All-electric miniature die-casting machine

A die-casting machine, all-electric technology, applied in the field of all-electric miniature die-casting machines, can solve the problems of unsuitable micro components, low processing precision, long processing cycle, etc., achieve simple and easy temperature control, good casting surface quality, and easy realization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is explained in detail below with reference to accompanying drawing:

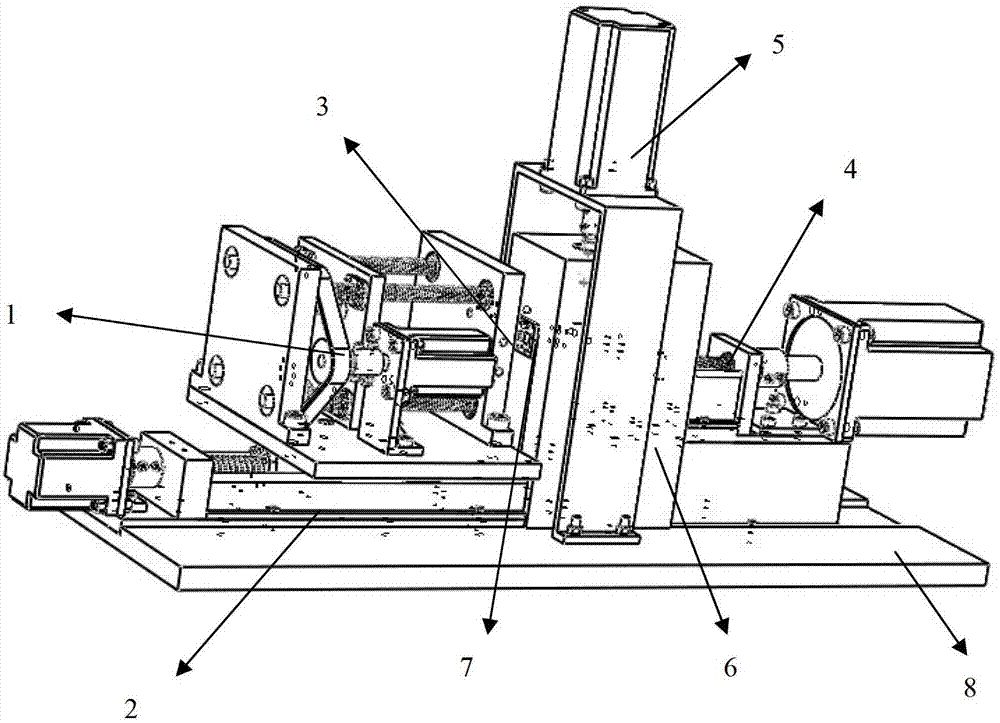

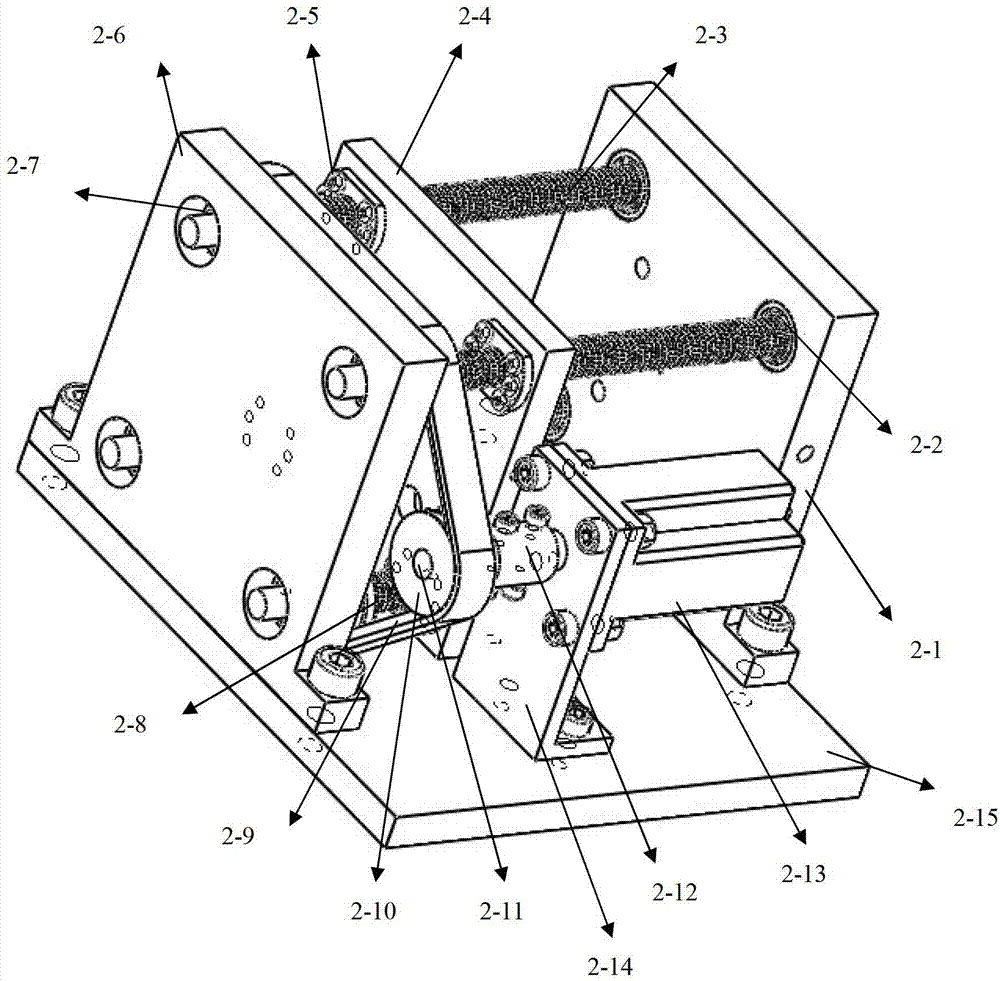

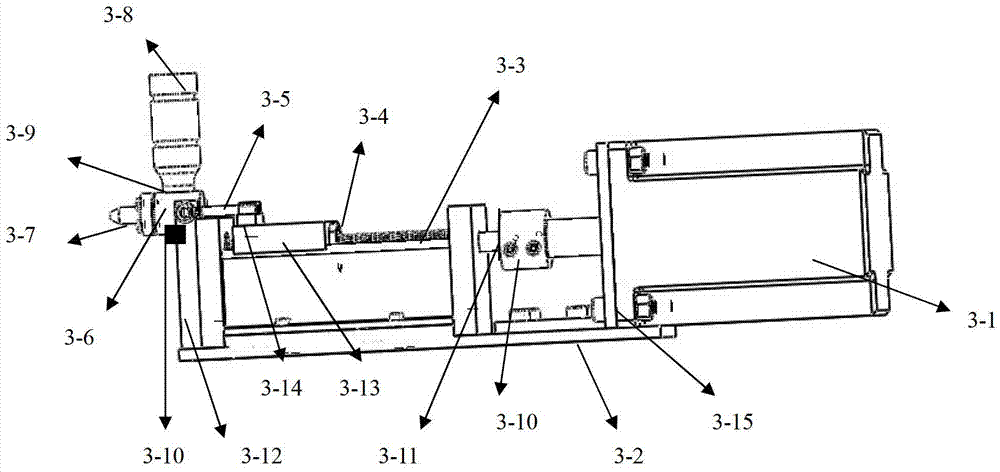

[0024] refer to figure 1 , an all-electric miniature die-casting machine, including a mold clamping system 1, the mold clamping system 1 is fixed on a screw drive system 2 by screws, the screw drive system 2 is fixed on a base plate 8 by screws, and an injection system 4 is fixed on the base plate 8 With the heat preservation system 6, the melting barrel, barrel, injection nozzle and plunger of the injection system 4 are all in the heat preservation system 6, and the injection system 4 cooperates with the quick-release installation valve 7, and the quick-release installation valve 7 passes through the connecting rod Connect with the electromagnet, the electromagnet is fixed on the supporting frame of the feeding system 5, the push block of the feeding system 5 cooperates with the melting barrel of the injection system 4, the supporting frame of the feeding system 5 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com