Power tool

A power tool and movement technology, which is applied in the field of gun drill power tools, can solve the problems of unusable power tools and achieve the effects of quick replacement, accurate and reliable process, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In a preferred embodiment of the power tool of the present invention, the power tool is a power screwdriver, which can be divided into a pneumatic screwdriver, a hydraulic screwdriver and an electric screwdriver according to the power source, and there are also DC and AC in the electric screwdriver. Take a moving screwdriver as an example for specific description.

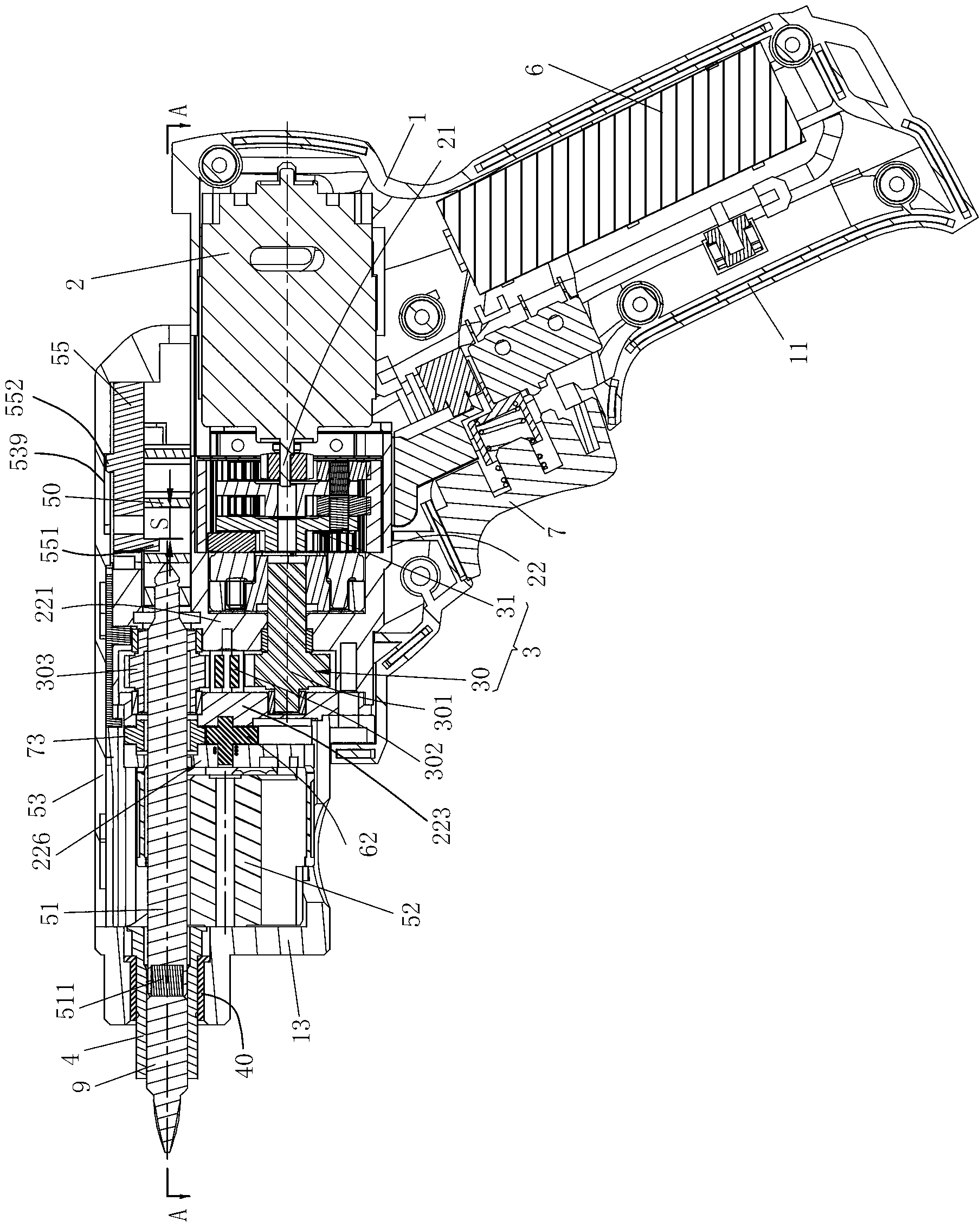

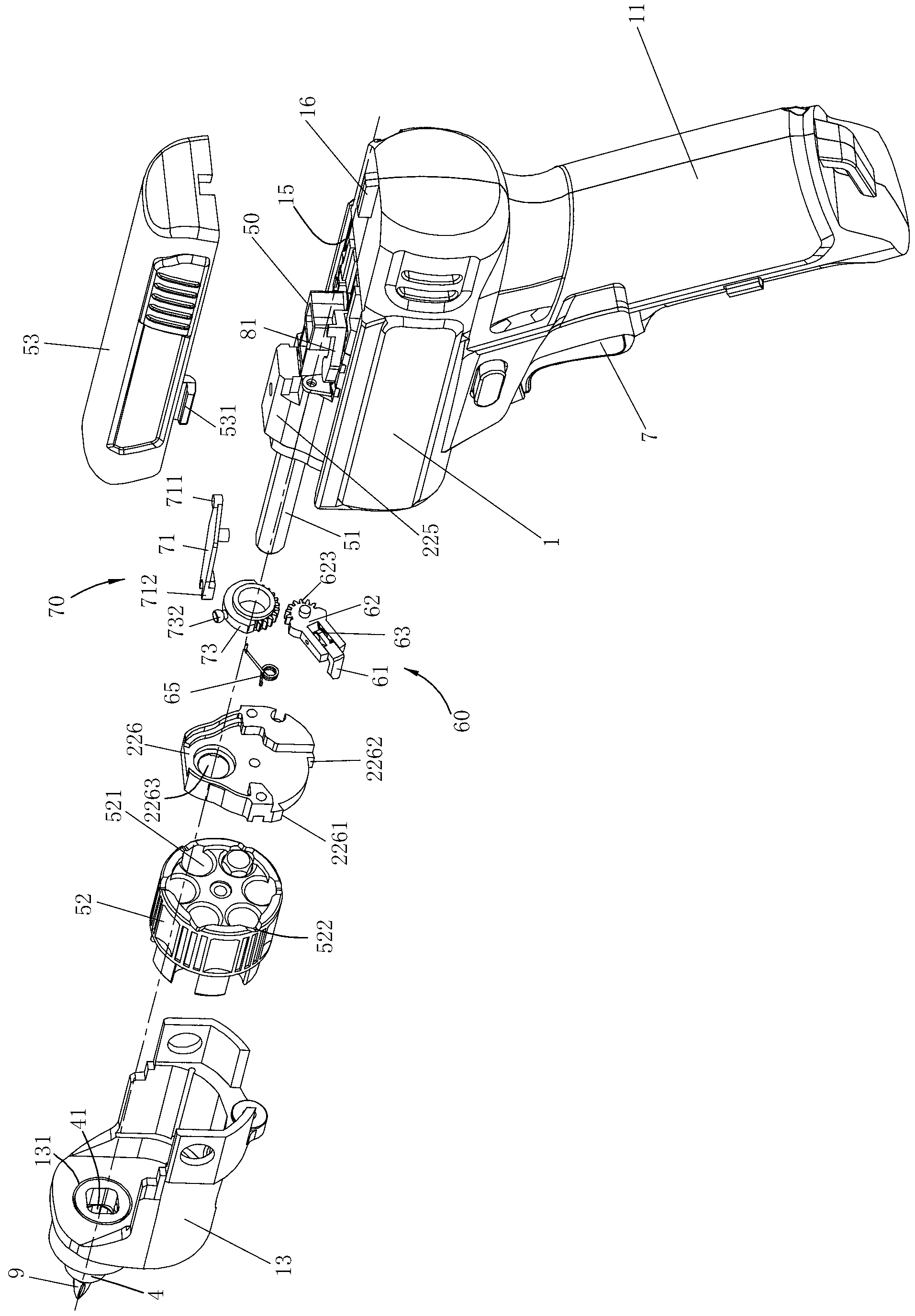

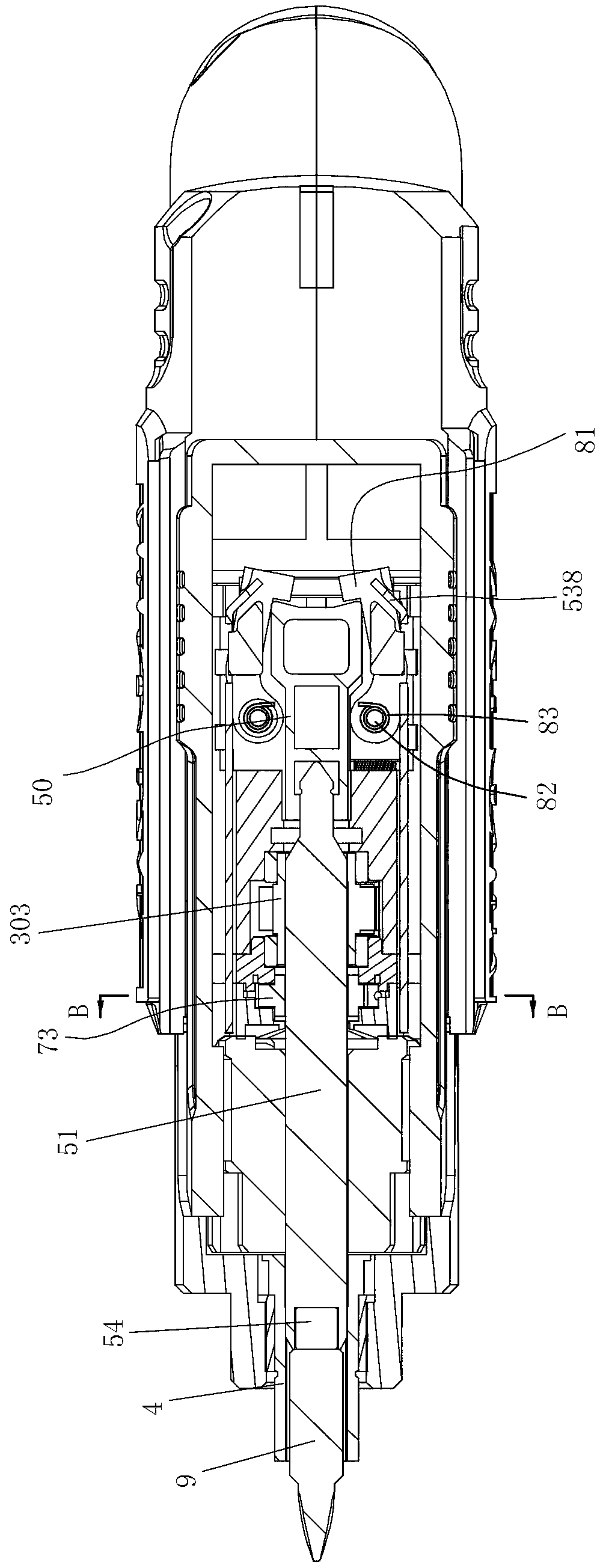

[0070] refer to Figure 1 to Figure 3 As shown, the DC electric screwdriver includes a casing 1 , a motor 2 , a battery 6 , a transmission mechanism 3 , a connecting shaft 51 , a storage clip 52 and an output shaft 4 . The casing 1 is composed of two symmetrical half shells assembled by screws (not shown). It has a horizontal part and a handle 11 part which is set at an obtuse angle with the horizontal part. The preferred angle of the present invention is 100 degrees to 130 degrees. Between degrees, it will be more comfortable when holding the handle 11 for operation. A button switch 7 is arranged on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com