Drilling and milling machining system with drill bit self-cooling function

A processing system and self-cooling technology, which is applied in metal processing equipment, drilling/drilling equipment, boring machine/drilling machine components, etc., can solve the problems of low integration and achieve improved chip removal speed, high integration, and guaranteed The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

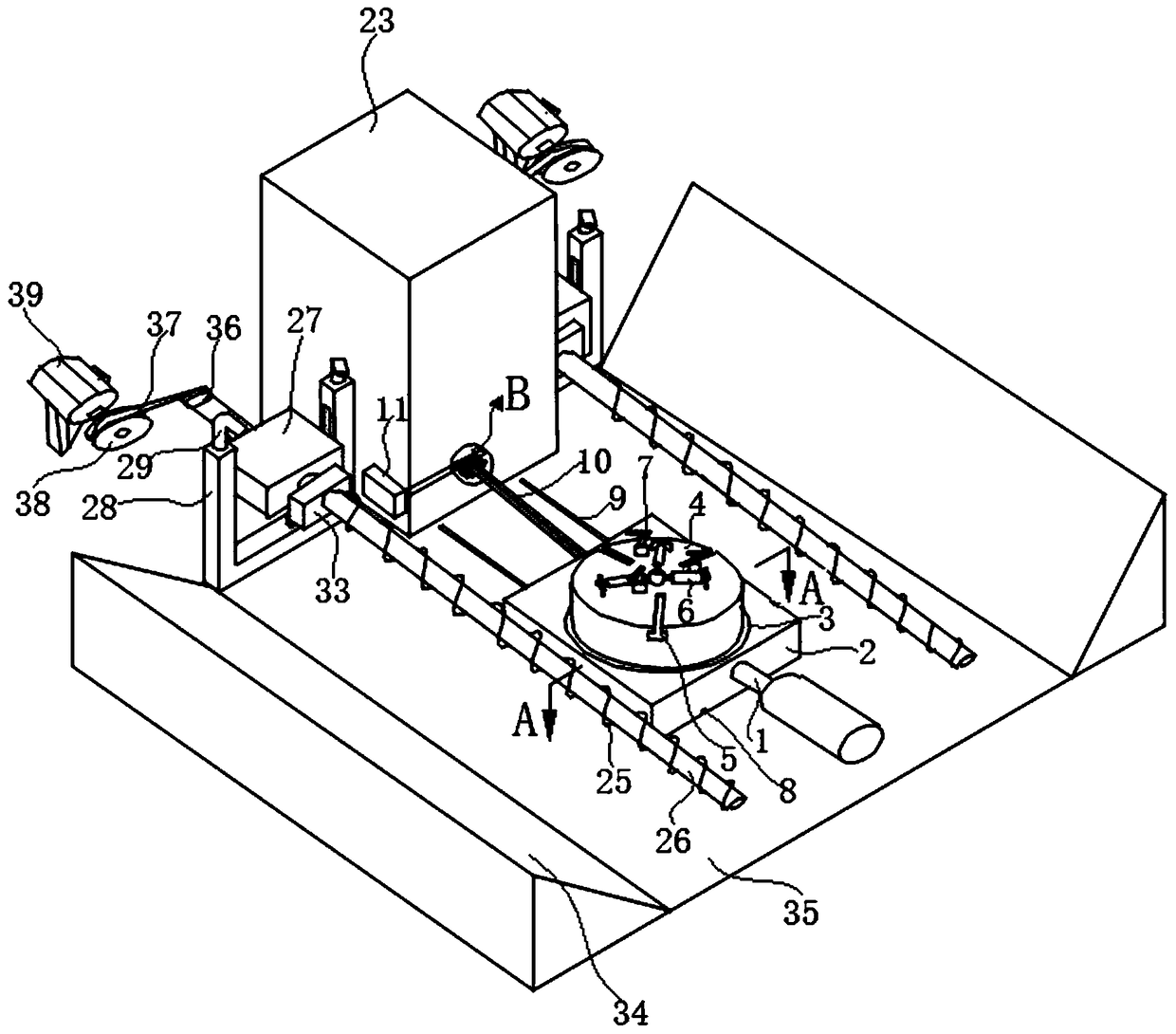

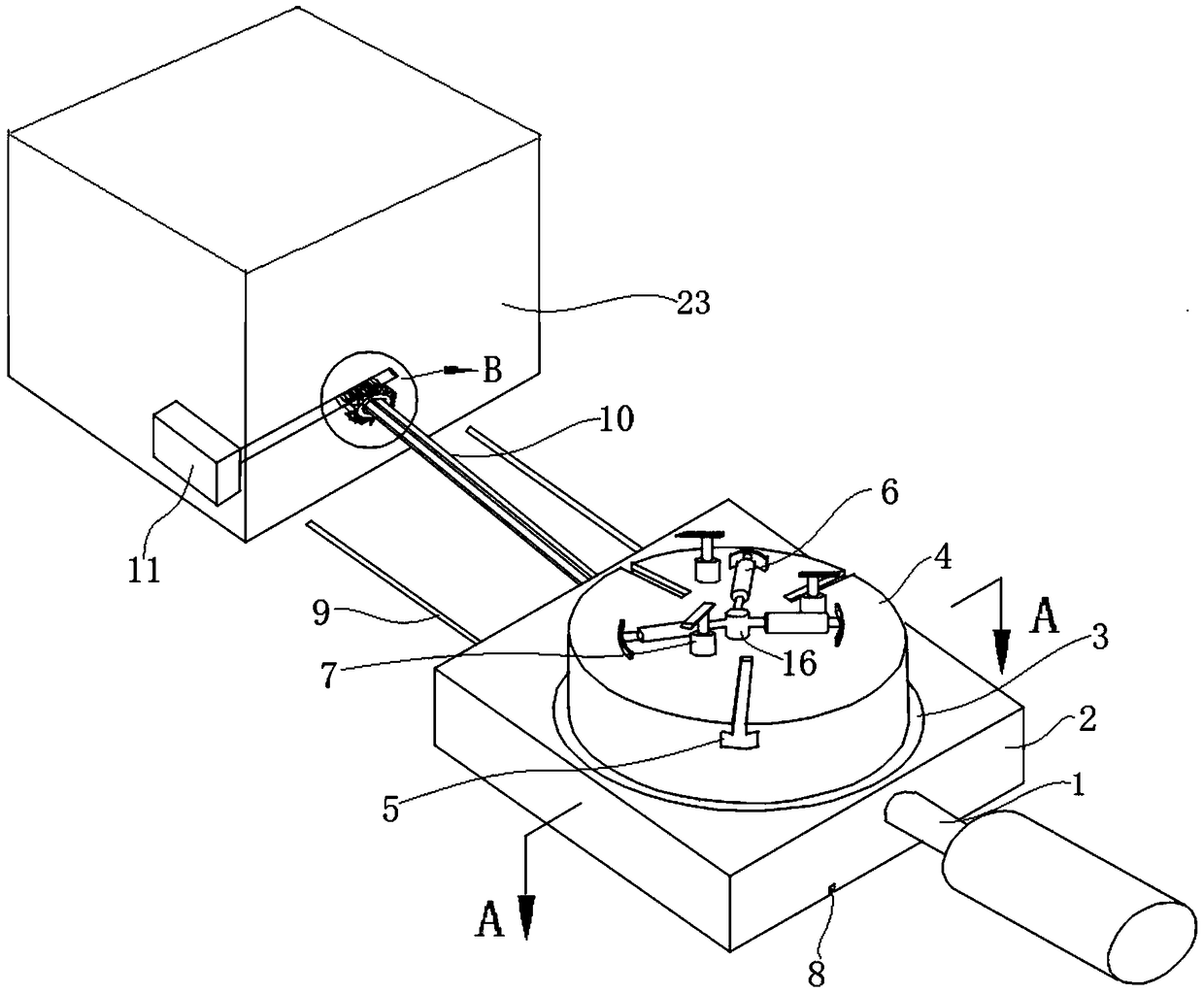

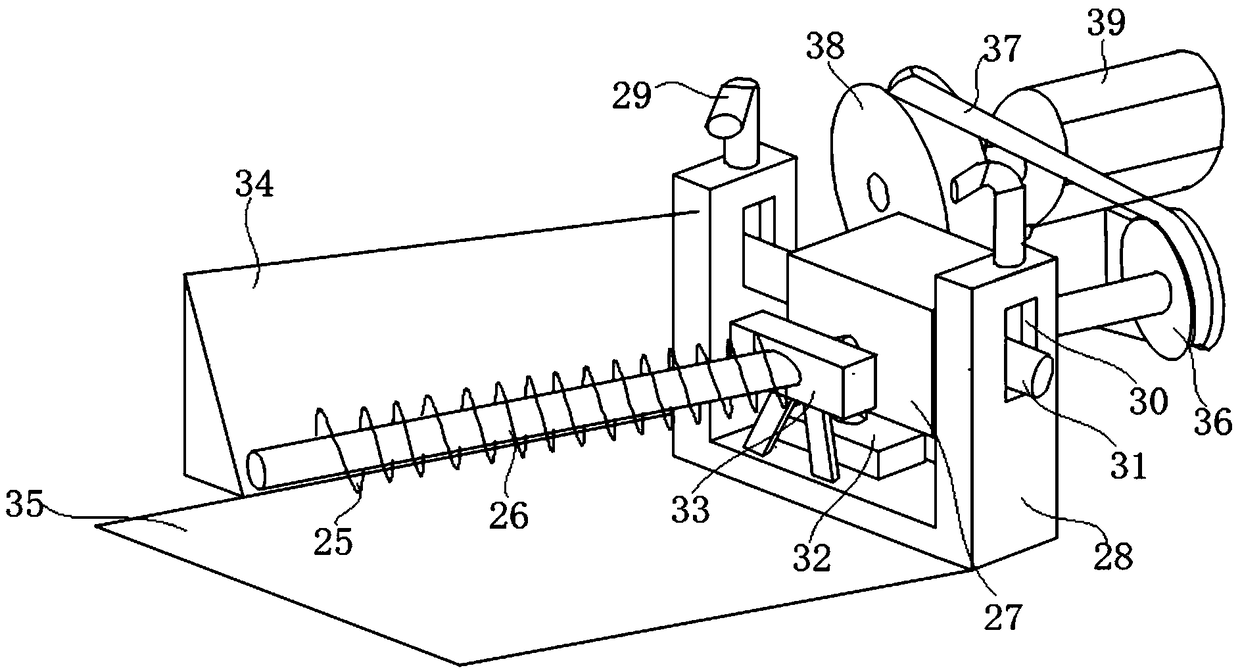

[0065] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 8 as well as Figure 9-13 , the drilling and milling processing system of this embodiment includes: a rotary pressing mechanism 7, a table mechanism, a drilling and milling mechanism, and chip removal mechanisms installed on both sides of the table mechanism, wherein the table mechanism includes: a rotary table 4, a working table Table base 2 and transmission box 23; rotary table 4, rotary table 4 is a cylindrical structure, three telescopic cylinders 6 are installed on the upper surface of rotary table 4, and the central axis of the output shaft of telescopic cylinder 6 passes through the top of rotary table 4 The center of circle of the surface; the end of the output shaft of the telescopic cylinder 6 is equipped with an arc plate 601, and the outer surface of the arc plate 601 is an arc surface; the workbench base 2, the upper surface of the workbench base 2 is provided with a...

Embodiment 2

[0075] refer to figure 1 , figure 2 , Image 6 with Figure 7 , the drilling and milling processing system of this embodiment, its structure is basically the same as that of Embodiment 1, further: the upper top surface of the turntable 4 is provided with three chute 5, and the chute 5 is along the radial direction of the upper top surface of the turntable 4 distribution, and the cross section of the chute 5 is an inverted "T" shape, the chute 5 is provided with a sliding piece 18 that can slide in the length direction of the chute 5, the upper end of the sliding piece 18 is equipped with a bearing slider 17, and the bearing slider The side of the block 17 facing the center of the top surface of the rotary platform 4 is a storage step 22, which is stepped and the side of the storage step 22 facing the center of the top surface of the rotary platform 4 is an arc surface; A spiral water pipe groove 4305 is opened on the circumferential surface at the bottom of the spiral chip...

Embodiment 3

[0079] refer to Figure 7 , the drilling and milling processing system of this embodiment, its structure is basically the same as that of Embodiment 2, and further: the side of the bearing slider 17 away from the center of the top surface of the rotary table 4 is a back plate 24, and an arc-shaped baffle plate 20 passes through The first spring 21 is connected on the back plate 24, and the side of the arc-shaped baffle plate 20 facing the center of the top surface of the turntable 4 is an arc surface; the opening at the top of the spiral water pipe groove 4305 is sealed by a sealing strip 4306 made of rubber material .

[0080] In this embodiment, the arc-shaped baffle 20 is connected to the back plate 24 through the first spring 21, and the arc-shaped surface of the side of the arc-shaped baffle 20 facing the center of the top surface of the rotary table 4 is in contact with the rotary support surface to be processed. Fitting, when the slewing bearing to be processed is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com