A vertical grinding roller sand making machine

A vertical mill and roll-making technology, applied in the field of mining equipment, can solve the problems of high production cost, low production efficiency, and high unit energy consumption, and achieve the effects of high production efficiency, low unit energy consumption, and large installed capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

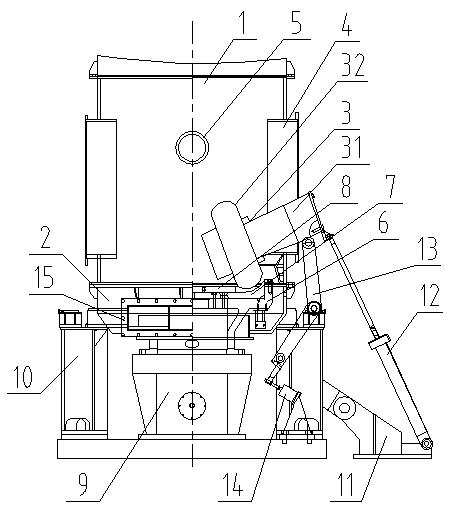

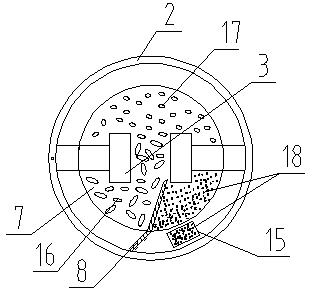

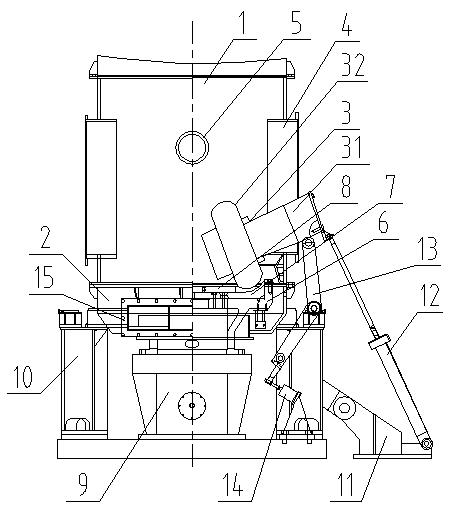

[0023] Such as figure 1 The vertical grinding roller sand making machine shown includes a base 10, a lower shell 2 on the base 10 and an upper shell 1 with a feed port connected to the lower shell 2, the lower shell 2 and the upper shell 1 constitutes a crushing cavity. A turntable 6 is arranged inside the lower casing 2, and a liner 7 is arranged on the turntable 6. The liner 7 is disc-shaped, and the edge of the disc-shaped liner 7 is arc-shaped. The turntable 6 is connected with the output shaft of the reducer 9 below the lower casing 2, and the reducer 9 is drivingly connected with the motor (not shown in the figure). A discharge port 15 is provided on one side of the lower case 2, and a water inlet 5 is provided on the side wall of the upper part of the upper case 1. Water is pumped from the water inlet 5 into the upper case 1, so that the finished particles that have been crushed up to the standard and the crushed intermediate product The tiny amount of powder produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com