Patents

Literature

288results about How to "Reliable process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

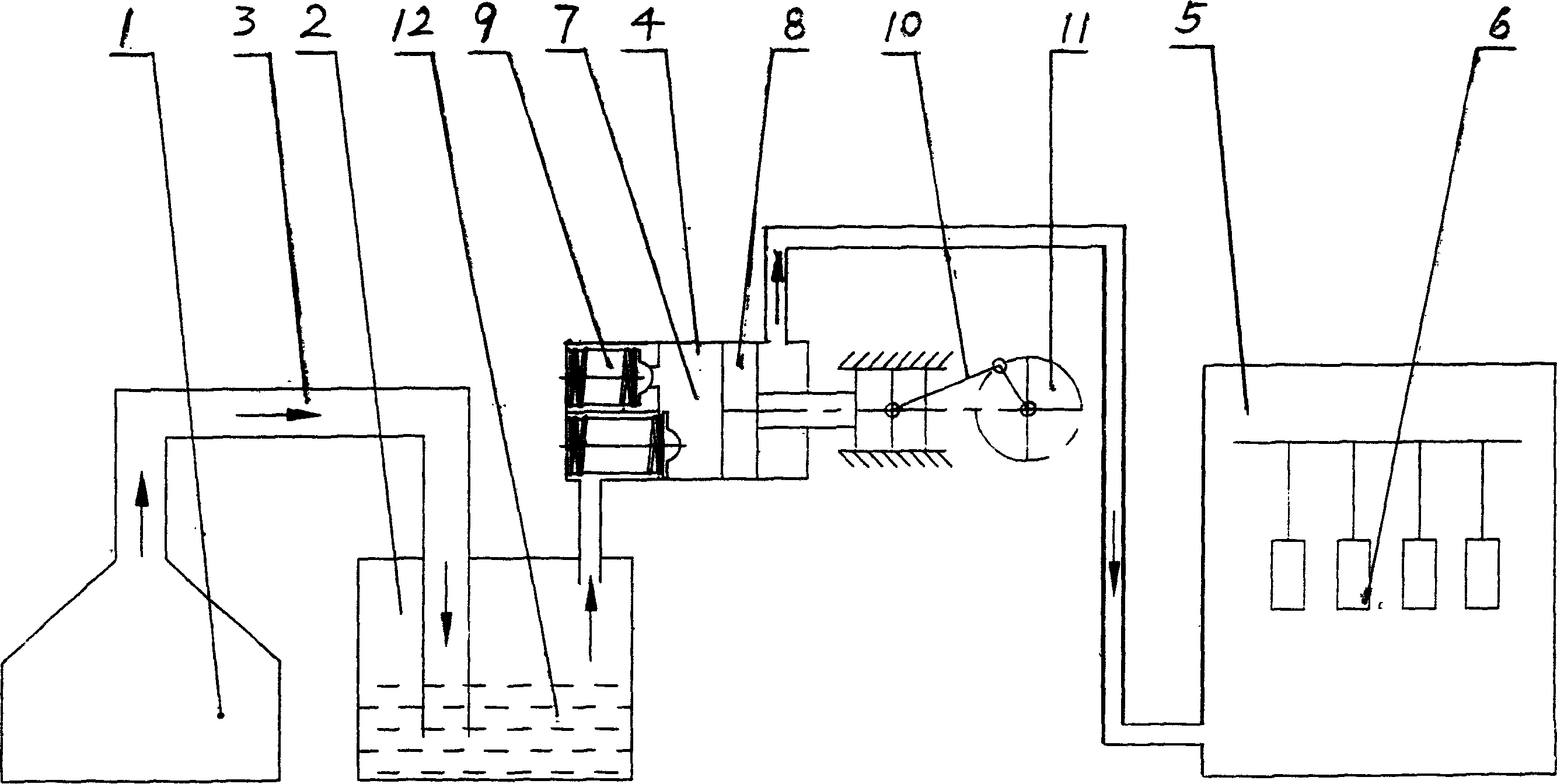

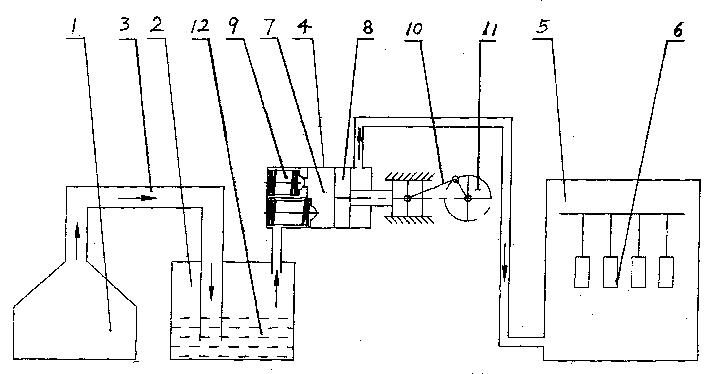

AC arc welding system and method thereof

InactiveCN101524781AReduce energy inputSimple and reliable processArc welding apparatusInterface circuitsWelding power supply

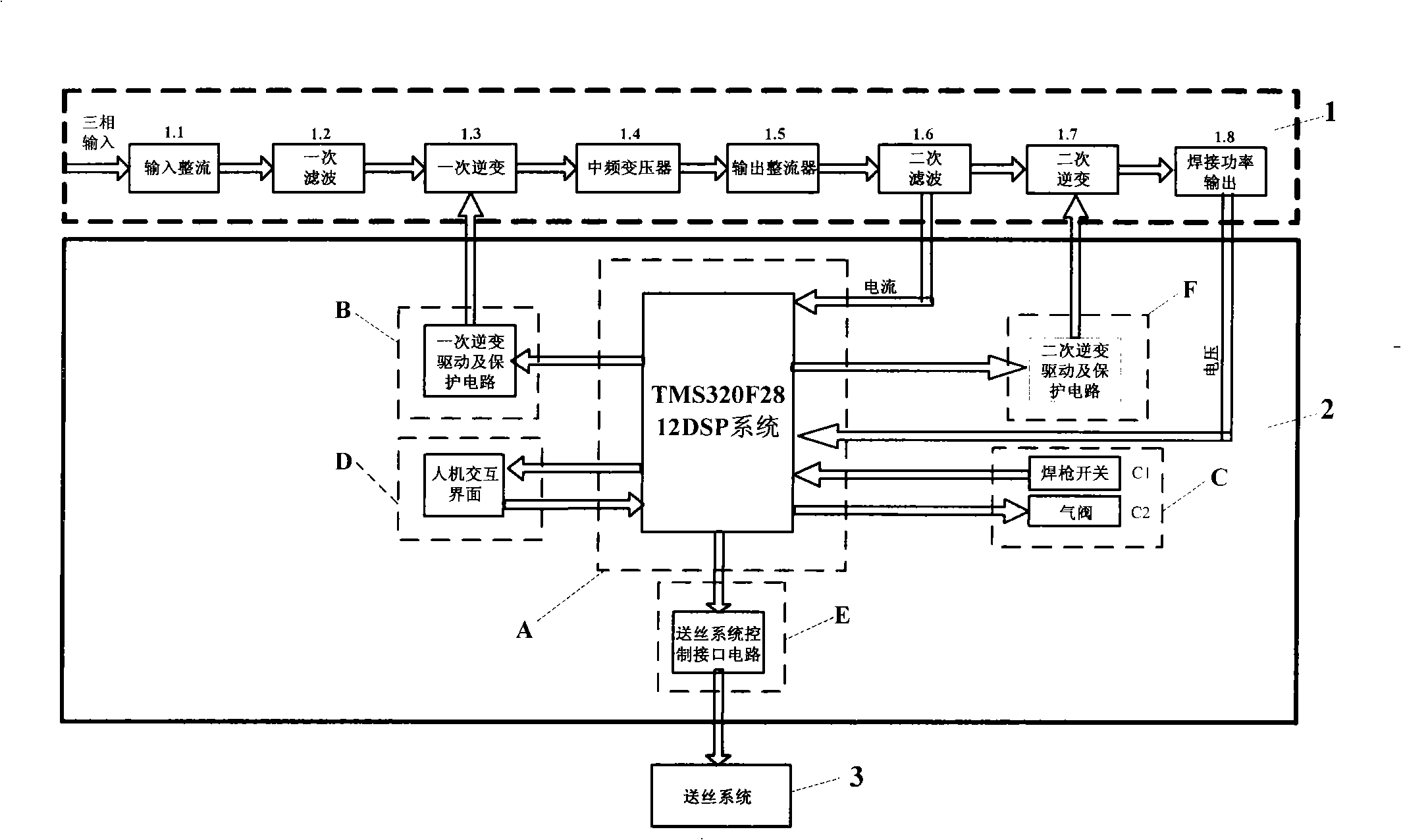

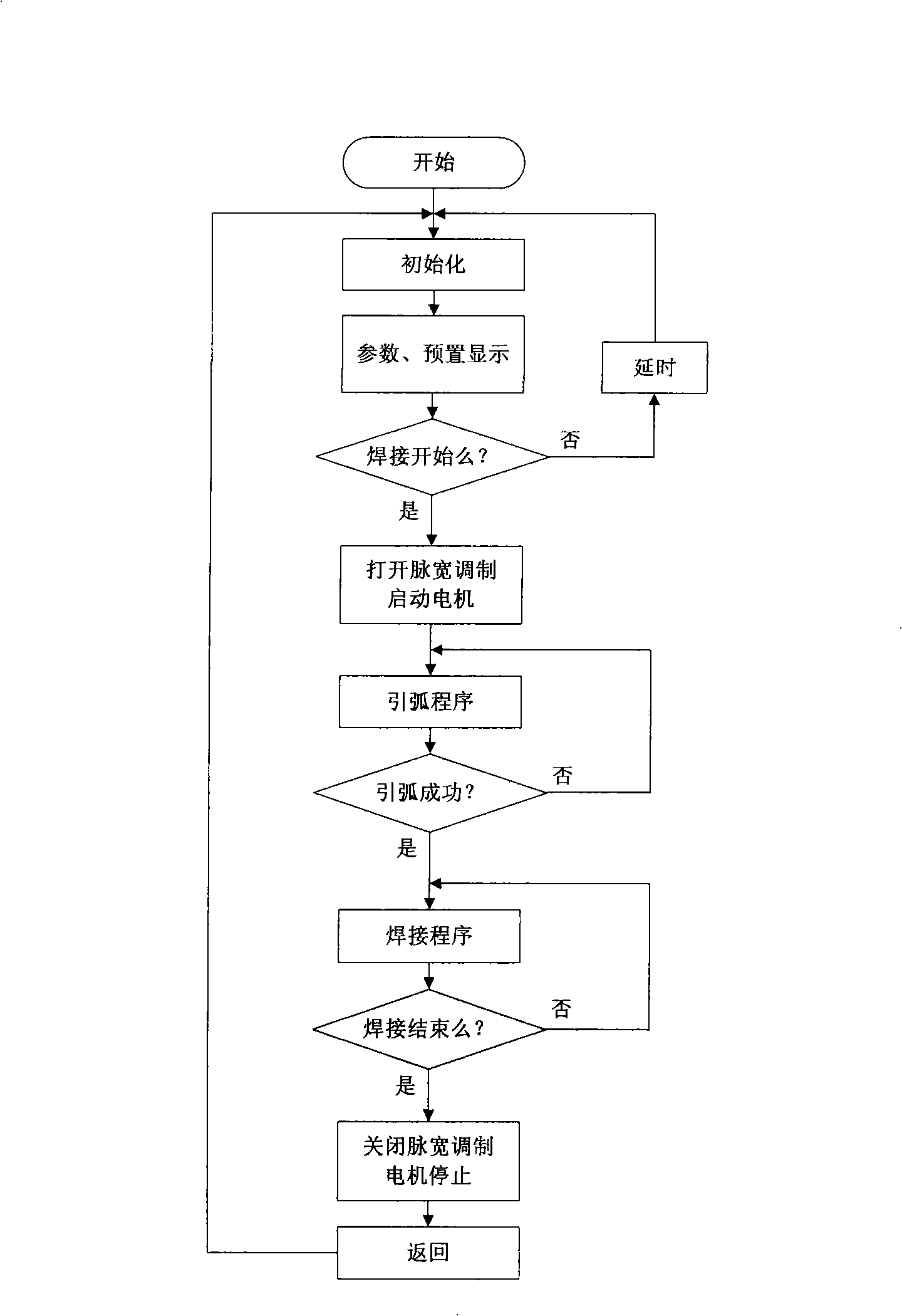

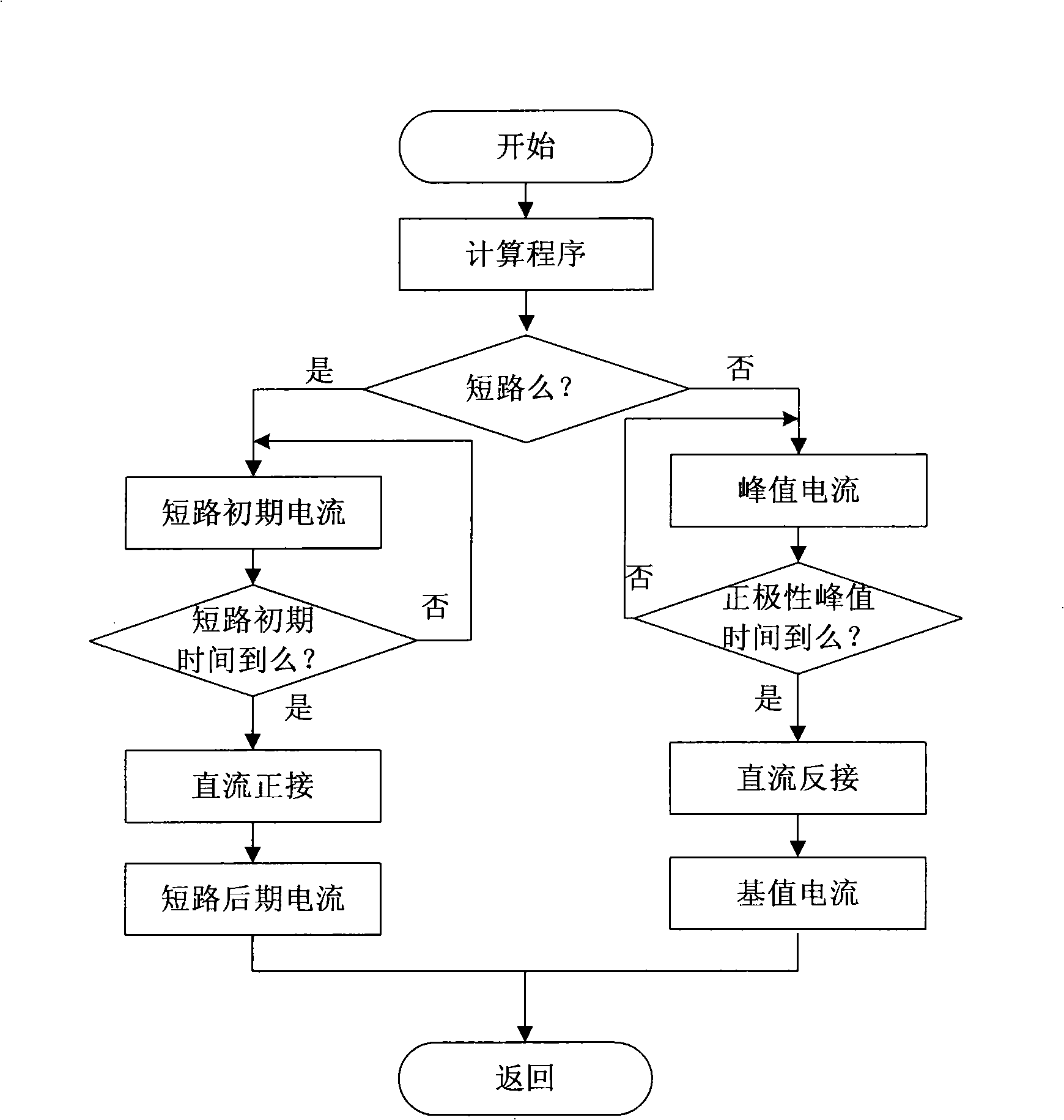

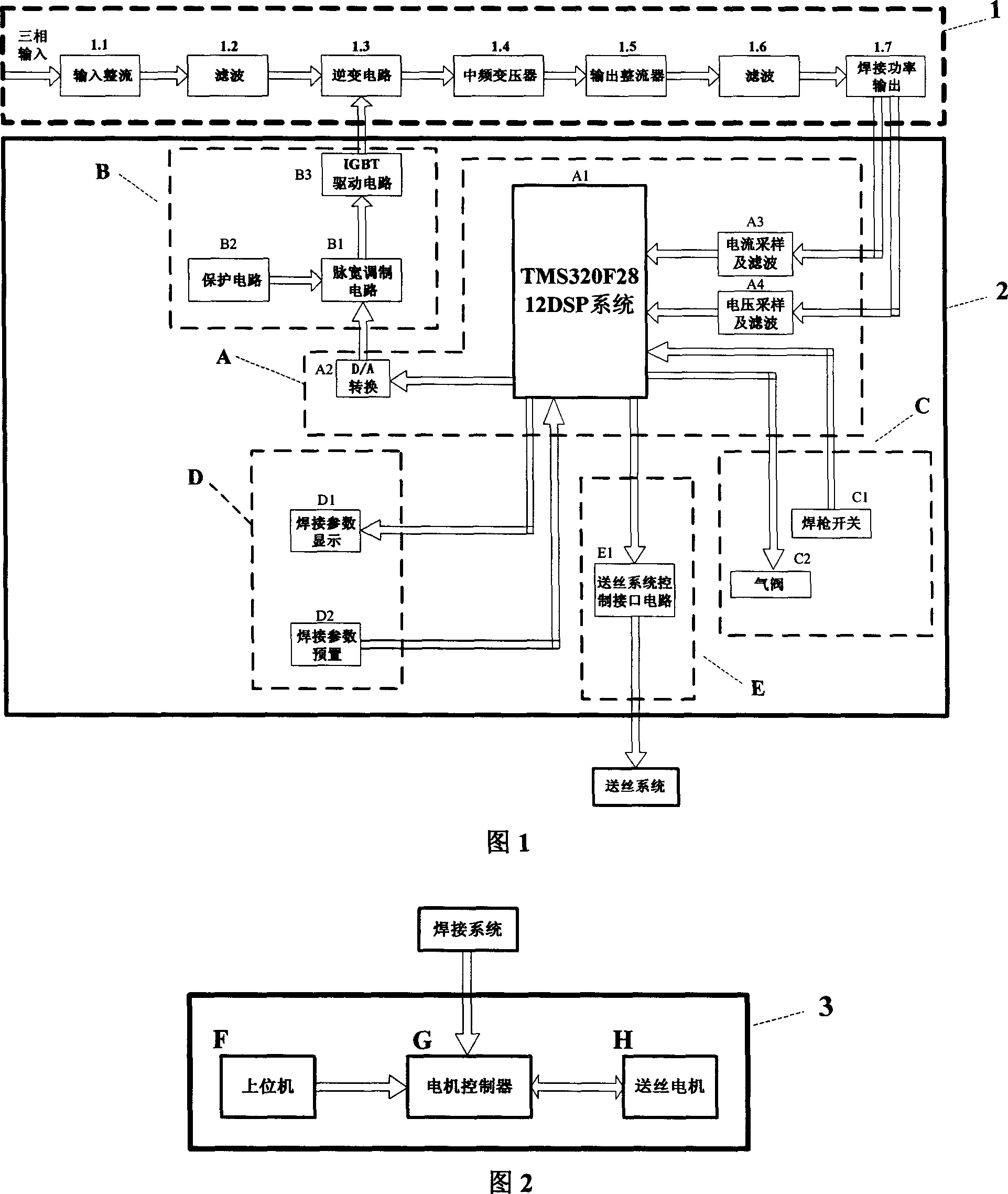

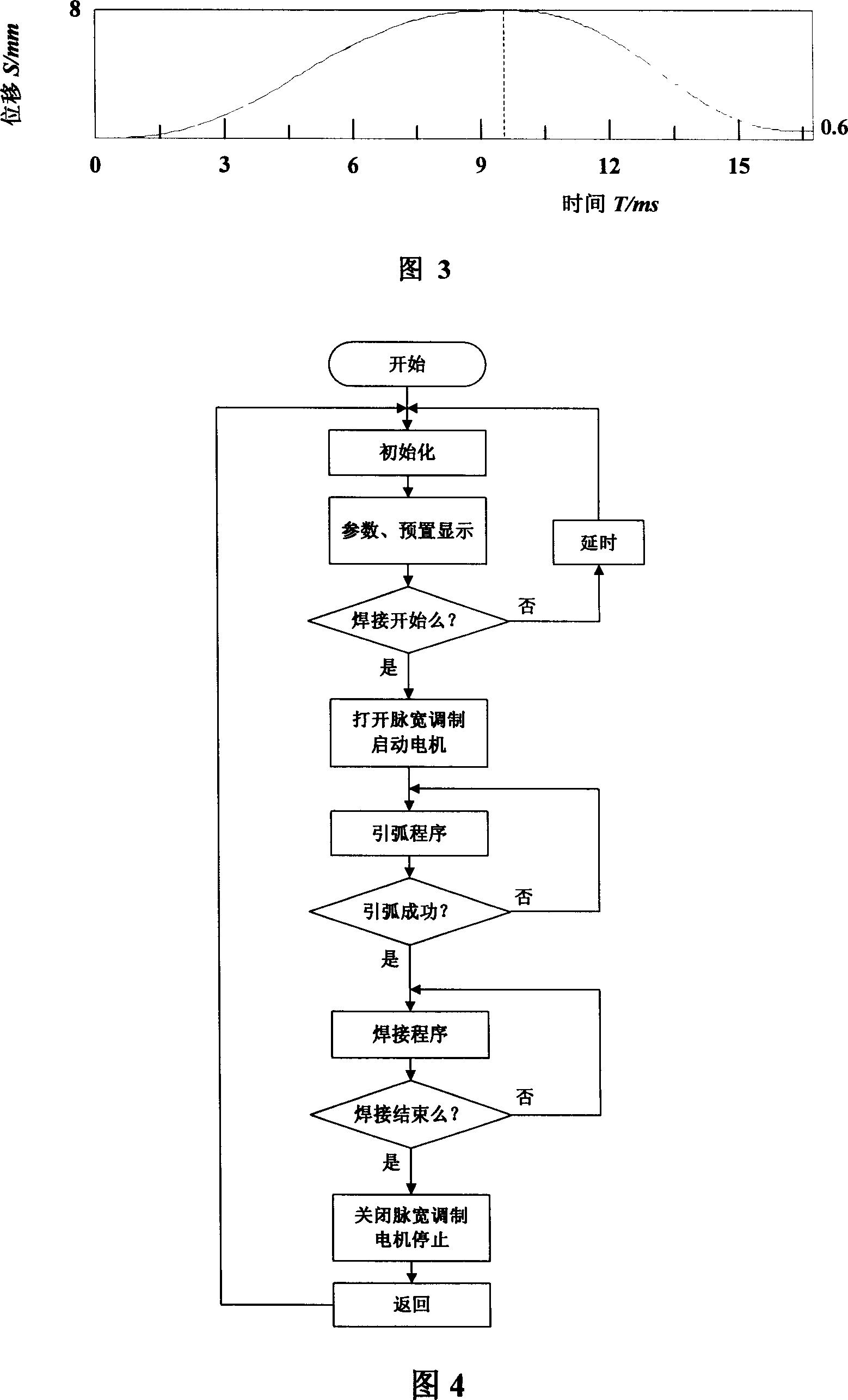

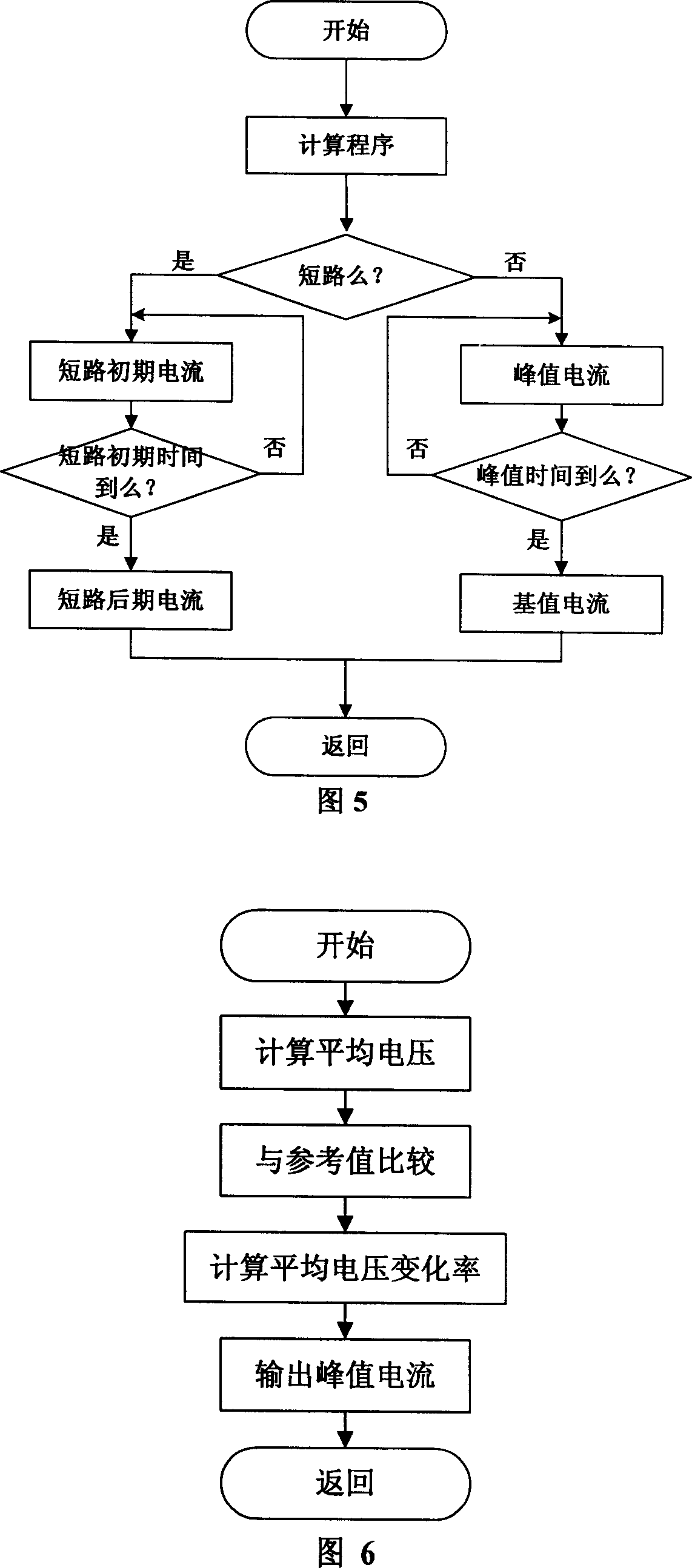

The invention relates to an AC arc welding system and a method thereof, belonging to the welding equipment and automation field. The system adopts a wire feeding mode of wire pushing and drawing. A power supply adopts an AC output mode. The system concretely comprises a welding power system and a wire feeding system. The welding power system mainly comprises a main circuit part (1) for providing power output for welding and a control circuit part (2) for controlling the output power of the main circuit. The wire feeding system adopts an AC servo motor as a wire feeding motor and controls an interface circuit (E) by the wire feeding system to receive signals sent by a DSP system (A). The wire feeding motor reciprocates to realize the wire pushing and drawing. Simultaneously, a welding power judges that the welding is in the short circuit / arcing state according to the feedback voltage to change the output polarity of the power. The droplet short circuiting transfer is finished under the function of welding pumpback tension. A small short circuit current is adopted. In addition, the straight polarity direct current is adopted at the arcing initial stage. More arc energy can be distributed to welding wires, and the heat input of base metal is lowered greatly.

Owner:BEIJING UNIV OF TECH

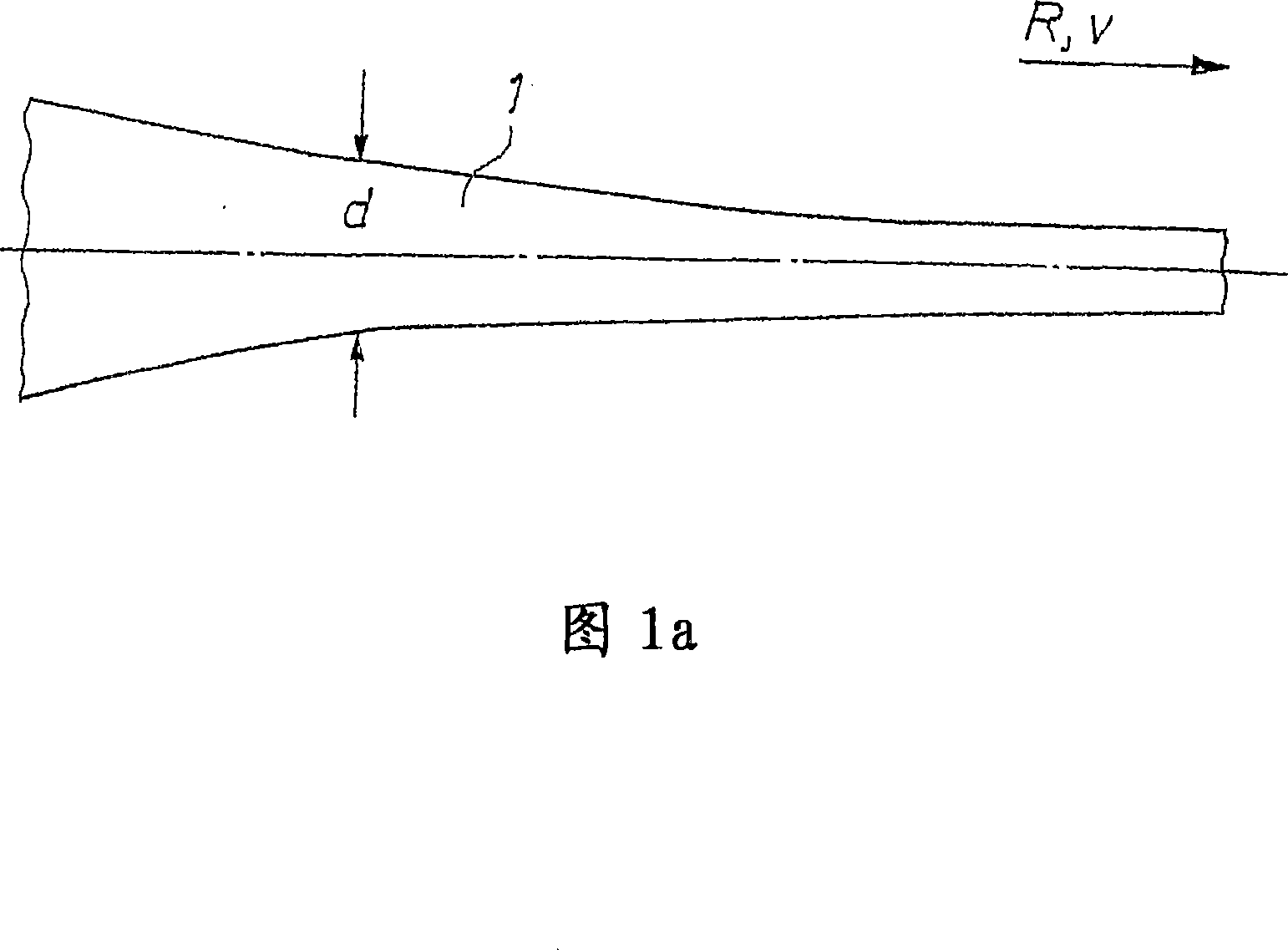

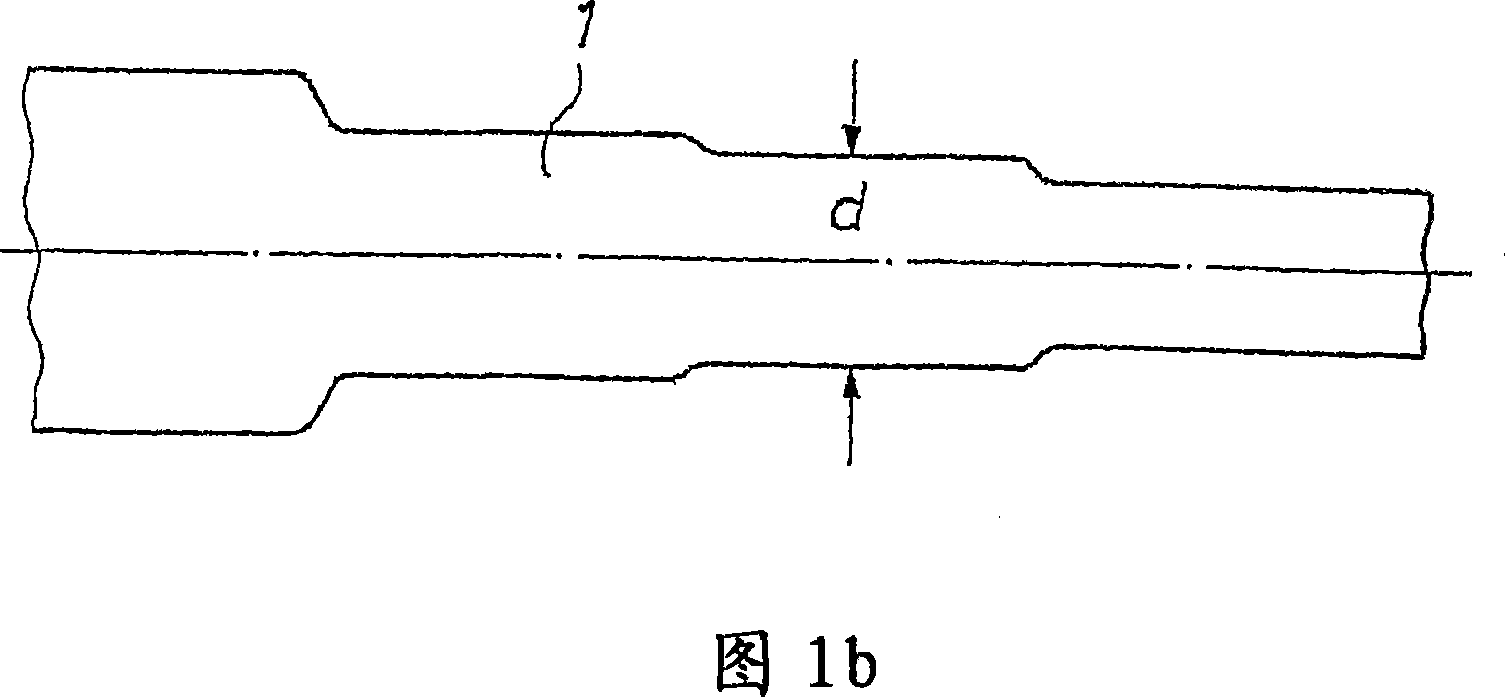

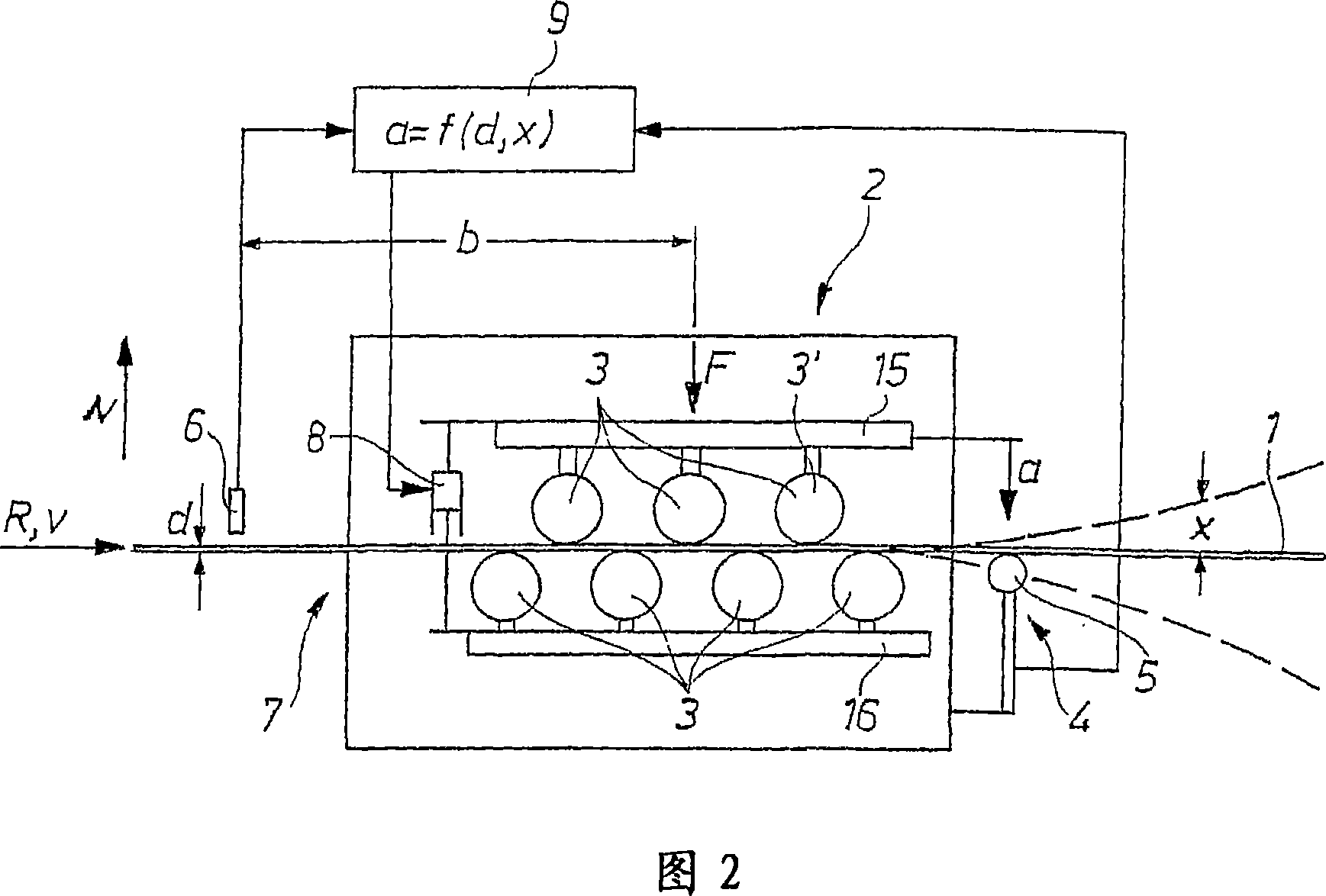

Method for straightening a metal strip and straightening machine

An improved medical treatment and medicine is provided to quickly and safely resolve HIV and other microbial infections. The inexpensive medicine can be self administered and maintained for the prescribed time. The attractive medicine comprises an antimicrobial concentrate comprising microbe inhibitors, phytochemicals or isolates. Desirably, the effective medicine comprises a surfactant and an aqueous carrier or solvent and a nutrient. In the preferred form, the medicine comprises: Echinacea and Commiphora myrrha phytochemicals, benzalkonium chloride, a sterile water solution, and folic acid.

Owner:SMS DEMAG AG

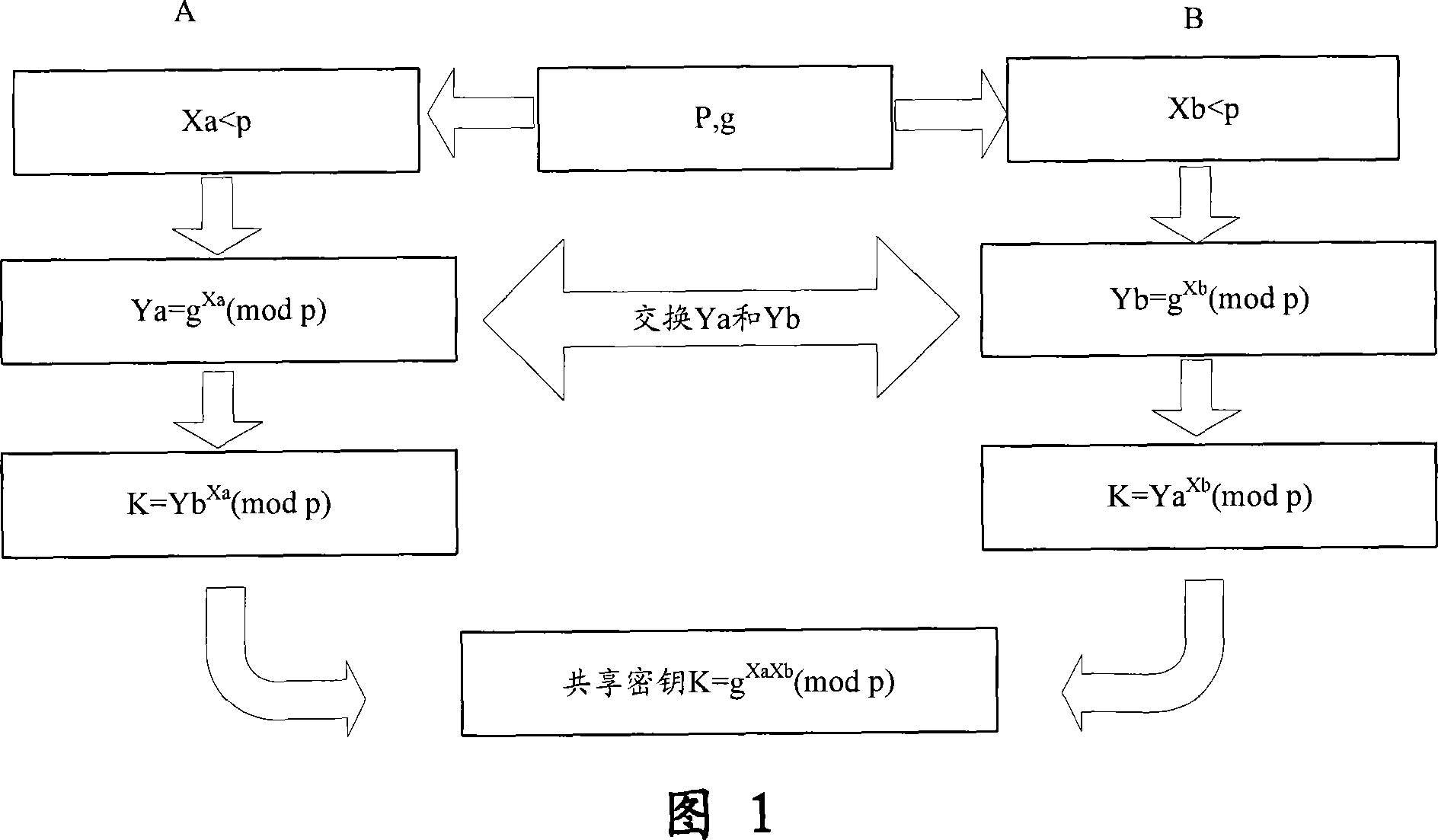

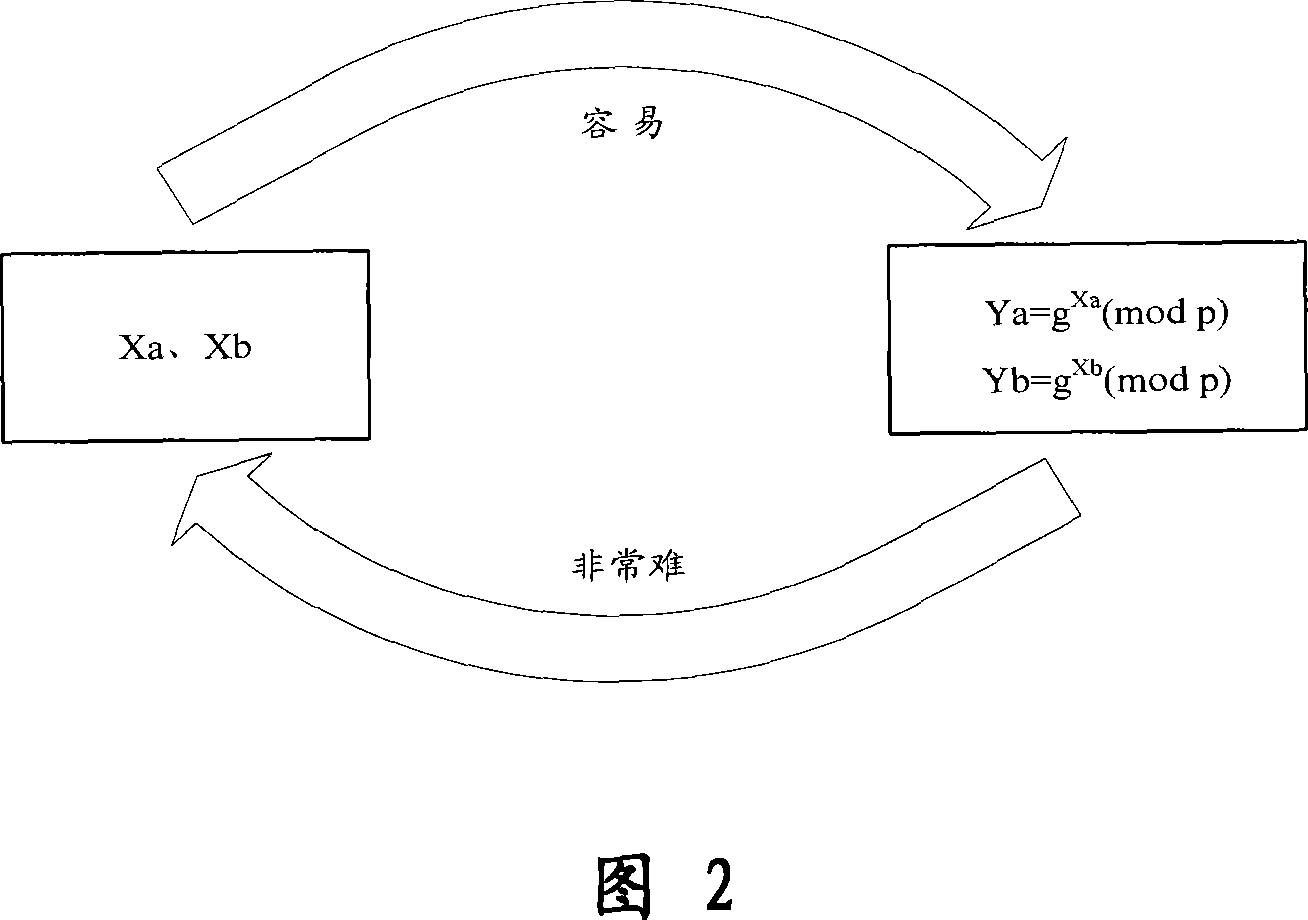

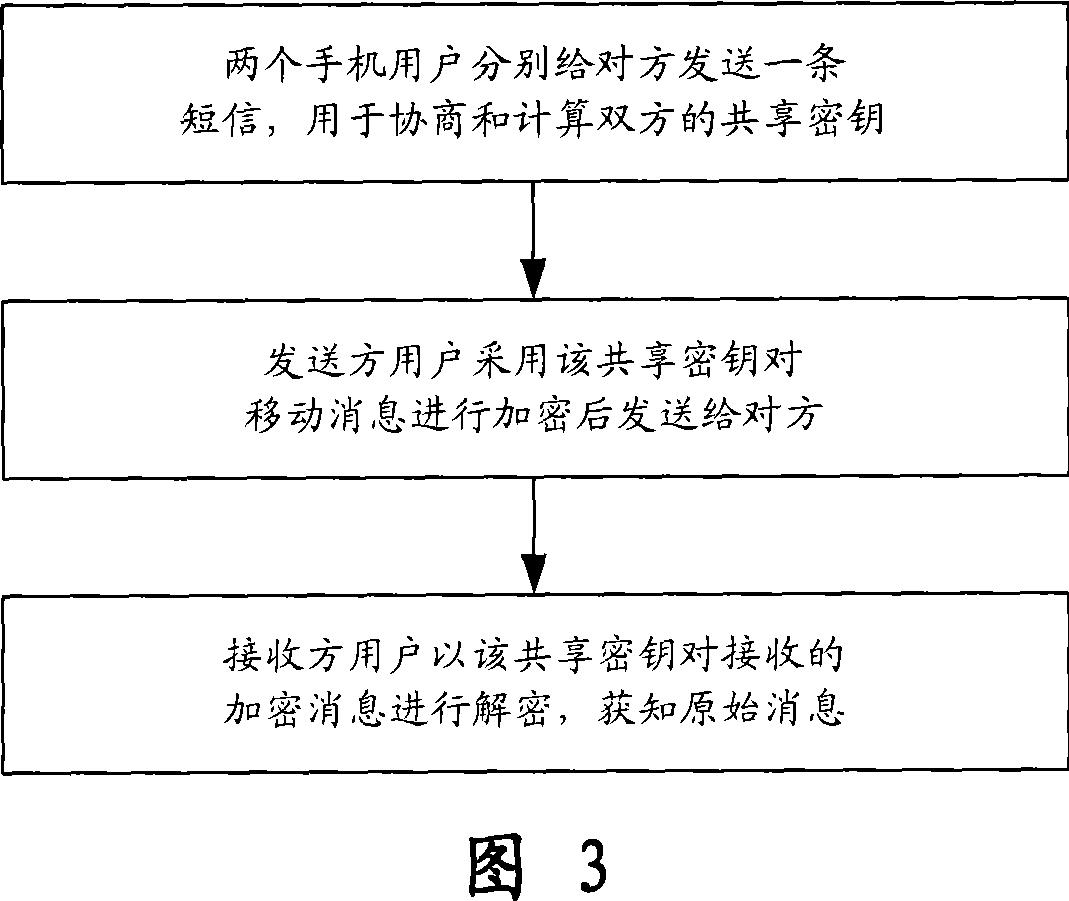

End-to-end encryption method and control device for the mobile phone SMS

InactiveCN101056176AEasy to operateCutting costsKey distribution for secure communicationUser identity/authority verificationEnd-to-end encryptionComputer hardware

A method for the end-end encryption of message sent by mobile, before communication, two mobile users may mutually negotiate through the Diffie-Hellman key switching algorithm and calculate respectively to establish a shared key for both parties; then after encrypted the mobile message with the shared key, sent to the other party; after another user received this encrypted message, decrypts the encrypted message with the shared key, presents the original information to the receiver. The control device for the invention is a control component equipped in the mobile for mutual communicating with the message transmitting and receiving module, consists of decryption module, interface presenting module, encryption message storage module, key management module and key negotiation module. The invention method is easier to realize, high feasibility, the structure of control device is simple, the operating of user is almost identical with the receiving and transmitting of ordinary mobile messages, but the method has higher safety, meets with the high safety demand for mobile messages.

Owner:BEIJING NETQIN TECH

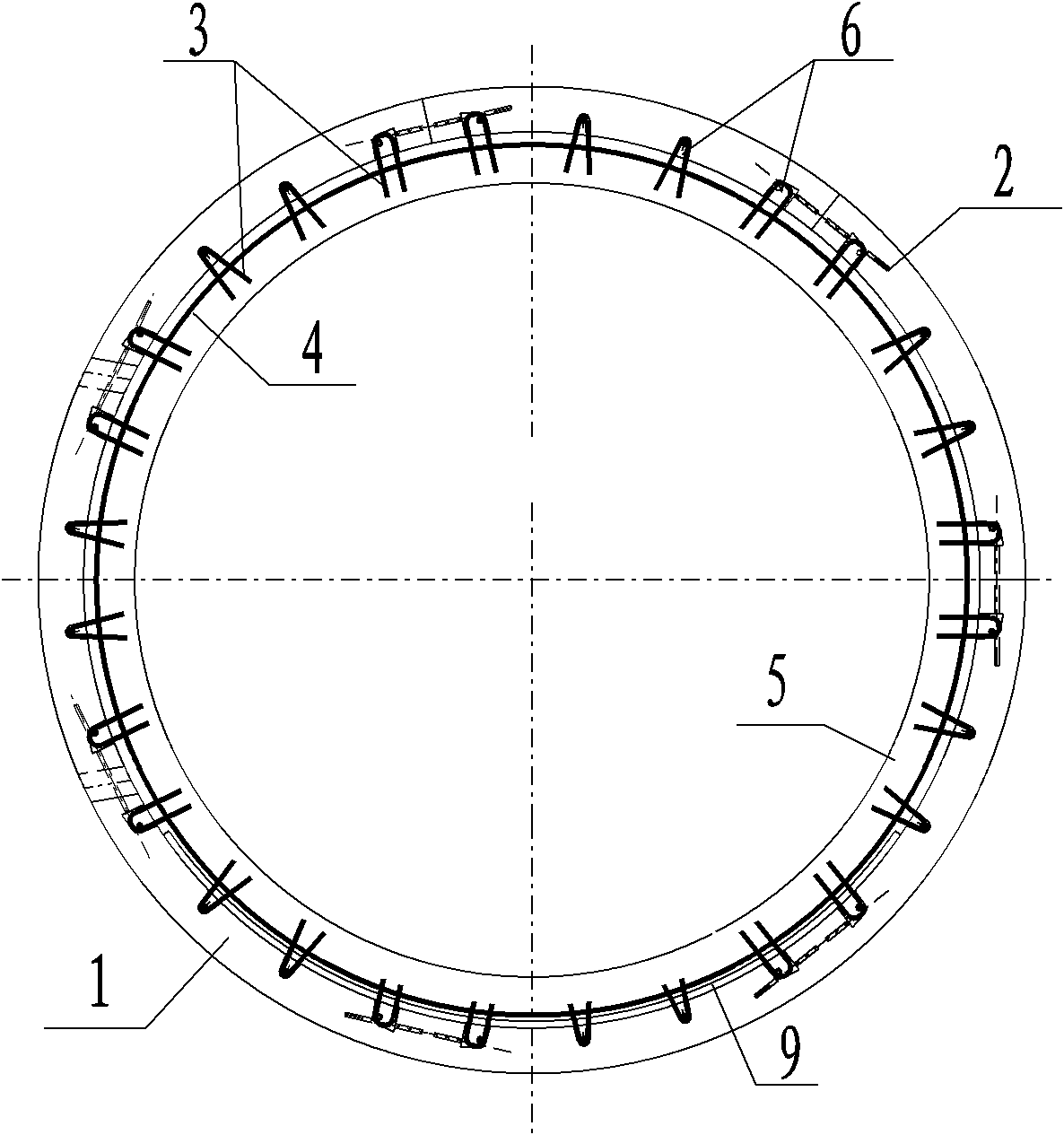

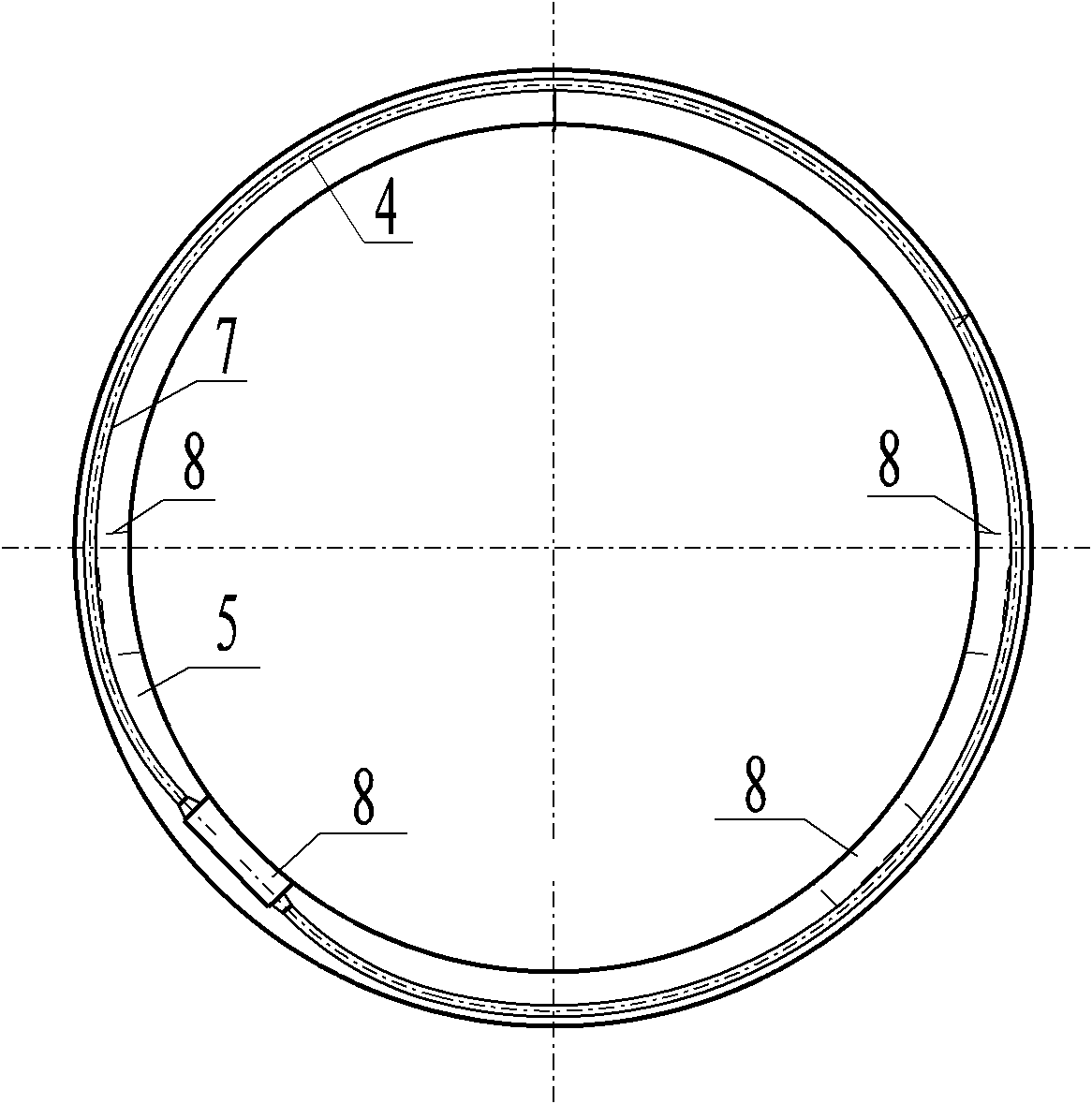

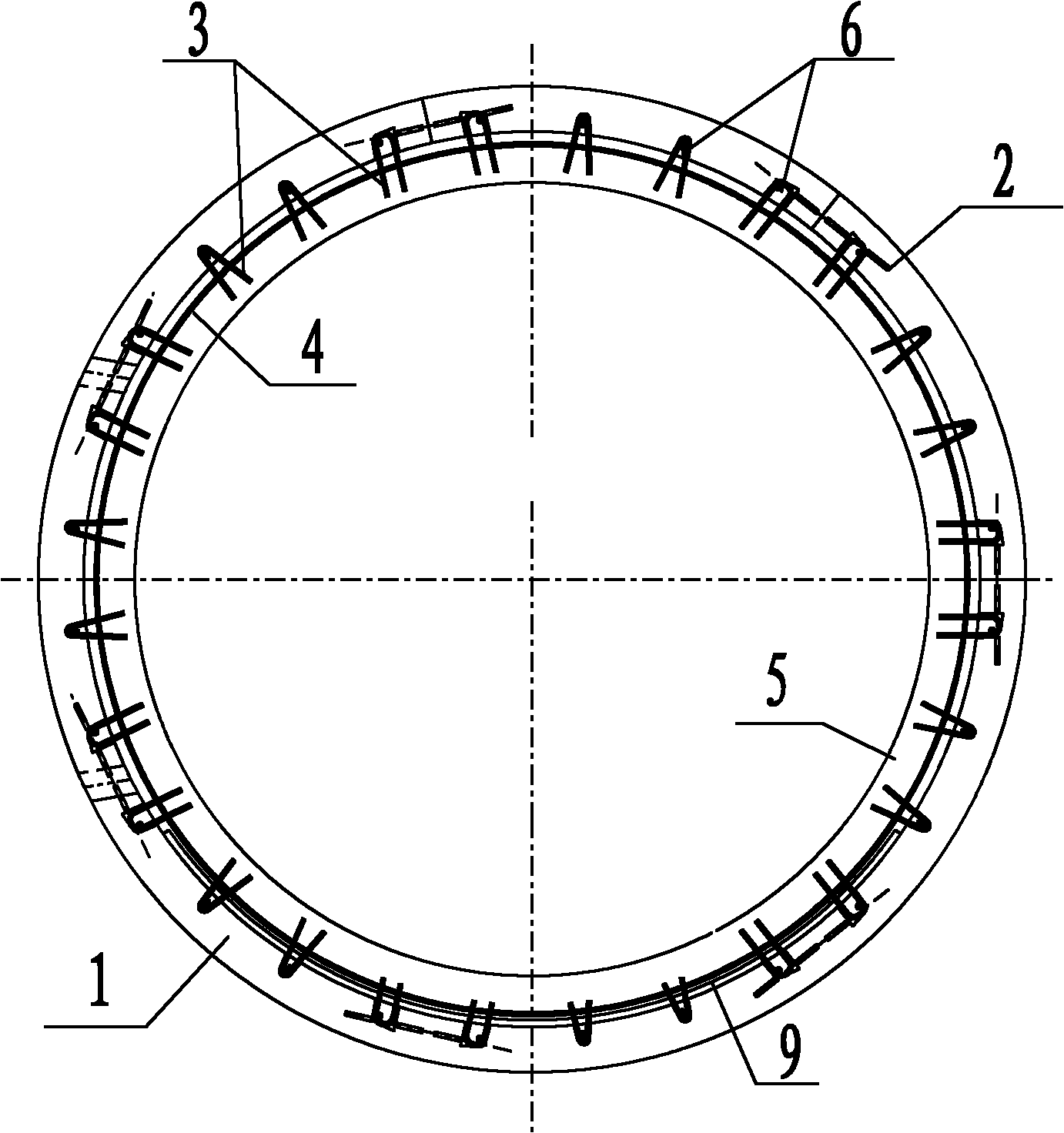

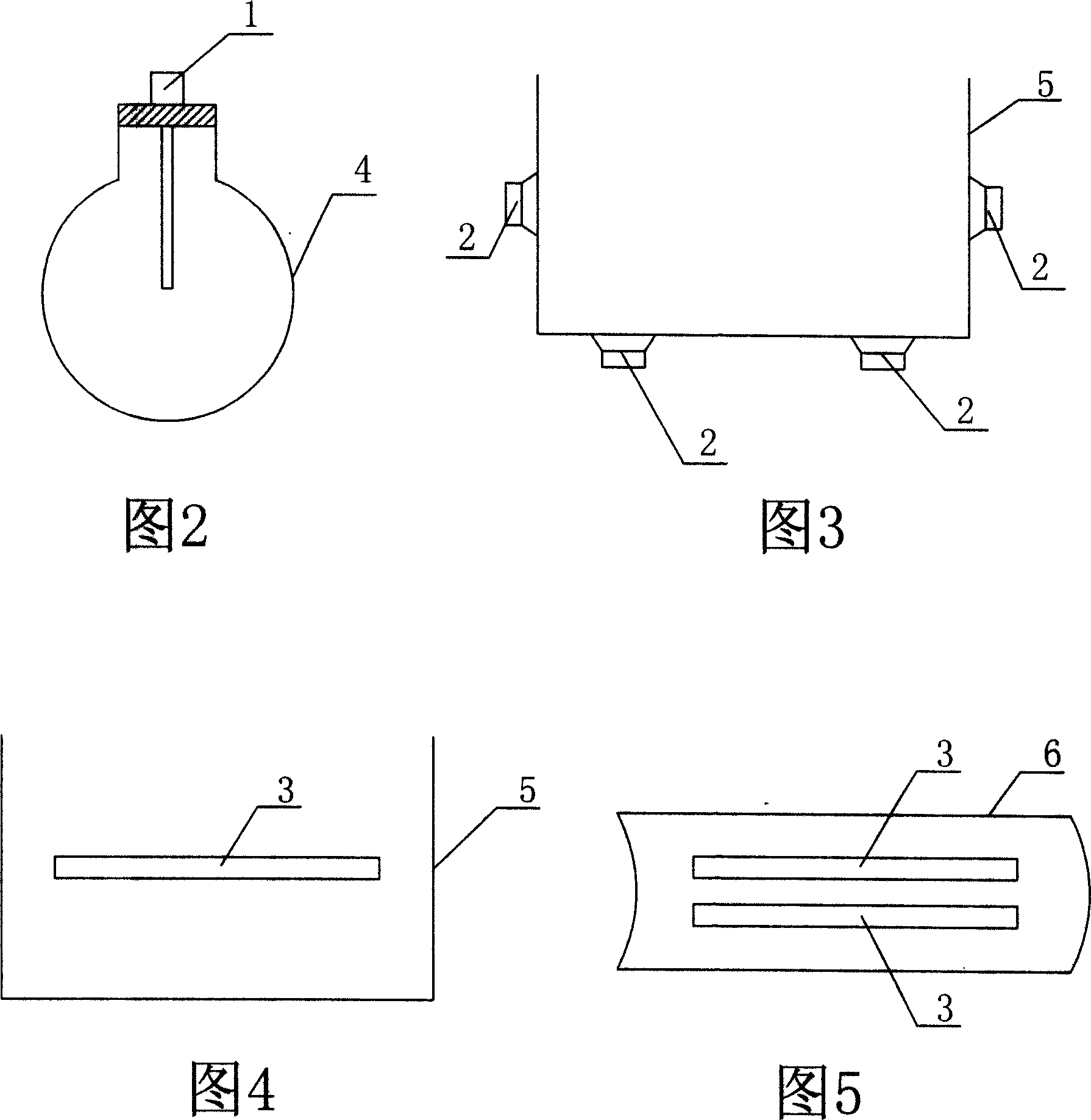

Water conveyance tunnel with prestressed composite lining for shield tunnelling

InactiveCN102191940AHigh degree of simulationLarge scale testUnderground chambersDrainageSocial benefitsReinforced concrete

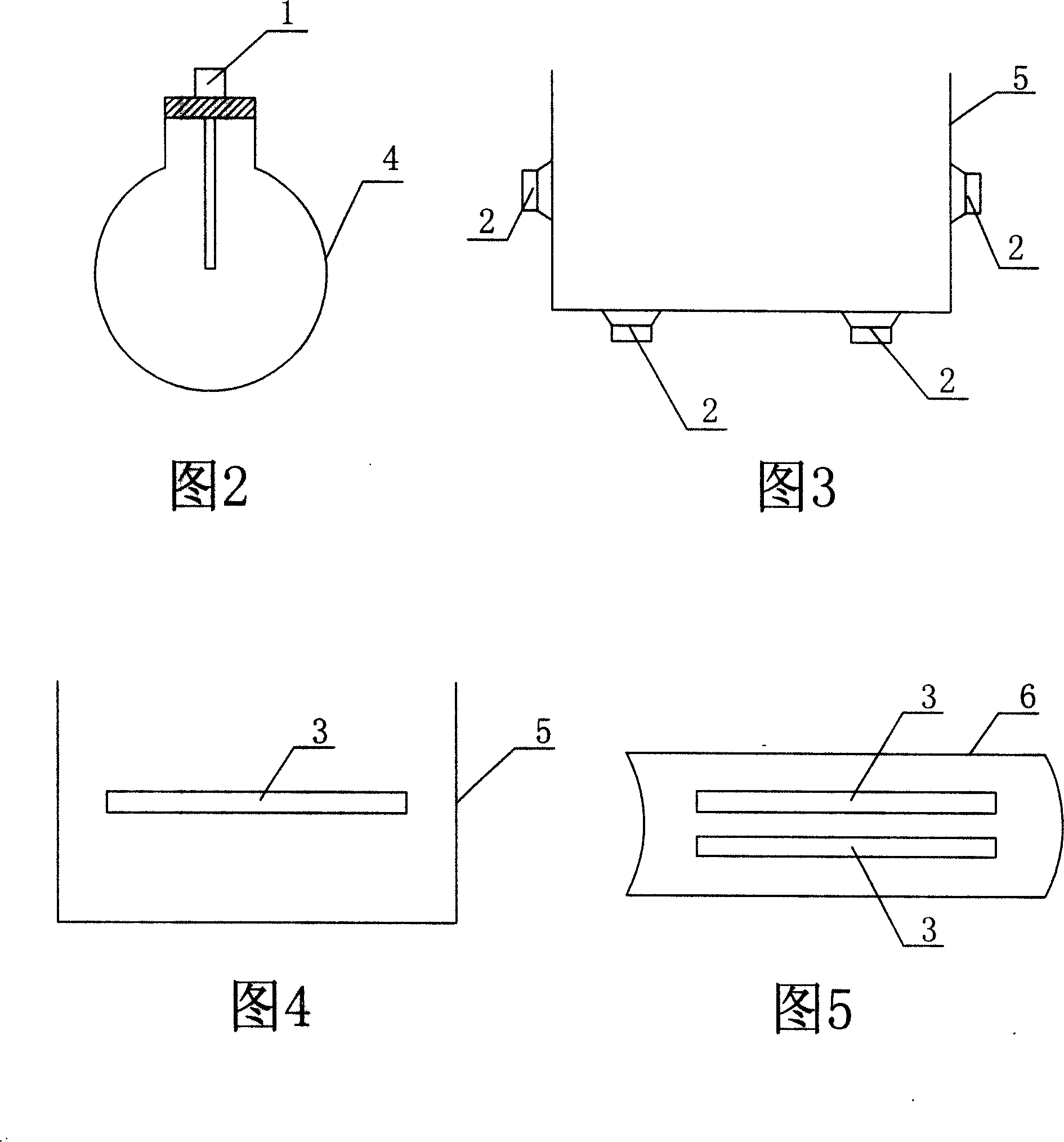

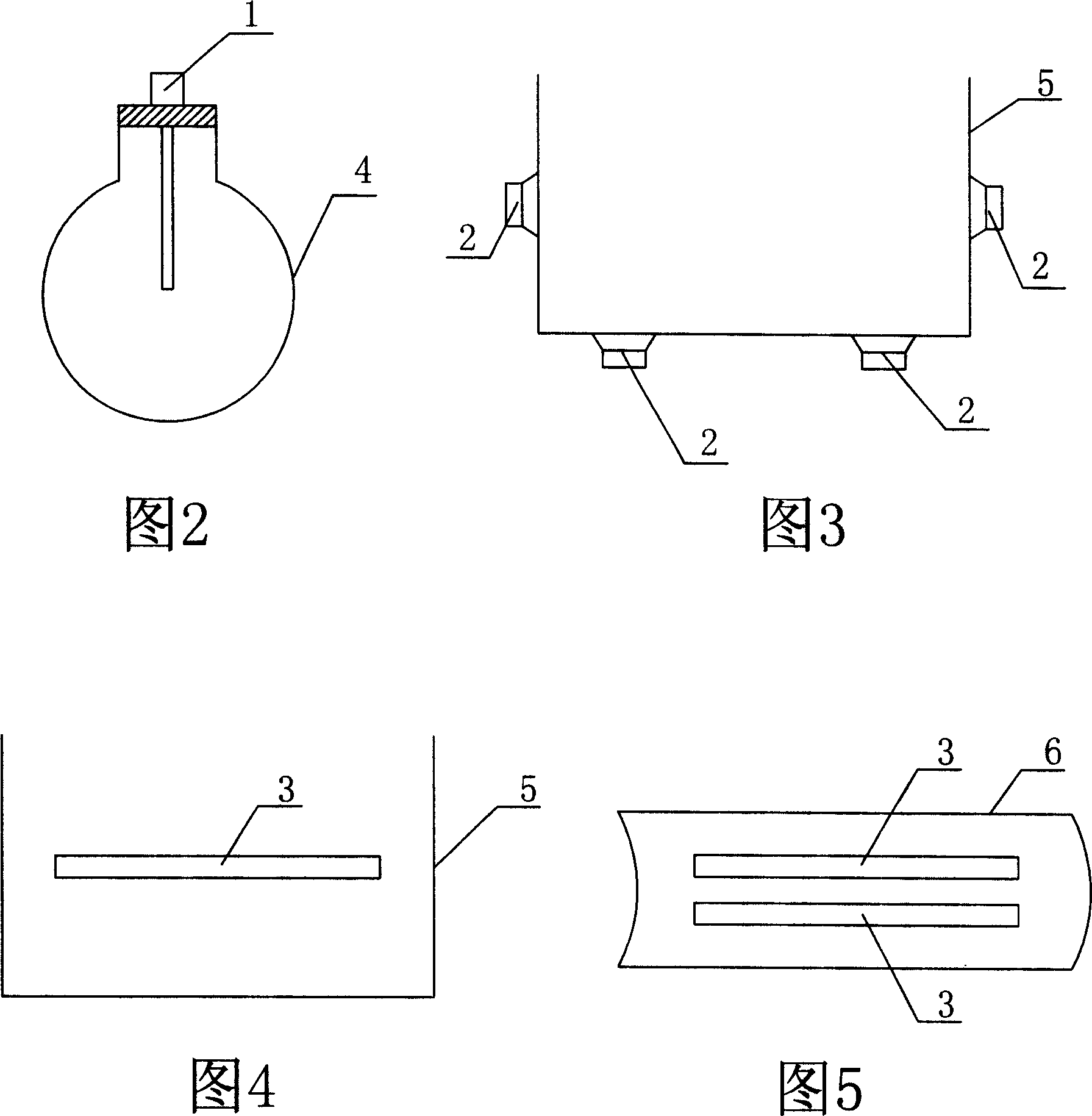

The invention provides a water conveyance tunnel with a prestressed composite lining for shield tunnelling. The tunnel comprises an ordinary reinforced concrete outer lining (1) which is formed by shield construction and is an assembled segment ring, wherein segments on the same ring are connected by connecting bolts (2); dowel bars (3) are installed in hand holes on the assembled segment ring; concrete is directly poured on the outer lining (1) to form an inner lining (5); shear keys (6) are formed in such a manner that concrete is filled in the hand holes of the outer lining; and the inner lining (5) and the outer lining (1) are combined via the dowel bars (3) and the concrete shear keys (6) to form a composite lining structure. Thus, the defects of great construction difficulty, long construction period and higher investment caused by the separated pressure pipeline water conveyance scheme for shield tunnelling are overcome. The technical problems of high head, high flow, high load and possibility of endangering the tunnel safety due to seepage of underground water, which are encountered when the soft soil layer of the riverbed is tunnelled in the shield tunnelling construction of the Yellow River crossing tunnel, are solved. Besides, the invention reduces the project investment and has obvious social benefits.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

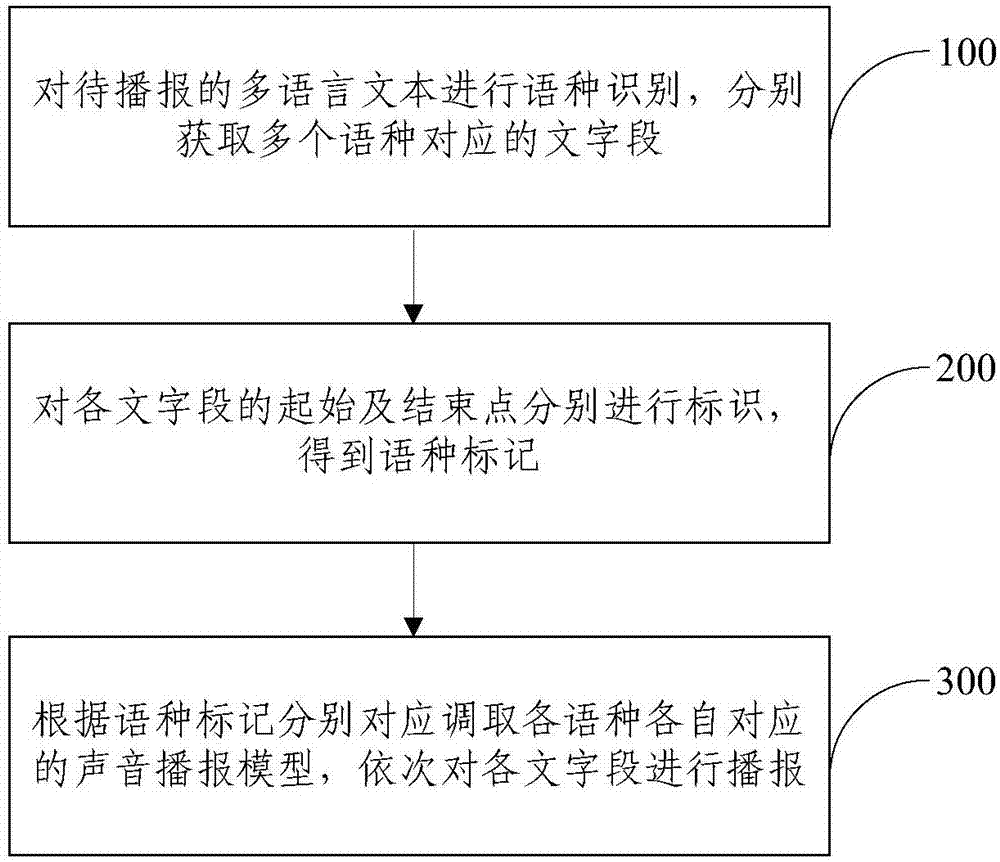

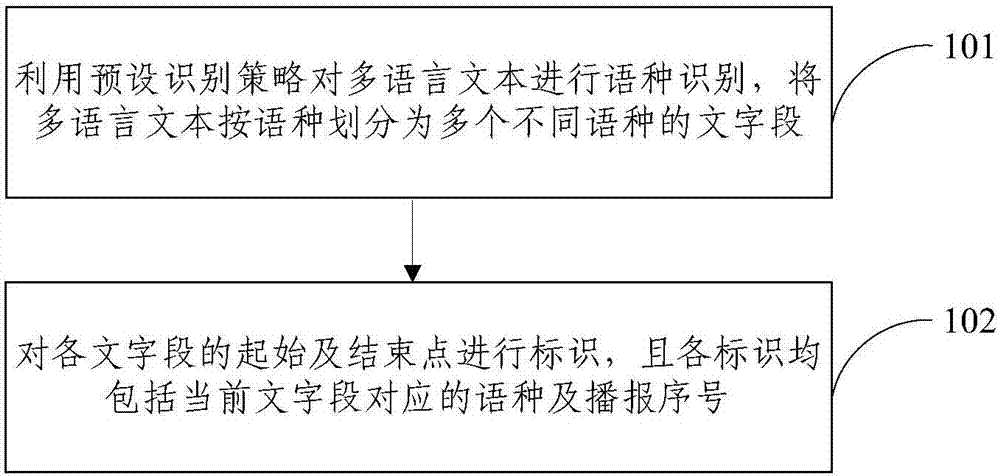

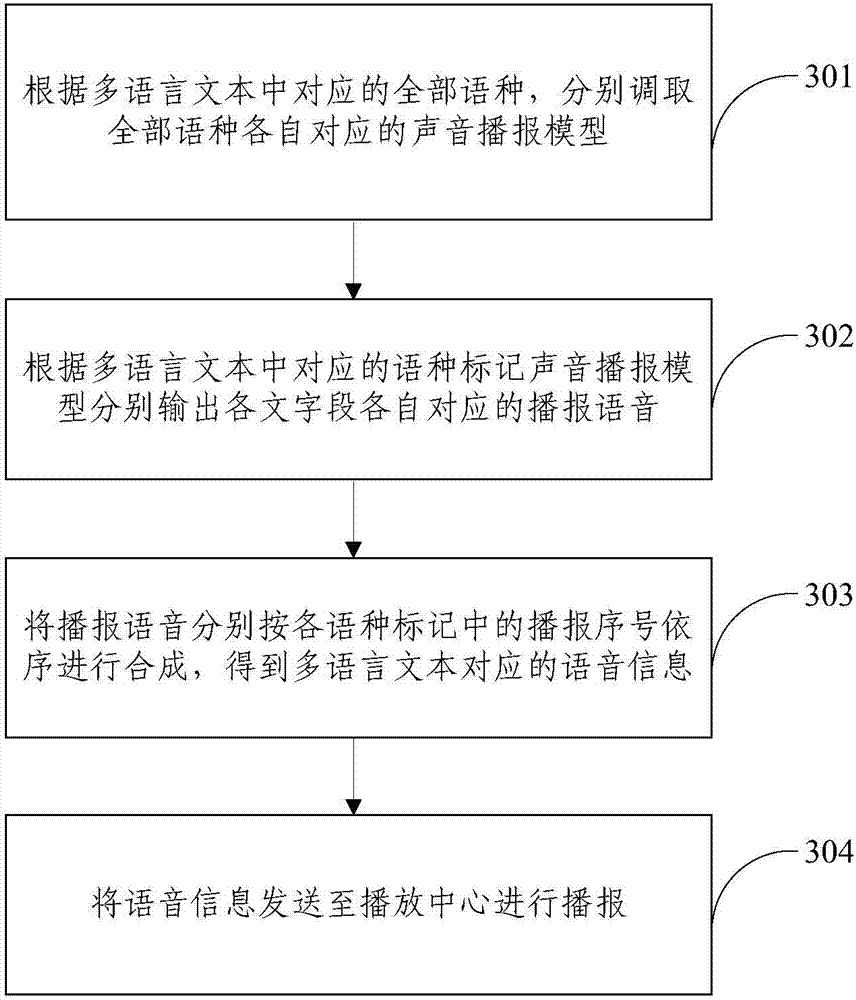

Multi-language text automatic broadcast method and system

InactiveCN106856091ARealization of automatic broadcastAutomatic broadcast flexibleSpeech synthesisMulti languageBroadcasting

The invention discloses a multi-language text automatic broadcast method and system. According to the method, language identification is performed on a multi-language text to be broadcasted, and text fields corresponding to multiple languages are respectively acquired; the start and end points of each text field are respectively identified so as to obtain language identifiers; and the corresponding sound broadcast type of each language is correspondingly called according to the language identifiers, and all the text fields are broadcasted in turn. The system is provided with a character identification module and a voice broadcast module. The method and the system are intelligent and flexible so that rapid and accurate automatic identification and broadcasting of the multi-language text can be realized, and the situation of omitting language information in identifying the multi-language text can be avoided.

Owner:BEIJING INTELLIGENT STEWARD CO LTD

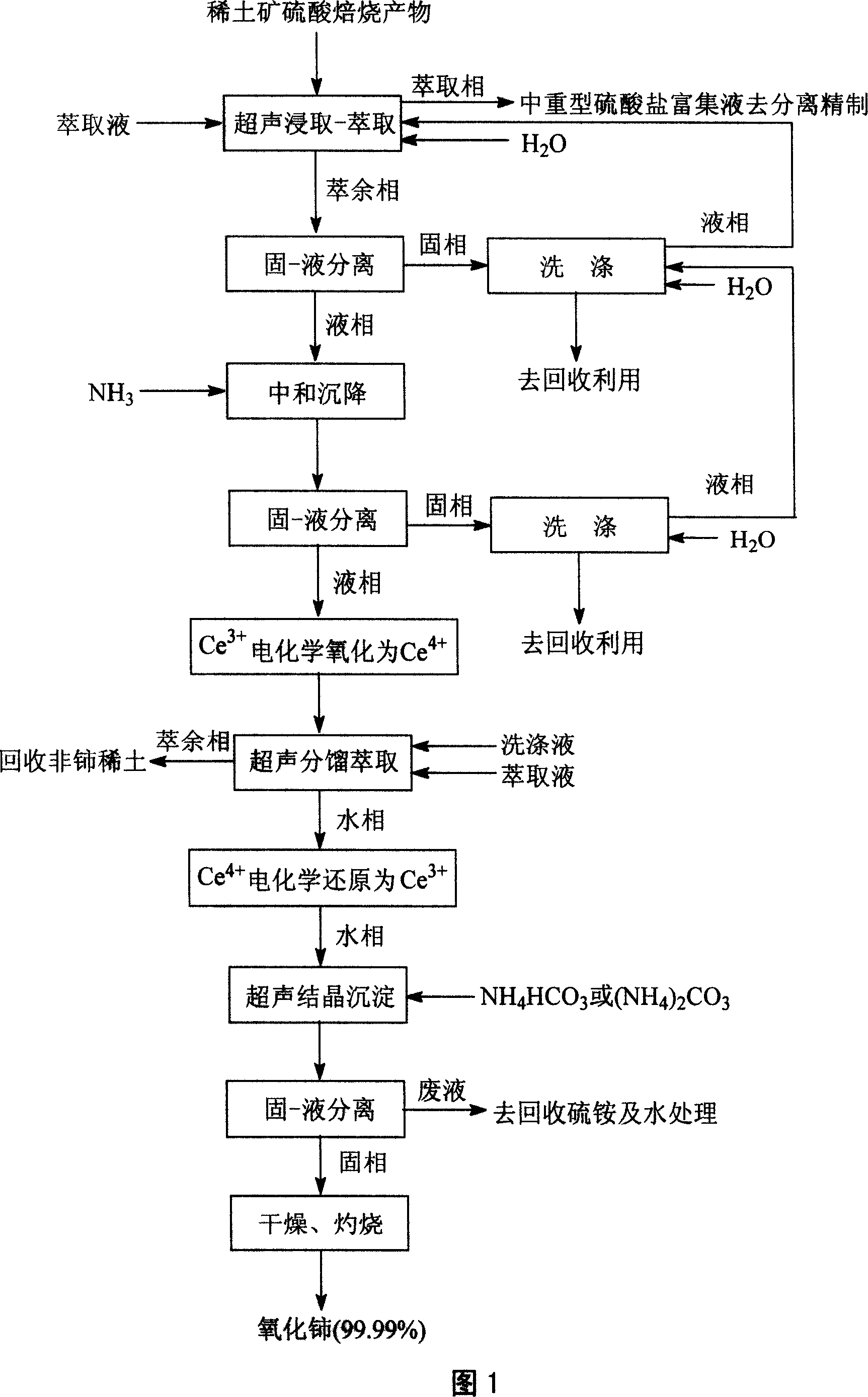

Method for preparing superfine high-purity cerium oxide by using rear earth ore sulfuric acid calcination products

InactiveCN101024504AIncrease speedImprove efficiencyRare earth metal compoundsProcess efficiency improvementSulfateRare earth

The invention relates to a method to make high purity cerium oxide that includes the following steps: taking ultrasonic leaching and extraction to gain rare earth sulfate enriched liquid; taking solid-liquid separation; taking neutralization deposition, taking solid-liquid separation, taking electrochemistry oxide to gain quadravalence cerous sulfate material liquid, taking ultrasonic fractional extraction, taking electrochemistry reducing to gain trivalence cerous sulfate, taking ultrasonic crystallization deposition to gain cerous sulfate crystal deposition, taking solid-liquid separation, drying and burning to gain the superfine high purity cerium oxide product of content over 99.99%, and the particle diameter is 0.01-10.0um. The advantages of the invention are that it improves leaching and extracting speed, improves yield, and purity, lowers cost and is environment protection.

Owner:常州市西南化工研究所 +2

Method and apparatus for detecting a plasma

InactiveUS20050067102A1Reliable processSimple and inexpensive monitoringLiquid surface applicatorsElectric discharge tubesEngineeringMaterials processing

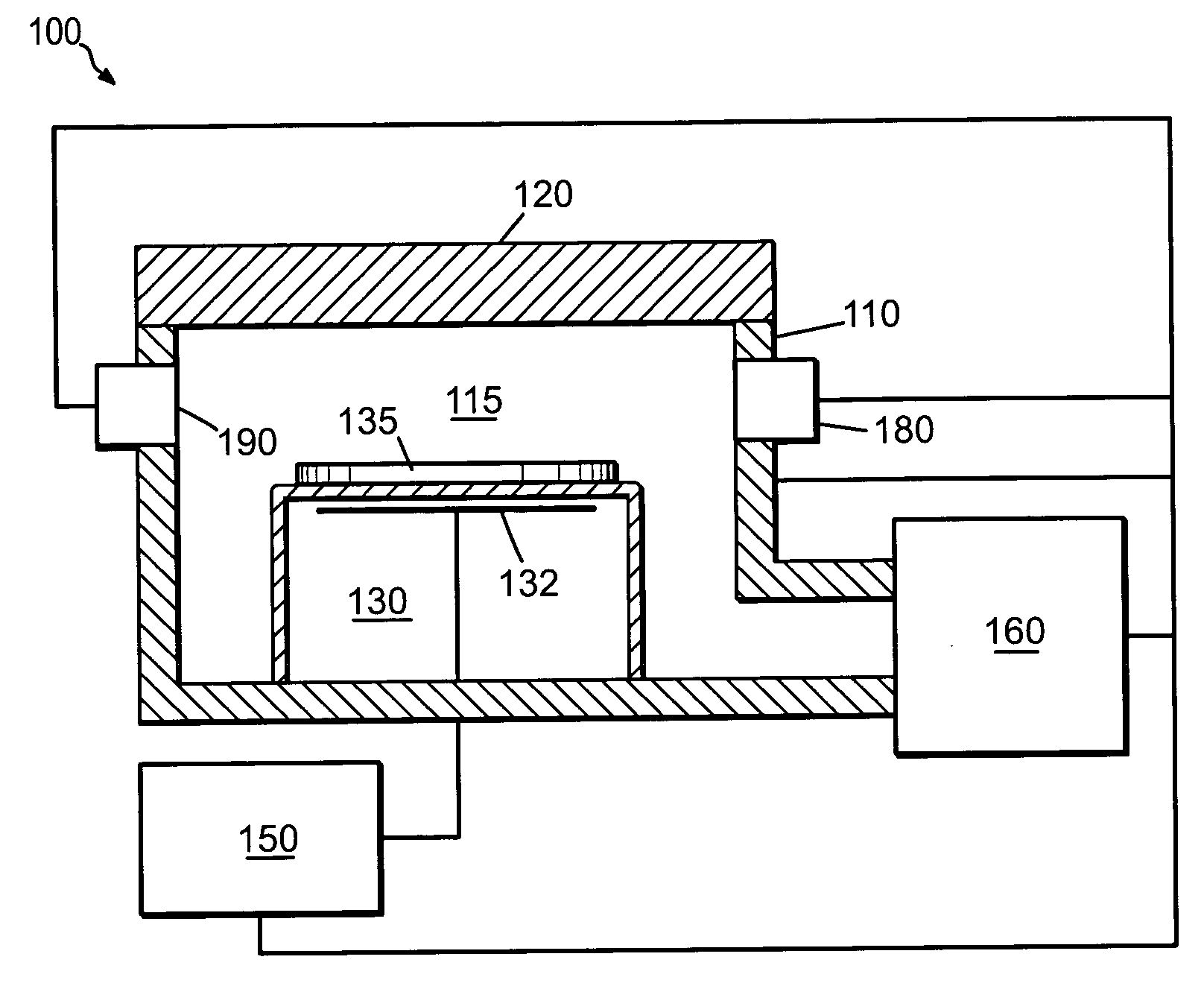

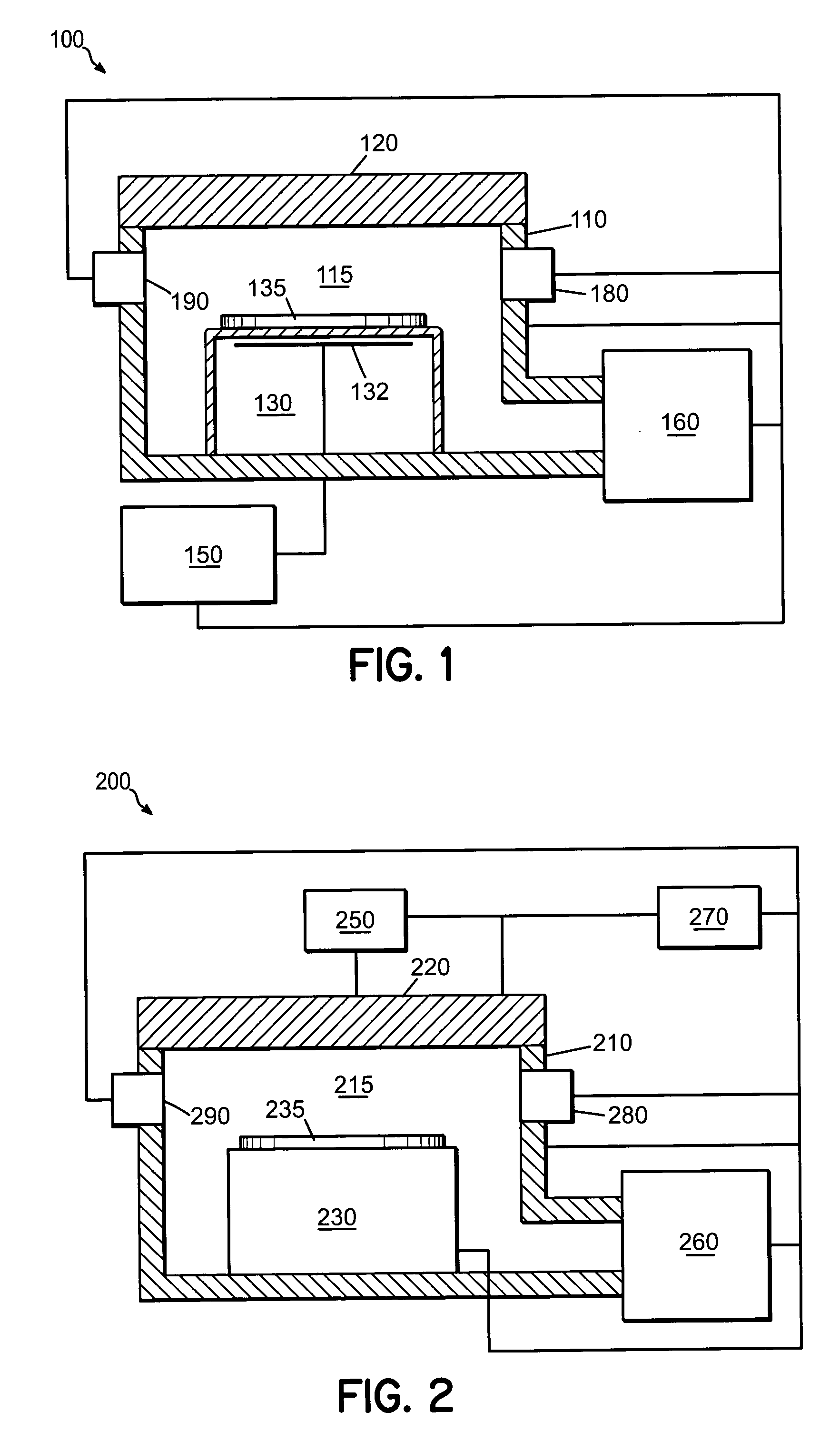

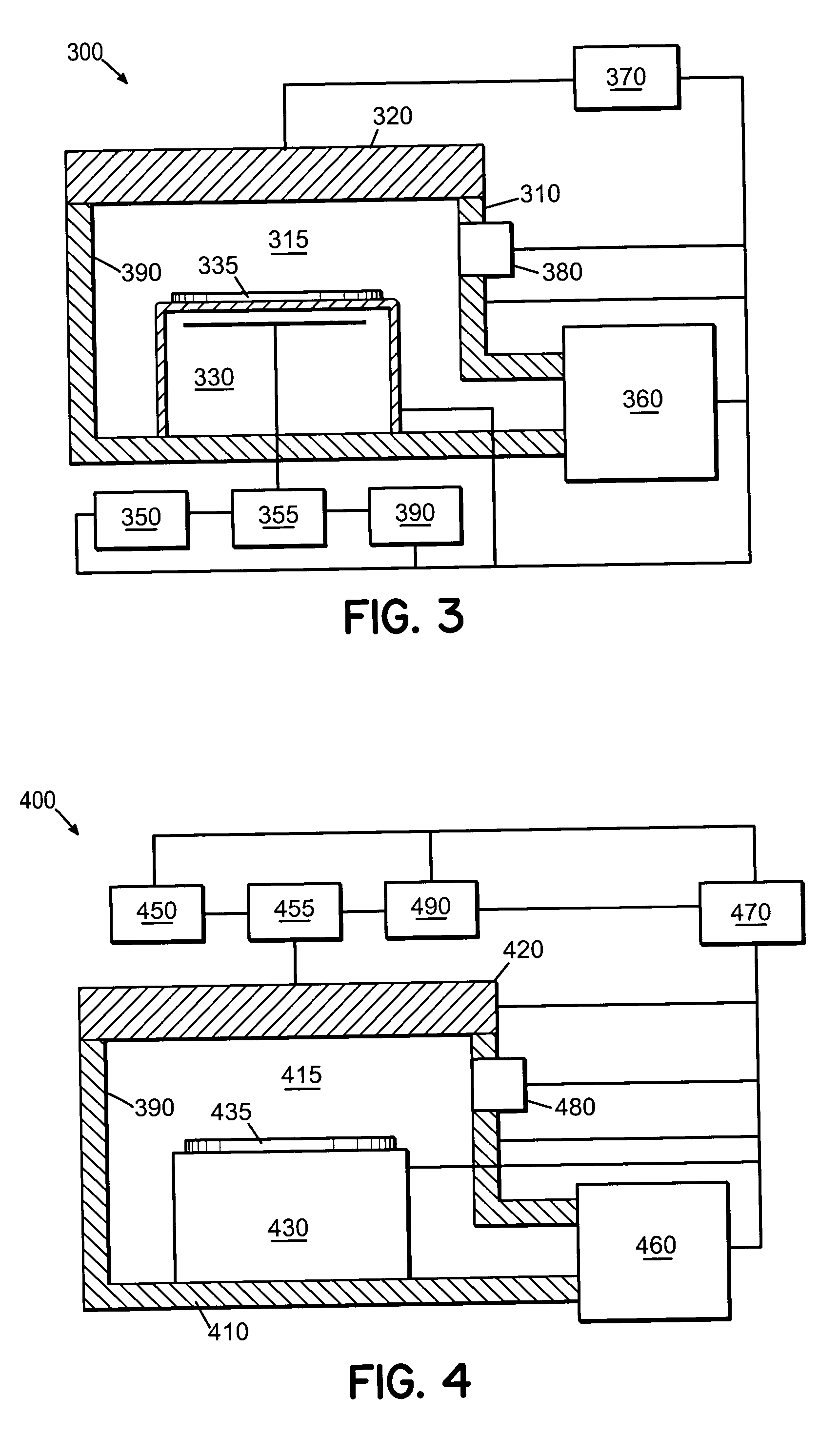

The present invention presents an improved apparatus and method for monitoring a material processing system, where the material processing system includes a processing tool, test signal source, and a filter / detector. The test signal source providing a first test signal and a second test signal to the processing chamber, and the filter / detector detecting an intermodulation product of the first test signal and the second test signal generated when a plasma is created.

Owner:TOKYO ELECTRON LTD

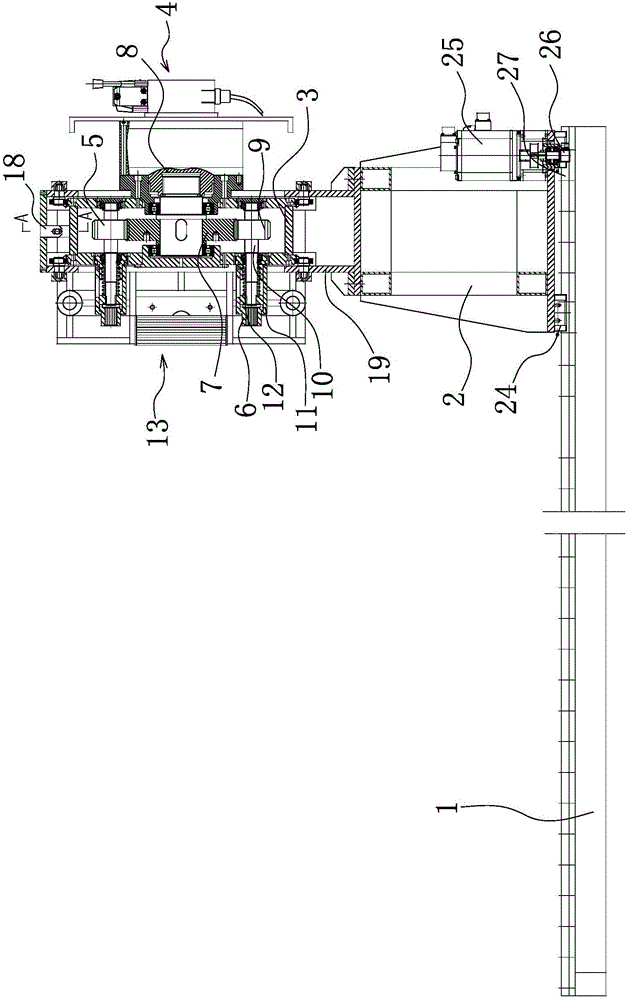

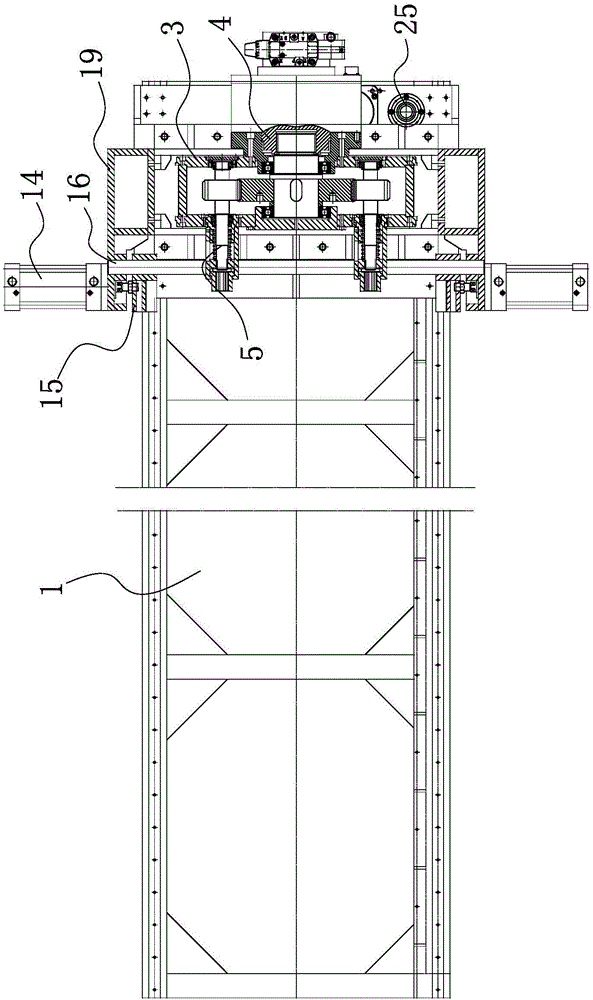

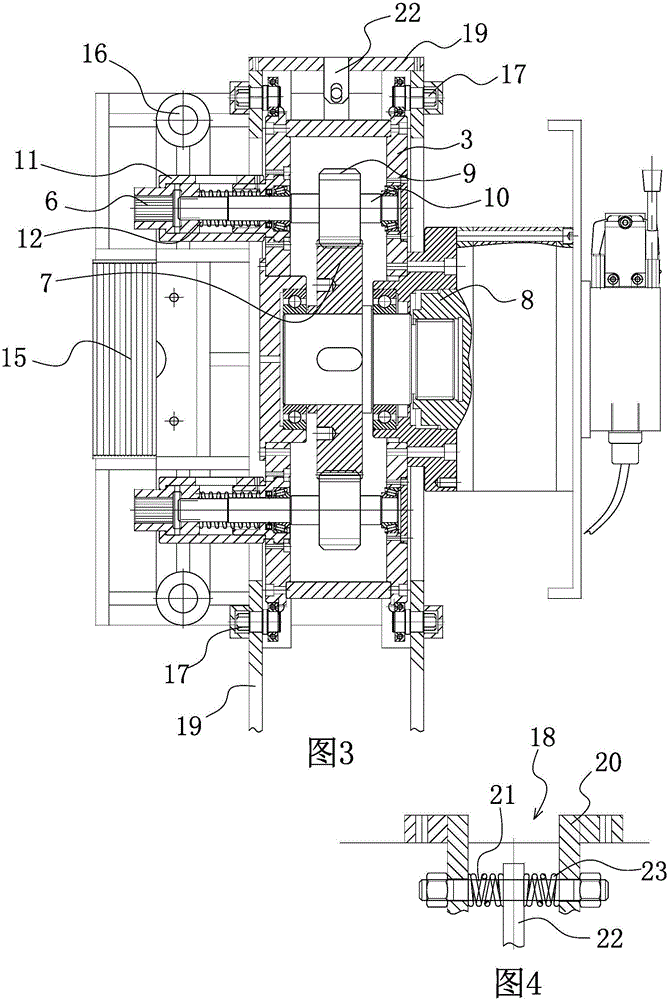

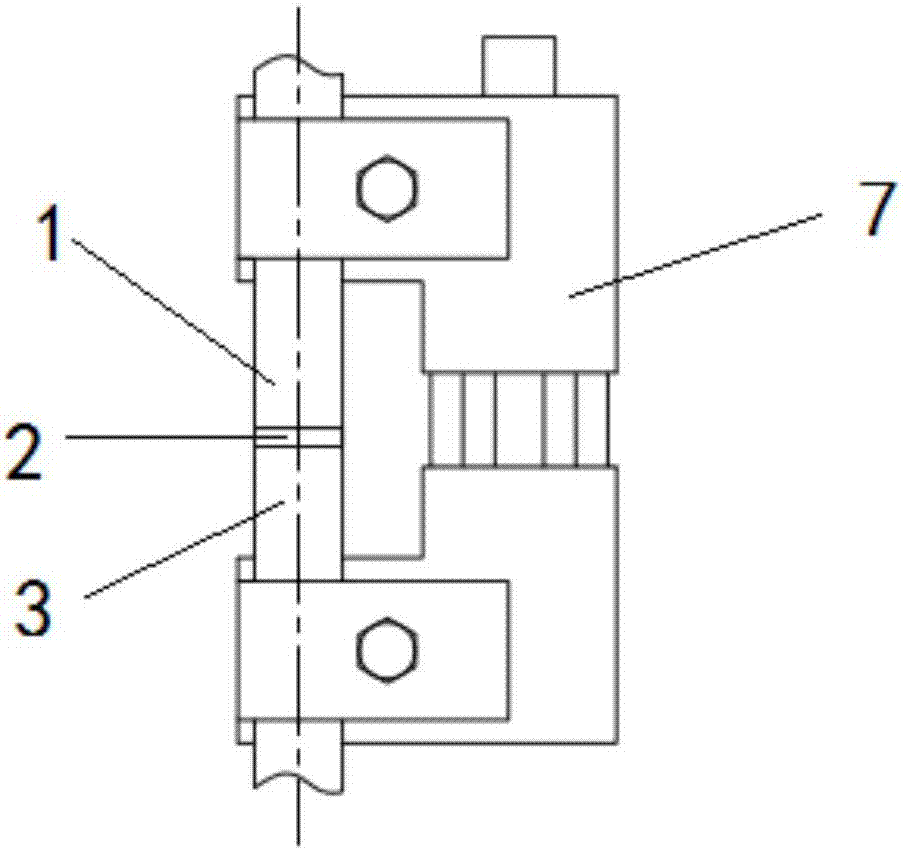

Machine for dismounting small nuts of fixed end plate by pipe mold

ActiveCN105666685AReliable processImprove work efficiencyDischarging arrangementEngineeringReciprocating motion

Owner:浙江兆弟技术有限公司

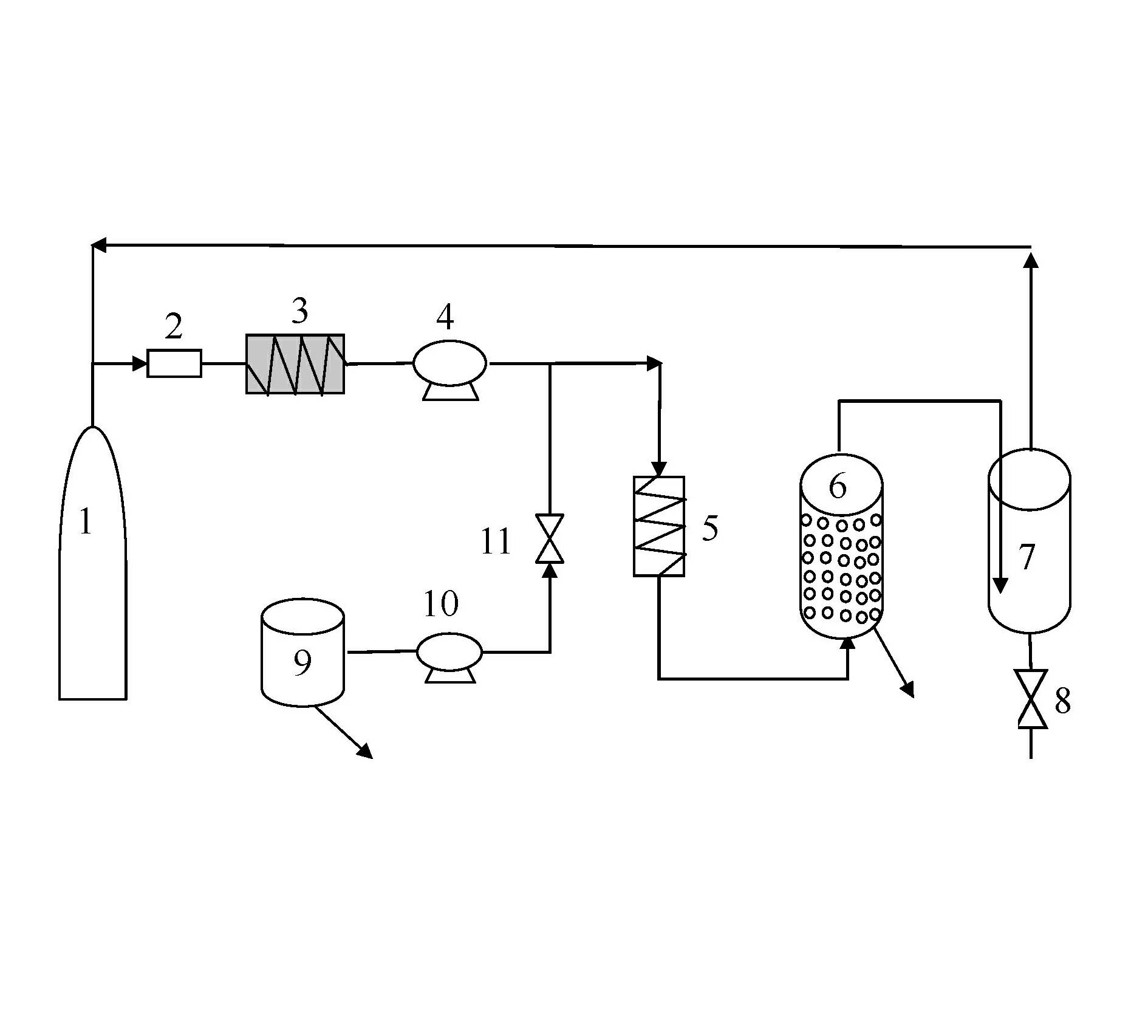

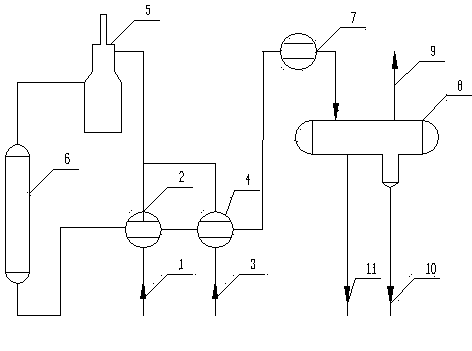

Novel supercritical carbon dioxide extraction technology for continuously carrying out fine extraction on liquid raw materials

InactiveCN102553295AContinuous productionShorten the production cycleSolid sorbent liquid separationLiquid solutions solvent extractionSlagLiquid state

The invention relates to a novel supercritical carbon dioxide extraction technology for continuously carrying out fine extraction on liquid raw materials. The liquid raw materials are filtered, have slag removed, and then are added into a container communicated to an extraction kettle; a random pressure and a random temperature are set in the range that the extraction pressure is higher than or equal to 7.3 MPa and the extraction temperature is higher than or equal to 3.2 DEG C; the flow of the liquid raw materials pumped into the extraction kettle from the container communicated to the extraction kettle is controlled and the flow rate of supercritical carbon dioxide pumped into the extraction kettle is regulated so as to change the ratio of supercritical liquid to a liquid sample to reach the optimal separation efficiency of different liquid samples and implement the continuous dynamic extraction; and fraction in a separation kettle is collected at regular time or continuously, so that corresponding extraction phases can be obtained; the extraction phases are absorbed by column chromatography fillers; and the extraction phases can be extracted by methods of changing the extraction pressure and the extraction temperature or changing the flow rate of the supercritical liquid or pumping a cosolvent and the like. According to the invention, the continuous supercritical carbon dioxide extraction of the liquid raw materials is implemented; the novel supercritical carbon dioxide extraction technology has the advantages of simple process flow, high repeatability, short process flow and wide application range, is convenient to operate, is green and has no pollution.

Owner:BIO SCENT INNOVATION XIAMEN

Air conditioning cabinet and air outlet control method implemented by same

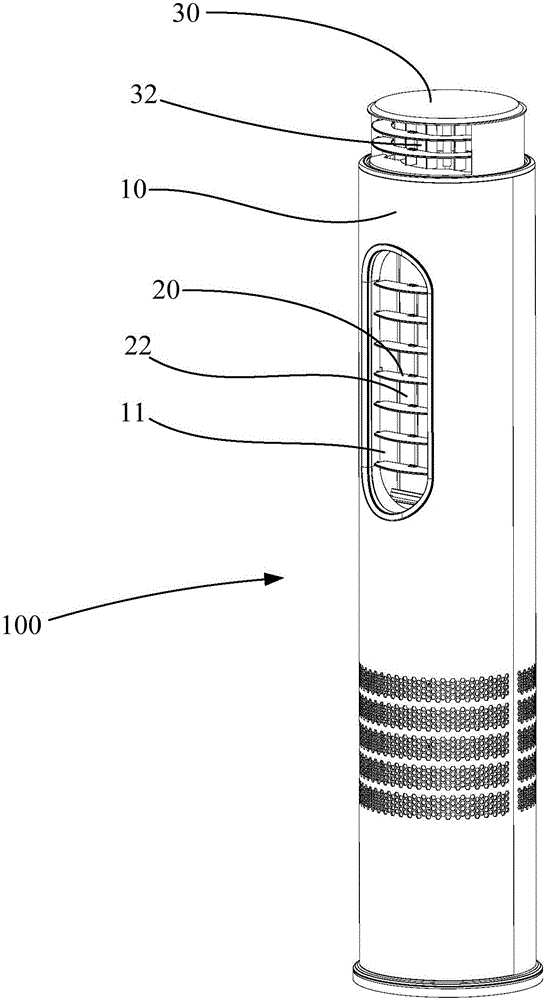

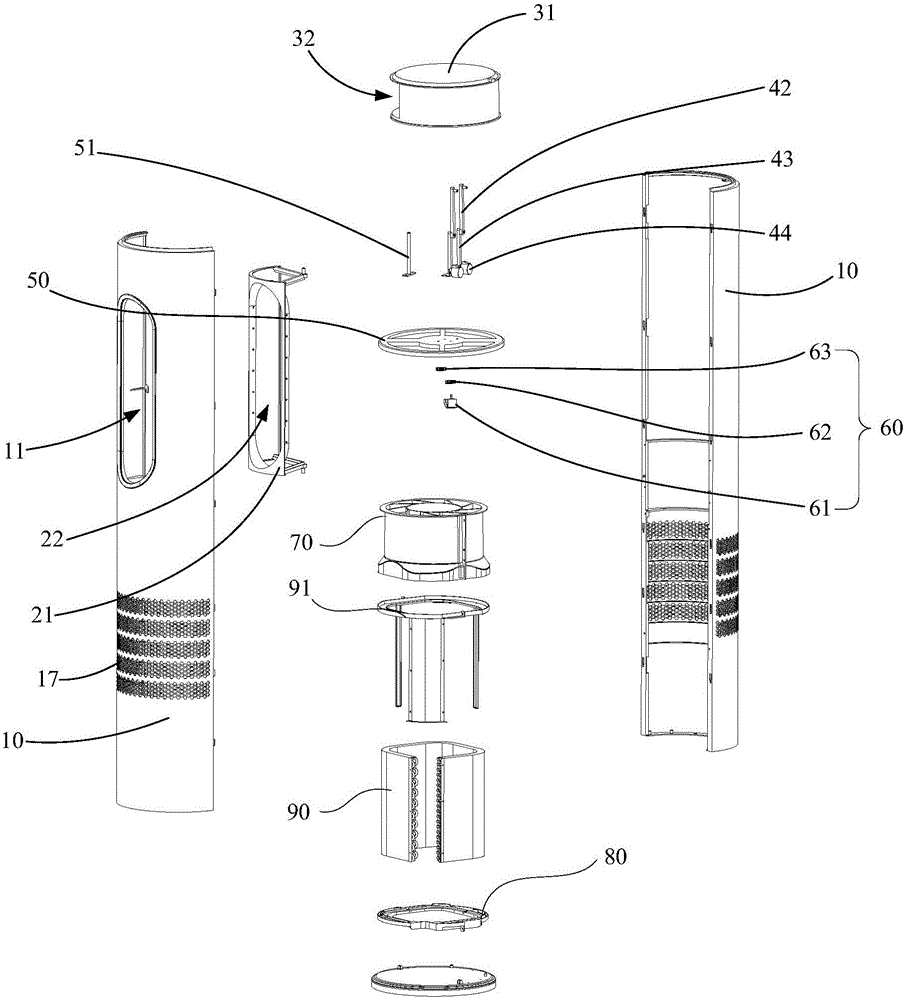

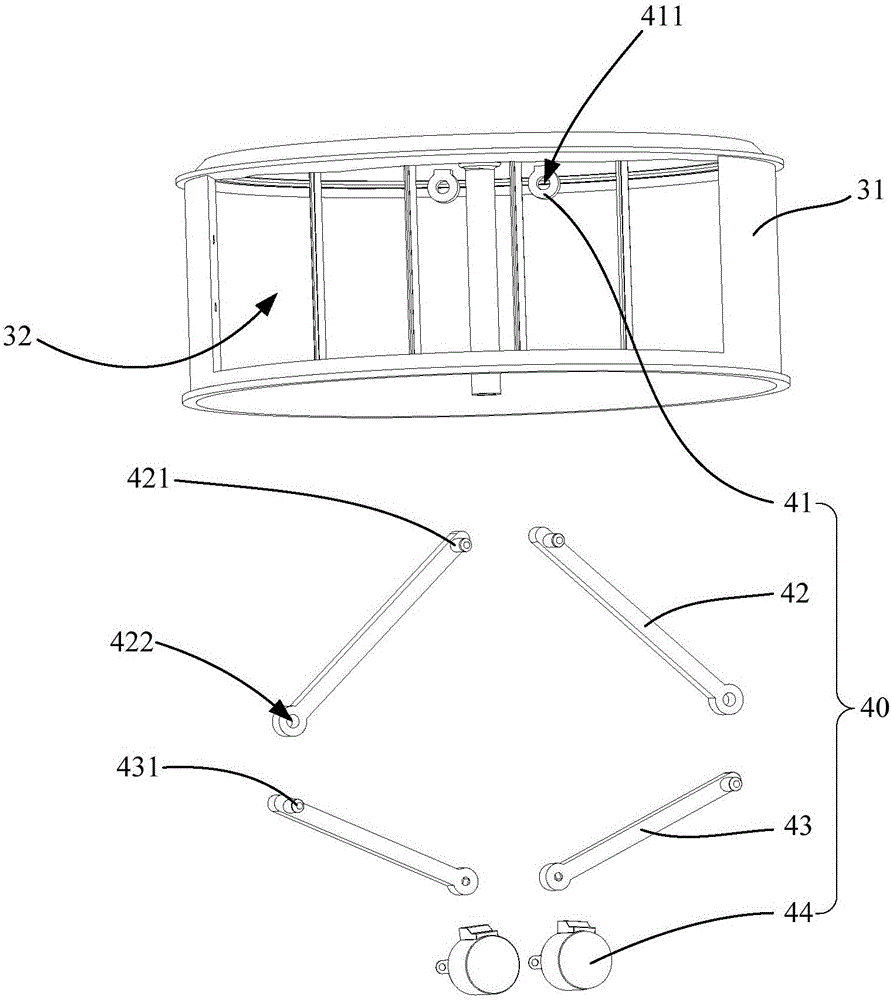

ActiveCN106287973AThe wind mode is reasonableAir outlet mode is validSpace heating and ventilation safety systemsLighting and heating apparatusAir conditioningAssembly structure

The invention discloses an air conditioning cabinet and an air outlet control method implemented by the same. The air conditioning cabinet comprises a shell, a front air outlet structure and a top air outlet structure. At least one air channel is formed in the shell; the front air outlet structure is arranged on the shell and is provided with a first air outlet communicated with air channels; the top air outlet structure is arranged at the upper end of the shell and is provided with a second air outlet communicated with the air channels, lifting structures are connected with the top air outlet structure and are arranged on the shell, a first rotary structure is connected with the lifting structures, the top air outlet structure can be driven by the lifting structures to move up and down, and a rotary disc, the lifting structures and the top air outlet structure can be driven by the first rotary structure to rotate relative to the shell. According to the technical scheme, the air conditioning cabinet and the air outlet control method have the advantages that the air outlet range of the air conditioning cabinet can be expanded, and the temperature of indoor air can quickly and effectively reach set temperature values; the air conditioning cabinet is simple in assembly structure, and the service comfort can be improved.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

Automatic welding technology for butt joint of low alloy steel and nickel base alloy dissimilar steel heat-exchange tubes

ActiveCN107052517AGuaranteed performanceGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesButt weldingButt joint

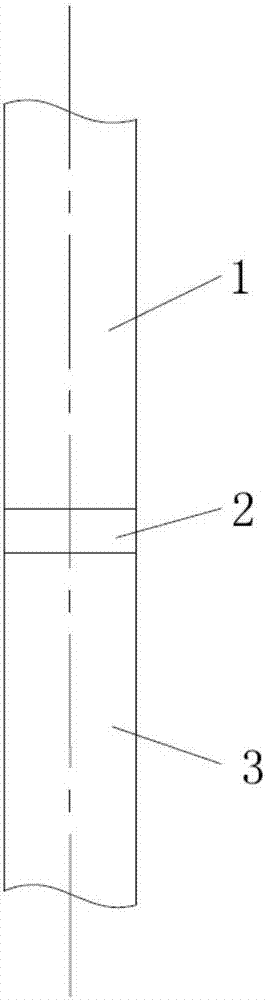

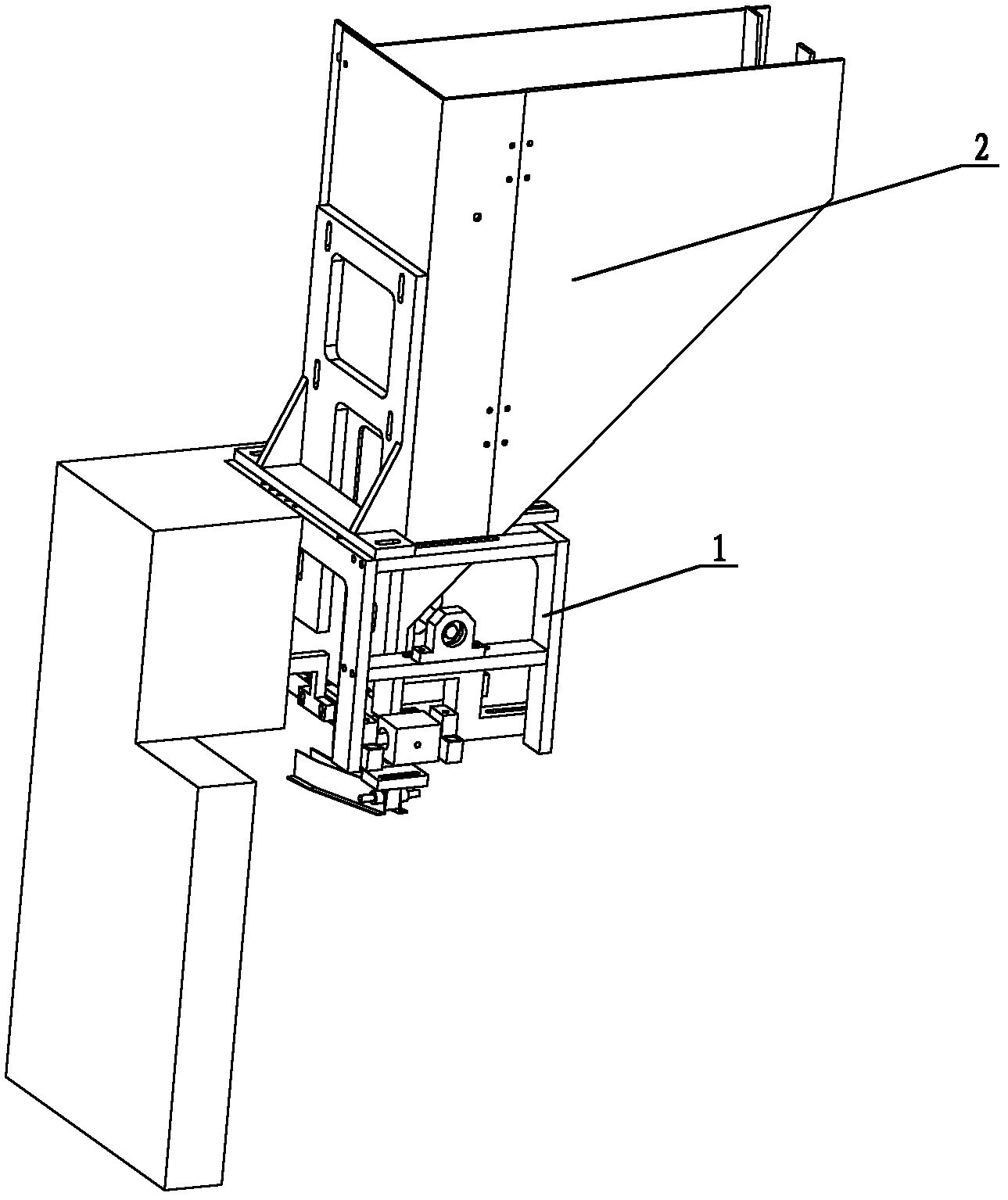

The invention discloses an automatic welding technology for butt joint of low alloy steel and nickel base alloy dissimilar steel heat-exchange tubes. The automatic welding technology comprises the following steps that a heat-exchange tube I (1), a heat-exchange tube II (3), and a melting ring (2) are cleaned; the heat-exchange tube I (1), the heat-exchange tube II (3), and the melting ring (2) are assembled; welding equipment is installed and debugged; and parameters of the welding technology are set, and welding treatment is started. The automatic welding technology for butting joint of low alloy steel and nickel base alloy dissimilar steel heat-exchange tubes combines special heat-exchange tube specifications and special welding technology parameters and choose of tungsten electrode, and is applied to butt welding between heat-exchange tubes of small diameters and big thick walls, the welding process is stable and reliable, formation of a welding joint is even and artistic, the welding joint is well fused, the welding efficiency is high, all destructive tests and physical and chemical performance tests are conducted, and the result meets the requirement for welding quality of the dissimilar steel heat-exchange tubes in a high temperature gas cooled reactor steam generator.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

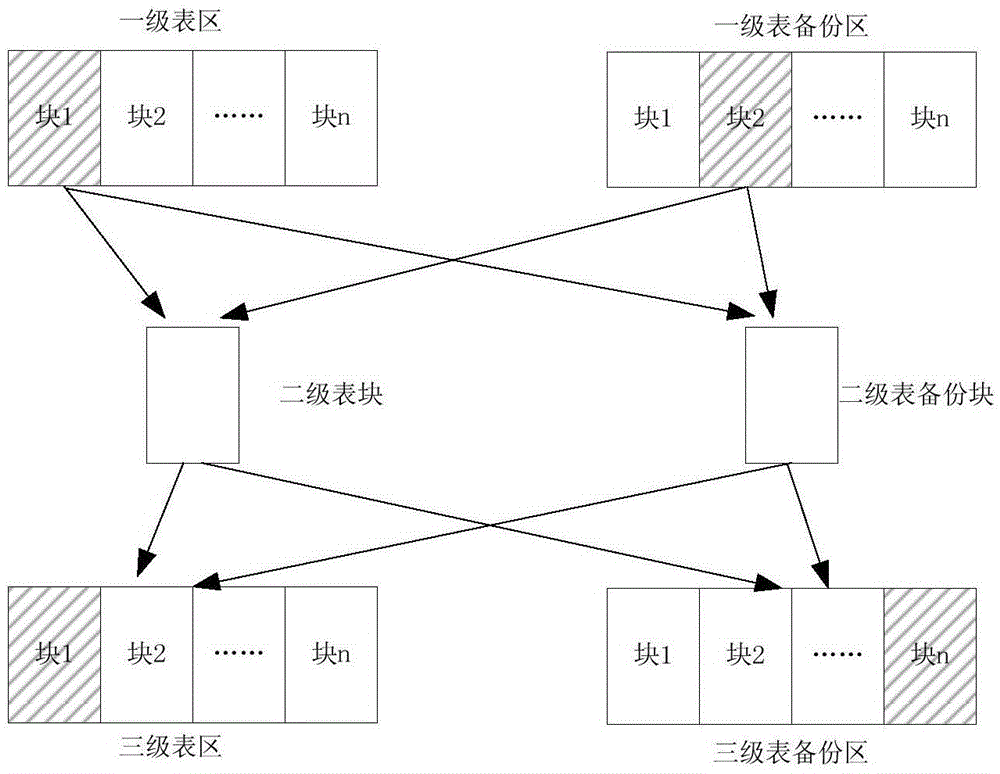

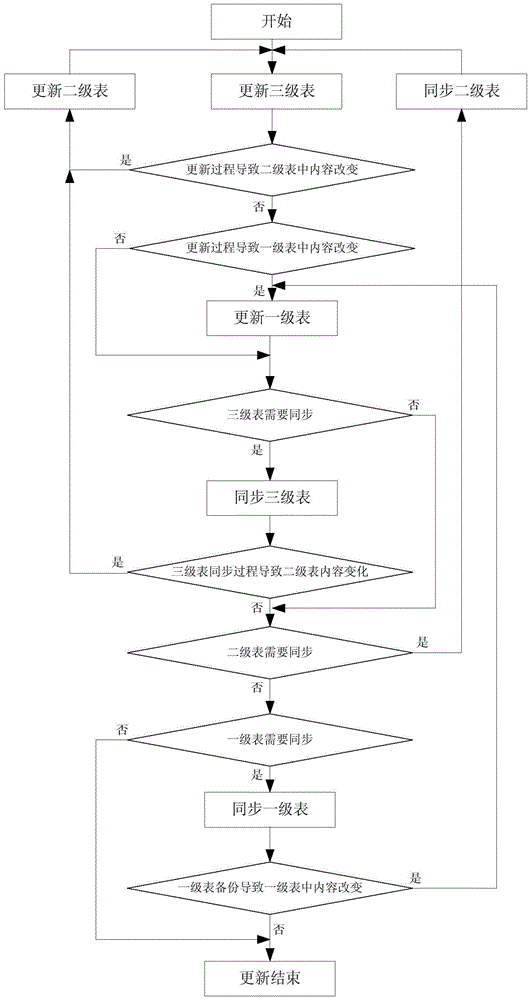

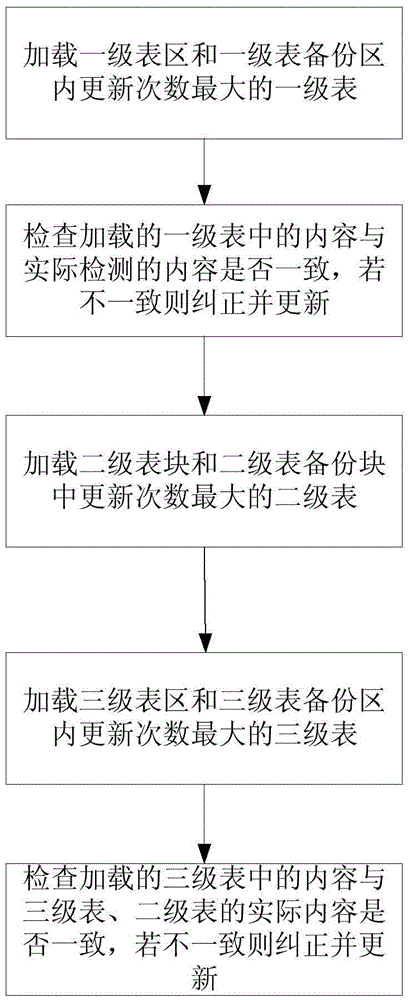

System power failure protection realizing method for NAND FLASH

ActiveCN105589767ASystem state recoveryEasy searchMemory loss protectionRedundant operation error correctionElectricityComputer architecture

The invention discloses a system power failure protection realizing method for a NAND FLASH. The method comprises following steps: 1, carrying out mapping management to all blocks in the NAND FLASH through a first level stable, a second level table and a third level table; 2, electrifying a system, loading the first level stable, the second level table and the third level table, recovering the system to a working state; 3, judging whether an abnormal power failure is generated in a data updating process according to the data in the tables; and 4, when the information stored in the NAND FLASH changes, updating the first level stable, the second level table and the third level table. According to the method of the invention, after the new first level stable, the new second level table or the new third level table is written successfully, the original first level stable, the original new second level table or the original new third level table is erased; the tables are located in a searchable address range; therefore, after the system is electrified again after the power failure, the system stores the data in the tables completely; and the system state can be recovered according to the data in the tables.

Owner:BEIJING MXTRONICS CORP +1

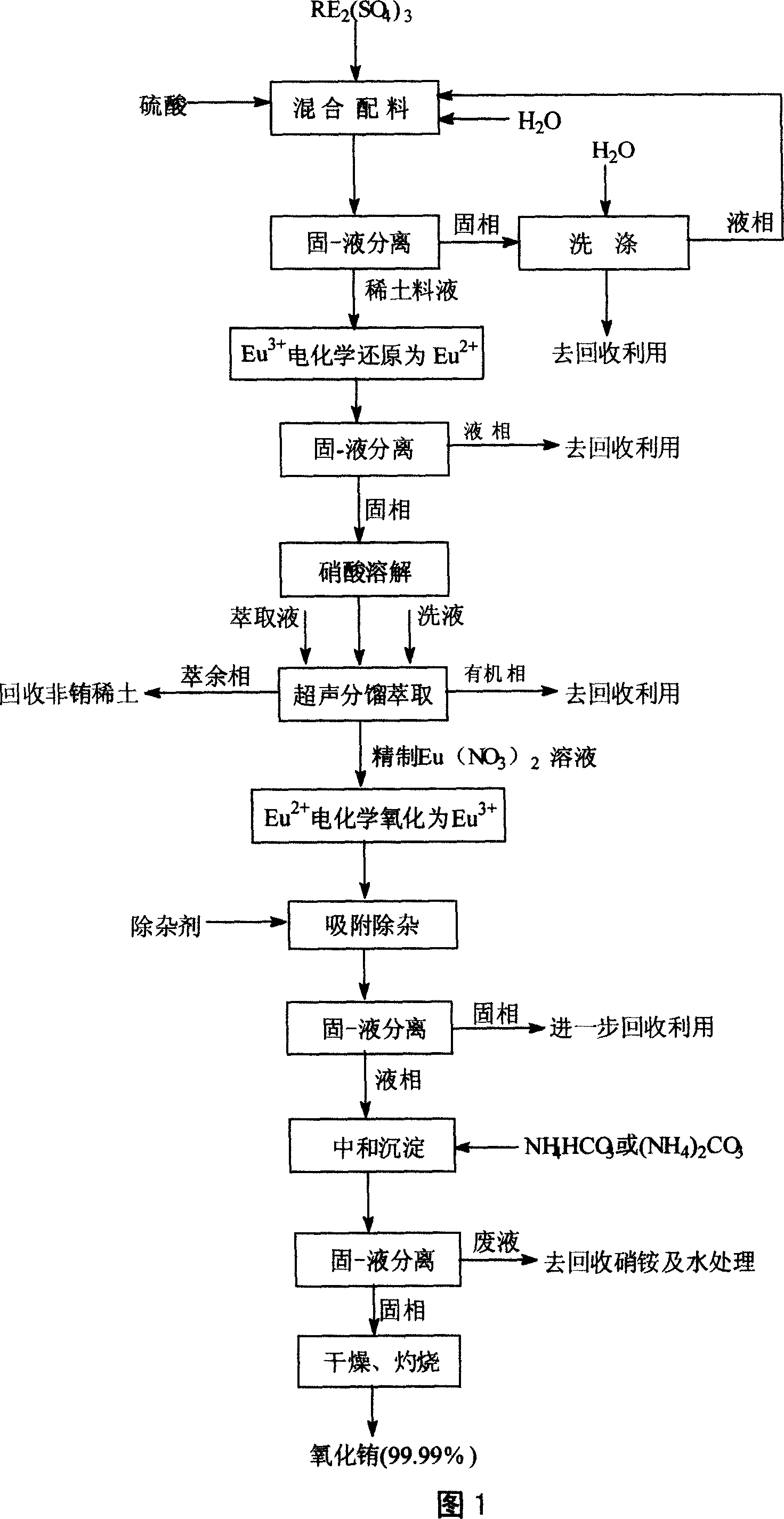

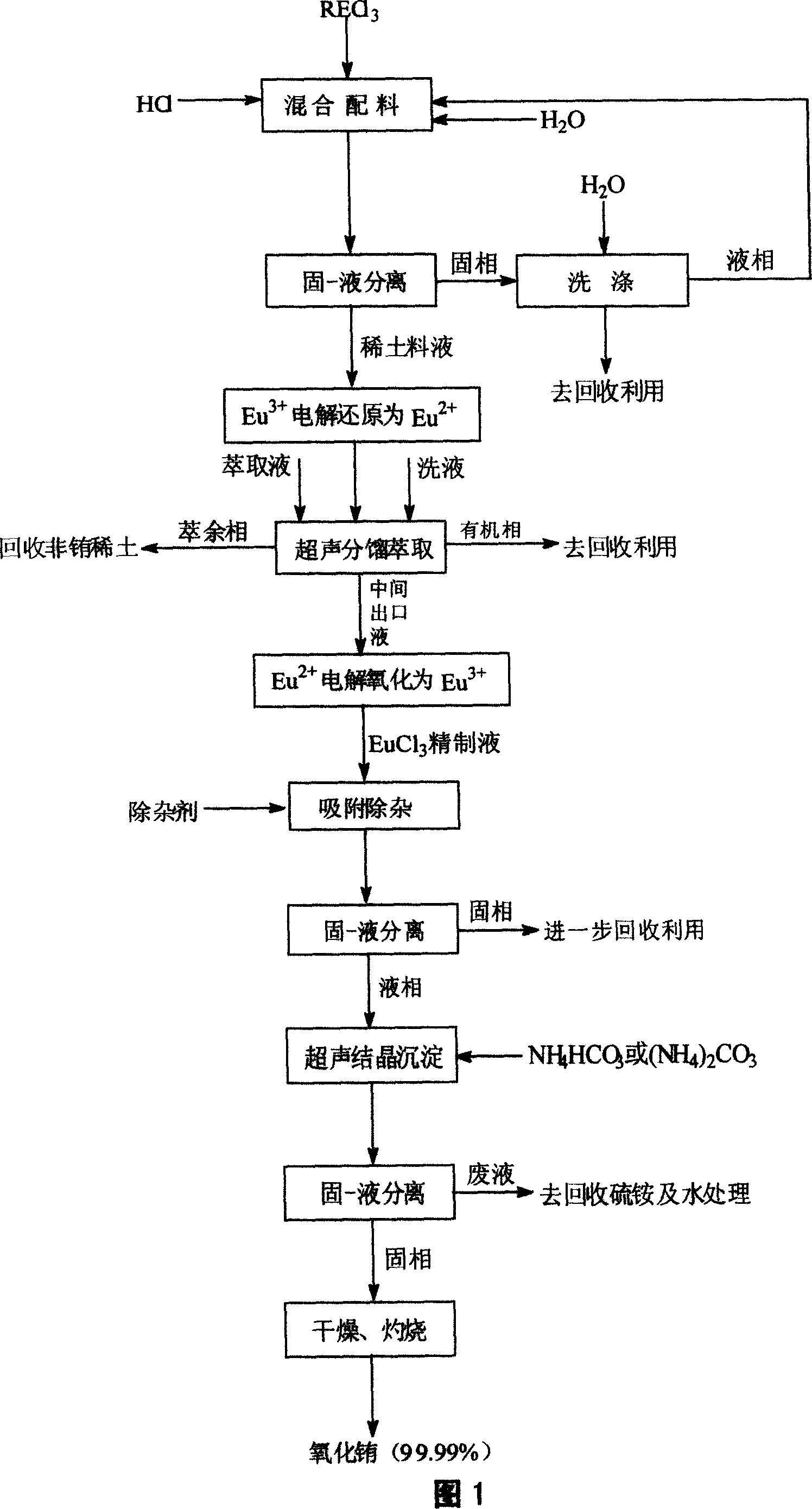

Method for preparing ultra-thin highly-pure europium oxide by europium-rich sulfuric acid rare earth

InactiveCN101012509AReduce consumptionImprove utilization efficiencyProcess efficiency improvementRare earthSlurry

The invention discloses a making method of europium oxide, which comprises the following steps: (1) blending raw material; (2) separating solid from liquid; obtaining the enriched slurry of europium sulfate rare earth; (3) proceeding electrochemical reduction; obtaining europium sulphate sediment; (4) separating solid from liquid; (5) dissolving through nitric acid; (6) fractionating; extracting; obtaining fined liquid of Eu (NO3) 2; (7) proceeding electrochemical oxidization; obtaining the fined liquid of Eu (NO3) 3; (8) adsorbing impurity; (9) crystallizing; sedimenting through ultrasound; producing Eu2 (CO3) 3 sediment; (10) proceeding solid-liquid separation; (11) drying; sintering; obtaining Eu2O3 with content not less than 99.99% and grain size at 0.01-10.0um.

Owner:CHANGZHOU HUANAN CHEM +2

Arc welding system and method with low energy input

InactiveCN1986135AReduce energy inputReliable processProgramme controlComputer controlElectric machineMotor controller

The present invention belongs to the field of welding equipment and automation technology, and is especially arc welding system and method with low energy input. The arc welding system operates in wire pulling and pushing feed mode, and has one welding system and one wire feeding system. The welding system includes one main circuit for providing the welding power directly and one control circuit for controlling the output power of the main circuit. The wire feeding system includes one upper computer, one motor controller and one wire feeding motor connected together. The wire feeding motor is AC servo motor and the upper computer has motor rotating program for setting the welding wire motion locus to control the welding process. The present invention has the advantages of simple control method and stable arc length.

Owner:BEIJING UNIV OF TECH

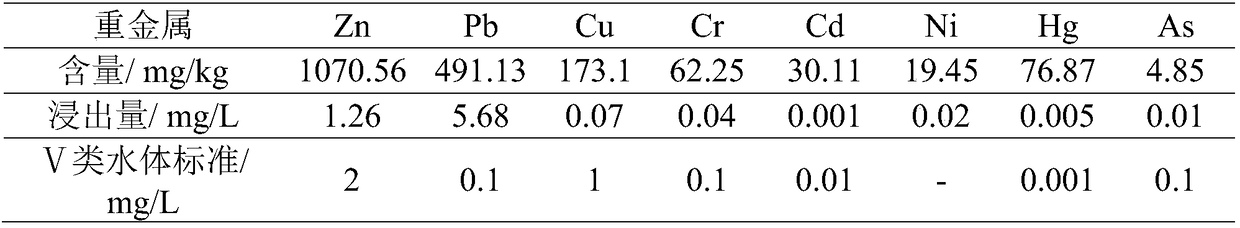

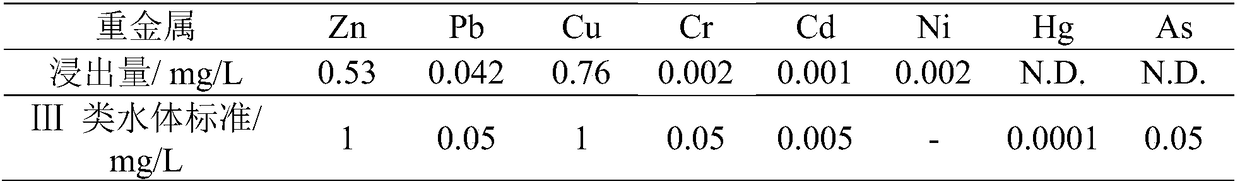

Method for making brick by household garbage incineration fly ash

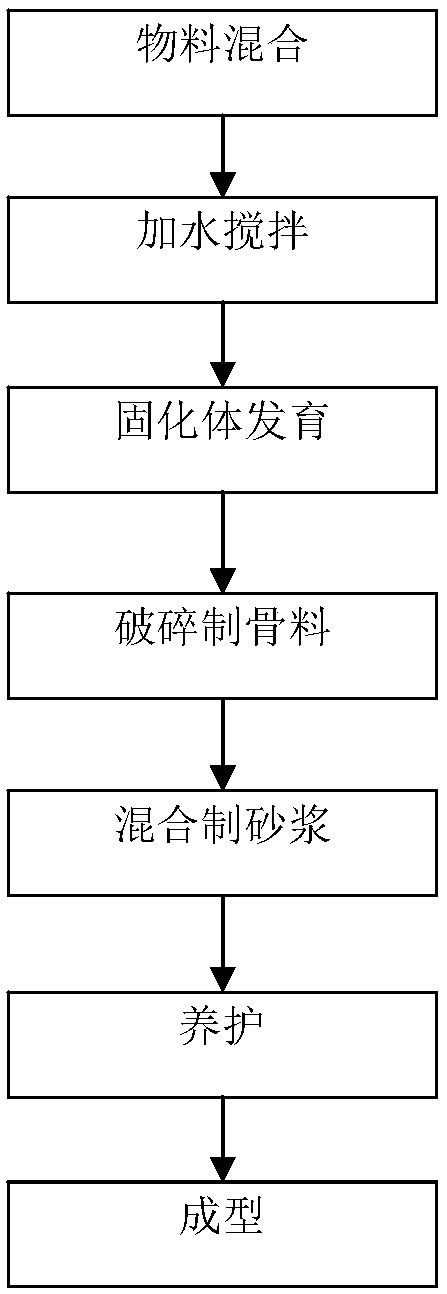

ActiveCN108409210ASimple processReliable processSolid waste managementSingle unit pavingsCalcium silicateBrick

The invention discloses a method for making a brick by household garbage incineration fly ash. The method includes the steps: (1) curing slurry prepared from the fly ash, MgO, cement and water to obtain a solidified body; (2) crushing the solidified body in the step (1) to obtain fly ash aggregate; (3) homogeneously mixing coal ash, NaOH, the water and the fly ash aggregate in the step (2); (4) curing and forming mortar in the step (3) to obtain the brick serving as a building material. Two gels including hydrated calcium silicate and geopolymers with different crystalline natures are matchedto manufacture the building material, multistage solidification and stabilization of heavy metals in the fly ash and building material recycling of the fly ash are realized, the mechanical performanceof the recycled building material is improved, the process is reliable, equipment and principles are simple, and the household garbage incineration fly ash in different regions and different furnaceprofiles can be safely and efficiently used.

Owner:TSINGHUA UNIV

Technology for preparing high-cleanliness and high-octane gasoline from methanol through one-step catalysis method

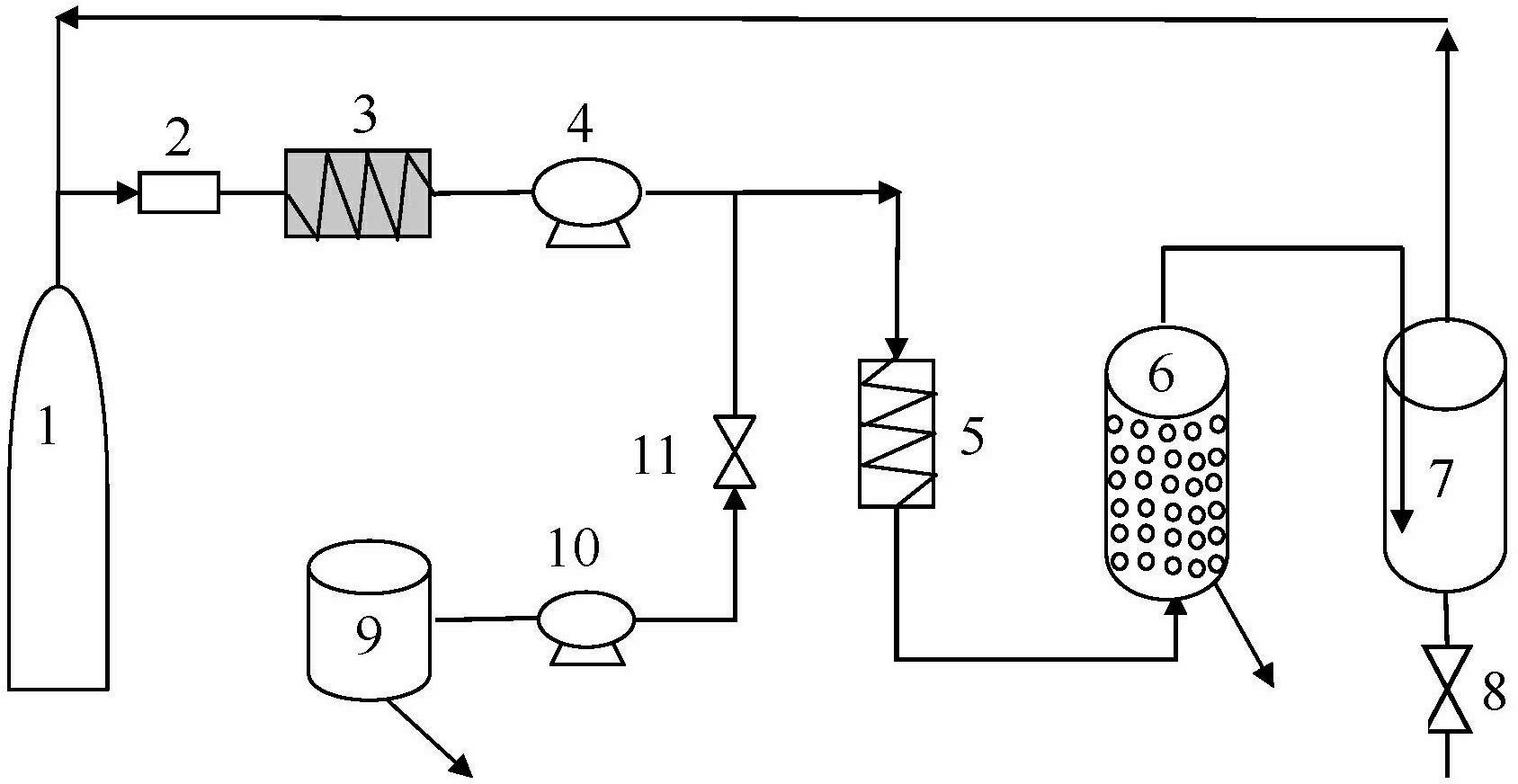

InactiveCN104130796AEasy to adjustPrecise temperature controlLiquid hydrocarbon mixture productionBio-feedstockGas compressorComponents of crude oil

The invention relates to a technology for preparing high-cleanliness and high-octane gasoline from methanol through a one-step catalysis method. The process of preparing gasoline from methanol is a strong heat release process, and existing technologies for preparing gasoline from methanol at home and abroad all adopt recycle gas (which mainly contains mixed methane, ethane, hydrogen, propane, butane, pentane, carbon monoxide, carbon dioxide and the like) as a heat taking medium to take away heat generated in a reactor, so as to control the outlet temperature of the reactor; liquefied gas (mainly containing propane and butane) produced by a device per se is adopted in the technology to substitute the recycle gas and enters the reactor to serve as a heat removal medium, and the liquefied gas rarely participates in reaction under the same reaction condition, the reaction product is basically unchanged. The technology has the advantages that a recycle gas compressor is not needed, the equipment investment is greatly reduced, the running power consumption of the device is reduced, the heat exchange flow of the device is optimized, the device is simple, stable and reliable in operation, and meanwhile, the public engineering grade is also reduced, so that the technology has significant practicability, huge economic benefits and wide application prospect.

Owner:张永魁

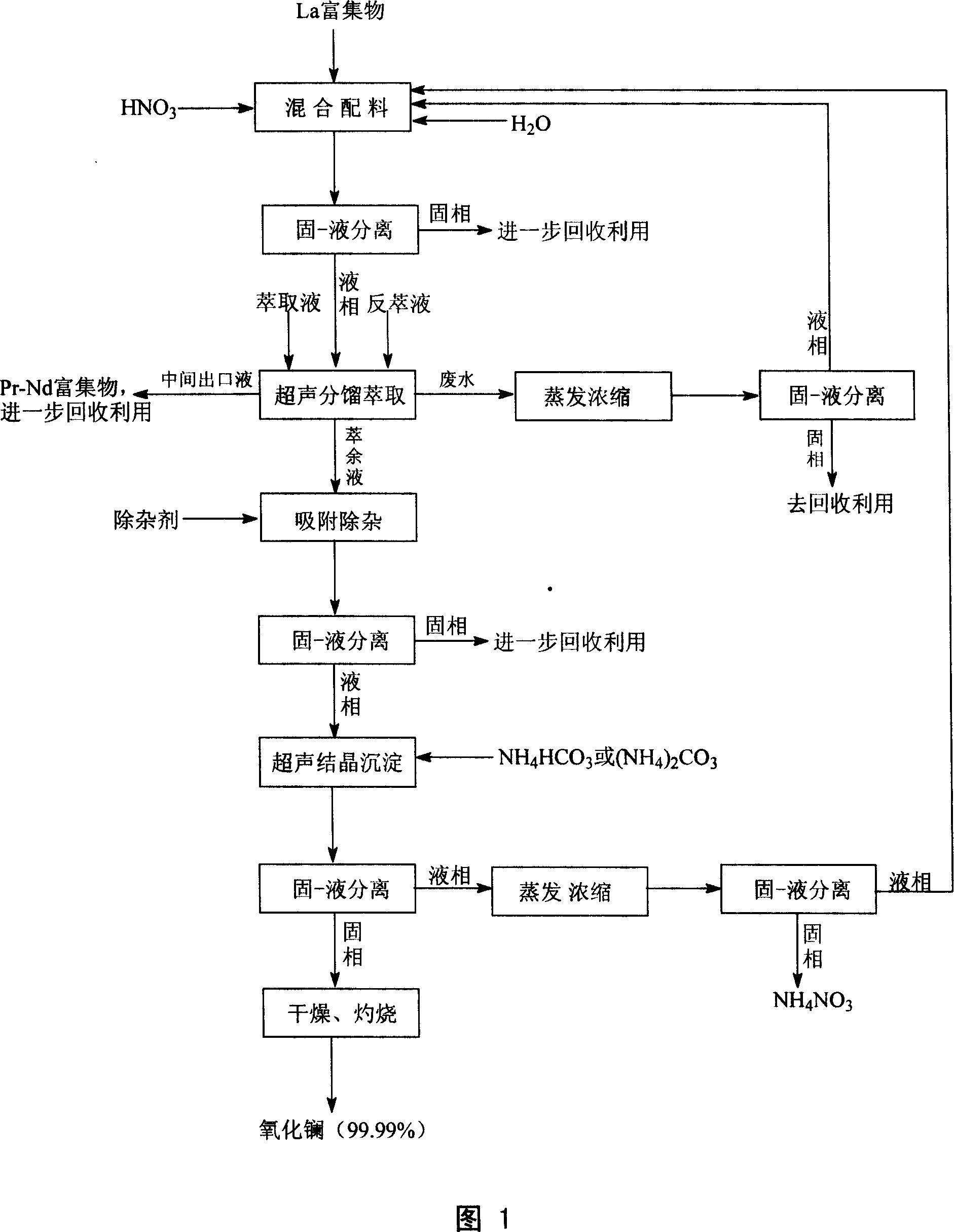

Method for preparing ultra-thin highly-pure lanthanum oxide by beneficiated lanthanum

The invention discloses a making method of lanthanum oxide, which comprises the following steps: (1) blending raw material to form enriched lanthanum slurry; (2) fractionating and extracting through ultrasound; obtaining La (NO3) 3 solution and promethium-neodymium enriched liquid; (3) adsorbing impurity; (4) separating solid from liquid; obtaining fined liquid of purified La(NO3)3; (5) crystallizing; sedimenting La2(CO3)3; (6) proceeding solid-liquid separation; (7) drying; sintering; obtaining La2O3 with content not less than 99.99% and grain size at 0.01-10.0um.

Owner:CHANGZHOU HUANAN CHEM +2

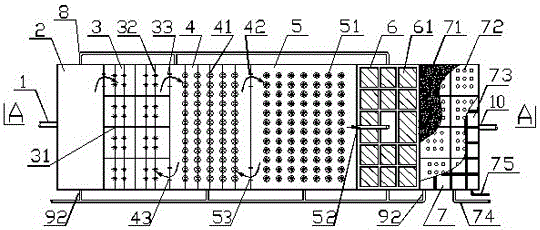

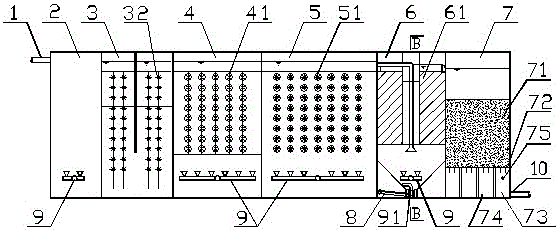

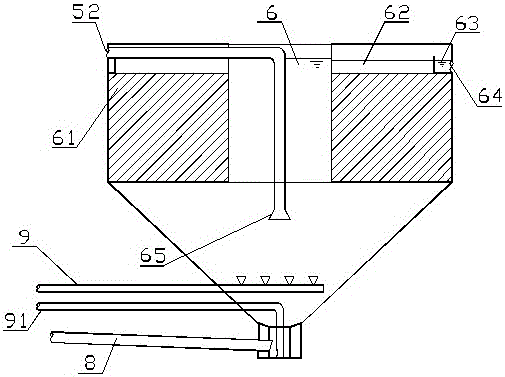

Zero-energy-consumption sewage treatment system and method for constructed wetlands

InactiveCN103159380AFacilitates respiratory exchangeStable water qualityMultistage water/sewage treatmentSiphonConstructed wetland

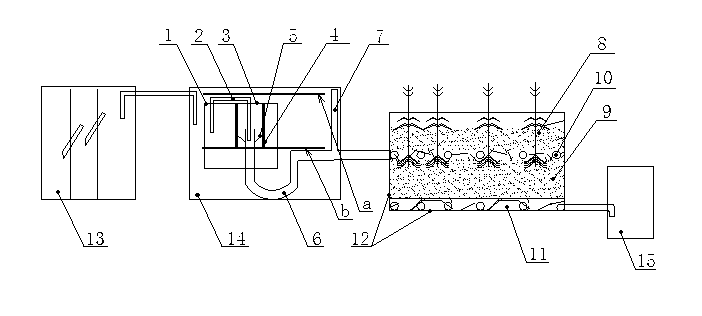

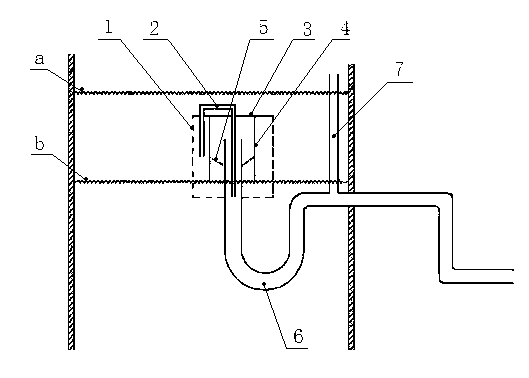

The invention discloses a zero-energy-consumption sewage treatment system and method for constructed wetlands. The system consists of a sewage pre-treatment system, an automatic siphon system, a constructed wetland purification system and a water collection system, wherein the sewage pre-treatment system comprises a three-squared septic-tank and a sewage siphon pool which is connected with the three-squared septic-tank through a pipeline; the automatic siphon system is arranged in the sewage siphon pool; the constructed wetland purification system is connected with the automatic siphon system; the water collection system is connected with the constructed wetland purification system through a pipeline; the constructed wetland purification system is an ecological system consisting of a substrate layer, plants, microorganisms and a water body and sequentially comprises a root layer, a water distribution layer, a substrate layer, a water collection layer and an anti-seepage layer from top to bottom. The system combines sewage treatment and wetland plants, automatically runs by virtue of the gravity generated by liquid level difference, is stable and reliable in treatment process, low in running cost and strong in nitrogen and phosphorus removing capability, facilitates breathing exchange of underground air, has a good treatment effect, and does not have sludge discharge.

Owner:恒蓝水务有限公司

Desiliconizing method for bauxite by dry method

InactiveCN101121538AThe process is simple and reliableAchieve sustainable developmentGas current separationAluminium oxides/hydroxidesEngineeringEnvironmental safety

A dry method desiliconization of a bauxite especially relates to the desiliconization method of an lateritic bauxite and an accumulating bauxite. The present invention is characterized in that the desiliconization process is that after dried, the bauxite is broken up and screened and the material under the screen is classified by the wind power. The material on the screen and the coarse grains classified by the wind power are taken as a combined concentrate and the fine grains classified by the wind power are taken as a tailing. The present invention has a stable and reliable process flow and does not need new water, capable of reclaiming the fine grain-level concentrate of more than 0.02mm effectively without the waste water pollution. The tailing can be stored or used to reclaim a goaf directly and make the refractory material and concrete. The investment construction and management of the tailing warehouse and the influence on the circumjacent environmental safety can be avoided.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

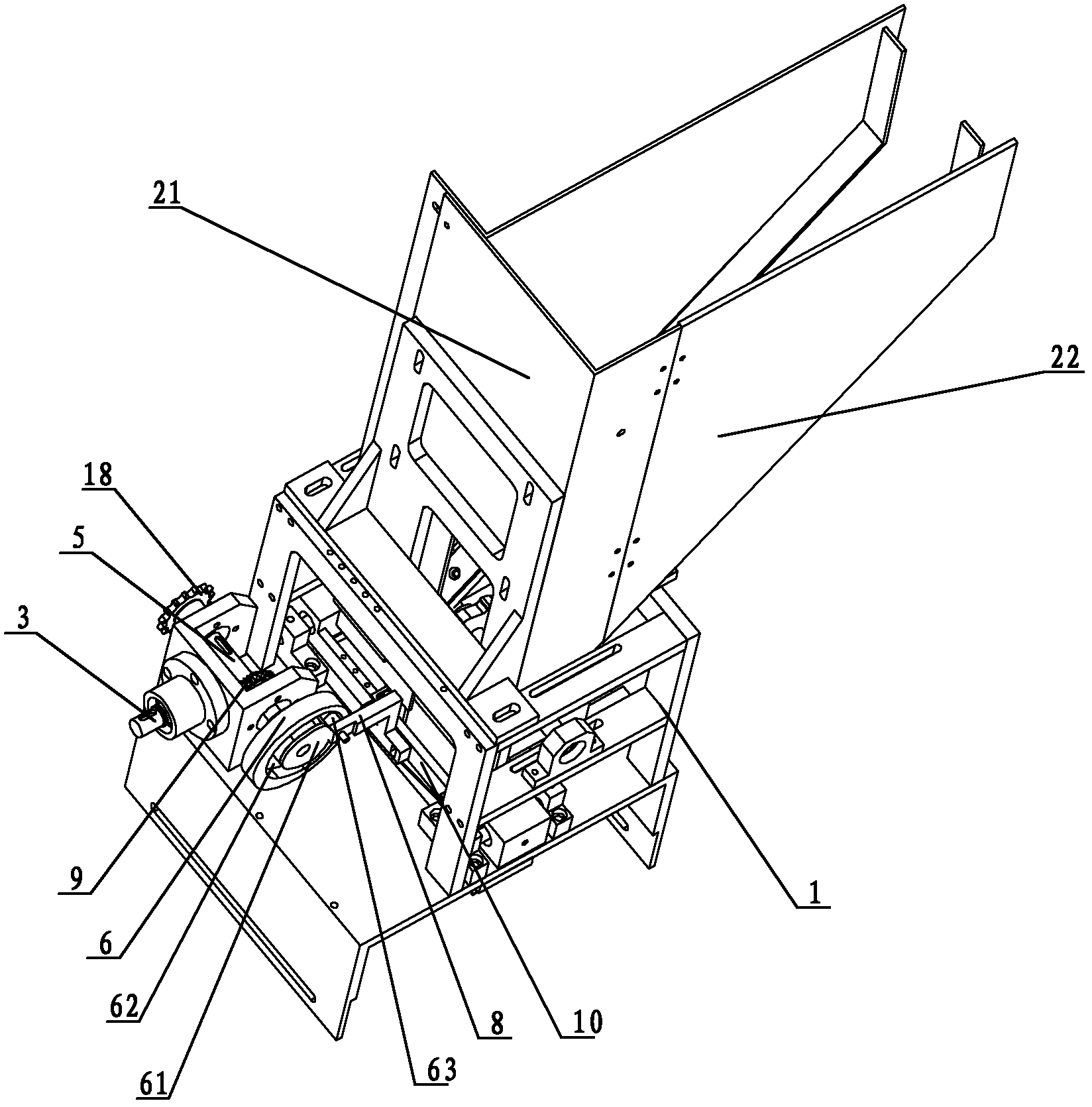

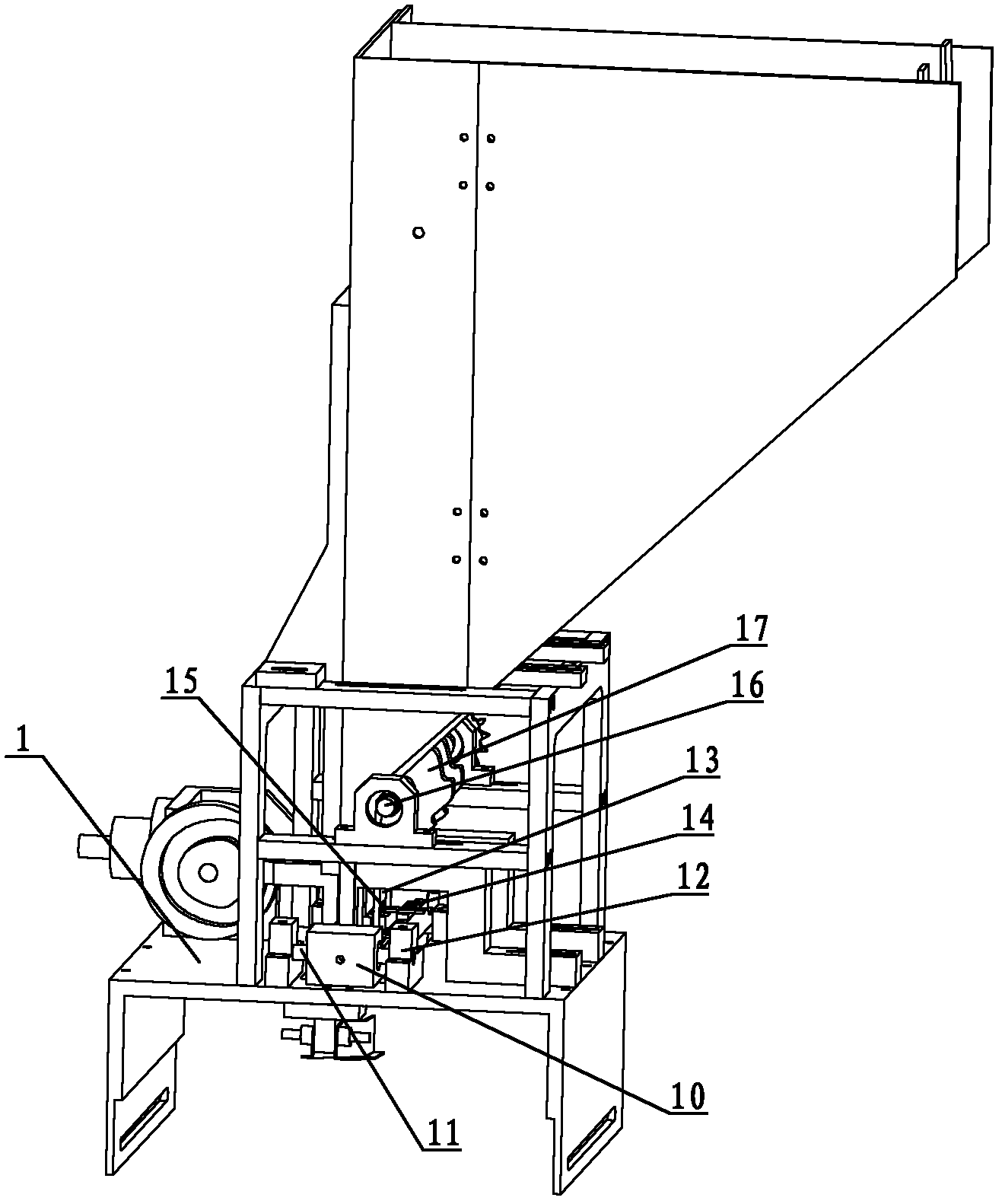

Feeder for straws

The invention relates to a feeder for straws, which mainly solves the problems of poor reliability, short service life, inaccuracy in arrangement of straw materials and poor feeding efficiency of an existing feeder for straws. A transmission mechanism of the feeder comprises a first transmission shaft, a rotary disk, a bearing and a push rod, the first transmission shaft is in transmission match with a driving shaft through a conical gear and is connected with the rotary disk, the rotary disk is provided with a 'cam-shaped' groove, a cam matched with the shape of the groove is arranged in the middle of the groove, a cam rail is formed between the outer wall of the groove and the outer surface of the cam, and the push rod is connected with the bearing arranged in the cam rail and is matched with a feeding mechanism. By adopting a cam mechanism to drive the feeding mechanism to move and realize feeding, the feeder is low in noise, stable and reliable in process and long in service life.

Owner:瑞安市金泰包装机械有限公司

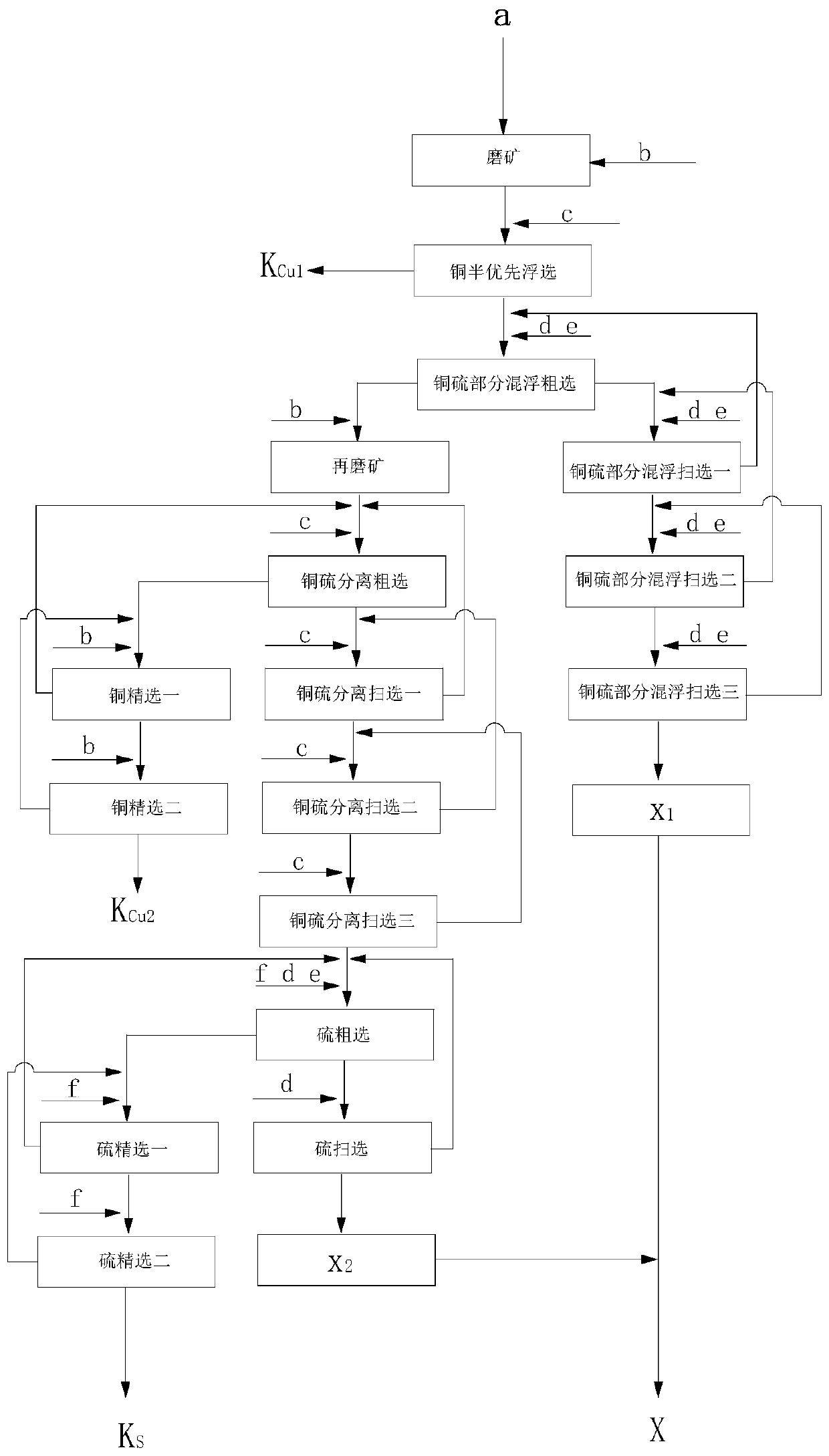

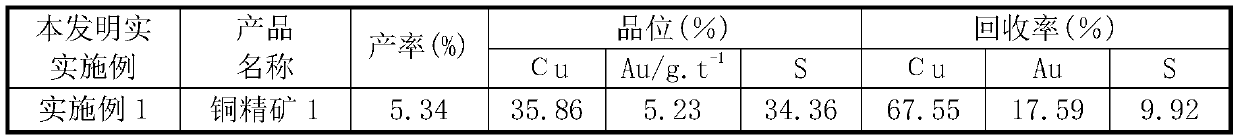

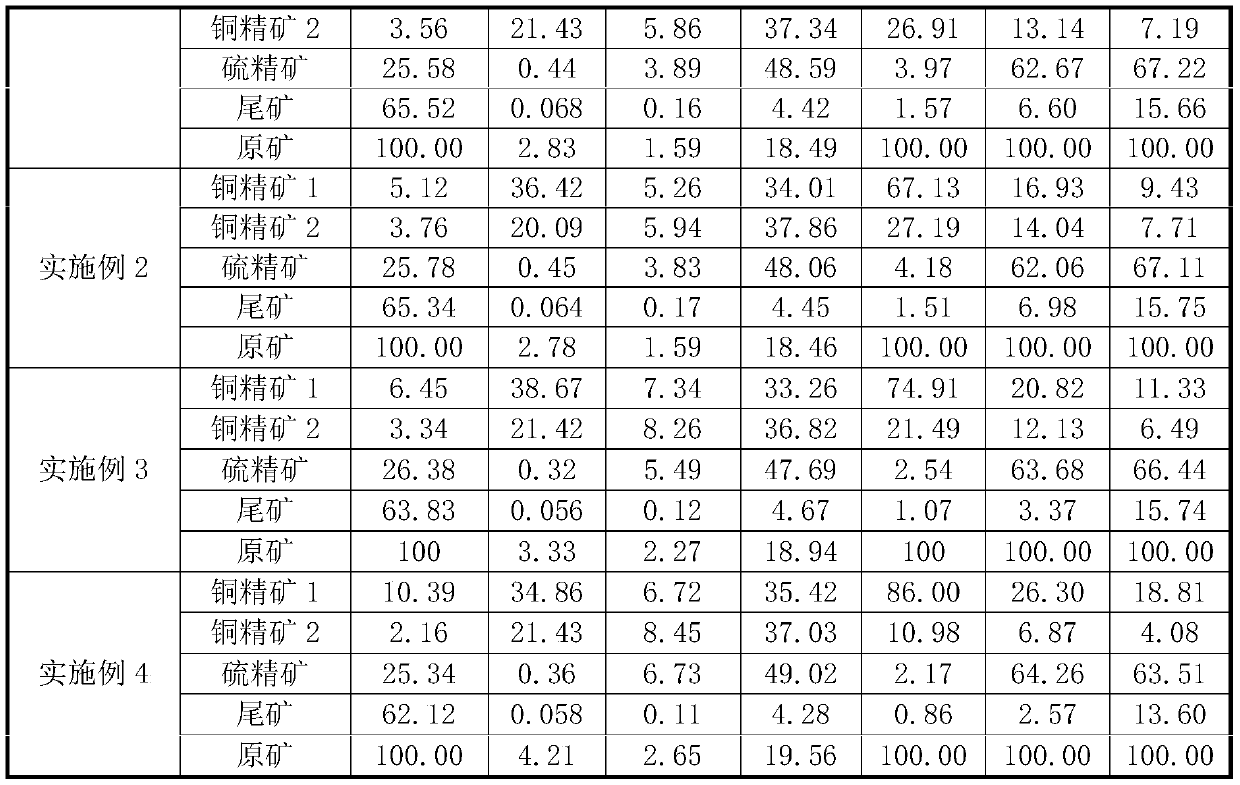

Ore dressing method for metal containing secondary copper sulfide ores

The invention relates to an ore dressing method for metal containing secondary copper sulfide ores. The method is characterized in half preferential copper floatation, branched Cu-S collective-selective floatation roughing, branch Cu-S separation roughing and differential reagent adding. Crude ores (a) are conventionally ground. Copper concentrate products 1 (KCu1) are obtained through half preferential copper floatation. Cu-S collective-selective floatation roughing is carried out in two paths: Cu-S collective-selective floatation scavenging and re-grinding Cu-S separation roughing. On one path, ore re-grinding and Cu-S separation roughing are carried out; and Cu-S separation roughing is carried out in two branches: on one branch, copper concentrate products 2 (KCu2) are obtained by carrying out secondary copper concentrating on copper crude ores and concentrates; and on the other branch, tailing third Cu-S separation scavenging, sulfur roughing and the sub-branches of carrying out secondary sulfur concentrating to obtain sulfur concentrate products (Ks) and carrying out sulfur scavenging to obtain tailings 2(X2) are carried out. On the other path, Cu-S collective-selective floatation scavenging is carried out, and tailings 1 (X1) are obtained through third collective-selective floatation scavenging. The method not only can realize Cu-S separation and ensure the grades and recycling rates of the copper concentrates and the sulfur concentrates, but also can reduce energy consumption, increase separation indexes and realize the early recycling of recyclable usable minerals in the ores. The method has the advantages of low ore grinding cost, simple reagent principles, stable and reliable technical process, great target mineral recycling effect, remarkable energy saving and consumption reduction and the like.

Owner:ZIJIN MINING GROUP

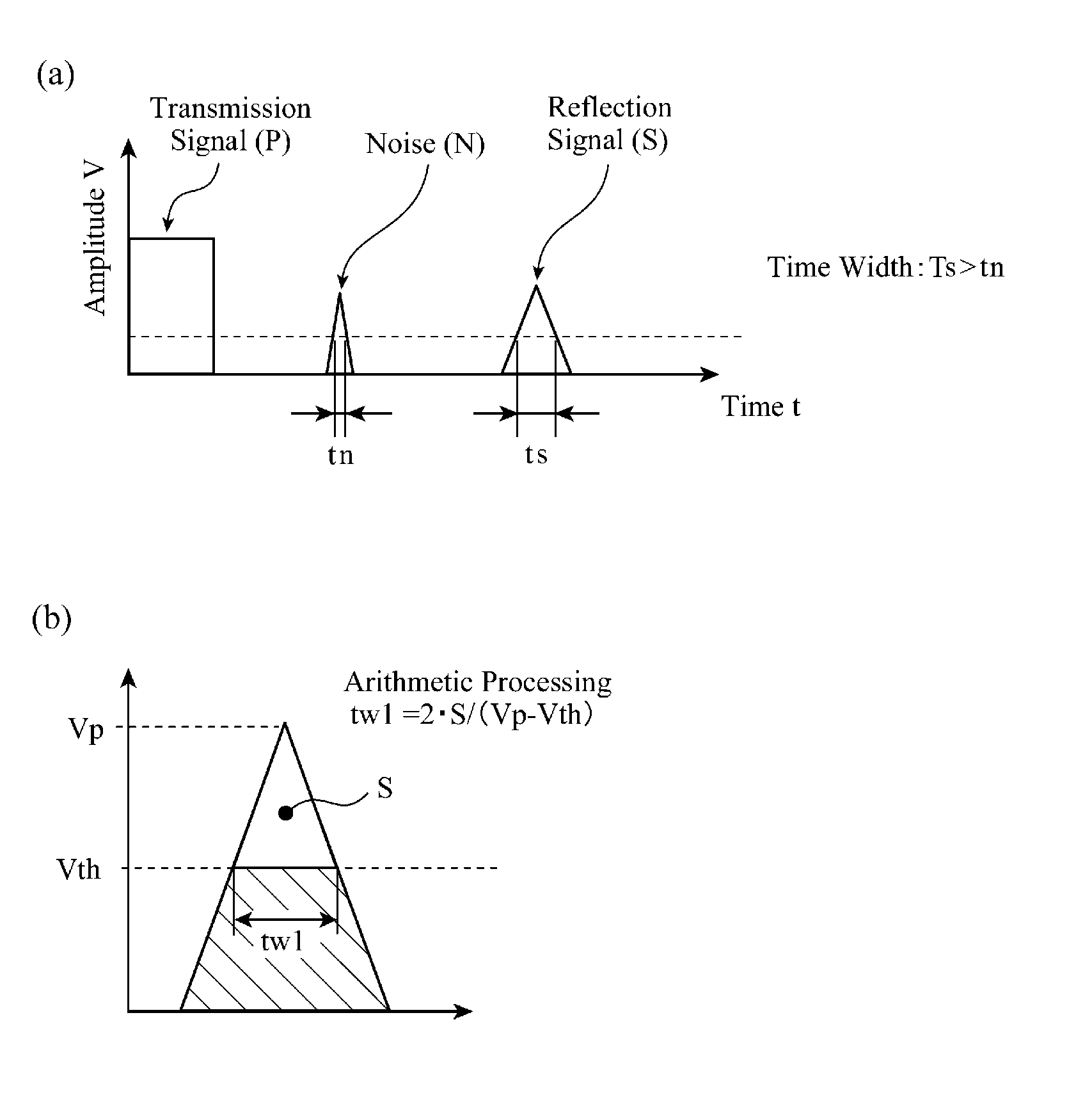

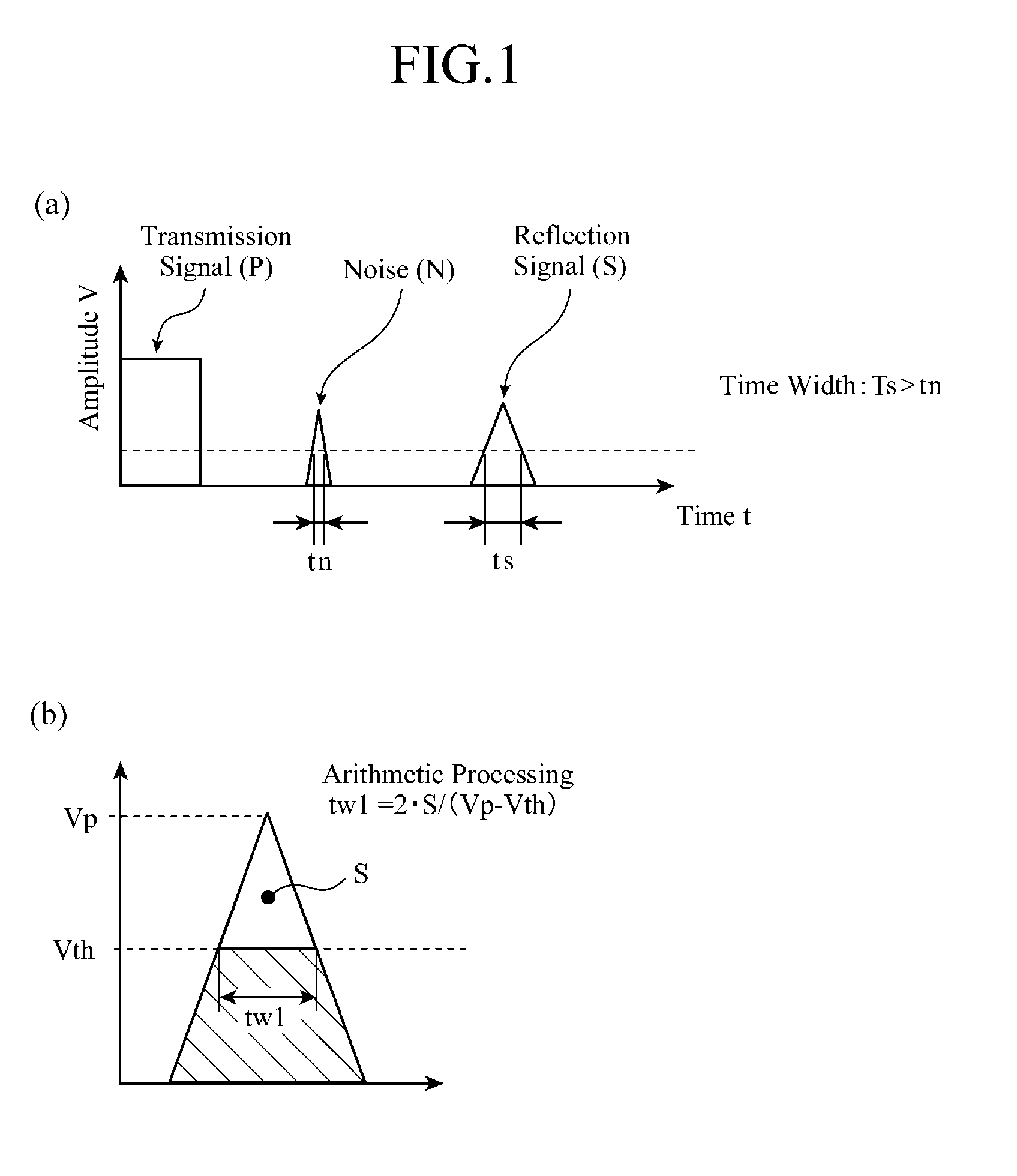

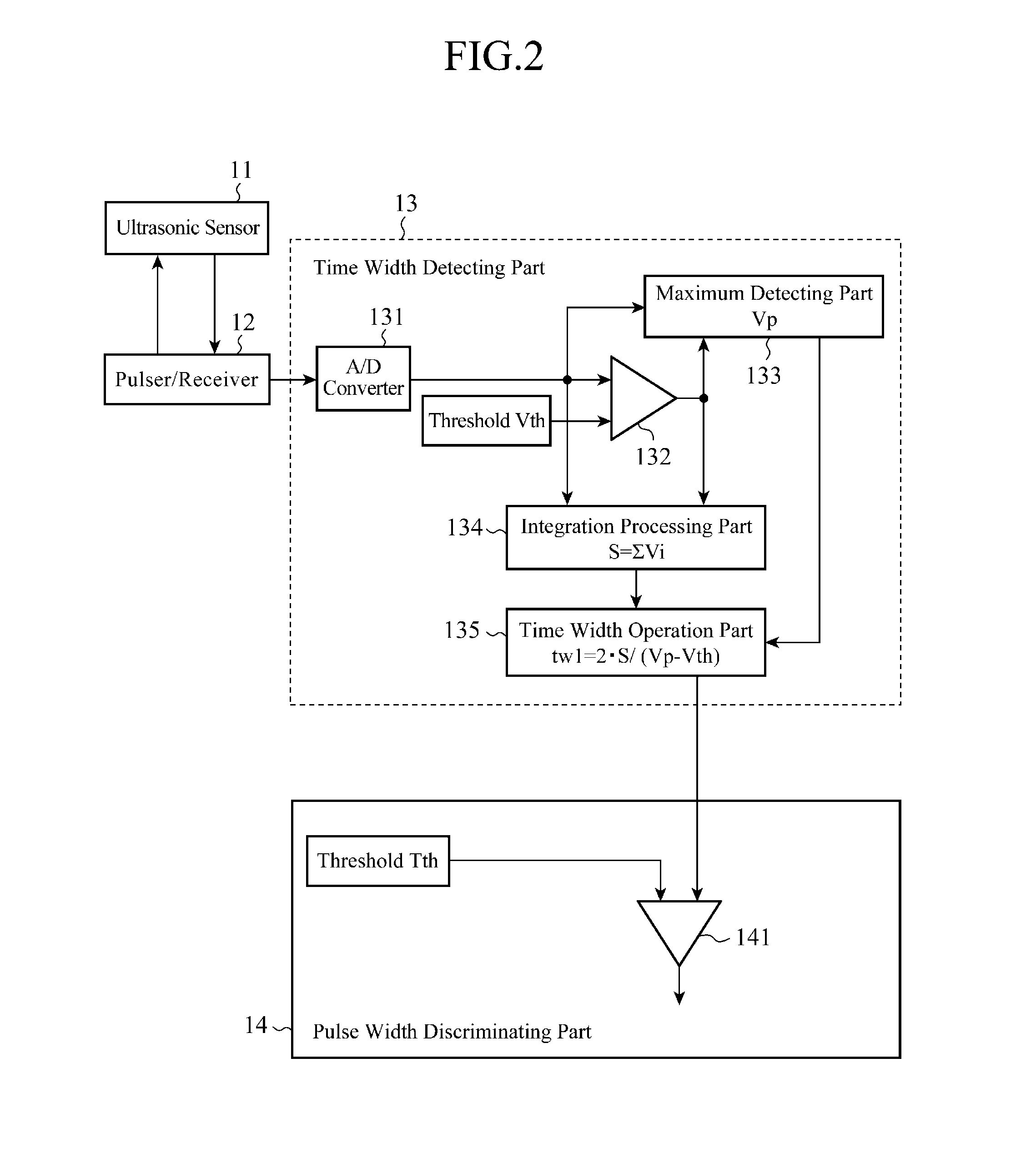

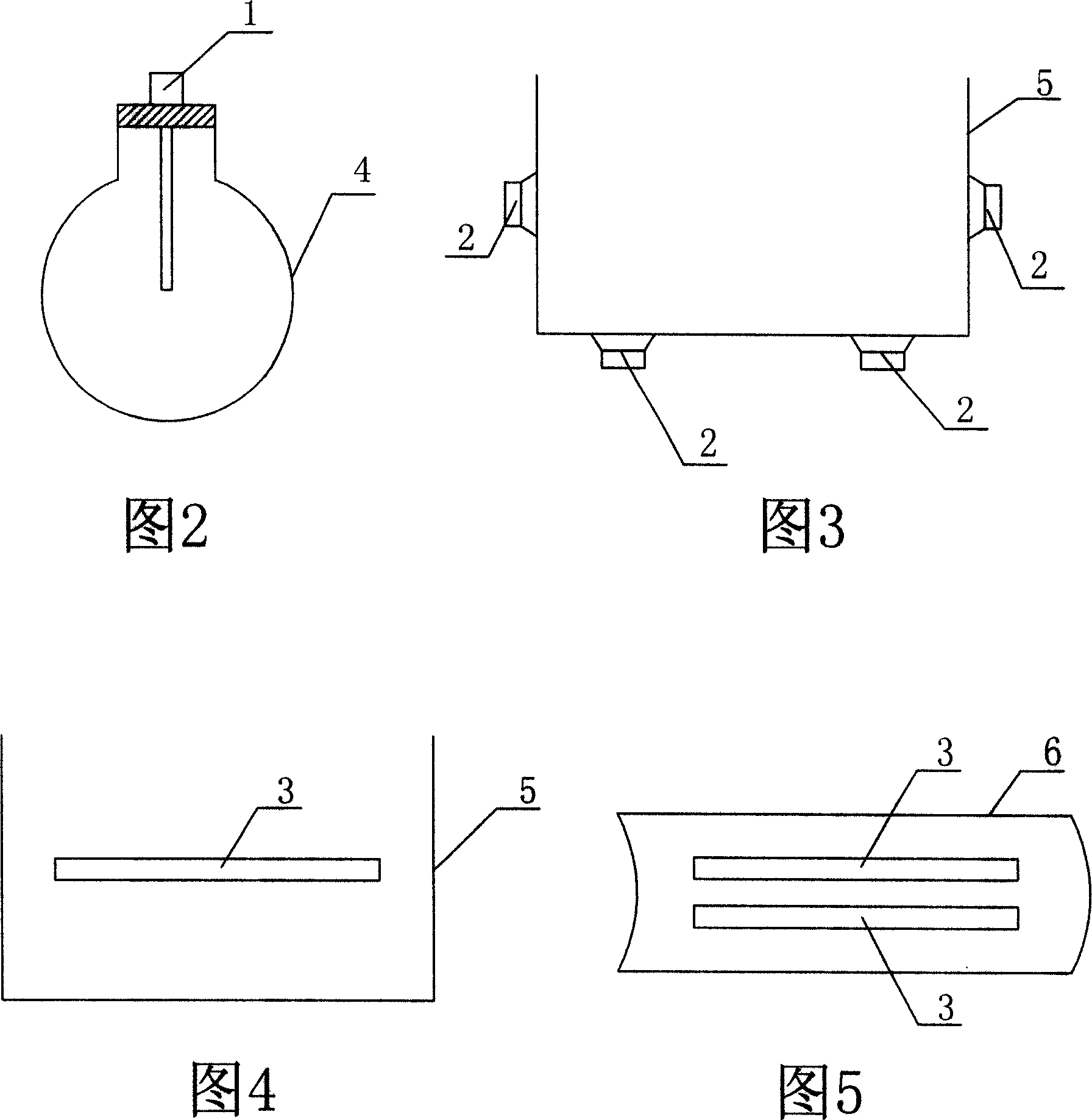

Ultrasonic detection device

ActiveUS20120099397A1Reliable processReliable discriminationAcoustic wave reradiationVIT signalsUltrasound pulse

An ultrasonic detection device is constructed in such a way as to include a discriminating processing unit (a time width detecting part 13 and a pulse width discrimination part 14) for approximating the shape of each signal which is a reflection signal which is reflected from an object as a result of transmitting a ultrasonic pulse toward the object, or a noise as an isosceles triangle and computing a pulse time width equal to the length of the base of the approximating isosceles triangle, and for discriminating between the reflection signal and the noise signal by determining whether the computed pulse time width exceeds a predetermined pulse width discrimination threshold. Therefore, the ultrasonic detection device can determine the pulse time width with stability, and carry out the discriminating process with a high degree of reliability.

Owner:MITSUBISHI ELECTRIC CORP

Process for preparing superfine high-purity europium oxide by using europium riched material

InactiveCN101024507AReduce consumptionEasy to controlRare earth metal compoundsProcess efficiency improvementGranularityRare earth

The invention relates to a method to make europium oxide that includes the following steps: mixing raw material, taking solid-liquid separation to gain enriched liquid containing europium acid rare earth, taking electrochemistry reaction to gain EuCl2 solution, taking ultrasonic to gain refined liquid of EuCl2, taking electrochemistry reaction to gain refined liquid of EuCl3, taking adsorption and trash extraction, taking ultrasonic crystal deposition to gain Eu2(CO3)3 crystal deposit, taking solid-liquid separation, drying and burning to gain the superfine high purity europium oxide product that has content over 99.99%, and the particle diameter is 0.01-10.0um. The advantages of the invention are that it improves leaching and extracting speed, and the particle diameter is small, and particle size distribution equal.

Owner:常州市西南化工研究所 +2

Filtering smoked meat products method

InactiveCN1456062AMaintain and improve gradeNo pollution in the processMeat/fish preservationEngineeringSmoke

Owner:王虎坚

Method for producing an extruded pressed screen and corresponding screen

InactiveCN1947315AEasy to installImprove sealingContact member assembly/disassemblyCoupling device detailsElectrical connectionInjection moulding

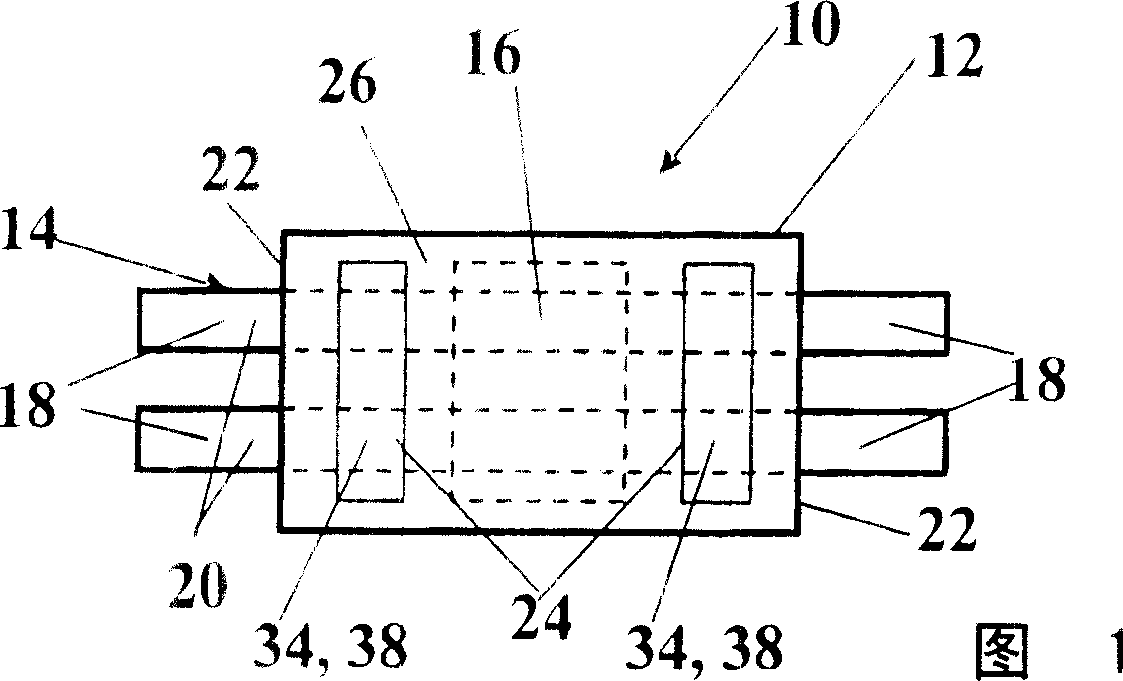

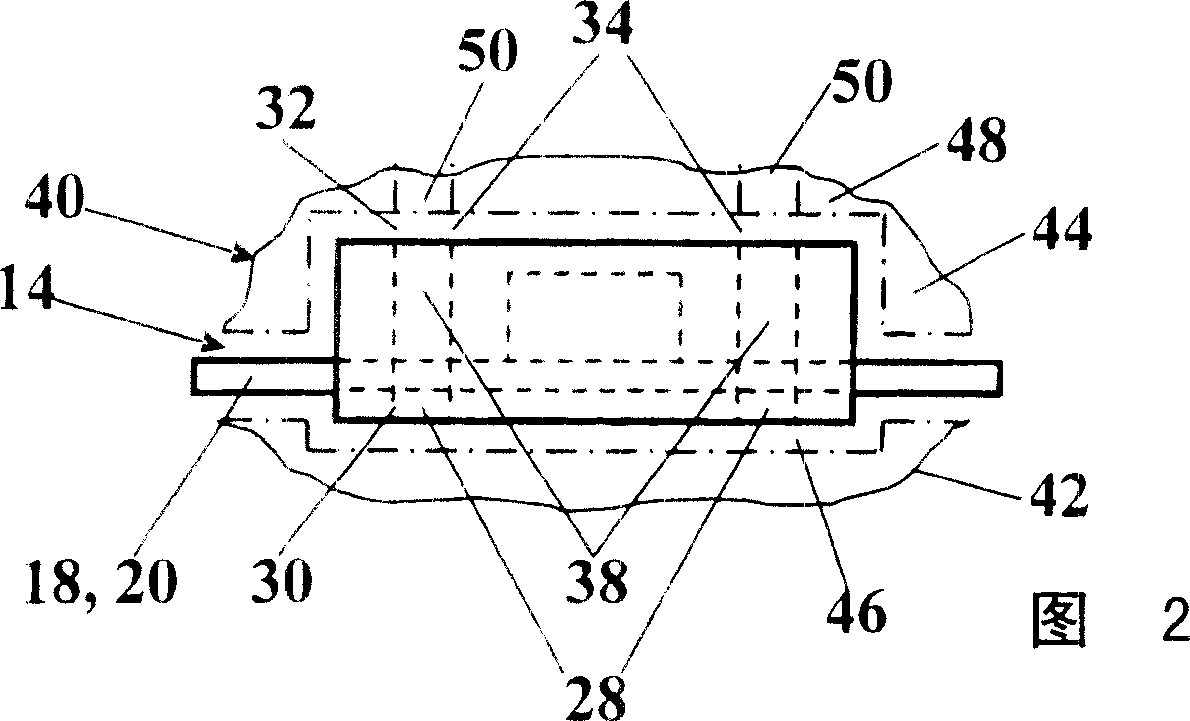

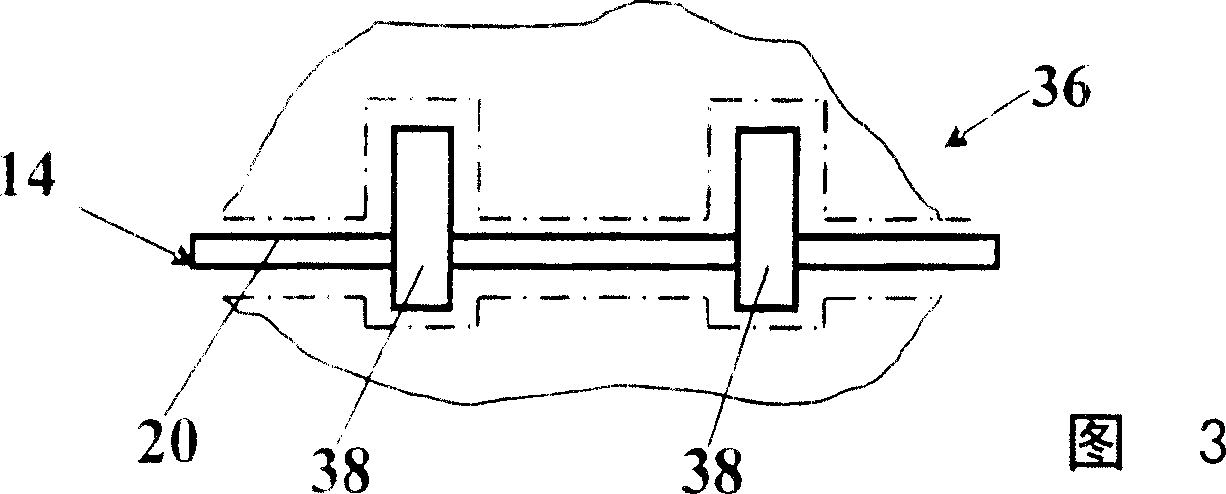

The invention relates to a method for producing an extruded pressed screen (14) on which components (16) are arranged, said screen being coated in plastic (26) in an injection mould (40). The inventive pressed screen (14) is fixed to a fixing point (28, 34) during the injection moulding process by means of a fixing element, such that the form thereof is maintained during said process. Said fixing element is a plastic element (38) which is coated by the injected plastic (26) in such a way that it seals the fixing point (28, 34). The invention also relates to an extruded pressed screen (14) that is inserted into a plastic housing (12) comprising a first and a second component (24, 26). Said pressed screen (14) is entirely coated with the second component (26), with the exception of the terminals (18) for the mechanical and / or electrical connection of the pressed screen (14). The first component (24) ends on a first outer side (30) and a second outer side (32) of the housing (12).

Owner:ROBERT BOSCH GMBH

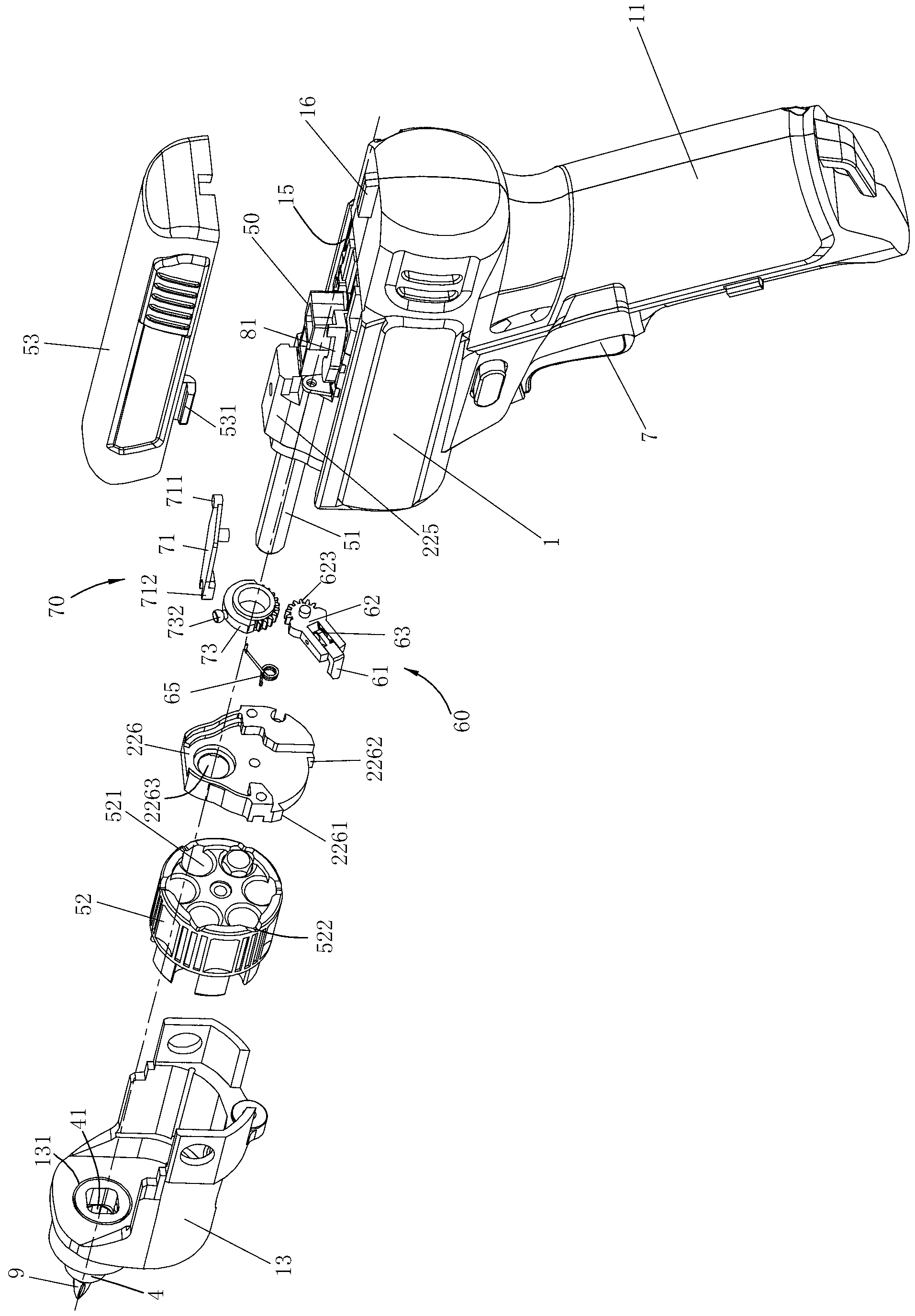

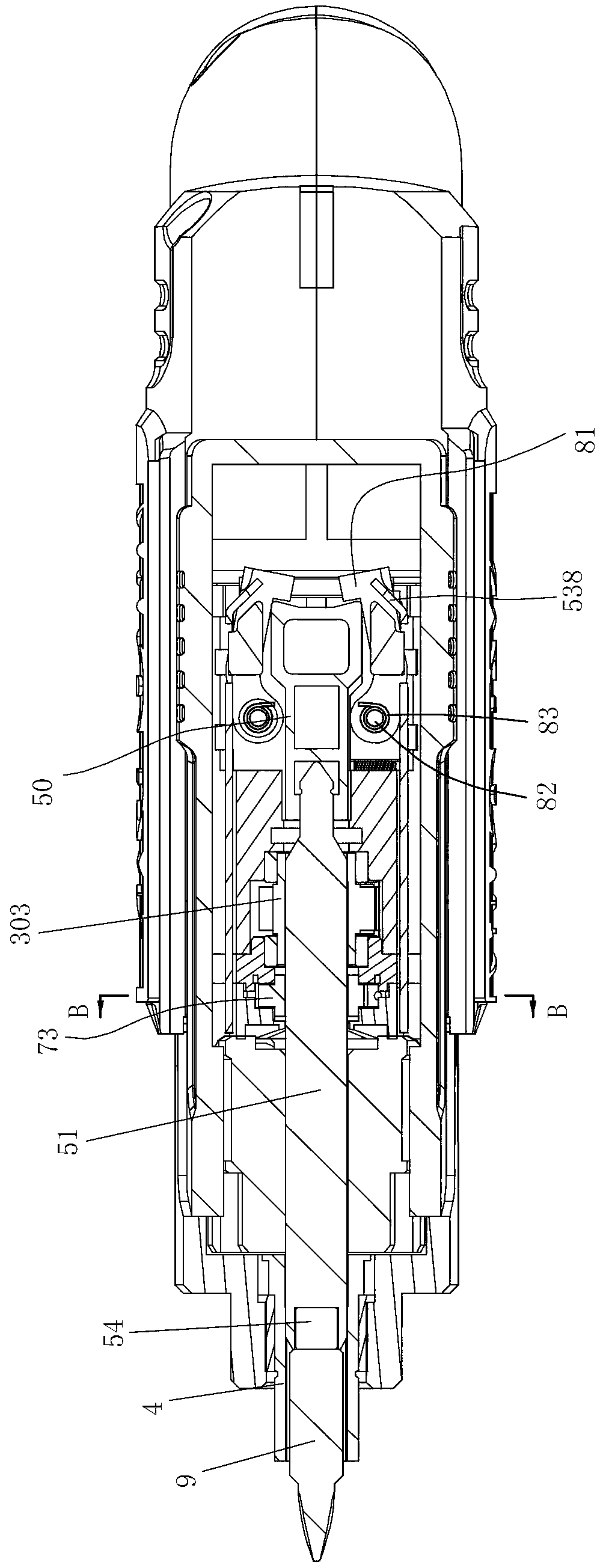

Power tool

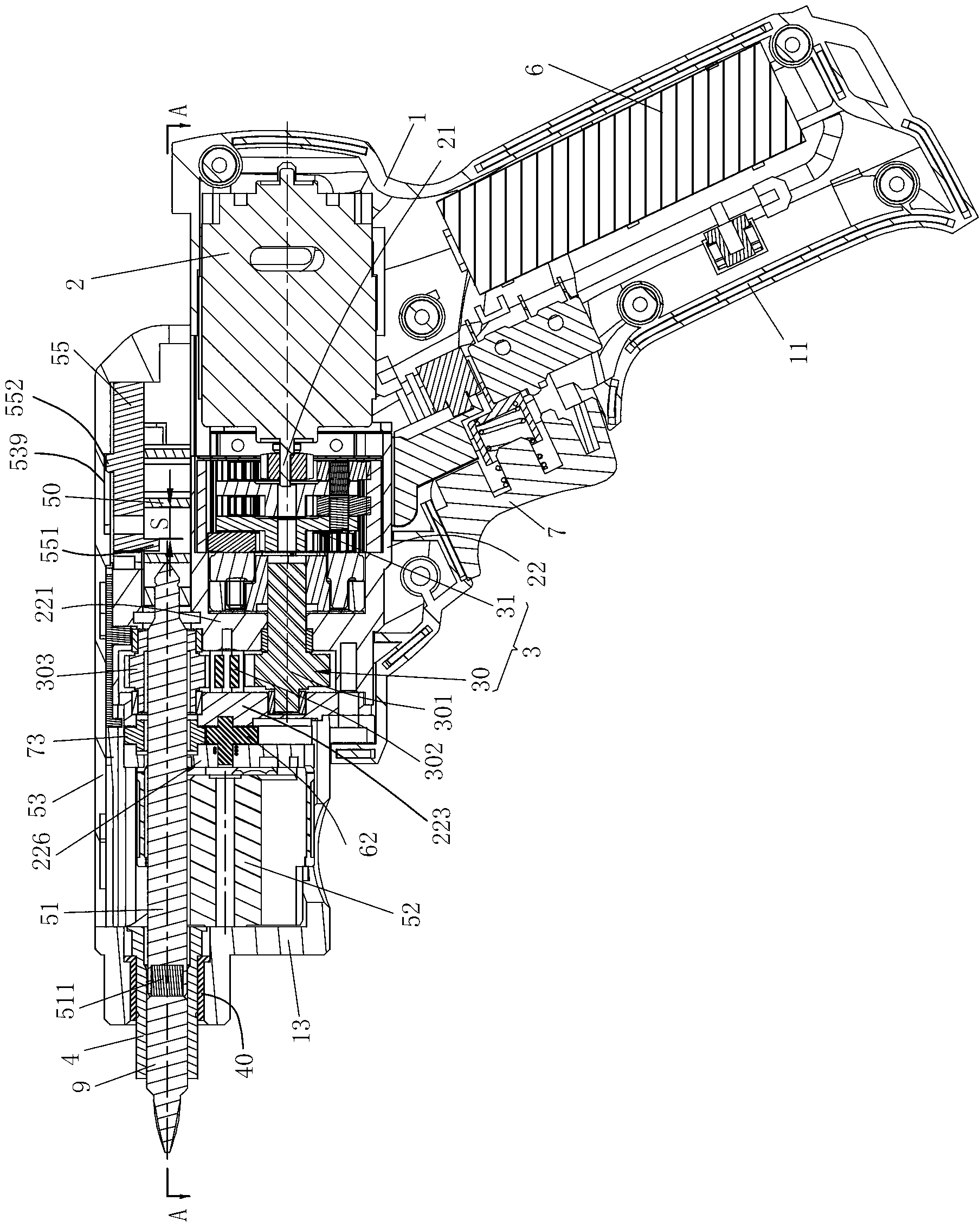

ActiveCN103252756AQuick changeImprove work efficiencyPortable power-driven toolsOperating pointPower tool

The invention relates to a power tool comprising a housing, an output shaft, a storage clamp, a connecting shaft, an operation part and an automatic switching device. A motor and a transmission mechanism are arranged in the housing. The output shaft is provided with an axially arranged shelter hole sheltering an operating head. Rotating power output by the motor is transmitted to the output shaft through the transmission mechanism. The storage clamp comprises a plurality of sheltering bins for sheltering the operating head. The connecting shaft can penetrate through one of the sheltering bins to enable the operating head in the sheltering bin to axially move between an operating position fittingly connected with the output shaft and release position of the operating head dropping out of the sheltering bins. The operation part is arranged on the housing and used for controlling axial motion of the connecting shaft. The automatic switching device responds to motion of the operation part and adjusts the position of the storage clamp through a control mechanism, and the control mechanism can be meshed with or separated from the storage clamp and can be operated to move from the starting position to the finish position so as to drive the storage clamp. A stopping mechanism is arranged in the housing, and limits the control mechanism to be separated from the storage clamp when the control mechanism moves to the finish position.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

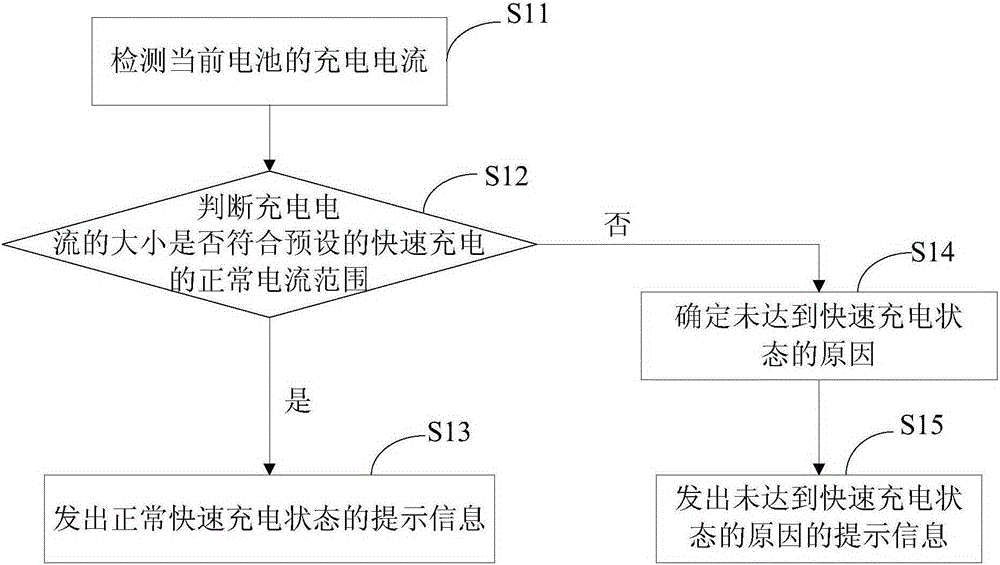

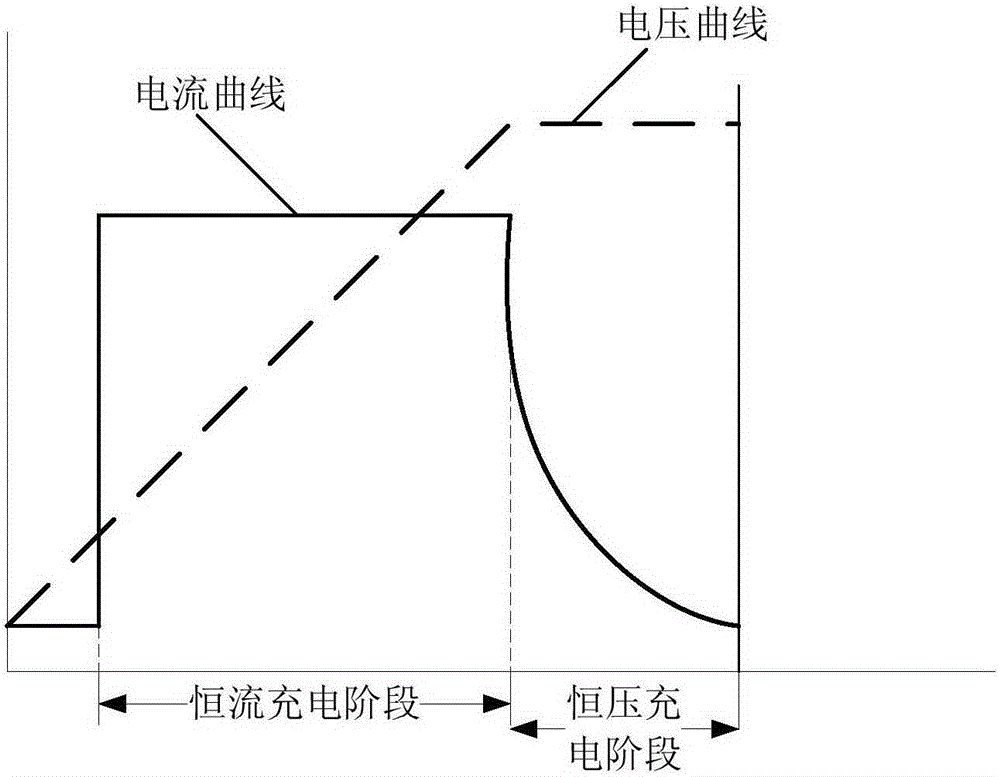

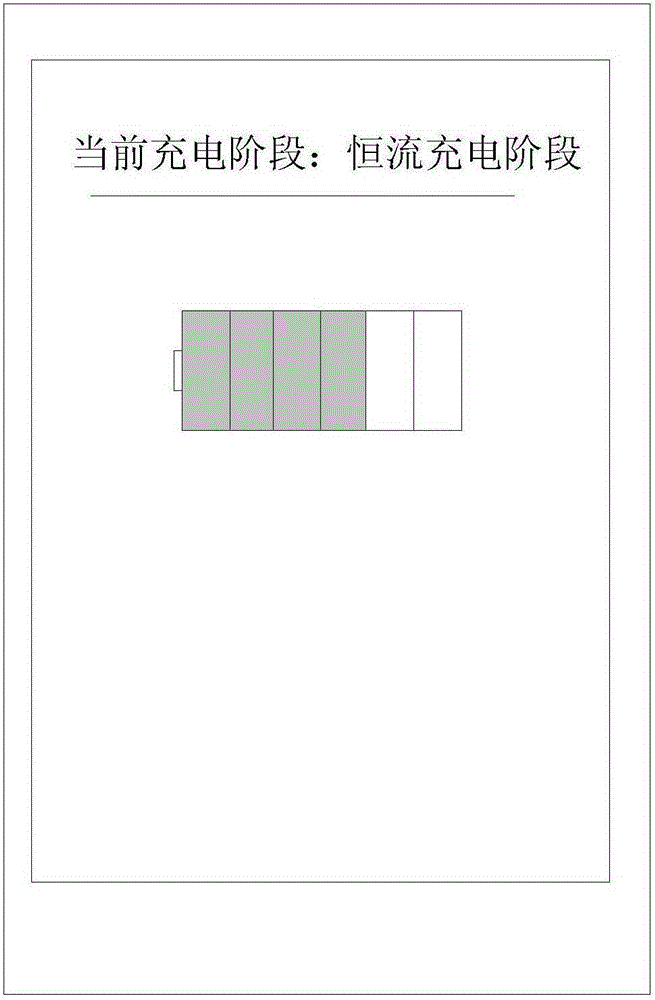

Prompting method and apparatus for rapid charging state

ActiveCN105356529AFast chargingFully understand the chargeCircuit monitoring/indicationDifferent batteries chargingCharge currentCurrent range

The invention discloses a prompting method and apparatus for a rapid charging state. The method comprises the steps of detecting charging current of a current battery; judging whether the magnitude of the charging current satisfies a preset rapid charging normal current range or not; if so, giving out prompting information for the normal rapid charging state; or otherwise, determining the reasons why the rapid charging state is not reached, and giving out prompting information for the corresponding reasons. According to the prompting method and apparatus for the rapid charging state, a user can know whether the current battery is in the rapid charging state or not more clearly and fully, and t he user can take corresponding measures, such as replacing non-ideal charging equipment and the like, based on the judging information to realize the rapid charging of the battery, so that the use experience of users is improved.

Owner:XIAOMI INC

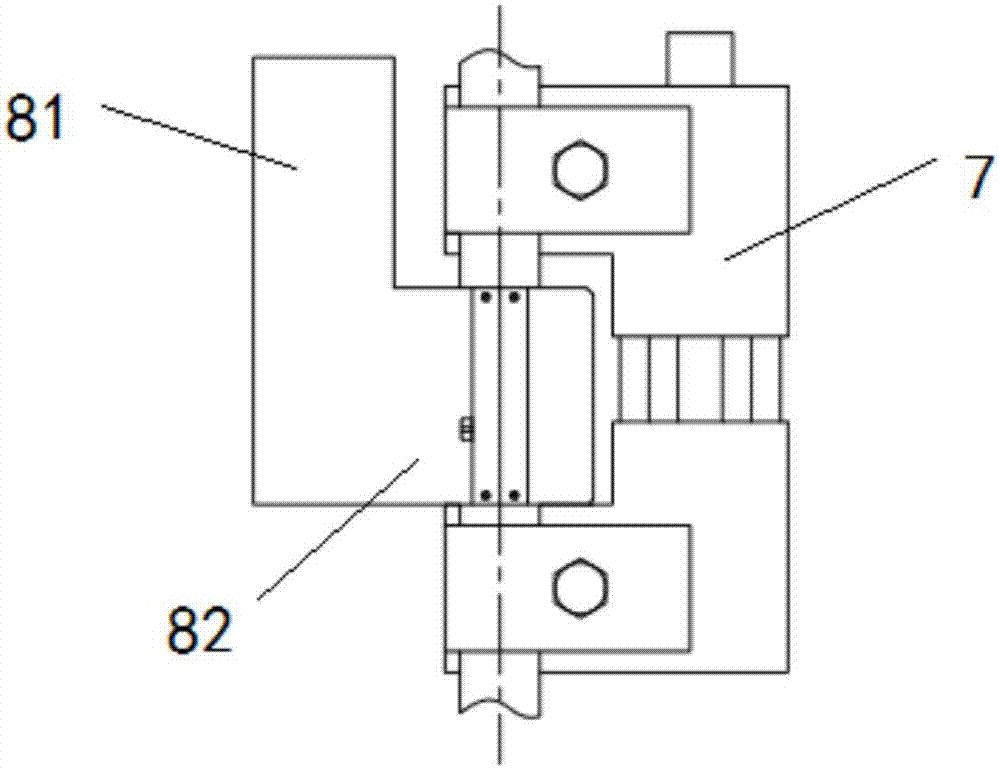

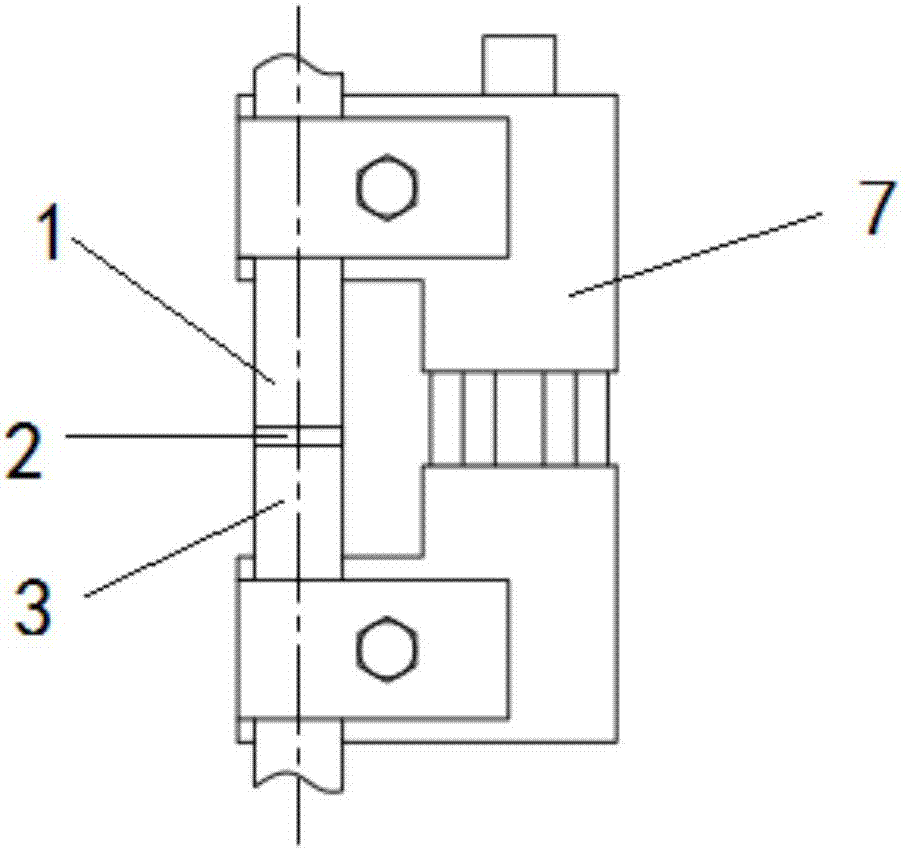

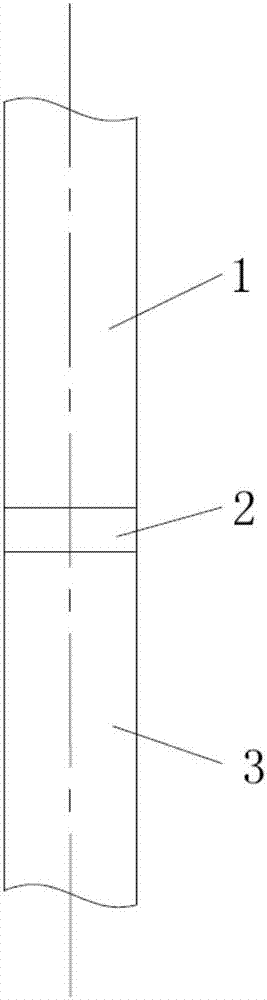

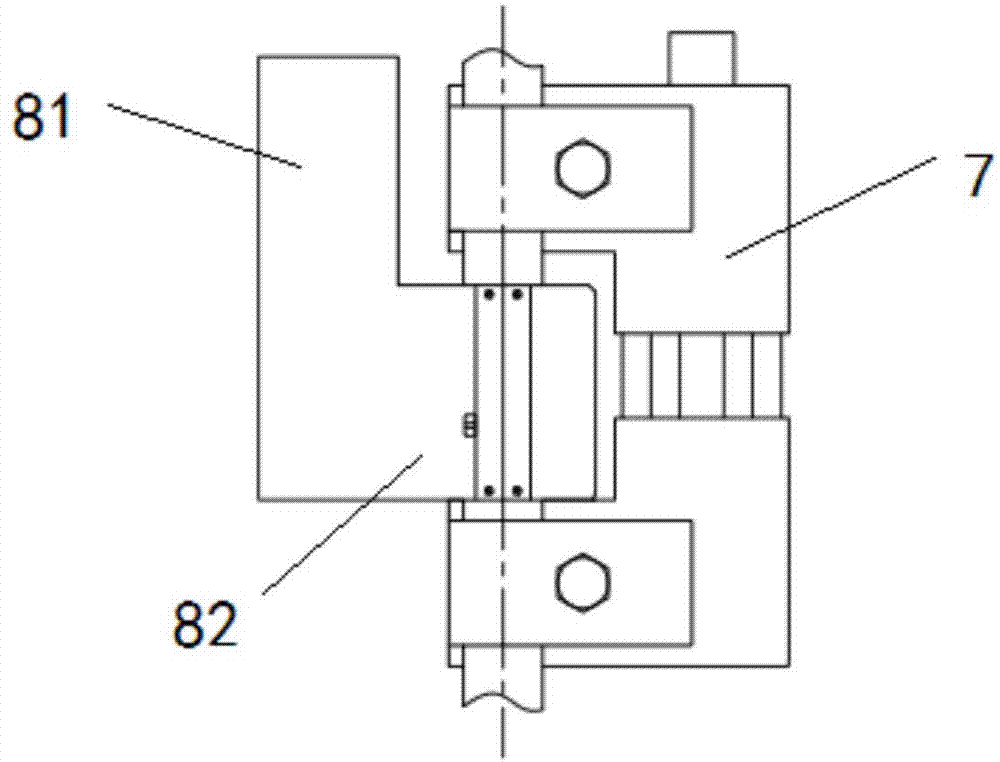

Automatic welding technology for nickel base alloy heat exchange pipe butt joint

ActiveCN106975826AGuaranteed performanceGuarantee welding qualityArc welding apparatusButt jointAlloy

The invention discloses an automatic welding technology for nickel base alloy heat exchange pipe butt joint. The technology comprises the following steps that a heat exchange pipe I (1), a heat exchange pipe II (3) and a melting ring (2) are assembled; welding equipment is installed and debugged; and welding process parameters are set, and welding is conducted. According to the automatic welding technology for nickel base alloy heat exchange pipe butt joint, the heat exchange pipes are fixed in the mode that the axes are vertical, tools (7) are adopted to assemble the heat exchange pipes and the melting ring to guarantee coaxiality of the heat exchange pipes and the melting ring; and a welding machine head of the welding equipment is matched with the tools (7) for clamping, the positions of a tungsten electrode and the melting ring are controlled, and automatic welding is conducted according to the set welding parameters and the operation requirements. The welding technology is stable in welding process and is implemented in small space with the minimum pipe wall interval being 41 mm, the quality of butt joint welding lines between the nickel base alloy heat exchange pipes can be effectively controlled, the situation that the double sides of the formed welding lines between the nickel base alloy heat exchange pipes do not sink can be controlled, meanwhile, the double sides of the formed welding lines do not exceed the surfaces of the heat exchange pipes by 0.45 mm, the magnitude of the pigging diameter phi is guaranteed, and the property of a heat exchange pipe butt joint connector meets the product requirements.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Technique for deeply purifying urban sewage

InactiveCN106145543ASimple structureReliable processTreatment involving filtrationSludge processingChemistrySewage

The invention discloses a technique for deeply purifying urban sewage. The technique comprises the following steps: (1) treating the sewage with regulating reservoir, and then putting into an anaerobic tank, an anoxia pool and an aerobiotic pool and performing biochemical treatment, thereby obtaining the purified water A; respectively maintaining sewage in the anaerobic tank, the anoxia pool and the aerobiotic pool for 2.5-3.5h, 5.5-6.5h and 11-13h; controlling the dissolved oxygen concentration in the anoxia pool and the aerobiotic pool at 0.25-0.4mg / L and 0.5-1.0mg / L; filling suspended filler into the aerobiotic pool, wherein the filling volume of the suspended filler is 65-75% of the volume of the aerobiotic pool; (2) putting the purified water A into a nitration settling pond for performing nitration settling treatment, thereby obtaining purified water B and nitrified sludge; returning the nitrified sludge to the regulating reservoir by a gas stripping system through a nitrified sludge return pipe; (3) purifying the purified water B with a deep bed filter chamber, thereby finishing deep purification for urban sewage. According to the technique, the organisms can be doubled, the treating effect can be increased, the tank volume can be reduced and the purifying technical equipment is simple in structure and reliable in process flow.

Owner:中电建环保科技有限公司 +1

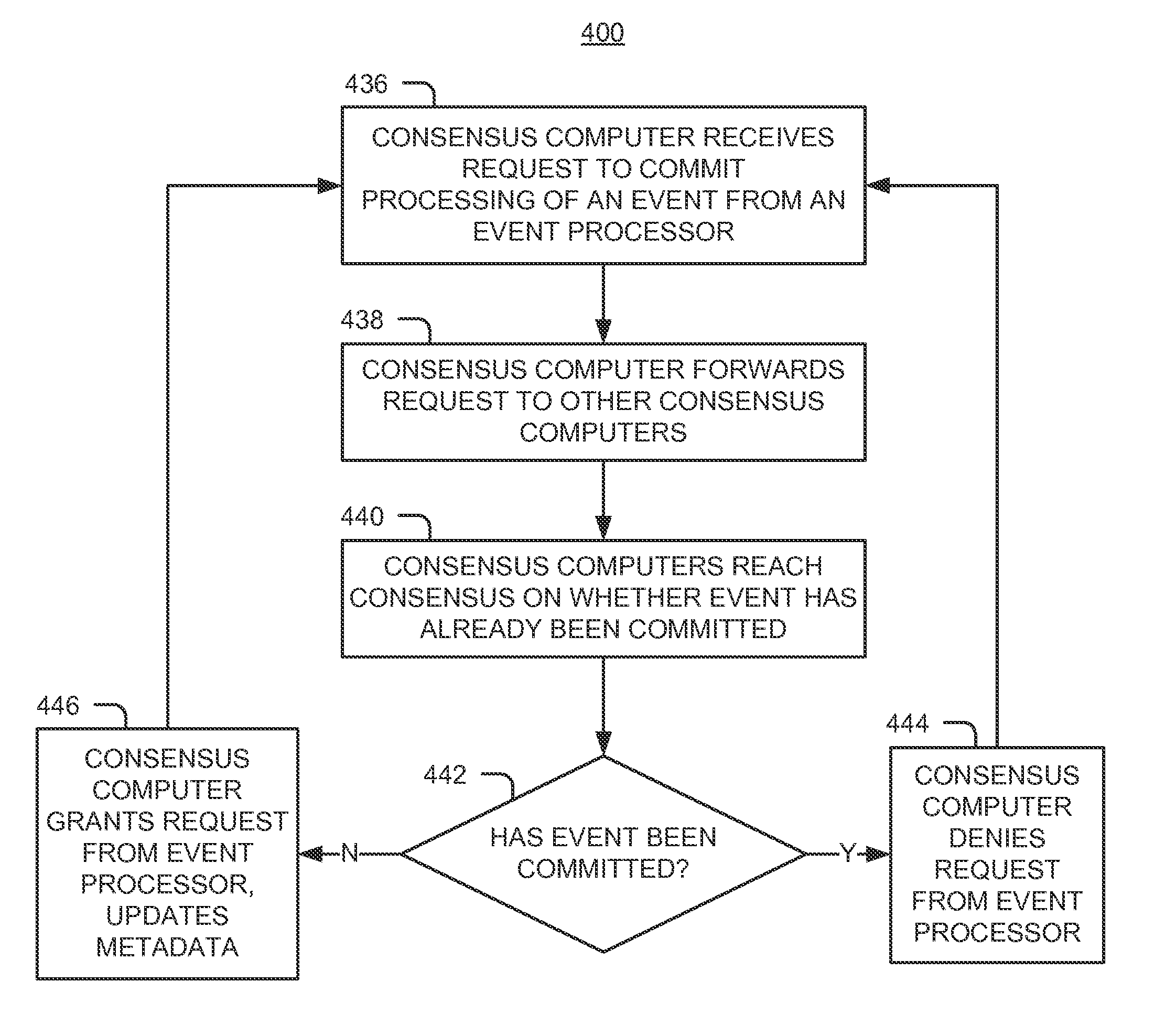

Disaster-proof event data processing

ActiveUS9172670B1Reliable processNon-redundant fault processingData switching networksData processingDistributed computing

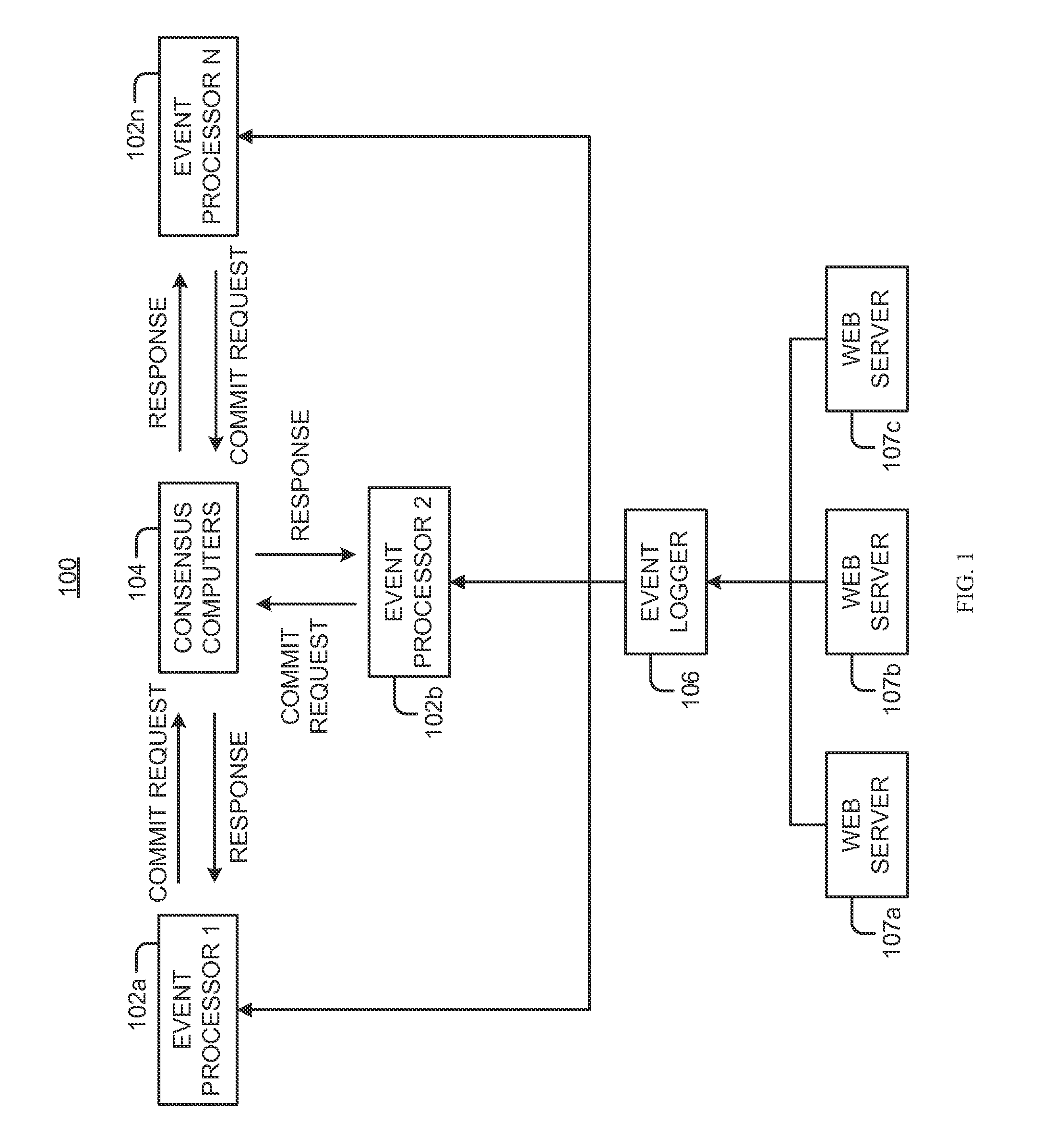

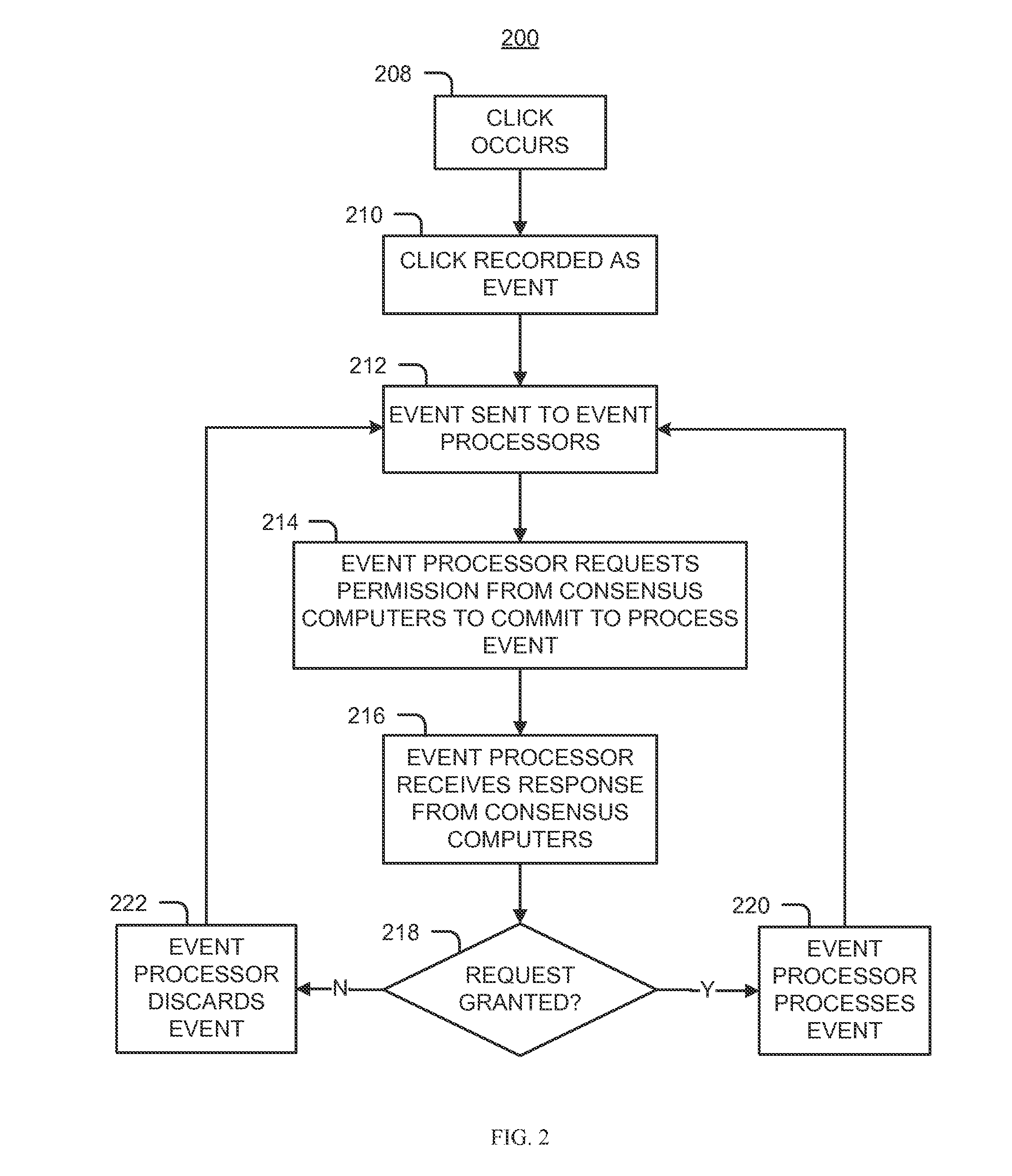

Systems and methods are disclosed herein for providing fault tolerant processing of events. The system includes multiple consensus computers configured to communicate with one another and multiple event processors configured to process data such as events. Each consensus computer is further configured to receive a request to process a unit of data from an event processor. A consensus computer communicates with at least one other consensus computer to reach consensus as to whether the unit of data has previously been assigned to an event processor for processing. Then, a consensus computer sends a message to the event processor that sent the inquiry including instructions to either process the unit of data or not process the unit of data. Because the consensus computers determine whether a unit of data has previously been assigned to an event processor, the system ensures that an event is not processed more than once.

Owner:GOOGLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com