Patents

Literature

122results about How to "Avoid reaction force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

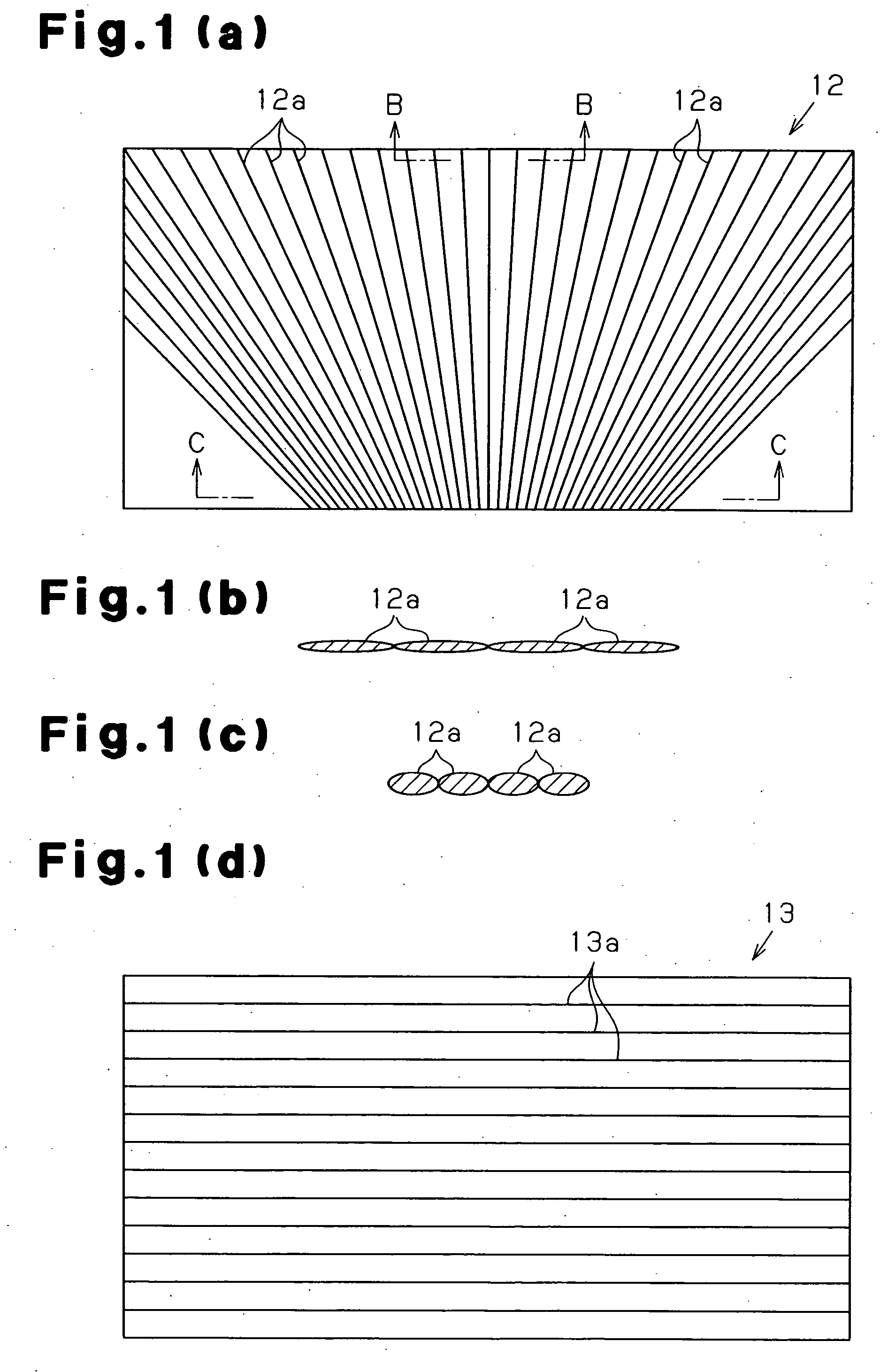

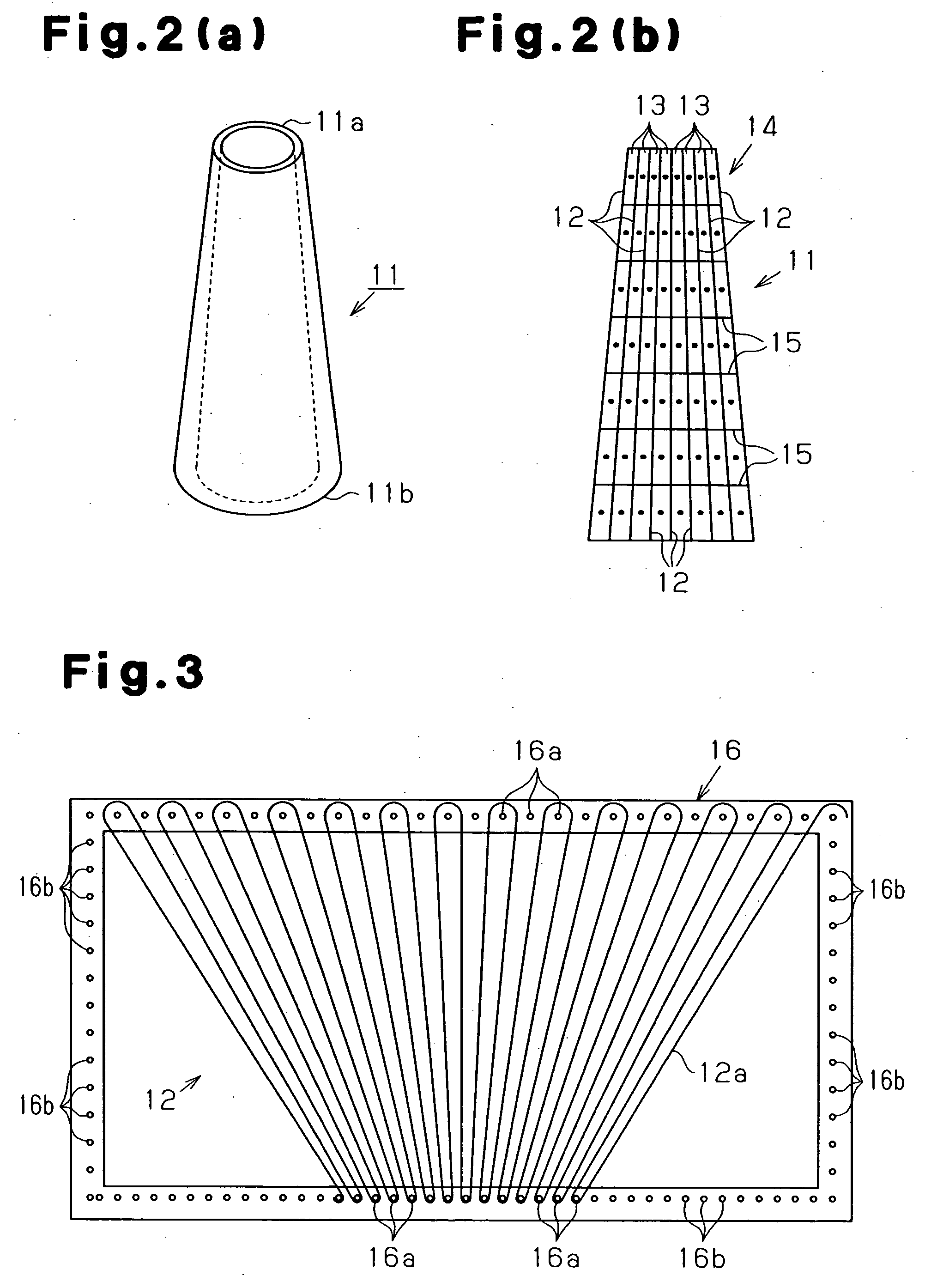

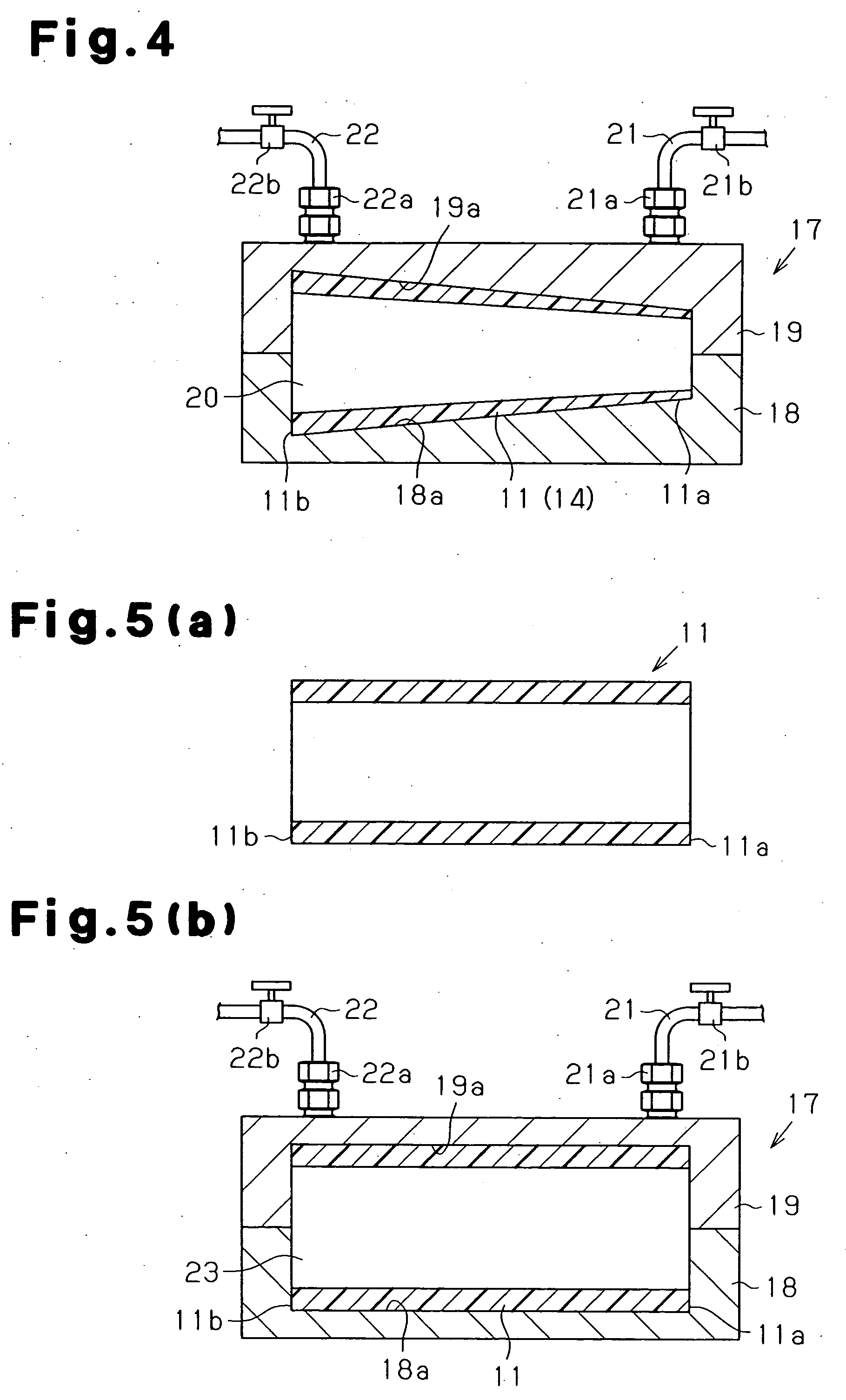

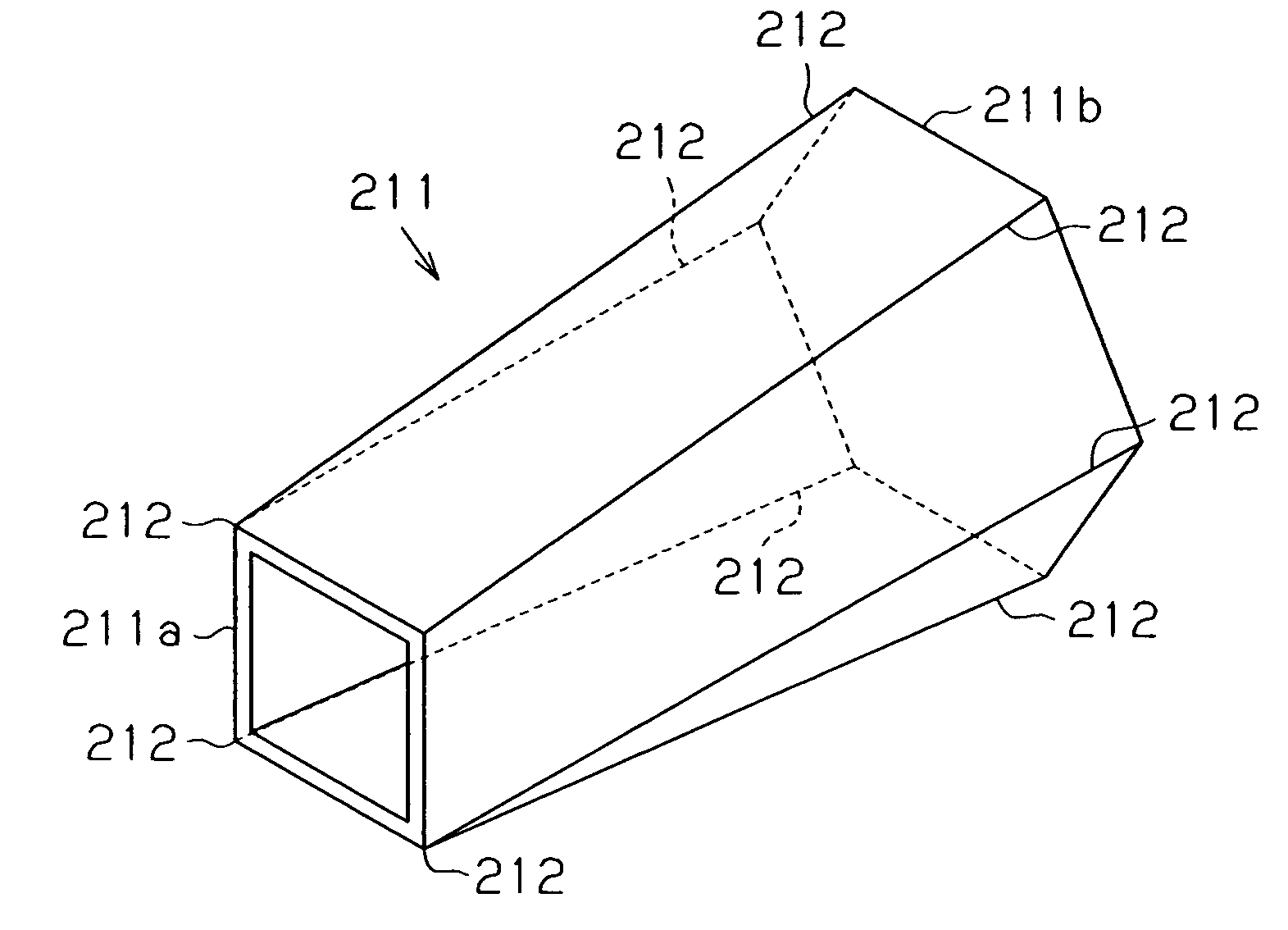

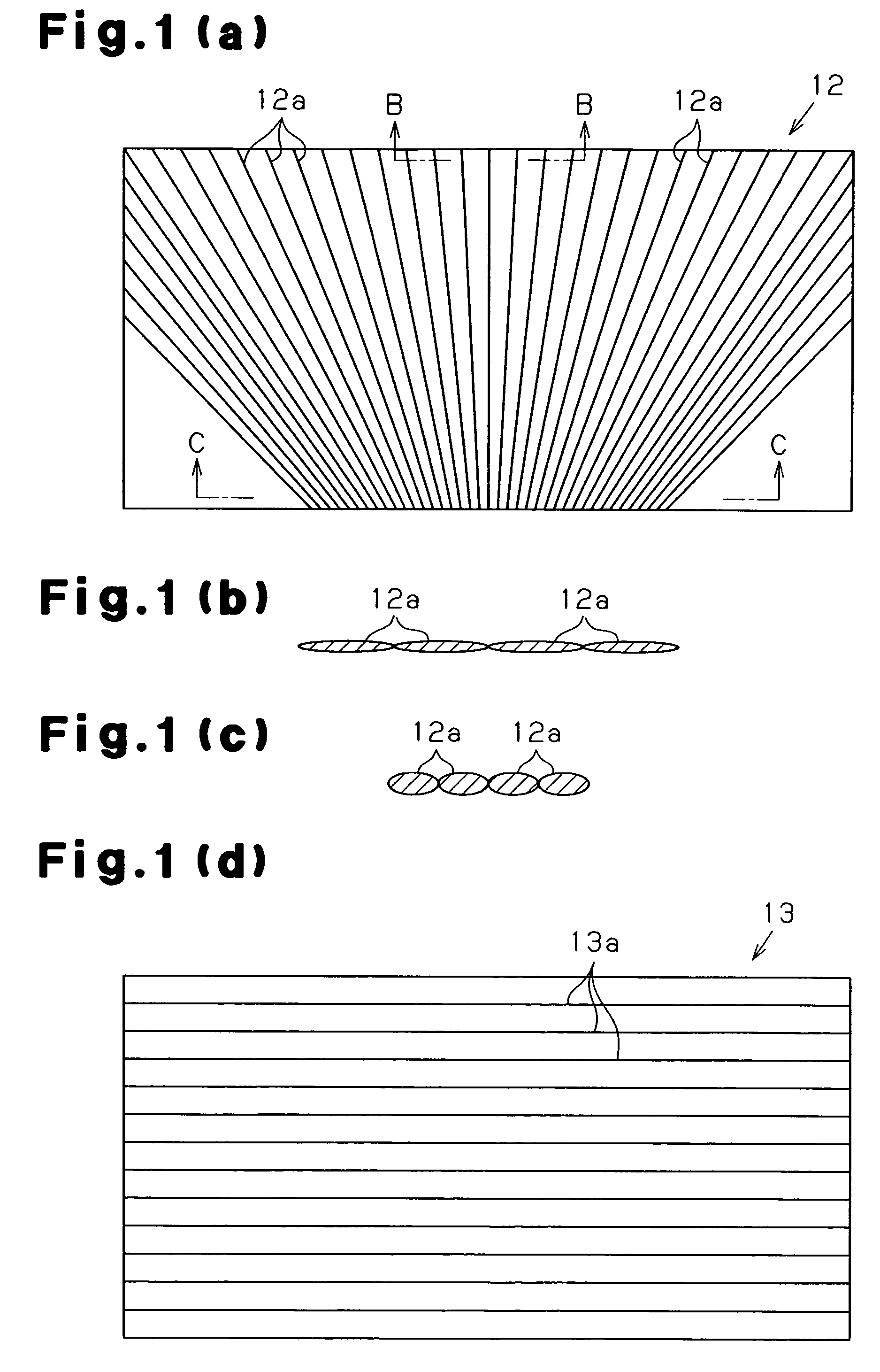

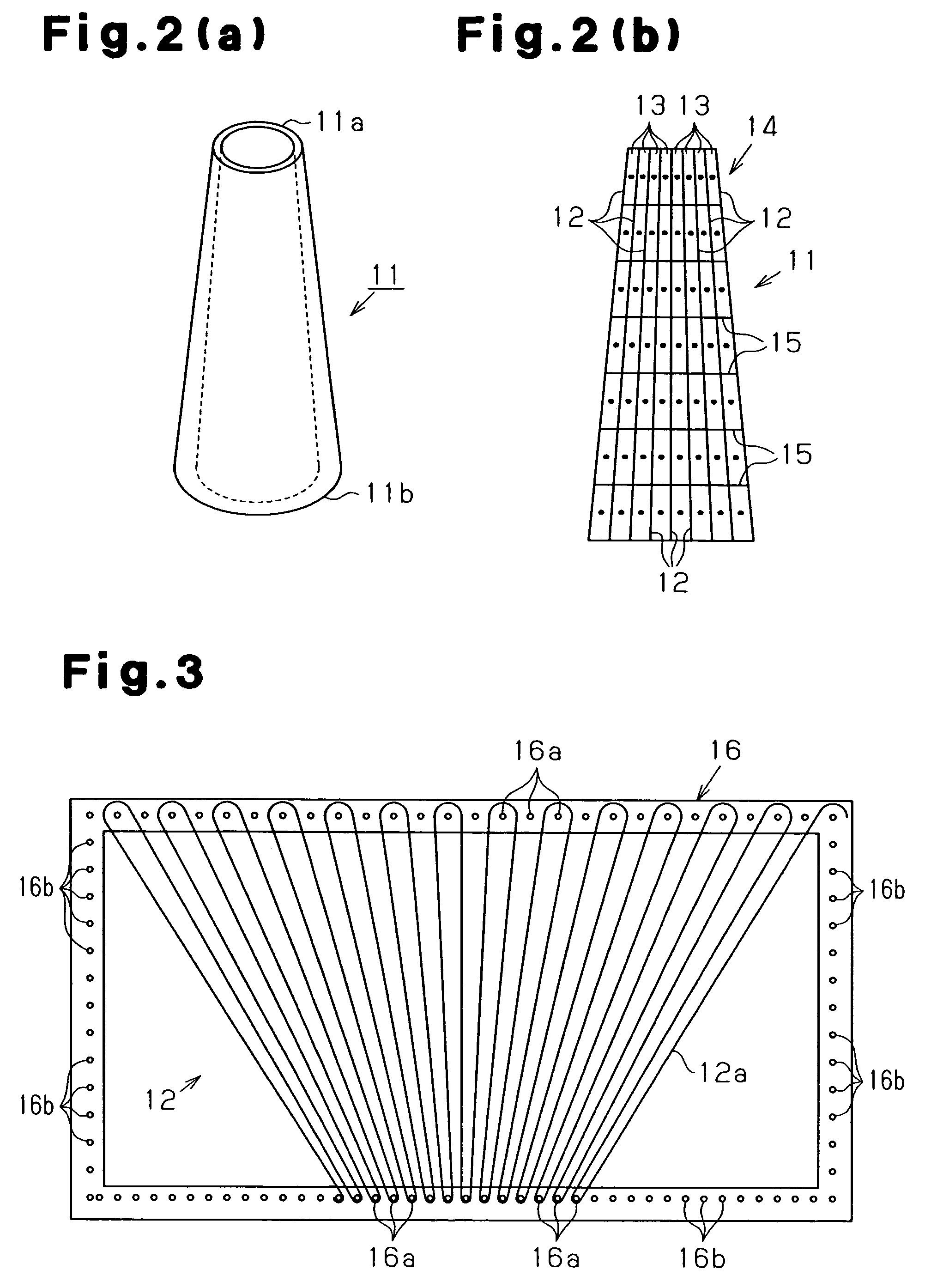

Energy absorber and method for manufacturing the same

ActiveUS20050147804A1Stably absorb energyIncrease in amountLayered productsPedestrian/occupant safety arrangementEnergy absorbingFiber layer

An energy absorber is crushed upon receiving compressive load, thereby absorbing energy. The energy absorber has a first end and a second end with respect to a direction of the compressive load. The energy absorber is formed of fiber-reinforced resin. The fiber-reinforced resin includes a stack of fiber layers having a compression direction fiber layer. The compression direction fiber layer includes fiber bundles of filament fibers. The fiber bundles are arranged such that the extending direction of the fiber bundles has a component of the direction of the compressive load. The density of the fiber bundles is gradually increased from the first end to the second end. Therefore, compressive load required for crushing is prevented from increasing at an early stage of crushing.

Owner:TOYOTA IND CORP

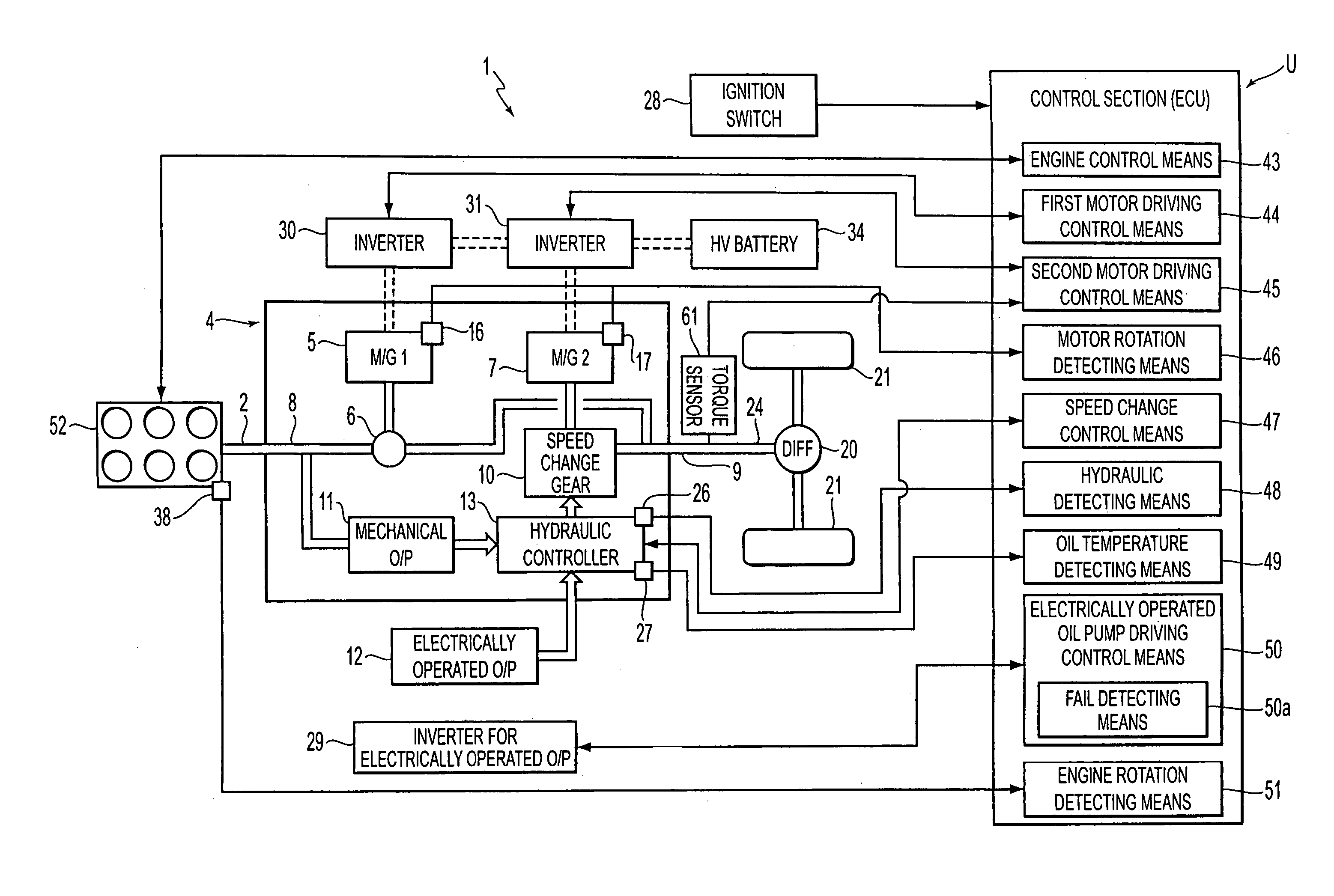

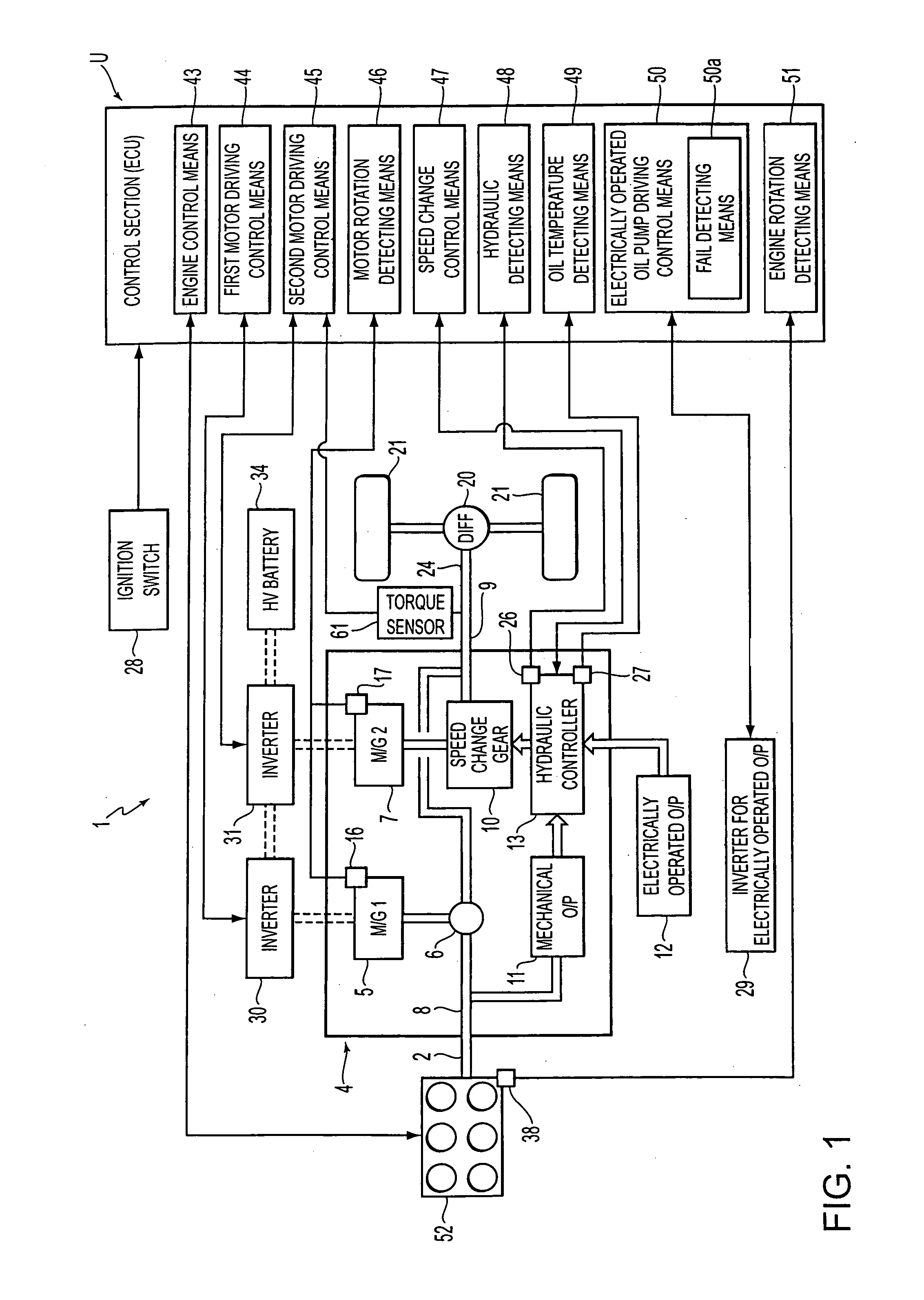

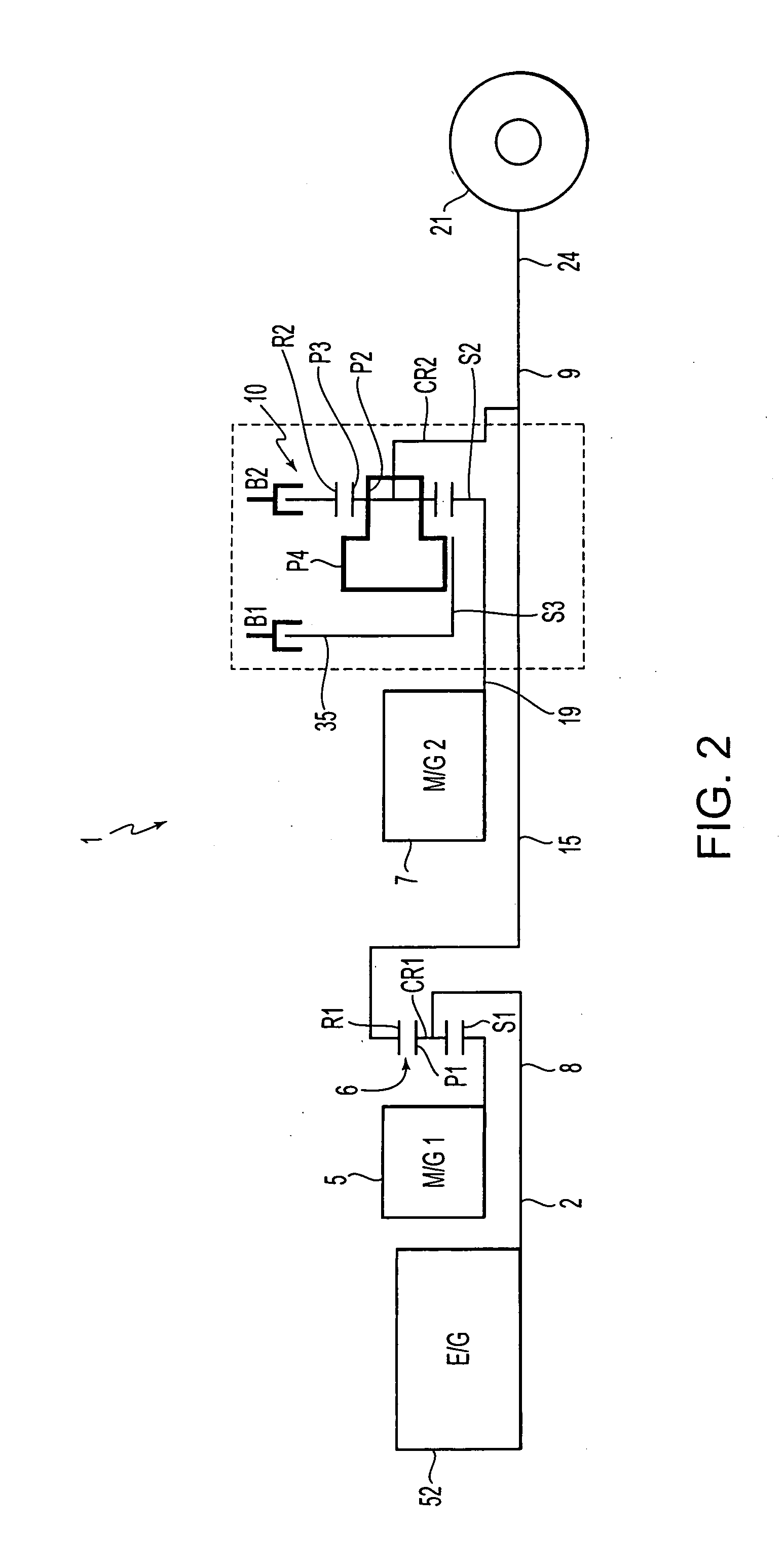

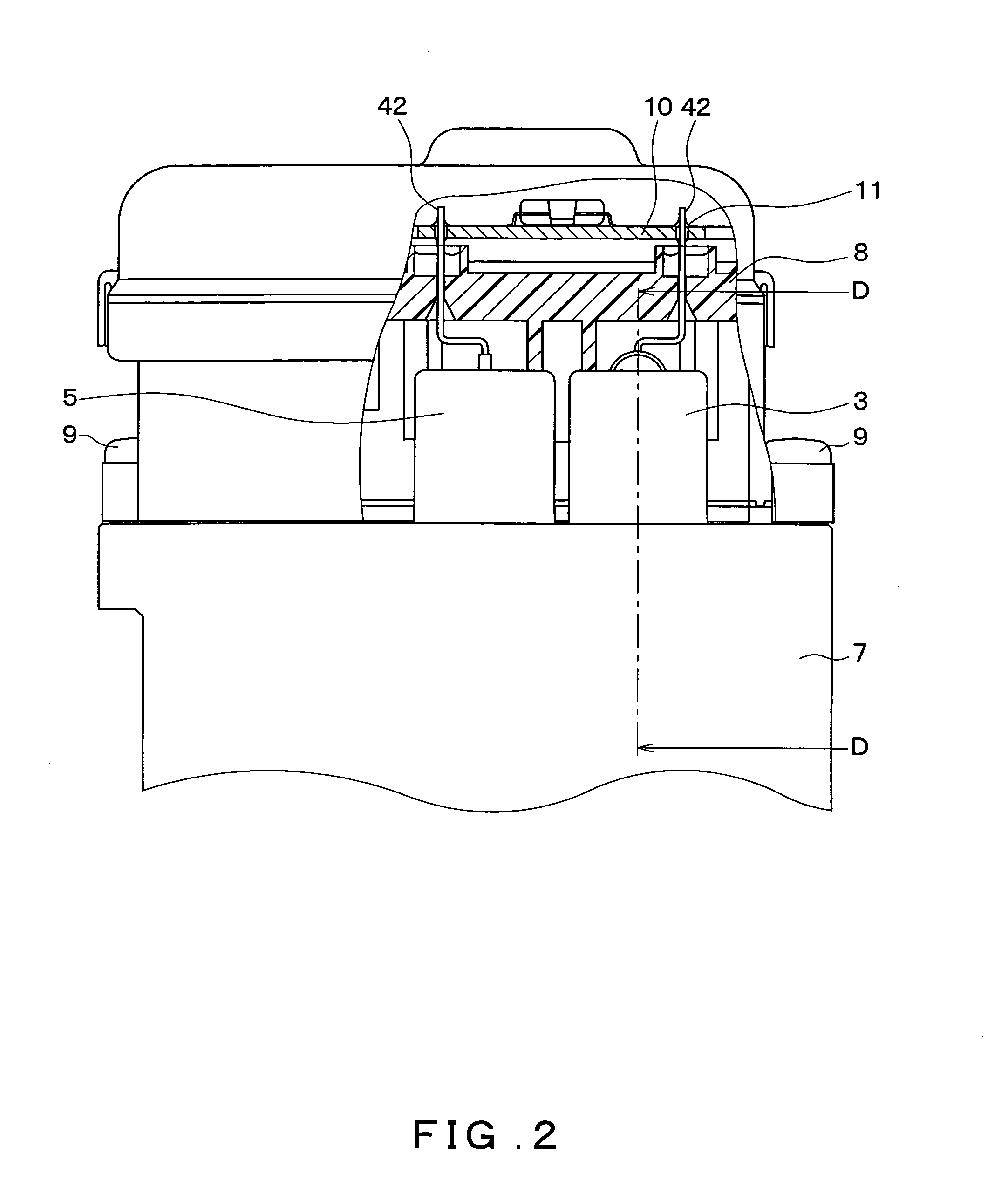

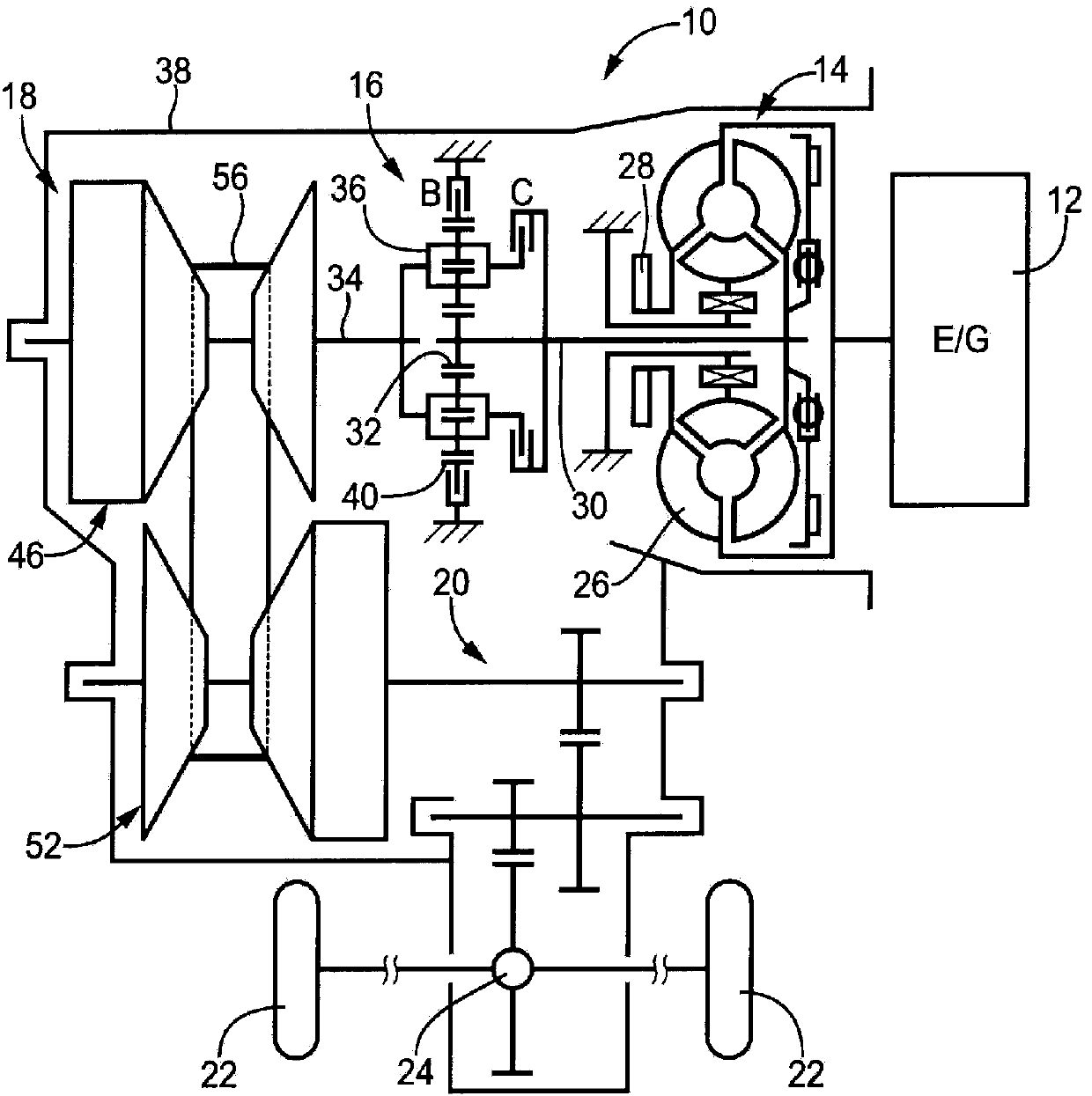

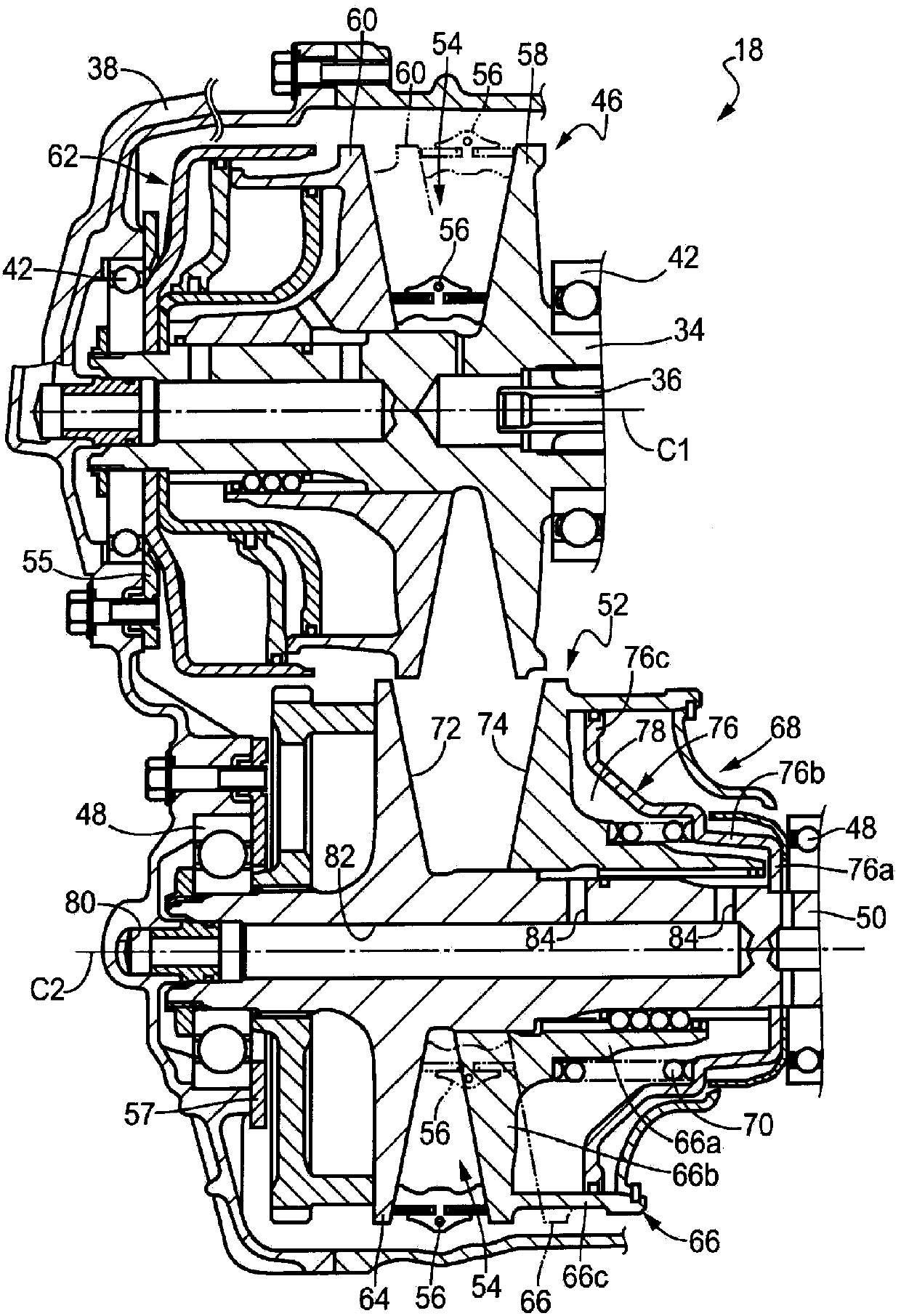

Drive unit for vehicle

ActiveUS20050124457A1Inhibition is effectiveIncrease speedElectric propulsion mountingToothed gearingsOil pressureAutomotive engineering

The drive unit for a vehicle has an engine driving control element for driving a first motor on the basis of an engine driving signal, and driving a second motor so as to restrain a reaction force in a power distributing planetary gear due to the driving of the first motor in a state in which the stepped speed change gear connects the second motor and an output shaft by brakes. Further, the drive unit has an electrically operated oil pump for generating an operating oil pressure of the brakes, and also has a control section having an electrically operated oil pump operation control element for operating the electrically operated oil pump prior to the control of the engine driving control element on the basis of an engine starting signal outputted in a vehicle stopped state.

Owner:AISIN AW CO LTD +1

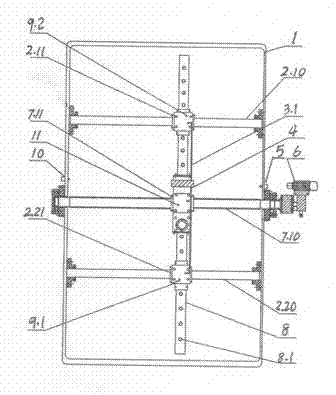

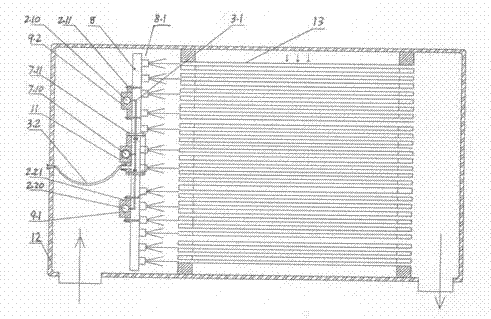

Online cleaning device for heat exchange tube of condenser

ActiveCN102401609AReduce internal drive jointsReduce the chance of failureFlush cleaningHigh pressure waterHigh pressure

The invention belongs to the field of cleaning, and provides an online cleaning device for a heat exchange tube of a condenser. The online cleaning device is mainly characterized in that: a conventional online cleaning mode is improved; a cleaning mechanism adopts a row of nozzles; the middle part of the row of nozzles is connected with a driving nut floating cavity body, and the end parts of therow of nozzles are connected with guide sleeve floating cavities; and a chemical cleaning agent gallipot is connected in series with a high-pressure water pipeline. The online cleaning device has theremarkable advantages of simple structure, running reliability, convenience for mounting and maintenance, high cleaning speed and good effects; moreover, the online cleaning device can be used for replacing rubber ball cleaning, also can be used together with the rubber ball cleaning and can realize all-round cleaning and the chemical cleaning of important parts.

Owner:深圳悦诚节能科技有限公司

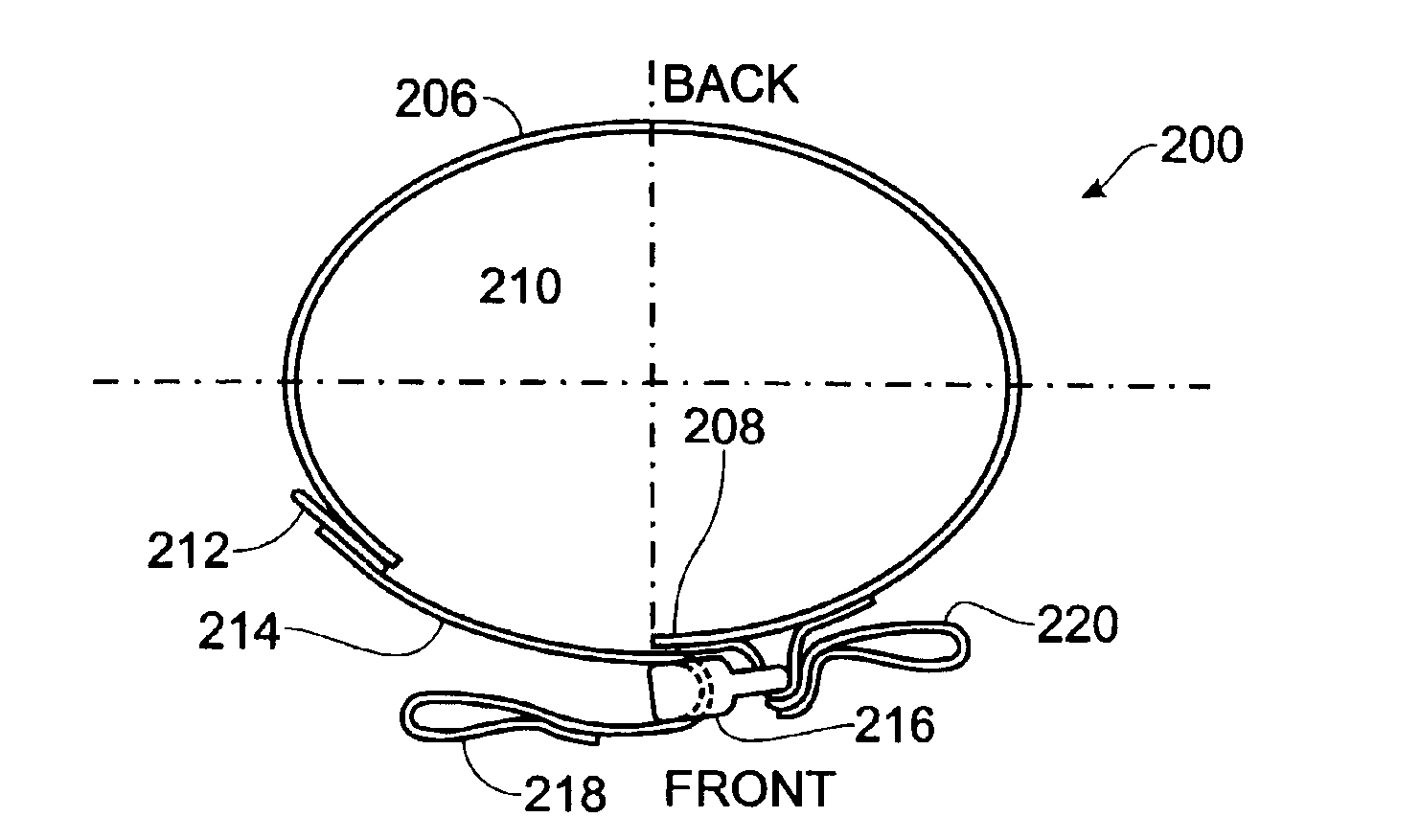

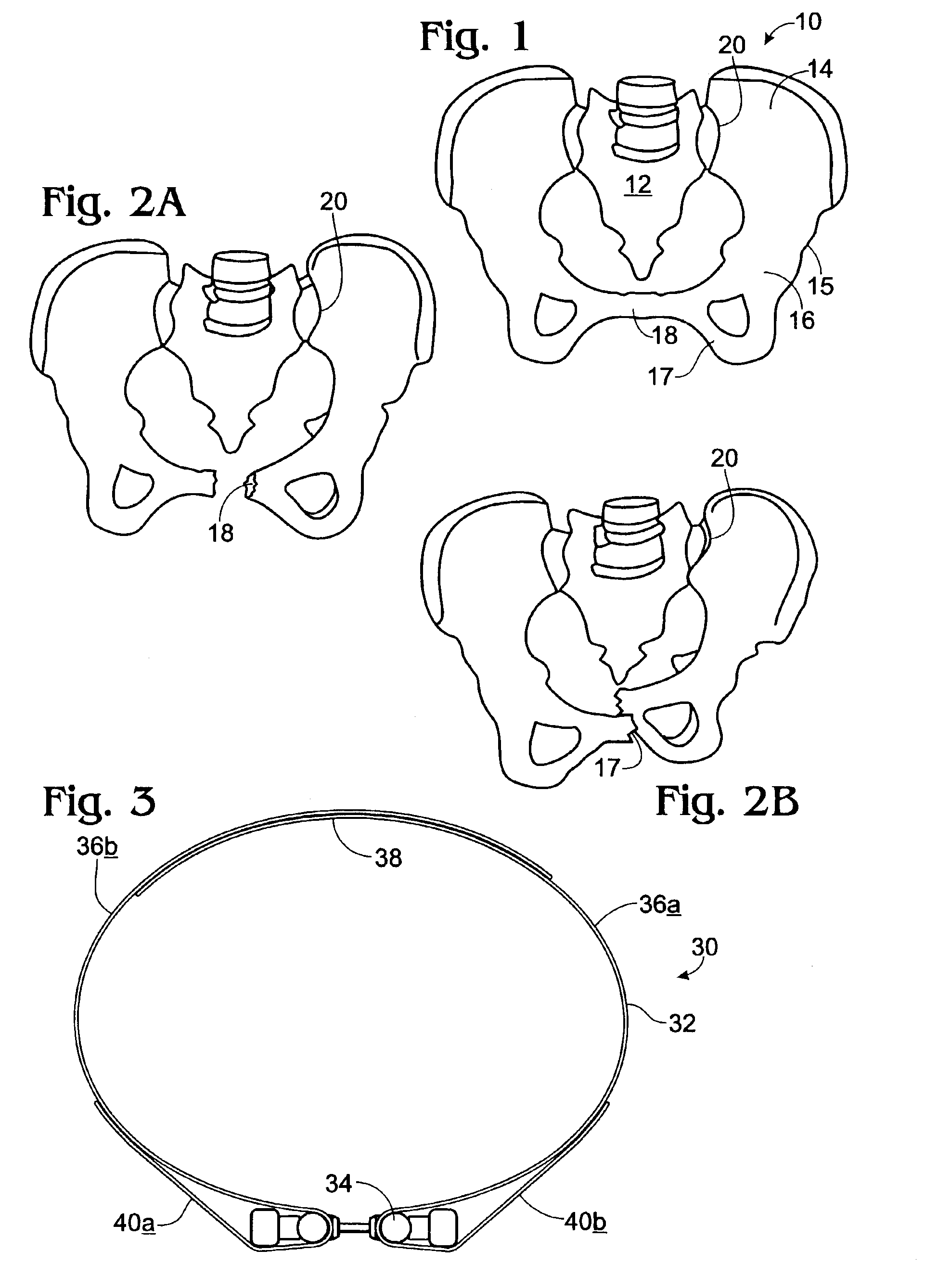

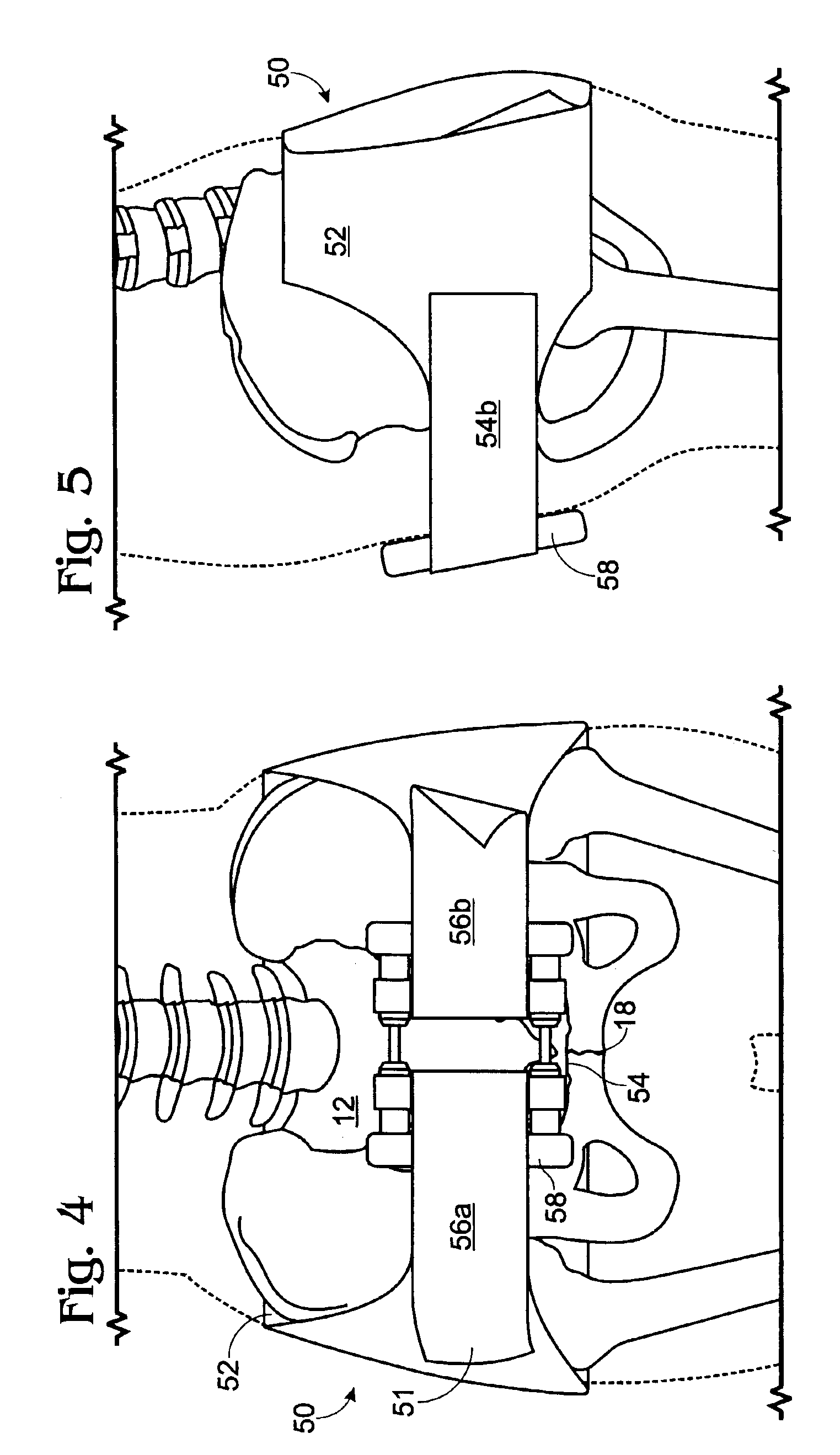

Apparatus and method for stabilizing pelvic ring disruption

ActiveUS7008389B2Quality improvementAvoid reaction forceSurgeryOrthopedic corsetsPelvic ringEngineering

Apparatus and methods for stabilizing a fractured pelvis in an emergency using a sling having a buckle designed to automatically lock the circumference of the sling at a tension level that has been predetermined to be effective for stabilizing a fractured pelvis without excessive or potentially damaging compression.

Owner:LEGACY EMANUEL HOSPITAL & HEALTH CENT

Energy absorber and method for manufacturing the same

ActiveUS7842378B2Energy stabilityIncrease volumeLayered productsPedestrian/occupant safety arrangementFiber bundleAbsorbed energy

An energy absorber is crushed upon receiving compressive load, thereby absorbing energy. The energy absorber has a first end and a second end with respect to a direction of the compressive load. The energy absorber is formed of fiber-reinforced resin. The fiber-reinforced resin includes a stack of fiber layers having a compression direction fiber layer. The compression direction fiber layer includes fiber bundles of filament fibers. The fiber bundles are arranged such that the extending direction of the fiber bundles has a component of the direction of the compressive load. The density of the fiber bundles is gradually increased from the first end to the second end. Therefore, compressive load required for crushing is prevented from increasing at an early stage of crushing.

Owner:TOYOTA IND CORP

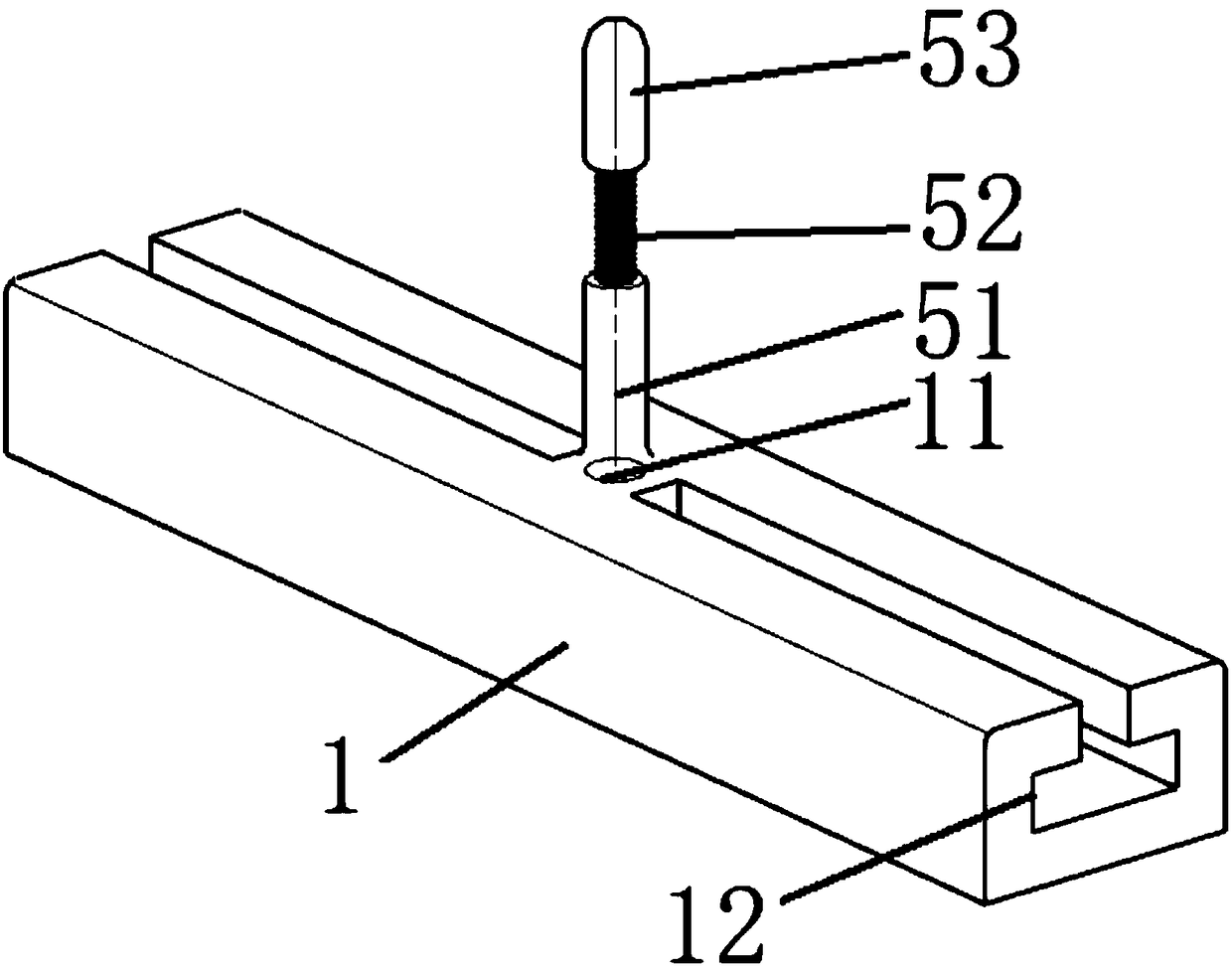

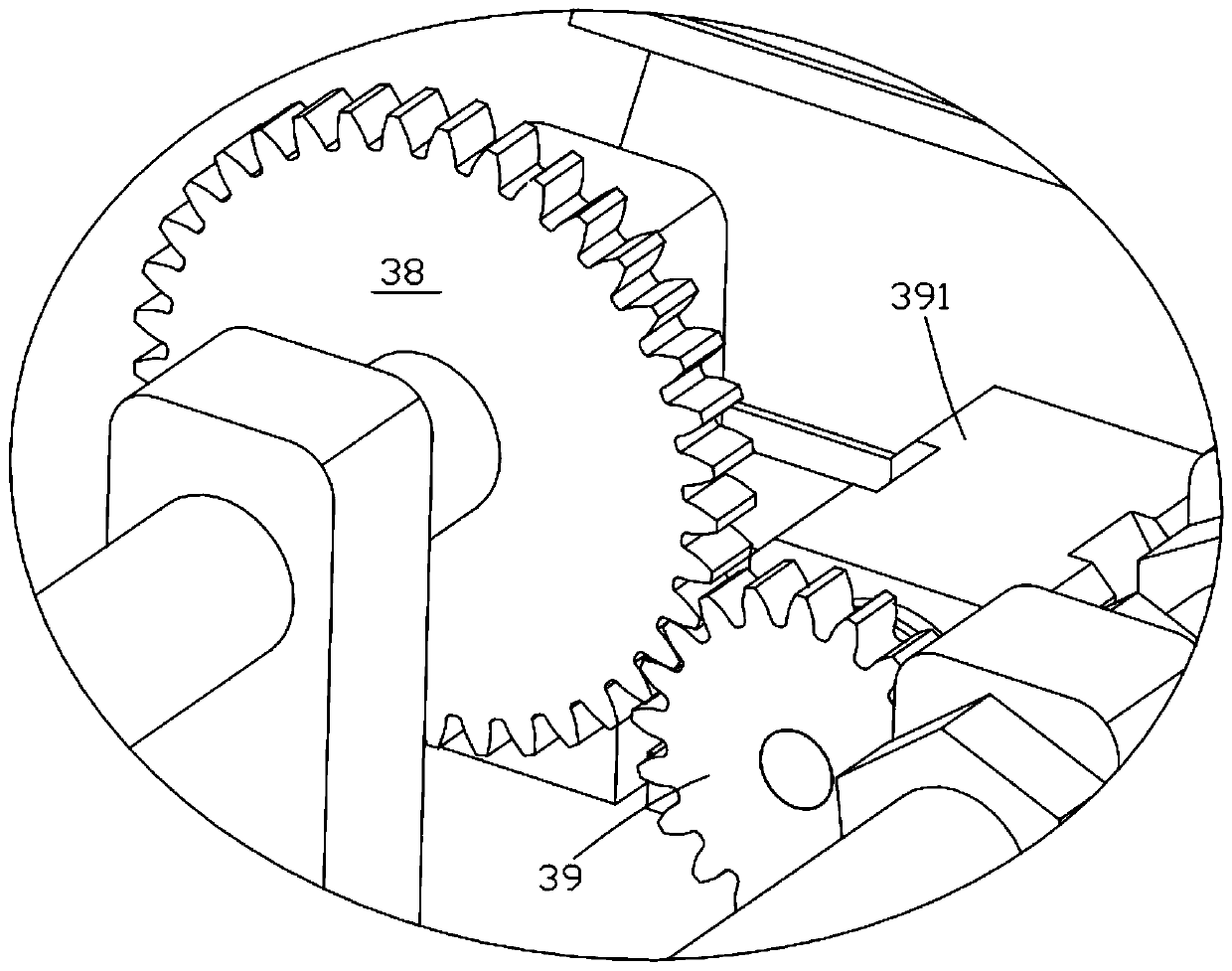

Soil sampler for biological soil enzyme activity determination

InactiveCN109187080ALabor savingImprove sampling efficiencyWithdrawing sample devicesPush outEngineering

The invention discloses a soil sampler for biological soil enzyme activity determination. The soil sampler comprises a handheld rod and a limiting frame; the lower end of the handheld rod is fixedly connected with the limiting frame; a movable sleeve is fixedly connected to the middle of the limiting frame; the lower end of the handheld rod is symmetrically connected with one ends of two telescopic rods; when a motor rotates, a rotating shaft can be driven to rotate, so that a sampling cylinder is driven to move downwards; the sampling cylinder can move downwards better due to the existence ofa spiral blade, so that the sampling can be performed better, the manual sampling is facilitated, and the labor force is reduced; the lower end of the spiral blade and the lower end of the sampling cylinder adopt conical structures, and in the sampling process, the sampling cylinder can enter the soil more easily, so that the sampling efficiency is improved; after the sampling is finished, in theprocess that a scraping plate moves downwards, a soil sample is pushed downwards, so that the soil sample is pushed out; and meanwhile, the inner side wall of the sampling cylinder is scraped by thescraping plate so as to ensure that the next sampling can be very smooth.

Owner:HEFEI HUAGAI BIOTECH CO LTD

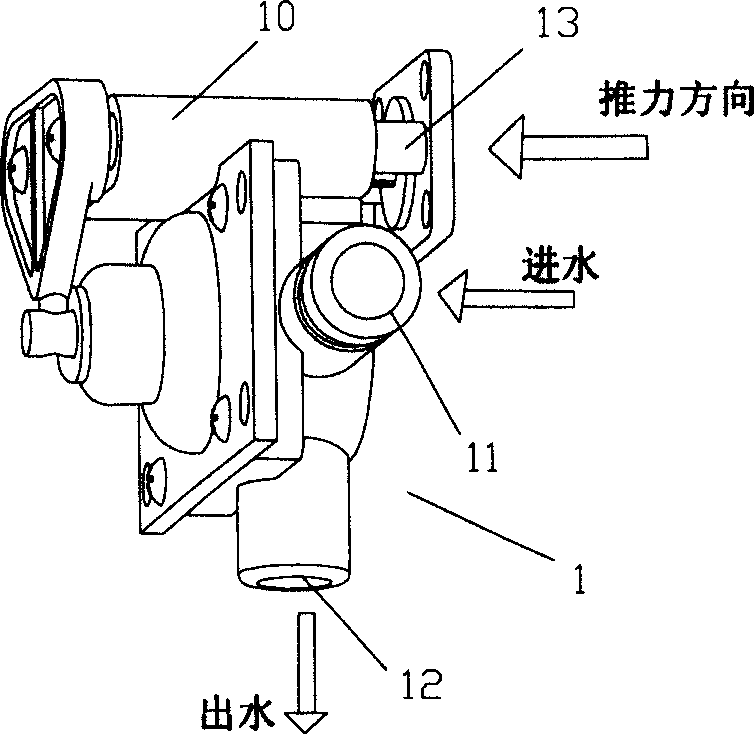

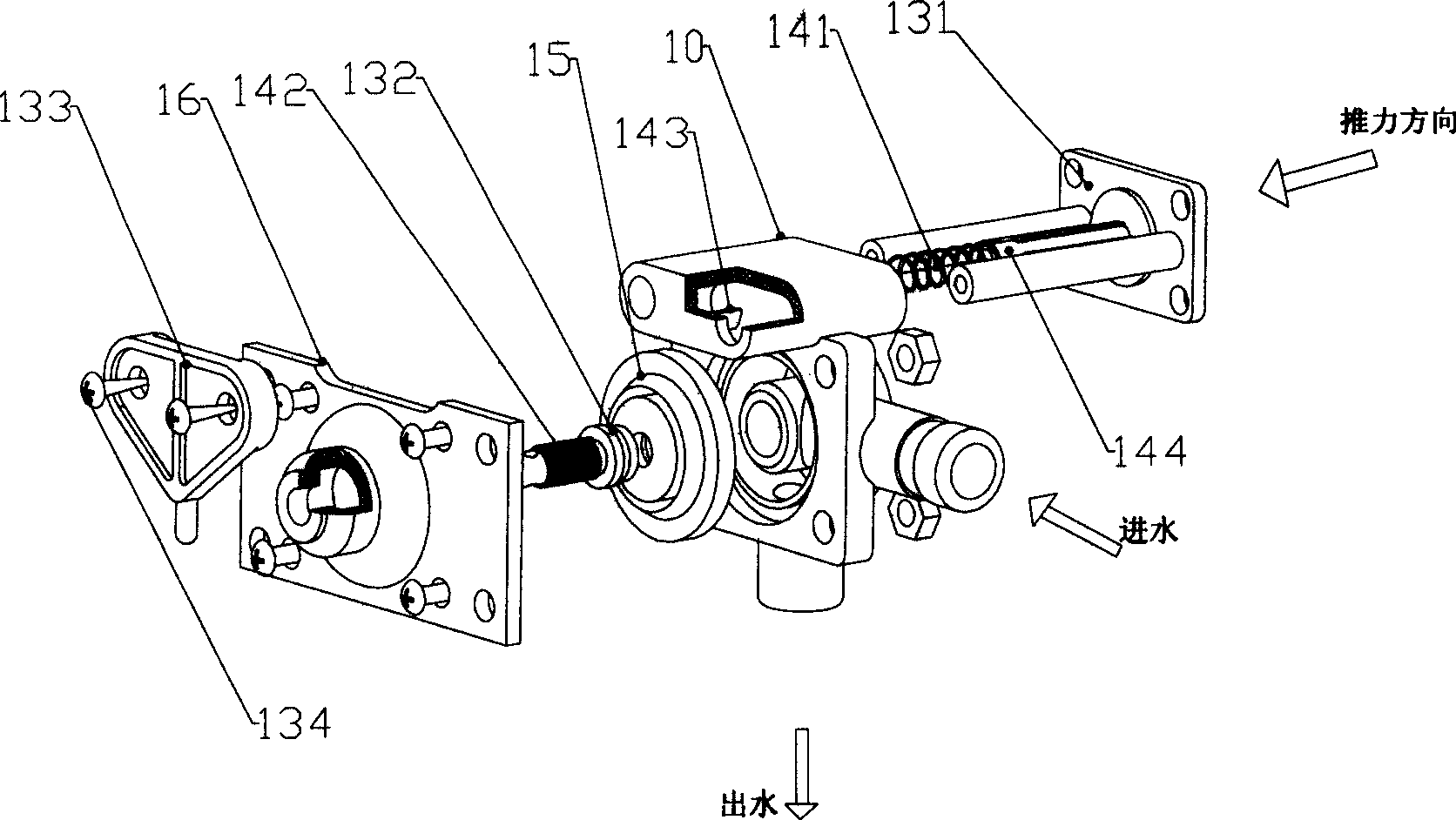

Small push force tap for water drinking machine

InactiveCN1587765ASimplify the assembly processHigh speedDiaphragm valvesEngine diaphragmsWater drinkingEngineering

The invention is small pushing-force watering trough cocket, which includes a valve body. The valve body is arranged with a water inlet and outlet. The character is: the inlet and the outlet are connected together with pipes; a linkage device and a elastic sealing element are arranged in the cavity of the valve; the linkage device includes moving pushing pole, valve pole and linkage; the valve pole is connected to the linkage, the linkage is fixed on the moving pushing pole, the moving pole, valve pole and the linkage are integrated together; and when the moving pushing pole bears the stress, the valve pole and the linkage move respectively; on the contacting part of the valve body and the valve body, the valve pole is arranged with the elastic sealing element the elastic sealing element and the outlet of the valve body are connected and seals the outlet, and when it bears the stress, it is separated with the outlet. The product in the invention has characters of excellent seal property, high product quality, simple, quick and high efficiency.

Owner:QIDI ELECTRIC GROUP

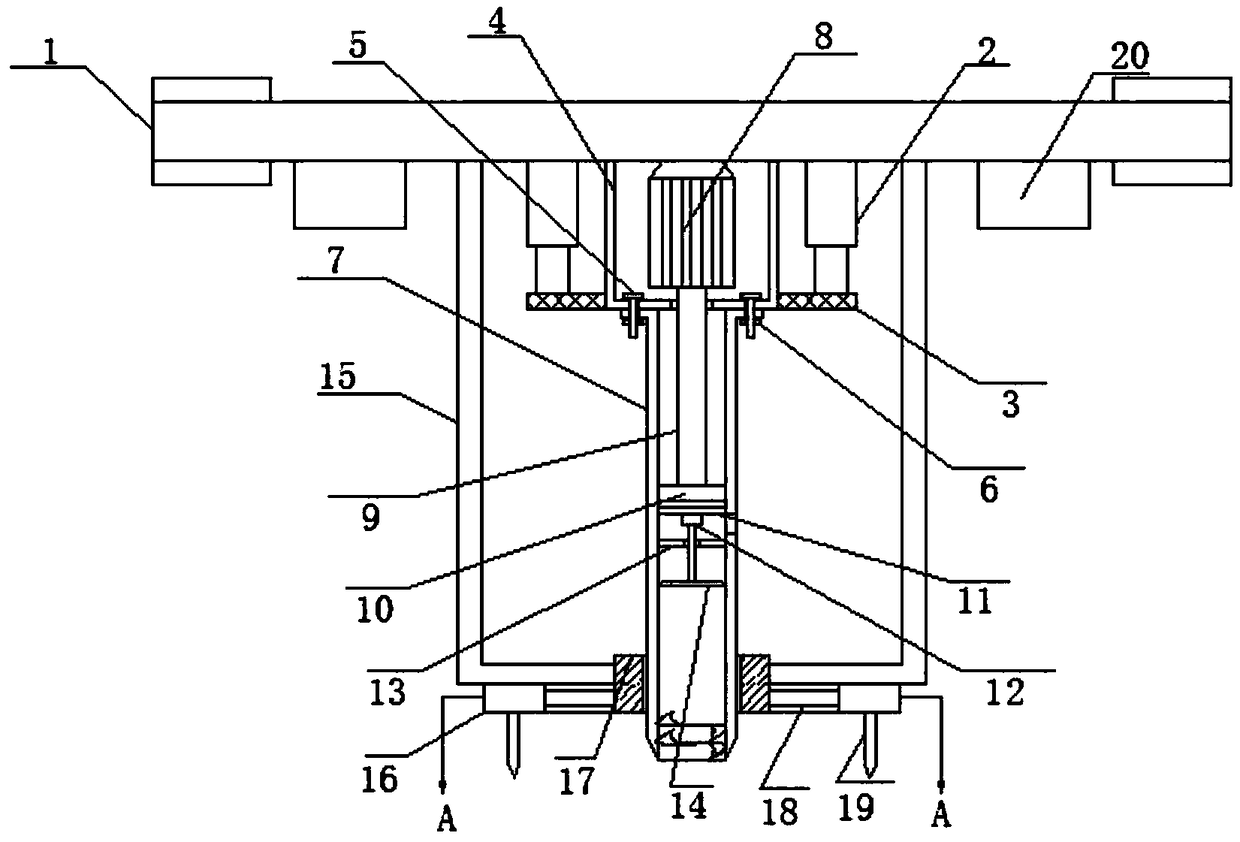

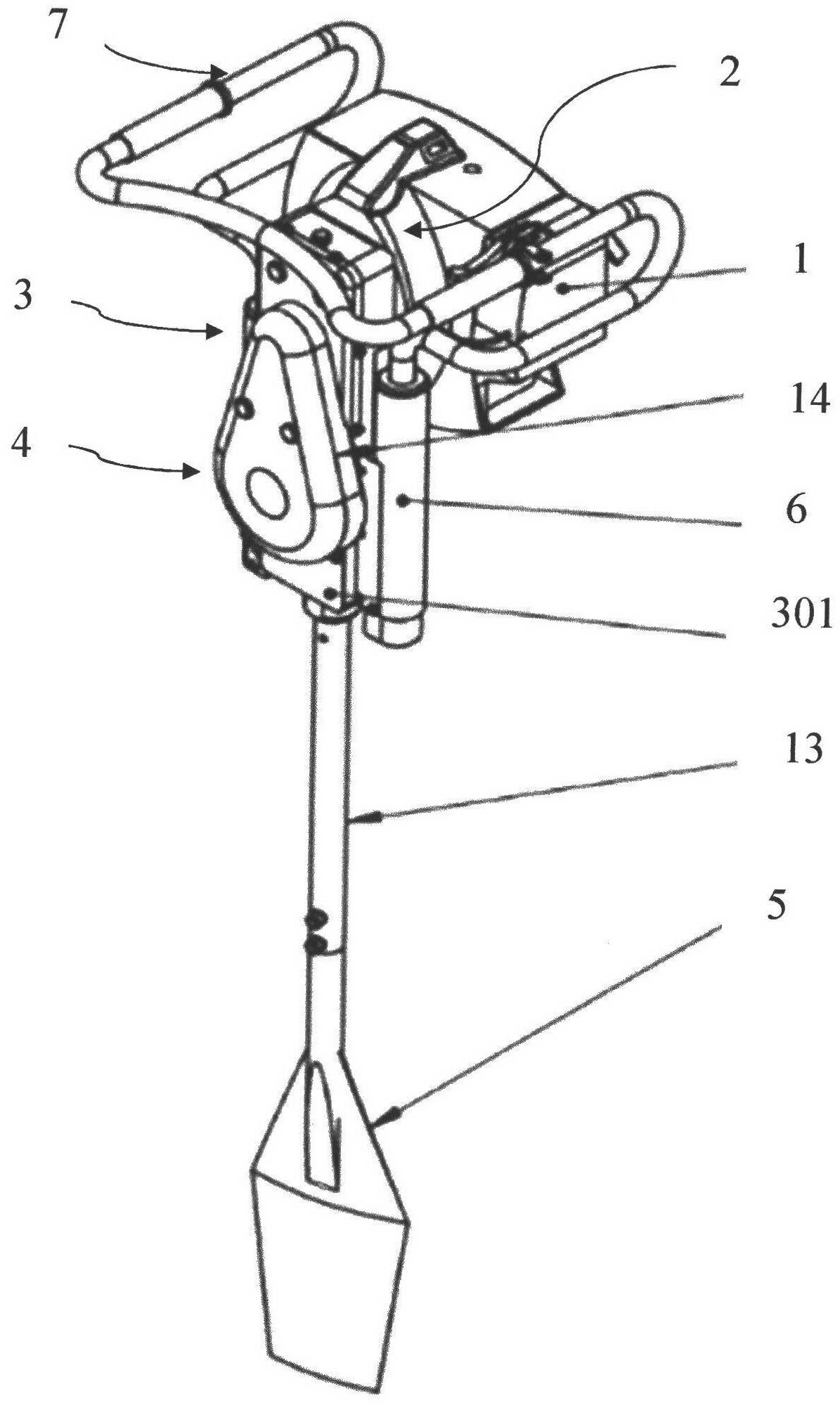

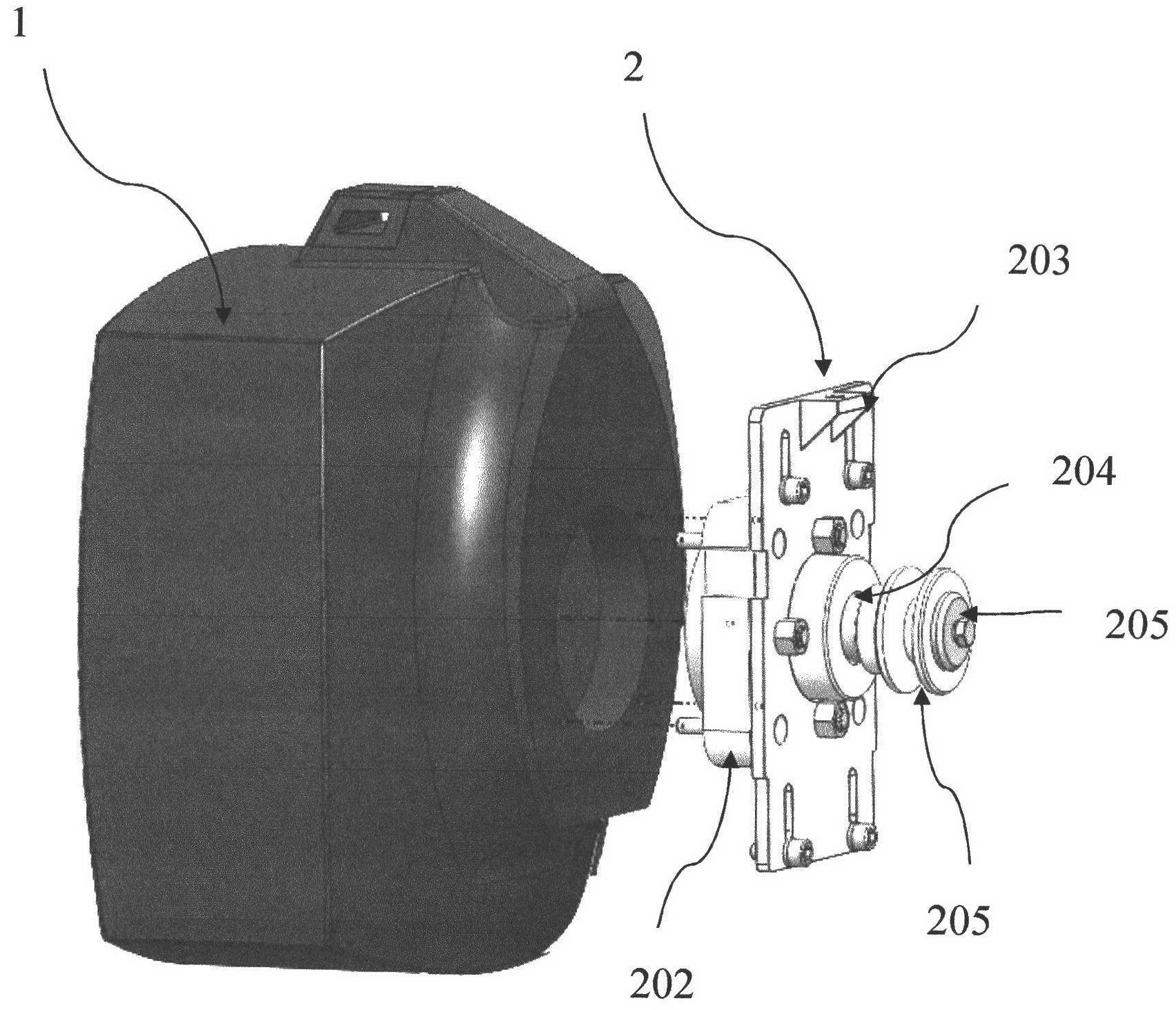

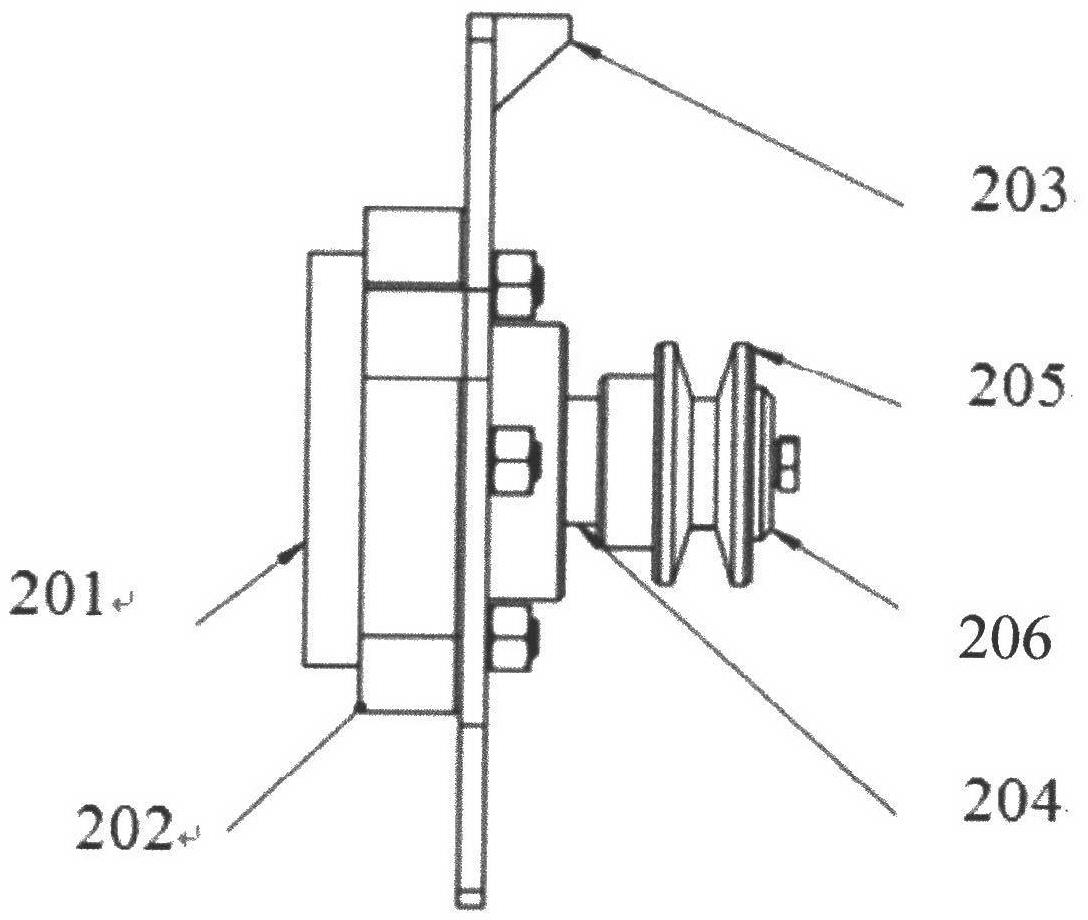

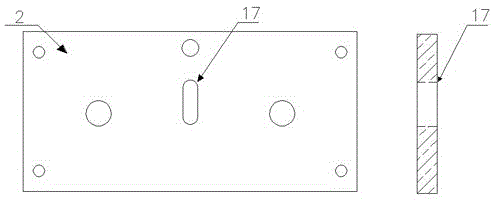

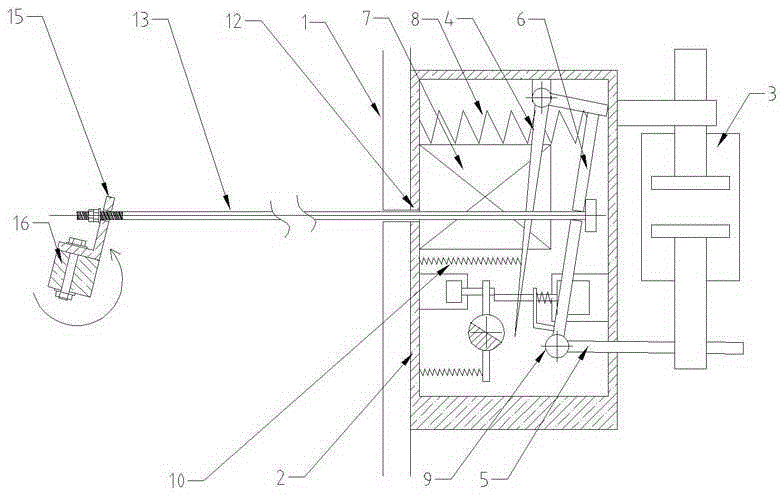

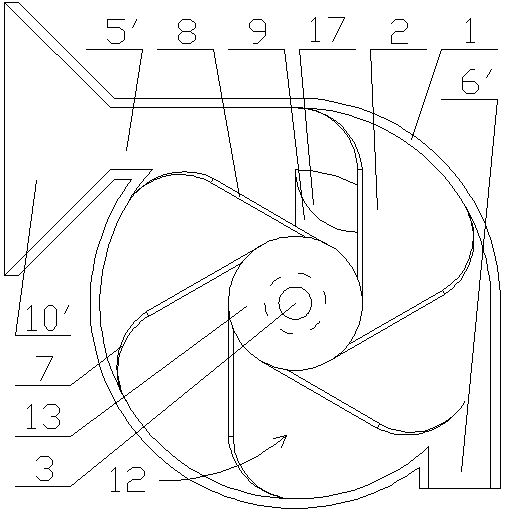

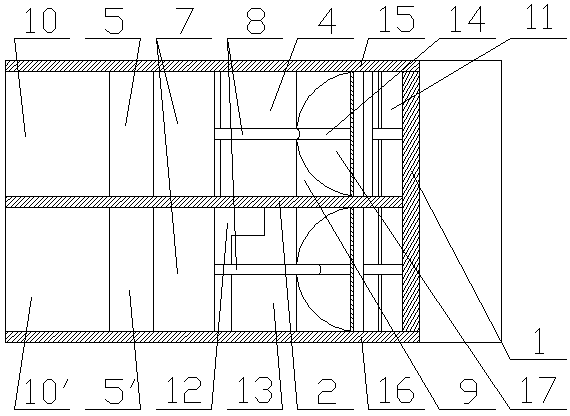

Portable tree digging machine

The invention discloses a portable tree digging machine, which comprises an engine, a machine seat device, a motive power connection device, a box frame connected component, a work head, a shock-absorbing device and an operation rod, wherein the machine seat device is arranged on the engine, the motive power connection device is arranged on the machine seat device, the box frame connected component is arranged at one end of the motive power connection device, the work head is arranged at the end part of the box frame connected component, the shock-absorbing device is arranged at the side surface of the box frame connected component, and the operation rod is connected with the shock-absorbing device. The portable tree digging machine solves the problems of low work efficiency, time waste, labor waste and the like of the traditional spade and has the characteristics that the practicality is high, the use is convenient, the efficiency is high, safety and reliability are realized, and the like.

Owner:江苏巧力林业机械科技有限公司

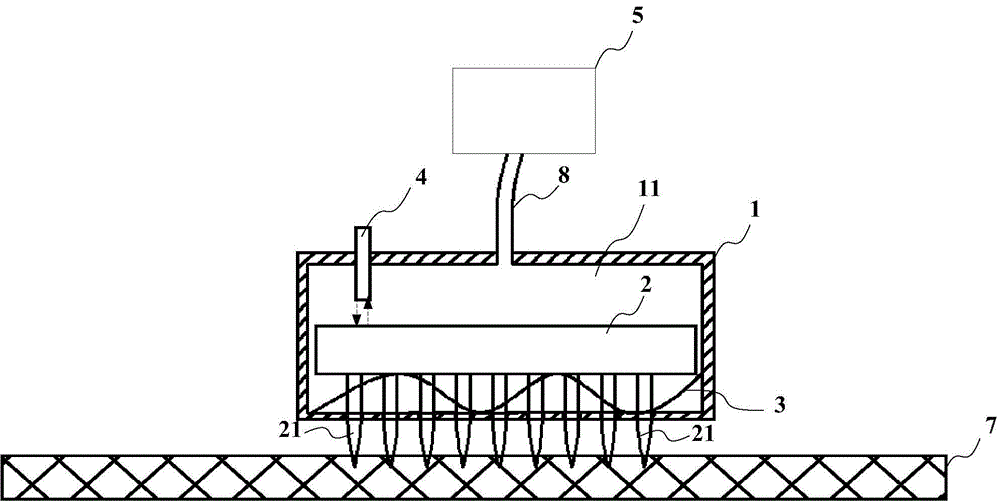

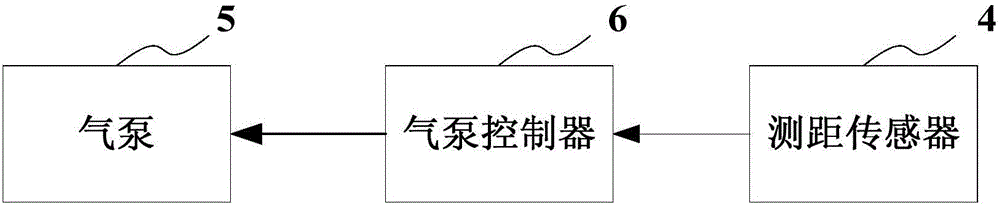

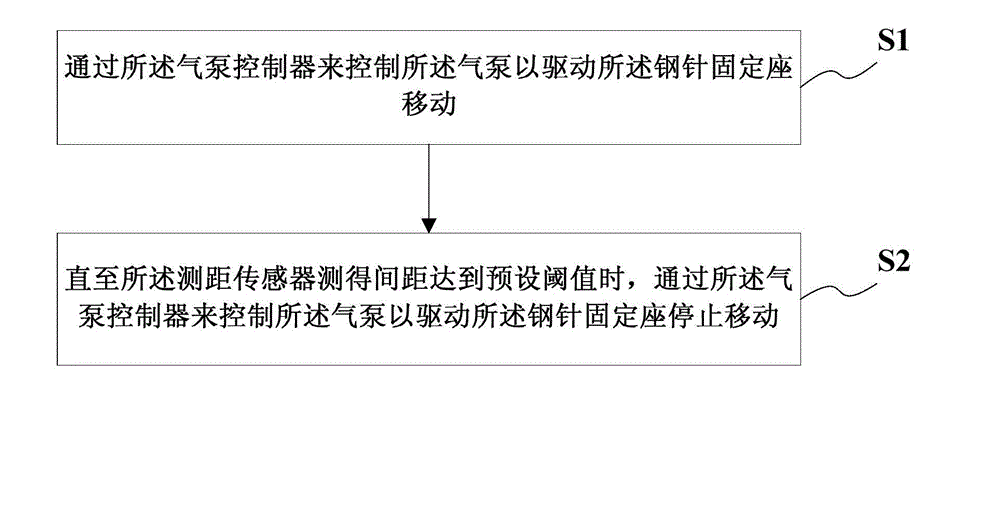

Flexible material moving device and method, and sewing device

InactiveCN104532488AAvoid reaction forceRealize resetSewing-machine control devicesAir pumpAtmospheric pressure

The invention provides flexible material moving device and method, and a sewing device. The moving device comprises a hollow device main body, an elastic part, a ranging sensor and an air pump controller; a steel needle fixing seat is movably arranged in the hollow device main body; a plurality of steel needles are convexly arranged on the lower surface of the steel needle fixing seat and pass through the bottom of the hollow device main body for inserting a flexible material; the upper surface of the steel needle fixing seat and the hollow device main body encircle a closed air pressure chamber which provides driving force for needling; the air pressure chamber is connected with an air pump through an air pipe; the elastic part is arranged in a clearance between the lower surface of the steel needle fixing seat and the hollow device main body and is extruded by the steel needle fixing seat to deform to provide elasticity for the steel needle fixing seat; the ranging sensor is arranged in the air pressure chamber and faces the upper surface of the steel needle fixing seat to measure the spacing between the steel needle fixing seat and the ranging sensor; the air pump controller is connected with the air pump to control the air pump so as to drive the steel needle fixing seat to move; the air pump controller is further electrically connected with the ranging sensor and drives the steel needle fixing seat to move until the spacing is equal to the preset threshold value. The moving device is accurate in controlling of the needling depth and is simple in structure.

Owner:JACK SEWING MASCH CO LTD

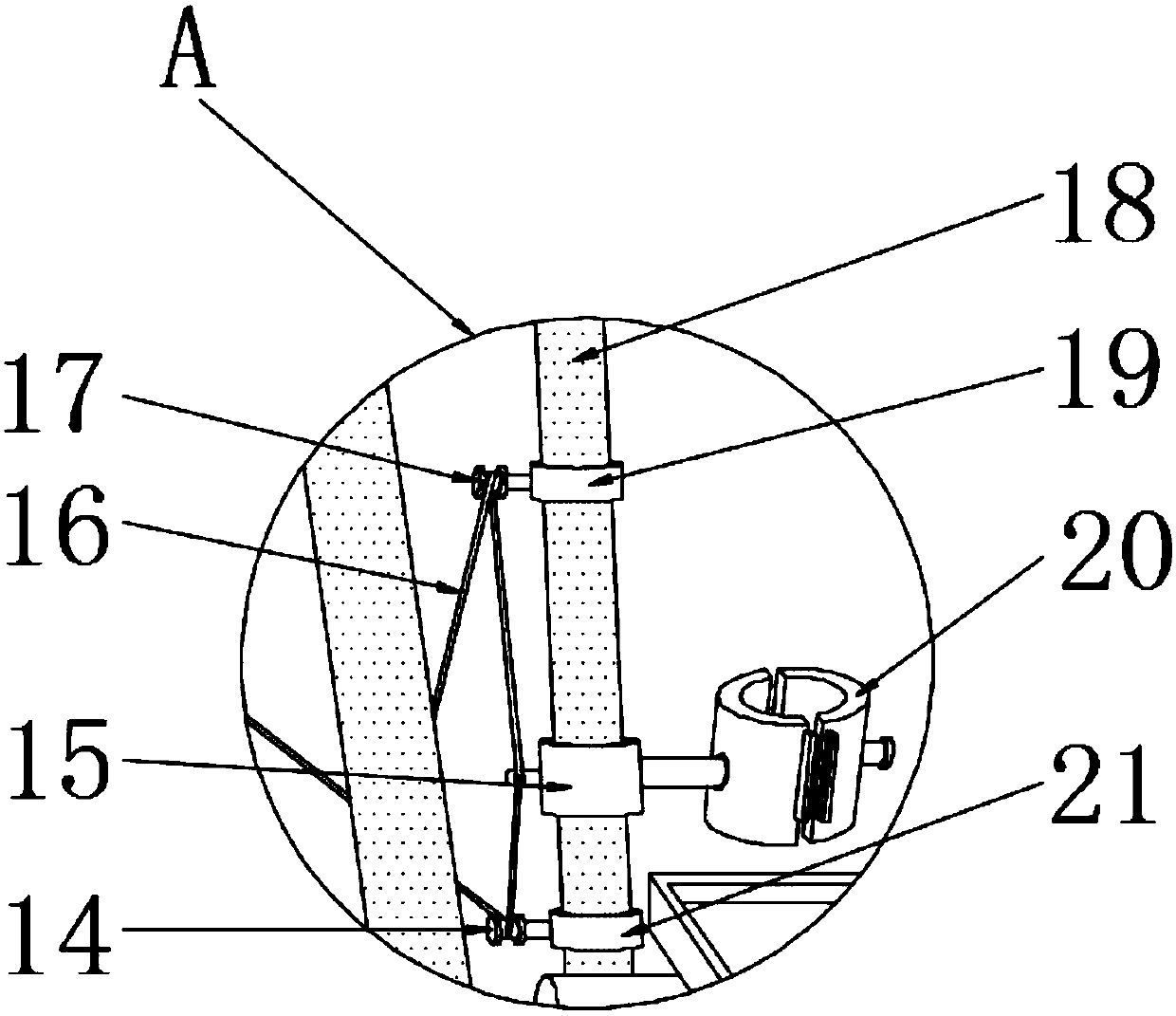

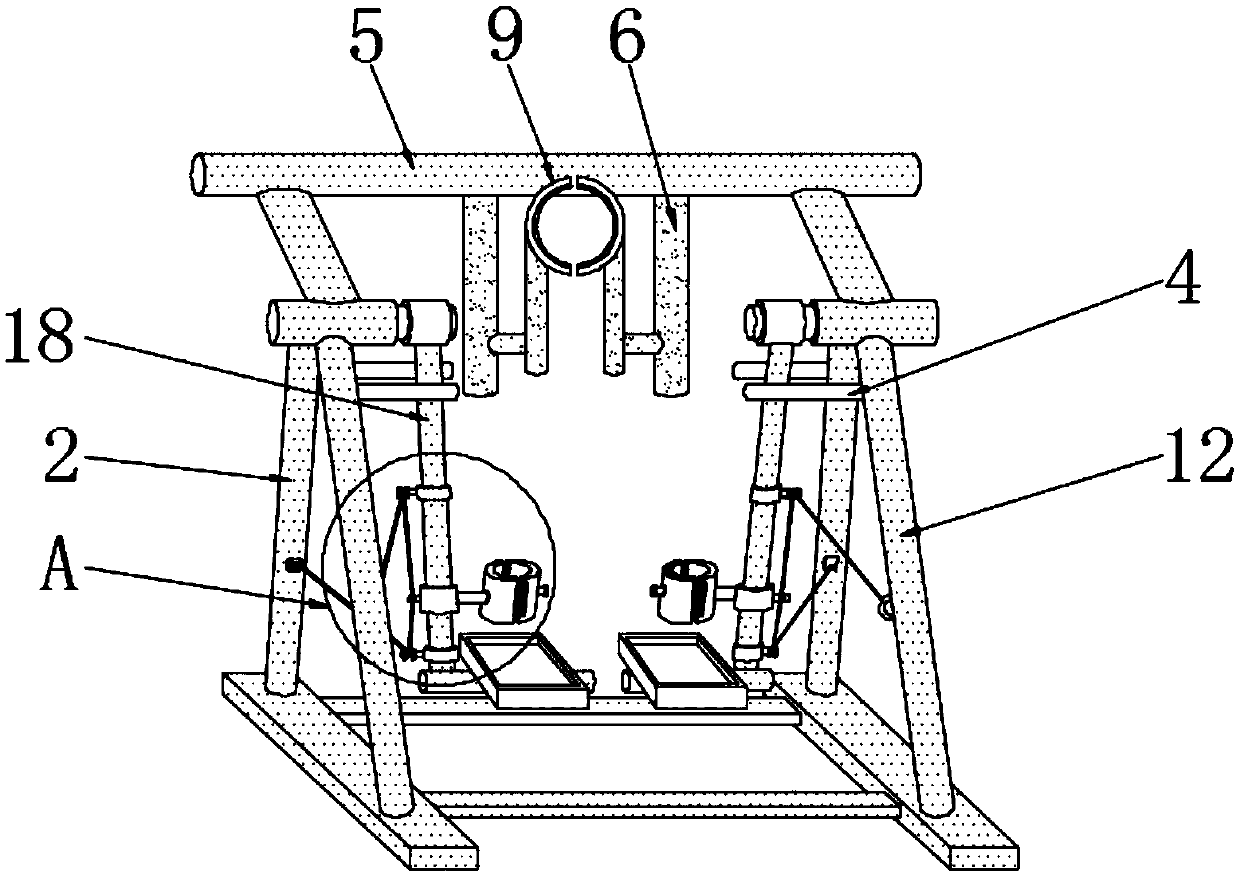

Bending and anti-cracking performance testing device and testing method

PendingCN109490096AAvoid breakageReduces the effects of bending fracturesMaterial strength using steady bending forcesTest fixtureTraining set

The invention discloses a bending and anti-cracking performance testing device and a testing method. The testing device comprises a base, clamping mechanisms, force application mechanisms and a bending guiding mechanism, wherein the clamping mechanism is used for clamping a test piece; the force application mechanisms are used for supporting and driving the clamping mechanism; when one pair of theforce application mechanisms get close to each other, the test piece is bent and the clamping mechanisms located at the end parts of the force application mechanisms are driven to rotate in the forceapplication mechanisms; and the bending guiding mechanism is used for limiting the test piece to be bent in the direction of the bending guiding mechanism. According to the bending and anti-crackingperformance testing device, the clamping mechanisms rotate in the force application mechanisms so as to prevent the test piece from being subjected to a counter force to crack a clamping position; theforce application mechanisms get close to each other to drive the test piece to bend, and influences, caused by stress concentration, on bending and cracking of the test piece, are reduced, so that the accuracy of testing results is improved; and the bending guiding mechanism is arranged and the bending direction is controllable when the test piece is bent, so that photographing equipment is fixed at a certain part when operation including photographing, collection and the like needs to be carried out and other positions do not need to be adjusted, and a test is carried out smoothly.

Owner:NANJING COMM INST OF TECH

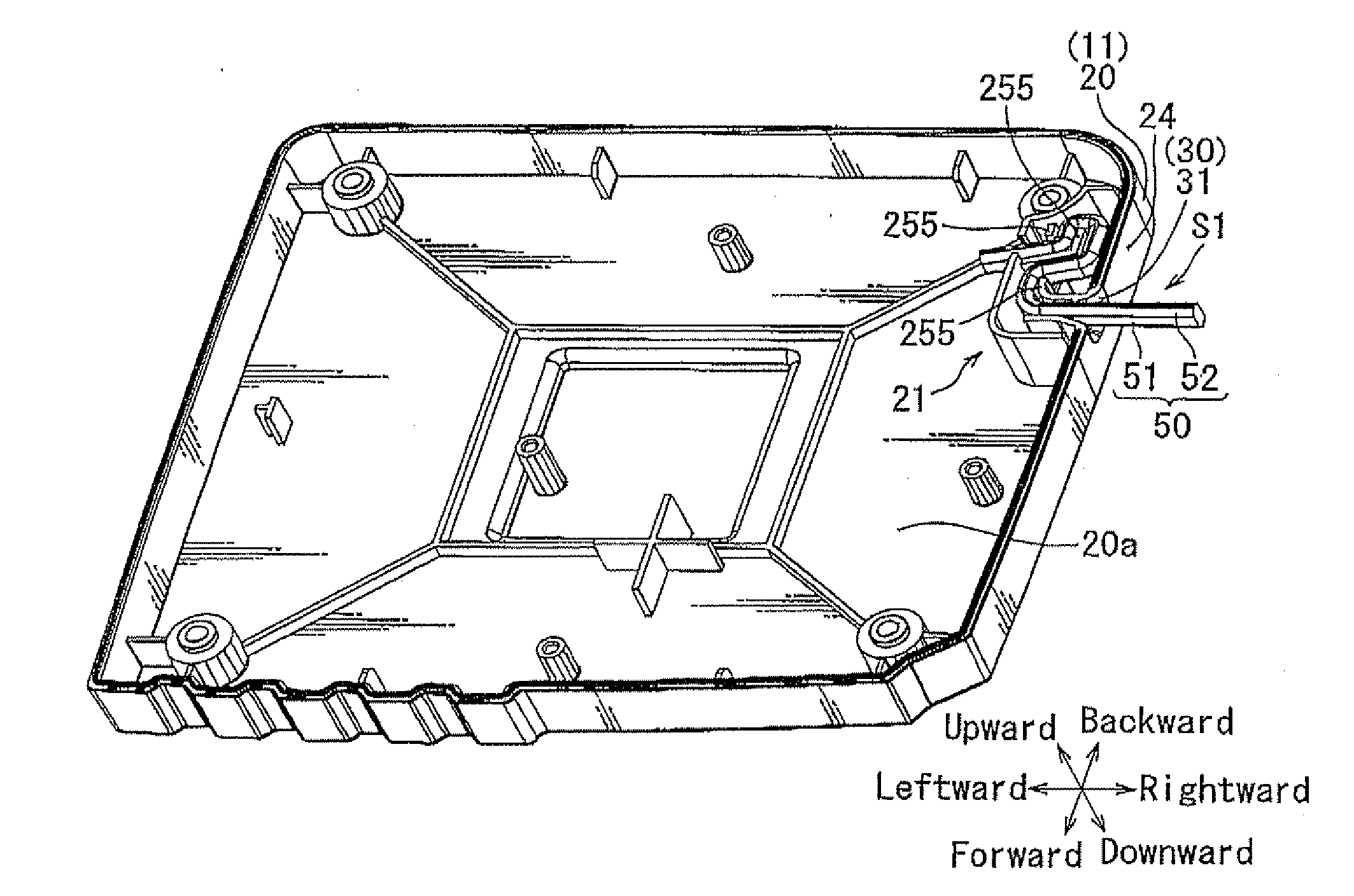

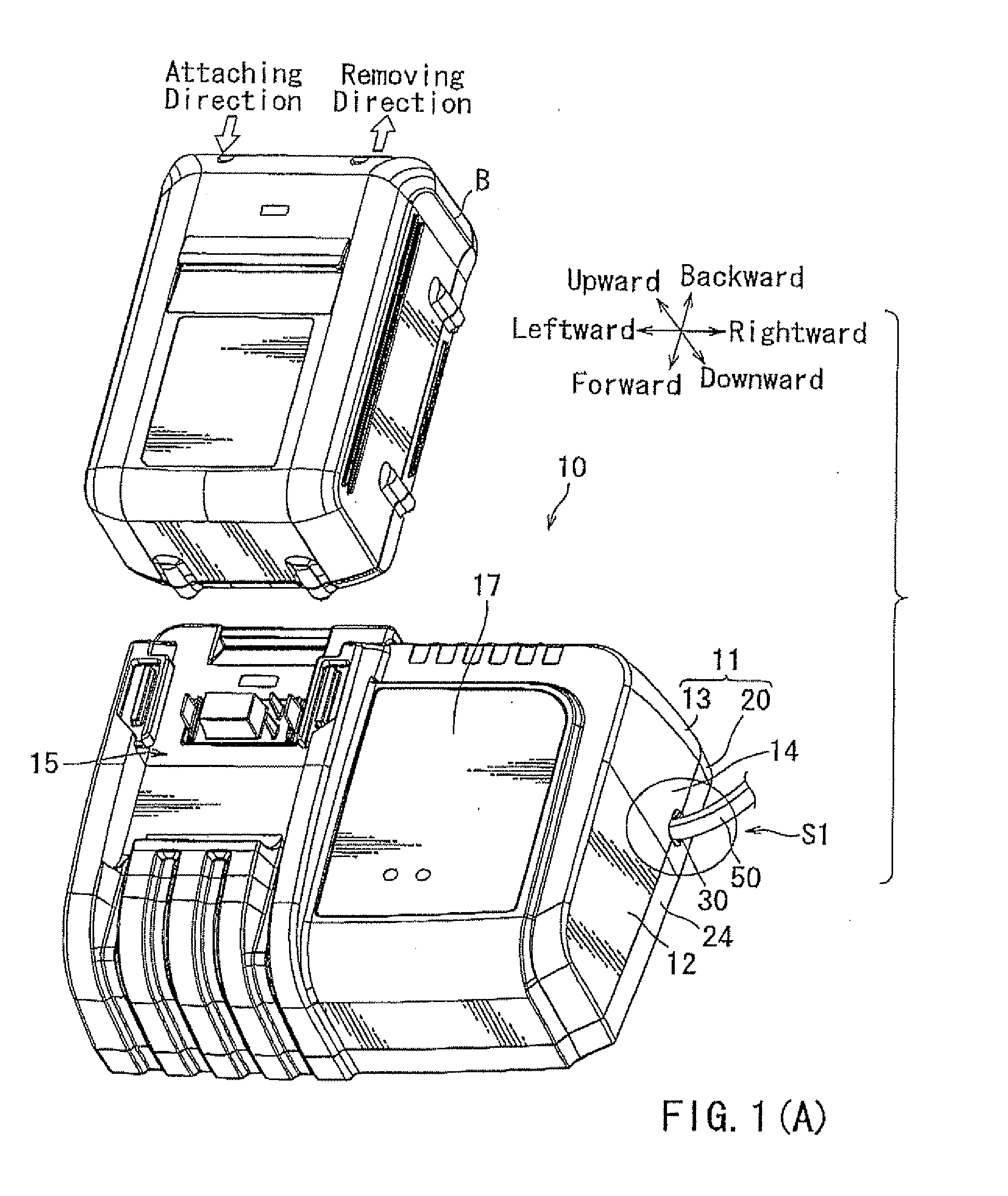

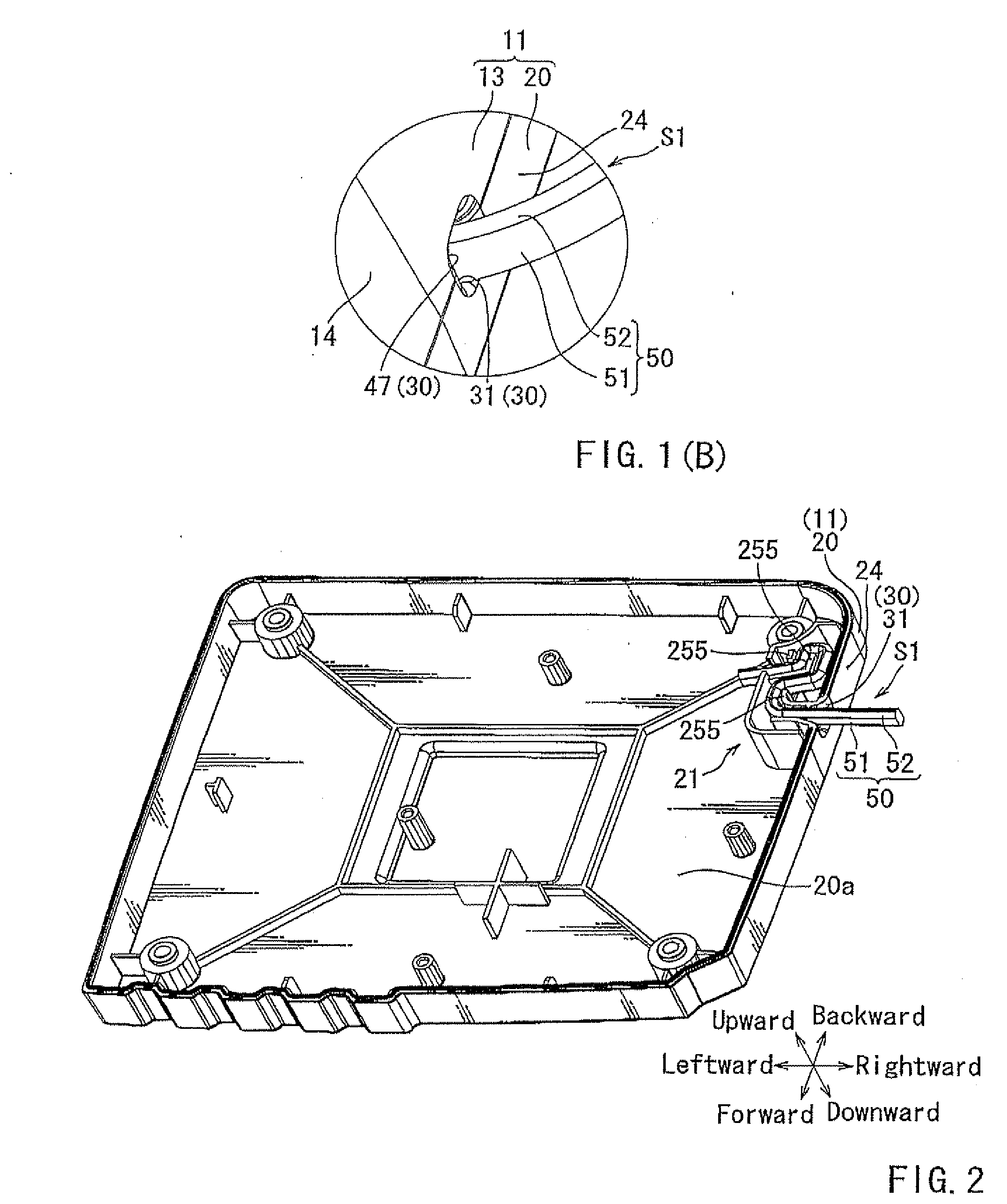

Power-supply cord arrangement structure

InactiveUS20120097425A1Effective distributionEasy to useCoupling device detailsInsulated cablesElectrical equipmentPower cord

A power-supply cord arrangement structure provided to an electrical equipment may includes a cord drawing hole that is formed in a housing of the electrical equipment and is configured to drawing a power-supply cord therethrough, and load support portions that are formed in the housing as a portion of the cord drawing hole and are configured to support a tensile load of the power-supply cord when the power-supply cord is pulled. The load support portions are oppositely asymmetrically formed in cord pulling directions.

Owner:MAKITA CORP

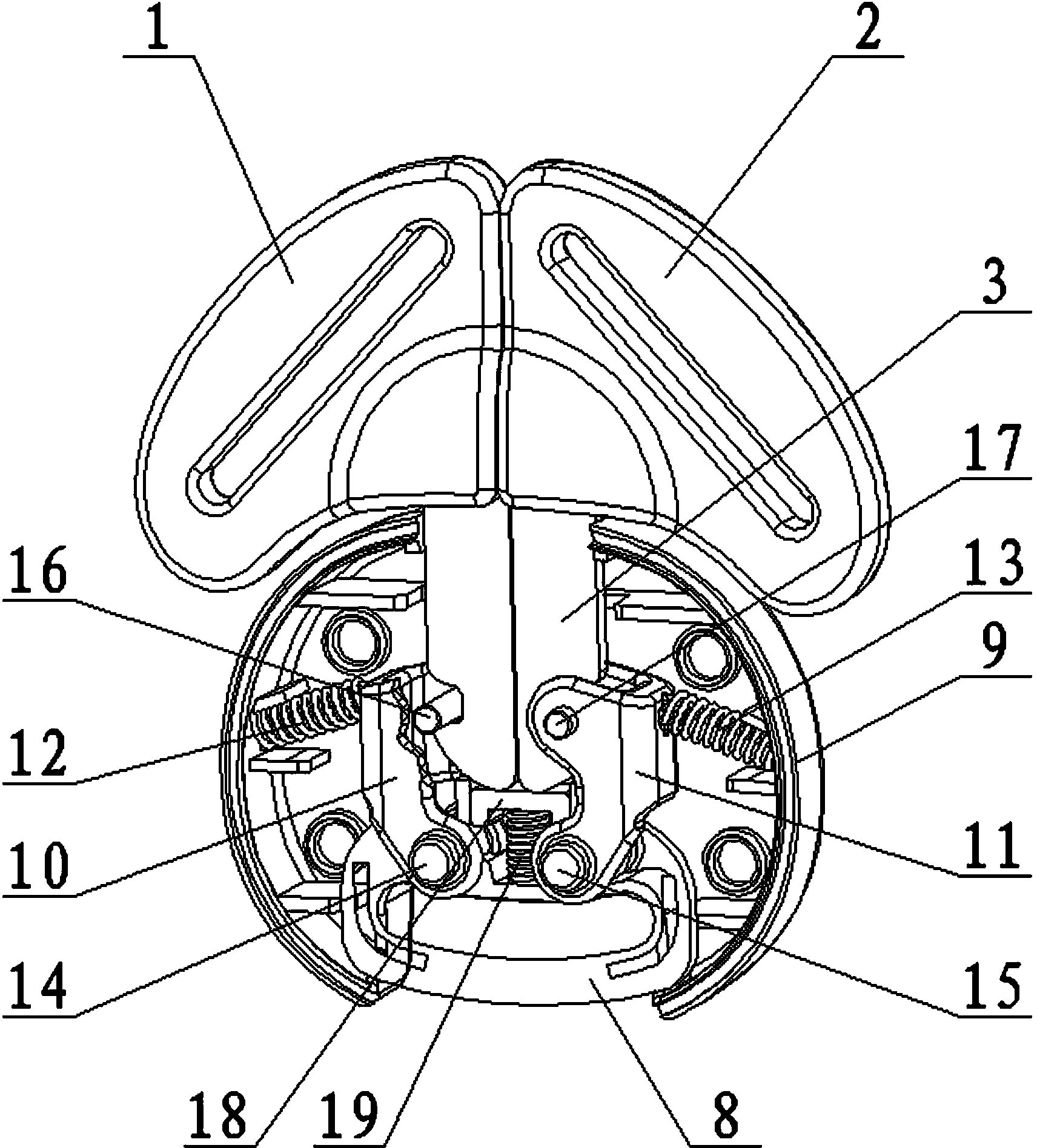

Safety buckle used for child automobile safety seat

The invention relates to a safety buckle used for a child automobile safety seat. The safety buckle comprises a left inserting piece, a right inserting piece, an upper cover, a lower cover, a button and a buckle core. Inserting hooks are arranged on the lower portion of the left inserting piece and the lower portion of the right inserting piece respectively, the inserting hooks are inserted into a cavity formed by correspondingly combining the upper cover and the lower cover, the inserting hooks and the buckle core in the cavity are in a corresponding inserted and locked state or a disengaged mode, and the button connected with the buckle core is arranged on the upper cover. An ejector block is used for elastically butting against the inserting pieces, swing block clamping shafts are elastically clamped into hook grooves, locking buckling and disengaging of the clamping shafts and the inserting pieces are constrained together, small-force buckling and large-force disengaging of the safety buckle are achieved, and the safety buckle is simple and compact in structure, smooth, convenient and fast to insert, stable and firm in locking, flexible in unbuckling, capable of effectively preventing a child from unbuckling the buckle by mistake and high in use safety.

Owner:JIANGSU HAPPY BABY SAFETY SEAT

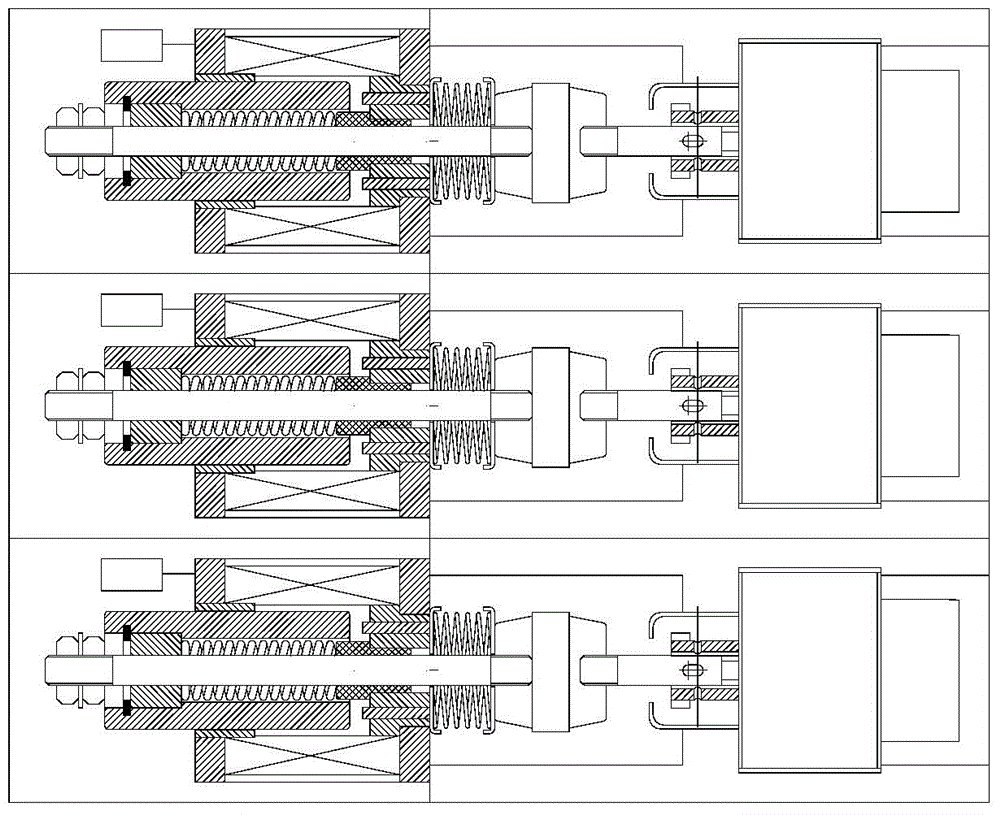

Mechanical emergency starting apparatus for start-delta voltage-reduction starting

InactiveCN106409600AGood consistency of mechanical emergency startMotion synchronizationHigh-tension/heavy-dress switchesAir-break switchesElectricityNational standard

The invention relates to a mechanical emergency starting apparatus for start-delta voltage-reduction starting. The apparatus is composed of an insulation isolating frame, a rear metal sealing plate, two sets of electromagnetic control mechanisms, a manual operating mechanism and two sets of vacuum switch tube parts. Each electromagnetic control mechanism set includes a closing holding buckle plate, a driving connecting lever, a closing armature, a closing coil, and a closing spring; a long pull rod passes through a straight slot formed in the rear metal sealing plate and then connects a counterbore formed in the closing armature; and a thread part formed at the other end of the long pull rod is connected with a U-shaped linkage block arranged on a linkage rod of the manual operating mechanism movably by a positioning pin. According to the invention, two alternating-current vacuum contactors can be driven synchronously to realize mechanical emergency starting. The provided apparatus meets regulations in the mandatory article 11.0.12 in the national standard GB 50974-2014 ''Technical Specifications of Fire-fighting Water Supply and Fire Hydrant System'' implemented on October 1st, 2014.

Owner:CHENZHOU DONGTANG ELECTRIC EQUIP

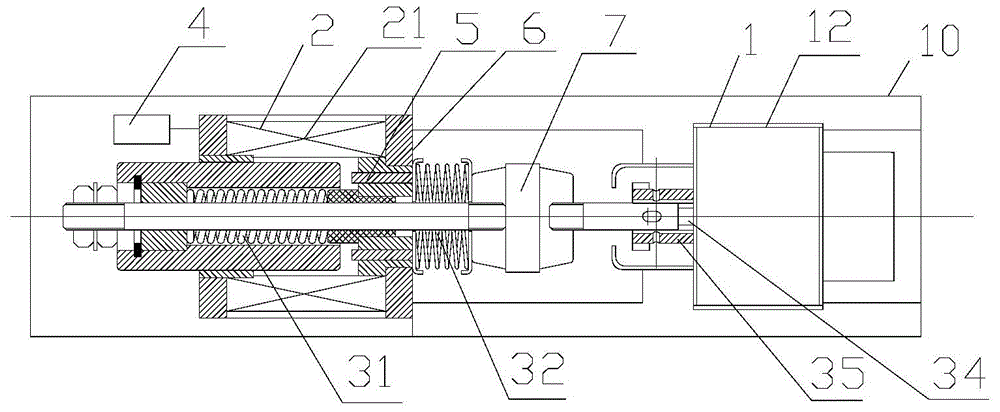

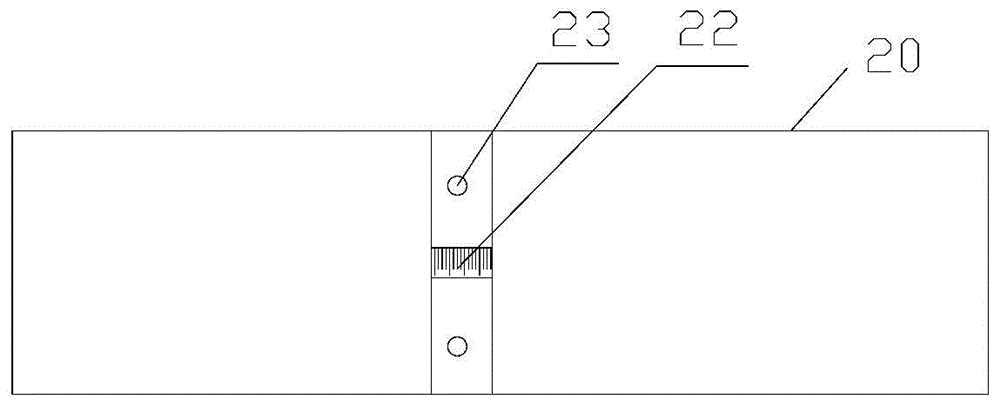

Vacuum alternating-current contactor for mechanical emergency

InactiveCN105355505AImprove synchronicityAvoid reaction forceHigh-tension/heavy-dress switchesAir-break switchesContactorElectrical isolation

The invention relates to a vacuum alternating-current contactor for mechanical emergency. The vacuum alternating-current contactor is composed of an insulated electrical isolation framework, a metal rear sealing plate, an electromagnetic operating mechanism, a manual operating mechanism and a vacuum switching tube; the electromagnetic operating mechanism is provided with a closing keeping buckle plate, a transmission crank arm, a closing armature, a closing coil and an opening spring; a counterbore is formed close to the edge in the longitudinal center of the closing armature, and the metal rear sealing plate is provided with a through hole opposite to the counterbore; a long pull rod penetrates through the through hole in the metal rear sealing plate, the capped portion of the long pull rod is connected with the counterbore of the closing armature, and the tapping portion of the long pull rod is connected with an L-shaped pull hook of a linkage rod of the manual operating mechanism. When a secondary control circuit fails or an electromagnetic coil of a vacuum switch is damaged, a fire-fighting water pump and a hydrant can be manually started for emergency by adopting the vacuum alternating-current contactor.

Owner:CHENZHOU DONGTANG ELECTRIC EQUIP

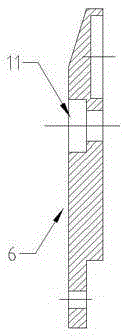

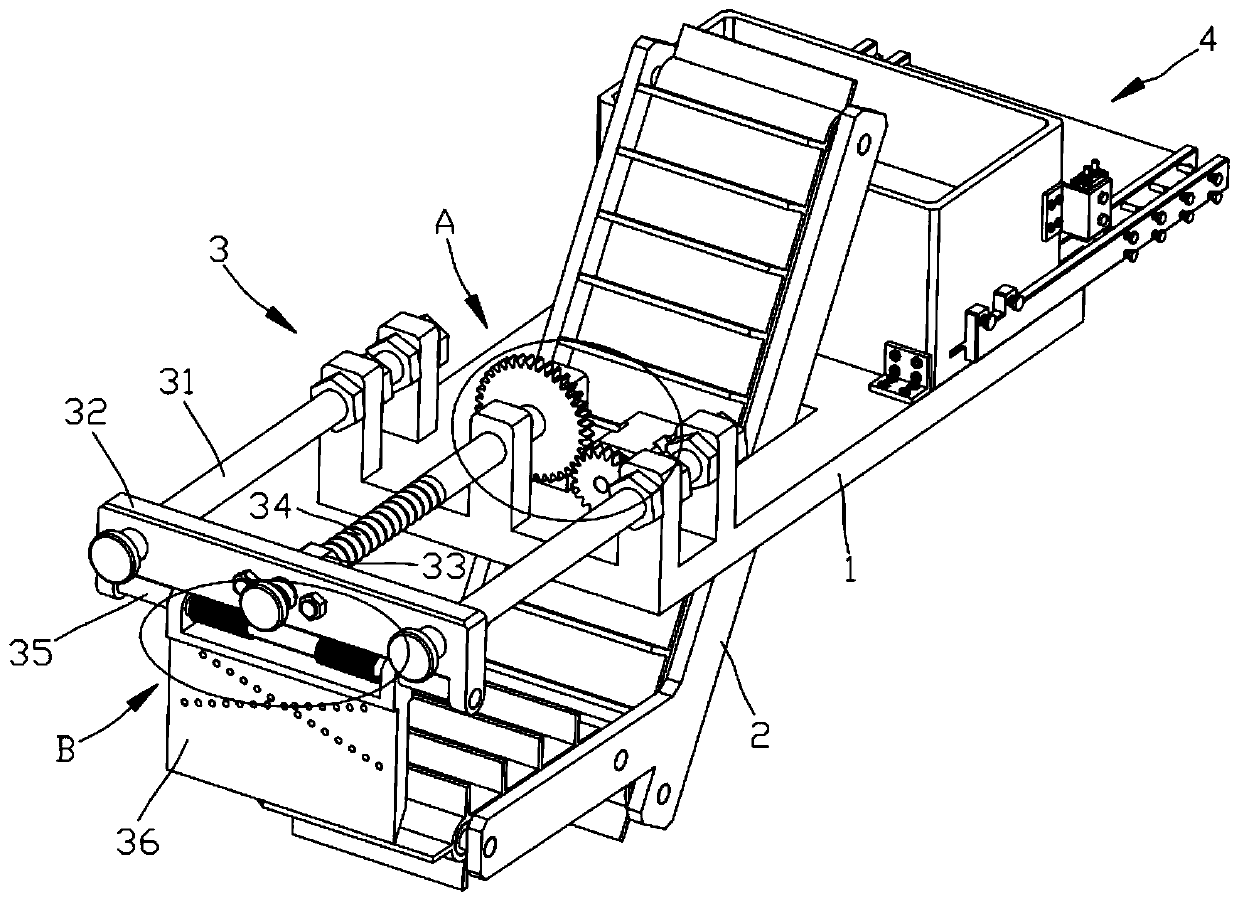

Dredging type silt cleaning device

InactiveCN109797795AAvoid reaction forceShaking violentlySoil-shifting machines/dredgersMarine engineeringElectric machinery

The invention provides a dredging type silt cleaning device. The dredging type silt cleaning device comprises a ship body, a lifting conveyor belt, a dredging mechanism and a transfer mechanism; the dredging mechanism comprises supporting rods, a sliding block, a sleeve, a lead screw, a connecting shaft, a shovel plate, torsional springs, a big gear, a small gear and a motor; the sliding block isinstalled on the ship body through the supporting rods; one end of the lead screw is installed on the ship body, the other end of the lead screw penetrates through the sleeve and the sliding block, and the lead screw is in power connection with the motor; the shovel plate is rotatably installed on the sliding block through the connecting shaft; and the transfer mechanism is fixedly installed on the ship body. The rotation movement between the lead screw and the sleeve is transformed into linear movement, and then the shovel plate is pushed to dredge silt; the shovel plate can rotate around thesliding block, and then the shovel plate is folded when the shovel plate move towards a silt stack; the shovel plate is prevented from generating counter-acting force by being in contact with the silt stack, and then it is ensured that the ship body cannot tempestuously waggle when dredging is carried out; and the silt is automatically transported outside of the ship body through the transfer mechanism, and the dredged silt is prevented from being transferred through manual work.

Owner:HUAINAN ZHONGXING MACHINERY MFG

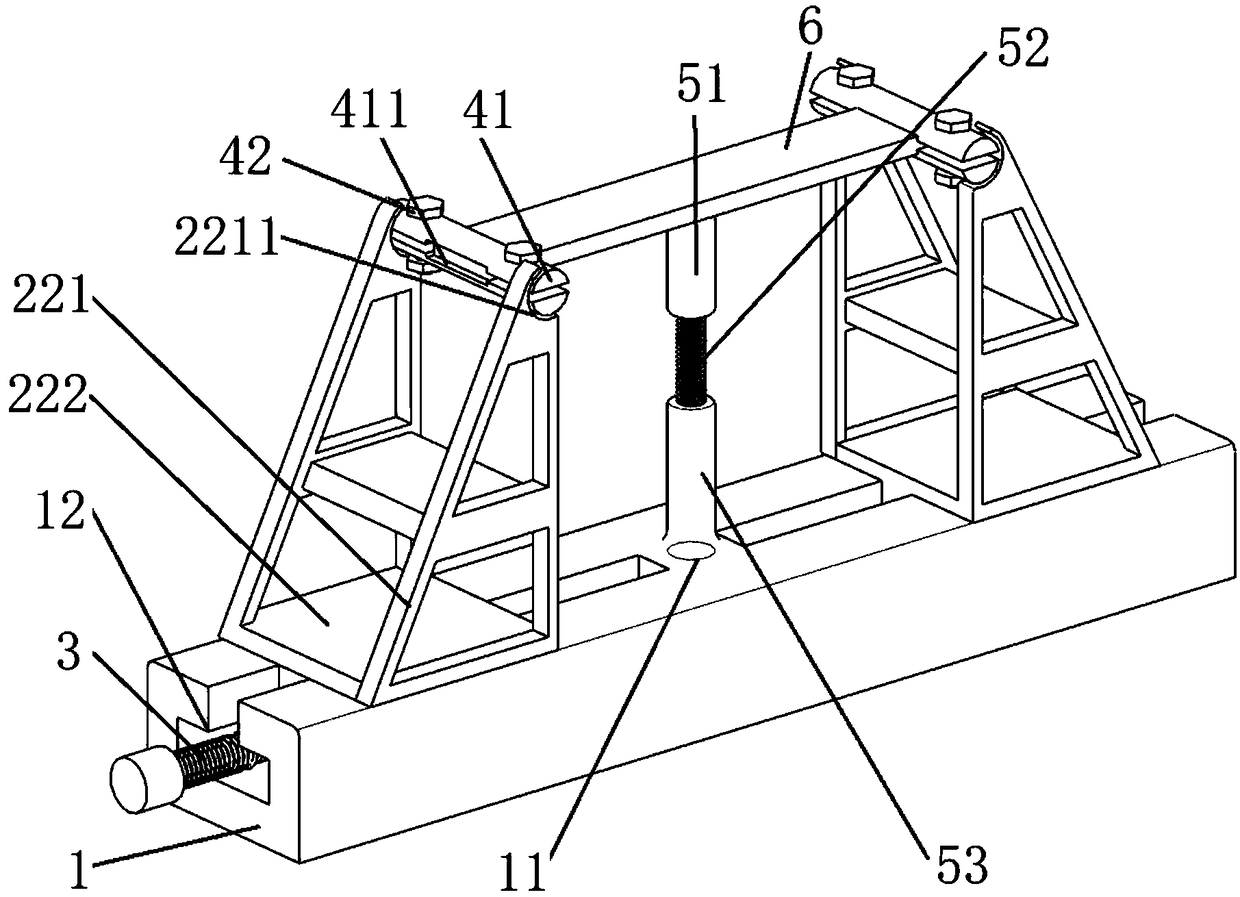

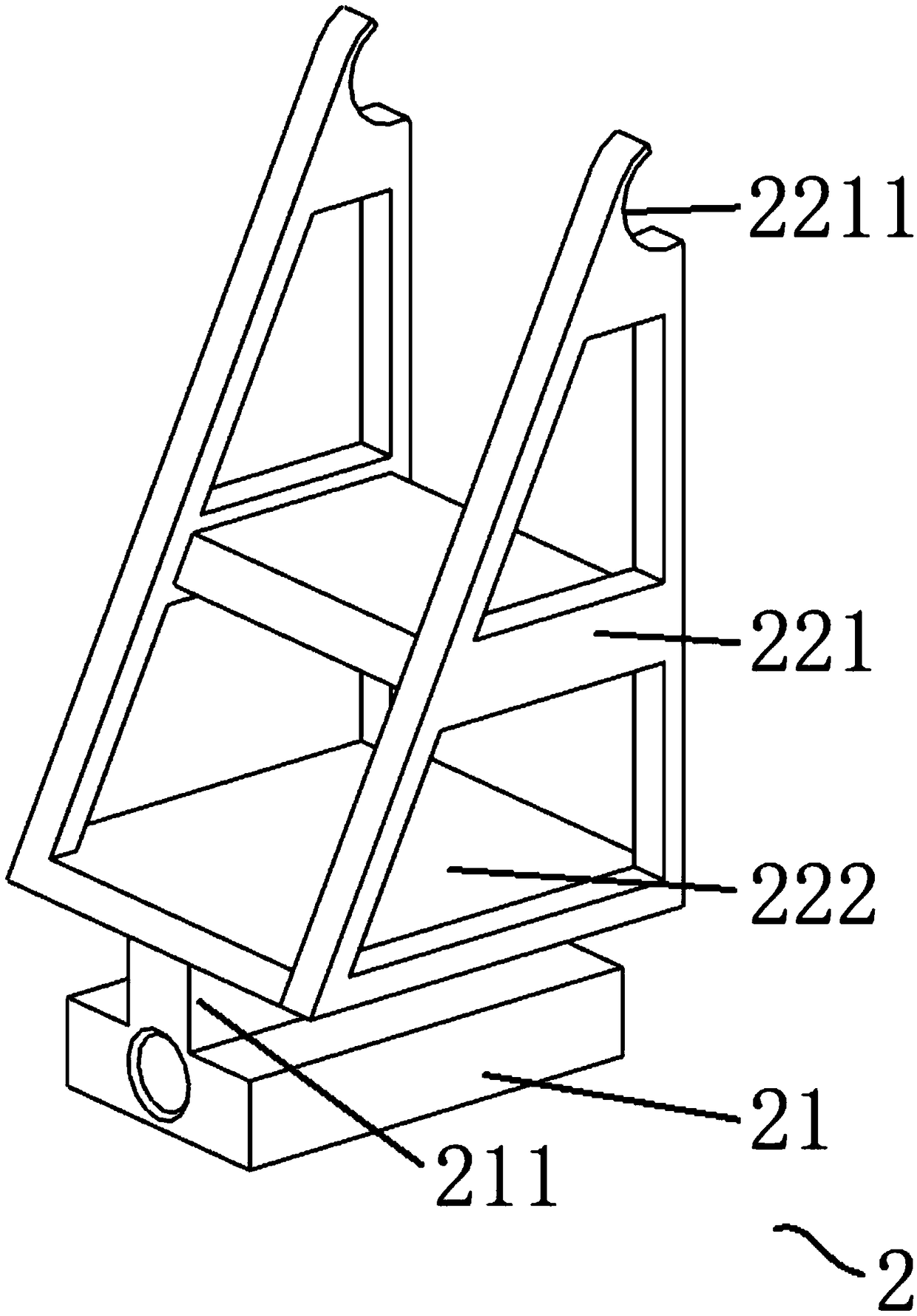

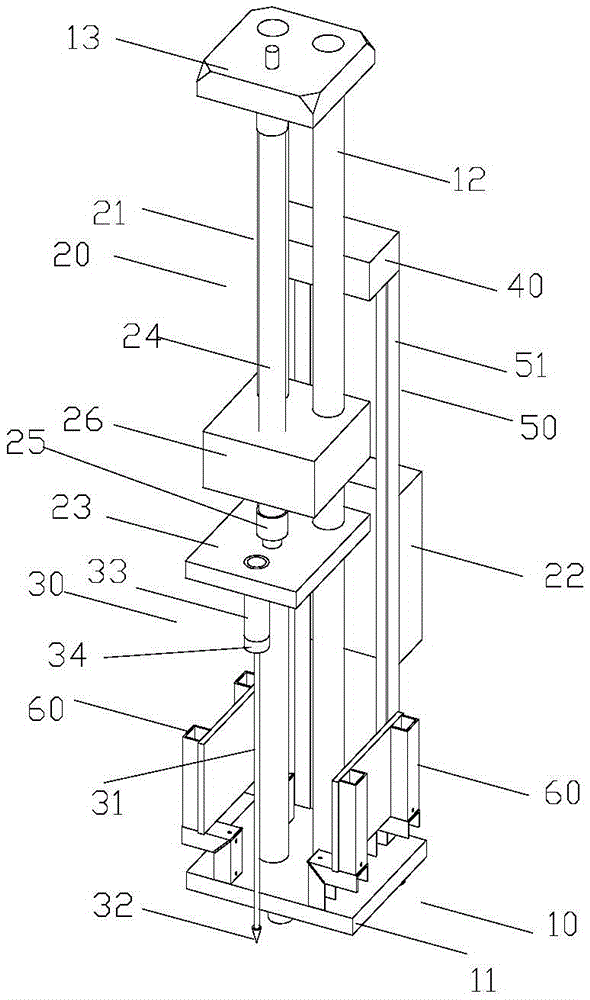

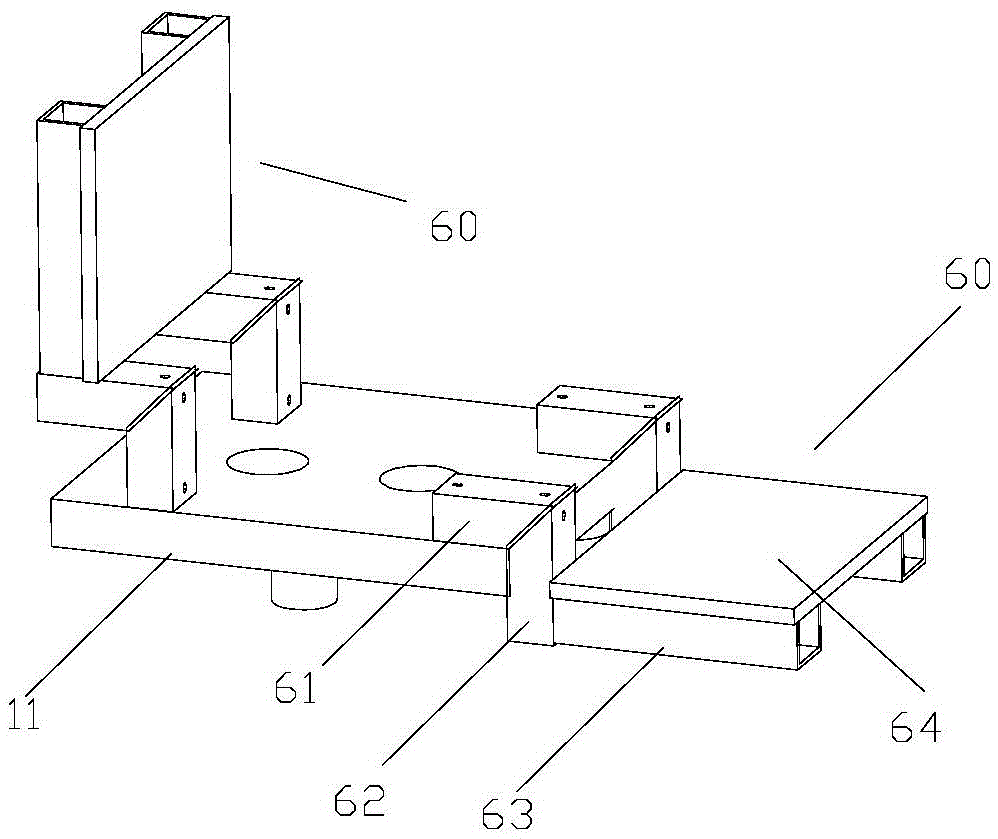

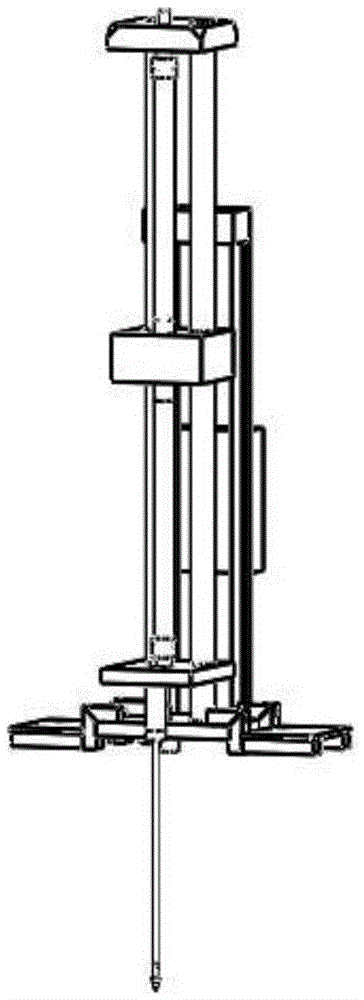

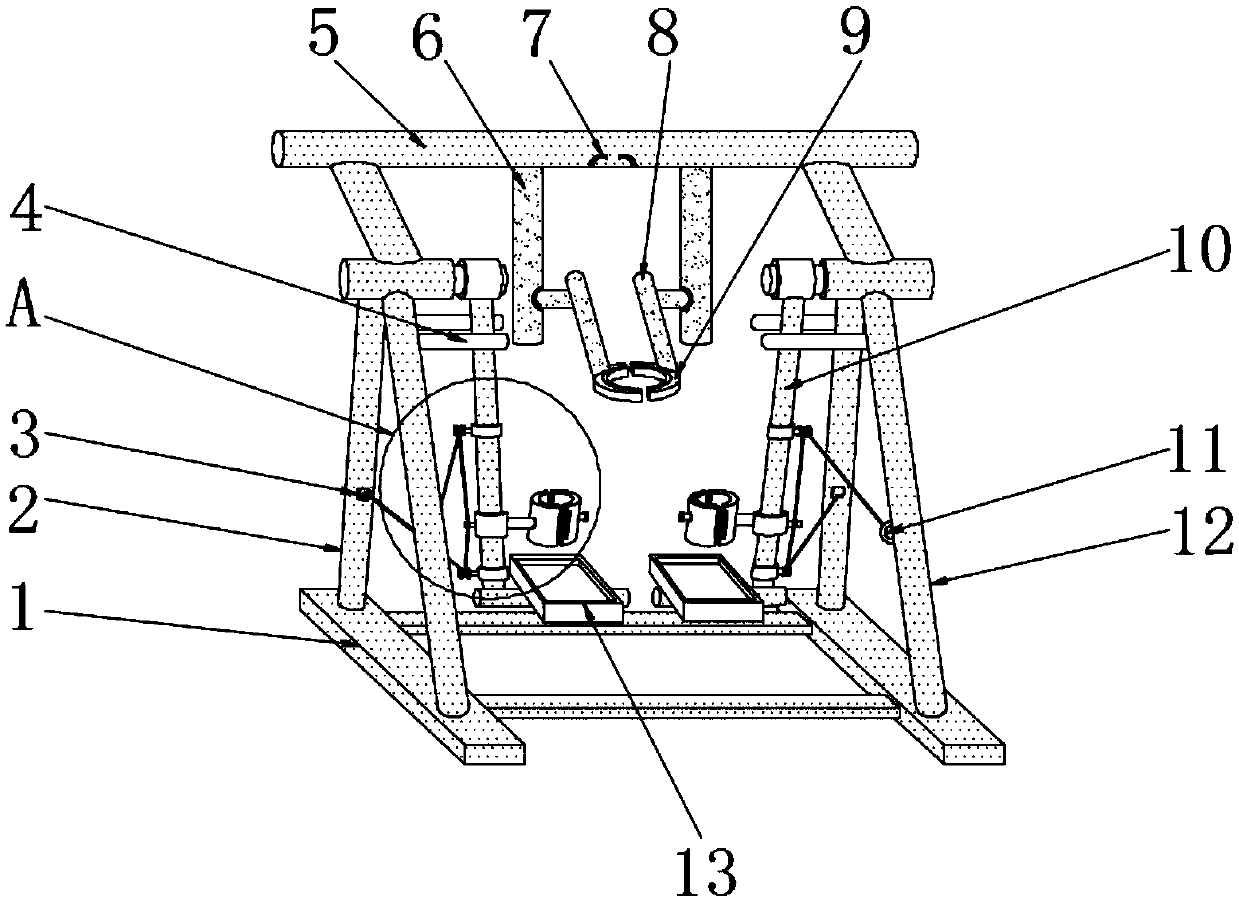

Portable soil measuring test device

InactiveCN105571953ASave spaceEasy to carryMaterial strength using tensile/compressive forcesHydraulic cylinderEngineering

The invention provides a portable soil measuring test device capable of performing conical index measuring and a pressure-sinking test. The portable soil measuring test device comprises a support, a hydraulic mechanism, a measuring test mechanism and a controller; the support comprises a bottom plate, a guide column erected on the bottom plate and a fixing top plate connected with the upper end of the guide column; the hydraulic mechanism comprises a hydraulic cylinder, a hydraulic driving unit driving the hydraulic cylinder and a slide block; one end of the cylinder body of the hydraulic cylinder is connected with the fixing top plate and the other end of the cylinder body of the hydraulic cylinder is connected with the guide column by a fixing part; a free end of a piston of the hydraulic cylinder is connected with the sliding block; the guide column penetrates through the slide block to guide the same; the measuring test mechanism comprises a measuring rod, a measuring head and a built-in pull press sensor; one end of the measuring rod is connected with the slide block and the other end of the measuring rod is connected with the measuring head, the built-in pull press sensor is arranged internally between the measuring rod and the measuring head; the controller is fixed on the bottom plate of the support by a mounting frame and controls the hydraulic mechanism and the measuring test mechanism.

Owner:MILITARY TRANSPORTATION UNIV PLA

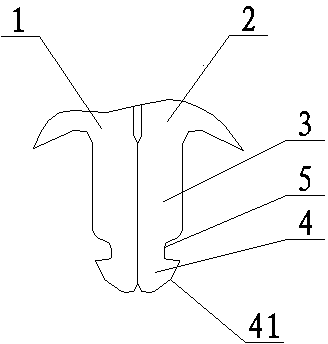

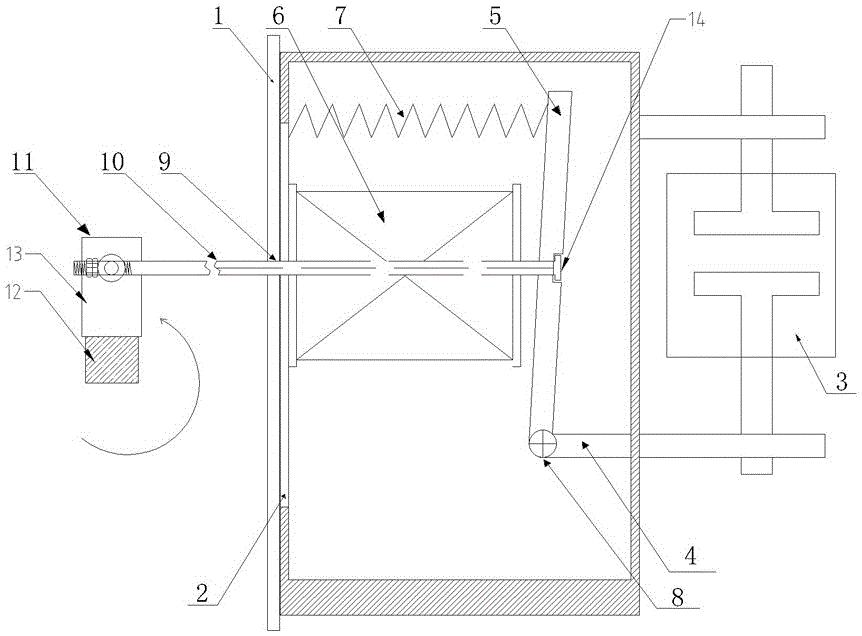

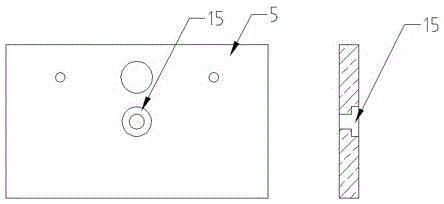

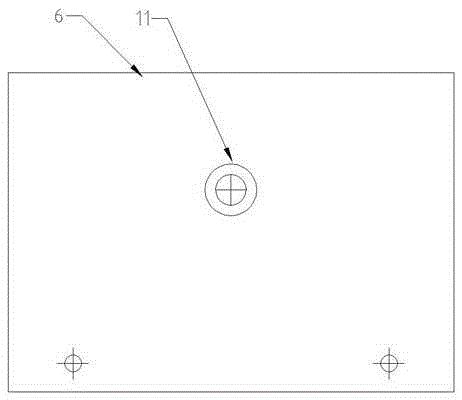

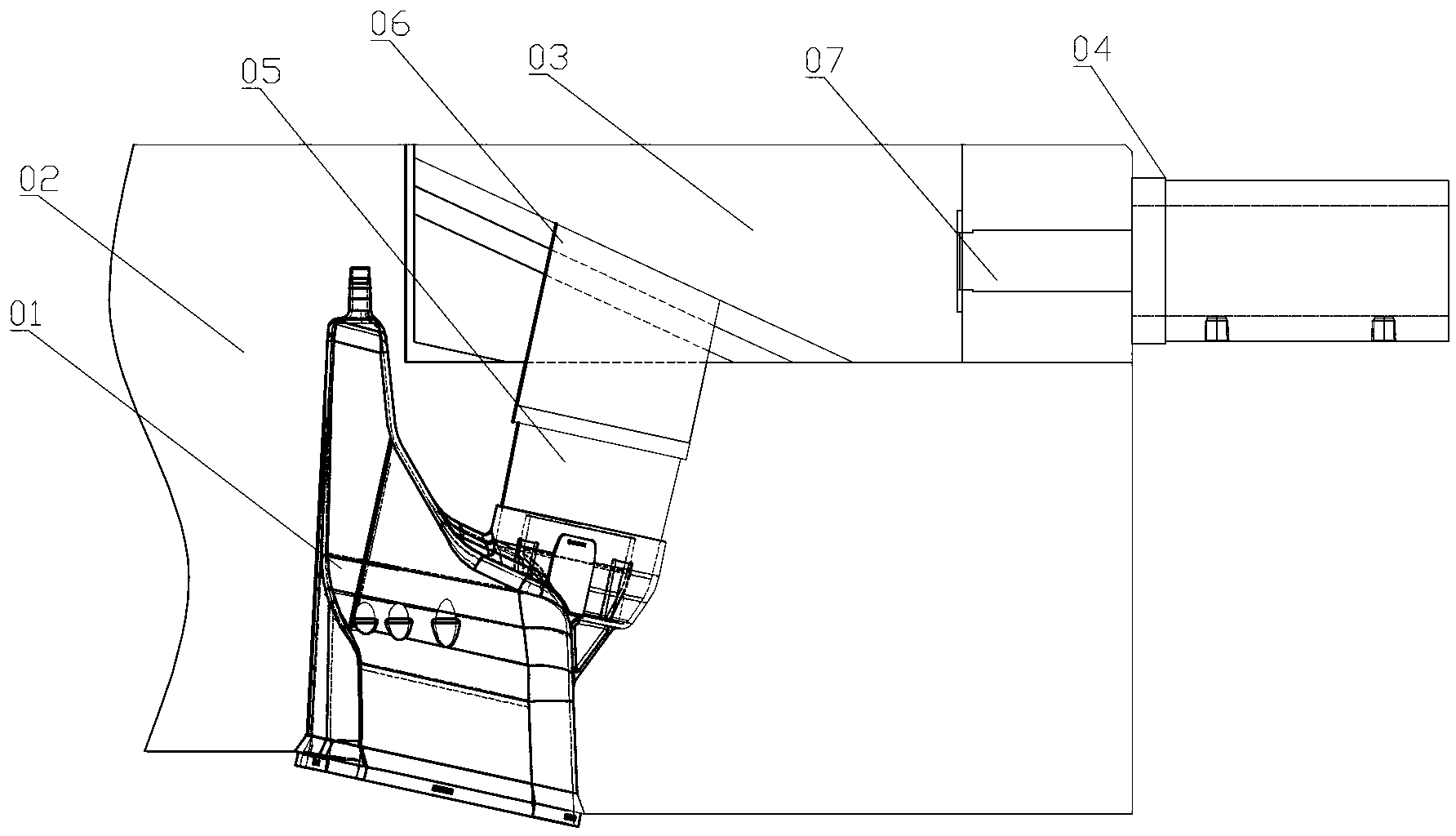

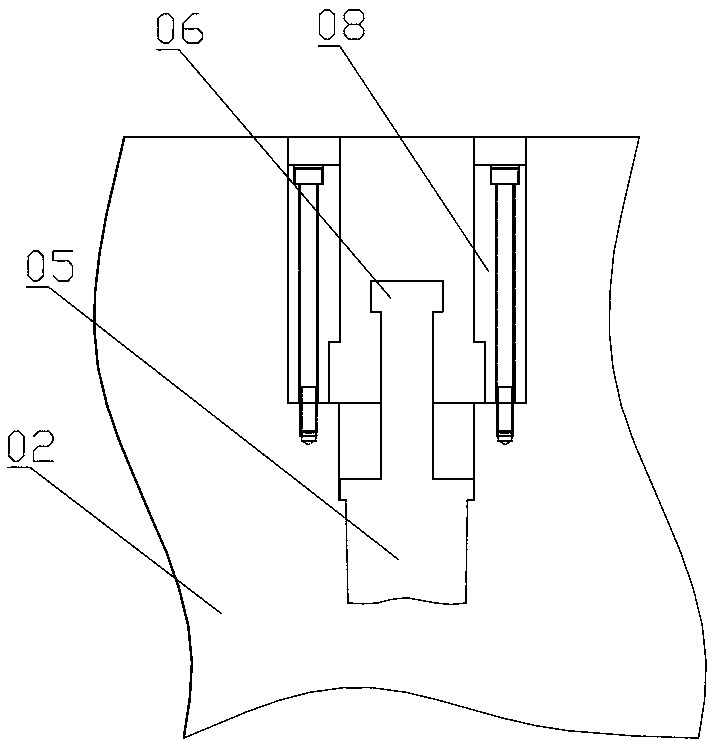

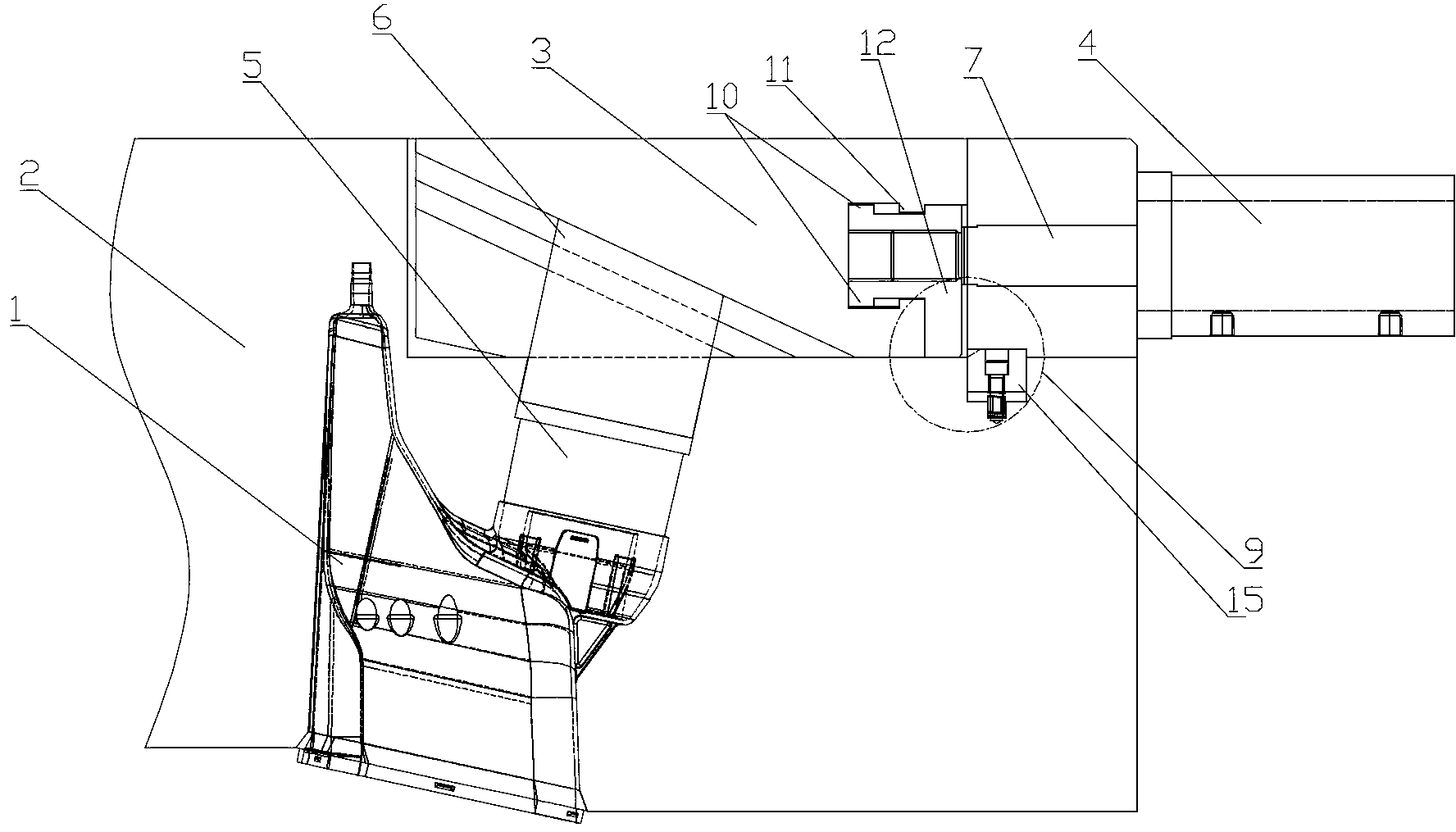

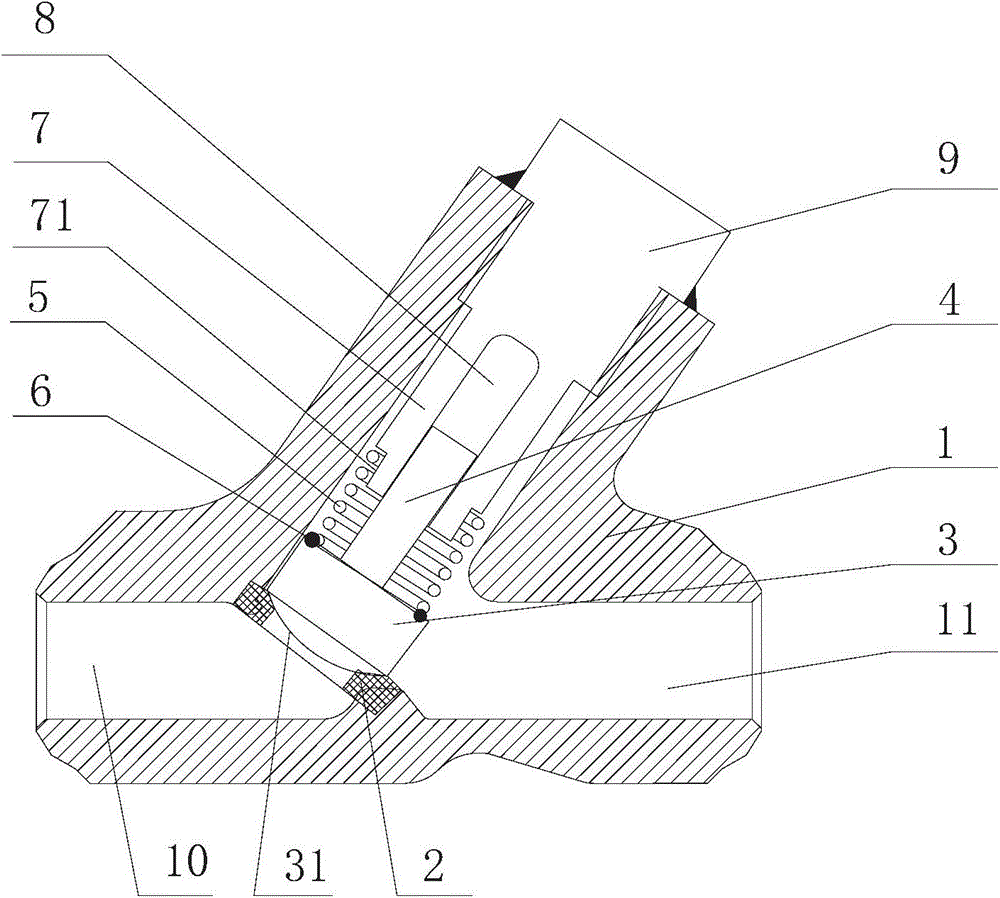

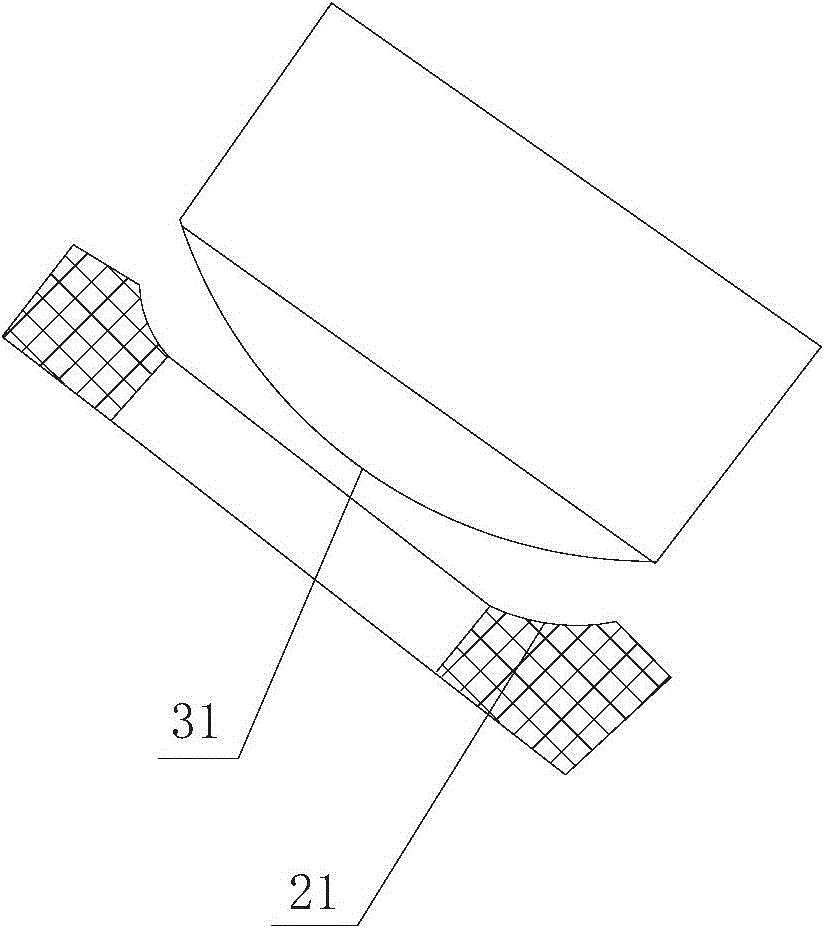

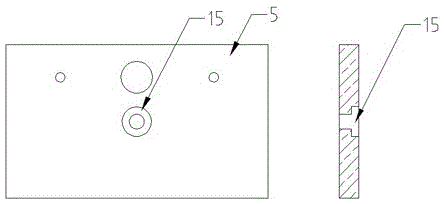

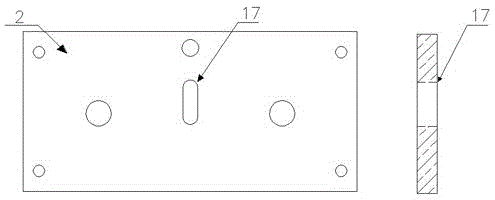

Self-locking structure for plastic mold cylinder slide block

The invention provides a self-locking structure for a plastic mold cylinder slide block. The self-locking structure is simple, low in manufacturing cost, safe and reliable. The self-locking structure comprises a fixed die (2), a first slide block (3), a cylinder (4) and a core-pulling body (5), wherein the first slide block (3) is in sliding connection with the core-pulling body (5) and the fixed die (2) respectively. The self-locking structure is characterized in that a stopper (15) is arranged between the first slide block (3) and the cylinder (4) and is embedded in the fixed die (2); an elastic part which can eject the upper part of the stopper (15) out of the fixed die (2) is arranged below the stopper (15); a block pressing part for pressing the upper part of the stopper (15) back to the fixed die (2) is arranged on the first slide block (3); one end of the block pressing part is fixedly connected with a piston rod (7) of the cylinder (4), and the other end of the block pressing part is in sliding connection with the first slide block (3); a limiting part for preventing the block pressing part from sliding out of one end close to the cylinder (4) is arranged on the first slide block (3); and when the block pressing part slides to the limiting part, the first slide block (3) can be driven to slide in the fixed die (2).

Owner:宁海县现代模具有限公司

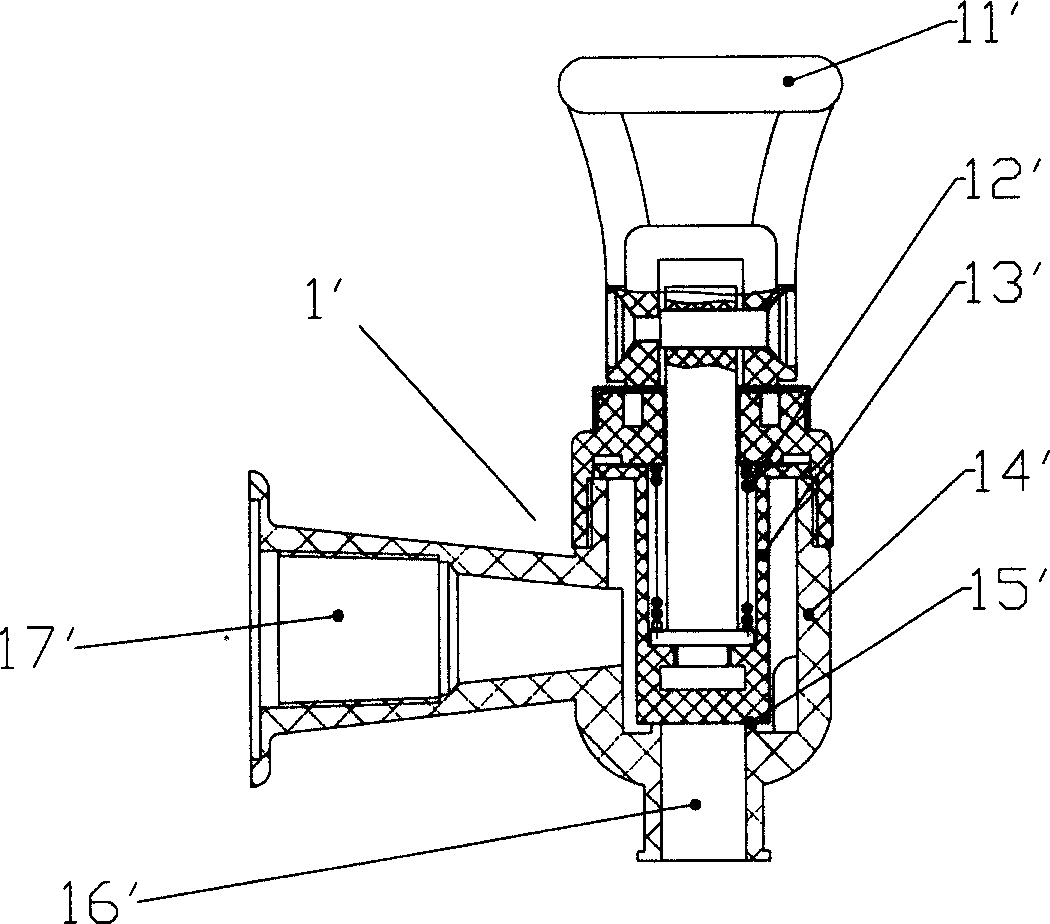

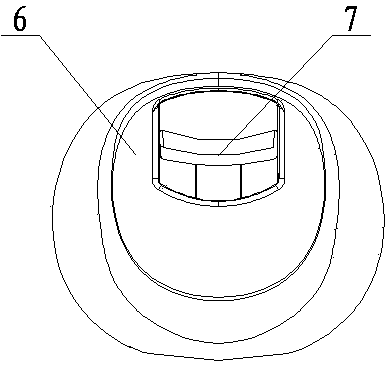

Novel lift check valve

Disclosed is a novel lift check valve. The novel lift check valve comprises a valve body, a valve seat, a valve clack and a valve rod. The valve seat, the valve clack and the valve rod are arranged inside the valve body. One end of the valve clack is connected with the valve rod, and the other end of the valve clack is connected with the valve seat. The novel lift check valve further comprises a self-sealing device. The self-sealing device comprises a spring, a lantern ring and a guide shaft, wherein the spring, the lantern ring and the guide shaft are arranged on the valve rod in sequence from the position of connection between the valve clack and the valve rod to the top in a sleeving mode. A cavity is arranged inside the guide shaft so that the valve rod can move back and forth in the cavity. By the adoption of the novel lift check valve, due to the fact that the self-sealing device is arranged, the valve clack and the valve seat can be rapidly opened and closed through the pressure difference of fluid, the sealing performance is good in the closing process, and backflow of the fluid is prevented in time. Meanwhile, the pressure of a water hammer can be reduced, and the service life of the novel lift check valve is prolonged.

Owner:SUZHOU KEDI FLUID CONTROL EQUIP

Single-stage vacuum contactor

ActiveCN105047472AStable voltageReduce feverHigh-tension/heavy-dress switchesAir-break switchesPressure systemSingle stage

The invention relates to a single-stage vacuum contactor. The single-stage vacuum contactor comprises an insulating frame and a cover lid arranged on the insulating frame. A vacuum arc extinguishing system, an electromagnetic system, a self-coupling voltage transformation rectification energy saving control module connected with the electromagnetic system, a transmission pressure system and an anti-damage dustproof auxiliary switch. The transmission pressure system comprises a return spring, an overtravel spring, a movable ejector rod and an anti-closing bounce spring which are arranged from left to right in order. The vacuum arc extinguishing system comprises an insulating shell body. The anti-closing bounce spring is arranged in the insulating shell body. A transformer is arranged in the self-coupling voltage transformation rectification energy saving control module. The electromagnetic system comprises a coil. The coil is arranged at the periphery of the return spring. An overtravel ejector rod is arranged between the overtravel spring and the return spring. The above structure is employed, the beneficial effects are that the structure is firm and reliable and the product service life is long.

Owner:上海翔洲电气科技有限公司

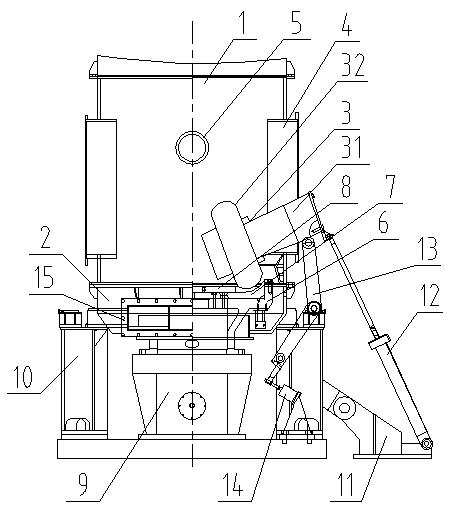

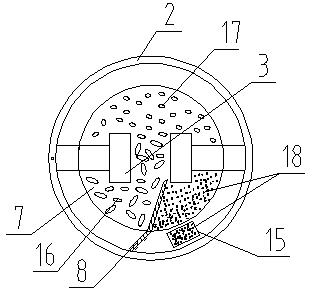

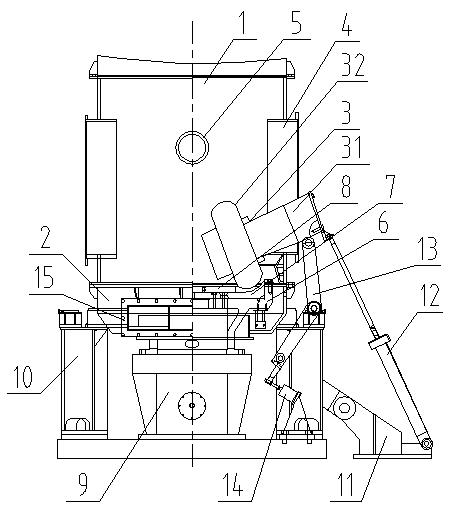

A vertical grinding roller sand making machine

InactiveCN102284320ASimple and reasonable structureIncrease installed capacityGrain treatmentsEngineeringRoller mill

The invention discloses a vertical grinding roller sand making machine. The machine comprises a base, a lower shell on the base and an upper shell which is connected with the lower shell and provided with a feed port, wherein a discharge port is formed on one side of the lower shell; a turnplate is arranged in the lower shell, and connected with a power mechanism; a crushing roller is arranged in the upper shell; and the crushing roller and the edge of the turnplate are alternately arranged. By adopting an incomplete bed grinding principle, a material between the crushing roller and the turnplate is instantly crushed by virtue of crushing methods, such as rolling, friction, mutual cutting of materials and the like. The machine has the advantage of simple structure, high loading capacity, high finished product content, low unit energy consumption and high production efficiency.

Owner:HENAN TONGXU MINING MACHINERY

Novel fitness strolling machine

ActiveCN109513171APrevents the phenomenon that the foot slips out of the pedalImprove toughnessMovement coordination devicesCardiovascular exercising devicesMassageEngineering

The invention discloses a novel fitness strolling machine. The strolling machine comprises a base, a first supporting frame is installed at the upper end of the base, a second supporting frame is installed on the part, corresponding to the first supporting frame, of the upper end of the base, and a first fixing seat is fixedly arranged on one side of the first supporting frame. Calves of a user can be conveniently conducted when the user exercises through a massage device, the blood circulation of the calves of the user is conveniently promoted to enhance the toughness of legs and relieve thefatigue of muscles, pedal supporting rods on the rolling machine is conveniently limited through limiting rods to prevent the influence on the user by larger swing arch of pedals, the swing amplitudeof the supporting rod can be relieved by using buffering plates and springs to prevent counter force from generating on the user due to excessive swing amplitude, limiting protection can be conveniently conducted through limiting rings when elderly people or children exercise, and therefore the problem that elderly people and children fall when exercise is avoided.

Owner:陈滨

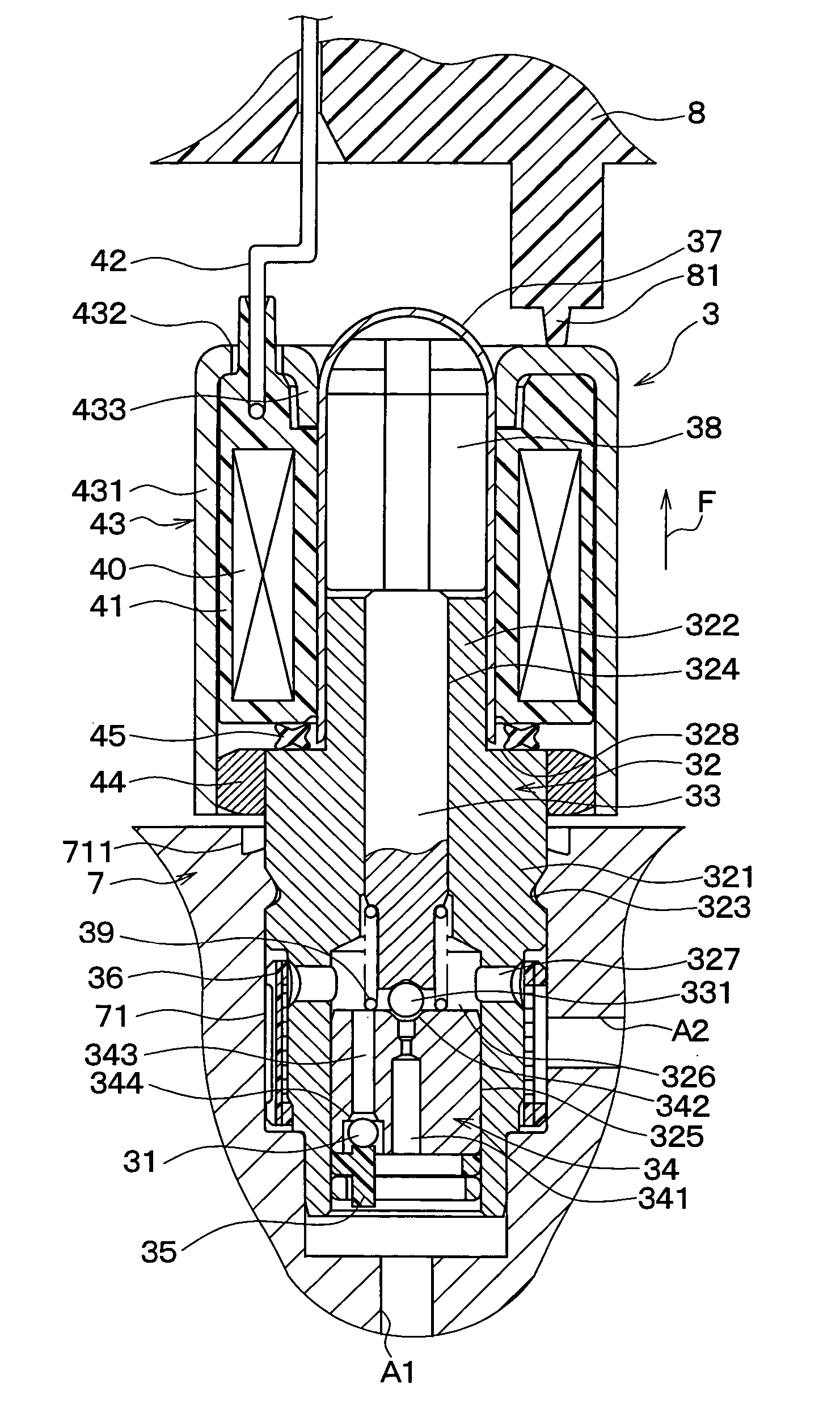

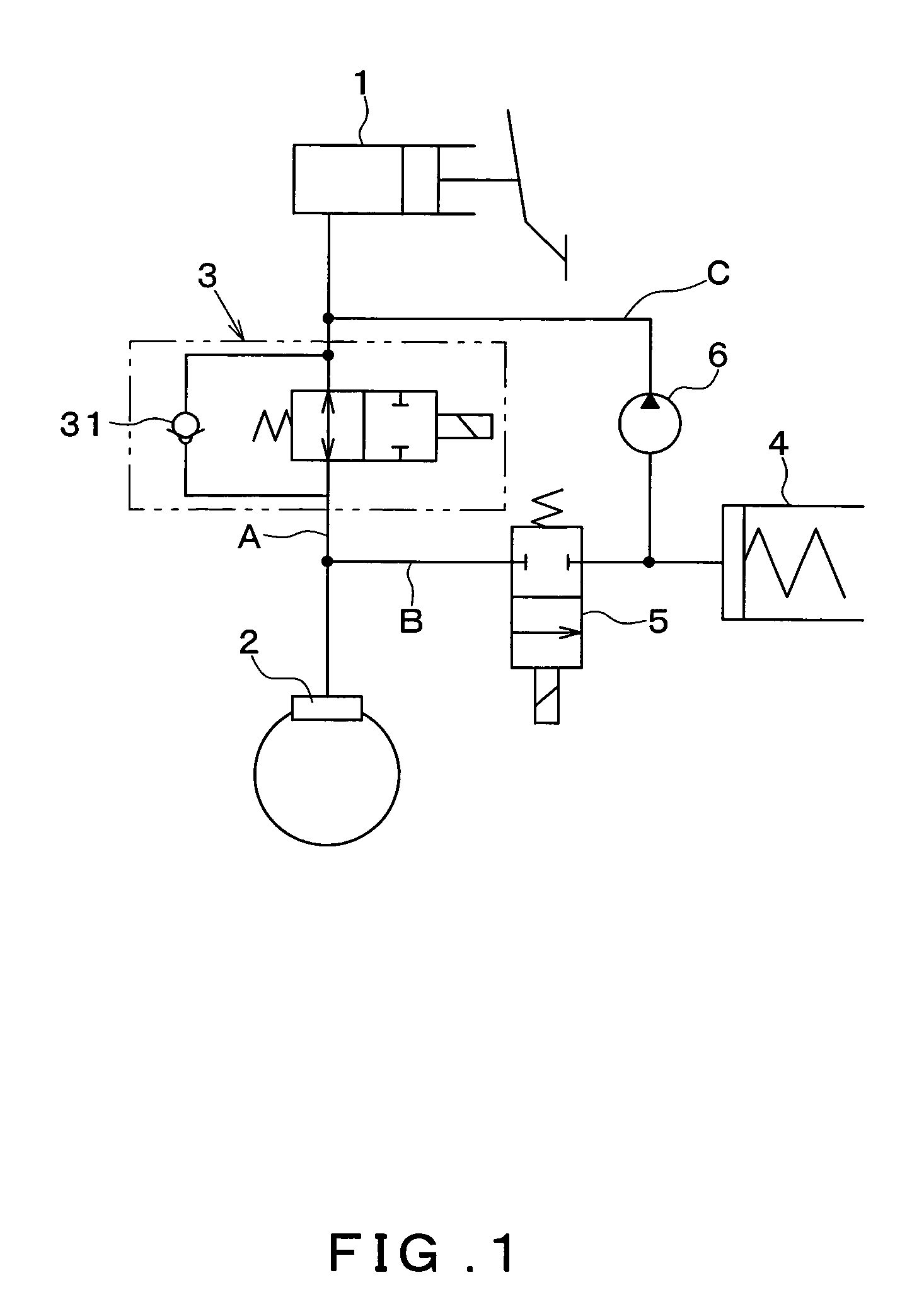

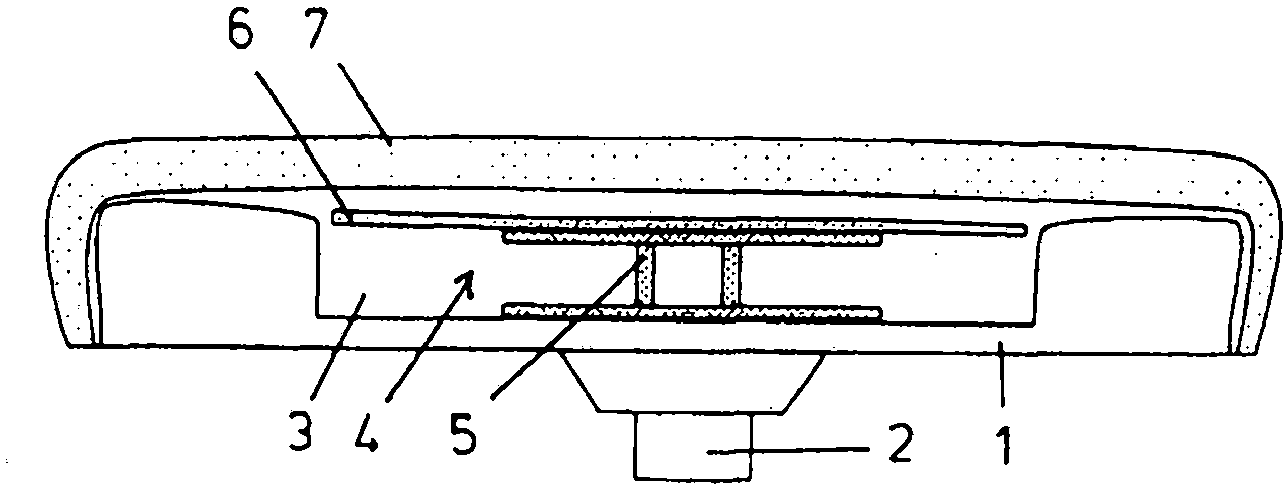

Fluid control apparatus

InactiveUS7048252B2Low costSmall sizeOperating means/releasing devices for valvesApplication and release valvesFluid controlEngineering

An elastic member made of rubber which urges a coil portion toward a cover is formed into a shape such that the elastic member can be deformed by bending. A rate of change in reaction force of the elastic member with respect to an amount of deformation in a bending deformation region is less than a case where the elastic member is subject to compressive deformation. Therefore, even in the case where the amount of deformation of the elastic member increases due to dimensional variation of a component part, the reaction force of the elastic member does not become excessively large.

Owner:ADVICS CO LTD

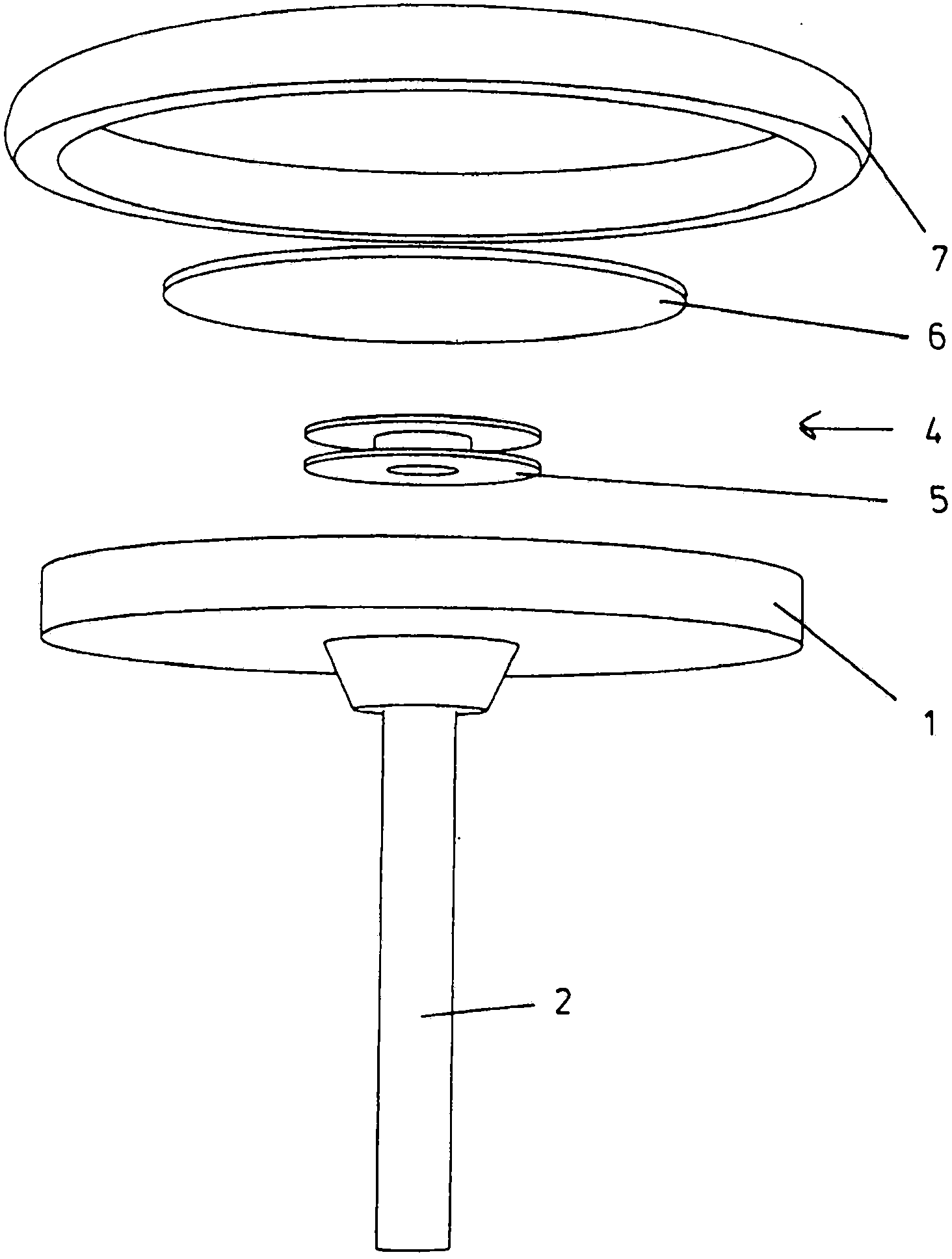

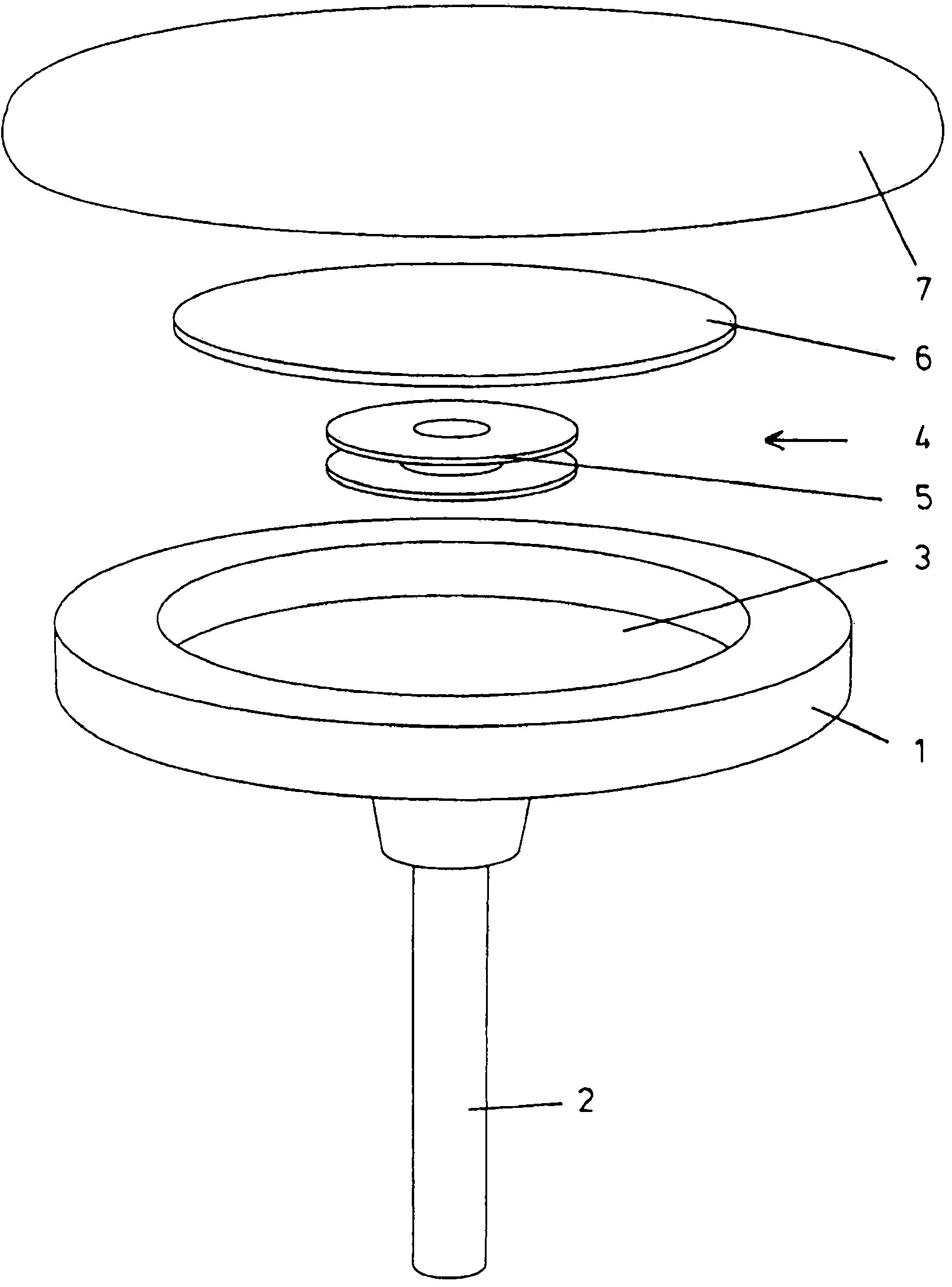

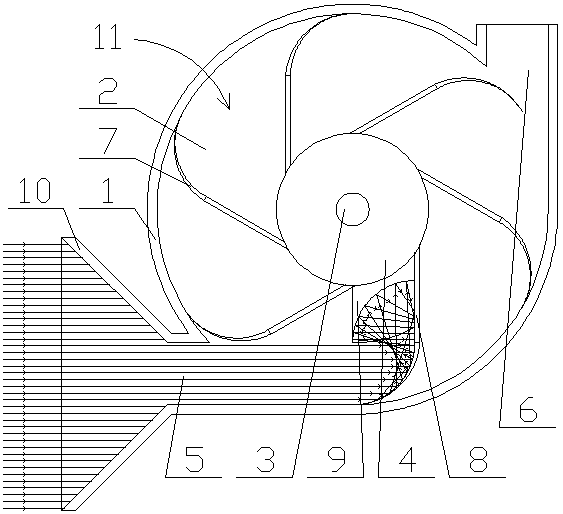

Piece of seating furniture

InactiveCN103517654APrecise center settingAvoid reaction forceStoolsRocking chairsEngineeringStructural unit

A piece of seating furniture has a seat plate (1) with a lower seat framework (2) arranged on the underside of said seat plate (1). Also provided is a tilting device (4), by means of which the person sitting on the piece of furniture can execute a tilting movement about a point of rotation located in the seat region. The tilting device (4) is formed by a structural unit which is separate from the seat plate (1) and is arranged on the seat plate (1) of the piece of furniture.

Owner:斯特凡·迈尔

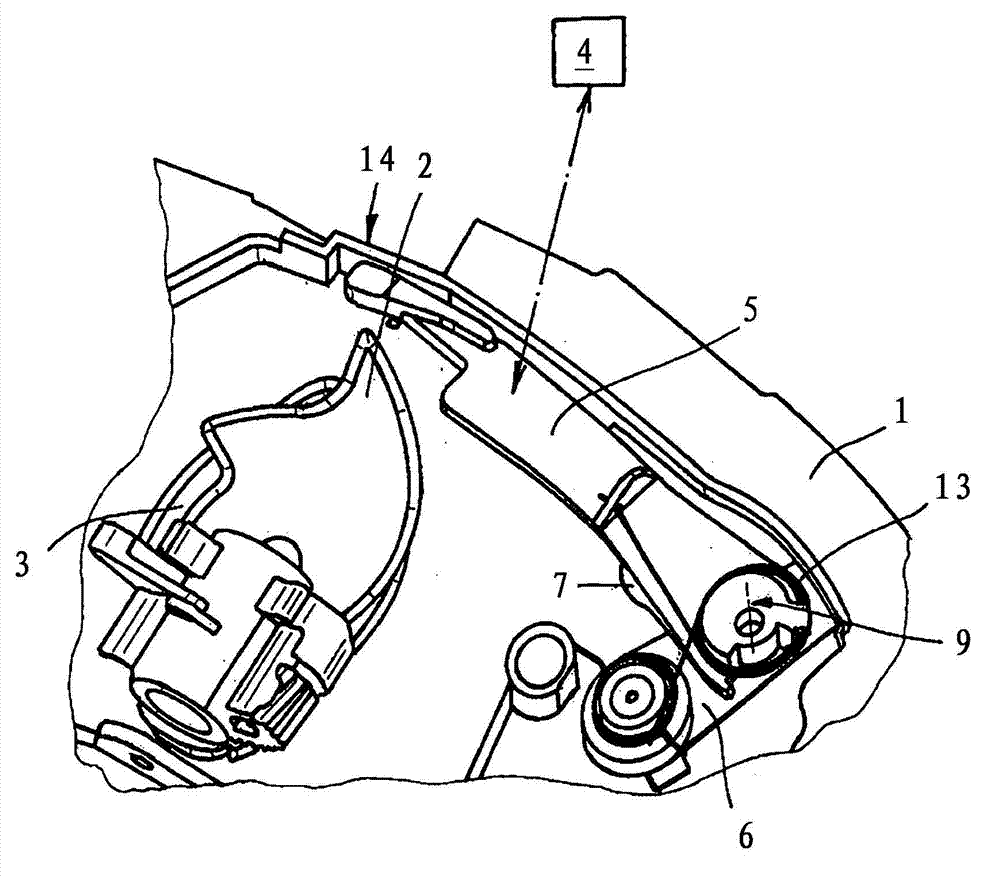

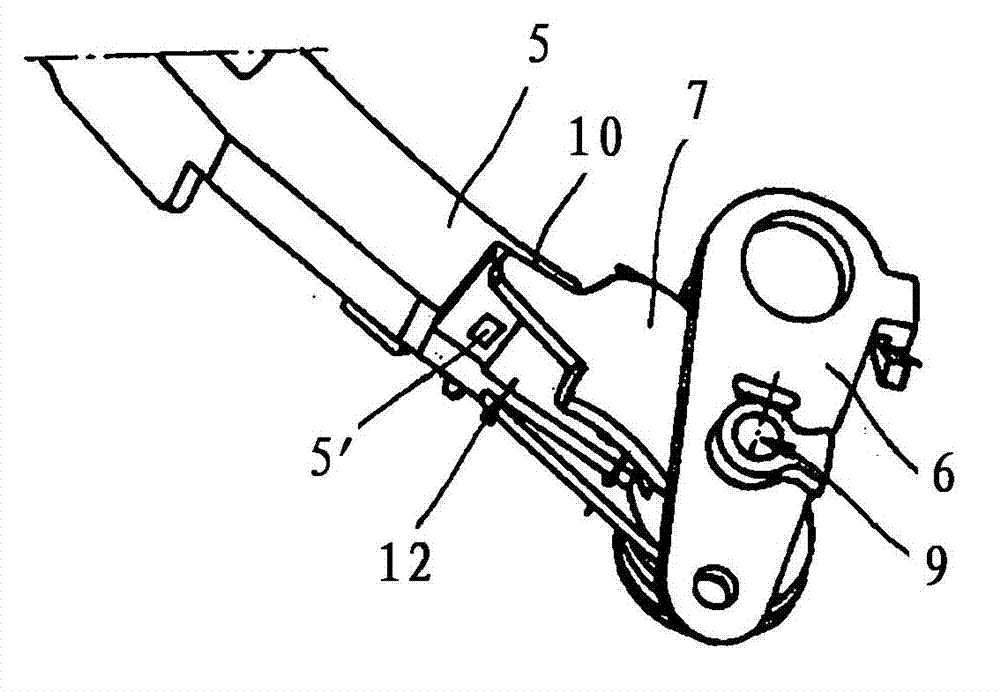

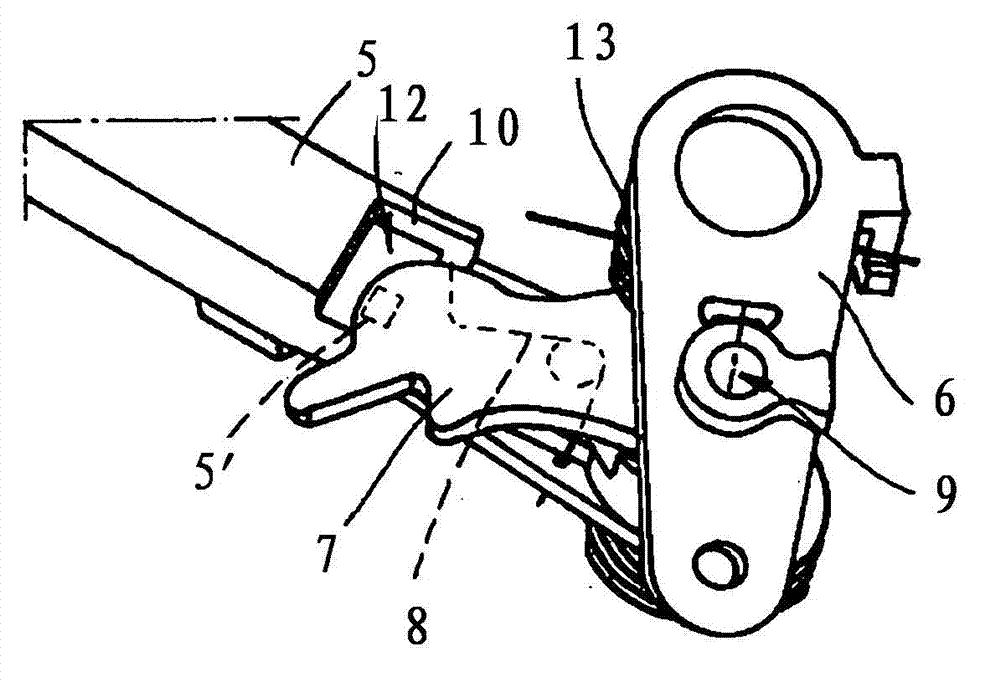

Motor-vehicle door lock

ActiveCN102791943AAvoid failureAvoid/or Plastic DeformationAutomatic securing/unlockingAccident situation locksEngineeringCar door

The present invention relates to a motor-vehicle door lock which is provided with a catch (2,3), with an actuating-lever mechanism (5, 6) which acts on the catch (2, 3). There is also a locking lever (7) which, together with the actuating lever (5), renders the actuating-lever mechanism (5, 6) inactive when accelerating forces of predetermined magnitude occur, for example in the event of a crash. According to the invention, the actuating lever (5) and locking lever (7) disable the actuating-lever mechanism (5, 6) mechanically, as a result of the accelerating forces occurring, by associated deflection. Following dissipation of the accelerating forces, the actuating lever (5) and locking lever (7) reconnect the actuating-lever mechanism (5, 6).

Owner:KIEKERT AG

Vehicle-mounted wind power generation energy complementation cruising device

InactiveCN109139382ALower speed lower limitImprove power generation efficiencyMachines/enginesWind motor combinationsLower limitEngineering

The invention discloses a vehicle-mounted wind power generation energy complementation cruising device. A partition plate is fixed in the middle in a barrel and divides the interior of the barrel intoa speed increaser cavity and a generator cavity. A speed increaser is arranged in the speed increaser cavity, and the generator is arranged in the generator cavity. The speed increaser and an outer rotor of the generator are in transmission connection and both rotate around a generator stator shaft in the same direction. The generator stator shaft is fixed to the axis of the barrel. Multiple blades are evenly distributed on the circumferential face of the speed increase and the circumferential face of the outer rotor of the generator. An air inlet and an air outlet are arranged on the side wall of the barrel. In the direction of airflow in the barrel, the air outlet is located on the rear side of the air inlet, and the air inlet direction of the air inlet is the tangential direction of the position where the blades pass through the air inlet. From the above structure, by means of the vehicle-mounted wind power generation energy complementation cruising device, the barrel is divided bythe partition plates into the speed increaser cavity and the generator cavity, the power generation efficiency is improved, and the vehicle speed lower limit value needed for efficient power generation is reduced.

Owner:张亚明

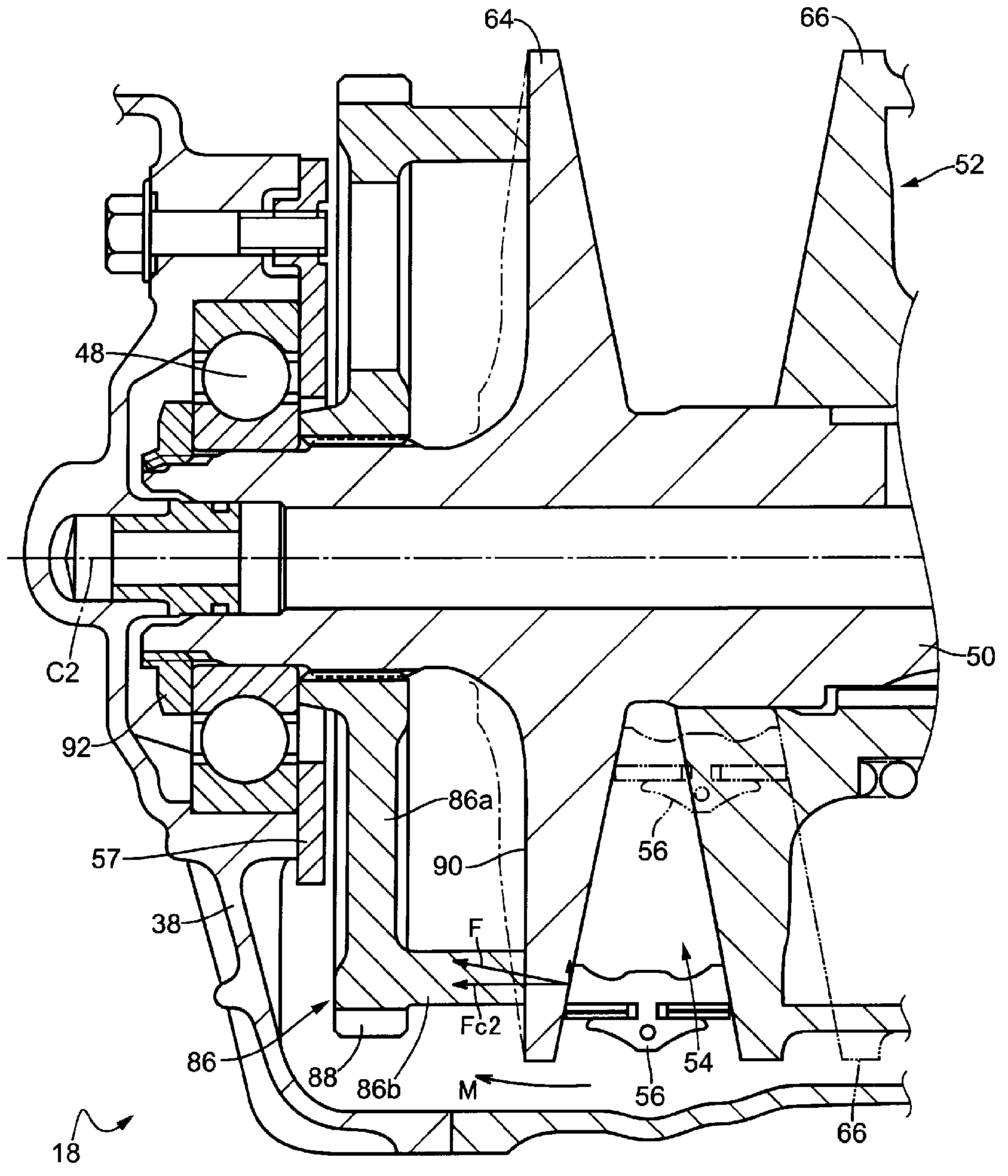

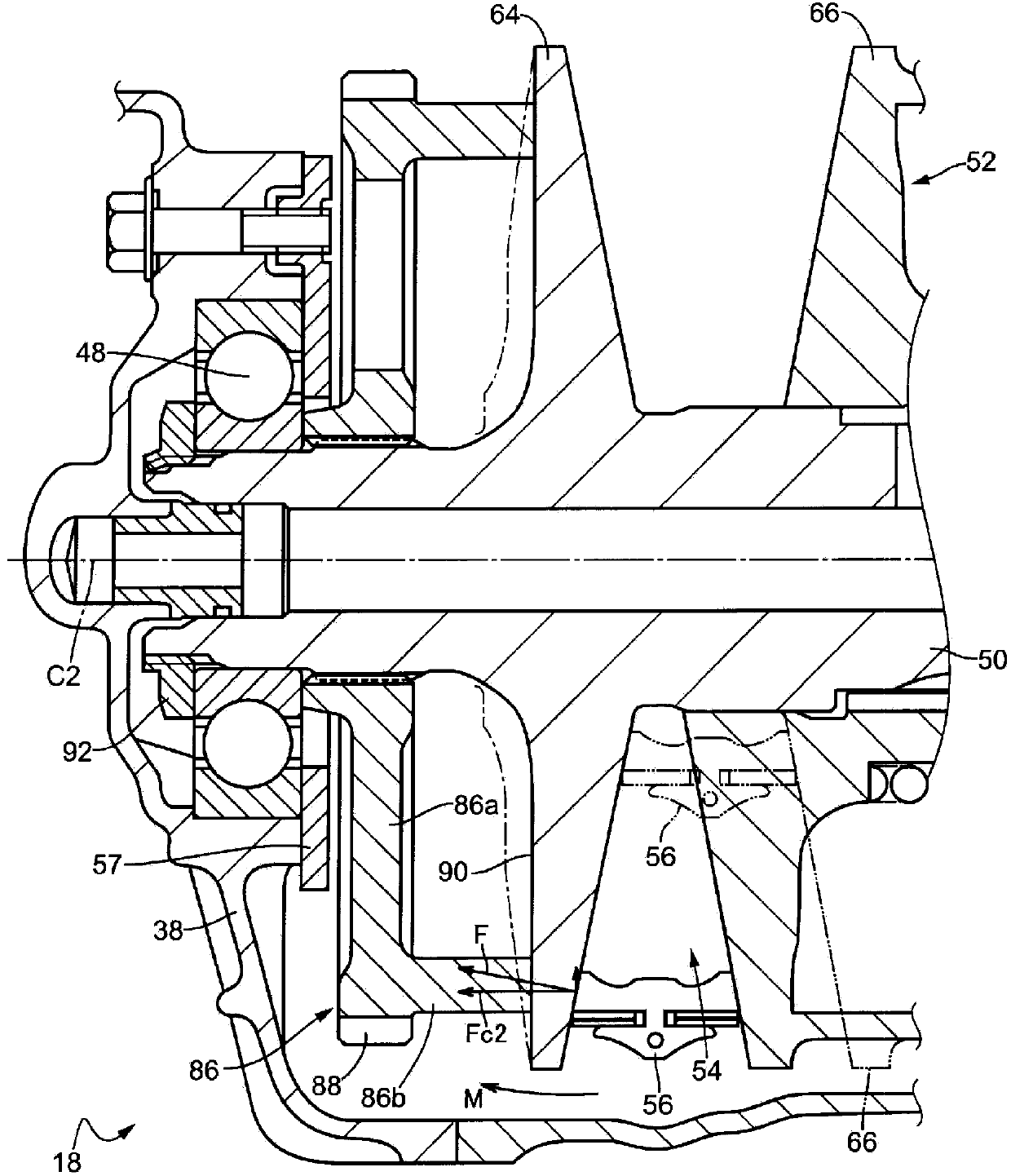

Belt Type Continuously Variable Transmission For Vehicle

InactiveCN102812267ACurb dumpingEasy to changeGearingGearing controlTransmission beltRadial position

Provided is a belt type continuously variable transmission for a vehicle such that the bending-over of a fixed sheave can be restricted. A parking gear (86) comprising a disk-shaped main body section (86a) and an annular protrusion (86b) is provided on that side of the fixed sheave (64) which is other than the side facing a movable sheave (66), said disk-shaped main body section (86a) being fixed to an output shaft (50), for example, by being splined together therewith, and said annular protrusion (86b) protruding from the main body section (86a) toward that wall surface of the fixed sheave (64) which is other than the side facing the movable sheave (66), that is, toward a back surface (90), and abutting the back surface (90) at that radial position which corresponds to the maximum engagement radius of a transmission belt (56). Therefore, even if the fixed sheave (64) is subjected to an axial reaction force (Fc2) in an axial direction (C2) by the transmission belt (56), that area of the back surface (90) of the fixed sheave (64) which is outward of the minimum engagement radius of the transmission belt (56) is supported by the parking gear (86), which is formed by adding only relatively simple changes to a conventional one. Consequently, the bending-over of the fixed sheave (64) can be restricted.

Owner:TOYOTA JIDOSHA KK

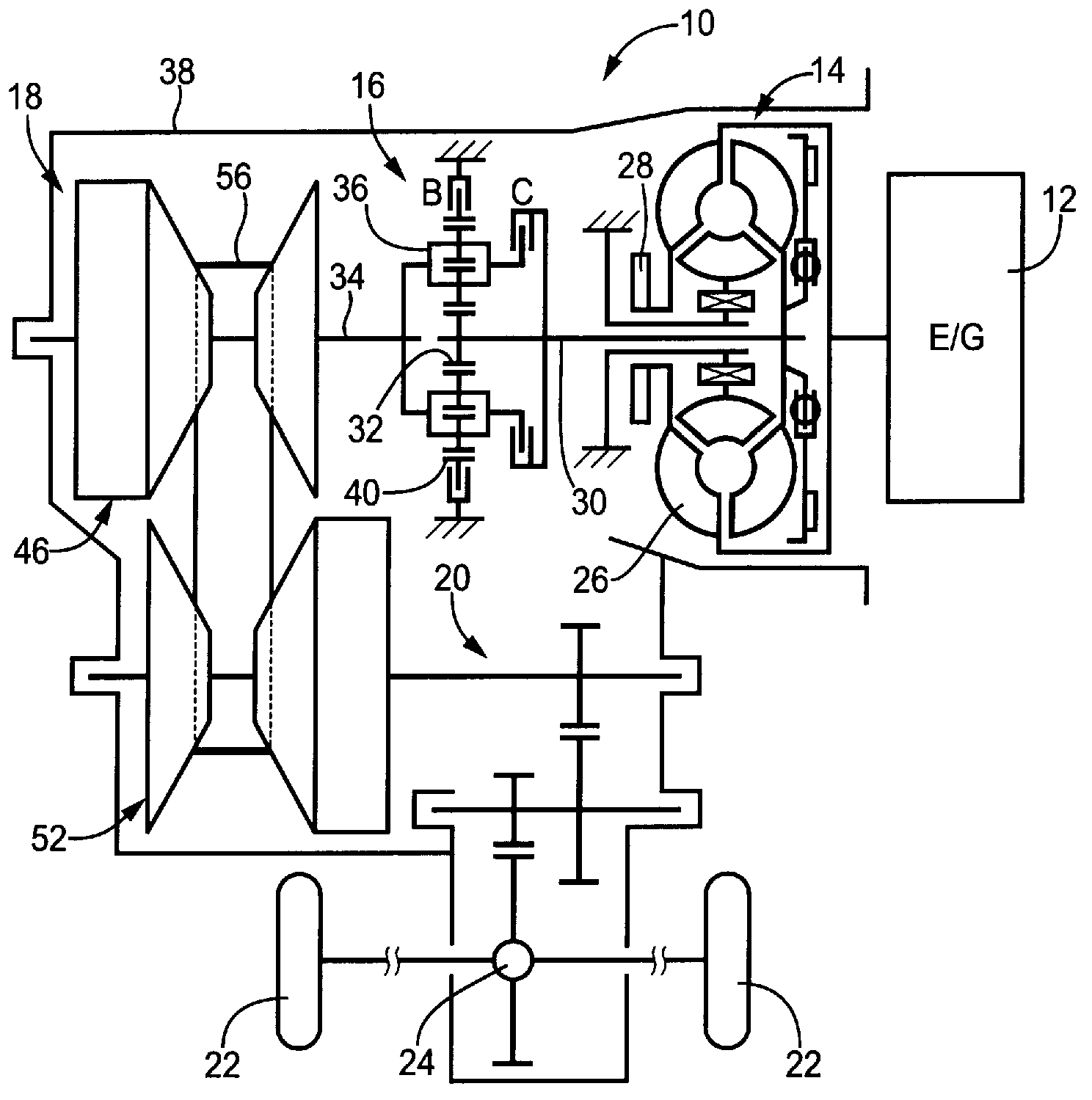

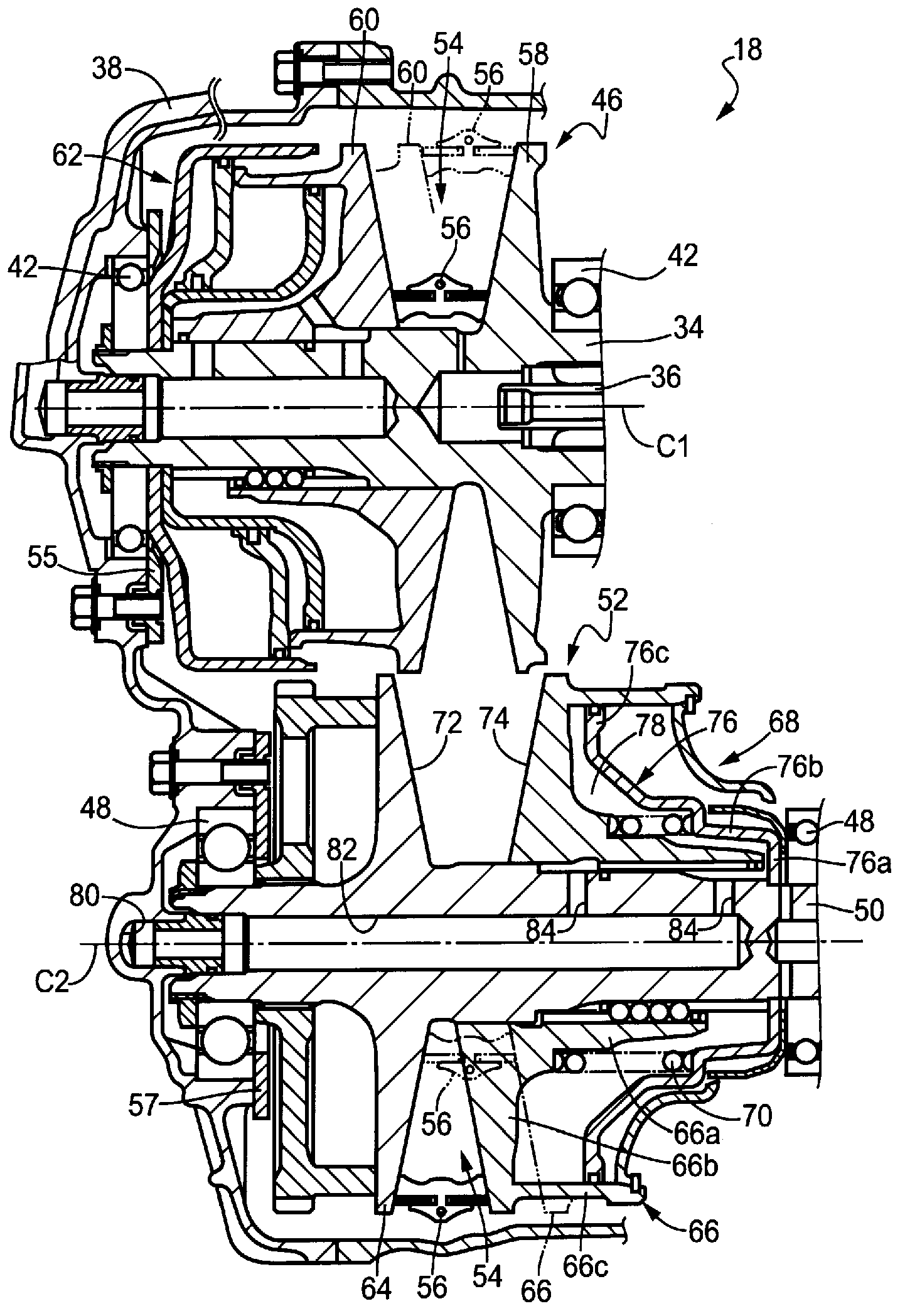

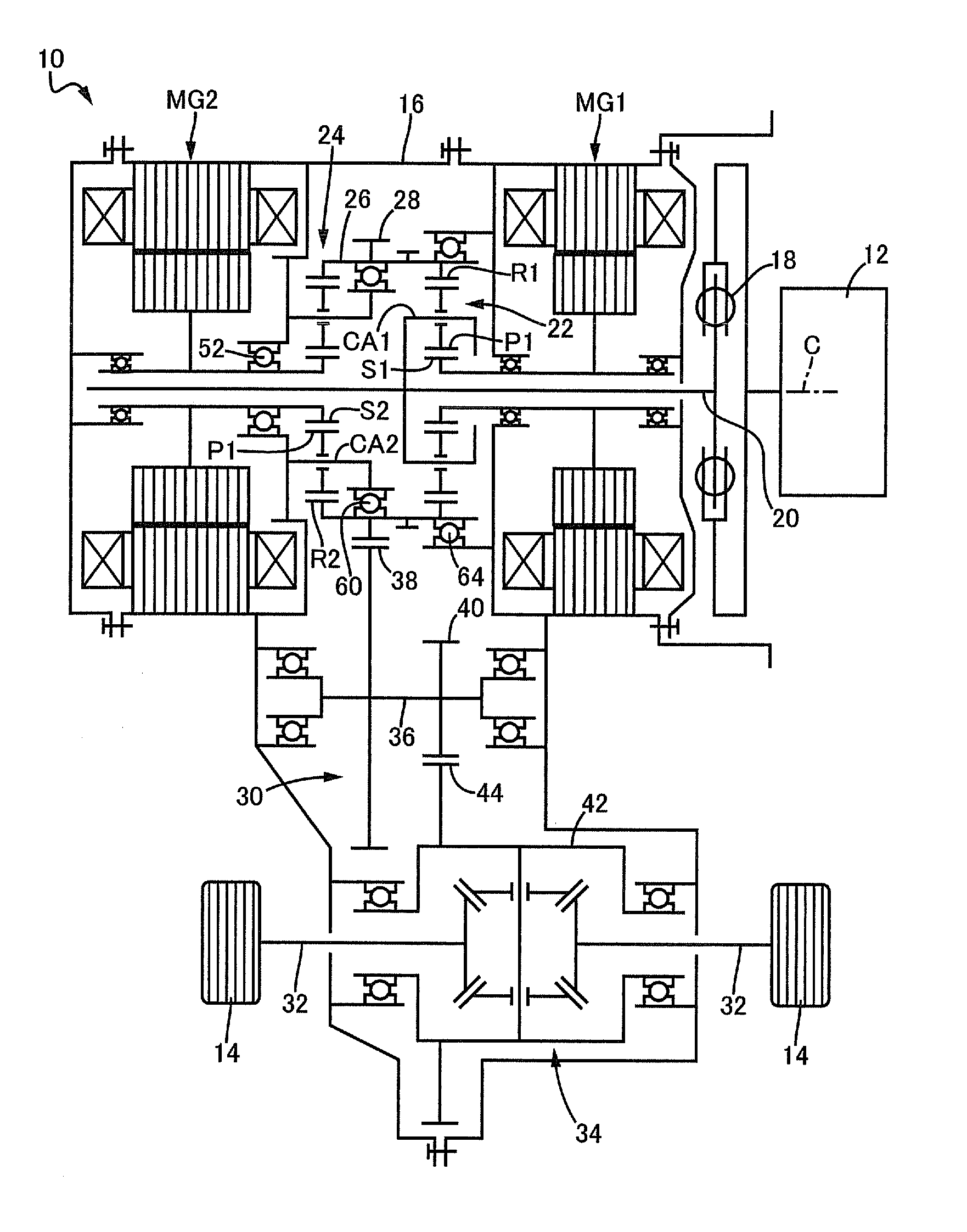

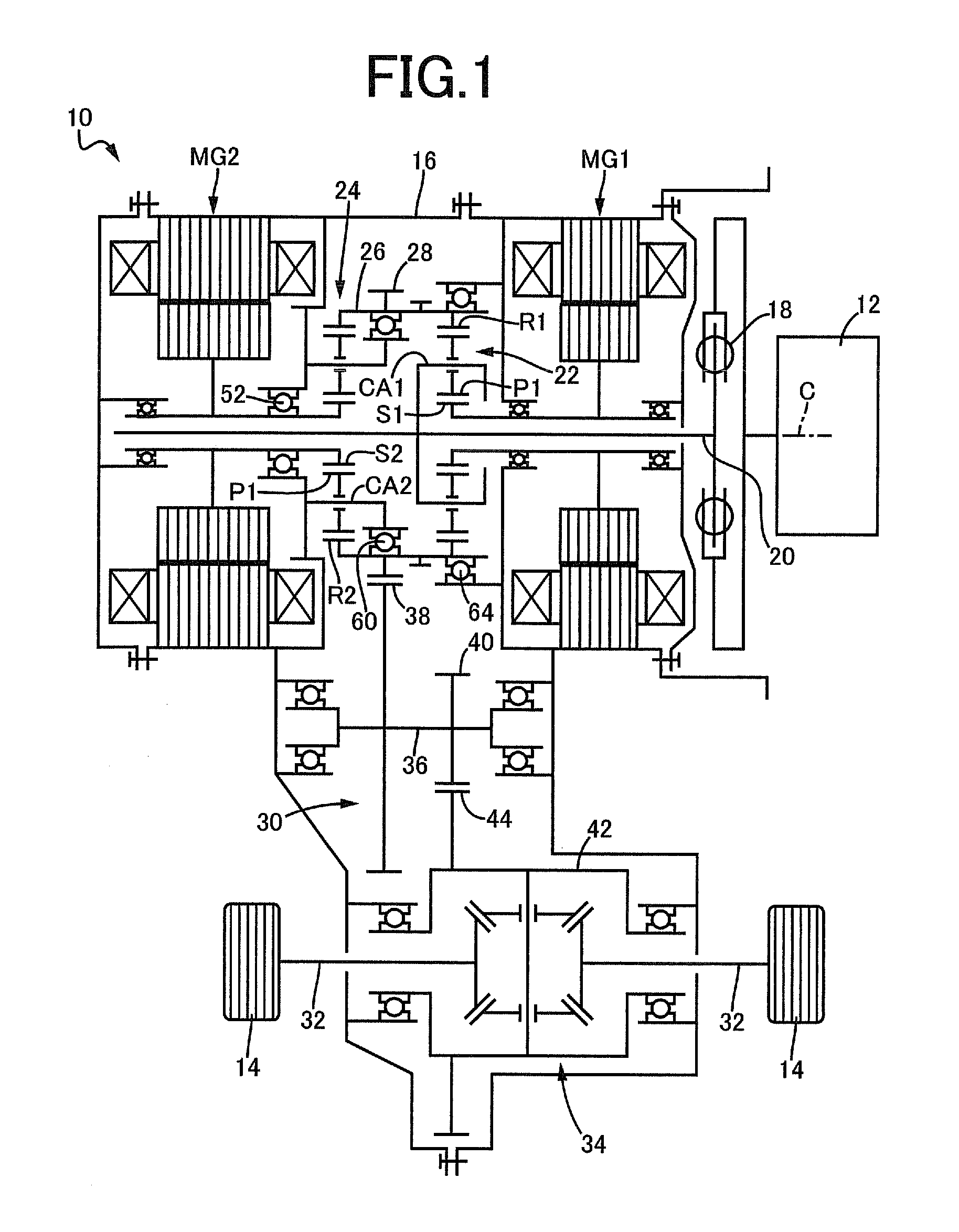

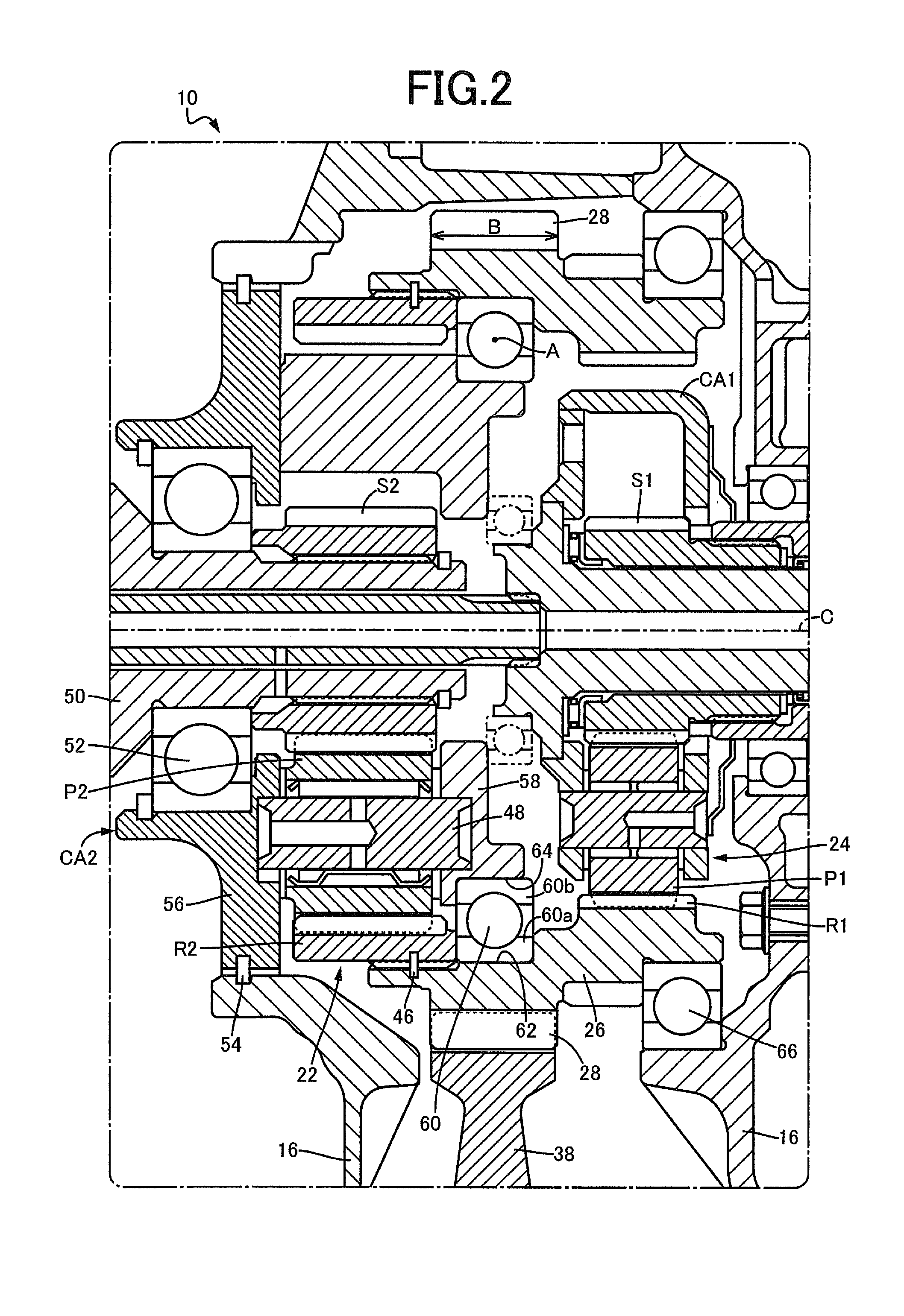

Vehicle power transmission device

InactiveUS8858377B2Suppression of generation of vibratory forceInhibitionHybrid vehiclesGearboxesEngineeringDistributed power

Owner:TOYOTA JIDOSHA KK

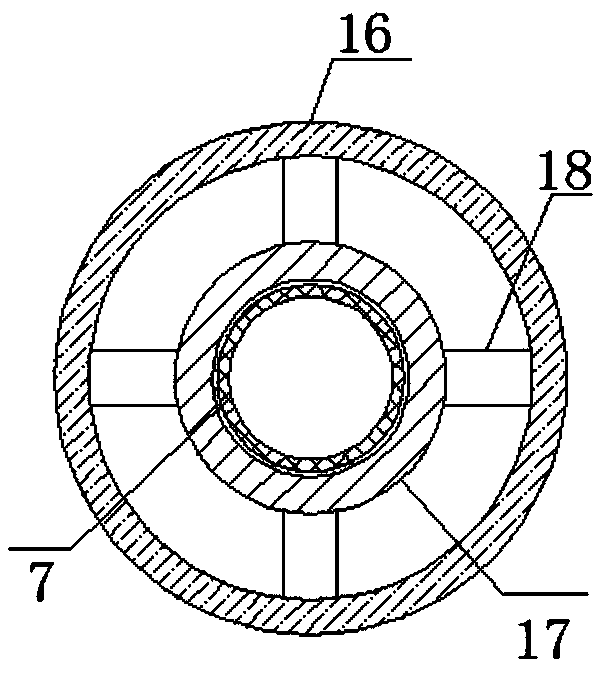

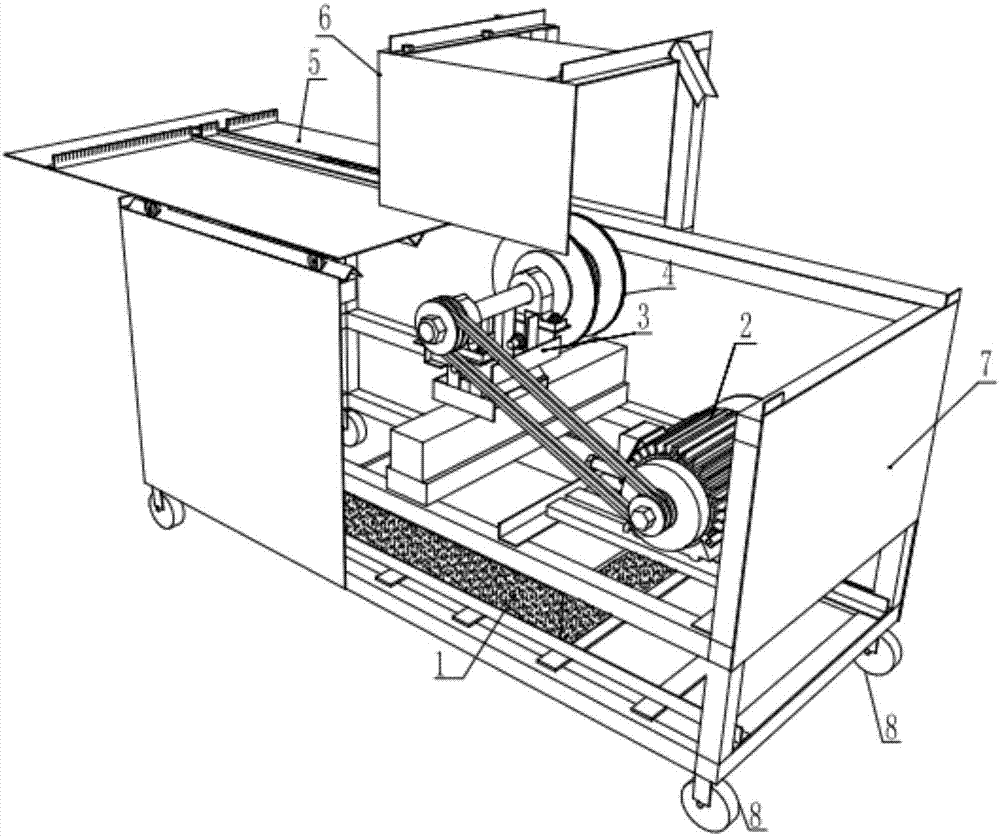

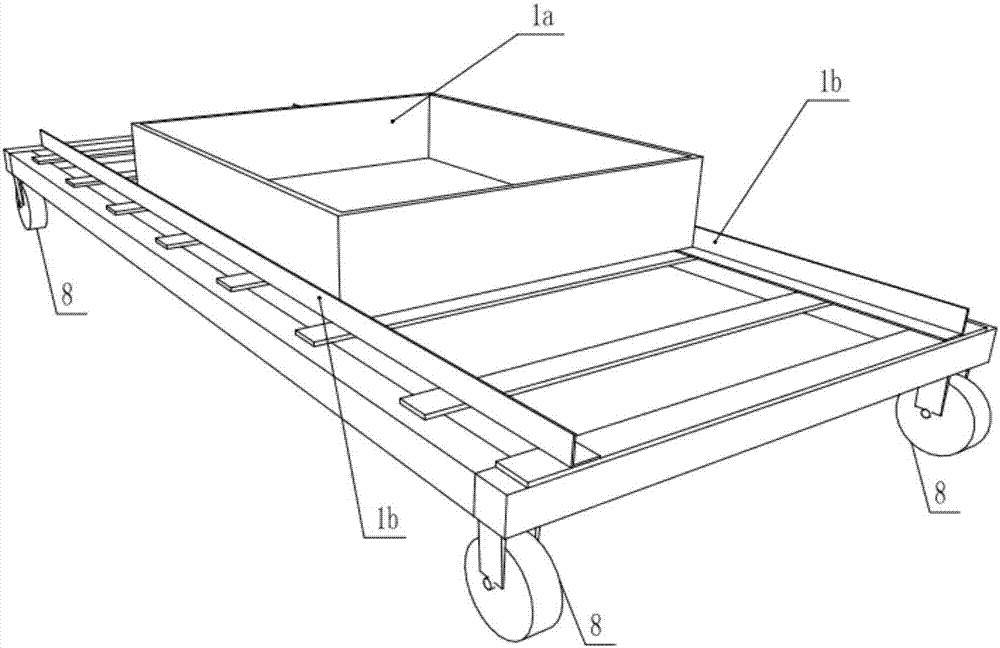

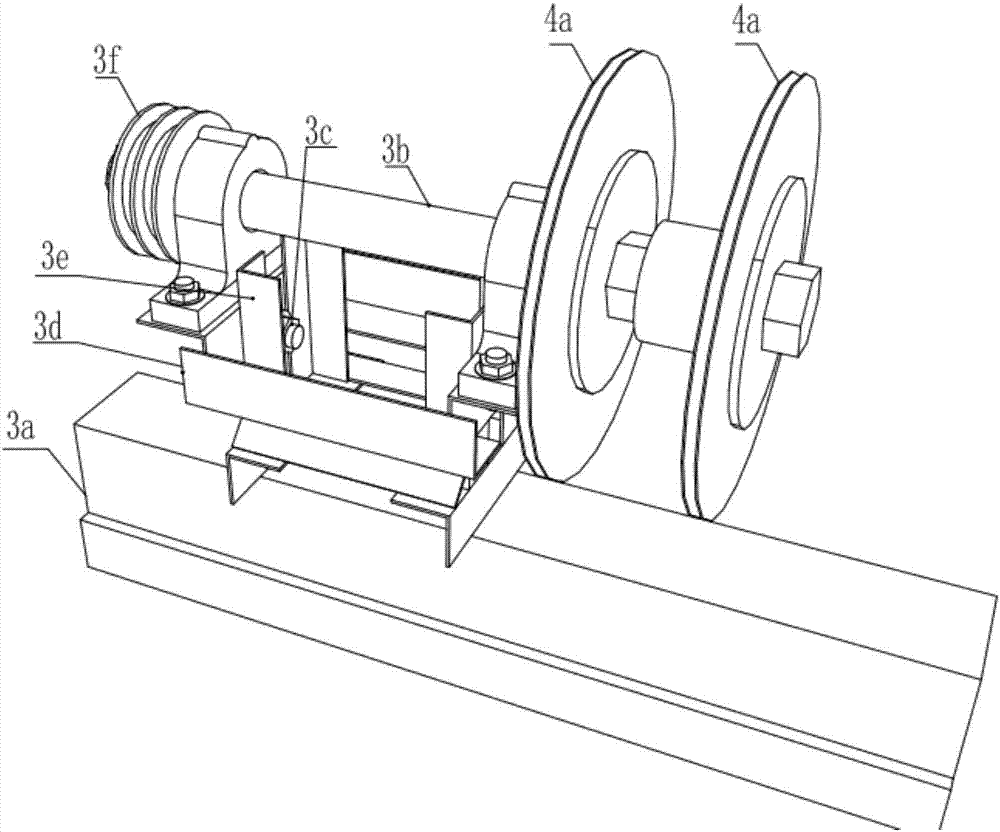

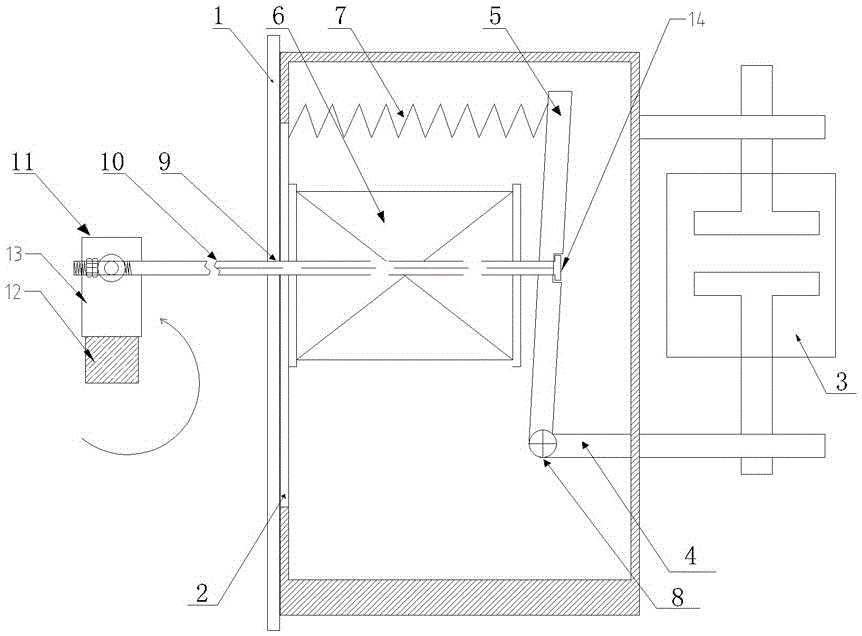

Integrated building block grooving machine

PendingCN107877715ASolve the problem of excessive dustEasy to useWorking accessoriesStone-like material working toolsArchitectural engineeringSlide plate

An integrated building block grooving machine comprises a rectangular crate (7) and a grooving device arranged in the crate, the grooving device comprises a dust falling water trough (1) formed in thelower portion of the crate and a grooving depth adjustment supporting seat (3) arranged above the dust falling water trough, the grooving depth adjustment supporting seat (3) is connected with an adjustable blade combination device (4) and a motor (2), a sliding plate (5) is arranged on the top face of a crate body of the crate (7), and a protective cover (6) is arranged on the position, corresponding to the adjustable blade combination device (4), above the sliding plate (5). According to the integrated building block grooving machine, the grooving depth, width and distance of a building block can be controlled, the grooving efficiency and the grooving quality are effectively improved, the problem that flying dust is over much in the mechanical grooving process is solved, and operation is safe and convenient.

Owner:YUNNAN CONSTR ENG GENERAL CONTRACTING

Mechanical emergency starting apparatus applied to star-delta voltage-reduction starting

InactiveCN106653472AGood consistency of mechanical emergency startMotion synchronizationHigh-tension/heavy-dress switchesAir-break switchesElectricityNational standard

The invention relates to a mechanical emergency starting apparatus applied to star-delta voltage-reduction starting. The mechanical emergency starting apparatus comprises an insulating electric-insulating framework, a metal back sealing plate, two sets of electromagnetic control mechanisms, a manual operating mechanism and two sets of vacuum switching tube parts, wherein each set of electromagnetic control mechanism is provided with a switching-on holding pinch plate, a transmission connecting lever, a switching-on armature, a switching-on coil and a switching-off spring; a long pull rod passes through a through slot in the metal back sealing plate and is connected with a countersunk head hole in the corresponding switching-on armature; and a screw thread part at the other end of the long pull rod is movably connected with a U-shaped linking block on a linking rod of the manual operating mechanism through a positioning pin. The mechanical emergency starting apparatus can synchronously drive two alternating current vacuum contactors to realize mechanical emergency starting; and regulation of No. 11.0.12 clause of national standard GB 50974-2014 ''fire water supply and hydrant system technical specification'' implemented on 1st, Oct. 2014 is satisfied.

Owner:CHENZHOU DONGTANG ELECTRIC EQUIP

Belt type continuously variable transmission for vehicle

A belt type continuously variable transmission for a vehicle includes: an input shaft and an output shaft disposed in parallel with each other; a pair of groove width variable pulleys disposed on the outer circumferential sides of the input shaft and the output shaft; and a transmission belt wound around each of V-grooves of the pair of the groove width variable pulleys, the belt type continuously variable transmission for a vehicle changing a winding diameter of the transmission belt by changing the groove widths of the V-grooves so as to continuously vary a gear ratio, wherein the groove width variable pulley includes a fixed sheave fixed to an outer circumferential surface of one of the input shaft and the output shaft, and a movable sheave disposed relatively non-rotatably on the one shaft and relatively movably in the direction of the shaft center of the one shaft so as to form the V-groove with the fixed sheave, wherein the belt type continuously variable transmission for a vehicle is disposed with a parking gear having a disc-shaped main body portion fixed to the one shaft on the side opposite to the movable sheave relative to the fixed sheave, and an annular projecting portion projecting from the main body portion toward a wall surface of the fixed sheave on the side opposite to the movable sheave and abutting on the wall surface of the opposite side on the outer circumferential side than the minimum winding diameter of the transmission belt, and wherein the annular projecting portion of the parking gear abuts on the wall surface of the fixed sheave on the side opposite to the movable sheave at a radial position corresponding to the maximum winding diameter of the transmission belt.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com