Patents

Literature

70results about How to "Easy drilling operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine-line PCB manufacturing method

InactiveCN104185377AAvoid side erosionReduce the binding forceConductive material chemical/electrolytical removalEtchingMetallurgy

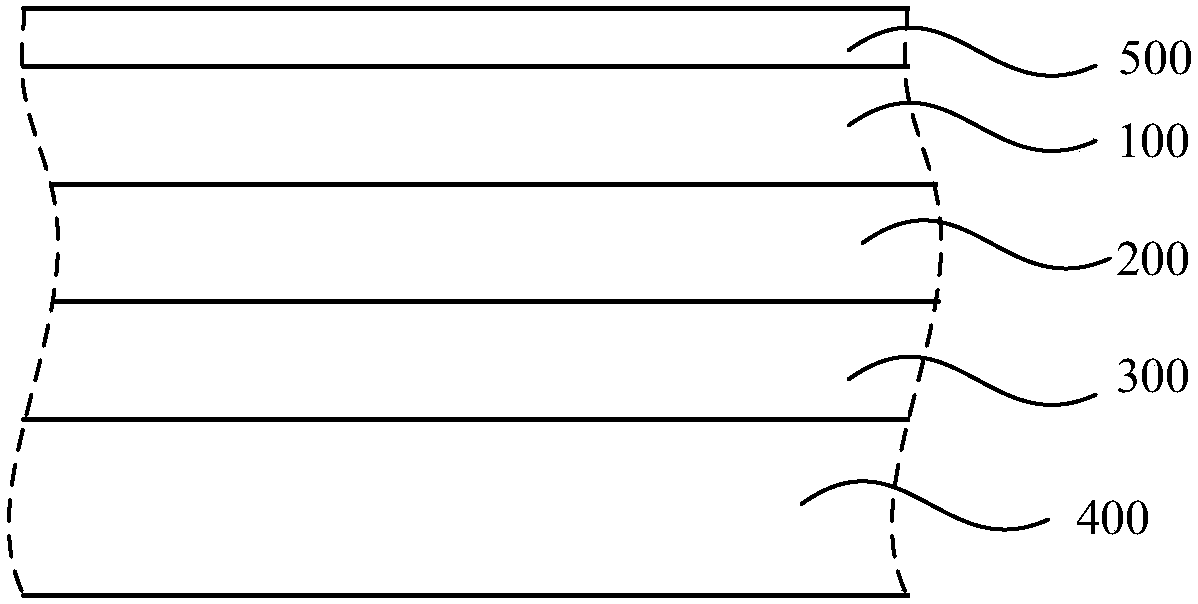

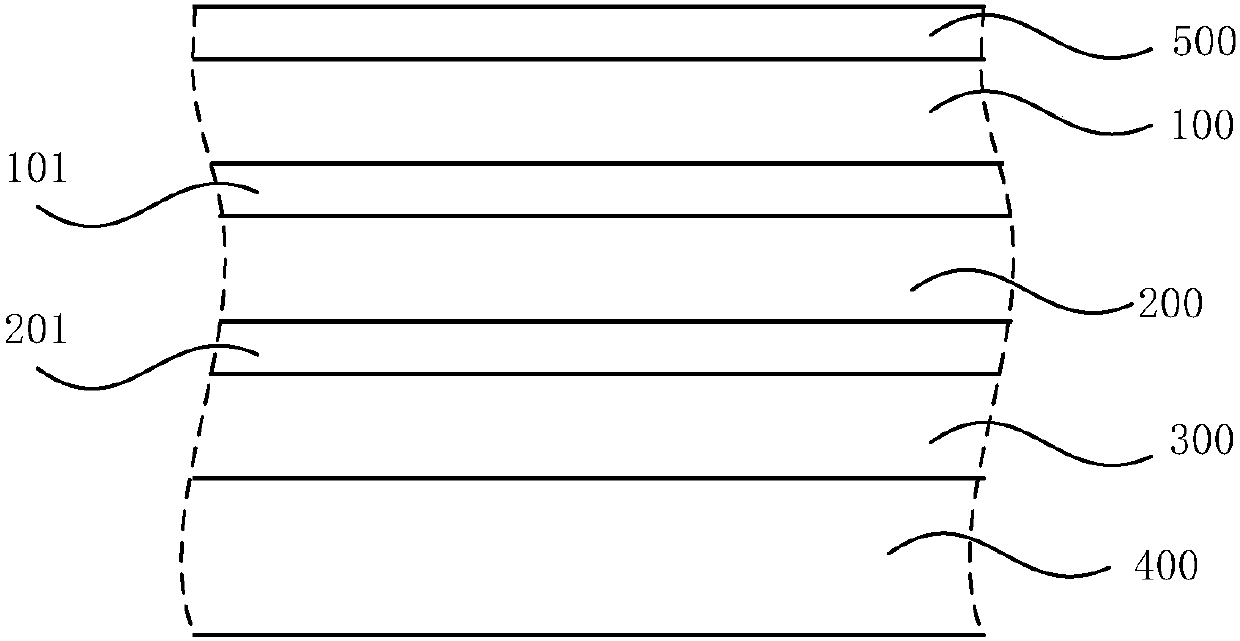

The invention relates to the technical field of PCB manufacturing, in particular to a fine-line PCB manufacturing method. The fine-line PCB manufacturing method sequentially comprises a press-fit step, a drilling step, a copper foil removal step, a copper deposition step, a step of transferring an outer layer image, a pattern plating step, a micro-etching step and a common back-end work procedure. Outer layer copper foil arranged on a multi-layer board in a press-fit mode is removed, copper deposition is carried out on a prepreg layer, pattern manufacturing and pattern plating are directly carried out on a copper deposition layer, and press-fit of a copper foil layer is omitted, so that a base copper layer is thin, a micro-etching mode is adopted in the outer layer etching process, and therefore the phenomenon of serious lateral erosion of the two sides of a line is avoided. The lateral erosion quantity of the two sides of the line is less than 1 micrometer and is reduced by ten times or more compared with that of the existing manufacturing process, and the manufacturing quality of a fine-line PCB is guaranteed. The smooth surface of the copper foil and the prepreg are bonded together in a press-fit mode, the binding force between the copper foil and the prepreg is reduced, the copper foil and the prepreg are poorly bonded, as a result, the hole collapse problem can be avoided in the drilling process, and the copper foil can be torn off after the drilling step.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

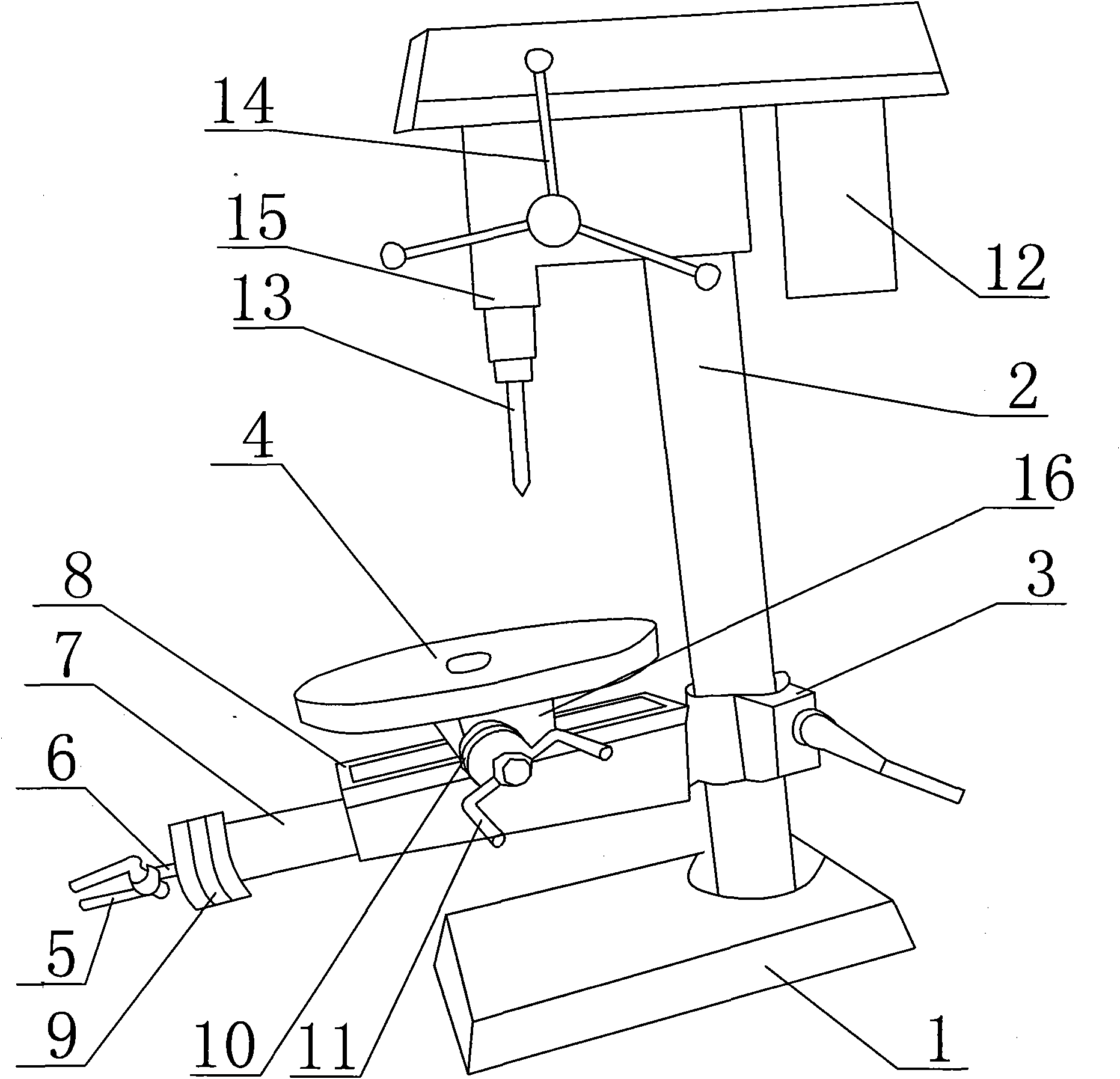

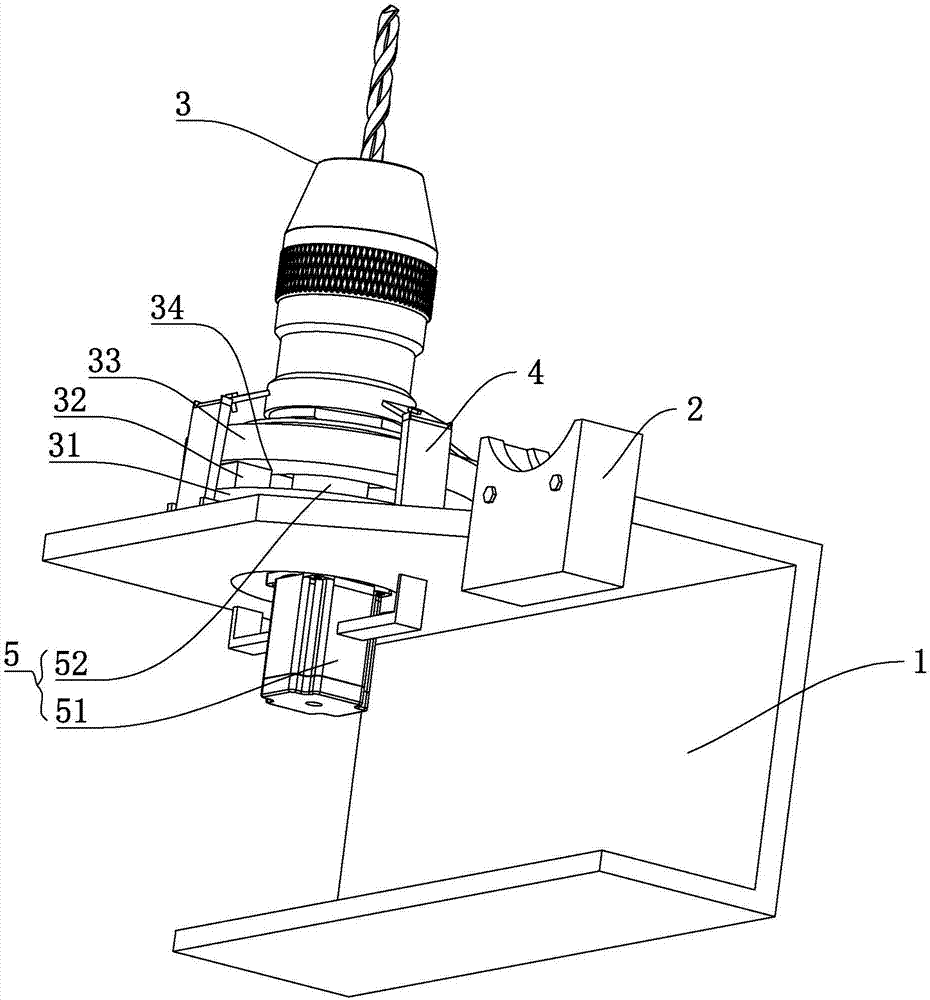

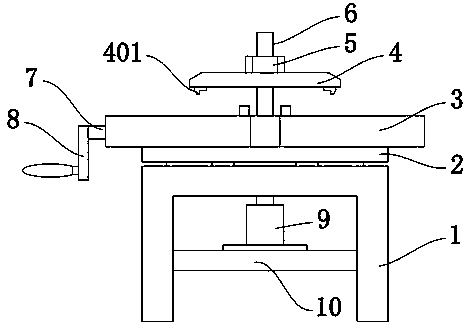

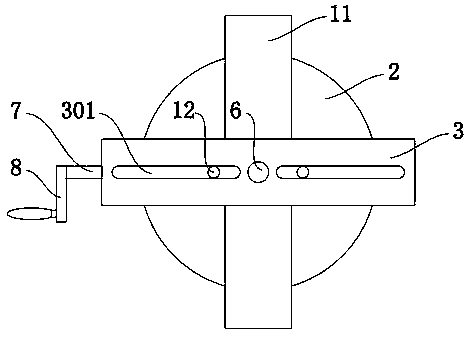

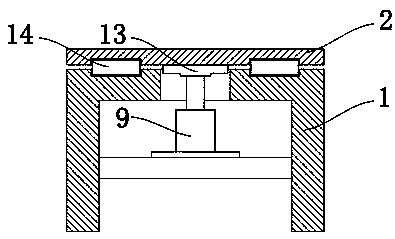

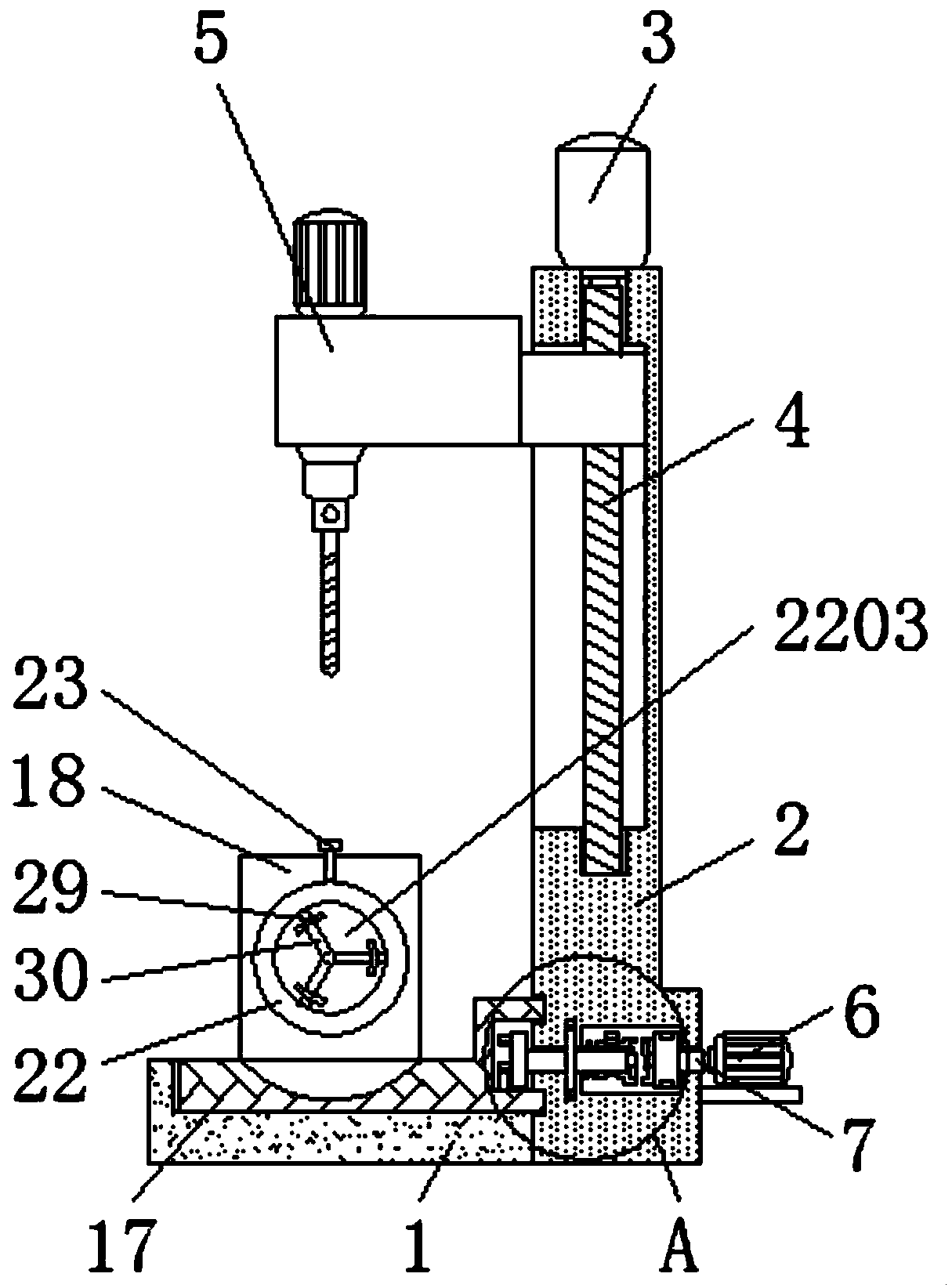

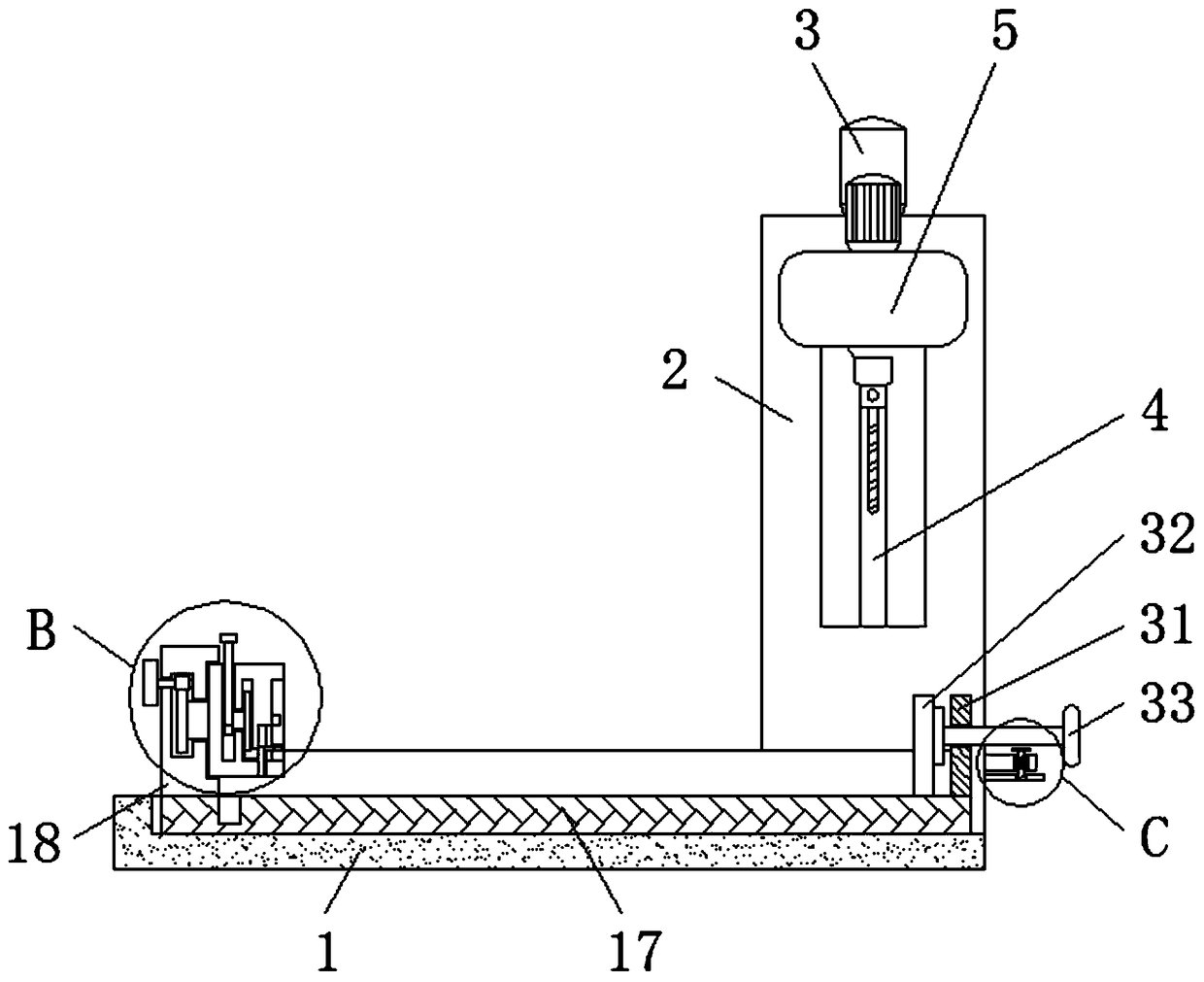

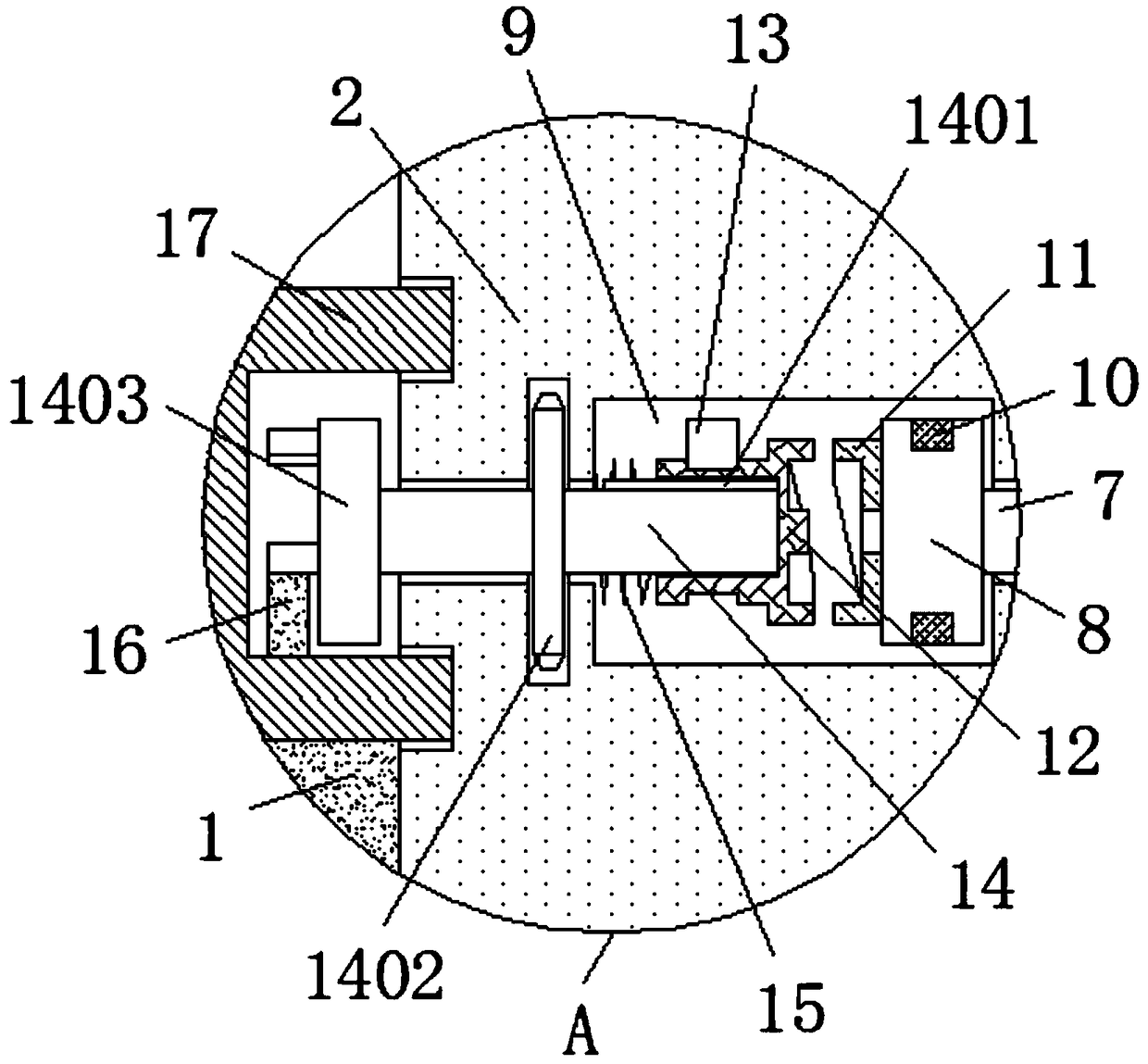

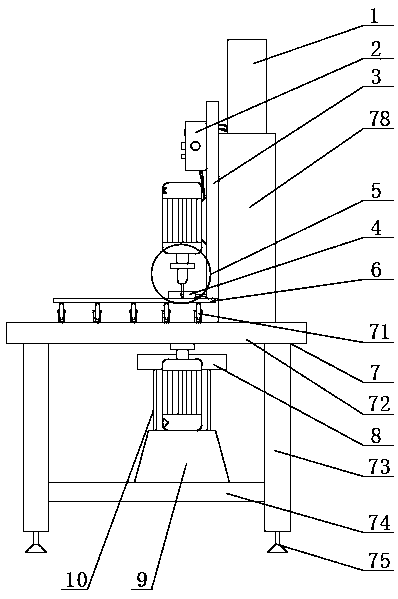

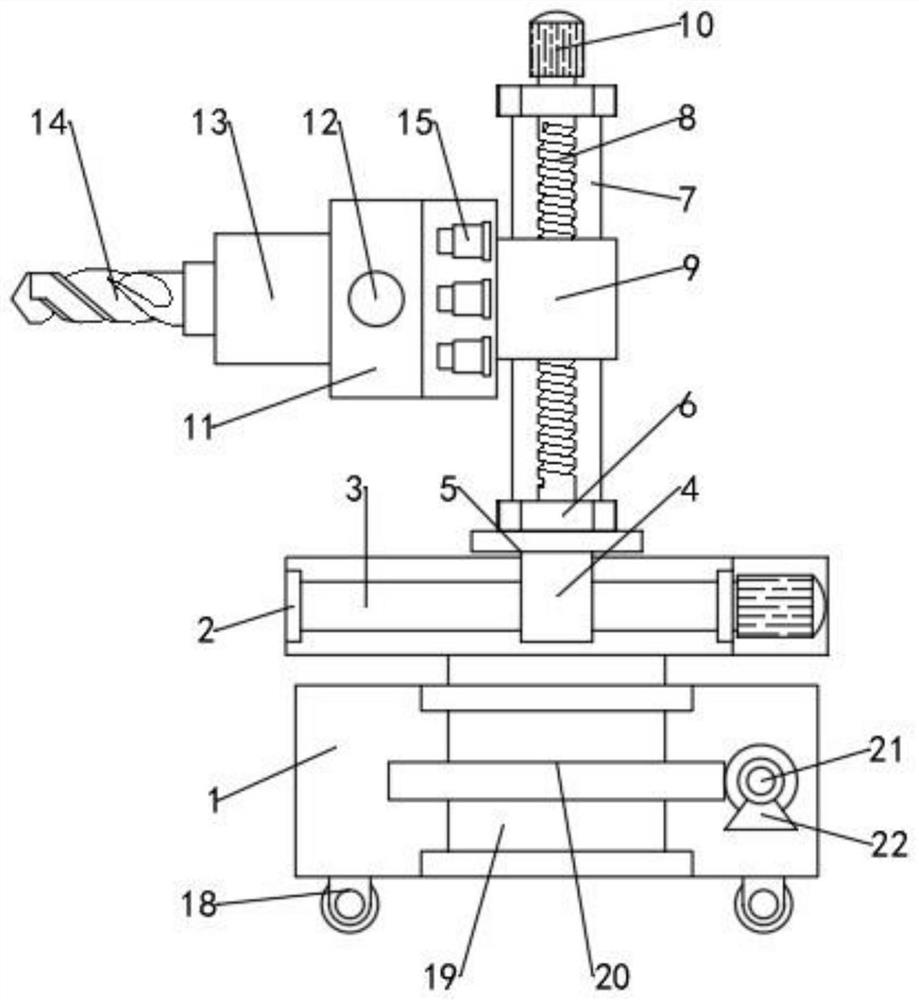

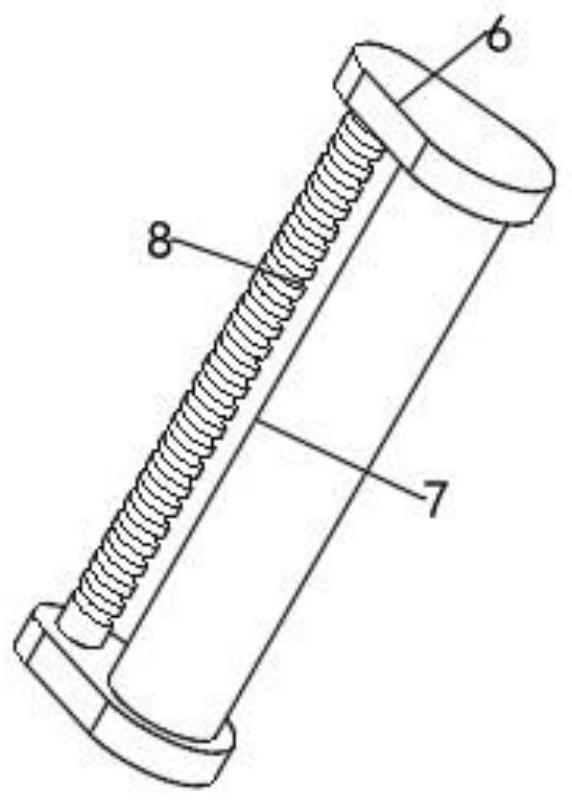

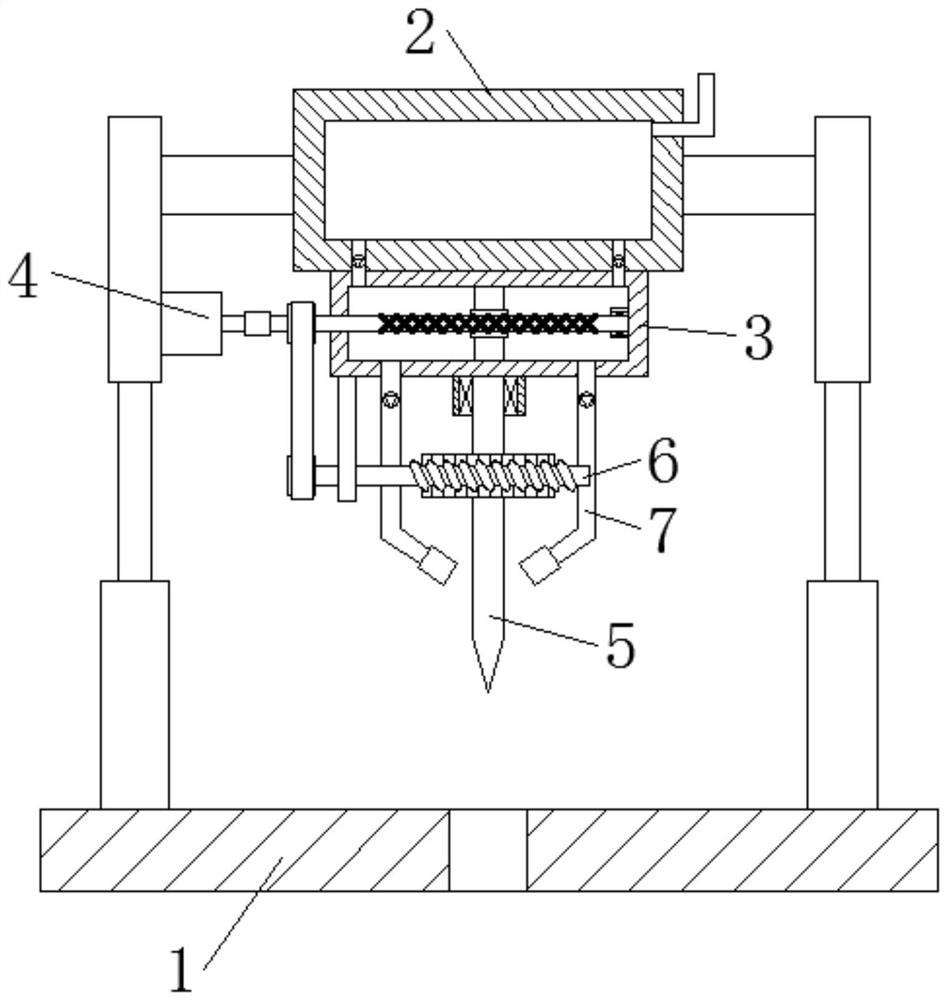

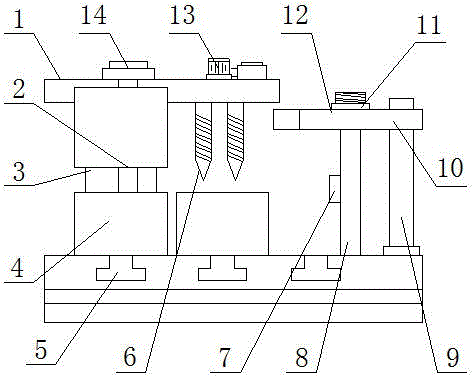

Multifunctional bench drill

InactiveCN101890518AEasy drilling operationSimple structureLarge fixed membersBoring/drilling componentsReciprocating motionEngineering

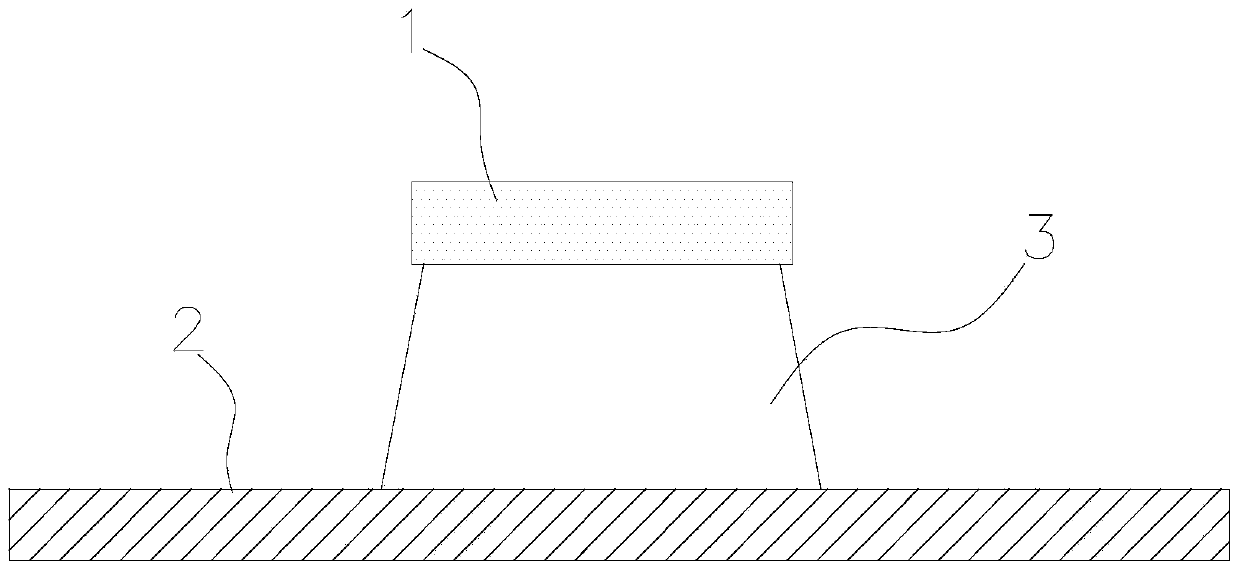

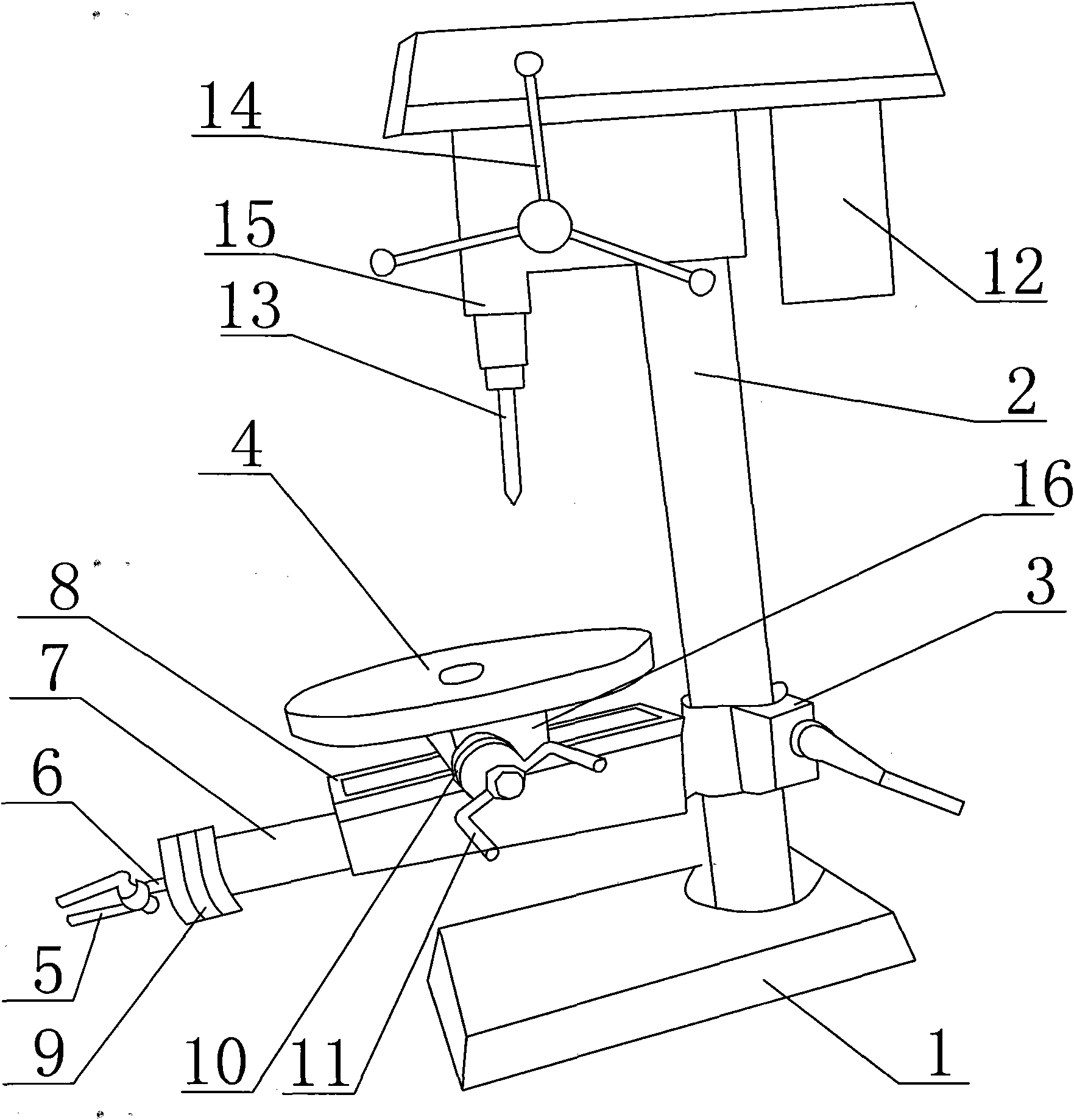

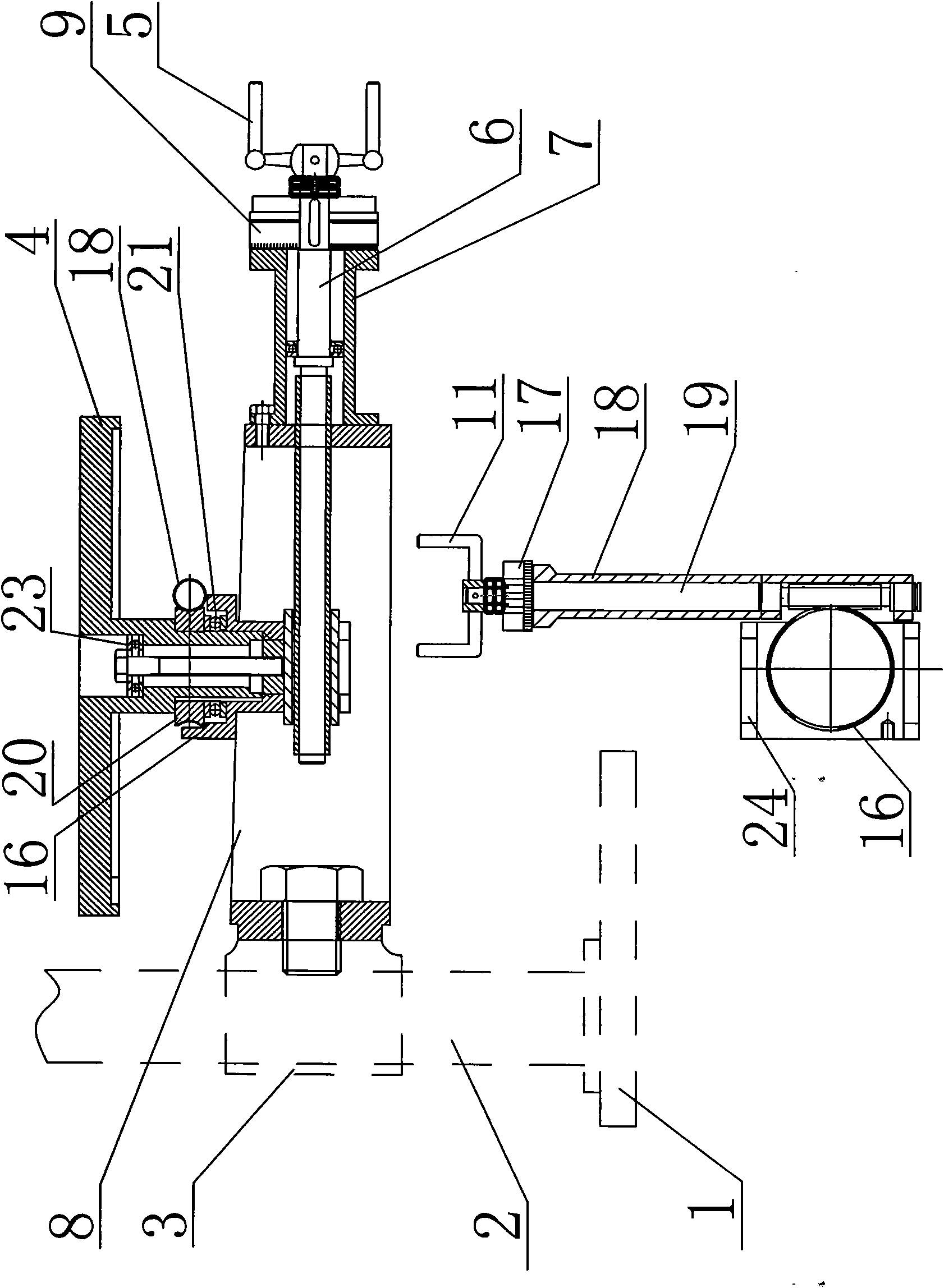

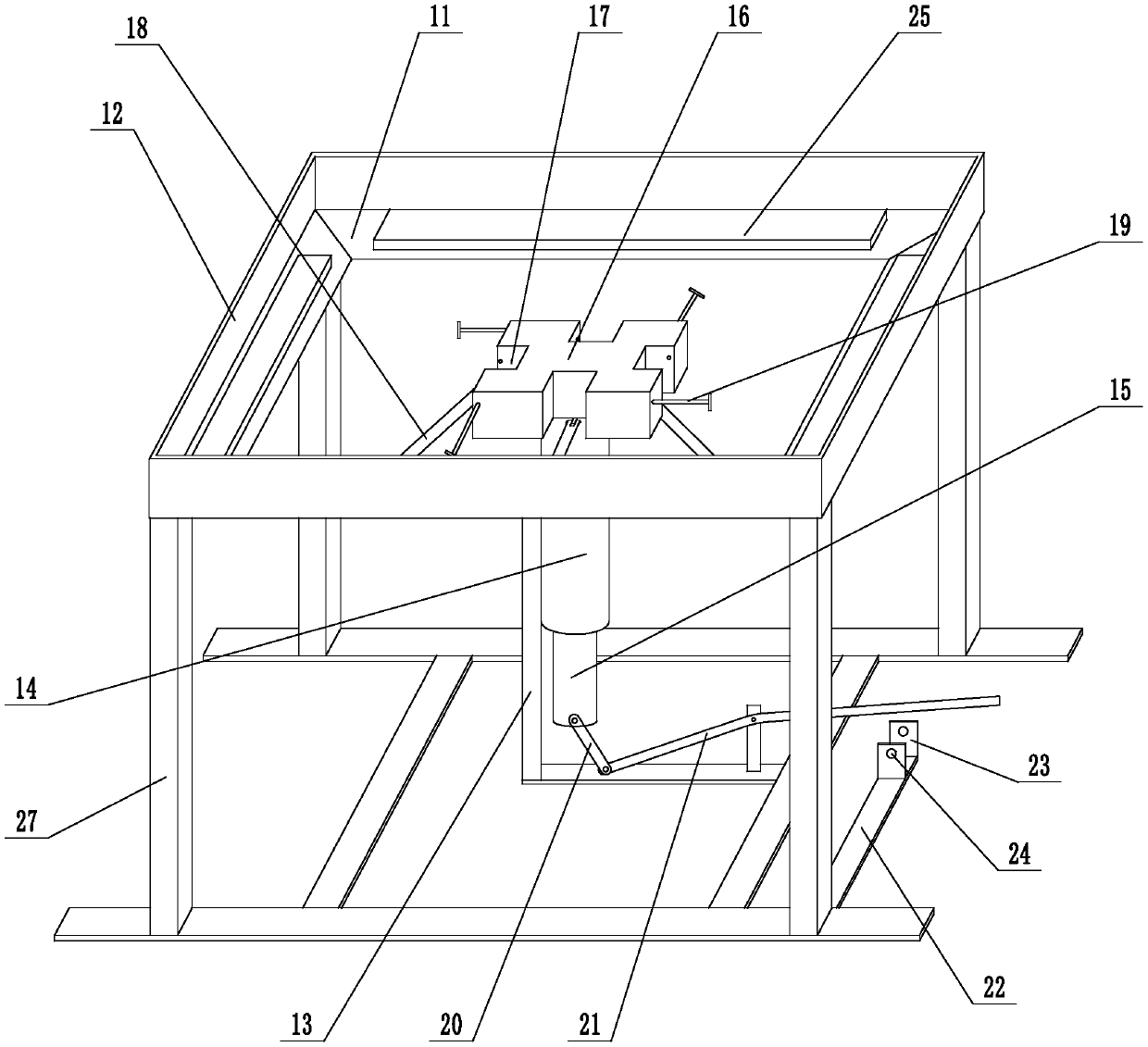

The invention discloses a multifunctional bench drill. The multifunctional bench drill comprises a pedestal, an upright post and a workbench, wherein a clamping sleeve capable of sliding along the upright post up and down is arranged on the upright post; a dovetail frame is arranged on the clamping sleeve; a step shaft sleeve is arranged on the dovetail frame; the top end of the step shaft sleeve is clamped on the dovetail frame and is relatively fixed on the dovetail frame through a pressing plate and a screw; the workbench is clamped in the step shaft sleeve; a horizontal through hole is reserved at the place close to the bottom end of the step shaft sleeve; a sleeve is fixedly connected in the horizontal through hole; internal threads are arranged in the sleeve; the other end of the dovetail frame is connected with a connecting sleeve; a lead screw is arranged at one end of the connecting sleeve; a large dial and a large handle are arranged on one end head of the lead screw; the other end of the lead screw sequentially passes through the connecting sleeve and the side wall of the dovetail frame and is then connected in the sleeve of the step shaft sleeve; and the threads on the lead screw are matched with the internal threads in the sleeve. Compared with the prior art, the multifunctional bench drill of the invention can realize the reciprocating motion of the workbench in the horizontal direction.

Owner:李积荣

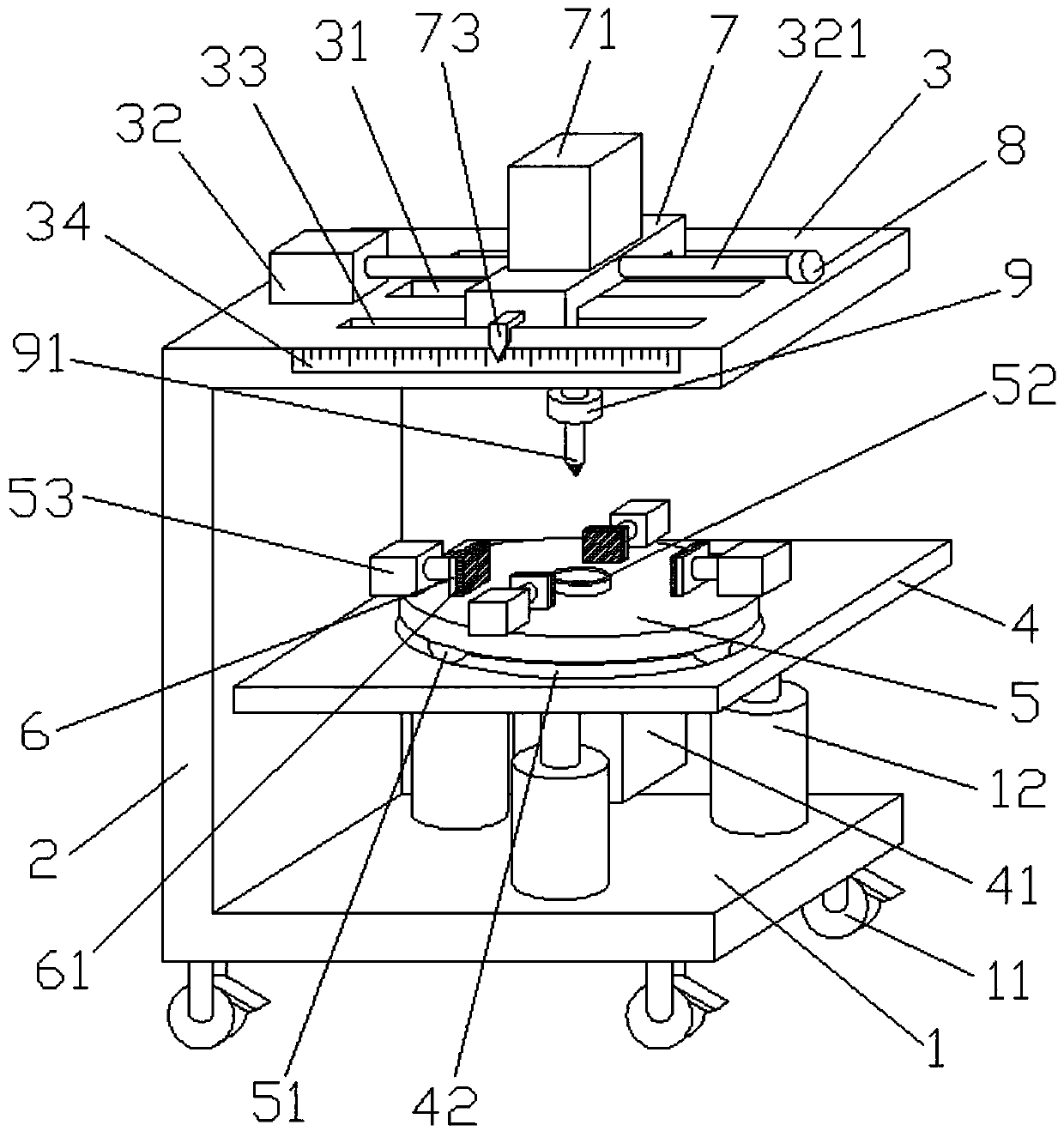

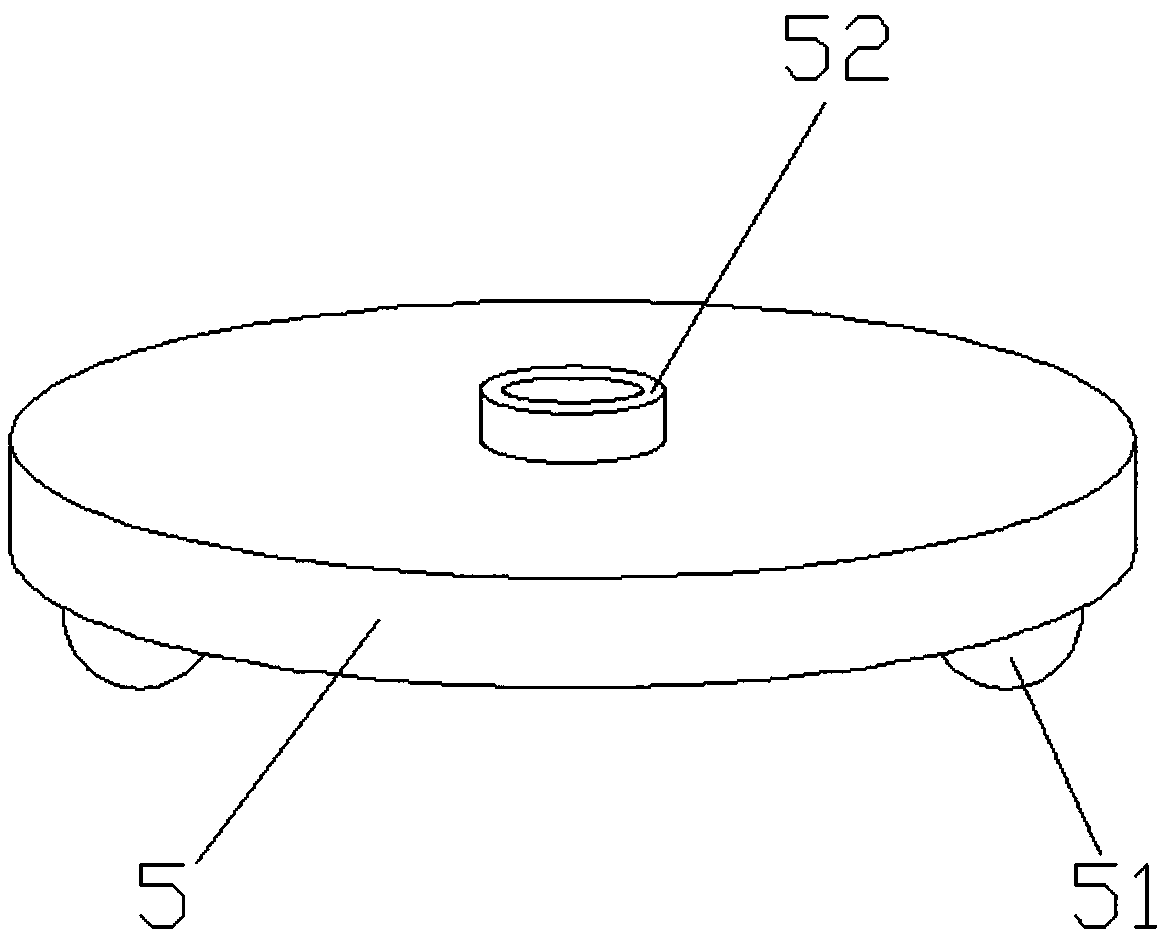

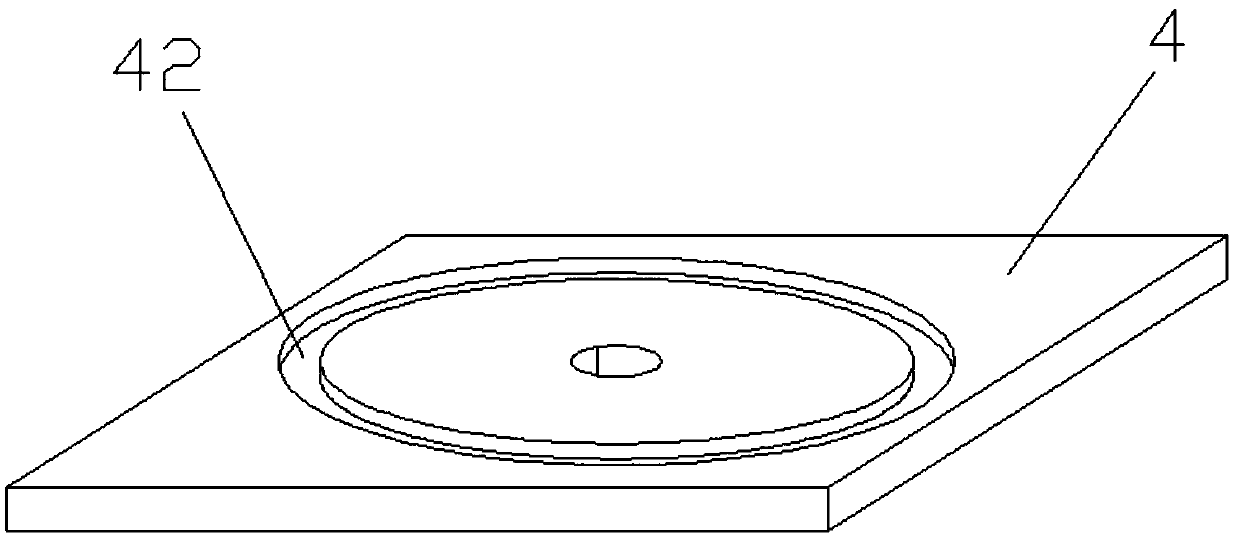

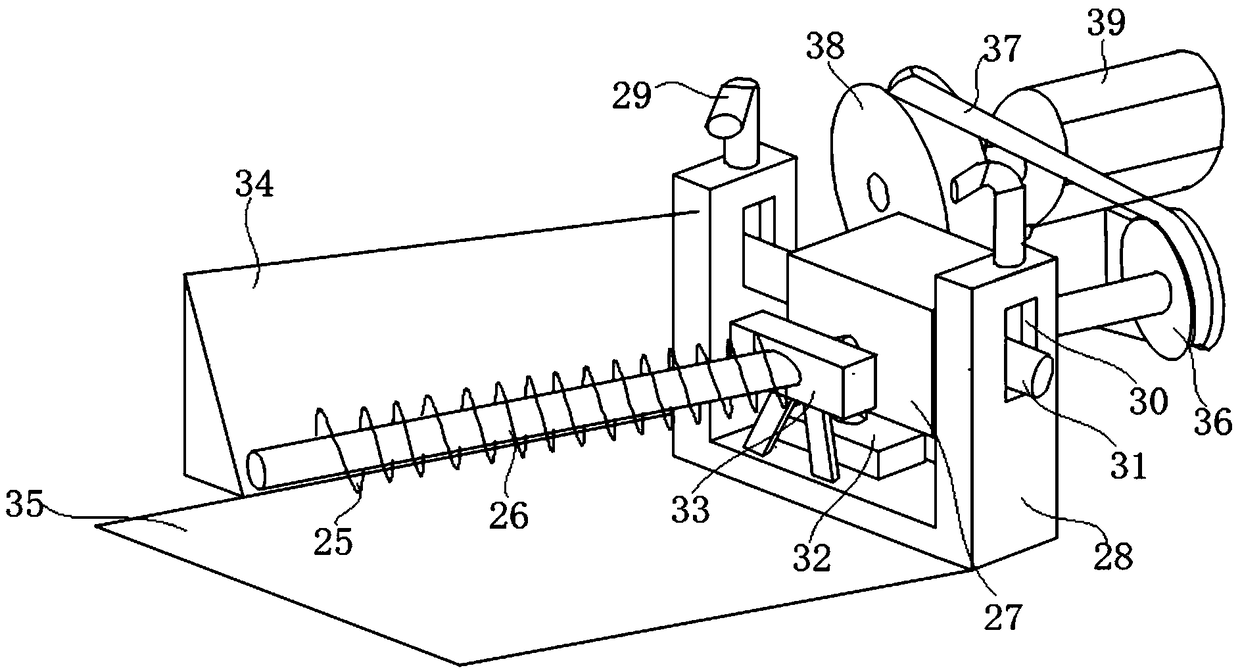

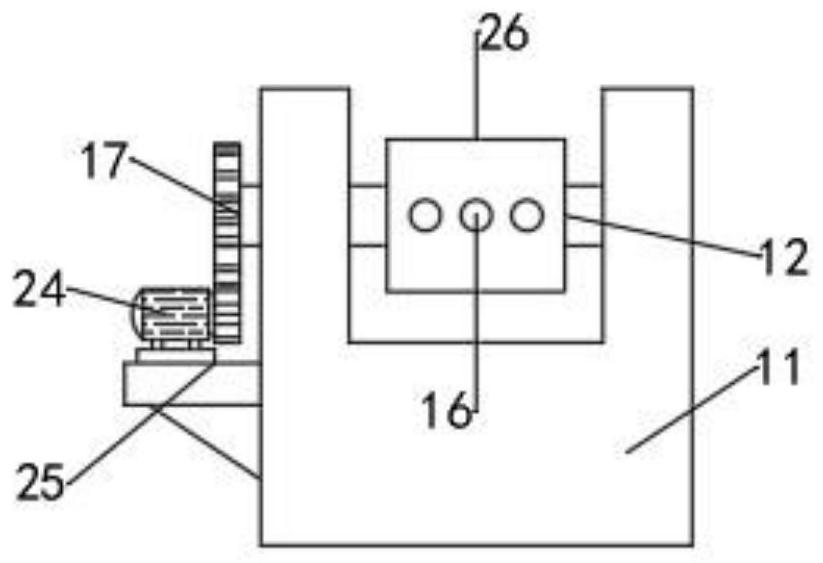

Drilling device for automobile engine hood

PendingCN109570559AHigh precisionReliable positioning and clampingWork clamping meansLarge fixed membersInstalled basePiston rod

The invention discloses a drilling device for an automobile engine hood. The drilling device comprises a bottom plate, a vertical plate and a top plate; a lifting air cylinder is installed at the topend of the bottom plate, a piston rod of the lifting air cylinder is connected with the lifting plate, the bottom end of the lifting plate is provided with a first motor, the rotating shaft of the first motor penetrates through the lifting plate to be connected with the rotating plate, balls are installed at the bottom end of the rotating plate, the balls are located in an annular groove formed inthe top end of the lifting plate, and a boss and positioning air cylinders are arranged at the top end of the rotating plate; and a sliding hole is formed in the middle of the top plate, a screw rodmotor is arranged at the top end of the top plate, a screw rod of the screw rod motor is provided with a sliding block, a second motor is arranged on the sliding block, a through hole is formed in thetop end of the sliding block, a rotating shaft of the second motor penetrates through the through hole and the sliding hole to be connected with a drill bit installing base, and a drill bit is installed on the drill bit installing base. The drilling device solves the problems that an existing drilling device is not fastened and a plurality of holes are not drilled conveniently; and the drilling device has the advantages of being capable of clamping and fastening, facilitating drilling of a plurality of holes and the like.

Owner:芜湖名阳机械制造有限公司

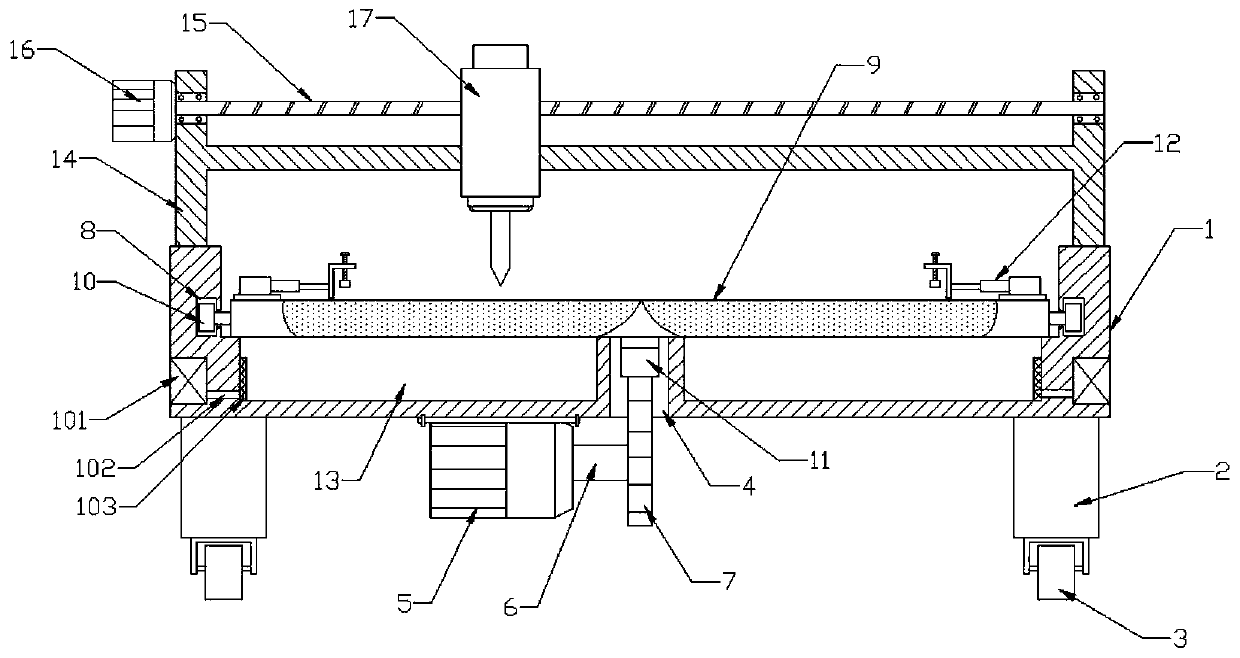

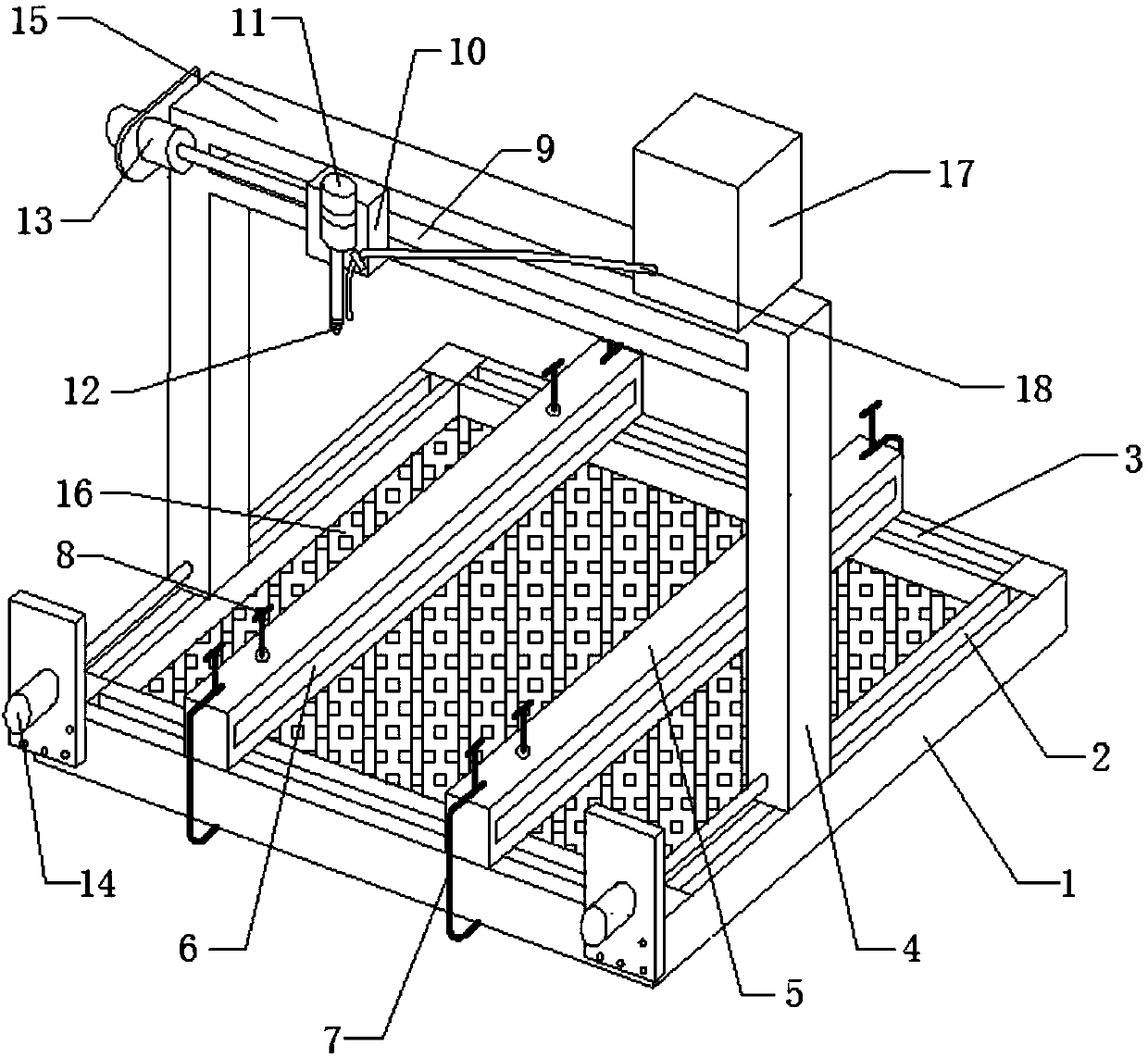

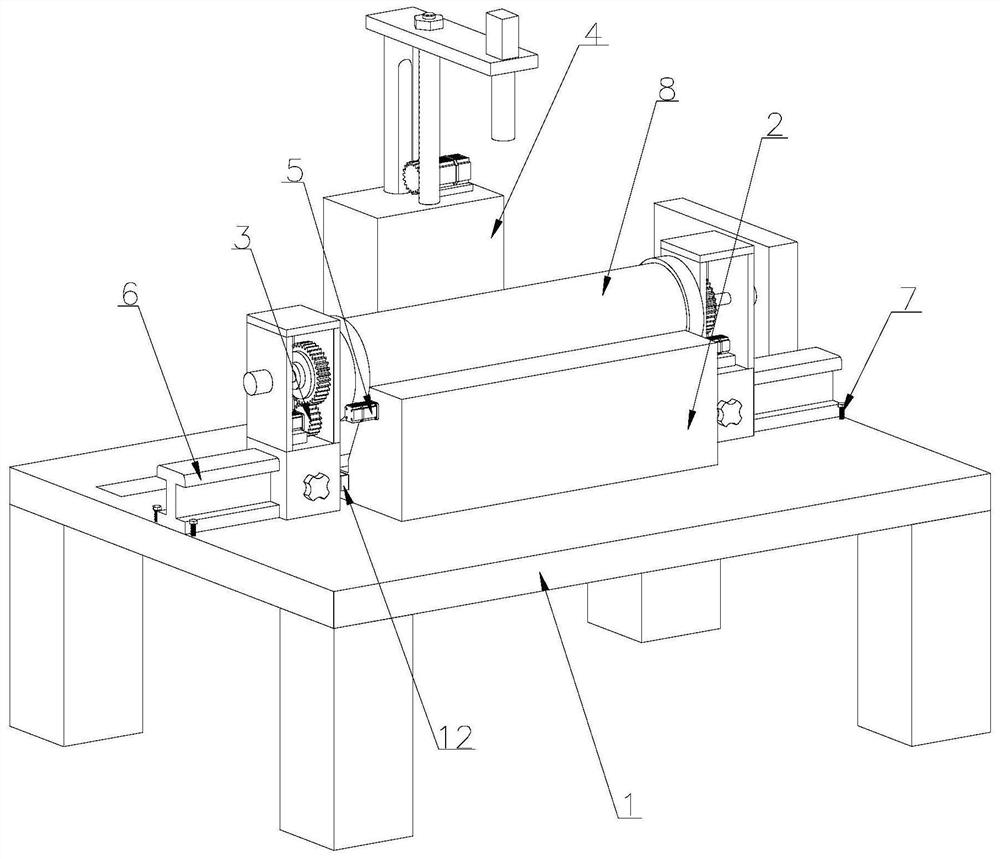

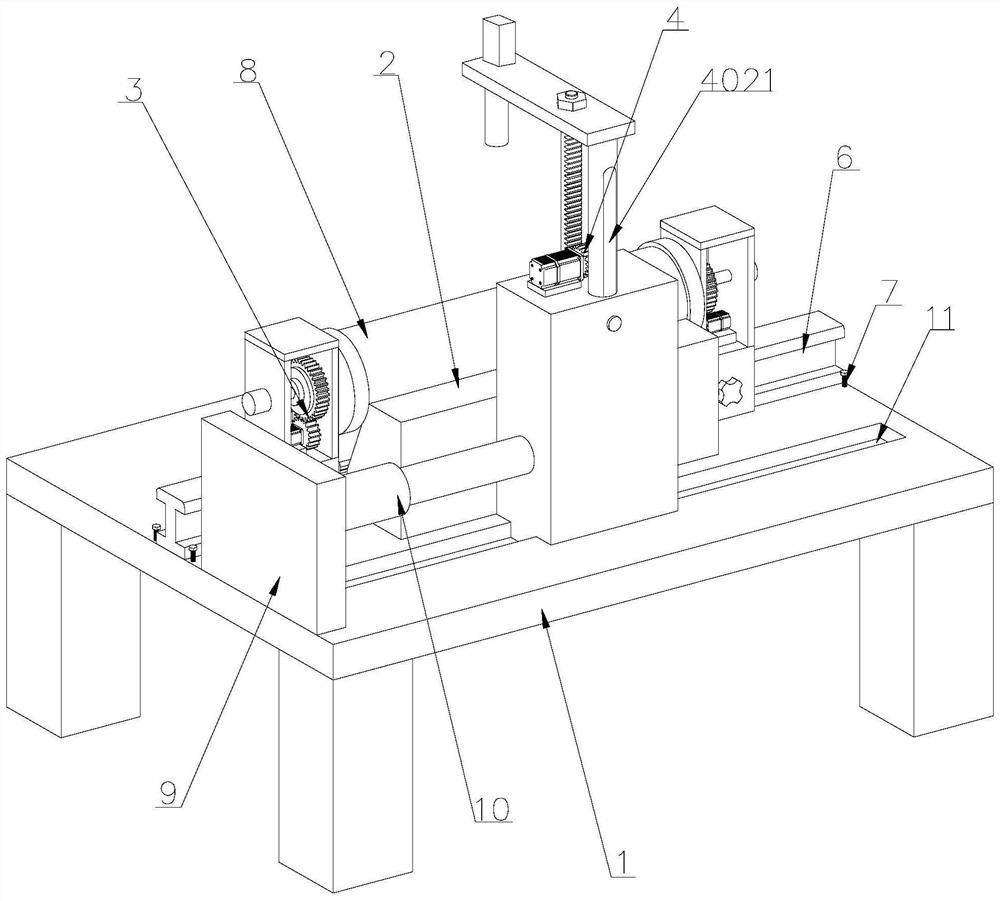

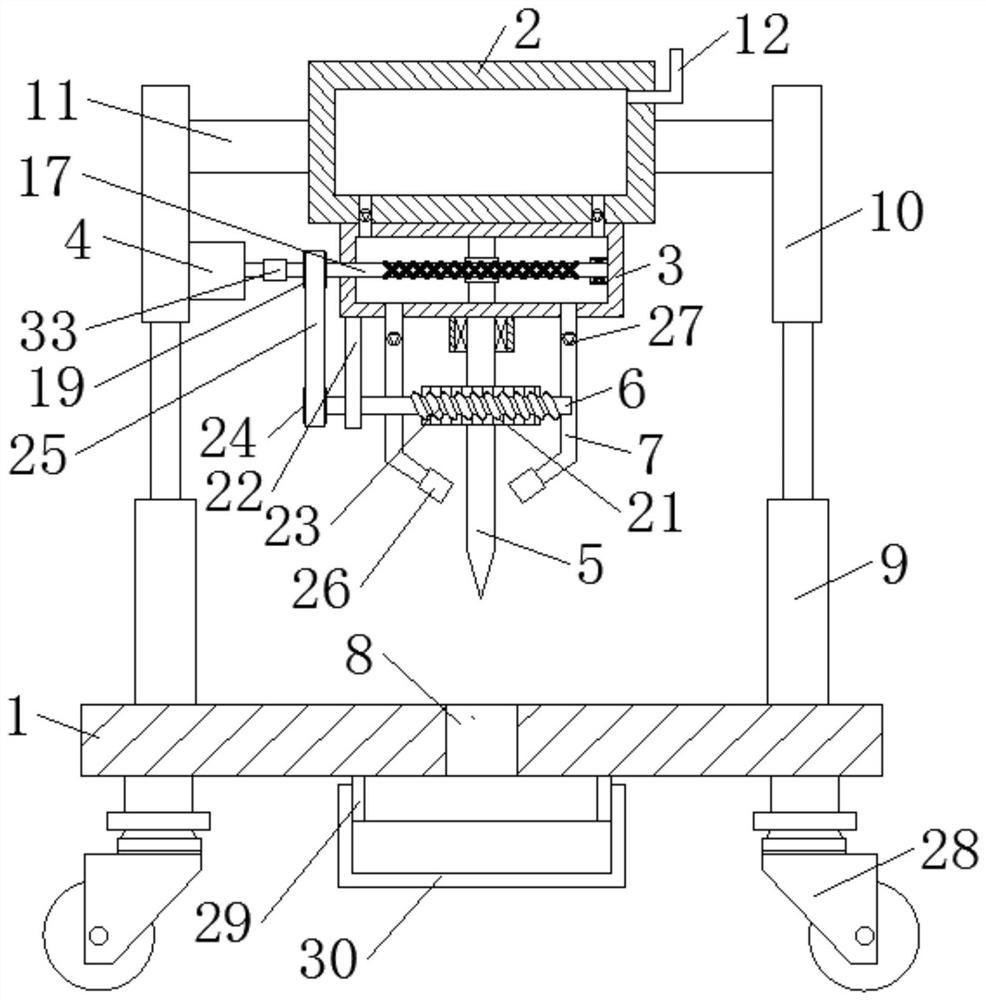

Drilling device for plate machining

InactiveCN109848730AEasy drilling operationEasy accessFeeding apparatusLarge fixed membersShaped beamGear wheel

The invention discloses a drilling device for plate machining. The drilling device comprises a worktable, bases are connected to the left side and the right side of the bottom of the worktable, a through groove is formed in the middle of the worktable, a driving motor is connected to the bottom of the worktable, a first rotating shaft is connected to the power output end of the driving motor, a driving gear is connected to the other end of the first rotating shaft, a guiding plate is arranged in an inner cavity of the worktable, pulleys are symmetrically connected to the left side wall and theright side wall of the guiding plate, a rack is connected to the bottom of the guiding plate, positioning mechanisms are connected to the left side and the right side of the top of the guiding platecorrespondingly, a chip collecting cavity is formed in the bottom of the inner cavity of the worktable, an I-shaped beam is connected to the middle section of the top of the worktable, a lead screw isarranged on the upper part of the I-shaped beam, a lead screw motor is connected to the left end of the lead screw, and a drilling mechanism is connected to the outer side of the circumference of thelead screw in a threaded mode. The drilling device is reasonable in structural design, and is high in stability during working, an aluminum plate can be subjected to multi-point drilling, the labor intensity is reduced, the working efficiency is improved, and the good working environment is maintained advantageously.

Owner:安徽金田加贝智能设备有限公司

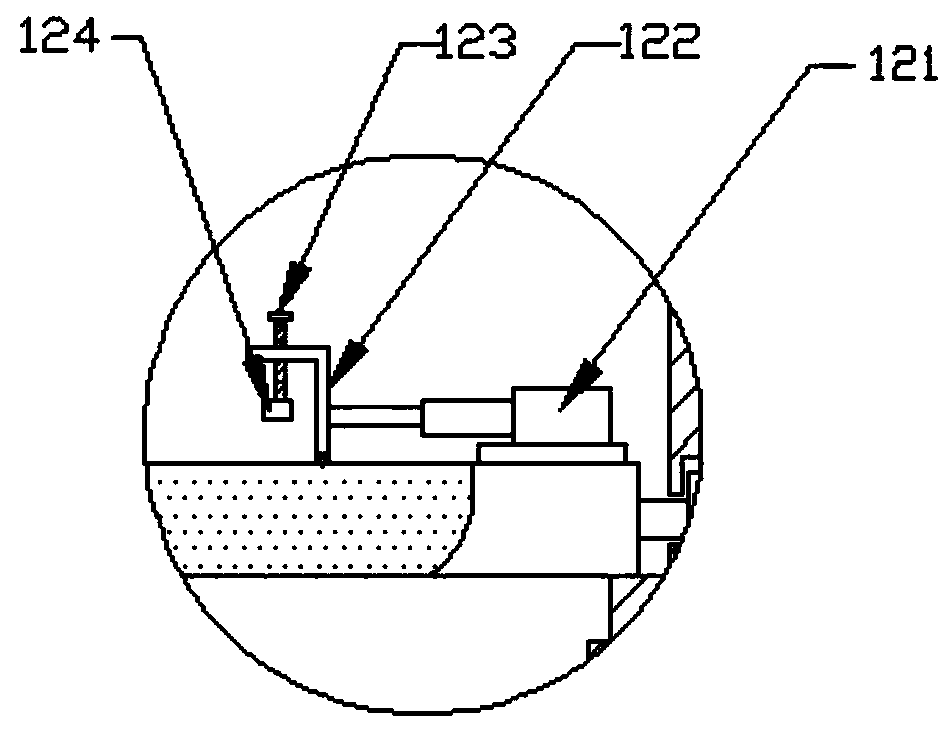

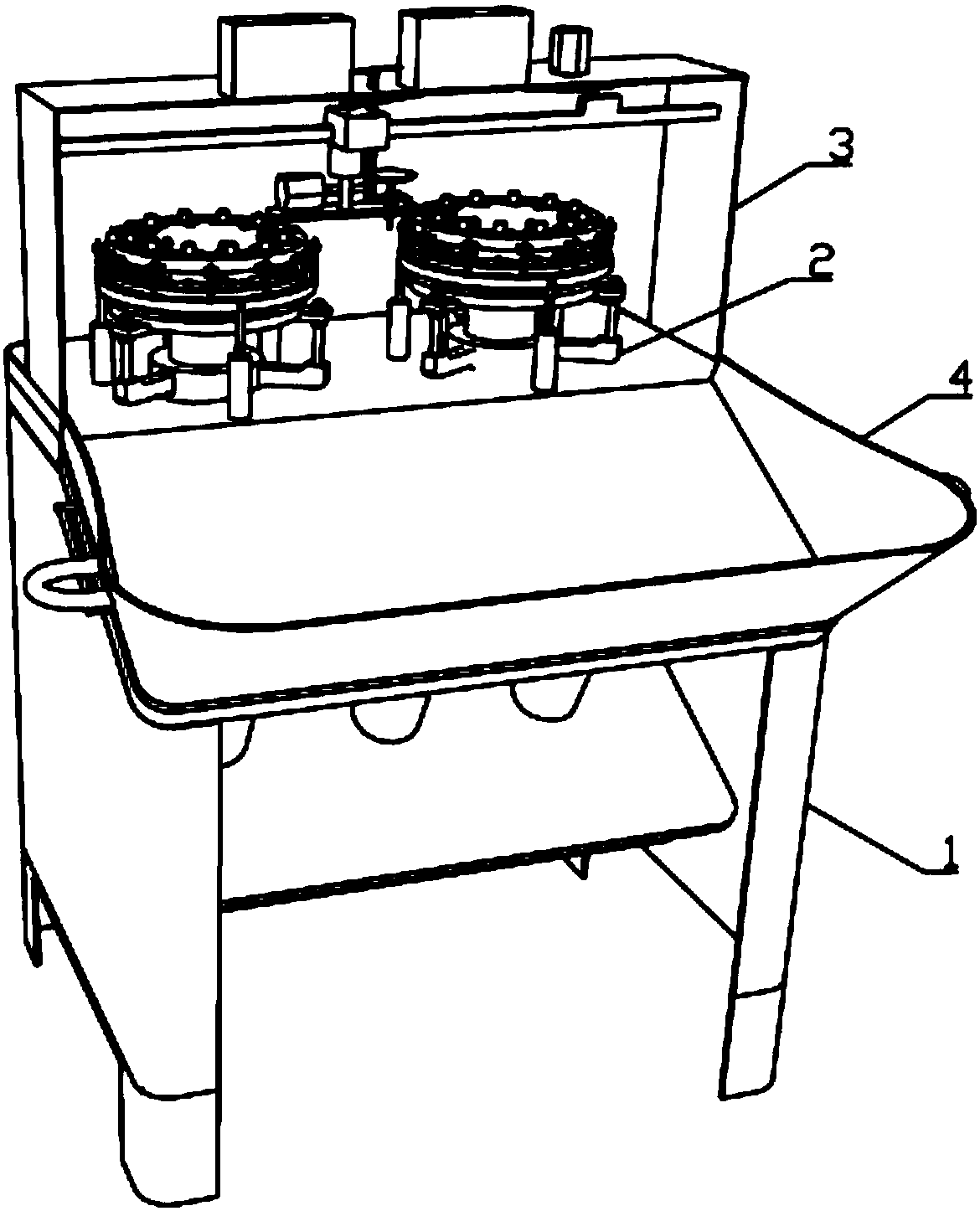

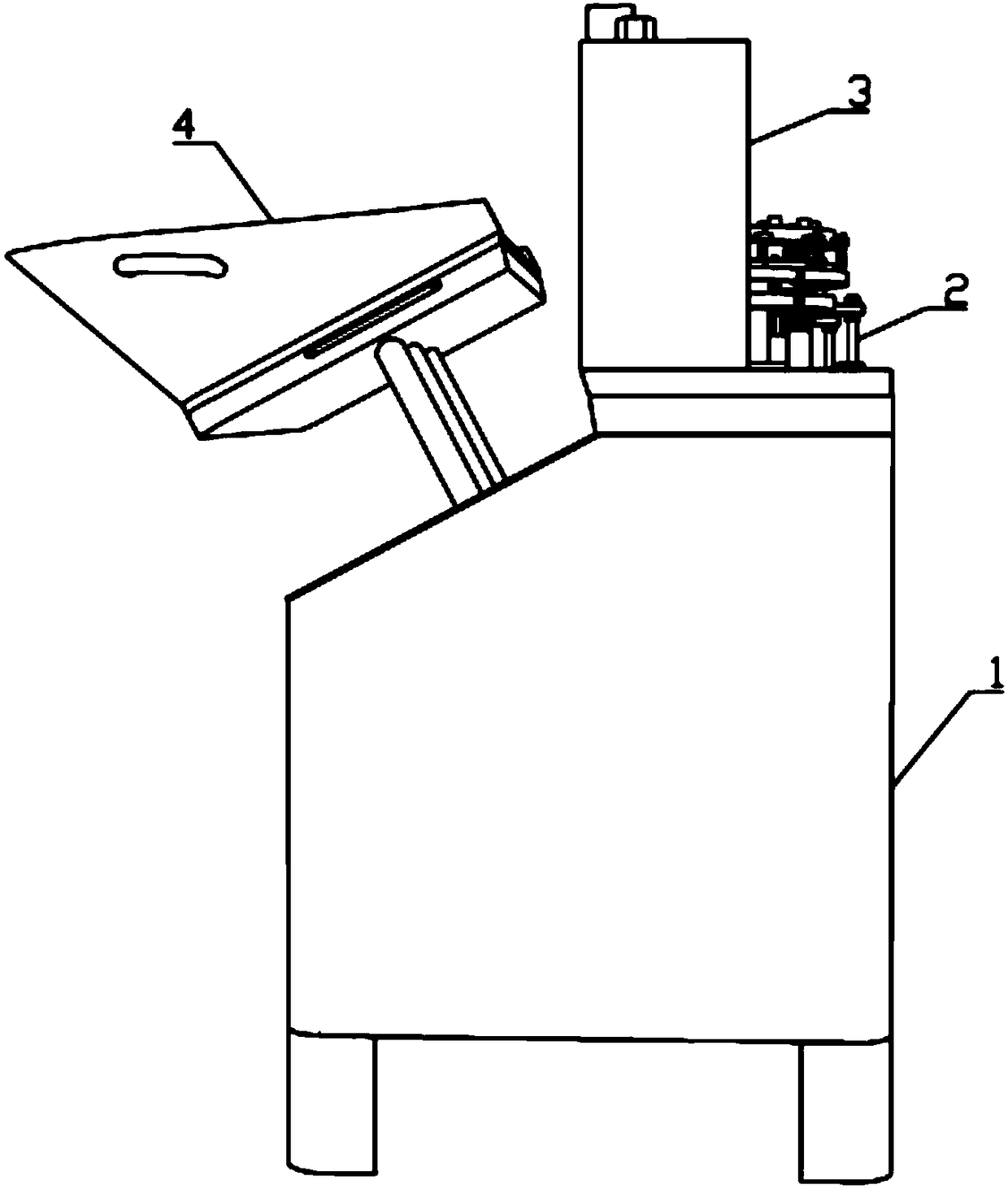

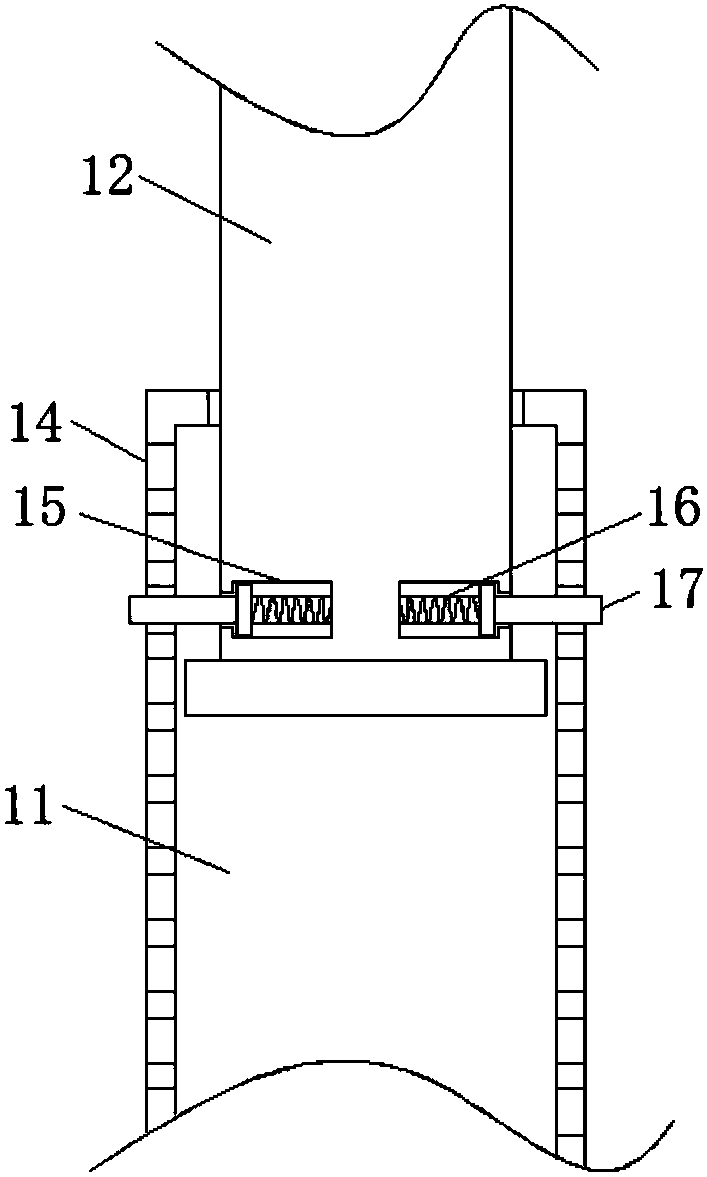

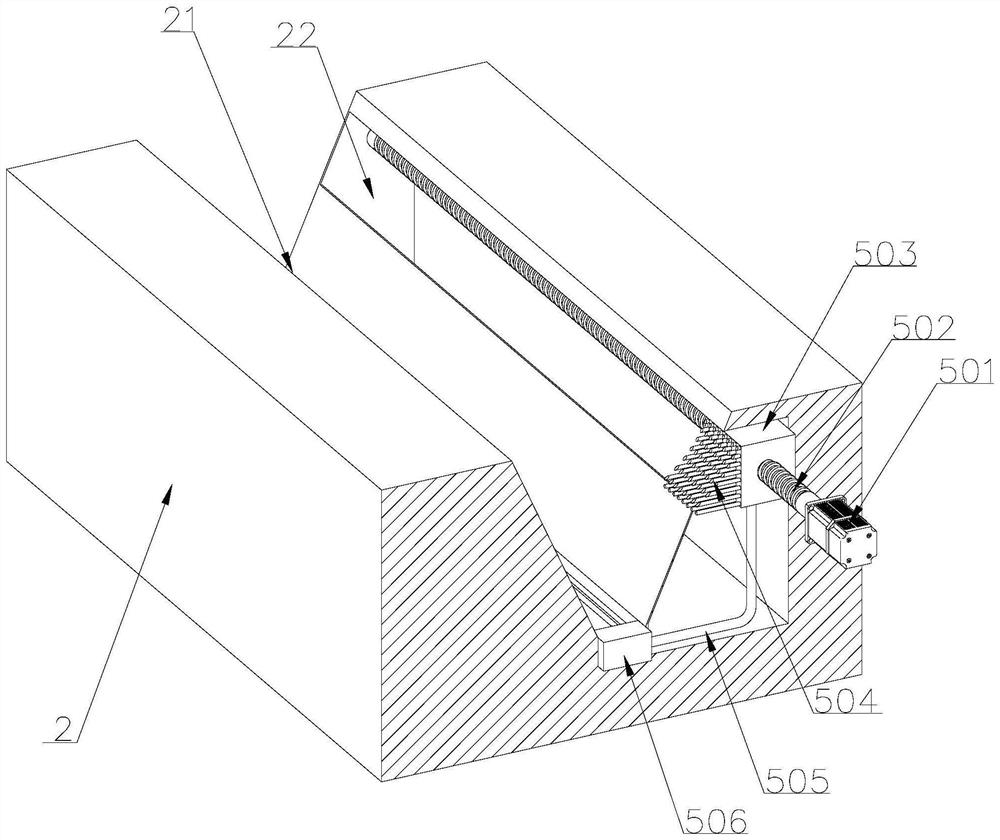

Double-set-fixture drilling machine convenient for workpiece storage and turnover

PendingCN108311726APositioning is simple and reliableEasy to installTransportation and packagingDeodrantsEngineeringDrilling machines

The invention belongs to the technical field of workpiece drilling and particularly relates to a double-set-fixture drilling machine convenient for workpiece storage and turnover. The double-set-fixture drilling machine comprises an operating platform, fixtures, a drilling mechanism and a workpiece storage mechanism, the operating platform comprises a left supporting component and a right supporting component, structures of the left supporting component and the right supporting component are symmetric left and right, the left supporting component comprises a baffle, the cross section of the baffle is in a U shape and the opening faces the right, the bottom surface of the baffle is horizontal and a front bent position and a rear bent position are fixedly provided with two support legs, themiddle front portion of the top surface of the baffle is in a horizontal shape and the middle rear portion is provided with a slope surface with the rear being low and the front being high from rear to front, an included angle between the slope surface and the horizontal bottom surface is 30-45 degrees, the top surface of the baffle is detachably provided with a sealing plate capable of sealing the top opening of the baffle, the middle front portions of the top surfaces of the left supporting component and the right supporting component are provided with a table surface plate, and the table surface plate is provided with two assembly holes.

Owner:唐莉

Expansion and contraction detecting method for multi-layer plate

InactiveCN109548288AReduce shrinkage test processIncrease productivityPrinted circuit manufactureIndustrial engineering

The invention provides an expansion and contraction detecting method for a multi-layer plate. The method comprises: determining an expansion-contraction coefficient by a production plate after early-stage pressing; modifying an expansion-contraction drilling belt based on the expansion-contraction coefficient; and carrying out drilling processing on the corresponding production plate according tothe expansion-contraction drilling belt. Therefore, the expansion and contraction measuring flow of a pressing plate can be simplified effectively; the drilling production efficiency can be enhanced;quick transferring to a next procedure for production is realized; the expansion and contraction of the plate can be monitored through a peripheral auxiliary hole during drilling; and production is carried out by direct setting the expansion and contraction data by a drilling bench, so that the efficiency is greatly improved.

Owner:HUIZHOU ZHONGJING ELECTRONICS TECH CO LTD

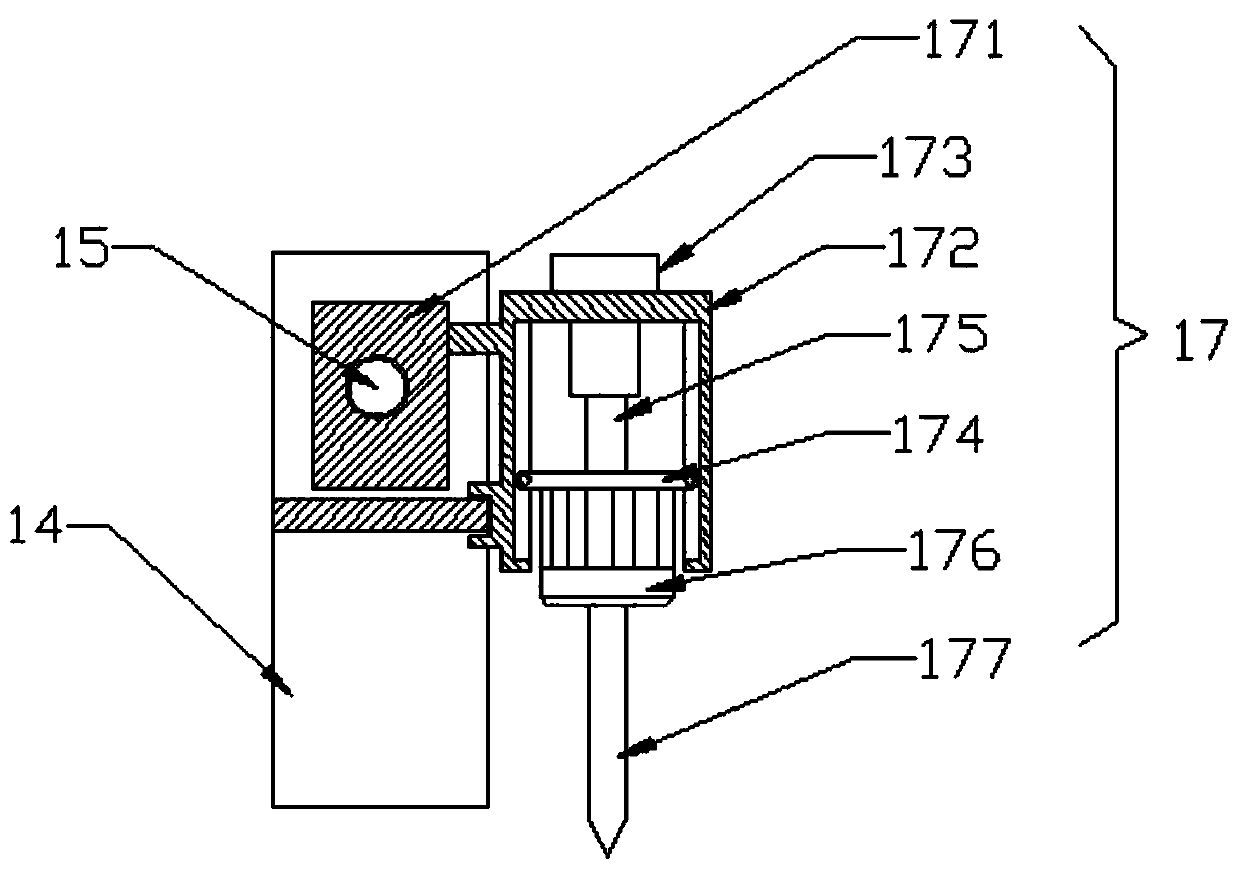

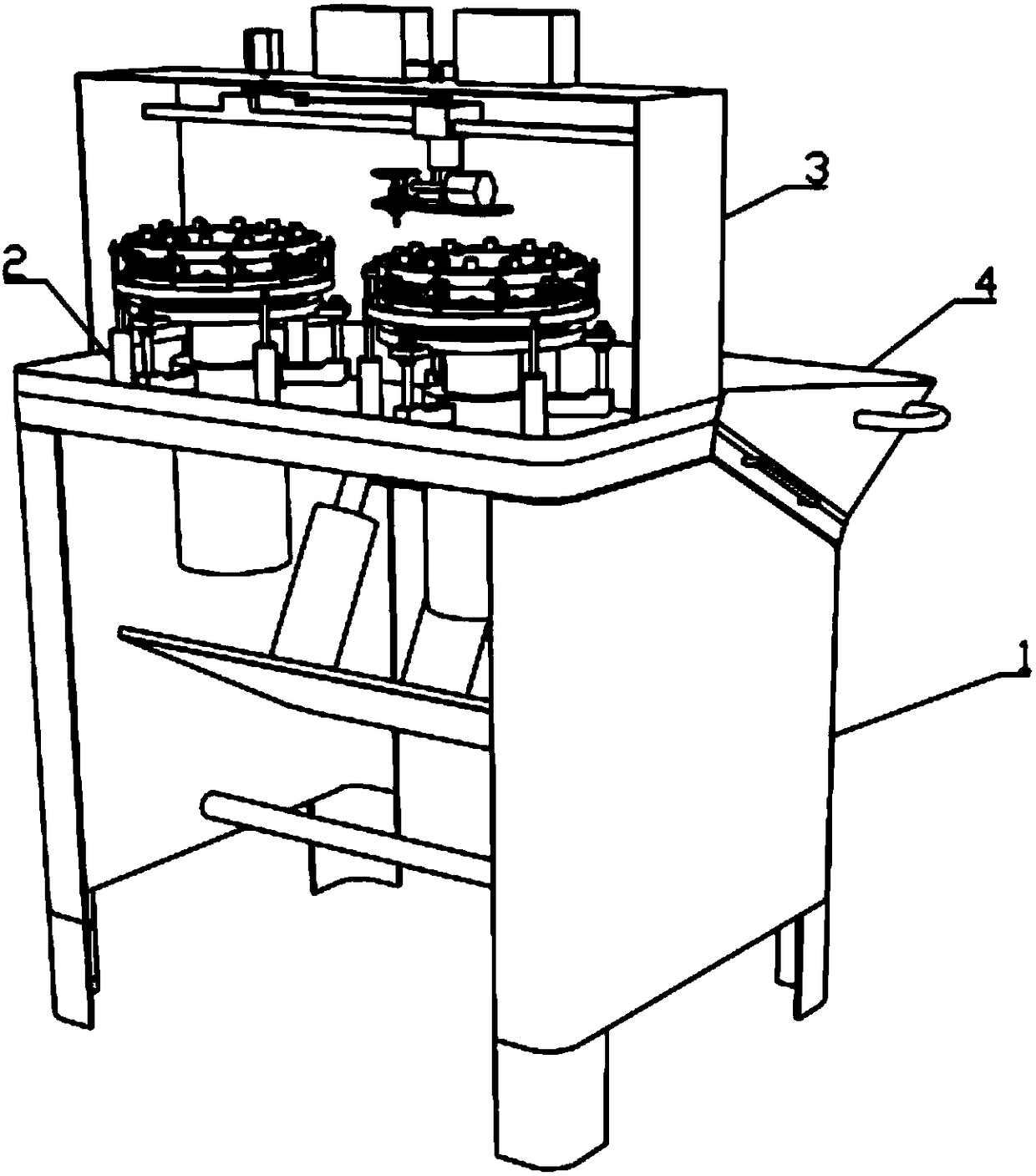

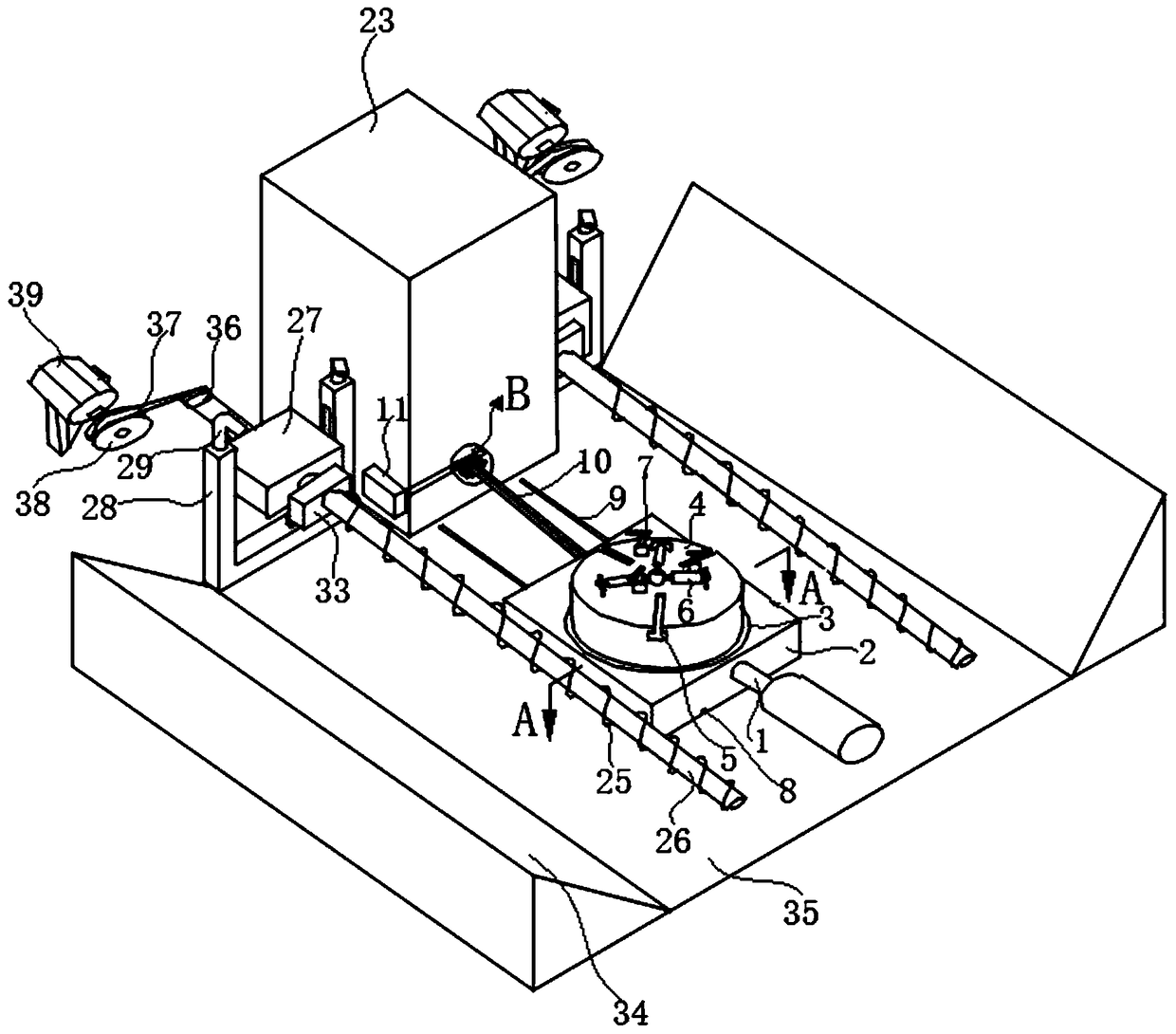

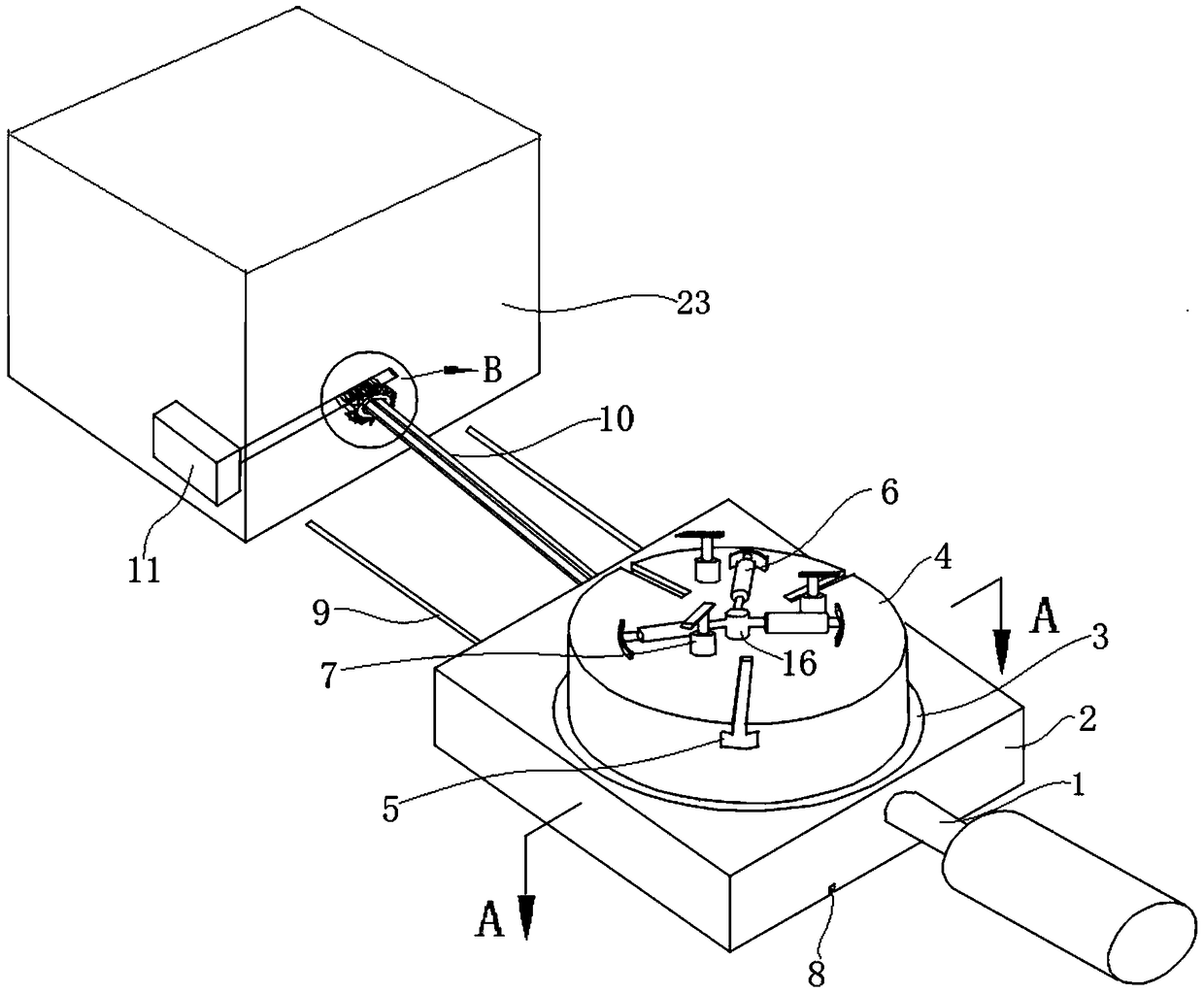

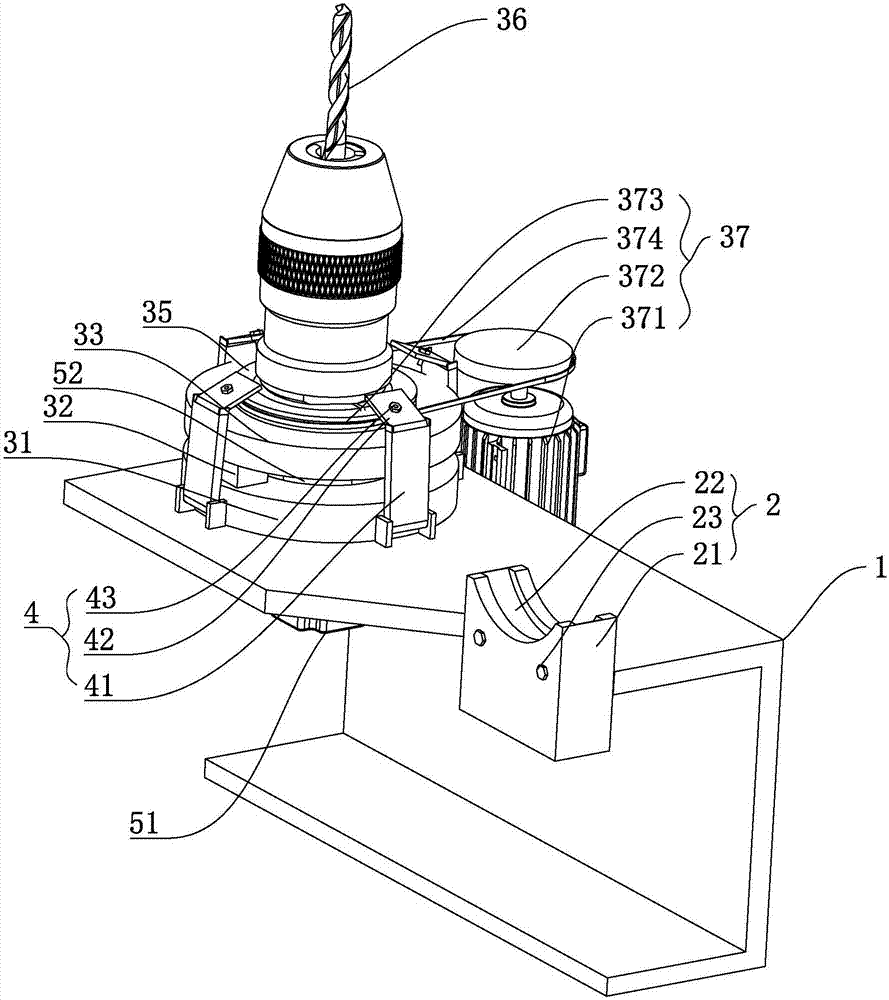

Drilling and milling machining system with drill bit self-cooling function

ActiveCN109128307AEnsure stabilityEasy dischargeTransportation and packagingLarge fixed membersEngineeringMachining system

The invention discloses a drilling and milling machining system with a drill bit self-cooling function, and belongs to the field of drilling and milling machining devices. The drilling and milling machining system comprises rotary pressing mechanisms, a worktable mechanism, a drilling and milling mechanism and chip removal mechanisms mounted on the two sides of the worktable mechanism correspondingly. The worktable mechanism comprises a rotary table, a plurality of telescopic cylinders are mounted on the upper top face of the rotary table, and the central axes of output shafts of the telescopic cylinders penetrate through the circle center of the upper top face of the rotary table. Arc plates are mounted at the ends of the output shafts of the telescopic cylinders. The drilling and millingmechanism comprises a base which is mounted above a transmission box. A rack is arranged on the base and provided with a milling and drilling machine. The milling and drilling machine comprises a self-cooling drill bit. The multiple rotary pressing mechanisms are mounted on the upper top face of the rotary table and comprise outer cylinder bodies, bearing seats and pressing plates. The drilling and milling machining system has the high integration level.

Owner:东台升华工具有限公司

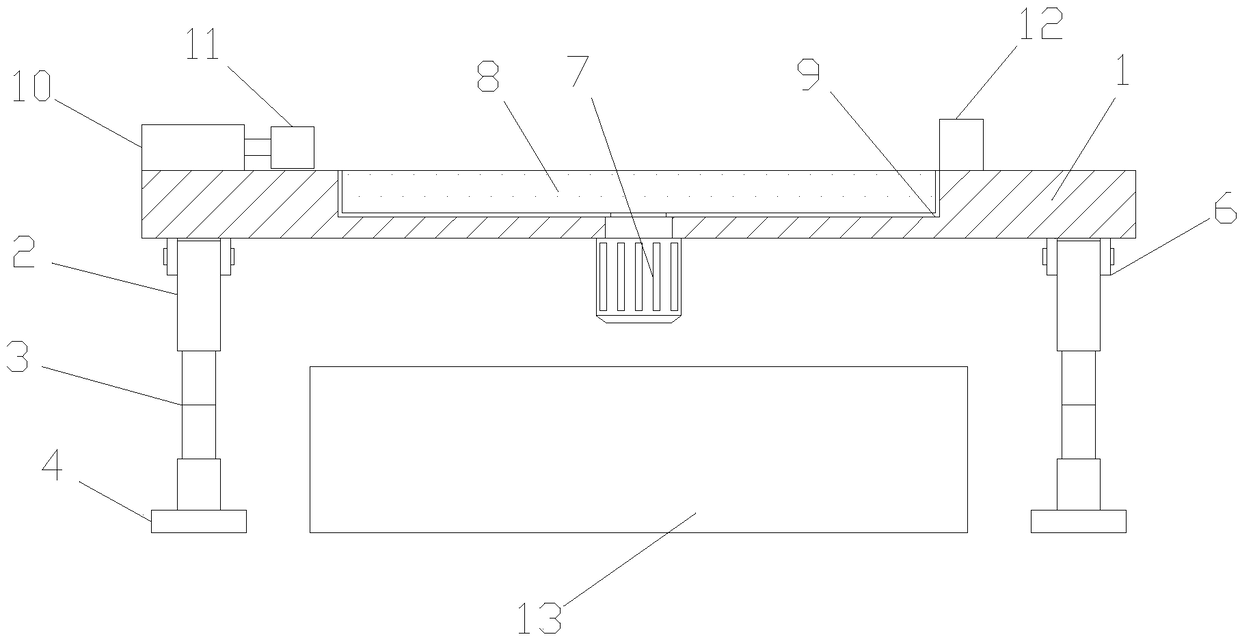

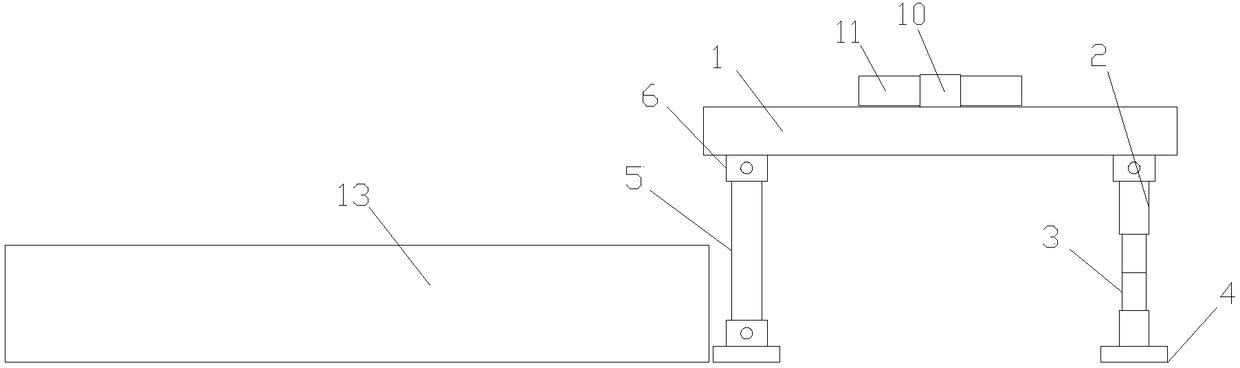

Locating and adjusting device for drilling automobile wheel hub

InactiveCN108406390AEasy to processSave human effortMetal working apparatusPositioning apparatusEngineeringCoupling

The invention discloses a locating and adjusting device for drilling an automobile wheel hub. The locating and adjusting device comprises a workbench, a first supporting leg and a second supporting leg are separately and movably connected to the front side and the rear side of the workbench through connecting pins, an electric push rod is arrange on the first supporting leg, and a cushion plate isarranged at the bottom of the first supporting leg. A cushion plate is further movably connected to the bottom of the second supporting leg through a connecting pin. A motor is arranged in the middleposition of the bottom of the workbench, and an output shaft of the motor penetrates through the workbench through a coupling and is connected with a rotary table. A first clamping block is connectedto the top of the left side of the workbench through an air cylinder, a second clamping block is fixedly installed to the position, located on one side of the rotary table, of the right side of the workbench, a material receiving slot is formed in the bottom of the rear side of the workbench, and a mesh plate is obliquely arranged in the material receiving slot. The locating and adjusting devicefor drilling the automobile wheel hub facilitates the drilling operation of automobile wheel hub, facilitates the drilling work of inclined position, facilitates the processing and saves manpower.

Owner:芜湖市新海域智能科技有限公司

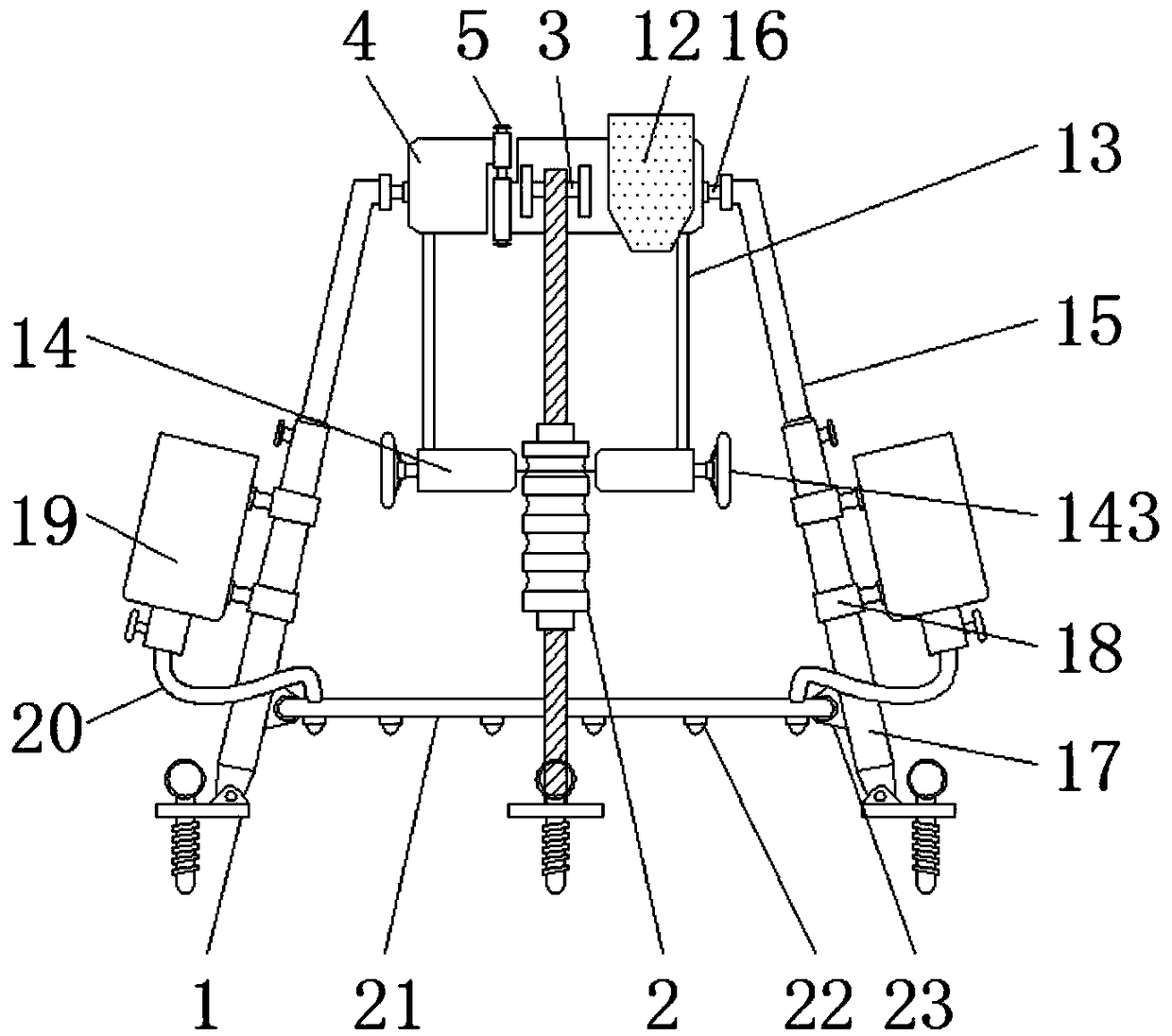

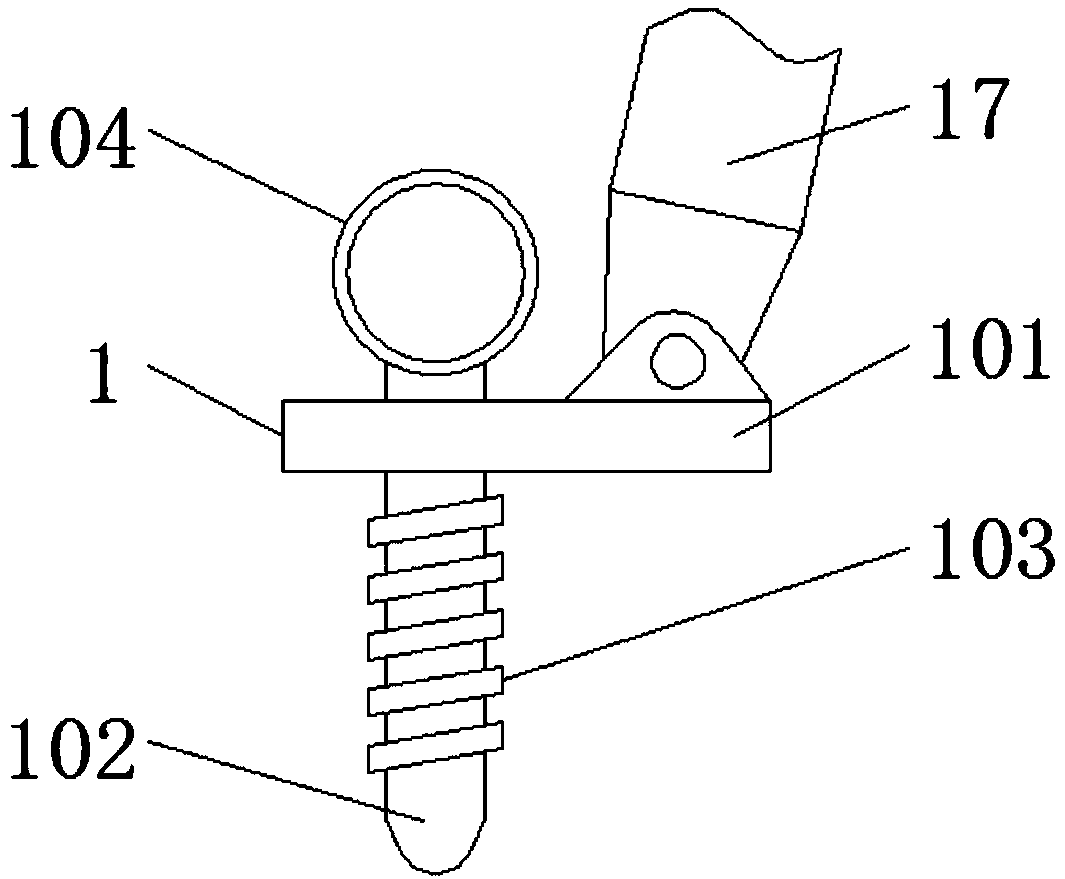

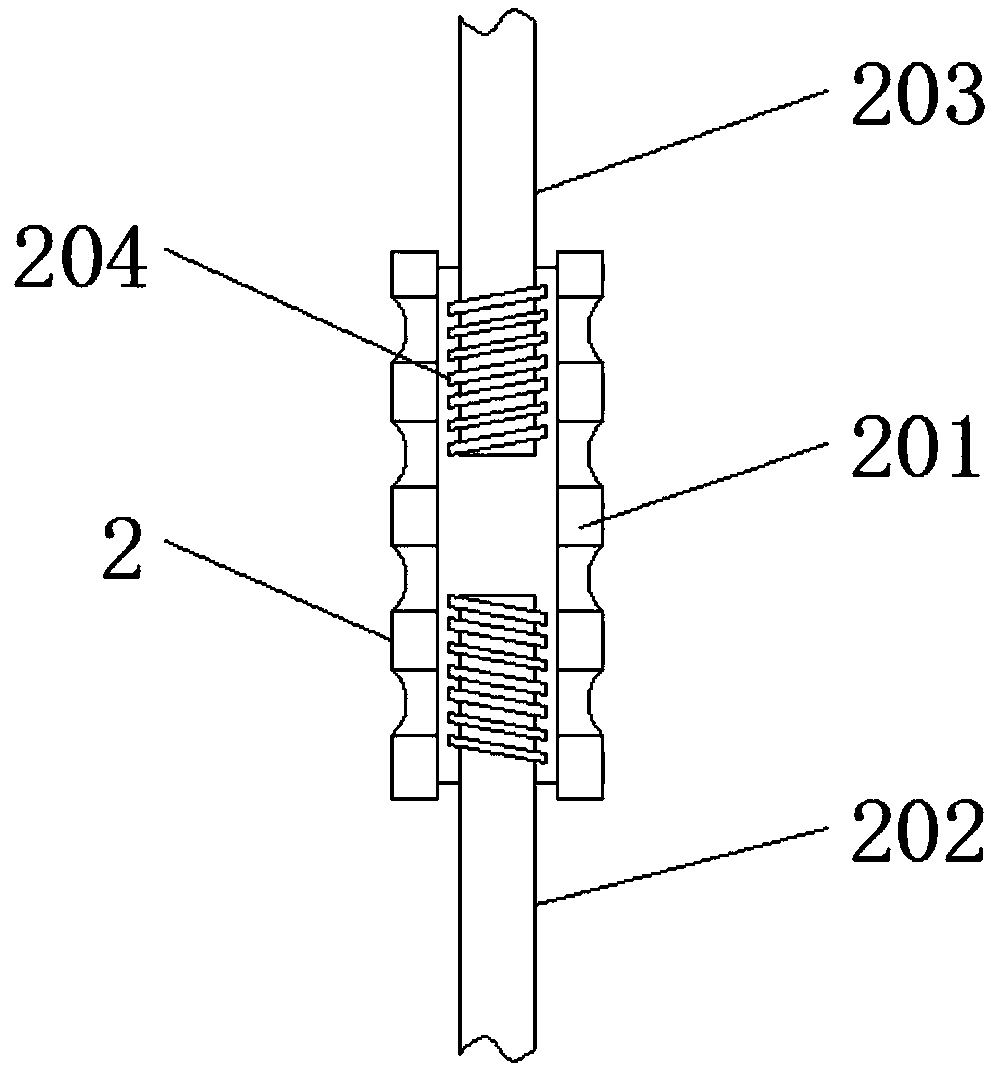

Tree supporting device with adjustable supporting aperture and angle for garden

The invention discloses a tree supporting device with an adjustable supporting aperture and angle for a garden. The tree supporting device with the adjustable supporting aperture and angle for the garden comprises a fixed base, fastening rings, pesticide bag boxes, limiting devices, supporting leg rods, a water containing device and a sprayer, wherein an adjusting device is mounted on the upper end surface of the fixed base; the fastening rings are connected with each other by hinges; a fixing piece is mounted on each fastening ring; each pesticide bag box is mounted on the outer surface of the corresponding fastening rings; each limiting device is connected with the lower end surface of the corresponding fastening ring by a vertical rod; the top end of each supporting leg rod is connectedwith the corresponding fastening ring by a cross shaft; the water containing device is connected with a sleeve through a mounting ring; and the sprayer is mounted on the lower end surface of a waterhose. By the tree supporting device with the adjustable supporting aperture and angle for the garden, the device can be integrally mounted manually under the condition that power supply equipment in awood is insufficient, a device fixing aperture and a tree supporting angle are conveniently adjusted, and functions are perfect.

Owner:吕林

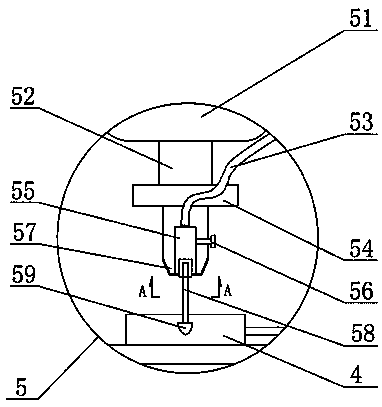

Vertical special drilling machine

PendingCN107570740AReduce the situation of not being able to see the drilling condition clearlySmooth rotationLarge fixed membersBoring/drilling componentsCushionDrilling machines

The invention discloses a vertical special drilling machine, and aims to provide a vertical special drilling machine with a drill bit facing upwards. The technical scheme of the vertical special drilling machine is characterized in that the vertical special drilling machine comprises a base; a supporting device is arranged on the base; a vertical upward drilling device is arranged on one side of the supporting device; the base is further provided with fixing devices for fixing the drilling device; and the drilling device comprises a cushion block fixed to the base, clamping blocks located on the cushion block and protruding upwards, a base plate arranged on the cushion block and matched with the cushion block, clamping grooves located in the base plate and matched with the clamping blocks,a bearing plate located on the base plate and rotationally connected with the base plate, the drill bit fixedly connected with the outer ring of the bearing plate and a driving device located on thebase and connected with the outer ring of the bearing plate.

Owner:无锡美高帝机械有限公司

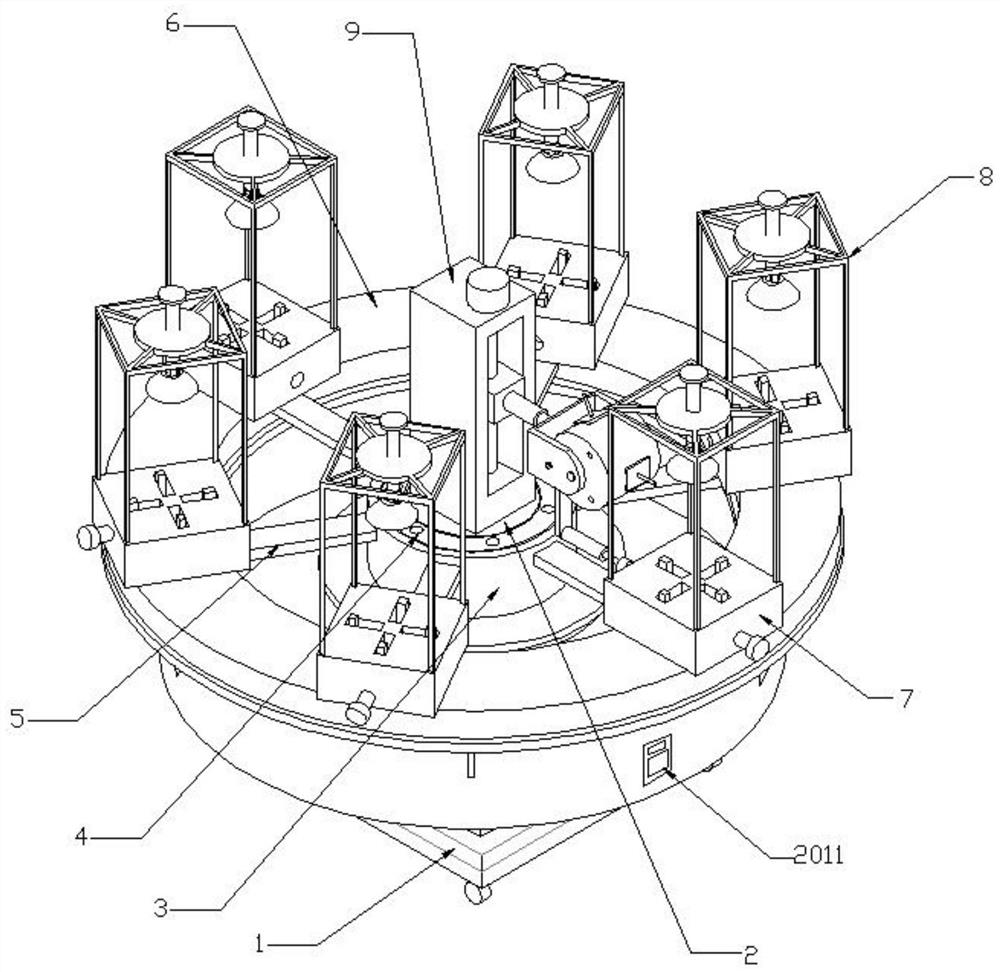

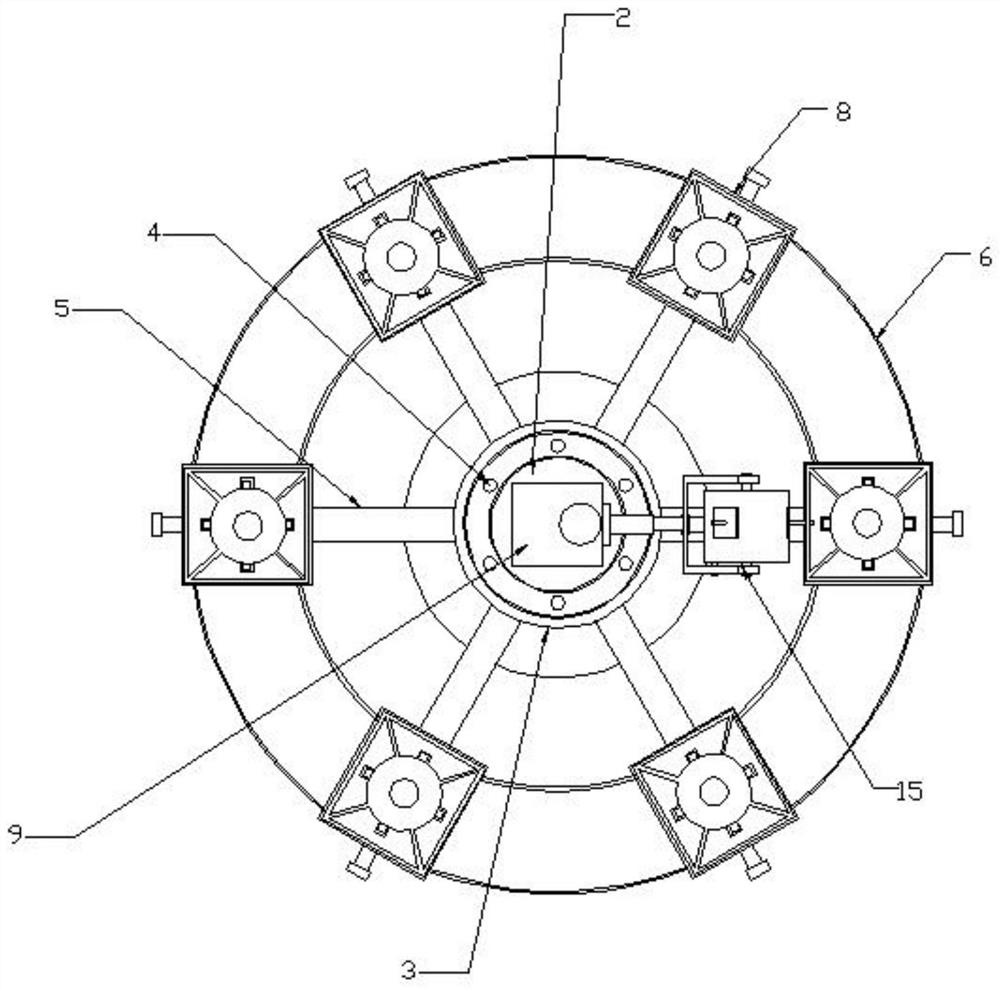

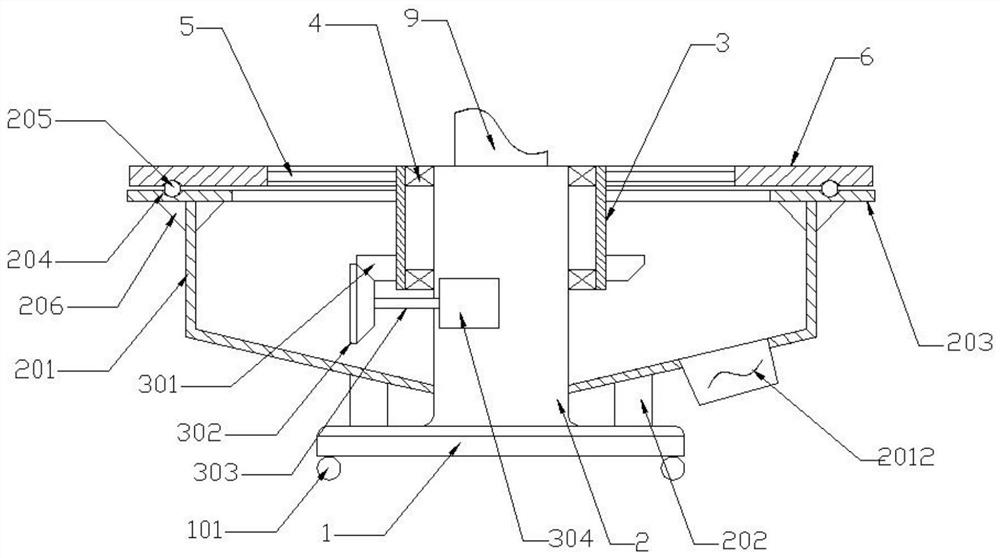

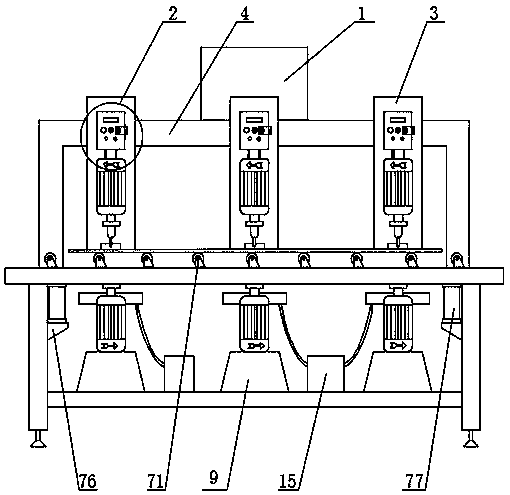

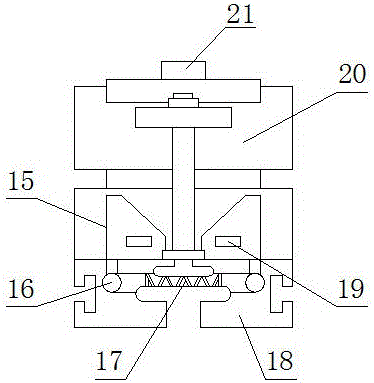

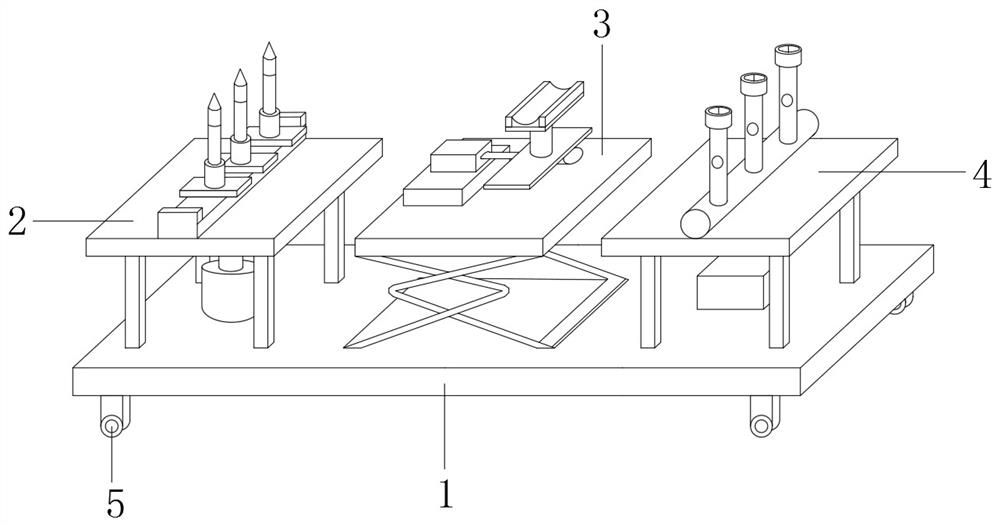

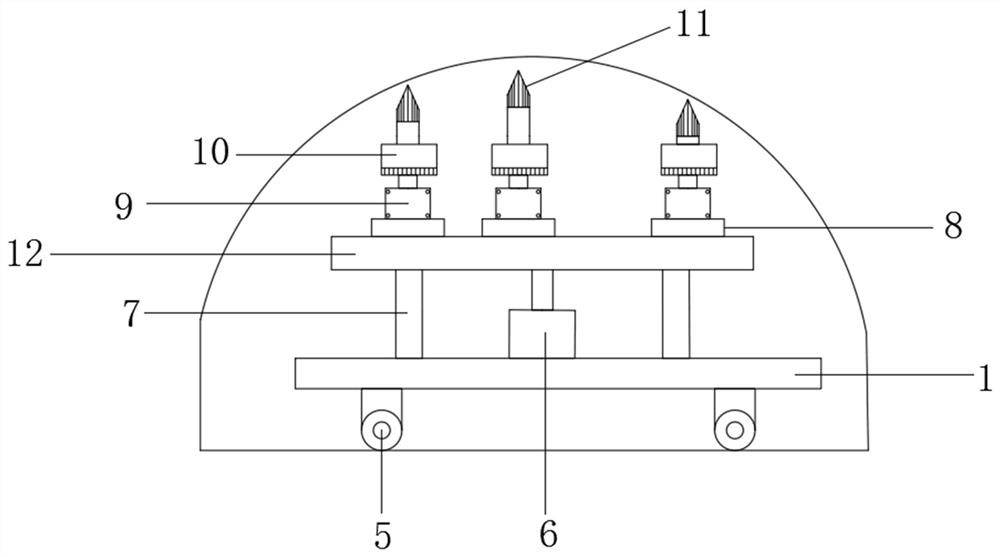

Platform device for multi-station mechanical automatic machining

ActiveCN112916891AReasonable structural designEasy drilling operationFeeding apparatusLarge fixed membersDrill holeSafety coefficient

The invention discloses a platform device for multi-station mechanical automatic machining. The platform device comprises a base, wherein the center of the top of the base is connected with a supporting column, the upper portion of the outer wall of the supporting column is sleeved with a sleeve, a sealing bearing is installed between the inner wall of the sleeve and the supporting column, the outer side wall of the circumference of the sleeve is connected with a plurality of sets of fixing rods in the circumferential direction, the ends of the multiple sets of fixing rods are jointly connected with an annular platform, the top of the annular platform is connected with multiple sets of clamping bases, the multiple sets of clamping bases are arranged in an annular array mode, the tops of the clamping bases are connected with limiting frames, and the tops of the supporting columns are connected with guide bases. The platform device is reasonable in structural design, multi-station drilling operation is facilitated, the levelness of the annular platform can be kept, the safety coefficient of machining is improved, the stability of the device during machining is improved, and the drilling efficiency is improved.

Owner:十堰市郧西县田森农林牧渔科技有限公司

Machine tool drilling fixing device

InactiveCN108723434AAccurate positioningImprove drilling accuracyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a machine tool drilling fixing device. The machine tool drilling fixing device comprises a bottom plate and a lead screw. The bottom plate is fixedly provided with a main supporting plate. The center position of the main supporting plate is fixedly provided with a positioning stud in a welded manner. The positioning stud is sleeved with a pressing plate. The main supportingplate is symmetrically provided with positioning pins. The main supporting plate is internally and rotationally connected with a lead screw. The bottoms of the positioning pins are integrally provided with nuts. The bottom of the bottom plate is fixedly connected with a top plate through bolts. The top plate is installed on an output shaft of a stepping motor through fixing pins. According to themachine tool drilling fixing device, the lead screw drives the positioning pins to do rectilinear motion and position a flange plate, positioning is accurate, the speed is large, and the drilling precision is advantageously improved; the pressing plate and the two positioning pins are distributed around the flange plate in a cross-shaped manner, the flange plate can be effectively fixed, and thestability of the flange plate is improved; and by means of the stepping motor, the bottom plate can be driven to drive the flange plate to rotate, and the flange plate is advantageously rotated so that drilling operation can be carried out on different positions.

Owner:张维秀

Automatic drilling device

InactiveCN109570547AEasy drilling operationHigh positioning accuracyMaintainance and safety accessoriesBoring/drilling machinesEngineeringDrill bit

The invention provides an automatic drilling device, which comprises a worktable, a supporting rod, fixing clamping plates, a first air cylinder, a second air cylinder and a third air cylinder. A first sliding rail is arranged on the worktable, and the supporting rod is slidably arranged on the first sliding rail; a cross beam is arranged at the top of the supporting rod, and a third sliding railis arranged on the side wall of the cross beam; a sliding block is slidably arranged on the third sliding rail, and the first air cylinder stretching out and drawing back in the vertical direction isarranged on the sliding block; a drill bit is arranged at the end of a retractable rod of the first air cylinder, and the second air cylinder stretching out and drawing back in the horizontal direction is arranged on the cross beam; the second air cylinder is connected with the sliding block through a retractable rod; and a second sliding rail perpendicular to the first sliding rail is further arranged on the worktable, and the two or more fixing clamping plates are slidably arranged on the second sliding rail. The automatic drilling device is convenient to operate and easy to control, manualoperation of workers is not needed, the drilling efficiency is improved, and the potential safety hazard is also effectively eliminated.

Owner:XINCHANG DINGSHI TECH CONSULTING SERVICE CO LTD

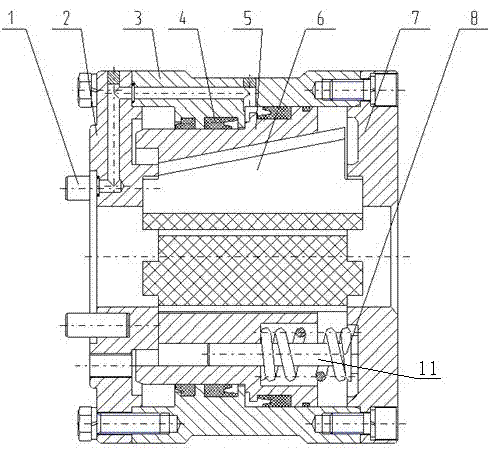

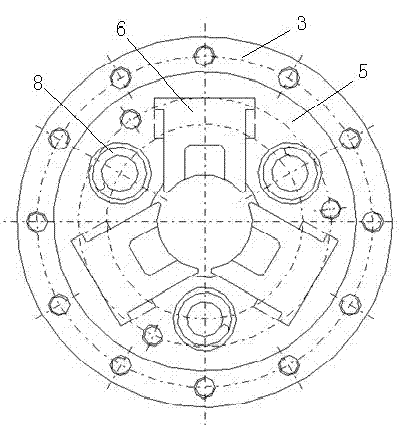

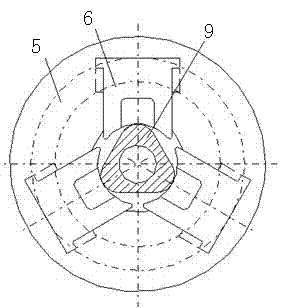

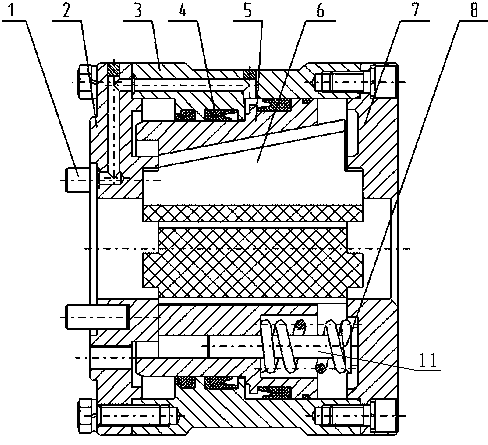

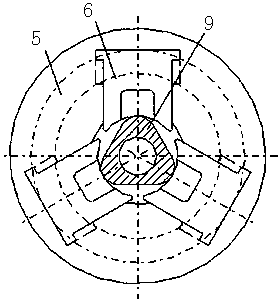

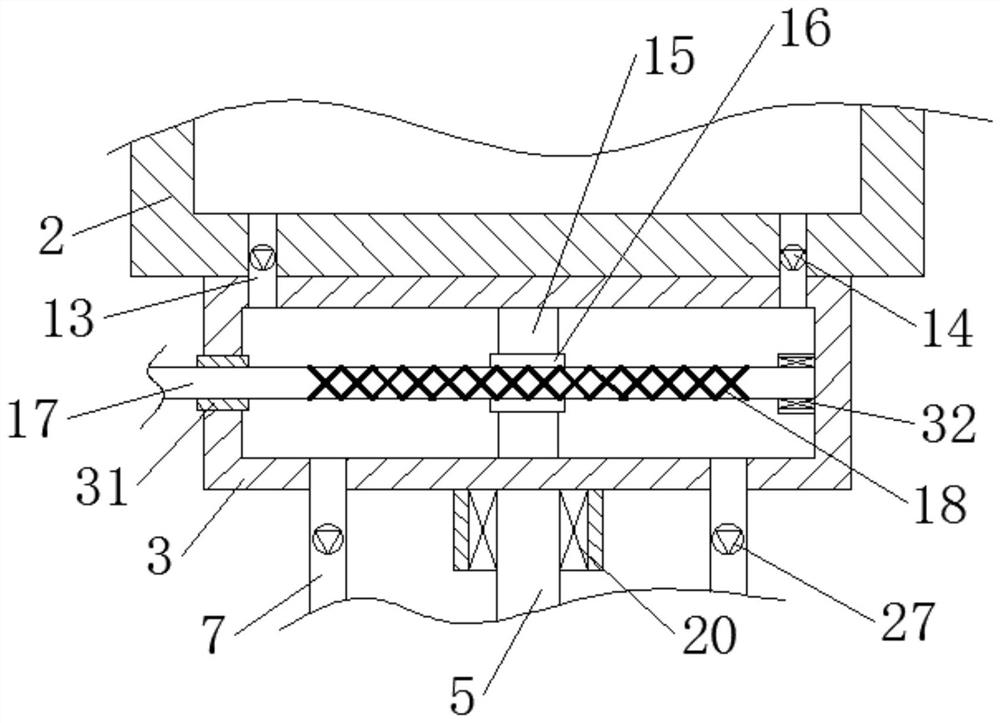

General drill rod clamping device used for coal mine drilling machine

InactiveCN102518403AEasy to install and removeHigh degree of automationDrilling rodsDrilling casingsCoalDrill hole

The invention discloses a general drill rod clamping device used for a coal mine drilling machine, which comprises construction members, such as a front end cover, a rear end cover, a shell, a slip sleeve, a slip, a clamping cylinder, an elastic resetting mechanism and the like. The device can be used as the chuck or the gripper of the drilling machine so as to solve the problem that the traditional full-hydraulic drilling machine drill rod clamping device used for the mine cannot directly clamp an anomalous drill rod. The drilling machine provided with the clamping device can be used for clamping a common circular drill rod and an anomalous drill rod with a non-circular surface under the condition of replacing no parts, and the the anomalous drill rod can obtain the same use efficacy as that of the common circular drill rod. When the anomalous drill rod is used for drilling holes, the drill rod can conveniently move vertically so as to greatly shorten the auxiliary operation time for using the anomalous drill rod to drill holes and greatly lower the technical requirement for a drilling machine operation worker. Meanwhile, the use safety coefficient of the drilling machine is improved.

Owner:CHONGQING UNIV

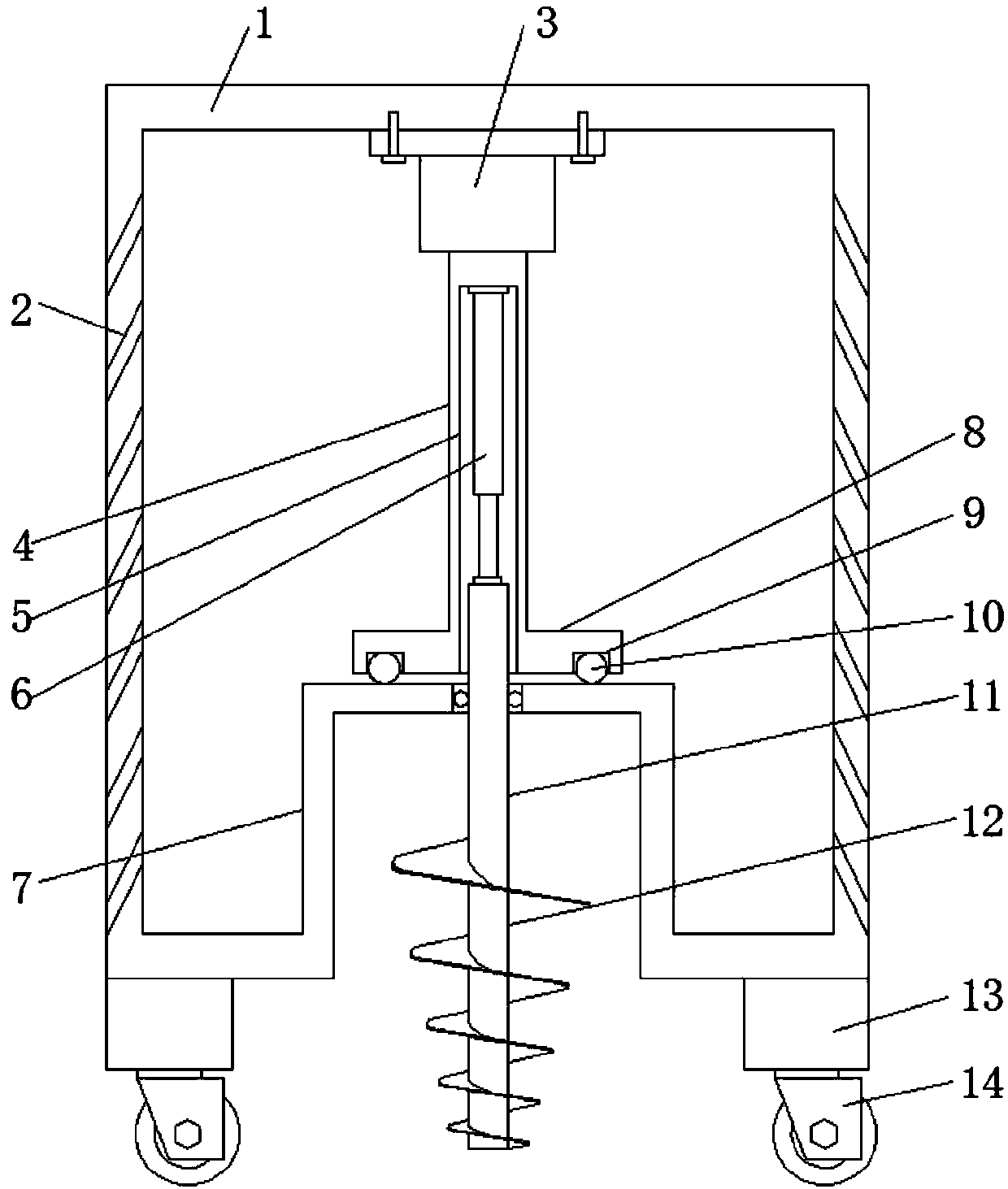

Seedling planting machine for garden

PendingCN107660359AEasy to moveEasy drilling operationPlantingFurrow making/coveringAgricultural engineeringElectric machinery

The invention discloses a seedling planting machine for a garden. The seedling planting machine comprises a shell, wherein the shell has a hollow chamber structure; heat radiating ports are formed onthe two sides of the shell; a rotating motor is arranged on an inner wall at the top end of the shell; a rotating rod is arranged in the shell; the rotating rod is connected with an output shaft of the rotating motor; a storage slot is formed on one side of the rotating rod away from the rotating motor; a cylinder is fixedly arranged on the inner wall of the top end of the storage slot; an expansion link is arranged under the cylinder; one end of the expansion link is fixedly connected with a piston rod of the cylinder; the other end of the expansion link extends to the lower side of the shell; support frames are arranged on the middle position of the bottom end of the shell; a spiral sheet is arranged between the support frames; the spiral sheet is welded on an outer side wall of the expansion link; a sliding plate is arranged at the bottom end of the rotating rod. The seedling planting machine for the garden is reasonably designed, is convenient for moving, is capable of performing different-depth drilling operation before the seedling planting, is capable of reducing the labor intensity of the worker and is capable of effectively increasing the seedling planting efficiency.

Owner:施秉县华隆农业科技发展有限公司

Bench drill for drilling holes in round pipe workpiece at equal intervals

InactiveCN109175459AAvoid misalignmentEasy to installPositioning apparatusMetal-working holdersEngineeringDC motor

The invention discloses a bench drill for drilling holes in a round pipe workpiece at equal intervals. The bench drill comprises a bottom plate and a DC motor, the right end of the bottom plate is provided with a side plate, the top end of the side plate is provided with a servo motor, the bottom end of the servo motor is provided with a first lead screw, the first lead screw is connected with theside plate, the outer side of the first lead screw is provided with a drilling device, and the drilling device is connected with the side plate; and the DC motor is mounted on the right side of the side plate, the DC motor is fixedly connected to a belt wheel through a first rotating shaft, the belt wheel is installed inside a mounting groove, and the mounting groove is formed inside the side plate. By means of the bench drill for drilling holes in the round pipe workpiece at equal intervals, when a worker manually operates the bench drill, a control handle is manually operated, the circularpipe clamped on the bench drill is transversely moved and transferred at equal intervals; and when transverse movement of the circular tube needs to be stopped, the control handle is manually pulled,transverse movement running is stopped, or reverse transverse movement is carried out.

Owner:谢炎武

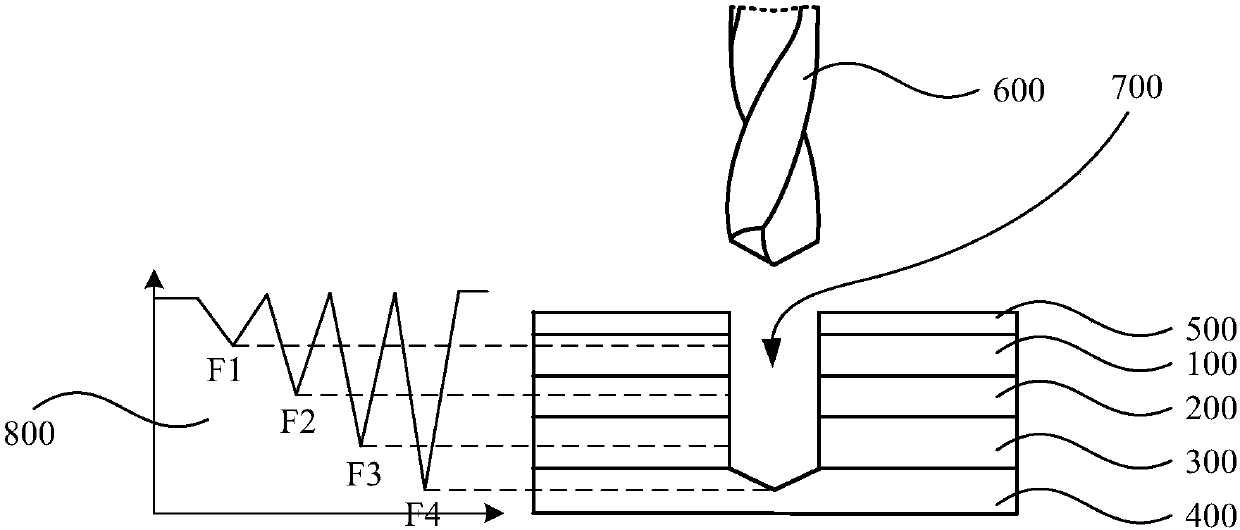

Overlapping-drilling method

InactiveCN107567193ASave energyEasy drilling operationPrinted circuit manufactureDrill downMachining

The invention relates to an overlapping-drilling method. The overlapping-drilling method includes: overlapping at least two layers of metal plates to be drilled; according to thickness of the metal plates in layer, setting a sequential process of a drill bit, of a drilling jig, relative to the metal plates; according to the sequential process, drilling the metal plates in an overlapping manner. With the above method that at least two layers of the metal plates are drilled in the overlapping manner according to the sequential process, multiple metal plates can be overlapped and drilled at one step, machining efficiency of the metal plates is greatly improved, manufacturing cost of products is lowered, and energy consumption is further lowered; further, due to the adoption of the multi-drilling method, drilling resistance of the drill bit drilling down is buffered and reduced, overload machining borne by a spindle is efficiently alleviated, and operation efficiency is improved by about 40%-70%.

Owner:HUIZHOU TECHUANG ELECTRONIC TECH CO LTD

Multi-drill-bit adjustable glass drilling device

PendingCN109278197AEasy to produceRapid productionWorking accessoriesStone-like material working toolsEngineeringScrew thread

The invention discloses a multi-drill-bit adjustable glass drilling device which comprises a circulating water system, a control box, three drill bit driving portions and a main machine frame. Multiple sets of universal pulleys are welded to the upper surface of a workbench, glass is placed on the tops of the universal pulleys, a machine frame cross beam is fixedly connected with one side of the upper portion of the workbench, a fixing plate is welded to one side of the machine frame cross beam, the bottom of the fixing plate is fixedly connected with a glass fixing protection cover, the glassfixing protection cover is flatly placed on the upper surface of the glass, supporting legs are fixedly connected with the four ends of the bottom of the workbench correspondingly, adjusting screws are in threaded connection with the bottoms of the supporting legs, a flat plate is welded to the inner sides of the bottoms of the four supporting legs, air cylinders are installed on the upper portions of air cylinder supporting frames, a motor fixing base is fixedly installed on the upper portion of the flat plate, a supporting plate is welded to the motor fixing base, and a waste box is fixedlyinstalled on the top of the supporting plate. Each drill bit driving portion is provided with two portions symmetrical up and down, drilling quality is ensured, a speed adjusting switch is provided for controlling the drilling speed, and the production efficiency is improved.

Owner:响水县泽州开发有限公司

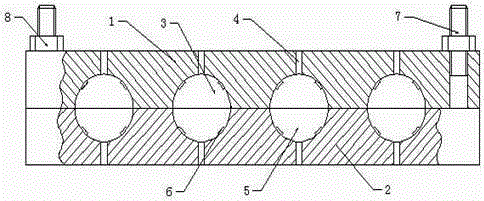

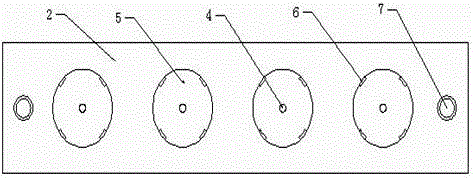

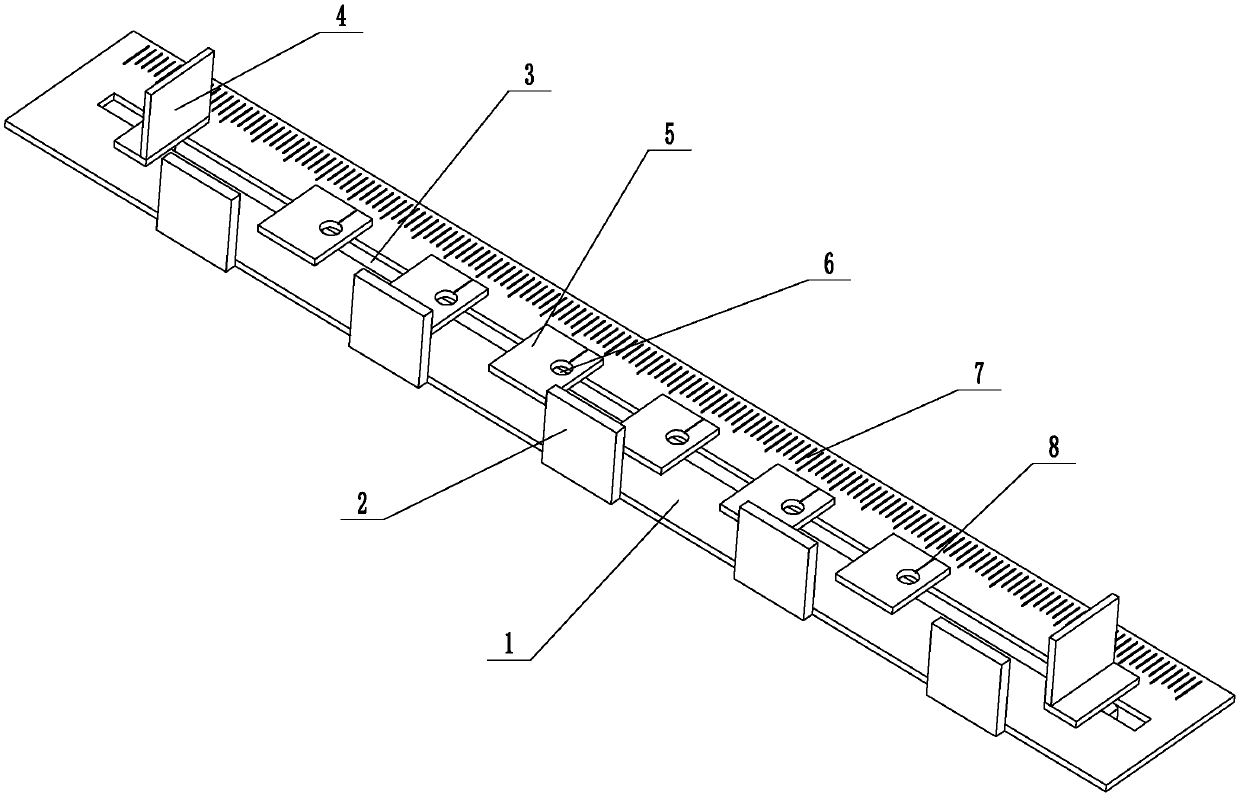

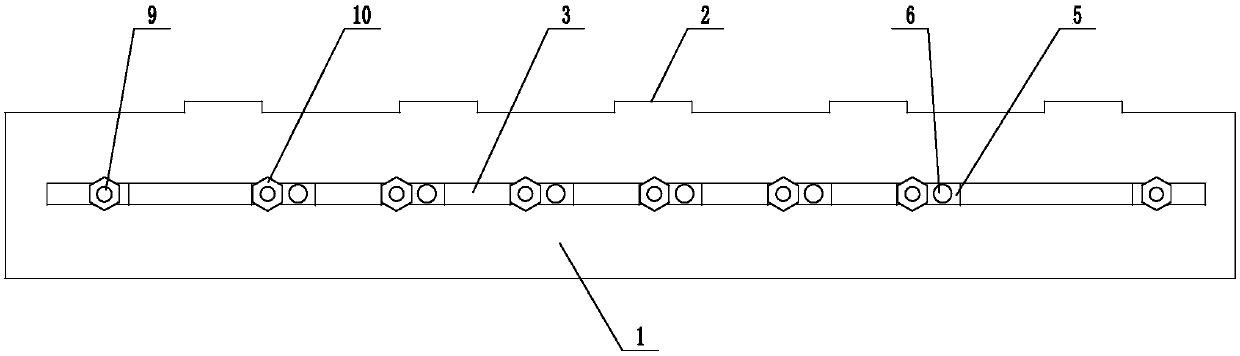

Buddha bead drilling mold

The invention discloses a Buddha bead drilling mold and belongs to the field of ornament machining. The Buddha bead drilling mold comprises an upper template and a lower template, wherein the upper template and the lower template are of rectangular long-strip block shapes with the same size; a plurality of upper positioning grooves are formed in the lower end face of the upper template in parallel; the upper positioning grooves are circular-arc-shaped; the upper positioning grooves are distributed along the middle line of the upper template; through drilling holes are formed in the circular-arc vertexes of the upper positioning grooves; the through drilling holes penetrate through the upper template; lower positioning grooves opposite to the upper positioning grooves are formed in the upper end face of the lower template; the structure of each lower positioning groove is the same as that of the corresponding upper positioning groove; at least two anti-sliding nails are arranged in each positioning groove. Compared with the prior art that one Buddha bead is machined by one time of positioning, the Buddha bead drilling template provided by the scheme can be used for simultaneously positioning and clamping the plurality of Buddha beads, and the operation of clamping the Buddha beads in conventional Buddha bead drilling operation is reduced. According to the scheme, the drilling machining efficiency is higher and the Buddha bead drilling machining quality is better.

Owner:CHONGQING CHANGSHOU YIMEI ACCESSORIES PROCESSING MILL

Drilling equipment for building construction

InactiveCN111761738AControl feed amountControl rateWorking accessoriesStone-like material working toolsArchitectural engineeringElectric machinery

The invention discloses drilling equipment for building construction. The drilling equipment comprises a base, a workbench is movably assembled above the base, and a fixed seat is movably connected onto the workbench. According to the drilling equipment for building construction, an overturning motor is arranged to control the position of an overturning seat, a drilling machine can conveniently perform multi-directional drilling operation, a plurality of limiting cylinders are uniformly distributed to be matched with limiting holes, the position of the overturning seat is conveniently and effectively fixed, the position of a cutter is prevented from changing when the drilling machine works, and drilling quality is ensured; the position of the cutter is controlled through a lifting screw rod and a sliding screw rod, tool setting is facilitated, and meanwhile, the feed amount and the feed rate of the cutter can be controlled; and in addition, the position of the workbench is controlled to rotate through meshing of a worm wheel and a worm, flexible operation of the cutter is facilitated, and drilling efficiency is improved.

Owner:曾勇

Drilling device for electric power engineering

PendingCN112658322AEasy drilling operationAchieve rotary motionMetal working apparatusPositioning apparatusEngineeringPower engineering

The invention discloses a drilling device for electric power engineering. The drilling device comprises a supporting frame and a workbench, wherein the workbench is installed at the top of the supporting frame, a V-shaped groove is formed in the middle of the workbench, fixed rotating mechanisms are arranged on the two sides of the workbench, the fixed rotating mechanisms are installed on the supporting frame, a drilling mechanism is further installed on the supporting frame, and the drilling mechanism is located on the rear side of the workbench. The inner wall of an electric power pipe is fixed through the fixed rotating mechanisms, the exterior of the electric power pipe cannot be shielded at all, the electric power pipe can be driven to rotate while any position of the whole electric power pipe is drilled conveniently, and therefore other positions on the same cross section of the electric power pipe are drilled, the electric power pipe does not need to be disassembled and fixed, time and labor are saved, and the working efficiency is improved.

Owner:国网山东省电力公司曹县供电公司

General drill rod clamping device used for coal mine drilling machine

InactiveCN102518403BAchieve clamping forceAchieve clampingDrilling rodsDrilling casingsCircular surfaceAbnormal shaped

The invention discloses a general drill rod clamping device used for a coal mine drilling machine, which comprises construction members, such as a front end cover, a rear end cover, a shell, a slip sleeve, a slip, a clamping cylinder, an elastic resetting mechanism and the like. The device can be used as the chuck or the gripper of the drilling machine so as to solve the problem that the traditional full-hydraulic drilling machine drill rod clamping device used for the mine cannot directly clamp an anomalous drill rod. The drilling machine provided with the clamping device can be used for clamping a common circular drill rod and an anomalous drill rod with a non-circular surface under the condition of replacing no parts, and the the anomalous drill rod can obtain the same use efficacy as that of the common circular drill rod. When the anomalous drill rod is used for drilling holes, the drill rod can conveniently move vertically so as to greatly shorten the auxiliary operation time for using the anomalous drill rod to drill holes and greatly lower the technical requirement for a drilling machine operation worker. Meanwhile, the use safety coefficient of the drilling machine is improved.

Owner:CHONGQING UNIV

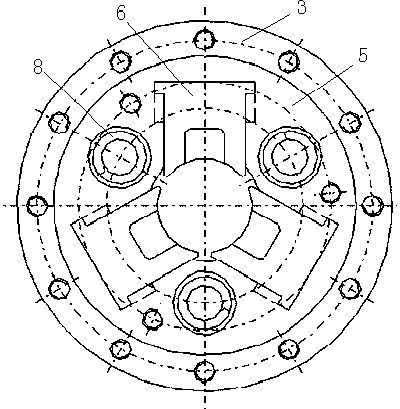

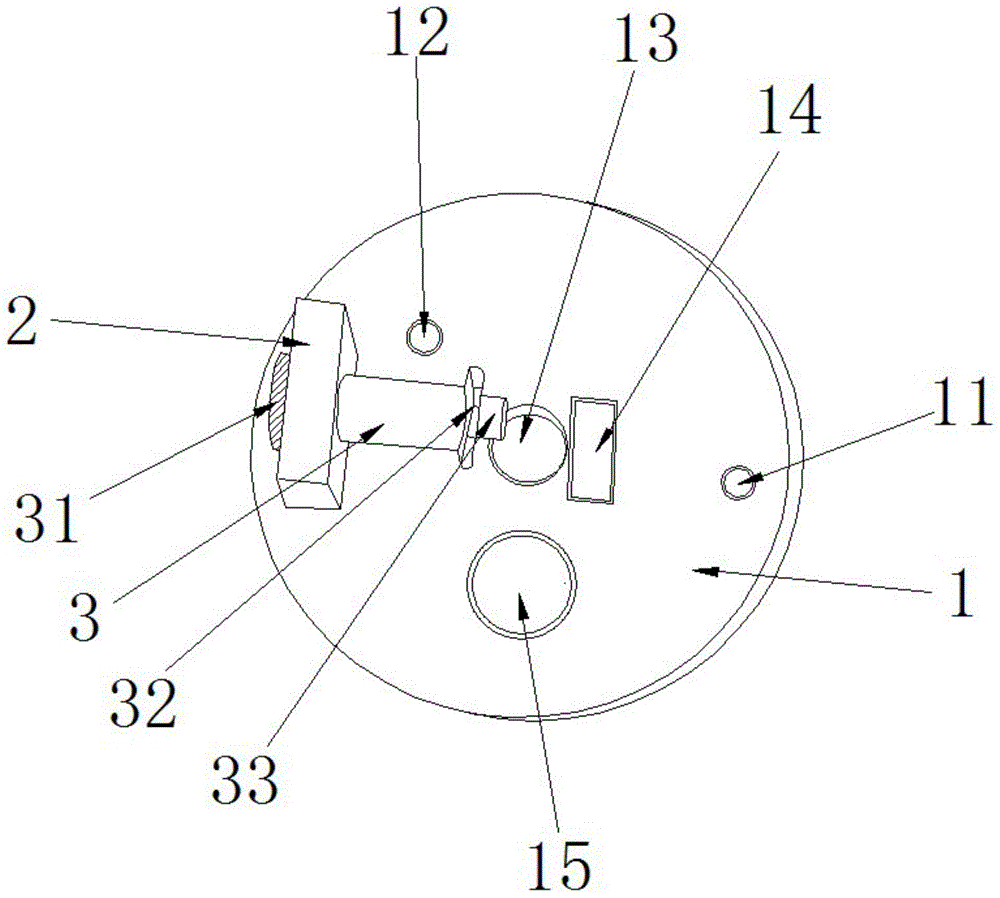

Tool fixture for drilling and tapping

InactiveCN104999300AEasy drilling operationAvoid replacementWork clamping meansPositioning apparatusCircular discQuality of work

The invention relates to a tool fixture for drilling and tapping. The tool fixture comprises a disk, a connecting block, a connecting shaft, a rotary plate and a clamped connector, wherein a first positioning hole and a second positioning hole are formed in the surface of the disk, and a first cutting hole is formed in the center of the disk; a fixing hole is formed in the right side of the first cutting hole, and a second cutting hole is formed behind the first cutting hole; the connecting block is connected with the disk, and a threaded hole is formed in the center of the connecting block; an external thread is arranged on the left side of the connecting shaft, and the connecting shaft is in mesh connection with the threaded hole in the center of the connecting block; the rotary plate is connected with the connecting shaft, and a spring is arranged in the connecting shaft; one end of the spring is connected to the bottom of the connecting shaft, and the other end of the spring is connected with the clamped connector. The tool fixture is convenient for a user to drill or tap, the working efficiency of constructors is effectively improved, the working quality of the constructors is greatly increased, and the working time of the constructors is effectively saved.

Owner:SFAM SCI & TECH JIANGSU

Electric bench drill capable of avoiding overheating

ActiveCN112276167AAvoid overheatingReduce complexityFeeding apparatusBoring/drilling componentsThermodynamicsElectric machine

The invention discloses an electric bench drill capable of avoiding overheating. The electric bench drill comprises a base plate, a water tank, a conveying bin, a motor, a drill rod, a rotating shaftand liquid outlet pipes. The electric bench drill has the advantages that the motor drives the drill rod to rotate, and meanwhile, the liquid outlet pipes supply cooling liquid, that is to say, the drill rod and the drilling position of a material are cooled while drilling is conducted, so that the overheating of the drill rod and the material can be avoided; the single motor provides power for rotation of the drill rod and supply of the cooling liquid at the same time, so that the complexity of equipment is reduced, the production cost of the equipment is effectively reduced, and the practicability and popularization of the device are improved; and when the drill rod rotates, synchronous lifting air cylinders which are symmetrically arranged left and right drive the drill rod to descend,so that drilling operation is more convenient.

Owner:胡满

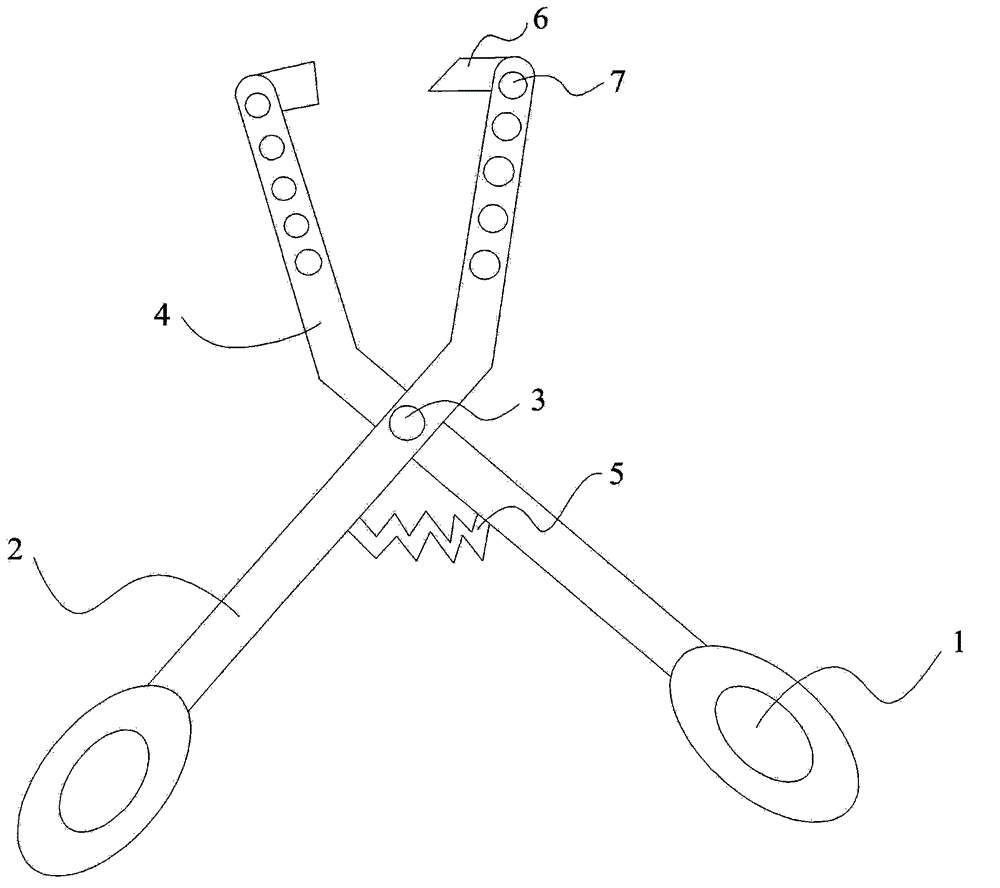

Fixing pliers used for orthopaedics

The invention belongs to the technical field of medical equipment and concretely discloses a pair of fixing pliers used for orthopaedics. The pair of fixing pliers comprises pliers heads, a spring, rings, pliers arm, a fixing shaft, pliers arms and pliers mouths. The pliers heads are fixedly provided with the pliers mouths. Middle portions of the pliers heads are provided with multiple small holes. The spring is mounted between the pliers arms. The lower portions of the pliers arms are provided with rings. The middle portions of the pliers arms are provided with fixing shafts. The pair of fixing pliers used for orthopaedics has following beneficial effects: the pair of fixing pliers has a simple structure and is used conveniently; and during fixation and restoration for orthopaedics, a great clamping force is obtained such that a fracture position is firmly fixed, thereby bringing convenience for drilling operation and screwing operation.

Owner:侯训凯

Tool clamp special for production of combination drilling machine

InactiveCN105773229AScientific and reasonable structureOperational securityMeasurement/indication equipmentsPositioning apparatusDistance sensorsDrilling machines

The invention discloses a tool clamp special for production of a combination drilling machine. The tool clamp comprises a U-shaped support and a bottom frame; locking devices are arranged inside the bottom frame; the U-shaped support is arranged on the right side of a bearing, and drill bits are arranged above the U-shaped support; a distance sensor is arranged on the left side of a moving rod. Compared with the prior art, the tool clamp special for production of the combination drilling machine has the beneficial effects that the structure is scientific and reasonable and the operation is safe and convenient; the U-shaped support is arranged inside the clamp and can clamp cylindrical work-pieces firmly; displacement sensors are arranged inside the U-shaped support and can recognize the distance between the support and the work-pieces, and therefore the distance can be adjusted in time and the work-pieces can be locked; the distance sensor is arranged on the left side of the moving rod, the distance between the work-pieces and the moving rod can be adjusted to be within a fixed range, and therefore the work-pieces can be pressed by a pressing plate conveniently, and the drilling operation is convenient.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

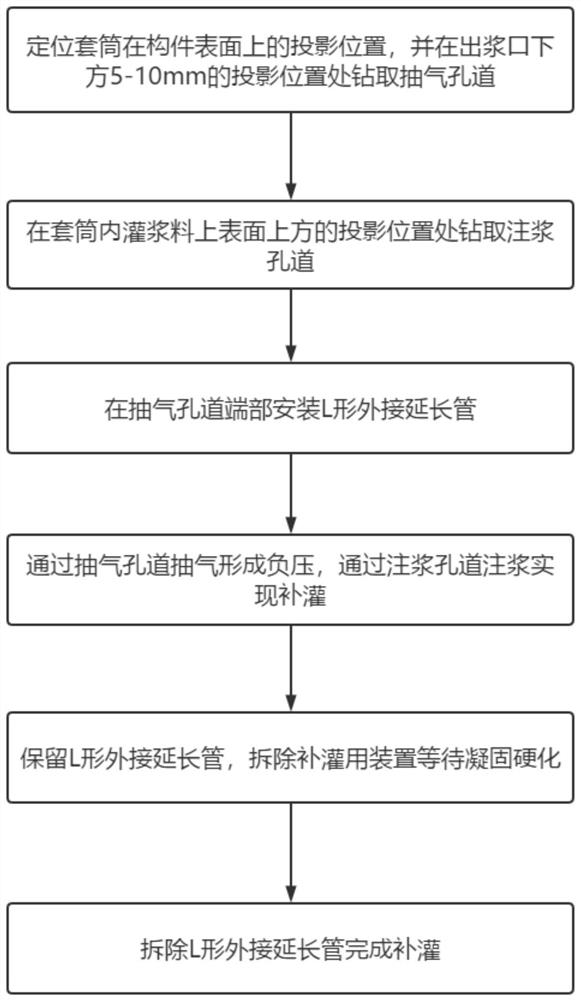

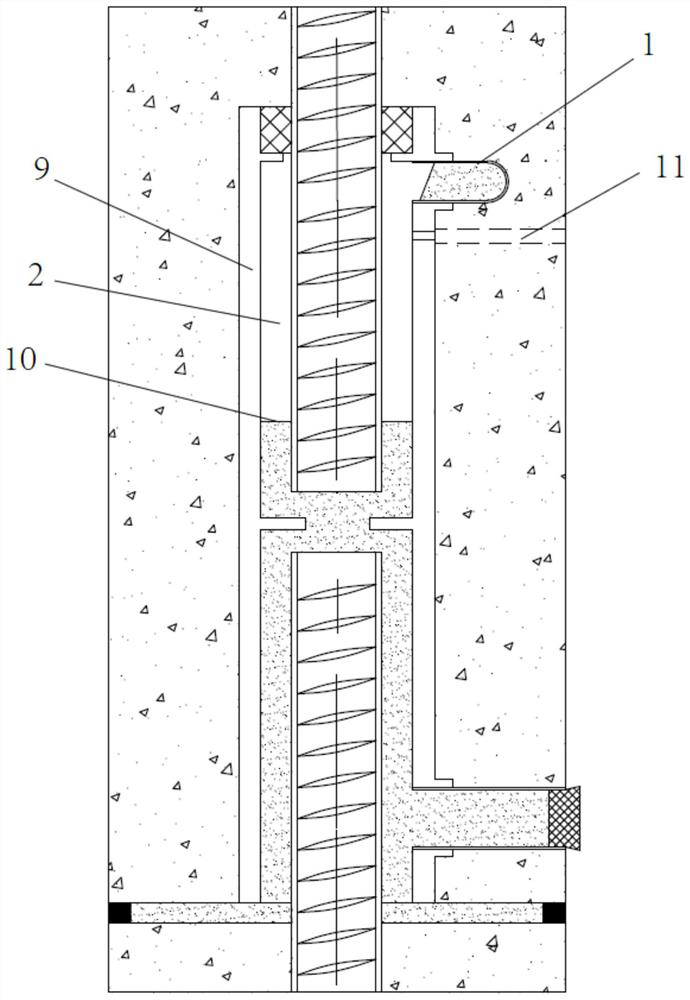

Supplementary filling treatment method for sleeve grouting defect under bent-pipe-shaped slurry outlet hole channel

ActiveCN113668776ALarge room for adjustmentEasy drilling operationBuilding reinforcementsBuilding material handlingButt jointSlurry

The invention discloses a supplementary filling treatment method for a sleeve grouting defect under a bent-pipe-shaped slurry outlet hole channel. The method comprises the steps that the projection position of a sleeve on the surface of a component is positioned, and an air exhaust hole channel is drilled in the projection position 5-10mm below a slurry outlet of the sleeve; the position of the upper surface of a grouting material in the sleeve is determined through grouting fullness detection, and a grouting hole channel is drilled in the position above the upper surface of the grouting material; the air exhaust hole channel is reamed, and an L-shaped external extension pipe is mounted; a grouting pipe is inserted into the outer wall of the sleeve through the grouting hole channel and is in butt joint with the drilling position of the wall of the sleeve; and an air exhaust pipe is inserted into a port of a vertical section of the L-shaped external extension pipe, slurry supplementary filling is started, and supplementary filling is completed. According to the supplementary filling treatment method, damage to the sleeve is small, and the supplementary filling treatment effect is excellent.

Owner:KUNSHAN CONSTRUCT ENG QUALITY TESTING CENT

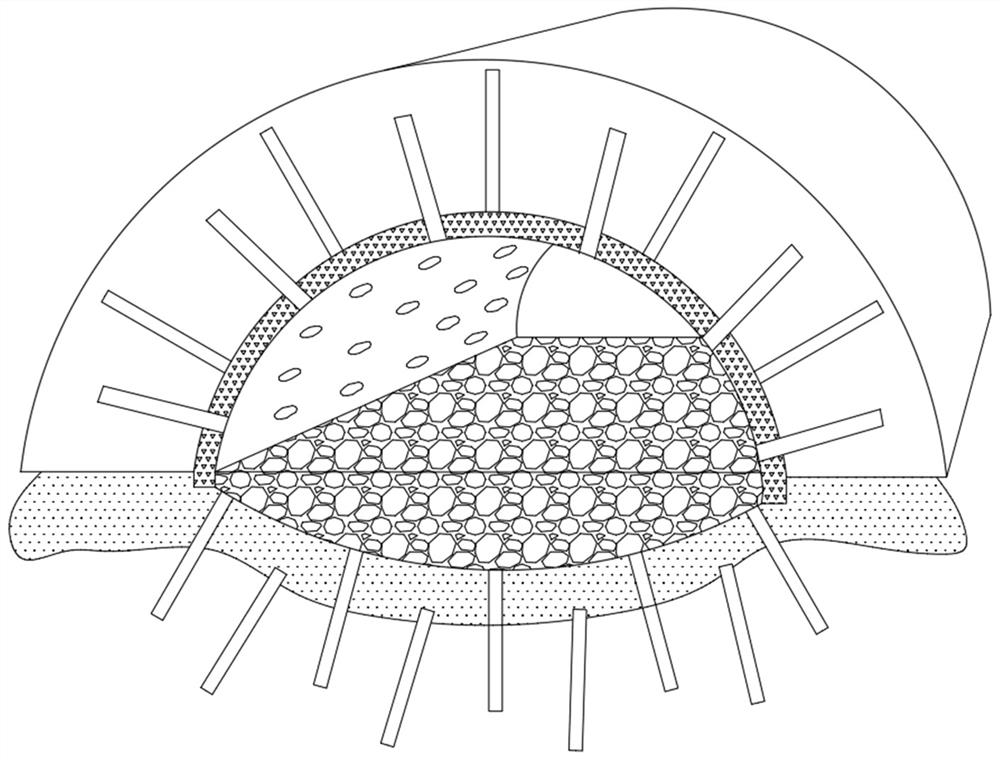

Grouting device for high rock burst and using method

ActiveCN113374508AEasy drilling operationImprove drilling efficiencyUnderground chambersDerricks/mastsHydraulic cylinderClassical mechanics

The invention relates to a grouting device for high rock burst and a using method. The grouting device for the high rock burst comprises a base, a roadway drilling mechanism, a multi-spray-layer sealing layer mechanism and a roadway grouting mechanism, wherein the roadway drilling mechanism, the multi-spray-layer sealing layer mechanism and the roadway grouting mechanism are sequentially arranged at the top of the base from left to right; the roadway drilling mechanism is composed of a first supporting plate, an angle adjusting mechanism, a sliding rail, a first hydraulic cylinder and a drilling motor, the sliding rail is fixedly connected to the top of the first supporting plate, the angle adjusting mechanism is composed of a self-moving air cylinder, a second hydraulic cylinder, a connecting rod and a second supporting plate, and the second hydraulic cylinder is fixedly connected to the top of the self-moving air cylinder; the self-moving air cylinder is slidably connected to the sliding rail, the two ends of the connecting rod are rotationally connected with the second hydraulic cylinder and the second supporting plate through pin shafts correspondingly, the functions of multi-position multi-angle adjusting drilling, concrete mortar extruding and trowelling and multi-position simultaneous grouting are achieved, and the construction efficiency of a homogeneous isotropic supporting ring body is effectively improved.

Owner:HUAIBEI PINGYUAN SOFTROCK SUPPORTING ENG TECH

AGM acid absorption saturability testing method

ActiveCN109100254AEasy drilling operationPrecise positioningWeighing by absorbing componentBottleChemistry

The invention discloses an AGM acid absorption saturability testing method and aims to overcome the defects of testing operation inconvenience and low testing accuracy for AGM acid absorption saturability. The AGM acid absorption saturability testing method disclosed by the invention comprises the steps as follows: a, completely full charging a storage battery, and placing the storage battery in an environment with a temperature of 25 plus and minus 3 DEG C for 24 hours; b, cutting an upper cover of the storage battery open; c, carrying out drilling on a position corresponding to each single lattice power supply at the bottom of the storage battery so as to form bottom collection holes; d, placing the storage battery on a bracket, weighing a weight S2 of an acid collection bottle, and correspondingly placing the acid collection bottle below the bottom collection holes; e, weighing a weight of an acid-containing dropping bottle and recording the weight as M2; f, titrating acid on AGM corresponding to each single lattice power supply, and until observing that acid flows out of the bottom collection holes, weighing a weight M3 of the acid-containing dropping bottle; g, after completing acid collection, weighing a weight S3 of the acid collection bottle; and h, disassembling the storage battery, taking out the AGM corresponding to the single lattice power supplies, weighing a weight D1, and acquiring a weight D2 of the dry AGM.

Owner:CHAOWEI POWER CO LTD

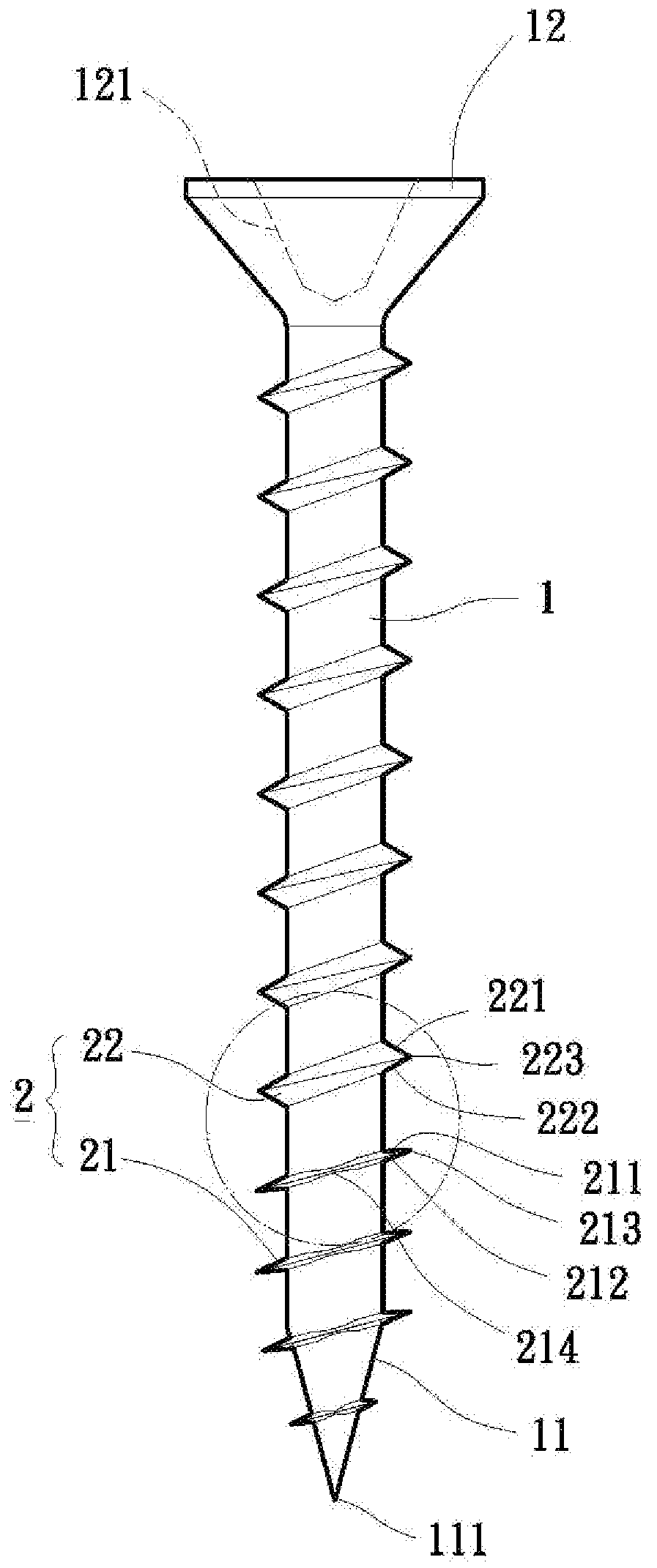

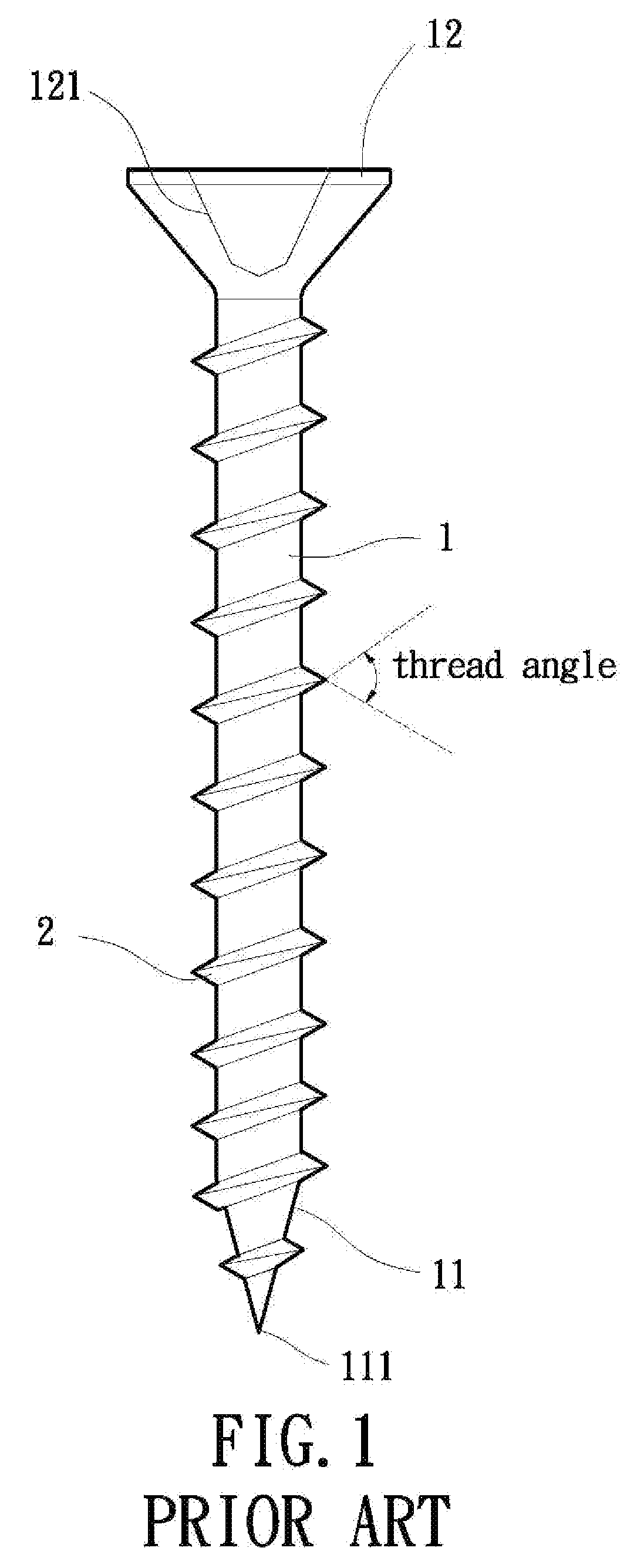

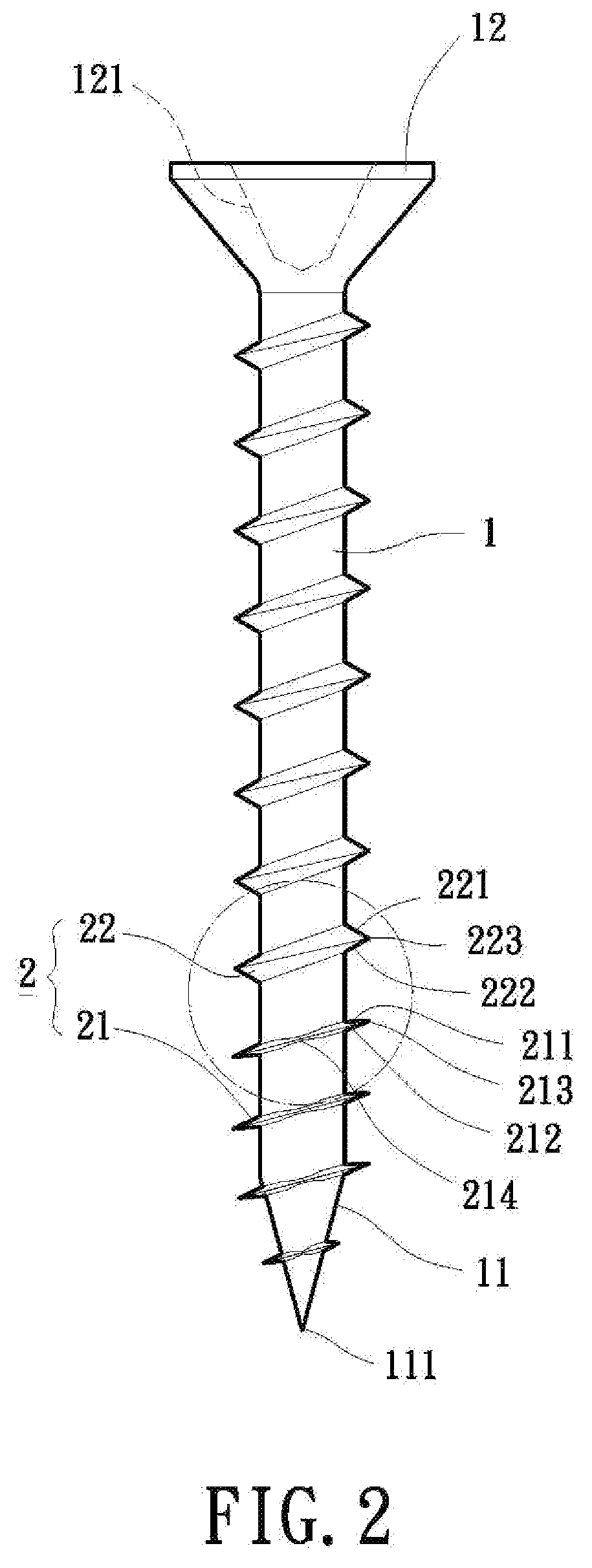

Screw member having two different thread angles formed on a sharp-edged thread

A screw member comprises a screw shank portion and a thread portion provided thereon. The screw shank portion has a bottom end formed with a tapered section, and a top end formed with a screw head portion. The thread portion is provided on an outer circumference of the screw shank portion. The thread portion includes a first thread section proximate the tapered section, and a second thread section proximate the screw head portion. The first thread section has a first thread angle of a sharp-edged thread smaller than a second thread angle of the second thread section such that the first thread section is easier to cut a rigid material.

Owner:EASYLINK IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com