Patents

Literature

48results about How to "Solve clamping problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

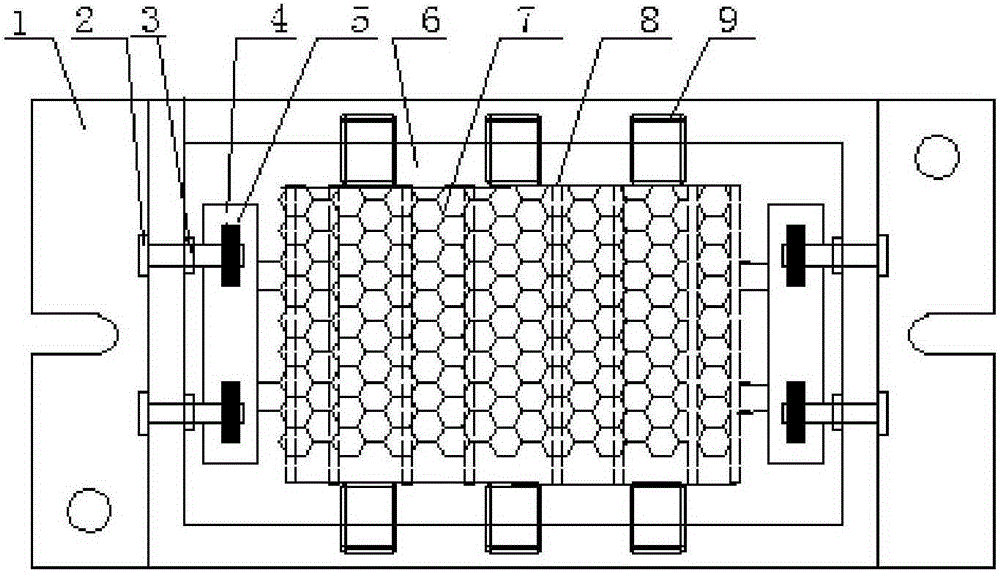

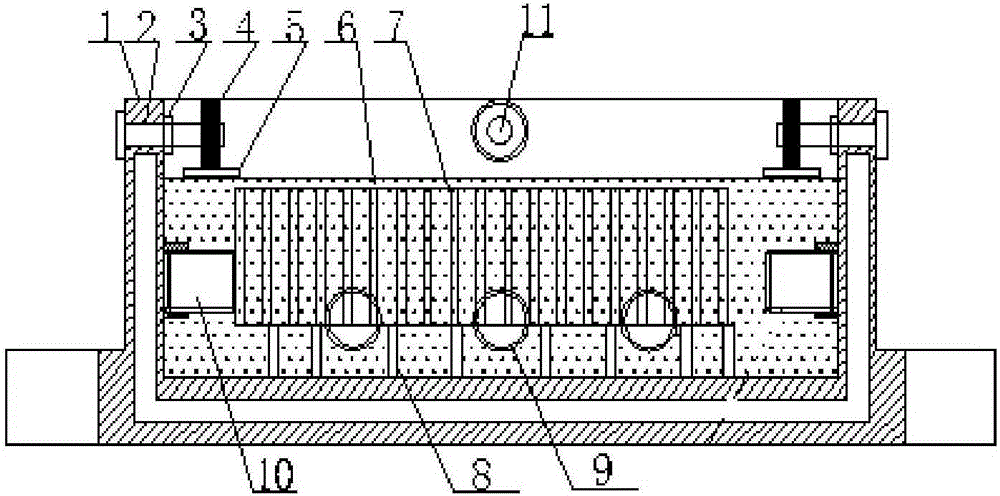

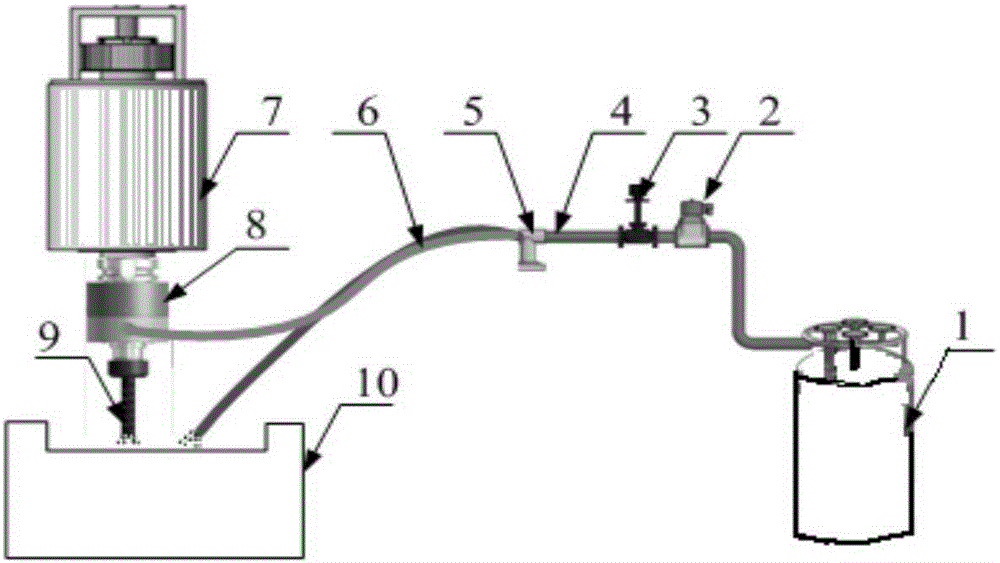

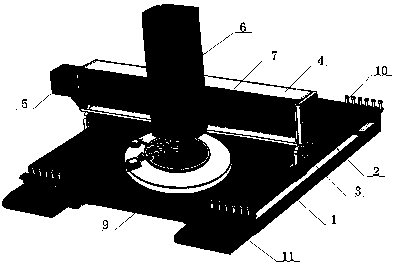

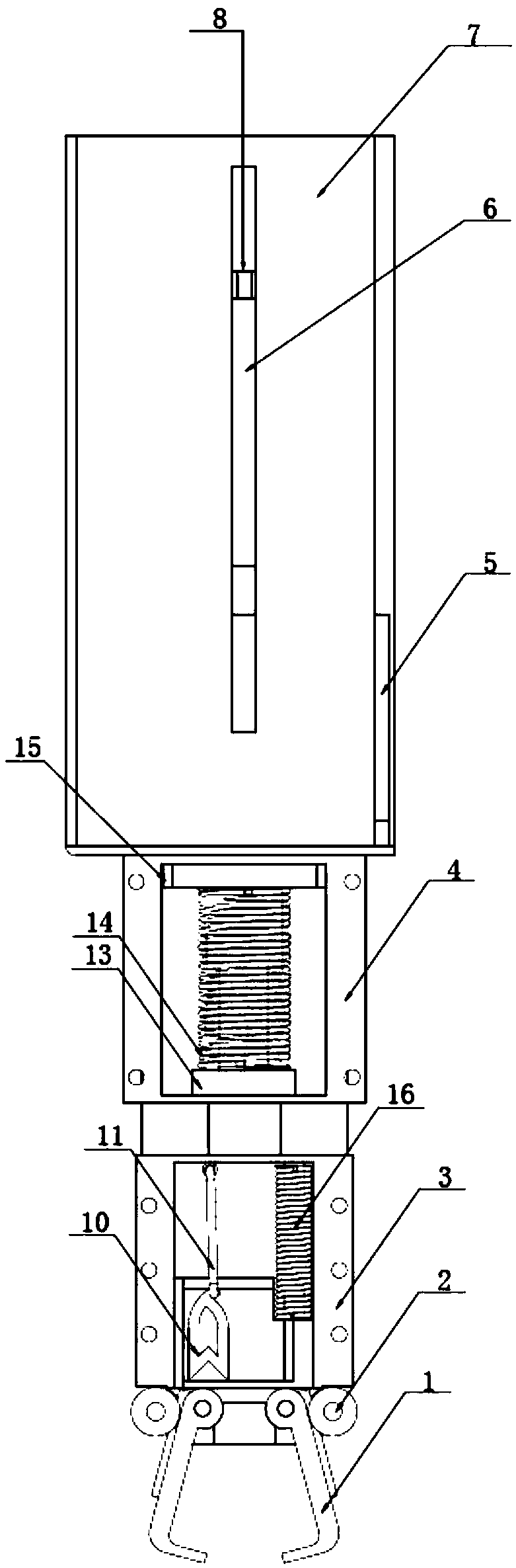

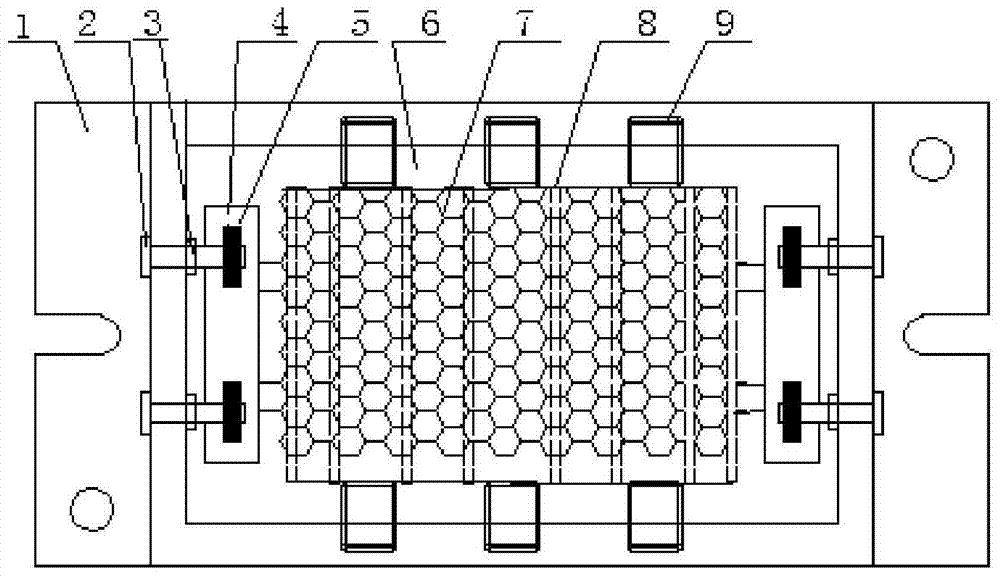

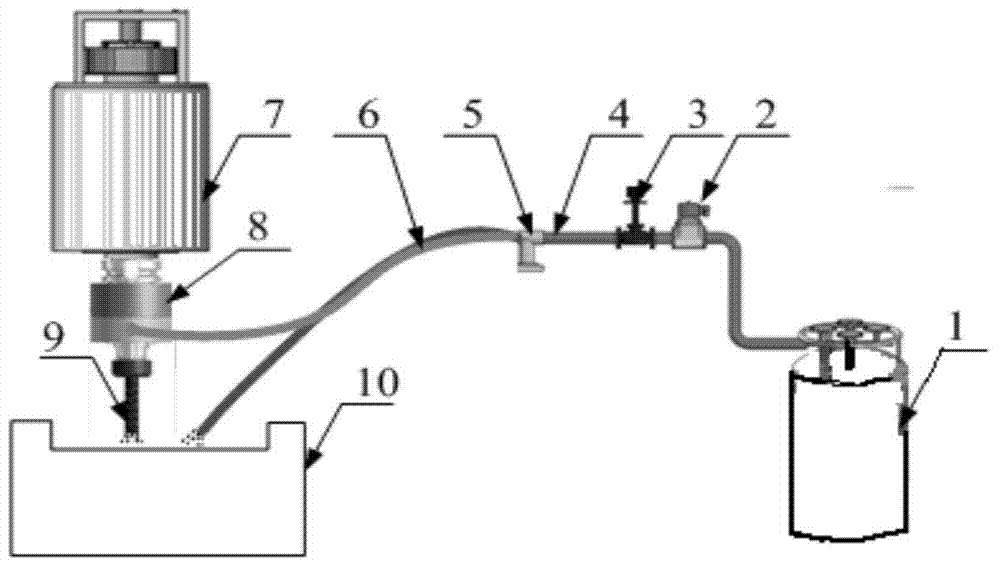

Ice immobilization machining method for metal honeycomb workpiece

ActiveCN105171460ASolve clamping problemsSuppression of processing defectsWork clamping meansMilling equipment detailsHoneycombLiquid nitrogen

The invention provides an ice immobilization machining method for a metal honeycomb workpiece, belongs to the field of machining technological methods and relates to a machine tool fixture device and a machining method for immobilizing a metal honeycomb material through an ice immobilization manner to achieve ultralow-temperature cutting. The method comprises the steps that after metal honeycomb holes arranged in a metal honeycomb ice immobilizing fixture are filled with low-temperature pure water or cutting liquid, the metal honeycomb ice immobilizing fixture is arranged in an adjustable refrigerating testing cabinet, and the freezing temperature and the refrigerating time are set; and then the metal honeycomb ice immobilizing fixture is clamped to a machine tool worktable, metal honeycombs are machined through a liquid nitrogen internal spraying cutter, and the freezing state is maintained through liquid nitrogen external spraying. The method achieves the purpose of clamping of the metal honeycomb workpiece difficult to machine, the freezing temperature of the pure water or the cutting liquid and the temperature maintaining degree are effectively controlled, the machining immobilizing effect can be better, and the cutting precision is improved; and the operation of the method is convenient, the immobilizing effect is stable, the machining efficiency is high, and the machining effect is good.

Owner:DALIAN UNIV OF TECH

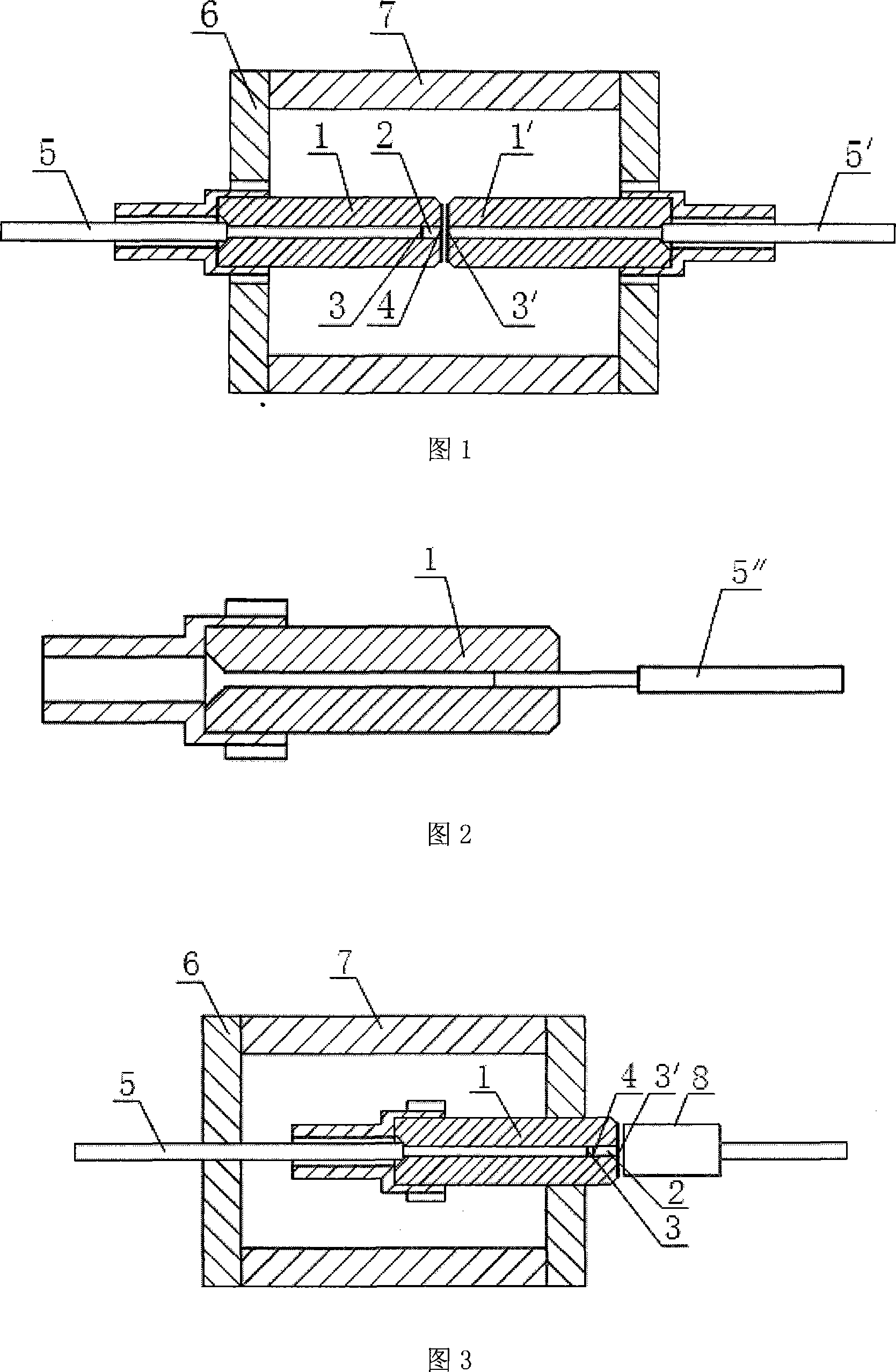

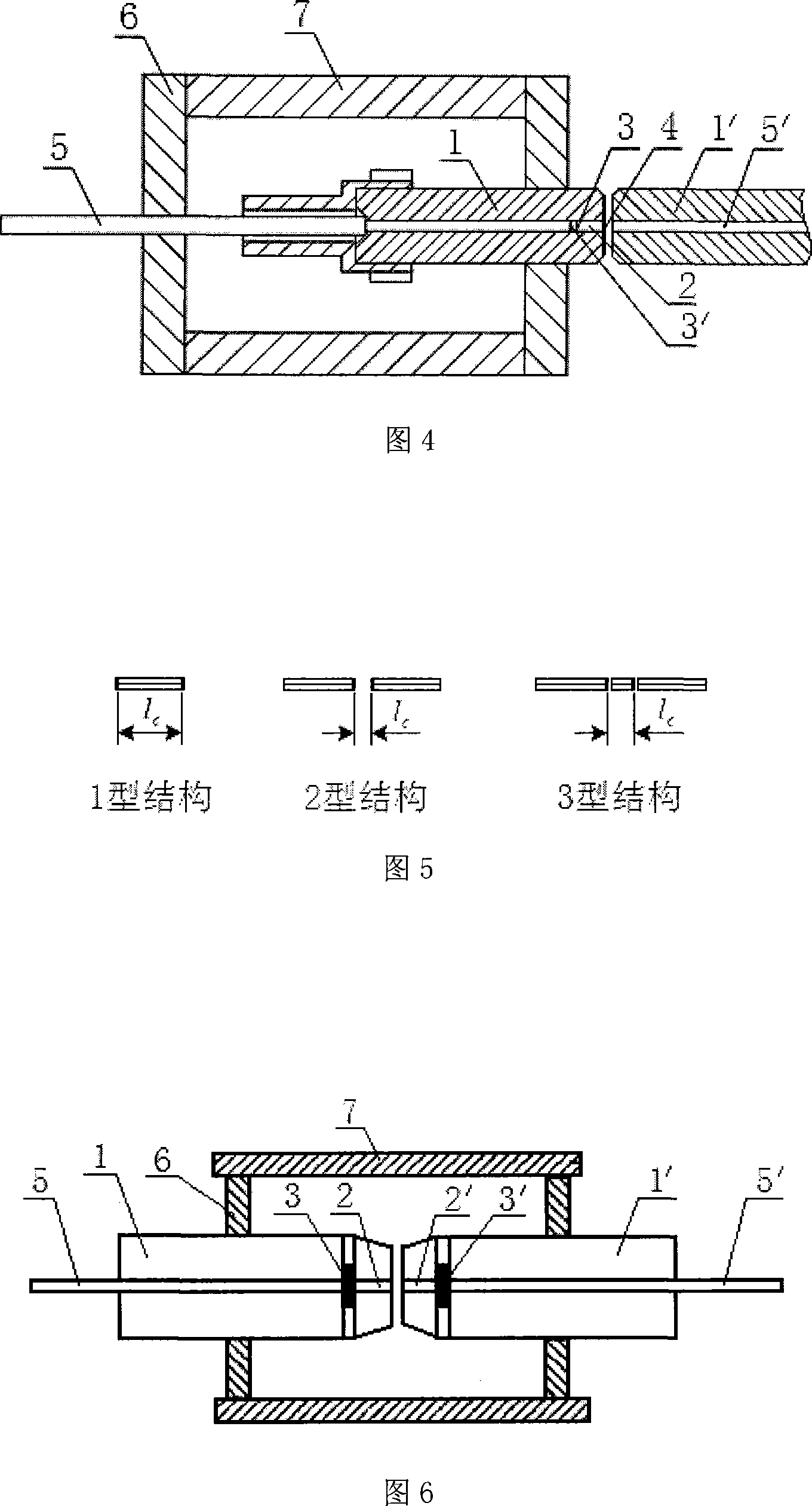

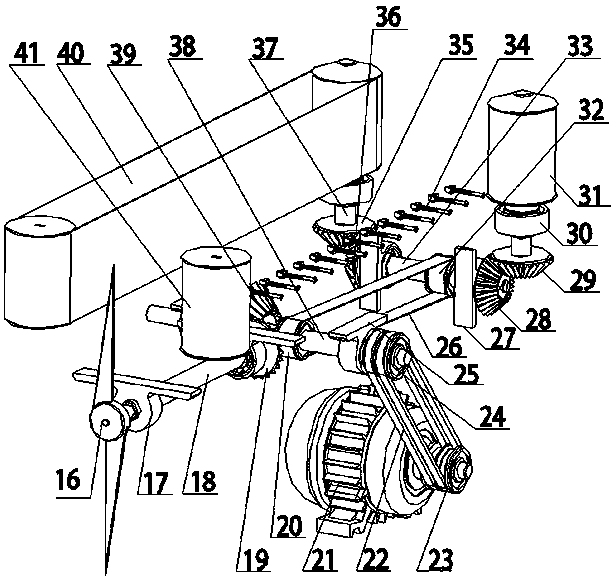

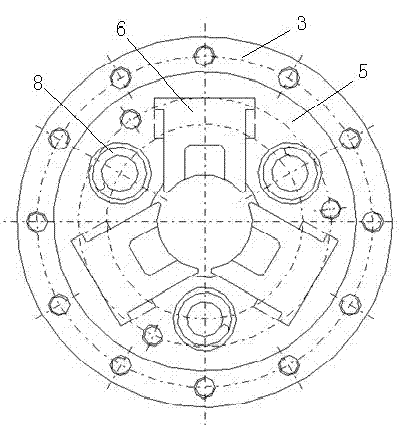

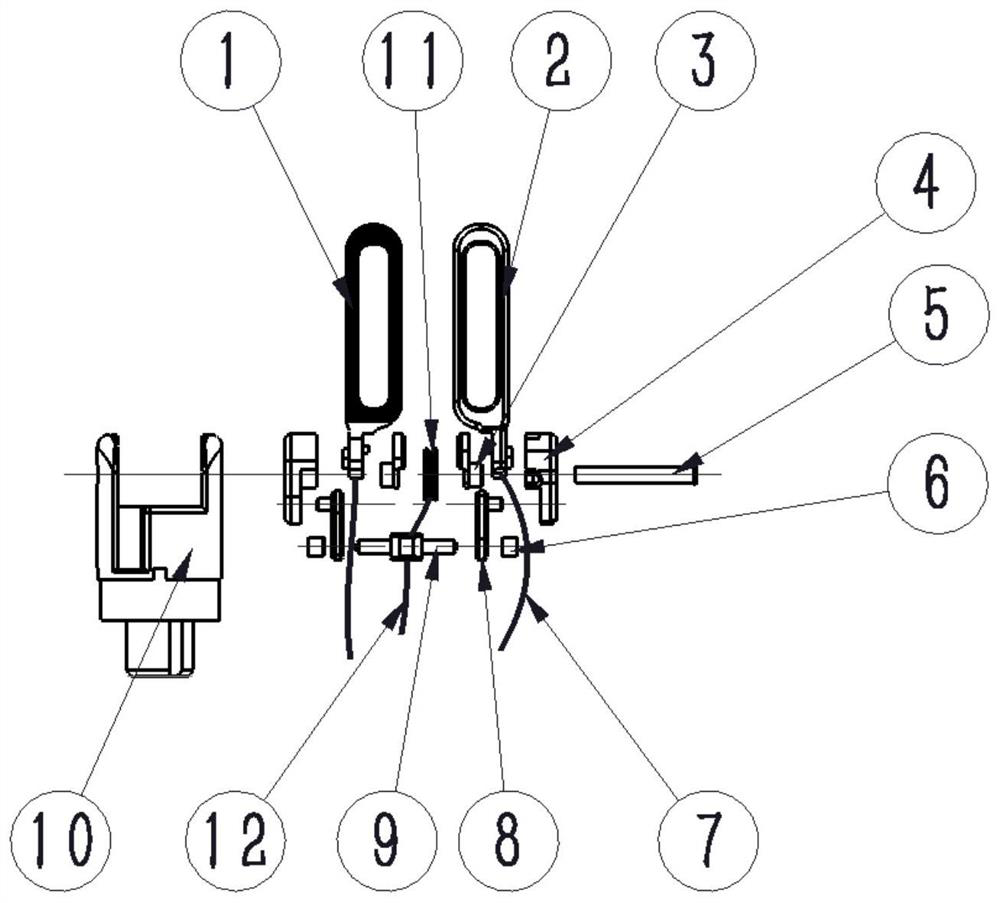

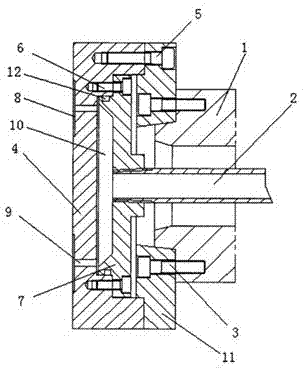

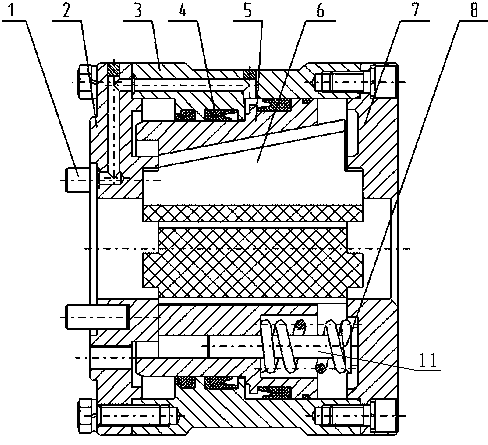

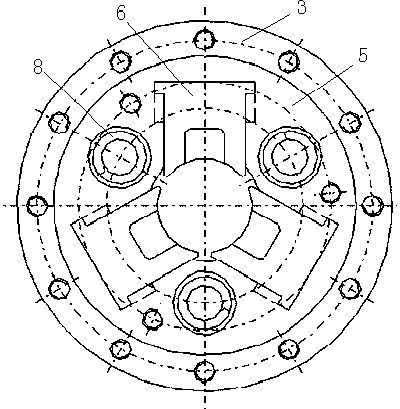

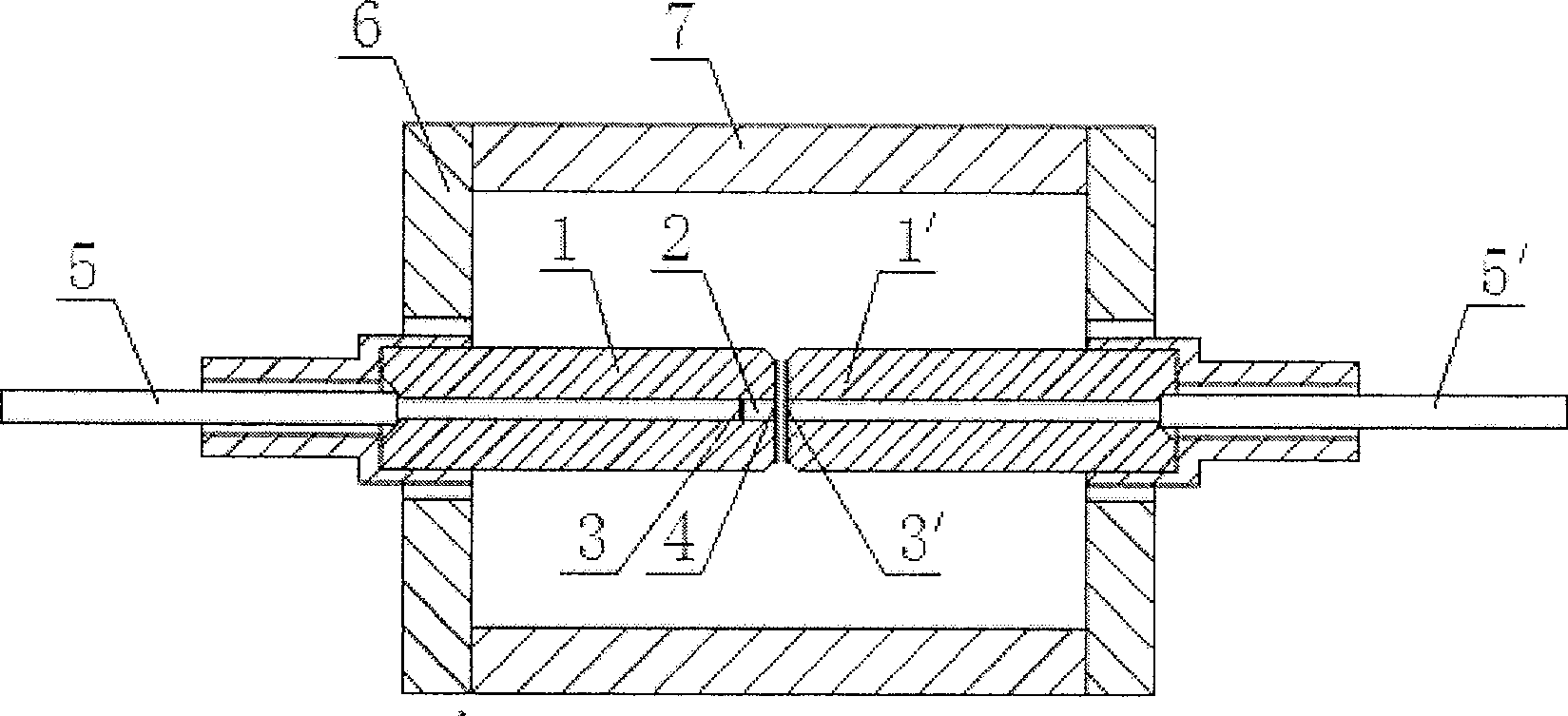

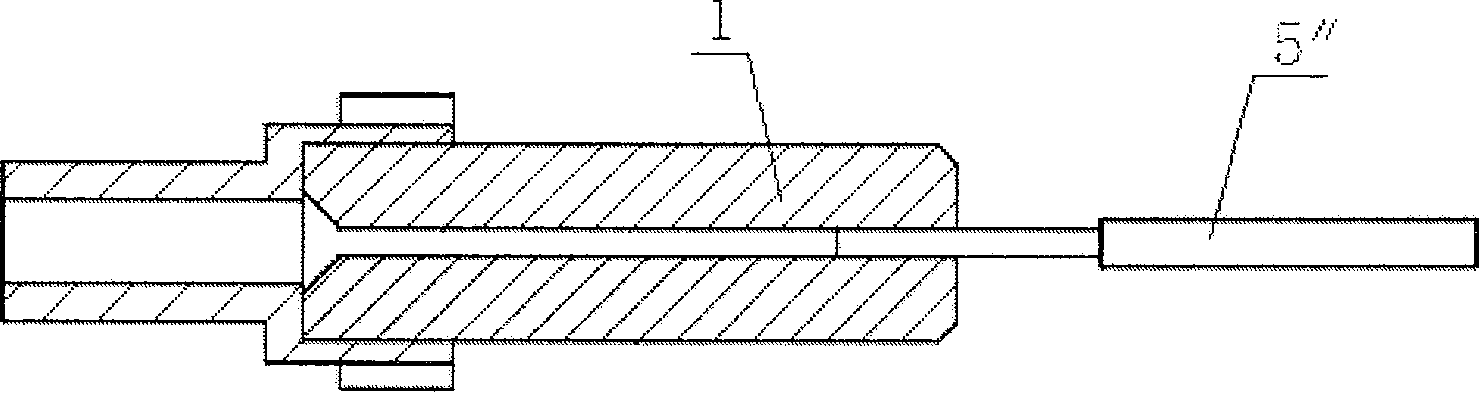

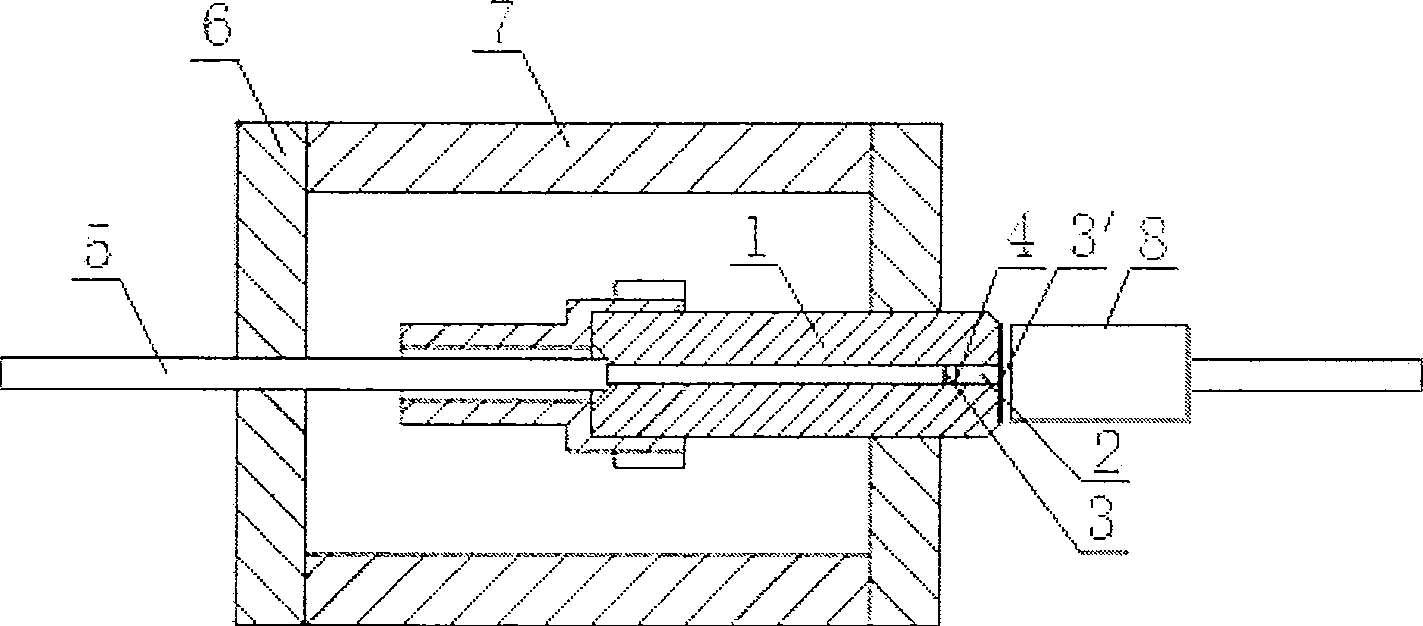

Turnning optical fibre method Fabry-perot filter

The present invention discloses a tunable optical fiber Fabry-Pero filter. The object is to provide the tunable optical fiber Fabry-Pero filter with a Fabry cavity optical fiber waveguide, easy manufacturing and low cost. The present invention comprises a core inset (1), the optical fiber waveguide (2), a high reflecting coating (3), an antireflection coating (4), an optical fiber (5), a support (6), a piezoelectric ceramics (7) and a fiber collimator (8); the optical fiber waveguide is fixed in one inner hole of the core insert. One end surface is placed in the inner hole of the core insert and the other end surface is placed on the same flat with the core insert end surface. The inner hole of the core insert which fixes the optical fiber waveguide is also inserted by the optical fiber. The optical fiber and the optical fiber waveguide are automatically aligned through the inner hole of the core insert. One of the two adjacent end surfaces of the optical fiber and the optical fiber waveguide is coated with the high reflecting coating. The end surface of the core insert or the other end surface of the core insert with optical fiber is coated with the high reflecting coating, so the optical fiber Fabry-Pero filter is formed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

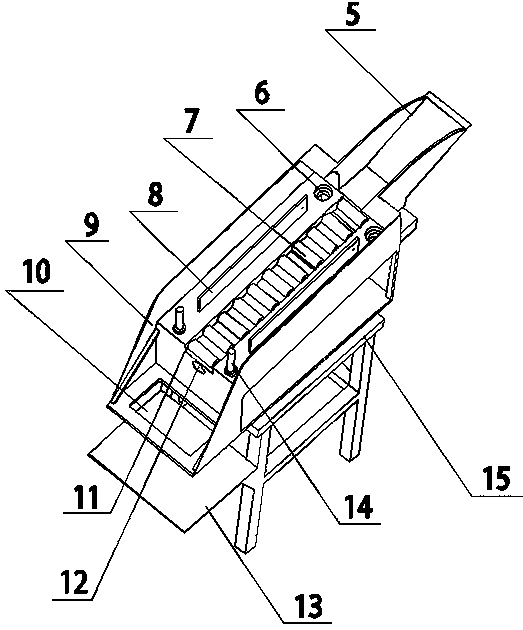

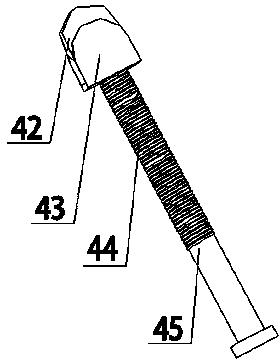

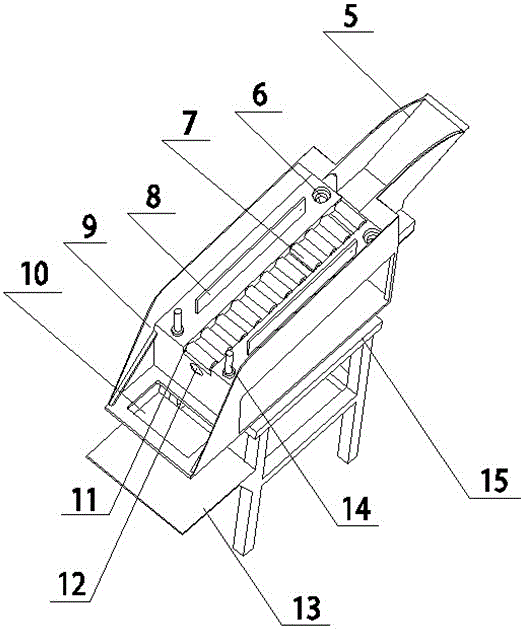

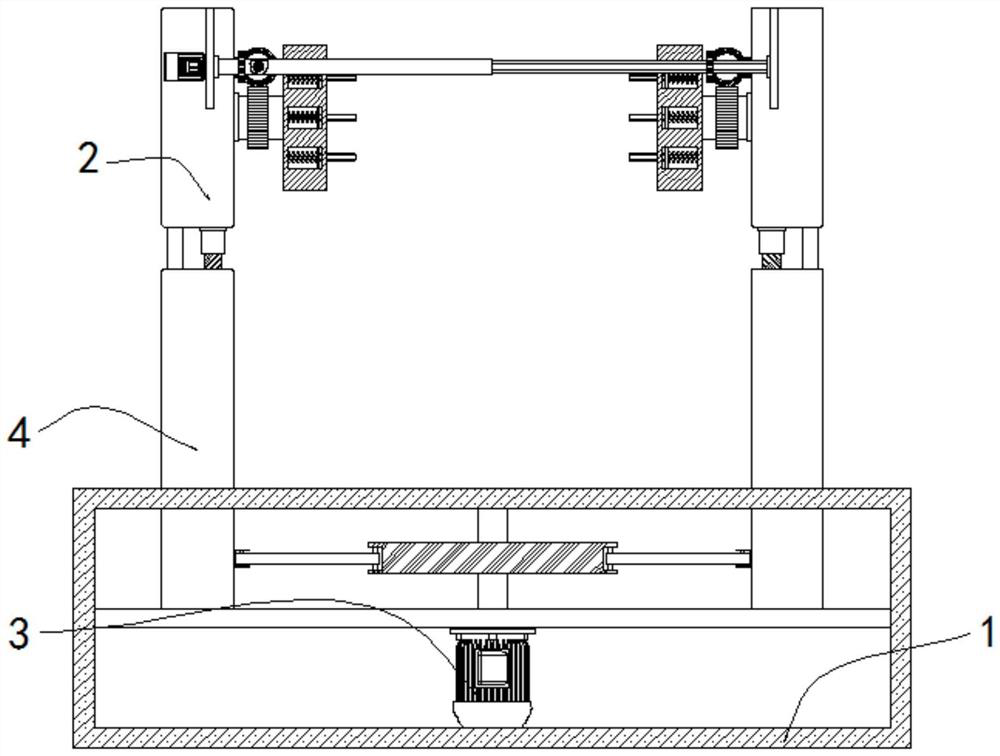

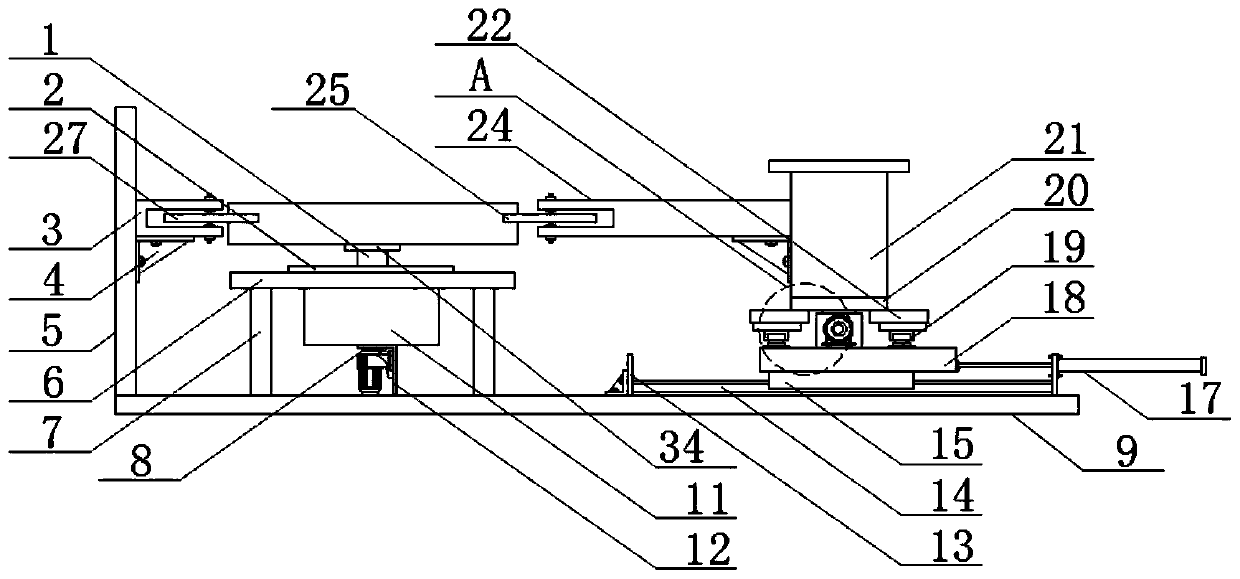

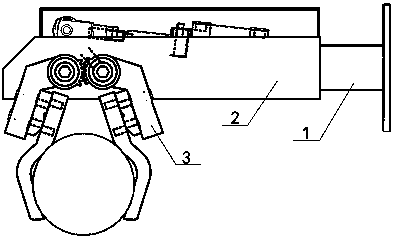

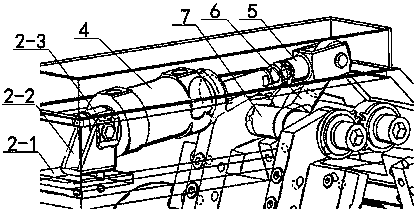

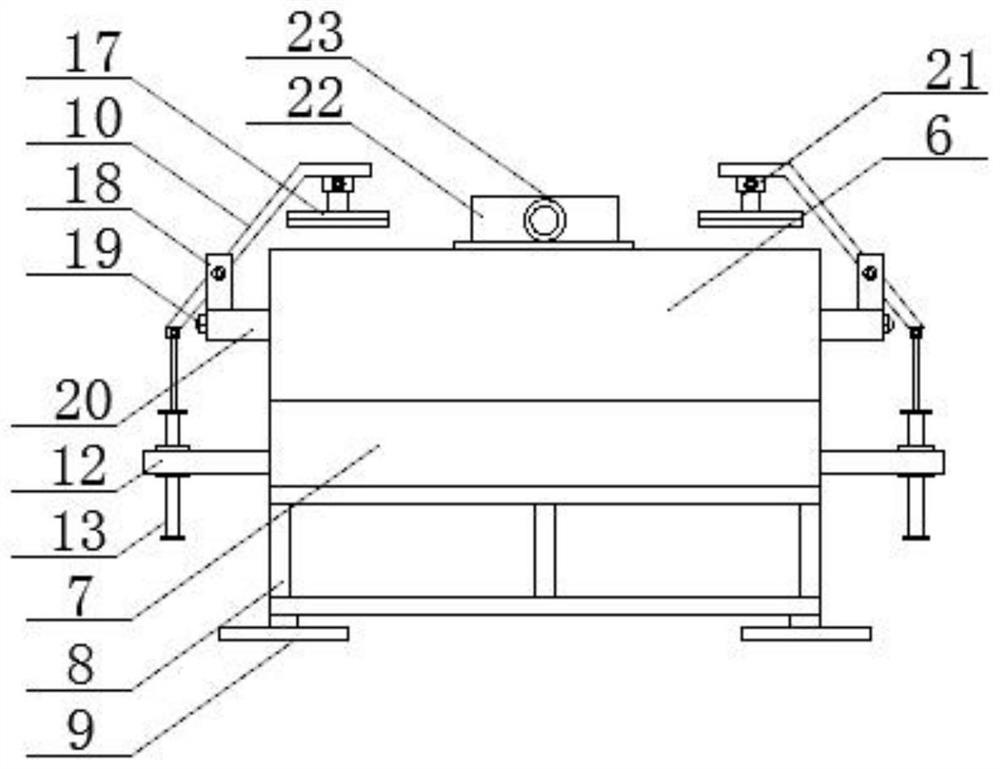

Feeding type automatic lotus root slicing machine

InactiveCN104385338ASlicing is stable and efficientClamp firmlyMetal working apparatusMechanical engineeringLotus root

The invention relates to a feeding type automatic lotus root slicing machine, in particular to novel lotus root processing equipment. The feeding type automatic lotus root slicing machine consists of a frame, a lotus root conveying unit, a lotus root clamping unit, a lotus root slicing unit and a lotus root slice collecting unit, wherein the lotus root conveying unit and the lotus root clamping unit are embedded together; and the lotus root clamping unit is contacted with a conveying belt on the lotus root conveying unit through a roller on a pressurizing chuck, so that processed lotus roots can be smoothly fed in the lotus root slicing unit through the lotus root conveying unit. The lotus root slicing unit is positioned at the tail end of the lotus root conveying unit; and the lotus root slice collecting unit is positioned rightly below the lotus root slicing unit. The feeding type automatic lotus root slicing machine adopts the pressurizing chuck to perform the point clamping for the lotus roots through flexible transition of the conveying belt, the lotus root conveying unit and the lotus root clamping unit are embedded together, and the lotus root conveying unit and the lotus root slicing unit are linked, so that the structure is compact, and the stability is enhanced; and all the component units of the whole machine are higher in working coordination degree, facilitate automatic production control, are excellent in use effect, and are strong in practicability.

Owner:WUHAN TEXTILE UNIV

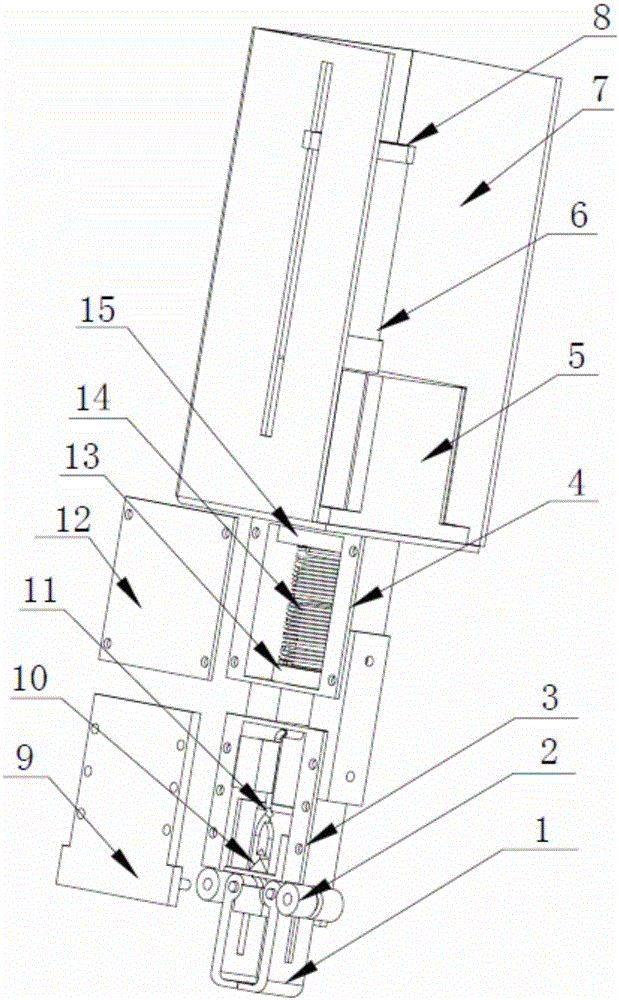

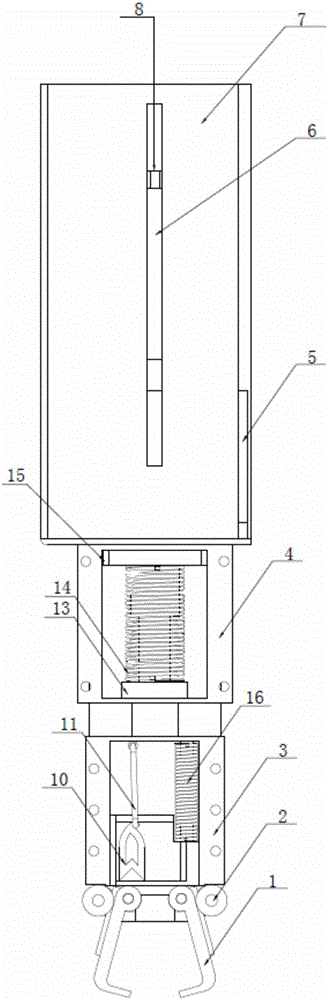

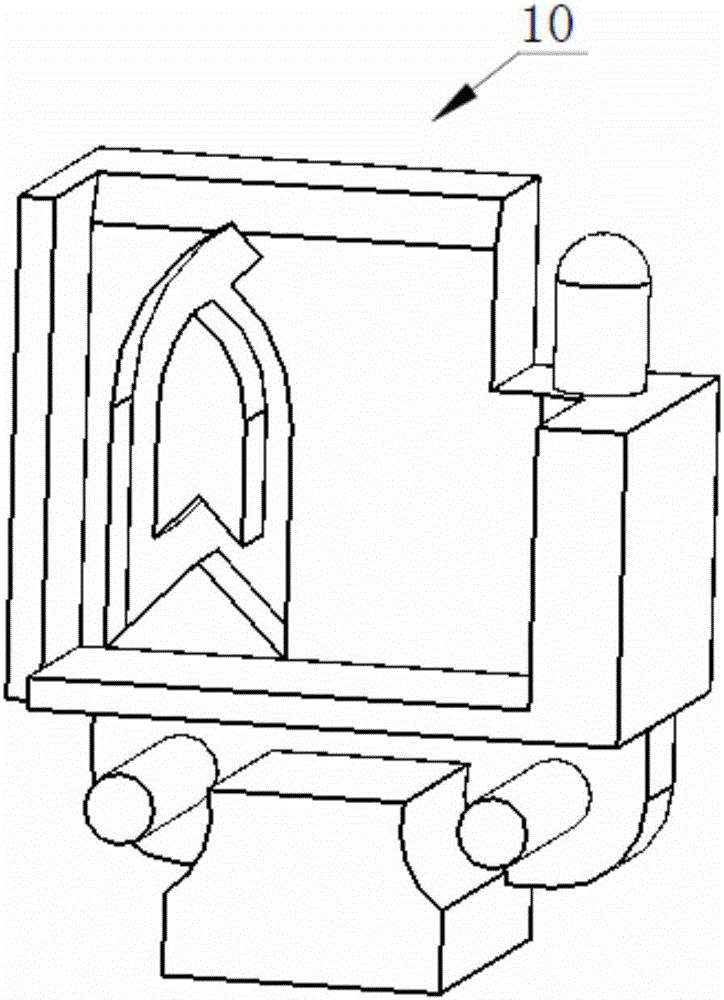

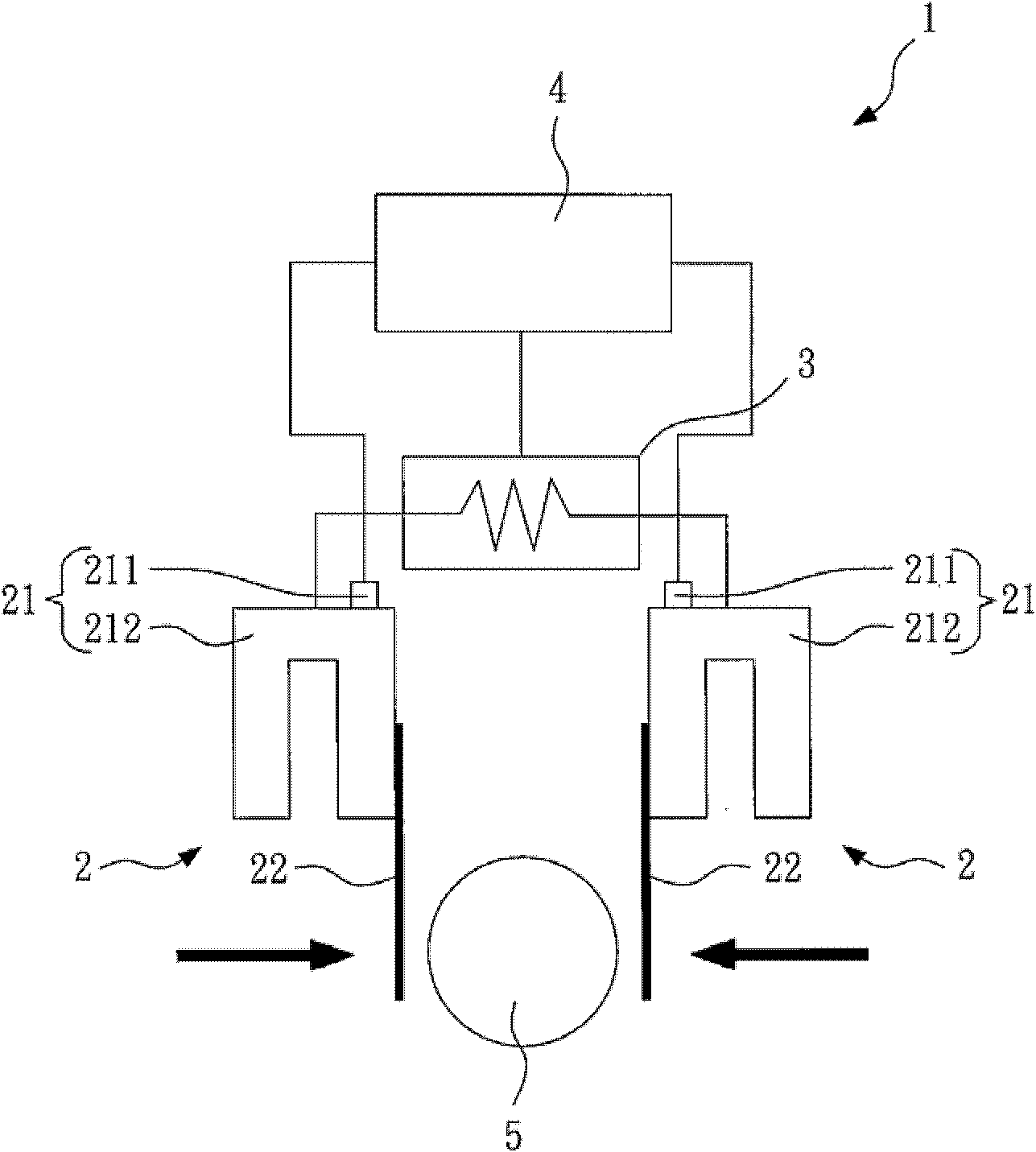

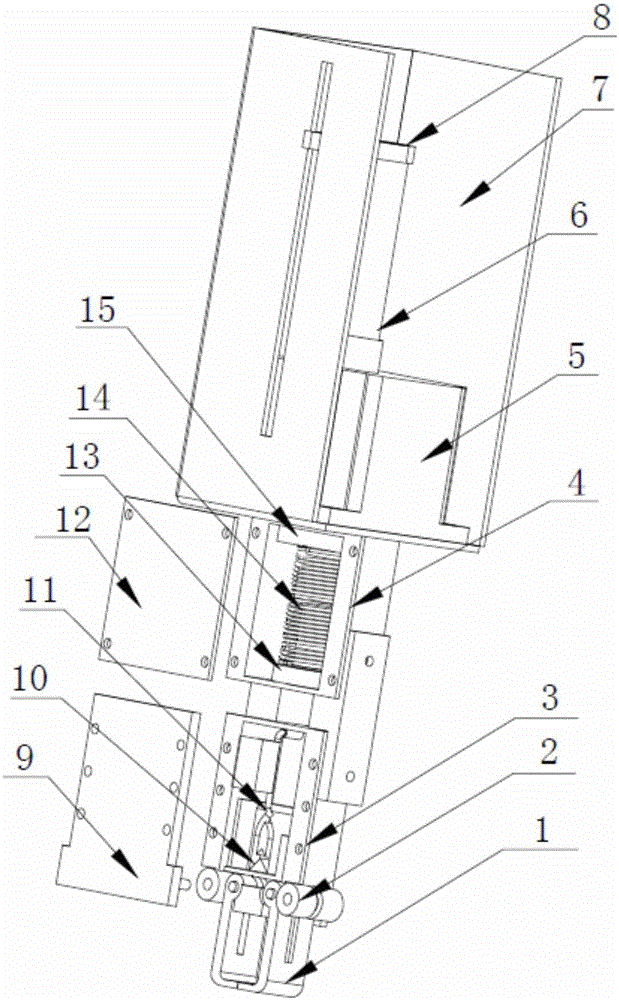

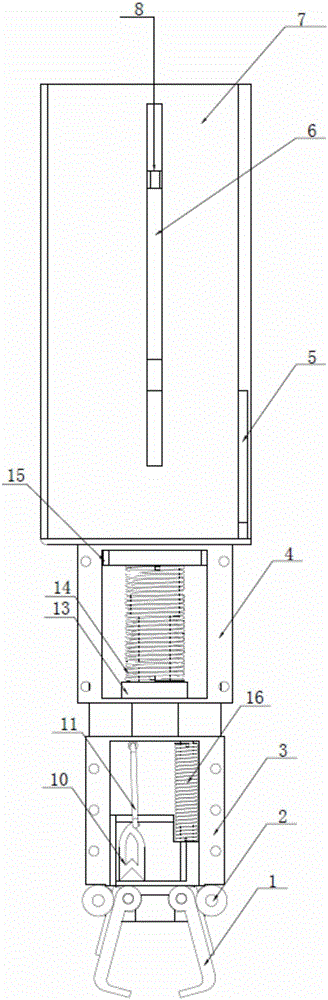

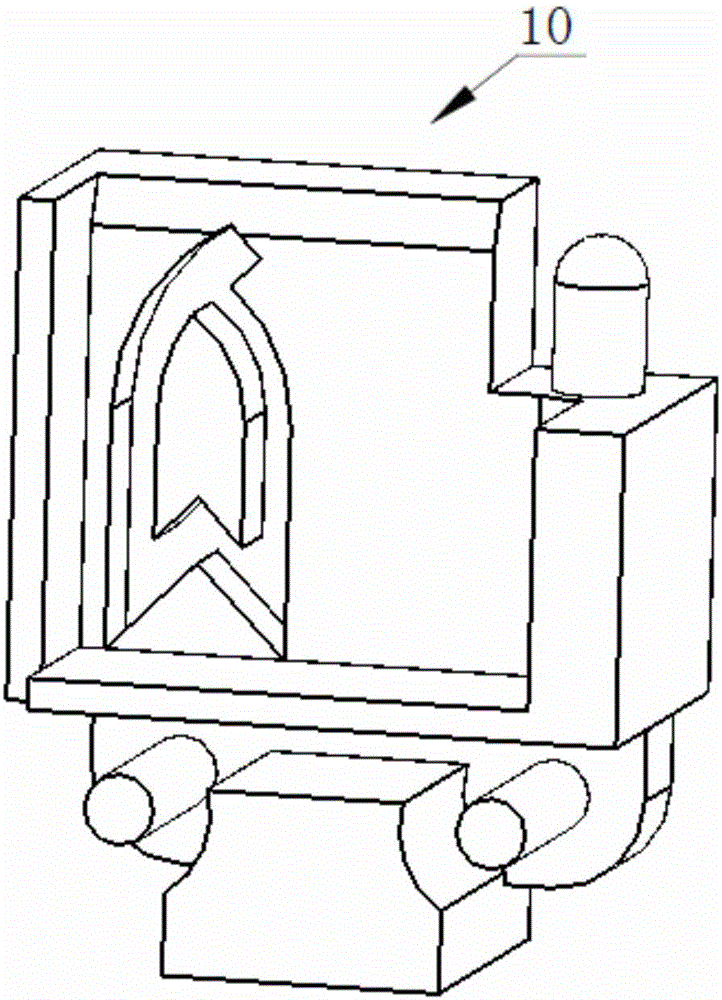

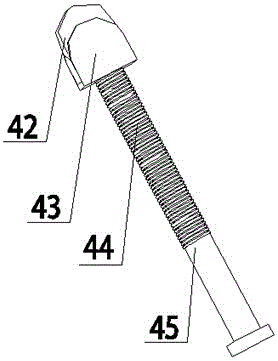

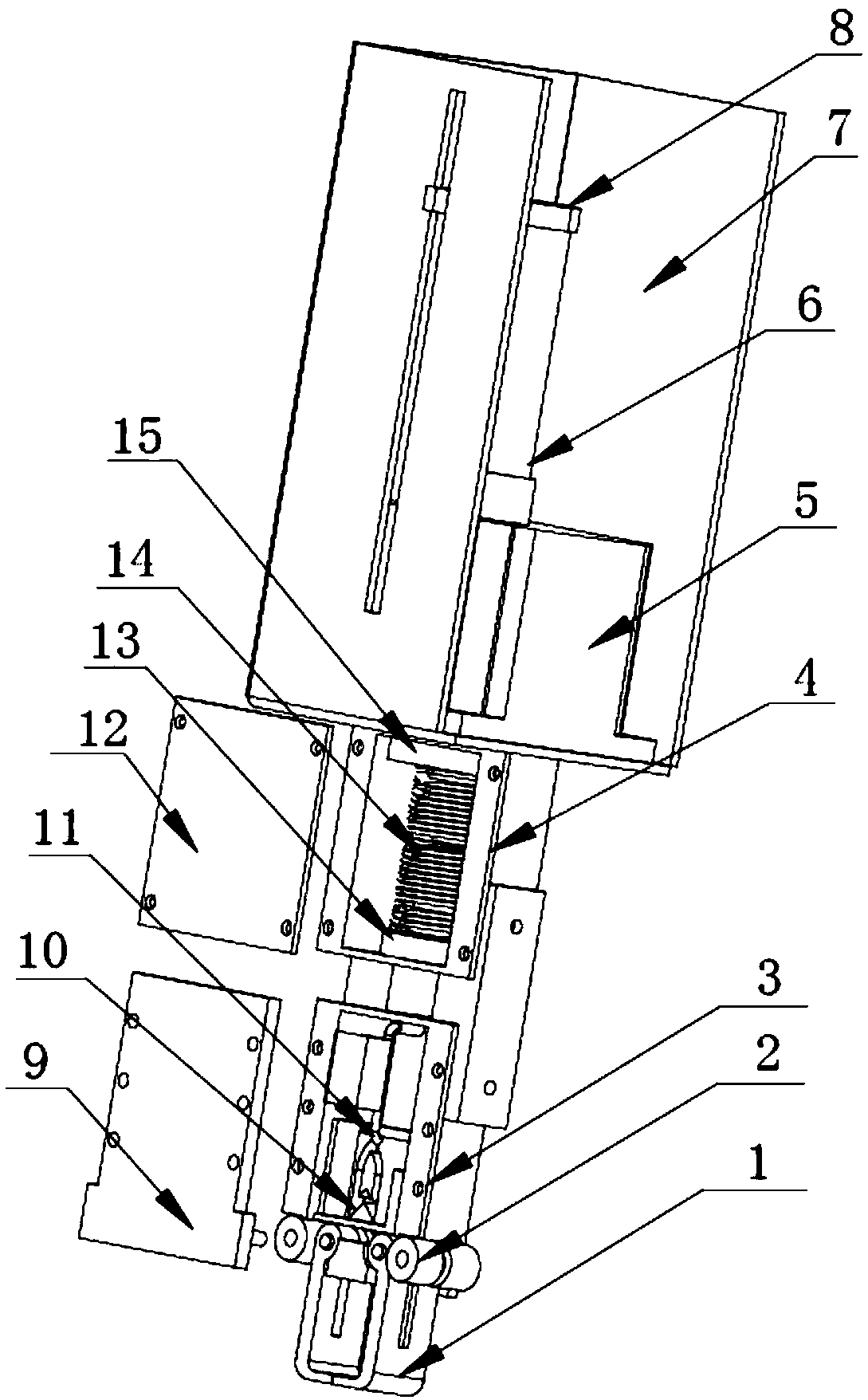

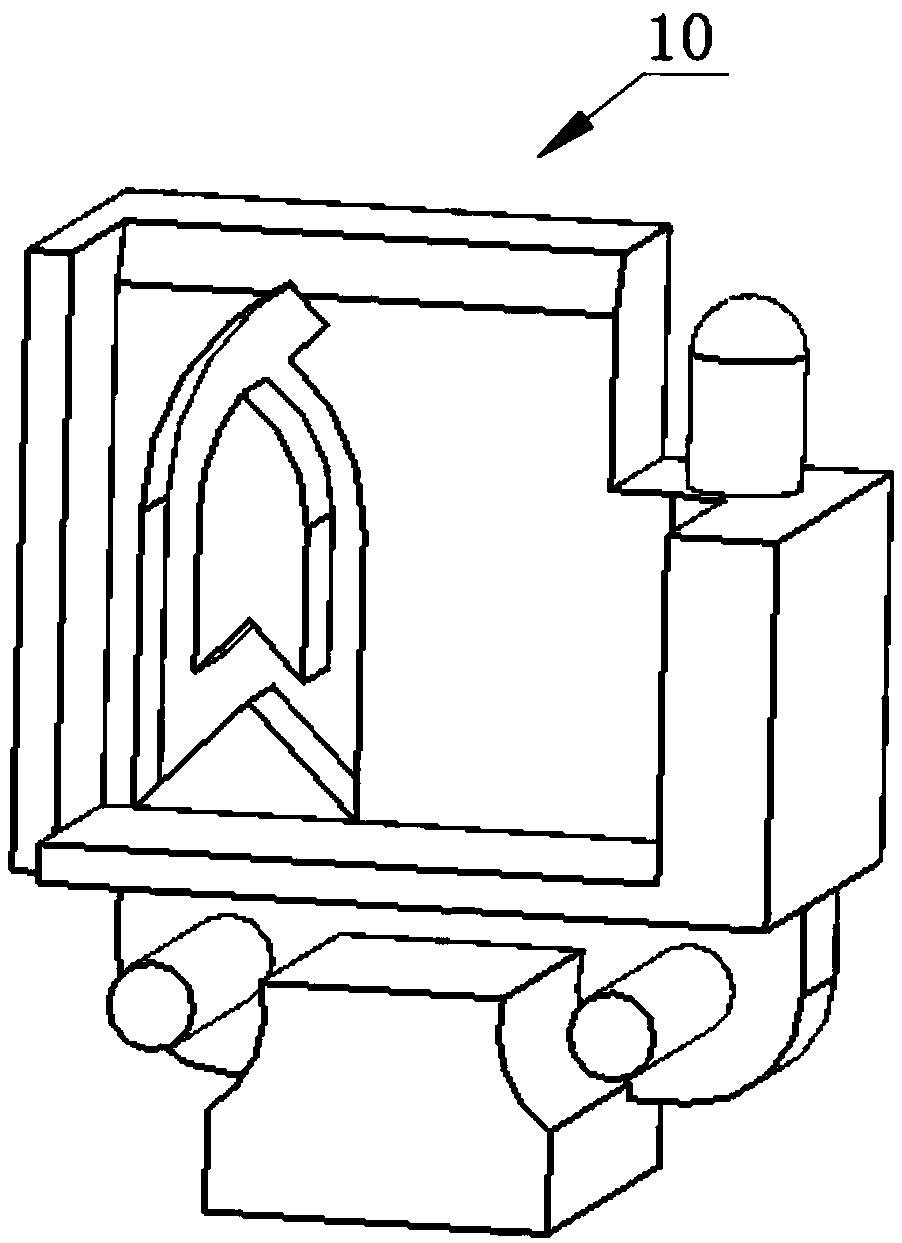

Uncapping mechanism of test tubes

ActiveCN106219467ASolve clamping problemsReduce external forceTight-fitting lid removalThreaded caps removalEngineeringLinear motor

The invention provides an uncapping mechanism of test tubes. The uncapping mechanism is used for removing caps of the test tubes and capping the test tubes and comprises a claw, buttons, a cover plate cavity, a transition cavity, a linear motor, a motor screw, a supporting metal plate, an upper gasket, a claw sealing plate, a claw fixing plate, a hook, a transition plate, a lower gasket, a first compression spring, a screw nut and a second compression spring. The uncapping mechanism of the test tubes is used for clamping the caps of the test tubes, and the caps of the test tubes can be clamped on the condition that external force exerted on the caps of the test tubes is reduced. In the process of removing the caps of the test tubes, the caps of the test tubes can simultaneously rise, rotate and cover the test tubes again. The uncapping mechanism is adaptable to the test tubes and the caps of the test tubes of different heights.

Owner:SUZHOU TOPMEDLAB MEDICAL SCI & TECH CO LTD

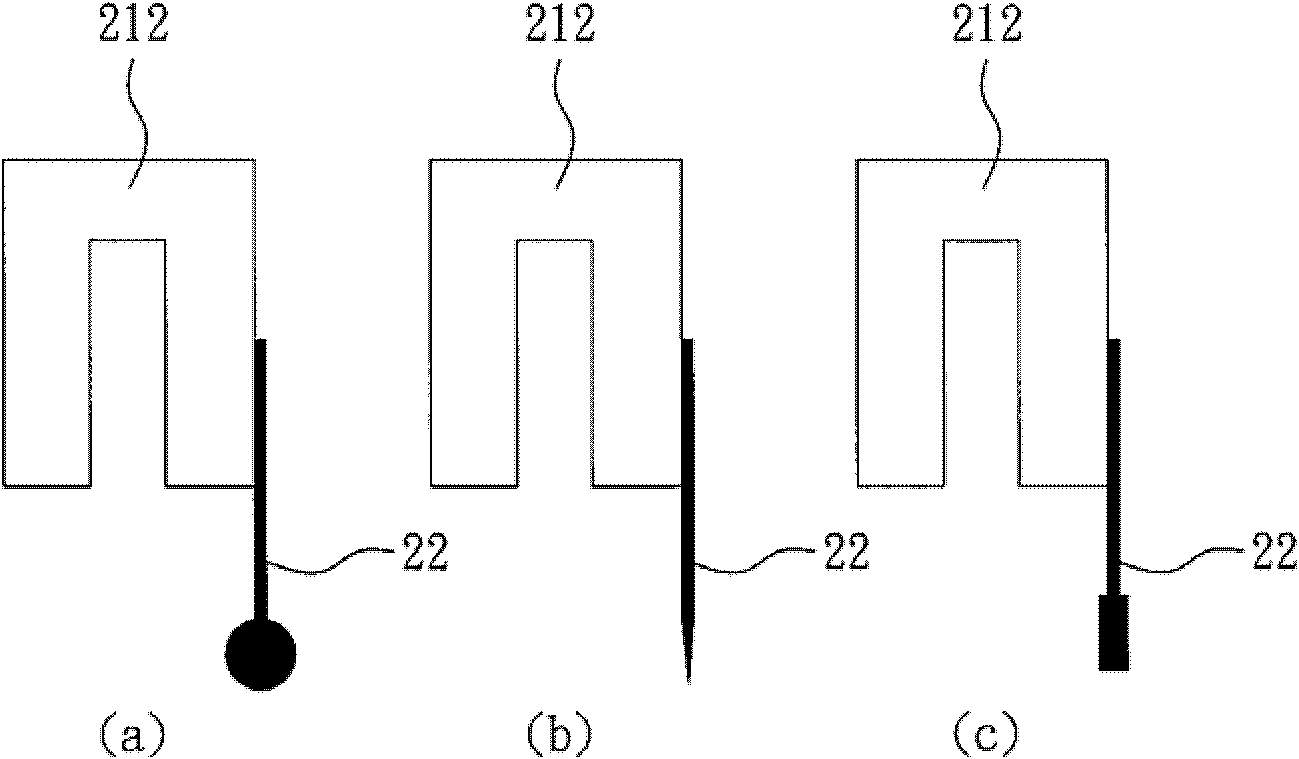

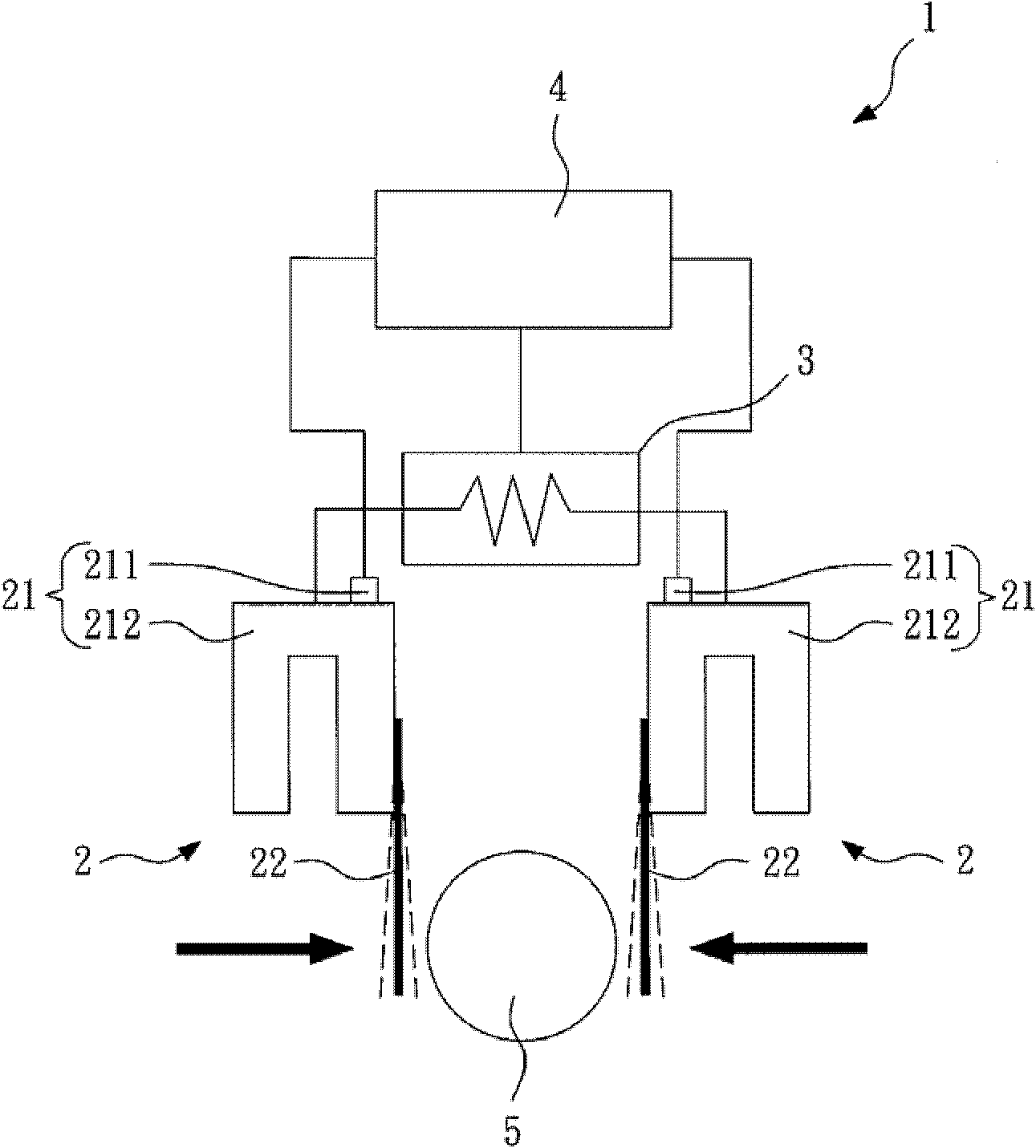

Micro-sensing clamping device

InactiveCN102485439AHigh intelligencePrevent slippingMicromanipulatorGripping headsEngineeringControl unit

The invention discloses a micro-sensing clamping device comprising two clamping units. At least one of the clamping units comprises a vibration device, which can be used to generate the vibration. A control unit is connected with the clamping units and a movable unit, and can be used to control the vibration generation of the vibration device and monitor the change of the vibration frequency / amplitude of the vibration device, and also can be used to control the movable unit to moving the clamping units in order to clamp, hole or loosen the clamp object according to the change of the vibration frequency / amplitude of the vibration device. Thereby the intelligent degree of the clamping can be improved, the delay or attachment problem of the object to be clamped can be overcome, the accurate control pick-up and put-away can be achived, the high practicability can be realized, and the problems capable of leading to the damage or slip-off of the object to be clamped can be overcome.

Owner:METAL INDS RES & DEV CENT

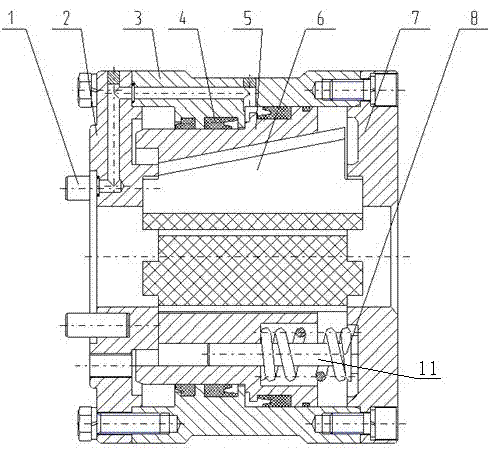

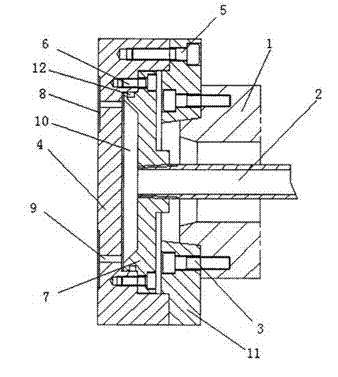

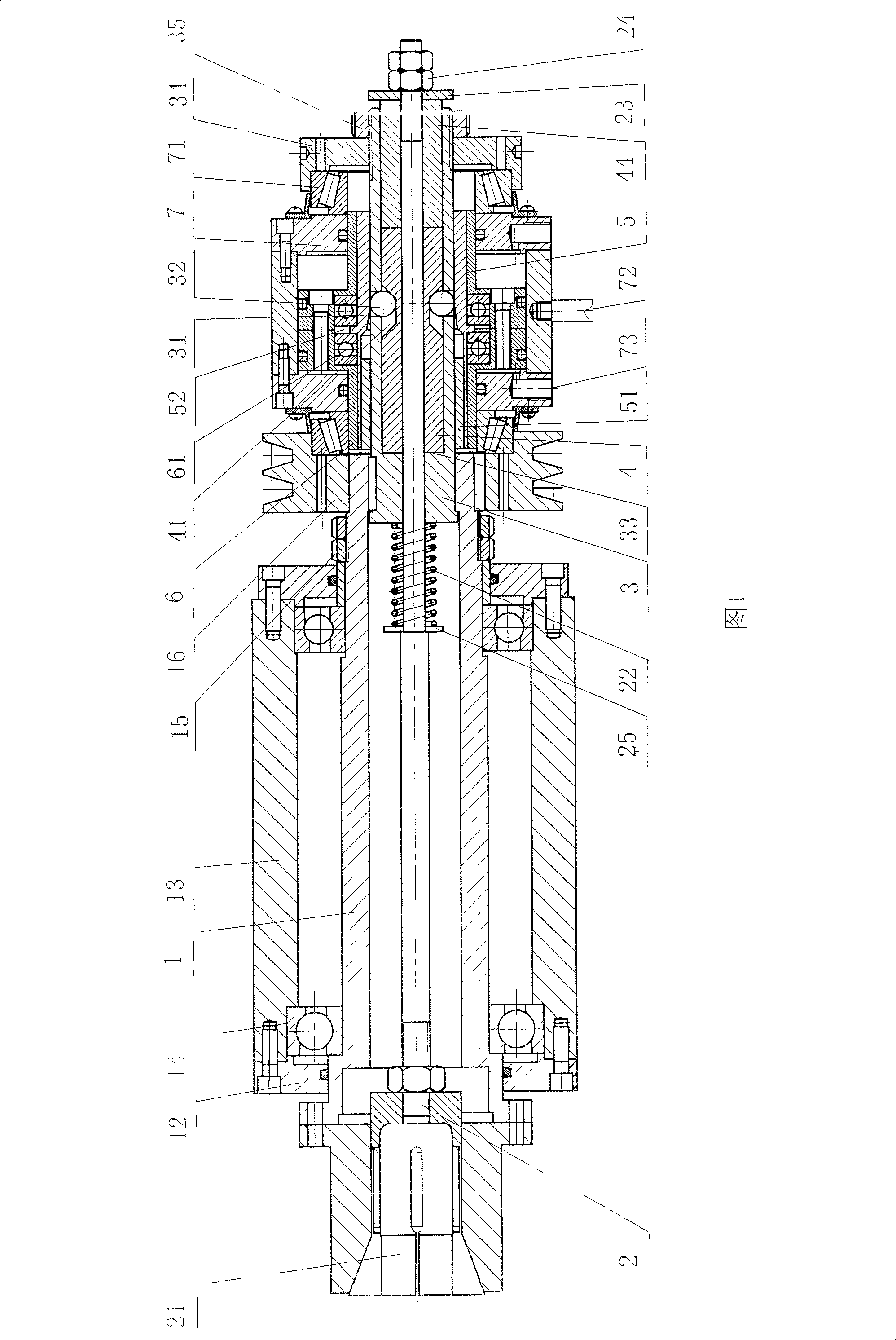

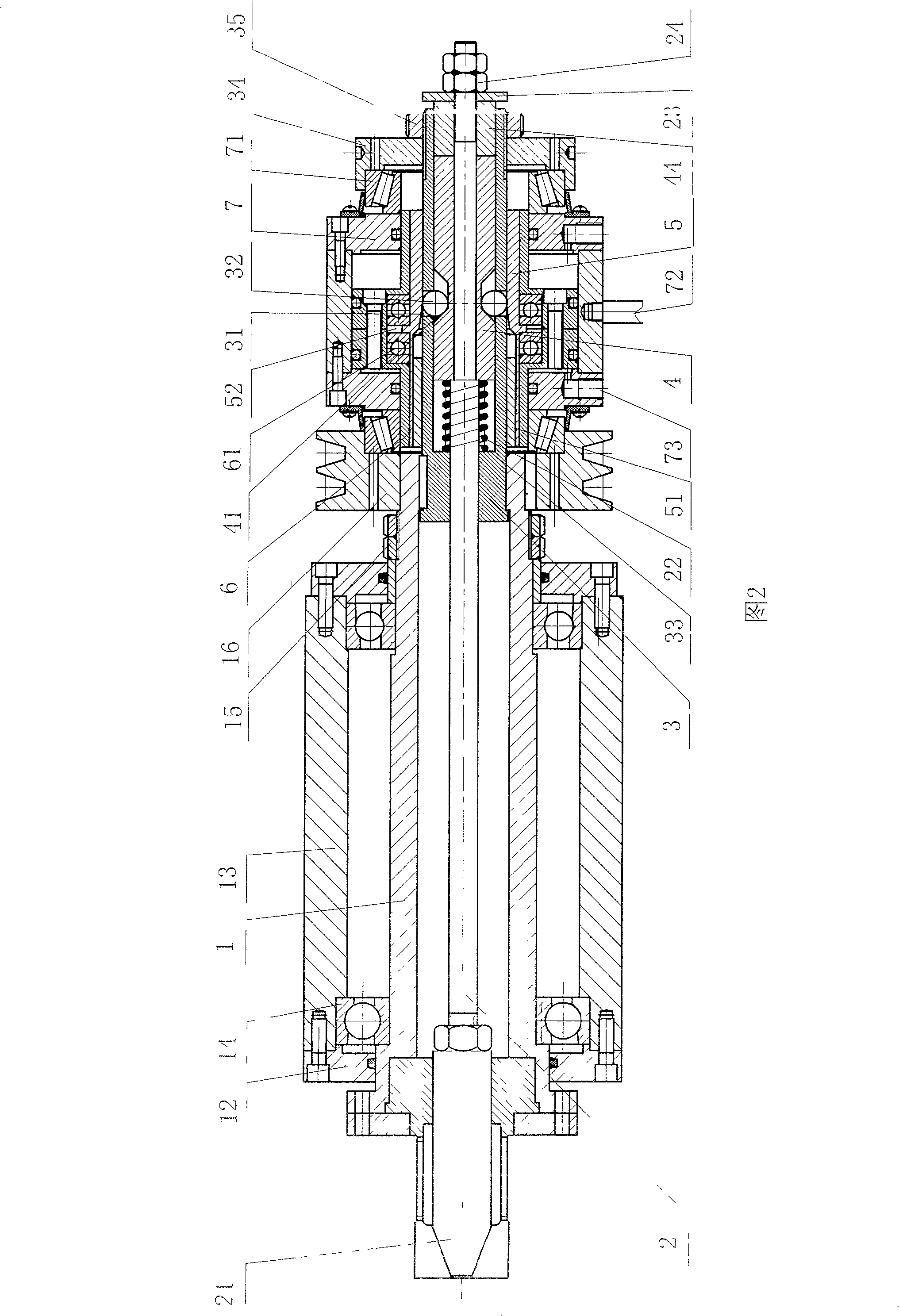

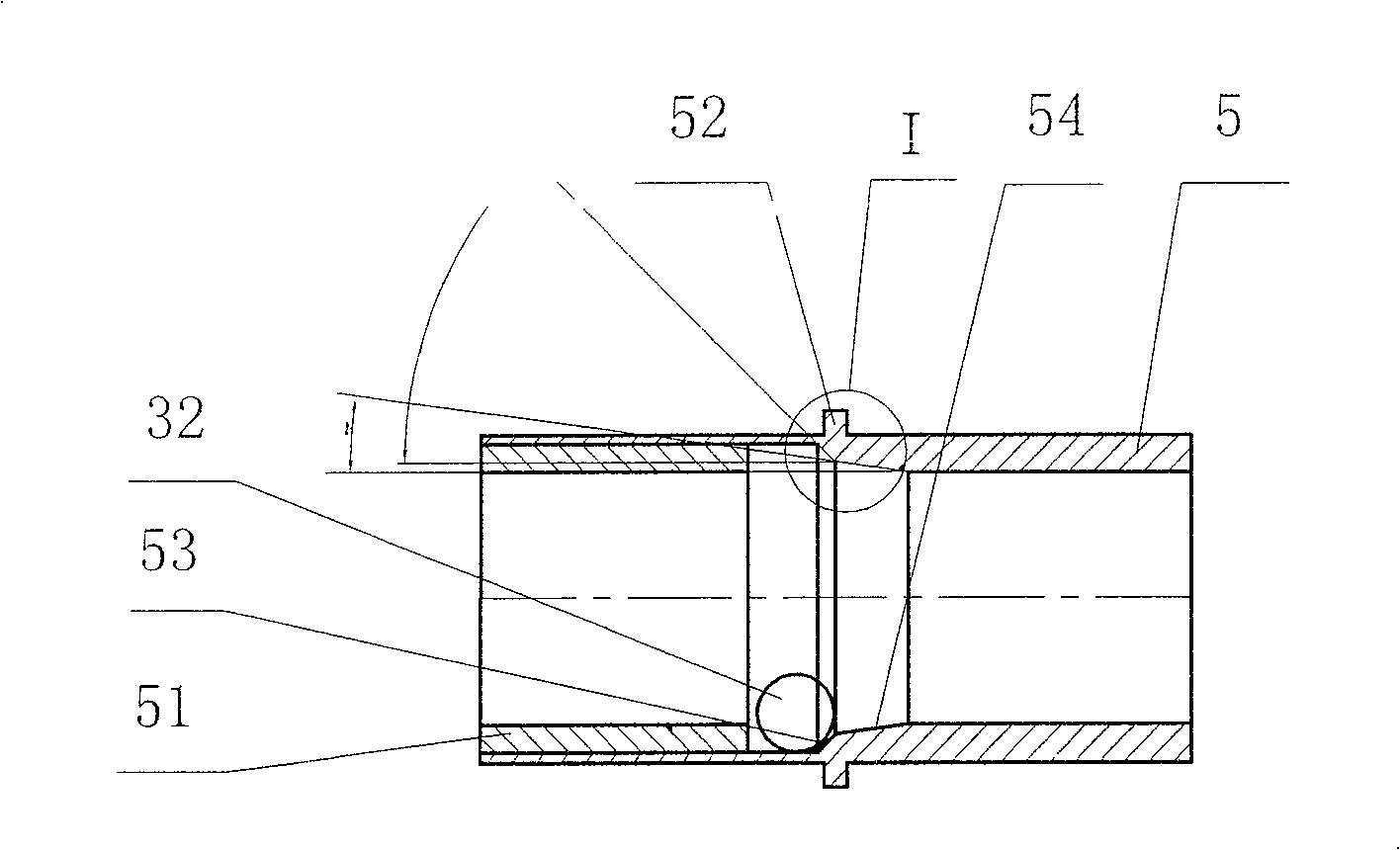

Air clamper in use for principal axis of lathe

InactiveCN1915565AImprove sealingReduced service lifeTurning machine accessoriesPositioning apparatusSteel ballMachine tool

A pneumatic fixture for the mainshaft of machine-tool is composed of a mainshaft with bearings, a central pull rod in said mainshaft and with front end connected to clamping spring and back end with clamp releasing mechanism, a steel ball sleeve on said pull rod and with radial through holes, pull rod sleeve in said steel ball sleeve and with a ring slot, steel balls in said ring slot and matched with external sleeve via said radial through holes, a piston module with bevel bearing, and a cylinder module.

Owner:宾焕南

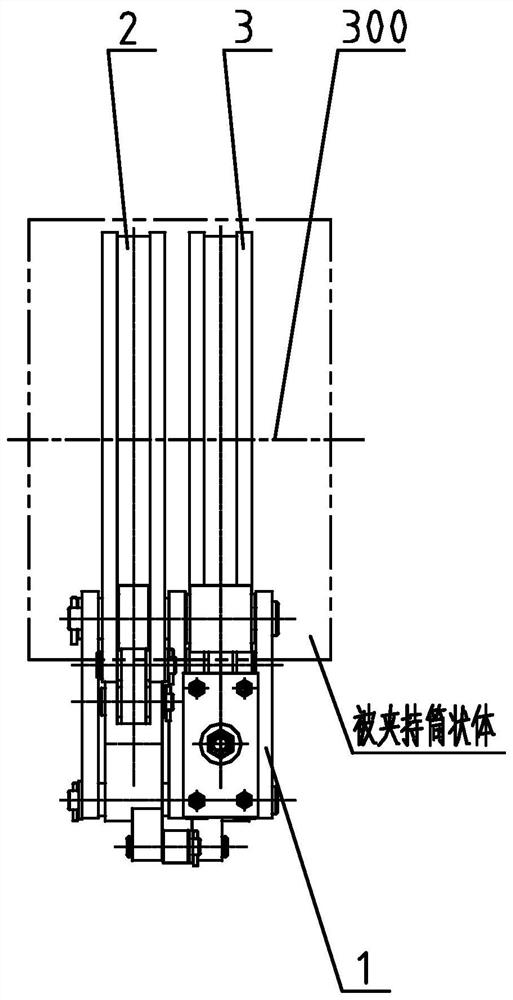

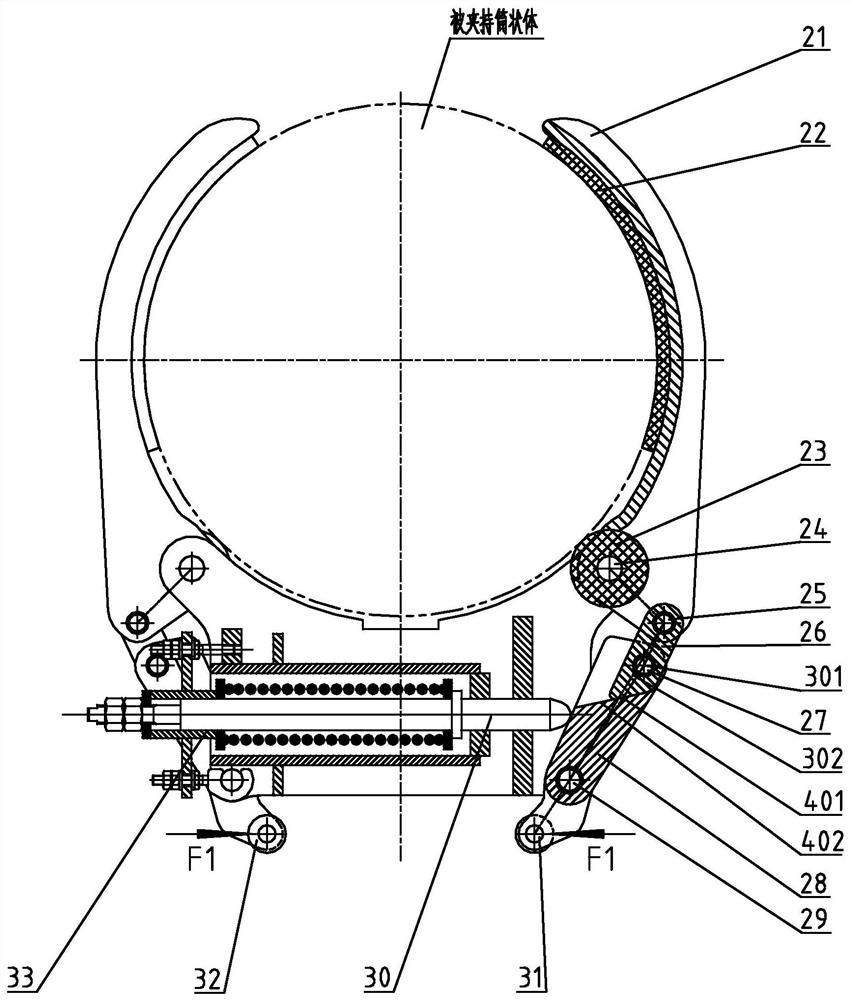

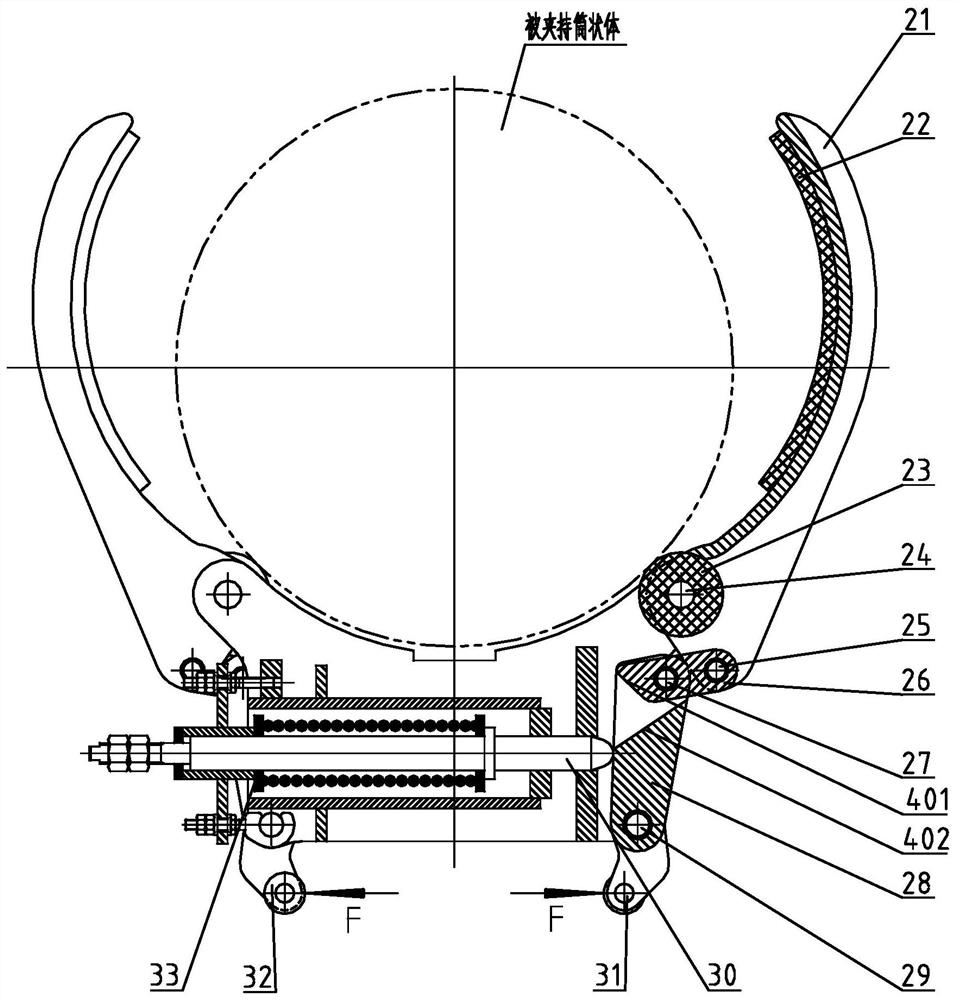

Cylindrical body holding claw device for warehouse

PendingCN113911521AProtection against accidental openingSolve the problem of layout spaceInternal fittingsSpring forceIndustrial engineering

The invention discloses a cylindrical body holding claw device for a warehouse, and belongs to the technical field of engineering. The device comprises a rack, holding claw mechanisms, spring assemblies and an ejector rod; the two holding claw mechanisms of the same structure are staggered along the axis of a clamped cylinder and are symmetrically arranged on the rack, the mounting position of one holding claw mechanism corresponds to the mounting position of one spring assembly, the ejector rod enables spring force of the spring assemblies to horizontally act on the holding claw mechanisms all the time, the holding claw mechanisms and the rack jointly form a four-connecting-rod mechanism, when external force horizontally acts on the bottom ends of the two holding claw mechanisms in the same direction, the holding claw mechanisms swing and cross over the 180-degree dead point of the four-connecting-rod mechanism to clamp and lock the cylindrical body, and when the external force reversely acts, the holding claw mechanisms are reversely opened to unlock the cylindrical body. The problem that the cylindrical body cannot be effectively parked in the warehouse of a moving carrier and cannot move and rotate is solved, clamping of the cylindrical body does not need power, and moving and transferring in the warehouse are facilitated.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Uncapping method of test tube

ActiveCN106044675ASolve clamping problemsReduce external forceTight-fitting lid removalThreaded caps removalEngineering

The invention provides an uncapping method of a test tube. The uncapping method is used for achieving the two work processes of test tube cap removal and test tube capping. The uncapping method is achieved through a test tube uncapping mechanism. The uncapping method of the test tube is used for solving the clamping problem of a test tube cap, and the test tube cap is clamped under the condition of reducing external force applied to the test tube cap. Meanwhile, in the test tube cap removal process, the functions that the test tube cup rotates while ascending and the test tube is capped with the test tube cap again can be achieved, and the uncapping method can be compatible with test tubes and test tube caps different in height.

Owner:SUZHOU TOPMEDLAB MEDICAL SCI & TECH CO LTD

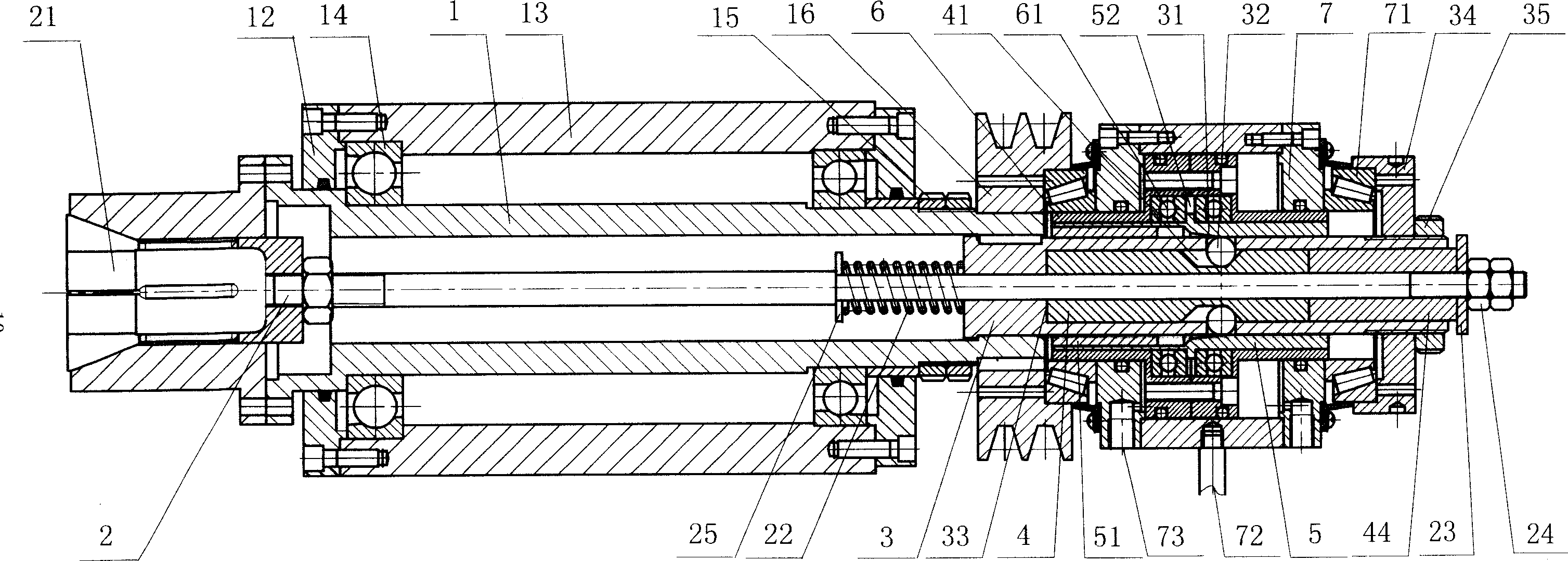

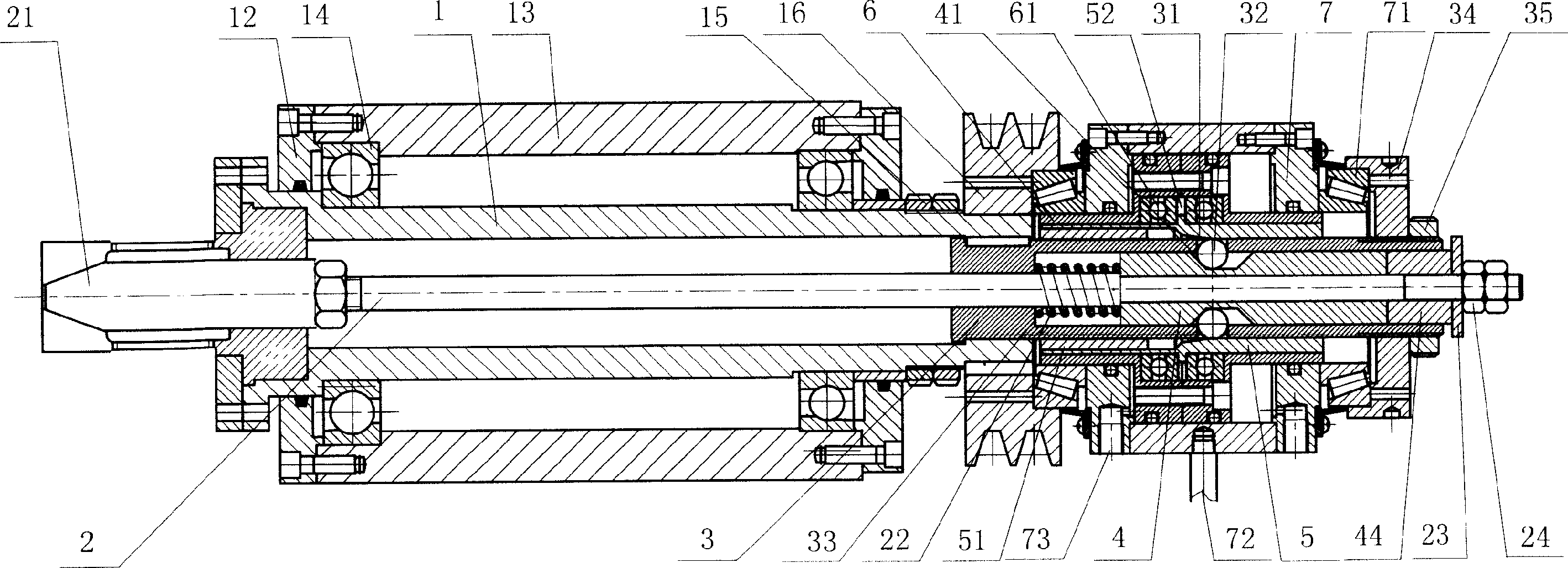

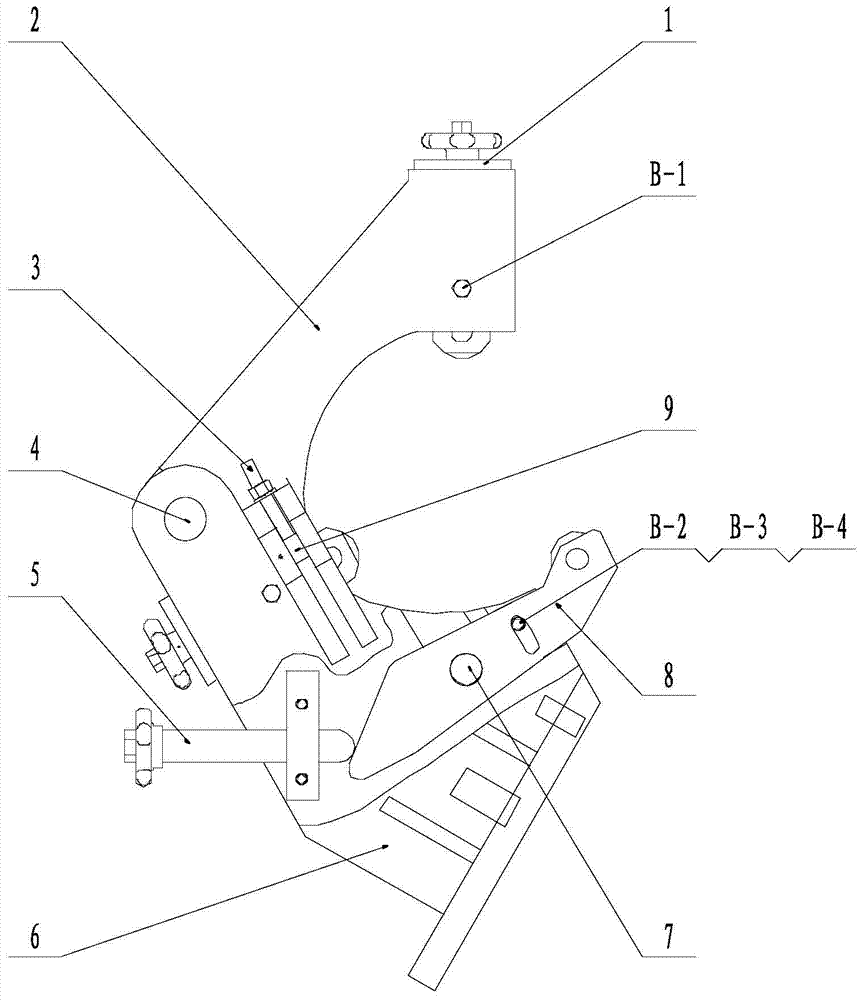

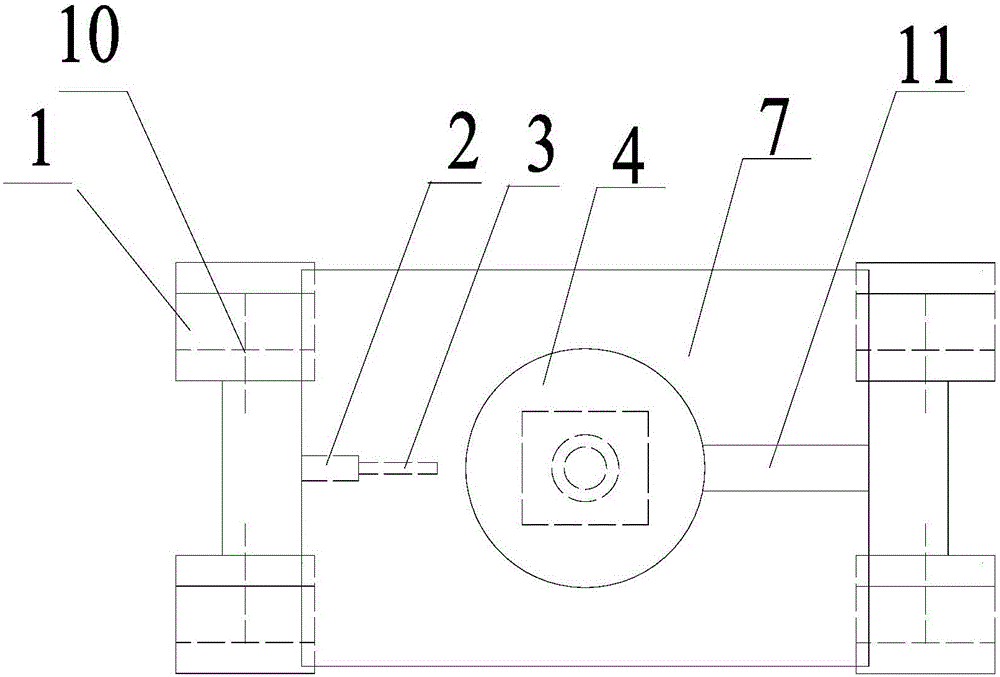

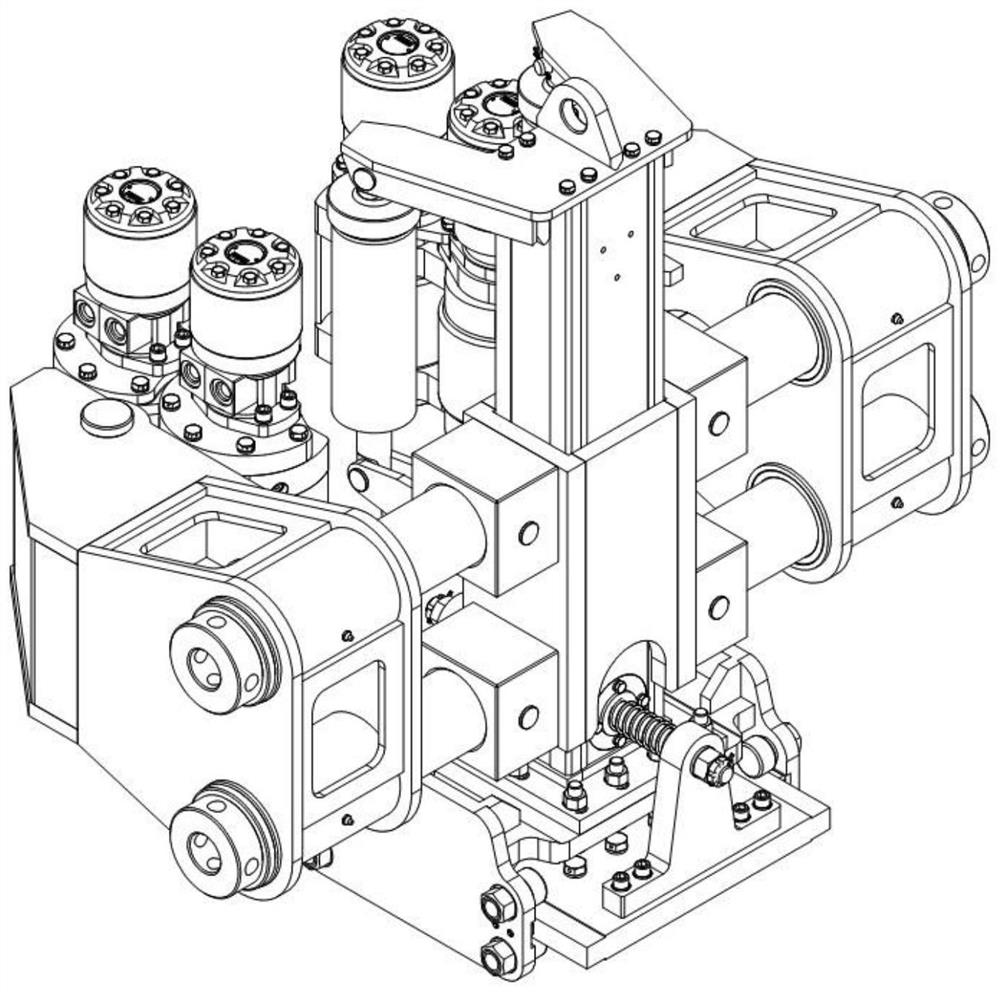

General drill rod clamping device used for coal mine drilling machine

InactiveCN102518403AEasy to install and removeHigh degree of automationDrilling rodsDrilling casingsCoalDrill hole

The invention discloses a general drill rod clamping device used for a coal mine drilling machine, which comprises construction members, such as a front end cover, a rear end cover, a shell, a slip sleeve, a slip, a clamping cylinder, an elastic resetting mechanism and the like. The device can be used as the chuck or the gripper of the drilling machine so as to solve the problem that the traditional full-hydraulic drilling machine drill rod clamping device used for the mine cannot directly clamp an anomalous drill rod. The drilling machine provided with the clamping device can be used for clamping a common circular drill rod and an anomalous drill rod with a non-circular surface under the condition of replacing no parts, and the the anomalous drill rod can obtain the same use efficacy as that of the common circular drill rod. When the anomalous drill rod is used for drilling holes, the drill rod can conveniently move vertically so as to greatly shorten the auxiliary operation time for using the anomalous drill rod to drill holes and greatly lower the technical requirement for a drilling machine operation worker. Meanwhile, the use safety coefficient of the drilling machine is improved.

Owner:CHONGQING UNIV

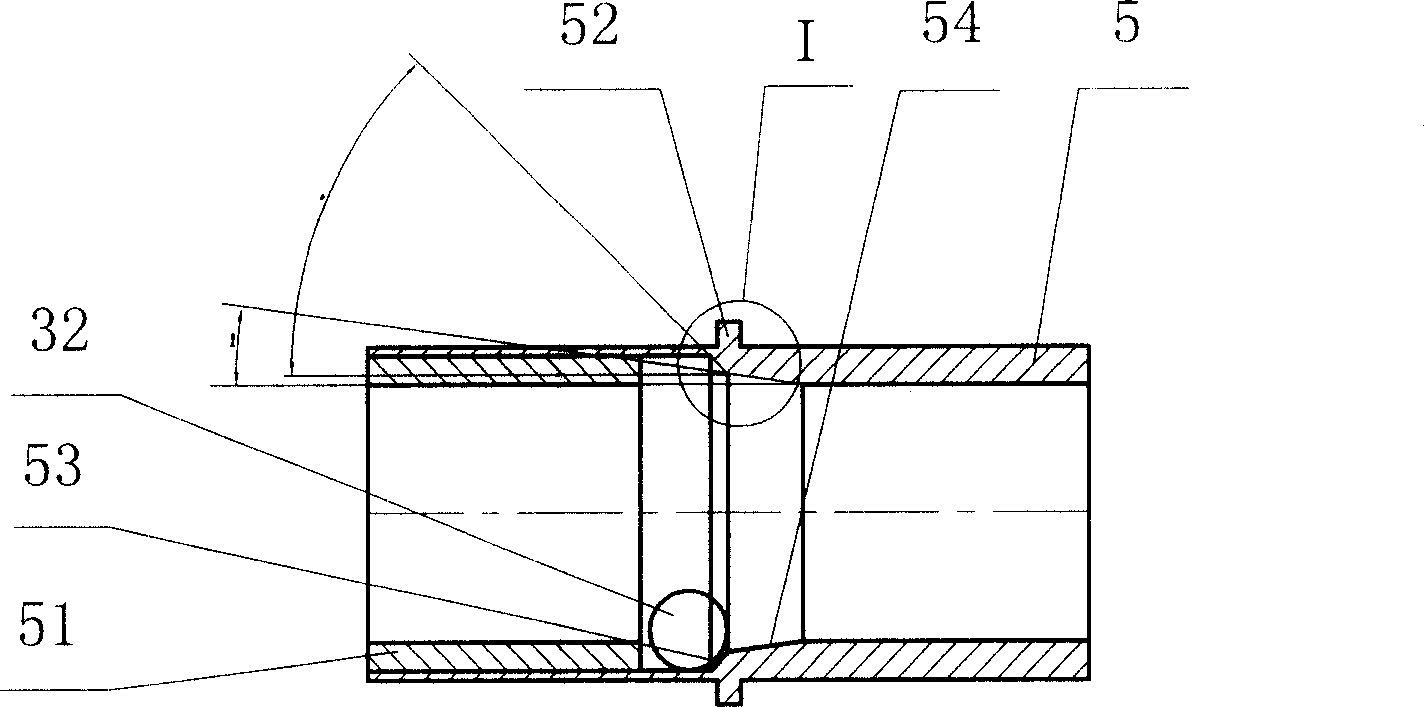

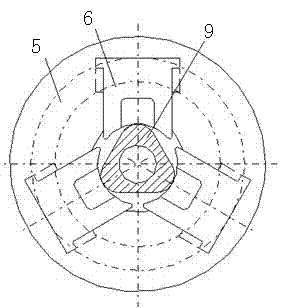

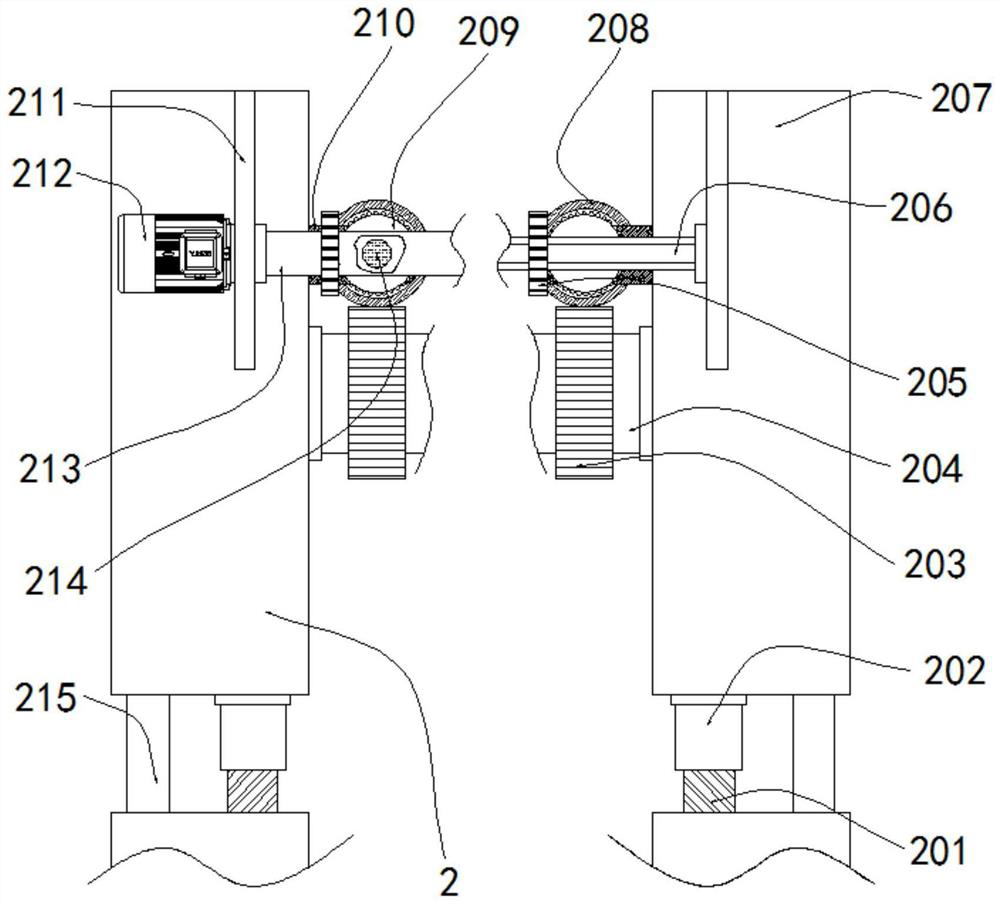

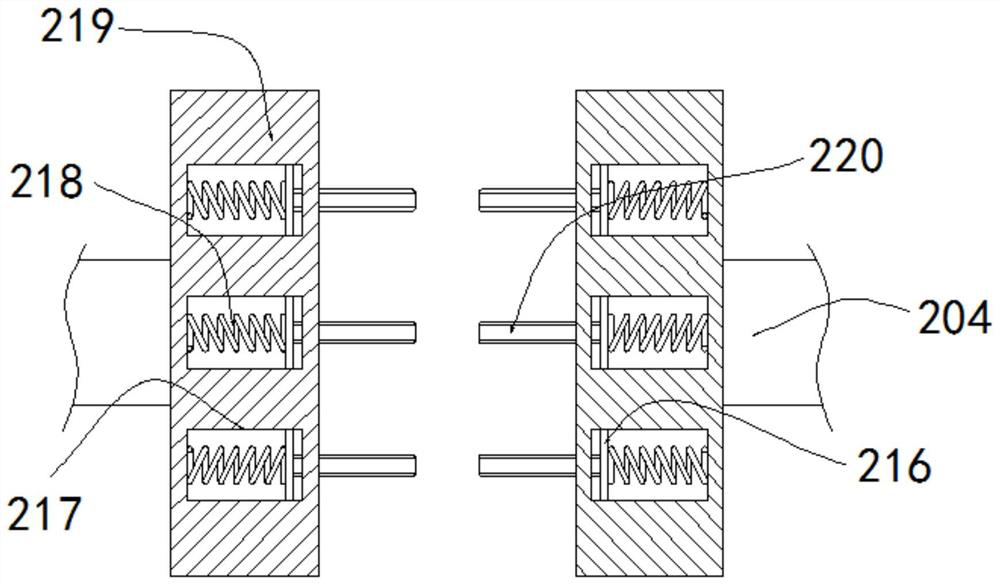

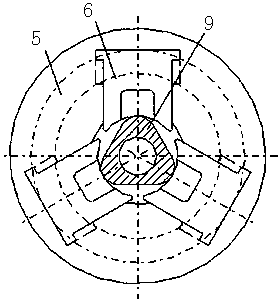

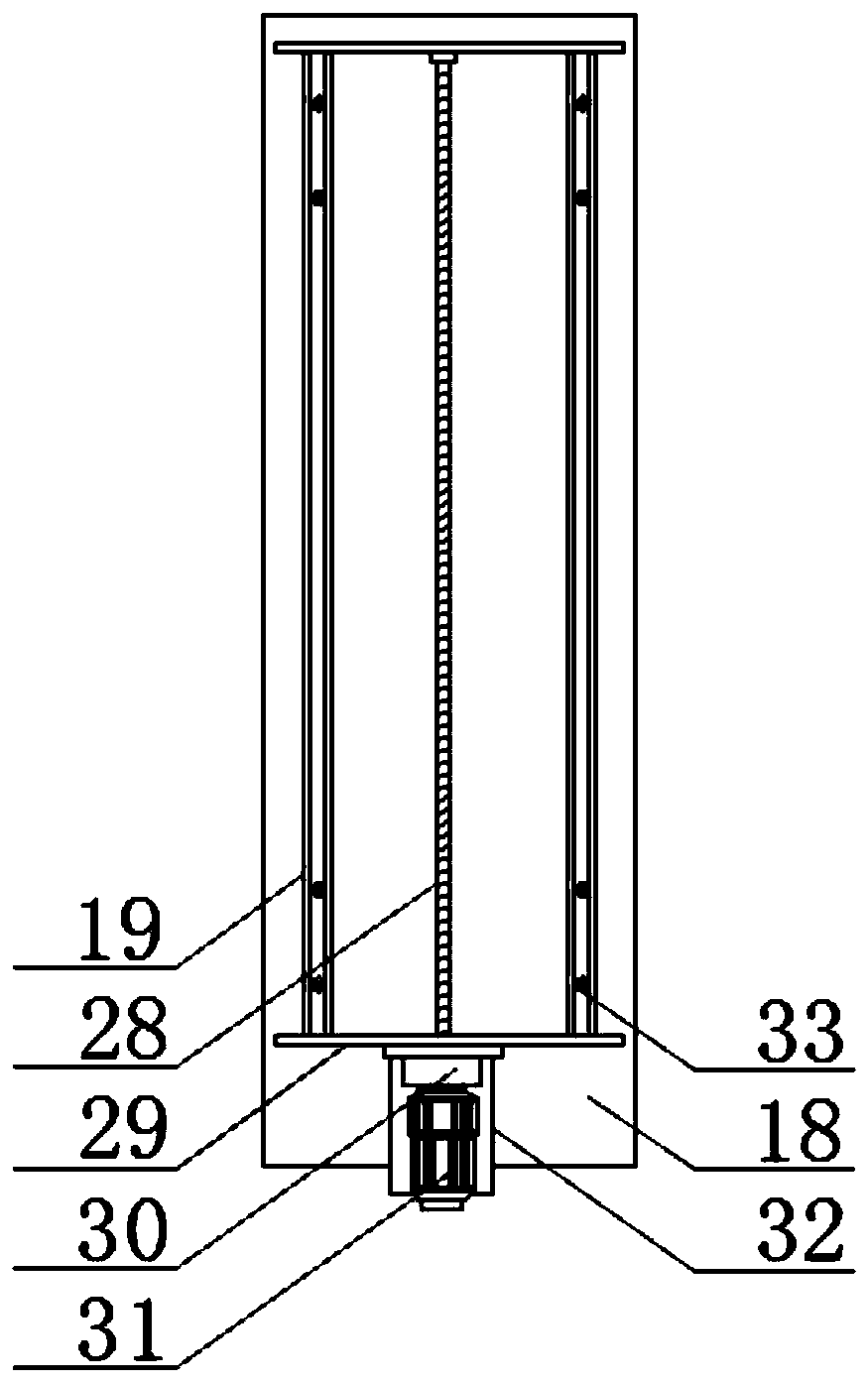

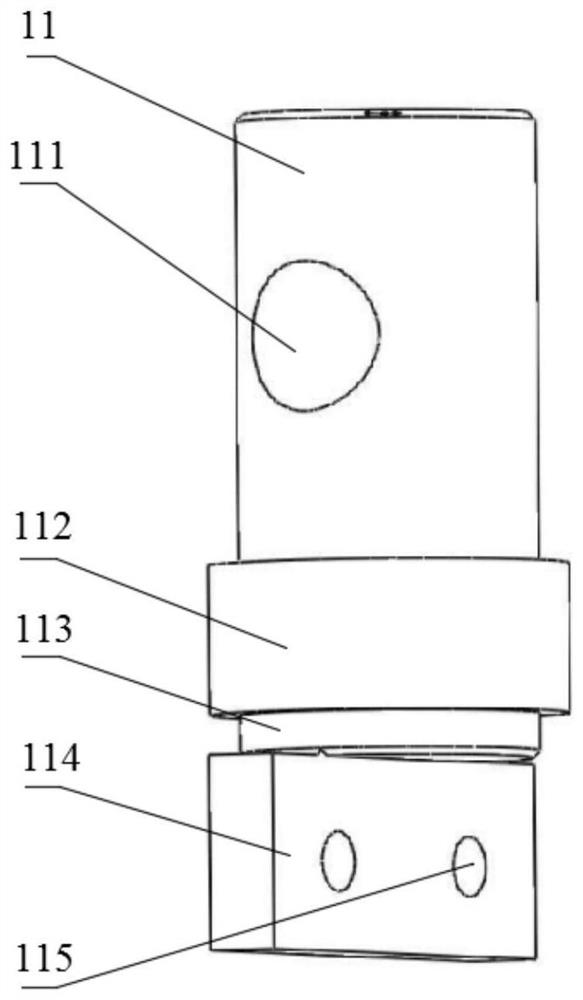

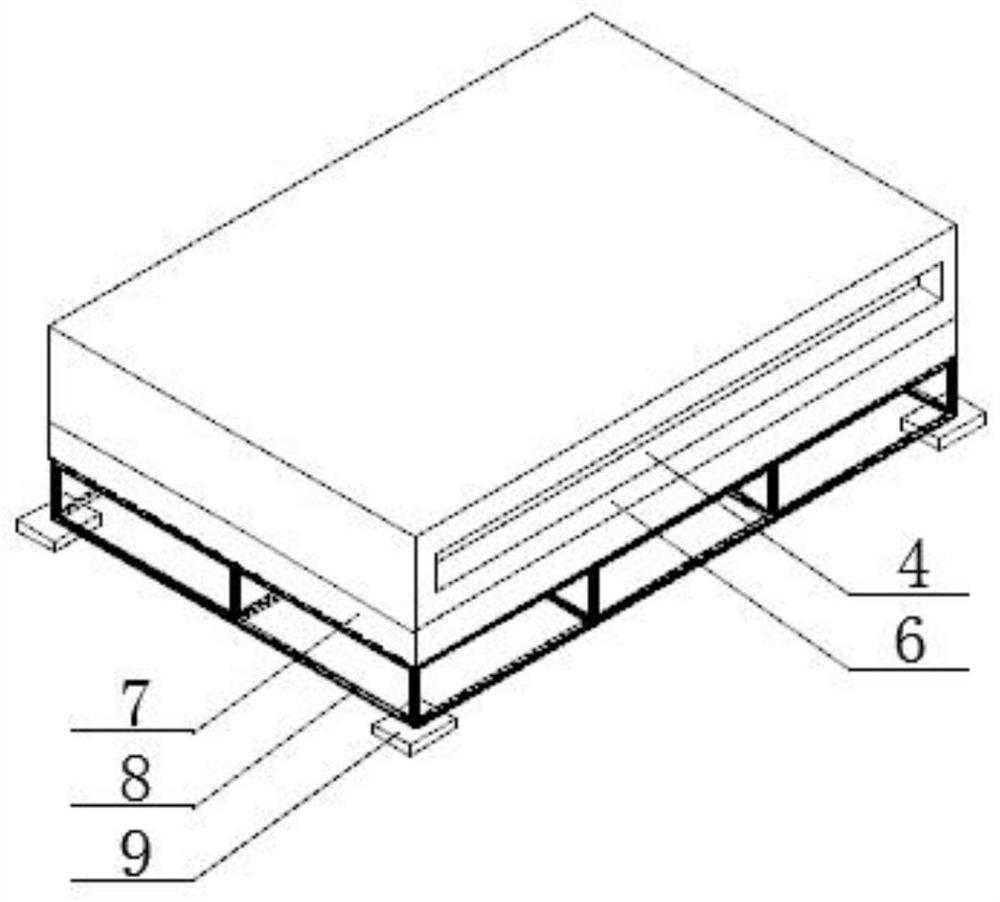

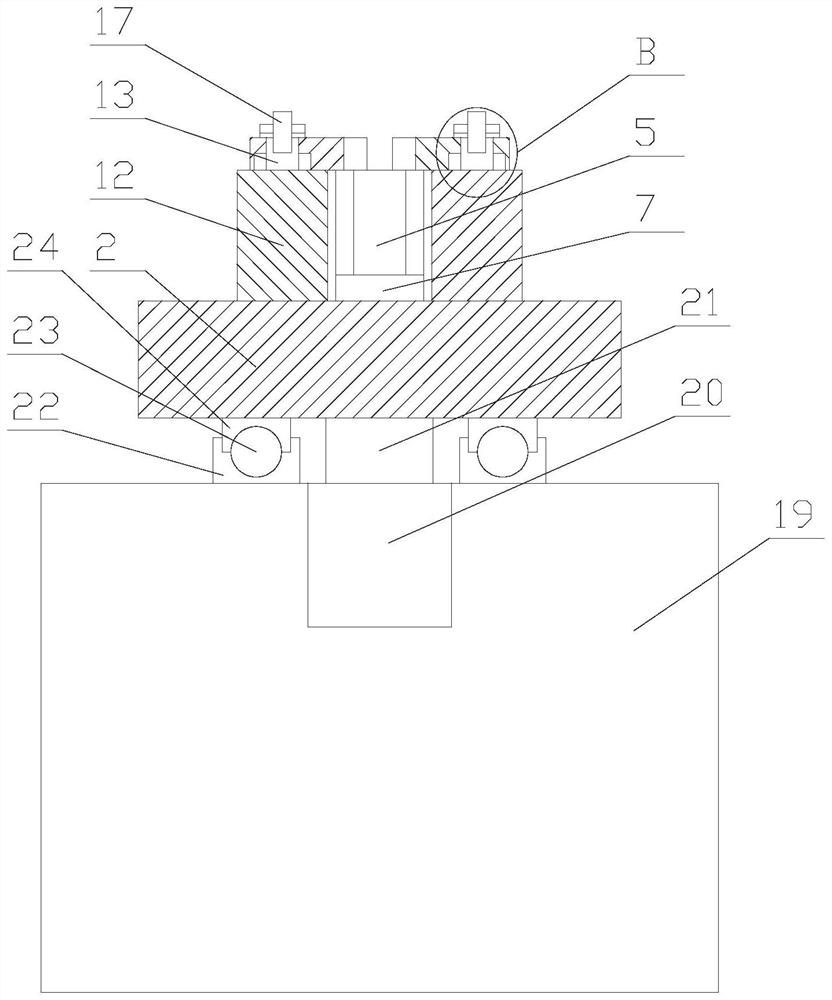

Semi-closed numerical control lathe center frame

ActiveCN103612128AMeet the requirements for clamping thin-walled cylindrical partsSolve clamping problemsLarge fixed membersNumerical controlEngineering

The invention discloses a semi-closed numerical control lathe center frame. A first guide block assembly is arranged at one end of a roll-over frame, and the other end of the roll-over frame is connected with a base through a roll-over frame rotary shaft and can rotate around the roll-over frame rotary shaft; a second guide block assembly is arranged on the base, and a fixing screw rod is arranged between the roll-over frame and the base; a rotary block assembly is connected with the base through a rotary block rotary shaft, and a rotary block adjusting screw rod is arranged on the base and abuts against the plane on one side of the rotary block assembly. By adjusting guide blocks and rotary blocks manually, the semi-closed numerical control lathe center frame achieves machining of thin-wall cylindrical elements, and solves the clamping problem of a numerical control lathe in machining thin, long and thin-wall parts. After the roll-over frame is opened, the parts are clamped on a three-jaw chuck of the numerical control lathe, and after primary clamping of the thin-wall cylindrical elements is finished, the roll-over frame is closed and fixed through a nut on the fixing screw rod; the guide blocks and the rotary blocks are adjusted, so that the middle portions of the thin-wall cylindrical elements are clamped. The semi-closed numerical control lathe center frame can meet the requirement that the numerical control lathe clamps the thin-wall cylindrical elements.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Feeding type lotus root automatic slicer

InactiveCN104385338BEffective clampingHigh in starchMetal working apparatusMechanical engineeringLotus root

Owner:WUHAN TEXTILE UNIV

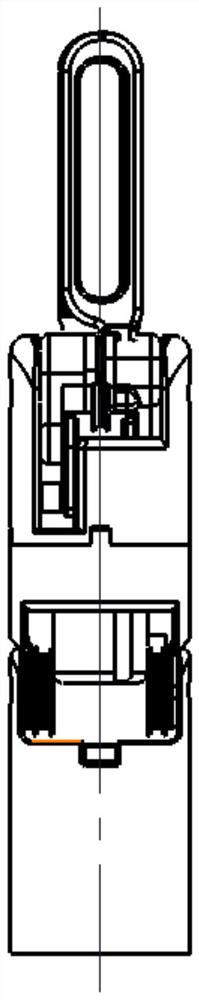

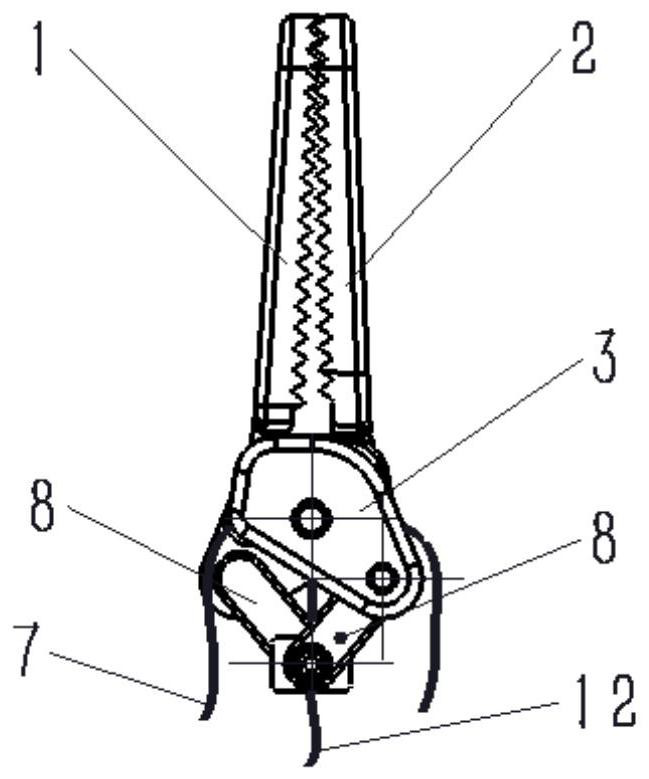

Bipolar electric energy forceps head for minimally invasive surgical instrument

InactiveCN112315576AHigh tensile strengthEffective opening and closing actionSurgical instruments for heatingSurgical forcepsLess invasive surgeryForceps

The invention relates to a bipolar electric energy forceps head for a minimally invasive surgical instrument, and solves the technical problems that an insulation isolation structure of two forceps blades of an existing electrode forceps head surgical instrument is poor in insulation effect, and the opening and closing actions of the two forceps blades adopt a spring type opening and closing clamping structure which causes difference to the opening angles of the forceps blades. The bipolar electric energy forceps head comprises forceps blades, isolation sheets, supporting sheets, a forceps shaft, a wire, bipolar connecting rods, a bipolar pull seat, a tail end support and a steel wire, wherein the two isolation sheets are fixedly connected with the two forceps blades correspondingly. the two supporting sheets are fixedly connected with the first isolation sheet and the second isolation sheet correspondingly; the forceps shaft penetrates through the two isolation sheets and the two supporting sheets; the upper end and the lower end of the first bipolar connecting rod are hinged to one end of the first isolation sheet and one end of the bipolar pull seat respectively, the upper end and the lower end of the second bipolar connecting rod are hinged to the other end of the second isolation sheet and the other end of the bipolar pull seat respectively, and a wire guide wheel is fixedly connected to the middle of the forceps shaft; and the end of the forceps shaft is located in a guide groove of the tail end support. The bipolar electric energy forceps head is widely applied to the technical field of minimally invasive surgery robots.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

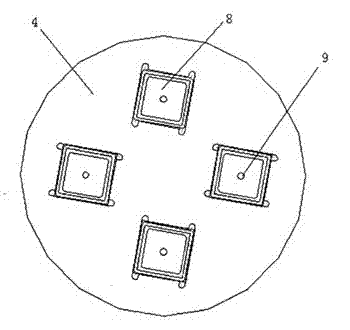

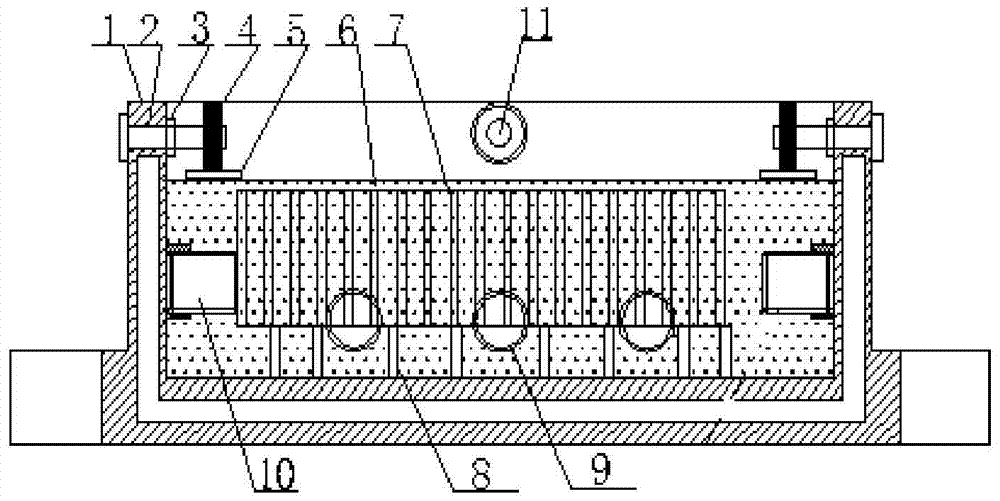

Vacuum sucking disc device of novel numerical control machine tool

InactiveCN102476303ASolve clamping problemsNo deformationPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention relates to a vacuum sucking disc device of a novel numerical control machine tool, and the vacuum sucking disc device belongs to a fixture tool of the numerical control machine tool. The vacuum sucking disc device of the novel numerical control machine tool has the structural characteristics that the vacuum sucking disc device of the novel numerical control machine tool comprises a fixture, a vacuum tube, a sealing block and a connection block, wherein the connection block is connected with a machine tool spindle; the fixture is connected with the connection block; a sealing block is arranged between the fixture and the connection block; the sealing block and the fixture mutually surround to form a vacuum slot; the vacuum slot is communicated with a vacuum hole arranged on the fixture; the position of the vacuum hole on the surface of the fixture is provided with a working slot; the vacuum tube is arranged in the machine tool spindle; one end of the vacuum tube is communicated with the vacuum slot; and the other end of the vacuum tube is communicated with a vacuumized device. The vacuum sucking disc device of the novel numerical control machine tool has the advantages of reasonable structure design, good sealing effect and no vibration under high-speed rotation, and sheet metal is machined at high precision without damage.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

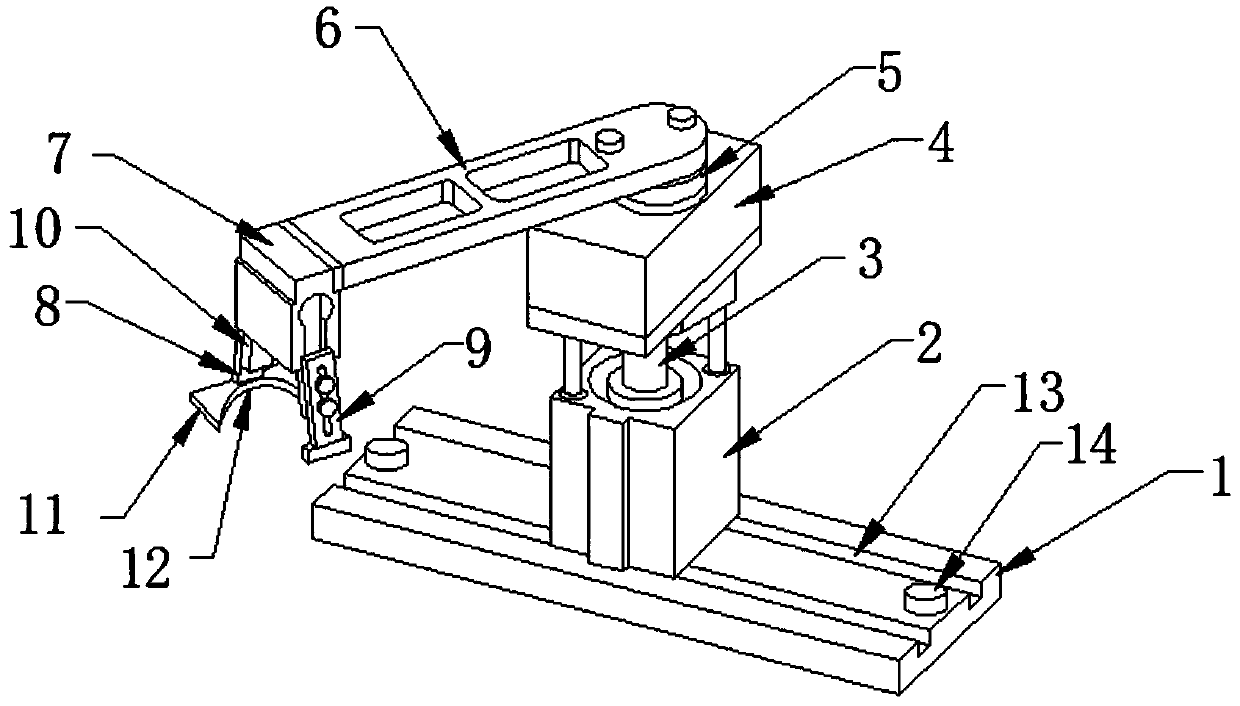

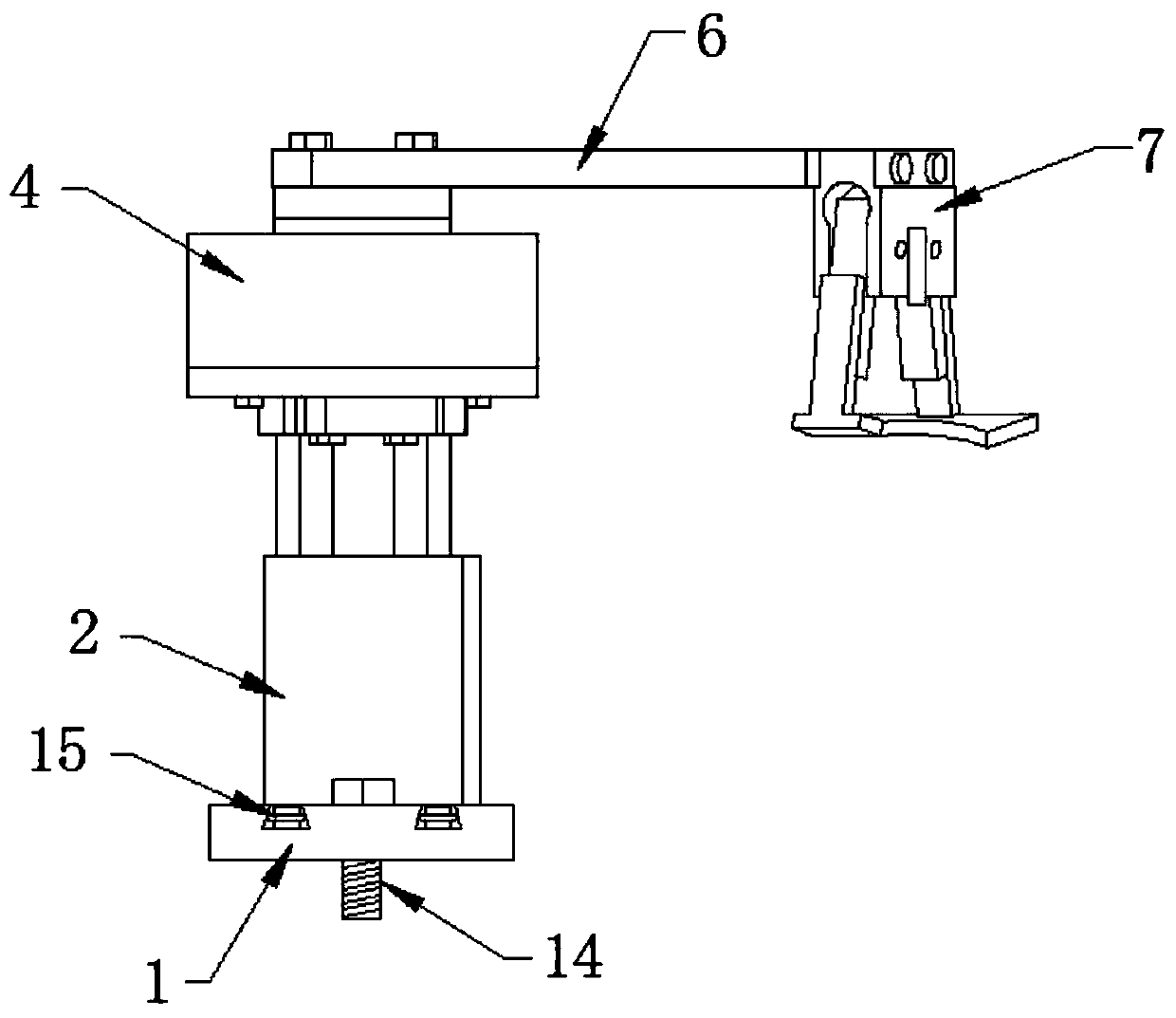

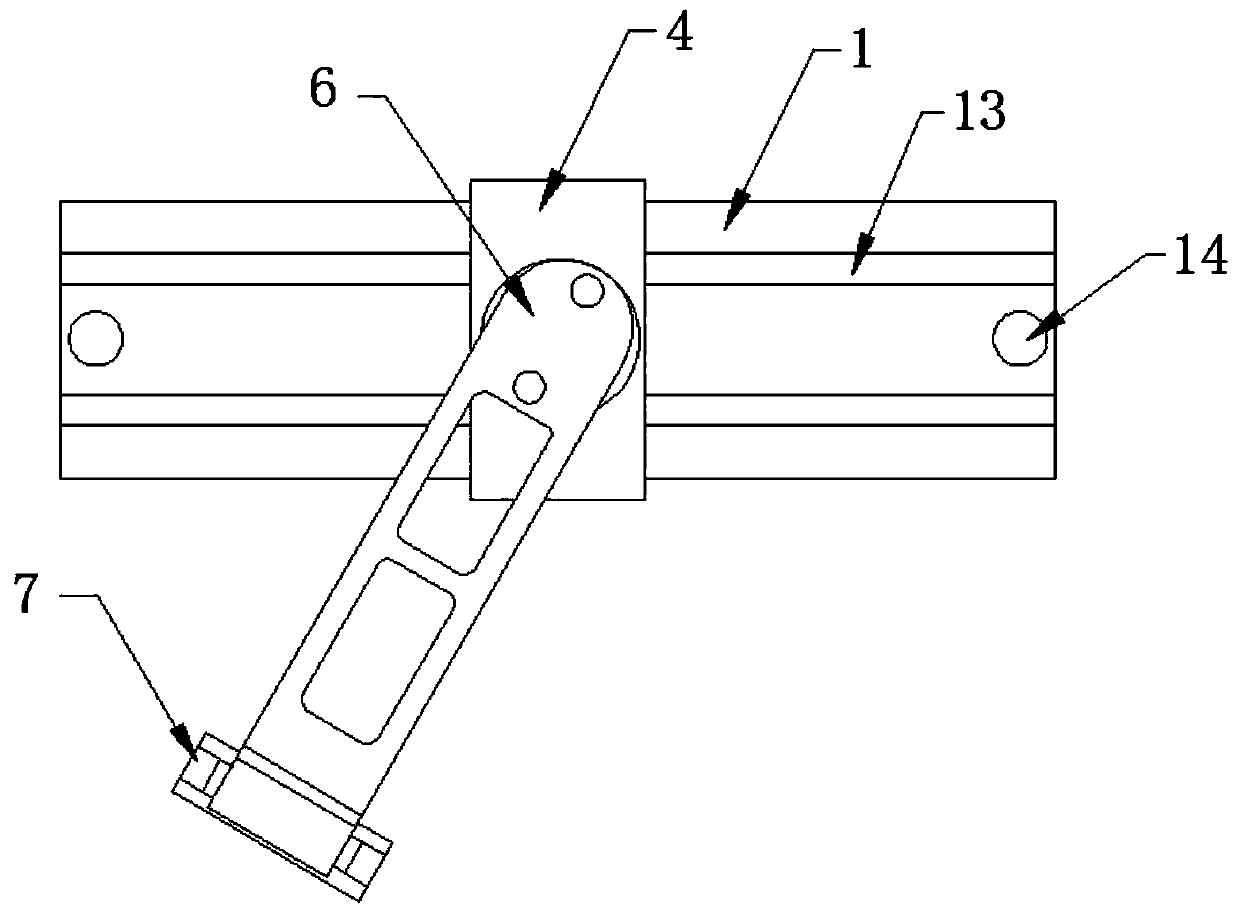

Circular mechanical clamping part convenient to adjust

PendingCN109551455ASolve clamping problemsEasy to useProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

The invention discloses a circular mechanical clamping part convenient to adjust. The circular mechanical clamping part convenient to adjust comprises a sliding base. The surface of the sliding base is provided with moving sliding rails. A lifting driving seat is mounted on the moving sliding rails. The top end of the lifting driving seat is provided with a lifting rod. The top end of the liftingrod is connected with a rotary base. The top end of the rotary base is provided with a rotary shaft. A rotary bracket is mounted on the rotary shaft. A working machine head is arranged at one end of the rotary bracket. The working machine head is provided with a first clamping rack and a second clamping rack. Through the circular mechanical clamping part convenient to adjust, the problems existingin clamping by a semicircular clamping part can be effectively solved. The clamping machine can do transverse movement through the moving sliding rails, conduct lifting adjustment through the liftingrods and conduct omni-directional adjustment through the rotary shaft and is easy and convenient to use and high in practicality.

Owner:HUBEI ENG INST

Air clamper in use for principal axis of lathe

InactiveCN100421847CImprove sealingReduced service lifeTurning machine accessoriesPositioning apparatusEngineeringSteel ball

Owner:宾焕南

Intelligent clamp for mechanical design

InactiveCN114871967AGood clamping effectHold steadyWork holdersWork benchesPhysicsIntelligent machine

The clamp for intelligent mechanical design comprises a box body, the upper surface of the box body is slidably connected with two moving blocks, one side of each moving block penetrates through and extends into the box body, a driving mechanism is arranged on the inner bottom wall of the box body, and an adaptive mechanism is arranged on the upper surface of each moving block. According to the clamp for intelligent mechanical design, the adaptive mechanism and the driving mechanism are arranged, through mutual cooperation of all structures of the adaptive mechanism and the driving mechanism, the clamp can clamp mechanical workpieces in different shapes, meanwhile, the clamping effect is good, clamping is more stable, the problem that only mechanical workpieces in regular shapes can be clamped is solved, and the clamping efficiency is improved. And meanwhile, when the mechanical workpiece needs to be designed, the mechanical workpiece can be rotated, so that the design of the mechanical workpiece is more convenient, and when the clamping design is carried out on the larger mechanical workpiece, the distance between the mechanical workpiece and the box body can be adjusted, so that the mechanical workpiece can normally rotate, and good power can be provided for the clamp.

Owner:齐羿

General drill rod clamping device used for coal mine drilling machine

InactiveCN102518403BAchieve clamping forceAchieve clampingDrilling rodsDrilling casingsCircular surfaceAbnormal shaped

The invention discloses a general drill rod clamping device used for a coal mine drilling machine, which comprises construction members, such as a front end cover, a rear end cover, a shell, a slip sleeve, a slip, a clamping cylinder, an elastic resetting mechanism and the like. The device can be used as the chuck or the gripper of the drilling machine so as to solve the problem that the traditional full-hydraulic drilling machine drill rod clamping device used for the mine cannot directly clamp an anomalous drill rod. The drilling machine provided with the clamping device can be used for clamping a common circular drill rod and an anomalous drill rod with a non-circular surface under the condition of replacing no parts, and the the anomalous drill rod can obtain the same use efficacy as that of the common circular drill rod. When the anomalous drill rod is used for drilling holes, the drill rod can conveniently move vertically so as to greatly shorten the auxiliary operation time for using the anomalous drill rod to drill holes and greatly lower the technical requirement for a drilling machine operation worker. Meanwhile, the use safety coefficient of the drilling machine is improved.

Owner:CHONGQING UNIV

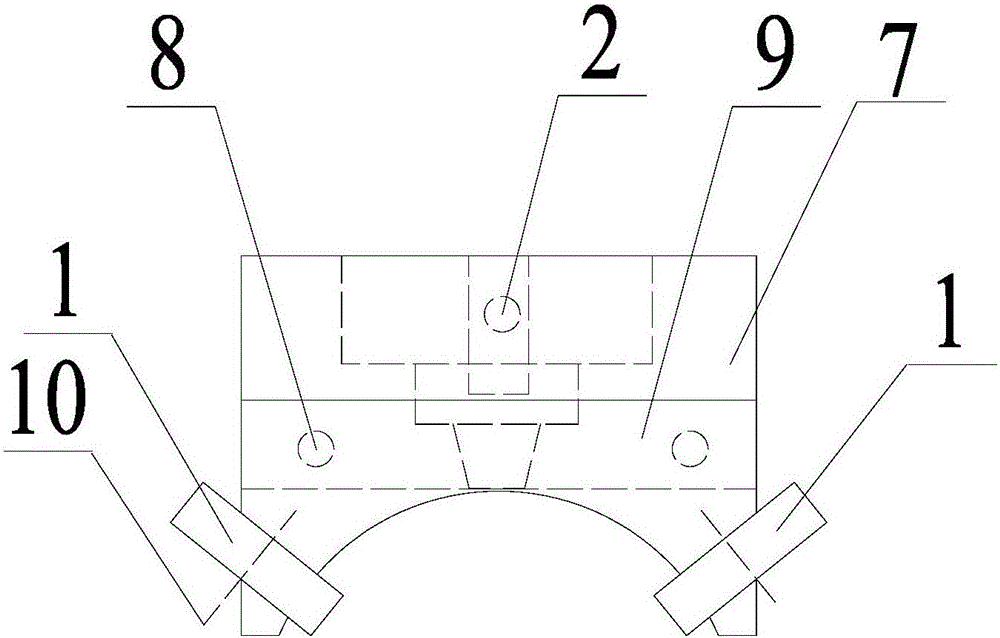

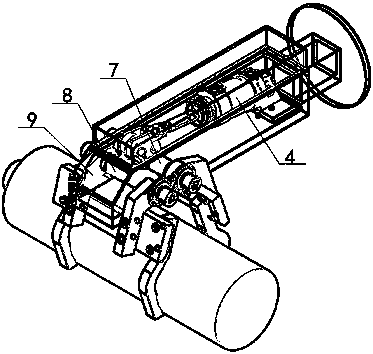

Boiler water cold wall pipe detection probe clamping device

InactiveCN105911151ASolve clamping problemsRealize the function of automatically applying couplantMaterial analysis using sonic/ultrasonic/infrasonic wavesCouplingWater cooling

The invention relates to a boiler water cold wall pipe detection probe clamping device. A step type through hole structure which has the communicated upper and lower side and is used for placing a probe is formed in the center of a case; a coupling agent exerting hole is formed in the casing and at one side of the step type through hole structure; one end of the coupling agent exerting hole is positioned in one side surface of the casing, and is connected with an external coupling agent exerting device; the other end of the coupling agent exerting hole is connected with one end of a coupling agent guide pipe positioned in the casing; the other end of the coupling agent guide pipe is positioned in the bottom surface of the casing; a downwards recessed probe wire groove communicated with the step type through hole structure is formed in one side, far away from the coupling agent exerting hole, of the upper end surface of the casing; the bottom surface of the casing is of an inwards recessed arc-shaped surface capable of being anastomotic with a measured pipe; the four end corners of the casing are respectively provided with guide wheels capable of rolling along the tested pipe. The boiler water cold wall pipe detection probe clamping device has the advantages that the coupling agents can be automatically exerted in the field detection process; the probe can be automatically regulated along the radian of the detection surface in the detection process; the tight attachment with the detection surface is ensured all the time; the detection precision and the detection efficiency are greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP

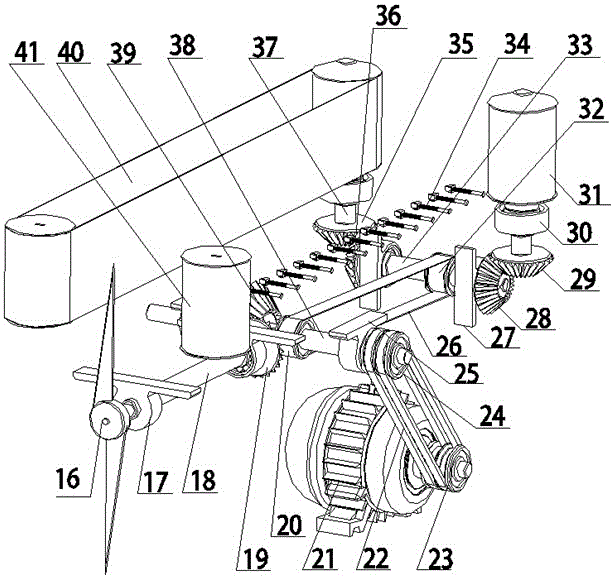

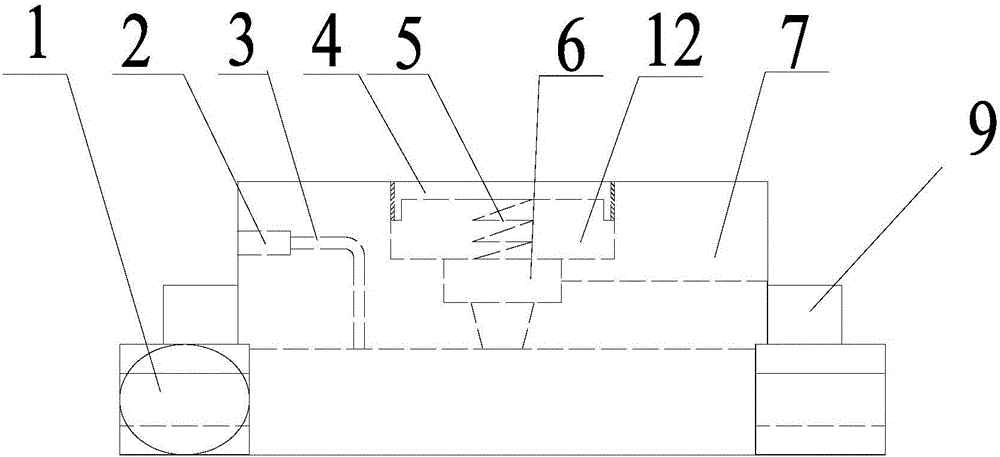

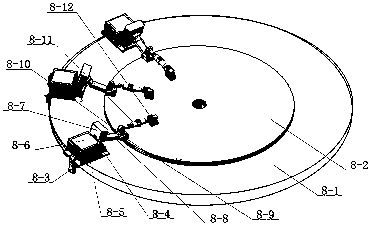

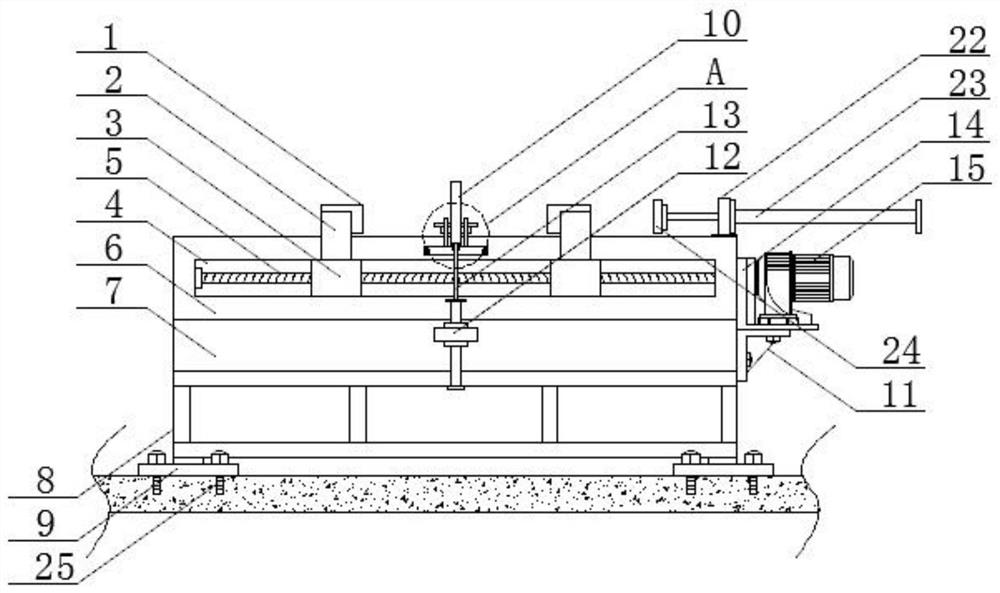

AC capacitor slot rolling sealing machine

InactiveCN105632793ASolve clamping problemsEasy maintenance and operationCapacitor manufactureWork in processEngineering

The invention relates to electronic component manufacturing process and equipment, and specifically relates to an AC capacitor slot rolling sealing machine. The AC capacitor slot rolling sealing machine is composed of an operation system, a work station rotating system, an aluminum shell pneumatic clamping system, a slot rolling system, a sealing system, a semi-finished product manipulator and a finished product manipulator part. The AC capacitor slot rolling sealing machine developed in the invention satisfies slot rolling and sealing process requirements of a CBB65A AC capacitor cylinder aluminum shell: (1) a pneumatic clamping device is adopted, so the clamping problem of a rotating disc type slot rolling sealing equipment aluminum shell having the small size is solved; (2) a spinning slot rolling device is adopted, so the AC capacitor slot rolling sealing machine is suitable for automatic production and also has the advantages of convenient operation and maintenance, good universality and the like; and (3) a function selection device is added, so waste of a core group or the aluminum shell is reduced, and the machine can also be changed into a multifunctional machine through function selection.

Owner:SHAANXI SHENGMAI PETROLEUM

Turnning optical fibre method Fabry-perot filter

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

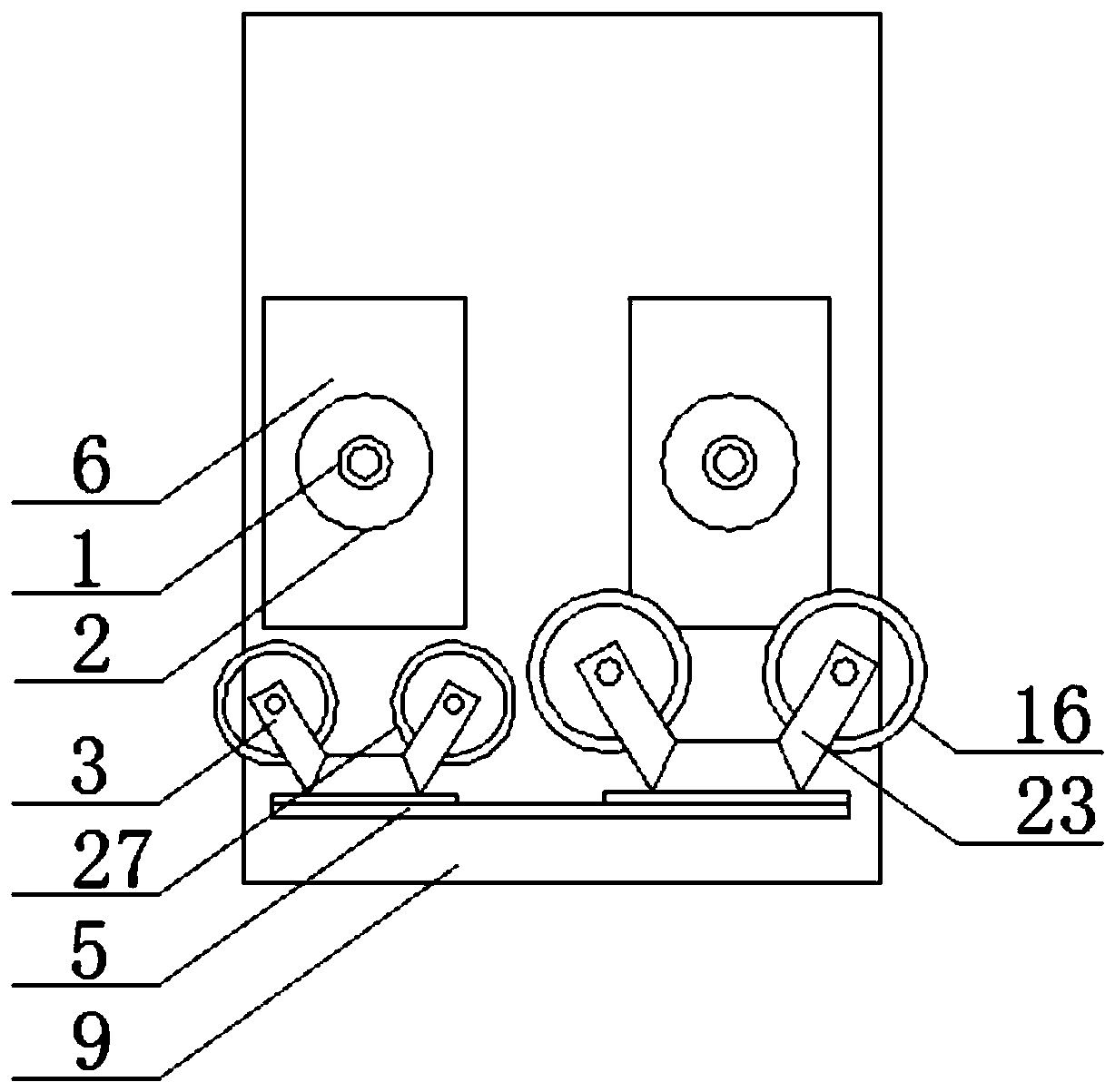

Adjustable stator coil processing tool and processing method

PendingCN110086306ASolve clamping problemsImprove stabilityManufacturing dynamo-electric machinesStator coilEngineering

The invention discloses an adjustable stator coil processing tool, which comprises a bottom plate, wherein the upper end of the bottom plate is fixed with a vertical plate at one side, one side of thevertical plate is fixed with two first mounting frame and two second mounting frame respectively through two supporting members, each first mounting frame is equipped with a first fixed wheel, each second mounting frame is equipped with a second fixed wheel, the upper end of the bottom plate is fixed with four bearing rods, the upper ends of the four bearing rods are fixed with a supporting platetogether, the supporting plate is provided with a rotating device, and the upper end of the rotating device is fixed with a positioning block. The invention further provides an adjustable stator coilprocessing method. According to the invention, the problem that it is unable to clamp and fix stators of different sizes is solved, the circumstance of low processing efficiency caused by the difference in stator stability is avoided, the circumstance of stator coil damage caused by the inability of bearing a strong electromagnetic force is also avoided at the same time, and the service life of the stator coil is prolonged.

Owner:天津天发总厂机电设备有限公司

Special clamp for drilling mechanism

ActiveCN108481021ASolve clamping problemsReduce operating costsWork clamping meansPositioning apparatusIndustrial engineeringDrilling machines

The invention discloses a special clamp for a drilling mechanism. According to the special clamp, the problem of clamping a cylindrical workpiece is solved, through the cooperative operation between ahydraulic driving assembly and a connecting rod assembly, the limitation that when a current drilling machine clamps the cylindrical workpiece, the clamping capacity is poor, the efficiency is low and the collapse is prone to occurrence are overcome, and the operation cost is greatly reduced; and the construction efficiency is improved, the benefits are increased, and the comprehensive performance of the special clamp is suitable for the needs of future development.

Owner:NINGBO C S I POWER CO LTD

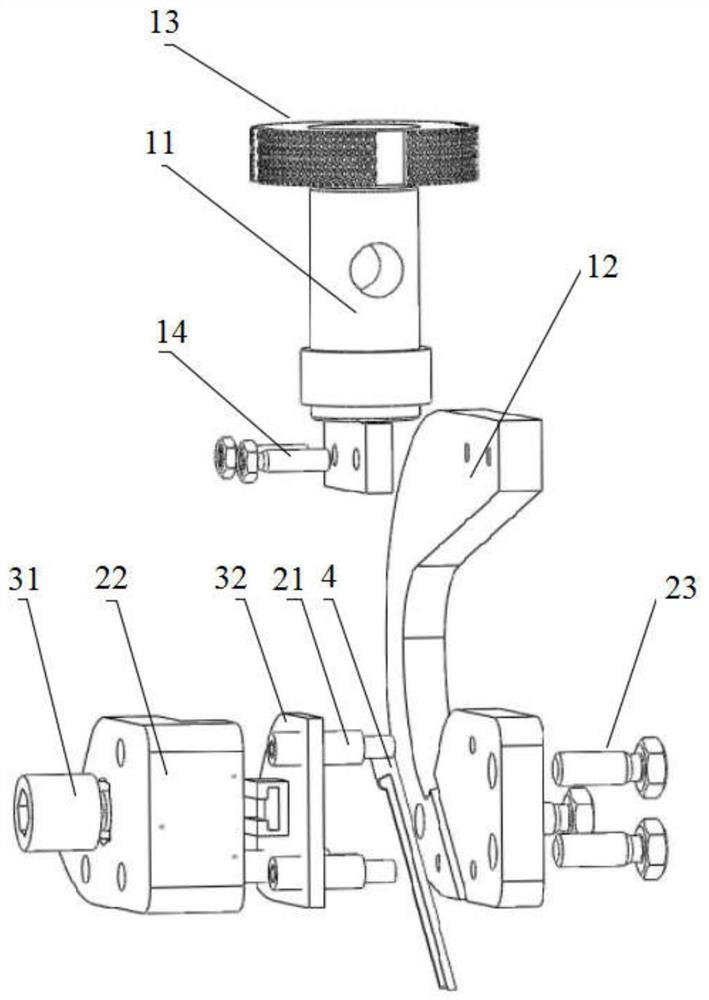

Blade clamping device for cutting edge sharpness testing

PendingCN112405402ASharpness test is not limitedSharpness test implementationWork holdersAnnular cutterStructural engineering

The invention provides a blade clamping device for cutting edge sharpness testing. The blade clamping device can solve the problem of local blade clamping of an annular cutter. The device comprises aconnecting and bearing mechanism, a guide mechanism and a pressing mechanism, wherein the connecting and bearing mechanism is used for connecting sharpness testing equipment, a blade accommodating groove is formed in the connecting and bearing mechanism, and a blade accommodating space for accommodating a blade to be tested can be formed between the blade accommodating groove and the pressing mechanism; the guide mechanism is connected to the connecting and bearing mechanism; the pressing mechanism is arranged on the guide mechanism and can move relative to the connecting and bearing mechanismunder the guide action of the guide mechanism so as to adjust the size of the blade accommodating space and press the blade to be tested; and the blade to be tested is a local blade which is sectioned from an annular blade.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

Plate punching mechanism, intelligent clamping device and using method

ActiveCN108044372ASolve the hole punching problemSolve clamping problemsMeasurement/indication equipmentsLarge fixed membersPunchingIndustrial engineering

The invention discloses a plate punching mechanism, an intelligent clamping device and an assembling and using method thereof, and the plate punching problem and the plate clamping problem are effectively solved. The whole-process operation is extremely simple, the accuracy is extremely high, the making cost is low, the effect is significantly enhanced, and the overall efficiency and operation reliability are greatly improved.

Owner:佛山联邦高登家私有限公司

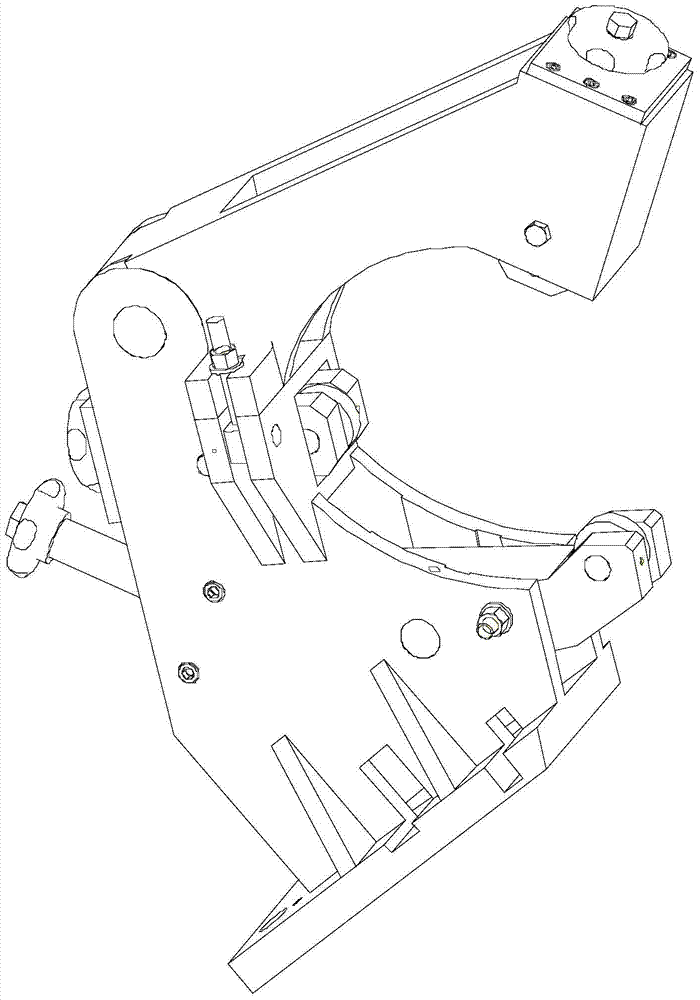

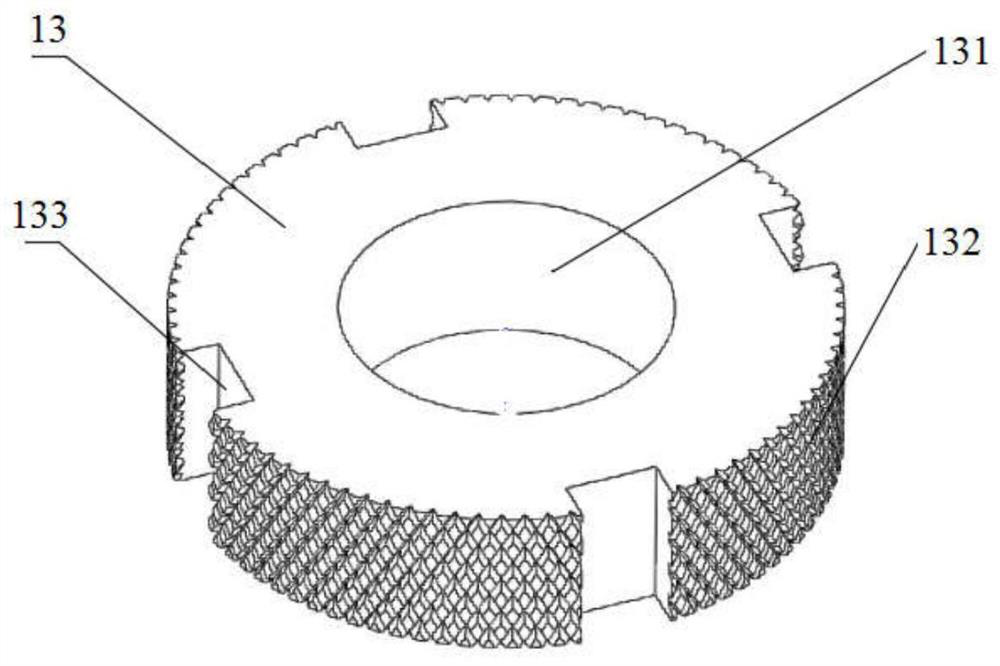

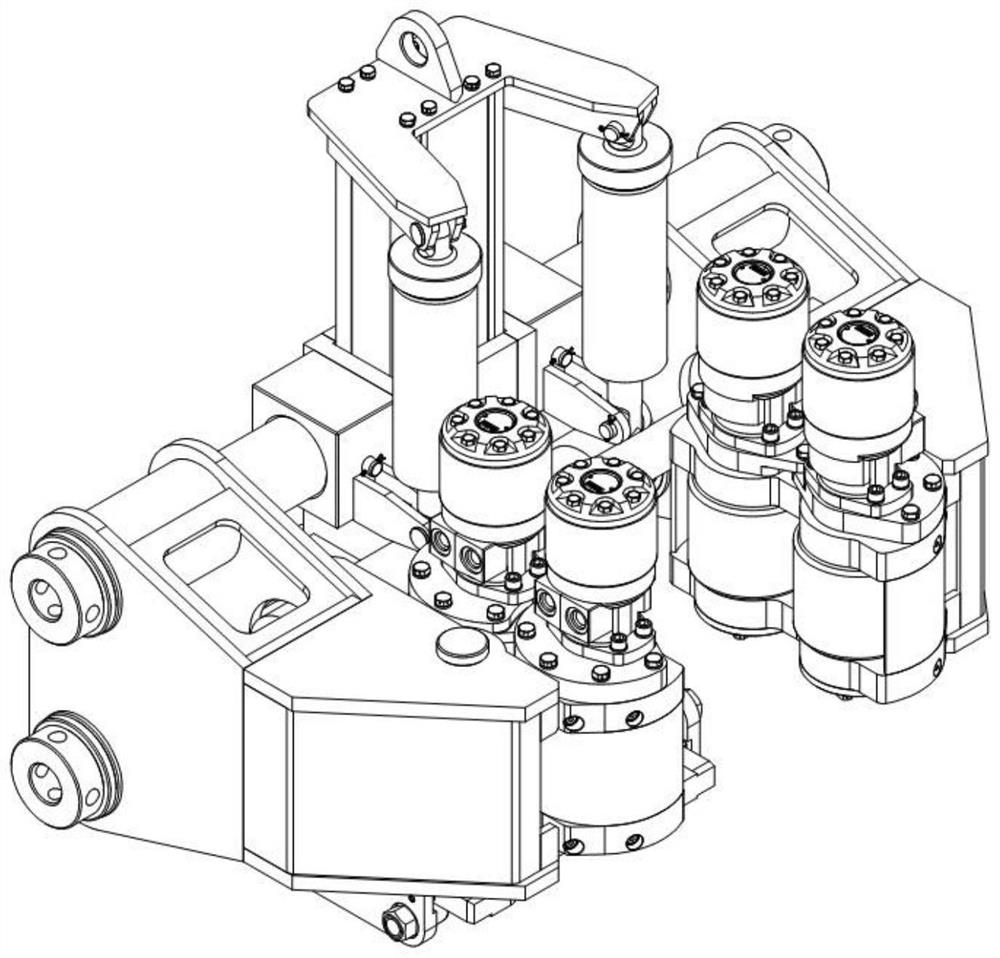

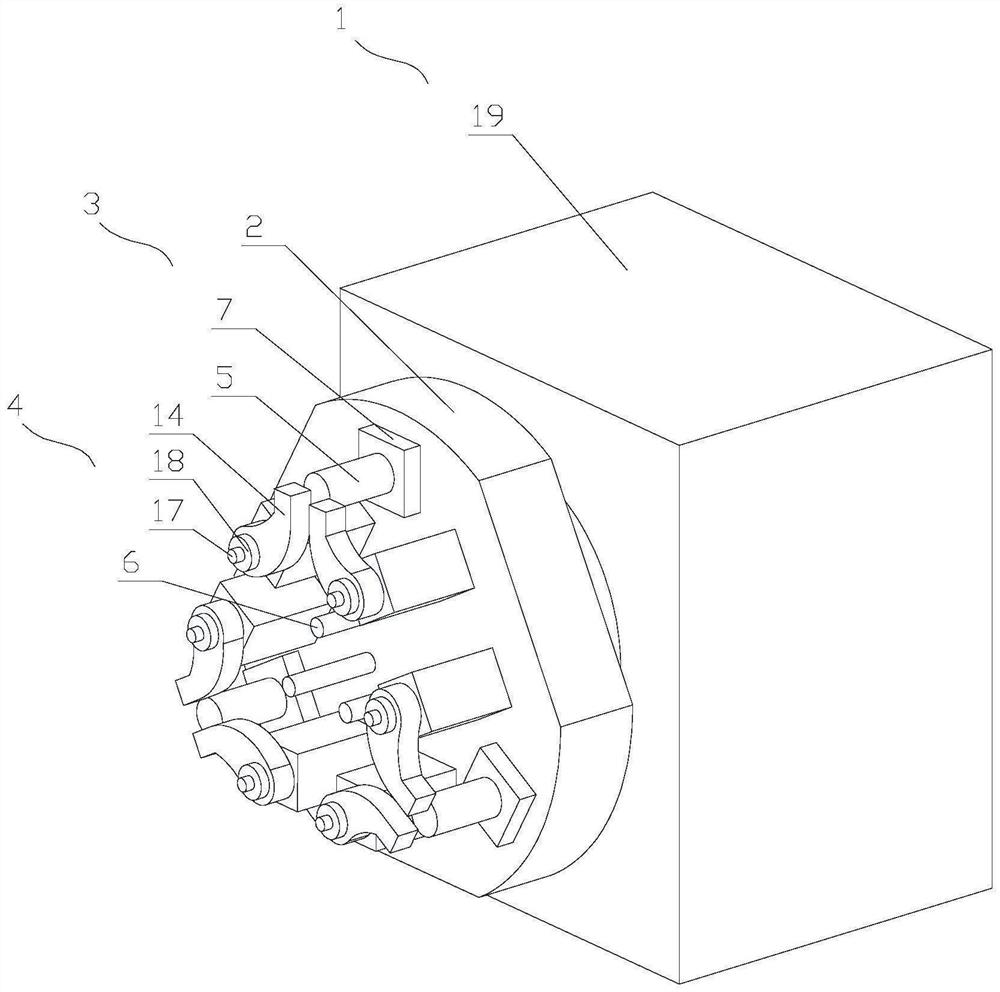

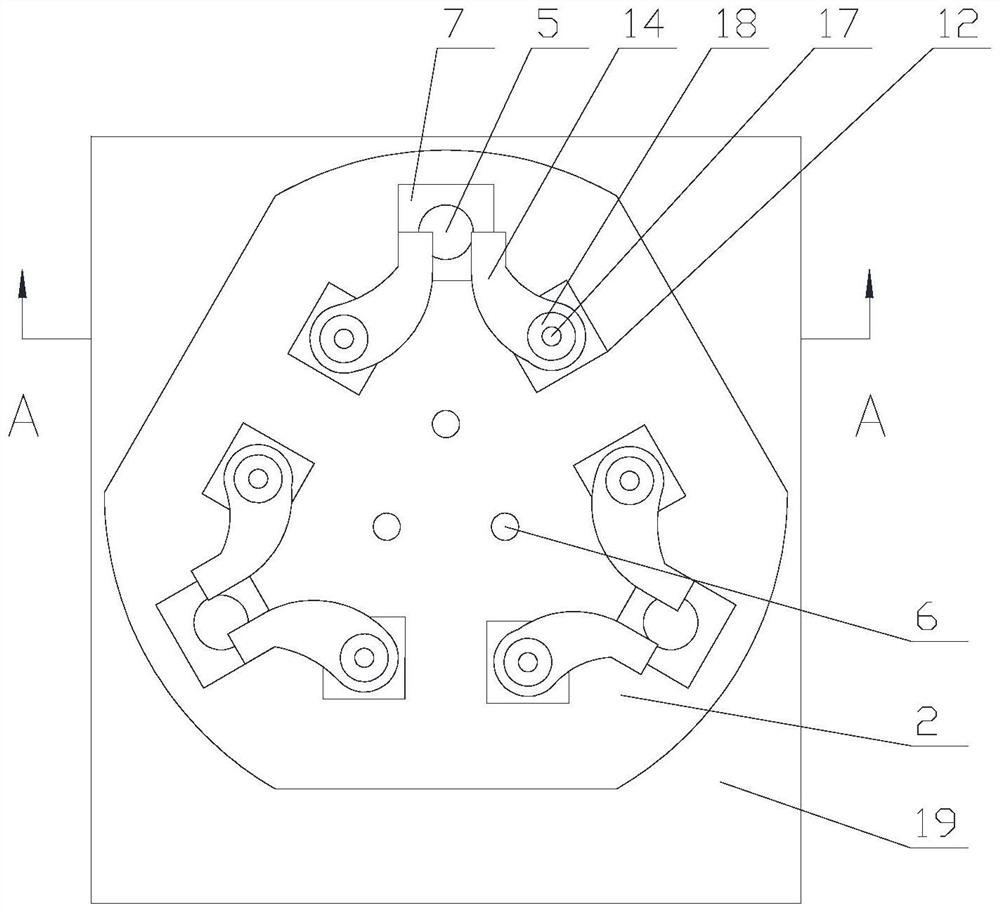

A spinner structure

ActiveCN112049588BSolve clamping problemsEasy to holdDrilling rodsDrilling casingsWell drillingOil drilling

The invention discloses a spinner structure, which belongs to the field of oil drilling equipment; the device includes a base body, a suspension assembly is arranged on the base body, and a support frame is arranged on the base body, and the support frame There are hooks on both sides, the hooks are provided with a rotary wheel assembly, the hooks can move along the support frame, and a driving device is also arranged between the hooks to control the displacement of the hooks; the seat The body is equipped with a guide frame, the support frame is sleeved on the guide frame, the support frame can slide up and down along the guide frame, and the two ends of the suspension assembly are assembled and connected with the guide frame and the support frame respectively; one of the present invention This kind of spinner structure can adjust the clamping distance through the hook through the driving device to solve the clamping problem of drilling tools with different diameters. Through this structure, the clamping of drilling tools with different diameters / sizes is effectively improved, and the drilling efficiency is improved effectively. The efficiency of making up and breaking down of the tool.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

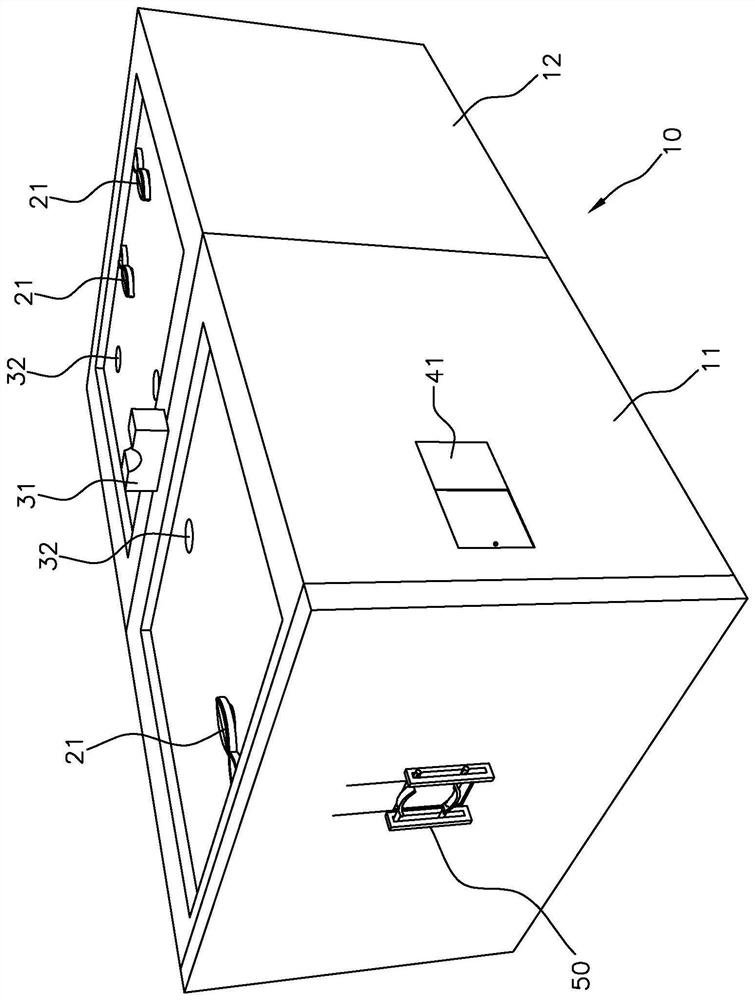

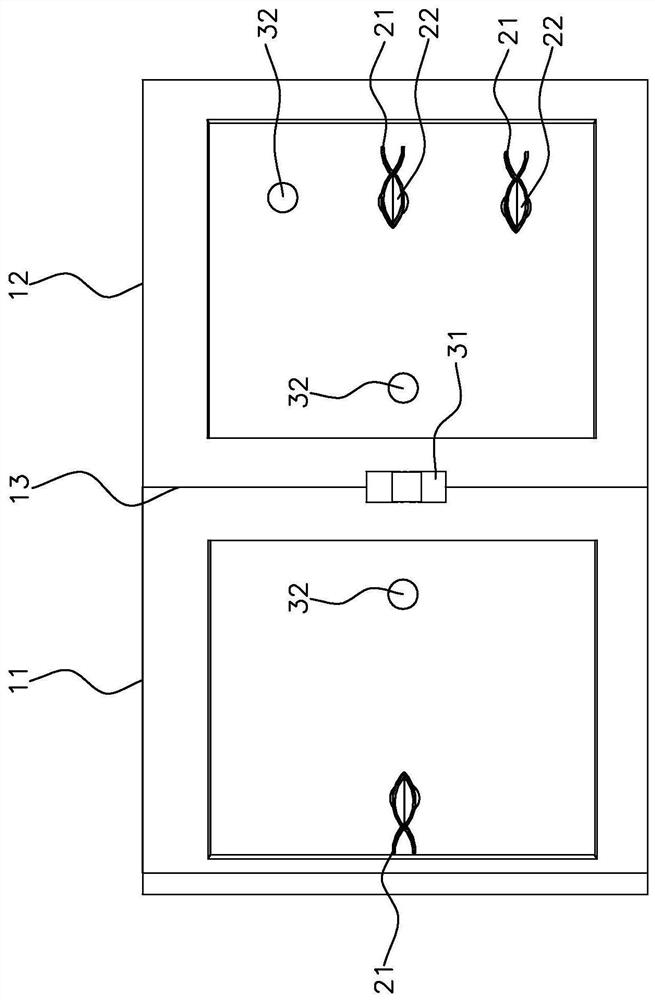

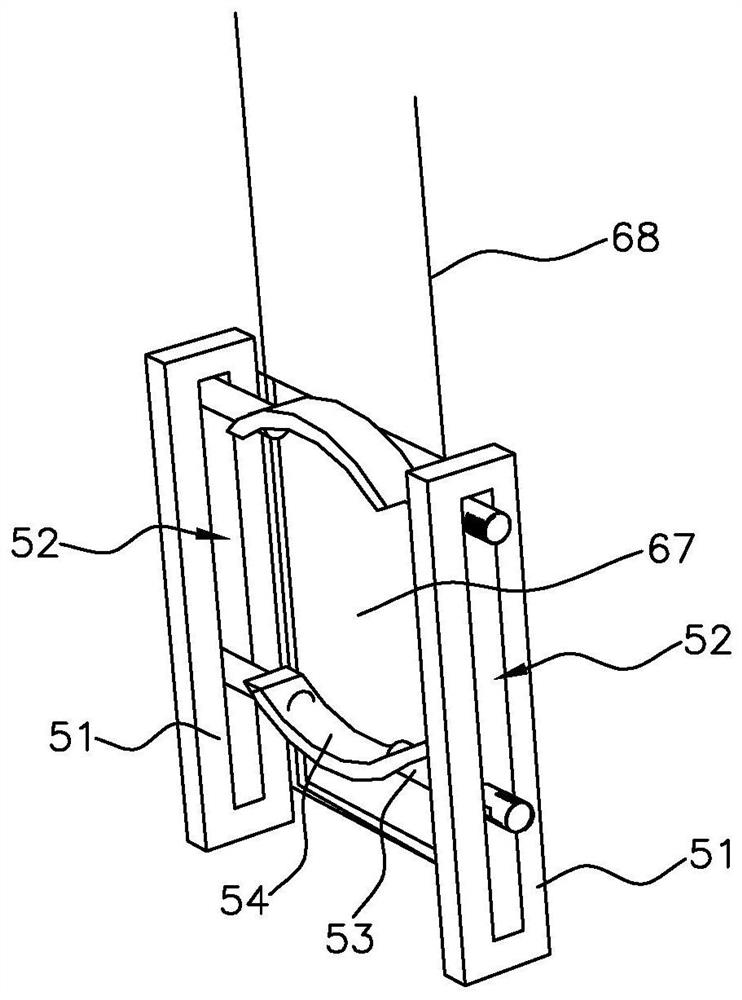

Device for testing electrochemical performance of energy storage type photo-generated anode

ActiveCN113504281AEasy to changeSolve clamping problemsMaterial electrochemical variablesShutterSalt bridge

The invention discloses a device for testing the electrochemical performance of an energy storage type photo-generated anode, and relates to the technical field of electrochemical property testing. The device comprises a box body, a plurality of electrode fixing assemblies and a shutter assembly, wherein the box body comprises a first groove and a second groove, the first groove and the second groove are respectively provided with a through hole for a salt bridge to penetrate through, and a salt bridge placement rack is arranged between the box bodies, and is used for fixing a salt bridge; the first groove and the second groove are both provided with the electrode fixing assemblies, and each electrode fixing assembly comprises a clamp with two clamping arms and is used for clamping an electrode; and the shutter assembly comprises a light barrier used for shielding a light source, a guide rail piece allowing the light barrier to slide and a driving unit used for controlling the light barrier to slide along the guide rail piece, and the driving unit drives the light barrier to slide, so that opening or closing of the light barrier is achieved, and the light source is enabled to pass through or be shielded. According to the embodiment of the invention, errors can be reduced, and light input and light-shade period can be controlled.

Owner:GUANGZHOU SOUNDWEL SCI & TECH CO LTD

Machine tool workbench facilitating clamping

InactiveCN112496779ASolve clamping problemsAchieve clamping and fixing effectLarge fixed membersPositioning apparatusEngineeringMachine tool

The invention discloses a machine tool workbench facilitating clamping. The workbench comprises a bearing table, an operation table is fixed to the upper end of the bearing table, a cavity is formed in the operation table, openings are formed at the two sides of the cavity, an adjusting device is arranged in the cavity, and two moving plates are arranged on the adjusting device; and the two ends of the two moving plates penetrate through the two openings correspondingly and extend to the two sides of the operation table, two moving blocks are fixed to the upper ends of the moving plates and located at the two sides of the operation table correspondingly, L-shaped clamping plates are fixed to one sides of the upper ends of the moving blocks, and the four L-shaped clamping plates correspondto one another. According to the workbench, the problem that parts of different sizes are inconvenient to clamp and fix is solved, meanwhile, the problem that the stability of the parts is poor is solved, the situation that the parts are wasted due to machining deviation caused by movement of the parts is avoided, the stability of the parts is improved, and meanwhile the machining efficiency is improved.

Owner:QINGYUAN POLYTECHNIC

A method for removing the cap from a test tube

ActiveCN106044675BSolve clamping problemsReduce external forceTight-fitting lid removalThreaded caps removalEngineeringTest tube

The invention provides an uncapping method of a test tube. The uncapping method is used for achieving the two work processes of test tube cap removal and test tube capping. The uncapping method is achieved through a test tube uncapping mechanism. The uncapping method of the test tube is used for solving the clamping problem of a test tube cap, and the test tube cap is clamped under the condition of reducing external force applied to the test tube cap. Meanwhile, in the test tube cap removal process, the functions that the test tube cup rotates while ascending and the test tube is capped with the test tube cap again can be achieved, and the uncapping method can be compatible with test tubes and test tube caps different in height.

Owner:SUZHOU TOPMEDLAB MEDICAL SCI & TECH CO LTD

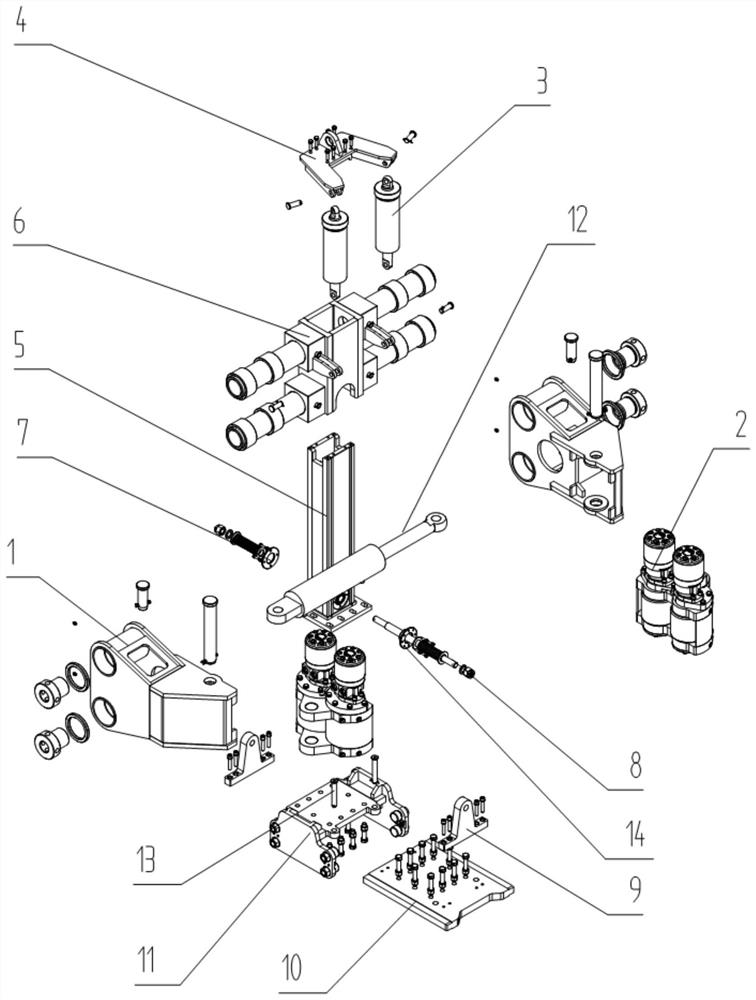

Fixture for connecting rod multi-procedure integrated machining

PendingCN114131376ASolve clamping problemsPositioning apparatusGrinding work supportsClassical mechanicsStructural engineering

The invention relates to the technical field of clamping devices, in particular to a clamp for connecting rod multi-procedure integrated machining, which comprises a driving mechanism, a mounting seat and three mounting mechanisms, and each mounting mechanism comprises two clamping assemblies, a wedging column, a limiting column, an abutting seat and two lifting assemblies. Large connecting rod holes and small connecting rod holes of a plurality of connecting rods are overlapped and sleeved on the wedging column and the limiting column respectively, the clamping assembly blocks the connecting rods on the wedging column, and the lifting assembly drives the abutting seat to slide on the mounting seat towards the direction of the clamping assembly and pushes the connecting rods to slide on the wedging column towards the direction close to the clamping assembly. The connecting rod is clamped between the clamping assembly and the abutting seat, the connecting rod is fixed, the two sides of the connecting rod can be machined, and the problem that an existing clamp can only clamp one connecting rod is solved.

Owner:苏垦银河汽车部件盐城有限公司

A processing method for ice-fixed metal honeycomb workpiece

ActiveCN105171460BSolve clamping problemsSuppression of processing defectsMilling equipment detailsPositioning apparatusHoneycombLiquid nitrogen

The invention provides an ice immobilization machining method for a metal honeycomb workpiece, belongs to the field of machining technological methods and relates to a machine tool fixture device and a machining method for immobilizing a metal honeycomb material through an ice immobilization manner to achieve ultralow-temperature cutting. The method comprises the steps that after metal honeycomb holes arranged in a metal honeycomb ice immobilizing fixture are filled with low-temperature pure water or cutting liquid, the metal honeycomb ice immobilizing fixture is arranged in an adjustable refrigerating testing cabinet, and the freezing temperature and the refrigerating time are set; and then the metal honeycomb ice immobilizing fixture is clamped to a machine tool worktable, metal honeycombs are machined through a liquid nitrogen internal spraying cutter, and the freezing state is maintained through liquid nitrogen external spraying. The method achieves the purpose of clamping of the metal honeycomb workpiece difficult to machine, the freezing temperature of the pure water or the cutting liquid and the temperature maintaining degree are effectively controlled, the machining immobilizing effect can be better, and the cutting precision is improved; and the operation of the method is convenient, the immobilizing effect is stable, the machining efficiency is high, and the machining effect is good.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com