Patents

Literature

46results about How to "Handling process safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

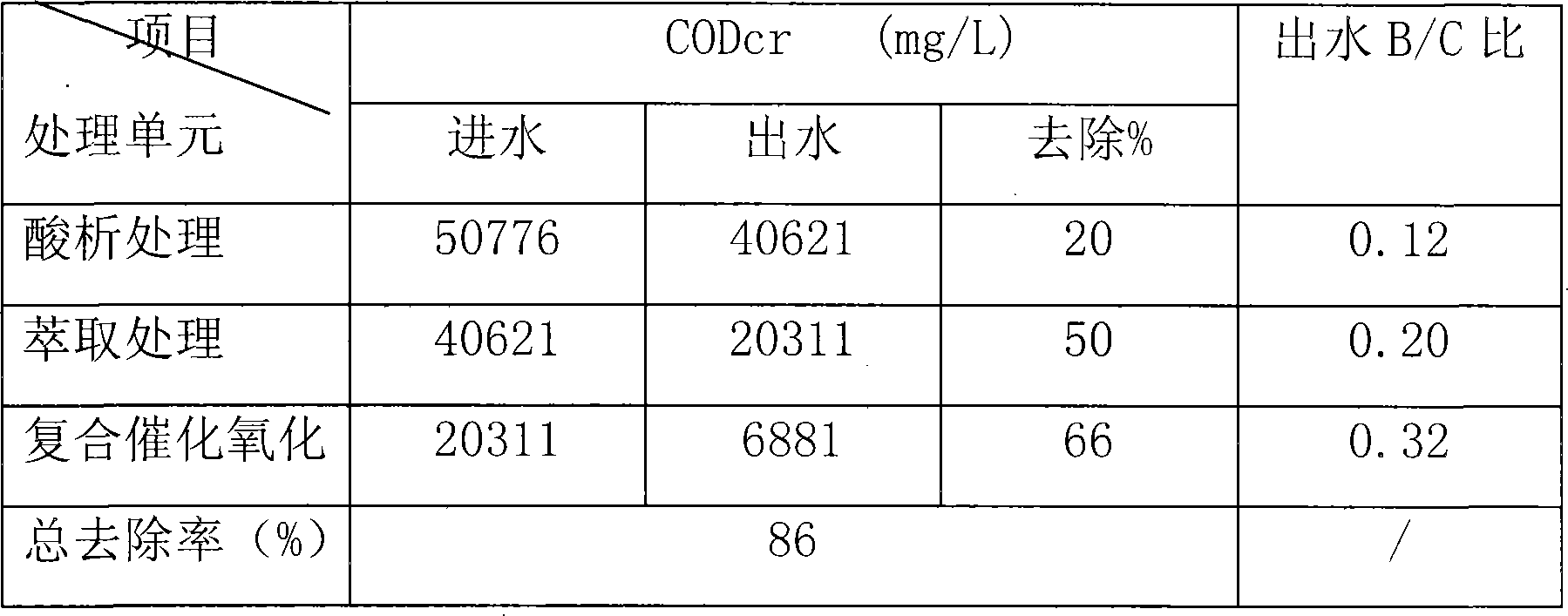

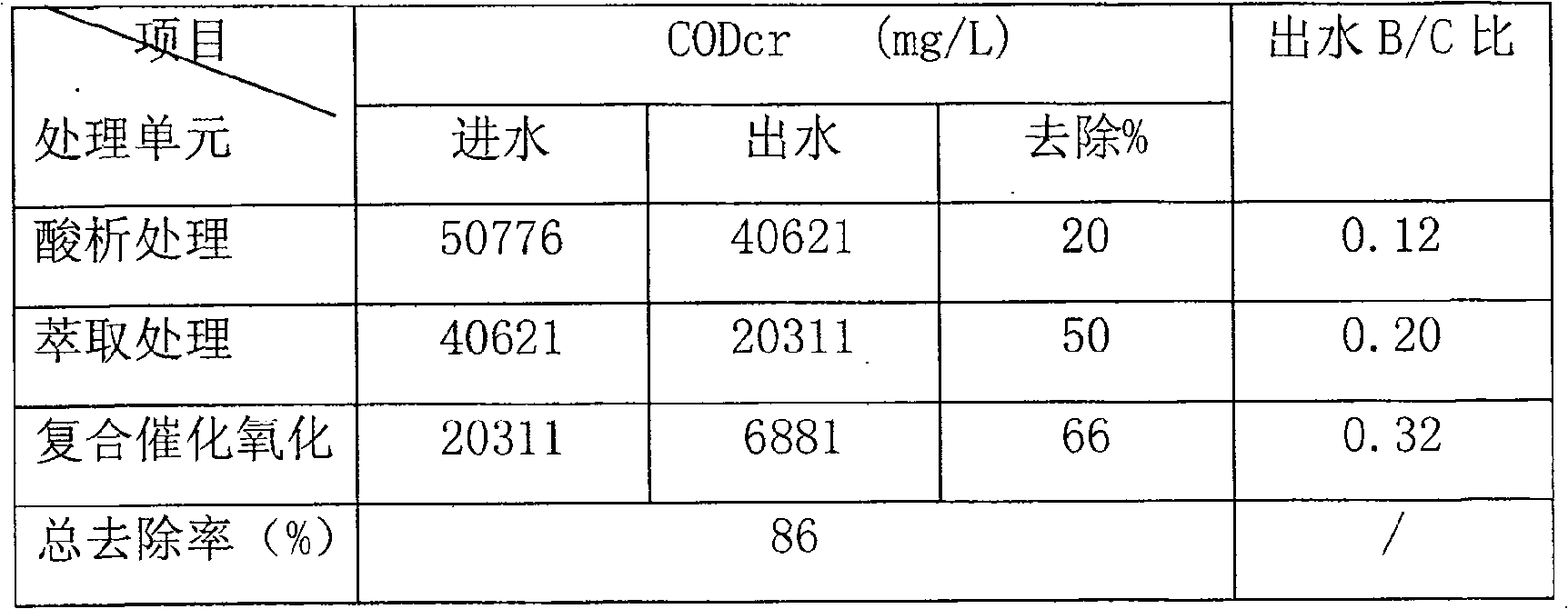

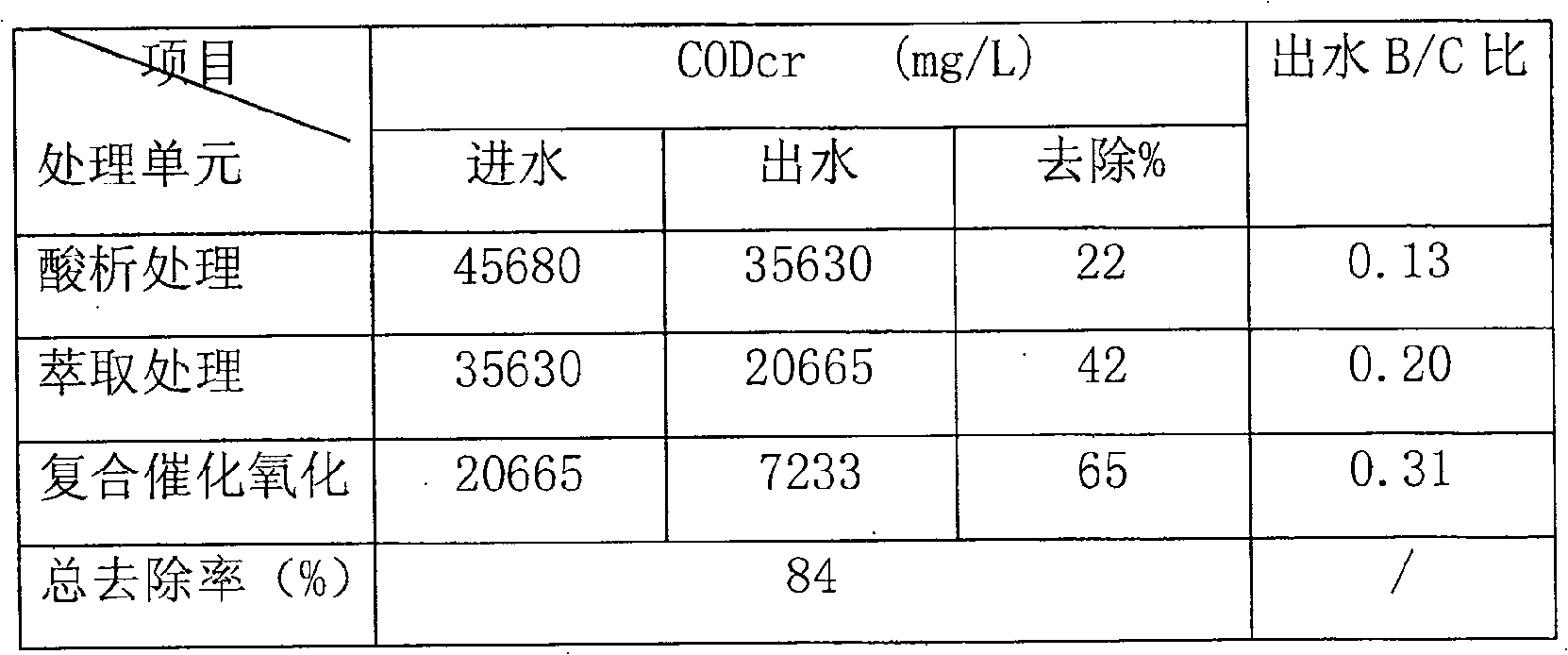

Chlopyrifos pesticides waste water treatment process

InactiveCN101172728APromote degradationImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCatalytic oxidationPendimethalin

The invention discloses a treatment process of waste water polluted by the pesticide of Dursban, and the process includes the procedures of acid eduction, complexation and extraction, Fenton oxidation and catalytic oxidation. The invention is characterized in that Dursban waste water and herbicide Pendimethalin waste water are comprehensively treated, thereby achieving the proposal of waste controlled by the waste, decreasing the load of organic pollutant being hard to be graded in the waste water, improving the biological degradability of the waste water, removing the pollutant from the waste water, and increasing the biochemical performance of the waste water. Besides, the invention has the advantages of safe and advanced technique, clean operation and low waste water treatment cost.

Owner:山东华阳农药化工集团有限公司

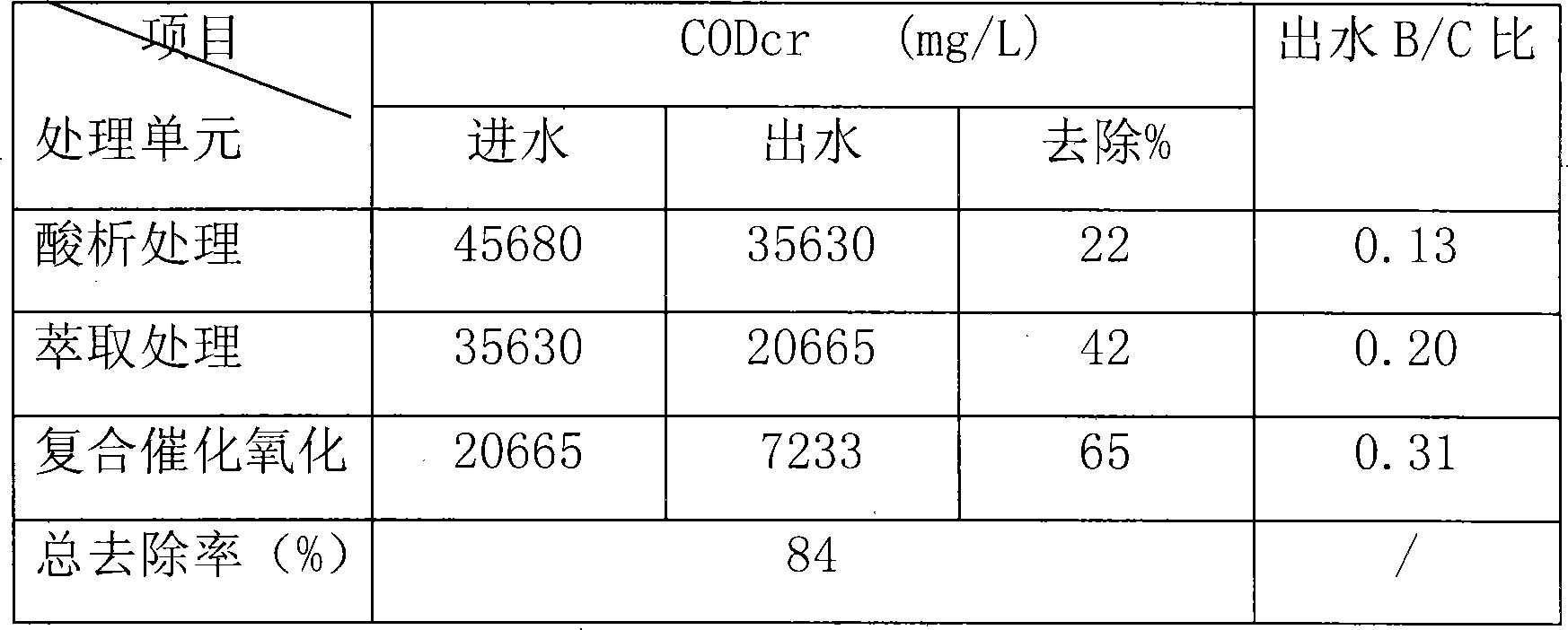

A method to reclaim and dispose waste secondary lithium ion battery

InactiveCN1964129AReduce cross contaminationReduce usageSolid waste disposalWaste accumulators reclaimingOrganic solventElectrical polarity

The related recovery and process method for waste secondary Li-ion cell comprises: separating cell shell, circuit board and cell core by mechanical means; discharging the core; then separating to obtain the shell and coiling material of cell core; putting the last one into some organic solvent to separate the cell polar material from collector foil, filtering to obtain the foil and active material for recovery by chemical way. With small investment, this invention is simple and safe and high yield.

Owner:BEIJING UNIV OF TECH

Method for preparing silk-fibroin-based water-absorbing material by grafting vinyl monomer

ActiveCN105924596AImprove the efficiency of graft copolymerization reactionHigh graft copolymerization efficiencyFermentationN-HydroxysuccinimideCarboxylic acid

The invention discloses a method for preparing a silk-fibroin-based water-absorbing material by grafting a vinyl monomer. Vinyl-containing carboxylic acid is grafted on the silk fibroin surface by the aid of EDC / NHS (1-ethyl-3-(3-dimethylaminopropyl)carbodiimide / N-hydroxysuccinimide), acrylamide (AM) and acrylic acid (AA) monomers are added, and a horseradish peroxidase / oxydol / acetylacetonate system is utilized to catalyze the silk fibroin-vinyl monomer graft copolymerization, thereby preparing the silk-fibroin-based water-absorbing material by a bioenzyme process. The method comprises the following steps: (1) preparing a silk fibroin solution; (2) grafting vinyl onto the silk fibroin surface by an EDC / NHS process; (3) catalyzing the silk fibroin-AM-AA graft copolymerization by using the horseradish peroxidase; and (4) forming the silk-fibroin-based water-absorbing material. Compared with the traditional process, the method has the advantages of high graft copolymerization efficiency and mild enzyme treatment conditions. The silk-fibroin-based composite water-absorbing material has the advantages of favorable water absorptivity, favorable water retention property and favorable biodegradability.

Owner:无锡市奥菲超细织物有限公司

Method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of laccase-TEMPO process

InactiveCN105734981AImprove grafting efficiencyIncrease the amount of graftingBiochemical fibre treatmentAnimal fibresQuinoneNitrogen oxides

The invention discloses a method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of a laccase-TEMPO process. Quinones active groups are generated through catalyzing tyrosine residual groups in real silks by laccase so that chitosan molecules are grafted on the real silks; then 2,2,6,6-tetramethylpiperidine-nitrogen oxide (TEMPO) is added and is used for catalyzing chitosan and tyrosine in the real silks to generate formyl groups, so that the grafting amount and bonding firmness of the chitosan on the real silks are increased, and the real silk fabric anti-crease and antibacterial finishing is realized. The method comprises the following specific steps of: (1) catalytically oxidizing the tyrosine residual groups in the real silks by the laccase; (2) taking the chitosan and the quinones active groups in the real silks to react; (3) catalyzing the real silks by laccase-TEMPO to graft the chitosan; and (4) washing the real silks with water and then treating. Compared with traditional chemical cross-linking-process vacuum fabric anti-crease and antibacterial finishing, the method has the advantages that the grafting efficiency of the chitosan is high, enzyme treatment conditions are moderate, the real silk fabric anti-crease and antibacterial effect is relatively good and the strength of the fabric is improved.

Owner:JIANGNAN UNIV

Dyeing and finishing method for durable press bombasine yarn dyed fabric

ActiveCN103451917ALittle strengthHigh surface finishBiochemical fibre treatmentDyeing processFiberCellulose

Belonging to the application technology field of yarn dyed fabric dyeing and finishing in the textile industry, the invention provides a dyeing and finishing method for a durable press bombasine yarn dyed fabric, and aims to solve the technical problems of easy fiber damage, undesirable antiwrinkling effect and poor washfastness, easy generation of formaldehyde residue and other ecological pollution. The method provided in the invention combines a chemical technique and a biological enzyme technique to carry out scouring and bleaching and dyeing on a bombazine fabric, that is to say, caustic soda, cellulose and catalase are taken for cotton fiber scouring and bleaching, soda ash, protease and lipase are taken for raw silk degumming and dyeing, and an active dye and laccase are employed to perform bombazine fiber dyeing and aftertreatment. Meanwhile, formaldehyde-free antiwrinkling resin is employed to perform liquid ammonia moist crosslinking on the fabric so as to improve the wrinkle resilience of the fabric. By applying the method provided in the invention to perform dyeing and finishing on the bombasine yarn dyed fabric, the fabric has a smooth surface and soft handfeel, also, the chroma of a dyeing waste liquid is reduced. When high antiwrinkling performance is acquired, the fabric strength is less reduced. The treatment process is safe and environment-friendly, thus being in line with the processing requirements of ecological textiles.

Owner:NANTONG XINLAI SILK GARMENTS

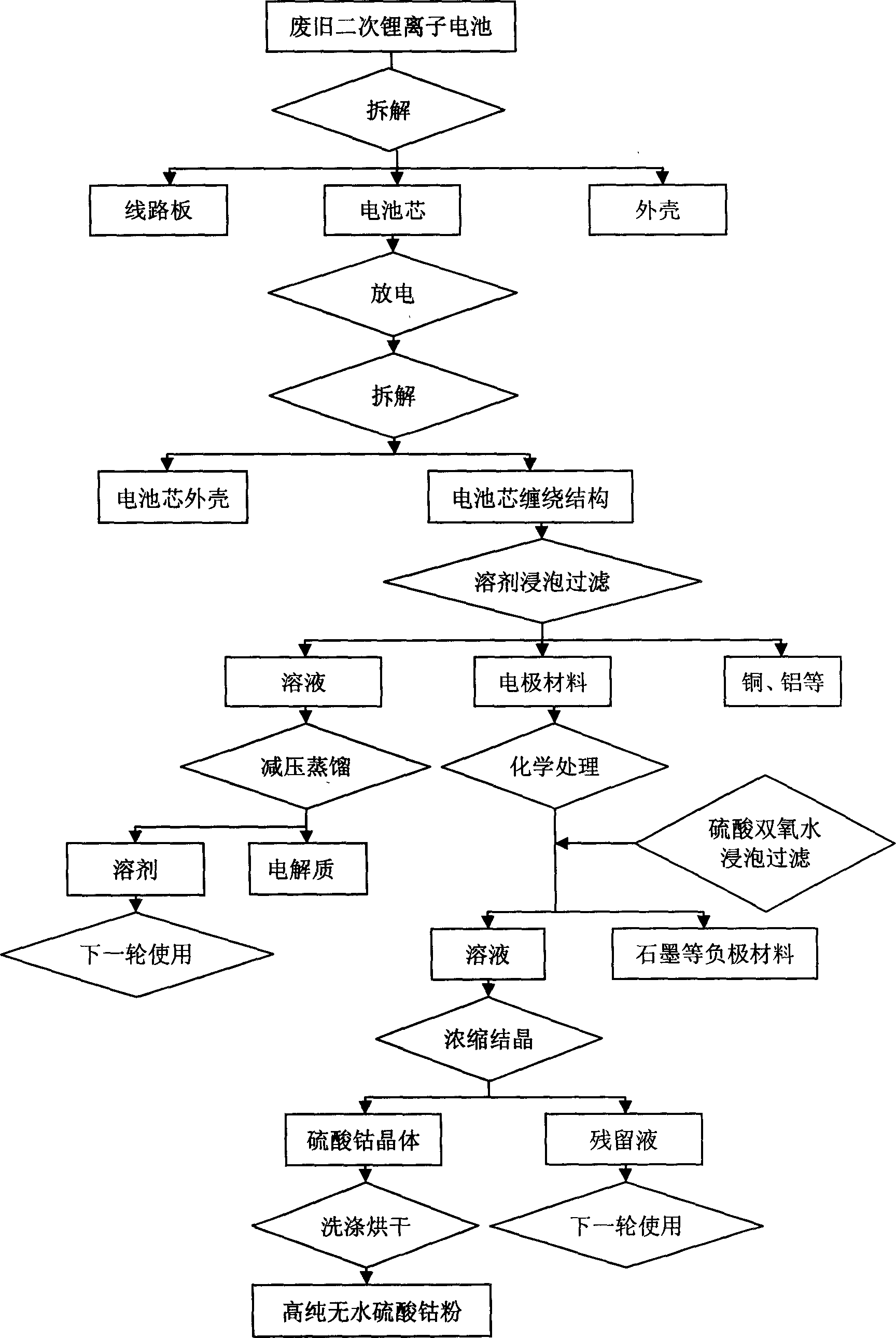

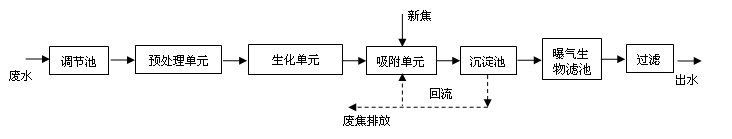

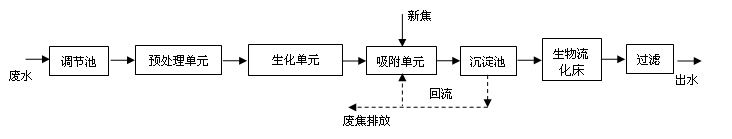

Method for treating coal chemical wastewater

InactiveCN102211839AEfficient treatment processHandling process safetyMultistage water/sewage treatmentWastewaterWater quality

The invention relates to a method for treating coal chemical wastewater, which comprises the following steps in turn: pretreatment, biochemical treatment with a first biochemical unit, adsorption treatment with an adsorption unit, sedimentation treatment with a sedimentation tank, and advanced biochemical treatment. The method solves the technical problems of high ozone electric power consumption, high cost and influence on yielding water quality because ozone is used for performing advanced treatment in the method for treating the coal chemical wastewater in the prior art. In the method for treating the coal chemical wastewater, the ozone is not used, resources are saved, and the yielding water quality can be well guaranteed, so the method is particularly suitable for treating the coal chemical wastewater.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

Method for preparing fibroin-base biomimetic mineralization material by grafting vinyl monomers

ActiveCN107099046AImprove the efficiency of graft copolymerization reactionHigh graft copolymerization efficiencyProtein solutionCarboxylic acid

The invention discloses a method for preparing a fibroin-base biomimetic mineralization material by grafting vinyl monomers. According to the method, carbodiimide (EDC) and N-hydroxy succinimide (NHS) are grafted with carboxylic acid containing ethylene and phenolic hydroxy groups on fibroin macromolecules, and horseradish peroxidase is utilized for catalyzing graft copolymerization of modified fibroin and acrylic acid monomers so as to obtain the fibroin-base biomimetic mineralization material. The method specifically comprises the following steps: (1) preparing a fibroin protein solution; (2) grafting carboxylic acid containing ethylene and phenolic hydroxy groups by virtue of an EDC / NHS method; (3) catalyzing graft copolymerization of the fibroin and the acrylic acid monomers; (4) forming a fibroin film protein; and (5) preparing the fibroin-base biomimetic mineralization material. Compared with the traditional methods, such as a chemical method or an ultraviolet irradiation, for triggering graft copolymerization of the fibroin and the acrylic acid monomers, the method has the advantages that the graft copolymerization efficiency of the fibroin and the acrylic acid monomers is high, the processing conditions are mild, and the prepared fibroin-base biomimetic mineralization material has excellent performance.

Owner:JIANGNAN UNIV

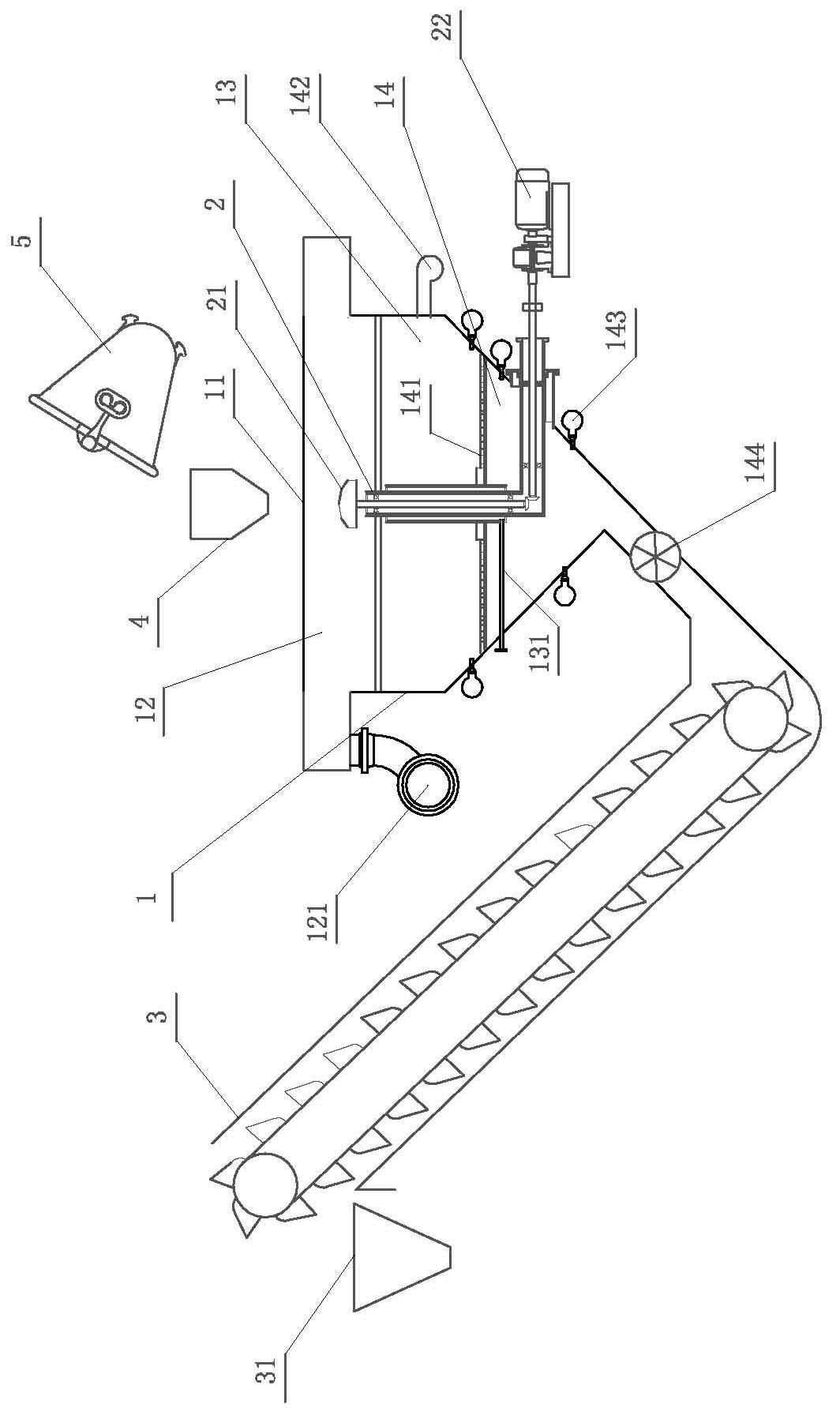

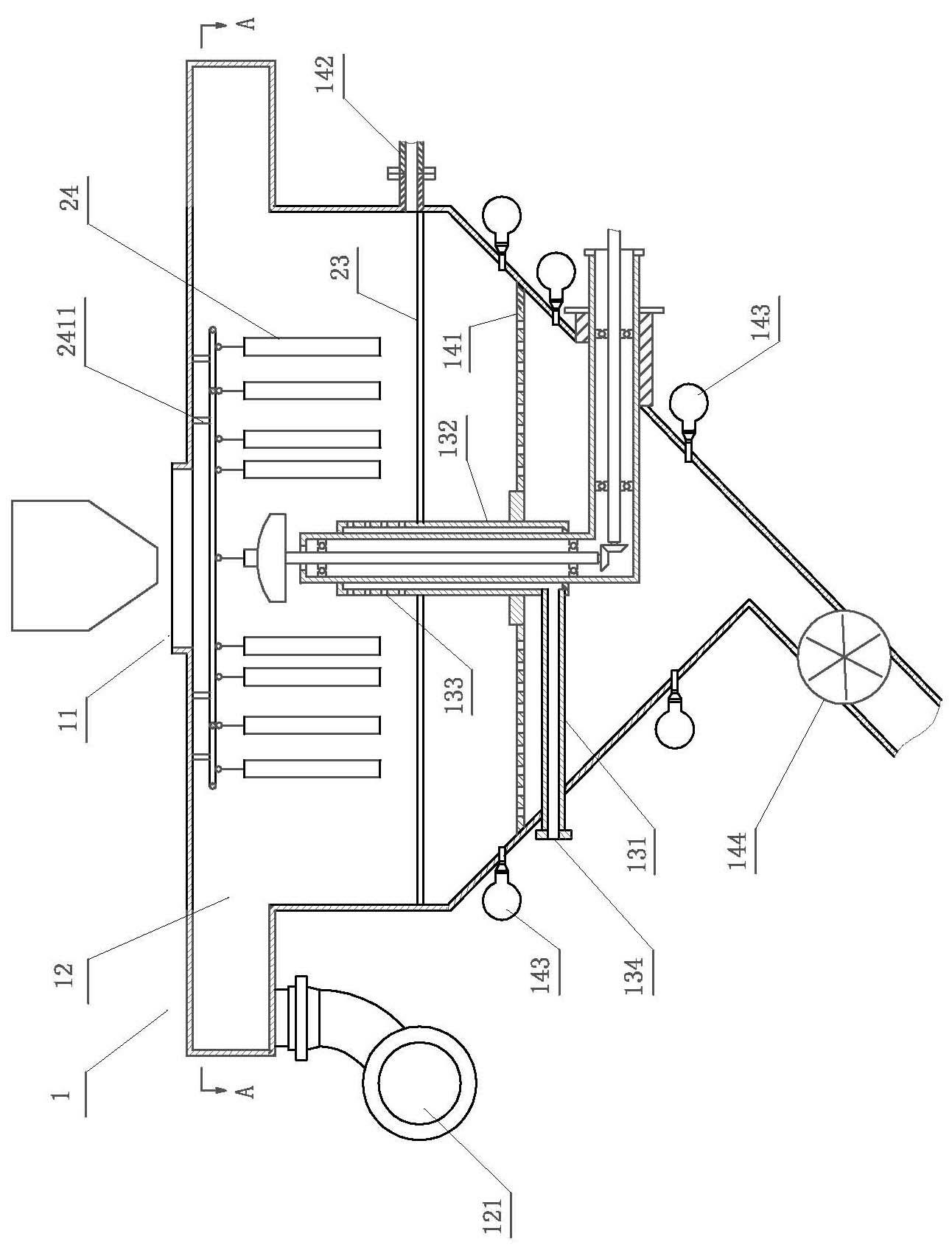

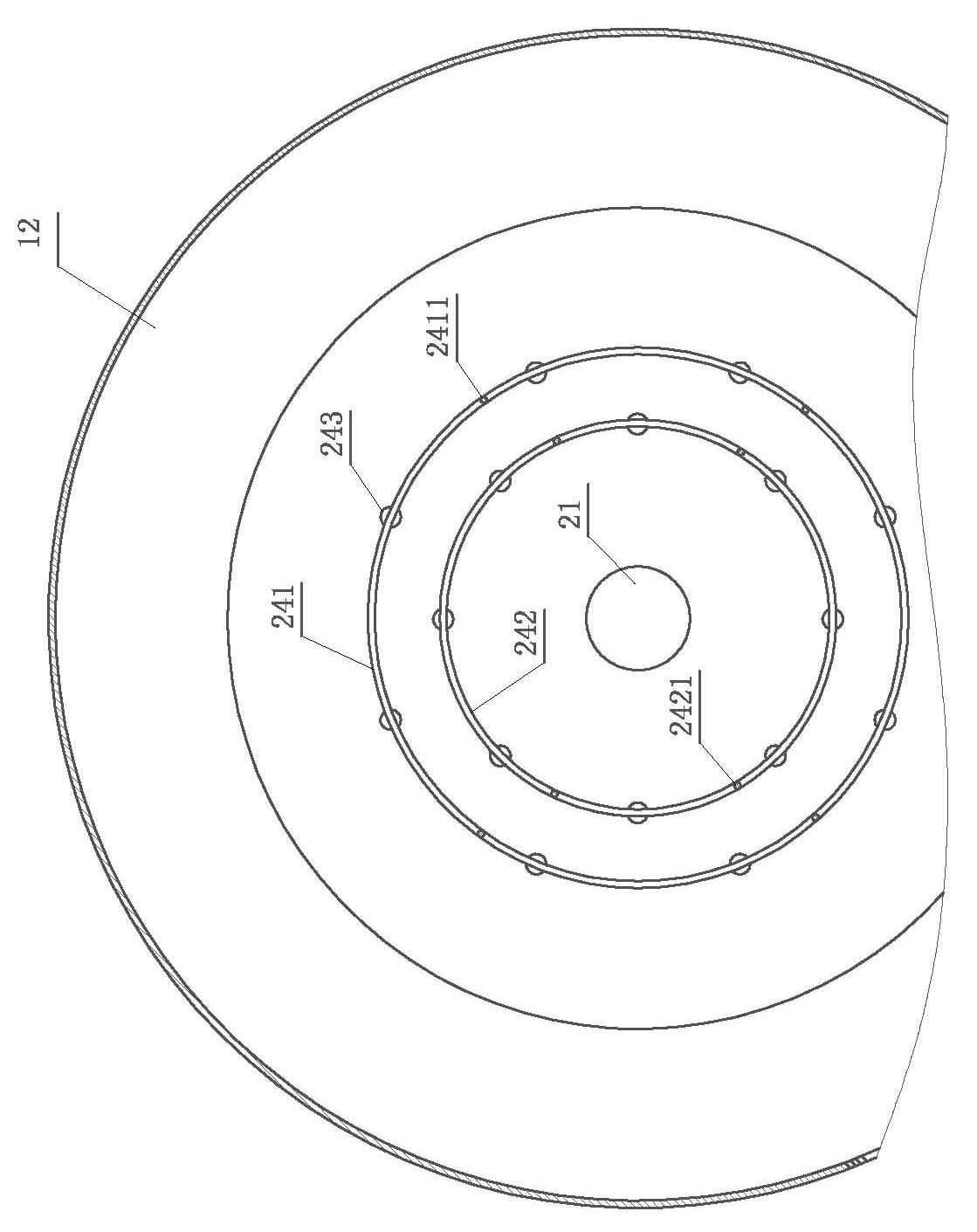

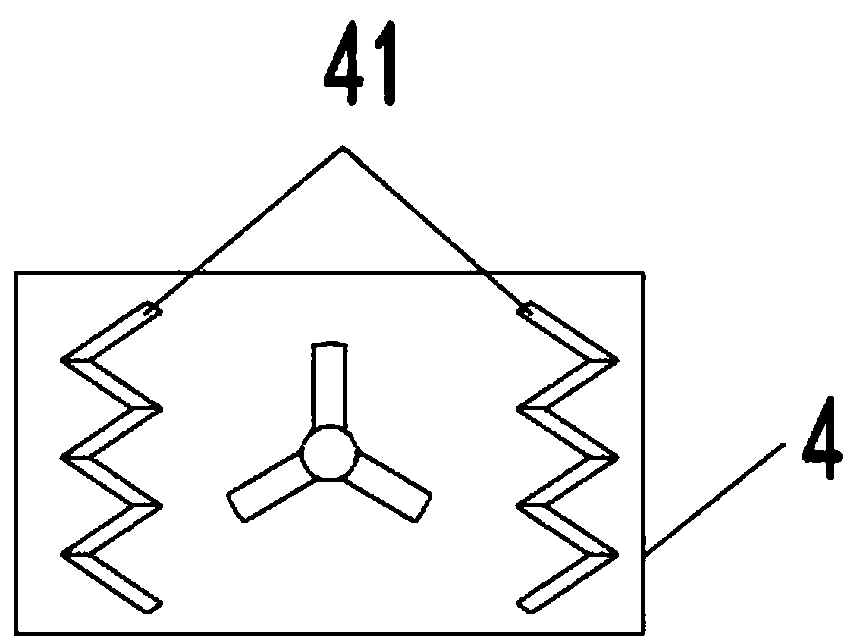

Ferronickel granulation method and ferronickel granulation device

The invention relates to a ferronickel granulation method, which includes the steps: treating high-temperature molten ferronickel by using a granulation device; collecting the high-temperature molten ferronickel into a molten iron jar and conveying the molten iron jar to a tipping device through conveying equipment; starting the granulation device and leading a horizontally rotating granulation disc to be 500-1000 revolution per minute; stating the tipping device to pour the high-temperature molten ferronickel into a hopper with an outlet positioned above the horizontally rotating granulationdisc; dropping the high-temperature molten ferronickel into the horizontally rotating granulation disc in the granulation device, centrifugally sputtering and granulating the high-temperature molten ferronickel by the horizontally rotating granulation disc to form high-temperature molten ferronickel grains, and crushing and cooling the high-temperature molten ferronickel grains through jet streamto form smaller ferronickel grains; dropping the ferronickel grains into a water quenching bin and forming fine ferronickel grains by means of water quenching; dewatering the fine ferronickel grains by a lifting dewaterer and feeding the fine ferronickel grains into a fine ferronickel grain collecting bin. The fine ferronickel grains generated by the ferronickel granulation method are small in grain size, and steelmaking time can be shortened.

Owner:唐山市嘉恒实业有限公司

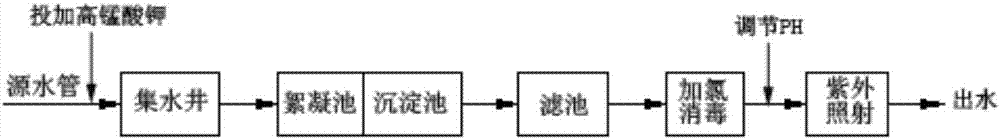

Treatment method for controlling halogenated disinfection byproducts in drinking water

InactiveCN107879522AReduce precursorsGood removal effectWater contaminantsTreatment involving filtrationChloramine BFiltration

The invention discloses a treatment method for controlling halogenated disinfection byproducts in drinking water. The treatment method comprises the following steps: (1) feeding source water into a water collection well through a source water tube, and adding potassium permanganate for preoxidation from the water outlet end of the source water tube, wherein the addition amount of the potassium permanganate is 0.5-2.0mg / L; (2) collecting water from the water collection wheel through a water collection pump room, coagulating with a coagulant, performing precipitation and filtration, and disinfecting the filtered water with chlorine or chloramines; and (3) adjusting the pH value of a disinfected water sample to 7-10, performing radiation treatment with ultraviolet light of which the wavelength is 150-280nm, and implementing light degradation by virtue of absorption properties of disinfection byproducts at the wave band. By adopting the treatment method disclosed by the invention, teratogenesis toxic substances in effluents are effectively reduced.

Owner:TIANJIN UNIV

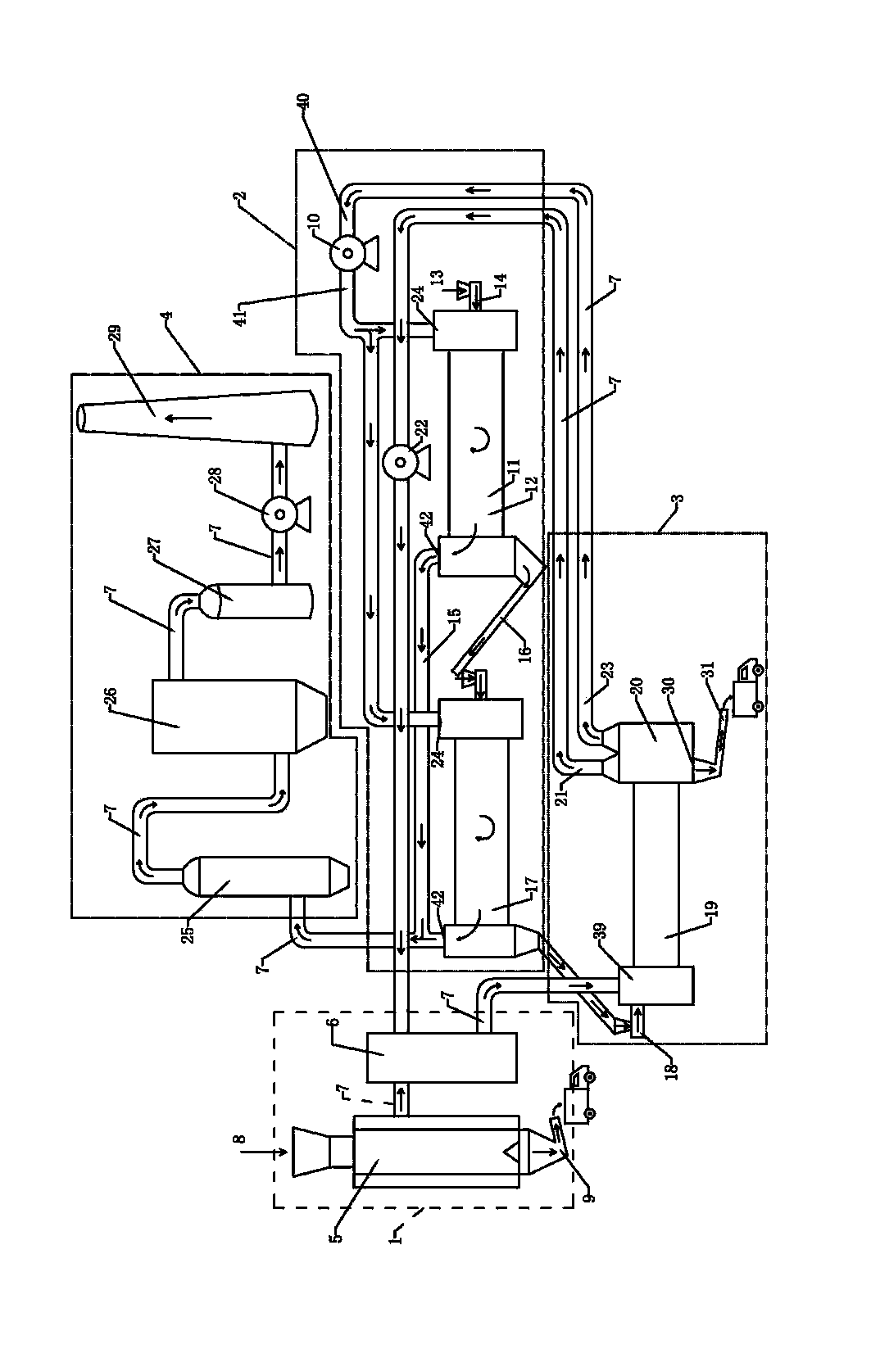

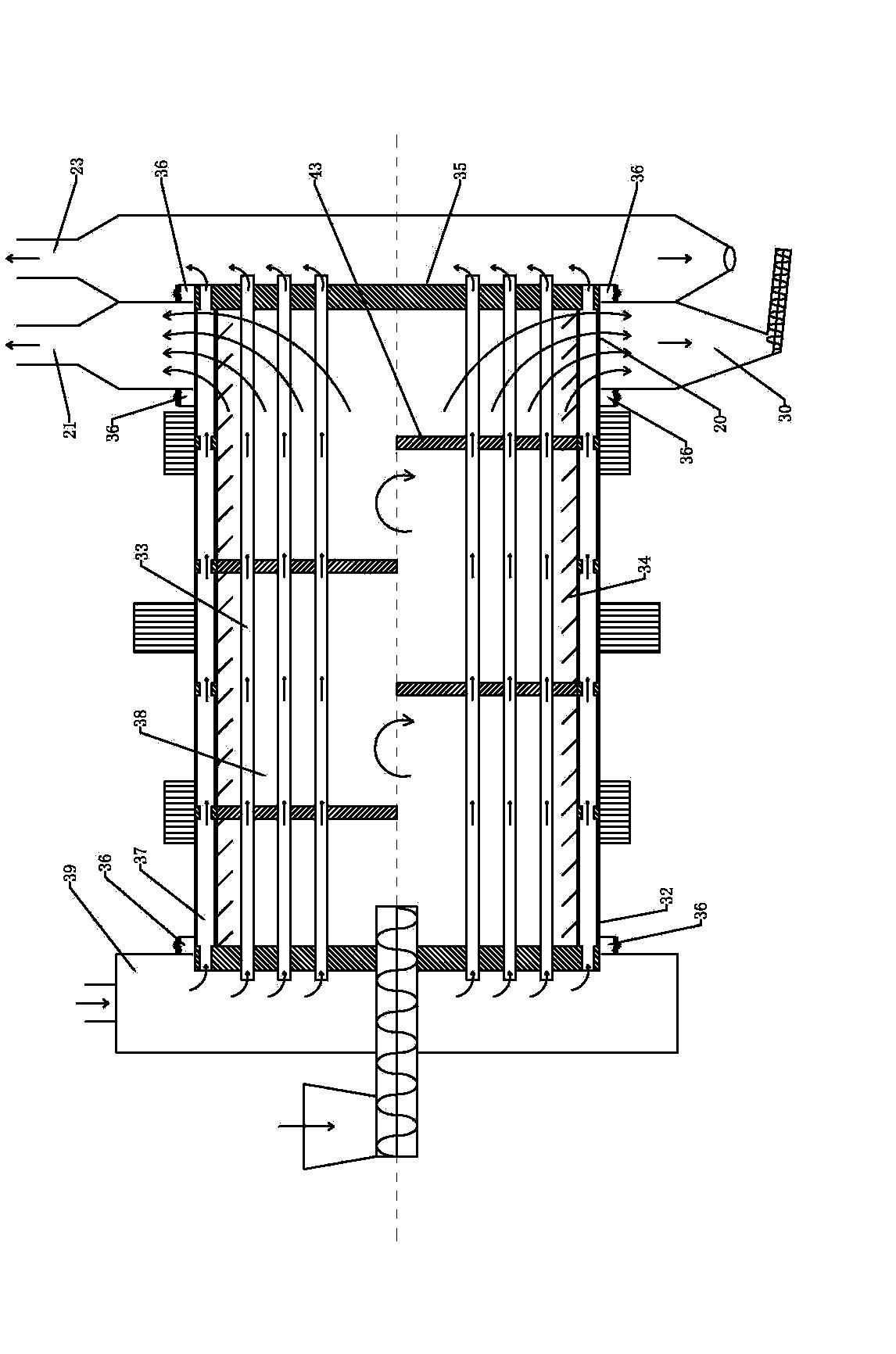

Sludge drying/pyrolysis/gasification/incineration integrated treatment system

InactiveCN103666504AGood energy saving effectSimple equipment structureSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisGas generatorPyrolysis

The invention discloses a sludge drying / pyrolysis / gasification / incineration integrated treatment system which comprises a burning system, a drying system, a pyrolysis and gasification system and a fume cleaning system, wherein the burning system comprises a gas generator and an incinerator; the drying system comprises a blower and Stage 1-5 drying machines; the pyrolysis and gasification system comprises a pyrolysis gasifier and a separator; and the fume cleaning system comprises a dedusting devulcanizer, a draught fan and a chimney which are respectively connected with each other through pipelines. The integrated treatment system disclosed by the invention has the characteristics of high safety and reliability, energy saving, emission reduction, low carbon, environment friendliness, low operating cost and the like, and realizes reduced, stabilized, harmless and recycling treatment.

Owner:浙江绍兴鸿杰节能环保科技有限公司

Method for immobilizing catalase with enzymatic silk fibroin film

ActiveCN103667239AHigh catalytic efficiencyReduce dosageOn/in organic carrierCatalytic oxidationTyrosinase

The invention discloses a method for immobilizing catalase with an enzymatic silk fibroin film, belongs to the field of textile biotechnology, aims to provide an environmental-friendly method for immobilizing catalase with the silk fibroin film, and expands the application of an enzymatic silk fibroin film material serving as a biosensor. Due to the catalytic oxidation function of tyrosinase, the silk fibroin film is grafted with catalase, so that not only is the immobilization between enzyme molecules and silk fibroin realized, but also the application performance of the silk fibroin film serving as a catalase carrier is improved. The method particularly comprises the technological processes such as preparation of a silk fibroin solution and the silk fibroin film, grafting enzymatic silk fibroin with catalase, washing with water, and carrying out aftertreatment. The enzymatic silk fibroin film prepared by the invention is used with a dissolved oxygen meter in a combined manner, so as to not only evaluate catalase contents in different systems, but also ensure repeated circulatory use; the properties of strength, elasticity and the like of the silk fibroin film are improved.

Owner:JIANGNAN UNIV

Method for preparing sericin film material based on enzymatically grafted vinyl monomer

ActiveCN106977671AImprove reaction efficiencyHigh graft copolymerization efficiencyPeptidesFermentationSolubilityProtein solution

The invention discloses a method for preparing a sericin film material based on an enzymatically grafted vinyl monomer. The method aims at catalyzing the graft copolymerization of sericin and a vinyl-containing ester monomer through an enzyme, decreasing the water solubility of the sericin and improving the moldability of the sericin film material. A phenolic hydroxyl containing primary amine compound is grafted onto sericin protein through a transglutaminase method; the reactivity of the sericin is improved; afterwards, the graft copolymerization of the sericin and the vinyl-containing ester monomer is catalyzed by means of horseradish peroxide; the sericin film material is prepared. The method comprises the following specific processes and steps of (1), preparing a sericin protein solution; (2), enzymatically making the sericin graft the phenolic hydroxyl containing primary amine compound through the enzyme; (3), catalyzing the graft copolymerization of the sericin and the vinyl-containing ester monomer through the enzyme; (4), molding the sericin film material. In comparison with a chemical method or an ultraviolet irradiation method and the like by which the graft copolymerization of the sericin and the vinyl monomer is initiated, the method provided by the invention is high in graft copolymerization efficiency; the enzyme treatment condition is mild; the moldability of the sericin film material is ameliorated.

Owner:JIANGNAN UNIV

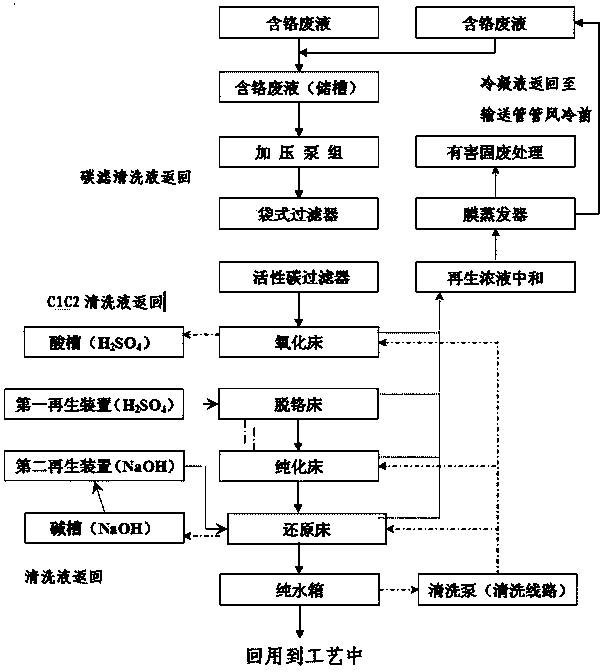

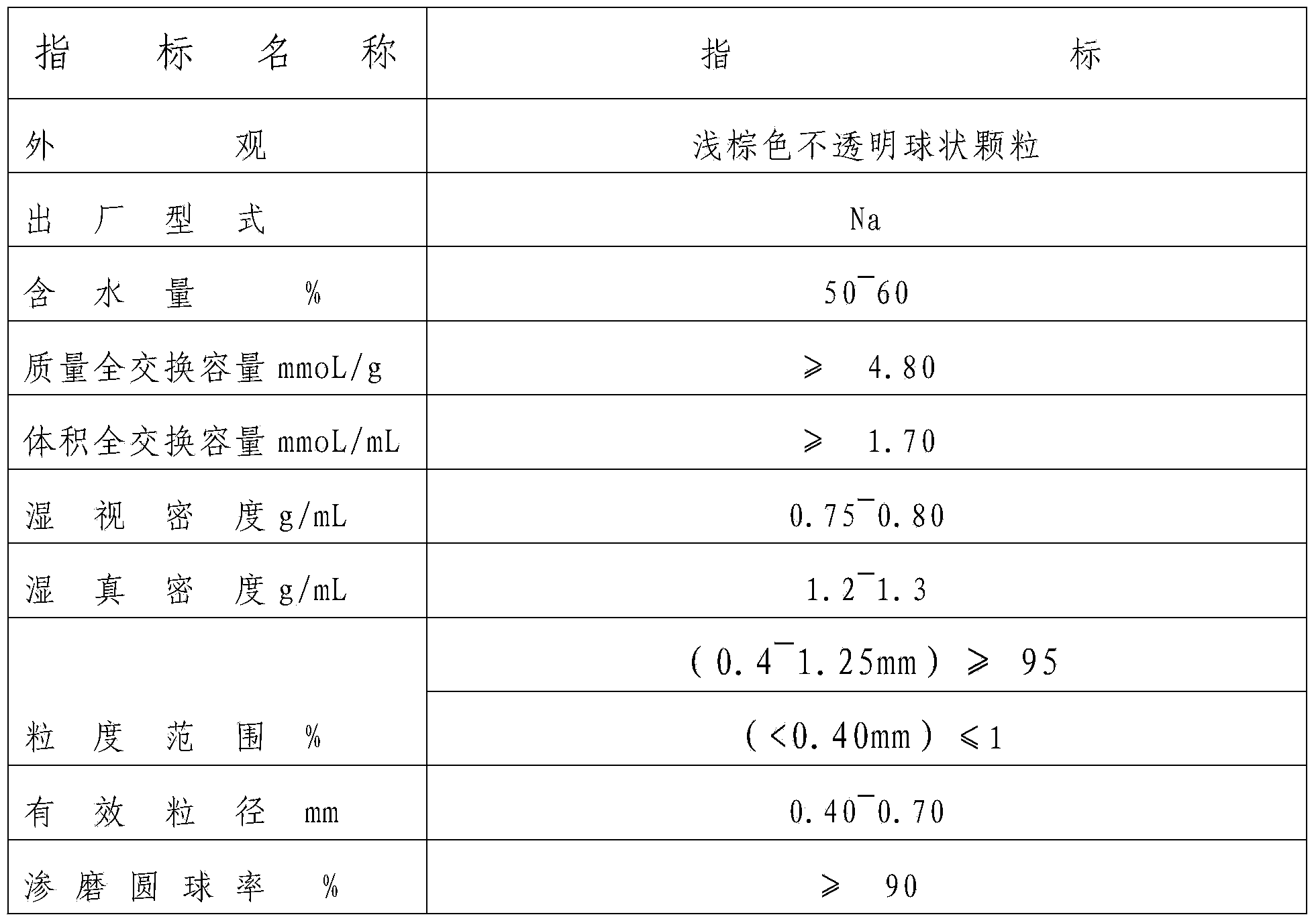

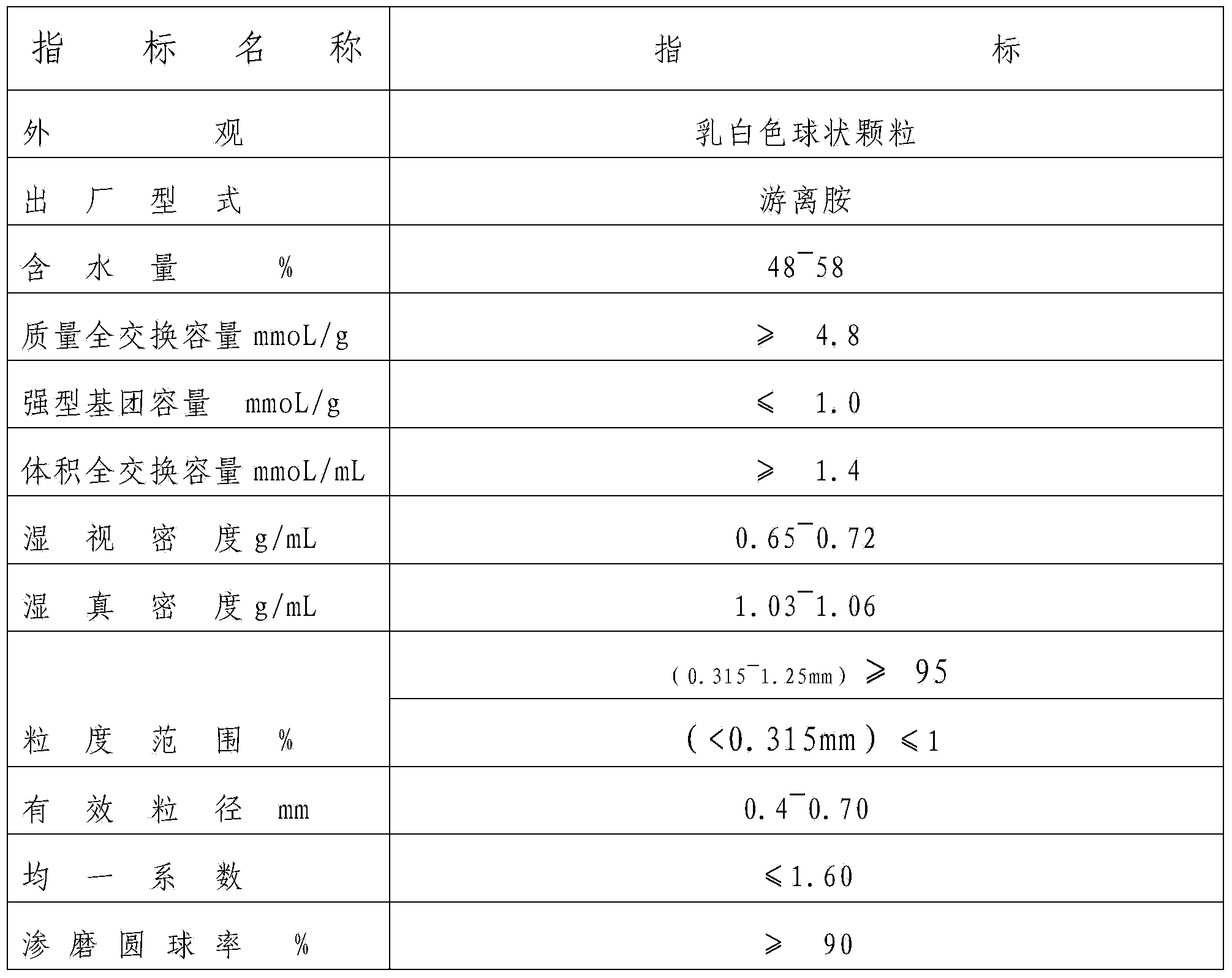

Comprehensive harmless treatment and recycling method for chromium-containing wastewater on electrolytic tinplate production line

InactiveCN104163517AHandling process safetyReliable processWater contaminantsWaste water treatment from metallurgical processProduction lineWastewater

The invention discloses a comprehensive harmless treatment and recycling method for chromium-containing wastewater on an electrolytic tinplate production line. The method comprises the following treatment steps: (1) inputting the chromium-containing wastewater into a filtering device for filtering; (2) inputting the filtered wastewater into an oxidization bed for treating; (3) inputting the wastewater treated by the oxidization bed into a dechromization bed for treating; (4) inputting the wastewater treated by the dechromization bed into a purification bed for treating; and (5) inputting the wastewater treated by the purification bed into a reduction bed for treating. The comprehensive harmless treatment and recycling method has the beneficial effects of safe and reliable treatment process, easiness in running and maintenance, reasonable equipment design, superior performance, high controllability, high automation degree, attractive and elegant layout of equipment, convenience in operation and management, reasonable investment and running cost and low treatment cost.

Owner:GUANGZHOU PACIFIC TINPLATE

Cocoon cooking and silk opening processing method

PendingCN111850702AReduce energy consumptionReduce pollutionDe-gumming silkPolymer scienceSILK SERICIN

The invention discloses a cocoon cooking and silk opening processing method. The processing method comprises the following steps: firstly performing impregnation loosening treatment on mulberry silkworm cocoons in a low-concentration a soda ash solution; then performing enzyme treatment on the mulberry silkworm cocoons in a mixed solution of protease and lipase; secondly, after washing the mulberry silkworm cocoons with water, peeling the cocoons to obtain cocoon caps; then opening the cocoon caps and then processing the opened cocoon caps into silk pockets; and finally, performing drying. Themethod can realize cocoon cooking processing under mild conditions; a cocoon shell structure is loosened, and thus, the removal effect of sericin components in mulberry silkworm cocoons is enhanced,the chemical oxygen demand (COD) value of cocoon cooking waste liquid is reduced, and the processing of floss silk products based on energy saving and emission reduction is realized.

Owner:徐州光彩丝绵制品有限公司

Chlopyrifos pesticides waste water treatment process

InactiveCN100546926CPromote degradationImprove biodegradabilityMultistage water/sewage treatmentWater/sewage treatment by neutralisationChlorpyrifosCatalytic oxidation

The invention discloses a process for treating chlorpyrifos pesticide wastewater, which comprises the process steps of acid analysis, complex extraction, Fenton oxidation, catalytic oxidation and the like. The present invention selects chlorpyrifos wastewater and the herbicide pendimethalin wastewater for mixed treatment, achieves waste treatment with waste, reduces the load of refractory organic pollutants in waste water, improves the biodegradability of waste water, and removes pollutants in waste water, For the purpose of improving the biodegradability of wastewater, the process is safe, advanced, clean and has low wastewater treatment cost.

Owner:山东华阳农药化工集团有限公司

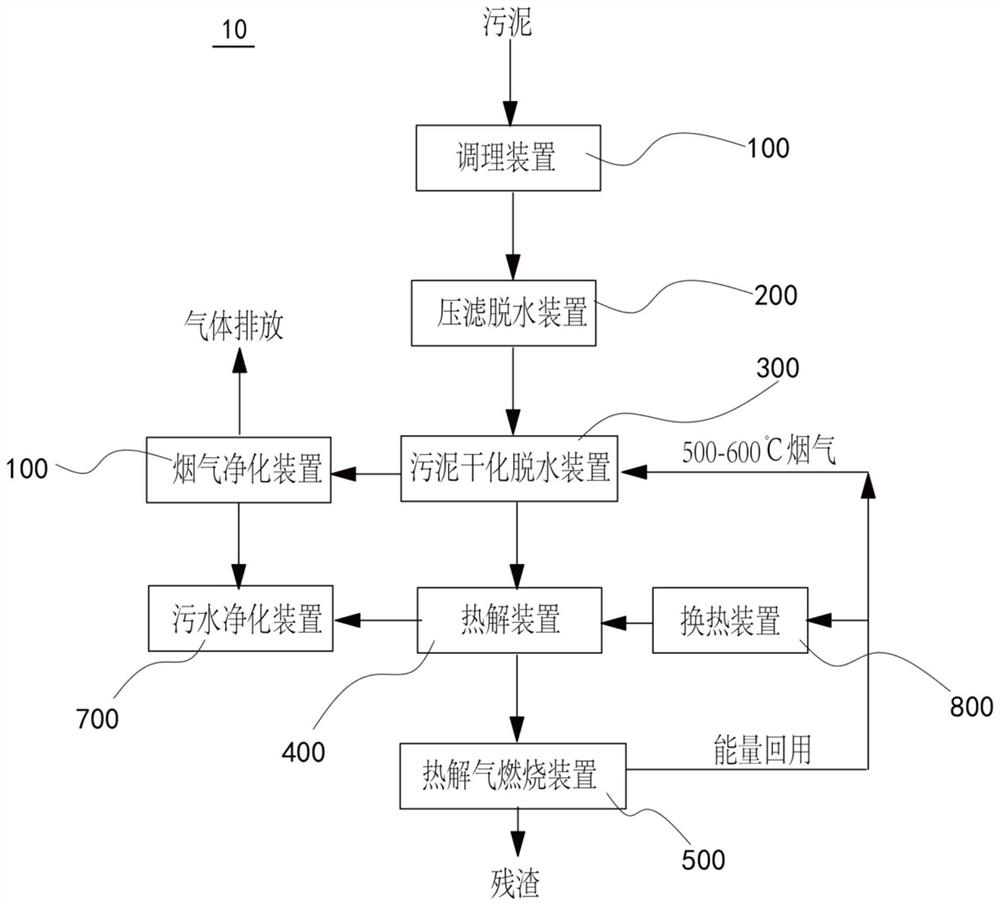

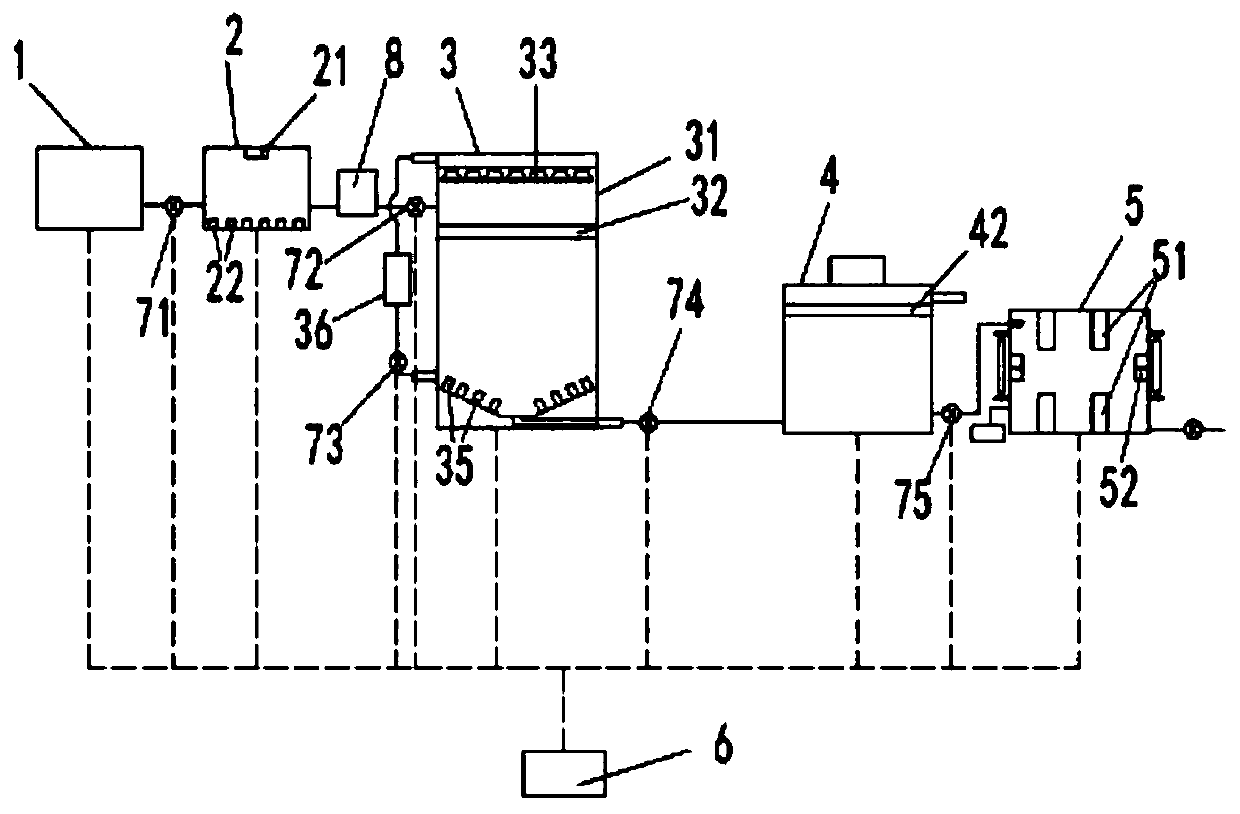

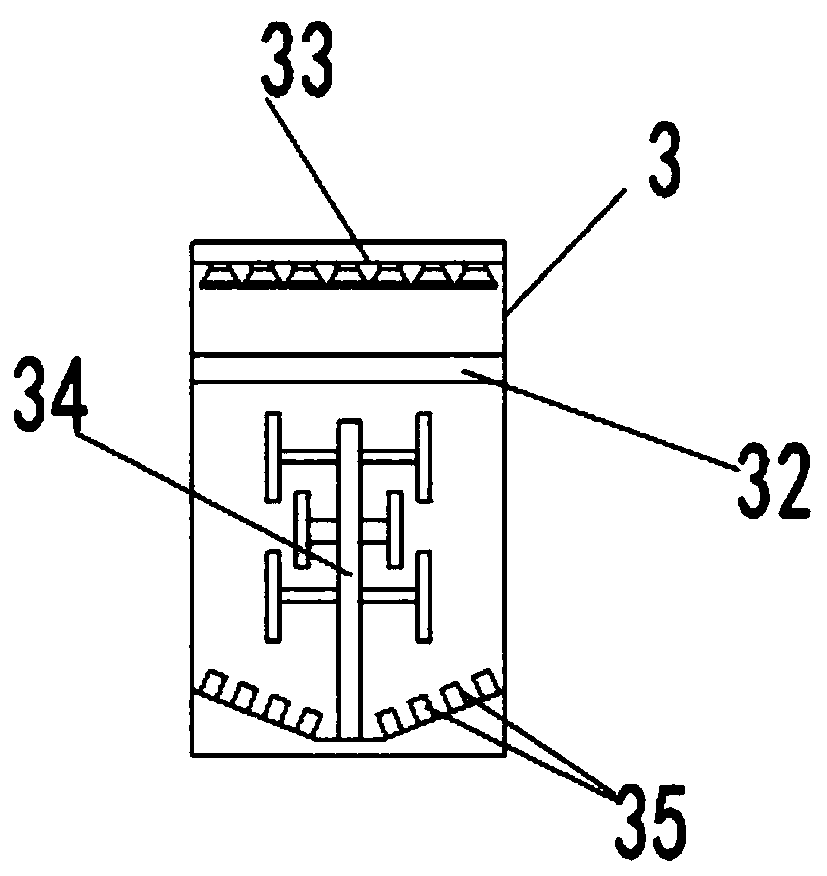

Sludge deep dehydration coupled biomass pyrolysis system and method thereof

PendingCN111960632AAchieve reductionAchieve stabilizationSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisFlue gasSludge

The invention discloses a sludge deep dehydration coupled biomass pyrolysis system and a method thereof. The sludge deep dehydration coupled biomass pyrolysis system comprises a sludge conditioning device, a filter pressing dehydration device, a sludge drying dehydration device, a pyrolysis device, a pyrolysis gas combustion device and a flue gas purification device, wherein the sludge conditioning device, the filter pressing dehydration device, the sludge drying dehydration device, the pyrolysis device and the pyrolysis gas combustion device are sequentially communicated, and the flue gas purification device is connected with the sludge drying dehydration device. The sludge deep dehydration coupled biomass pyrolysis system has the advantages of sludge dehydration reduction, full utilization of a heat value, few technological processes and low operation cost, can realize recycling of pyrolysis productivity, meets the national requirements of sludge reduction and harmless treatment, andachieves the goal of resource utilization.

Owner:SHENZHEN HONGKONG INSTITUTION OF IND EDUCATION & RES ENVIRONMENTAL ENG TECH CO LTD +1

Integrated control aquaculture wastewater combined treatment technology and device

ActiveCN109650617AHandling process safetyNon-toxic treatment processWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsDecompositionFiltration

The invention discloses an integrated control aquaculture wastewater combined treatment technology and device. The technology includes the following step of S1, pretreatment; S2, oxidation; S3, filtration; S4, adsorption. The device mainly comprises a filtering tank, an adjusting tank, a decomposition tank, a pulse electric floating tank, an adsorption tank, water suction pumps and a PLC; the adjusting tank is communicated with the filtering tank through a first water inlet pump, the pulse electric floating tank is communicated with the decomposition tank through the fourth water suction pump,and the adsorption tank is communicated with the PLC through the fifth water suction pump and the pulse electric floating tank and is electrically connected with the filtering tank, the adjusting tank, the decomposition tank, the pulse electric floating tank, the adsorption tank, the water suction pumps and the PLC. The treatment technology is safe, free of pollution, excellent in degradation effect and capable of meeting emission standards.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

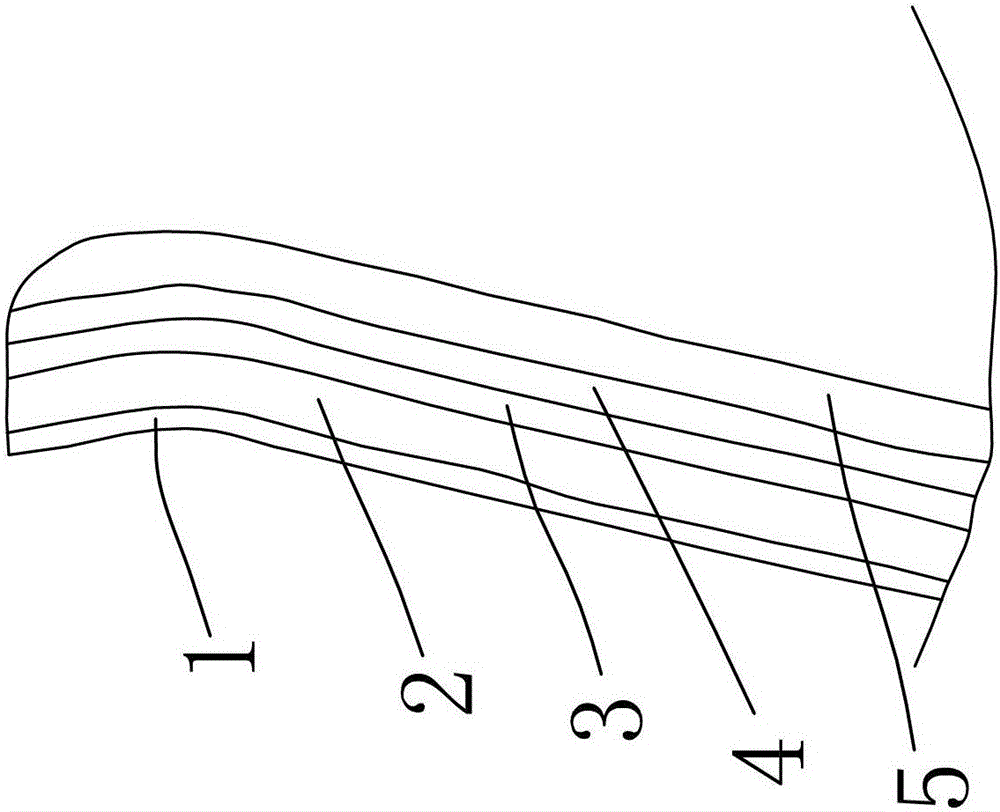

Layer structure and layer structure treatment process for automobile decoration

ActiveCN103318102BReasonable structure arrangementNice appearanceAnodisationLayered productsWaxFiber

The invention belongs to the technical field of automobile accessories and provides an automobile decorative sheet layer structure and the layer structure processing technology of the automobile decorative sheet layer. The automobile decorative sheet layer structure structurally comprises a non-woven layer, an aluminum part layer, a beech layer, a fiberboard layer and a walnut layer from inside to outside. The fiberboard layer is formed by wood fibers, a bonding formula, a flame-retarding formula and a waterproof formula. According to the processing technology, firstly, electrolytic oxidation is performed on the surface of the aluminum part layer, wax removing is performed before electrolytic oxidation, and a mixture of the flame-retarding formula, a gluing formula and the bonding formula is sprayed on the wood fibers which undergo hot grinding, and the fiberboard layer is formed through the procedures of drying, paving, hot pressing and sanding. The automobile decorative sheet layer structure and the layer structure processing technology of the automobile decorative sheet layer have the advantages that the technology processing process is green and safe and protects the environment; all the technology procedures are simple, therefore, yield is improved, a qualification rate is improved, production cost is reduced, and maintenance is easy; the layer structure after being processed is reasonable in layout, beautiful in appearance, and good in corrosion resistance, and the defects such as cracking and rusting are overcome; meanwhile, a high-quality film layer is formed on the outer surface of the layer structure, and therefore the corrosion resistance performance is enhanced.

Owner:宁波劳伦斯汽车内饰件有限公司

Wastewater treatment process

InactiveCN101684026AReasonable workmanshipHandling process safetyMultistage water/sewage treatmentWaste water treatment from plant processingFiltrationSample water

The invention discloses a wastewater treatment process which comprises the following steps: sampling 1000mL of water, adding lime milk liquid and stirring, then adding Dyl coagulant and stirring, thenadding 0.1 percent PAM solution, stirring and then settling and separating, taking 910mL of supernate, oxidizing, recording the time, the electric current and the voltage, then dosing for coagulation, and taking the supernate for sand filtration and carbon adsorption. The wastewater is treated by adopting the treatment methods of coagulating, oxidizing, coagulating again, sand-filtering and carbon-adsorbing, therefore, the removal rate of CODCr is higher, and all indexes reach national discharge standards; and the method has simple process and small coverage area of a device.

Owner:杜小青

A kind of preparation method of antioxidant silk fibroin film based on enzymatic grafting

The invention discloses a preparation method of an enzymatic grafting based antioxidant silk fibroin membrane, and belongs to the biological technical field of textiles. With the help of tyrosinase, antioxidant flavonoids compounds are grafted onto silk fibroin surface after catalytic oxidation; and by crosslinking of tyrosine and the flavonoids compounds in the enzymatic silk fibroin, the antioxidant properties of the silk fibroin membrane is enhanced. The specific processes include silk fibroin solution preparation, silk fibroin membrane preparation, grafting of the flavonoids compounds on the enzymatic silk fibroin and after treatment of the modified silk fibroin membrane. The silk fibroin membrane prepared by the preparation method has improved antioxidant and antimicrobial properties, and the membrane material mechanical properties also are improved. Compared with a silk fibroin membrane modification method based on chemical crosslinking, the enzymatic modification method is low in energy consumption, high in efficiency, less in pollution and in favour of environmental protection.

Owner:广东资恩解码基因检测科技有限公司

Fibroin based water absorbing material preparation method based on coupling and enzymatic graft copolymerization

ActiveCN108623759AImprove the reaction efficiency of graft copolymerizationImprove reaction efficiencyCosmetic preparationsToilet preparationsMaterials preparationPersulfate

The invention discloses a fibroin based water absorbing material preparation method based on coupling and enzymatic graft copolymerization and belongs to the technical field of textile chemistry. According to the method disclosed by the invention, diazo salt is prepared by diazotization of arylamine containing vinyl, then the diazo salt generates coupling reaction with fibroin, and finally enzymatic fibroin and hydrophilic vinyl monomer generate graft copolymerization to improve hydrophilia of a fibroin material. The preparation method comprises the following specific technologies and steps: (1) fibroin solution preparation; (2) preparation of diazo salt containing vinyl; (3) fibroin coupling reaction; (4) graft copolymerization between the enzymatic fibroin and hydrophilic vinyl monomer;(5) fibroin based water absorbing material formation. Compared with introducing vinyl monomer on fibroin through a chemical crosslinking method and then utilizing persulfate or chemical methods of anultraviolet radiation method and the like to trigger the graft copolymerization between the fibroin and the hydrophilic vinyl monomer, the preparation method disclosed by the invention has the advantages of high graft copolymerization efficiency and moderate enzyme treatment conditions; furthermore, the fibroin based water absorbing material has the advantage of good water absorption.

Owner:JIANGNAN UNIV

Silk floss finishing method

InactiveCN111705512AHigh catalytic efficiencyIncrease the amount of graftingBiochemical treatment with enzymes/microorganismsVegetal fibresFiberPolymer science

The invention discloses a silk floss finishing method. The silk floss finishing method comprises the following steps of: A, preparing an amino-containing antibacterial agent finishing liquid, whereinthe amino-containing antibacterial agent comprises polylysine, chitosan with deacetylation exceeding 85% and chitosan quaternary ammonium salt with deacetylation exceeding 85% and substitution degreeof 60-90%, and dipping silk floss into the finishing liquid; B, adding laccase into the finishing liquid in the step A, and continuously dipping the silk floss subjected to dipping treatment in the step A; C, cleaning the silk floss treated in the step B in water; and D, drying the silk floss treated in the step C. The silk floss finishing method disclosed by the invention has the advantages thatby virtue of the laccase, the amino-containing antibacterial agent is grafted on the surface of silk floss fiber by catalysis, so that the silk floss product is endowed with antibacterial effect; andthe silk floss finishing method has the characteristics of safe treatment process and lower production energy consumption, and ecological functional processing of the silk floss product is realized.

Owner:徐州光彩丝绵制品有限公司

A method for preparing sericin film material based on enzymatic graft copolymerization

ActiveCN108517028BImprove reaction efficiencyHigh graft copolymerization efficiencyPolymer scienceSILK SERICIN

The invention discloses a method for preparing sericin film material based on enzymatic graft copolymerization, and belongs to the technical field of textile chemistry. According to the method, through coupling reaction and catalyzing, graft copolymerization is conducted on a vinyl ester monomer, so that the water solubility of sericin protein is reduced, and the forming effect of the sericin filmmaterial is improved; through diazotization of vinyl-containing arylamine, diazonium salt is prepared, then the diazonium salt and the sericin protein are subjected to coupling reaction, and finally,enzymatic graft copolymerization is conducted on sericin and the vinyl ester monomer to prepare the sericin film material. The method comprises the following processes and steps of (1) preparation ofthe vinyl-containing diazonium salt; (2) the sericin protein coupling reaction; (3) enzymatic graft copolymerization of the sericin and the monomer; (4) forming of the sericin film material. Comparedwith a method in which a chemical cross-linking method is adopted for introducing a vinyl monomer, and then persulfate or an ultraviolet radiation method and the like is used for triggering graft copolymerization of the sericin and the vinyl ester monomer, the method has high graft copolymerization efficiency, mild enzymatic treatment conditions, and improved formability of the sericin film material.

Owner:JIANGNAN UNIV

A method for enzymatically preparing silk fibroin/elastin composite membrane material

ActiveCN105218842BHigh catalytic efficiencyReduce dosageFermentationCatalytic oxidationBiocompatibility Testing

The invention discloses a method for preparing a fibroin and elastin composite membrane material through an enzymic method. Beta-tyrosinase is applied to amino acid conversion in fibroin, the number of tyrosine residues in fibroin protein is increased, fibroin is catalytic oxidized to be crosslinked with elastin, and a fibroin and elastin composite membrane is prepared. The method comprises the steps that 1, a fibroin solution is prepared; 2, the beta-tyrosinase and phenol are added, and serine in the fibroin is catalyzed to be converted to tyrosine; 3, the tyrosinase is added in the fibroin solution, and the tyrosine residues on the fibroin are catalytic oxidized to be reacted with the elastin; 4, fibroin and elastin are dried through air to form the membrane or dried through refrigeration to form the membrane. Compared with a functional fibroin membrane prepared from traditional chemical cross-linking, according to the method for preparing the fibroin and elastin composite membrane material through the enzymic method, the enzyme catalysis efficiency is high, the enzyme treatment condition is mild, and the composite membrane performance can be obviously improved; the fibroin and elastin composite membrane which is built through the enzymic method is good in biocompatibility, and the membrane material mechanical property is improved.

Owner:JIANGNAN UNIV

A method for enzymatic silk fibroin film immobilization of catalase

ActiveCN103667239BHigh catalytic efficiencyReduce dosageOn/in organic carrierCatalytic oxidationTyrosinase

The invention discloses a method for immobilizing catalase with an enzymatic silk fibroin film, belongs to the field of textile biotechnology, aims to provide an environmental-friendly method for immobilizing catalase with the silk fibroin film, and expands the application of an enzymatic silk fibroin film material serving as a biosensor. Due to the catalytic oxidation function of tyrosinase, the silk fibroin film is grafted with catalase, so that not only is the immobilization between enzyme molecules and silk fibroin realized, but also the application performance of the silk fibroin film serving as a catalase carrier is improved. The method particularly comprises the technological processes such as preparation of a silk fibroin solution and the silk fibroin film, grafting enzymatic silk fibroin with catalase, washing with water, and carrying out aftertreatment. The enzymatic silk fibroin film prepared by the invention is used with a dissolved oxygen meter in a combined manner, so as to not only evaluate catalase contents in different systems, but also ensure repeated circulatory use; the properties of strength, elasticity and the like of the silk fibroin film are improved.

Owner:JIANGNAN UNIV

A kind of method of anti-crease and antibacterial finishing of real silk fabrics by laccase-tempo method

InactiveCN105734981BImprove grafting efficiencyIncrease the amount of graftingBiochemical fibre treatmentAnimal fibresQuinoneWrinkle skin

The invention discloses a method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of a laccase-TEMPO process. Quinones active groups are generated through catalyzing tyrosine residual groups in real silks by laccase so that chitosan molecules are grafted on the real silks; then 2,2,6,6-tetramethylpiperidine-nitrogen oxide (TEMPO) is added and is used for catalyzing chitosan and tyrosine in the real silks to generate formyl groups, so that the grafting amount and bonding firmness of the chitosan on the real silks are increased, and the real silk fabric anti-crease and antibacterial finishing is realized. The method comprises the following specific steps of: (1) catalytically oxidizing the tyrosine residual groups in the real silks by the laccase; (2) taking the chitosan and the quinones active groups in the real silks to react; (3) catalyzing the real silks by laccase-TEMPO to graft the chitosan; and (4) washing the real silks with water and then treating. Compared with traditional chemical cross-linking-process vacuum fabric anti-crease and antibacterial finishing, the method has the advantages that the grafting efficiency of the chitosan is high, enzyme treatment conditions are moderate, the real silk fabric anti-crease and antibacterial effect is relatively good and the strength of the fabric is improved.

Owner:JIANGNAN UNIV

A process for treating phosphorus-containing pesticide wastewater

ActiveCN104529080BRaise the pHReduce dosageTreatment using aerobic processesWater contaminantsEvaporationTherapeutic effect

The invention discloses a technique for treating pesticide wastewater containing phosphorus. The technique for treating the pesticide wastewater containing the phosphorus comprises the technical processes of multiple-effect evaporation, neutralization, flocculent setting, biological treatment, advanced oxidation of ozone and the like, novel densely-supporting padding is arranged in the biological process, and thus the treatment effect at the biological stage is improved. According to the technology, glyphosate mother liquor wastewater, mother liquor from amination and condensed washing secondary wastewater are mixed to treat waste and reduce the load of all organic pollutants in the wastewater. The B / C ratio of the wastewater difficult to degrade is increased, the technique is safe and advanced, operation is stable, operating cost is low, and maintenance is easy.

Owner:SUZHOU SUJING NEW MATERIALS IN ENVIRONMENTAL PROTECTION

A method for preparing silk fibroin-based water-absorbent material based on coupling and enzymatic graft copolymerization

ActiveCN108623759BImprove the reaction efficiency of graft copolymerizationImprove reaction efficiencyCosmetic preparationsToilet preparationsPolymer scienceAbsorbent material

The invention discloses a fibroin based water absorbing material preparation method based on coupling and enzymatic graft copolymerization and belongs to the technical field of textile chemistry. According to the method disclosed by the invention, diazo salt is prepared by diazotization of arylamine containing vinyl, then the diazo salt generates coupling reaction with fibroin, and finally enzymatic fibroin and hydrophilic vinyl monomer generate graft copolymerization to improve hydrophilia of a fibroin material. The preparation method comprises the following specific technologies and steps: (1) fibroin solution preparation; (2) preparation of diazo salt containing vinyl; (3) fibroin coupling reaction; (4) graft copolymerization between the enzymatic fibroin and hydrophilic vinyl monomer;(5) fibroin based water absorbing material formation. Compared with introducing vinyl monomer on fibroin through a chemical crosslinking method and then utilizing persulfate or chemical methods of anultraviolet radiation method and the like to trigger the graft copolymerization between the fibroin and the hydrophilic vinyl monomer, the preparation method disclosed by the invention has the advantages of high graft copolymerization efficiency and moderate enzyme treatment conditions; furthermore, the fibroin based water absorbing material has the advantage of good water absorption.

Owner:JIANGNAN UNIV

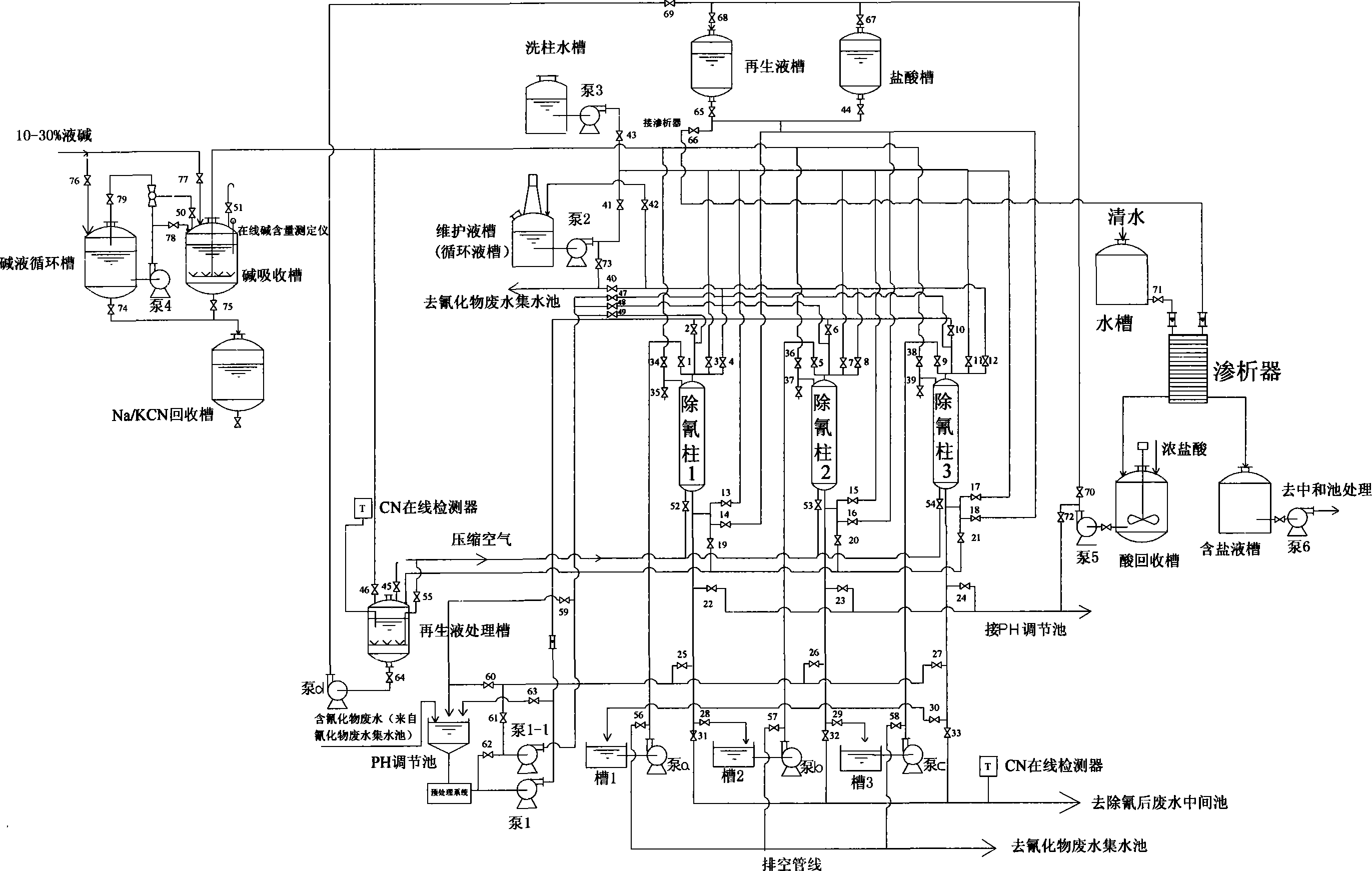

Ion exchange treatment process for cyanide containing wastewater

InactiveCN101367569BEasy to handleReduce salt contentIon-exchange column/bed processesWater/sewage treatment by ion-exchangeIon exchangeIon-exchange resin

The invention discloses an ion exchange method treatment technology of the waste water which comprises cyanide. The ion exchange method treatment technology combines the waste water pH value adjustment, absorption, regeneration and maintenance with the recovery of CN<-> ion and hydrochloric acid, realizes ion exchange automatic processing of the CN<-> ion in the waste water which comprises cyanide, has the advantages of high operation automaticity, being safe and reliable, good waste water treatment effect, being capable of recycling the cyanide, low operation cost, effective maintenance to ion exchange resin, long-term and stable working performance and so on. Compared with the chemical method to treat the waste water which comprises cyanide, the ion exchange method treatment technology has the advantages that the ion exchange method treatment technology does not need to add chemical agent in the waste water, has low salt rate in the waste water after being treated, is favor of the recycling of the waste water, and can recycle the cyanide.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV

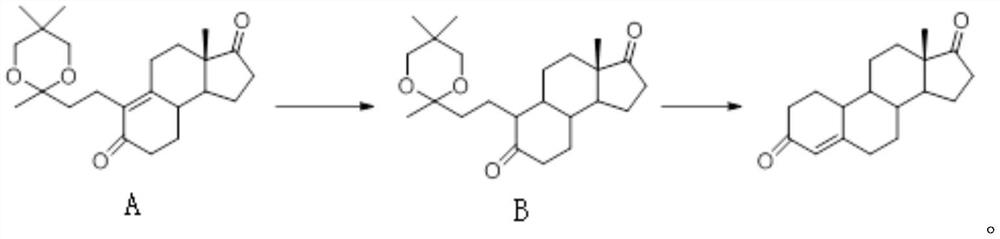

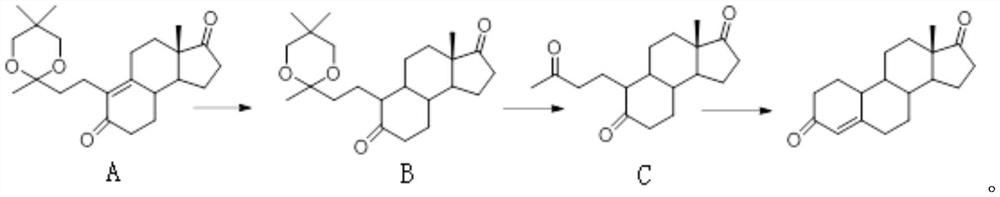

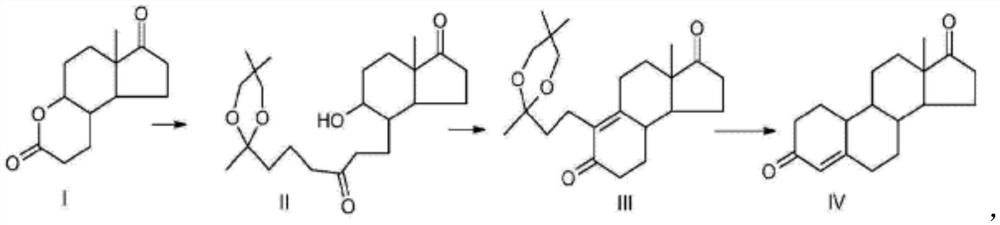

Preparation method of 19-nor-4-androstenedione

The invention belongs to the technical field of steroid hormone preparation, and particularly relates to a preparation method of 19-nor-4-androstenedione, which comprises the following steps: mixing a compound A, ethanol and pyridine, adding palladium on carbon, introducing hydrogen, and reacting to obtain a compound B; the compound B and isopropanol are mixed, an acid solution is added, the acid solution is a hydrochloric acid solution or a salt solution of alkali metal which is dissolved to be acidic, reaction and treatment are conducted, and 19-nor-4-androstenedione is obtained, the reaction route is as follows: the yield and purity of the product can be effectively improved, and the product is white.

Owner:HUNAN NORCHEM PHARMACEUTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com