A method to reclaim and dispose waste secondary lithium ion battery

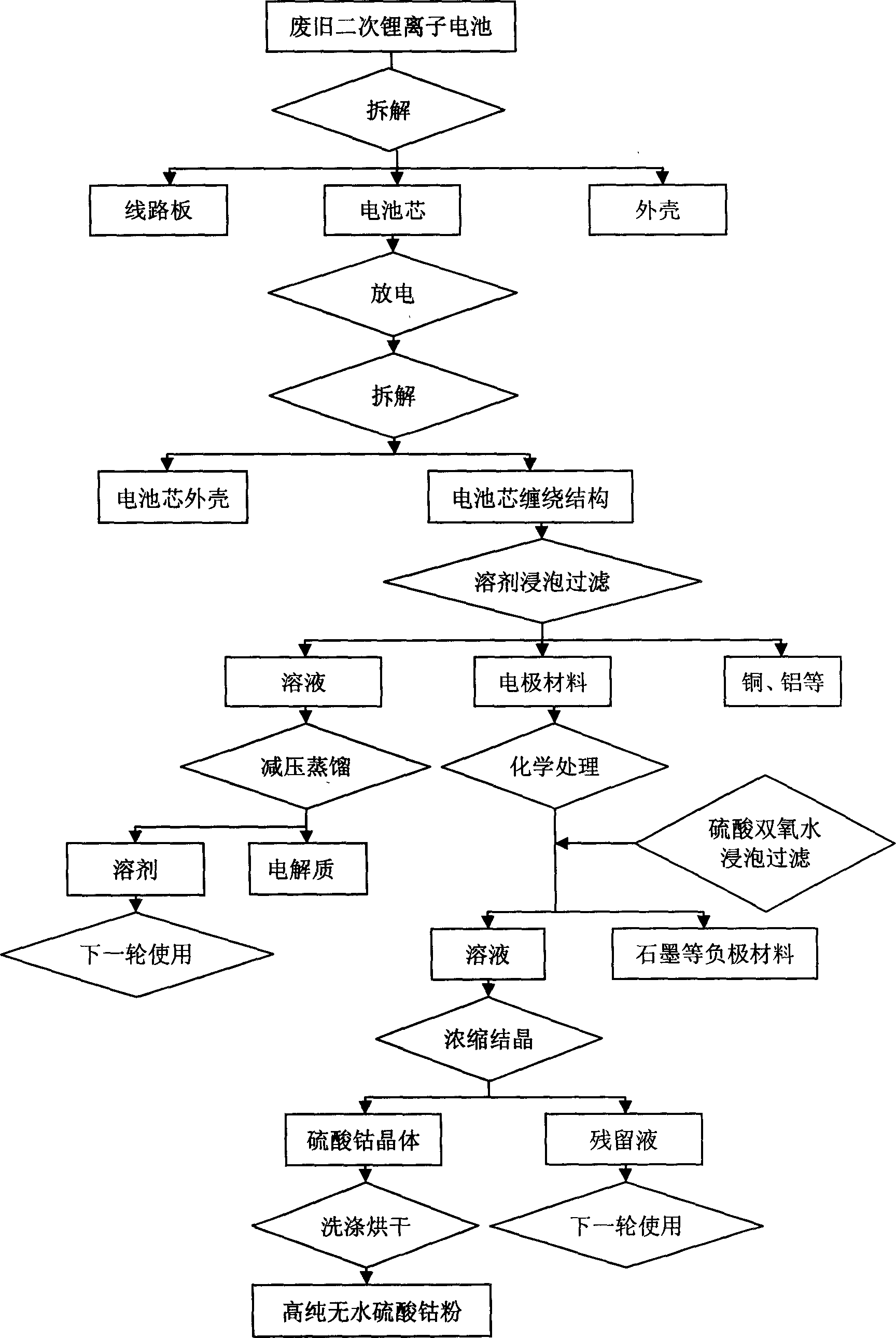

A lithium-ion battery, recycling technology, applied in battery recycling, electronic waste recycling, waste collector recycling, etc., can solve the problems of electrode material and carrier film shell metal adhesion, mechanical processing hazards, environmental pollution, etc., to achieve high efficiency and safety. The effect of clean industrialization, reduction of corrosion resistance requirements, and reduction of cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] A waste battery marked with the words "lithium-ion battery", model A4NN4229A, nominal voltage 3.7V, weight 19.6g, measured voltage 3.6V. Carry out manual disassembly to obtain the plastic case (identified as PC), circuit board and battery core. The battery core is put into the discharge circuit, the circuit resistance is 3.5 ohms, and the voltage drops to 0.3V after 20 minutes. The battery core is continued to be manually disassembled to obtain the battery core casing (aluminum) and the battery core winding structure. The battery core winding structure was placed in 20ml of propylene carbonate, soaked at 70°C for 30 minutes, the positive and negative electrode materials were soft and separated from the current collector foil, and the current collector copper foil, aluminum foil and insulating paper tape were taken out, and the black substance was obtained by filtration. The solution was distilled at 70°C under 0.5 atmospheric pressure environment, and 5ml of residual li...

example 2

[0034] A waste battery marked with the words "lithium-ion battery" and "Li-ion", model TJT-SA P802, nominal voltage 3.6V, weight 19.6g, measured voltage 0.1V. Mechanically cut to obtain a plastic casing (marked as PC), a circuit board and a battery core. The battery core does not need to be discharged, and is further mechanically cut directly to obtain the battery core casing (aluminum) and the battery core winding structure. Put the winding structure of the battery core into 20ml of dimethylacetamide, soak at room temperature, and assist with mechanical stirring. After 30 minutes, the positive and negative electrode materials are soft and completely separated from the current collector foil. Take out the current collector copper foil, aluminum foil and insulating paper tape , and filtered to obtain black matter. The solution was distilled at 50°C and 0.2 atmospheric pressure, and 6ml of residual liquid (a concentrated solution of electrolyte in dimethylacetamide) was collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com