Overlong sectional material machining device and method

A processing device and processing method technology, applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of channel steel with large flexibility, complex deformation shape, and out-of-tolerance processing dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The ultra-long profile processing device provided in this embodiment includes a milling machine and two supports. The workbench of the milling machine is adjustable in height and can be fed along the length direction of the workpiece; two clamps for positioning the workpiece are fixed in parallel on the workbench. There are rollers on the top of the bracket, which can reduce the friction when the workpiece moves; two brackets are set on both sides of the worktable, and keep a certain distance from the worktable, and the bracket and the fixture are on the same line.

[0036] Working principle of this embodiment: the processing method of the above-mentioned ultra-long profile processing device includes the following steps: the channel steel is fixed on the workbench by the clamp, and the protruding parts of the two ends of the workpiece are supported by the bracket. At this time, the height of the top of the bracket and the workbench Same, record the height of the worktabl...

Embodiment 2

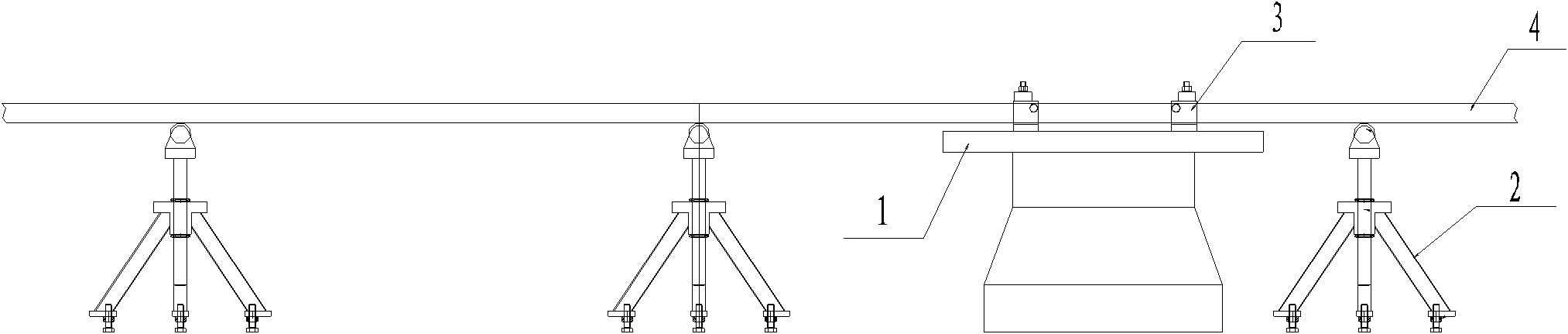

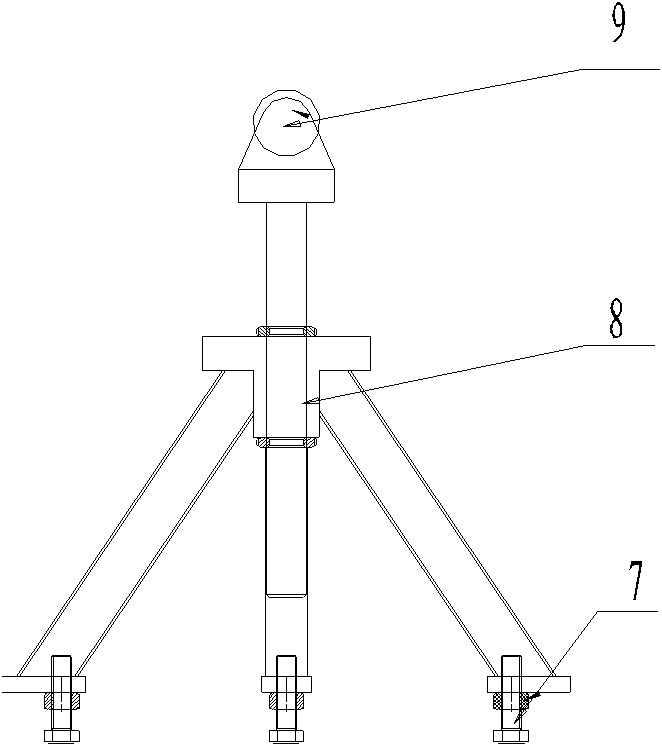

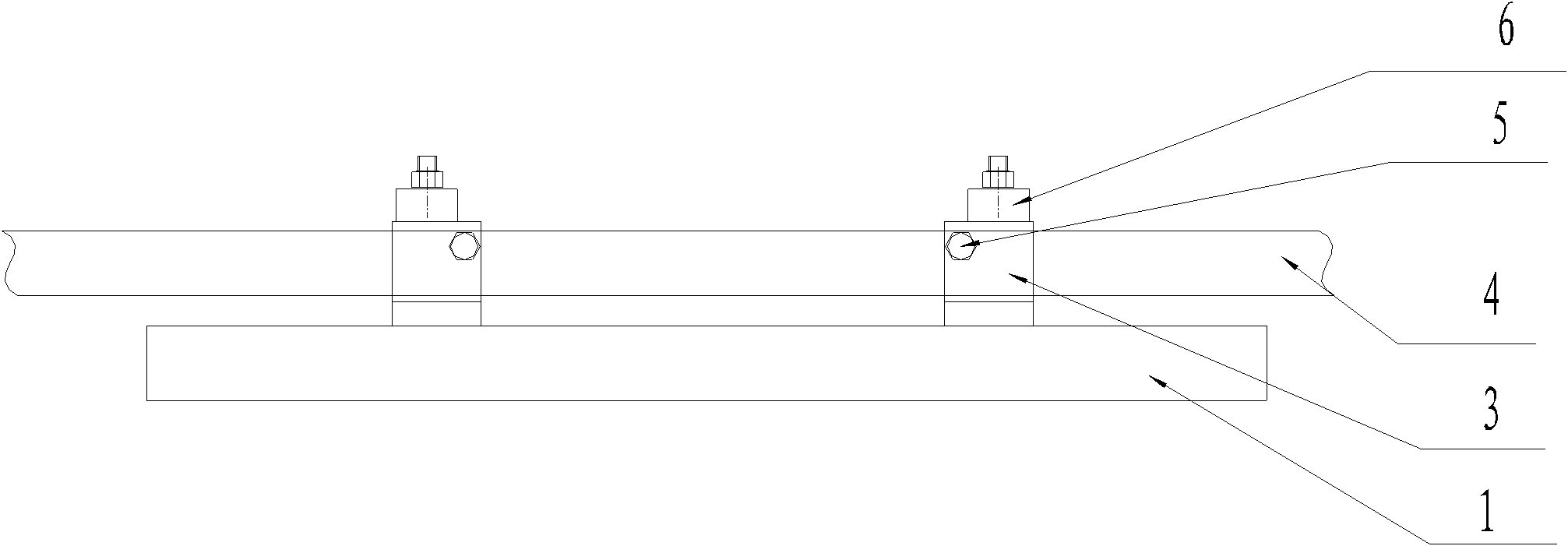

[0038] figure 1 It is the structural representation of milling machine of the present invention; figure 2 for figure 1 left view of image 3 It is a structural schematic diagram of the workbench of the present invention; Figure 4 for image 3 top view of Figure 5 for image 3 left view of .

[0039] Such as figure 1 As shown, the ultra-long profile processing device provided by the present embodiment includes a workbench 1 and three supports 2, the height of the workbench 1 of the milling machine is adjustable, and it can be fed along the length direction of the workpiece 4; Two fixtures 3 for positioning workpieces, three brackets 2 are set on both sides of the workbench 1 respectively, the distance between the brackets 2 and the workbench 1 is greater than the feed distance of the workbench 1, the three brackets 2 and the two fixtures 3 on the same line.

[0040] Such as figure 2 As shown, the stand includes a height-adjustable stand body. The top of the suppo...

Embodiment 3

[0046] This embodiment provides a method for processing super-long profiles, which is used to process welding notches of super-long channel steel, which specifically includes the following steps:

[0047] A. Install the two fixtures in parallel on the workbench of the vertical milling machine;

[0048] B. Place the brackets on both sides of the workbench of the vertical milling machine. The processed channel steel is placed on the brackets; the height of the brackets is adjusted roughly and finely to make the height of the channel steel consistent with the installation height of the fixture, and write down the workbench (original position value) height value;

[0049] C. Clamp the channel steel with a fixture to realize the horizontal and vertical positioning of the channel steel; start the milling machine, the milling machine table feeds and processes the notch, feeds to 100-150mm from the end of the stroke, and stops;

[0050] D. Loosen the fixture, lower the workbench, ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com