Machine for dismounting small nuts of fixed end plate by pipe mold

A technology for fixing end plates and nut machines, applied in the construction field, can solve the problems of unsuitability for automatic production and low efficiency, and achieve the effects of high work efficiency and stable and reliable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

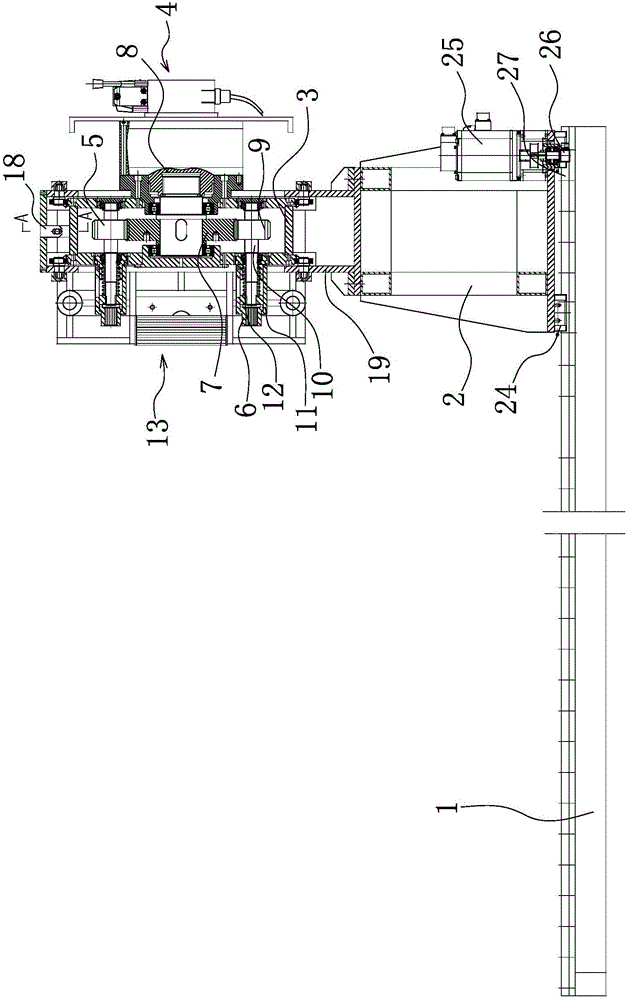

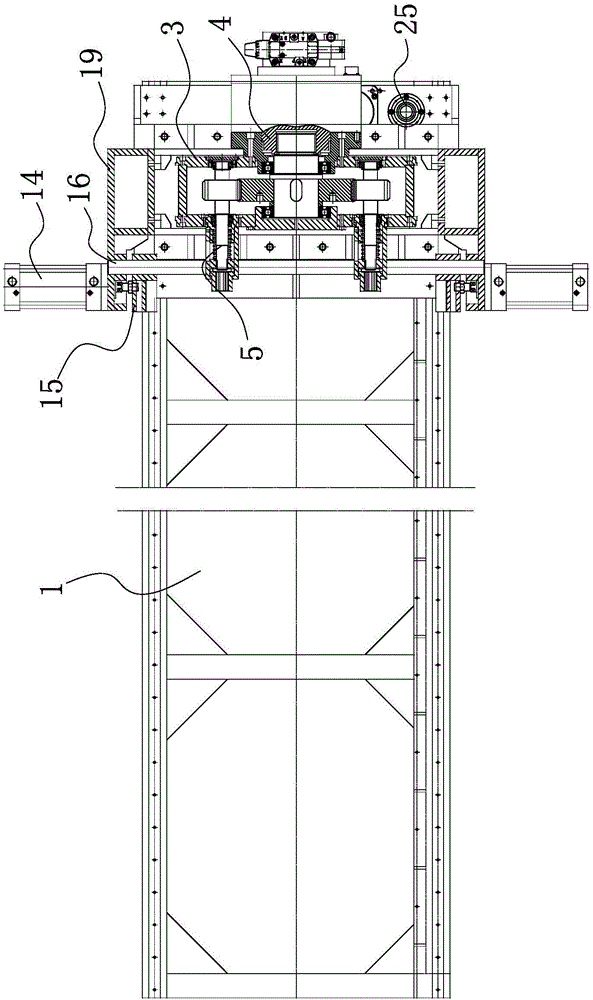

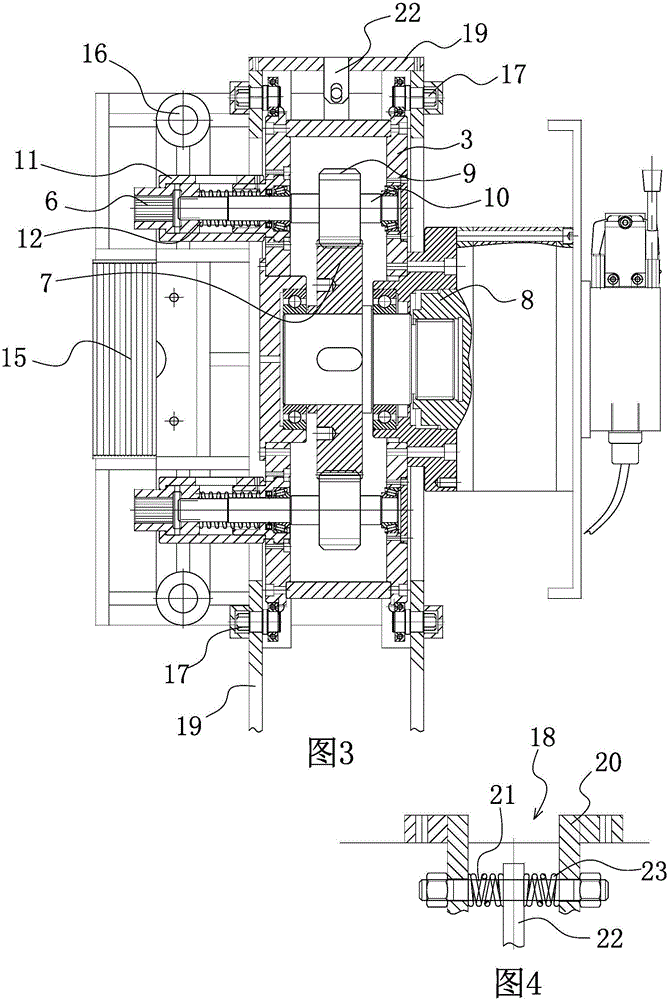

[0034] Such as figure 1 As shown, a small nut machine for dismantling and fixing the end plate of the pipe mold includes a machine table 1, which can be fixed on the foundation. The moving frame 2, the frame 2 is provided with a gear box 3, the gear box 3 is connected with a gear mechanism 4, and the gear mechanism 4 is meshed along the circumference of the gear mechanism 4 Several demoulding assemblies 5 and the ends of the demolding assemblies 5 extend out of the gear case 3, and the ends of the demolding assemblies 5 also have nut sleeves 6 that match the nuts on the fixed end plates, The demoulding assembly 5 can rotate in the circumferential direction, and the frame 2 can move close to the fixed end plate on the pipe mold. When the nut sleeve 6 is caught in the nut on the fixed end plate, the nut can be realized by the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com