Machine tool workbench facilitating clamping

A workbench and machine tool technology, applied in the field of machine tools, can solve problems such as poor stability, inability to clamp parts of different sizes, poor practicability, etc., and achieve the effect of improving stability and convenient pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

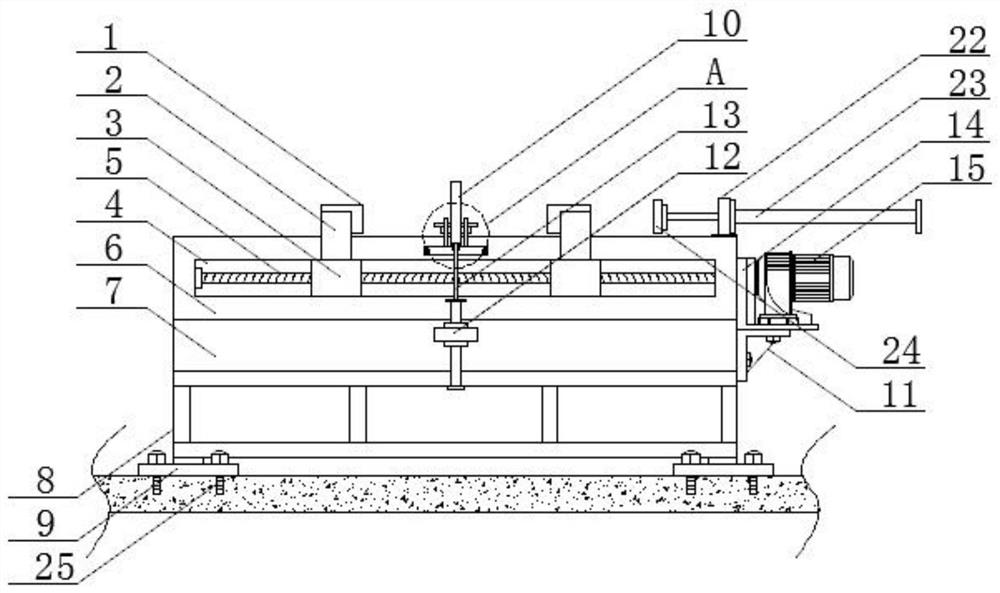

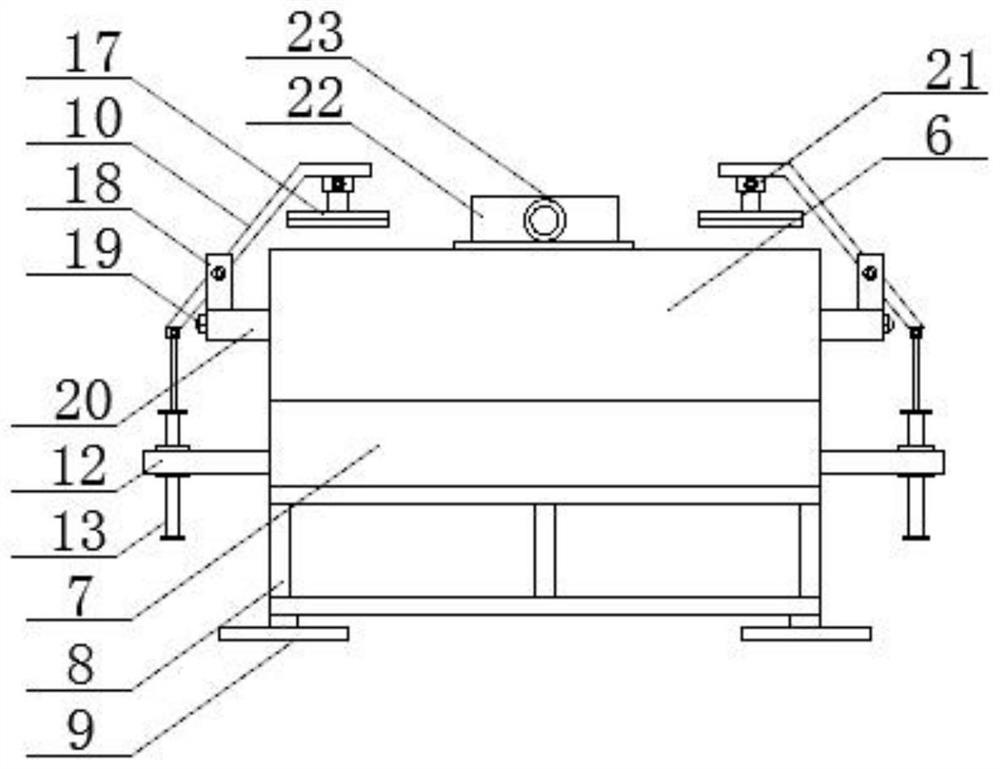

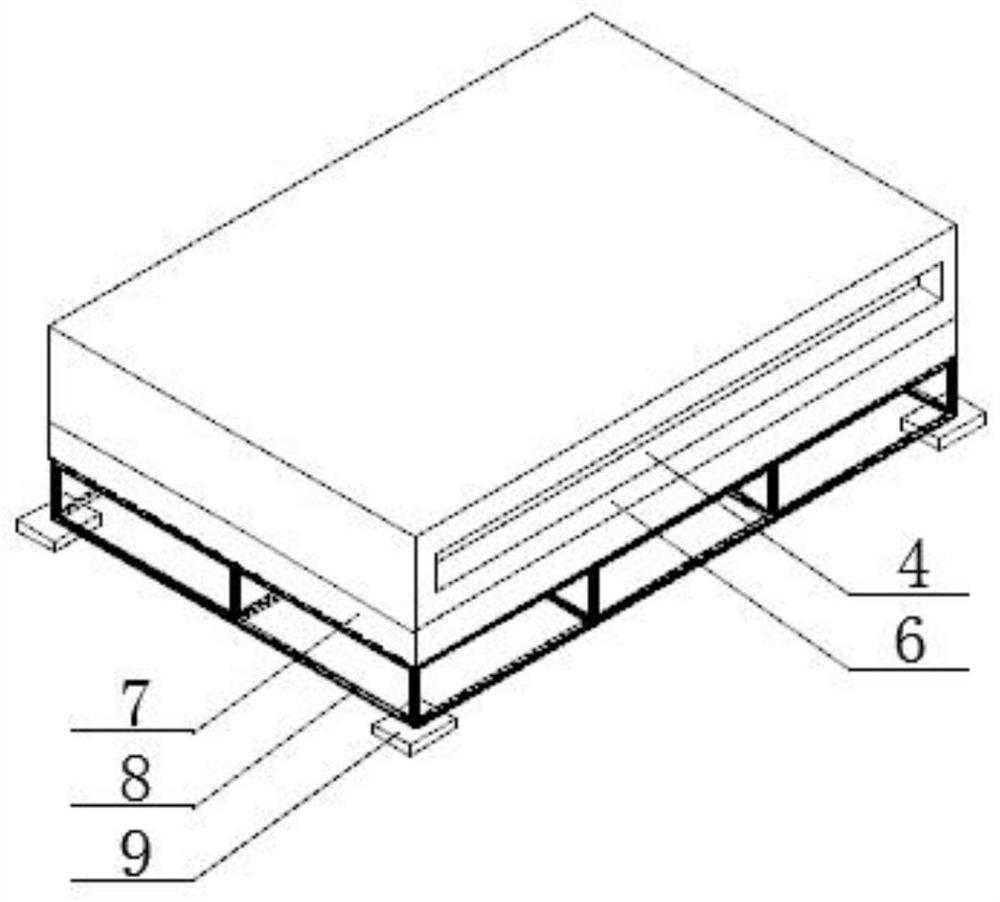

[0029] refer to figure 1 , 2 , 3, 4, a kind of machine tool workbench that is convenient to clamp, comprises bearing platform 7, plays the effect of supporting and fixing, and the upper end of bearing platform 7 is fixed with operating platform 6, is convenient to process parts, and operating platform 6 is provided with empty There are openings 4 on both sides of the cavity, and an adjustment device is provided in the cavity. Two moving plates 3 are arranged on the adjustment device. On both sides of the table 6, two moving blocks 2 are fixed on the upper end of the moving plate 3, and the moving of the moving plate 3 drives the moving block 2 to move, and the two moving blocks 2 are respectively located on both sides of the console 6, and the upper end of the moving block 2 is There is an L-shaped clamping plate 1 fixed on the side, and the movement of the moving block 2 drives the L-shaped clamping plate 1 to move, and the four L-shaped clamping plates 1 correspond to each ...

Embodiment 2

[0033] refer to figure 1 , 2 , 3, 4, 5, a machine tool workbench that is convenient to clamp, includes a bearing platform 7, which plays a role of support and fixation, and the upper end of the bearing platform 7 is fixed with an operation platform 6, which is convenient for processing parts. There is a cavity, openings 4 are provided on both sides of the cavity, an adjustment device is provided in the cavity, and two moving plates 3 are arranged on the adjustment device, and the two ends of the two moving plates 3 respectively pass through the two openings 4 and extend To both sides of the console 6, two moving blocks 2 are fixed on the upper end of the moving plate 3, the moving of the moving plate 3 drives the moving block 2 to move, and the two moving blocks 2 are respectively located on both sides of the operating table 6, and the moving blocks 2 An L-shaped clamping plate 1 is fixed on one side of the upper end, and the movement of the moving block 2 drives the L-shaped...

Embodiment 3

[0038] refer to figure 1 , 2 , 3, 4, 6, a machine tool workbench for easy clamping, including a bearing platform 7, which plays the role of support and fixation, the upper end of the bearing platform 7 is fixed with an operation platform 6, which is convenient for processing parts, and the operation platform 6 is equipped with There is a cavity, openings 4 are provided on both sides of the cavity, an adjustment device is provided in the cavity, and two moving plates 3 are arranged on the adjustment device, and the two ends of the two moving plates 3 respectively pass through the two openings 4 and extend To both sides of the console 6, two moving blocks 2 are fixed on the upper end of the moving plate 3, the moving of the moving plate 3 drives the moving block 2 to move, and the two moving blocks 2 are respectively located on both sides of the operating table 6, and the moving blocks 2 An L-shaped clamping plate 1 is fixed on one side of the upper end, and the movement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com