Patents

Literature

371results about How to "Reduce external force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

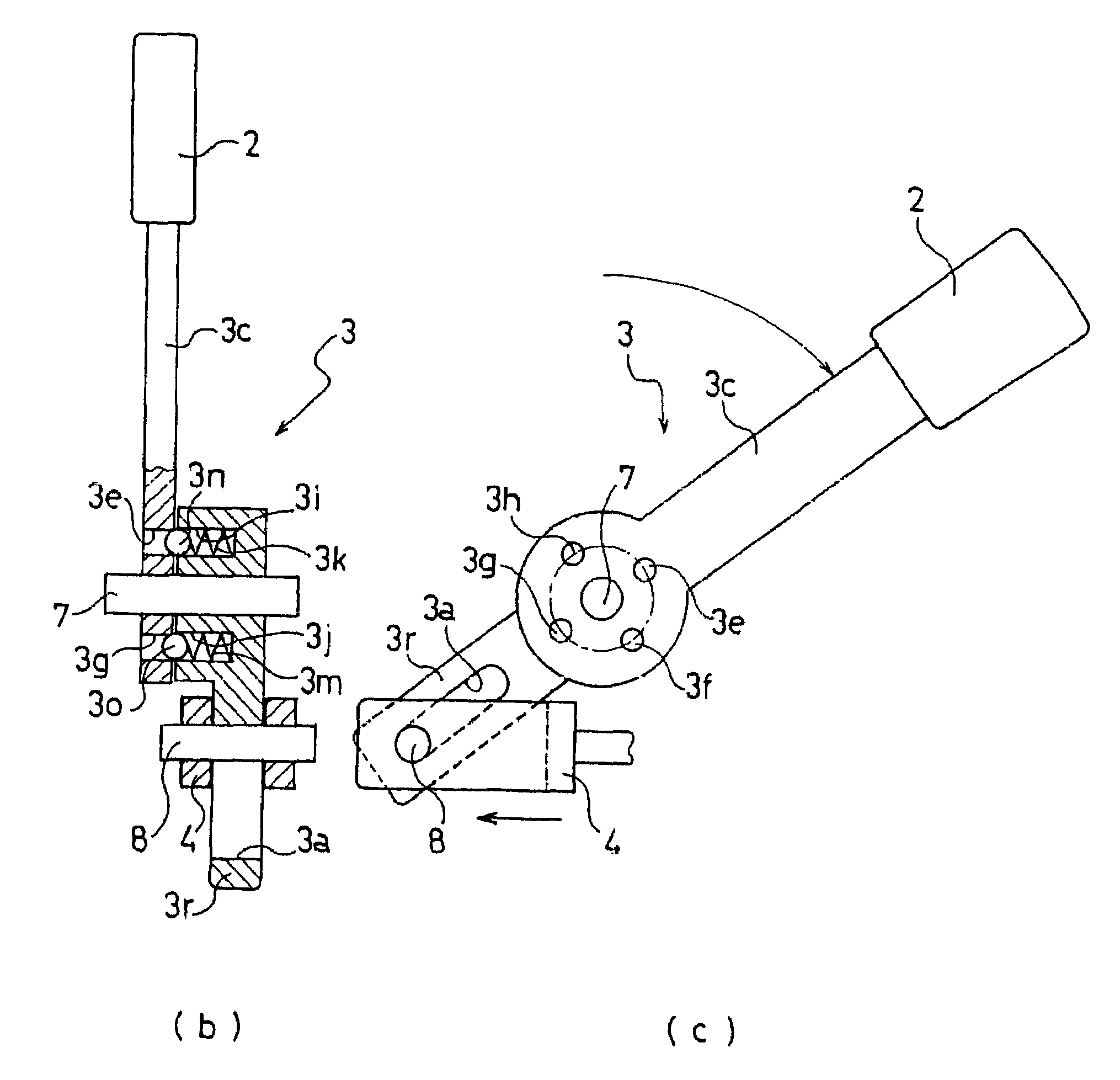

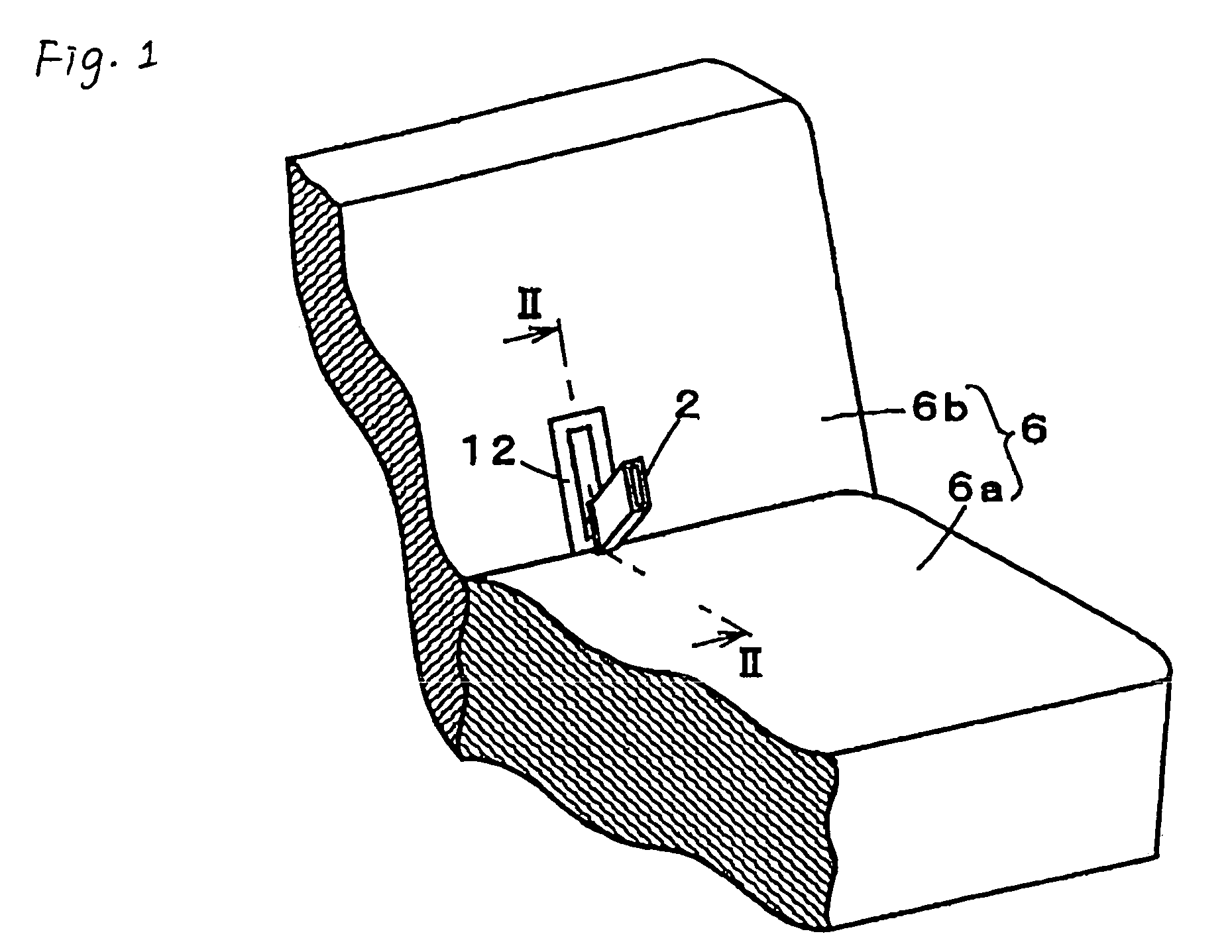

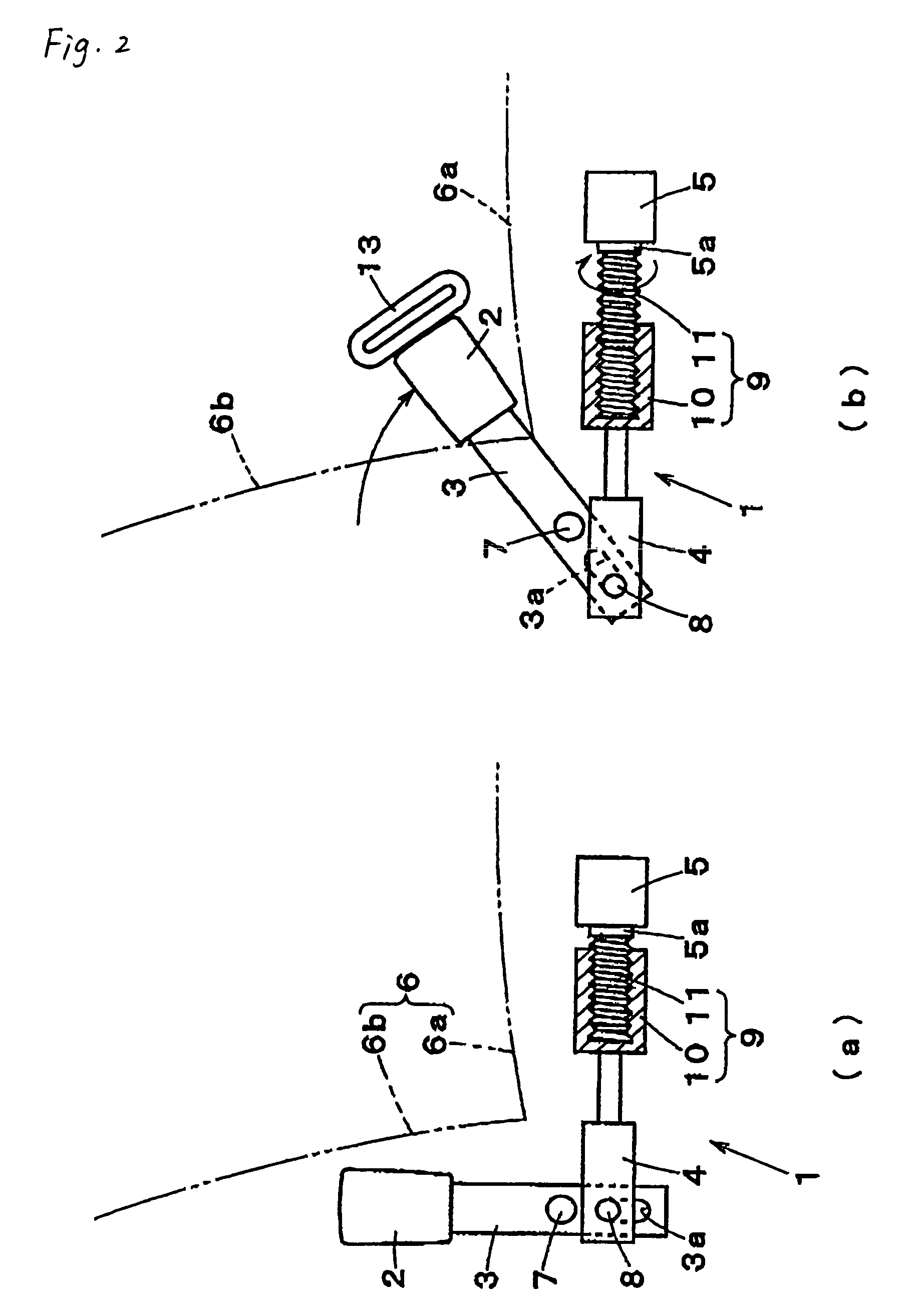

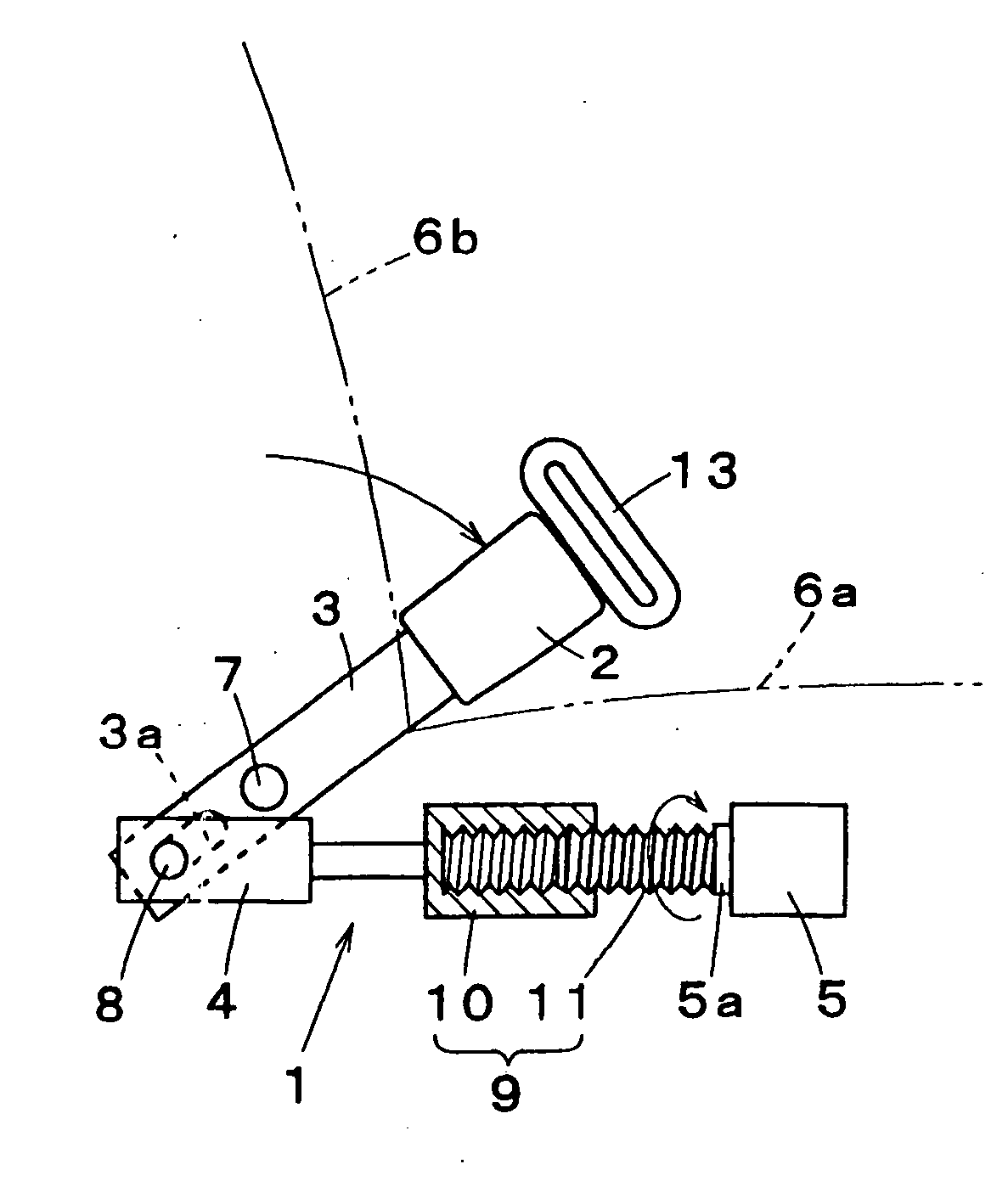

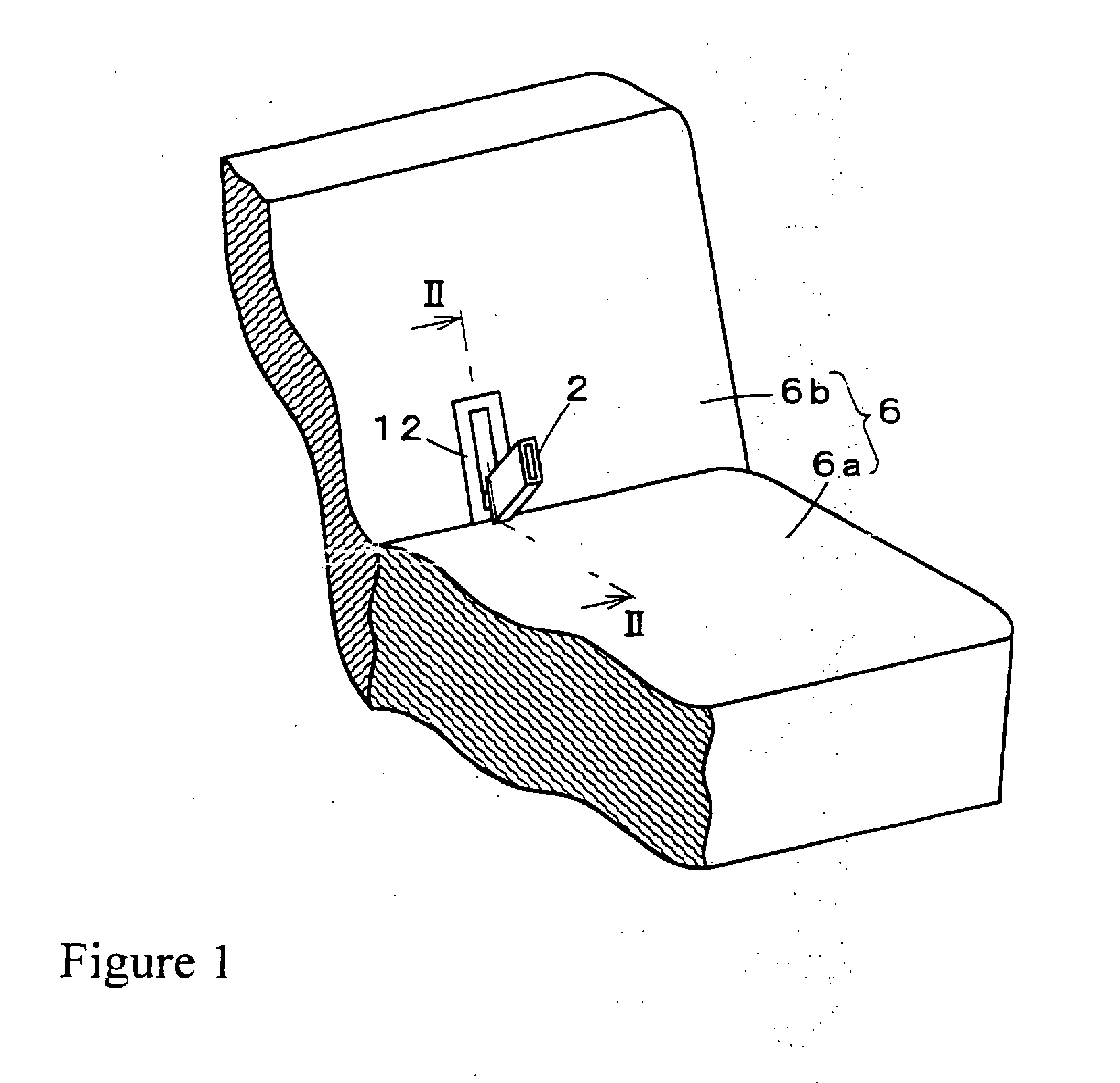

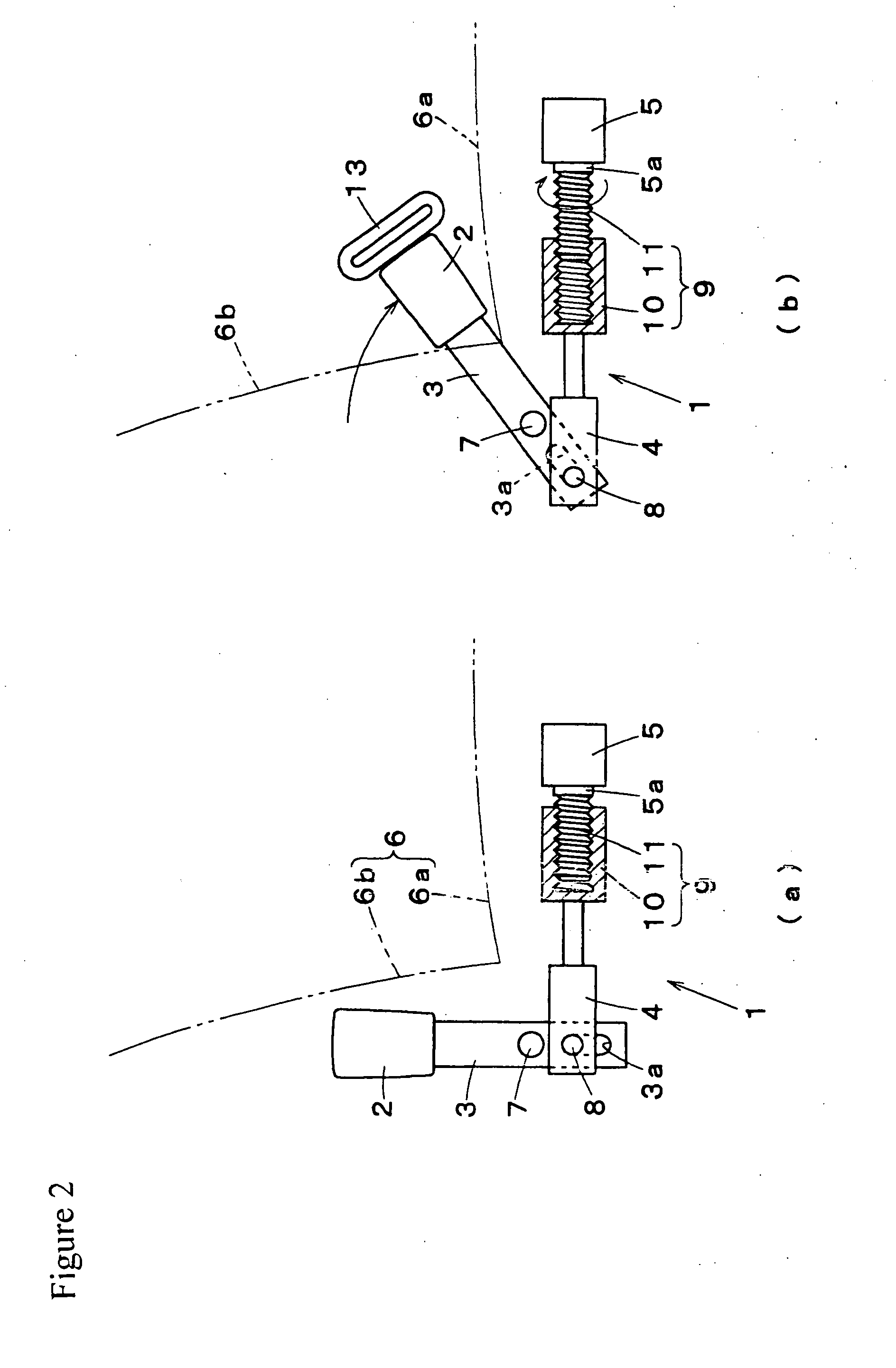

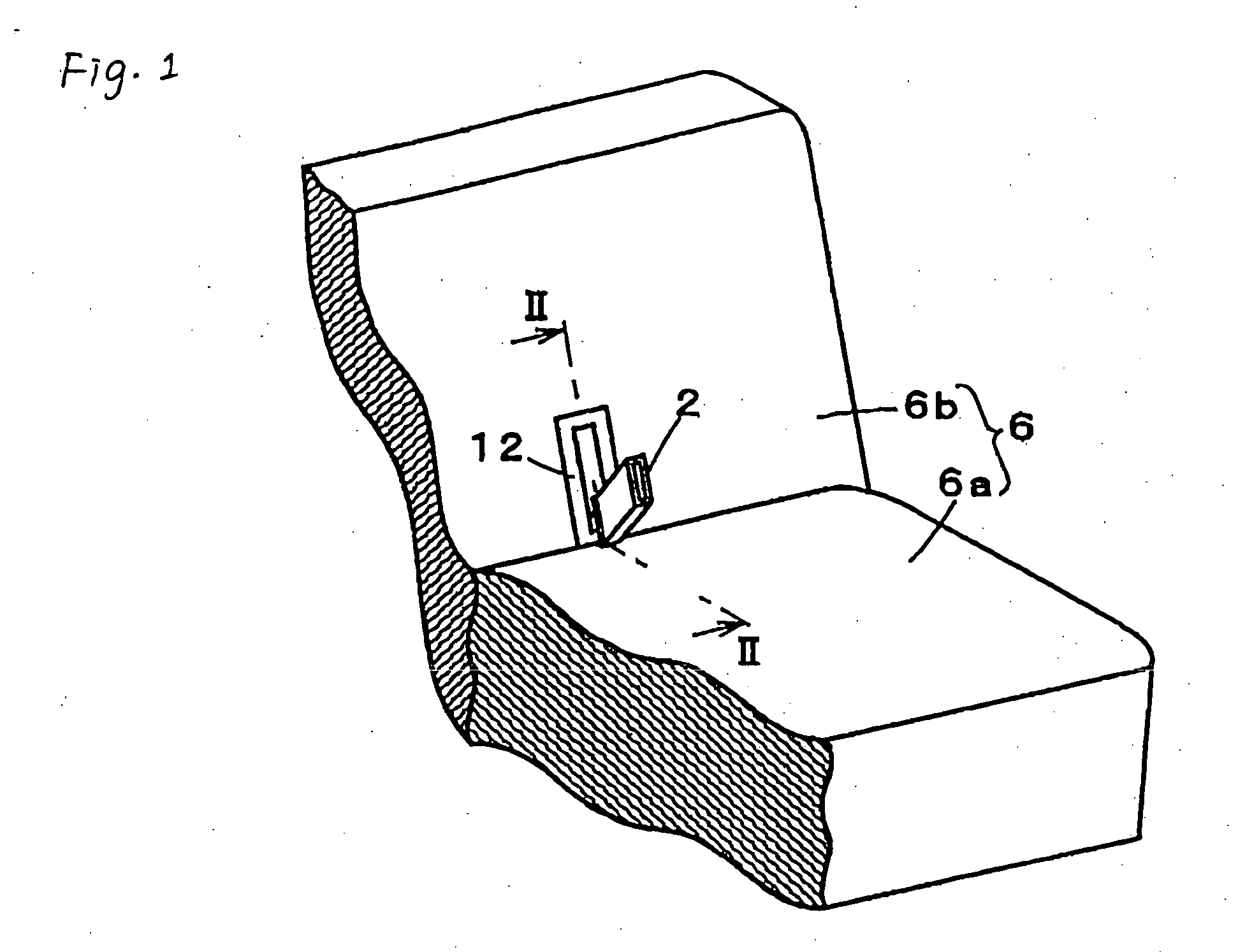

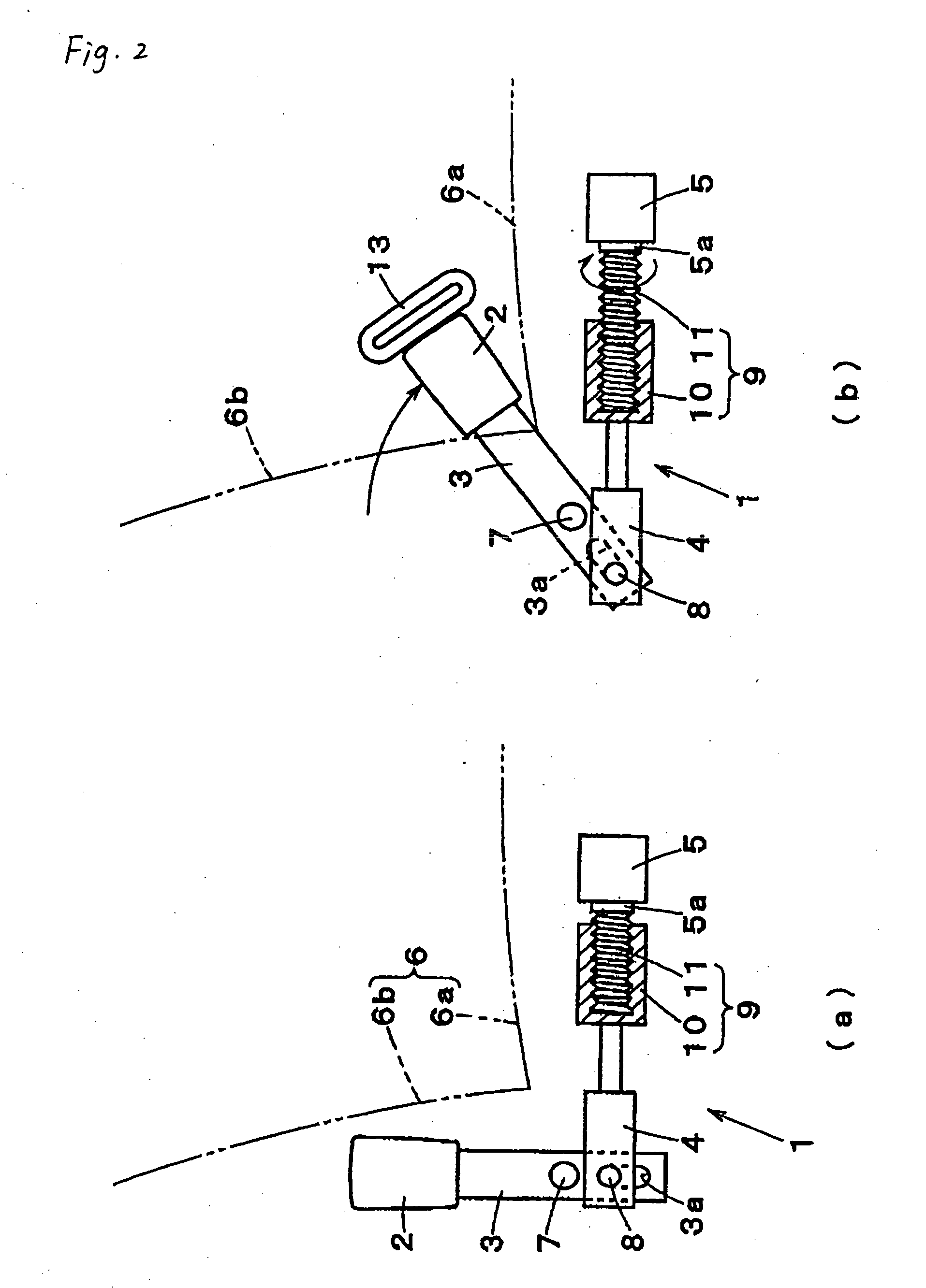

Seat belt buckle

InactiveUS7407193B2Reduce external forceSmoothly sit on and get off vehicle seatSafety beltsBelt control systemsSeat beltEngineering

A buckle device that includes a buckle with which a tongue supported by a seat belt becomes engaged, and buckle-moving device which moves the buckle between a storage position at which the buckle is stored when the buckle is not used and a use position at which the buckle is retained in a used state in which the seat belt is fastened. The buckle may be hidden in the vehicle seat at the storage position. The buckle does not obstruct the occupant when the occupant sits on or gets off the vehicle seat, and the occupant can smoothly sit on or get off the vehicle seat.

Owner:TAKATA CORPORATION

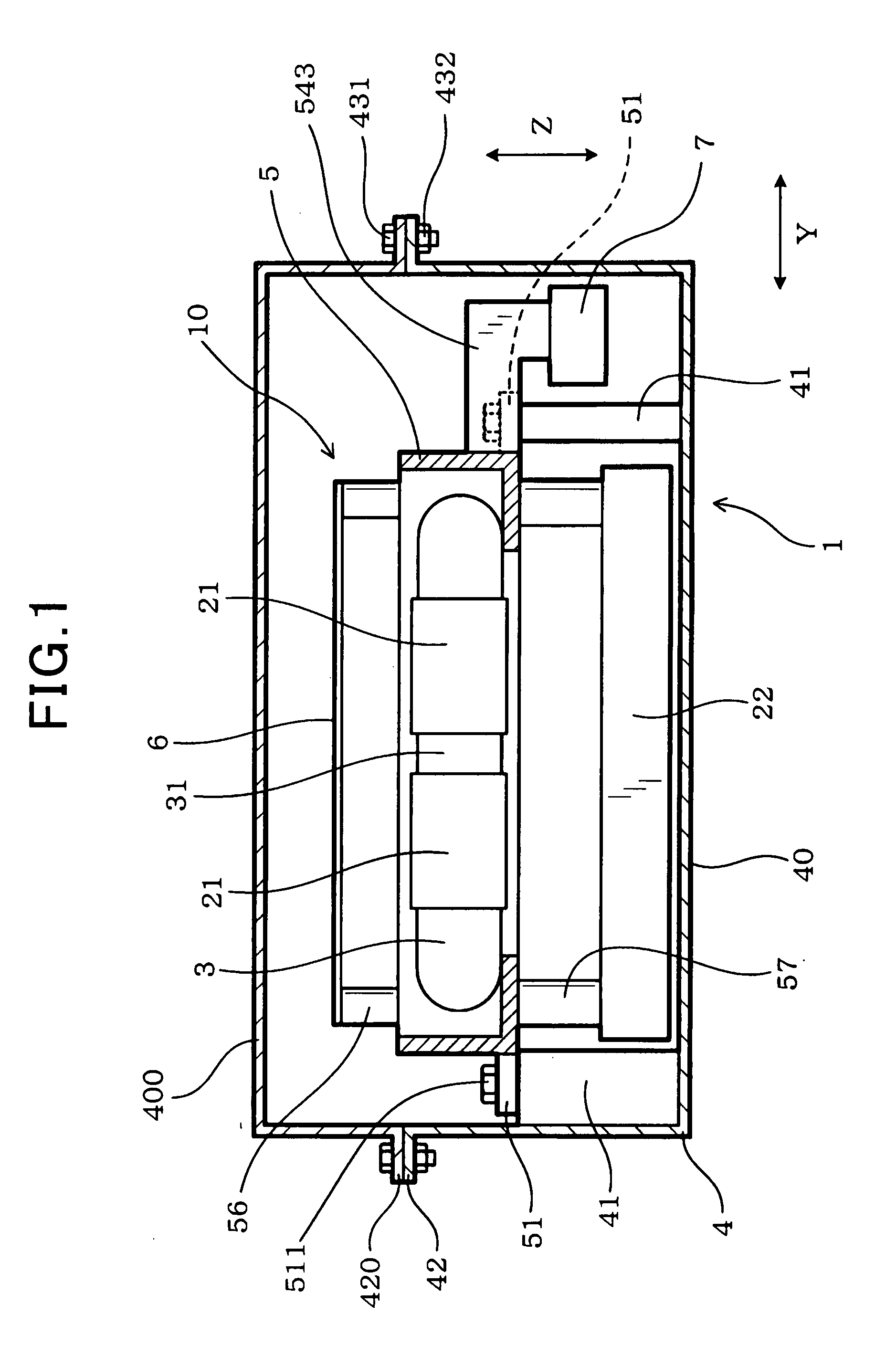

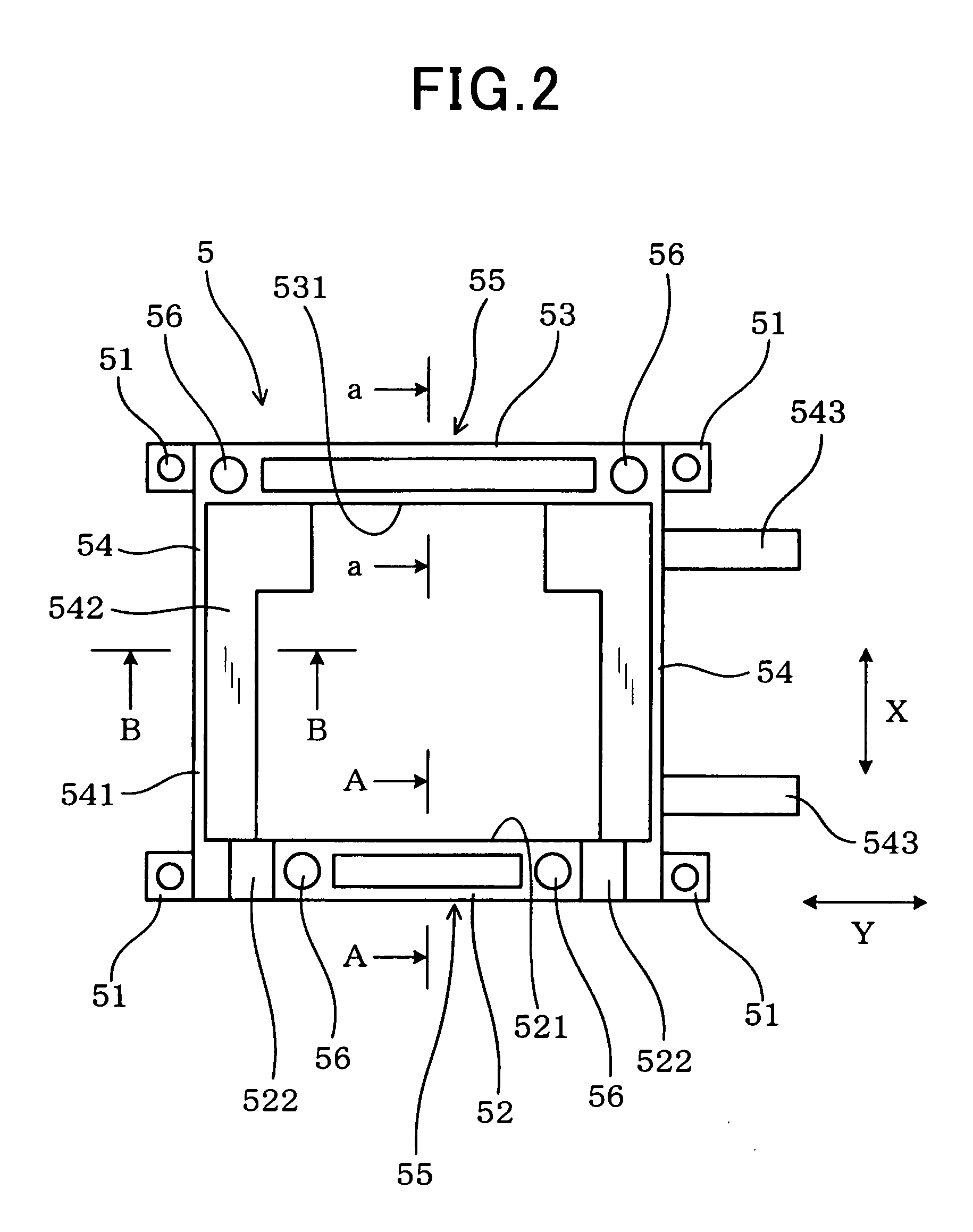

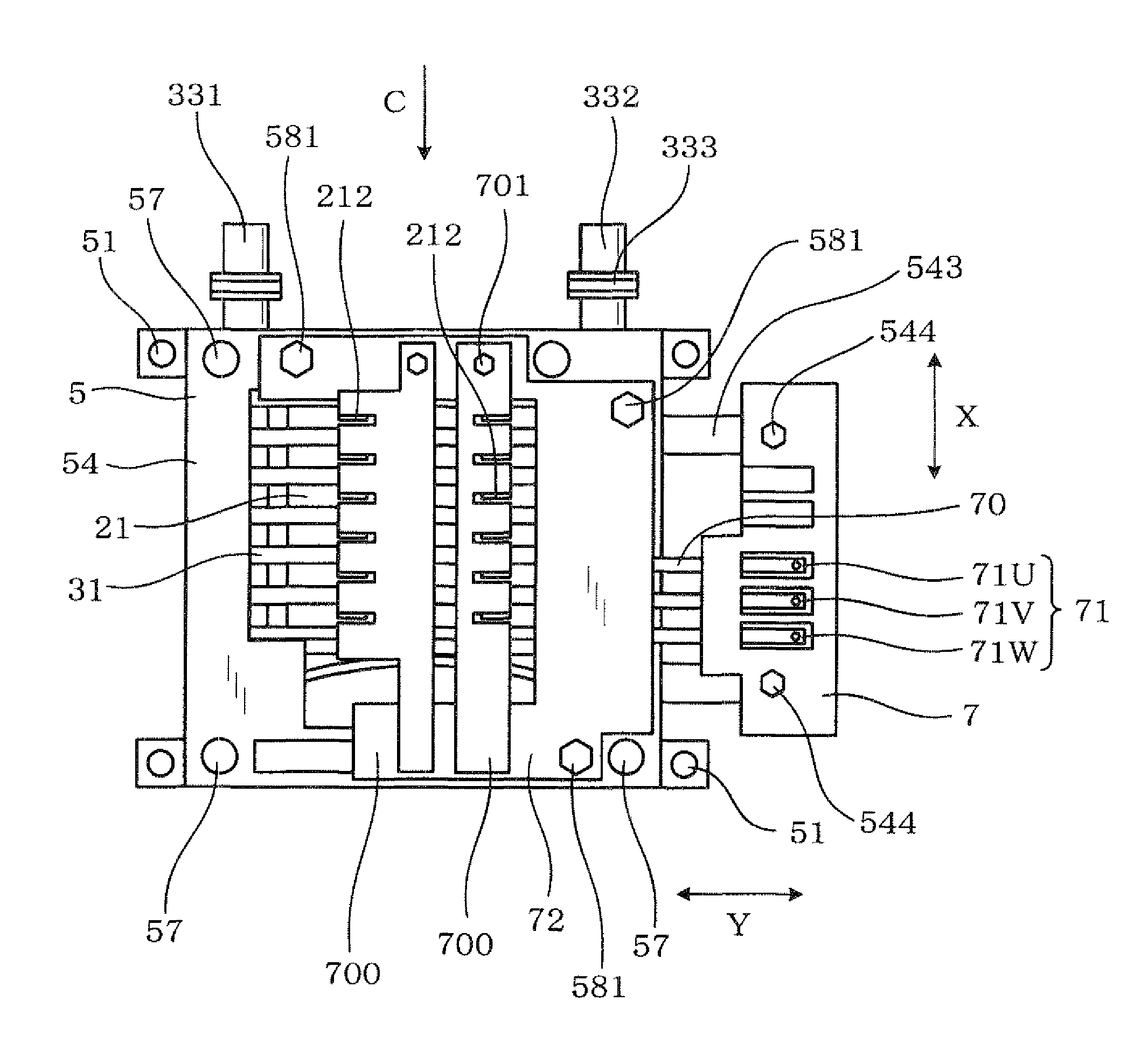

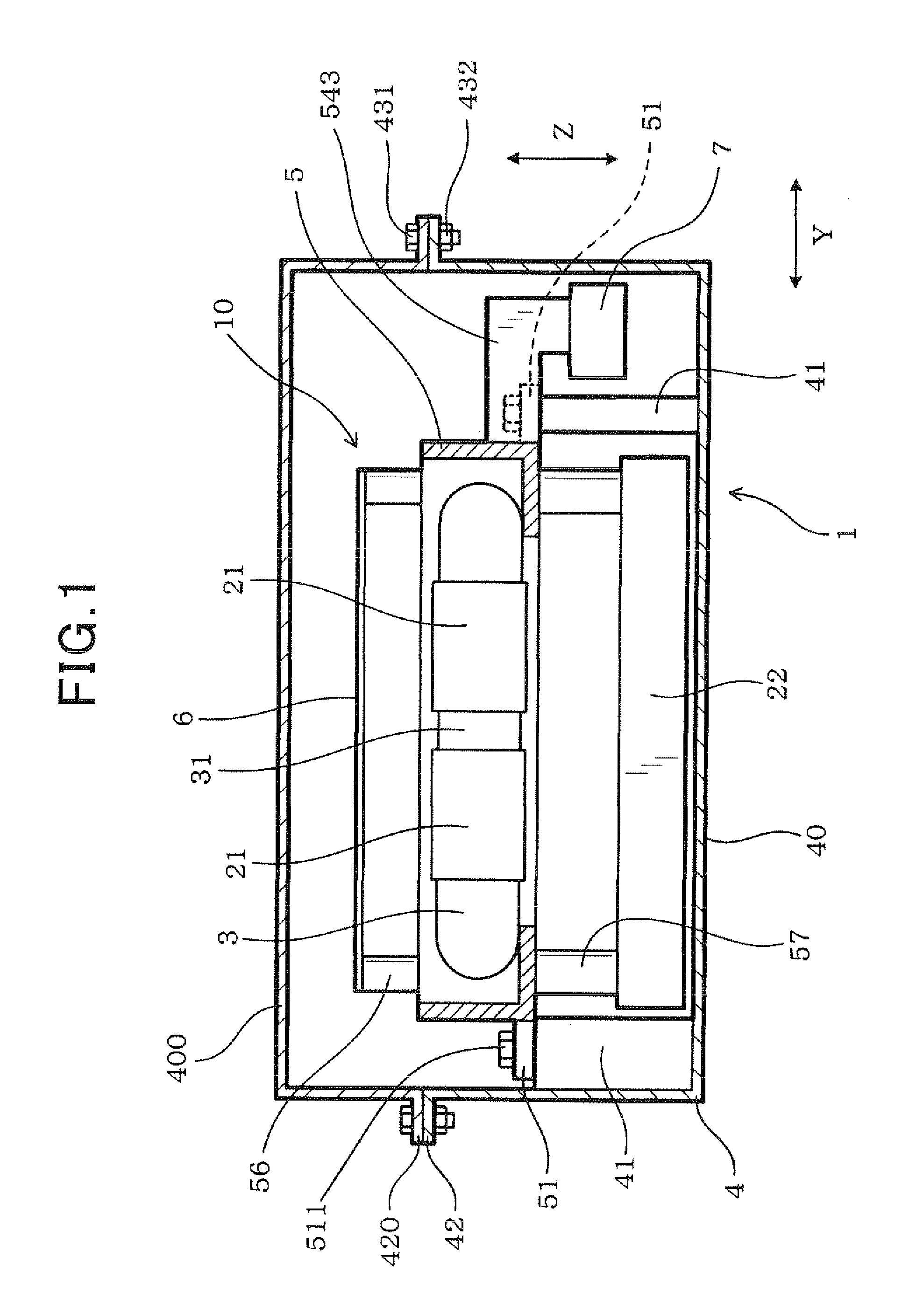

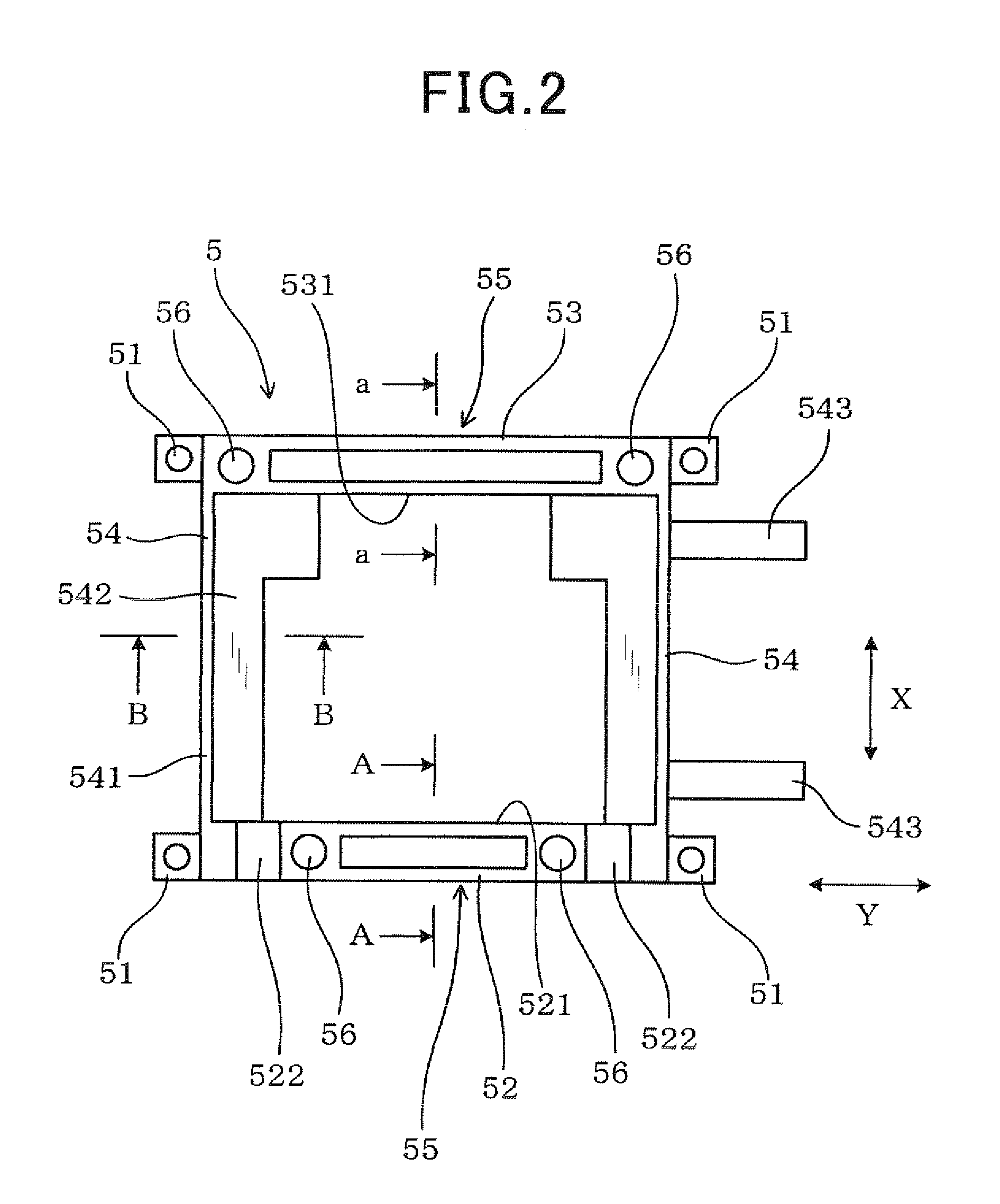

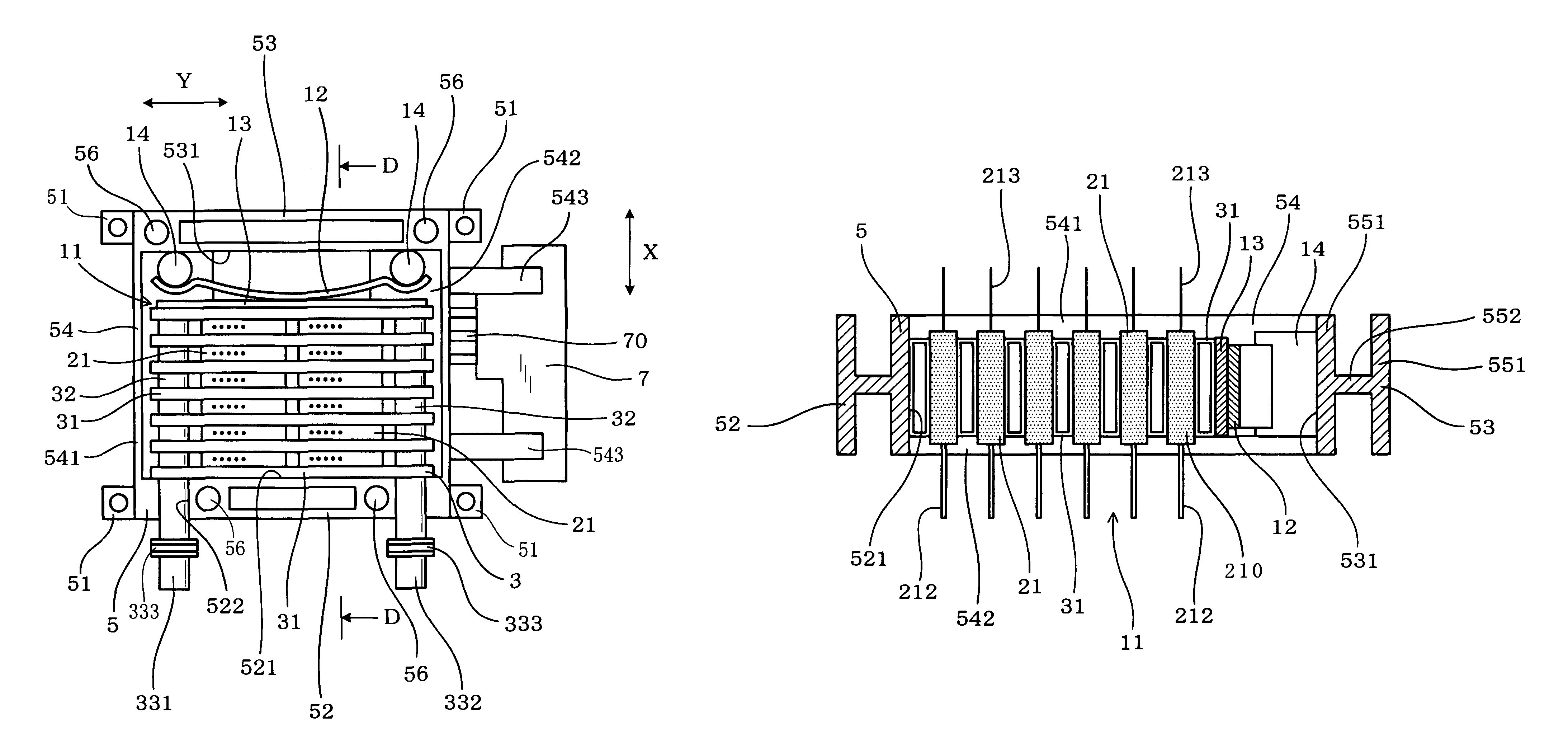

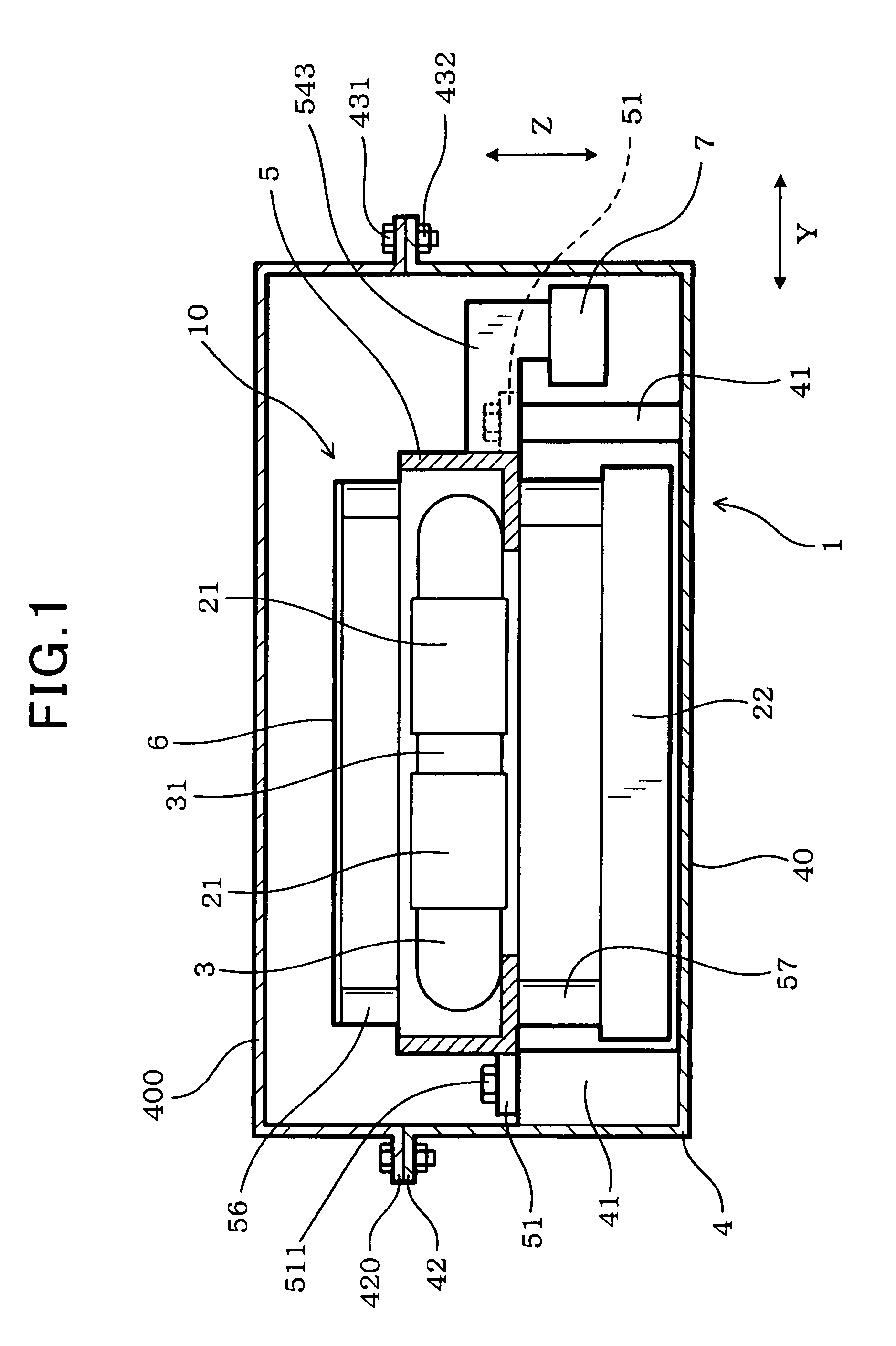

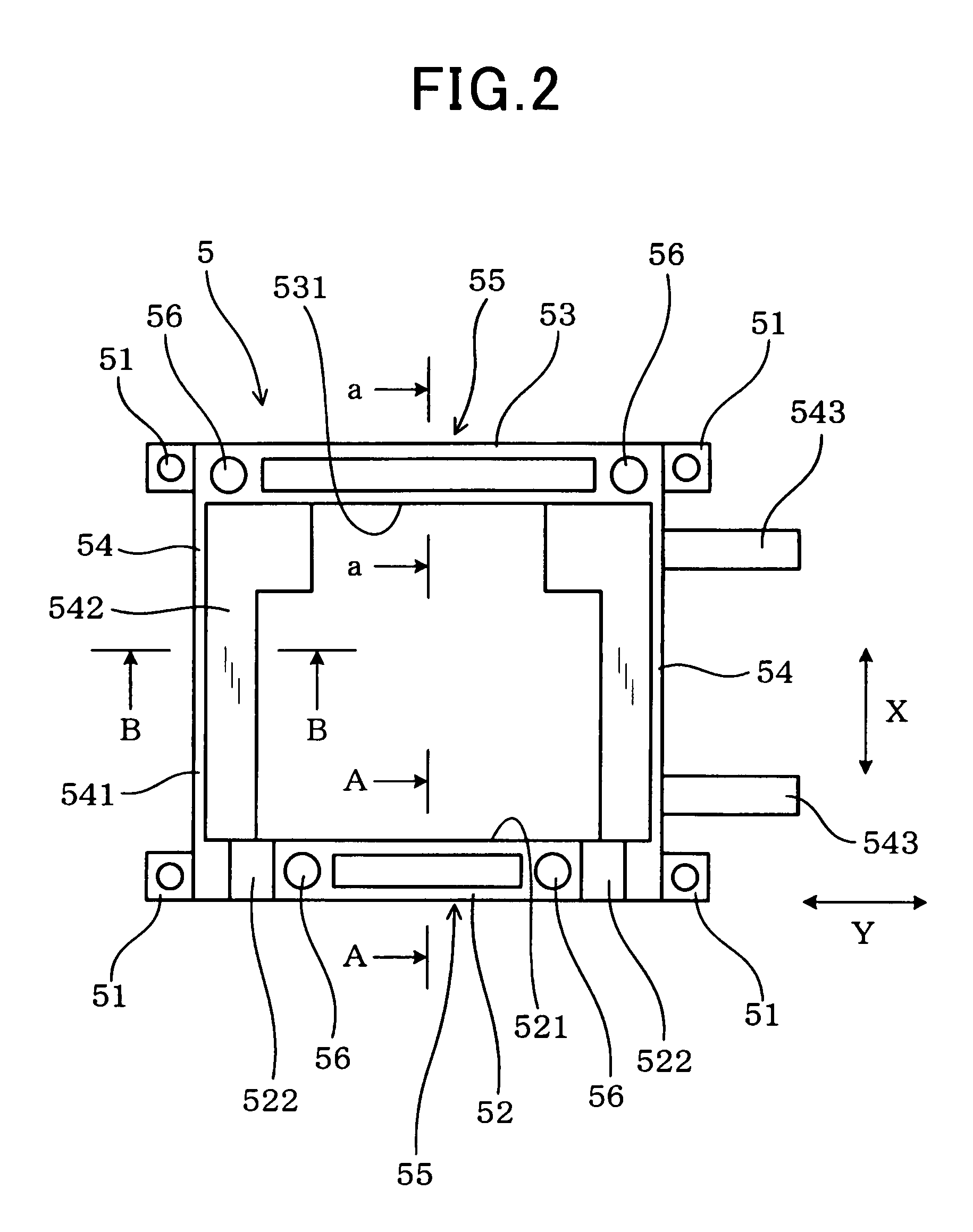

Power conversion apparatus

ActiveUS20110194249A1Reduce external forceImprove rigidityConversion constructional detailsSemiconductor/solid-state device detailsHemt circuitsElectronic component

Owner:DENSO CORP

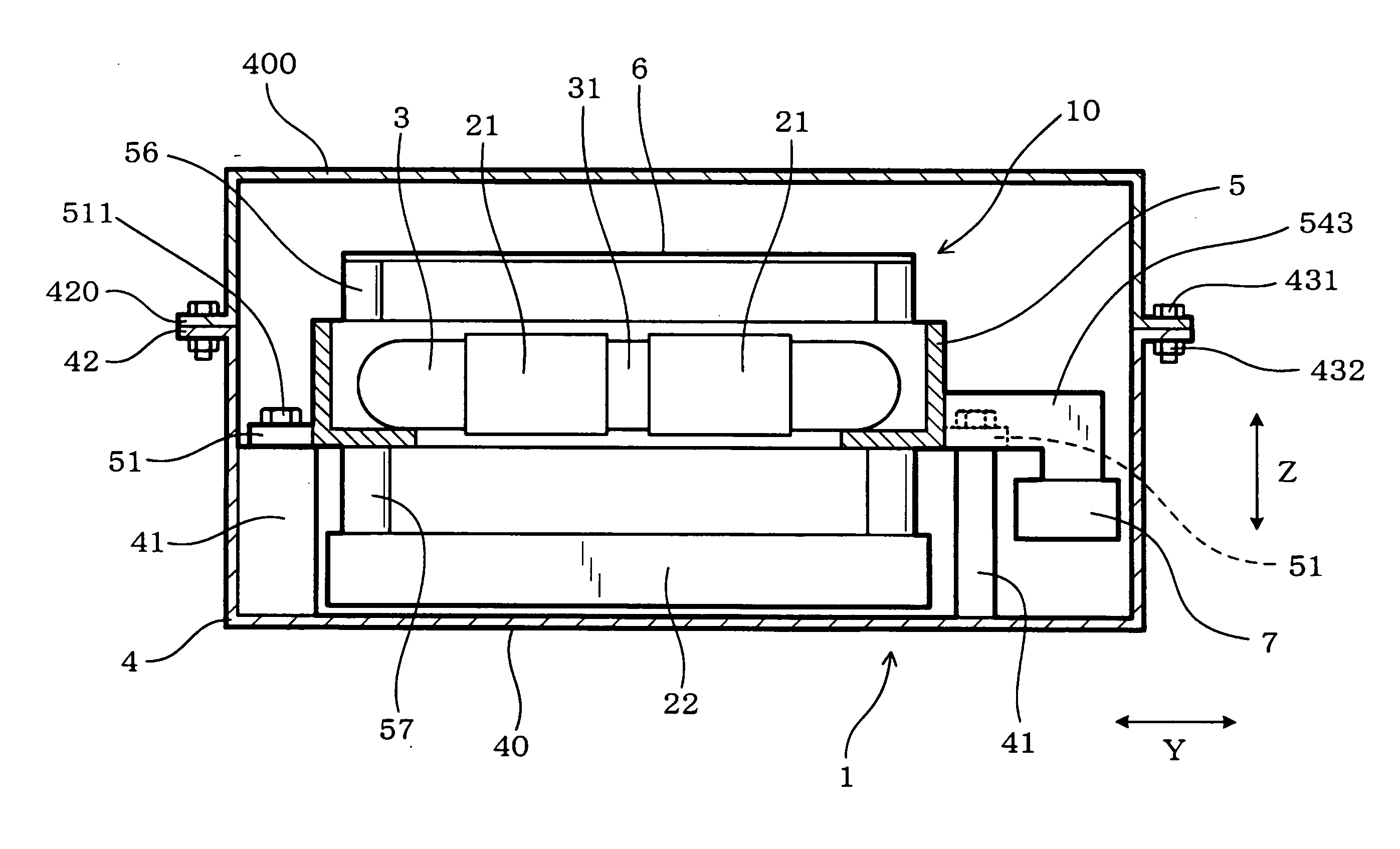

Power conversion apparatus

ActiveUS20110194247A1Reduce external forceImprove rigidityConversion constructional detailsSemiconductor/solid-state device detailsEngineeringElectronic component

In a power conversion apparatus, electronic components and a cooler are integrated in a frame as an internal unit. The internal unit is fixed within a case through the frame. The frame has such a shape that the electronic components are surrounded by the frame, and includes a first wall section, and second and third wall sections extending from both sides of the first wall section. The cooler includes a coolant introduction tube and a coolant discharge tube. The coolant introduction tube and the coolant discharge tube project outward from to the frame. The first to third wall sections include a support wall section supporting at least one of the coolant introduction tube and the coolant discharge tube, and a frame wall section not supporting the coolant introduction tube and the coolant discharge tube. The thickness of the support wall section is larger than the thickness of the frame wall section.

Owner:DENSO CORP

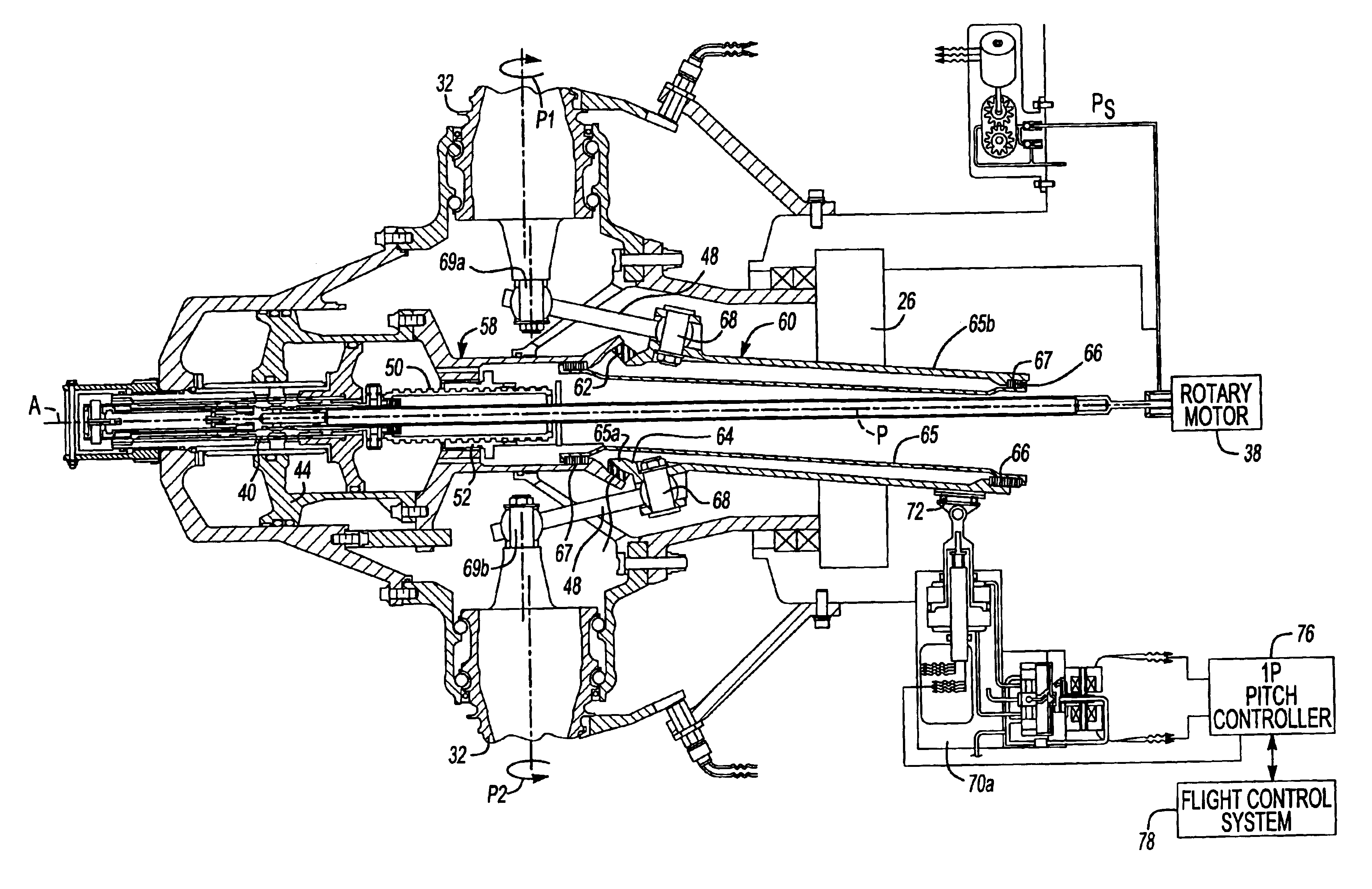

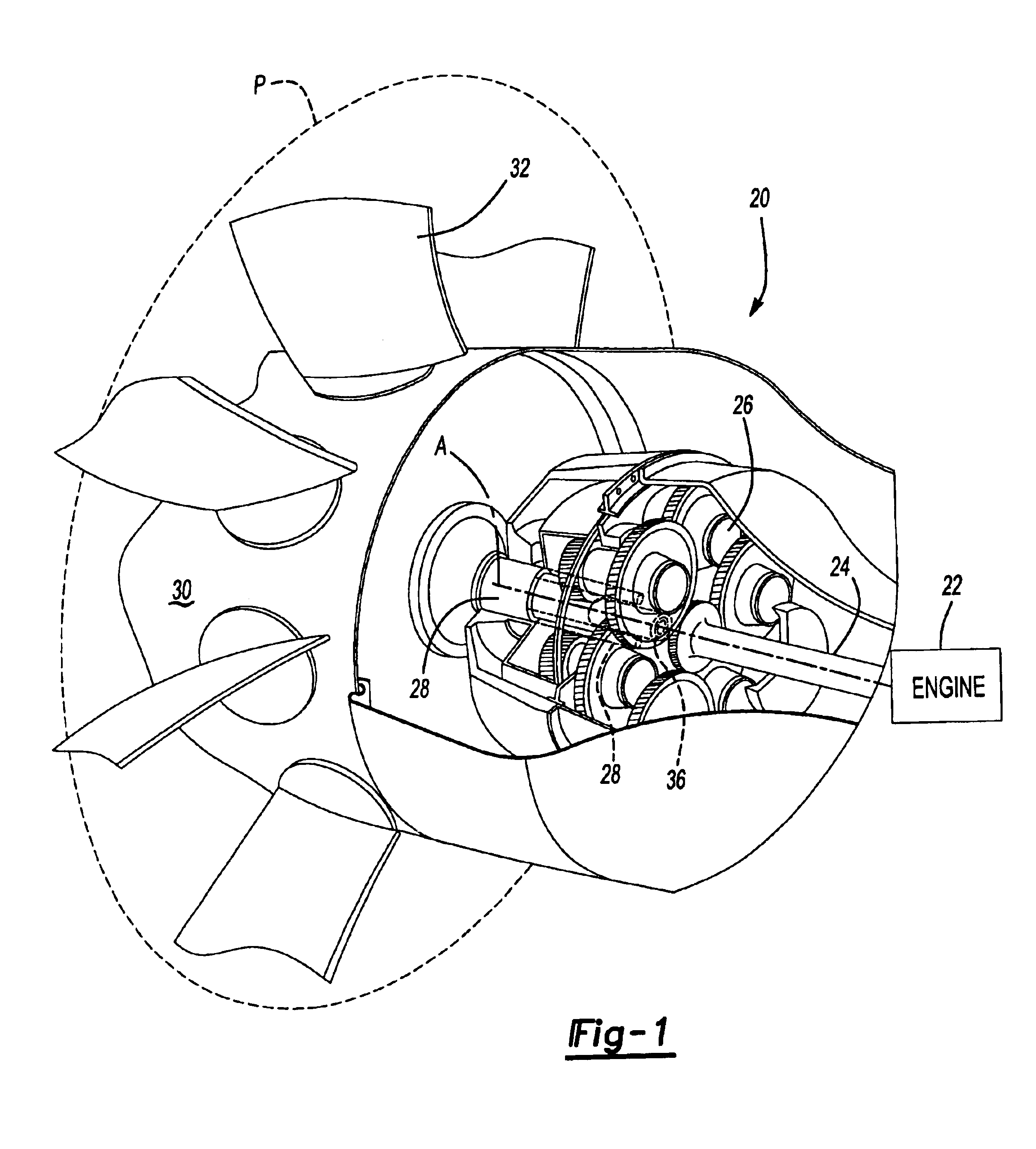

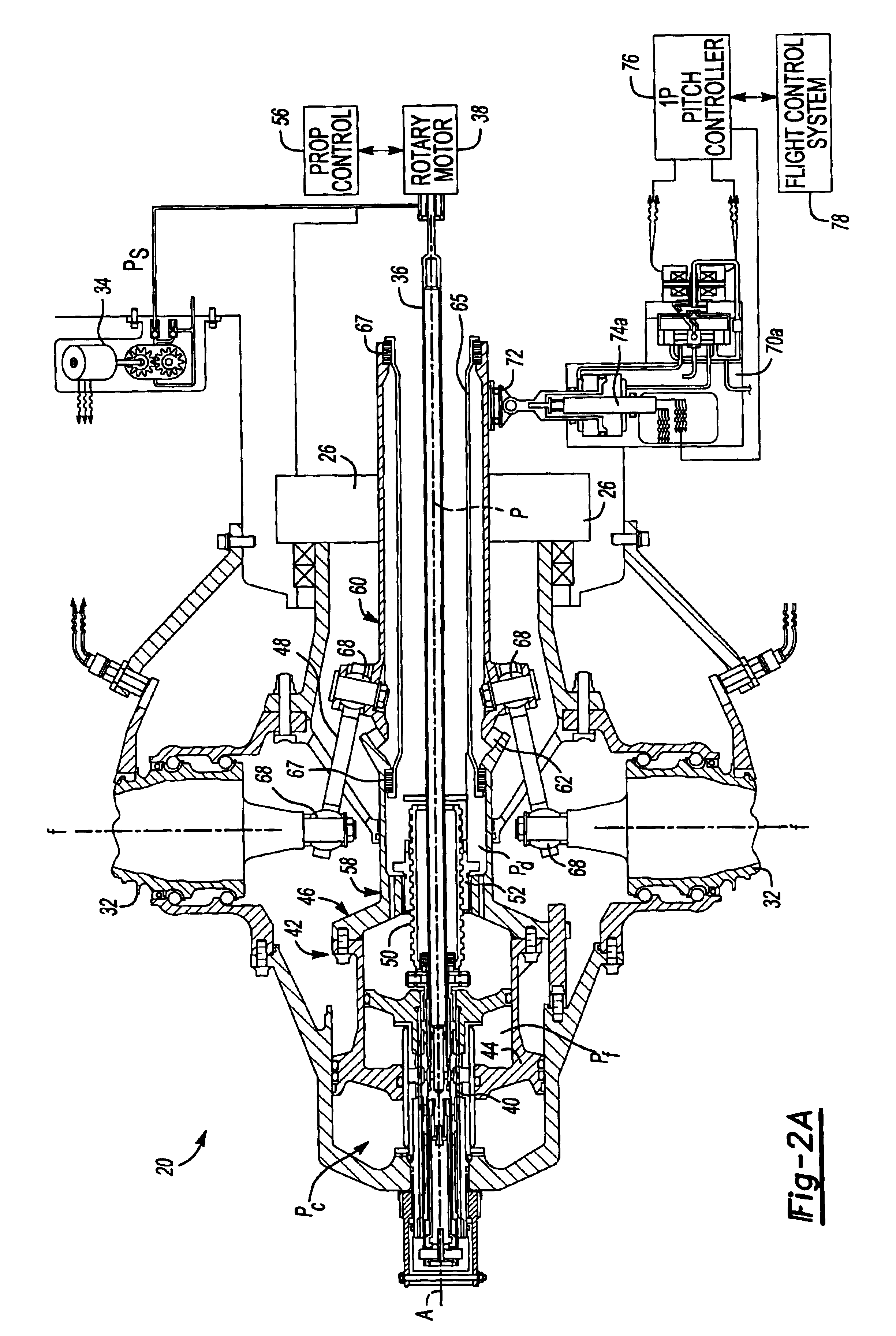

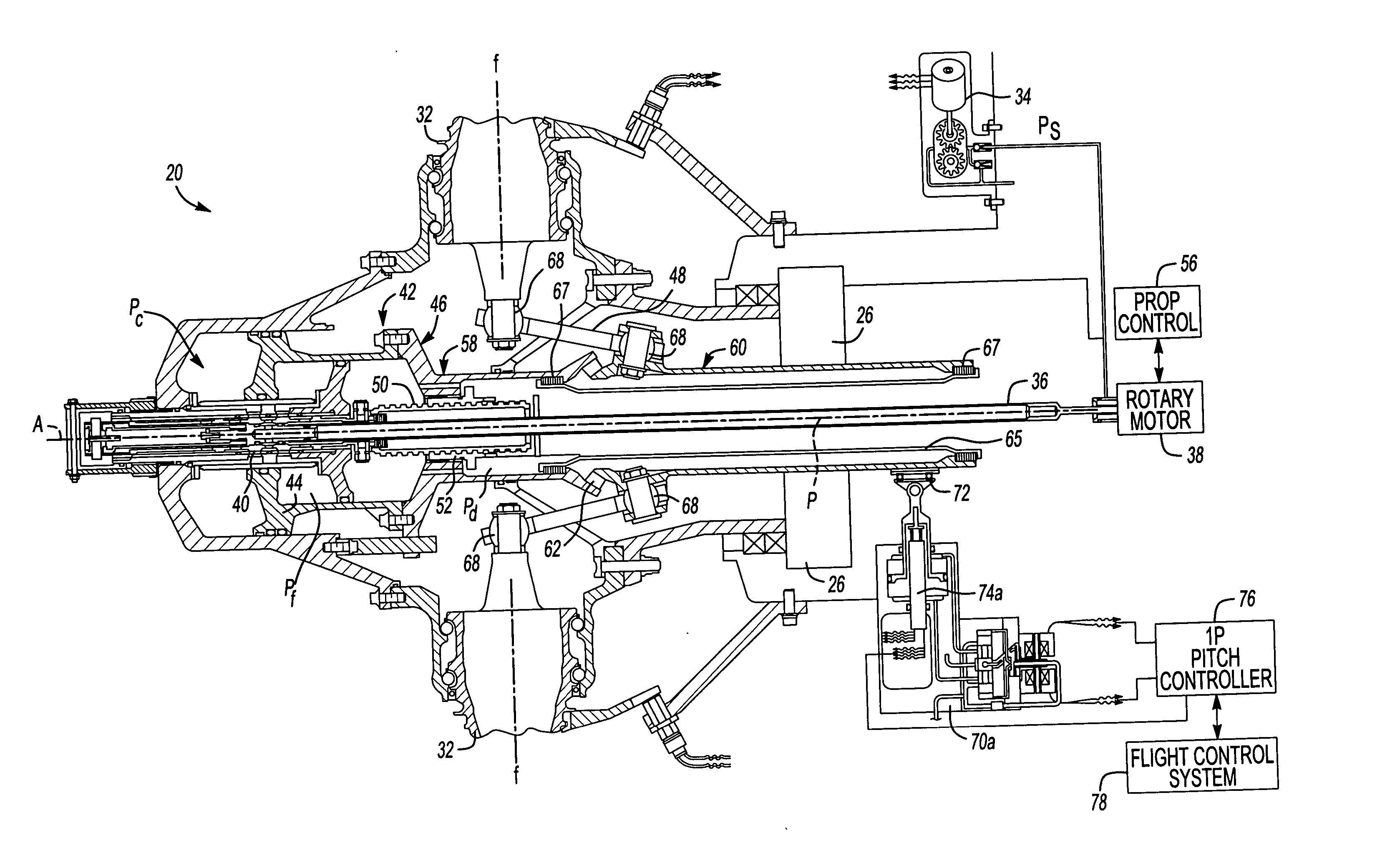

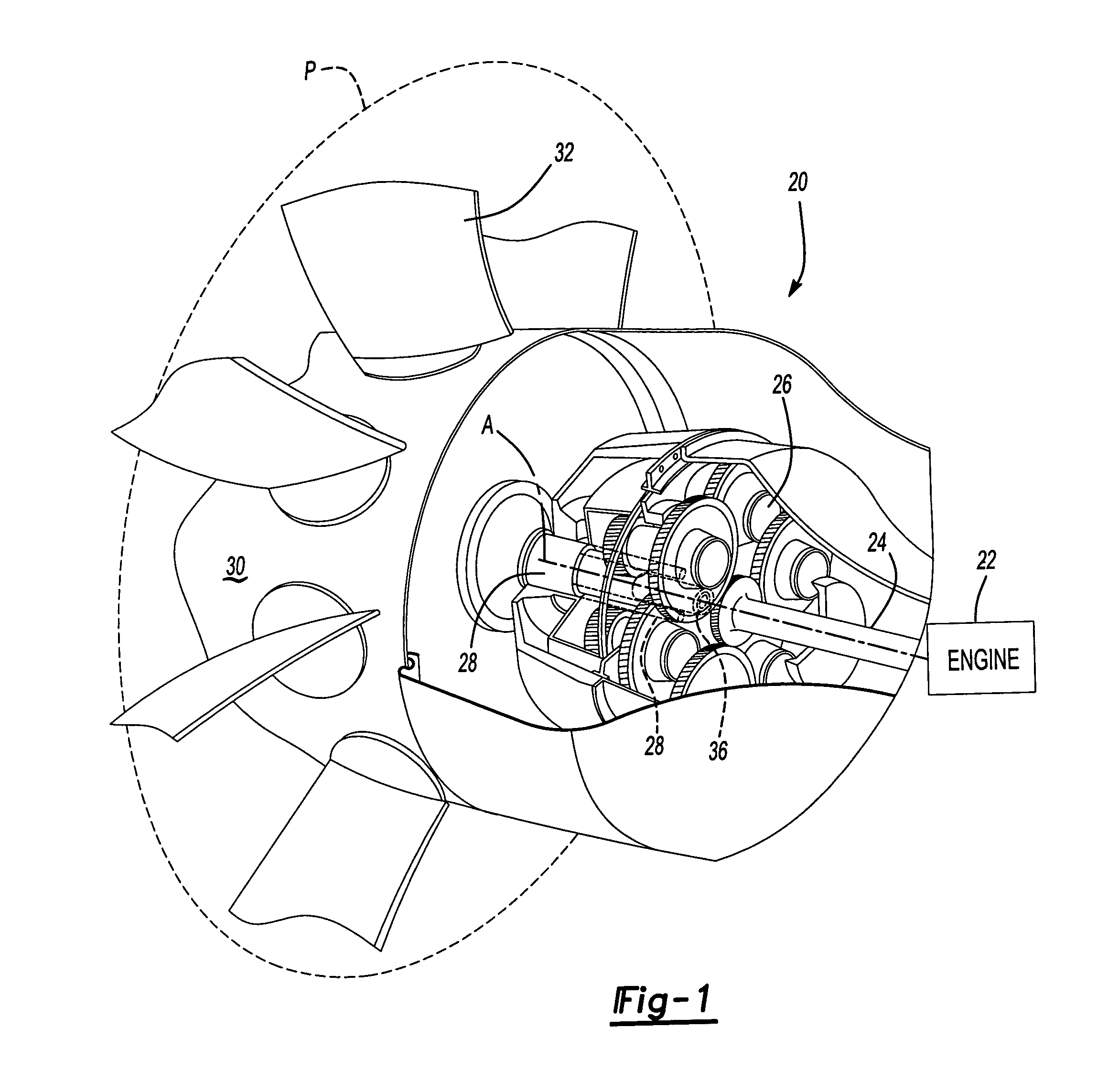

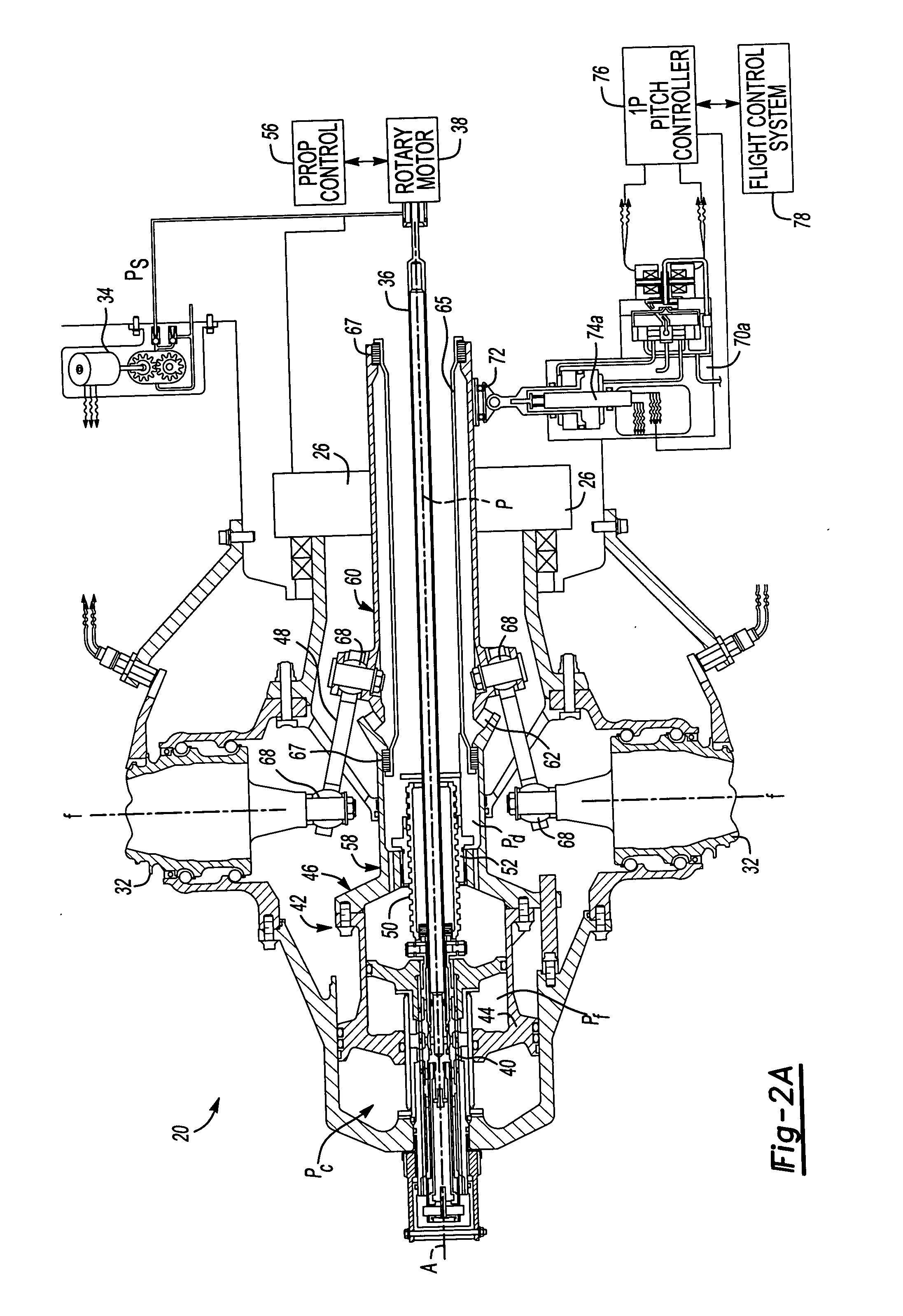

Cyclic actuation system for a controllable pitch propeller and a method of providing aircraft control therewith

InactiveUS6981844B2Minimize undesired cyclic loadReduce external forcePropellersAircraft controlAttitude controlNormal pitch

A propeller control generates a once per revolution (1P) blade thrust variation through cyclic pitch of rigidly mounted non-flapping propeller blades. The resultant shaft bending moment is used to provide aircraft attitude control. Axial translation of a pitch change assembly including a pitch change yoke along an axis of rotation drives a pitch link attached to each propeller blade to collectively change the propeller blade pitch angle. The pitch change yoke includes a translating pitch change yoke portion and an articulatable pitch change yoke portion. Deflection of the articulatable pitch change yoke portion changes the pitch change effect of each pitch link as a function of its angular position such that a sinusoidal pitch angle is superimposed on normal pitch angle. Cyclic pitch change actuators deflect the articulatable pitch change yoke portion in any angular direction while the linear deflection of the cyclic pitch change actuators generate the magnitude of the cyclic pitch.

Owner:HAMILTON SUNDSTRAND CORP

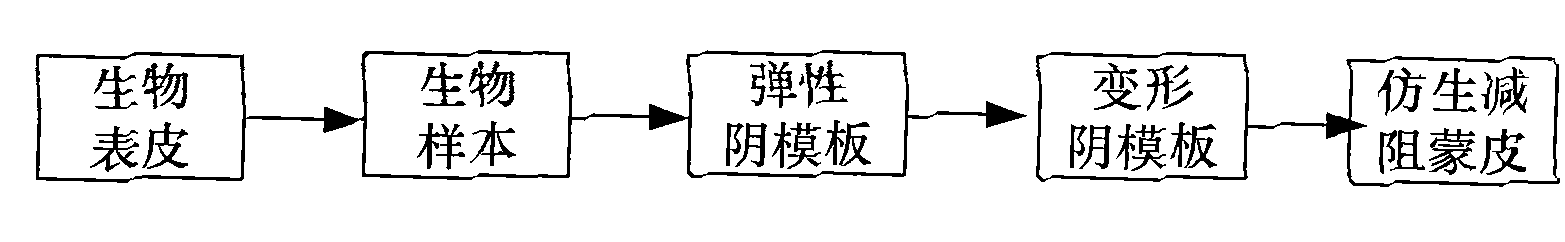

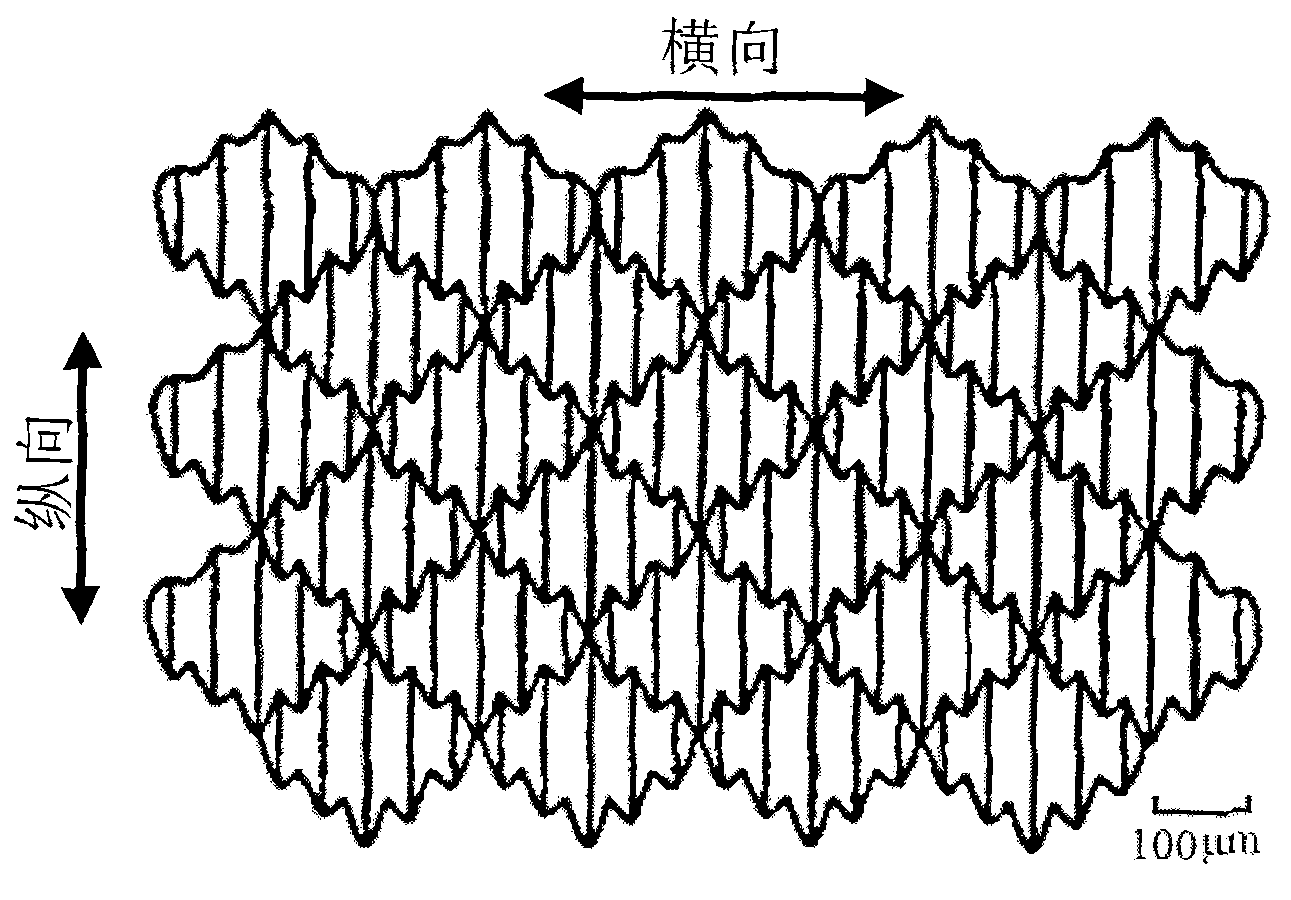

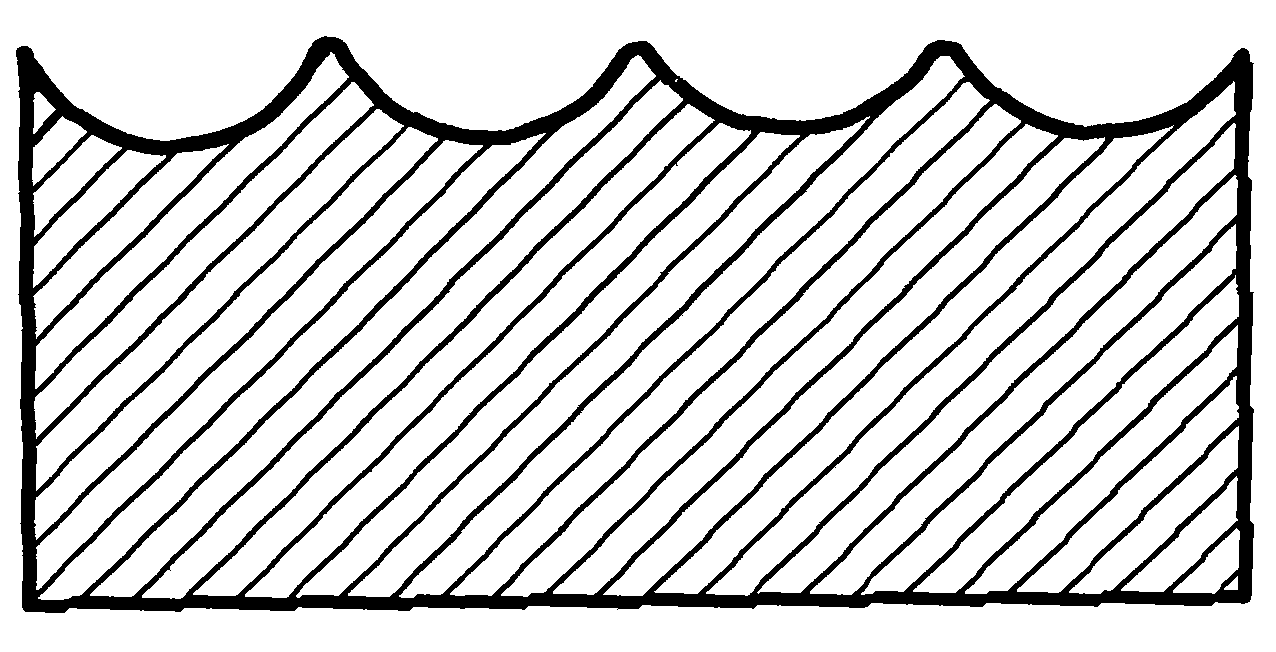

Manufacture method of transformative shark-simulation anti-drag skin based on adjustable surface appearance and size

InactiveCN101913407AReduce external forceIncrease elasticityWatercraft hull designHydrodynamic/hydrostatic featuresSkin appearanceManufacturing technology

The invention relates to a manufacture method of a transformative shark-simulation anti-drag skin based on adjustable surface appearance and size, which comprises the following four steps:(1) manufacturing a shark-skin biometric template; (2) manufacturing a silicon rubber elastic female template; (3) manufacturing a transformative shark-appearance-simulation anti-drag skin and researching a law;and (4) manufacturing the transformative shark-appearance-simulation anti-drag skin according to the requirements of application objects. The elastic female template manufactured by applying the invention has more than 95% of similarity to that of original shark skin appearance, the size of the skin surface appearance of the shark-simulation anti-drag skin manufactured by applying the invention can be adjusted according to the parameters of the common speed, the dielectricviscosity and the like of the application objects, and the anti-drag effect of the shark-simulation anti-drag skin approaches the optimum state. The manufacture method of a transformative shark-simulation anti-drag skin based on adjustable surface appearance and size has good utility value and wide application prospects in the field of simulation manufacture technology.

Owner:BEIHANG UNIV

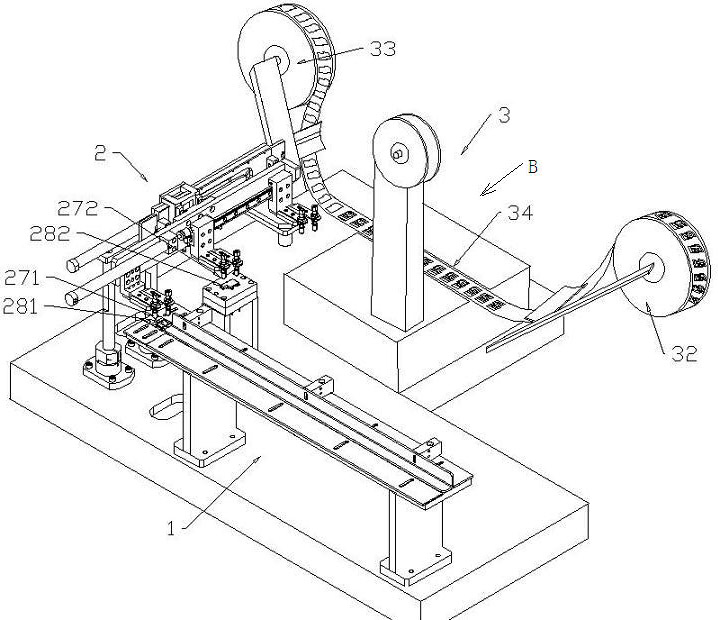

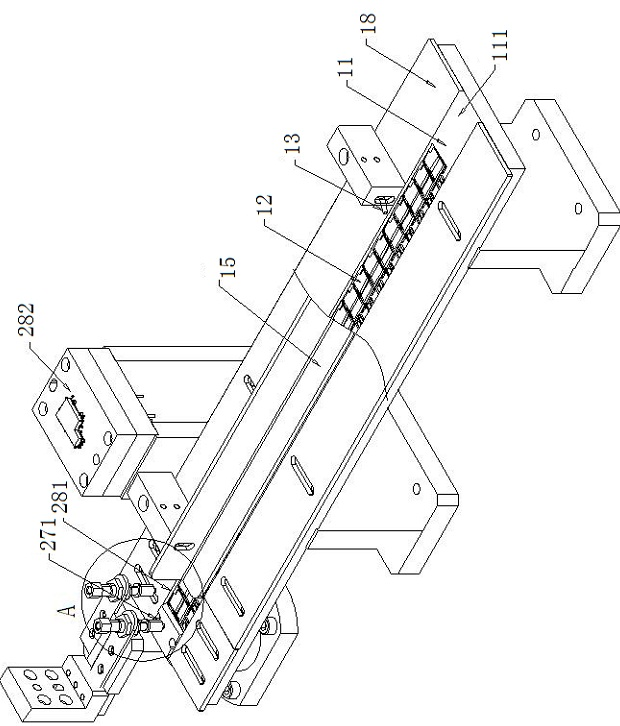

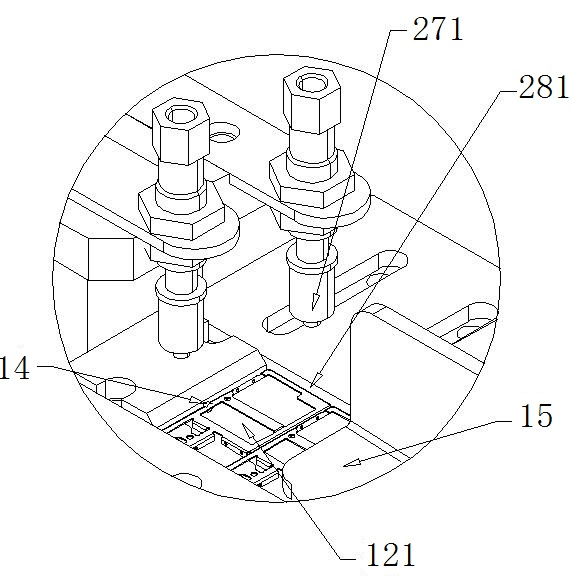

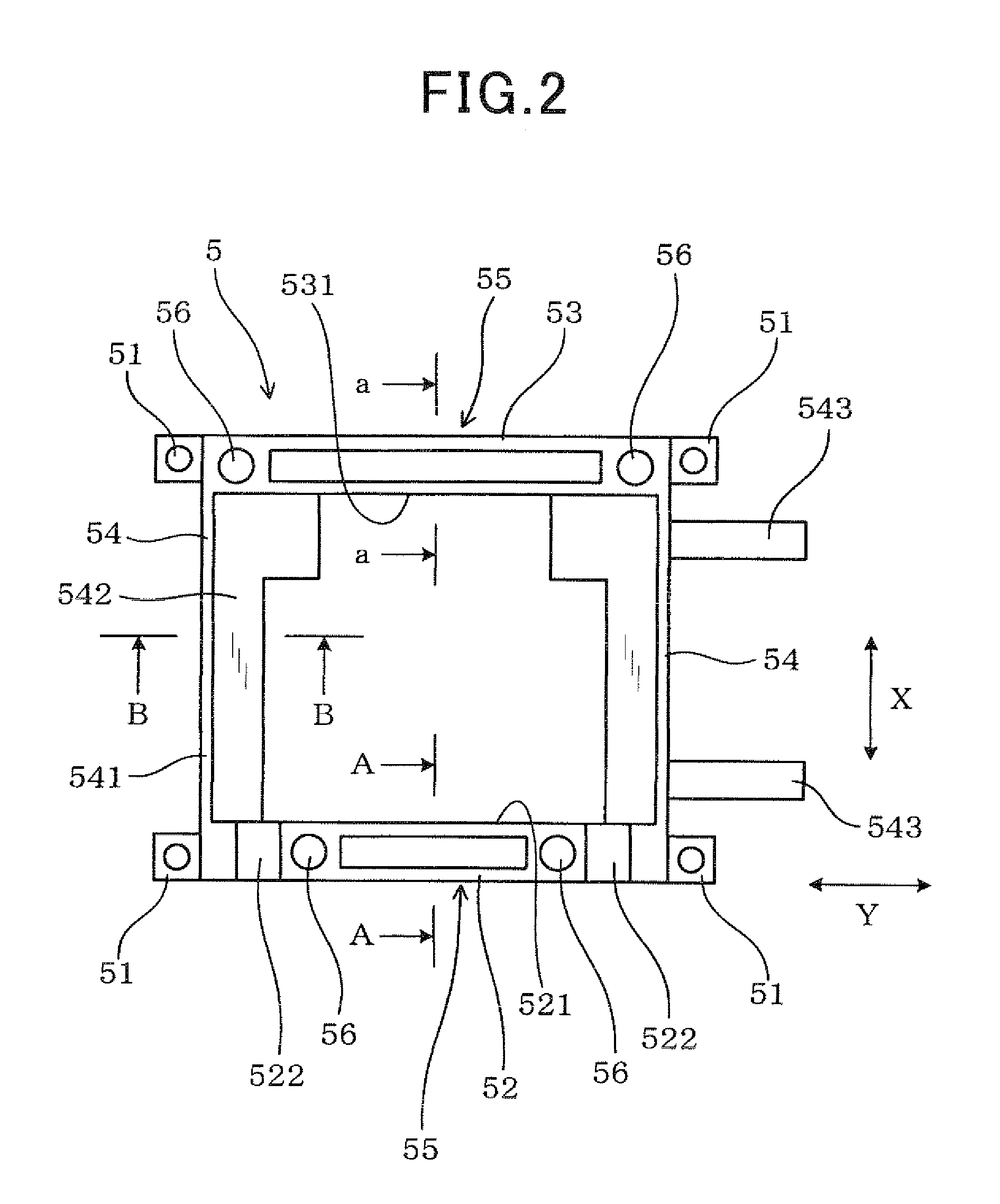

Integrated machine for automatically detecting flatness and packaging carrier belt for shielding case

ActiveCN102673822AFully automatedReduce quality impactPackaging automatic controlEngineeringAutomation

The invention discloses an integrated machine for automatically detecting flatness and packaging a carrier belt for a shielding case. The integrated machine comprises a blowing and feeding mechanism, a double stroke transmission mechanism, an automatic packaging mechanism and a controlling device. Shielding cases to be detected enter into a first work station in the blowing and feeding mechanism orderly, the controlling device controls the double stroke transmission mechanism to execute a first stroke, a first nozzle sucks the shielding cases at the first work station and conveys the shielding cases to a second work station for flatness detection, a second nozzle sucks the qualified shielding cases detected at the second work station and conveys the shielding cases to a third work station to be arranged on the carrier belt, and the carrier belt where the shielding cases are arranged is automatically packaged by an adhesive tape and coiled automatically by a receiving disc. The integrated machine provided by the invention detects and conveys the shielding cases automatically, sorts qualified and unqualified products and arranges the qualified products on the carrier belt automatically. The carrier belt is automatically packaged by the adhesive tape and operators do not contact with the detection and packaging process of the shielding cases, thereby realizing automation of the packaging process of the shielding cases.

Owner:南通诚业德精密组件有限公司

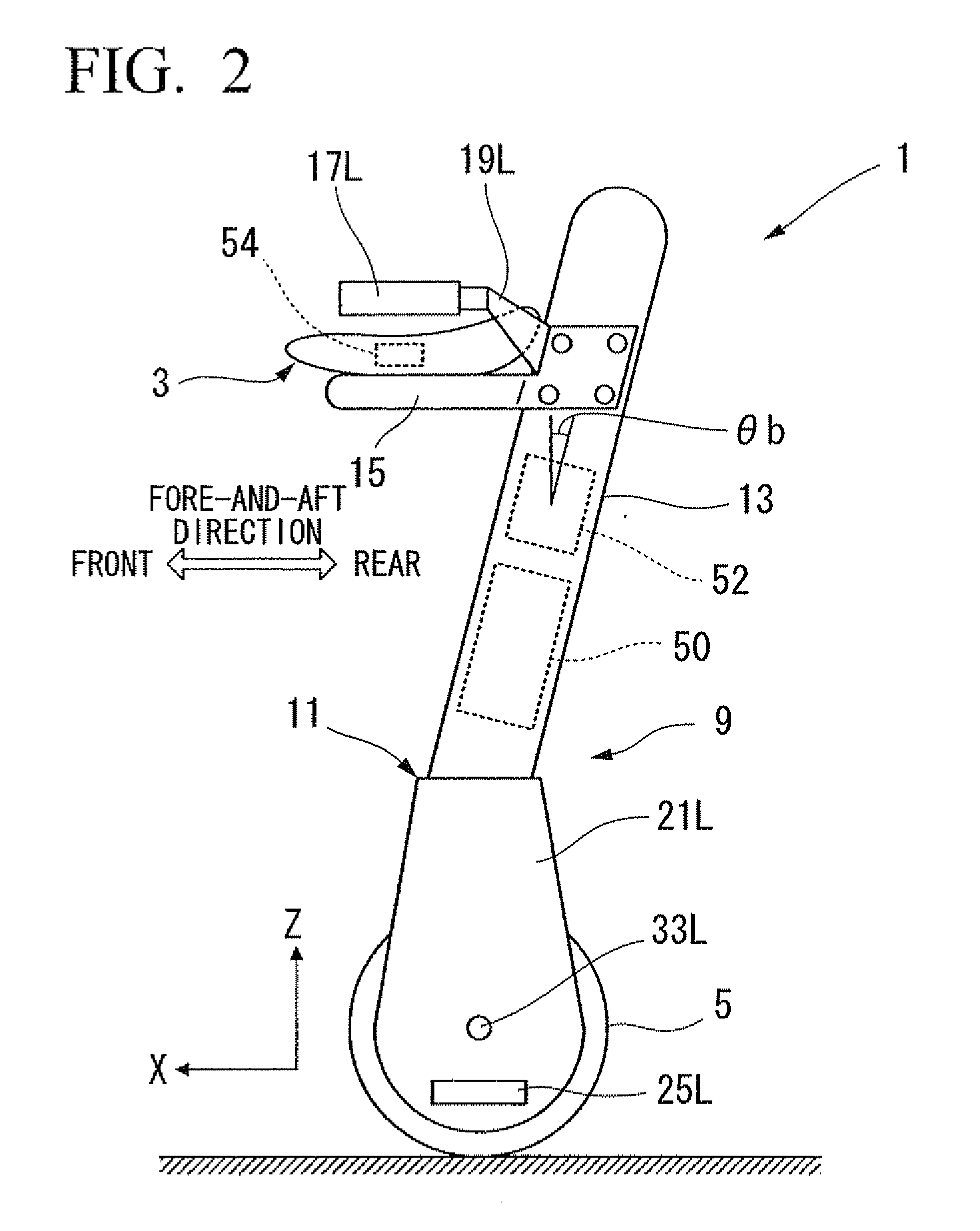

Inverted pendulum type moving body

ActiveUS20110071752A1Reduce external forceReduces gain coefficientSpeed controllerUnicyclesInformation controlEngineering

An inverted pendulum type moving body moving over a floor surface in a self standing manner, the inverted pendulum type moving body comprising: an information acquisition unit obtaining a state information indicating a current state of an another moving body; and a movement control unit controlling a movement of a self moving body, based on the state information, so that a state of the self moving body with respect to the current state of the another moving body satisfies a predetermined condition established so that the self moving body and the another moving body moves in alignment.

Owner:HONDA MOTOR CO LTD

SBS (Styrene-Butadiene-Styrene) modified asphalt and production method thereof

The invention discloses SBS (Styrene-Butadiene-Styrene) modified asphalt and a production method thereof. The SBS modified asphalt mainly comprises the components of matrix asphalt No.70, linear SBS, a solubilizer and a stabilizer, wherein the linear SBS accounts for 3.6% to 4.2% be weight of the of matrix asphalt No.70, the solubilizer accounts for 2.0% to 3.0% by weight of the matrix asphalt No.70, and the stabilizer accounts for 0.16-0.18% be weight of the matrix asphalt No.70. The production method of the SBS modified asphalt comprises the following steps of: (1) heating the matrix asphalt No.70 to 175 DEG C to 185 DEG C; (2) adding the linear SBS and uniformly stirring; and (3) adding the solubilizer and the stabilizer and thoroughly grinding twice by using a colloid mill to obtain the SBS modified asphalt. The production method adopted in the invention effectively shortens the modified time and is low in production cost.

Owner:XUZHOU CITY LUXING HIGHWAY ENG

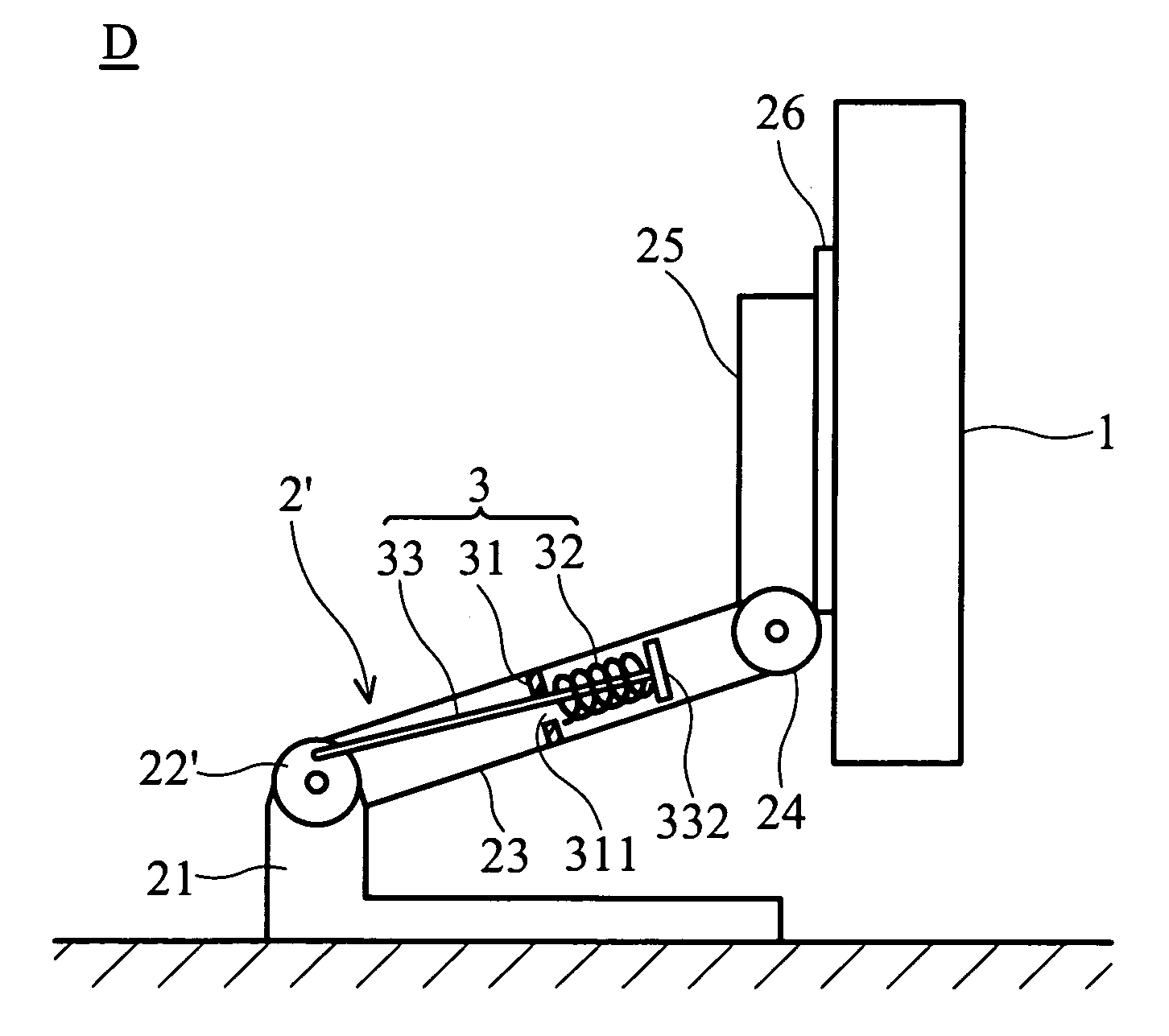

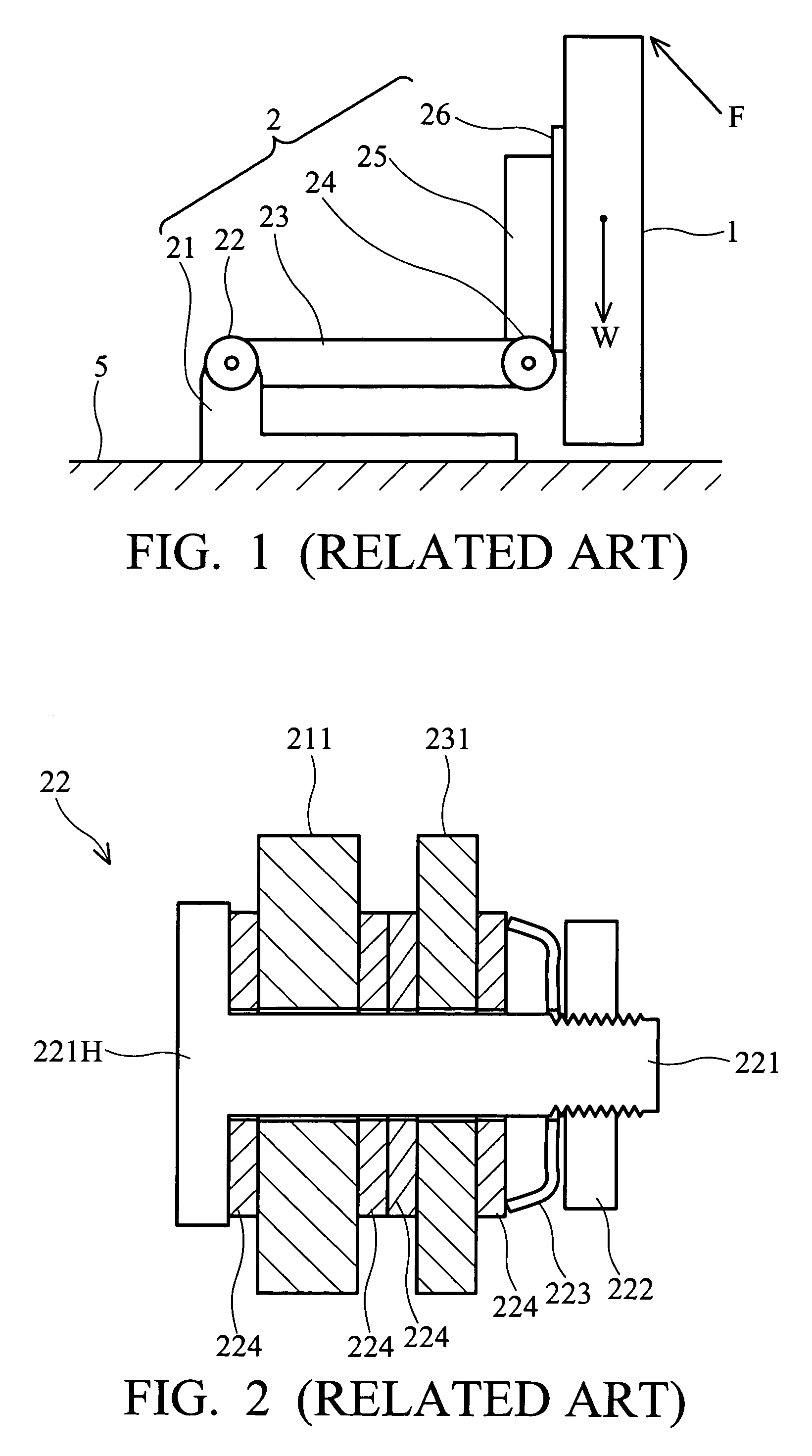

Liquid crystal display

ActiveUS7258311B2Easy to liftEasily lifted and adjustedStatic indicating devicesStands/trestlesLiquid-crystal displayEngineering

A liquid crystal display having a supporting base, a display unit and a pre-force mechanism. The supporting base has at least one pivot and at least two sections joined thereby, and the display unit is connected to the supporting base, exerts a first torque on the pivot by the weight of the display unit. The pre-force mechanism is connected to the pivot and exerts a second torque on the pivot. The first torque is opposite to the second torque.

Owner:QUISDA CORP +1

Seat belt buckle

InactiveUS20060231317A1Smoothly sitSmoothly get off vehicle seatBelt retractorsSafety beltsSeat beltEngineering

A buckle device that includes a buckle with which a tongue supported by a seat belt becomes engaged, and a buckle-moving device which moves the buckle between a storage position at which the buckle is stored when the buckle is not used and a use position at which the buckle is retained in a used state in which the seat belt is fastened, wherein the buckle-moving device is adapted to move the buckle between the storage position and the use position with a rotational movement, and wherein the buckle device further comprises a buckle-supporting member that is adapted to support the buckle and includes an external-force-reducing mechanism which reduces an external force applied to the buckle-supporting member if the external force is larger than a predetermined force, wherein the external-force-reducing mechanism is a buckle-moving device that allows the buckle to move in a fore-and-aft direction of a vehicle when the external force is applied to at least one of the buckle and the buckle supporting member in the fore-and-aft direction of the vehicle. The buckle may be hidden in the vehicle seat at the storage position. The buckle does not obstruct the occupant when the occupant sits on or gets off the vehicle seat, and the occupant can smoothly sit on or get off the vehicle seat.

Owner:TAKATA CORPORATION

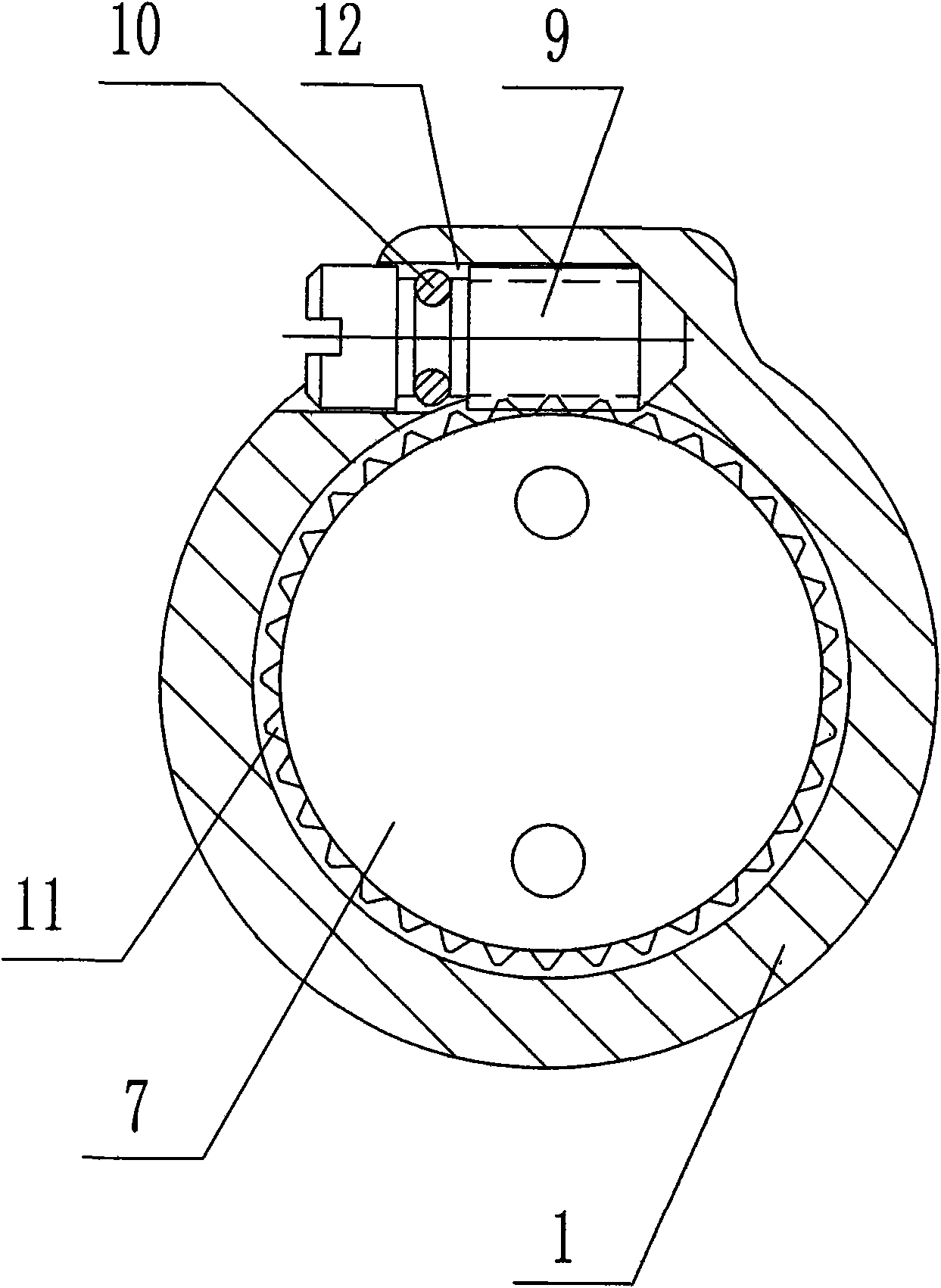

Adjusting mechanism capable of micro-controlling back lash of pinion and rack

InactiveCN101672359APrecise control of gap valueSensitivity amplificationMechanical steering gearsGearing detailsDisplacement controlEngineering

The invention relates to an adjusting mechanism capable of micro-controlling the back lash of a pinion and a rack, belonging to the technical field of motor steering. The adjusting mechanism capable of micro-controlling the back lash of the pinion and the rack is constituted by a main body cover, a pinion shaft, a rack, a support seat of the rack, an adjustment plug, a back lash adjusting worm, acheck pin of the worm and the like, wherein, the pinion shaft and the rack are fixed in the main body cover, and the support seat of the rack, a back lash preloaded spring and the adjustment plug arearranged at one side of the rack. A mounting hole of the worm is opened on the main body cover, in which the back lash adjusting worm is arranged, and the tail part of the adjustment plug is processedwith splined teeth. The invention utilizes the principle that the worm gear has large drive ratio, thereby magnifying the sensitivity of the back lash accuracy control of a rack and pinion steering gear by times, correspondingly reducing the used external force when adjusting the worm, and enlarging the controllable range of tolerance clearance. The invention also can be combined with angle and displacement control equipment so that the clearance control can be automatically finished by the equipment, not only the gap value can be accurately controlled, but also the clearance adjustment can be efficiently finished, and thereby the process control capability is greatly improved.

Owner:荆州恒隆汽车零部件制造有限公司

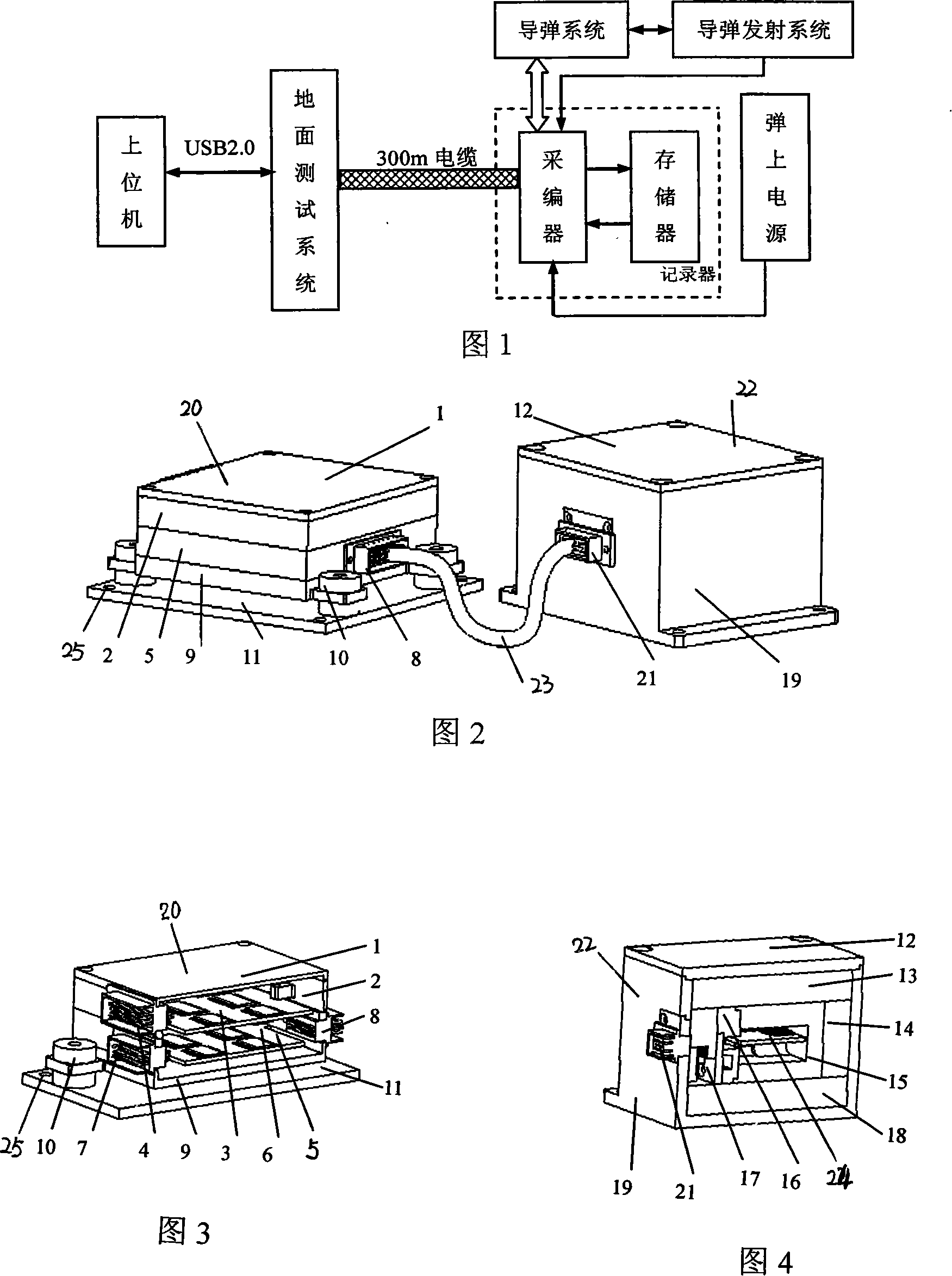

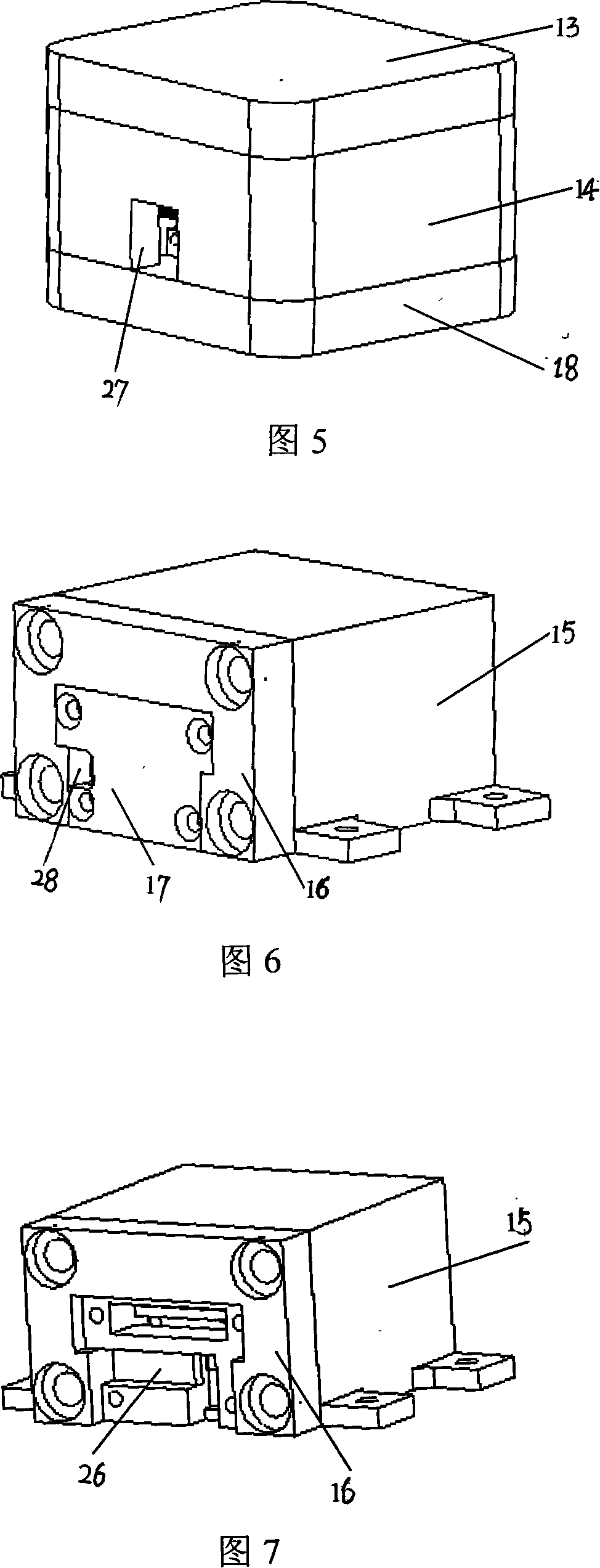

Missile-borne solid state recorder

InactiveCN101105869AEasy maintenanceMany acquisition channelsRegistering/indicating working of vehiclesSolid state recorderData records

The invention relates to the technical field of data record instruments, or a missile-borne solid record designed to solve the current solid recorder's flaws such as big bulk, restricted design of protection structure, poor anti-overloading performance, and incapability of repeated use. The device consists of a collector and a memorizer. As a drawer structure, the collector is composed of a cover board, a signal input module, a collection control module, and a base. As an embedded structure, the memorizer is composed of a shell, a separation cushion body, and a storage circuit arranged in the separation cushion body. The collector has the advantages of multiple collection channels and adjustable high sampling rate. Through the increase of the number of module layers, the invention can lift the number of collection channels, thus being suitable for the measurement of dynamic parameters of a variety of aircrafts; the memorizer can prevent internal storage circuit board from being damaged, and the data stored are safe and reliable in the circumstance of high overload. The invention can be used repeatedly. The invention has the advantages of small volume, high universality, high sampling rate, adjustable channel number, simple operation, low cost, etc.

Owner:ZHONGBEI UNIV

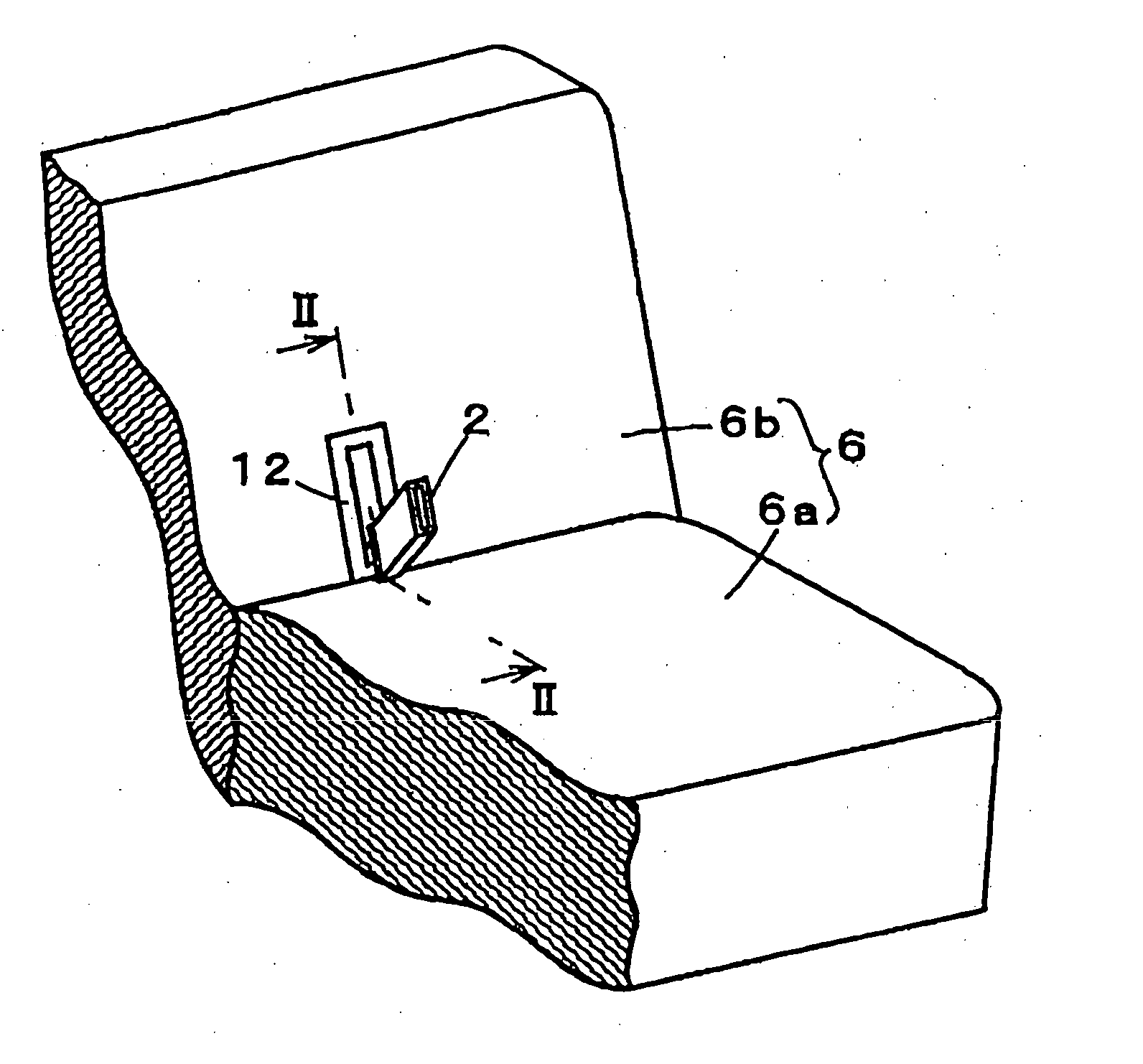

Seat belt buckle

InactiveUS20050206150A1Smoothly sitSmoothly get off vehicle seatSafety beltsPedestrian/occupant safety arrangementSeat beltEngineering

A buckle device that includes a buckle with which a tongue supported by a seat belt becomes engaged, and buckle-moving device which moves the buckle between a storage position at which the buckle is stored when the buckle is not used and a use position at which the buckle is retained in a used state in which the seat belt is fastened. The buckle may be hidden in the vehicle seat at the storage position. The buckle does not obstruct the occupant when the occupant sits on or gets off the vehicle seat, and the occupant can smoothly sit on or get off the vehicle seat.

Owner:TAKATA CORPORATION

Power conversion apparatus

ActiveUS8929097B2Improve rigidityImprove maintainabilitySubstation/switching arrangement detailsSemiconductor/solid-state device detailsEngineeringElectronic component

Owner:DENSO CORP

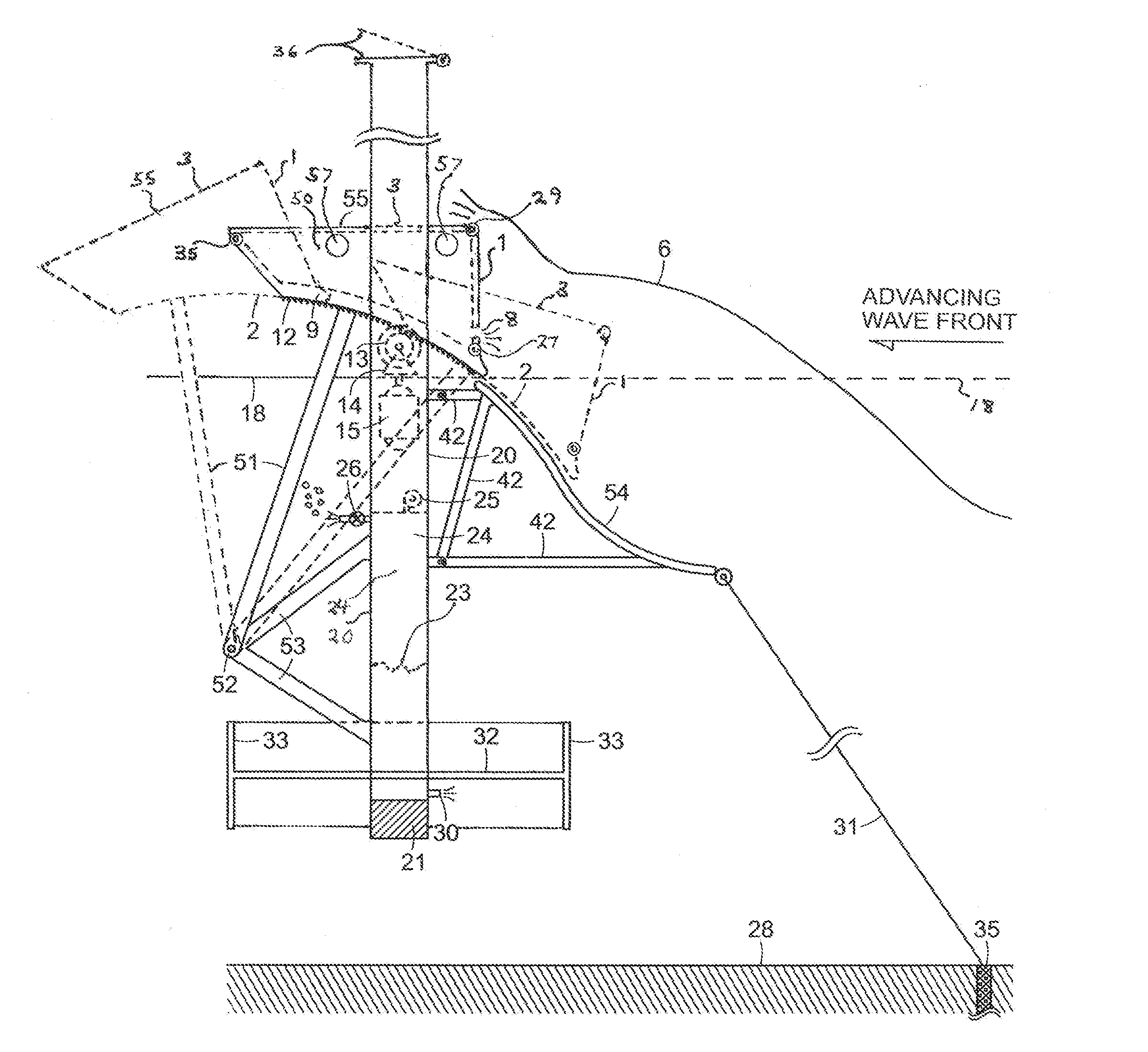

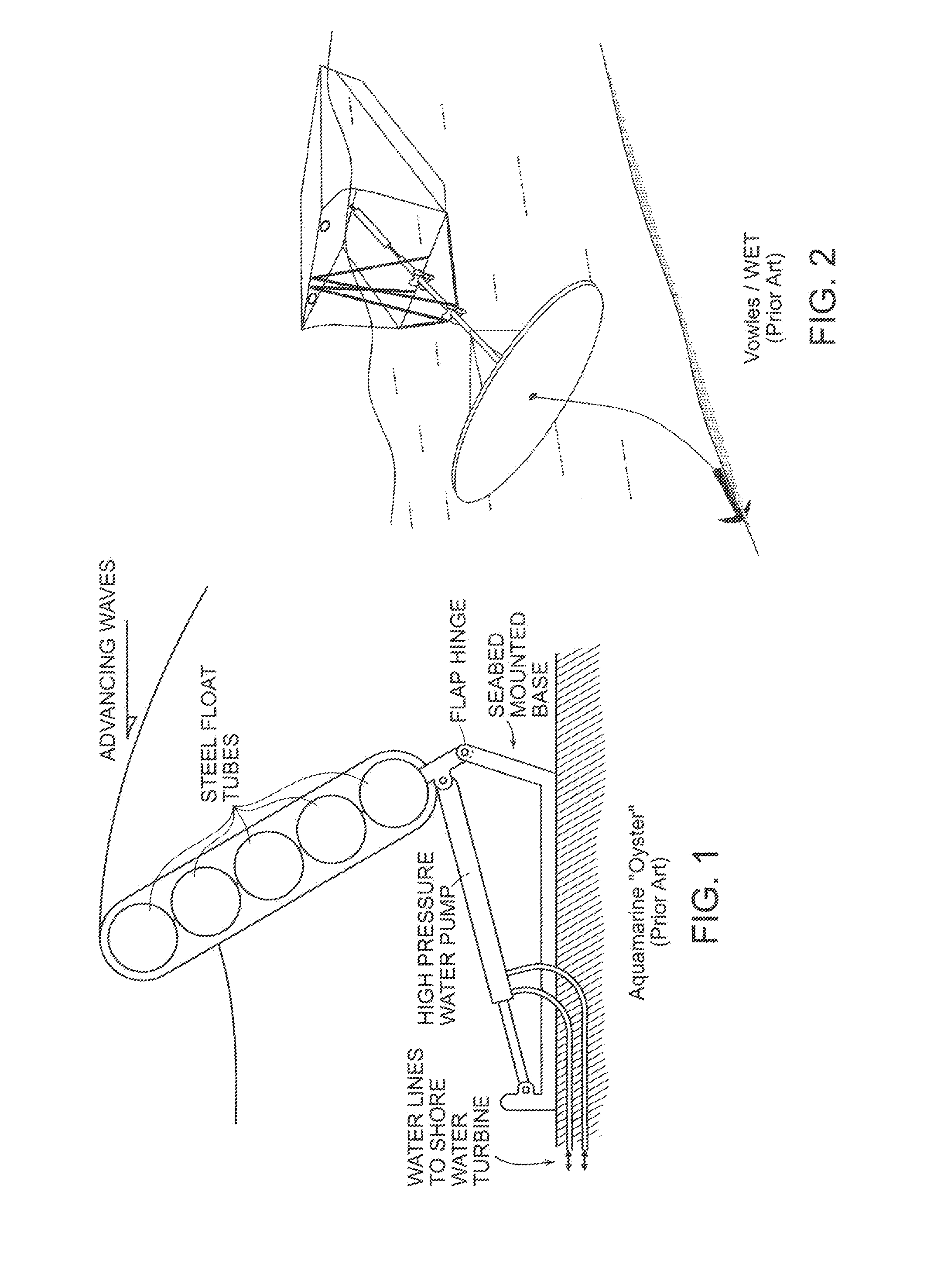

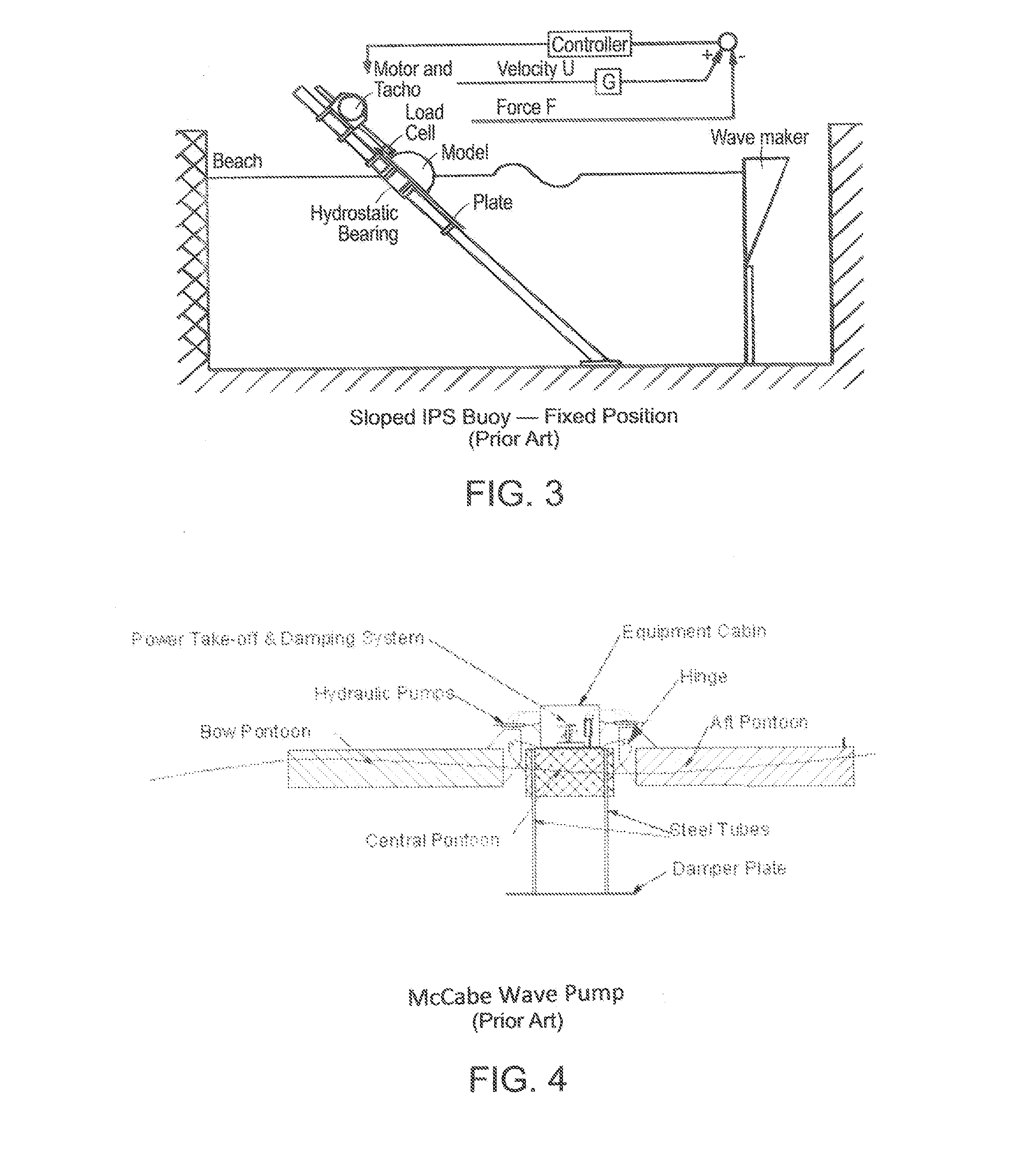

Multi-Capture Mode Wave Energy Converter With Submergible Float

InactiveUS20140097617A1Light weightInexpensive materialsBuoyancy controlRenewable energy machinesEngineeringBuoyancy function

An ocean wave energy converter (WEC) uses one or more buoyant elongated float(s) mechanically linked to a motion-stabilized, controlled-submergence depth frame by either swing or lever arms or down-sloping tracks defining and orienting the motion of the floats relative to the frame to capture both heave and surge wave energy forces. The submerged depth of the frame and attached float(s) is adjusted for optimal wave energy capture or submerged sufficiently to fully submerge the float(s) during severe sea conditions. The elongated float's compliant wave-impacting forward wall combined with total submergence during severe sea states allows the elongated float(s) to self-orient parallel to oncoming wave fronts to intercept and capture maximum wave energy per unit of WEC volume, weight and cost.

Owner:ROHRER TECH

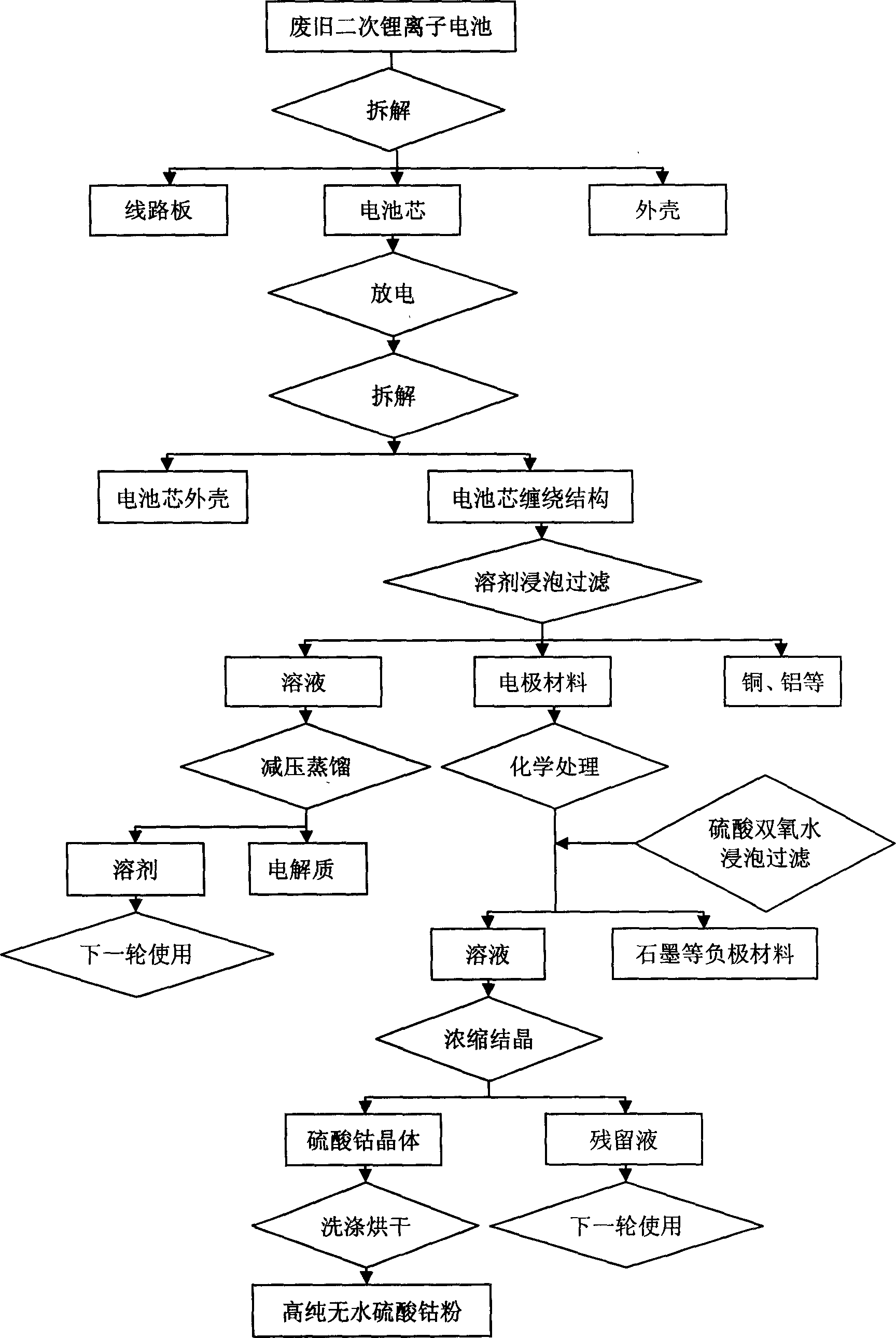

A method to reclaim and dispose waste secondary lithium ion battery

InactiveCN1964129AReduce cross contaminationReduce usageSolid waste disposalWaste accumulators reclaimingOrganic solventElectrical polarity

The related recovery and process method for waste secondary Li-ion cell comprises: separating cell shell, circuit board and cell core by mechanical means; discharging the core; then separating to obtain the shell and coiling material of cell core; putting the last one into some organic solvent to separate the cell polar material from collector foil, filtering to obtain the foil and active material for recovery by chemical way. With small investment, this invention is simple and safe and high yield.

Owner:BEIJING UNIV OF TECH

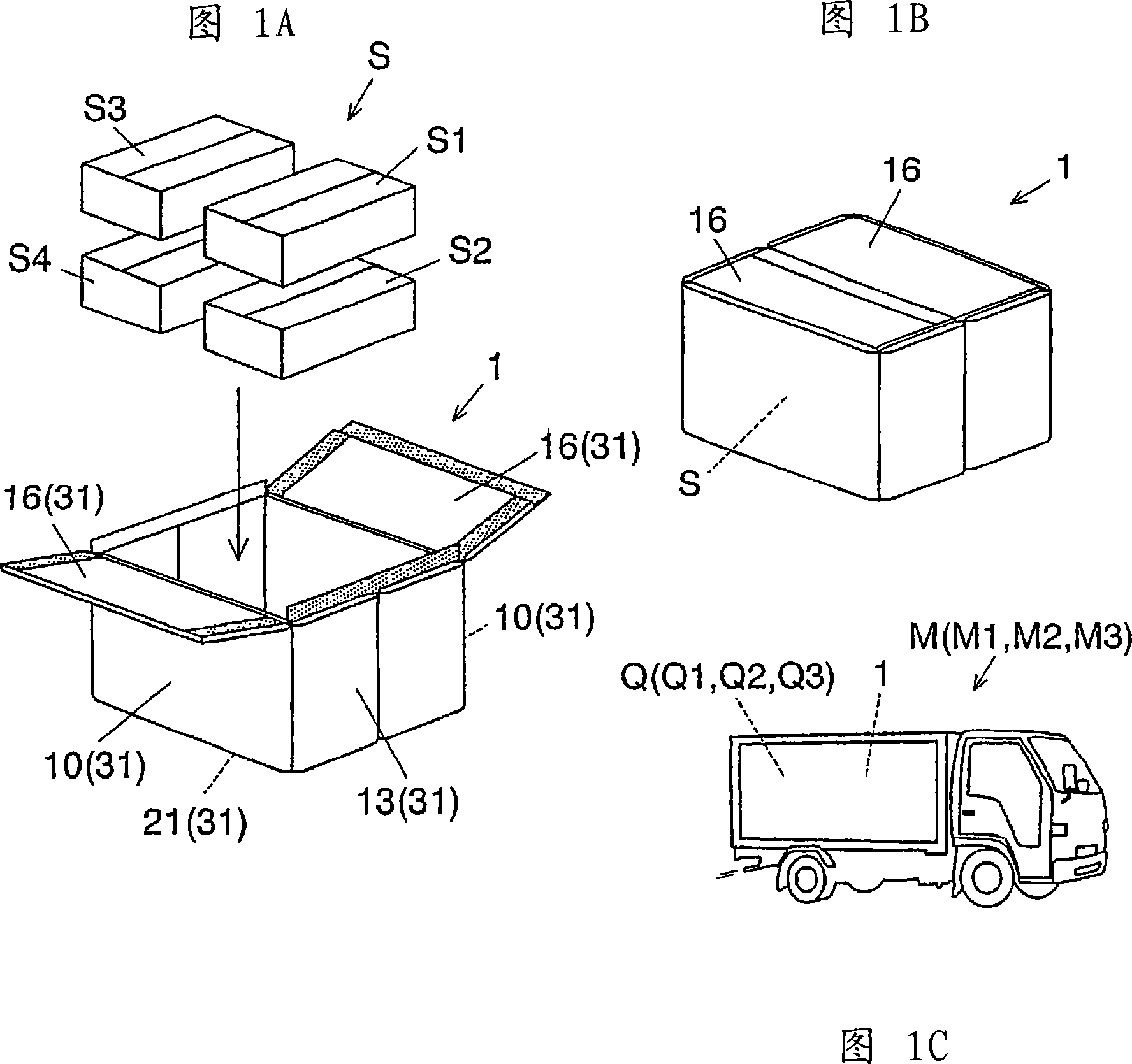

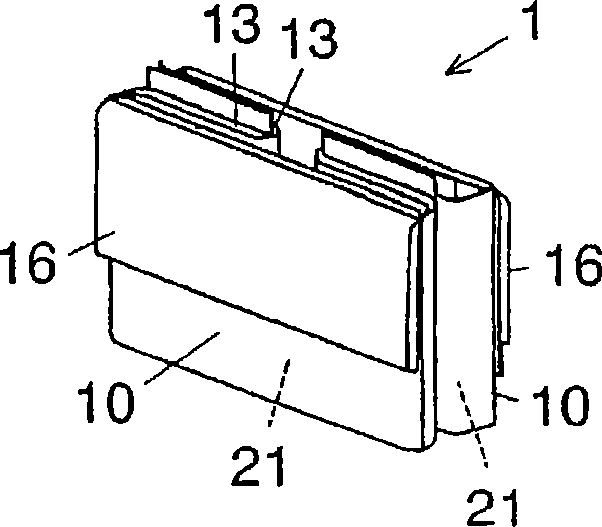

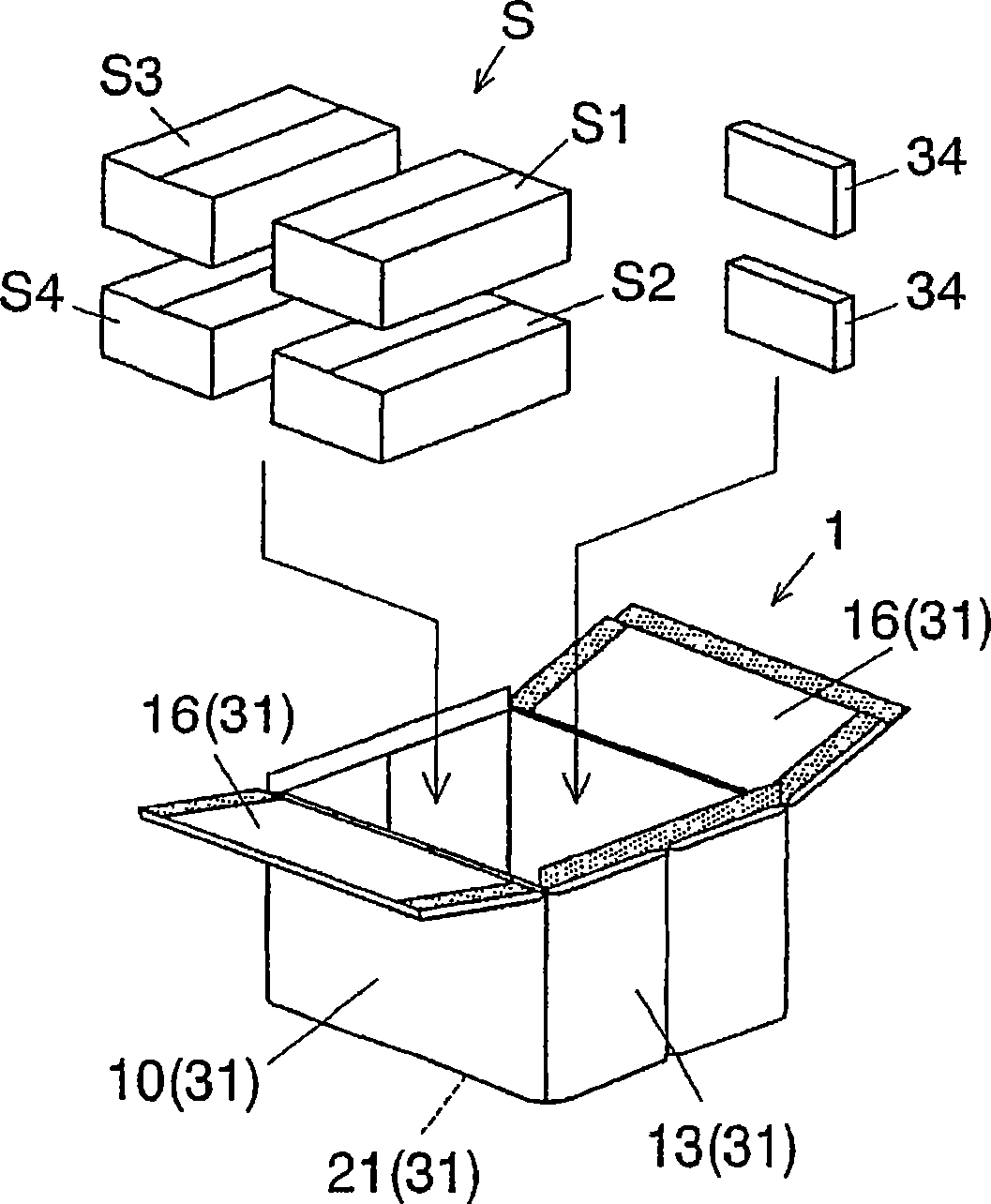

Foldable heat insulating container and distribution method

ActiveCN1914469AReduce delivery costsImprove distribution efficiencyDomestic cooling apparatusLighting and heating apparatusRefrigerator carThermal insulation

Provided is a frozen commodity distribution method reduced in labor and cost while holding the quality of frozen commodities and a cold insulation container unfoldable and foldable in a short time while providing high cold insulation performance. In the distribution method, the frozen commodities requiring cold insulation are stored in the cold insulation container formed of a vacuum thermal insulation material, and the cold insulation container is distributed by a refrigerator car, cold insulation car, or a room temperature car other than a chill car. In the foldable cold insulation container, each of peripheral wall parts, cover parts, and bottom face parts is formed by including the vacuum thermal insulation material in a sheet material, and the peripheral wall parts of the cover parts adjacent to the continuously arranged peripheral wall parts are foldable since the vacuum thermal insulation material is divided along pleat lines. When the container is used, the cover parts and the bottom face parts are rotated in closed attitudes to form into a box. When the container is not used, the bottom face parts are bent to the inside or outside of the peripheral wall parts, the cover parts are bent in the reverse direction of the bottom face parts, and the peripheral wall parts are allowed to approach each other while bending the peripheral wall parts inward along the pleat lines, stacked on each other, and folded.

Owner:PANASONIC CORP

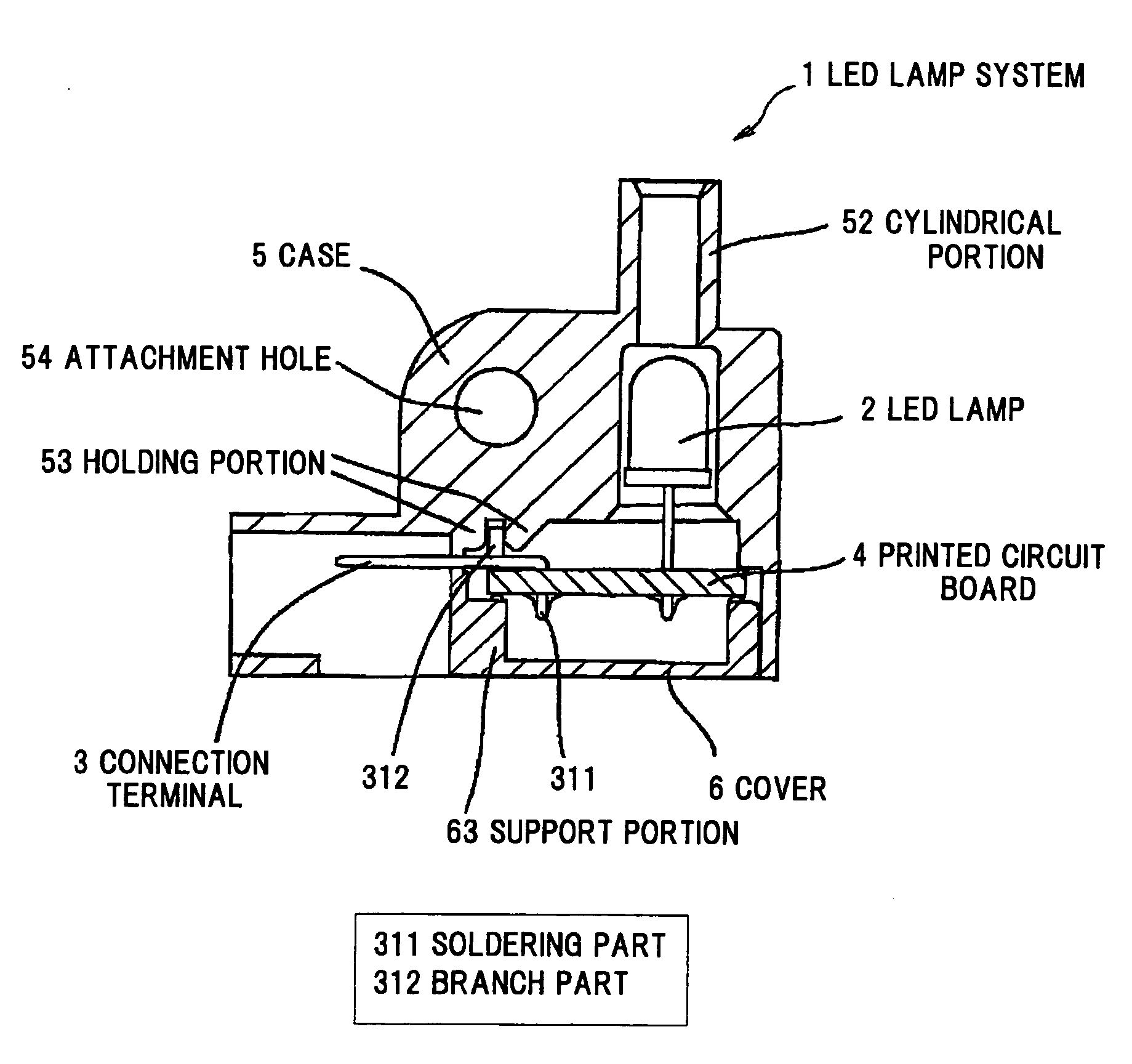

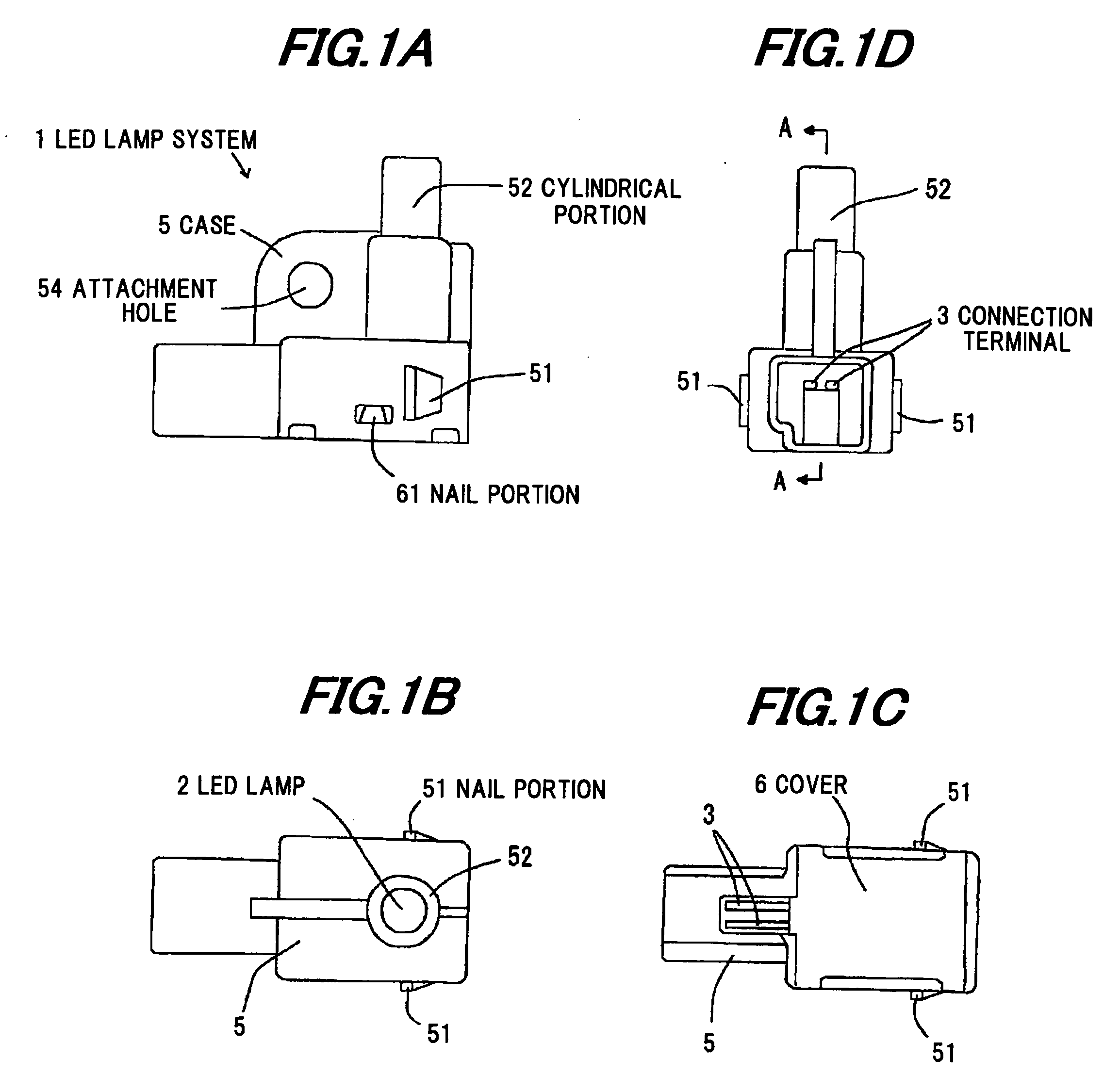

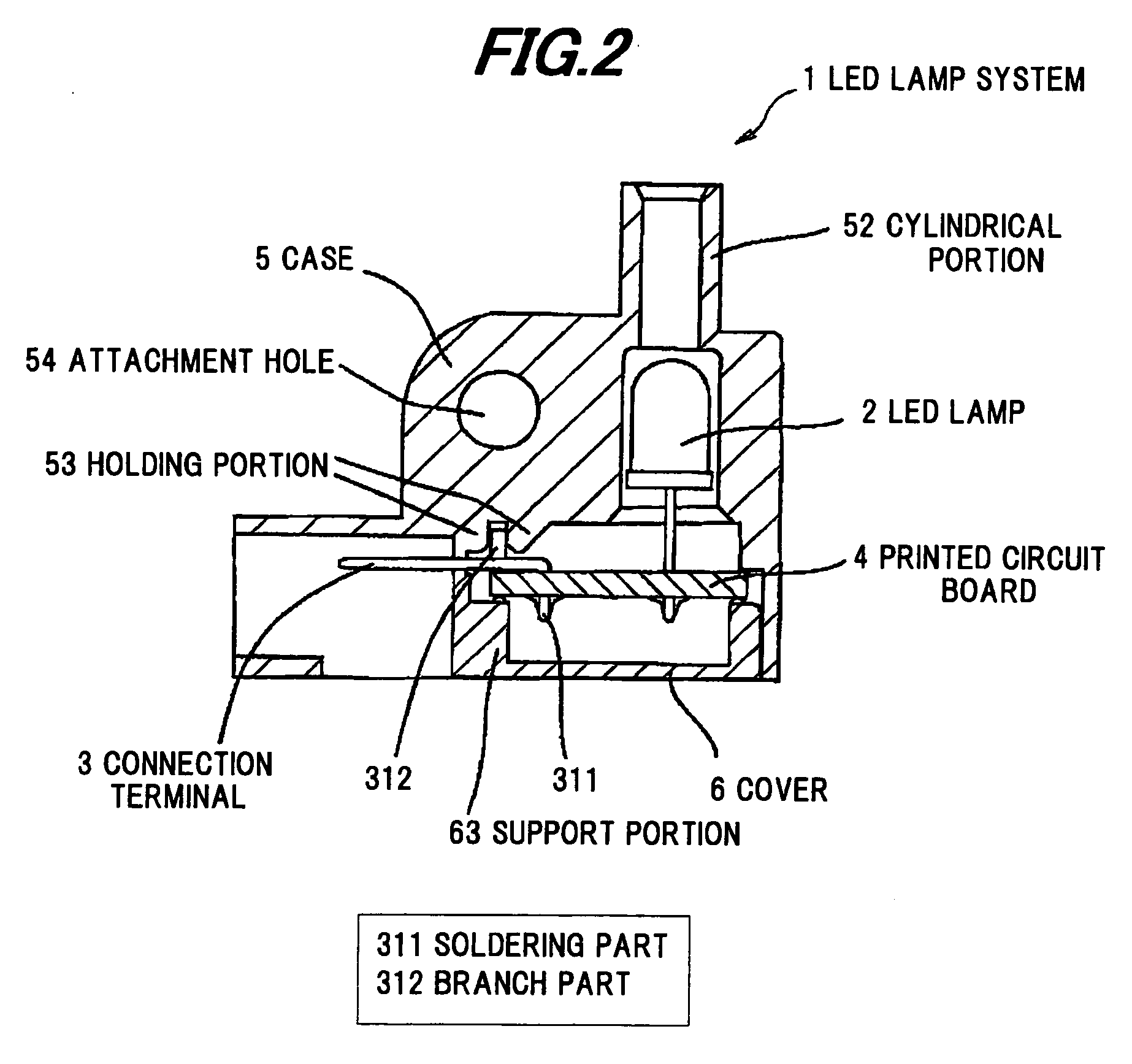

Led lamp system and method of making same

ActiveUS20090224645A1Avoid failureAvoid connectionLight guidesElectric circuit arrangementsEngineeringLED lamp

An LED lamp system includes a light emitting diode (LED) lamp, a printed circuit board on which the LED lamp is mounted, a connection terminal including a soldering part inserted and soldered to the printed circuit board, a body part extending parallel to the printed circuit board, and a branch part extending from the body part in a predetermined direction, a case to which the printed circuit board is fixed, the case including a holding portion for holding the branch part of the connection terminal, and a cover for enclosing the LED lamp and the printed circuit board in association with the case.

Owner:TOYODA GOSEI CO LTD

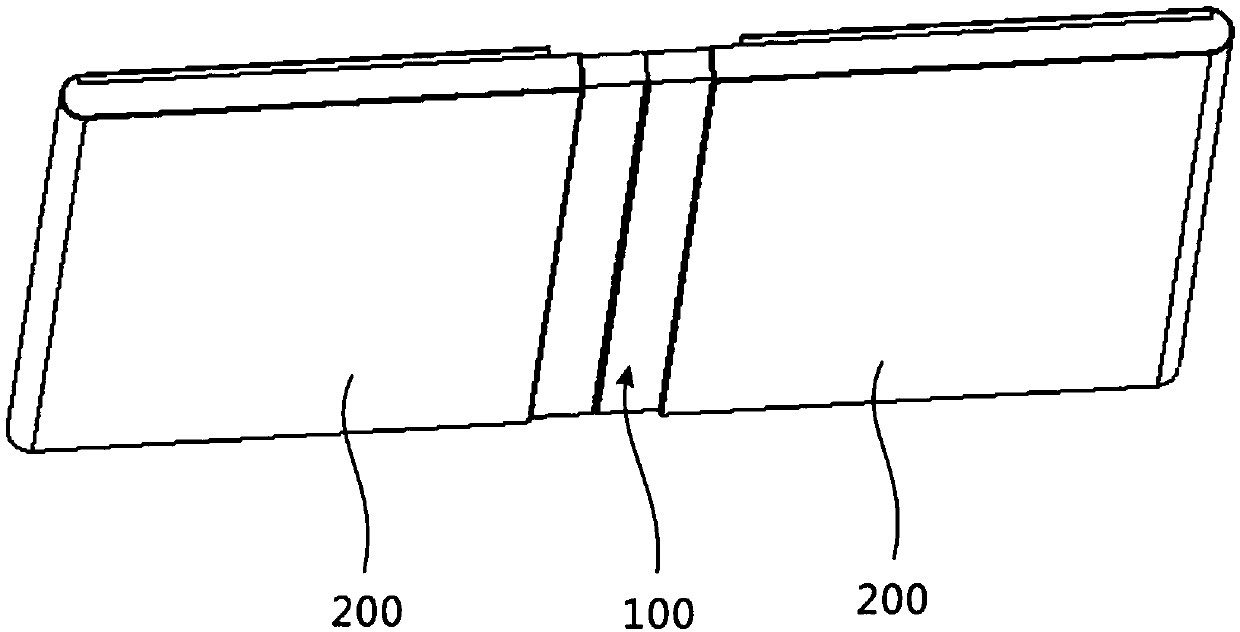

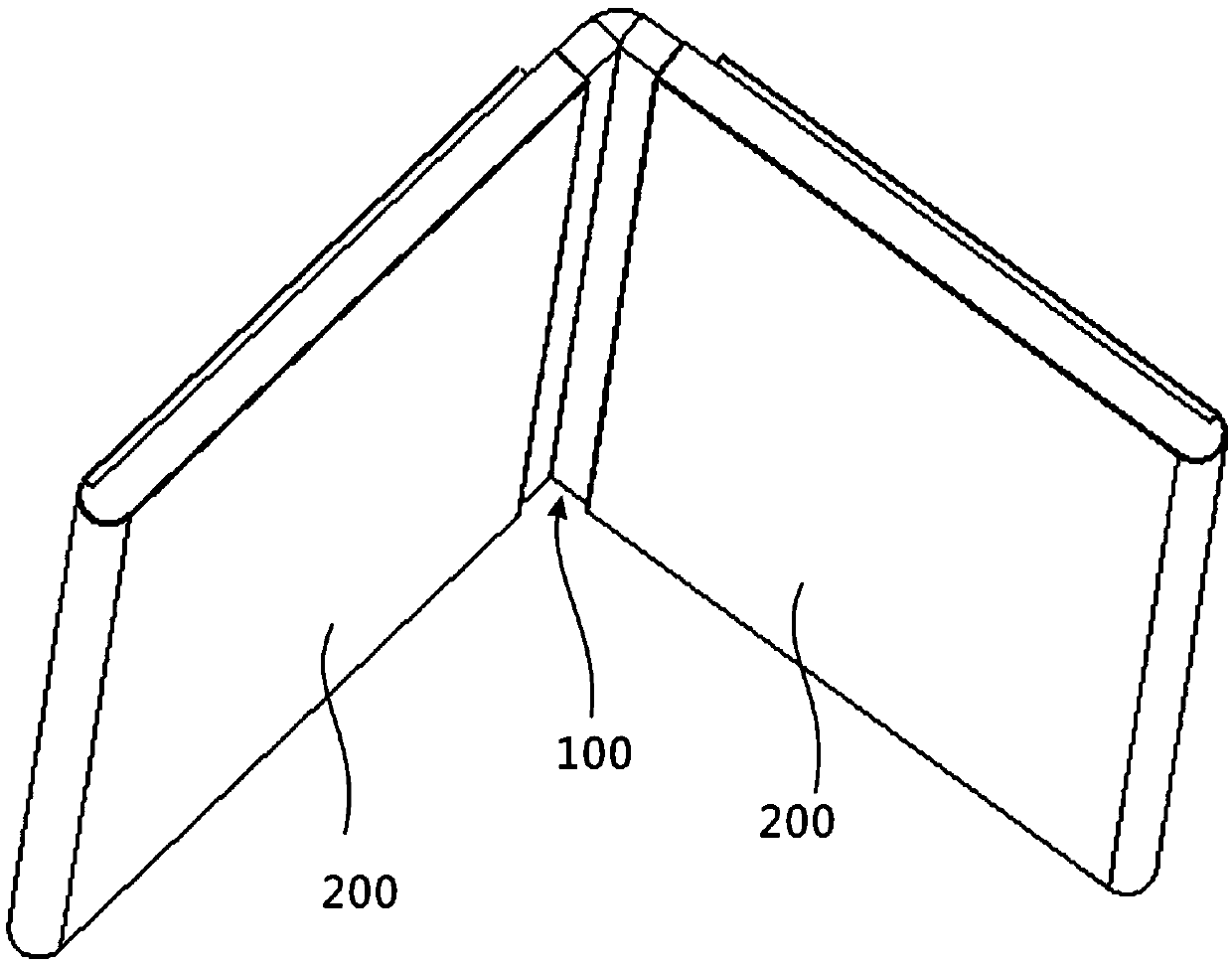

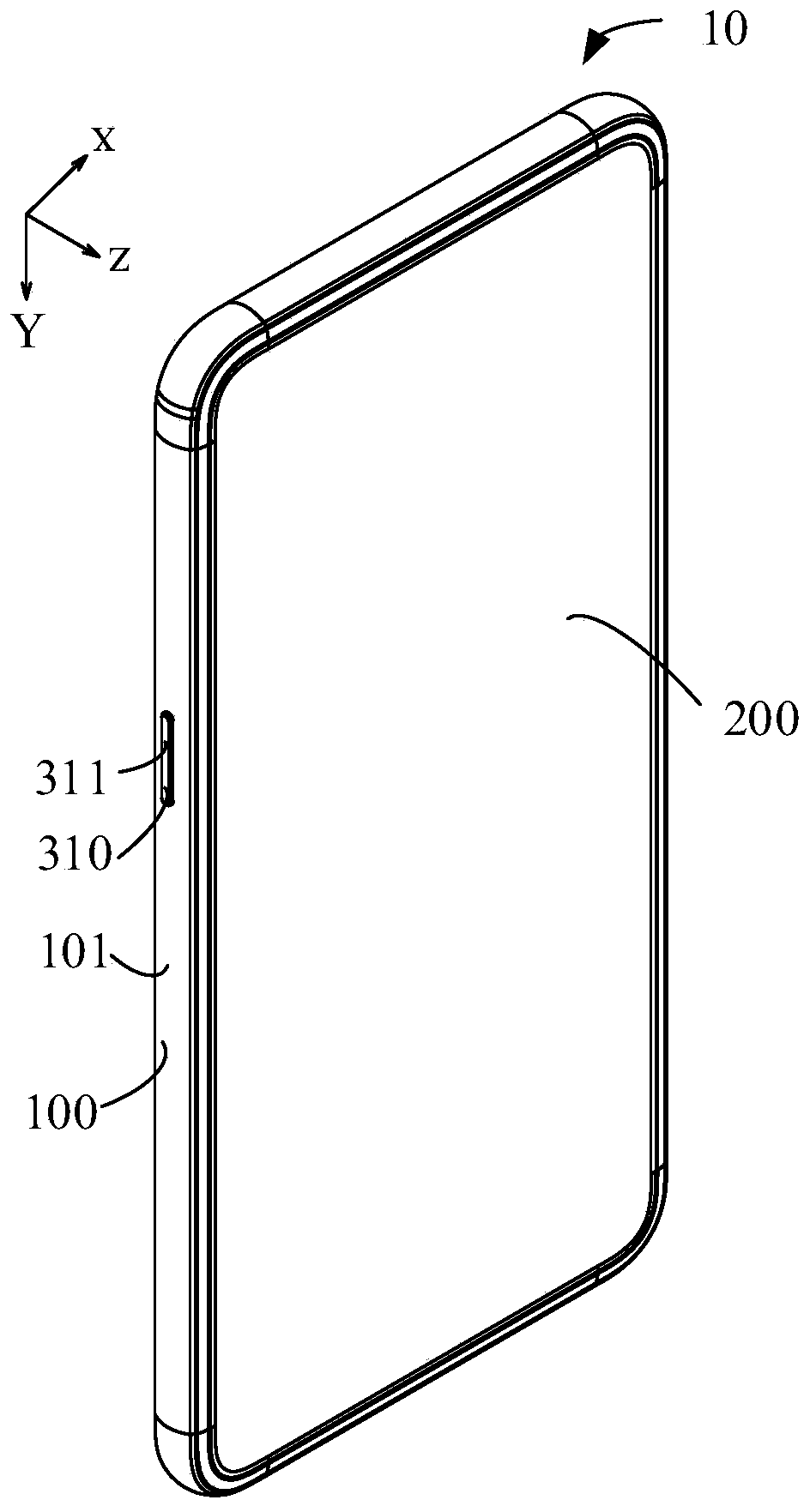

Rotating mechanism and folding terminal

ActiveCN109936648AExtended service lifeReduce external forceCasings with display/control unitsDetails for portable computersEngineeringFixed length

The invention discloses a rotating mechanism and a folding terminal. The rotating mechanism comprises a guide shaft, at least two rotating pieces and at least two constant-length units, and the rotating pieces are arranged on the two sides of the guide shaft. An arc-shaped groove is formed in the guide shaft; an arc-shaped part is arranged on the rotating piece and is arranged in the arc-shaped groove in a sliding manner. The constant-length unit is in a long-strip shape which has a fixed length and can be bent, the positioning end of the constant-length unit is fixedly or rotationally connected with the rotating piece located on one side of the guide shaft, and the sliding end of the constant-length unit is slidably connected to the rotating piece located on the other side of the guide shaft. The folding terminal is provided with the rotating mechanism. Through cooperation of the arc-shaped groove and the arc-shaped part, the two rotating pieces can rotate relative to the guide shaft,and then folding is achieved; when the rotating piece rotates around the guide shaft, the sliding end of the constant-length unit slides relative to the rotating piece, so that the total length of the folding terminal on the plane where the flexible screen is located is not changed, the flexible screen can bear the minimum external force in the folding process, the flexible screen is protected, and the service life is prolonged.

Owner:HUAWEI TECH CO LTD

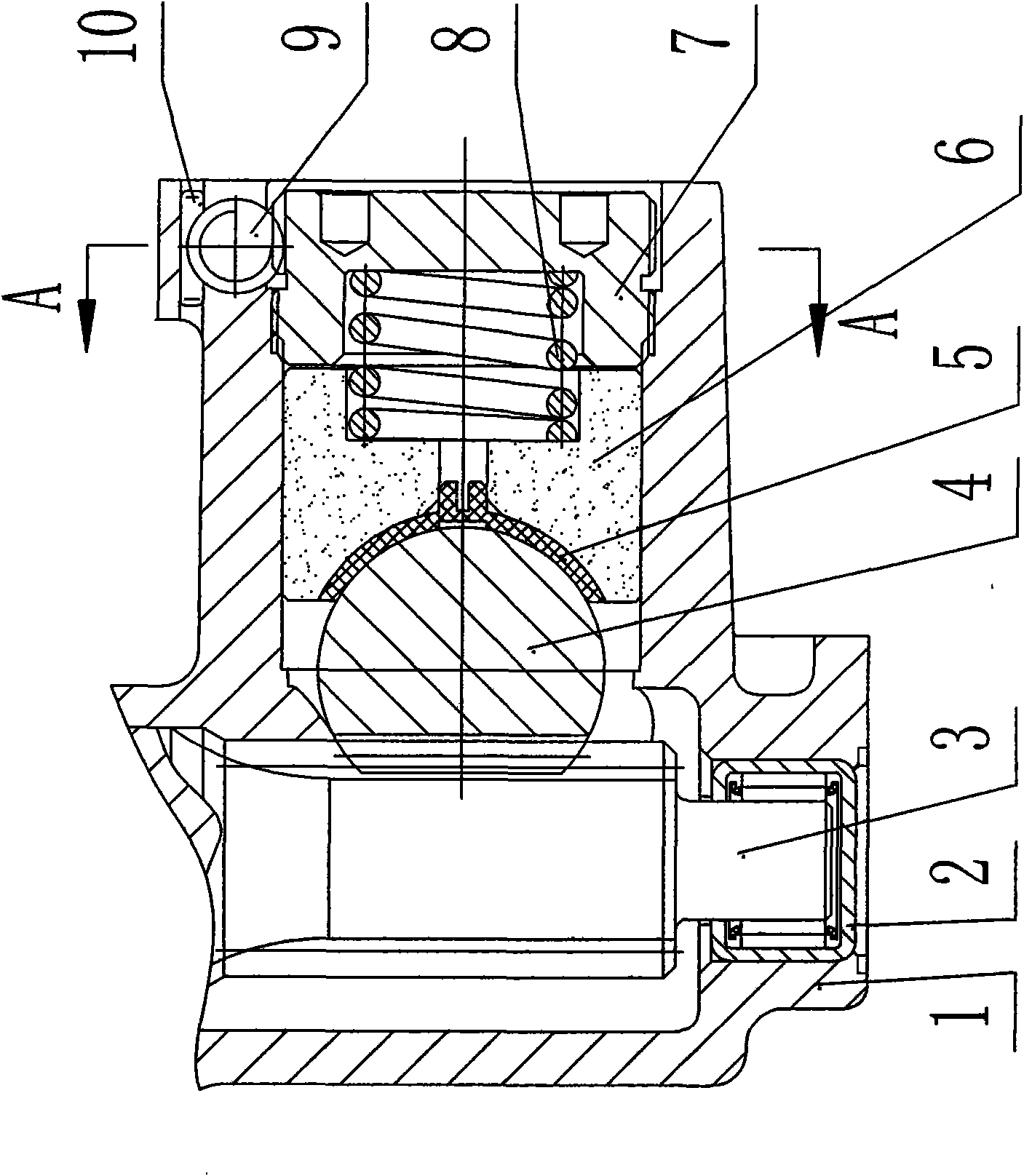

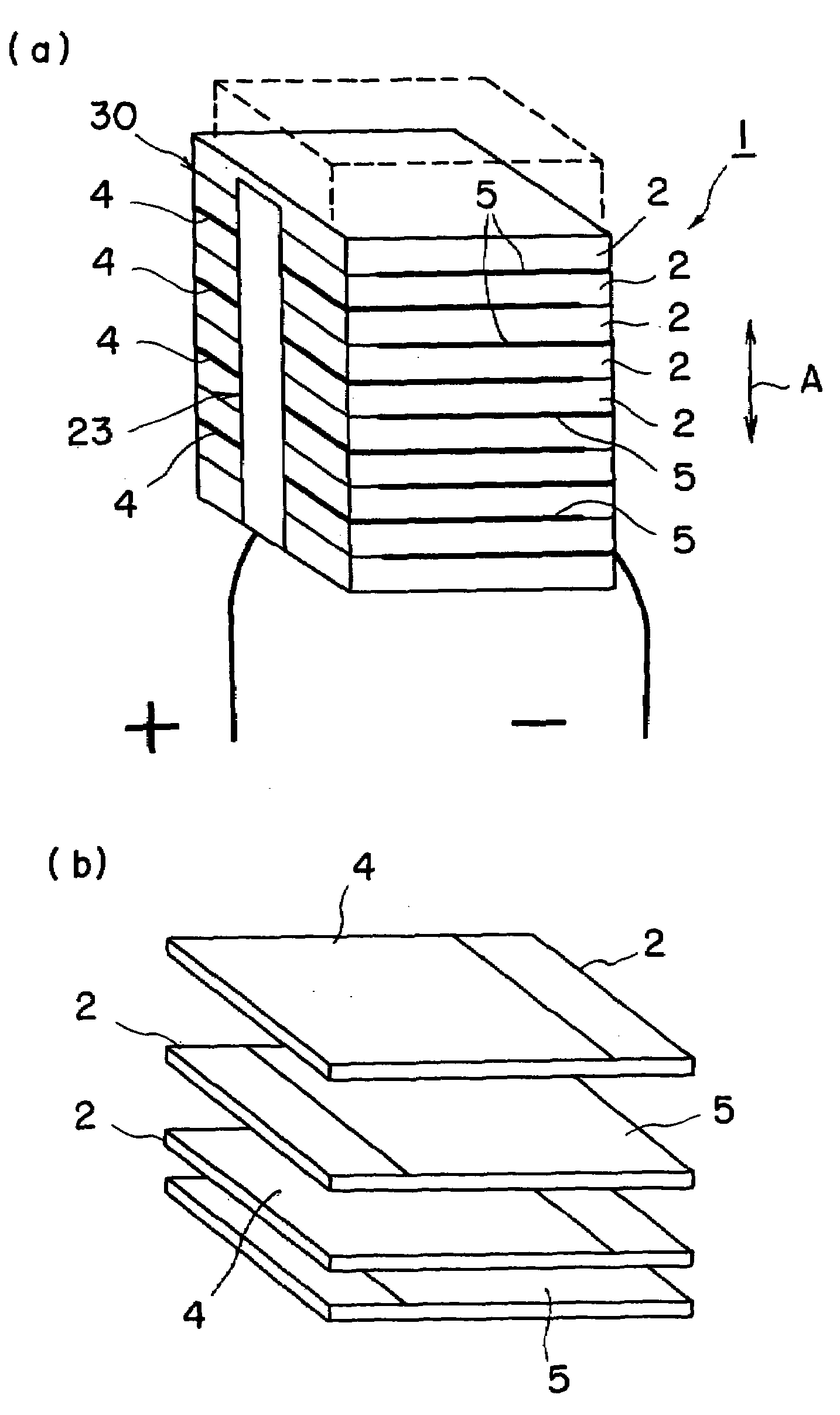

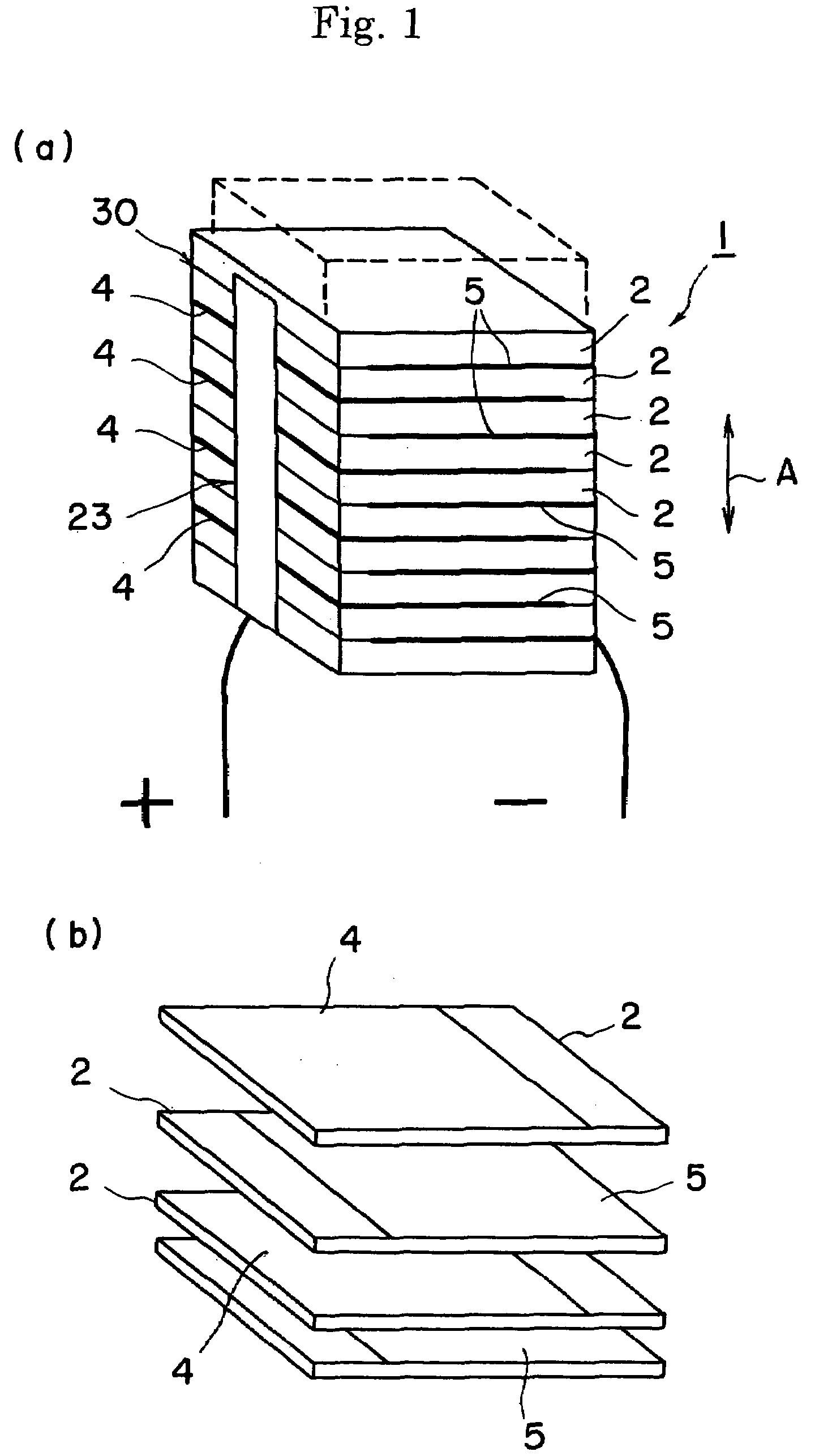

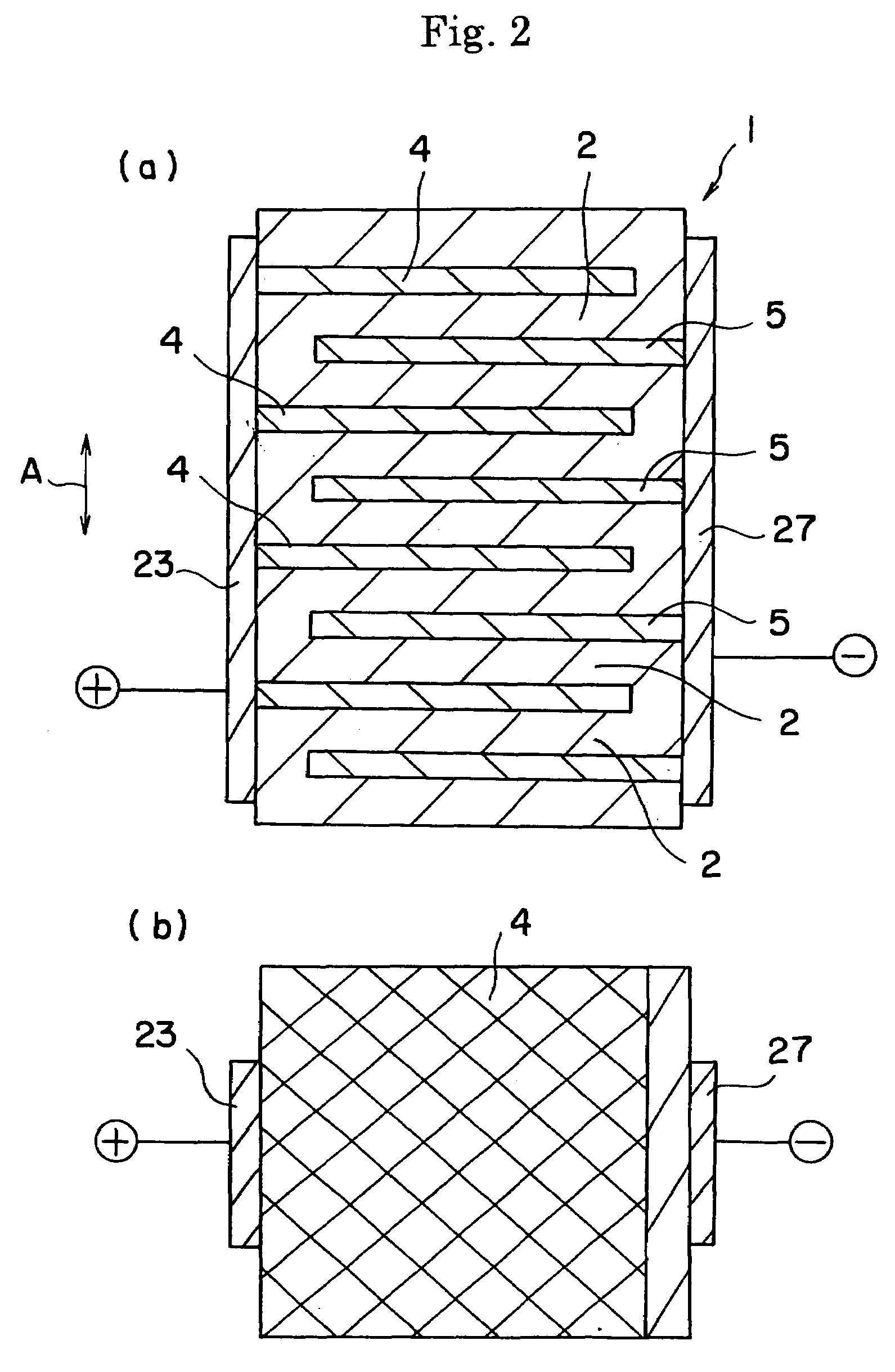

Multilayer piezoelectric devices and method of producing same

InactiveUS20070164639A1Increase displacementIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectrical and Electronics engineering

A multilayer piezoelectric device has a laminated body 1 having piezoelectric layers 2 laminated in the direction of a given axis “A” and internal electrode layers 4, 5 each disposed between two respective neighboring piezoelectric layers 2. The device further has a underlying layer 3 disposed on a side of the laminated body 1 and electrically connected to the internal electrode layers 4, 5, a first conductive reinforcing layer 10 joined to the underlying layer 3, a second conductive reinforcing layer 11 joined to the first conductive reinforcing layer 10, and a conductive joining material 9 joining the underlying layer 3 to the first conductive reinforcing layer 10. The second conductive reinforcing layer 11 is not directly joined by means of the conductive joining material 9.

Owner:NGK INSULATORS LTD

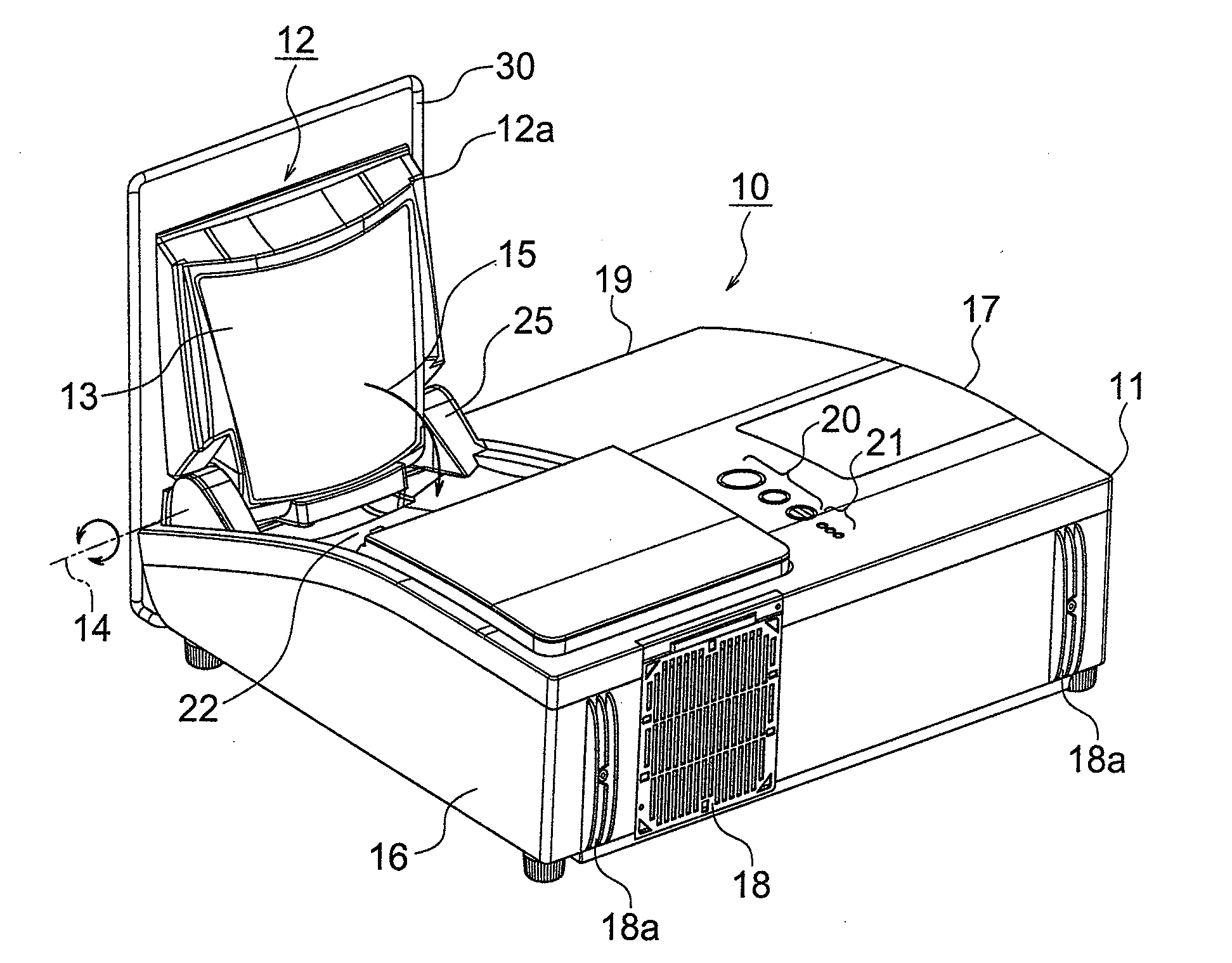

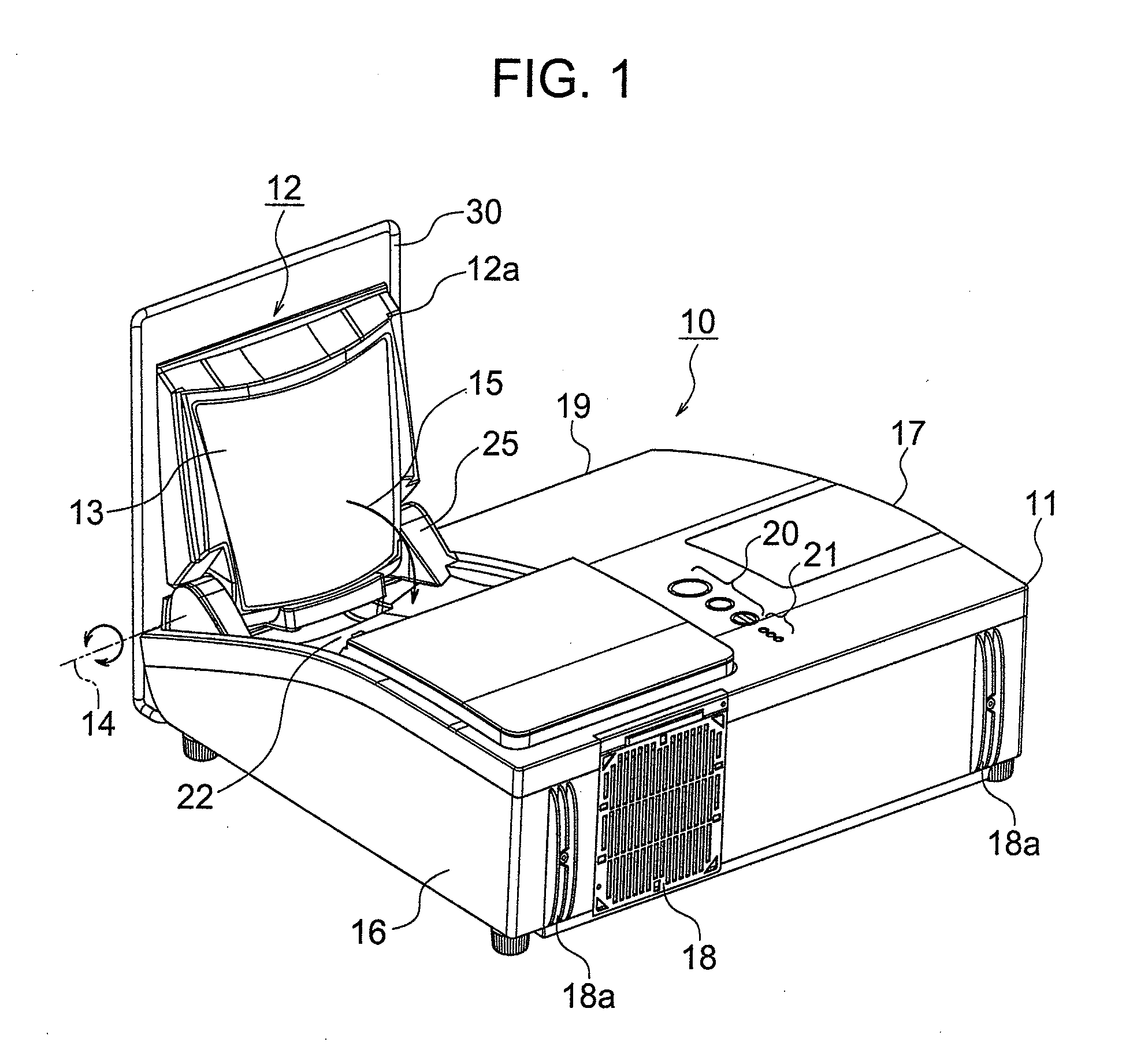

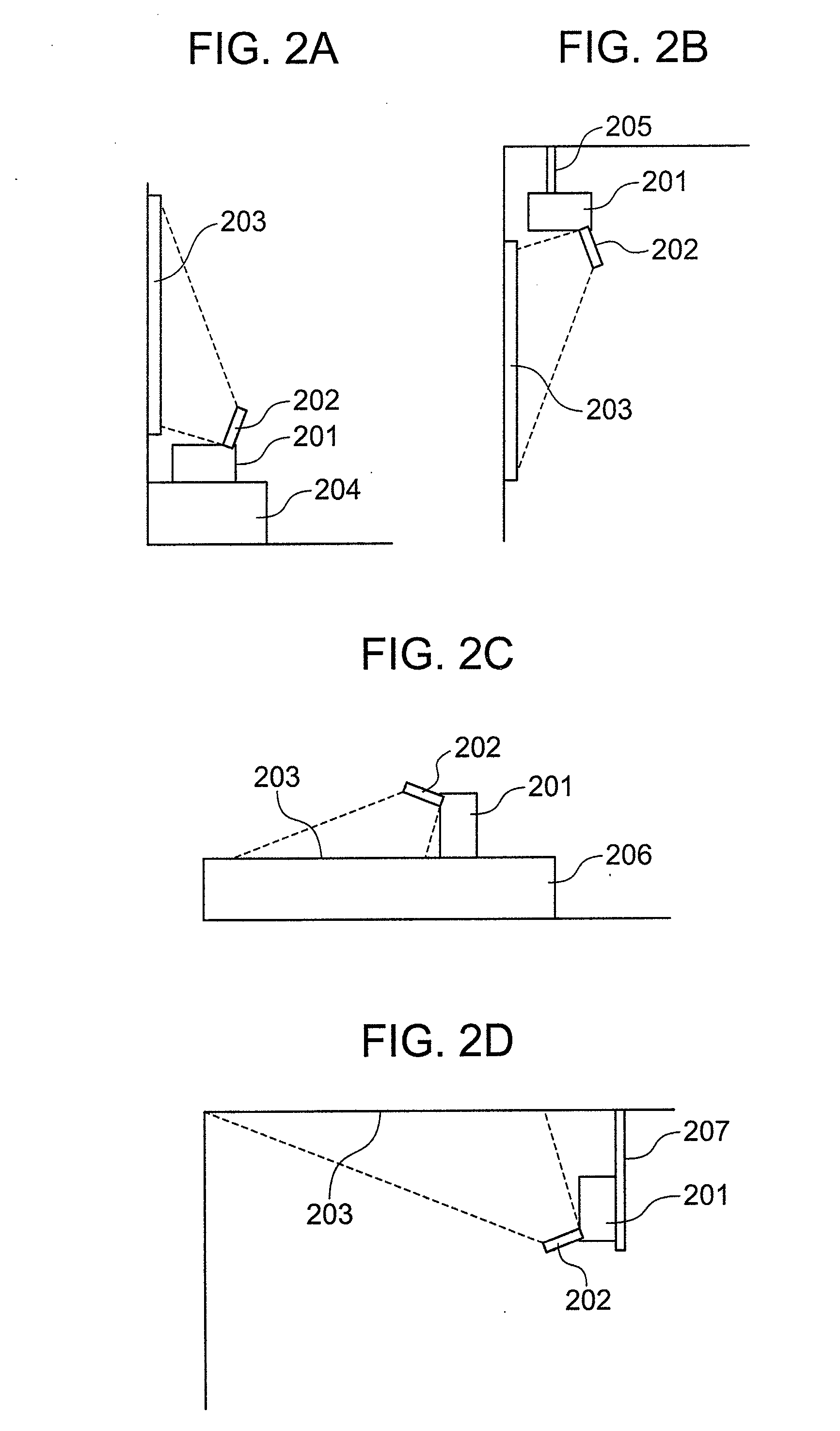

Video Projection System

InactiveUS20090122274A1Avoid external forceReduce external forceProjectorsColor television detailsProjection systemPhysics

A roll bar for protecting a projection mirror is attached so as to avoid exerting an external force to the projection mirror portion, direct thereto upon a turnover the projection apparatus. Further, in the case of no attachment of the roll bar for protecting the projection mirror portion, the projector apparatus is prevented from being started. Further, when the projector apparatus is carried away, the roller bar for protecting the projection mirror serves as a handle.

Owner:MAXELL HLDG LTD

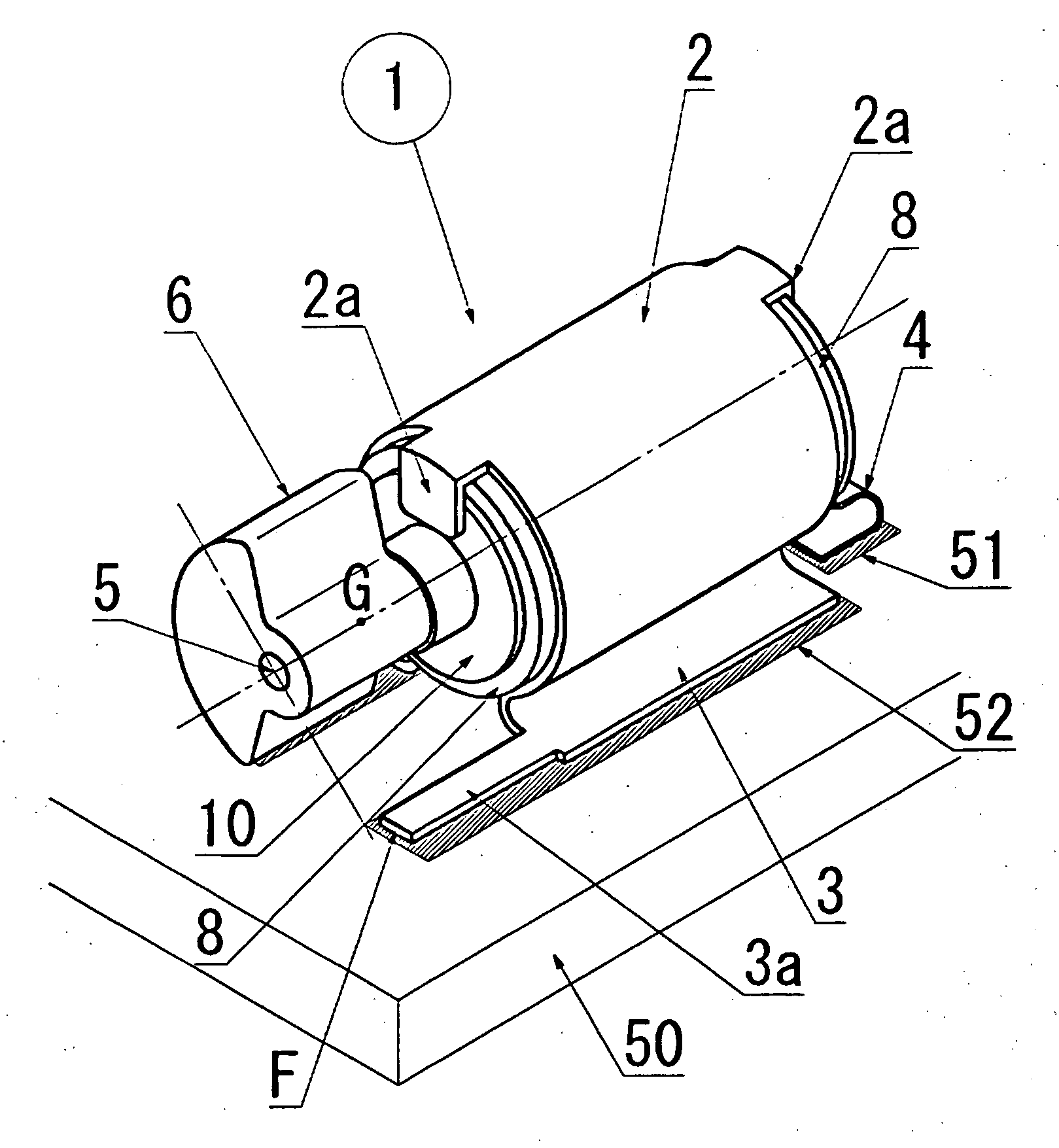

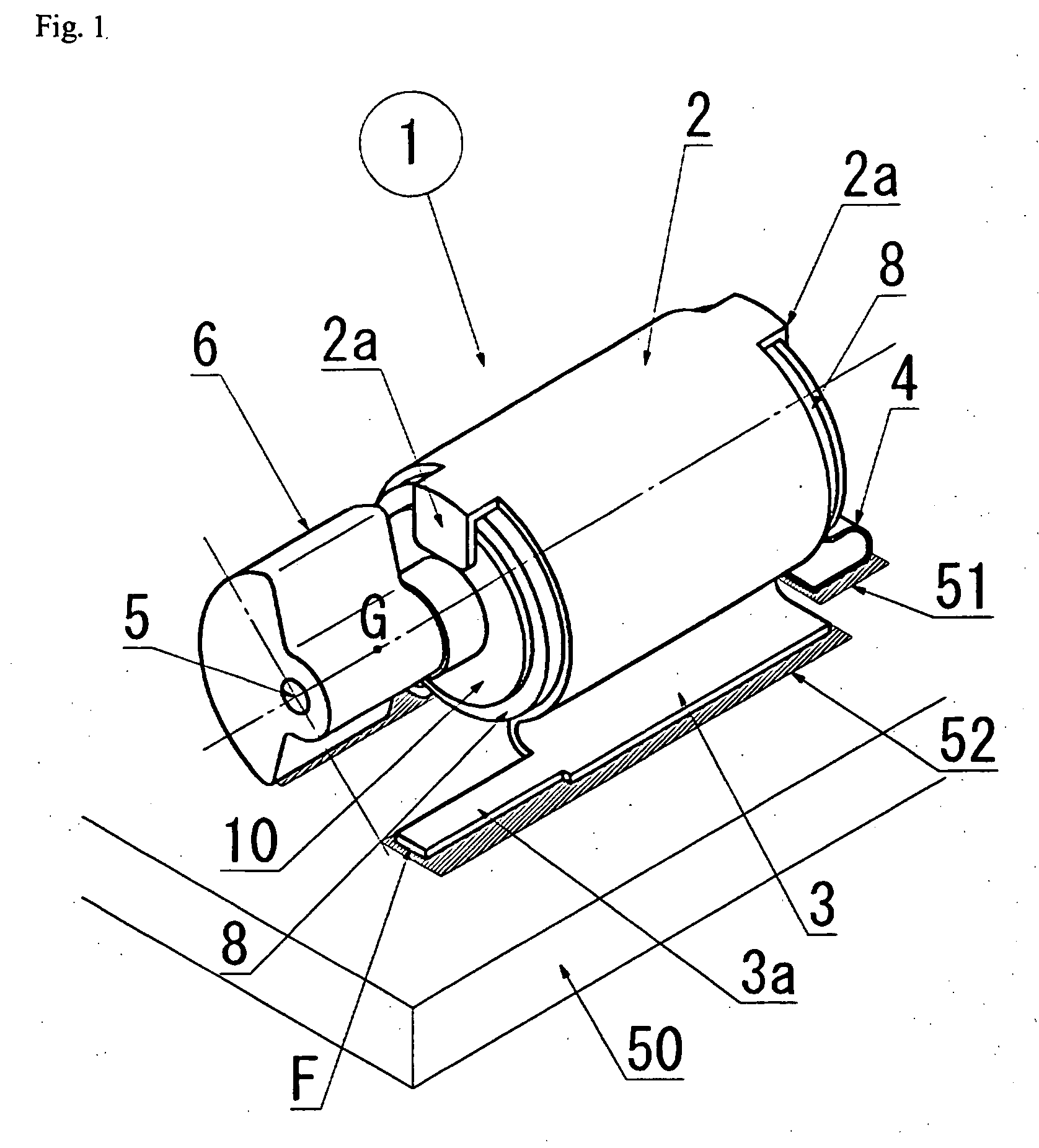

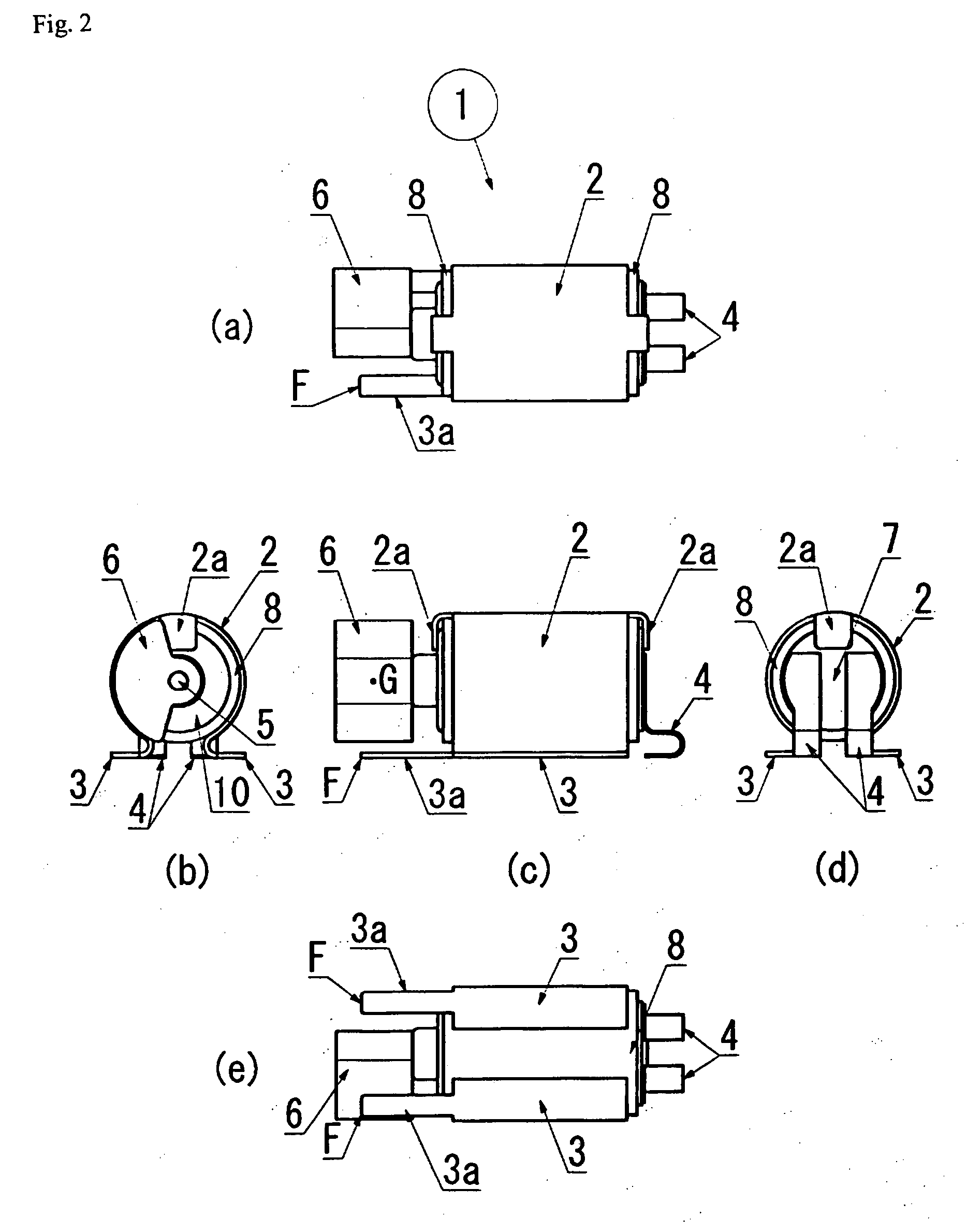

Surface Mount Type Vibration Motor and Fixation Structure

InactiveUS20080309180A1Easy to installGuaranteed normal transmissionPrinted circuit aspectsMechanical vibrations separationSurface mountingEngineering

In a solder reflow process, a vibration motor is stably mounted on a circuit board by changing the design of a partial shape of a soldered motor holder without changing the design of a vibration motor body and securing a sufficient soldering area to completely perform solder bonding to prevent a soldered portion of a motor holder from peeling off the circuit board.[Solution] To provide a surface mount type vibration motor, wherein the pedestals of a motor holder comprise the support plates that are in contact with stationary lands on a surface of a circuit board and extend in the axial direction of an output shaft, end portions of the support plates are arranged between the position of an eccentric weight and the end surface of the eccentric weight along the axial direction, and the support plates are not arranged just under an axis of said output shaft where the distance between the weight and the circuit board is minimum.

Owner:NAMIKI PRECISION JEWEL CO LTD

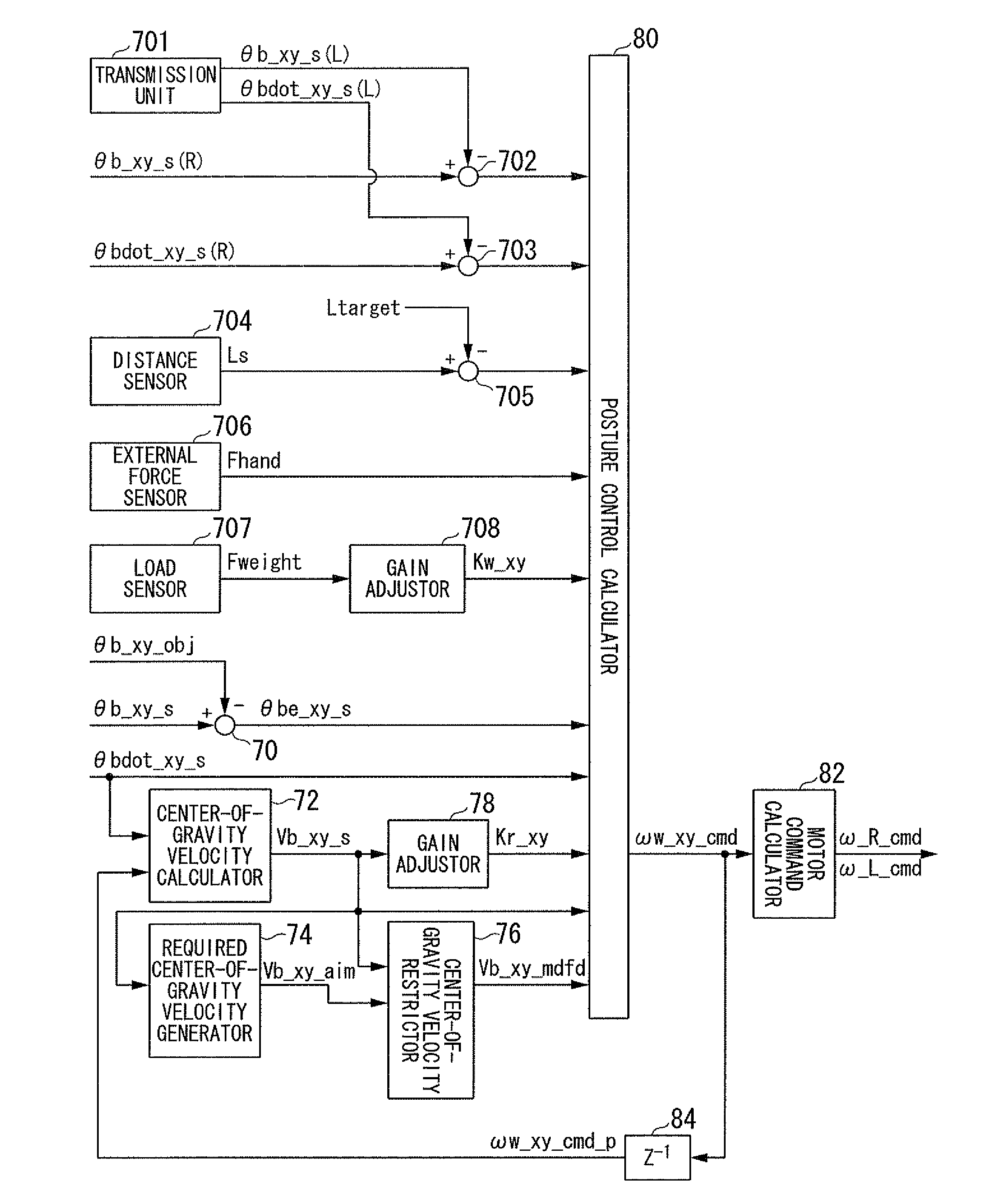

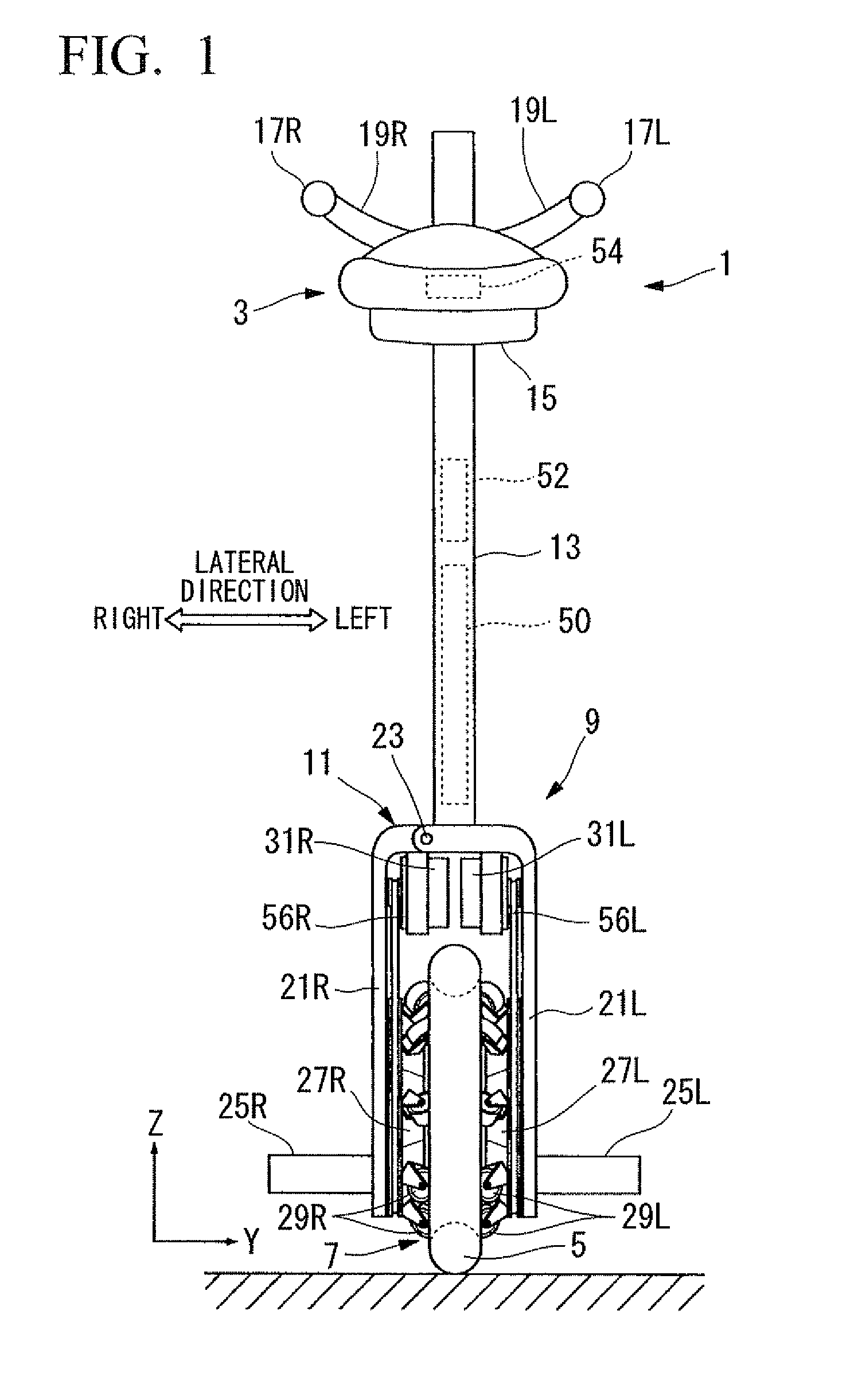

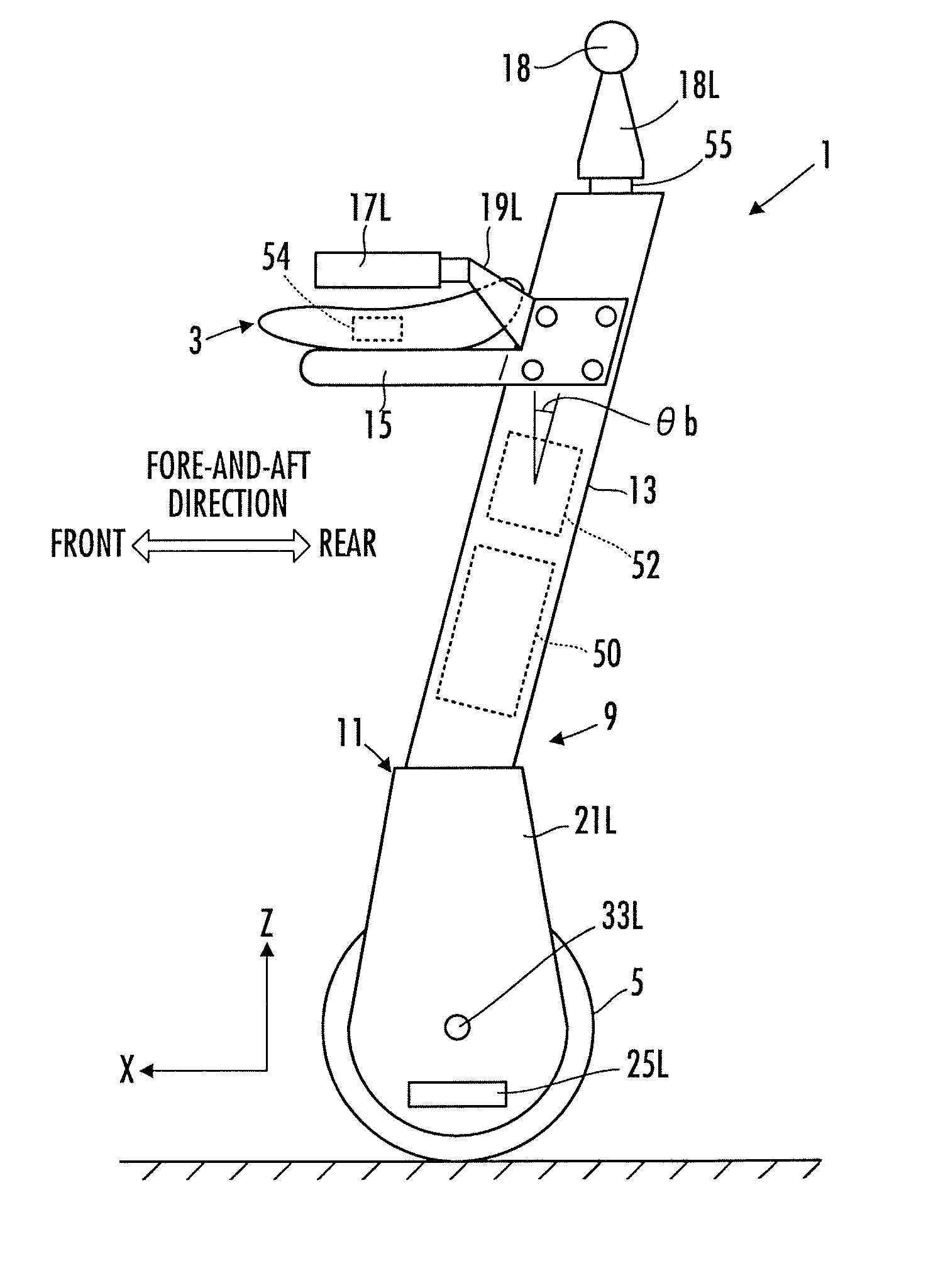

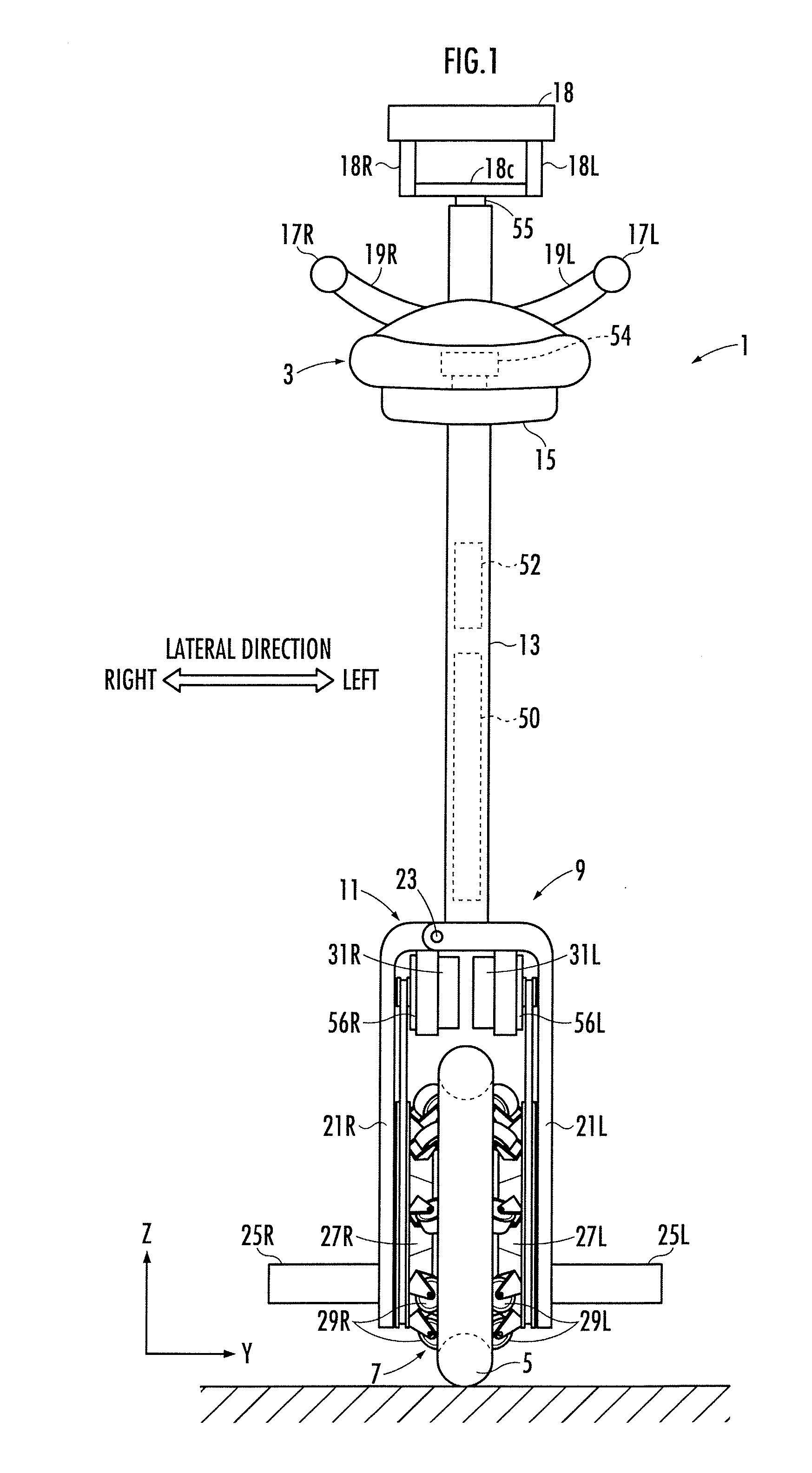

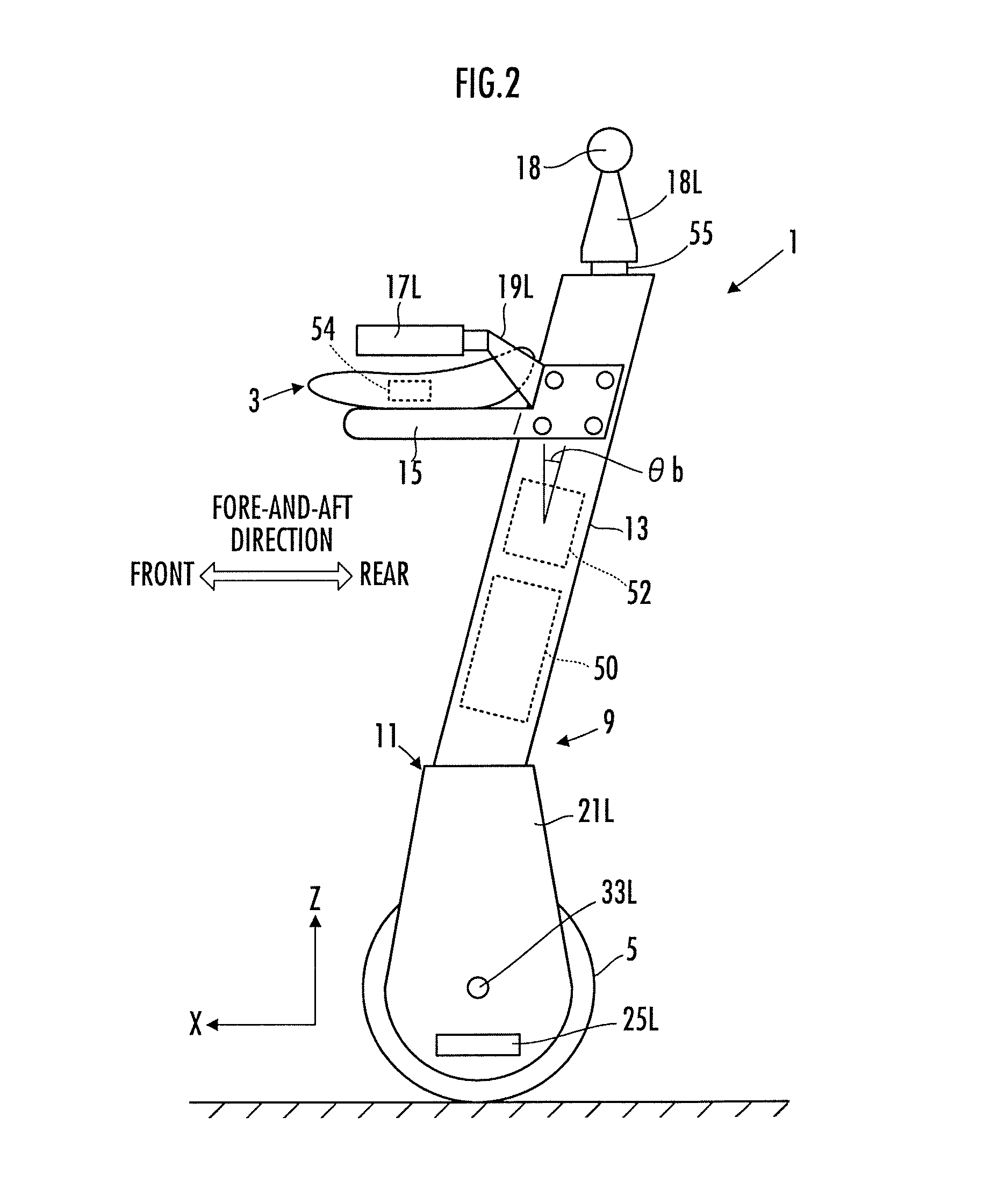

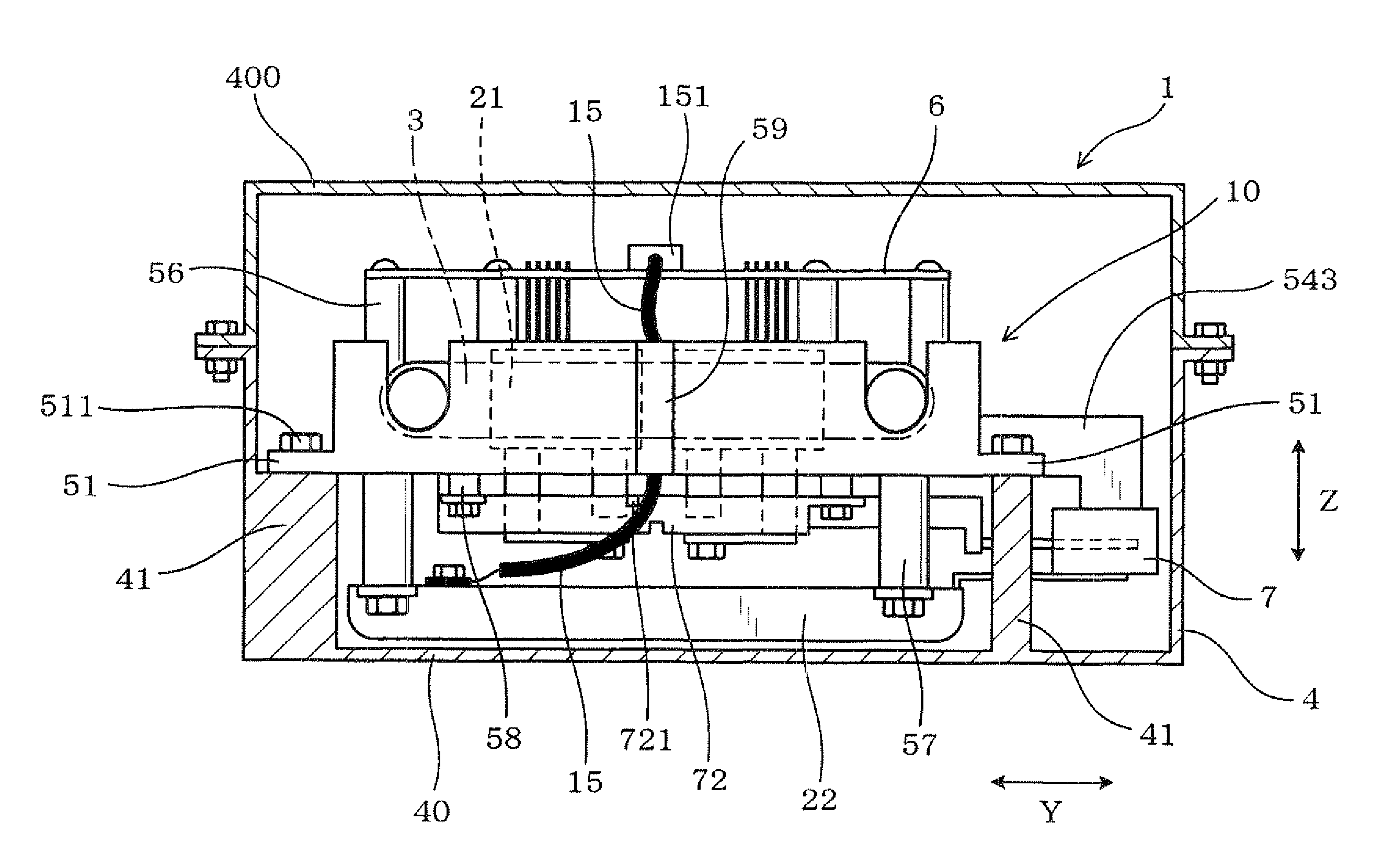

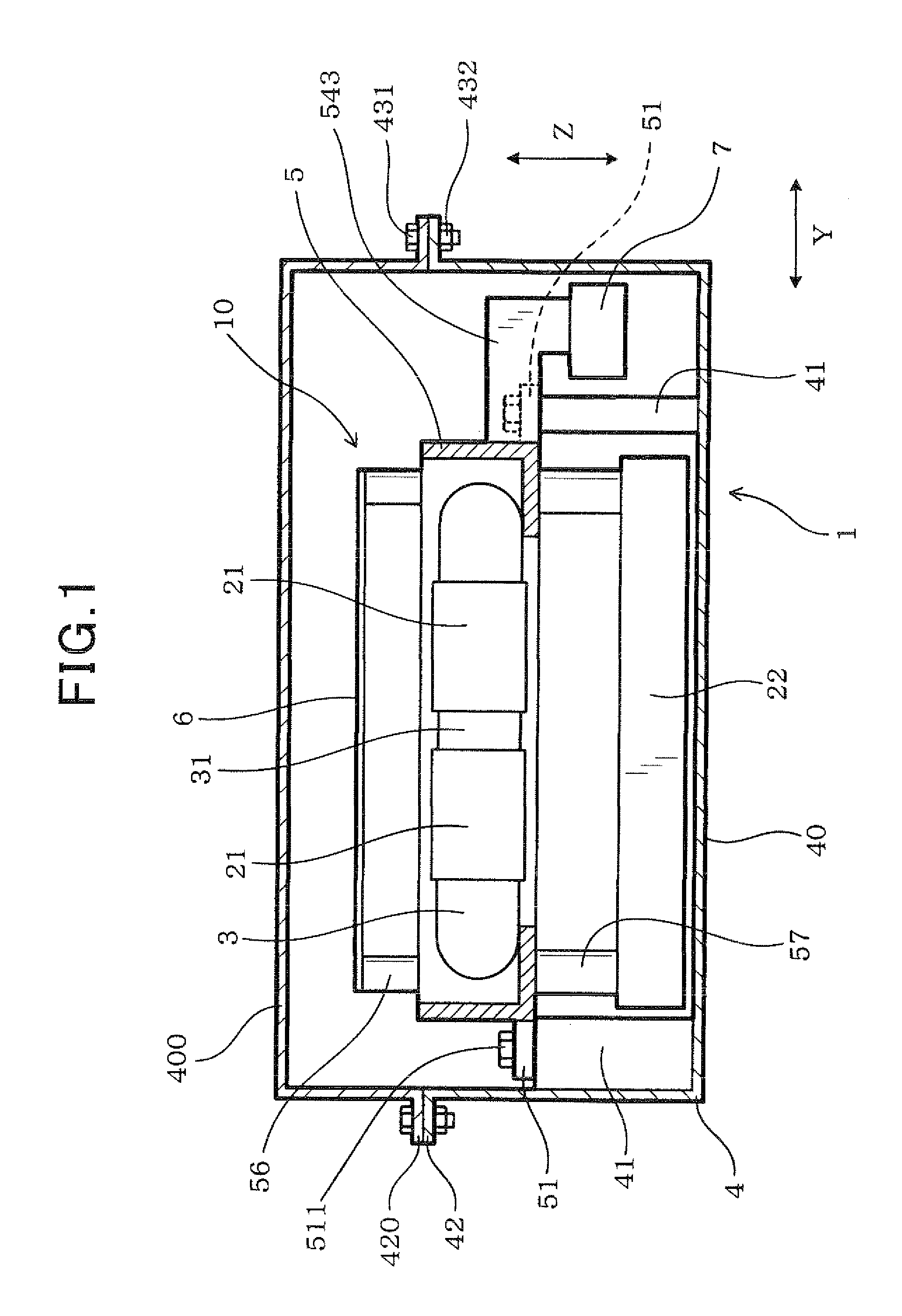

Control device of inverted pendulum type vehicle

ActiveUS20120173088A1Smooth movementReduce external forceUnicyclesDigital data processing detailsControl theoryForce sensor

Provided is a controller for an inverted pendulum type vehicle capable of moving the vehicle smoothly. The inverted pendulum type vehicle 1 is provided with a grip 18 at a upper end portion of a base body 9. A grip-acting external force F acting on the grip 18 is detected by a force sensor 55. According to the detected grip-acting external force F, a required center-of-gravity velocity generator 74 determines required center-of-gravity velocities Vb_x_aim and Vb_y_aim, and on the basis thereof, a traveling motion unit controller determines a manipulated variable for control.

Owner:HONDA MOTOR CO LTD

Power conversion apparatus

ActiveUS8582291B2Improve rigidityImprove maintainabilityDigital data processing detailsConversion constructional detailsElectronic componentElectric power

In a power conversion apparatus, electronic components and a cooler are integrated in a frame as an internal unit. The internal unit is fixed within a case through the frame. The frame has such a shape that the electronic components are surrounded by the frame, and includes a first wall section, and second and third wall sections extending from both sides of the first wall section. The cooler includes a coolant introduction tube and a coolant discharge tube. The coolant introduction tube and the coolant discharge tube project outward from to the frame. The first to third wall sections include a support wall section supporting at least one of the coolant introduction tube and the coolant discharge tube, and a frame wall section not supporting the coolant introduction tube and the coolant discharge tube. The thickness of the support wall section is larger than the thickness of the frame wall section.

Owner:DENSO CORP

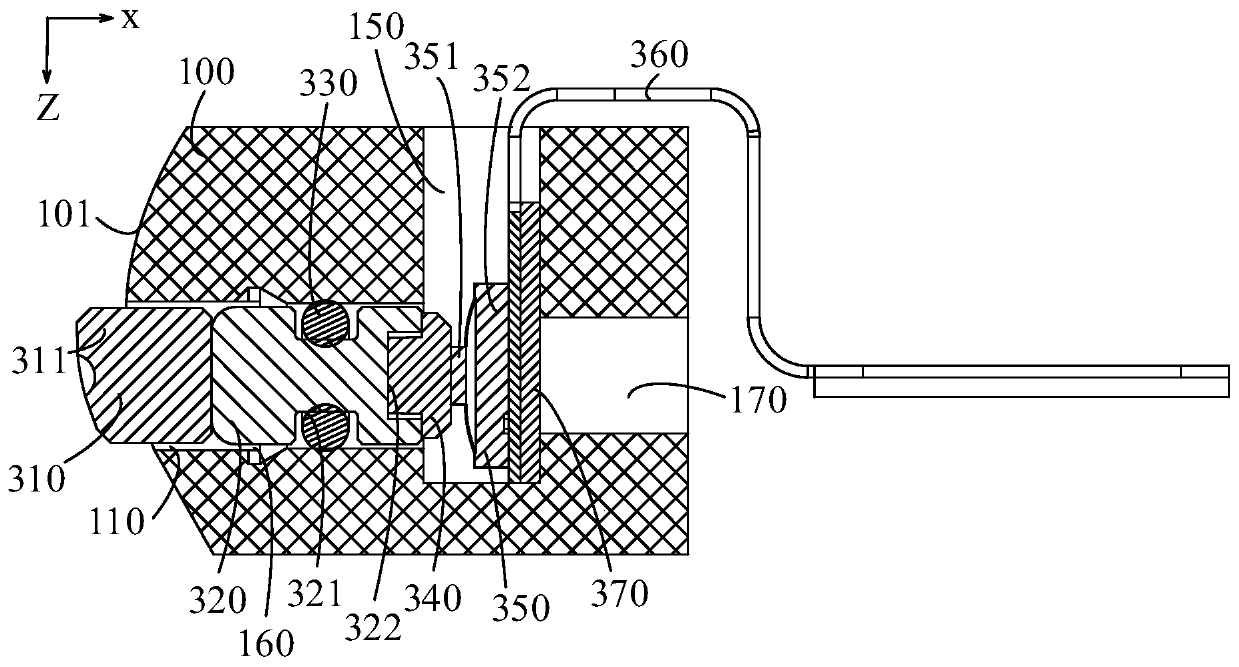

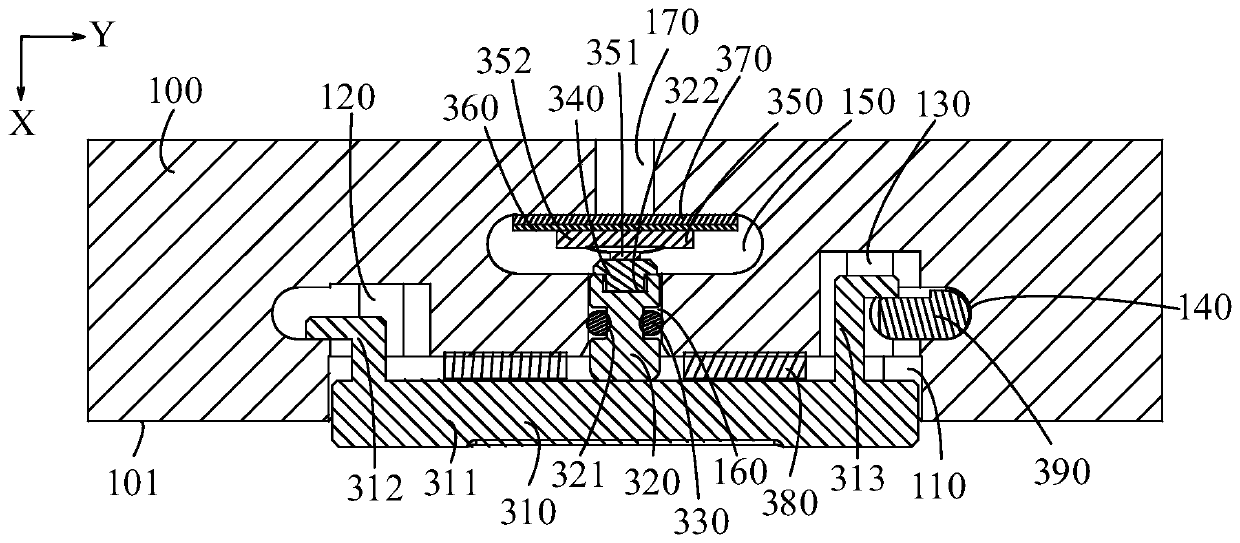

Mobile terminal

ActiveCN110138949AReduce impactExtended service lifeTelephone set constructionsEngineeringComputer terminal

The application relates to a mobile terminal, comprising: a housing provided with a guide hole; a key cap which is arranged in the shell in a penetrating manner and can move relative to the shell; a guide piece which is located in the guide hole and comprises an elastic piece located at the end, wherein the end, away from the elastic piece, of the guide piece makes contact with the key cap; and aswitch, the key cap can abut against the guide piece so that the elastic piece can abut against the switch. According to the mobile terminal, the switch is pressed by the elastic piece, the guide pillar is prevented from directly contacting the switch, the impact force on the switch is reduced, and the service life of the switch is prolonged. The keycap and the guide pillar are of a split structure, so that the keycap can be obliquely mounted, and the mounting of the key assembly is simpler. The main body part of the keycap is in surface contact with the guide pillar, so that the direct transmission of external force impact to the switch can be reduced under the condition that the hand feeling is not influenced, and the probability of external force and impact damage to the switch can be effectively reduced under the condition that the hand feeling is not influenced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

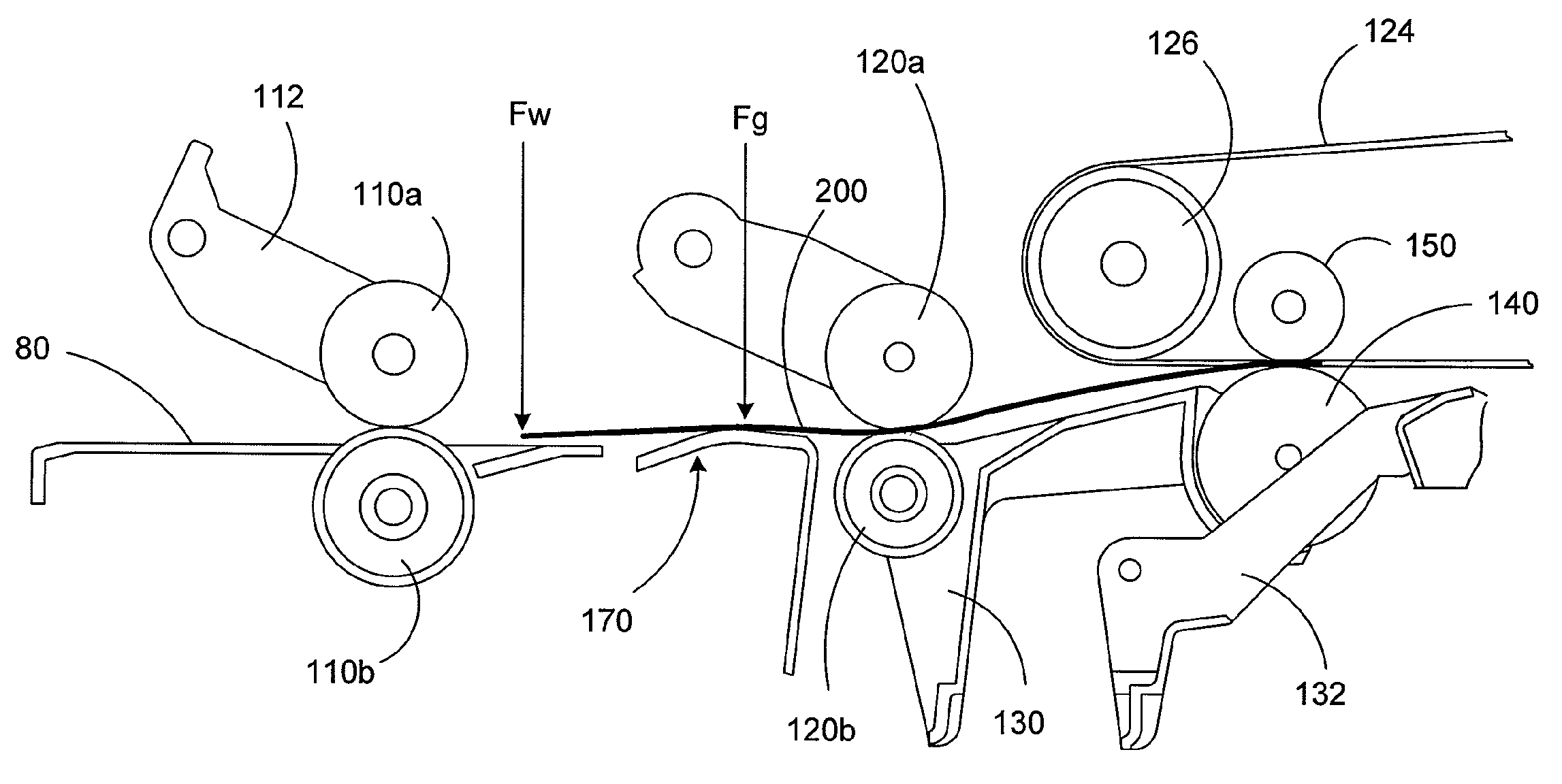

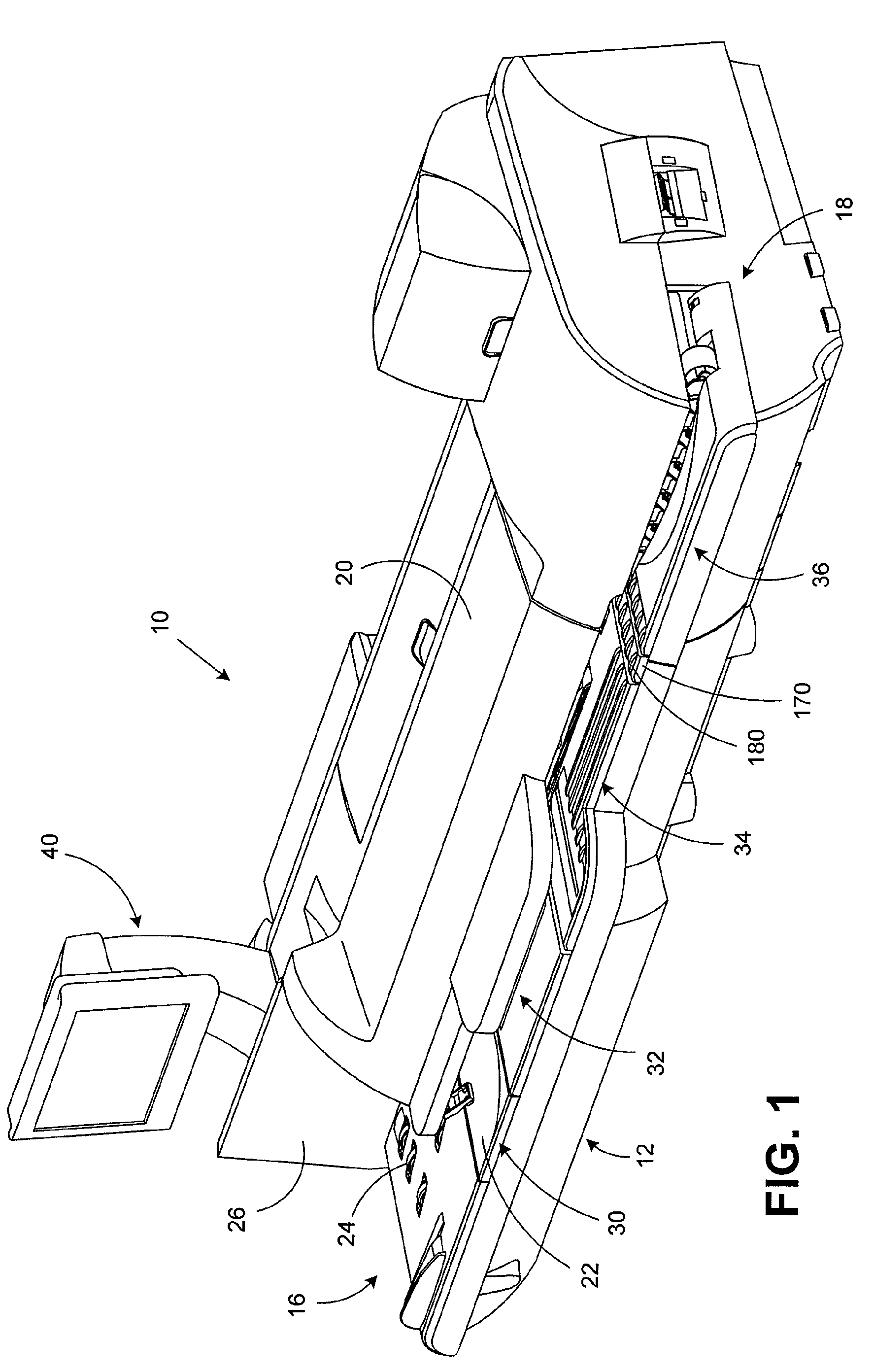

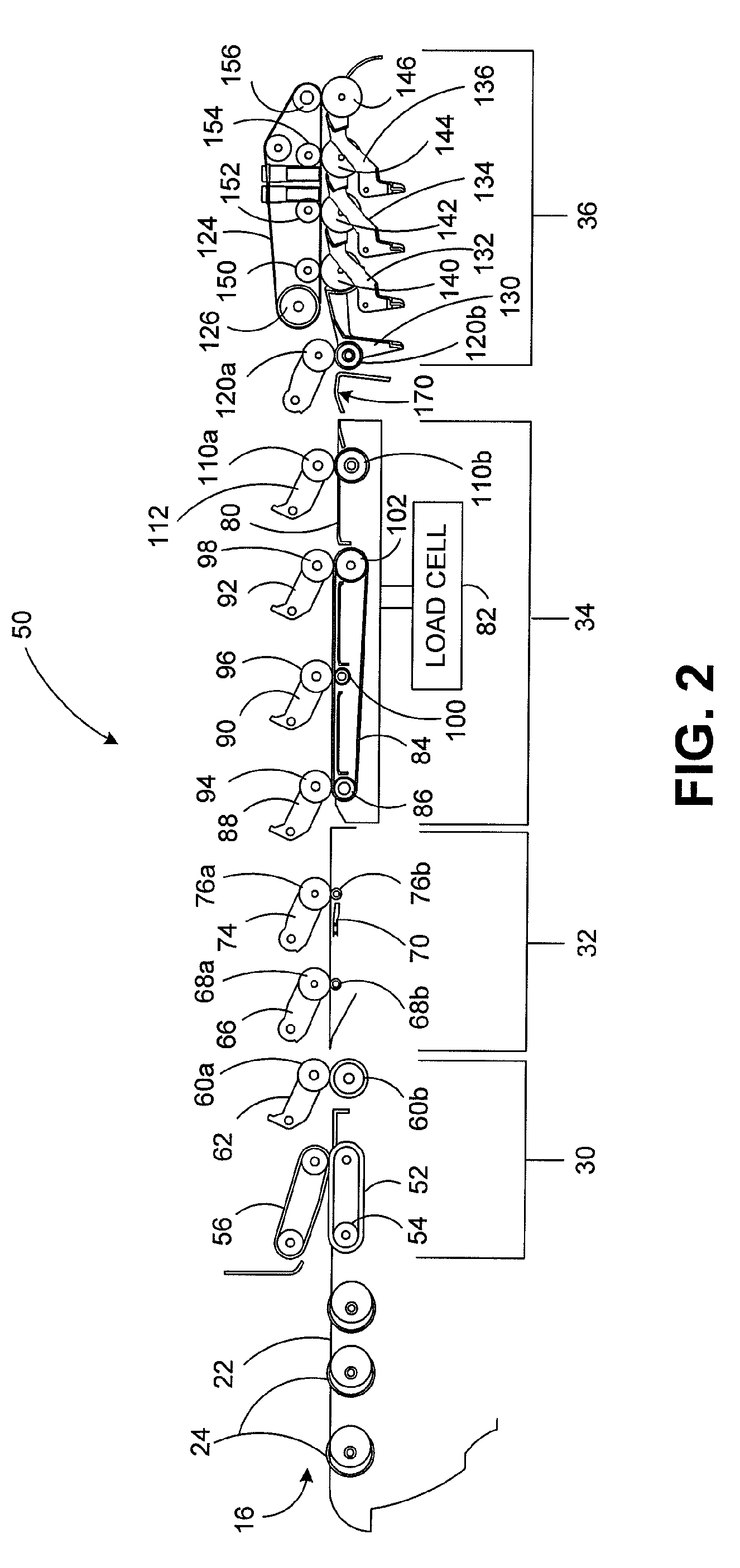

Mailing machine transport system including a guide to reduce the impact on the weighing device caused by the trailing edge of the mailpeice

ActiveUS8178796B2Reduce external forceFast weighingWeighing apparatus detailsFranking apparatusTransport systemTrailing edge

A mail processing system having a transport that reduces the amount of oscillation of the scale to allow for faster weighing of mail pieces is provided. A mailing machine includes a plurality of different modules through which mail pieces are fed by a transport system. A guide piece is provided in the transport path between the weighing module and the subsequent module, e.g., a printing module. The guide piece is structured such that forces imparted on the weighing platform of the weighing module by the trail edge of a mail piece being transported off of the weighing platform are reduced. Because of the reduction in this significant external force on the weighing platform, a faster weighing algorithm can be used on more mail pieces, thereby increasing the throughput of the mailing machine.

Owner:PITNEY BOWES INC

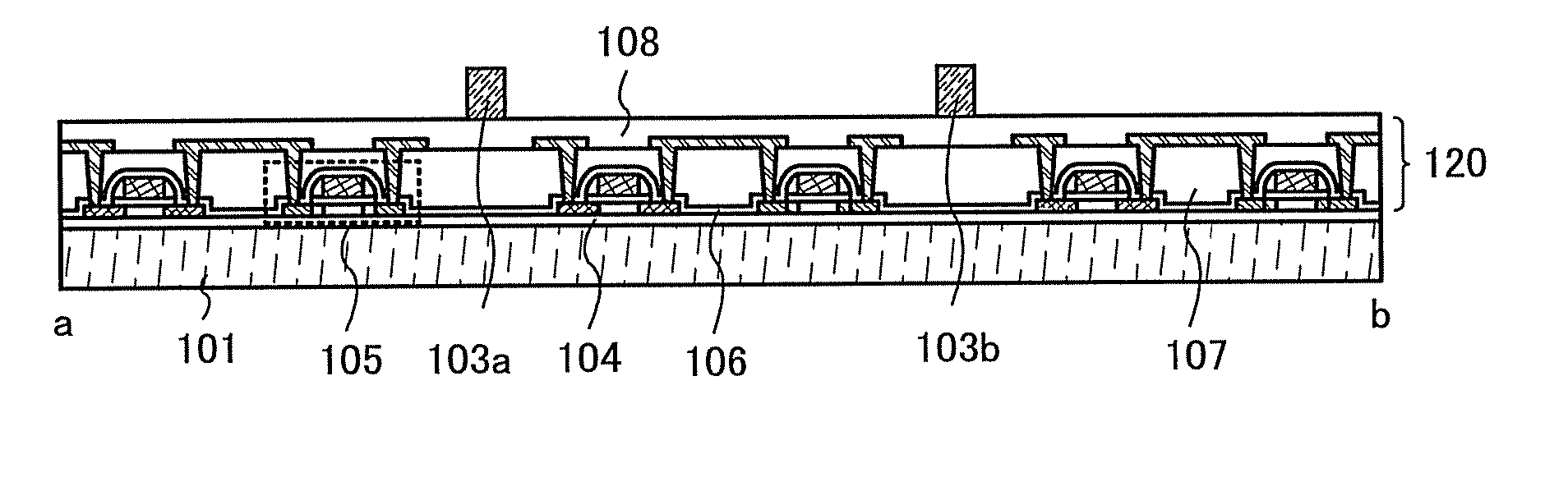

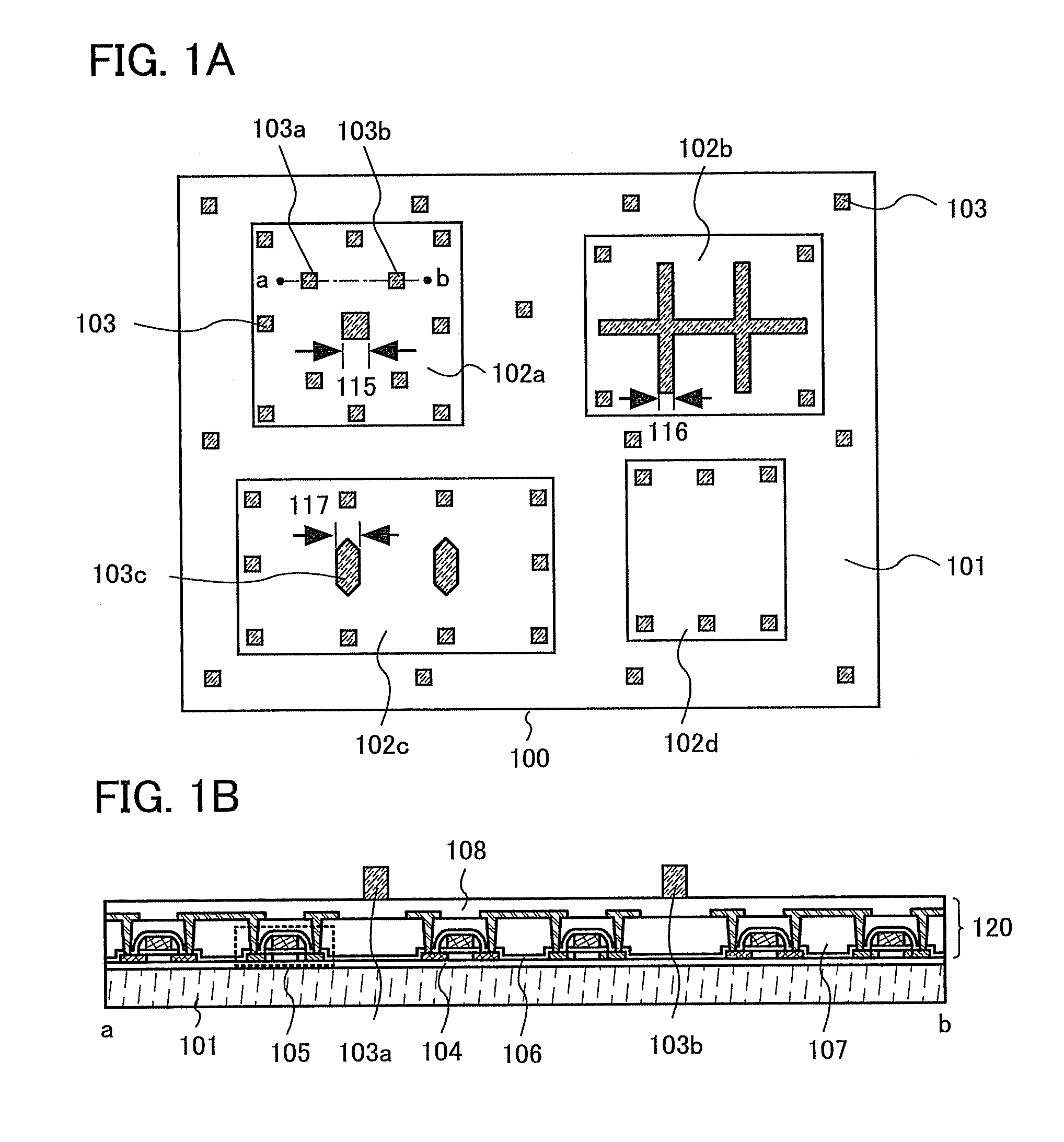

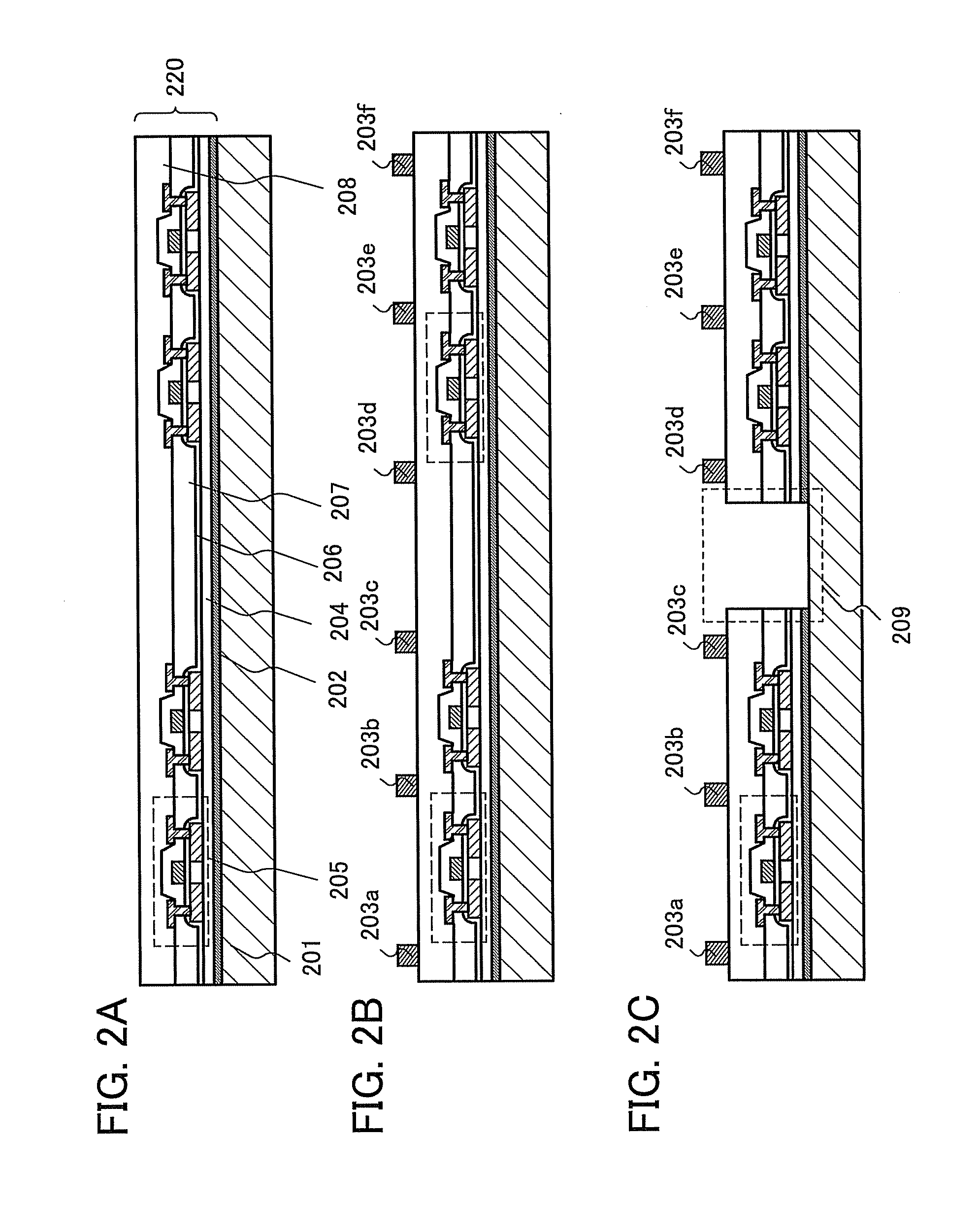

Semiconductor Device and Method for Manufacturing Semiconductor Device

InactiveUS20080237805A1Reduce external forceHighly reliable semiconductor deviceSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

An object is to provide a semiconductor device which is not easily broken even if stressed externally and a method for manufacturing such a semiconductor device. A semiconductor device includes an element layer including a transistor in which a channel is formed in a semiconductor layer and insulating layers which are formed as an upper layer and a lower layer of the transistor respectively, and a plurality of projecting members provided at intervals of from 2 to 200 μm on a surface of the element layer. The longitudinal elastic modulus of the material for forming the plurality of projecting members is lower than that of the materials of the insulating layers. (111 words)

Owner:SEMICON ENERGY LAB CO LTD

Cyclic actuation system for a controllable pitch propeller and a method of providing aircraft control therewith

ActiveUS20050079053A1Without complexityMinimize undesired cyclic loadPropellersAircraft controlAttitude controlEngineering

A propeller control generates a once per revolution (1P) blade thrust variation through cyclic pitch of rigidly mounted non-flapping propeller blades. The resultant shaft bending moment is used to provide aircraft attitude control. Axial translation of a pitch change assembly including a pitch change yoke along an axis of rotation drives a pitch link attached to each propeller blade to collectively change the propeller blade pitch angle. The pitch change yoke includes a translating pitch change yoke portion and an articulatable pitch change yoke portion. Deflection of the articulatable pitch change yoke portion changes the pitch change effect of each pitch link as a function of its angular position such that a sinusoidal pitch angle is superimposed on normal pitch angle. Cyclic pitch change actuators deflect the articulatable pitch change yoke portion in any angular direction while the linear deflection of the cyclic pitch change actuators generate the magnitude of the cyclic pitch.

Owner:HAMILTON SUNDSTRAND CORP

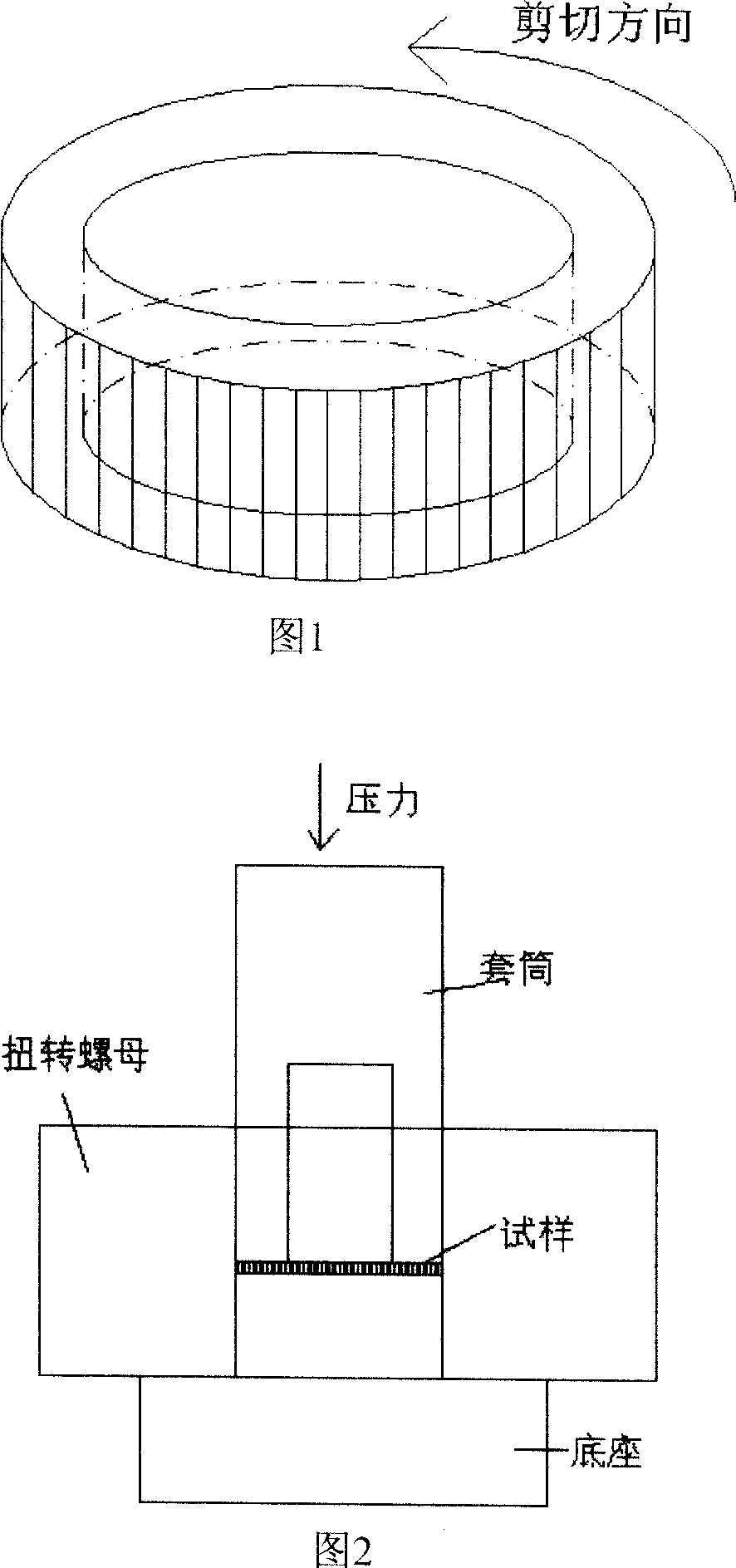

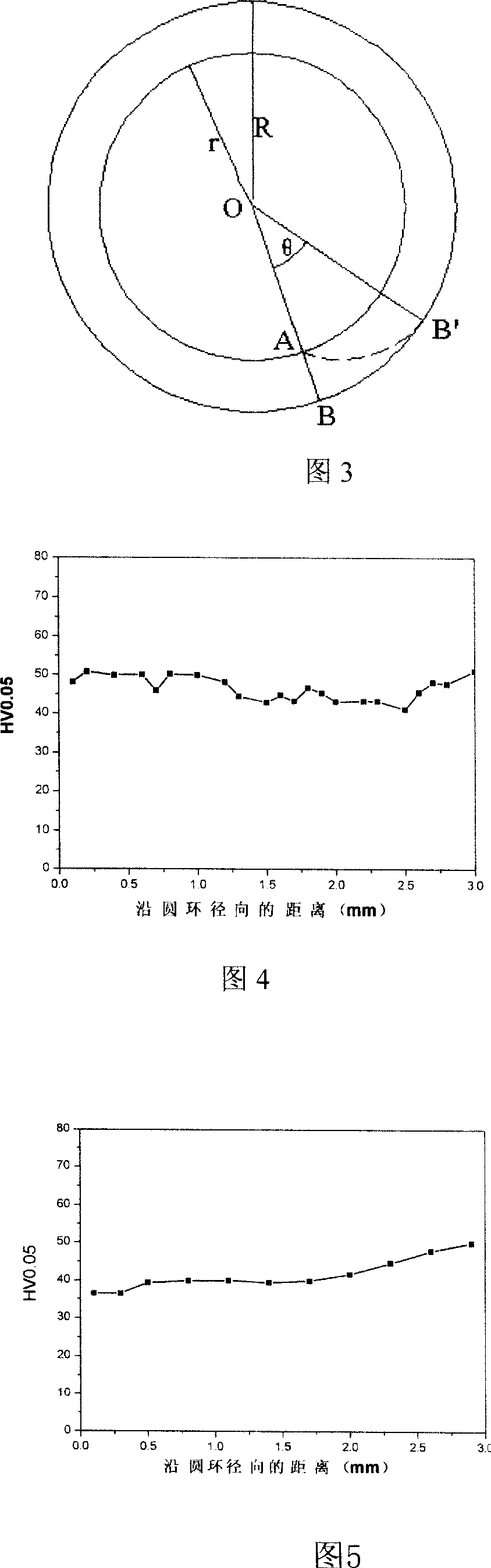

Forced plasticity deforming method for preparing super fine crystal material

InactiveCN1987400ASimple installationUniform and controllable deformationPreparing sample for investigationShearing deformationPressure load

The mold composed of base, sleeve and torsion nut is adopted in the invention. Opening circular ring sample is placed on the base; next, sleeve is loaded and pressed; then the torsion nut is mounted. The mold with sample being loaded is placed on the platform. Using pressure acts on the sleeve vertically. When pressure reaches to a prearranged value, the pressure load is kept, and torsion nut is twisted. Thus, under action of shearing force, the material generates even plastic deformation. Afterward, under action of friction force of inner and outer toroid mold drives torsion so as to generate shearing deformation to treat material. The method generates larger amount of deformation in theory, and magnitude of amount of deformation can be controlled.

Owner:SHANGHAI JIAO TONG UNIV

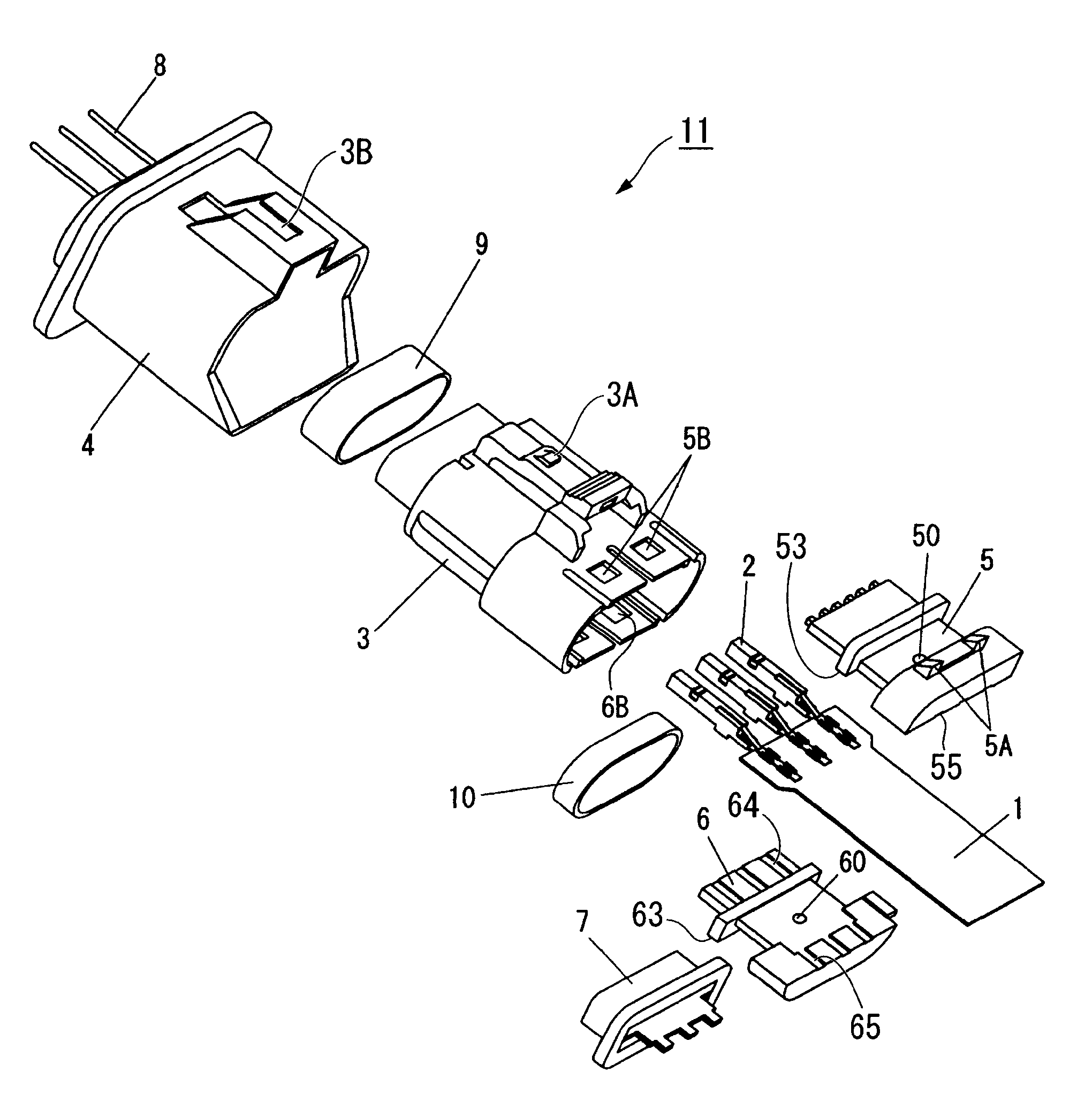

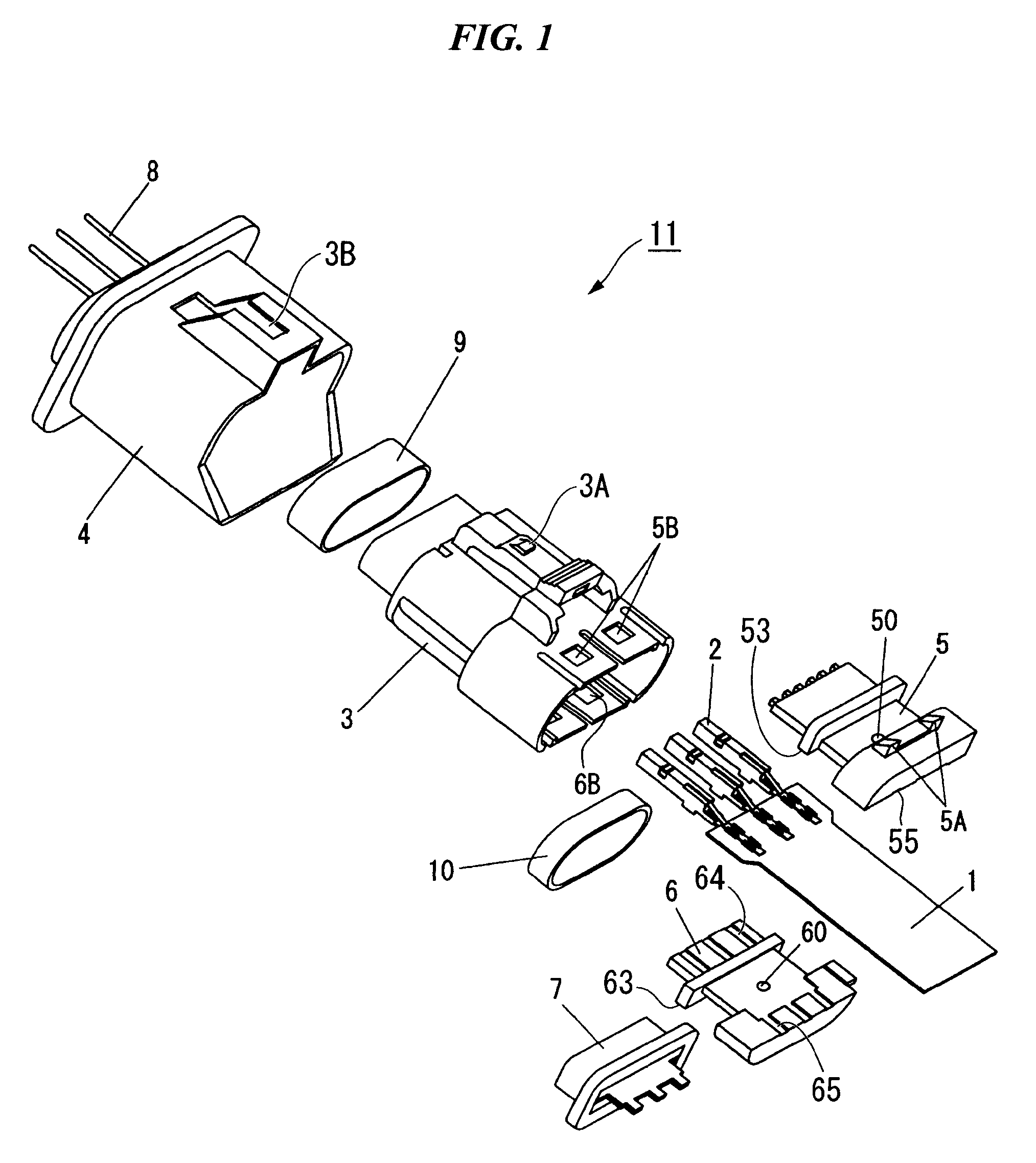

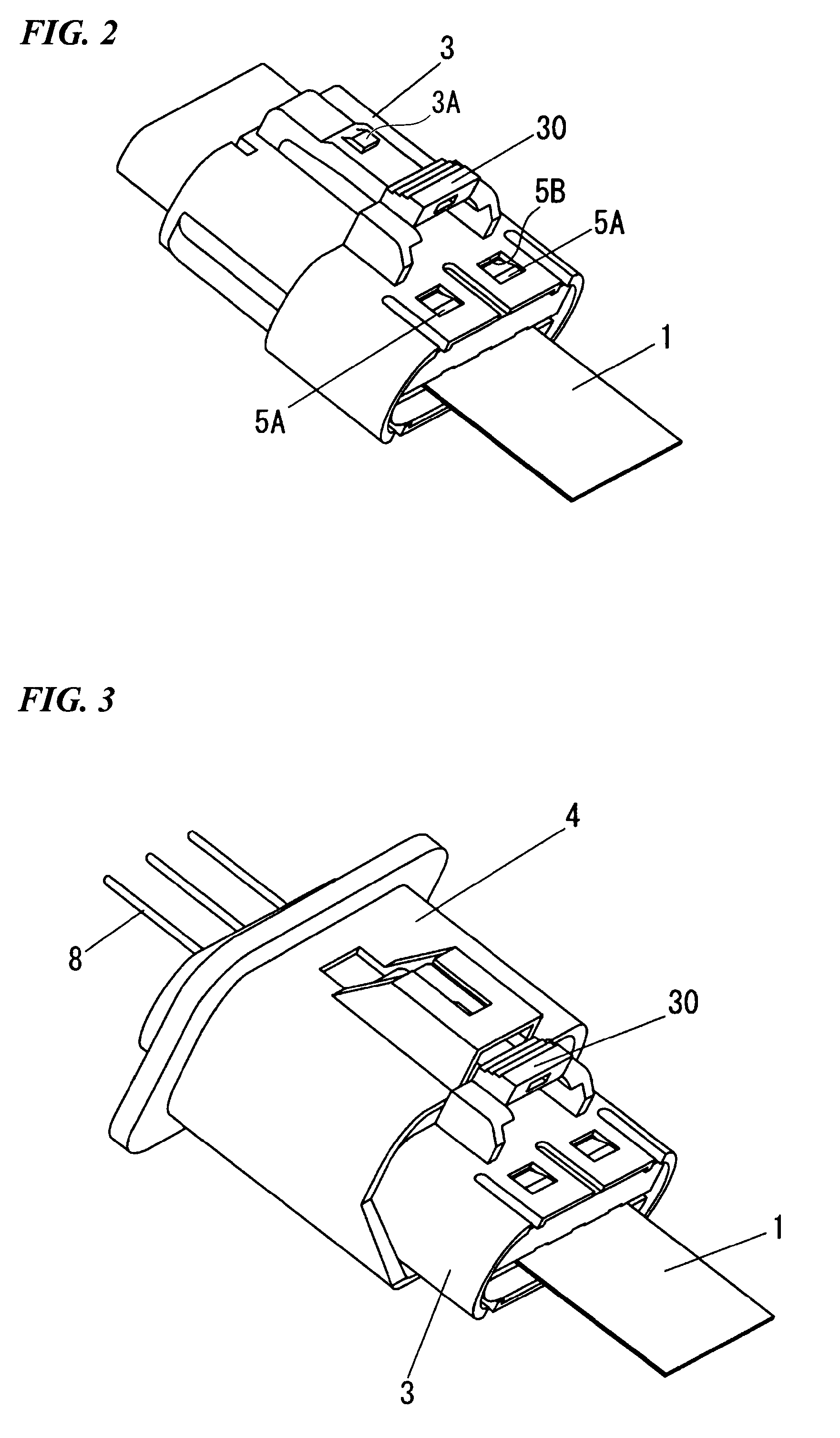

Waterproof connector for flexible substrate

InactiveUS7883359B2Not to impair spring effectInhibit deteriorationCoupling contact membersCouplings bases/casesEngineeringHot-melt adhesive

A waterproof connector for a flexible substrate includes: a flexible substrate which includes an insulating film with a conductive pattern formed thereon; a connection terminal joined to the conductive pattern at a terminal section of the flexible substrate; a housing which accommodates the connection terminal; a retainer which includes a vertically assembled pair of members, a forward end thereof holding the connecting section of the conductive pattern and the connection terminal and a rear end thereof surrounding the flexible substrate; a hot-melt adhesive provided on an inner circumference of the retainer at non-joint areas with the flexible substrate and provided on an outer circumference of the retainer so as to make the flexible substrate and the retainer adhere closely to each other; engaging member provided in the outer circumference of the retainer; and receiving member provided in the housing. The engaging member and the receiving member are engaged together to fix the retainer and the housing.

Owner:FUJIKURA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com