General drill rod clamping device used for coal mine drilling machine

A drill pipe clamping, coal mine drilling rig technology, applied in drill pipe, drill pipe, earthwork drilling, etc. Simple operation, reduced auxiliary time, quick loading and unloading of drill pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

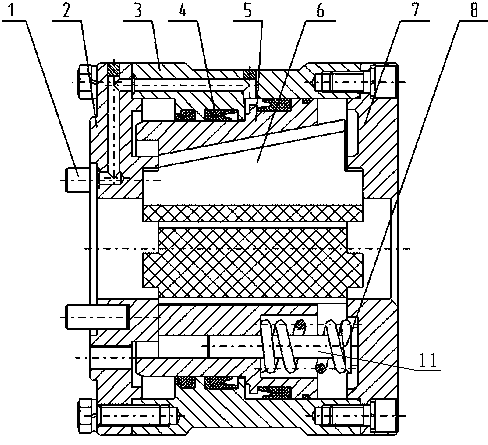

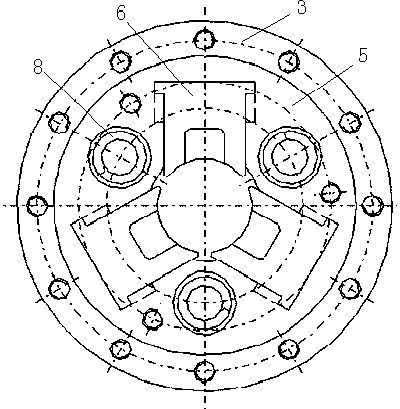

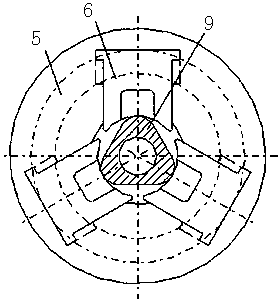

[0020] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] In specific implementation, such as figure 1 and figure 2 As shown, a universal drill pipe clamping device for a coal mine drilling rig includes a front end cover 7, a rear end cover 2 and a cylindrical casing 3 fixed between the two, and the casing 3 is provided with a Sliding overall cylindrical slip sleeve 5, in which several slips 6 that can slide in the radial direction are evenly distributed along the circumference of the slip sleeve 5, and the cross section of the side of the slip sleeve 6 facing the slip sleeve 5 is T-shaped and It is slidably clamped and fitted in the T-shaped groove of the inner cavity of the slip sleeve 5, and the mating surface of the T-shaped groove and the slip 6 is arranged obliquely along the axial direction, and the inner surface of the slip 6 is a concave arc surface , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com