Patents

Literature

390results about How to "Achieve clamping and fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

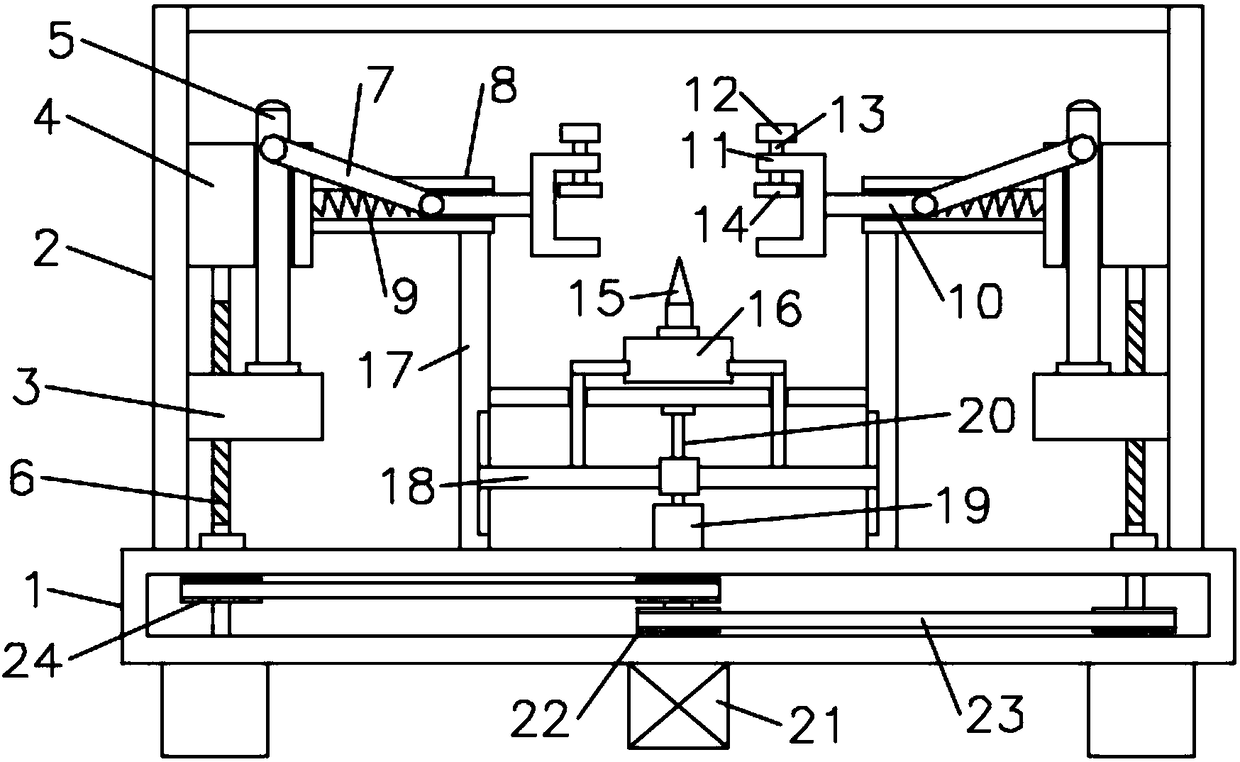

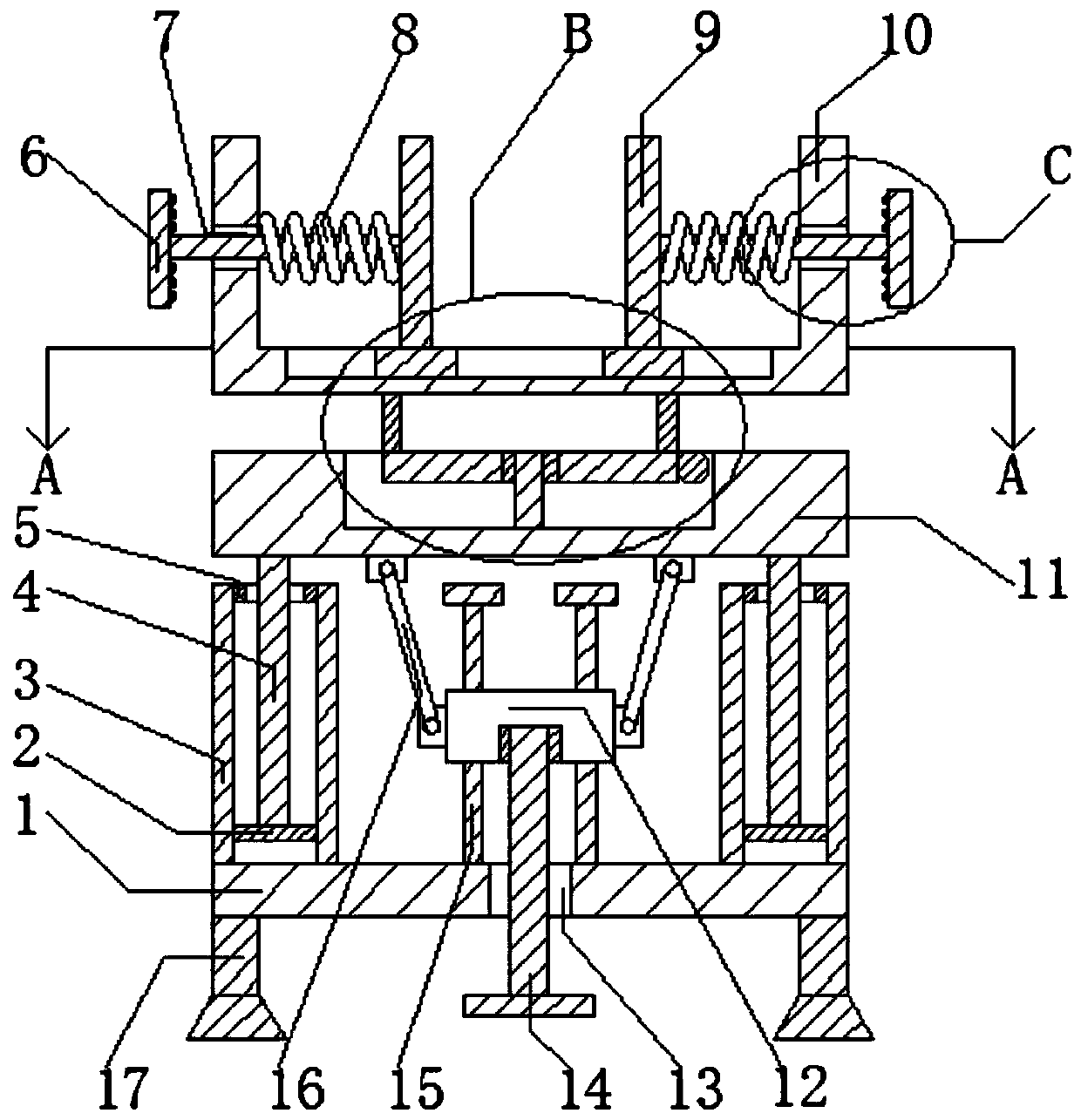

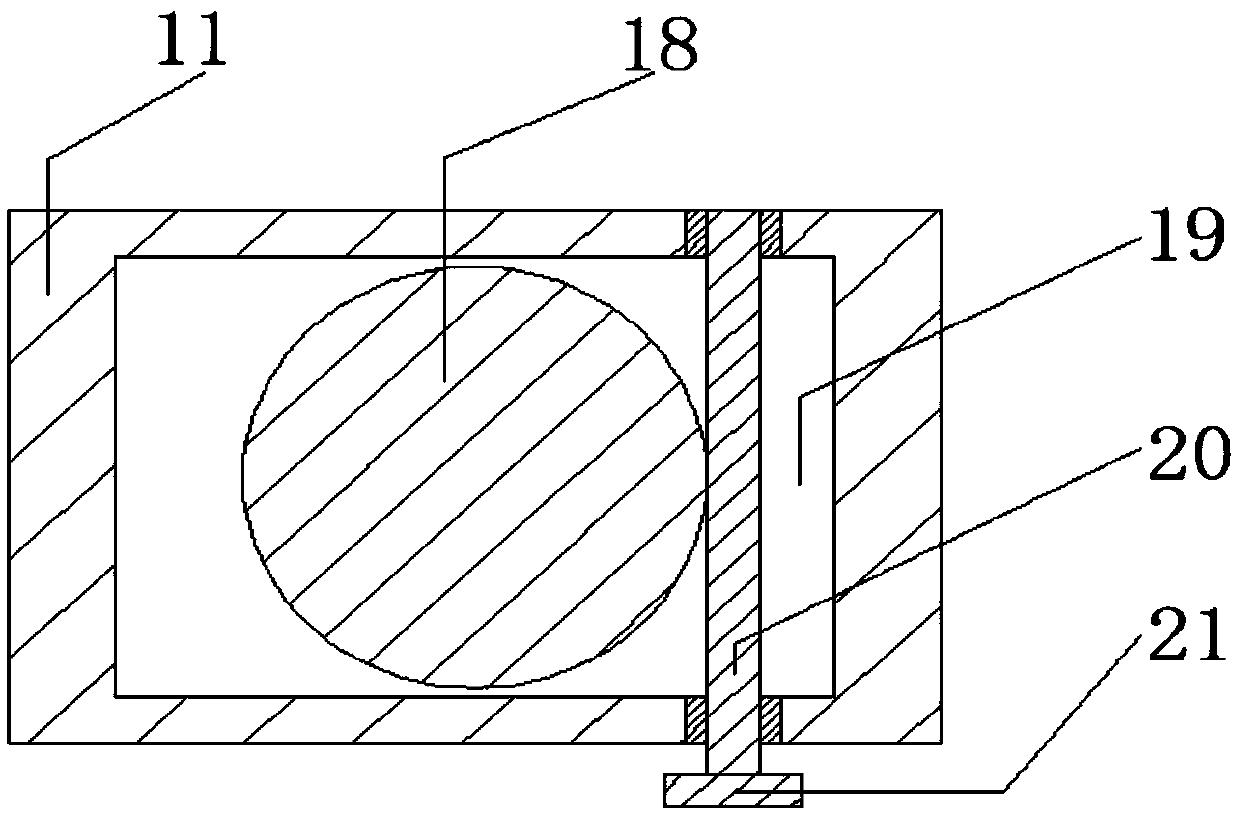

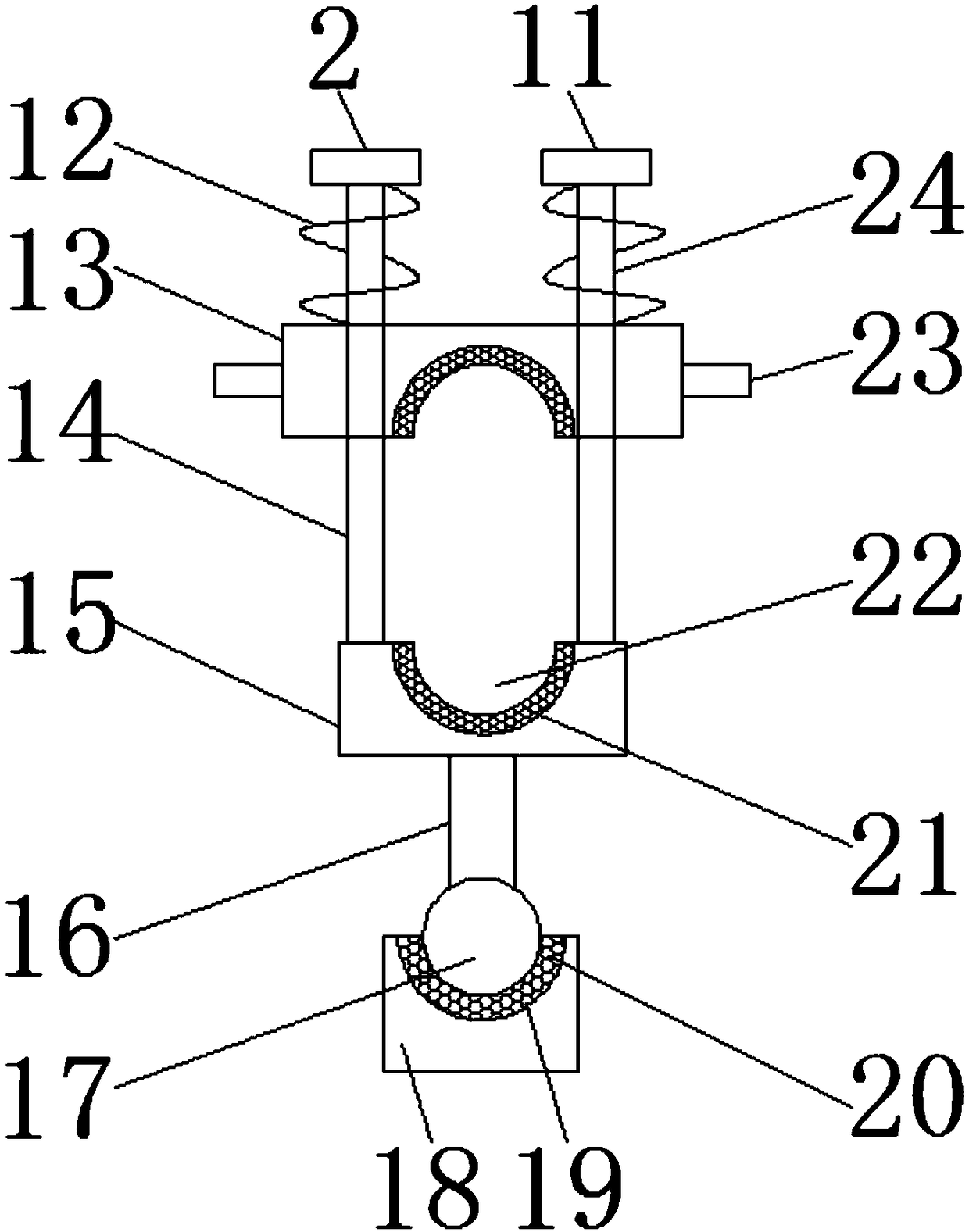

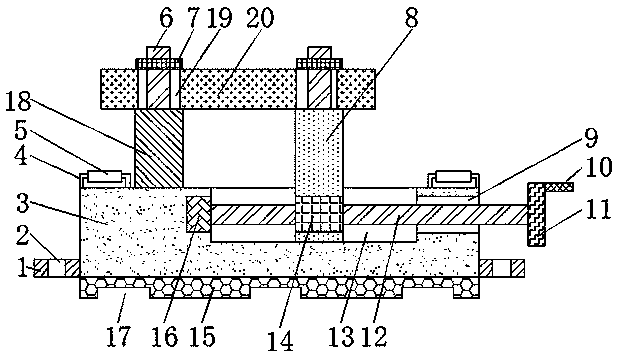

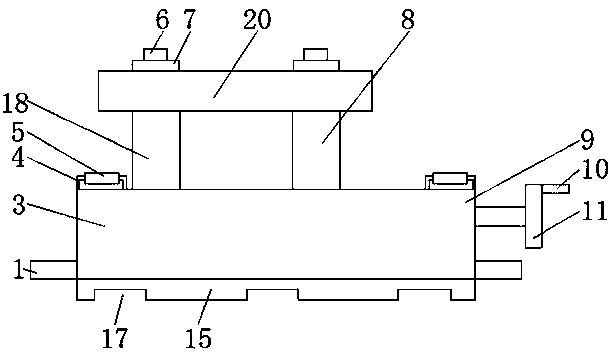

Small-displacement reciprocating rolling friction abrasion test device

InactiveCN101750259AAuthentic, reliable and effective simulationAuthentic, reliable and effective analysisInvestigating abrasion/wear resistanceRolling resistanceTangential force

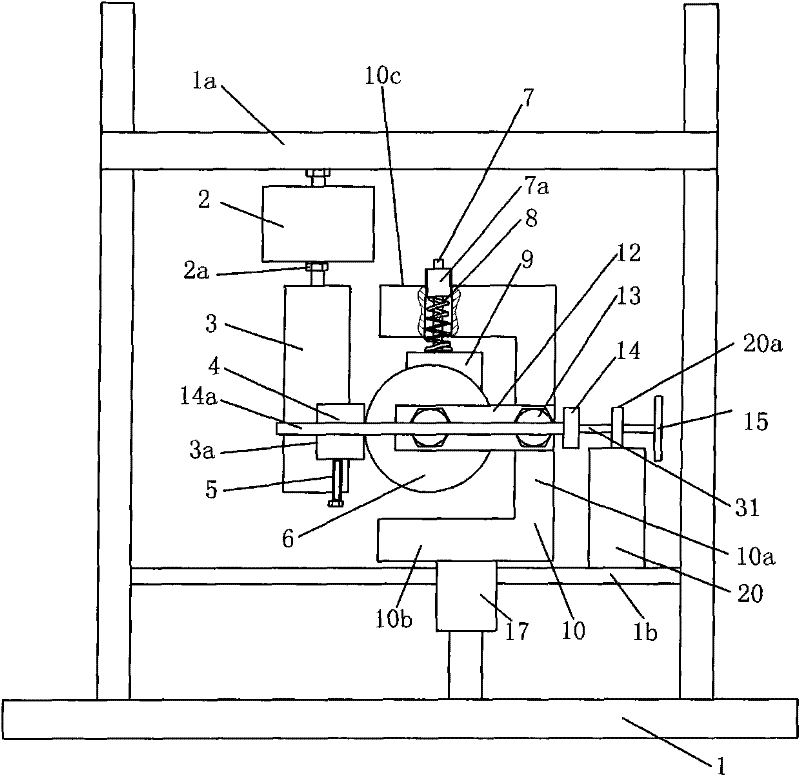

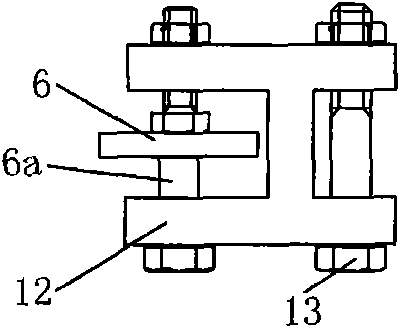

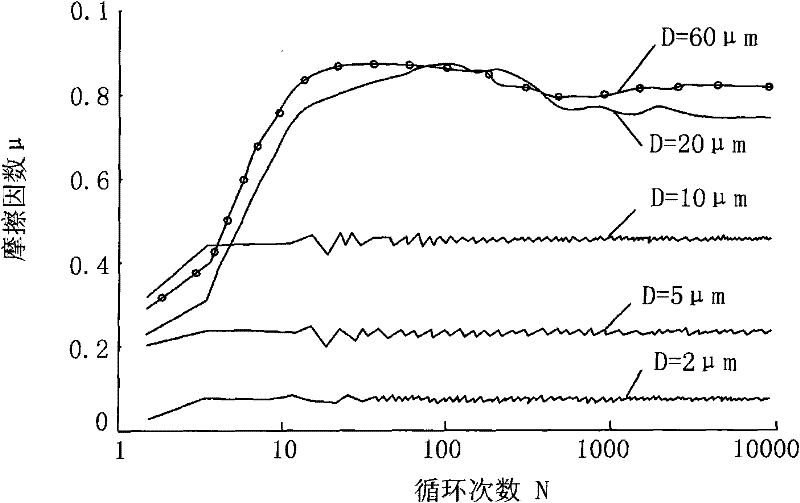

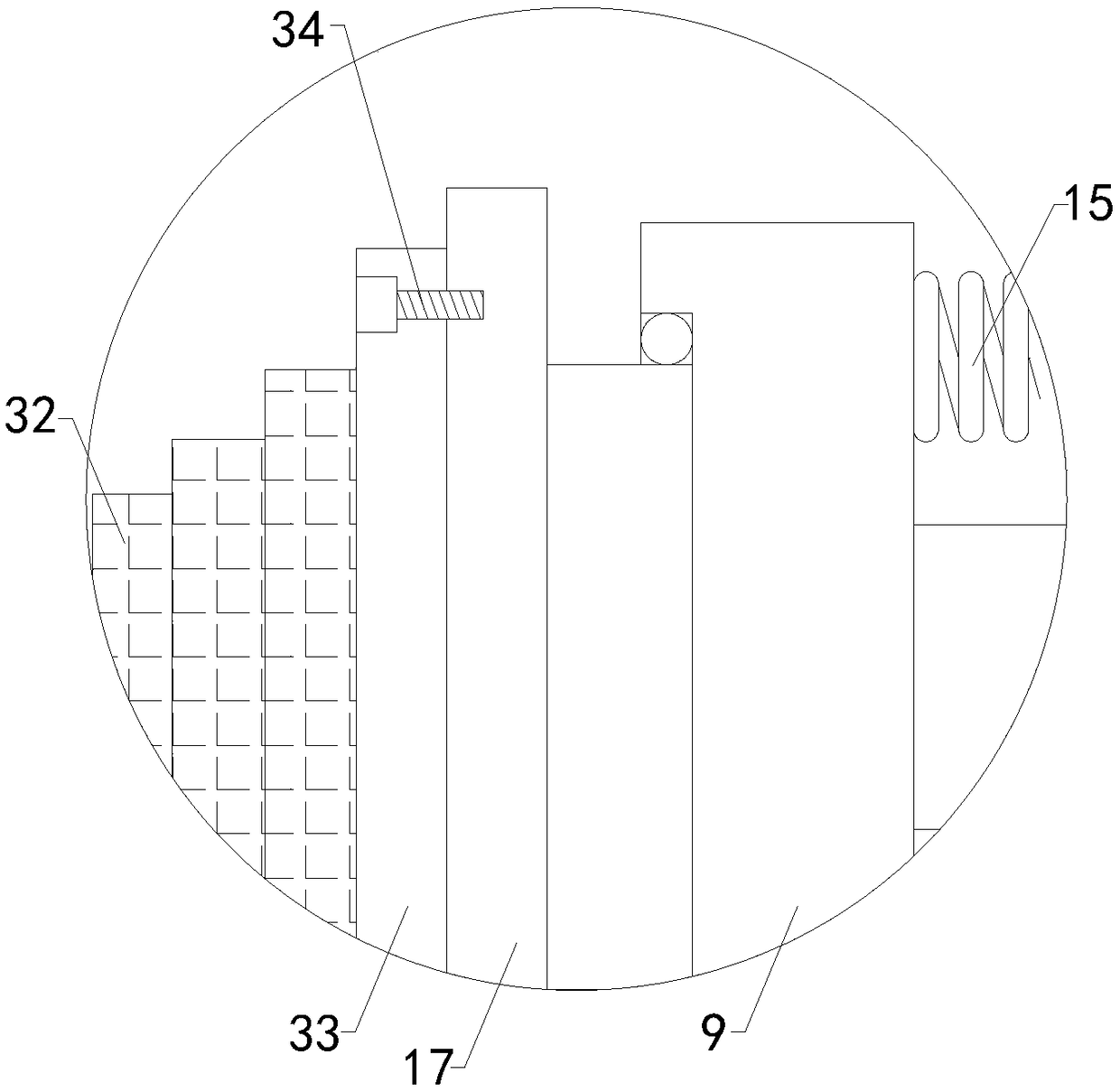

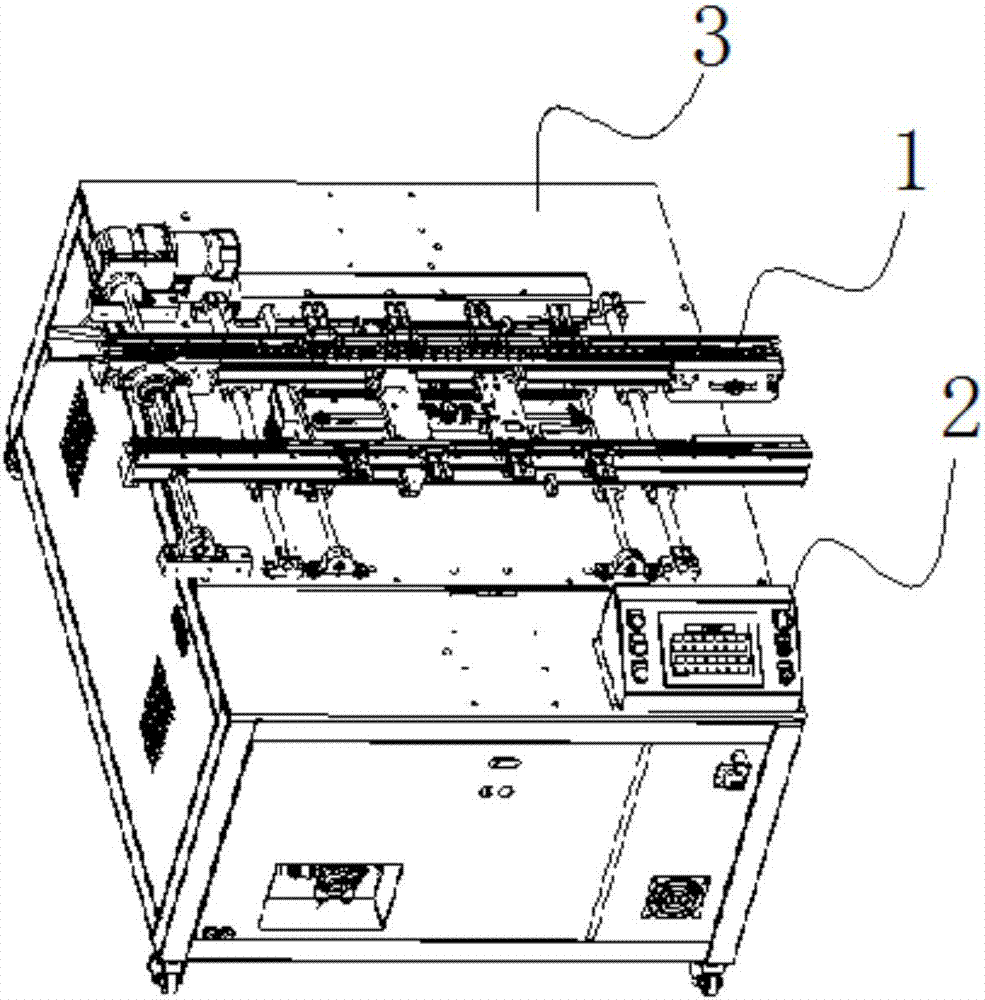

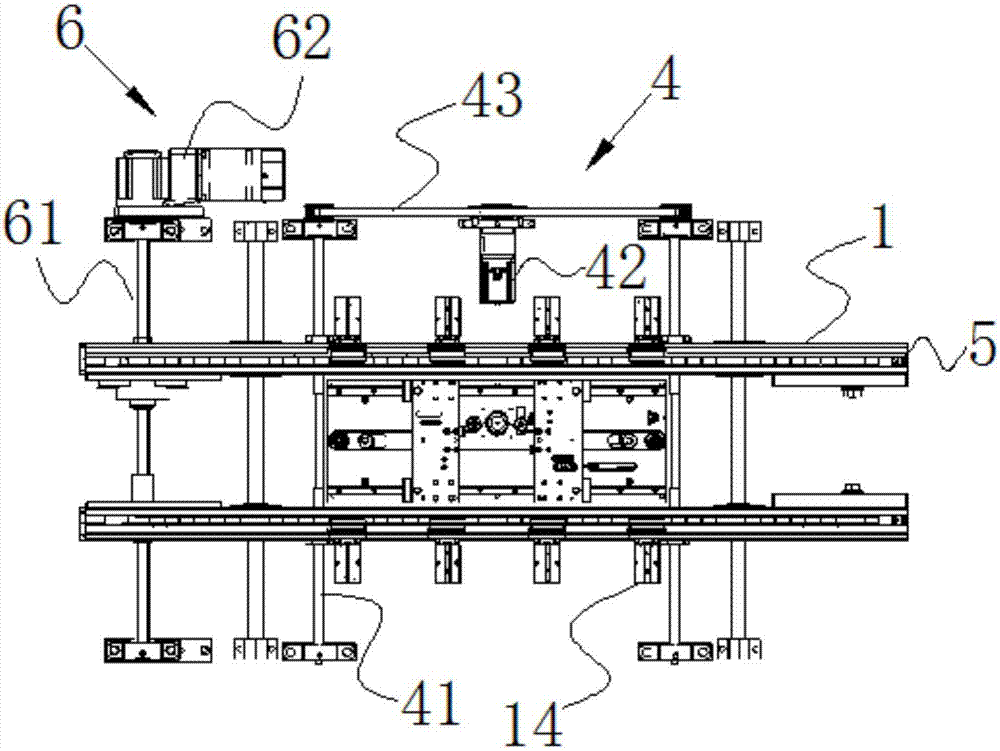

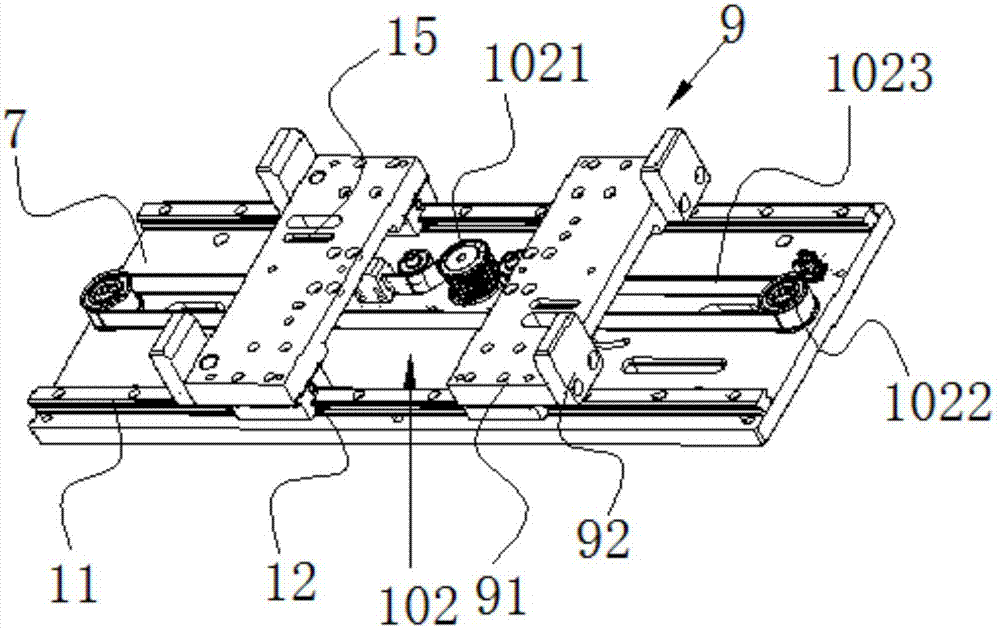

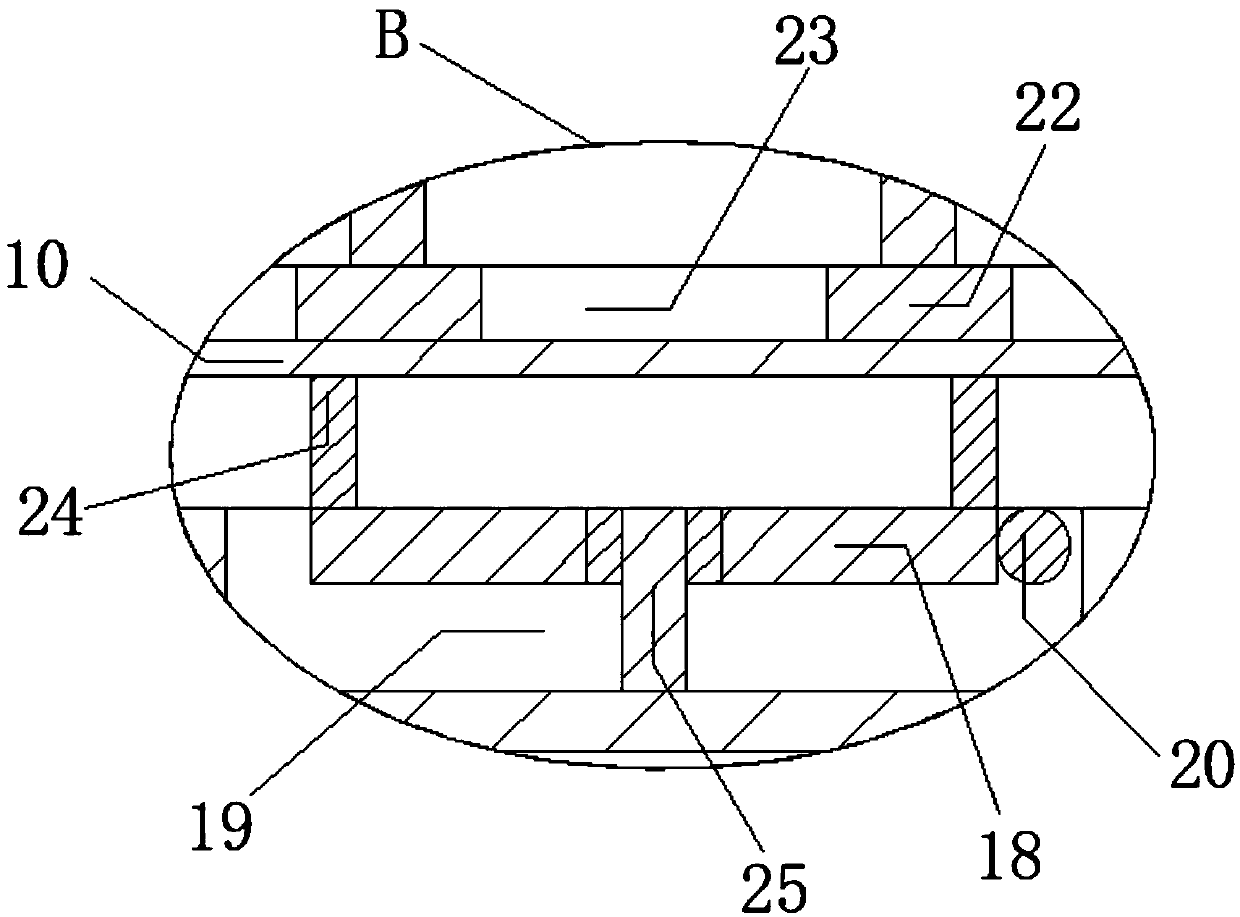

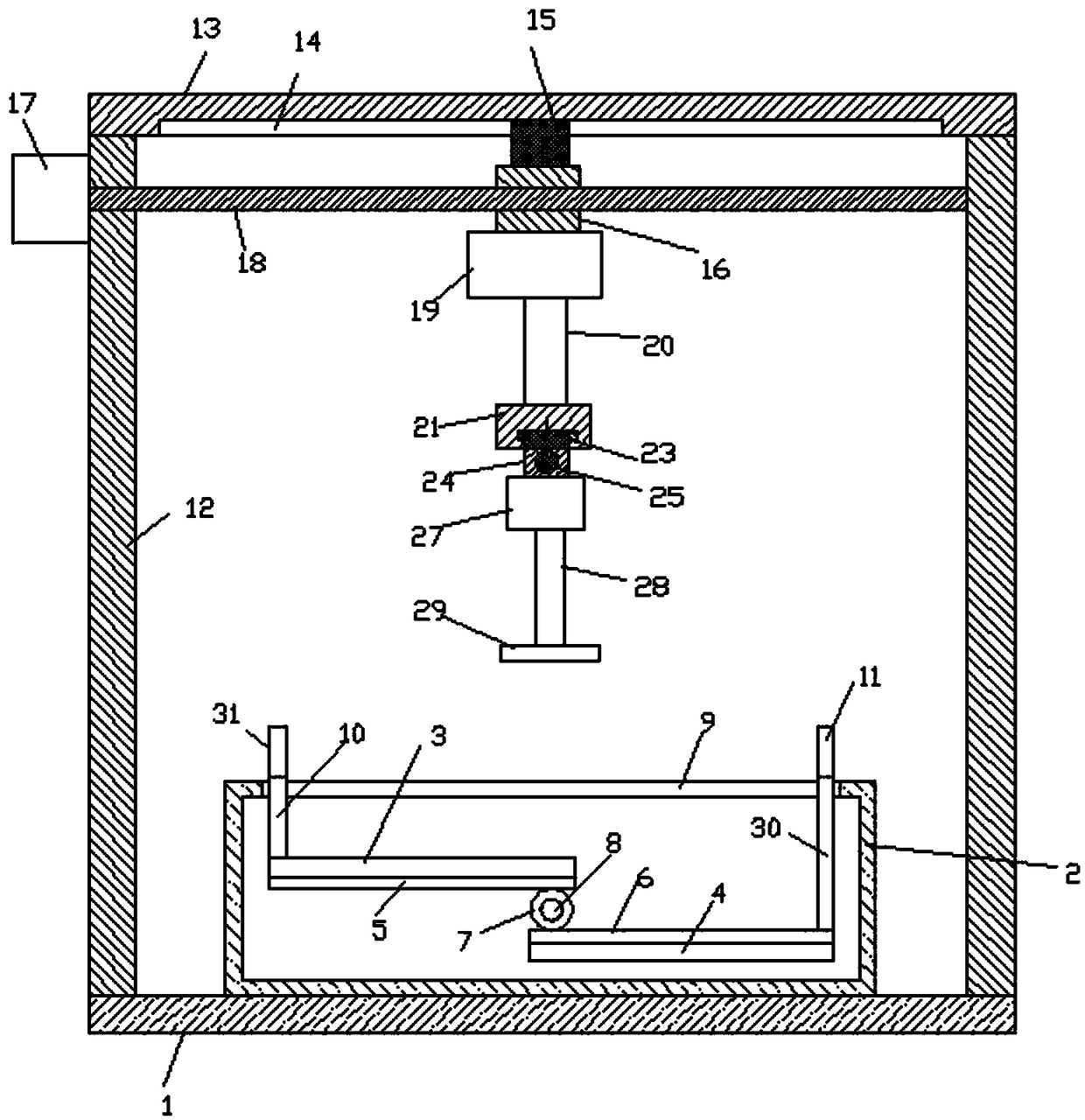

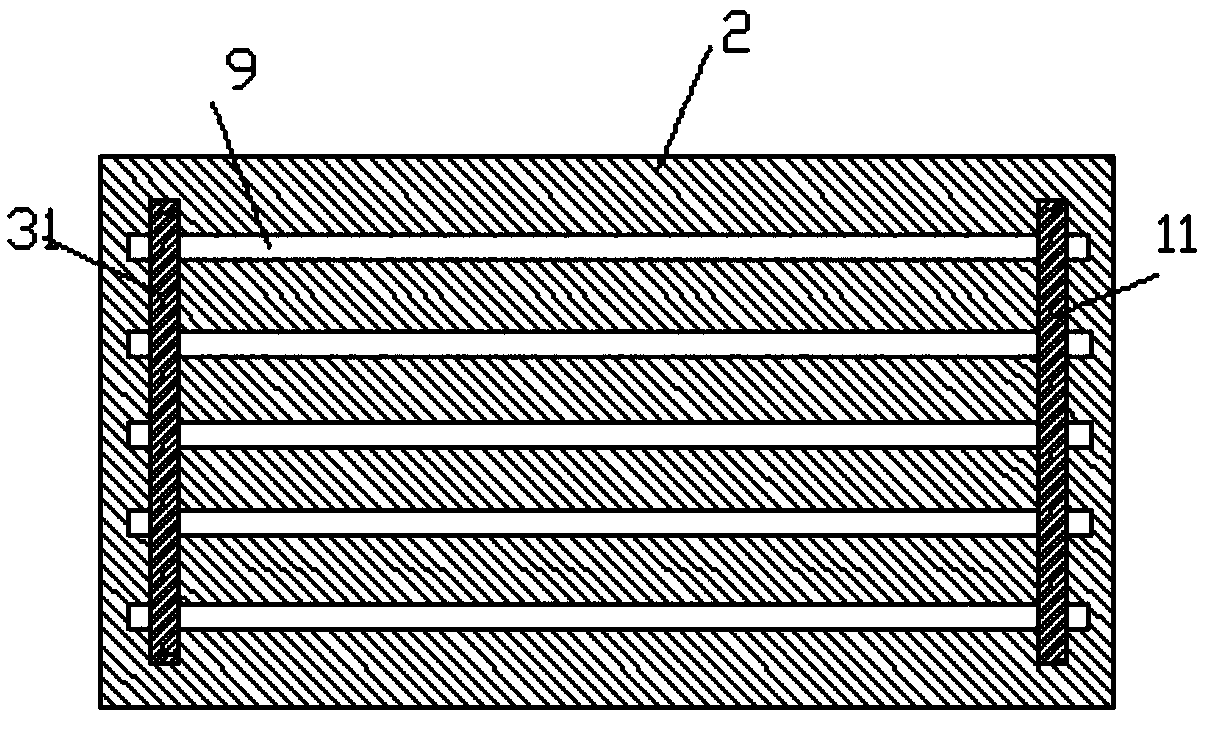

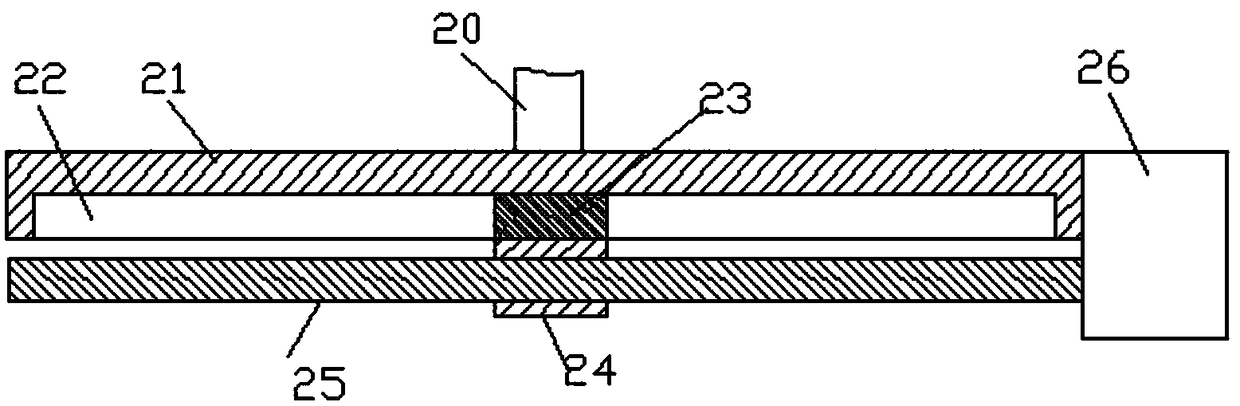

The invention relates to a small-displacement reciprocating rolling friction abrasion test device. A plane sample clamp is fixedly connected below a cross beam of a hydraulic friction test machine by a tangential force sensor; a rolling sample clamp is positioned at the right side of the plane sample clamp and is fixed on a vertical column of a support frame; a bottom plate of the clamp support frame is connected on a hydraulic piston of the hydraulic friction test machine; the right side of the clamp support frame is provided with a normal force; a screw at the right side of the normal force sensor is connected on a support nut by threads, and the end part of the screw is connected with a rotating disc; the support nut is fixed on a work platform surface of the hydraulic friction test machine by a support seat; and a U-shaped connecting piece at the left side of the normal force sensor is sheathed on the vertical column of the clamp support frame. The small-displacement reciprocating rolling friction abrasion test device can simulate the friction abrasion between a plane sample and a rolling body more really and reliably, is convenient to microscopically analyze the test result, and has high degree of automation, simple and convenient operation, high accuracy of control and test and good repeatability of test data.

Owner:SOUTHWEST JIAOTONG UNIV

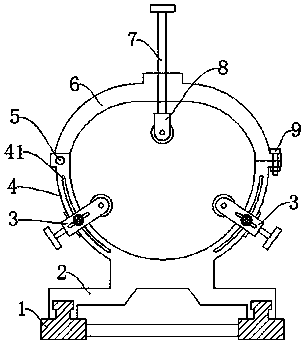

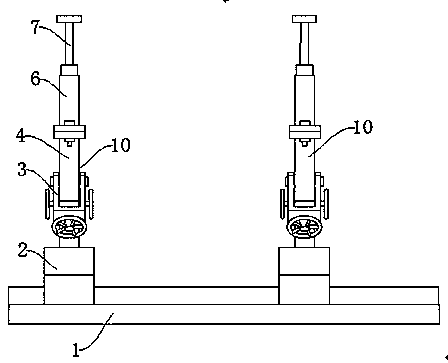

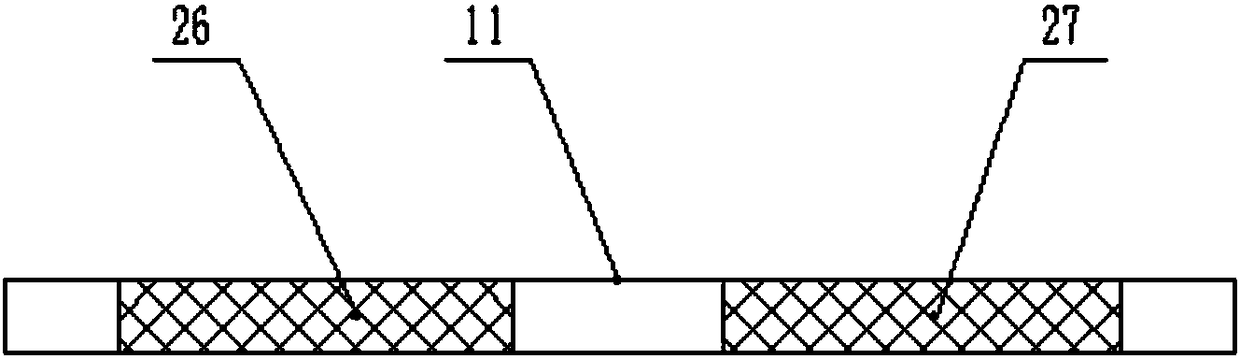

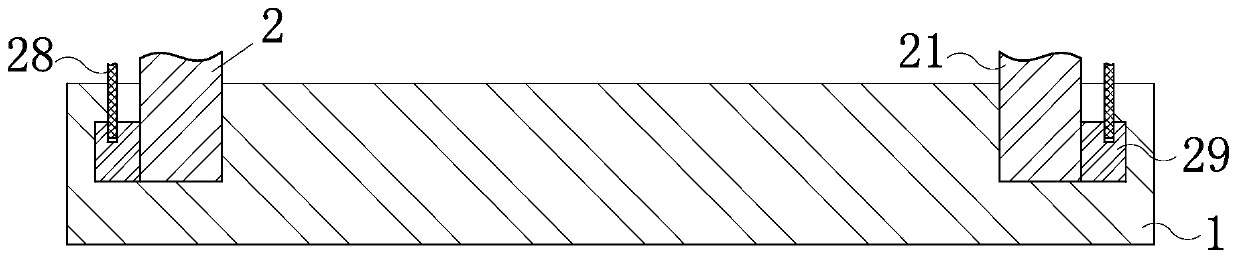

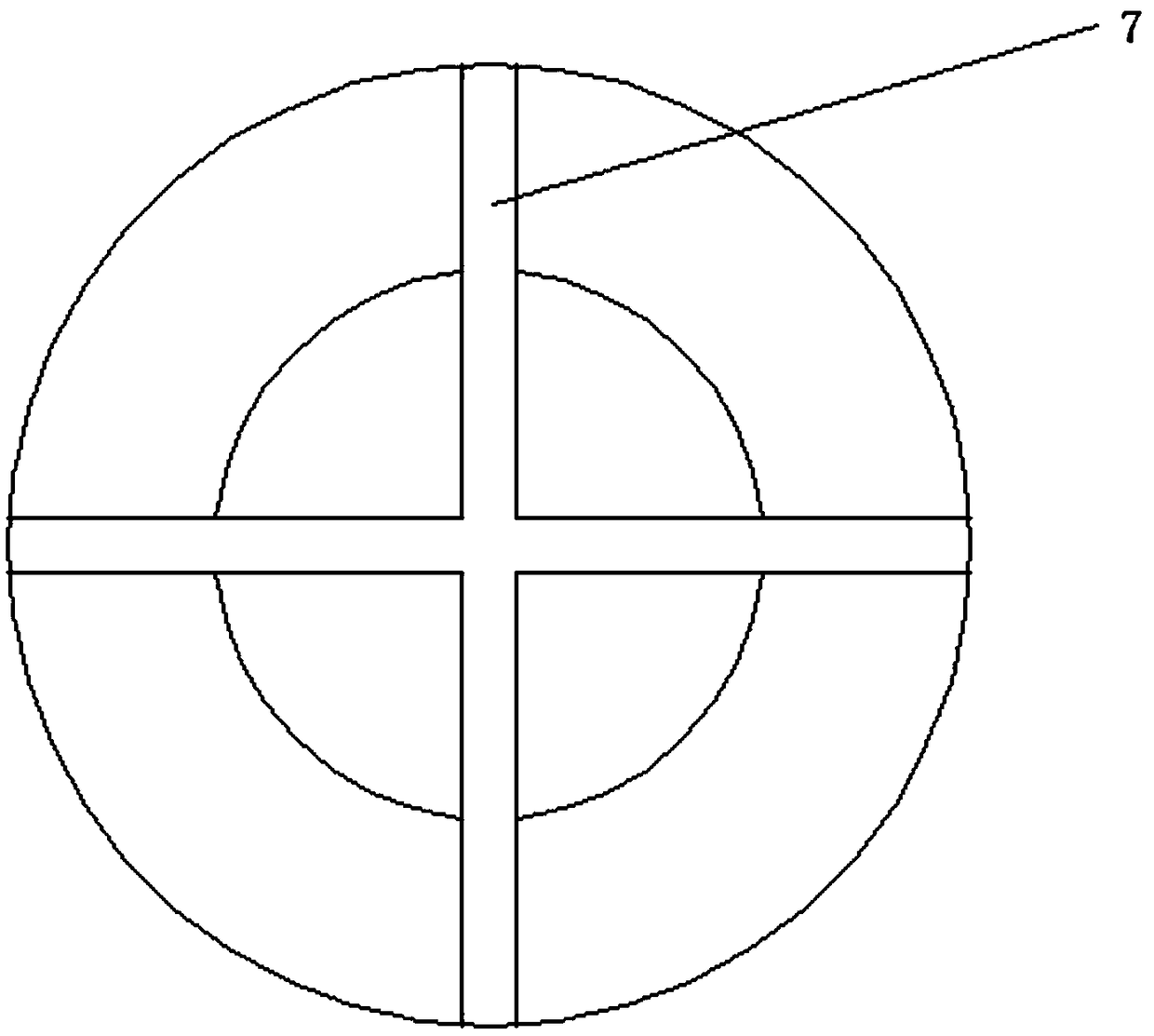

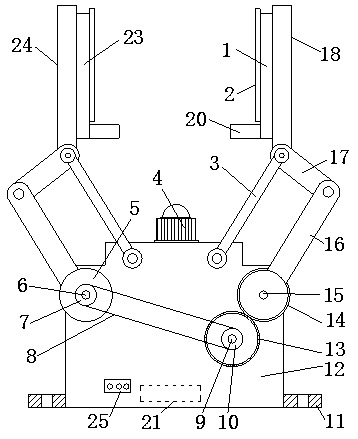

Special fixture for arc-shaped plate

ActiveCN107932117AAchieve clamping and fixingEasy to adjustWork holdersPositioning apparatusEngineeringMechanical engineering

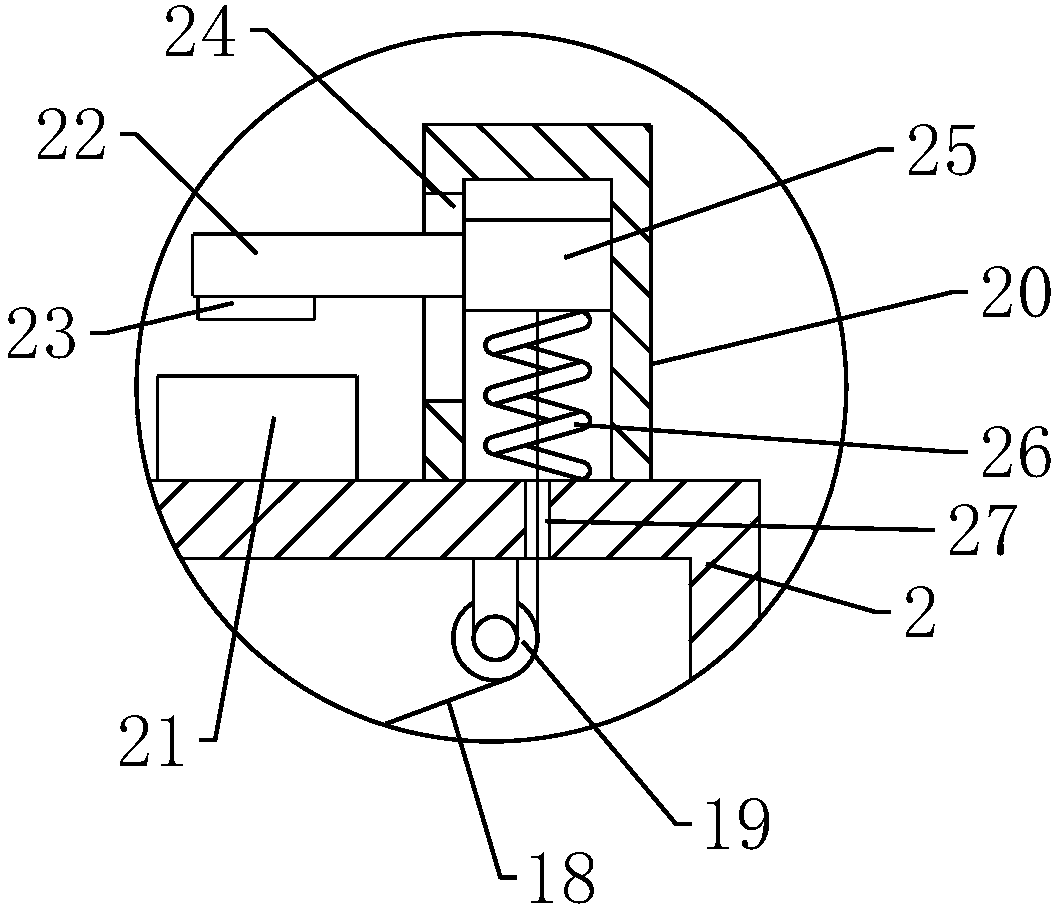

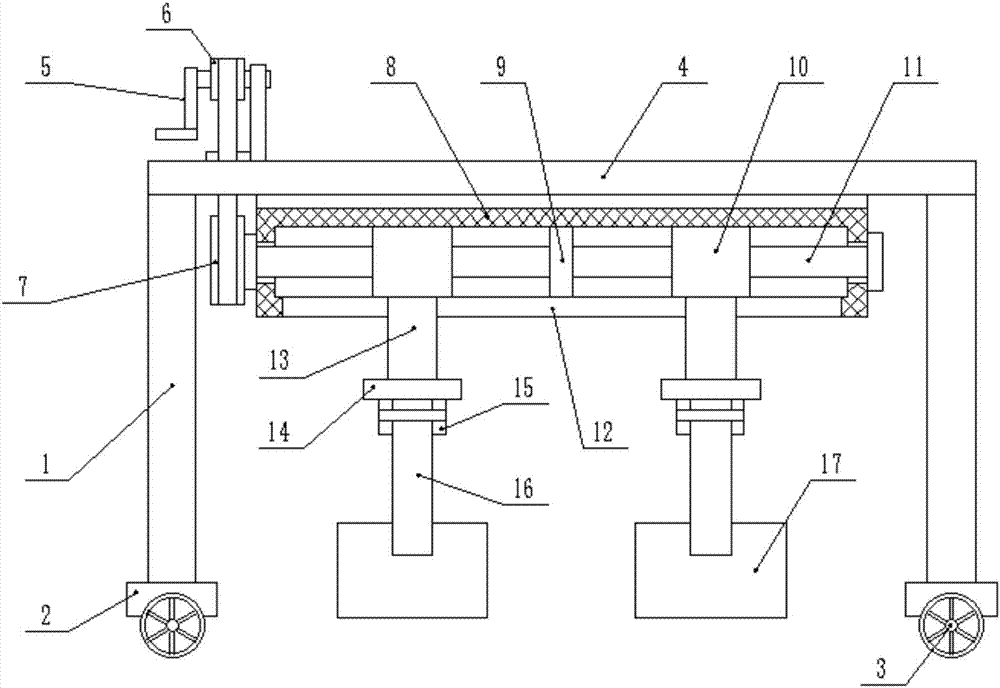

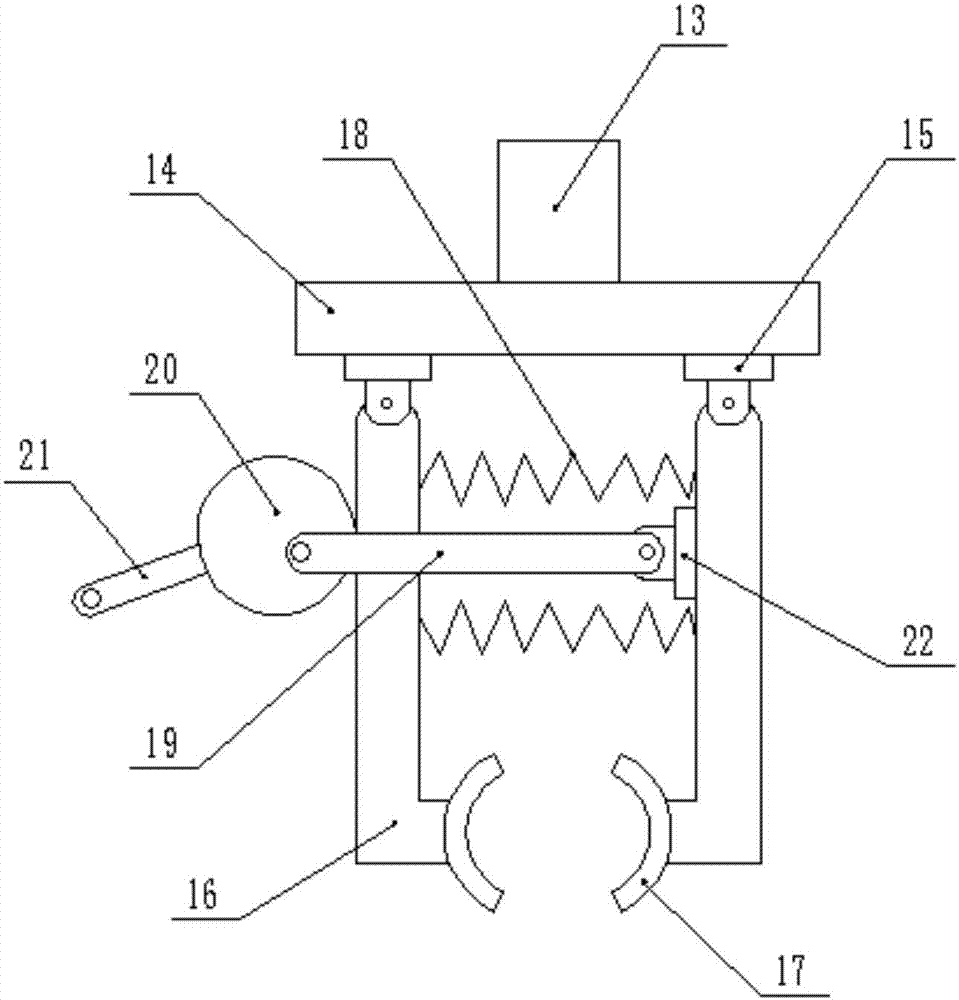

The invention discloses a special fixture for an arc-shaped plate. The special fixture comprises a guide rail and a plurality of clamping mechanisms. The multiple clamping mechanisms are arranged on the guide rail, and each clamping mechanism comprises a base, two arc-shaped supporting plates and a supporting arm, wherein the bases are slidably mounted on the guide rail, every two arc-shaped supporting plates are arranged above the corresponding base, and each arc-shaped supporting plate is one fourth of a round ring. The special fixture for the arc-shaped plate has the beneficial effects thatthe arc-shaped plate is jacked up through two tight jacking devices arranged at the bottom of the arc-shaped plate, a compressing device is arranged on the inner side of the arc-shaped plate, a compressing wheel is utilized to compress the arc-shaped plate to the jacking device from the inner side, and accordingly clamping and fixing of the arc-shaped plate are achieved. A first slide groove formed in the arc-shaped plate is convenient for adjusting the positions of the tight jacking devices, and accordingly the arc-shaped plates with different outline radius sizes can be clamped conveniently. A second slide groove is convenient for adjusting the length of a supporting wheel extending into the inner sides of the arc-shaped supporting plates so as to clamp the irregular arc-shaped plates.

Owner:青岛自动化仪表有限公司

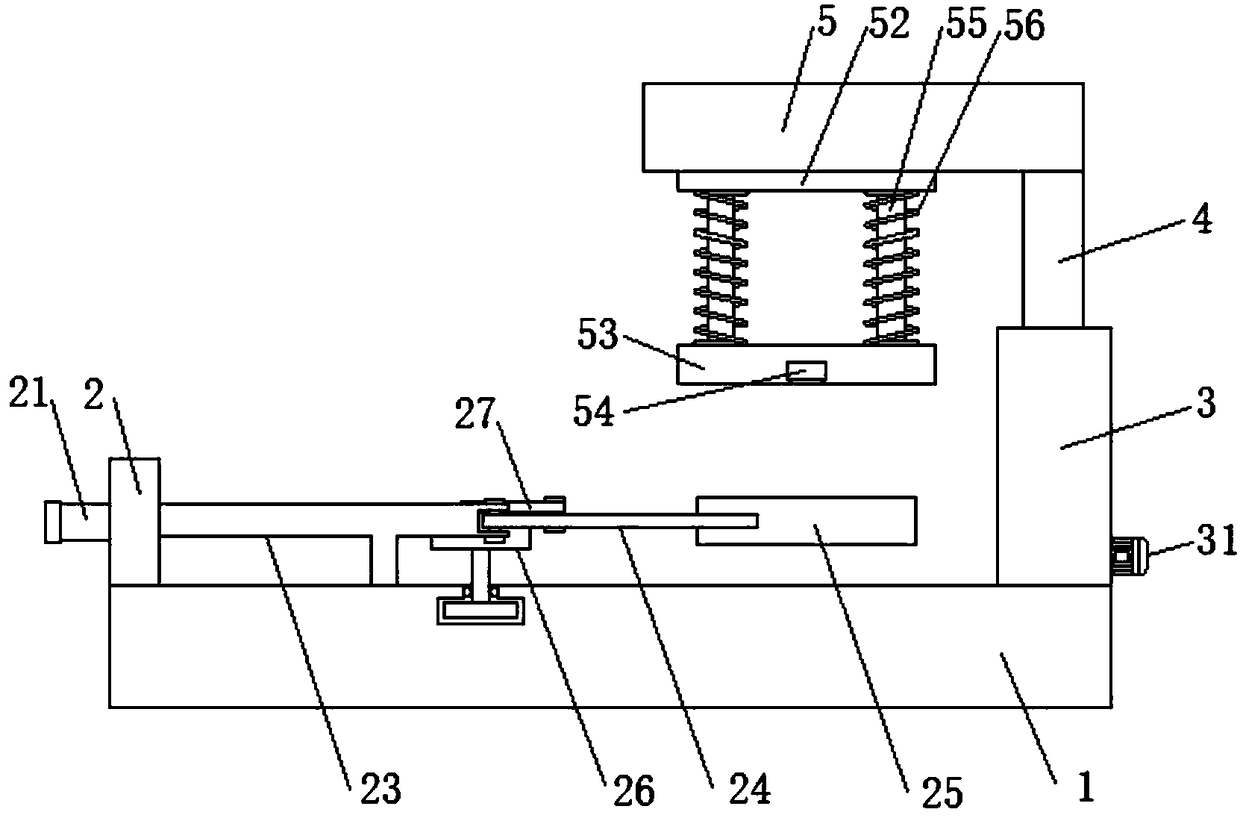

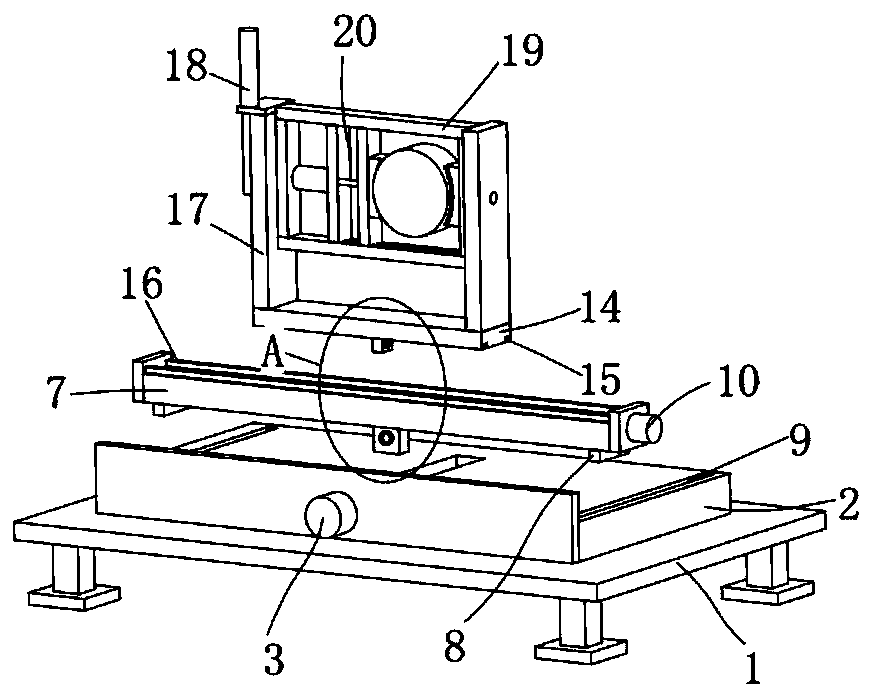

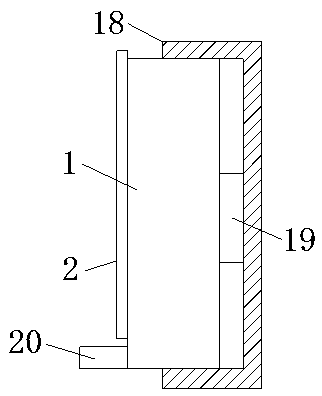

Metal circular pipe welding device

InactiveCN108971788AAchieve clamping and fixingPrevent movementWelding/cutting auxillary devicesAuxillary welding devicesWeld seamThreaded pipe

The invention relates to the technical field of metal circular pipe welding processing auxiliary devices, in particular to a metal circular pipe welding device which comprises an operation panel, fourgroups of legs, a welding machine, a left fixed plate, a right movable plate, a left lead screw, a limit square column, a left barrier, a right barrier, a circular boss, a support rod, an upper clampplate, a lower clamp plate, an upper rotary arm, a lower rotary arm, two groups of support springs, a left rotary shaft, a right rotary shaft, a right ejecting plate, a left hand wheel, a rear support plate, an upper ejecting plate, two groups of threaded pipes, two groups of threaded rods, a movable block and a mounting plate. A welding gun is arranged at an output end of the welding machine. The metal circular pipe welding device has the advantages that welded metal circular pipes can be fixedly clamped by the metal circular pipe welding device, two groups of metal circular pipes can be prevented from moving in welding procedures, and the use reliability can be improved; butted weld seams of two groups of circular pipes can be continuously circumferentially welded by the metal circularpipe welding device, weld protrusions at welded circumferential locations can be reduced, follow-up polishing treatment working procedures can be reduced, accordingly, labor force and the economic cost can be reduced, and the practicality can be improved.

Owner:太仓市凯润尔展示器材有限公司

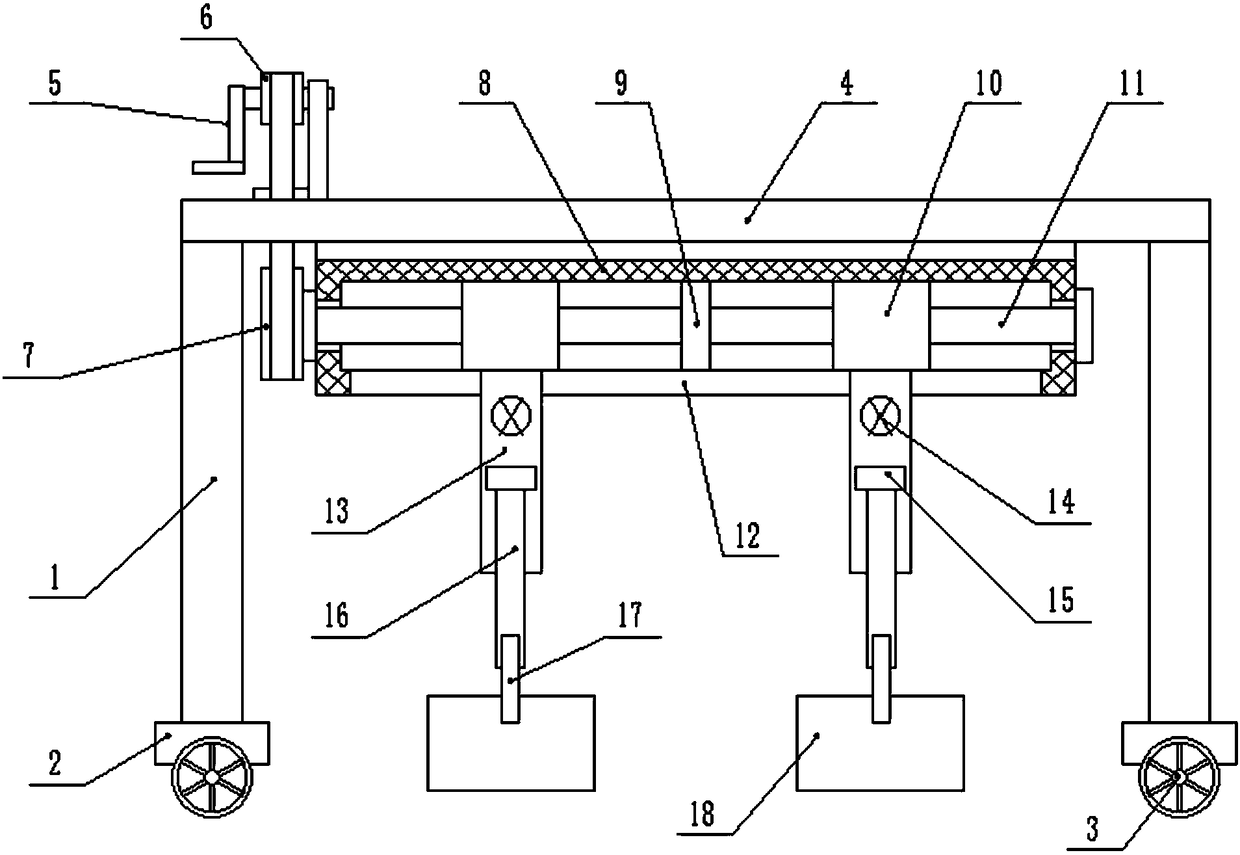

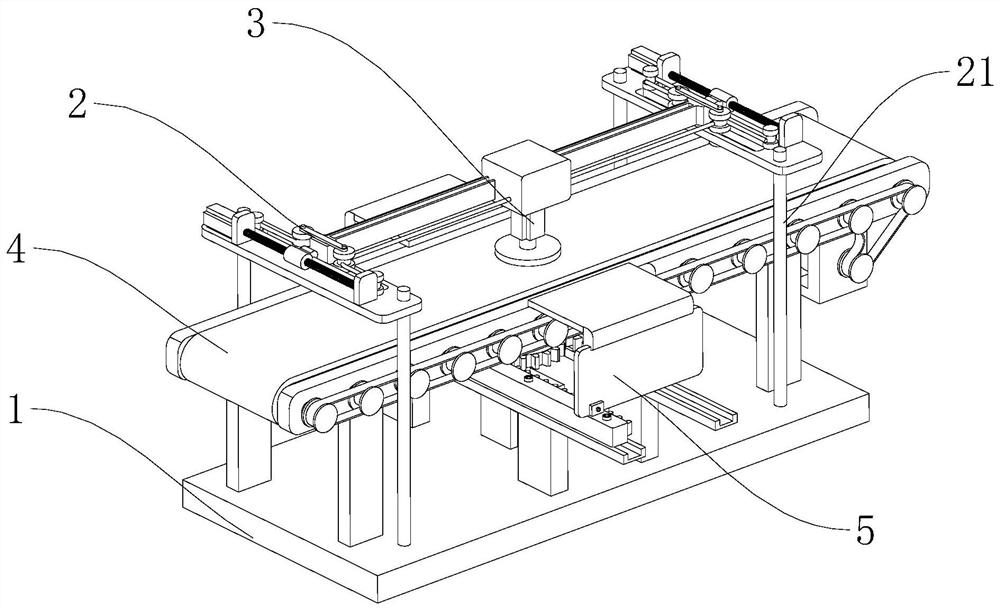

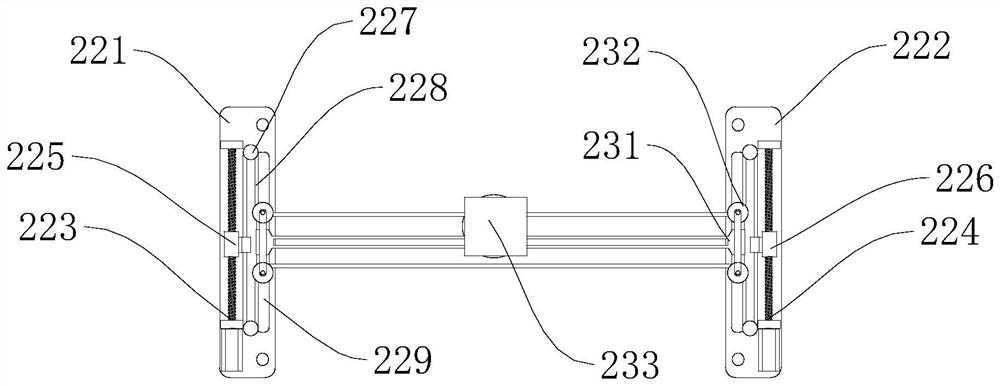

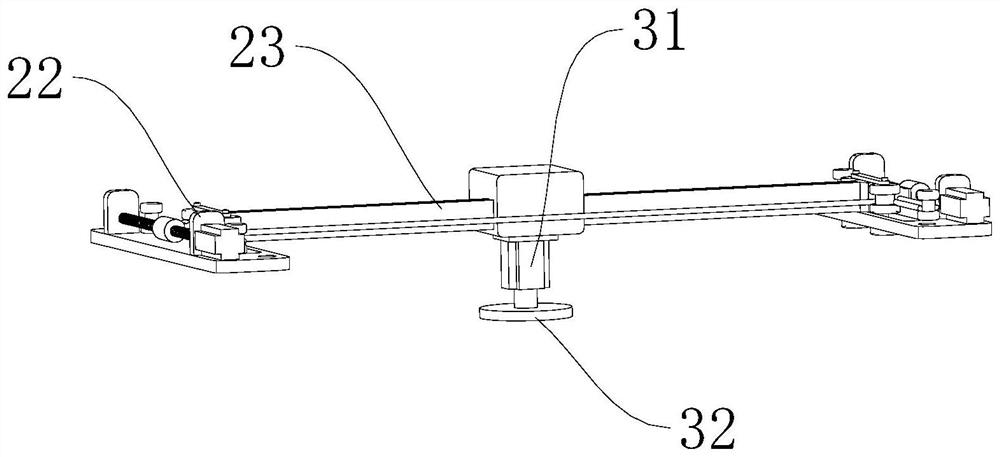

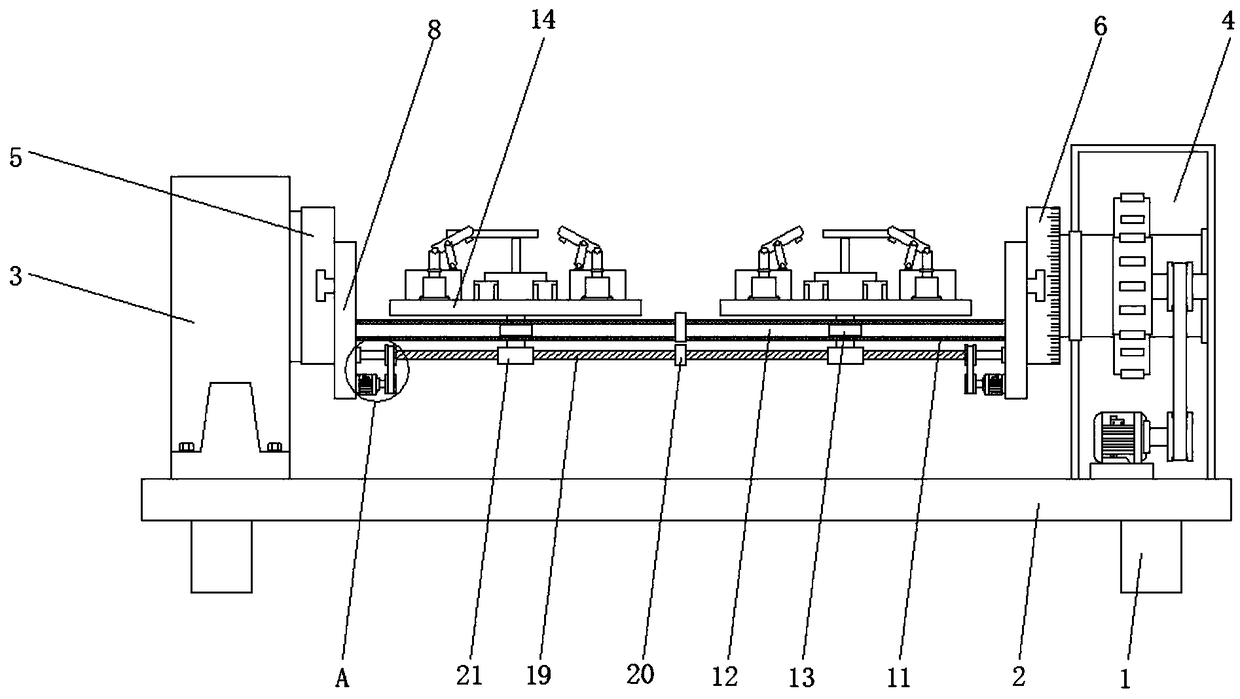

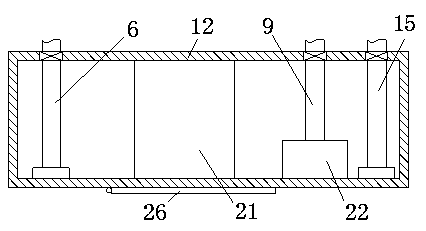

Material conveying and locating device

ActiveCN107487614AAchieve clamping and fixingIncrease productivityConveyorsFinal product manufactureAutomatic controlEngineering

The invention discloses a material conveying and locating device comprising conveying rails, a controller and a workbench. The material conveying direction is defined as the forward direction. The workbench is provided with the two forward-backward-direction conveying rails which are located on the left side and the right side of the workbench correspondingly. The conveying rails are provided with a distance-changing driving mechanism. The distance-changing driving mechanism drives the two conveying rails to go close to each other or go away from each other so as to adjust the distance between the two conveying rails. The conveying rails are provided with conveying chains, and the direction of the conveying chains is consistent with that of the conveying rails. Conveying driving mechanisms are connected to the conveying chains. A lifting plate is arranged above the workbench. A lifting driving mechanism driving the lifting plate to move up and down is arranged below the lifting plate. The lifting plate is provided with a front locating block and a rear locating block which are matched with materials front and back. The two locating blocks go close to each other or go away from each other through a front-back clamping driving mechanism so as to clamp or loosen the materials. Full-automatic control is adopted for the whole production process of the material conveying and locating device, workforce is liberated, and production efficiency is improved.

Owner:KUNSHAN TUOYU AUTOMATION TECH CO LTD

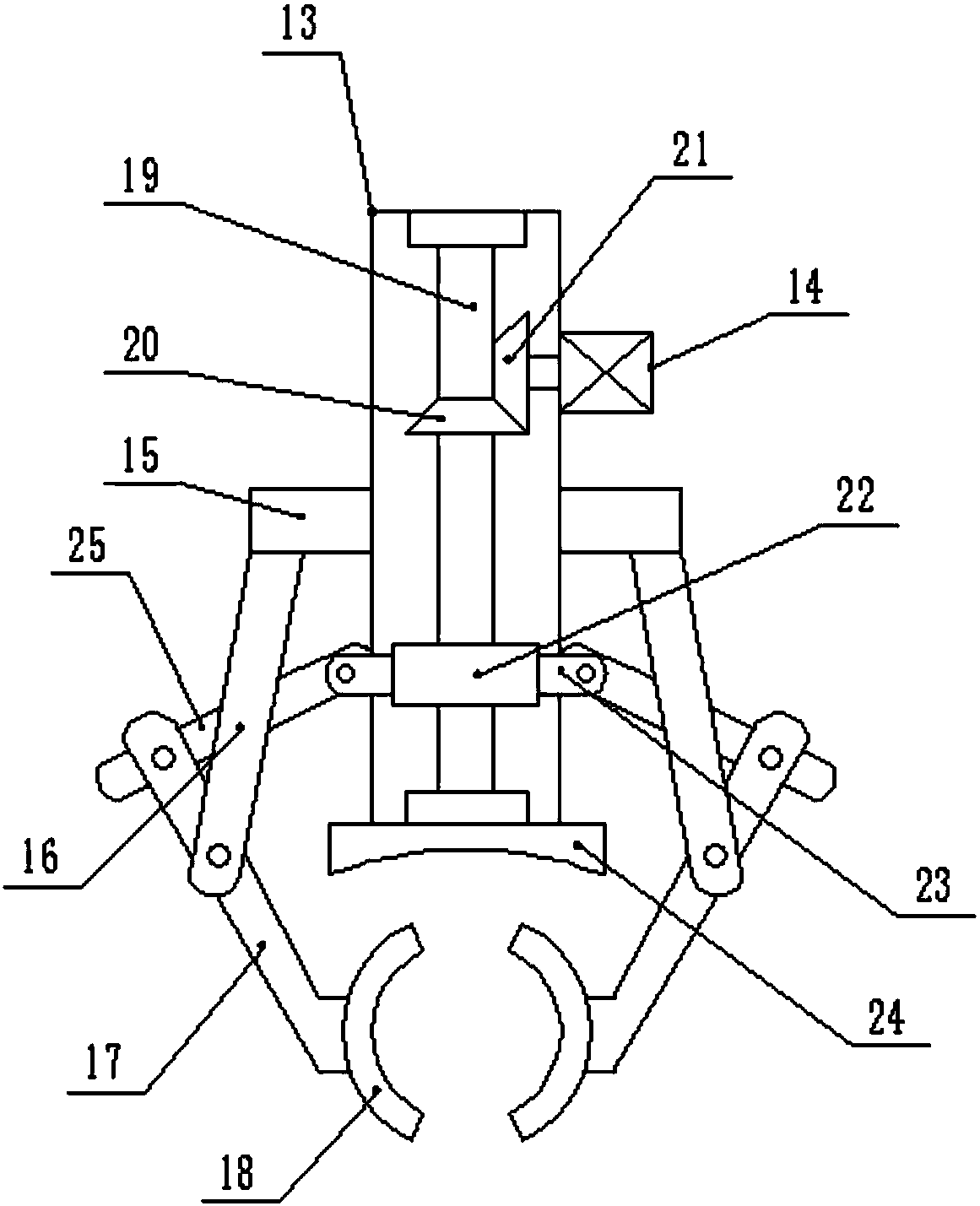

Hoop type power cable wiring butt joint device

InactiveCN108183432AReasonable structureInnovative designApparatus for joining/termination cablesPower cableButt joint

The invention discloses a hoop type power cable wiring butt joint device. The device comprises a bracing frame, wherein an upper end of the bracing frame is equipped with a cross board, a middle portion of a lower end of the cross board is equipped with a guide sleeve, the guide sleeve is internally equipped with a screw, a left end of the screw is connected with a driven sprocket, an upper end ofthe driven sprocket is connected with an active sprocket through a chain, middle portions of two ends of the screw are connected with sliding blocks, lower ends of the sliding blocks are equipped with fixing sleeves, the fixing sleeves are internally equipped with screw rods, middle portions of upper ends of the screw rods are equipped with driven gears, right ends of the driven gears are connected with active gears, middle portions of lower ends of the screw rods are equipped with lifting blocks, two ends of the lifting blocks are fixed with lifting rods, the other ends of the lifting rods are hinged with first connection rods, and lower ends of the first connection rods are hinged with second connection rods. The device is advantaged in that clamping and fixing of power cables at two ends are realized, butt joint of the power cables after clamping is realized, not only can butt joint efficiency of the power cables be enhanced, but also labor intensity of workers can be further reduced, and butt joint demands of the multi-core power cables are satisfied.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

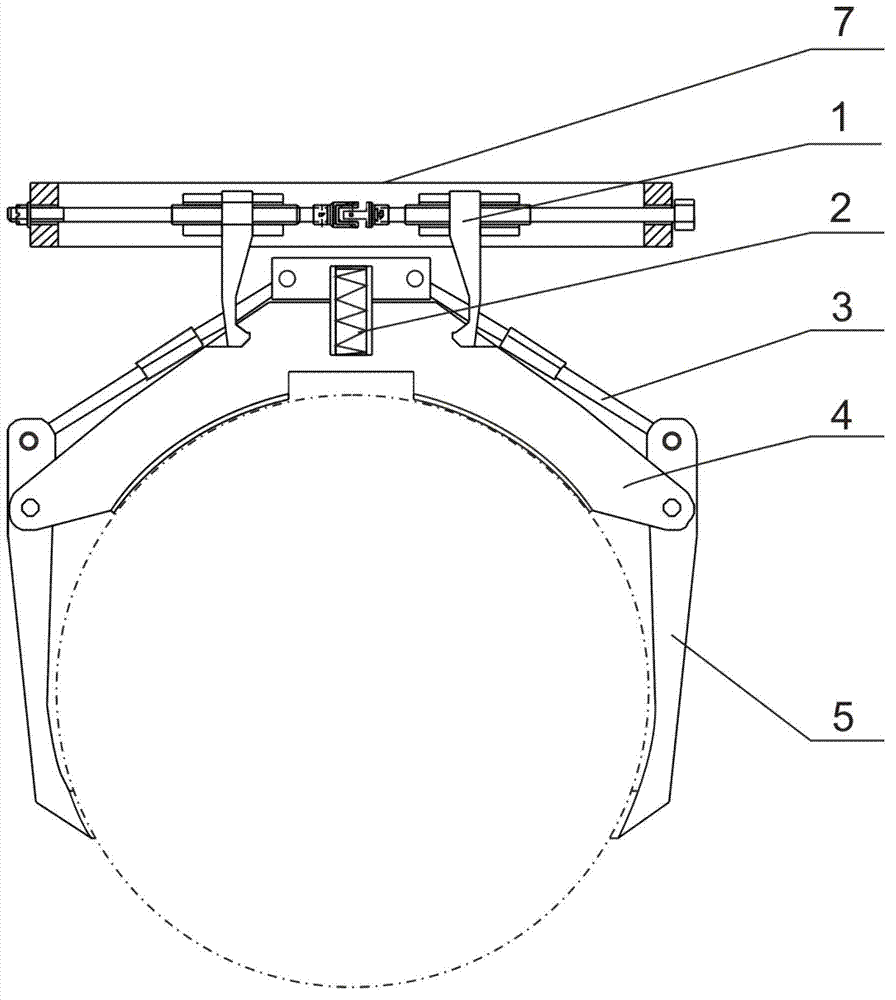

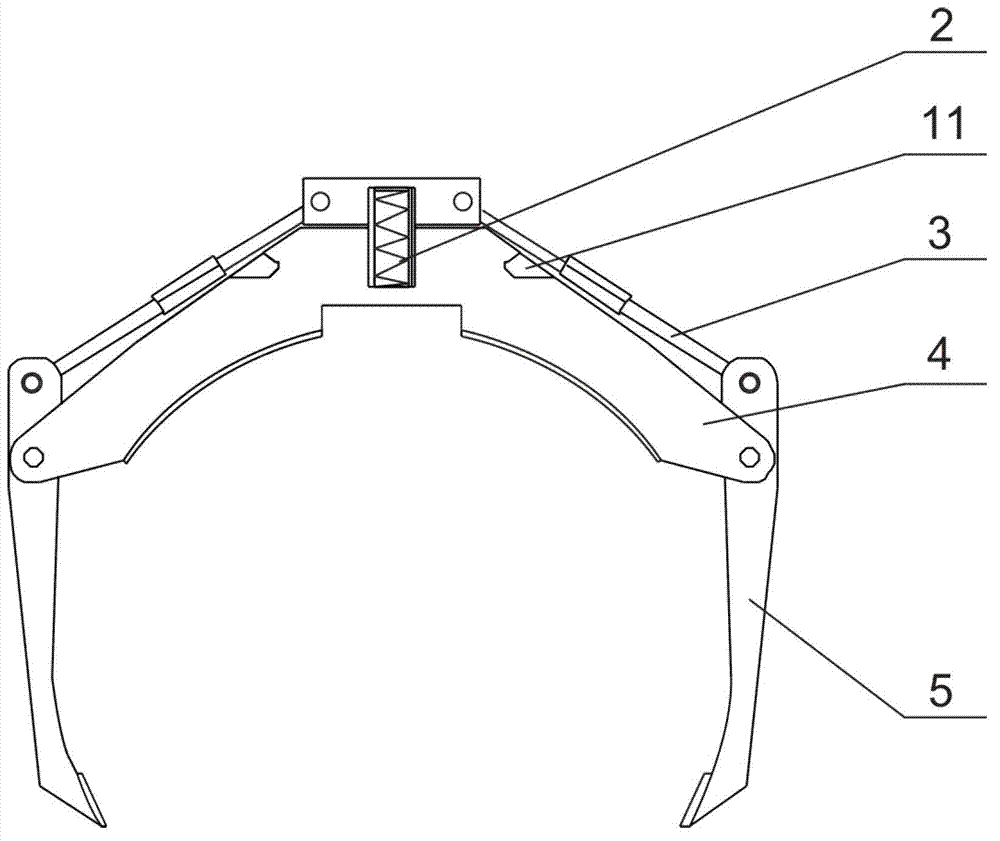

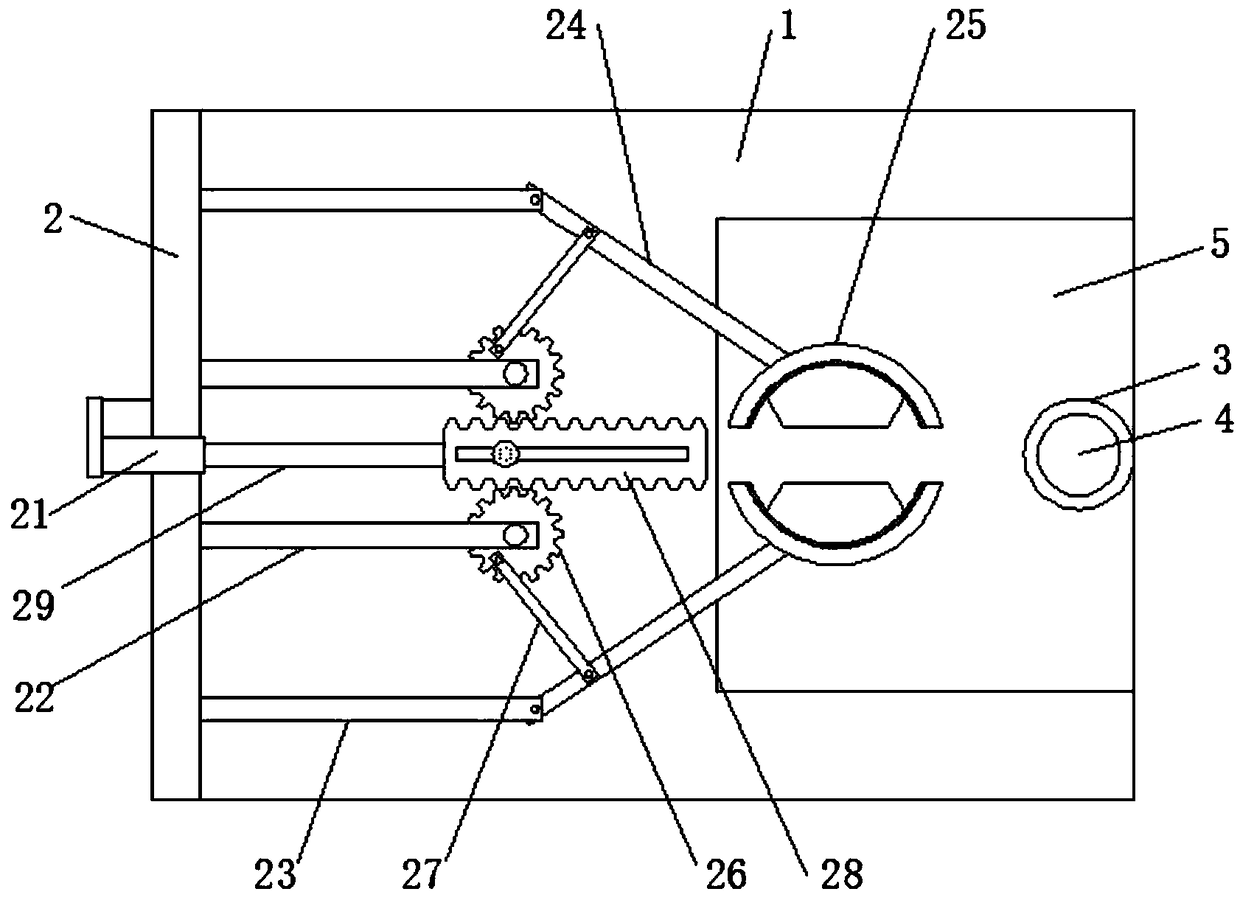

Universal hoisting clamp for circular tube

ActiveCN102923563AAchieve clamping and fixingWill not be damagedLoad-engaging elementsSelf lockingScrew thread

The invention discloses a universal hoisting clamp for a circular tube. The universal hoisting clamp comprises a clamp, a base, a reducing motor mounted at the right end of the base, a left screw rod and a right screw rod, which are mounted in the base, and a saddle seat, wherein claws are mounted on the left screw rod and the right screw rod through threads, a groove is formed in the saddle seat, the tail ends of the claws are shaped like hooks and articulated with the groove formed at the upper part of the saddle seat, the top end of the clamp is articulated with a push rod, the top end of the push rod is articulated with the top end of the saddle seat, and the 1 / 3 part at the upper end of the clamp is articulated with the tail end of the saddle seat. The fastening by the clamp is adopted for replacing the conventional fastening by a steel wire rope, the clamping and the fixing against barrel pieces with different diameters can be realized, the structure is simple, and the range of applications is wide; and the claws driven by self-locking threads are used for fastening, automatic unlocking can be avoided, the operation is safe and reliable, and the surfaces of the barrel pieces can not be damaged due to friction during the hoisting process after being wound with the steel wire rope.

Owner:贵州航天特种车有限责任公司

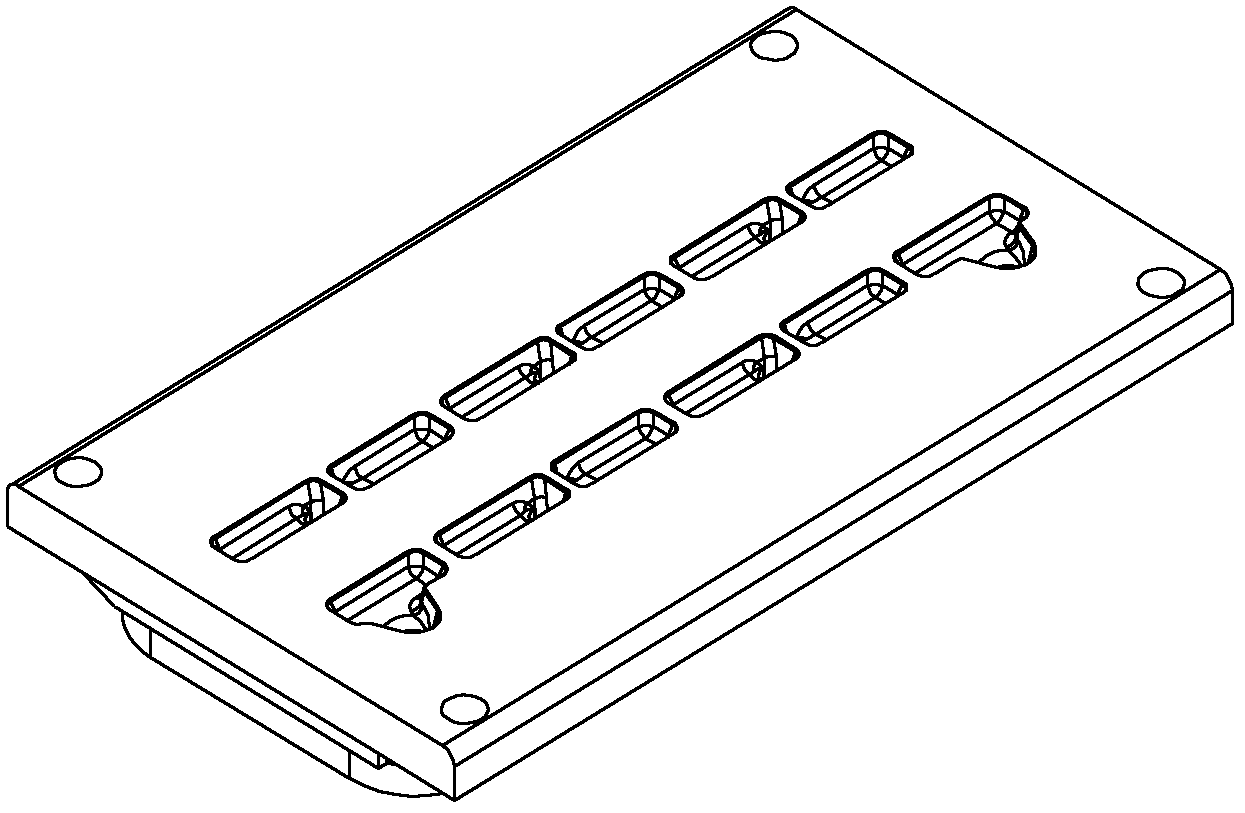

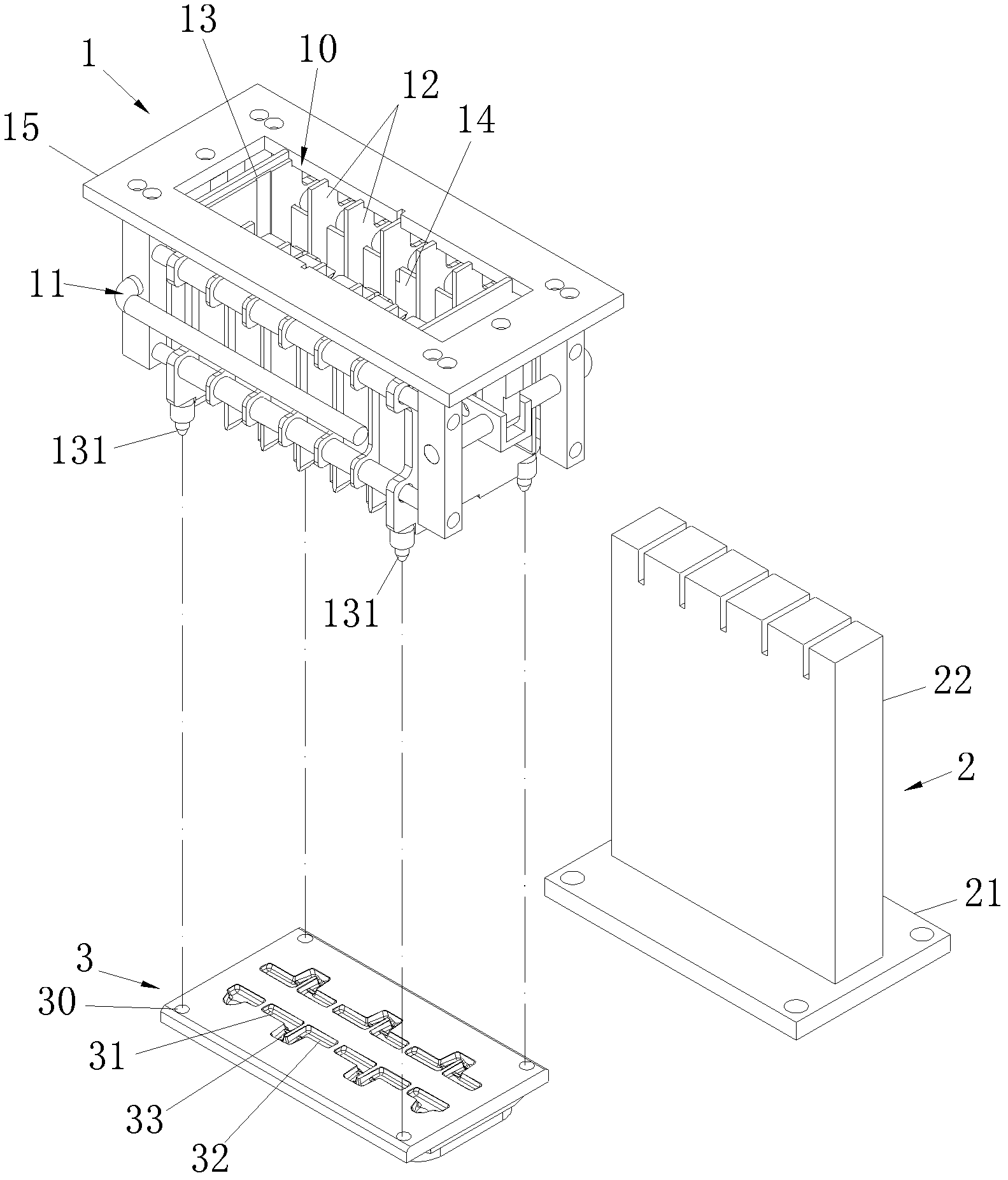

Novel molding mechanism for storage battery busbar

InactiveCN102306737AShorten the production cycleReduce manufacturing costCell component detailsElectrical batteryBusbar

The invention discloses a molding mechanism for storage battery busbars. The mechanism comprises a plate pack arranging mechanism, a cast welding mold, and a plate pack ejection apparatus. A plurality of molding units are orderly distributed on the upper surface of the cast welding mold. The molding units are composed of anode grooves and cathode grooves. The positions of an anode groove and a cathode groove of neighboring molding units are interlaced. The anode groove of a former molding unit is communicated to a cathode groove of a latter molding unit through a bridge groove. A plate pack composed of a plurality of battery monomers are clamped and fixed in the plate pack arranging mechanism. With the cooperation of the plate pack arranging mechanism and the cast welding mold, positive busbars, a negative busbars and bridge structures used for connecting the positive busbars and the negative busbars are molded through cast welding. With the cooperation of the plate pack ejection apparatus and the plate pack arranging mechanism, the bending of the bridge structures and the packaging of the busbars are accomplished.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

Stamping drilling device for production of automobile parts

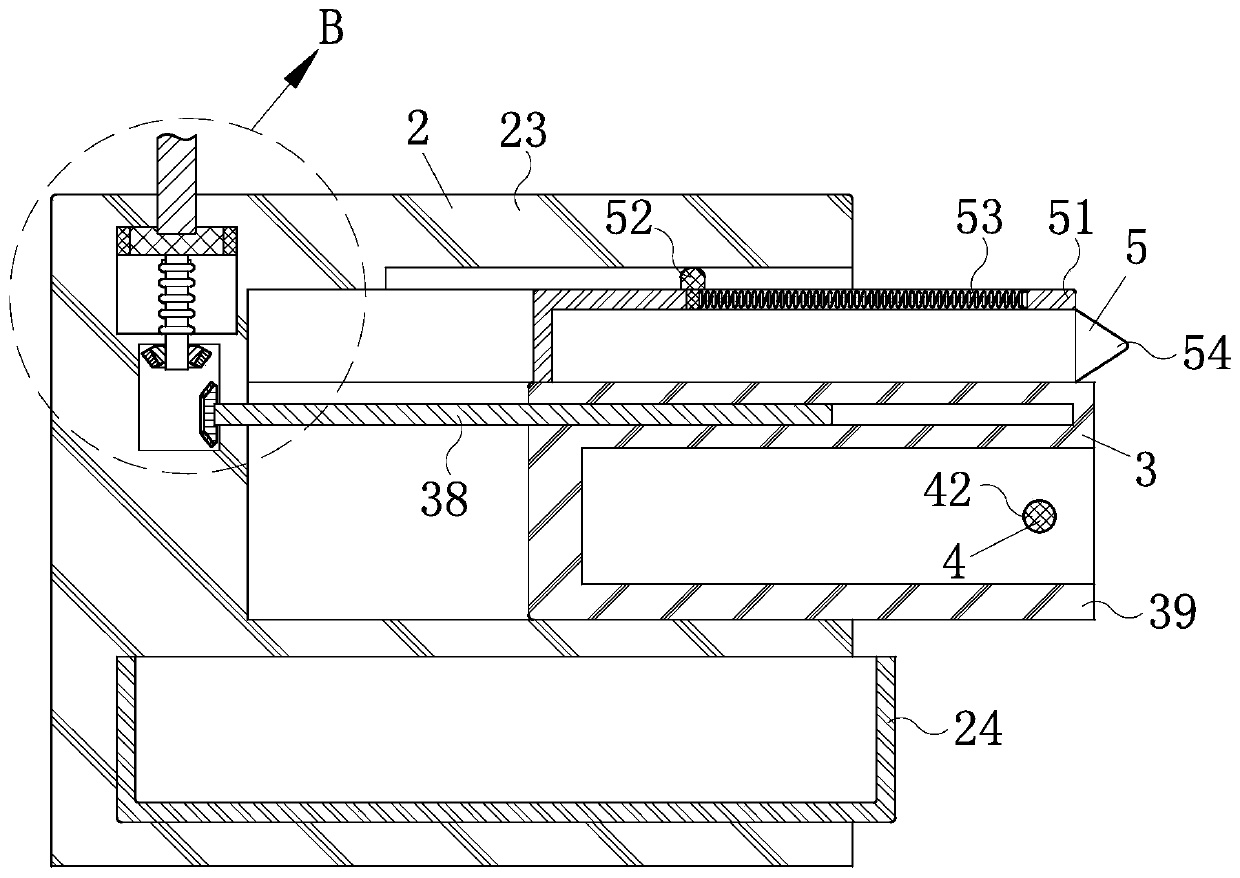

InactiveCN108544269AAchieve clamping and fixingRealize stamping drillingLarge fixed membersPositioning apparatusMachiningDriving mode

The invention discloses a stamping drilling device for production of automobile parts. The stamping drilling device for production of automobile parts comprises a supporting bottom case, lifting sliding blocks, vertical rails, horizontal rails, workpiece grooves, a drill, a lifting plate, a forward and reverse rotating motor and a screw rod. Supporting posts are fixedly erected on the tops of thetwo ends of the supporting bottom case in a welded mode, clamping mechanisms for clamping and fixing automobile parts are arranged on the two supporting posts correspondingly, supporting vertical plates are symmetrically and fixedly arranged at the top end of the middle of the supporting bottom case, and the lifting plate is arranged between the two supporting vertical plates in a vertical slidingmode. The screw rod is installed in the middle of the lifting plate in a threaded connection mode, the forward and reverse rotating motor for driving the screw rod to rotate is fixedly installed at the top end of the middle of the supporting bottom case, a drilling motor is erected on the lifting plate in a fixedly connected mode, and the top end of an output shaft of the drilling motor is connected with the drill in a driving mode. The stamping drilling device for production of automobile parts facilitates clamping and fixing of automobile parts, is beneficial to drilling machining of automobile parts, and greatly reduces the manual labor intensity.

Owner:HEFEI LIANSEN YUTENG NEW MATERIAL TECH DEV CO LTD

Valve pressure tester for pipeline

InactiveCN108132129AAchieve clamping and fixingQuick fixMeasurement of fluid loss/gain rateGear driveProtection mechanism

The invention discloses a valve pressure tester for a pipeline. The tester comprises a fixed pedestal, a valve fastening mechanism, a stable elevating mechanism and a test protection mechanism; the valve fastening mechanism comprises a positioning vertical plate welded to one side of the top of the fixed pedestal, a push rod motor is mounted in the external end surface of the positioning verticalplate, the internal end surface of the positioning vertical plate is connected two supporting cross bar and fixing cross bar groups, one end of each fixing cross bar is rotationally provided with an adjusting long rod, one end of the adjusting long rod is welded to a valve clamping plate, one end of each supporting cross bar is rotationally provided with a first gear, the top edge position of thefirst gear is rotationally provided with a swing rod, one end of the swing rod is rotationally connected with the adjusting long rod, and the first gear drives the swing rod and the adjusting long rodto swing left and right in the rotation process. Thus, valves of different specification can be fixed rapidly and undergo pressure test, the valves are protected against damage and deformation in valve pressure test process, and the valve using quality and testing efficiency are improved.

Owner:何志方

Drilling device for building construction decorative board

InactiveCN108161078AAchieve clamping and fixingEasy to clamp and fixPositioning apparatusBoring/drilling componentsArchitectural engineeringScrew thread

The invention discloses a drilling device for a building construction decorative board. The drilling device comprises a base, a drilling platform, a collection box, a drill bit, a lead screw, movablesliding blocks, pull ropes, fixed sleeves, support seats and pressure plates. The outer peripheries of the two sides of the lead screw are correspondingly sleeved with the upper portions of the two movable sliding blocks through inner threaded through holes in a threaded manner. The fixed sleeves are fixedly arranged on the upper surfaces of the two ends of the drilling platform. A lifting slidingblock is arranged in an inner cavity of the upper portion of each fixed sleeve. A spring is fixedly arranged in an inner cavity in the lower portion of each fixed sleeve. The other ends of the pressure plates are fixedly mounted on the lifting sliding blocks. The support seats are correspondingly and fixedly arranged on the upper surfaces of the two ends of the drilling platform. The support seats are located under the ends of the pressure plates. One end of each pull rope is fixedly connected with the corresponding lifting sliding block, and the other ends of the pull ropes are fixedly connected with the movable sliding blocks. The drilling device is simple in structure, convenient and fast to operate, capable of clamping and fixing the decorative board conveniently, high in safety and suitable for application and popularization, and the drilling efficiency is improved.

Owner:长沙双合盛企业管理有限公司

Abutting device for wiring of tensioning power cable

InactiveCN107979035AReasonable structureInnovative designElectrical testingApparatus for joining/termination cablesPower cableEngineering

The invention discloses an abutting device for wiring of a tensioning power cable. The abutting device comprises a support rack, wherein a horizontal plate is arranged at an upper end of the support rack, a guide sleeve is arranged at a middle part of a lower end of the horizontal plate, a screw rod is arranged in the guide sleeve, a left end of the screw rod is connected with a driven chain wheel, an upper end of the driven chain wheel is connected with a driving chain wheel via a chain, sliding blocks are connected with middle parts of two ends of the screw rod, fixed posts are arranged at lower ends of the sliding blocks, support plates are arranged at lower ends of the fixed posts, first limitation blocks are arranged at two sides of a lower end of each support plate, a clamping rod ishinged with lower ends of the first limitation blocks, a clamping ring is arranged at an inner side of the clamping rod, a second limitation block is arranged at a middle part of the clamping rod andis hinged with a pull rod, and a rotation wheel is hinged with the other end of the pull rod. By the abutting device, power cables at two ends are clamped and fixed, abutting of the power cables after being clamped is further achieved, the abutting device is simple to operate, the abutting efficiency of the power cable is achieved, meanwhile, the labor intensity of a worker is also reduced, and the abutting demand of a multi-core power cable is satisfied.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Stamping and drilling device for mobile phone shell piece

InactiveCN108339994AEasy to drillAchieve clamping and fixingBoring/drilling machinesEngineeringMechanical engineering

The invention discloses a stamping and drilling device for a mobile phone shell piece. The stamping and drilling device comprises a base, lifting blocks, vertical guide rails, transverse guide rails,supporting frames, a drill bit, a vertical hydraulic telescopic rod and a transverse hydraulic telescopic rod; supporting upright columns are fixedly erected to the tops of the two ends of the base ina welding manner respectively and are provided with clamping mechanisms used for clamping and fixing a mobile phone shell respectively; each clamping mechanism comprises the lifting blocks, the vertical guide rails, a supporting vertical rod, a supporting connection rod, a connection spring, a supporting transverse rod and a supporting frame; a top plate of the supporting frame is rotationally provided with a screw rod in a threaded connection manner; a clamping block is arranged at the bottom end of the screw rod; a drilling motor is installed at the top end of a piston rod on the vertical hydraulic telescopic rod; and the drill bit is installed at the top end of an output shaft of the drilling motor. The stamping and drilling device disclosed by the invention is simple and reasonable instructure, can clamp and fix the mobile phone shell conveniently and is convenient and rapid to operate, is beneficial to drilling and processing of the mobile phone shell, greatly lowers the labor intensity of a worker, is high in working efficiency and is suitable for popularization and use.

Owner:盛梁科

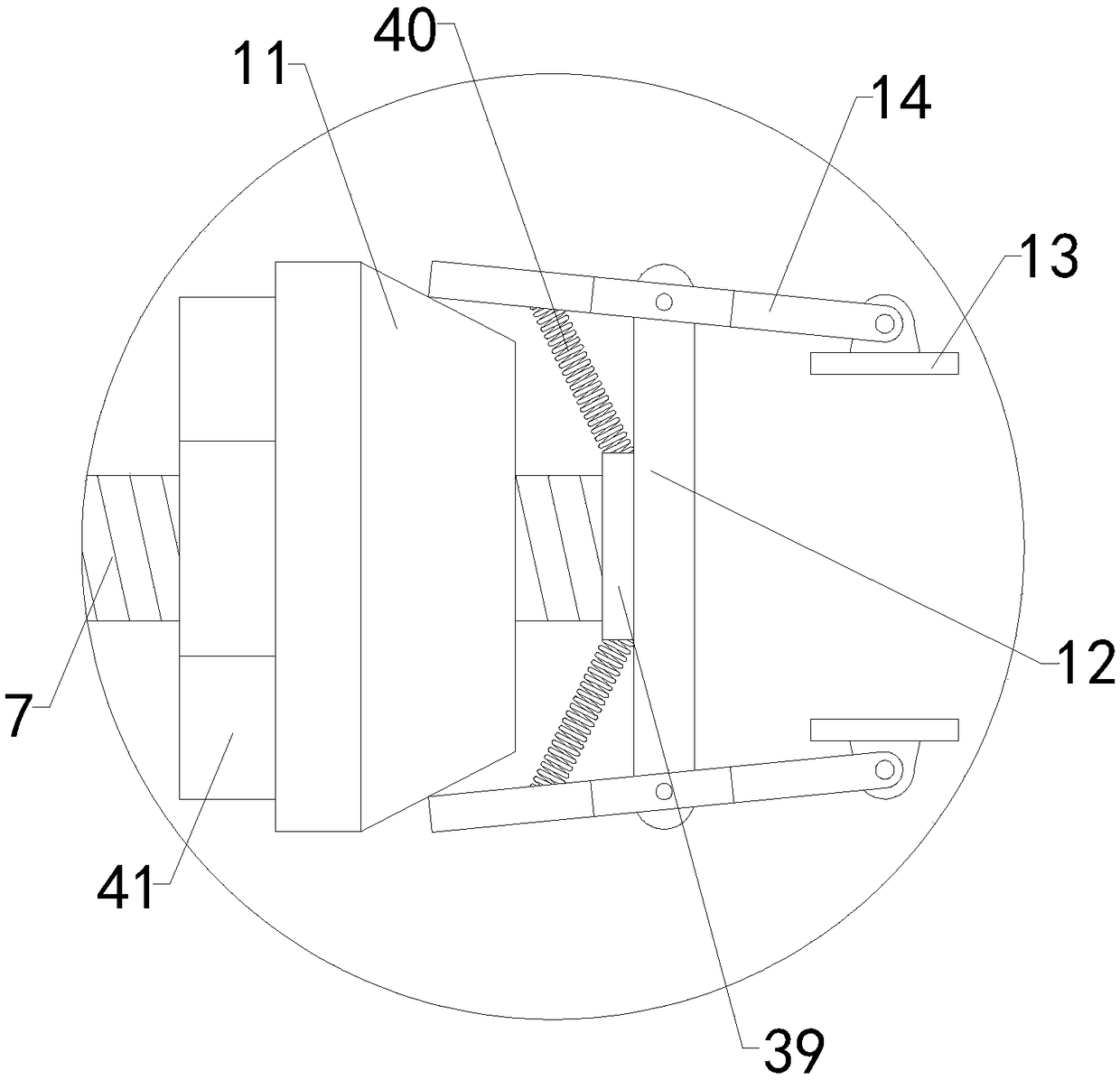

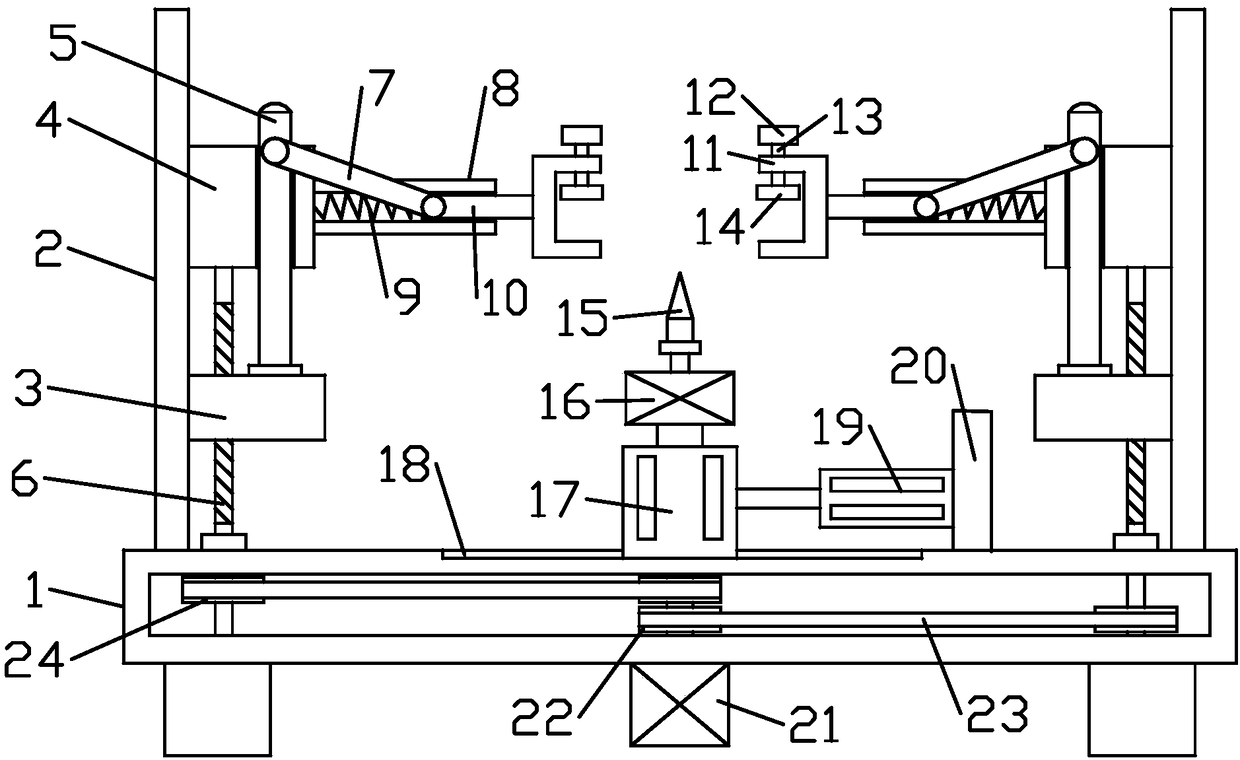

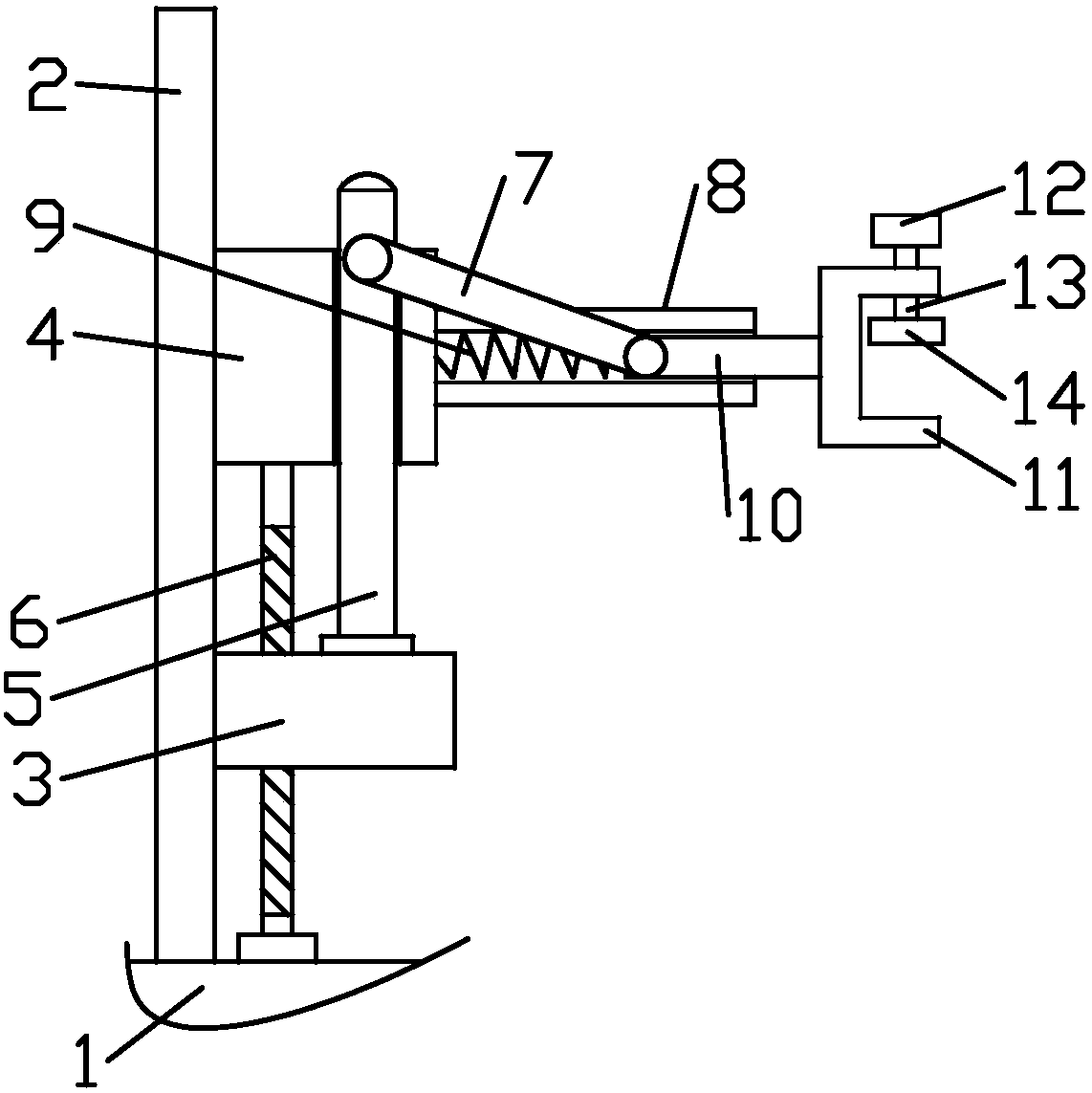

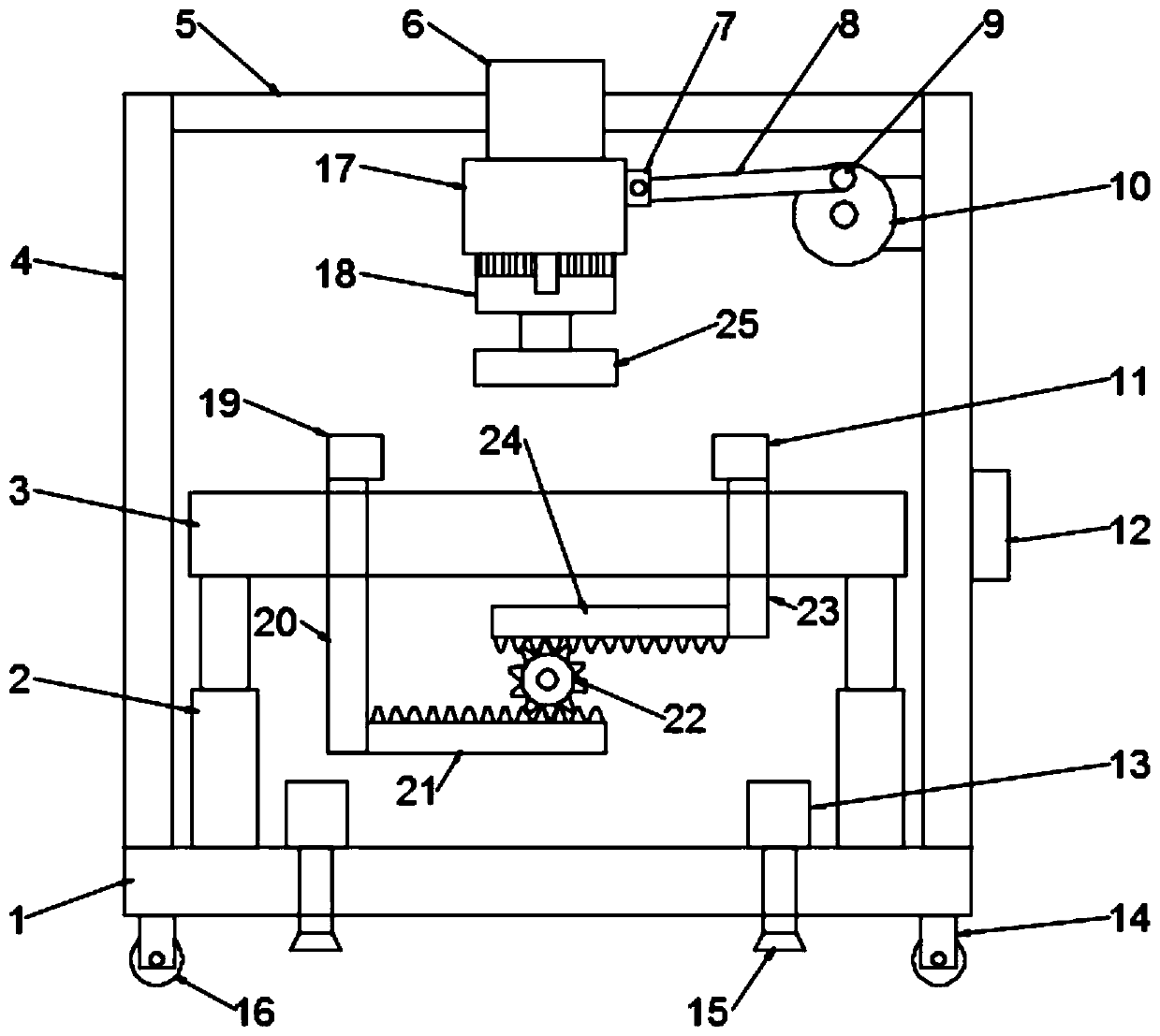

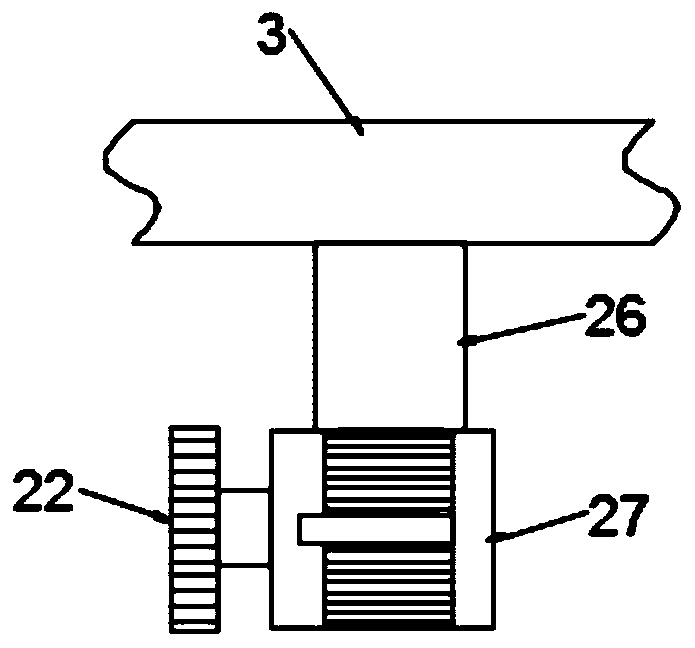

Automatic automobile crankshaft grinding device

InactiveCN111546151AAchieve clamping and fixingHigh degree of automationRevolution surface grinding machinesAutomatic grinding controlElectric machineryAutomotive engineering

The invention relates to the technical field of crankshaft machining equipment, in particular to an automatic automobile crankshaft grinding device. The automatic automobile crankshaft grinding devicecomprises a bottom plate, side supporting plates are connected to the left side and the right side of the upper end face of the bottom plate, and a workbench is arranged above the bottom plate; a hydraulic telescopic rod is connected between the bottom plate and the workbench, a controller is installed on the side face of one of the side supporting plates, the hydraulic telescopic rod is electrically connected with the controller, a grinding motor is arranged above the workbench, an output shaft of the grinding motor is connected with a grinding disc, and the grinding motor is electrically connected with the controller; and the automatic automobile crankshaft grinding device further comprises a moving mechanism and a clamping mechanism. The moving mechanism can drive the grinding motor and the grinding disc to reciprocate left and right to automatically grind an automobile crankshaft, the automobile crankshaft can be clamped through the clamping mechanism, the situation that in the grinding process, the automobile crankshaft moves, and consequently the grinding process is affected is avoided, and the automation degree is high.

Owner:何效平

Supporting device for spraying electromechanical device

PendingCN108672182AImprove spraying efficiencyEasy to adjustSpraying apparatusEngineeringMechanical engineering

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

Grinding device for automobile accessory machining

InactiveCN108747669AAchieve clamping and fixingSimple structureEdge grinding machinesGrinding carriagesEngineeringServomotor

The invention relates to a grinding device for automobile accessory machining. The grinding device comprises a base and a grinding mechanism. A containing box is fixedly connected to the upper side ofthe base. Vertical plates are symmetrically and fixedly connected to the upper side of the base relative to the containing box. A transverse plate is fixedly connected to the top ends of the verticalplates. A first sliding groove is formed in the lower side of the transverse plate and is internally in sliding connection with a first sliding block. The lower side of the first sliding block is fixedly connected with a first threaded block internally provided with a first threaded hole. The grinding mechanism comprises a second servo motor, an air cylinder and a grinding motor. The second servomotor is fixedly connected to the upper end of the outer side of one vertical plate. A first threaded rod is arranged on the right side of the second servo motor and is in threaded connection into the first threaded hole. The air cylinder is fixedly connected to the lower side of the first threaded block. A piston rod is arranged on the lower side of the air cylinder. A long strip is fixedly connected to the lower side of the piston rod, the lower side of the long strip is in sliding connection with the grinding motor, a grinding shaft is arranged on the lower side of the grinding motor, anda grinding disc is arranged at the lower end of the grinding shaft. The grinding device is simple in structure, convenient to operate and suitable for usage and popularization.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

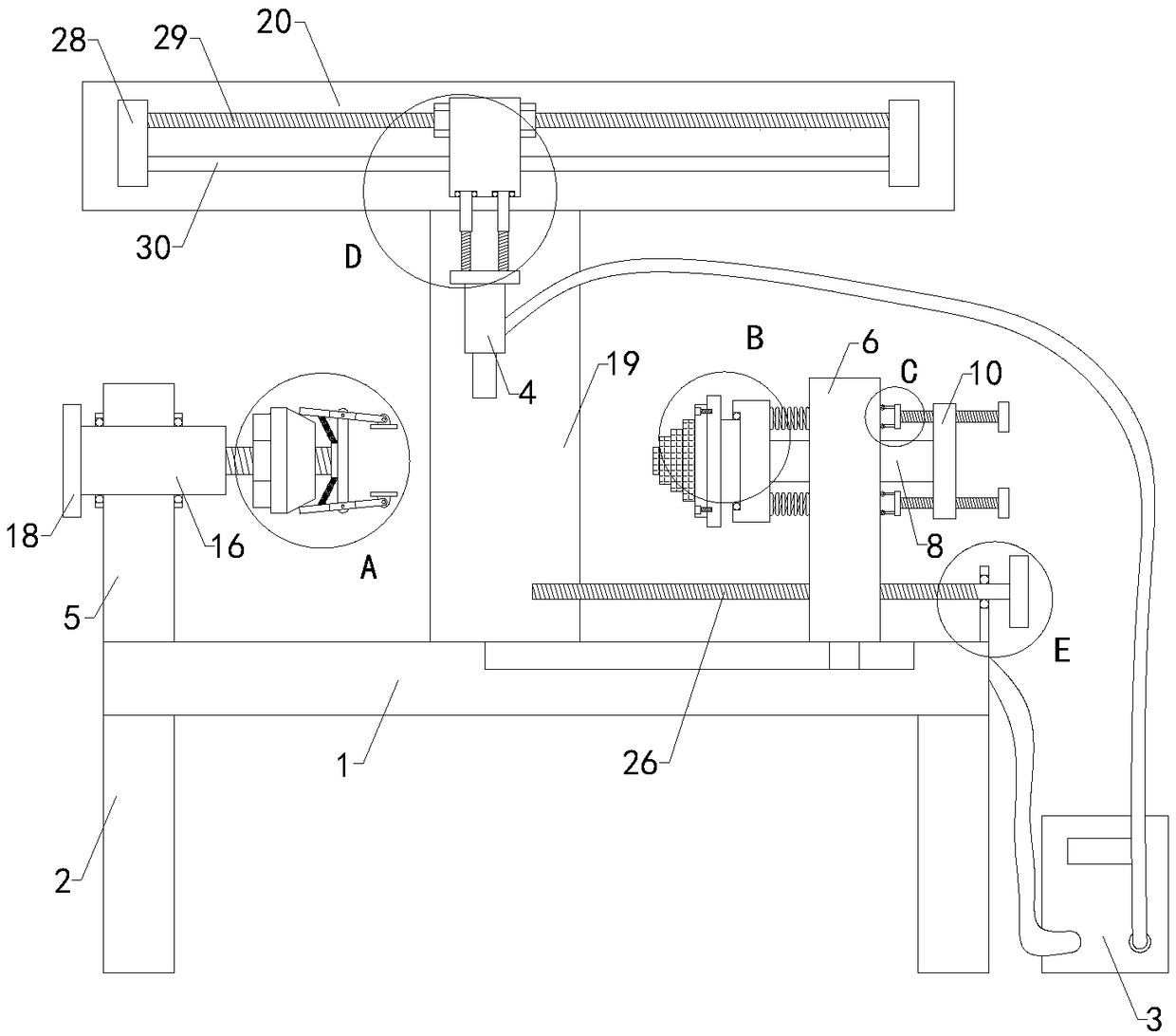

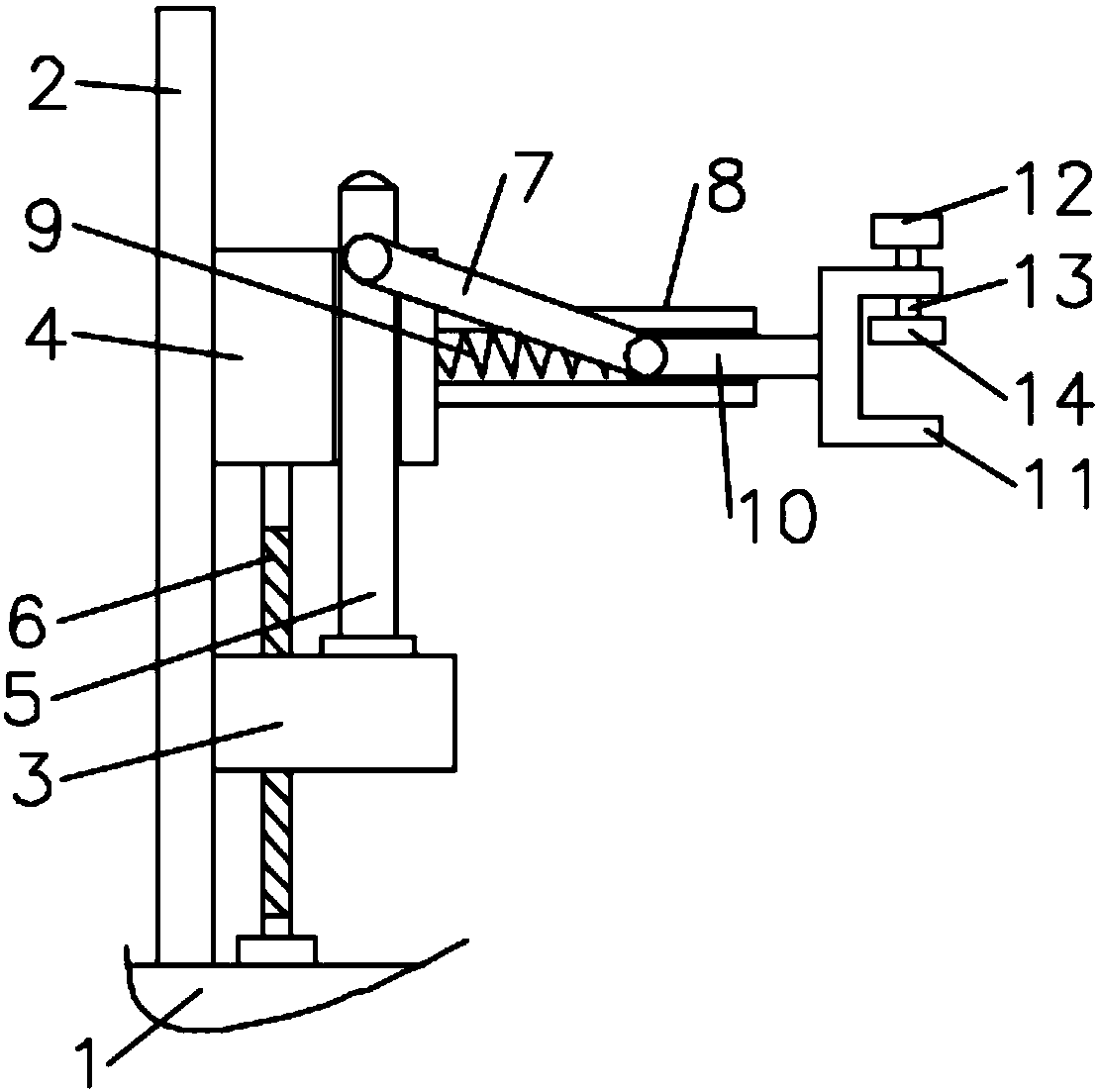

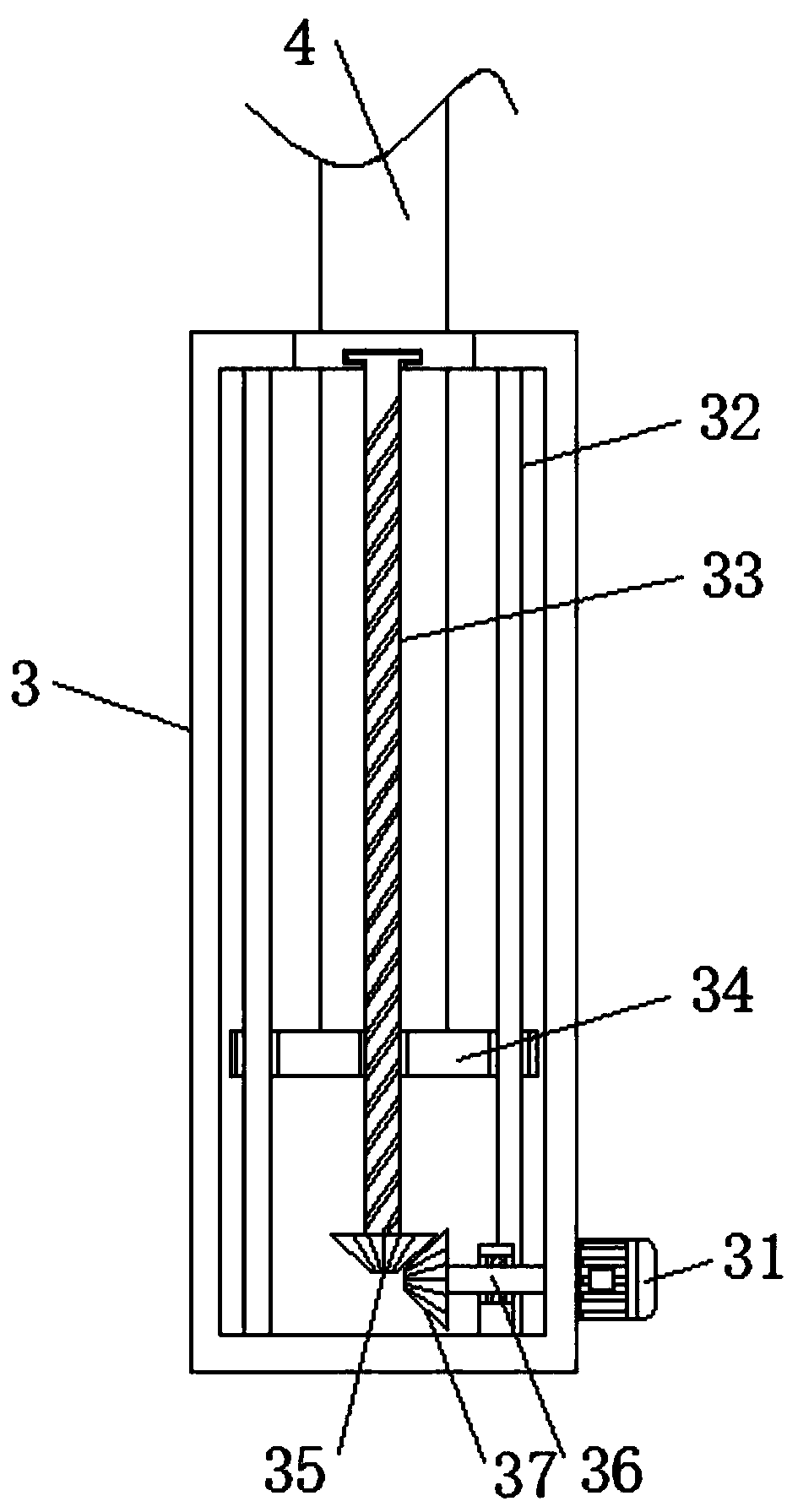

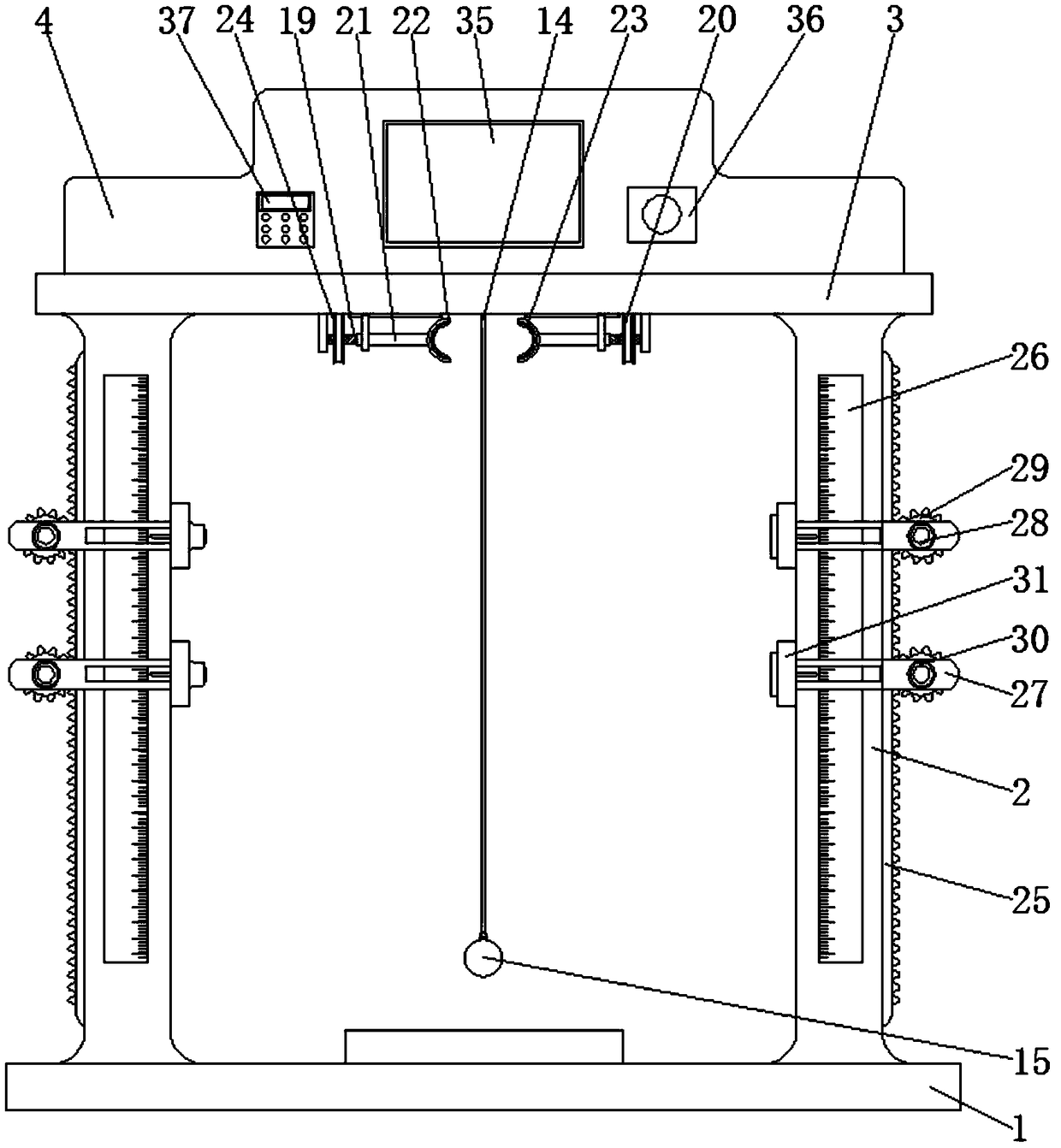

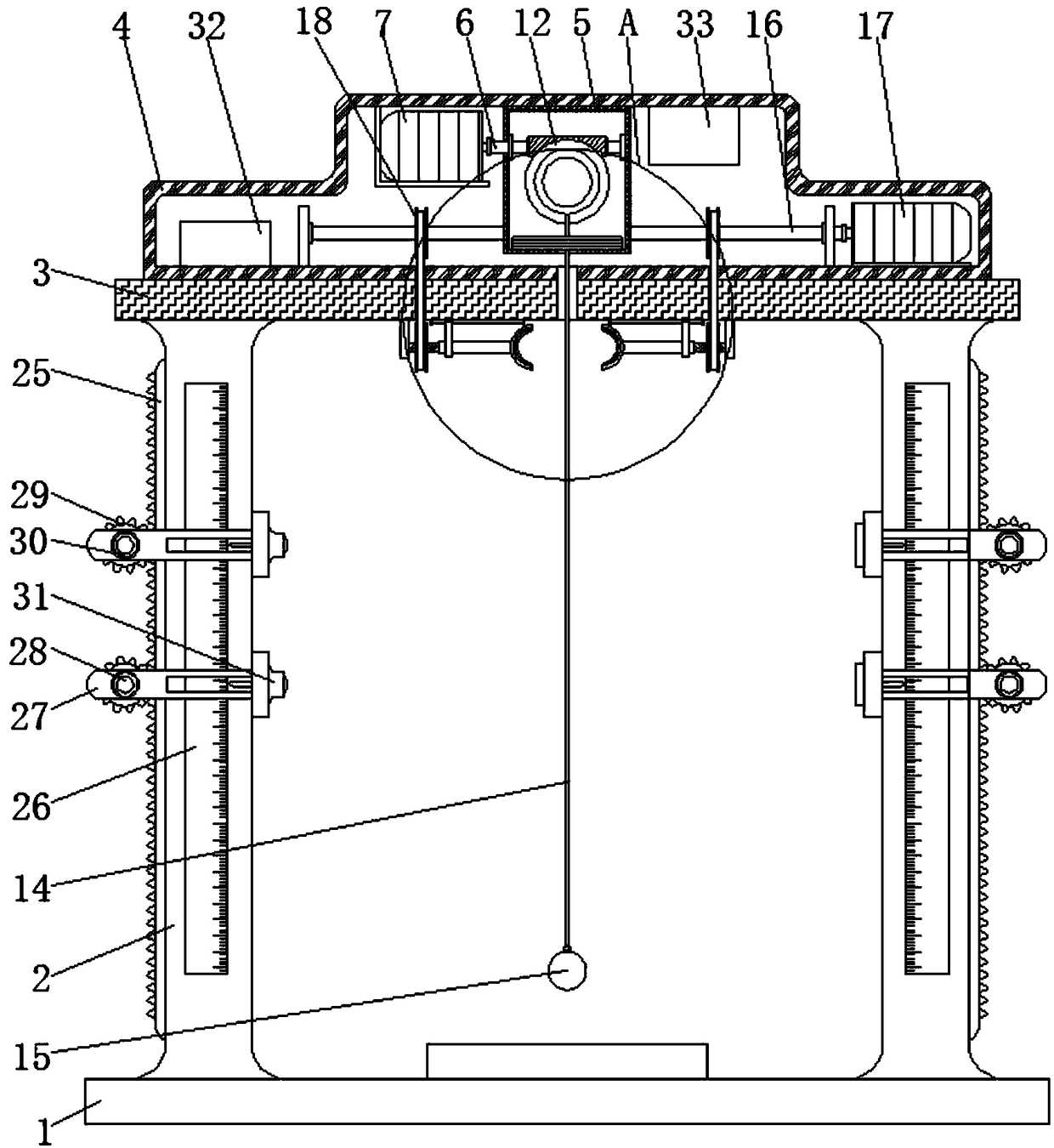

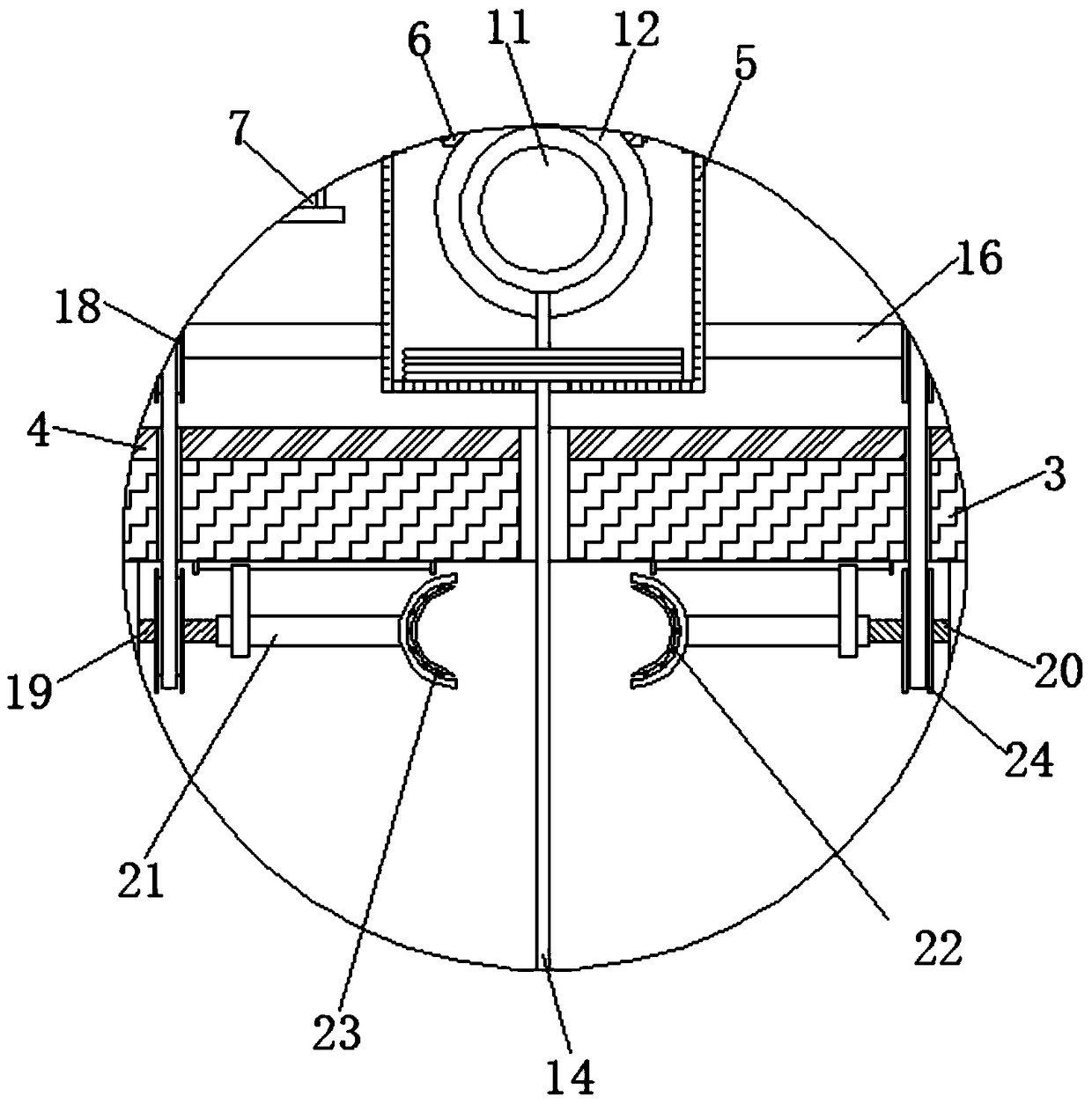

Free falling body gravity acceleration measuring instrument

InactiveCN109147503AHigh degree of automationReduce workloadEducational modelsEngineeringGravitation

The invention discloses a free falling body gravity acceleration measuring instrument, and relates to the technical field of teaching experiment facilities. The measuring instrument includes a bottomplate, the two sides of the top of the bottom plate are respectively and fixedly connected with supporting frames, a mounting plate is fixedly connected to the top parts of the supporting frames, anda mounting box is fixedly connected to the top of the mounting plate, a wire winding box is fixedly connected to the top of the inner wall of the mounting box, a worm is rotationally connected betweenthe two sides of the inner wall of the wire winding box through a bearing, one end of the worm penetrates through the wire winding box and extends to one side of the wire winding box. According to the free falling body gravity acceleration measuring instrument, the situation that the measuring instrument requires the experimenter to manually pick up the experimental ball after the end of an experiment, re-put the ball to the highest point and wait for the next experiment can be avoided, the automation degree of the measuring instrument is greatly improved, the working burden of experimentersis reduced, so that the experiment ball can be automatically retracted rapidly and conveniently, so that the measurement work of the gravity acceleration of the free falling body by an experimenter isgreatly facilitated.

Owner:吕振阳

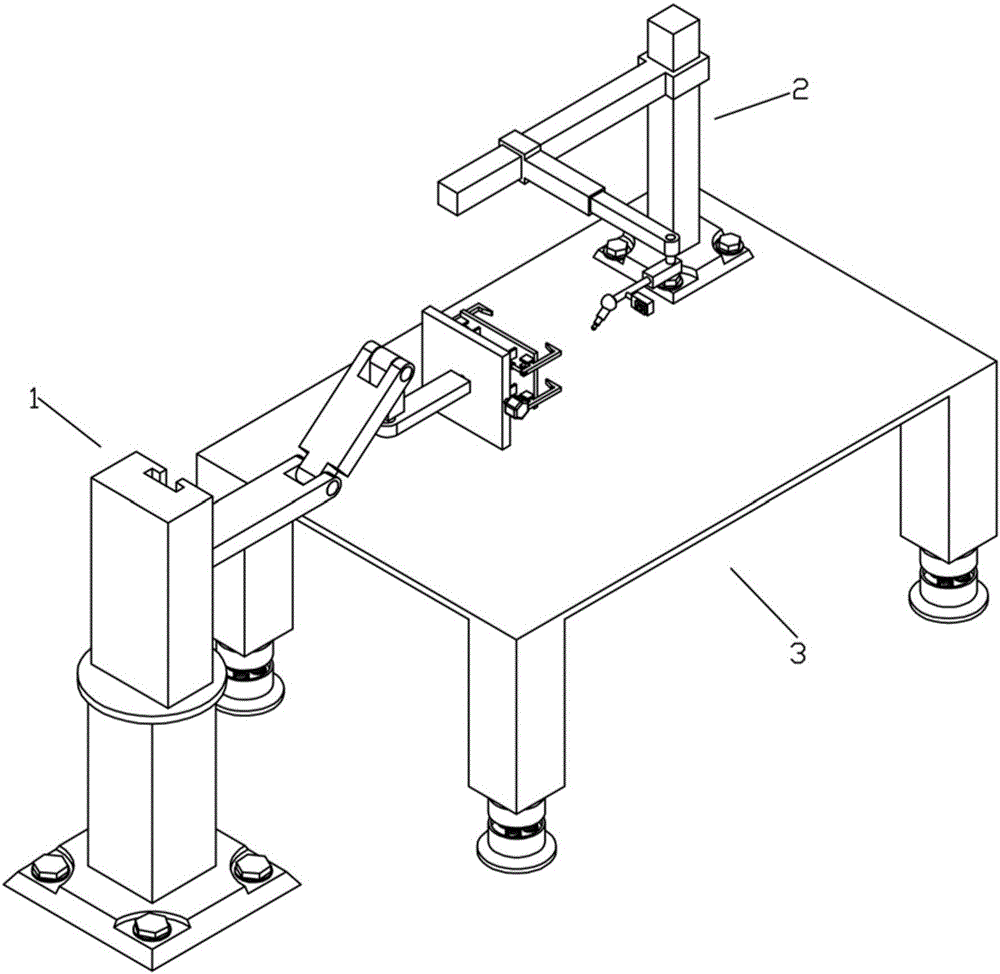

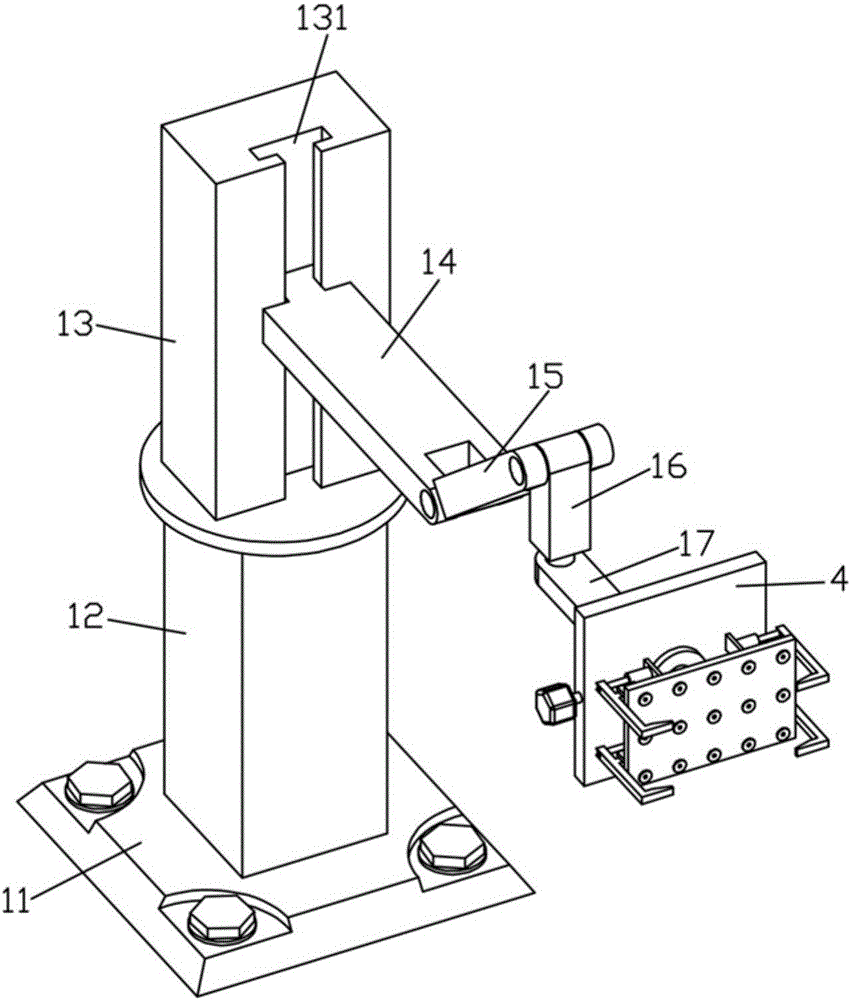

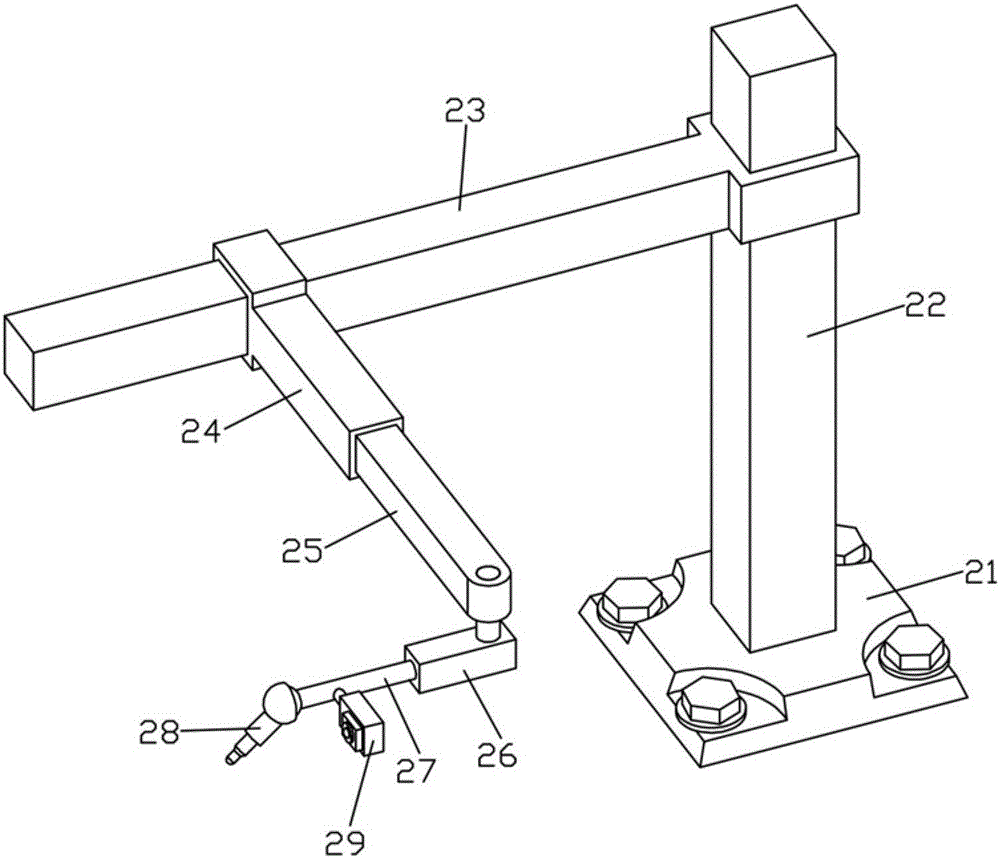

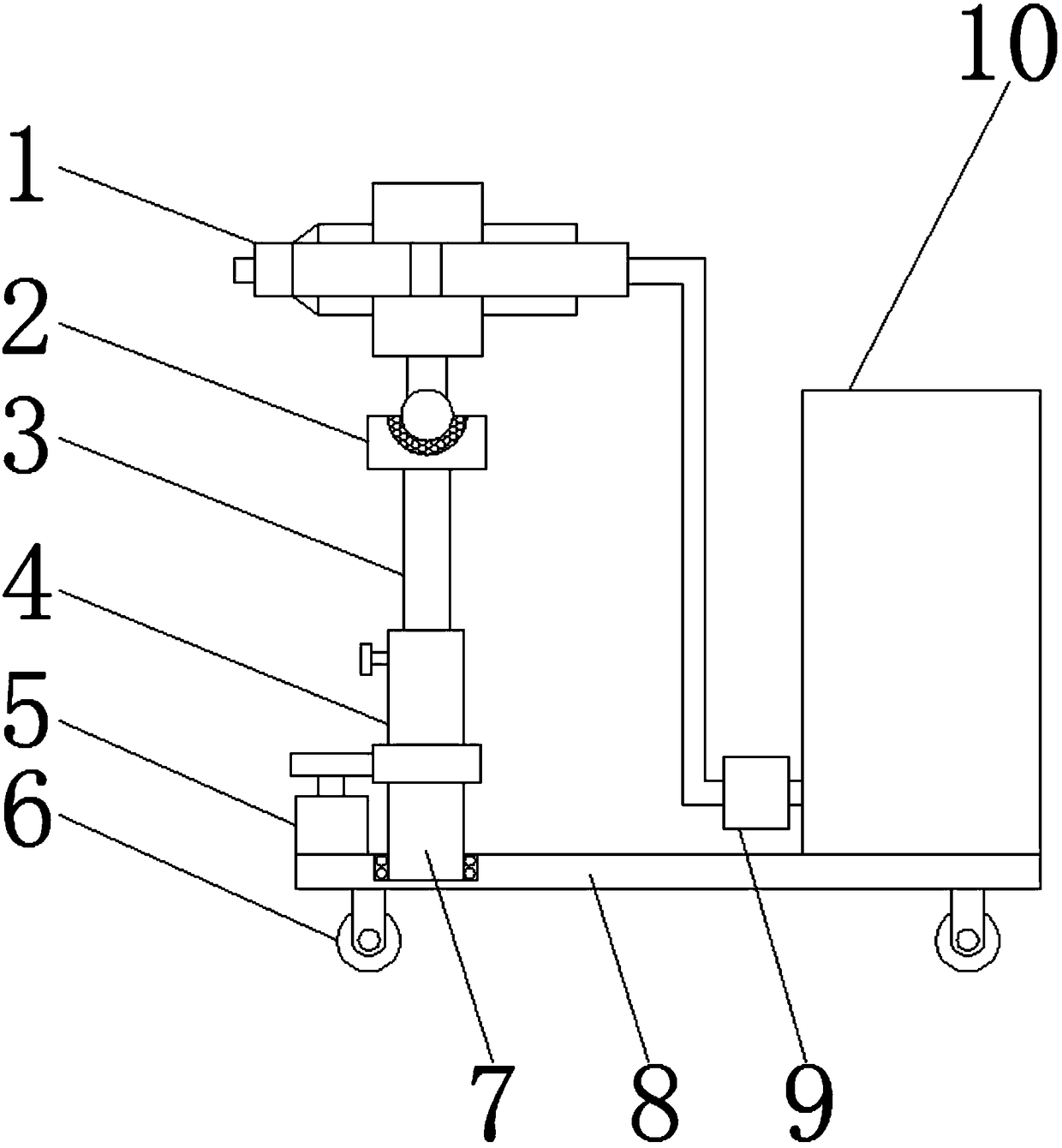

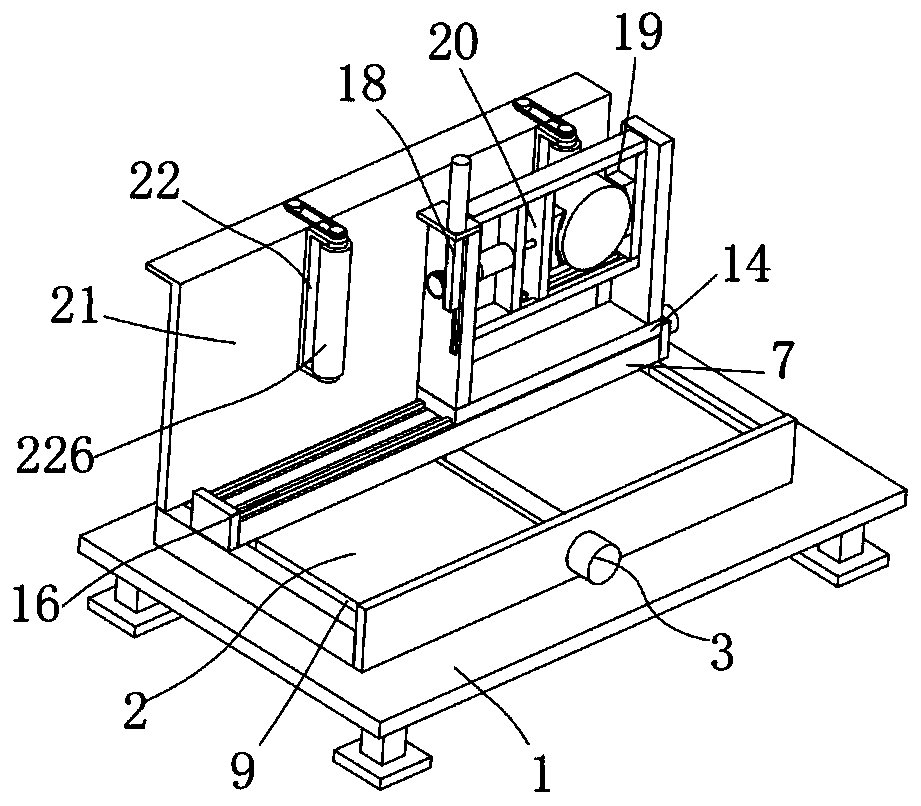

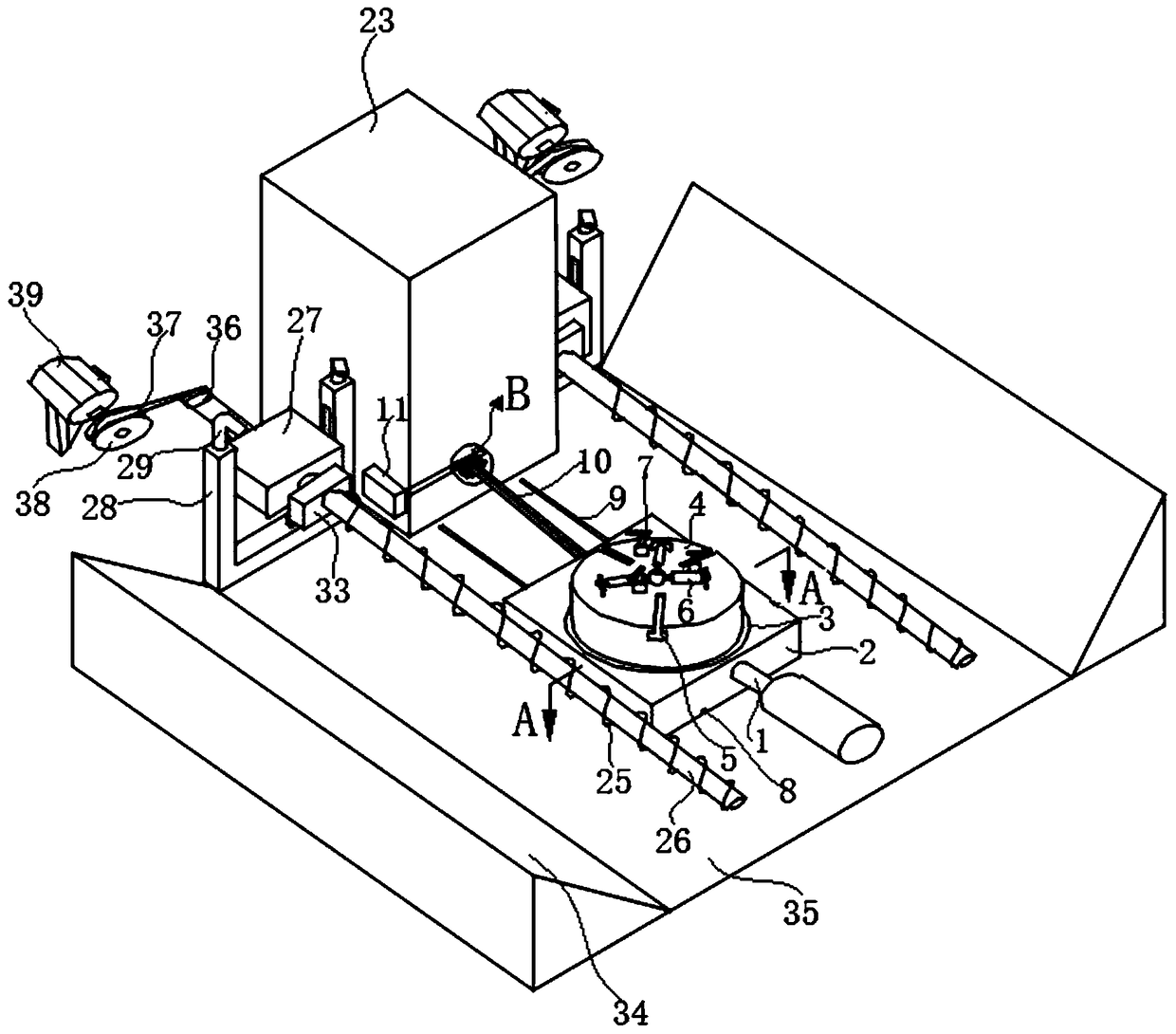

Intelligent welding equipment

ActiveCN105904143AAchieve clamping and fixingSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMulti degree of freedom

The invention discloses intelligent welding equipment. The intelligent welding equipment comprises a multi-degree-of-freedom welding manipulator assembly, a CCD camera, a welding clamp and a control cabinet. The multi-degree-of-freedom welding manipulator assembly, the CCD camera and the welding clamp are all electrically connected with the control cabinet. The control cabinet is located beside the welding clamp. The multi-degree-of-freedom welding manipulator assembly is located on a workbench. The CCD camera is located on the multi-degree-of-freedom welding manipulator assembly. The control cabinet comprises an upper computer and a PLC. The PLC controls action of the multi-degree-of-freedom welding manipulator assembly and action of the welding clamp in real time. In the welding process, a workpiece is fixed through the welding clamp, the multi-degree-of-freedom welding manipulator assembly welds the workpiece, the CCD camera photographs the workpiece in the welding process in real time and transmits photographed photos to the upper computer, and the upper computer analyzes and judges photo information. The intelligent welding equipment can clamp and fix different workpieces and complete the welding process rapidly, and is simple in structure and high in automation degree.

Owner:长春致远新能源装备股份有限公司

Regulating type fire extinguishing device for fire control

InactiveCN108144232AMeet different height needsAchieve clamping and fixingFire rescueFire controlWater storage tank

The invention discloses a regulating type fire extinguishing device for fire control. The regulating type fire extinguishing device comprises a motor, a rod body, universal wheels, a base, a second non-slip mat, a first non-slip mat, a water storage tank, and a sprayer; a barrel body is driven to rotate by using the rotation of the motor to drive a rotating seat to rotate, so that regulation of the water injection direction of the sprayer is further realized, manual regulation is not required, and a lot of manpower is saved; by adjusting the rod body to expand in the barrel body, the regulation of the height of the rotating seat is realized, the regulation of the height of the sprayer is further realized, and different height requirements of users in different situations and heights are met; by arranging the universal wheels, the device is conveniently moved for the users, therefore the fast fire extinguishing of the users is further facilitated when the fire occurs; and by arranging the second non-slip mat, the friction between the inner wall of a fixed groove and the sprayer is increased, and the effect of fixing the sprayer is improved.

Owner:ZHONGHUI ELECTROMECHANICAL TECH

Polishing device and technology for false tooth machining

ActiveCN111251143APrevent overthrowUndershootGrinding drivesLapping machinesPolishingFixed prosthodontic

The invention relates to a polishing device for false tooth machining. The polishing device comprises a base, an installation seat which is placed on the base and is used for fixing a false tooth in the polishing process, a support fixed to the base and a grinding tool which is installed at the end, away from the base, of the support and is used for grinding the false tooth. The polishing device is characterized in that a magnetic worktable is arranged on the upper end face of the base; multiple concentric ring-shaped grooves are formed in the lower end face of the installation seat; magnets are arranged in the ring-shaped grooves; and a clamping mechanism used for clamping and fixing the false tooth is arranged on the installation seat. The polishing device has the effects that the relative position between the installation seat and the base is conveniently adjusted, and therefore the grinding process is more convenient.

Owner:泉州市超维医疗科技有限公司

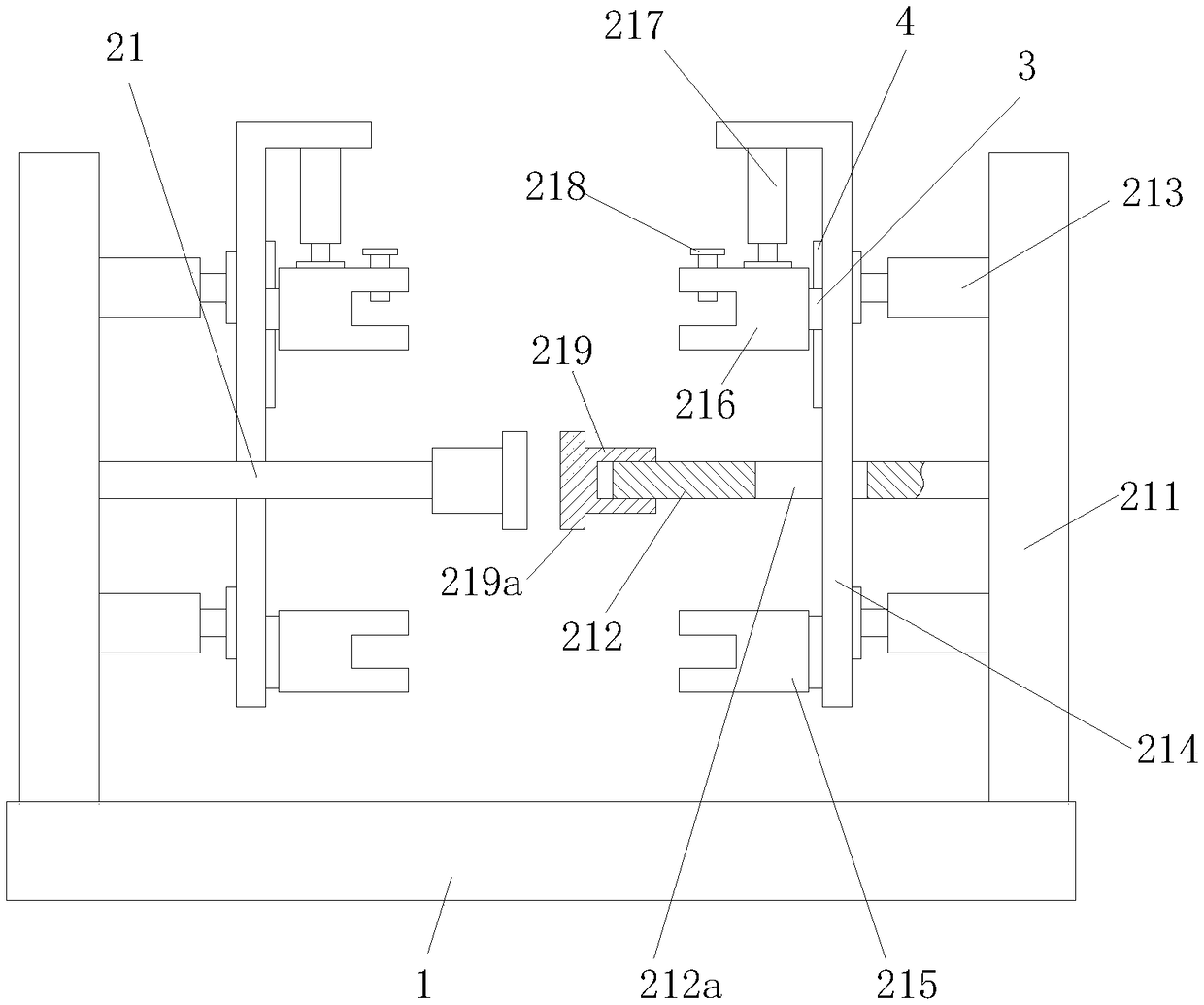

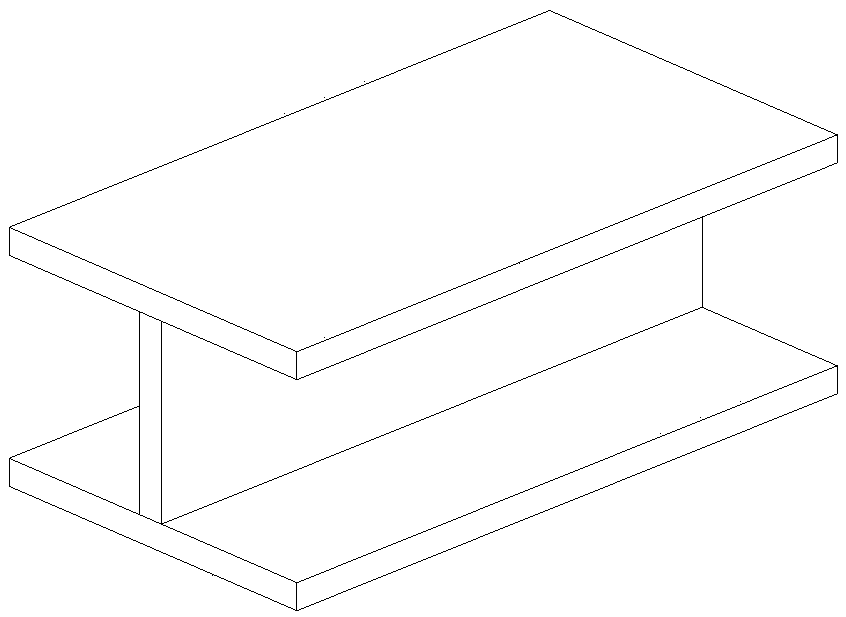

Fixing device used for splicing forming of H-shaped steel

InactiveCN109048162AReasonable structural designHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringH shaped

The invention relates to a fixing device used for splicing forming of H-shaped steel. The fixing device comprises a workbench and two fixing mechanisms distributed in the length direction of the workbench. Each fixing mechanism comprises two positioning units which are arranged symmetric front and back. Each positioning unit comprises a vertical plate, a positioning rod fixed to the middle of thevertical plate, horizontal pushing air cylinders fixed to the vertical plate, an upright plate connected with the output ends of the horizontal pushing air cylinders, a lower U-shaped clamping block fixed to the upright plate, an upper U-shaped clamping block in vertical sliding connection with the upright plate, and a downward pushing air cylinder fixed to the upright plate, wherein the output end of the downward pushing air cylinder is connected with the upper U-shaped clamping block. The top of the upper U-shaped clamping block is in threaded connection with an adjustable bolt. The adjustable bolt is vertically arranged and can be screwed into a U-shaped port of the upper U-shaped clamping block. The free end of the positioning rod is in screw thread fit with a cylindrical sleeve. A pressing block is arranged on the cylindrical sleeve. According to the fixing device used for splicing forming of the H-shaped steel, all steel products used for splicing assembly of the H-shaped steel can be fixed and clamped, the positioning precision is high, the quality of the formed H-shaped steel is high, the labor intensity is effectively relieved, and the working efficiency is improved.

Owner:WUHU DINGHENG MATERIAL TECH

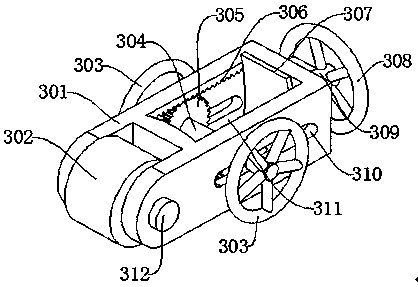

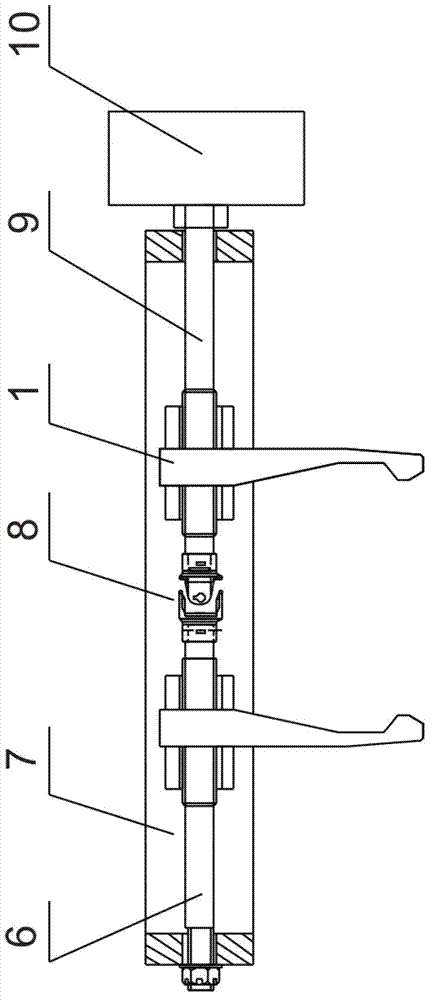

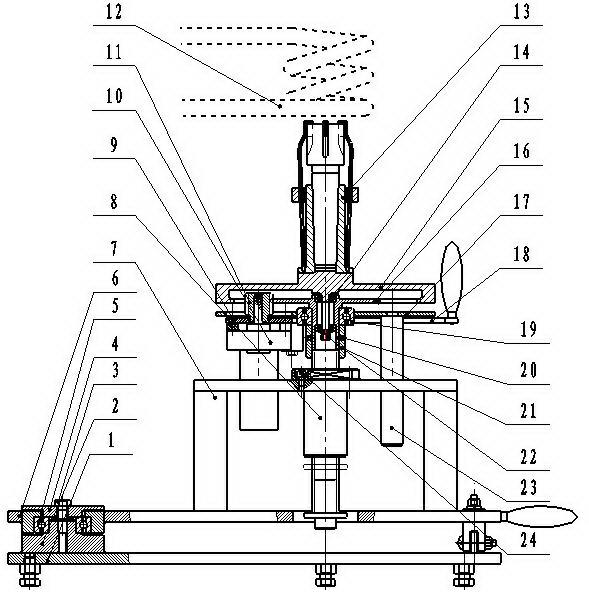

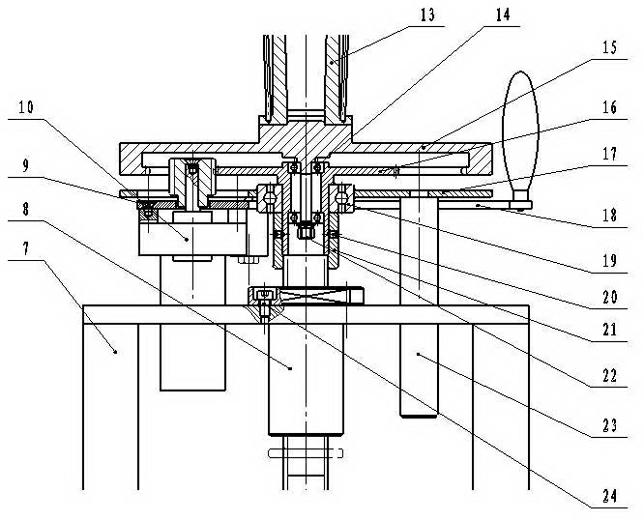

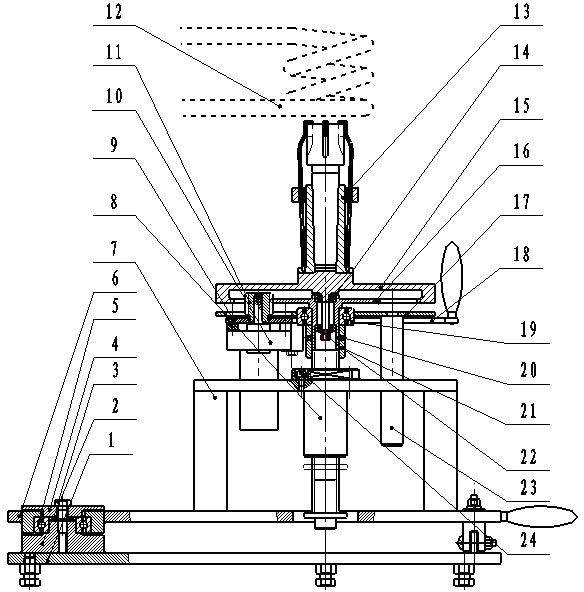

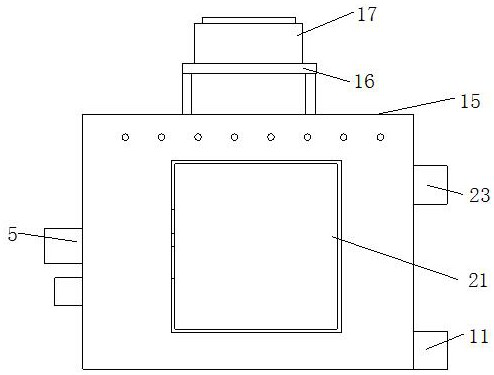

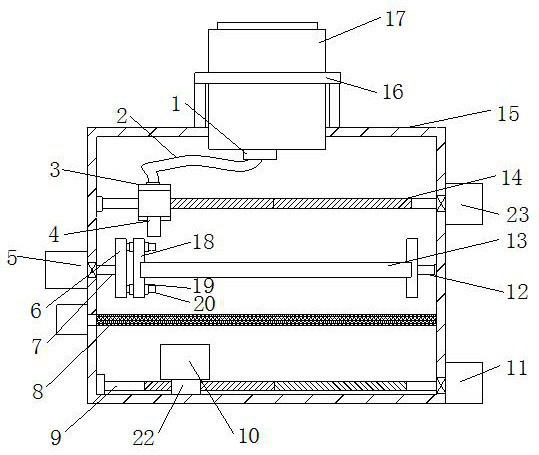

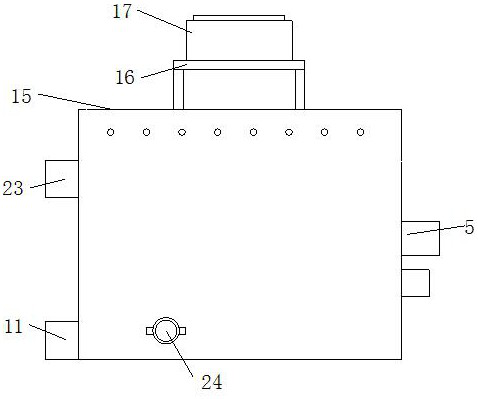

High-frequency induction cutter welding device

InactiveCN102672337ALoading and unloadingAvoid interferenceHigh frequency current welding apparatusCarbideEngineering

The invention relates to the field of welding processing, in particular to a cutter welding device of a welded carbide end milling cutter heated in a high-frequency induction manner. The cutter welding device comprises a driving component, a lifting component, a rotating component, a gear shift component, a base component and a welding component, wherein the driving component is used for realizing power output, the lifting component and the rotating component are connected with the driving component and used for realizing lift and the rotation of the cutter, the gear shift component is matched with the lifting component and the rotating component, connected with the driving component and used for realizing the unicity of the movements of lift and rotation, the base component is connected with the lifting component and used for realizing the change of a working table position, and the welding component is connected with the rotating component and used for fixedly clamping the end milling cutter and realizing high-frequency induction welding by finally putting the carbide end milling cutter to be welded into an induction coil. The high-frequency induction cutter welding device is simple in structure, convenient and rapid to use, even in welding temperature distribution, very obvious in economical benefit, capable of effectively improving welding and processing efficiency and welding quality of the carbide end milling cutter, and scrappage is lowered.

Owner:JIANGSU UNIV

Cleaning device for plate processing

PendingCN111822417AAchieve clamping and fixingTurn overDrying gas arrangementsCleaning using liquidsElectric machineryWater storage tank

The invention discloses a cleaning device for plate processing, and relates to the field of plate processing. According to the cleaning device, the problem that an existing cleaning device cannot drya cleaned plate can be solved. By means of the following scheme, the cleaning device comprises a device shell, wherein a water storage tank is fixedly mounted at the upper end of the device shell; a first motor is fixedly mounted at the left end of the device shell; an output shaft of the first motor is connected with a drive shaft; the right end of the drive shaft passes through the device shelland extends to the inside of the device shell to be fixedly provided with connecting plates; a rotating shaft is rotationally mounted on the right wall inside the device shell; the left end of the rotating shaft is located in the device shell; clamping plates are installed at one ends, close to each other, of the rotating shaft and the connecting plate; inserting grooves are formed between the twoconnecting plates; and anti-skid patterns are arranged on the inner walls of the inserting grooves. The cleaning device for plate processing is good in cleaning effect, convenient to dry, high in automation degree, simple in operation and high in practicability.

Owner:何晓华

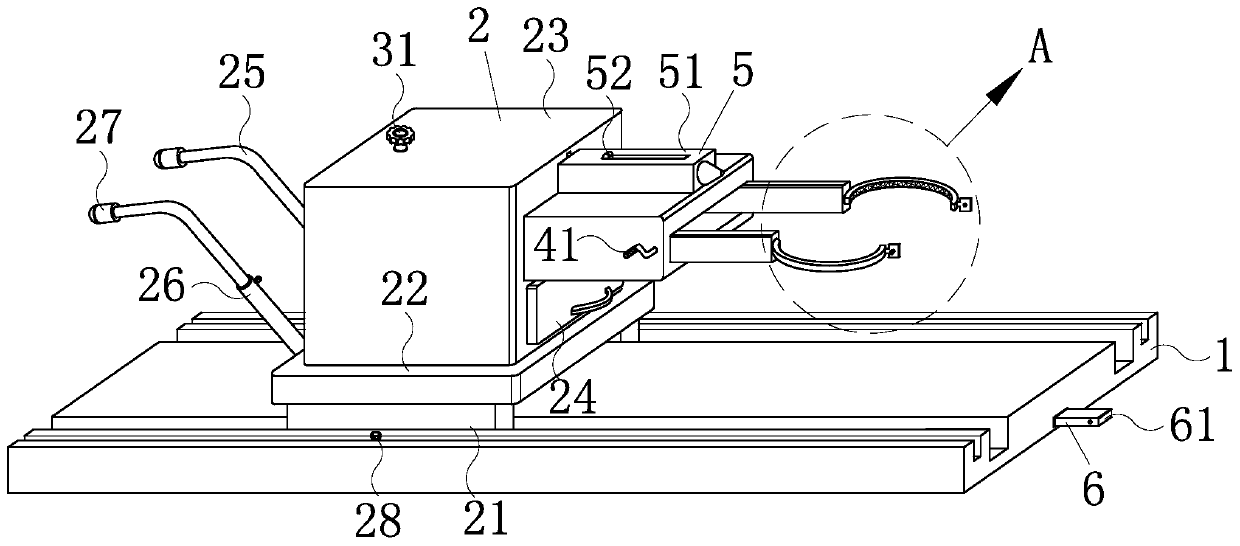

Waterproof glue spraying device for photoelectric circuit boards

InactiveCN112871506AEasy to replace the brush headSpraying in all directionsSpraying apparatusElectrical and Electronics engineeringMechanical engineering

The invention discloses a waterproof glue spraying device for photoelectric circuit boards, and belongs to the technical field of photoelectric circuit board processing equipment. The waterproof glue spraying device for the photoelectric circuit boards comprises a base plate, a conveying device, a gluing driving device, a gluing device and a clamping device. The conveying device is installed on the base plate; the gluing driving device is installed on the base plate and located above the conveying device; the gluing device is arranged at the bottom end of the gluing driving device; and the clamping device is installed on the base plate and located below the conveying device. According to the device, waterproof glue spraying operation can be continuously conducted on a batch of photoelectric circuit boards, specifically, an operator firstly places the batch of circuit boards sequentially on the conveying device for conveying, each circuit board is clamped and fixed by the clamping device when passing through the position of the clamping device, then the gluing driving device above the circuit board drives the gluing device to carry out spraying operation on the circuit board, the circuit board is conveyed to the next processing site after spraying is completed, and then spraying operation is carried out on the next circuit board.

Owner:合肥高地创意科技有限公司

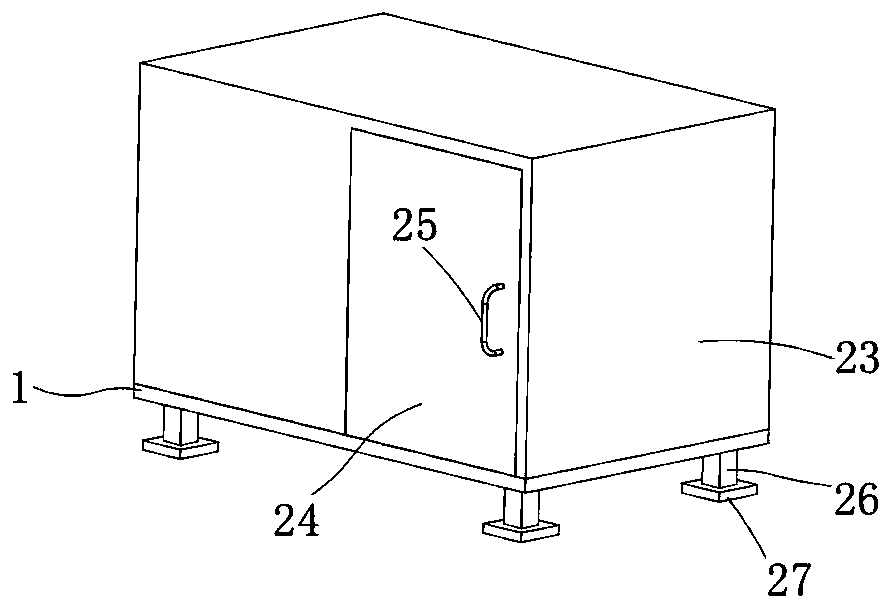

Maintenance equipment for high-voltage distribution system

ActiveCN111585201AEasy to fixAchieve clamping and fixingApparatus for overhead lines/cablesSwitchgearButt jointDistribution system

The invention relates to the technical field of high-voltage power distribution maintenance, in particular to maintenance equipment for a high-voltage power distribution system. The maintenance equipment comprises guide rail plates, a main body mechanism, a placement mechanism, a fixing mechanism, a marking mechanism and butt joint mechanisms; during use, the placement mechanism is placed in the main body mechanism, so that the fixing mechanism is convenient to adjust; the fixing mechanism is arranged in the placement mechanism, and a maintained cable is convenient to clamp and fix through a spiral screw rod principle; the marking mechanism is arranged at the top end of the placement mechanism, and the maintained part is conveniently marked through a simple spring reset device and simple operation of a user, so that convenience is brought to reinforcement and maintenance of maintenance personnel in the future; and the butt joint mechanisms are arranged at the two ends of each guide rail plate, and the multiple guide rail plates can be freely connected through corresponding clamping connection, and therefore, the length of the device base can be freely increased, and maintenance andconnection of distribution lines with different fracture intervals can be conveniently achieved.

Owner:山东邦巨实业有限公司

Efficient polishing device for optical element production

InactiveCN110026852ARealize automatic adjustmentConvenience to workOptical surface grinding machinesEngineeringMechanical engineering

The invention discloses an efficient polishing device for optical element production. The efficient polishing device for optical element production comprises an installation plate, a position adjustment mechanism, a rotation mechanism, a clamping mechanism and a polishing mechanism, wherein the position adjustment mechanism comprises a first sliding mechanism and a second sliding mechanism which are orthogonal in sliding direction, the first sliding mechanism is used for controlling the rotation mechanism and the clamping mechanism to perform front-back movement so as to move close to or far away from the polishing mechanism, the second sliding mechanism is used for controlling the rotation mechanism and the clamping mechanism to perform left-right movement, and the rotation mechanism drives an optical element in the clamping mechanism to automatically turn over. By adopting the above structure, the efficient polishing device for optical element production completes two-side rough polishing and fine polishing on the same device for the optical element after achieving one-time clamping of the optical element, improves work efficiency, and reduces cost.

Owner:江西亦成光电科技有限公司

Double-station clamp for engine support bracket

InactiveCN108705341AShorten clamping positioning timeReachable detachable installationPositioning apparatusMetal-working holdersEngineeringFlat panel

The invention discloses a double-station clamp for an engine support bracket. The double-station clamp comprises base support legs, wherein a limiting clamp groove is formed in each of a left supportrotating shaft and a right support rotating shaft; a clamping plate is arranged on the side, close to the interior, of each of the left support rotating shaft and the right support rotating shaft; a limiting clamp block is fixedly connected to the side, close to the outside, of each clamping plate; side hold-down mechanisms are fixedly connected to the top of an operation panel and located on twosides of the back side of a front limiting block; and a top end hold-down mechanism is fixedly connected to the position, close to the middle of the back side, of the top of the operation panel. The double-station clamp relates to the technical field of clamps; the clamp and the whole engine support bracket are detachably mounted; the clamping positioning time of the engine support bracket is shortened during processing; the processing and production efficiency is improved; double-station clamping and fixing of the engine support bracket are realized; the processing progress is improved; the distance between double stations is guaranteed; and the stations are prevented from influencing each other during processing.

Owner:安徽永泰汽车零部件有限公司

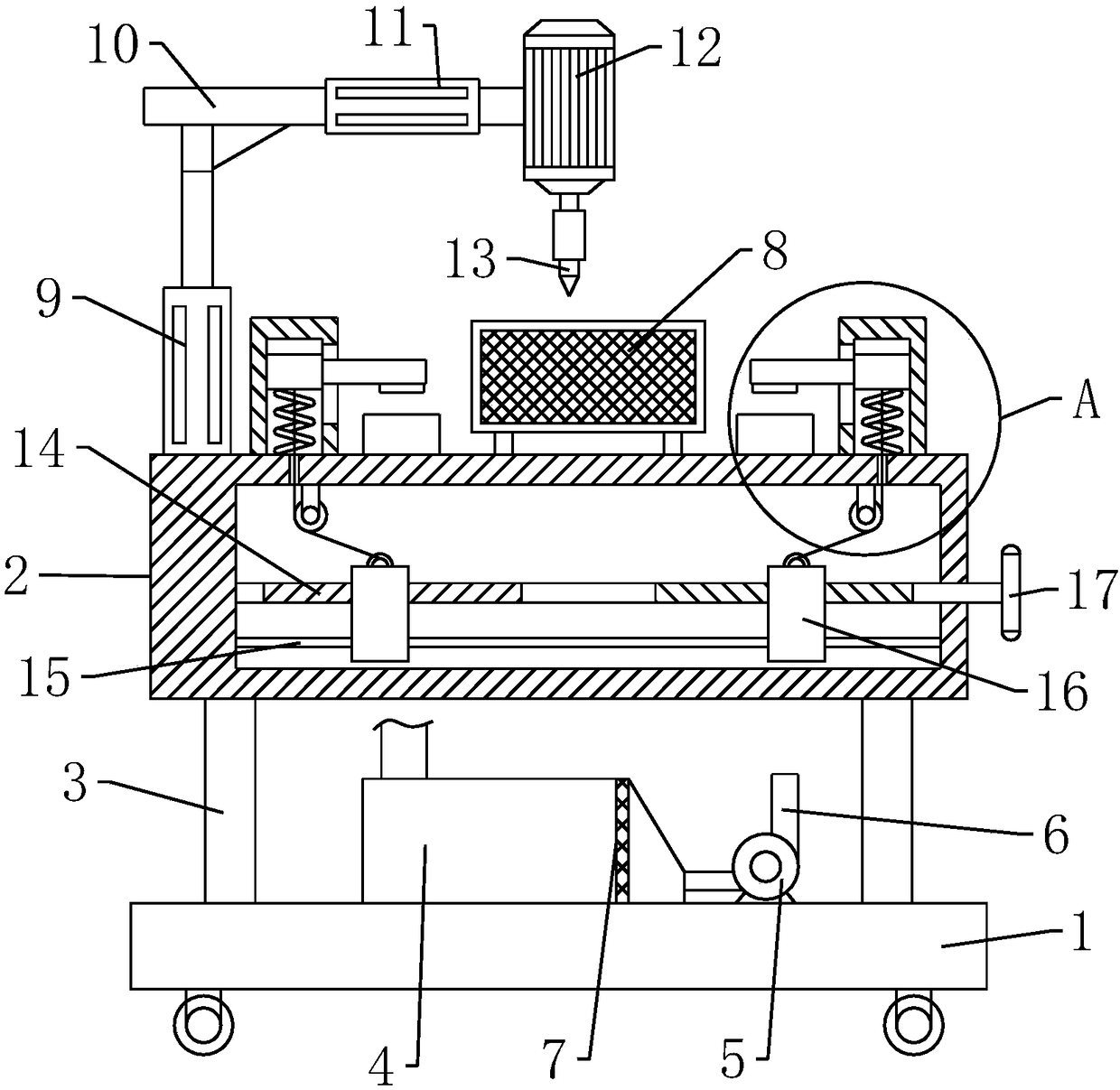

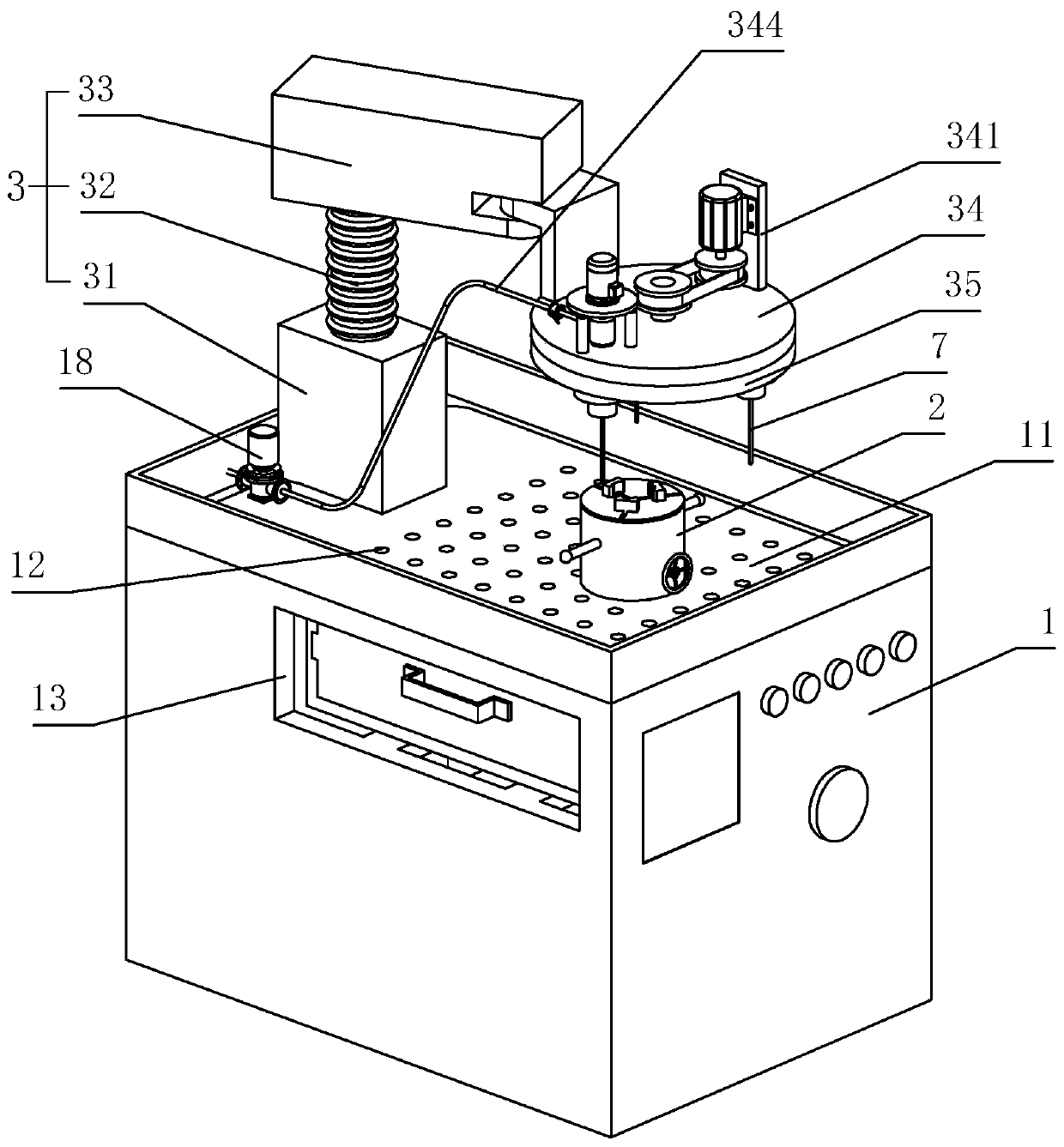

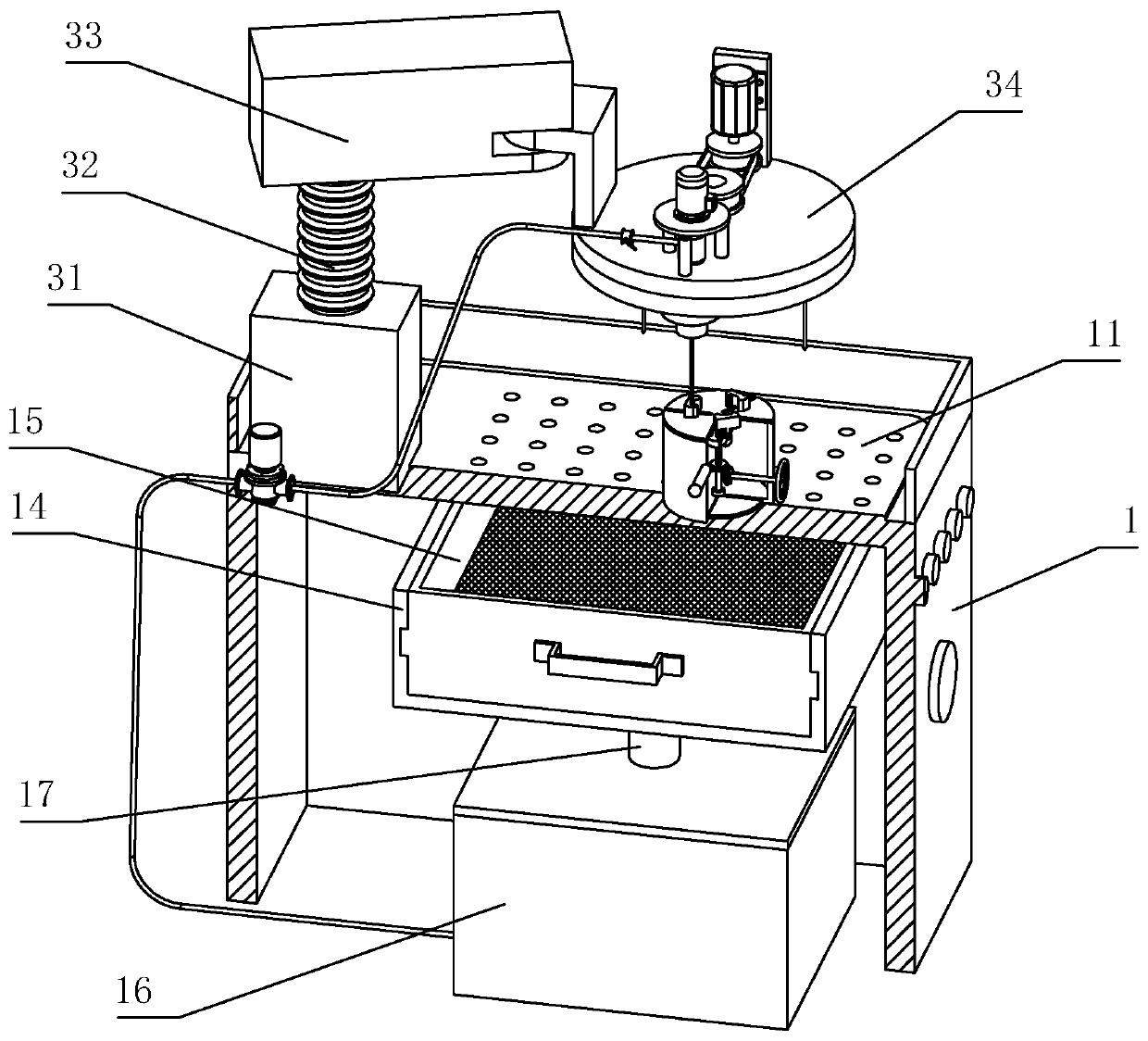

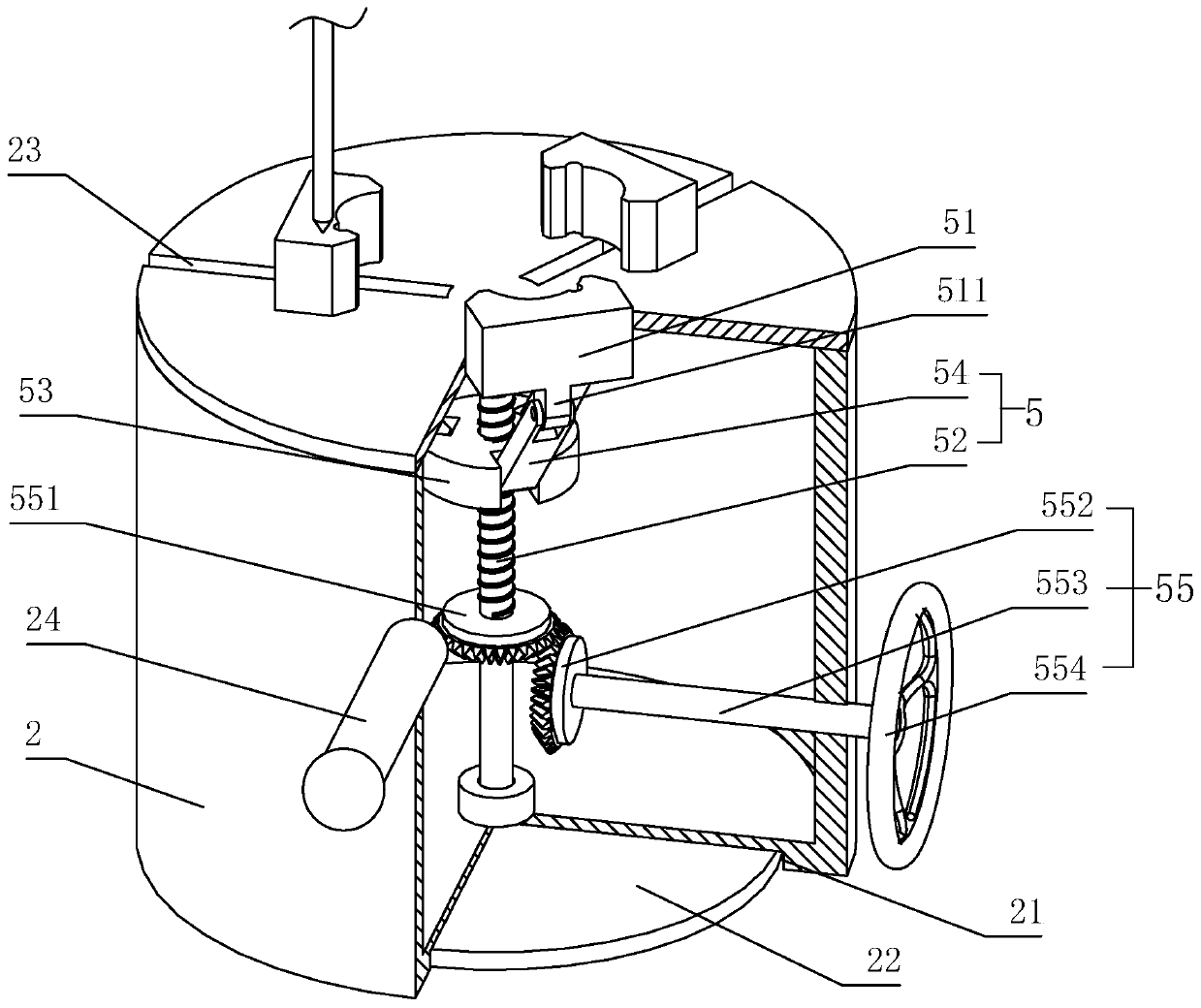

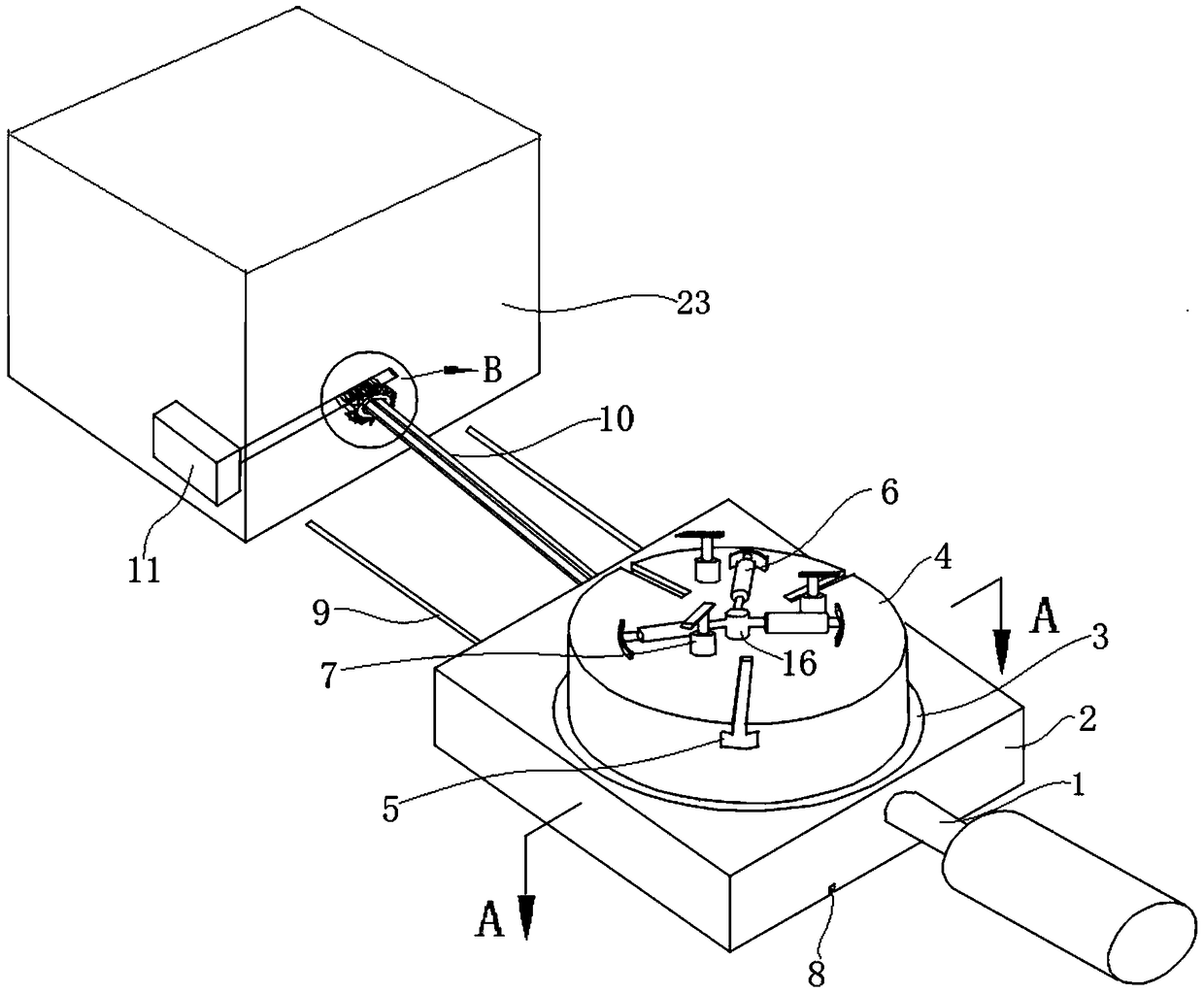

Drilling and milling machining system with drill bit self-cooling function

ActiveCN109128307AEnsure stabilityEasy dischargeTransportation and packagingLarge fixed membersEngineeringMachining system

The invention discloses a drilling and milling machining system with a drill bit self-cooling function, and belongs to the field of drilling and milling machining devices. The drilling and milling machining system comprises rotary pressing mechanisms, a worktable mechanism, a drilling and milling mechanism and chip removal mechanisms mounted on the two sides of the worktable mechanism correspondingly. The worktable mechanism comprises a rotary table, a plurality of telescopic cylinders are mounted on the upper top face of the rotary table, and the central axes of output shafts of the telescopic cylinders penetrate through the circle center of the upper top face of the rotary table. Arc plates are mounted at the ends of the output shafts of the telescopic cylinders. The drilling and millingmechanism comprises a base which is mounted above a transmission box. A rack is arranged on the base and provided with a milling and drilling machine. The milling and drilling machine comprises a self-cooling drill bit. The multiple rotary pressing mechanisms are mounted on the upper top face of the rotary table and comprise outer cylinder bodies, bearing seats and pressing plates. The drilling and milling machining system has the high integration level.

Owner:东台升华工具有限公司

Tool fixture convenient to adjust for welding of circuit board

InactiveCN108513453AAvoid leaningReduce forcePrinted circuit assemblingSoldering auxillary devicesComputer engineeringWelding

The invention discloses a tool fixture convenient to adjust for welding of a circuit board. The tool fixture comprises a base, wherein a sliding groove is formed in a right side of an upper surface ofthe base, a sliding block is clamped to the sliding groove and is adaptive to the sliding groove, a first through hole is formed in a middle part of an inner side wall of the sliding groove and is arranged in a right side of the sliding groove, a bearing is fixedly embedded to a middle part of the inner side wall of the sliding groove and is arranged at a left side of the sliding groove, a firstnut is fixedly embedded to a lower part of a right side surface of the sliding block and is arranged in the sliding groove, a screw rod is arranged at a right side of the base and is adaptive to the first nut, and a left side surface of the screw rod sequentially penetrates through the first through hole and the first nut and extends to the sliding block. In the tool fixture convenient to adjust for welding of the circuit board, the screw rod is arranged, rotation of the screw can be converted to adjustment of distance between two studs under effects of the first nut and the sliding block, sothat the circuit board with different lengths can be clamped and fixed, and the purpose of reducing production cost is achieved.

Owner:芜湖致新信息科技有限公司

Clamp for printing metal products

InactiveCN110153762ASolve the problem of simple structure and poor protection effectAchieve clamping and fixingRotary pressesPositioning apparatusEngineeringMetal

The invention discloses a clamp for printing metal products, and relates to the field of machinery. The clamp for printing metal products aims at solving the problems that an existing fixing device for printing is simple in structure and poor in protection effect. According to the technical scheme, the clamp for printing metal products is characterized by comprising a workbench, a controller and aservo motor are fixedly arranged on the inner wall of the workbench, a first rotating shaft and a third rotating shaft are symmetrically and rotationally mounted on the left side and the right side of the inner wall of the workbench through bearings respectively, a second rotating shaft is fixedly connected to a power output shaft of the servo motor, the front end of the first rotating shaft, thefront end of the second rotating shaft and the front end of the third rotating shaft penetrate through the workbench and extend to the outside of the front side of the workbench, a rotating disc is fixedly arranged at the outer end of the first rotating shaft in a sleeving mode, the outer end of the second rotating shaft is fixedly sleeved with a complete gear, and the outer end of the third rotating shaft is fixedly sleeved with an incomplete gear. The clamp is simple and convenient to operate, good in fixing effect, wide in application range, good in protection effect and suitable for popularization and application.

Owner:丁宏建

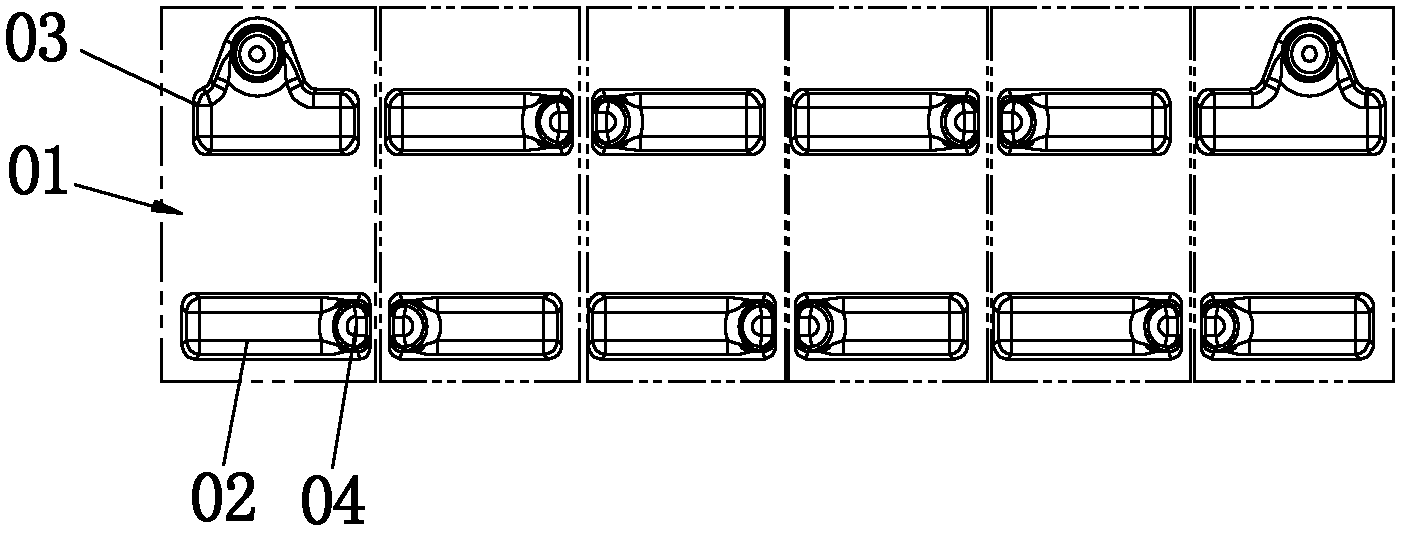

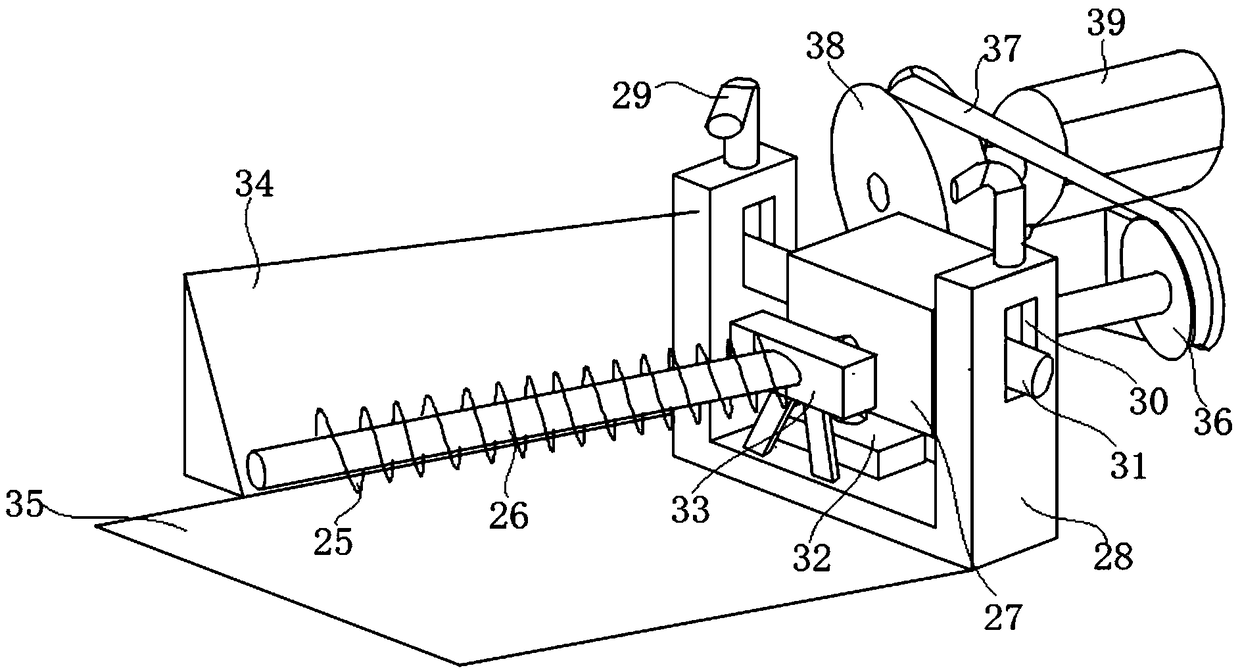

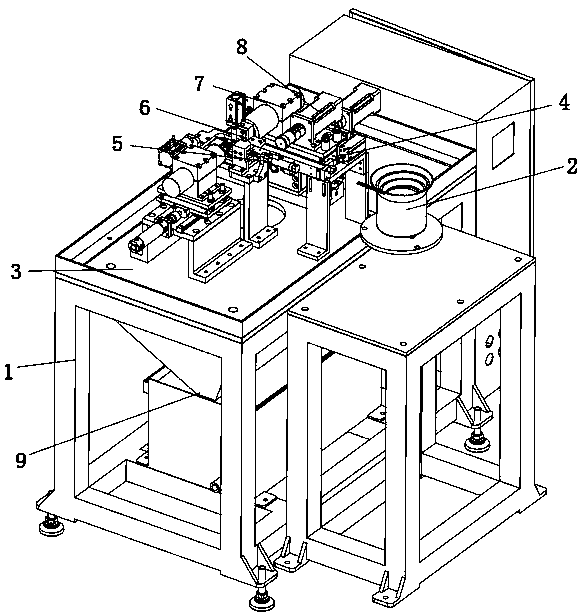

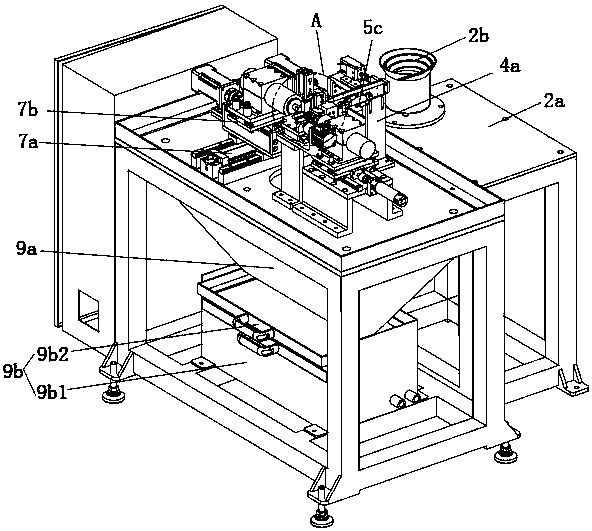

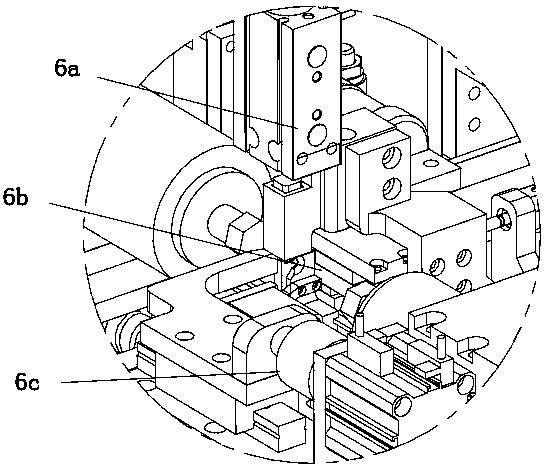

Automatic tapping machine for T-shaped nut

InactiveCN108044359AAchieve clamping and fixingSimple structureOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining process

The invention relates to the field of part machining, in particular to an automatic tapping machine for a T-shaped nut. The automatic tapping machine comprises a supporting frame; a feeding device isarranged beside the supporting frame; a bottom plate which is fixedly connected with the supporting frame and is horizontally arranged is arranged at the top part of the supporting frame, and the toppart of the bottom plate is provided with a transferring device, a conveying device, a positioning device, a drilling device, a tapping device and a discharging device which are sequentially arrangedalong the workpiece machining process; the feeding device comprises a bearing frame and a material vibrating plate which are arranged beside the supporting frame, and the output end of the material vibrating plate is provided with a conveying channel; and the transferring device comprises a first installing frame and a first driving air cylinder, wherein a fixed block is arranged on the side wallof the first driving air cylinder, a guide plate is arranged at the output end of the first driving air cylinder, a movable block is arranged on the guide plate in a sliding mode, and a guide plate which is horizontally arranged is arranged at the front end of the movable block. The automatic tapping machine has the advantages that structure is simple, the automation degree is high, labor and production cost are reduced, and the production efficiency is improved.

Owner:毛慧杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com