Hexagonal cuff turning-over shaping device

A technology of equipment and fixing seat, which is applied in the direction of setting/elongating circular fabrics, textiles and papermaking, fabric surface trimming, etc. It can solve the problems of asymmetric angle of hexagonal cuffs, non-uniform turned-out angles, and inability to realize angle forming, etc. Achieve good shaping effect, fast operation speed, and avoid the effect of inaccurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

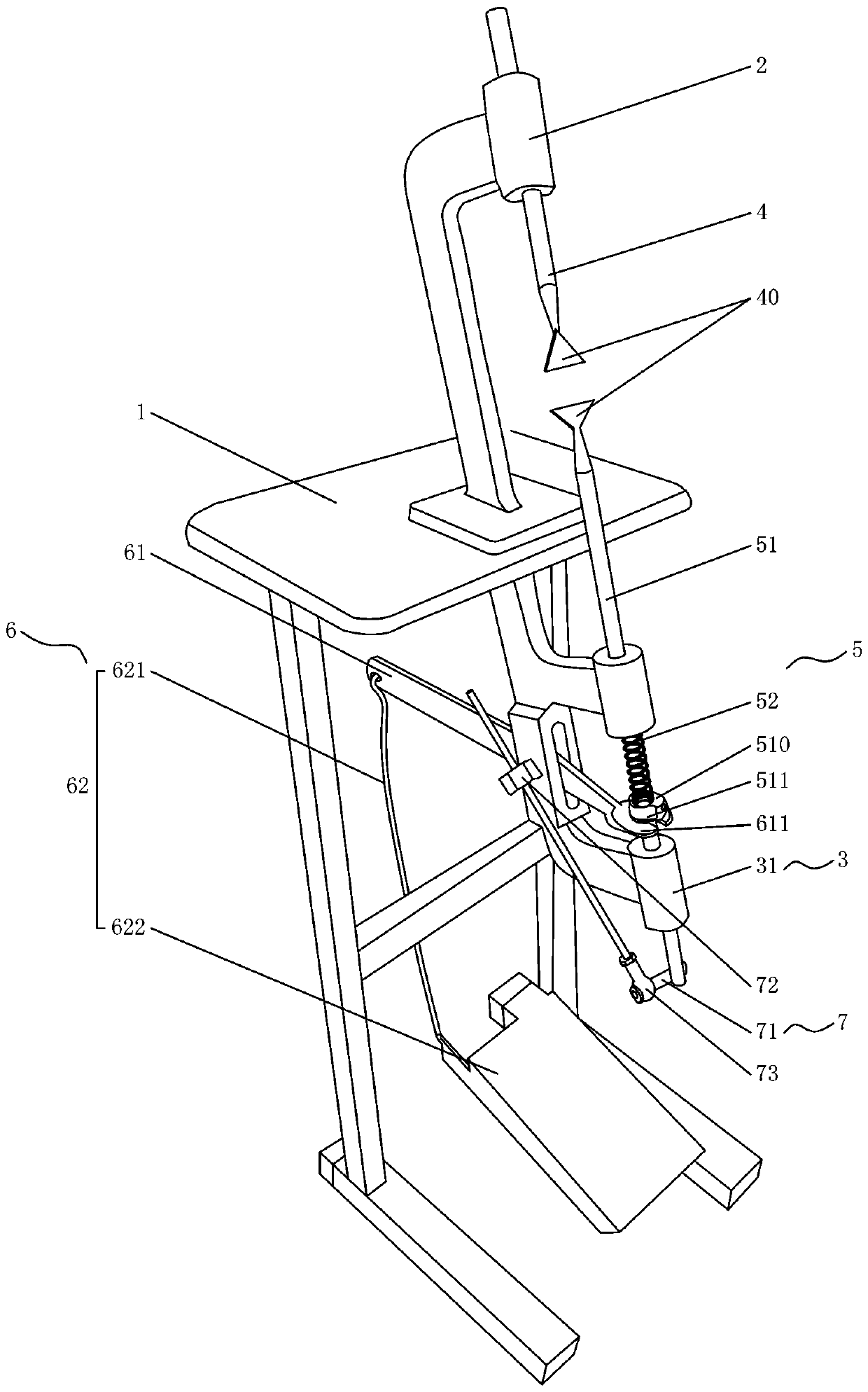

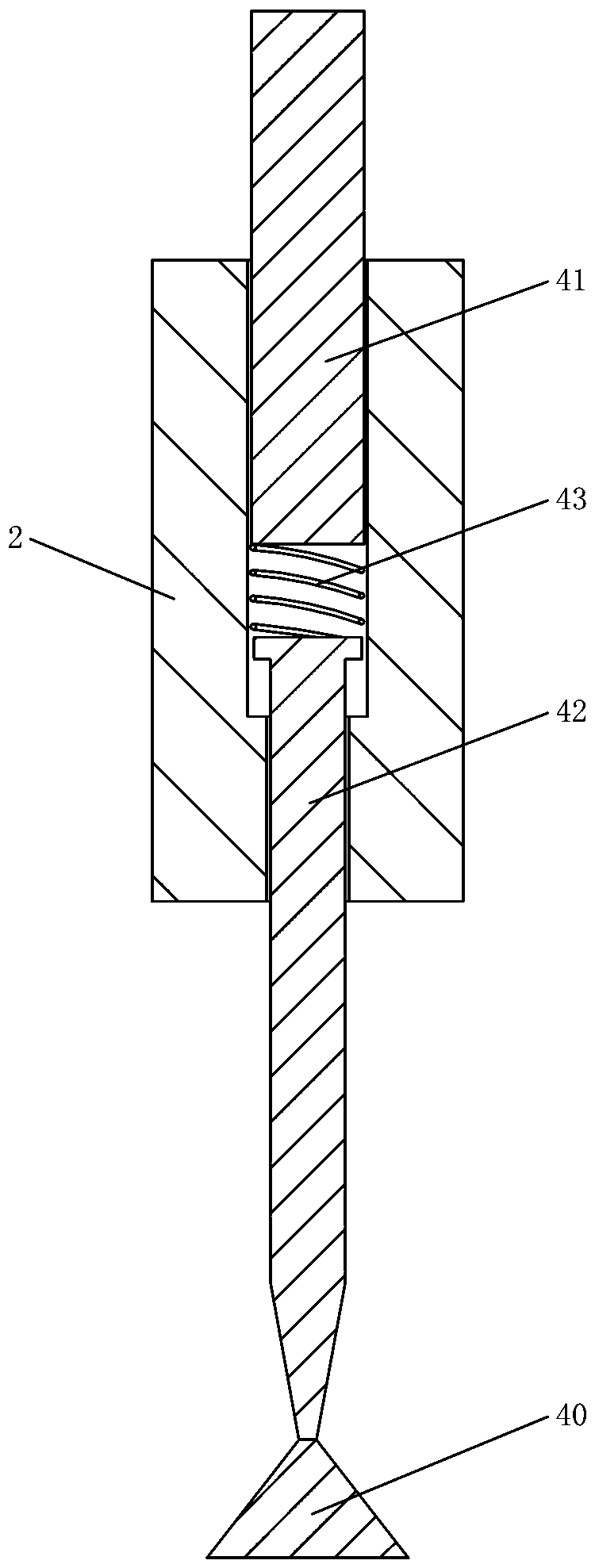

[0035] Wherein, the upper fixed seat 2 and the lower fixed seat 3 are all fixed on the frame 1, and are respectively used for installing the first clamping and shaping unit 4 and the second clamping and shaping unit 5; preferably, the first clamping and shaping unit Both the unit 4 and the second clamping and shaping unit 5 are detachably installed on the upper fixing base 2 and the lower fixing base 3; On the seat 3, and form a sliding fit with it; the first clamping and shaping unit 4 and the second clamping and shaping unit 5 are all formed with a shaping end 40 for shaping the cuff, and the two shaping ends 40 are flat and oppositely arranged; drive The structure 6 is installed on the frame 1, and is used to push the second clamping and shaping unit 5 to move toward the side where the first clamping and shaping unit 4 is located, so that the two shaping ends 40 grip the cuff and make it regular. corners.

[0036] Preferably, the shaping ends 40 of the first holding and sh...

Embodiment 2

[0046] The structure of the hexagonal cuff turning and shaping equipment provided by embodiment two is basically the same as that of the hexagonal cuff turning and shaping equipment provided by embodiment one, the main difference is:

[0047] Wherein, alternatively, the second clamping and shaping unit 5 can also adopt the following embodiments to realize its function: the second clamping and shaping unit 5 includes a first push rod, a second push rod and a spring; The first sliding joint and the second sliding joint; the first push rod is passed through the first sliding joint, and its upper end forms the above-mentioned shaped end 40; the second push rod is passed through the second sliding joint, and It should be understood that the connection relationship between the second push rod and the driving end of the drive structure 6 should be a relationship of abutment or affixation along the axial direction of the second push rod, so as to realize the driving of the drive struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com