Instrument and method for testing stratum in-situ thermal property of ground source heat pump and heat exchange quantity of buried pipe

A technology of ground source heat pump and buried pipe, which is applied in the field of testing the ground source heat pump buried pipe system of the new technology of HVAC, which can solve the problem of not being able to simulate the heat transfer and thermal conductivity test at the same time, increasing the system volume, and inconvenient transportation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

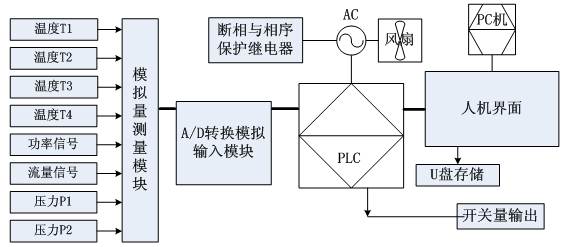

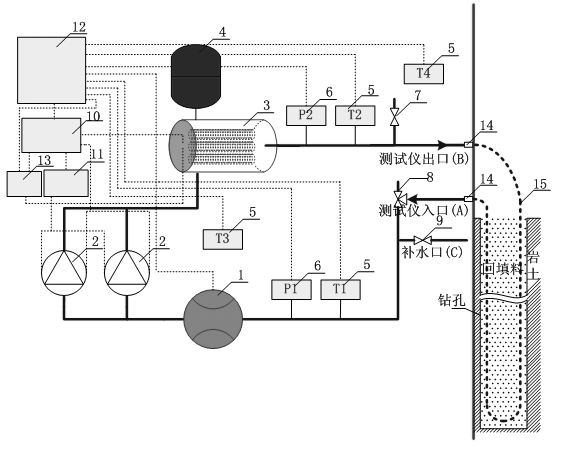

[0070] figure 1 It is a schematic diagram of the principle structure of the tester, which includes a pipeline circulation system, a test system and a monitoring system.

[0071] The pipeline circulation system is composed of flow sensor 1, circulating water pump 2, electric heater 3, expansion tank 4, exhaust valve 7, special joint 14, U-shaped buried pipe 15, three-way valve 8 and water supply valve 9, One side of the flow sensor 1 is threaded to the inlet A of the tester through a DN32 stainless steel pipe. There is a three-way valve 8 connected to this section of the pipeline. The water supply valve 9 is connected to the C-end pipeline, and the other side of the LWGY-25 turbine flow sensor 1 is connected with the PWN-162 circulating water pump 2 through a DN32 stainless steel pipe, and the upper part of the circulating water pump 2 is connected to the rated heating power through the pipeline. The lower part of the 12KW electric heater 3 is connected by welding, and the upp...

Embodiment 2

[0081] Figure 5 For tester test flowchart, the testing process of the present invention specifically includes the following steps:

[0082] Step 1: Preparation before system initialization test.

[0083] Bury the buried pipe filled with circulating fluid in the stratum where the holes are drilled according to the design requirements. After the boreholes are backfilled, place them for 2 to 3 days to restore the ground temperature to the initial state, reduce the disturbance of the boreholes to the stratum, and ensure the measurement results accurate.

[0084] Connect the two ends of A and B of the tester circulation pipeline with the two ends of the U-shaped underground pipe 15 respectively with a special joint 14, so far a complete loop is formed.

[0085] After turning on the power, open the exhaust valve 7, the water supply valve 9, open the three-way valve 8 to the exhaust state, turn on the circulating water pump 2, adjust the speed of the water pump to adjust the flow...

Embodiment 3

[0108] The effective depth of the buried pipe is 80m. The buried pipe in the test hole is single U-shaped, and the PE100-φ25mm high-density polyethylene pipe is used. The backfill of the buried pipe is a mixed slurry of bentonite and fine sand (1:4). The borehole diameter is φ150mm, and the circulating medium in the pipe is clear water.

[0109] A, B two ends of the tester circulation pipeline of embodiment 1 are respectively connected with the two ends of the U-shaped buried pipe 15 with the PE joint with internal thread of DN32 and the PE reducing joint of DN32-DN25, wherein the variable There is hot-melt welding between the diameter joint and the U-shaped buried pipe, and between the PE joint with internal thread, and the threaded connection between the PE joint with internal thread and the tester, thus forming a complete circuit.

[0110] After turning on the power, open the exhaust valve 7 and water supply valve 9, open the three-way valve 8 to the exhaust state, select t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com