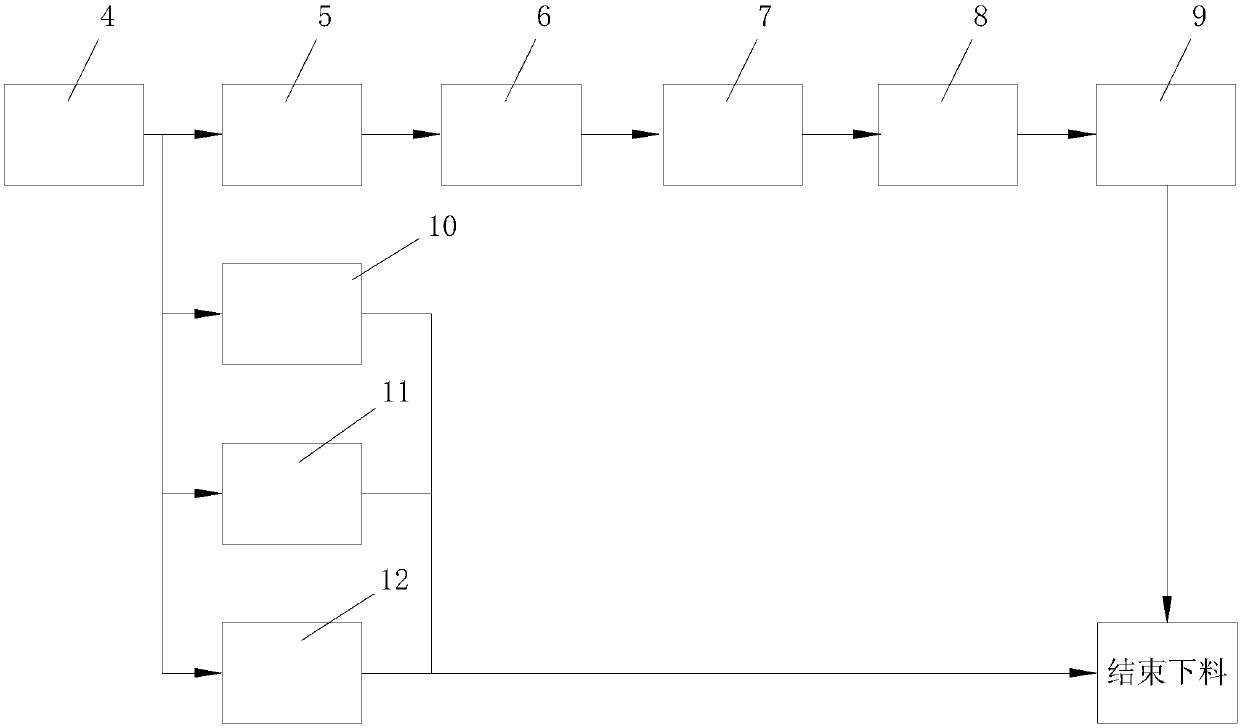

[0016] As shown in the drawings, the present invention includes: a controller 1, a power supply system, a manipulator 2, a testing device, a sample to be tested, and a PC 3, wherein the sample to be tested is a battery; the power supply system is connected to the controller 1, and the controller 1 The power supply system provides the required power supply voltage frequency for the manipulator 2, test equipment, samples to be tested, and PC 3; the manipulator 2 is used to grab the samples to be tested, and the manipulator 2 is a robot that is customized and equipped with a communication module with communication functions. , the input end of the manipulator 2 is connected to the controller 1, and the controller 1 controls the manipulator 2 to perform related actions such as grabbing, carrying objects or operating tools by sending instructions; the test equipment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com