Bending and anti-cracking performance testing device and testing method

A test device and crack resistance technology, applied in the field of testing, can solve the problems of the test piece affecting the test accuracy, affecting the test accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

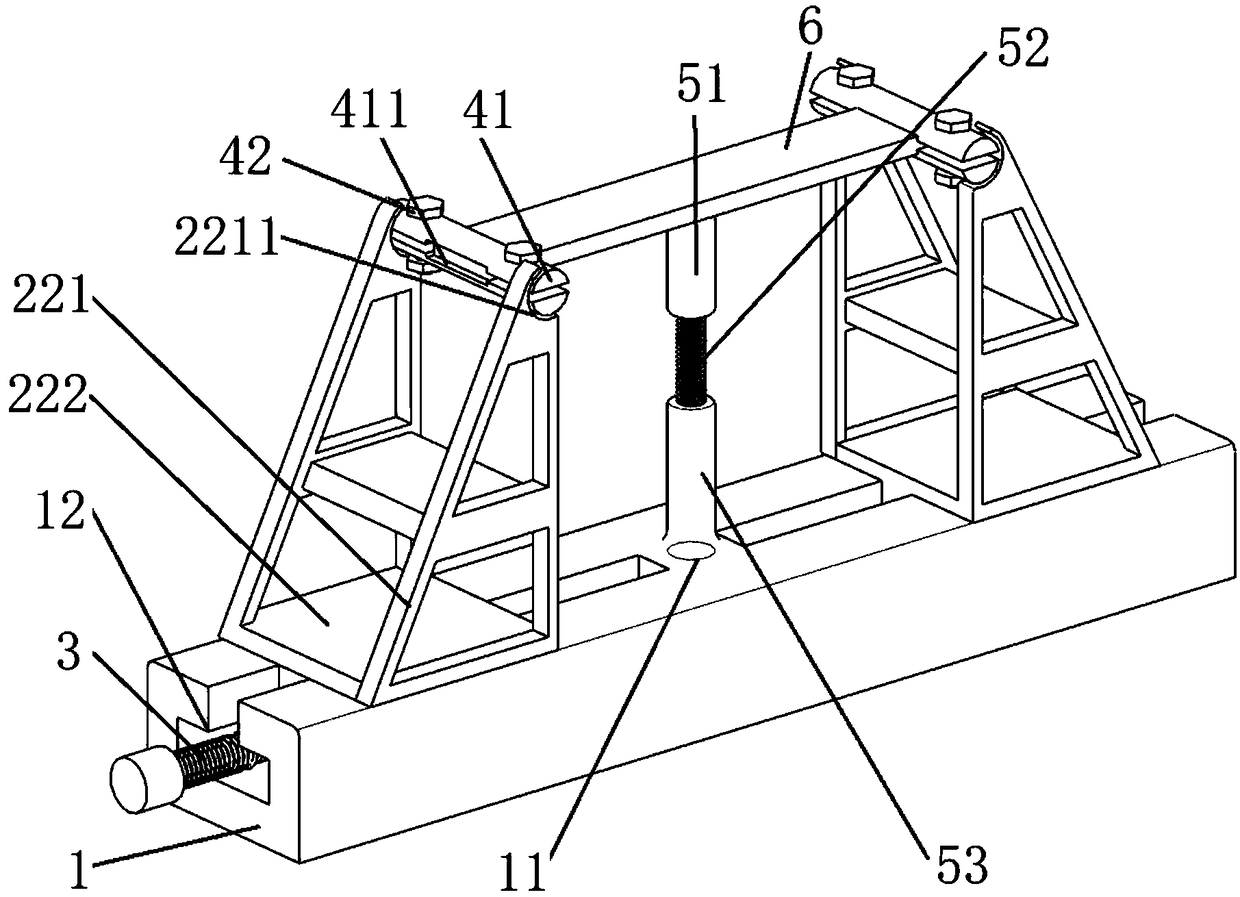

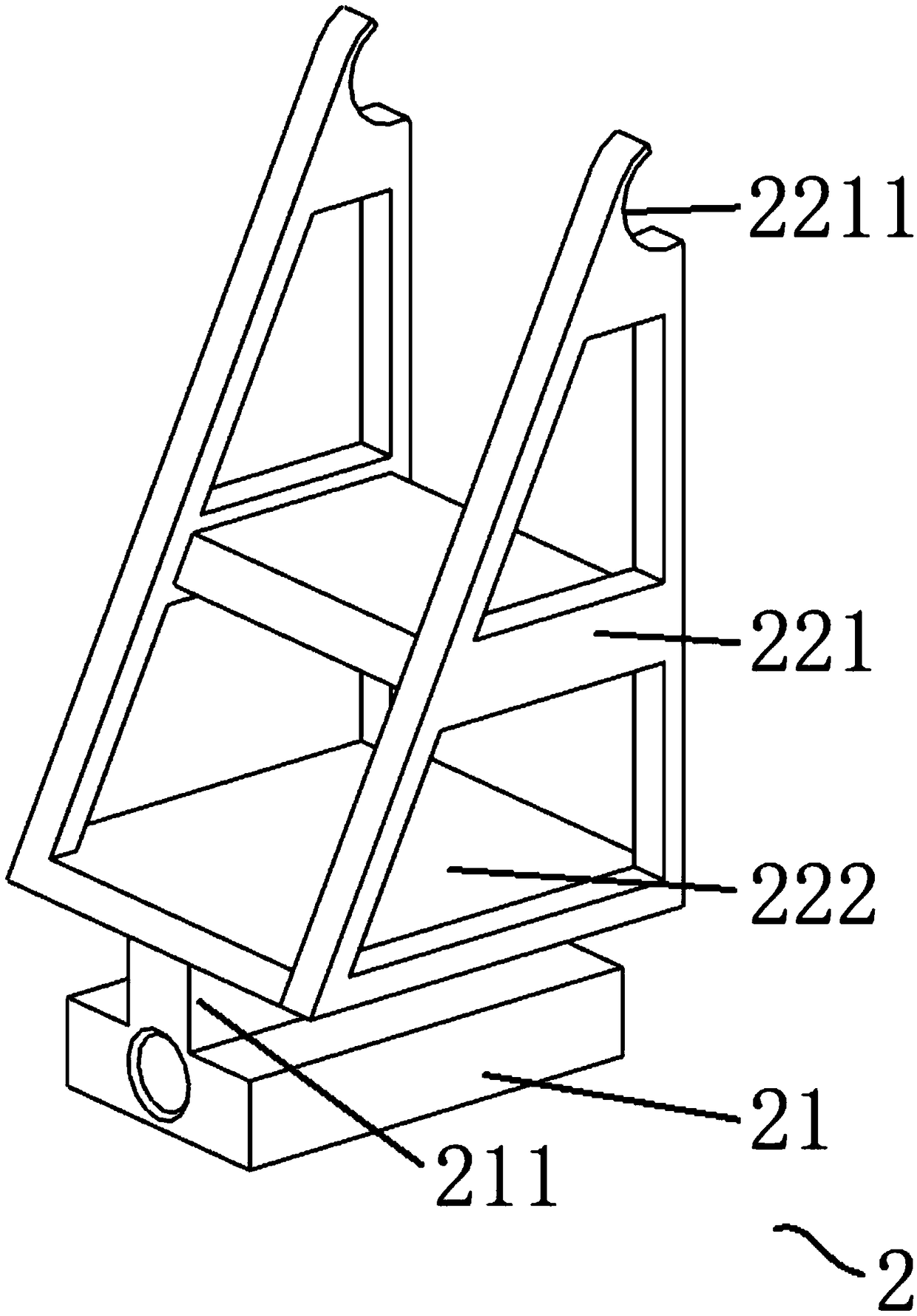

[0074] This embodiment provides a bending crack resistance testing device, which includes: a base 1, a force applying mechanism, at least one pair of clamping mechanisms, a bending guiding mechanism and an image processing system. The clamping mechanism is used to clamp the test piece 6; the force applying mechanism includes a pair of supporting components 2 and a driving component, wherein the supporting component 2 is movably arranged on the base 1 to support and fix the clamping mechanism; the driving component drives the supporting component 2 to move ; The bending guide mechanism is fixed on the base 1, and one end thereof abuts against the side surface of the test piece 6 to limit the bending of the test piece 6 in the direction where the bending guide mechanism is located. It should be noted that the test piece 6 in this embodiment is a plate-shaped resin material test piece. Of course, it can also be a test piece 6 made of other materials.

[0075] Such as figure 1 a...

Embodiment 2

[0085] This embodiment provides a test method for a fracture test using the bending crack resistance test device in Example 1, which includes the following steps in sequence:

[0086] S1: Assemble the test piece 6 in the clamping mechanism: specifically, first place the test piece 6 in the clamping space 411 formed by the semi-cylindrical body 41, and then figure 1 and Figure 4 Bolt 42 is shown locked.

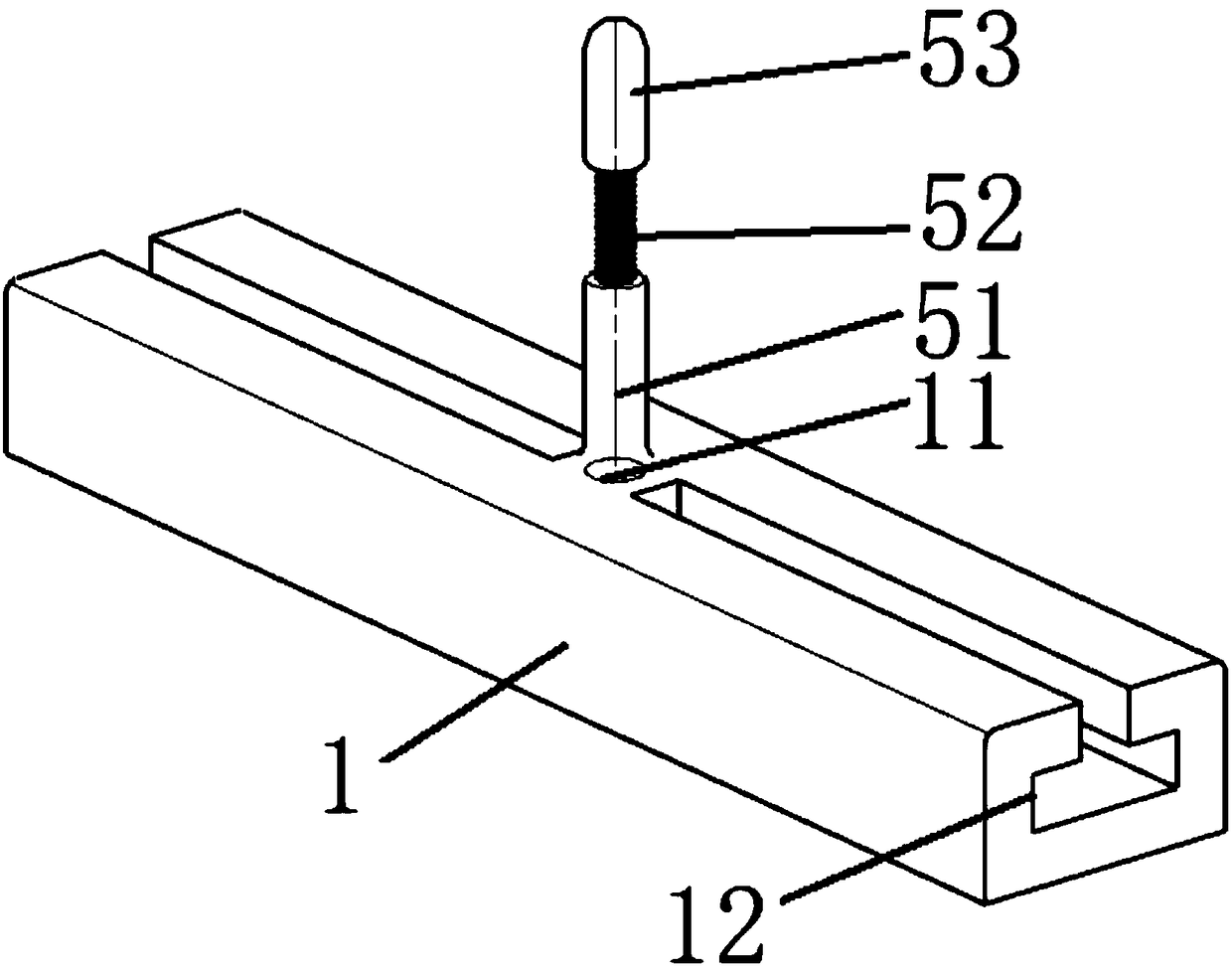

[0087] S11: Adjust the length of the bending guide mechanism so that it abuts against the surface of the test piece 6: specifically, adjust the length of the bending guide mechanism by adjusting the screw 52 .

[0088] S2: The driving component such as a motor or manpower drives the supporting component 2 to move closer, so that the test piece 6 in the clamping mechanism is bent until it breaks;

[0089] Step S3 carried out simultaneously with step S2: the image acquisition device captures and collects a number of bending shape images of the test piece 6 at different moment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com