Patents

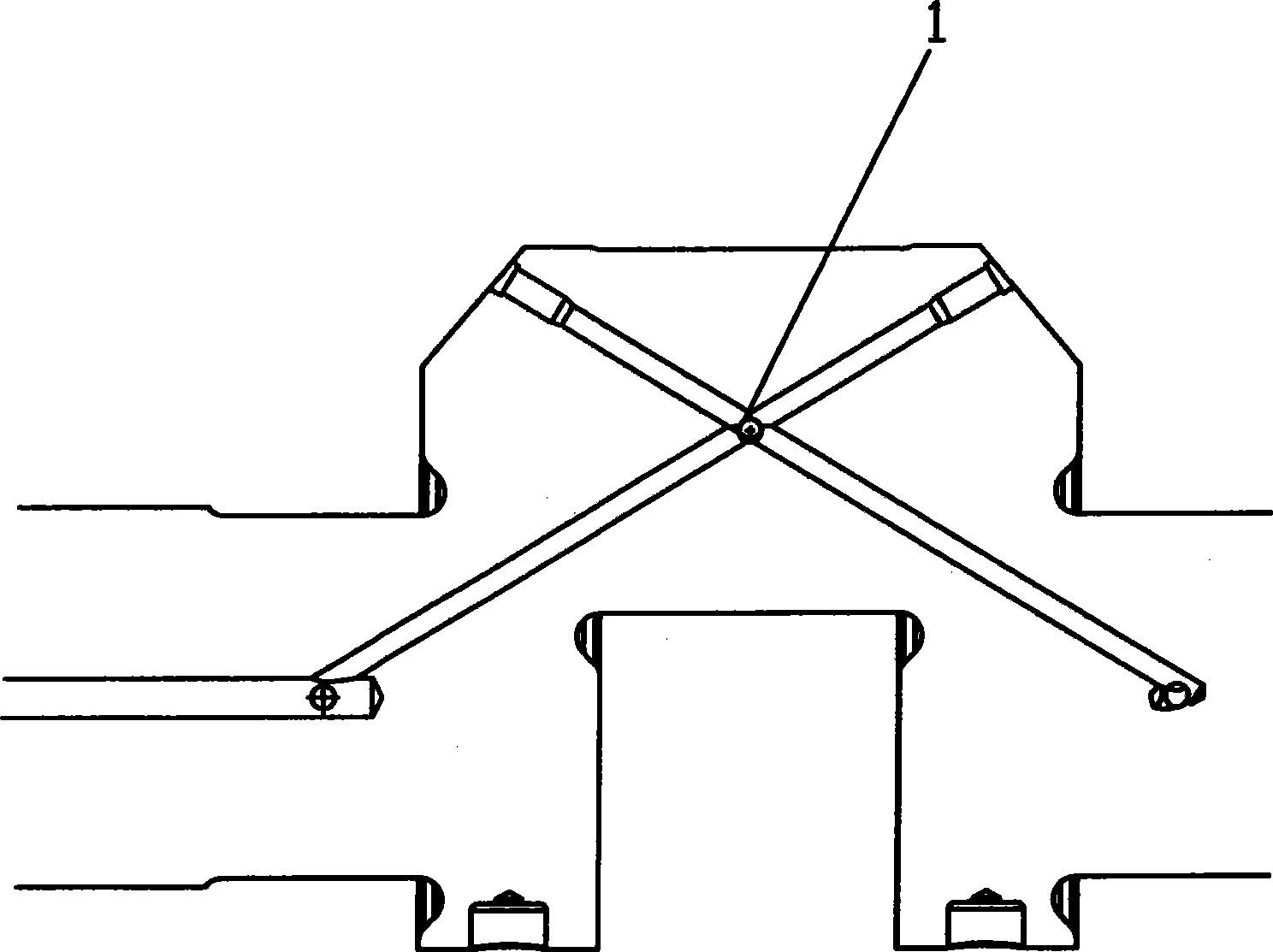

Literature

208 results about "Gun drill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

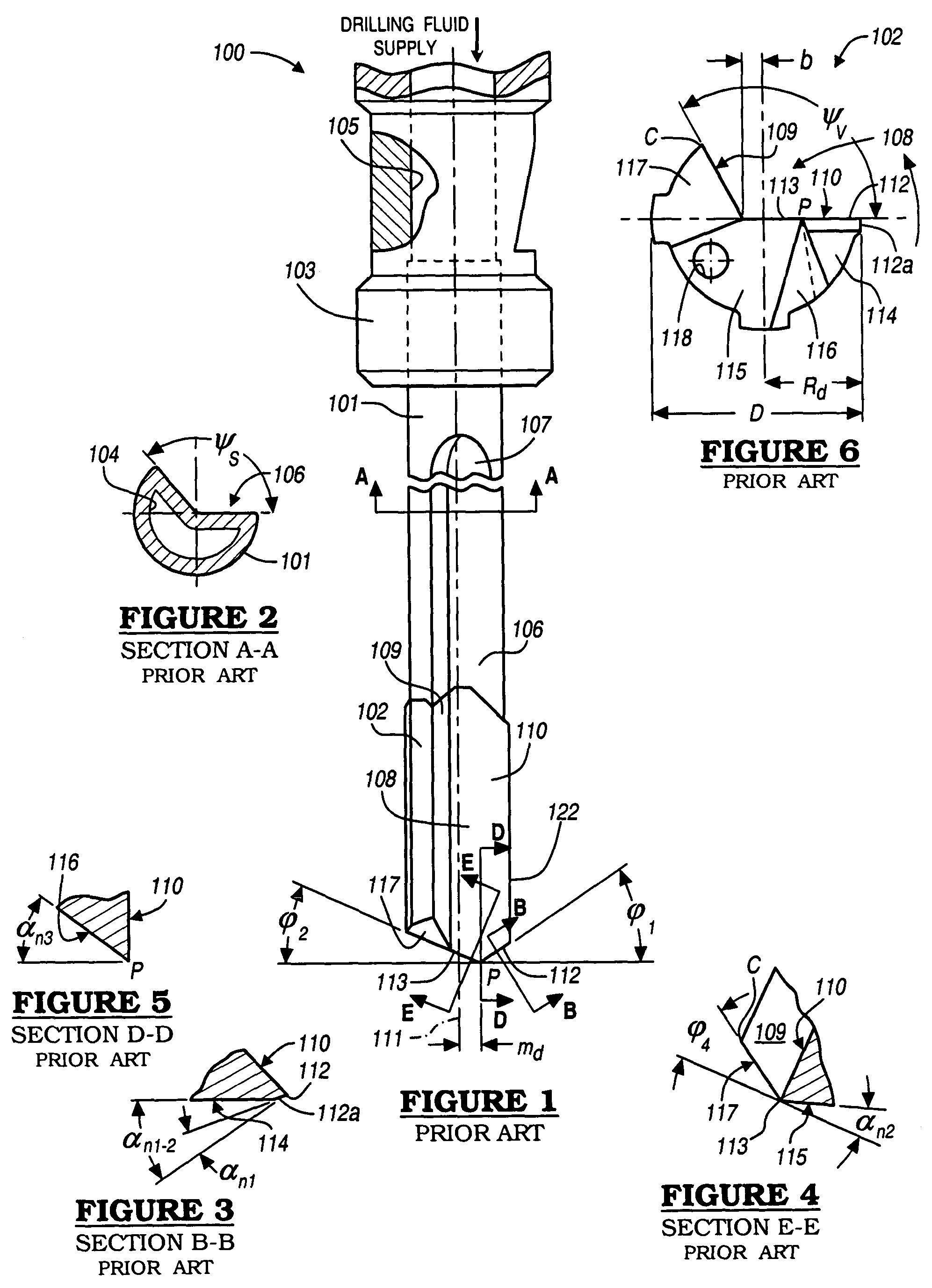

Gun drills are straight fluted drills which allow cutting fluid (either compressed air or a suitable liquid) to be injected through the drill's hollow body to the cutting face. They are used for deep drilling—a depth-to-diameter ratio of 300:1 or more is possible. Gun barrels are the obvious example; hence the name. Other uses include moldmaking, diemaking, and the manufacture of combustion engine parts such as crankcase, cylinder head, and woodwind musical instruments, such as uilleann pipes, as gun drills can drill long straight holes in metal, wood, and some plastics. The coolant provides lubrication and cooling to the cutting edges and removes the swarf or chips from the hole. Modern gun drills use carbide tips to prolong life and reduce total cost when compared with steel tips. Speed of drilling depends on the material being drilled, rotational speed, and the drill diameter; a high speed drill can cut a hole in P20 steel at 30 inches per minute.

Method for manufacturing hollow sodium inflating valve with closed disc end

ActiveCN103990944AReduce uniformityGuaranteed depthMetal-working apparatusMachines/enginesGun drillWelding defect

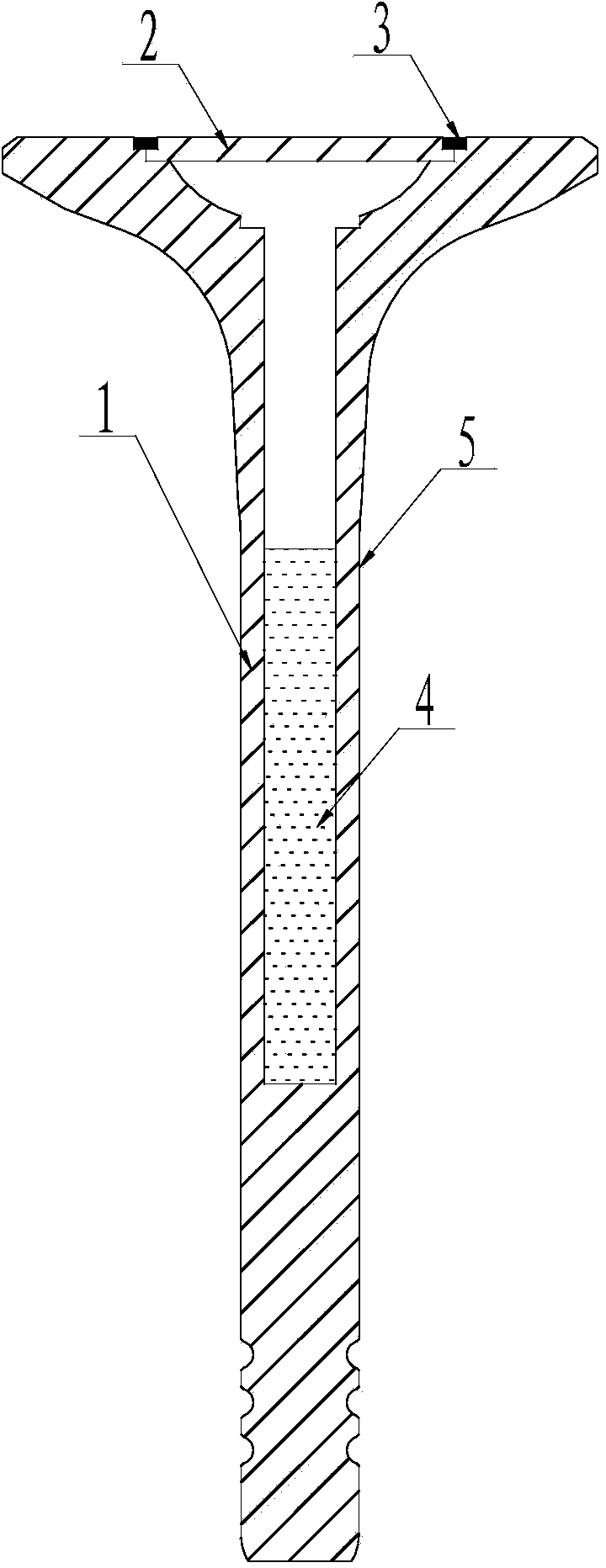

The invention discloses a method for manufacturing a hollow sodium inflating valve with a closed disc end, belongs to a production method of valves of internal combustion engines, and particularly relates to the method for manufacturing the hollow sodium inflating valve with sodium serving as a coolant. According to the method, a pre-workblank with the end shaped like the head of garlic of a bar is formed by the thin and long bar through an electric pier; then, the valve is forged and pressed into the shape of a gas outlet valve workblank through the one-time forging and pressing process in the forging procedure, wherein the valve workblank forming process is in a high temperature state, simple in process route, low in manufacturing cost and high in efficiency. An inner hole of the valve is machined through a deep hole gun-drill, and therefore the diameter of the inner hole, the depth of the inner hole, the roughness of the inner hole, the coaxiality of the inner hole and the evenness of the wall thickness can be ensured, the machining rhythm is quick, efficiency is high, and cost is low. By means of the method of utilizing steps at the welding point of a disc end face sealing cover and the valve, welding defects are reduced, and welding strength is high.

Owner:济南沃德汽车零部件有限公司

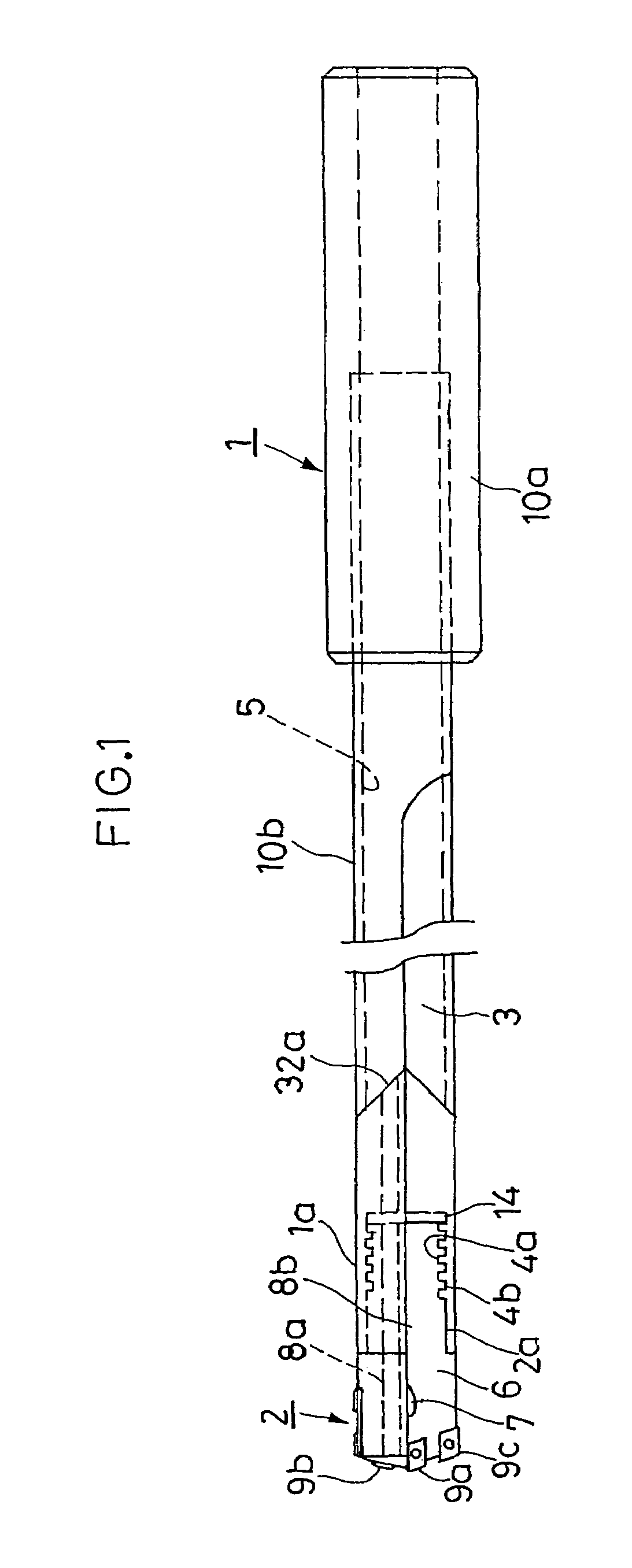

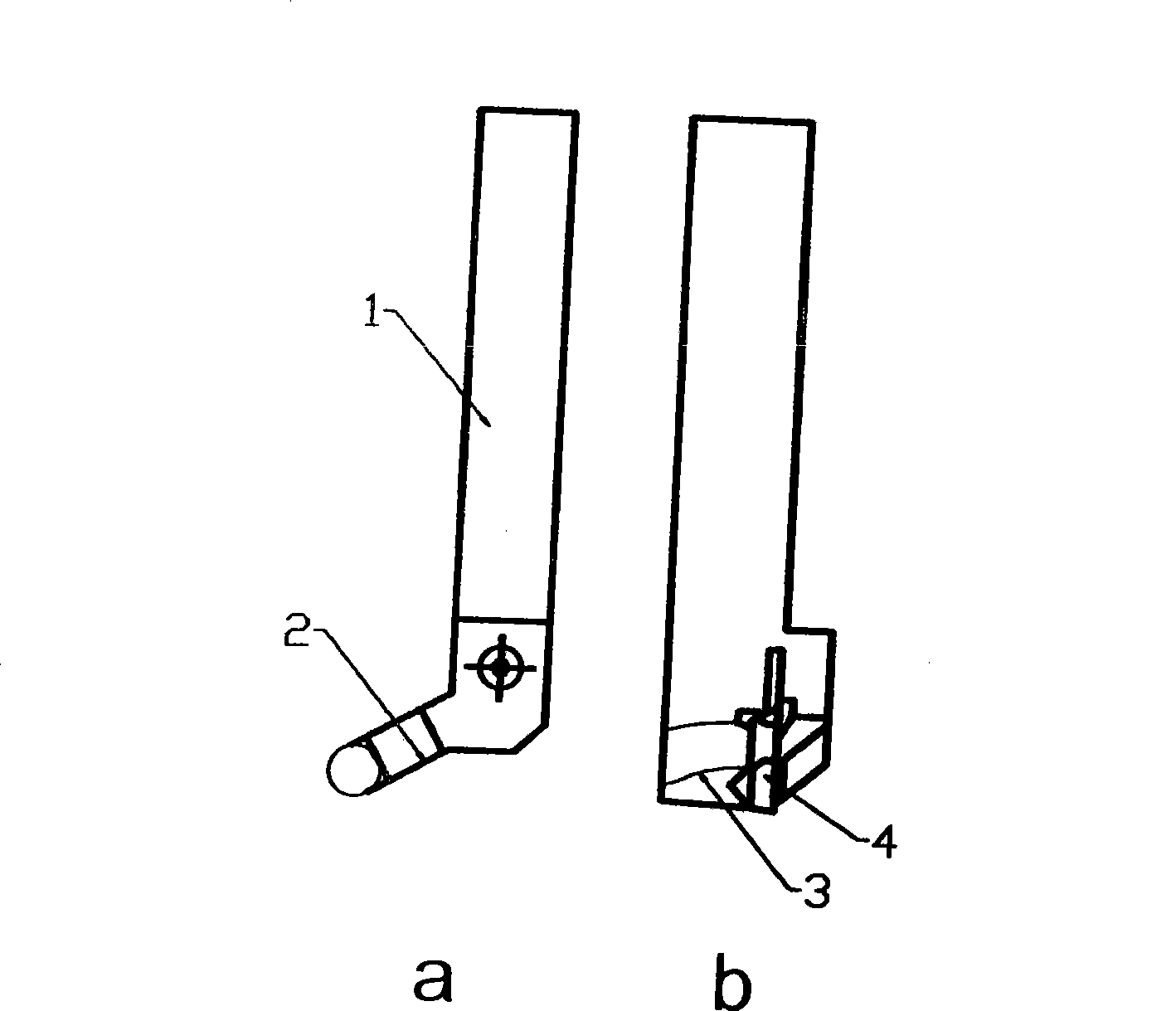

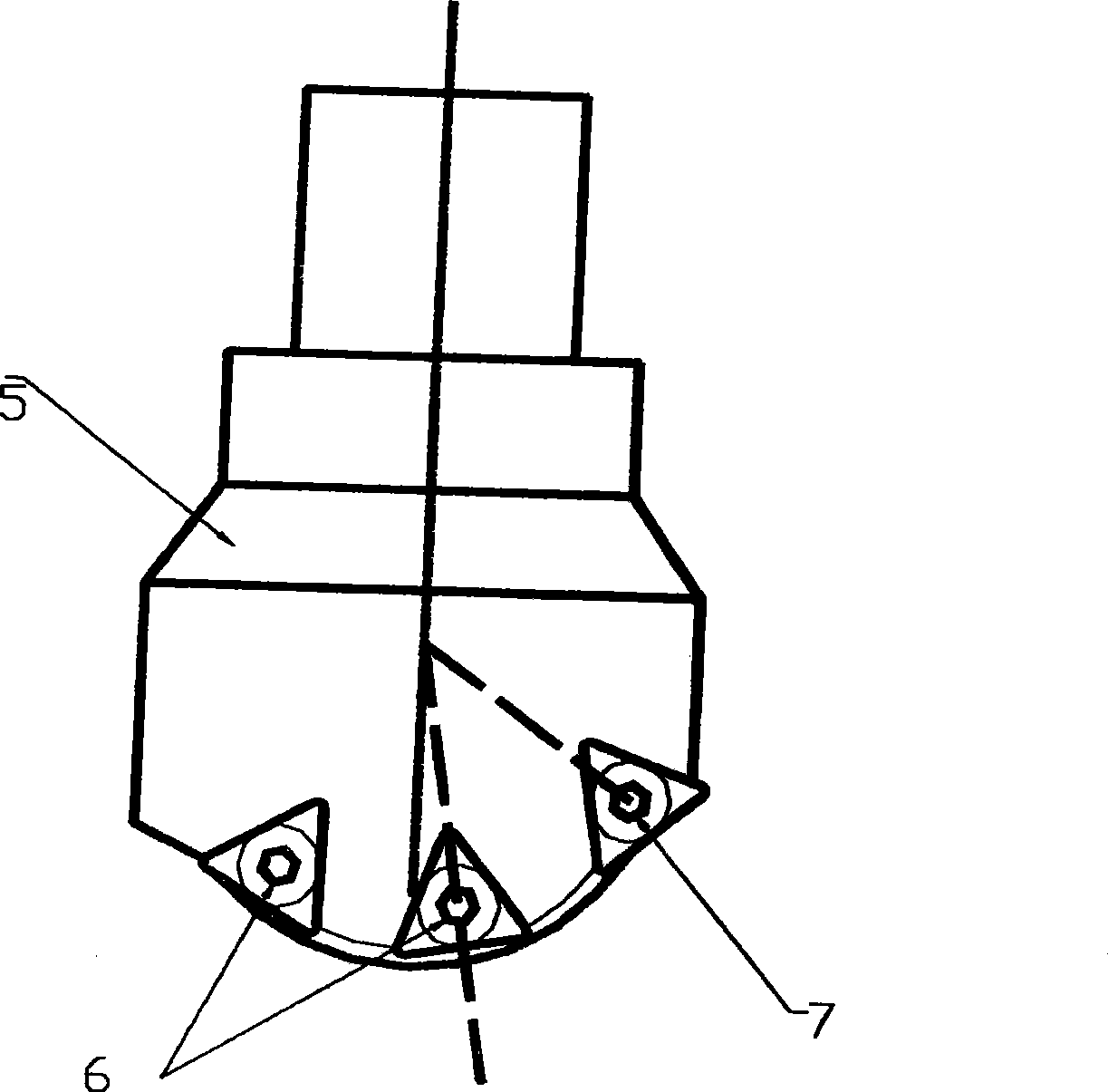

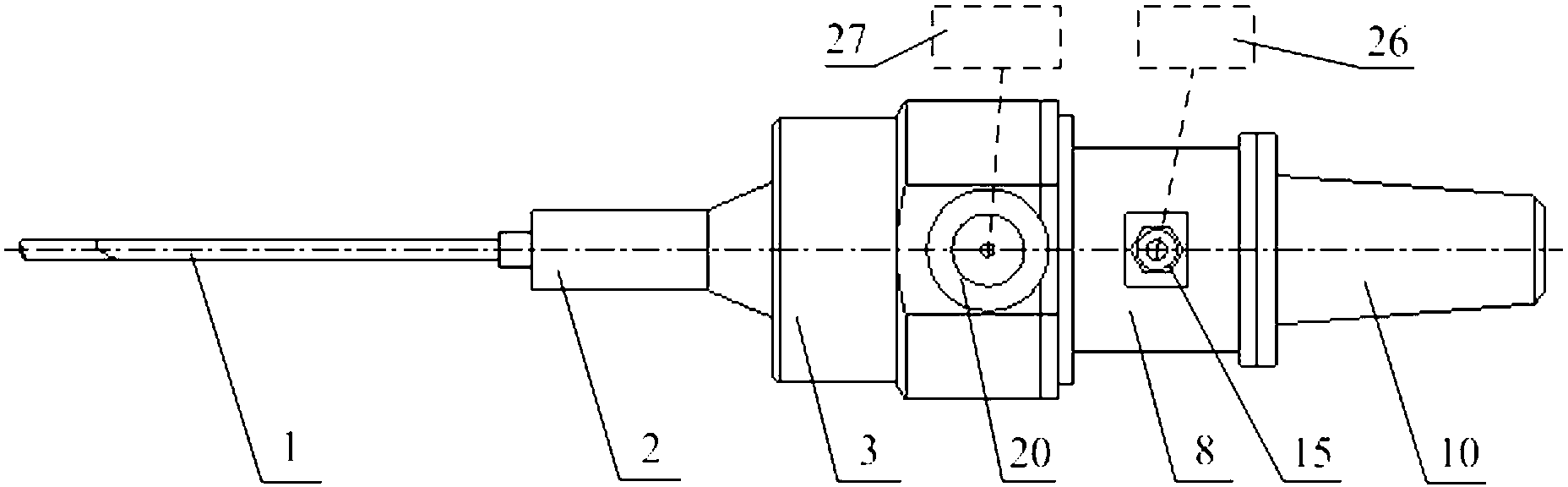

Deep hole cutter

ActiveUS7004691B2High in dischargeabilityImprove cutting efficiencyWood turning toolsTransportation and packagingEngineeringGun drill

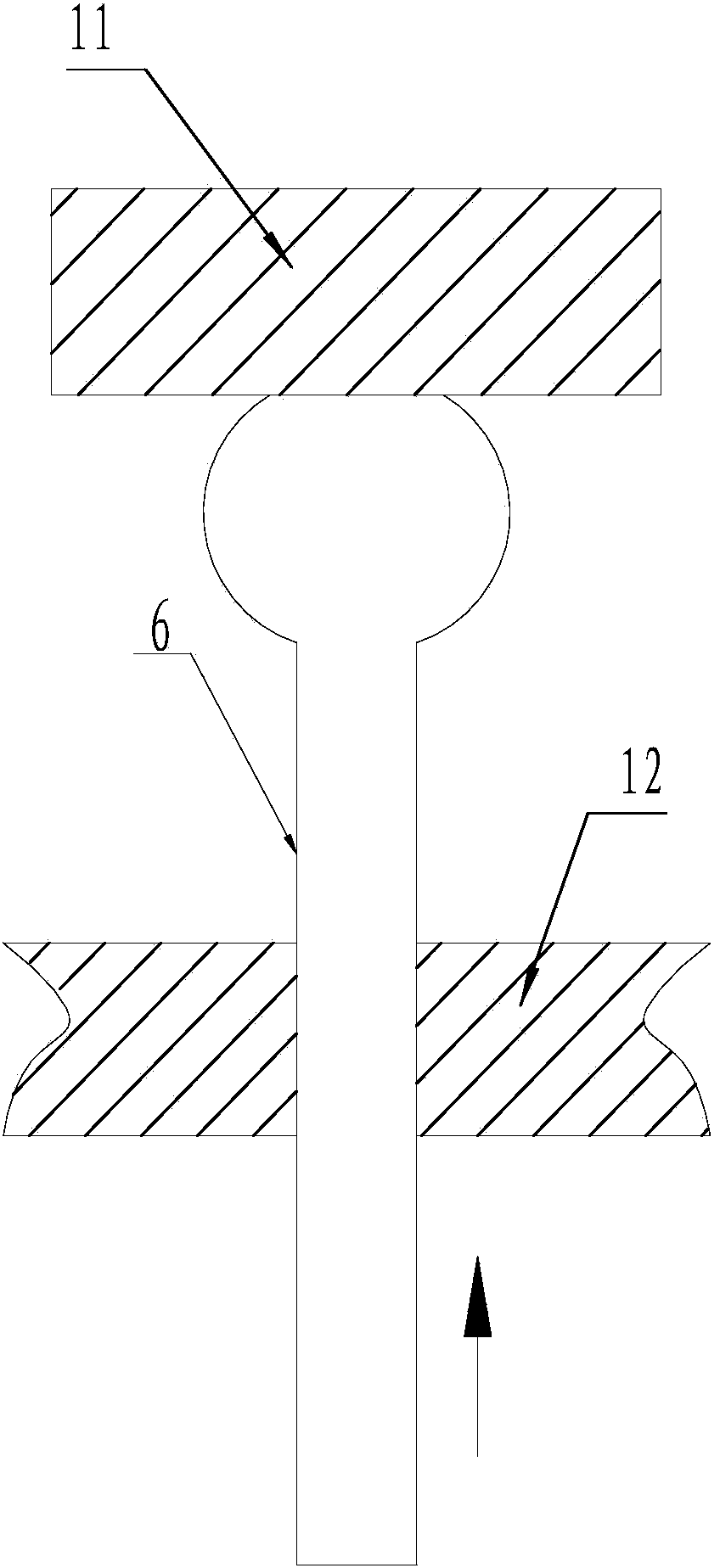

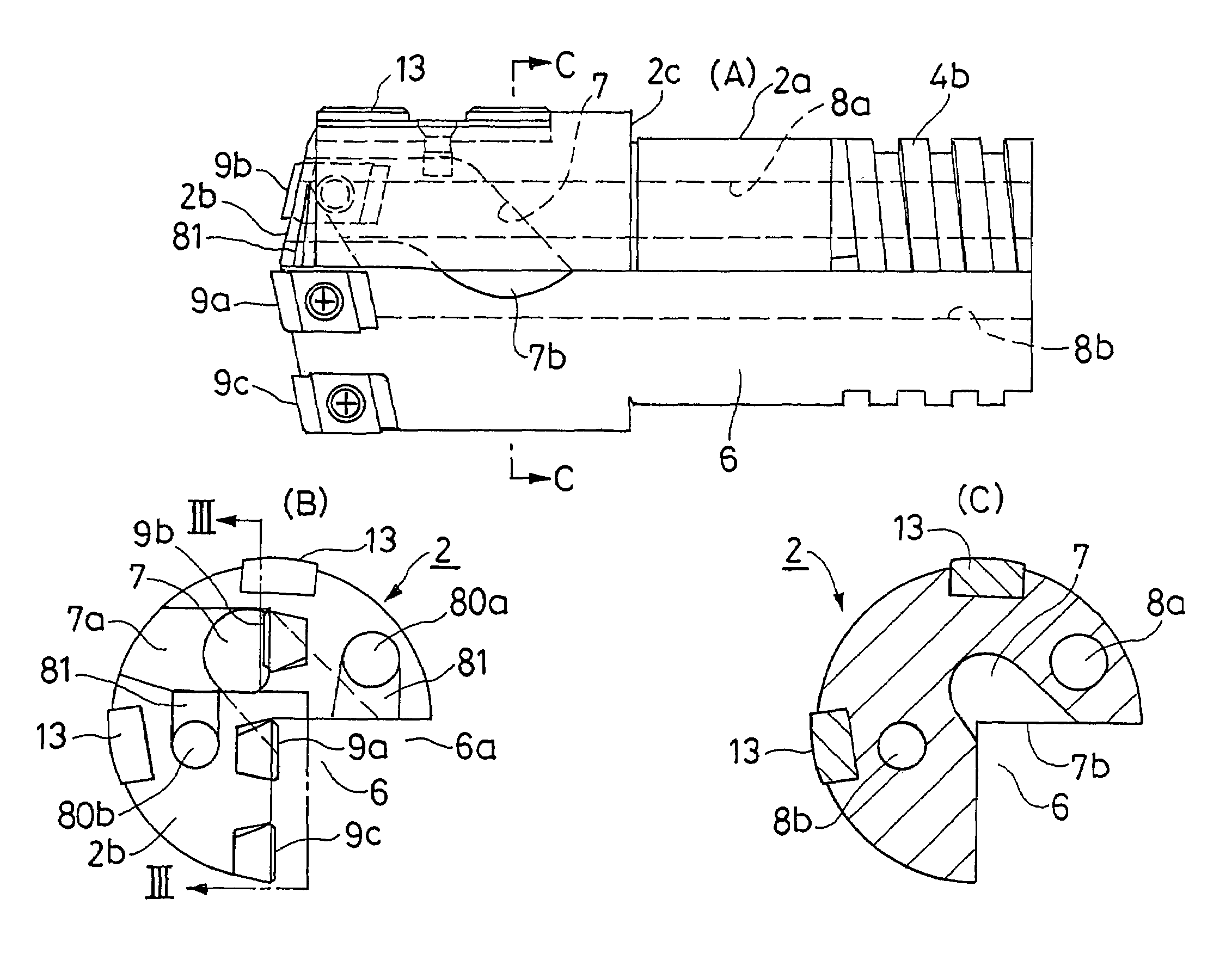

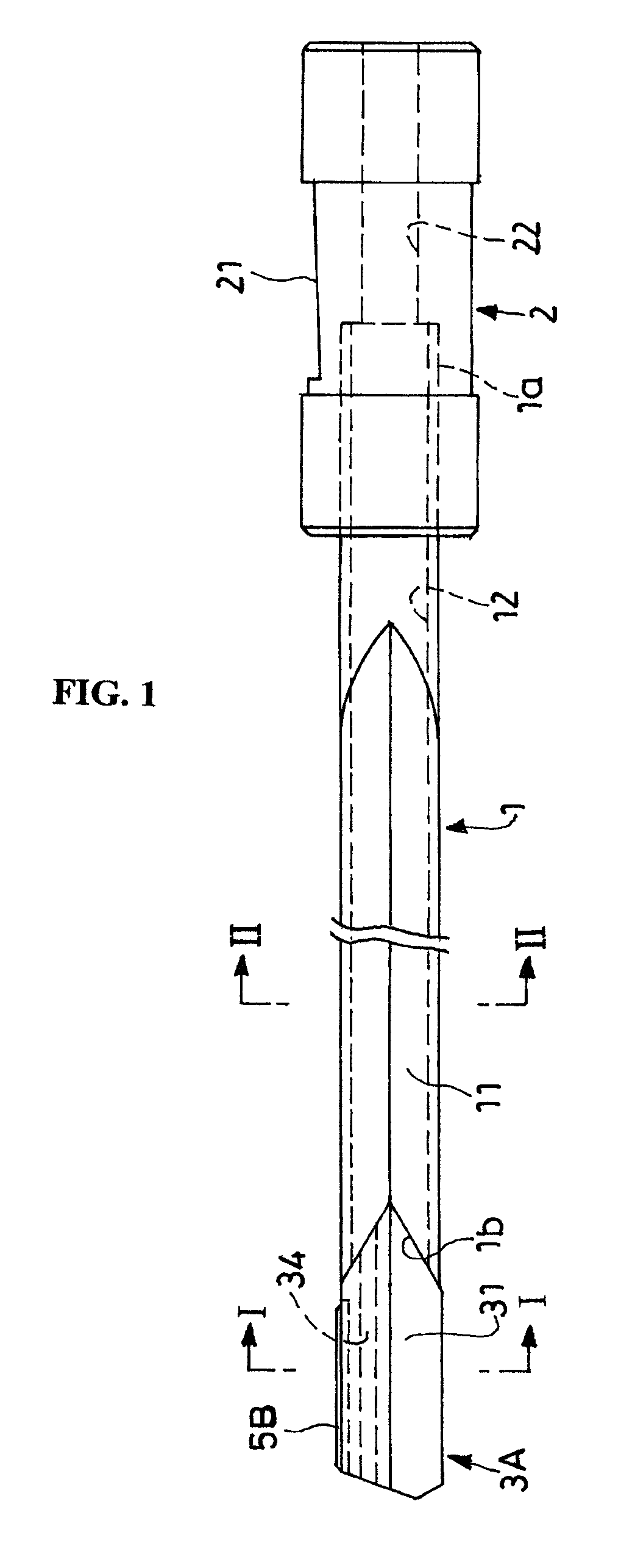

A deep hole cutter for a gun drill system includes a tool shank and a cutting head with two or more cutting edges. The tool shank and the cutting head are separate members connected strongly by threads. The shavings produced by the cutting edges can be discharged together with the coolant supplied through the hole cutter. The shaving dischargeability is improved for higher cutting efficiency.The tool shank 1 has one outer axial discharge groove 3. The cutting head 2 has one outer axial discharge groove 6 in linear alignment with the discharge groove 3. The cutting head 2 also has a discharge port 7a formed in its front end. The cutting head 2 further has a bypass passage 7 formed in it and extending between the discharge port 7a and the discharge groove 6. The cutting edges 9a and 9c face the discharge groove 6. The cutting edge 9b faces the discharge port 7a.

Owner:YUNITAKKU

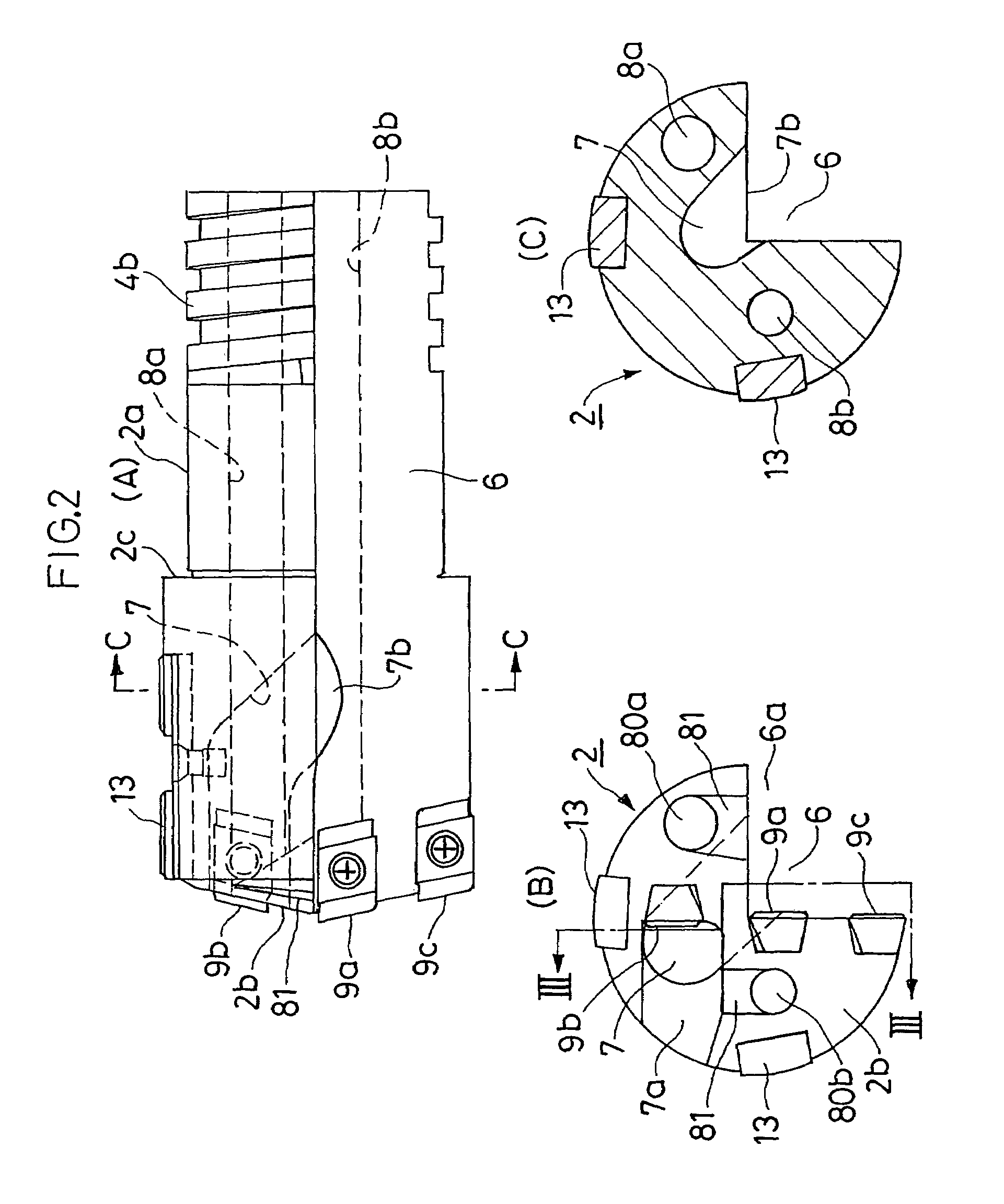

Gundrill

InactiveUS7195428B2Improve fluid flowWood turning toolsTransportation and packagingFluteWell drilling

Owner:FORD GLOBAL TECH LLC

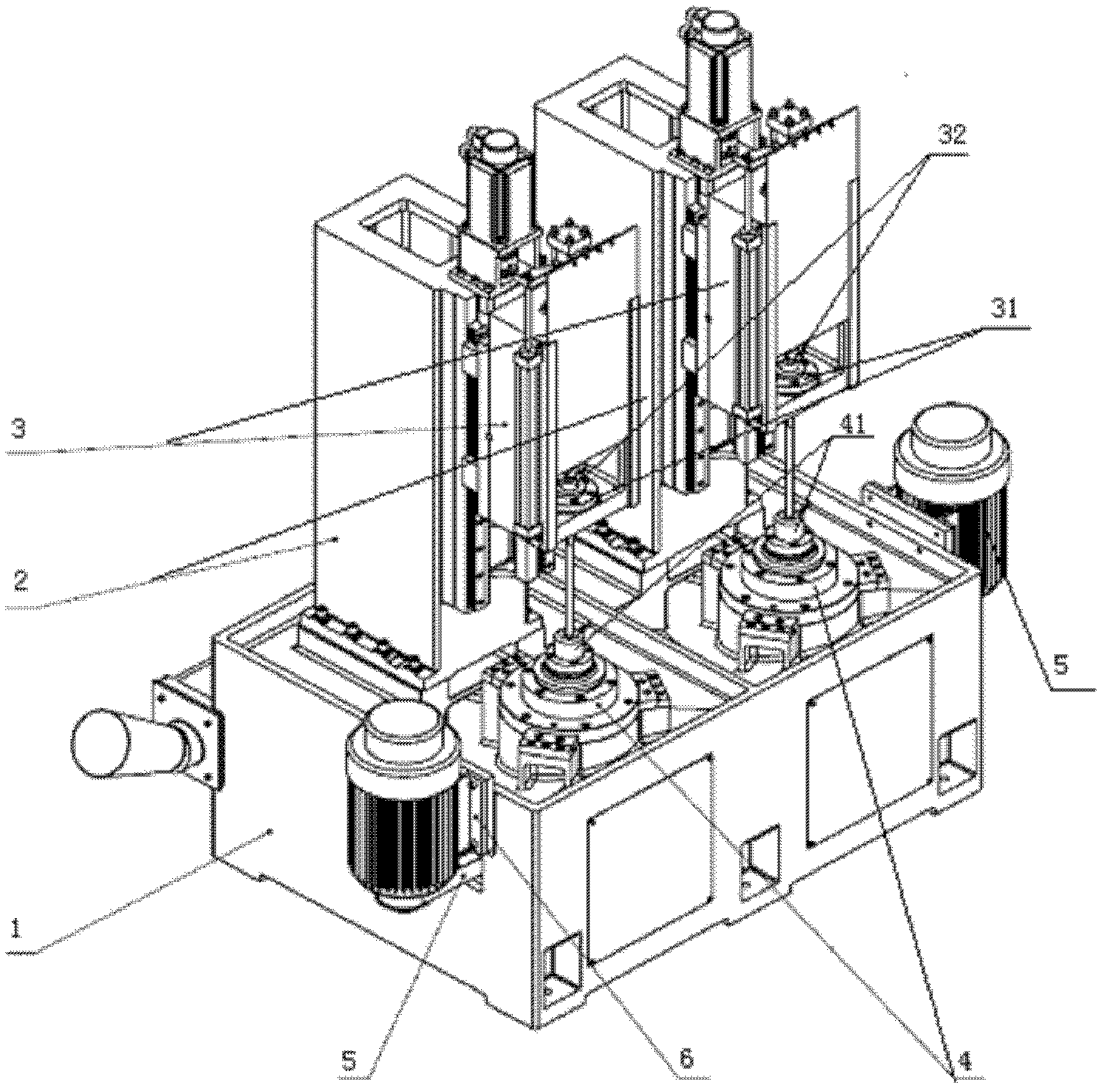

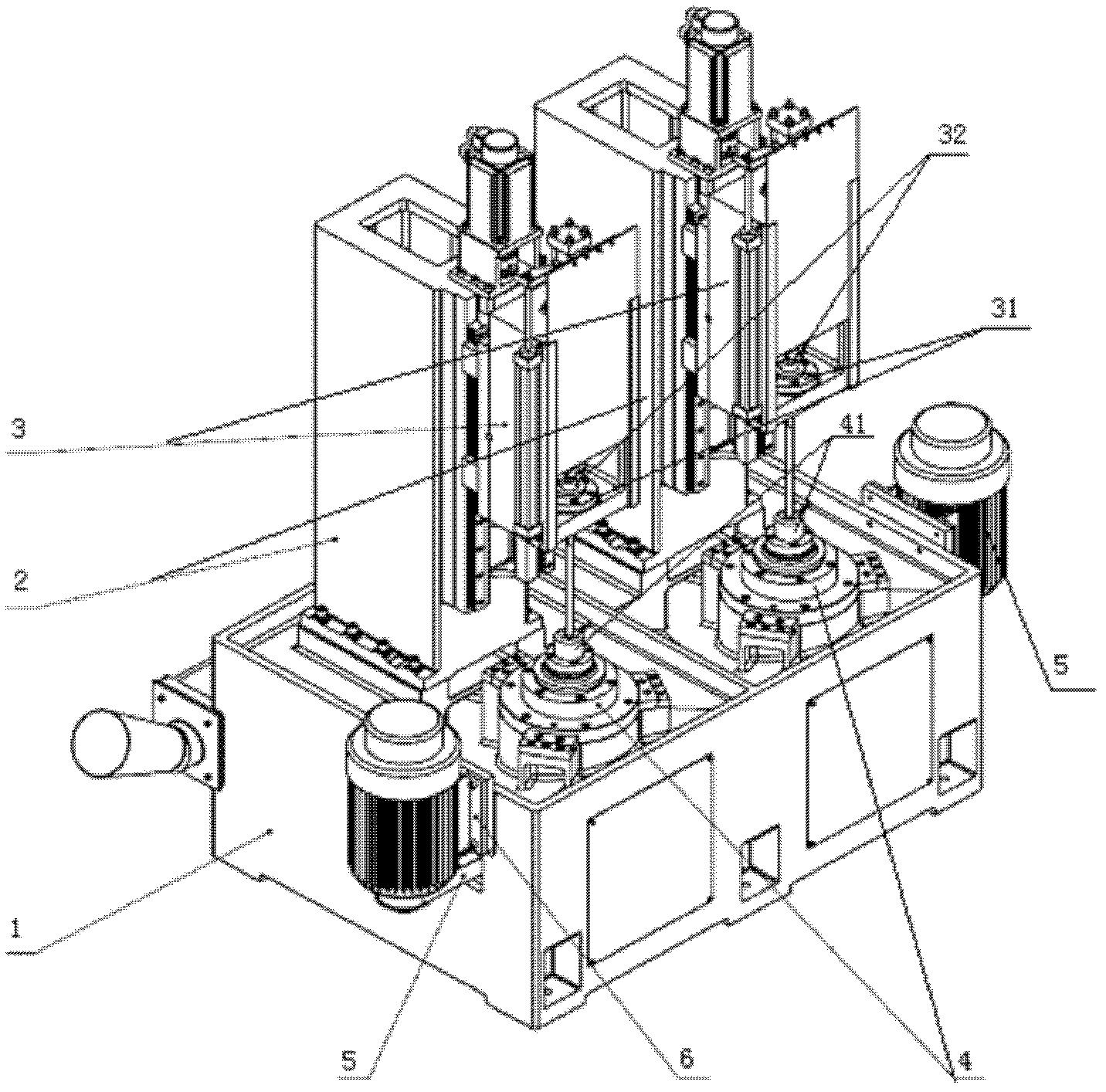

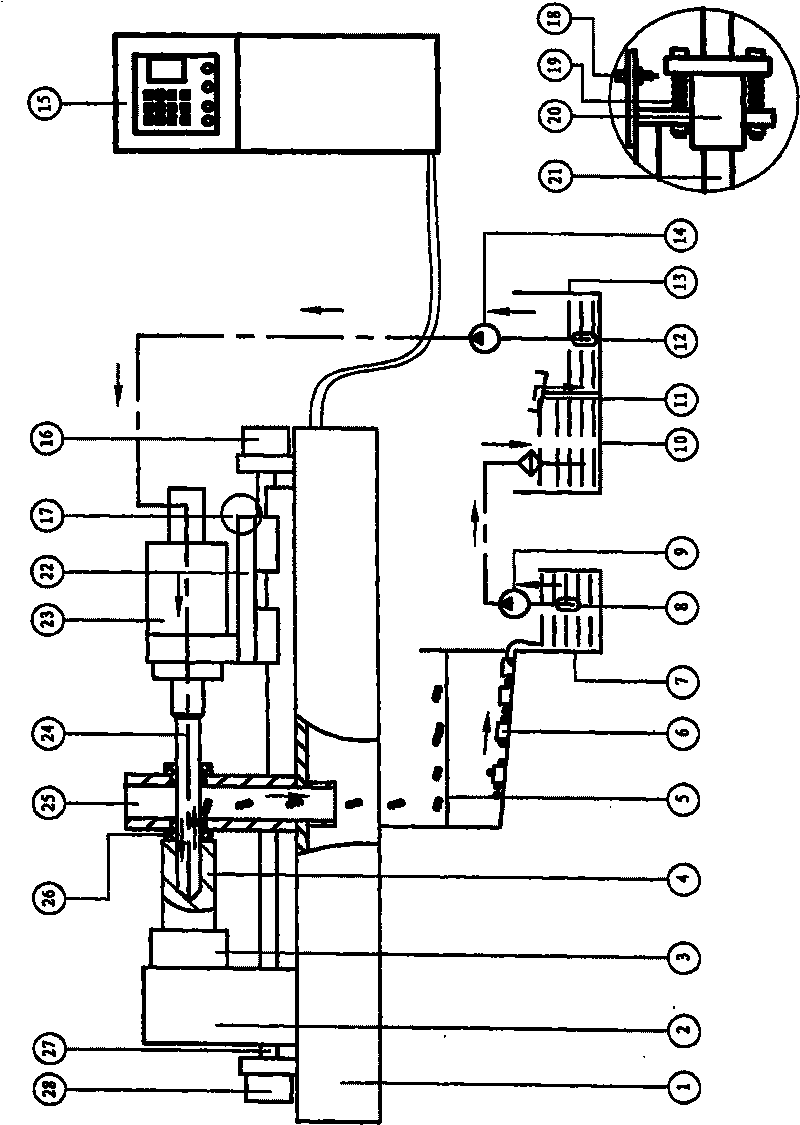

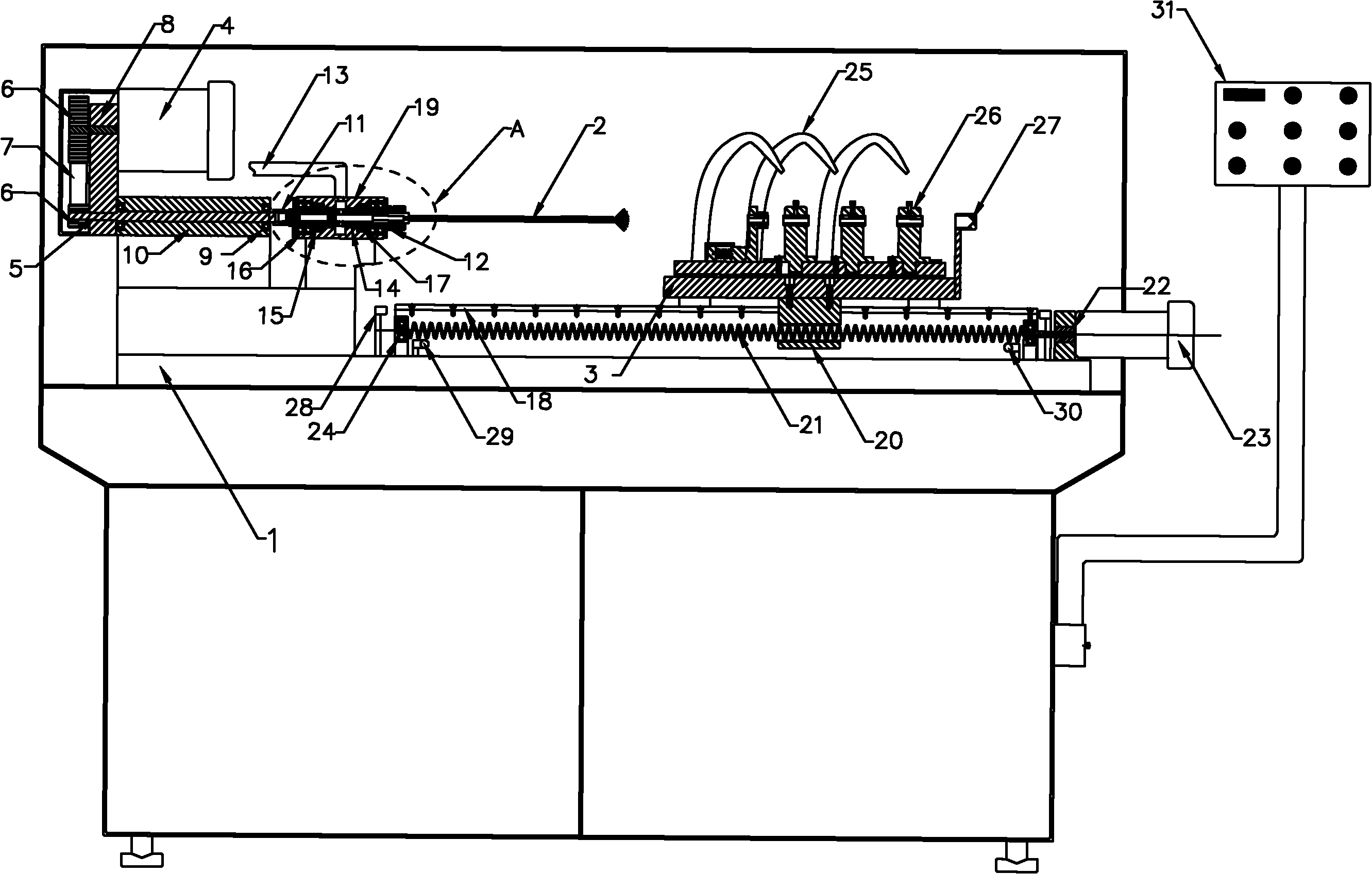

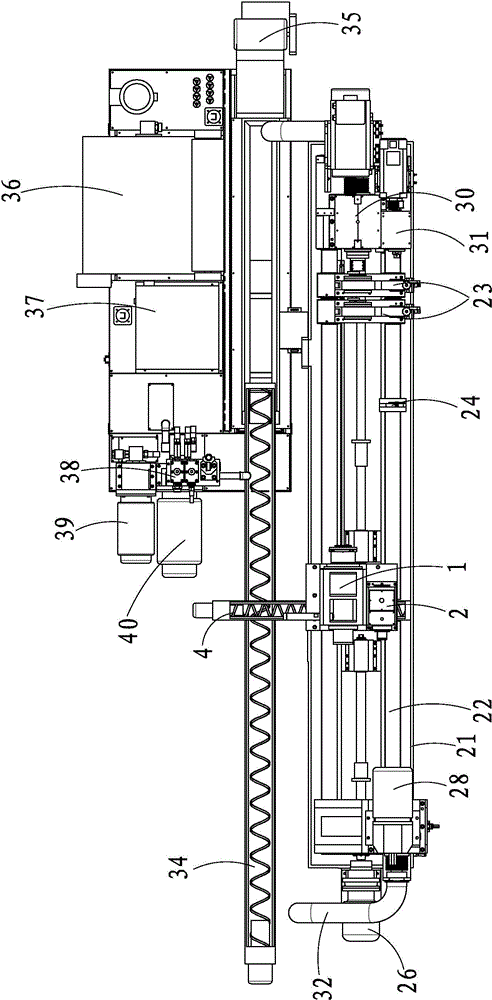

Numerical control inverted double-station deep hole drilling machine

InactiveCN102615305AEnsure dimensional accuracyEnsure internal surface finishBoring/drilling componentsMaintainance and safety accessoriesNumerical controlWork unit

The invention discloses a numerical control inverted double-station deep hole drilling machine. The numerical control inverted double-station deep hole drilling machine comprises a double-station machine body component, wherein the rear table surface of the machine body component is fixedly and vertically provided with a left frame type upright post component and a right frame type upright post component; two frame type compressing components are connected with the left upright post component and the right upright post component respectively along a sliding plate up and down by taking a slide rail as a guide; the compressing components are provided with drill bushing assembly seats, drill bushings and hydraulic oil cylinders, so that workpieces can be positioned and clamped; the front table surface of the machine body component is fixedly provided with a left main shaft component and a right main shaft component; the main shaft of the main shaft components is provided with a special deep hole gun drill; both sides of the machine body component are fixedly provided with variable frequency speed regulation motors; and the variable frequency speed regulation motors are in transmission connection with the main shaft components through synchronous belts. An inverted structure that a drill is arranged on the lower side effectively improves the chip removal and the heat dissipation during the deep hole machining and improves the surface accuracy of parts at the same time. A left working unit and a right working unit can be alternately used in waiting time during operation, so that the production efficiency is improved.

Owner:ANHUI LICHENG MACHINERY EQUIP

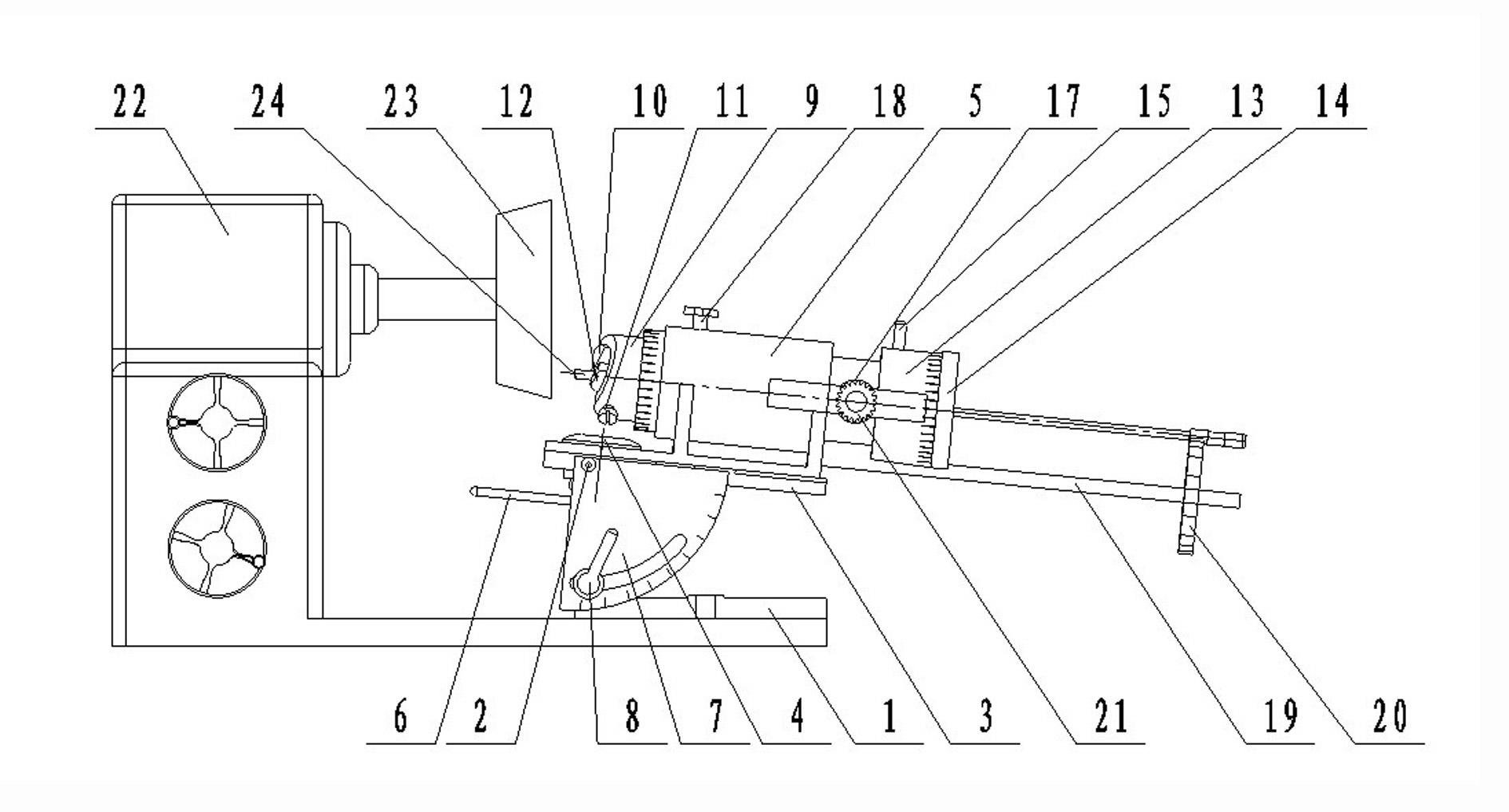

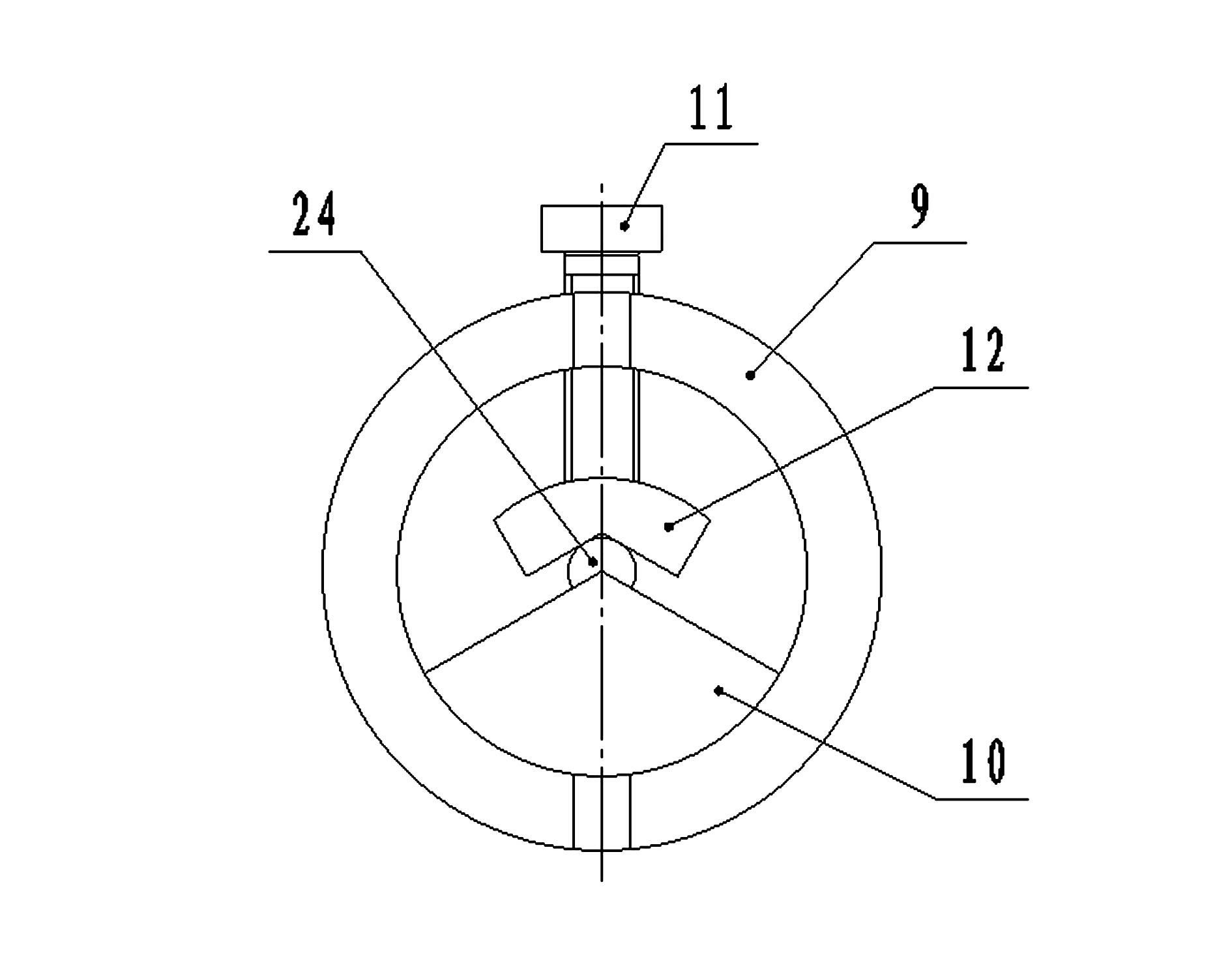

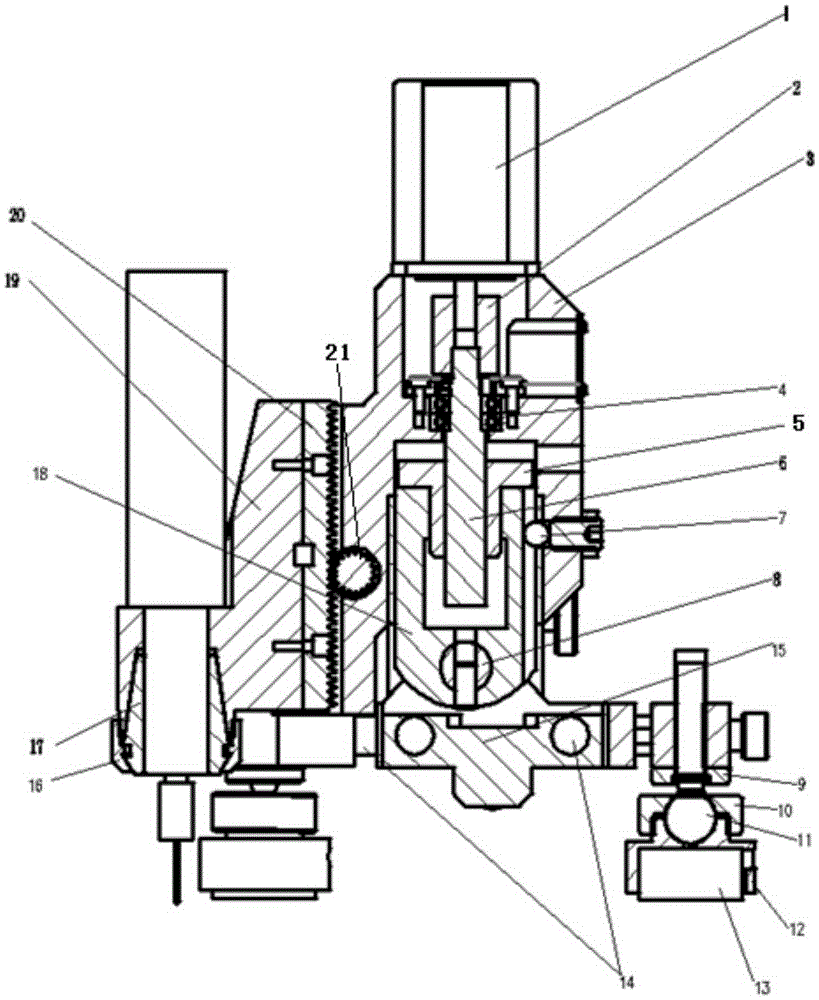

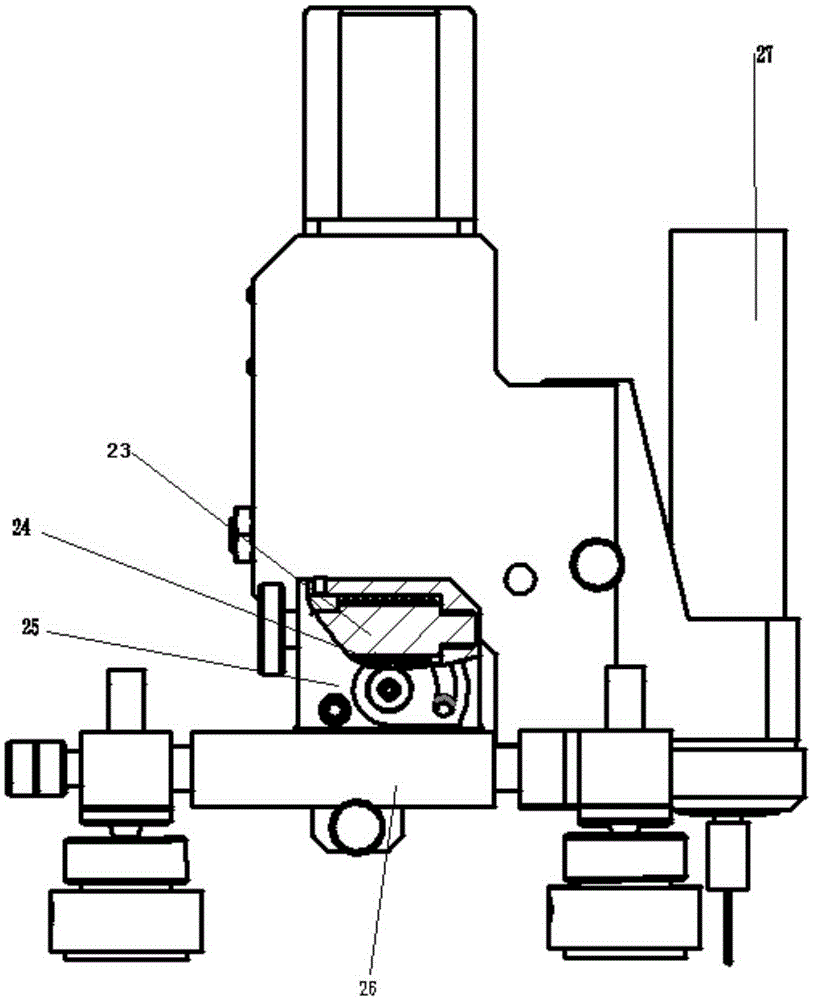

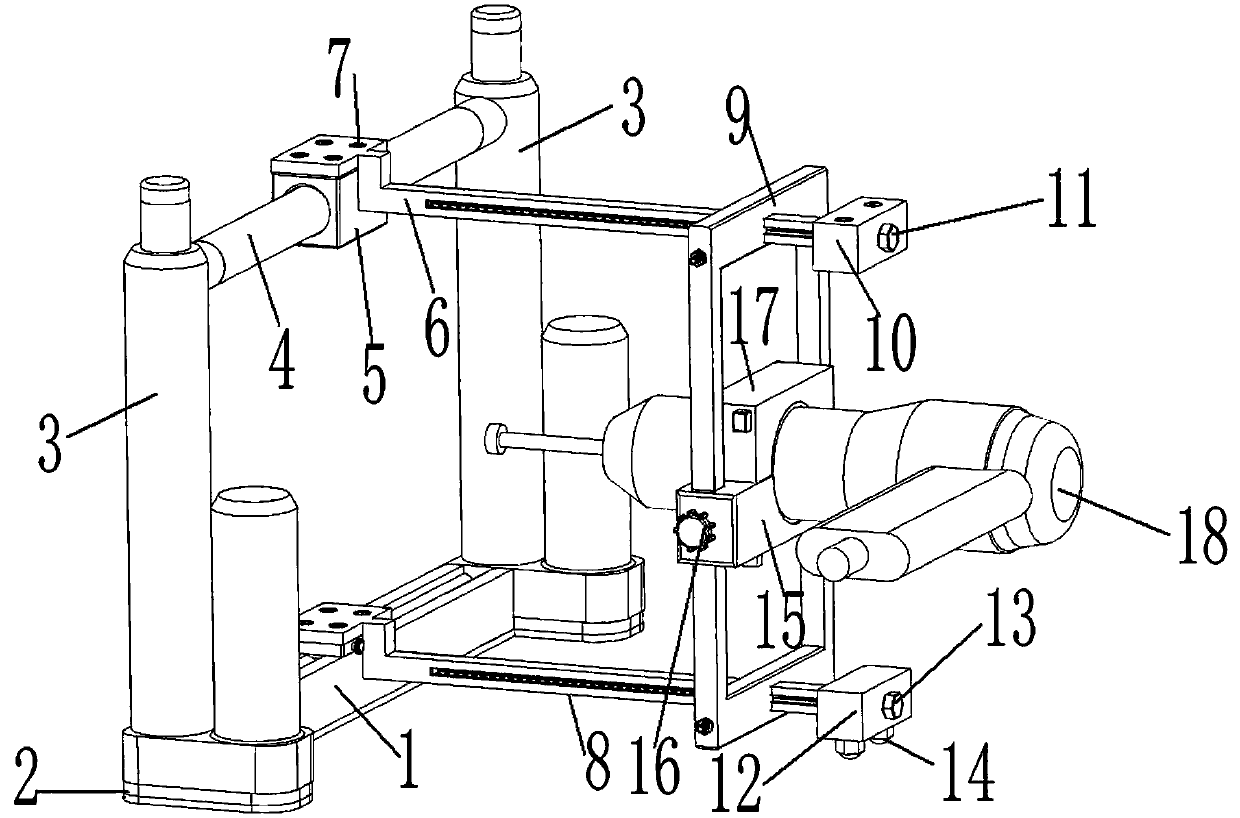

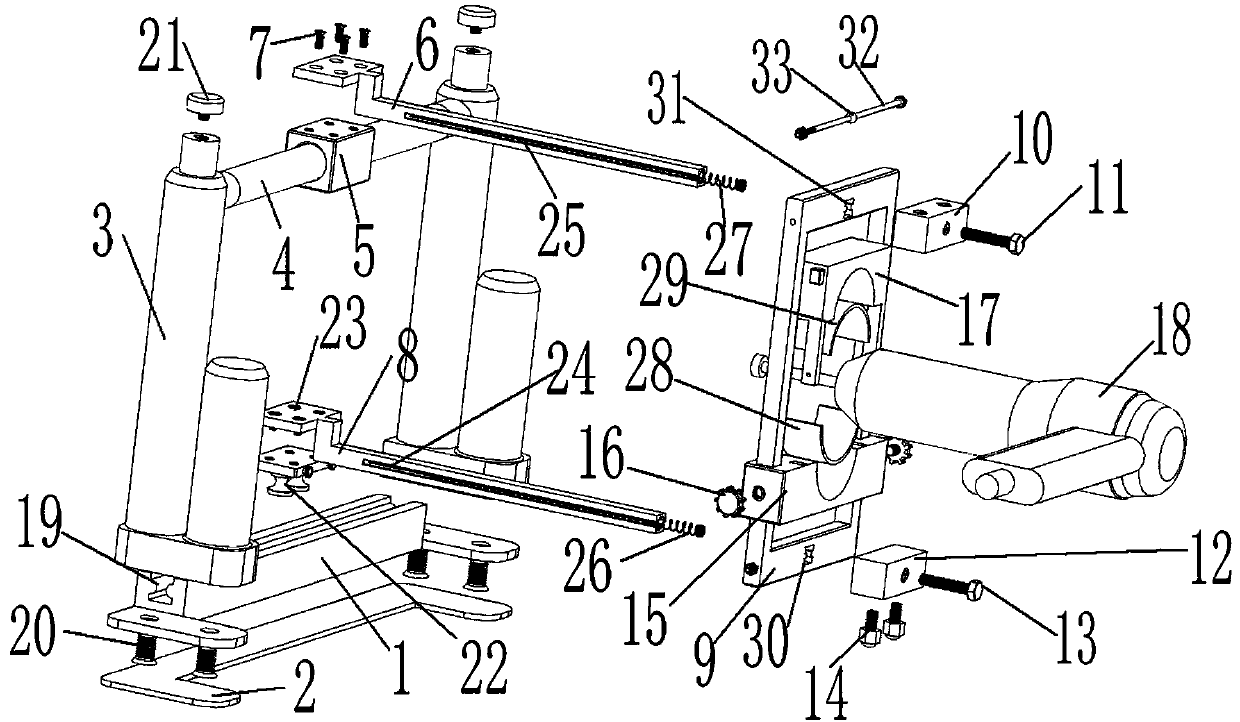

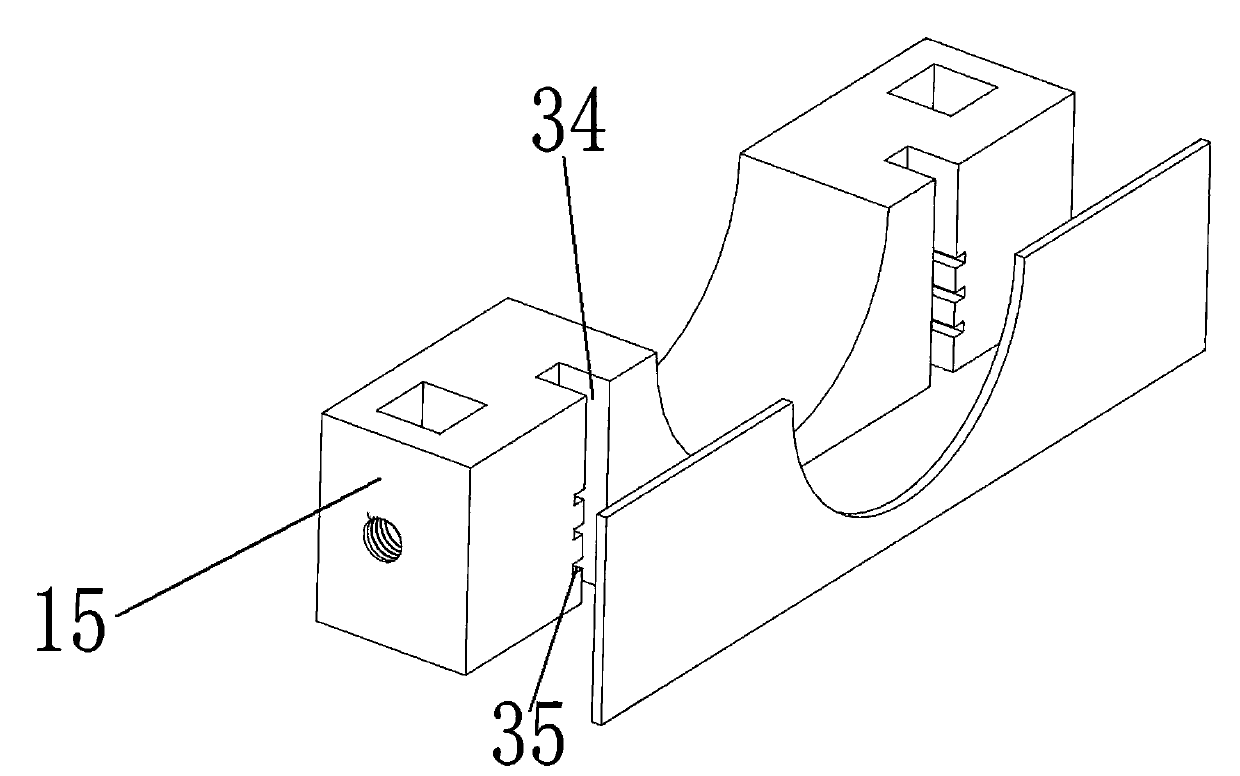

Cutter sharpening device of gun drill

The invention relates to a cutter sharpening technology of a gun drill and particularly relates to a cutter sharpening device of the gun drill. According to the invention, the problem that the traditional cutter sharpening device of the gun drill cannot mill a rear cutter face of a main cutting edge of the gun drill into a spiral face is solved. The cutter sharpening device of the gun drill comprises a base; the base is horizontally provided with a first rotating shaft; an inner and outer angle dial is horizontally arranged at the middle part of the first rotating shaft in a penetrating manner and a second rotating shaft is vertically arranged at the center of the inner and outer angle dial in the penetrating manner; a sleeve support is vertically arranged at the upper end of the second rotating shaft in the penetrating manner; an inner and outer angle locking handle is connected with the lower end of the second rotating shaft; a main shaft graduated disk is arranged at the front end of the outer side wall of the sleeve support; a main shaft sleeve is sleeved on the inner side wall of the sleeve support; a V-shaped positioning block is fixedly arranged at the front end of the inner side wall of the main shaft sleeve; and a cam and a feeding hand wheel are sleeved at the back end of the side wall of the main shaft sleeve. According to the invention, based on a brand-new structure, the problem that the traditional cutter sharpening device of the gun drill cannot mill the rear cutter face of the main cutting edge of the gun drill into the spiral face is effectively solved, sothat the cutter sharpening device of the gun drill is applicable to carrying out cutter sharpening on the gun drill.

Owner:ZHONGBEI UNIV

Gun drill

Owner:ISCAR LTD

Tool and method for processing half-speed machine crankshaft

ActiveCN101462178AGuarantee product qualityIncrease productivityMilling cuttersTurning toolsEngineeringMachine tool

The invention relates to a tool and a method for machining a crankshaft of a medium speed machine. The machining tool is provided with a cutter for machining a load release groove, a R40 special molding cutter for machining the surface of a balance block and a plug of a crossed hole of a drill gun. The machining method comprises: firstly, according to the prior method, a crankshaft billet of the medium speed machine is subjected to primary TR forging and molding; a main journal, a turning journal, the load release groove, the output end of the load release groove and a free end flange are subjected to machining; the milling balance block ,the shape of a turning arm, and end flange drilling are evenly distributed with holes and screw holes are subjected to machining; the main journal and the turning journal are ground and are subjected to final finishing; subsequently, the load release groove is processed through the cutter for machining the load release groove from outside to inside for a few times by delamination. The R40 special molding cutter is used to machine the surface of the balance block in a vertical cutting mode. The gun drill drills and cuts a guide hole and an oil hole to a crossed hole, and a plug is adopted in the crossed hole. A phi 700 flange hole is drilled through an aiguille and is machined through a Mohs lengthening drill bush. The tool and the method for machining can ensure the quality of a product and greatly improve production efficiency.

Owner:武汉重工铸锻有限责任公司

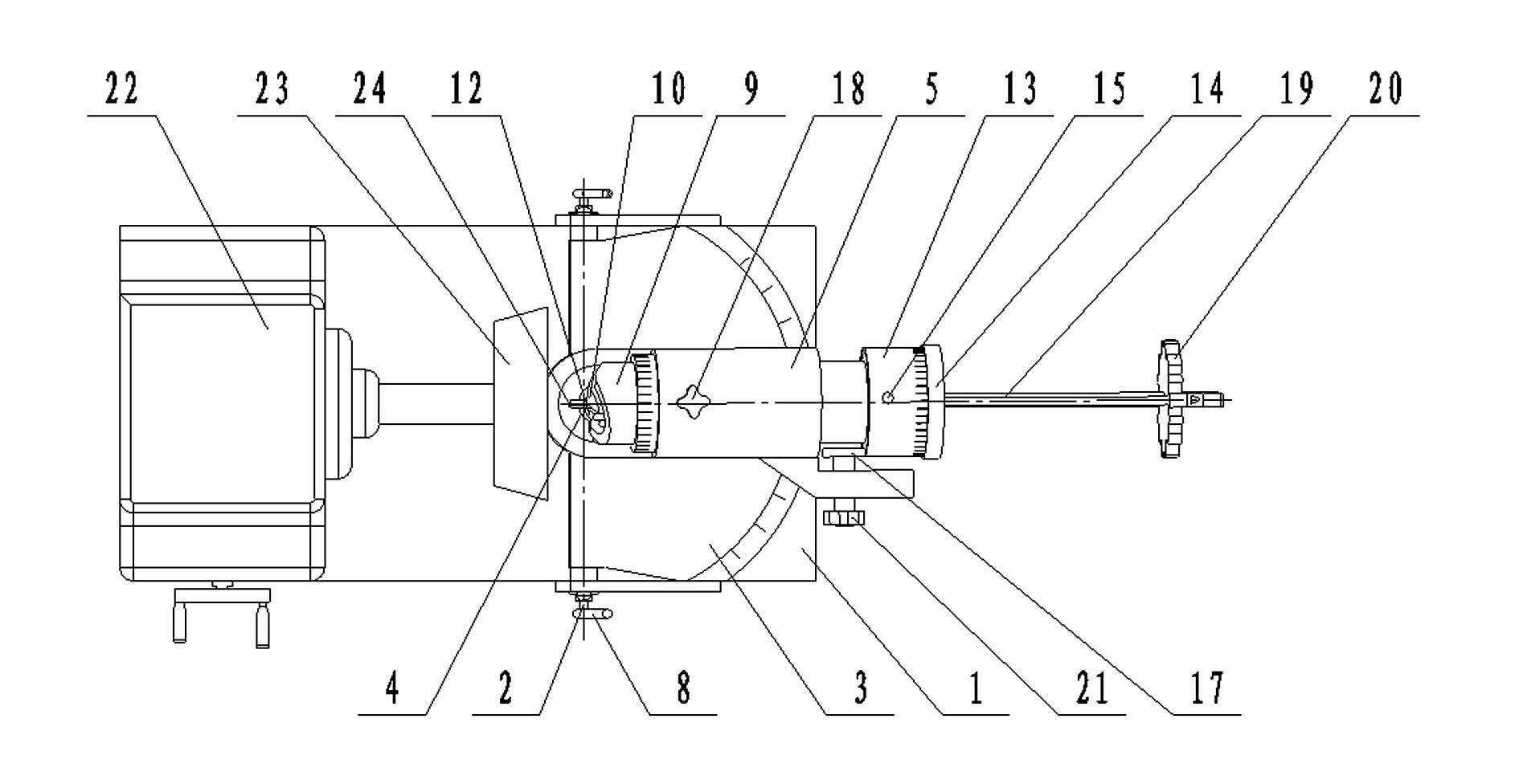

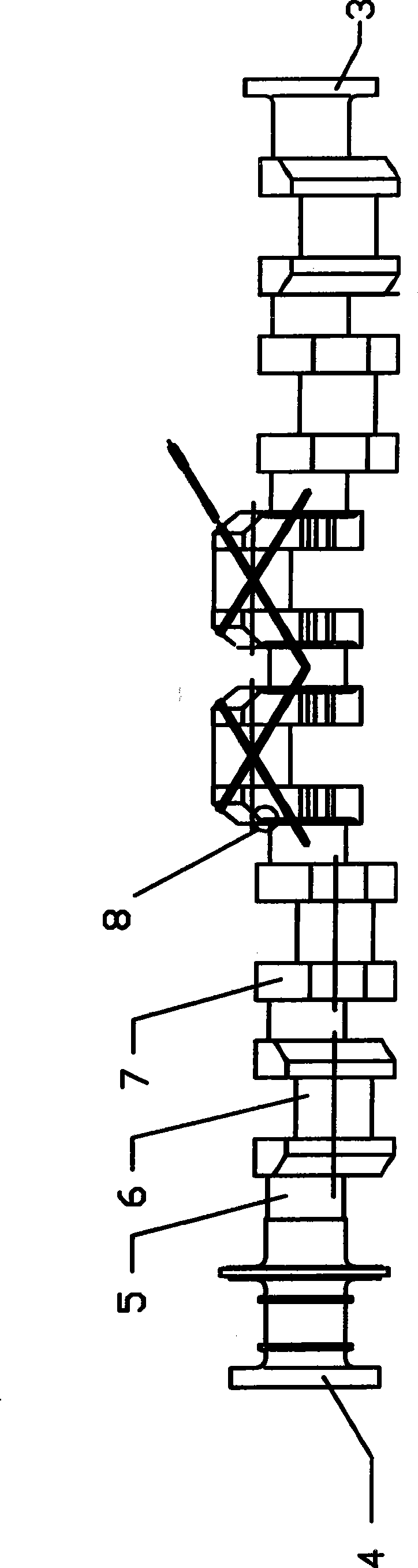

Numerical control high-effective deep hole gun drill

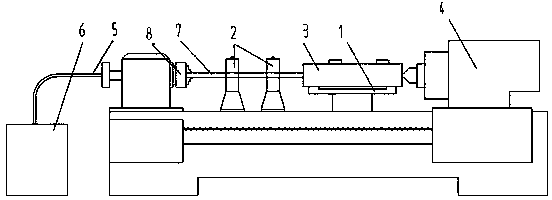

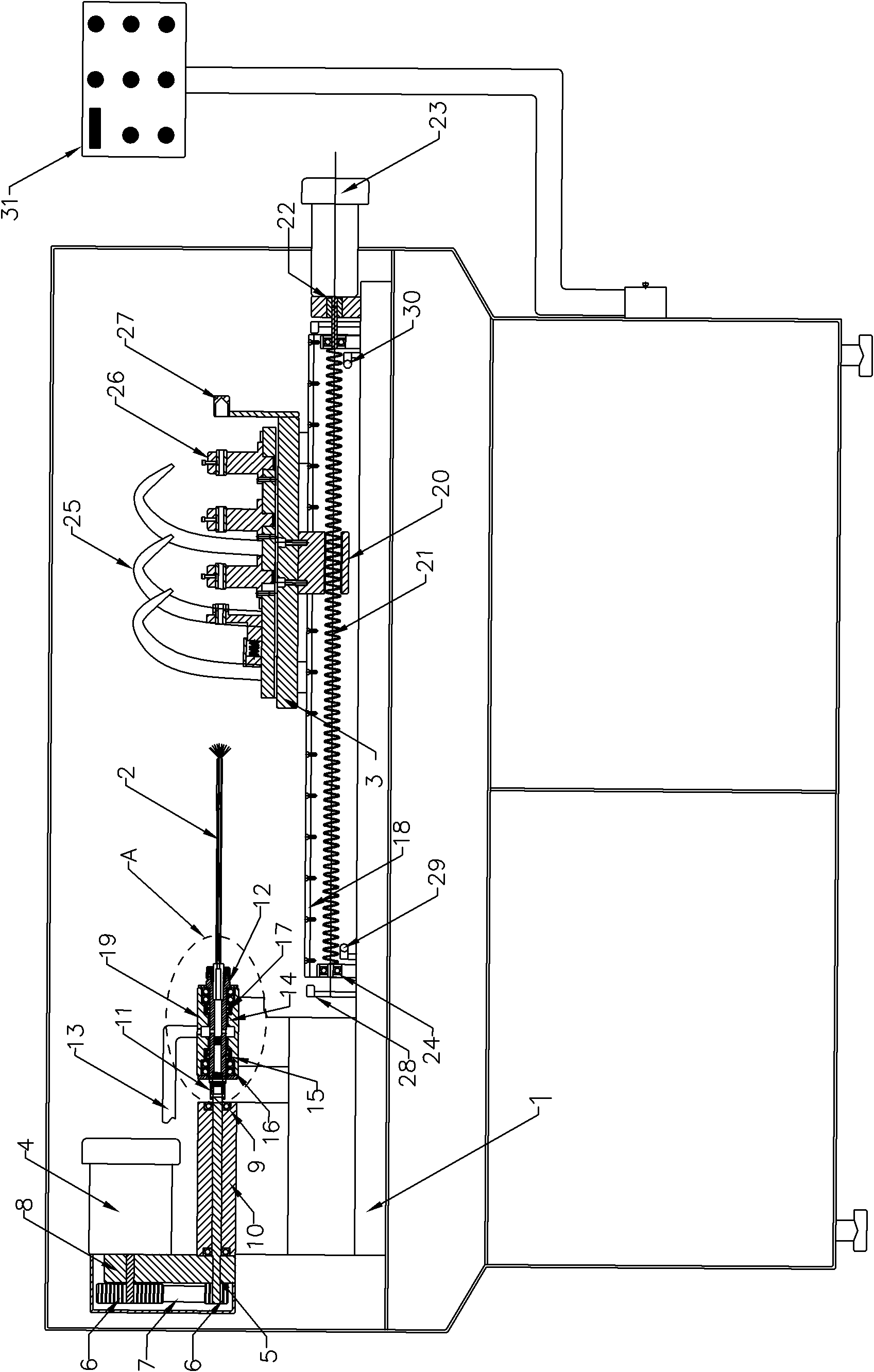

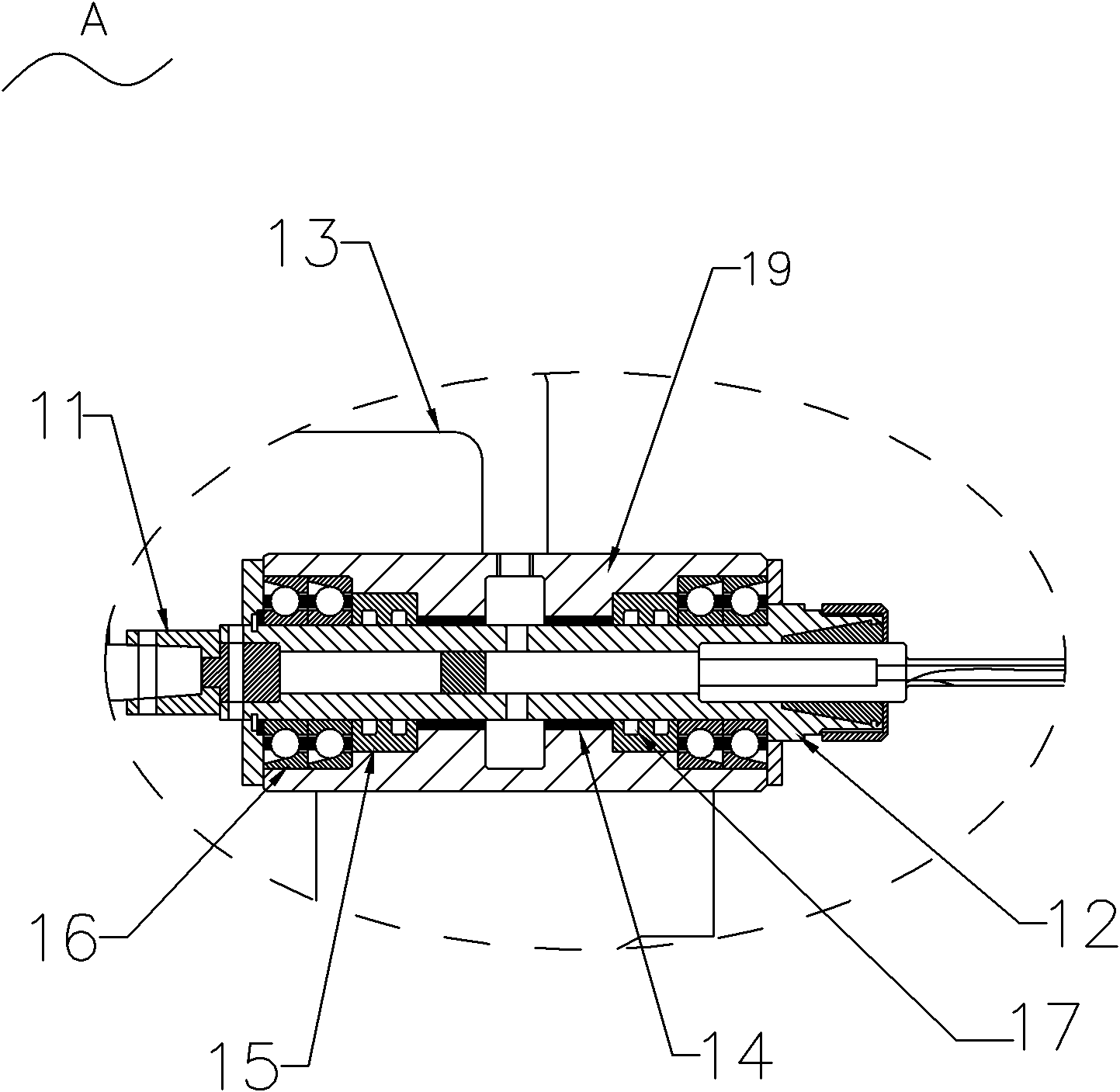

InactiveCN101733441AMeet processing needsReduce processing costsLarge fixed membersChucksNumerical controlElectricity

The invention relates to a numerical control high-effective deep hole gun drill, comprising a lathe body, a power distribution / control system, a main spindle box, a feeder, a cutter arranged in the feeder, a chip collection unit, a front-end drive stepping motor and a rear-end drive stepping motor, wherein the main spindle box, the chip collection unit and the feeder are mounted on the lathe body, the front-end drive stepping motor and the rear-end drive stepping motor are controlled by the power distribution / control system, the feeder is driven by the rear-end drive stepping motor, a sealing device is mounted outside the chip collection unit, the chip collection unit is driven by the front-end drive stepping motor through a rack, the front-end drive stepping motor and the rack are mounted on the front end of the lathe body, a three-jaw chuck used for clamping workpieces is arranged on the main spindle box, a magnetic grid filter unit is arranged below the lathe body, the inlet of the magnetic grid filter unit is connected with the outlet of the chip collection unit, the feeder is provided with an overload protective device, and the overload protective device is electrically connected with the power distribution / control system. The invention meets the deep hole processing demand in the machinofacture and other manufacturing industries.

Owner:HUADONG INSTR & METER FACTORY YUEQING CITY

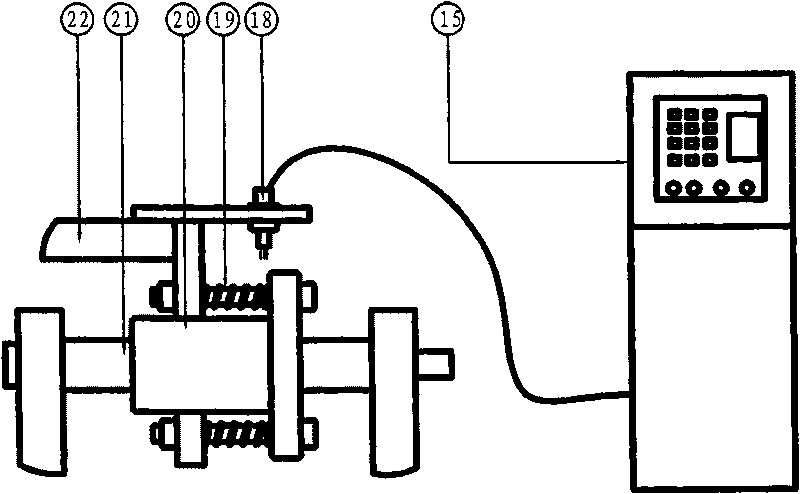

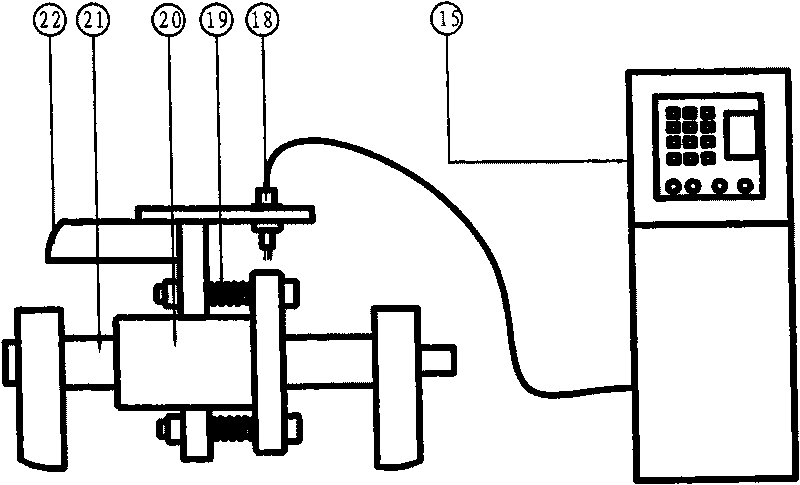

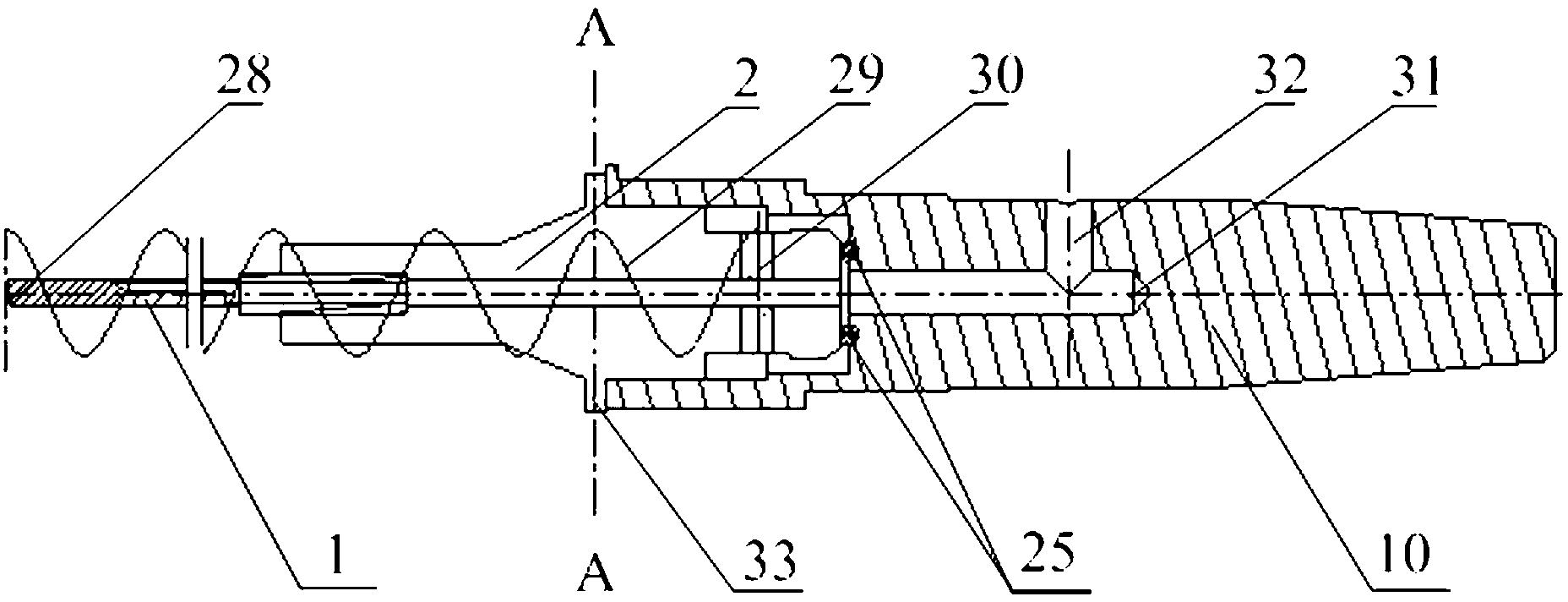

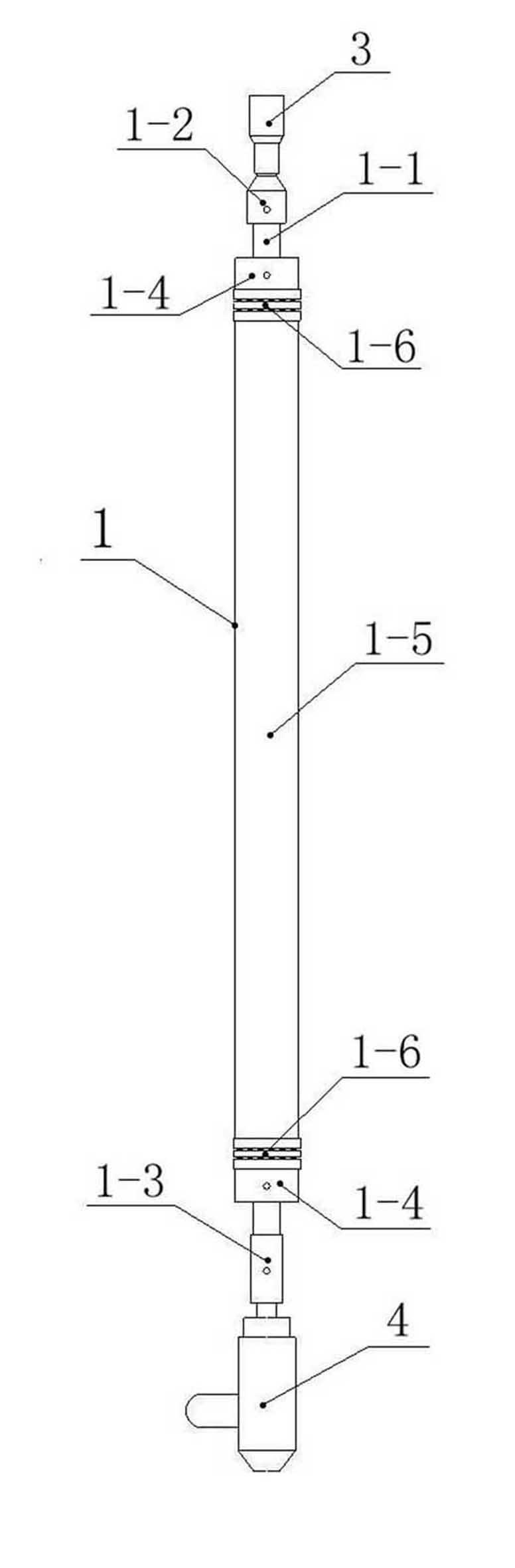

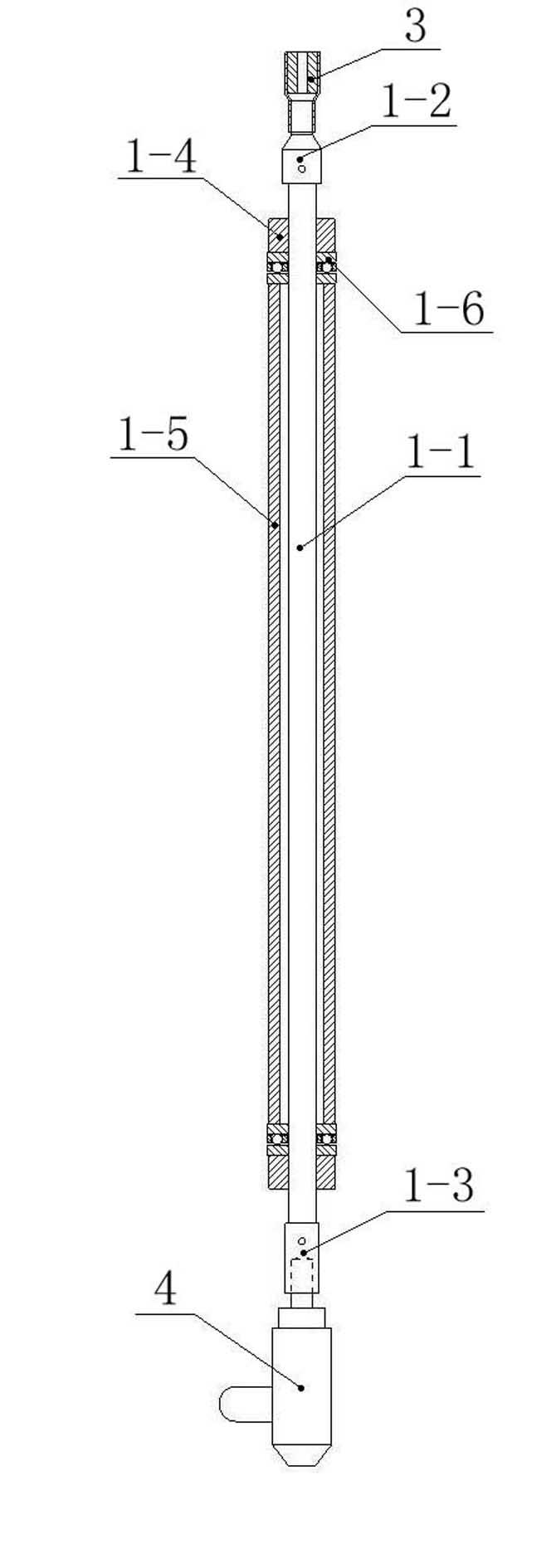

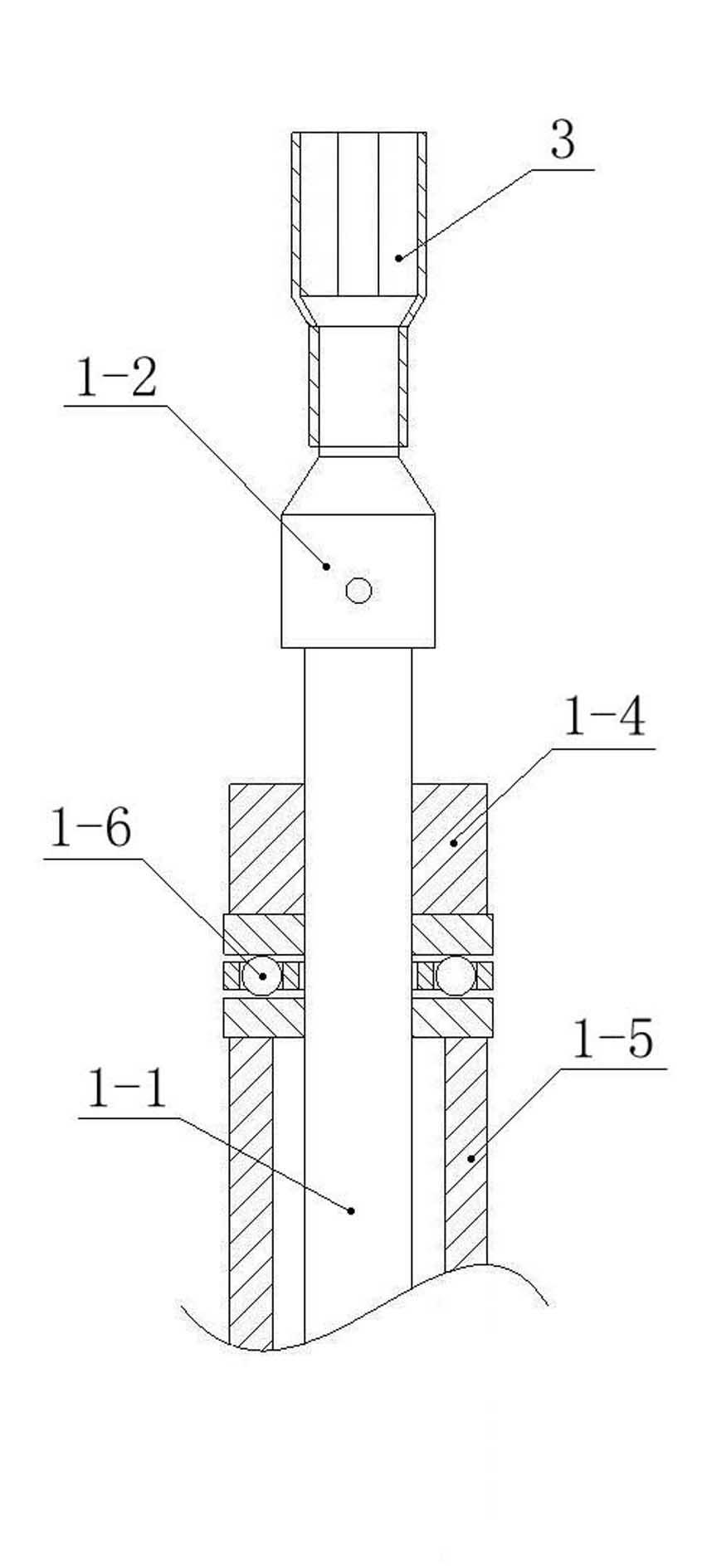

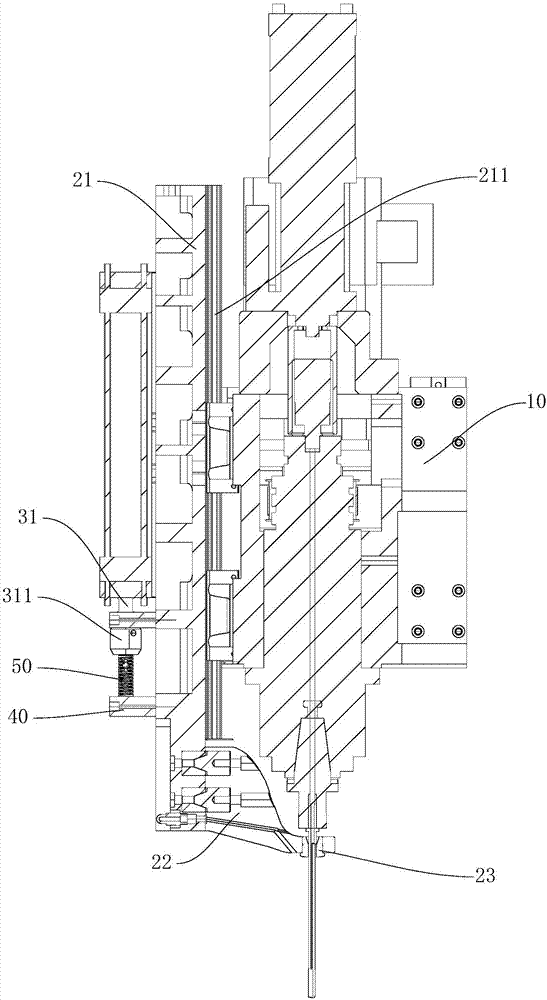

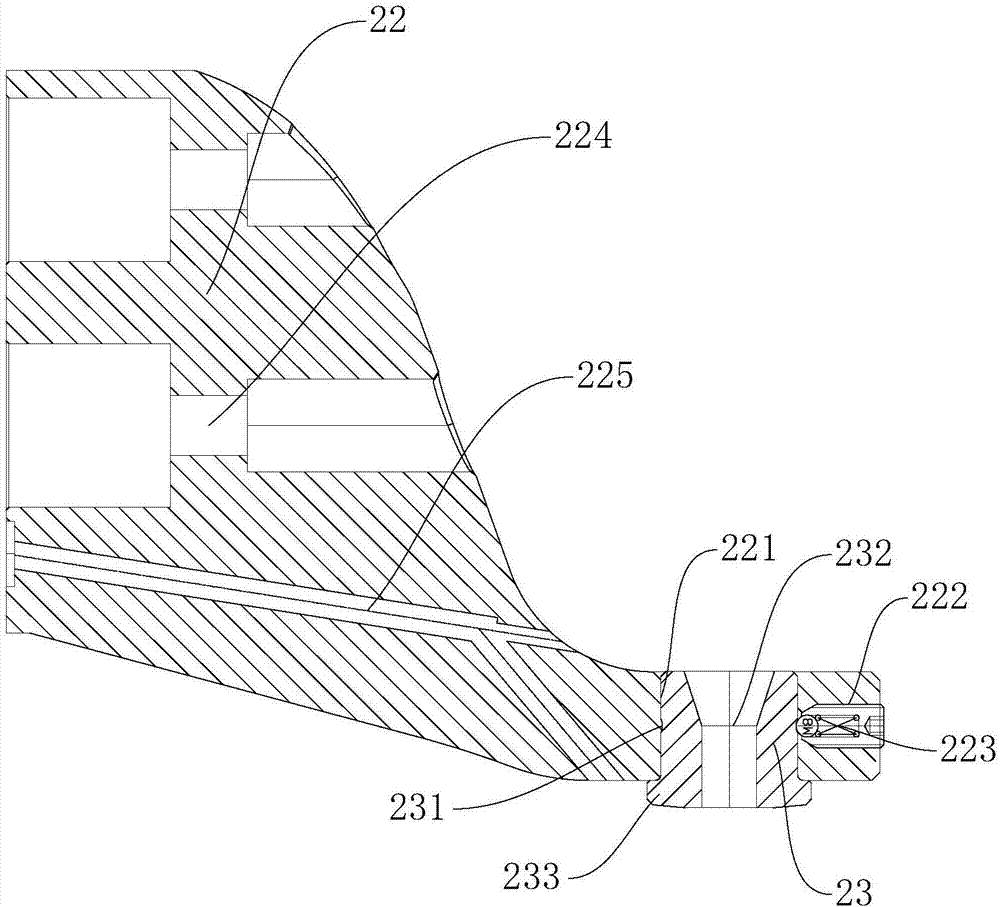

Ultrasonic vibration assisted deep hole machining device

The invention relates to a deep hole machining device, in particular to an ultrasonic vibration assisted deep hole machining device. The ultrasonic vibration assisted deep hole machining device solves the technical problems that a tool is abraded severely, the surface quality is poor, and an oil supply device supplies oil inconveniently during the existing deep hole machining. The ultrasonic vibration assisted deep hole machining device comprises a drilling rod internally provided with a hollow structure, a connecting handle internally provided with a cavity, and an integrated amplitude transformer internally provided with a transducer, wherein one end of the connecting handle is opened; a cavity penetrating front and back is arranged in the center of the integrated amplitude transformer; the middle rear part of the integrated amplitude transformer is located in the cavity of the connecting handle and fixedly connected with the connecting handle; the front end of the integrated amplitude transformer is fixedly connected with the rear end of the drilling rod; and the cavity of the drilling rod is communicated with the cavity of the integrated amplitude transformer. The device applies ultrasonic vibration machining into deep hole machining of a gun drill, can effectively reduce a cutting force and cutting temperature and prolong the service life of the tool, reduces the surface roughness, and improves the machining precision.

Owner:ZHONGBEI UNIV

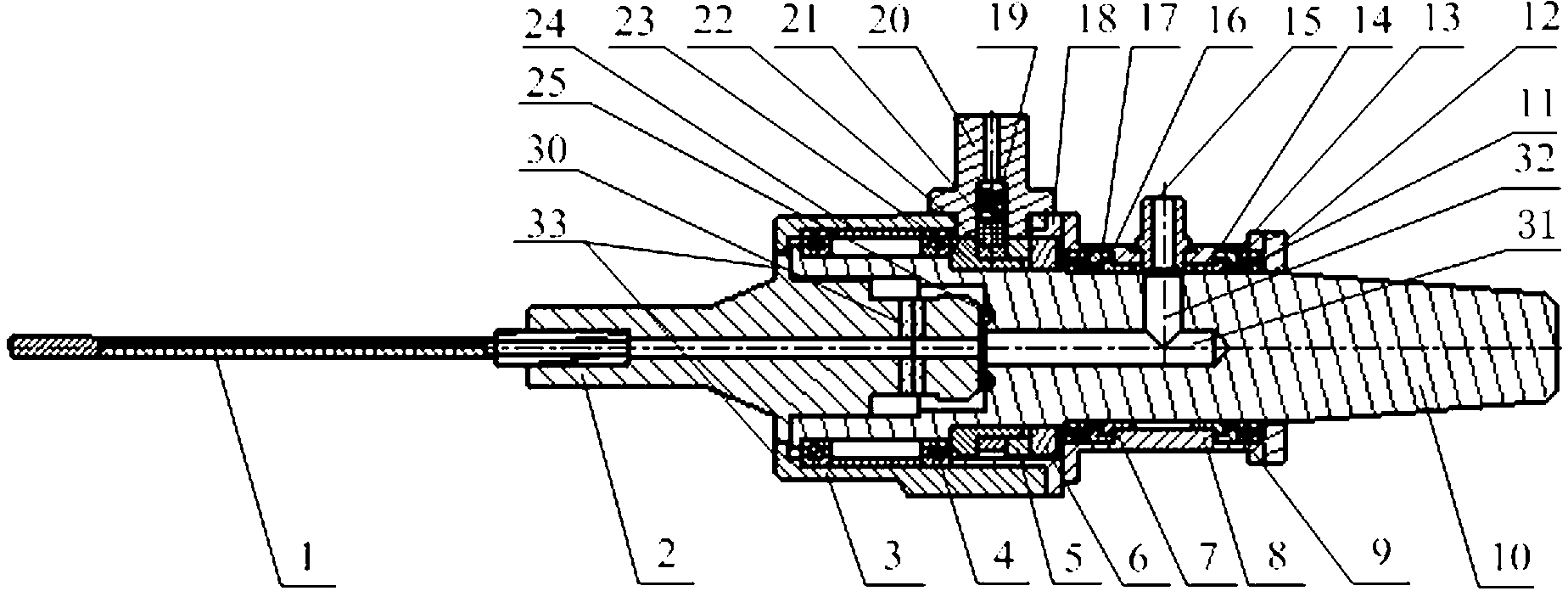

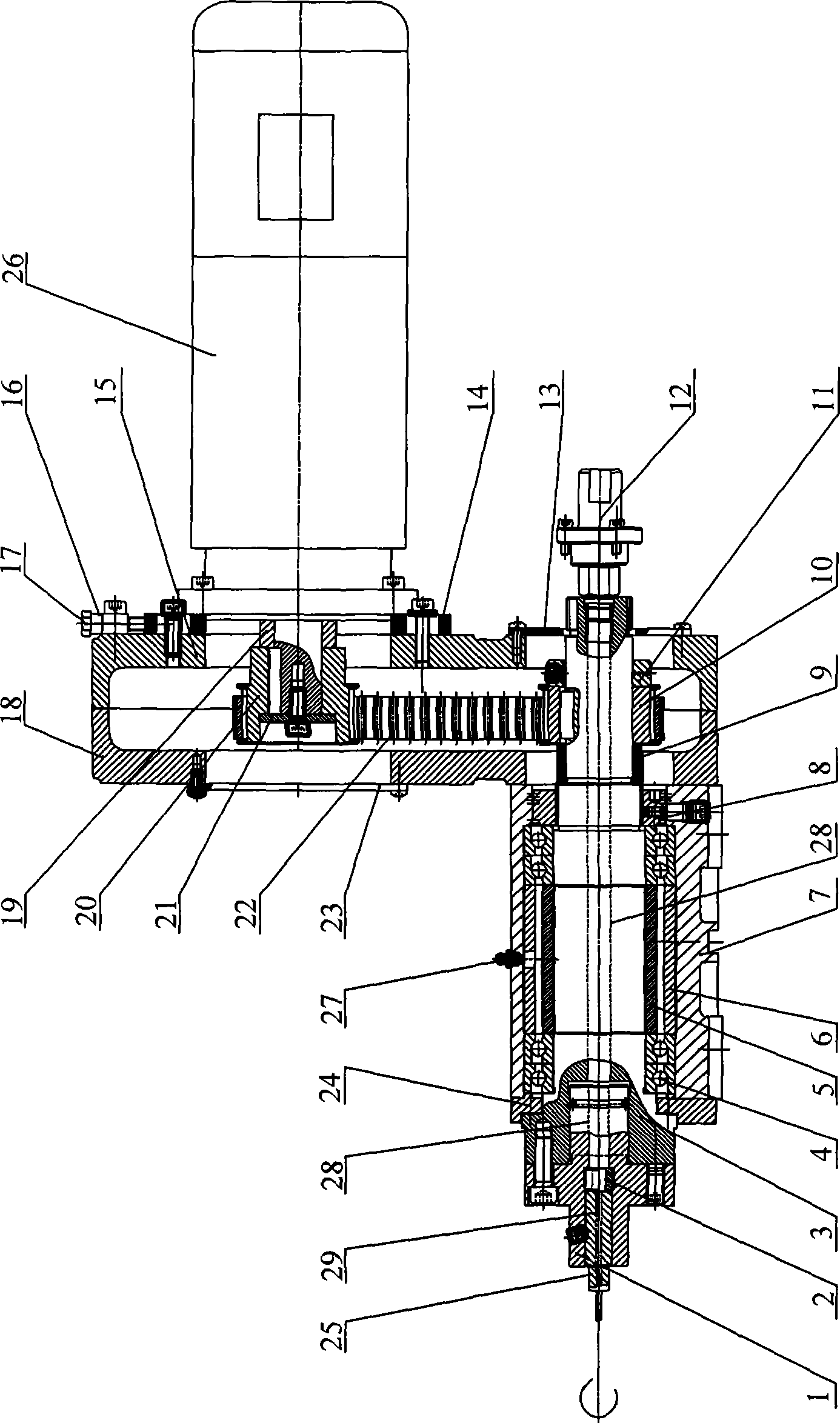

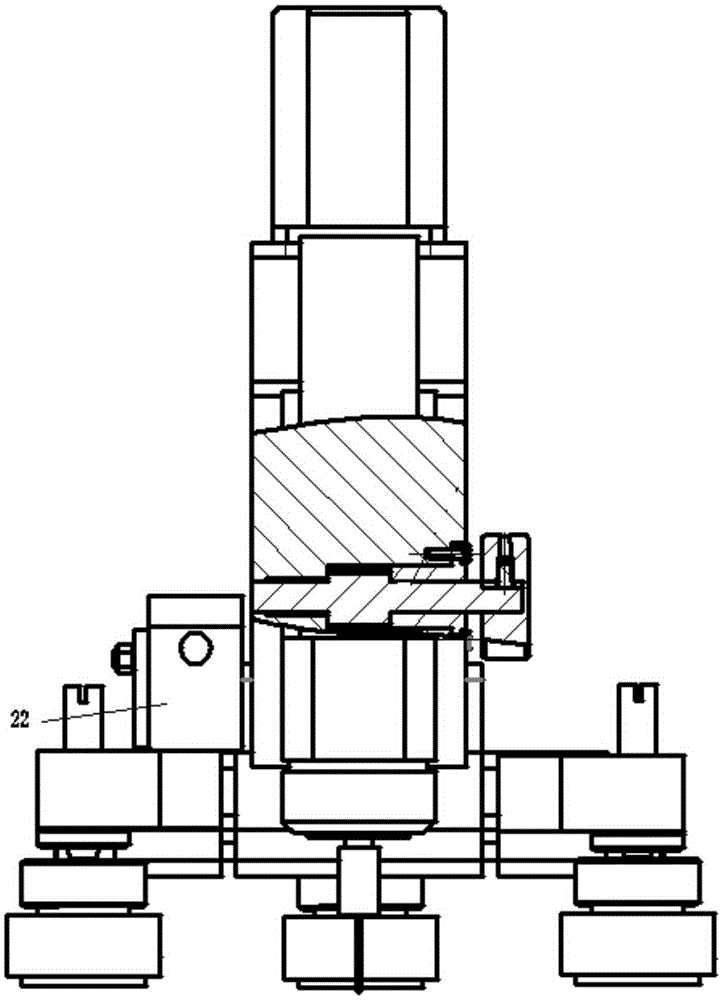

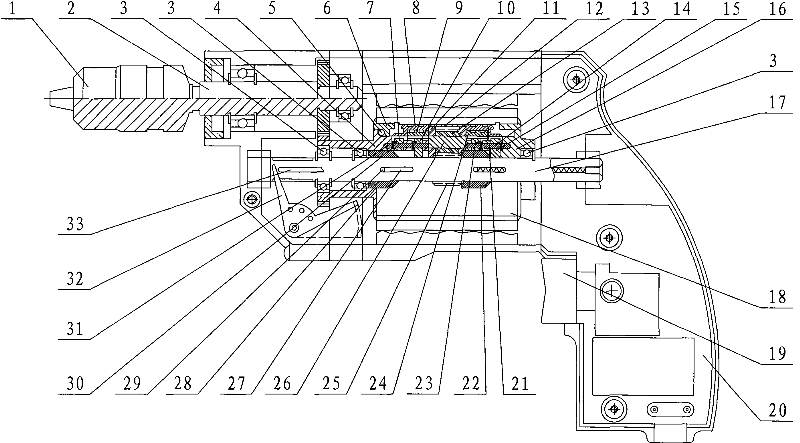

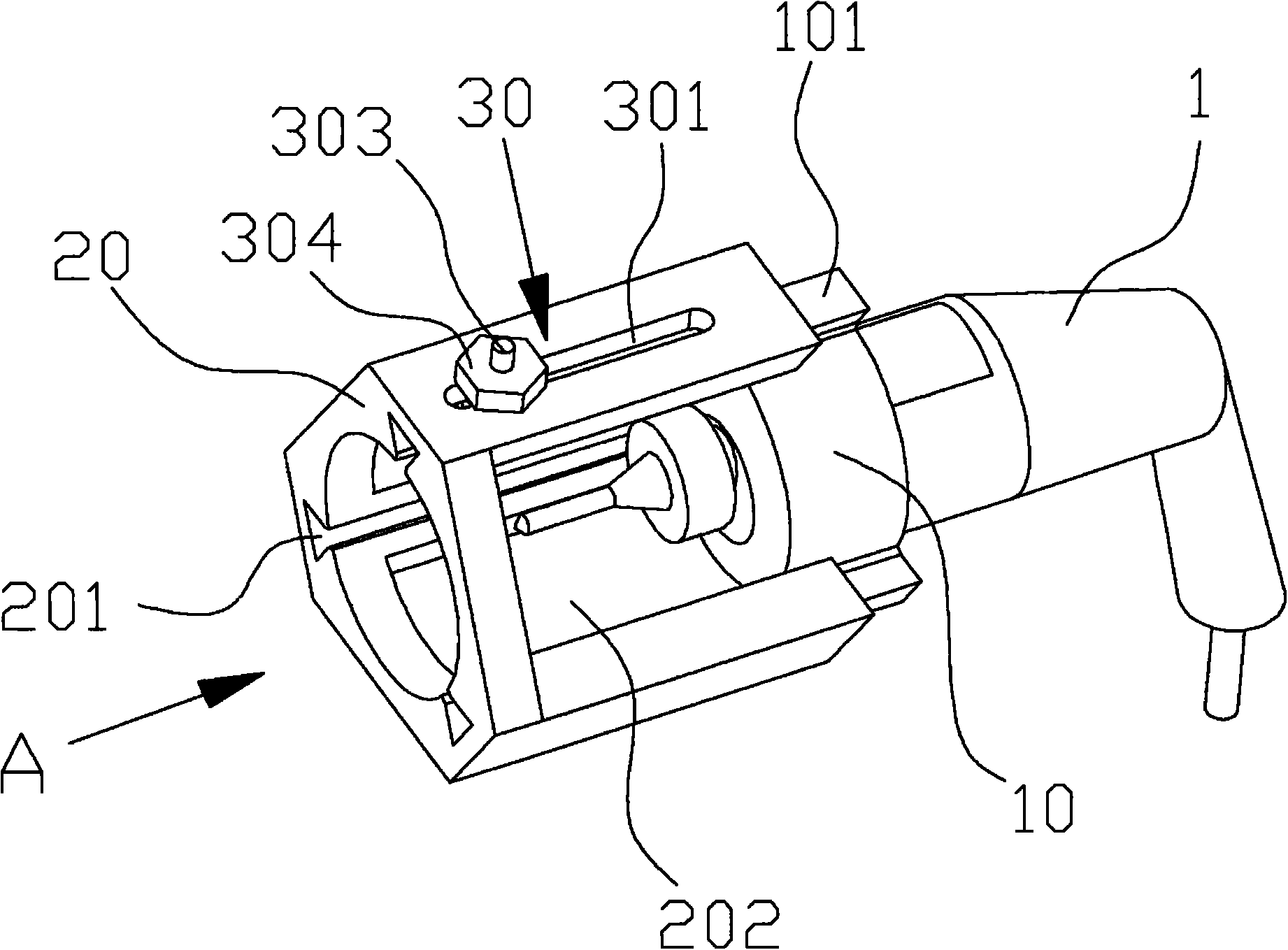

Power head structure of deep-hole drilling machine

ActiveCN101502887AEasy to fixWide speed rangeBoring/drilling componentsMaintainance and safety accessoriesDrive wheelEngineering

The invention relates to a unit head structure of deep hole drilling machine. The front end part of an output shaft of a spindle motor extends into a hollow cavity of a motor mounting box body; an output shaft of the spindle motor is provided with a drive wheel; a spindle seat is fixed on a front box body and the spindle seat is internally connected with a spindle in a rotating way; a synchronous drive belt is fixed on a synchronous pulley and the drive wheel; the spindle is sheathed with a spindle bushing and is fixed with a tool holder clip. The invention is characterized in that shaft holes are arranged inside the spindle and the tool holder clip; a rotary joint is arranged in the rear end part of the shaft hole of the spindle; a gun drill is arranged in the front end part of the shaft hole of the tool holder clip; the gun drill is internally provided with a cooling liquid ejection hole communicated with the shaft holes of the spindle and the tool holder clip. With wide range of rotation speed, the invention can achieve 500 to 8,000r / min stepless speed regulation; with small structure, the motor can be arranged on the left side or right side of the rectangular box body according to the need; cooling liquid of 12MPa can pass through the spindle; the fixation of the gun drill is convenient and the axial fine regulation can be made.

Owner:鹰普(中国)有限公司 +1

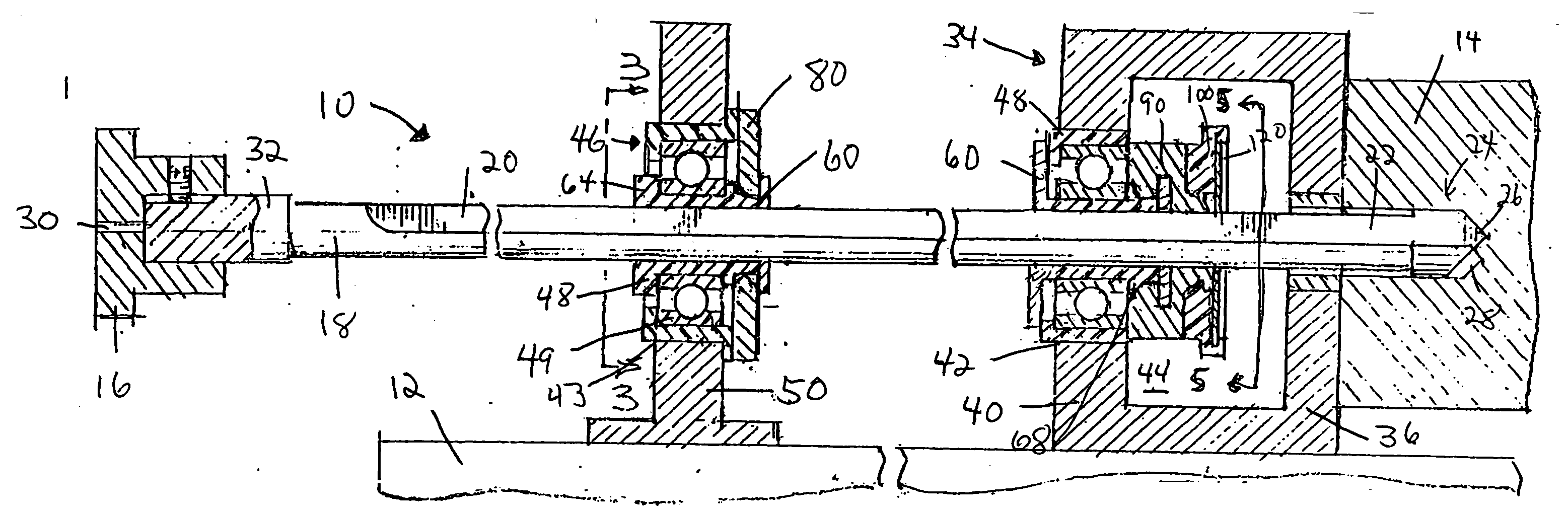

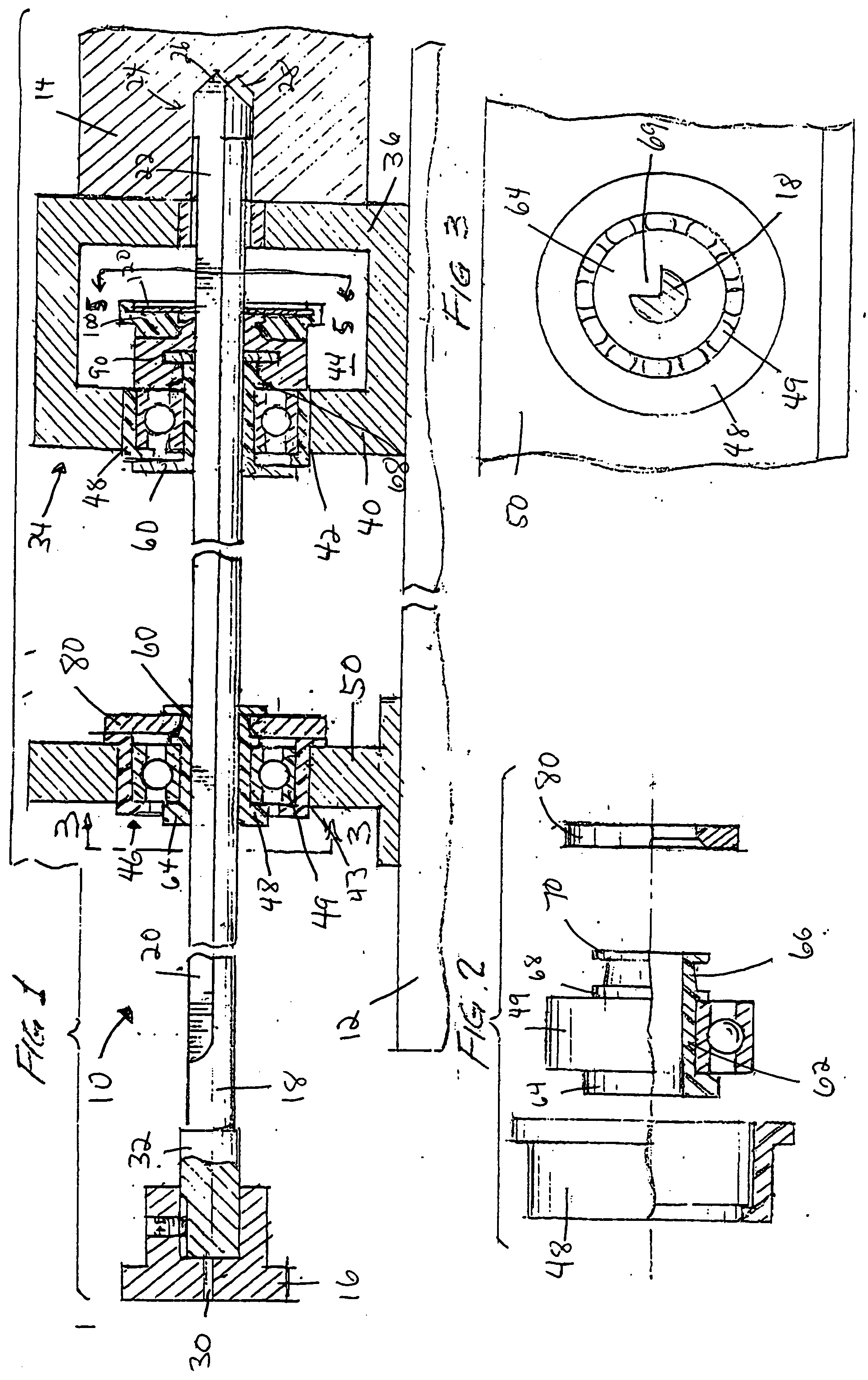

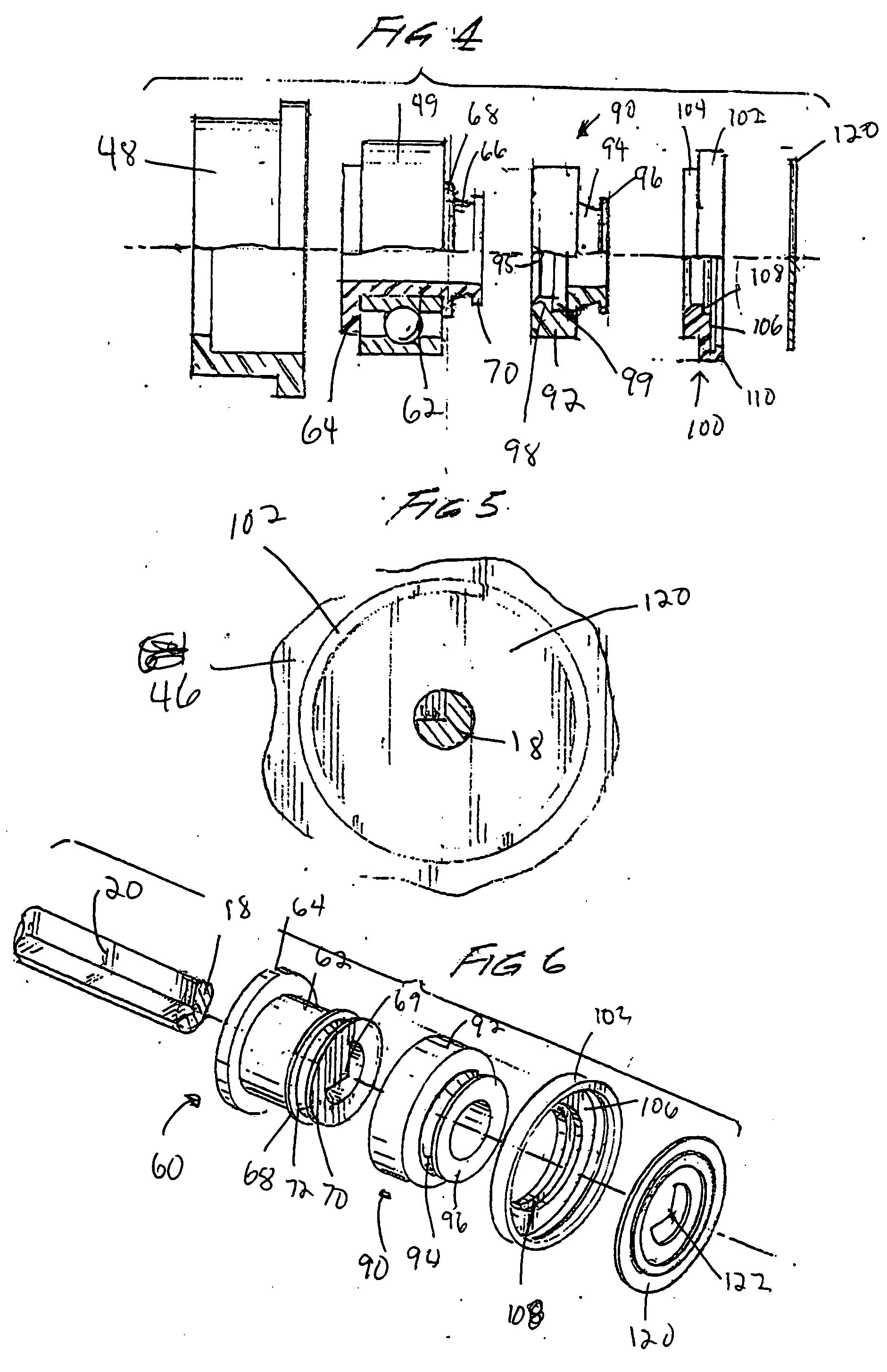

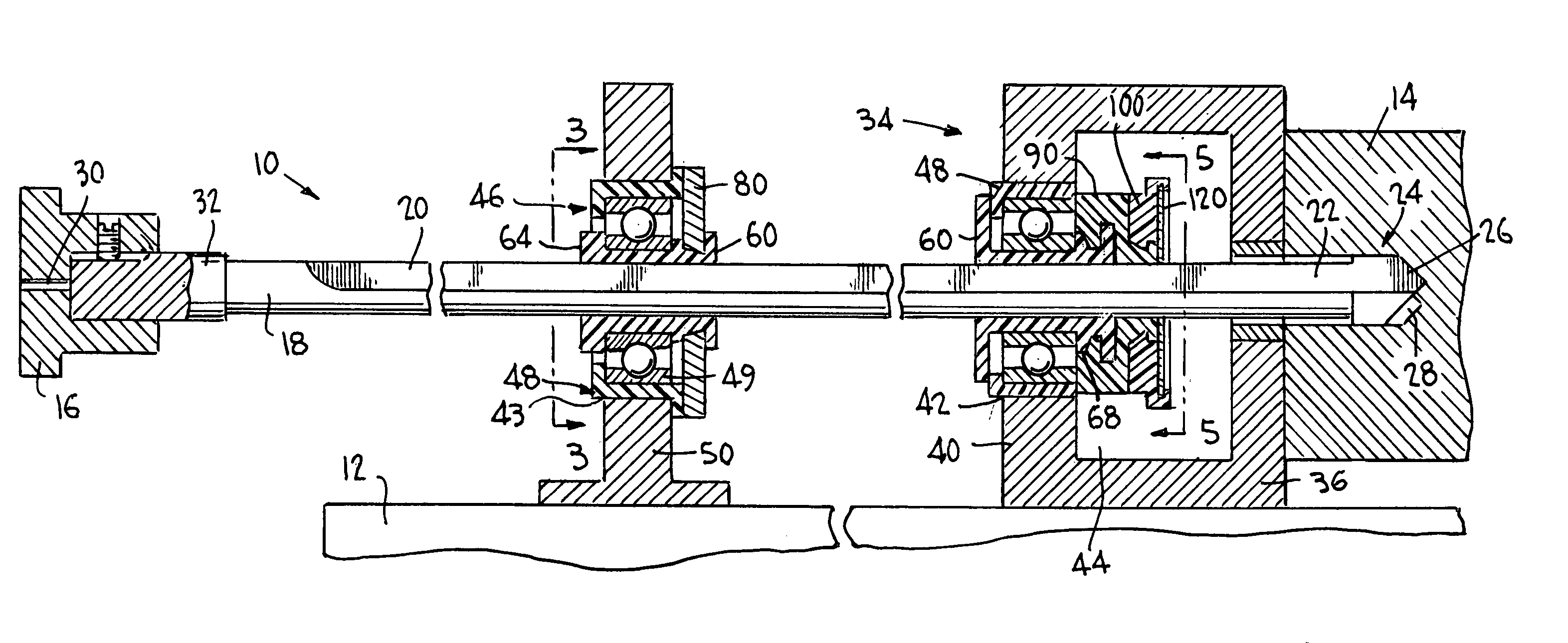

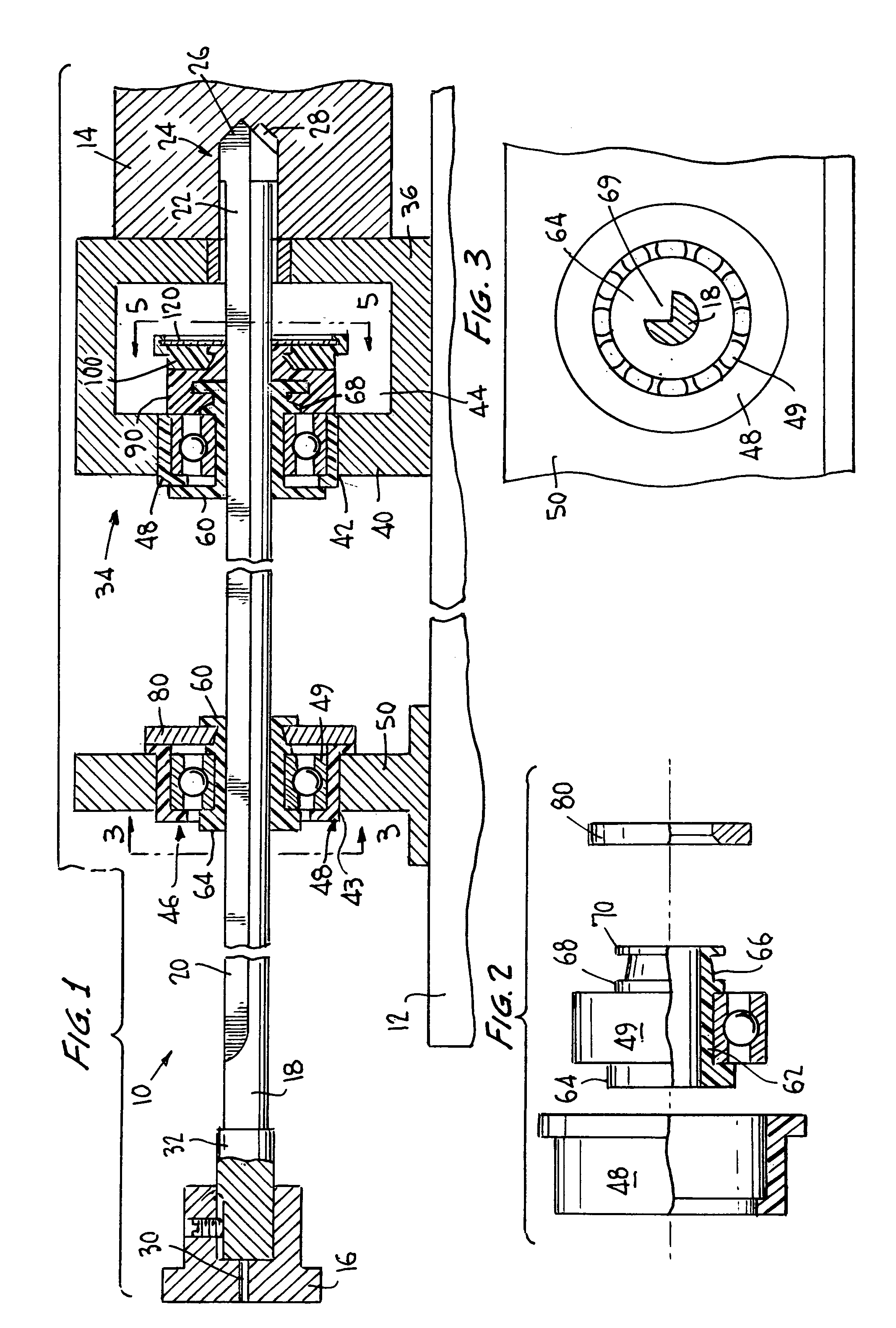

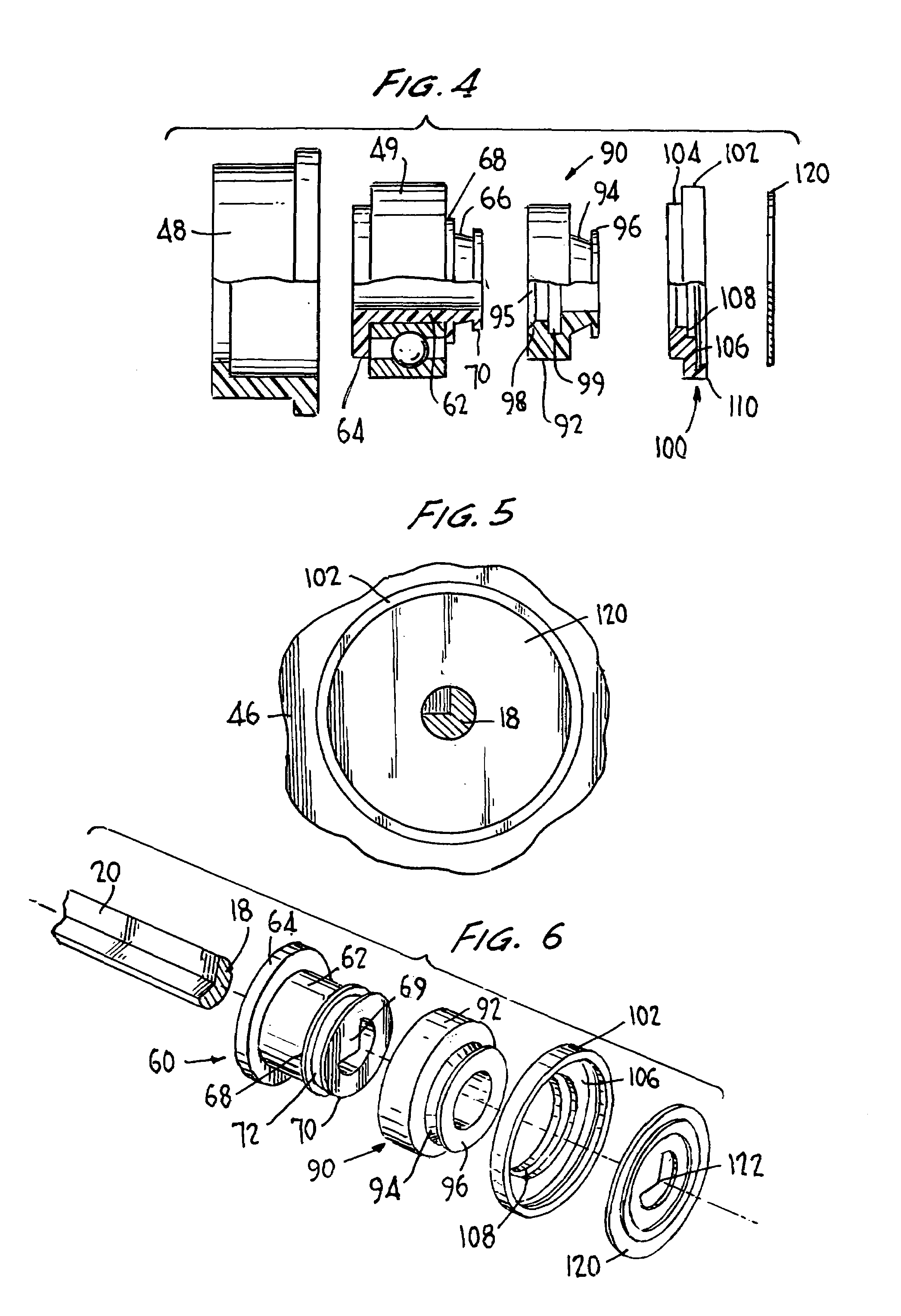

Gun drill guide and gun drill guide assembly

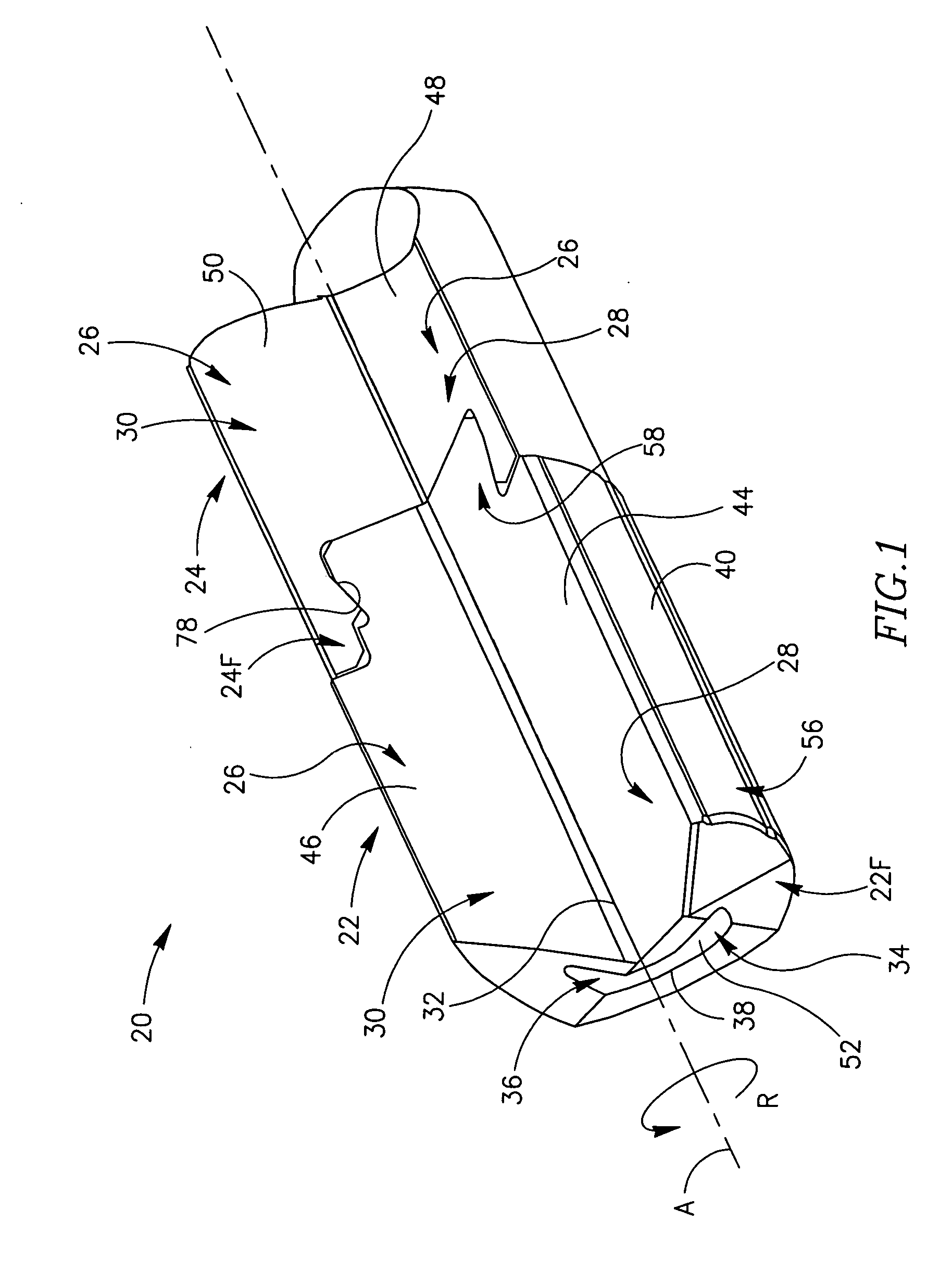

ActiveUS20050169719A1Easy to operateIncreased wear and durabilityThread cutting feeding devicesTransportation and packagingEngineeringDrill guide

A gun drill guide is disclosed comprising a cylinder body member of a resilient polymer material having a central opening extending therethrough, a radially extending flange means at one end thereof to engage the end face of a bearing assembly and an annular groove near the opposite end thereof defined by second and third radially extending flanges for engaging the opposite end face of the bearing assembly. A locking member, a chip deflector assembly, a stabilizer assembly or other guide attachment are disclosed which may be attached to the drill guide.

Owner:F J FEDDERSEN

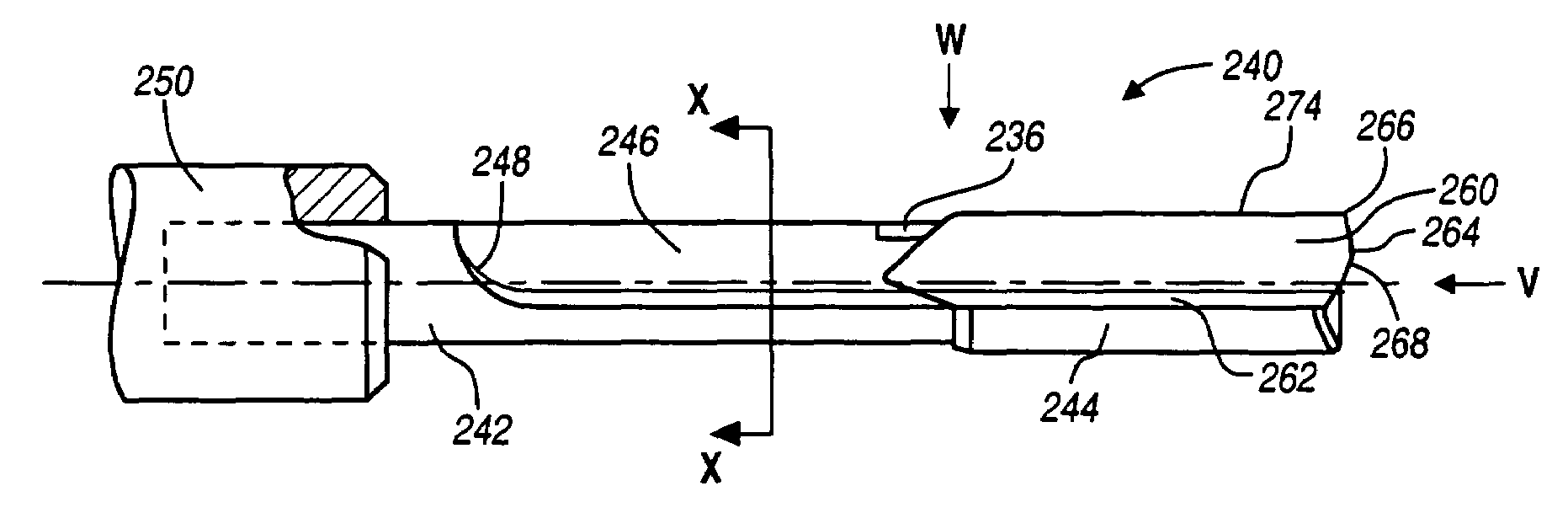

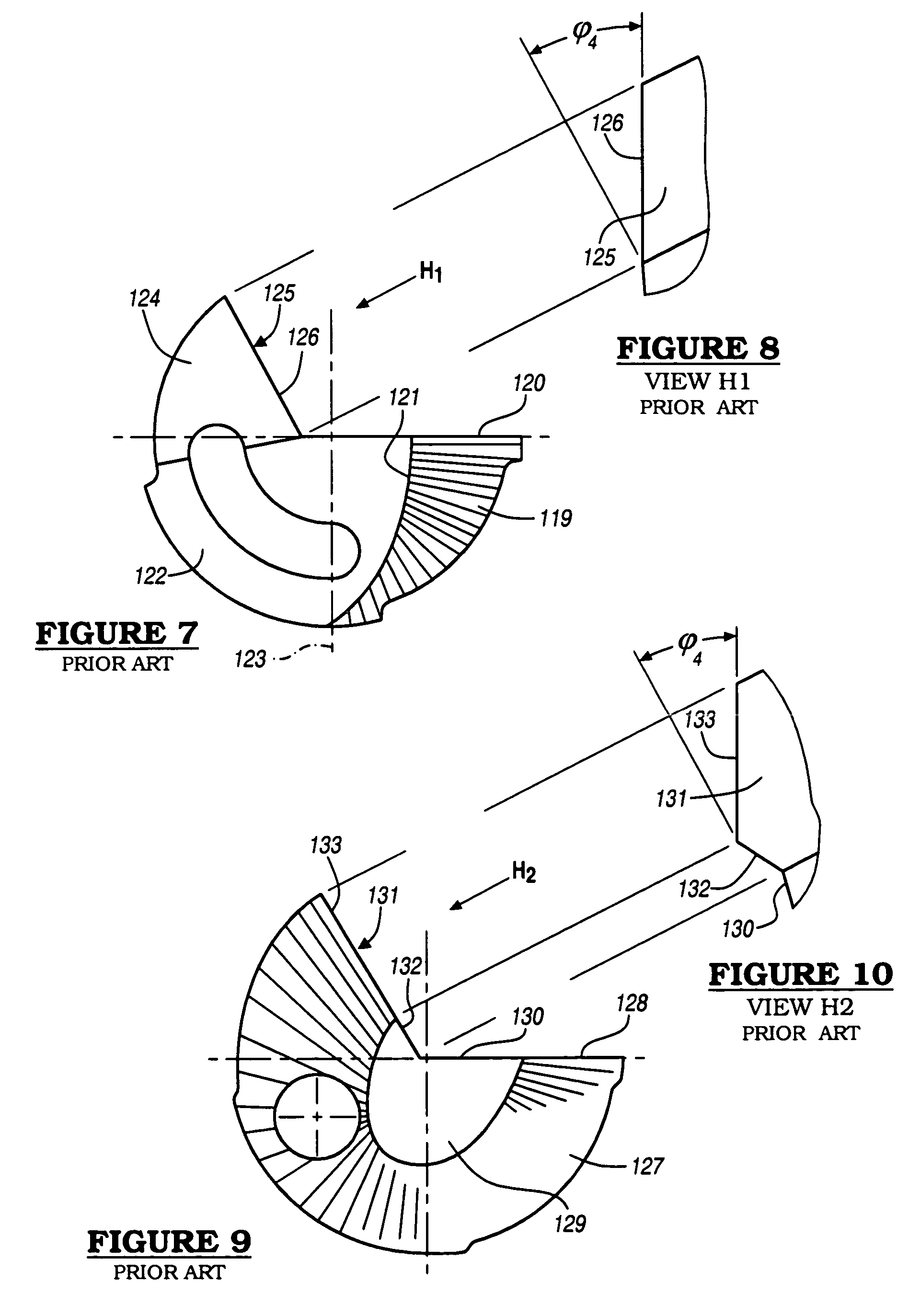

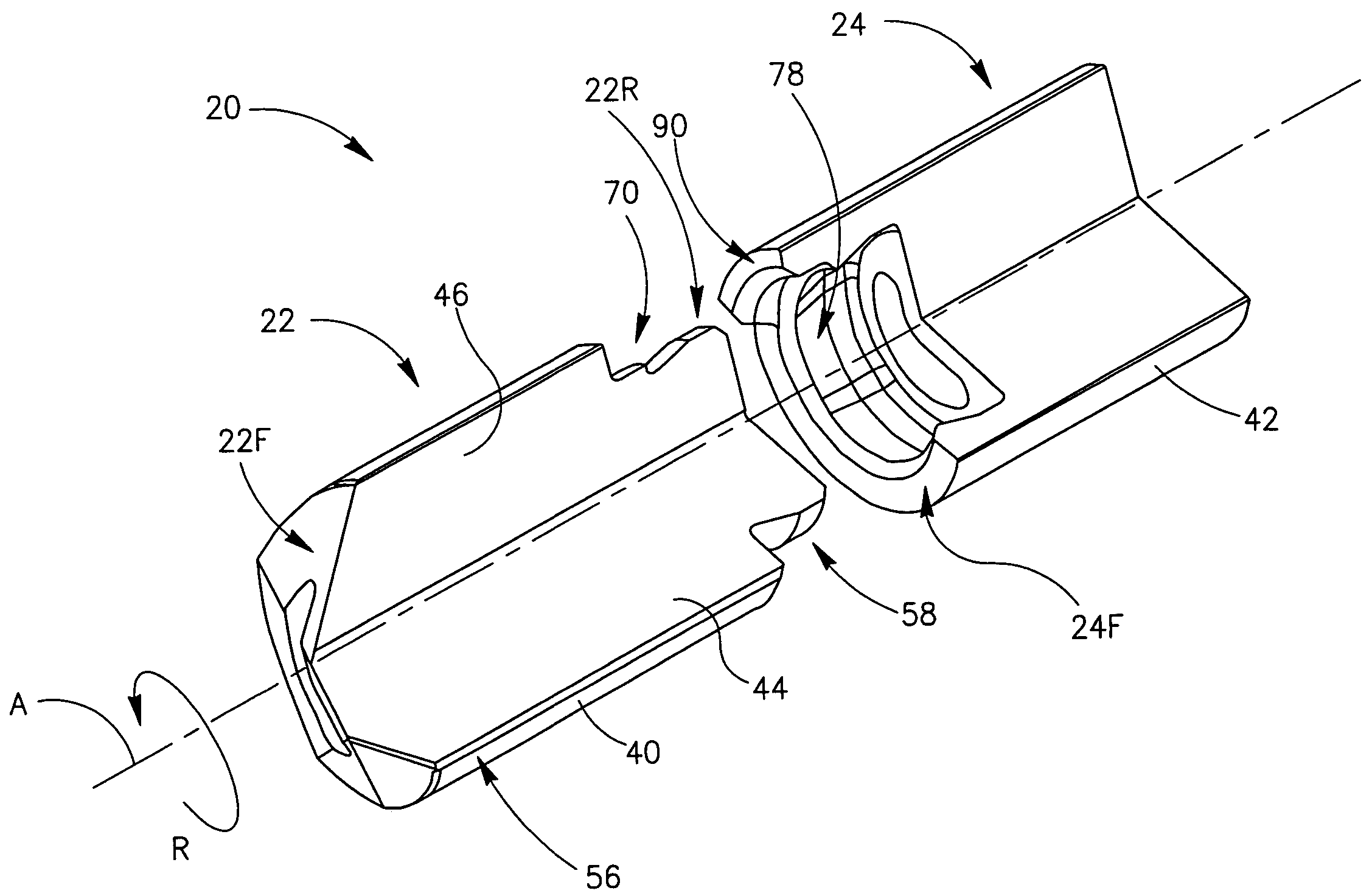

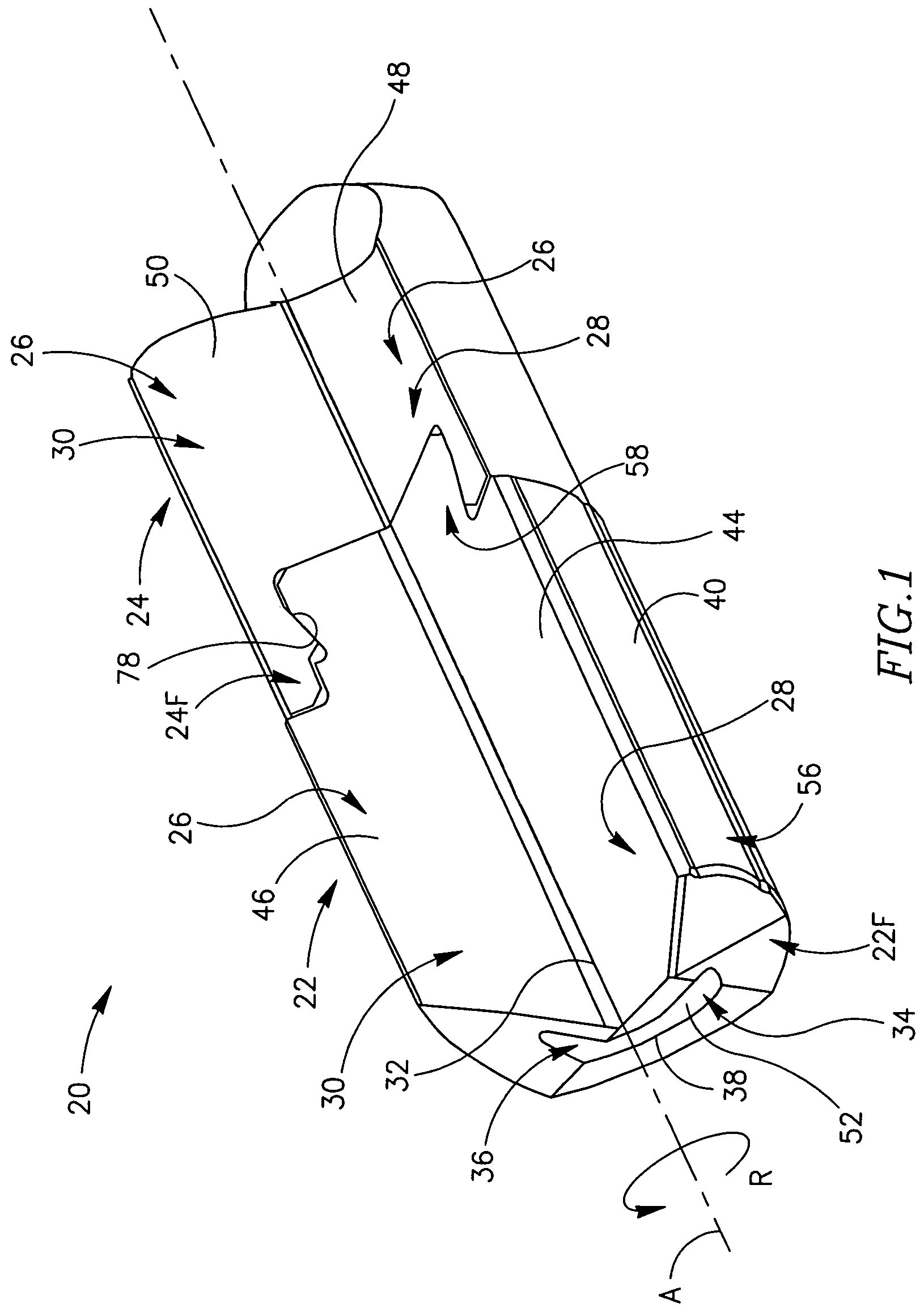

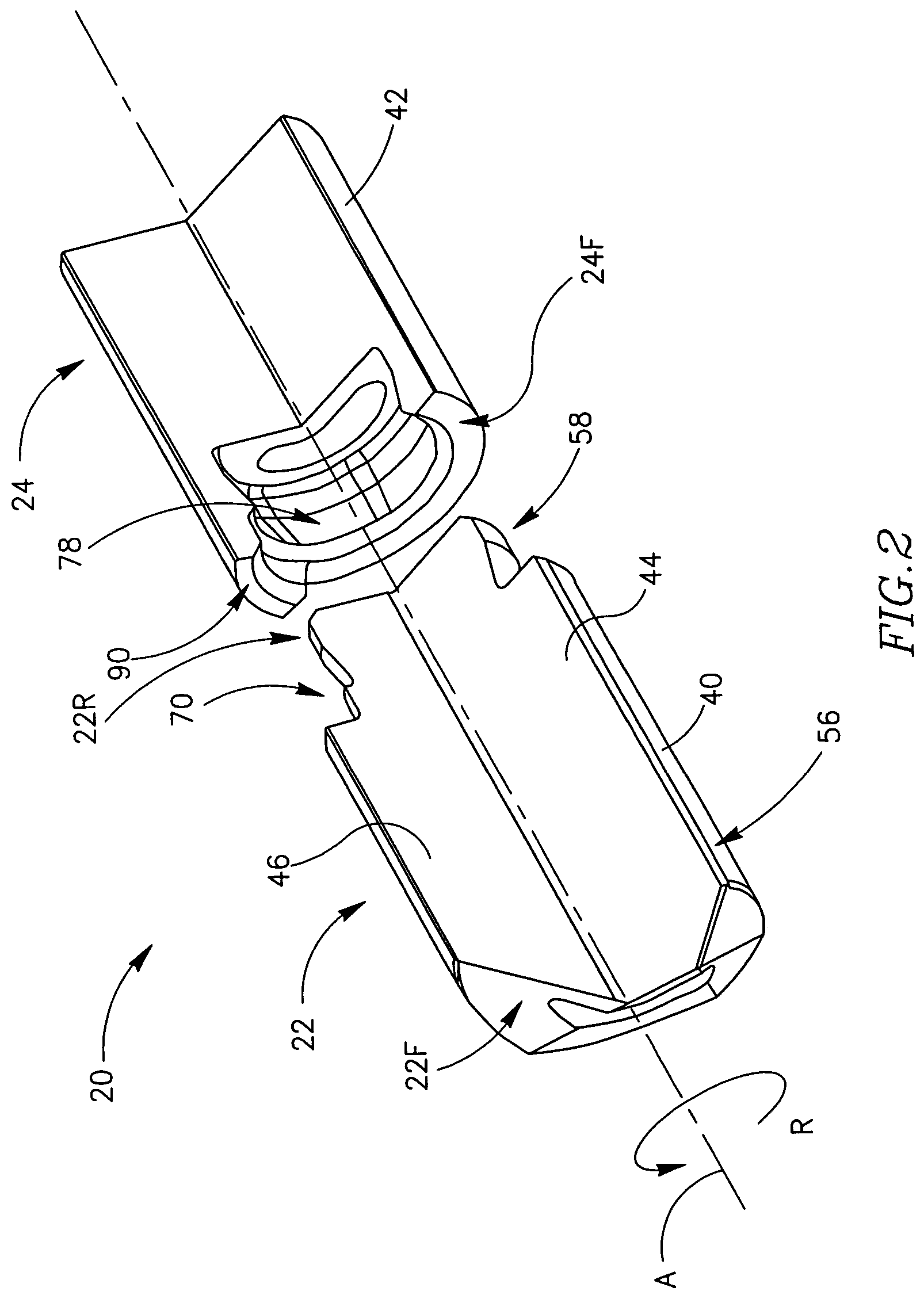

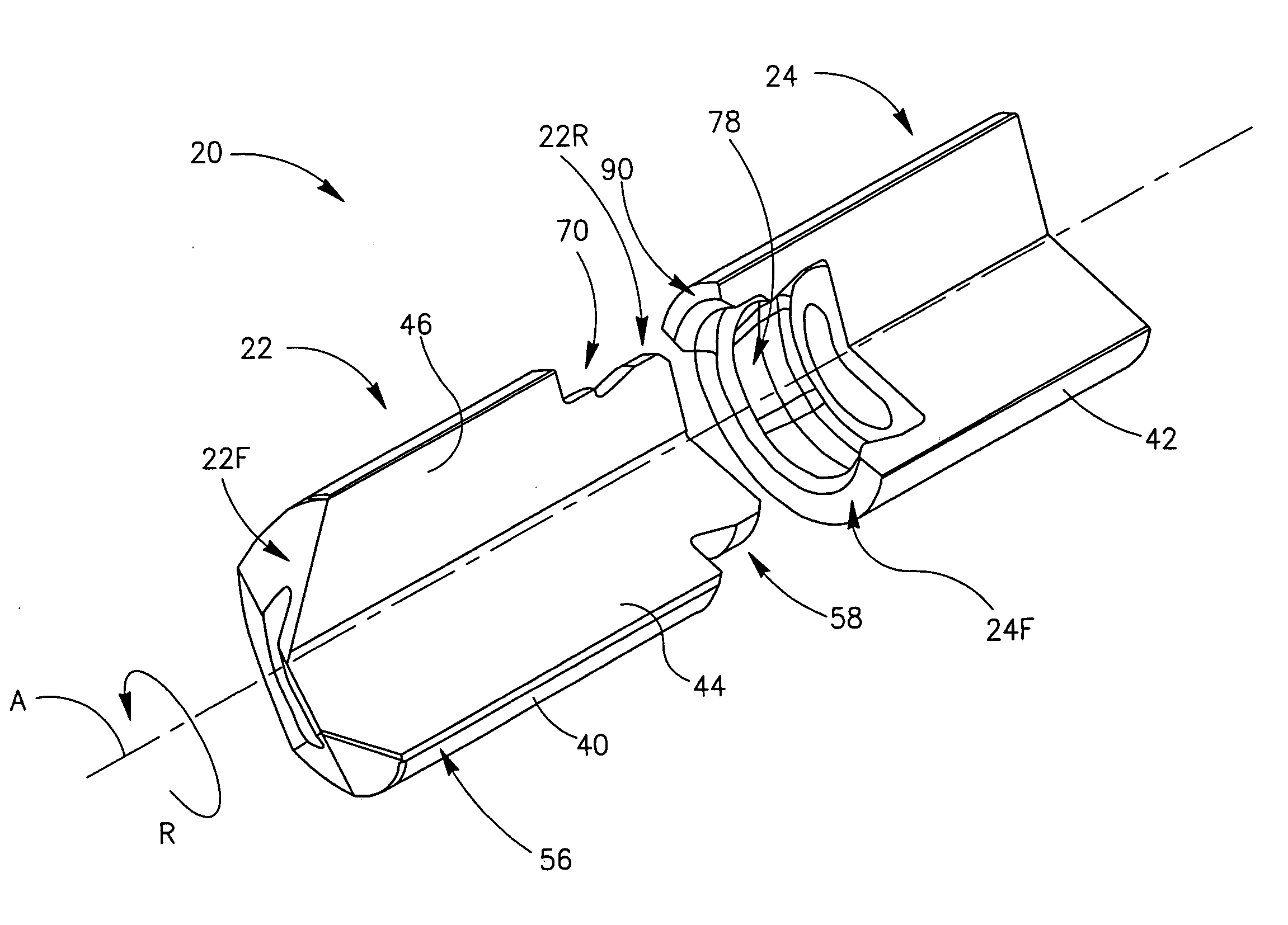

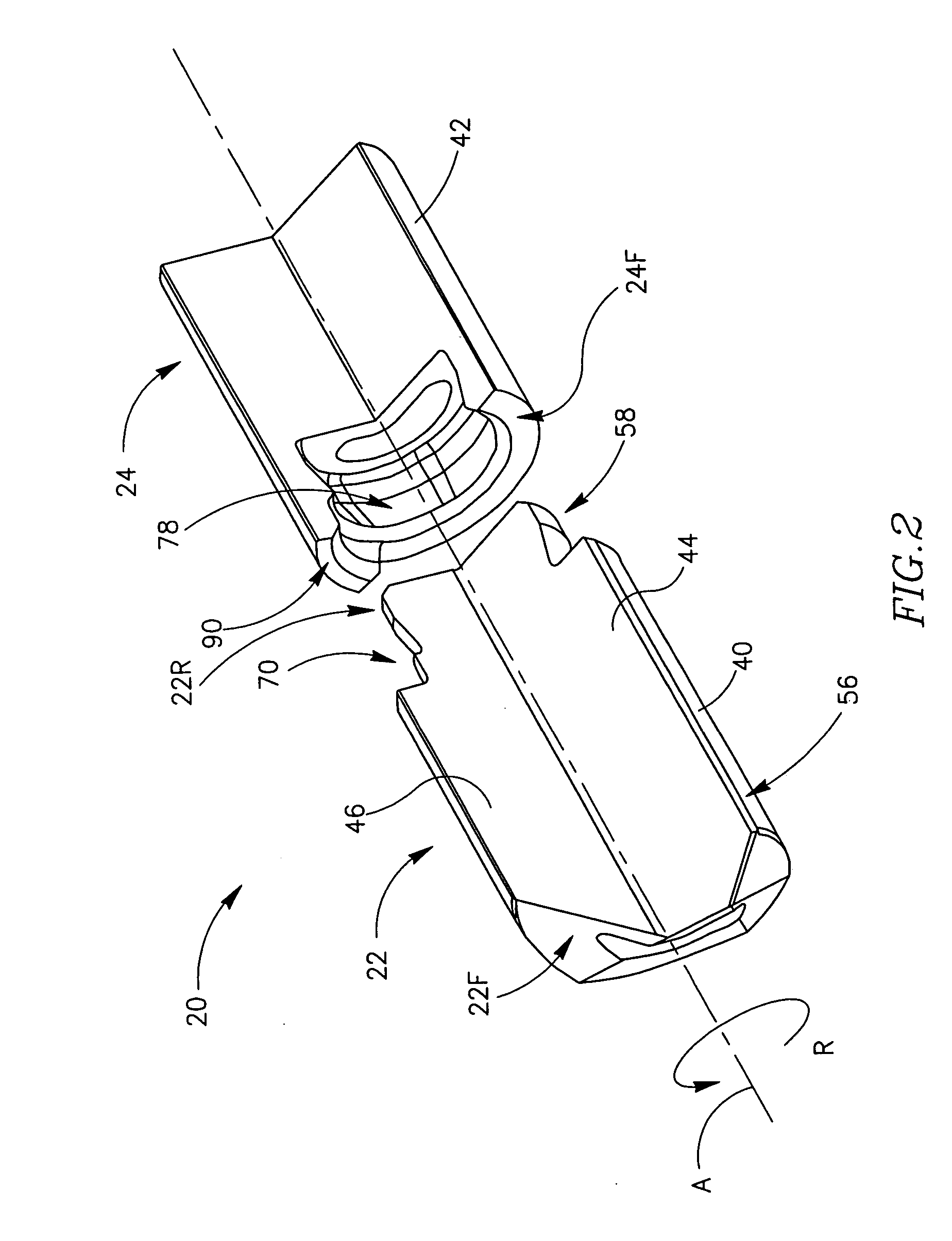

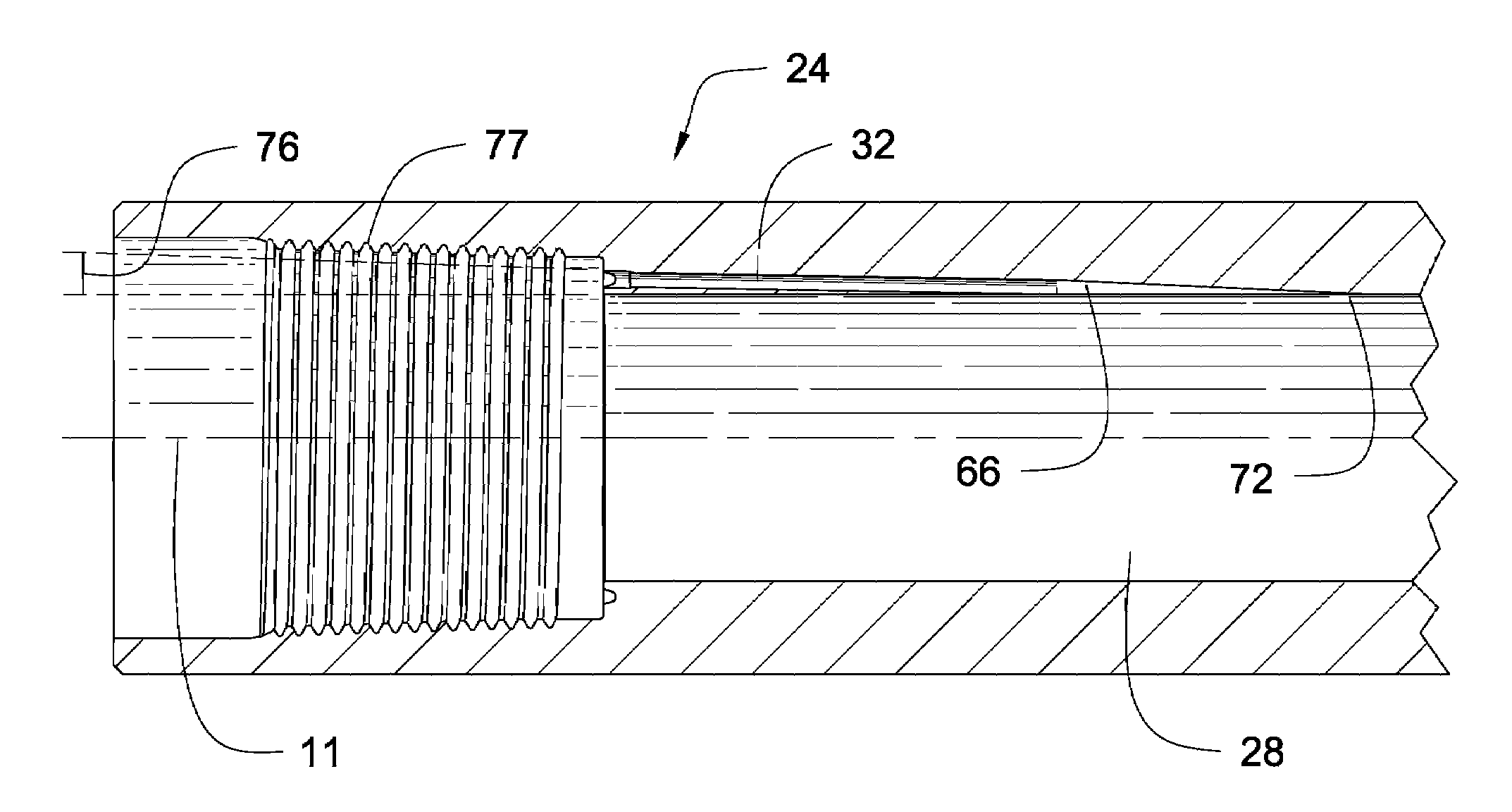

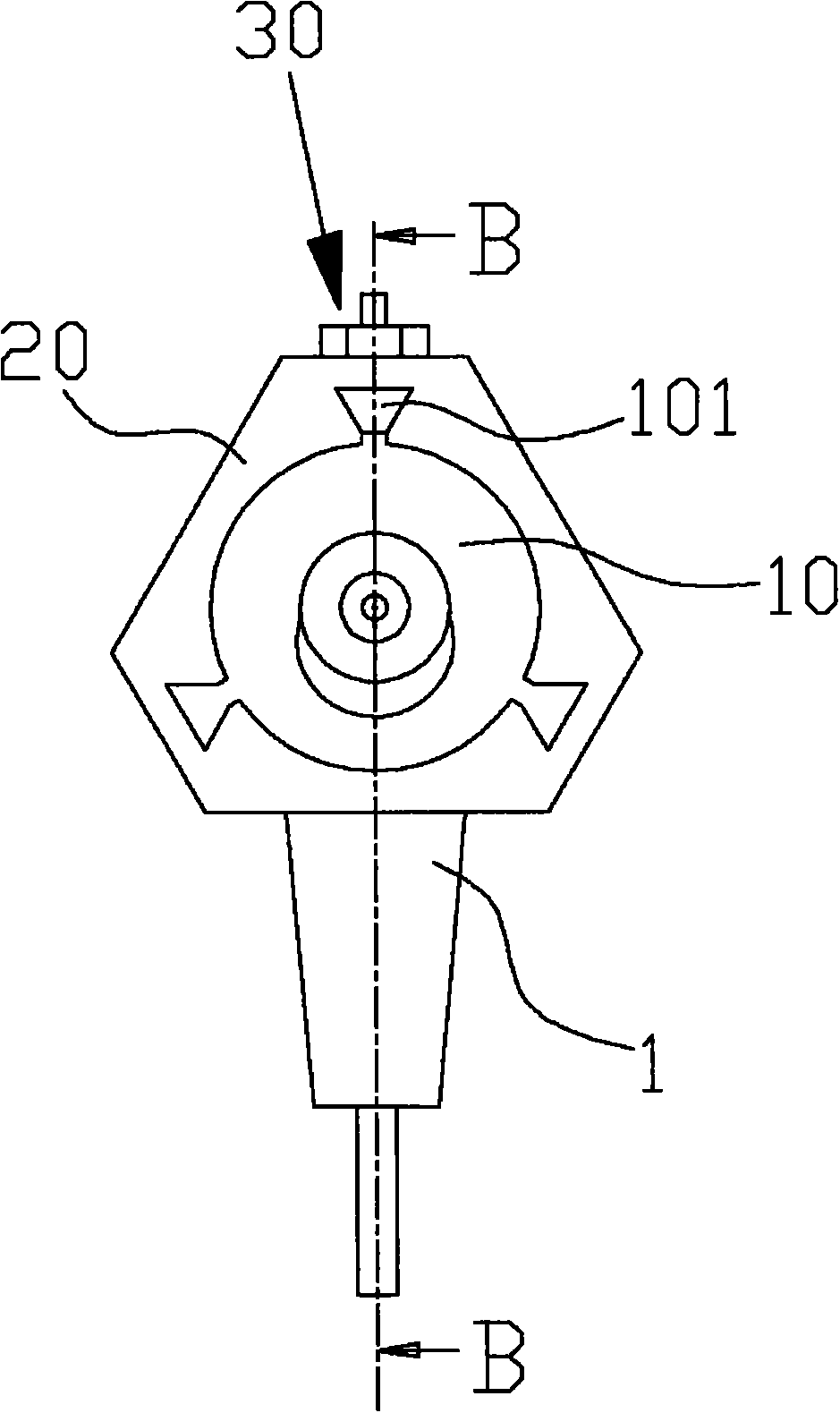

Gun drill

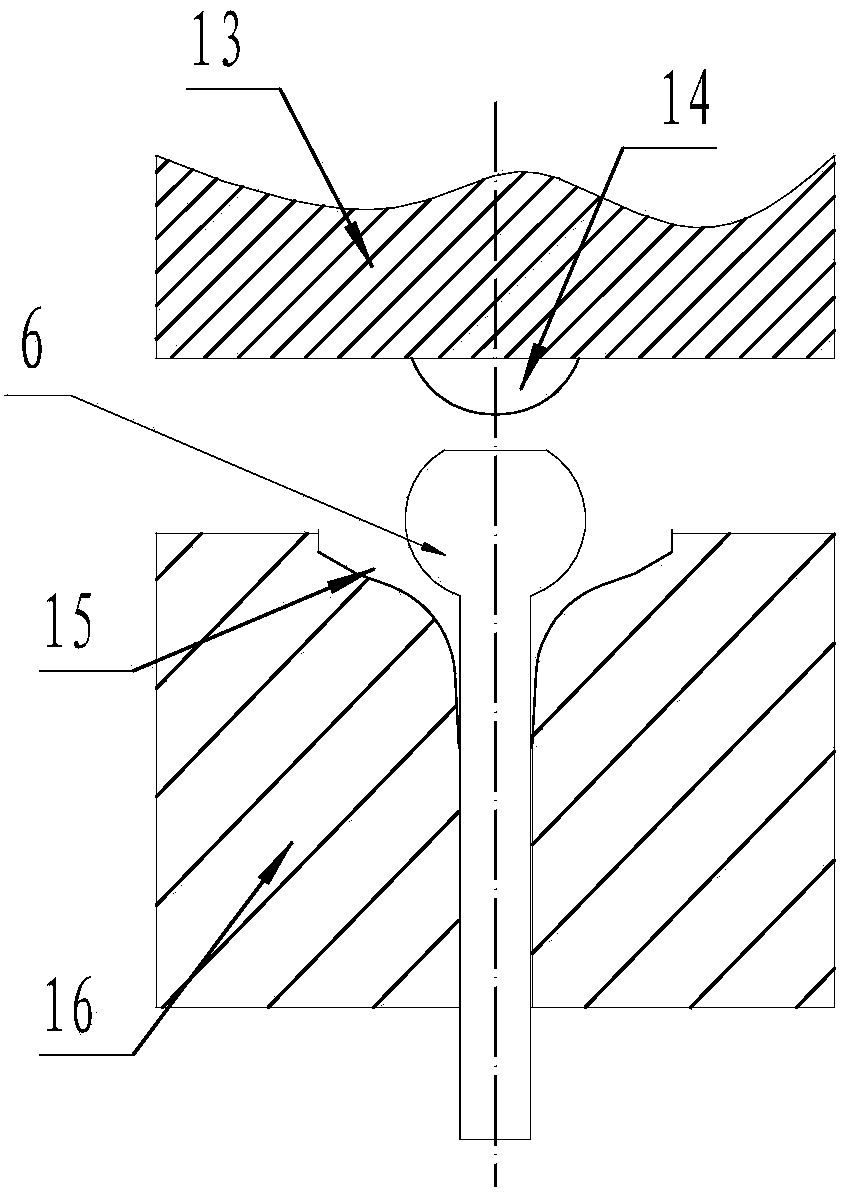

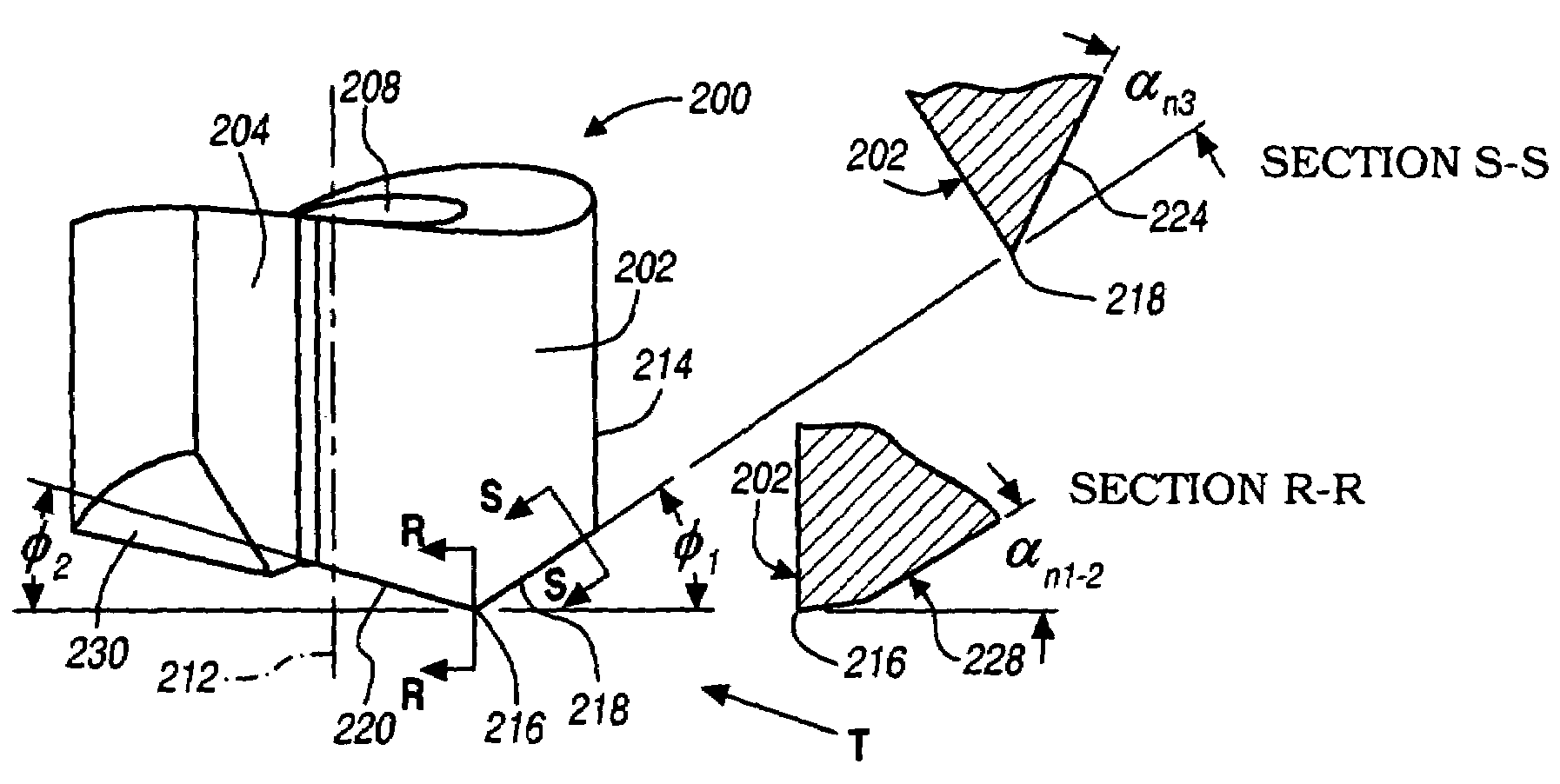

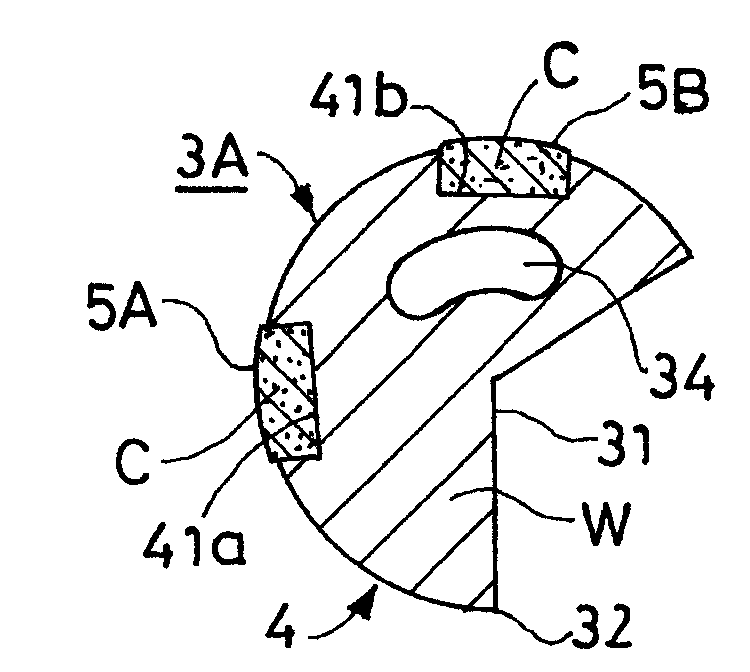

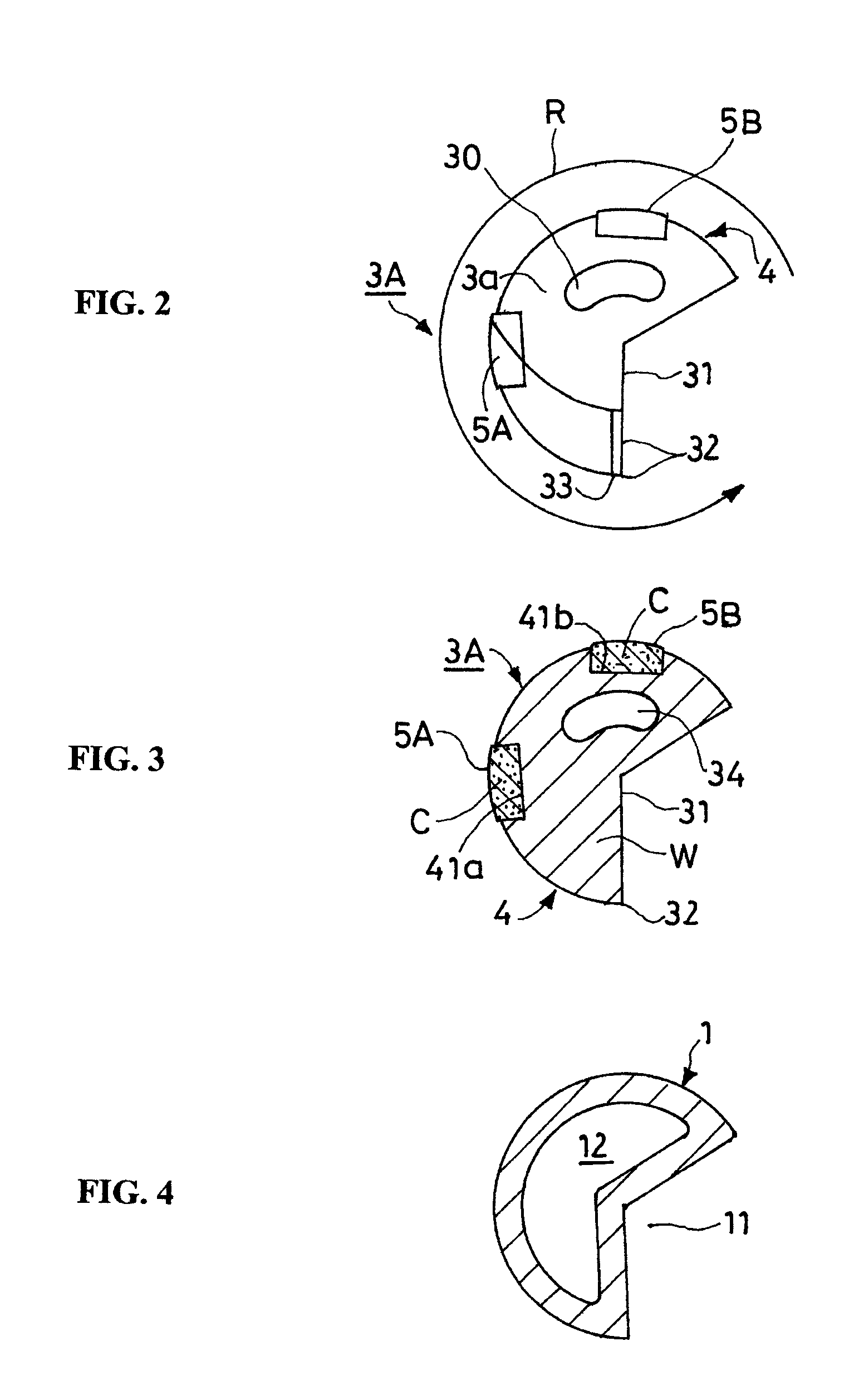

A gun-drill comprises a cutting-head detachably secured to a shank, having a common longitudinal axis and comprising mating peripheral surfaces. A shank coupling portion comprises a forwardly tapering shank fixation surface is formed at a front end of the shank, and a cutting-head coupling portion comprising a forwardly tapering cutting-head fixation surface is formed at a rear end of the cutting-head. Both the shank and the cutting-head coupling portion extend over a peripheral coupling angle φ of more than 180°. The shank and the cutting-head are assembled by positioning the cutting-head leading face in front of the shank trailing face, slidably inserting the cutting-head coupling portion into the shank coupling portion laterally to the axis of rotation A and rotating the cutting-head relative to the shank in a direction opposed to the direction of rotation R so that the cutting-head coupling portion and the shank coupling portion interlock co-axially.

Owner:ISCAR LTD

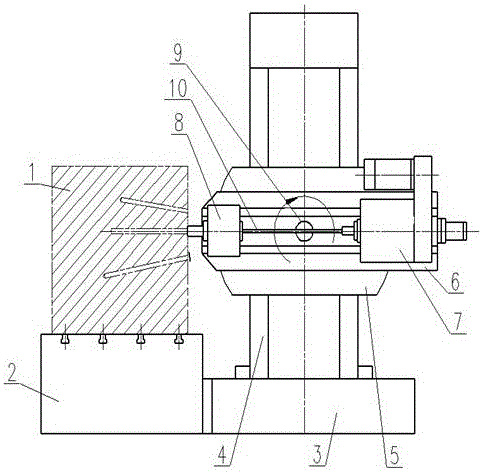

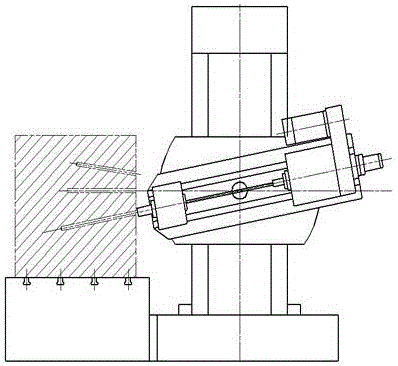

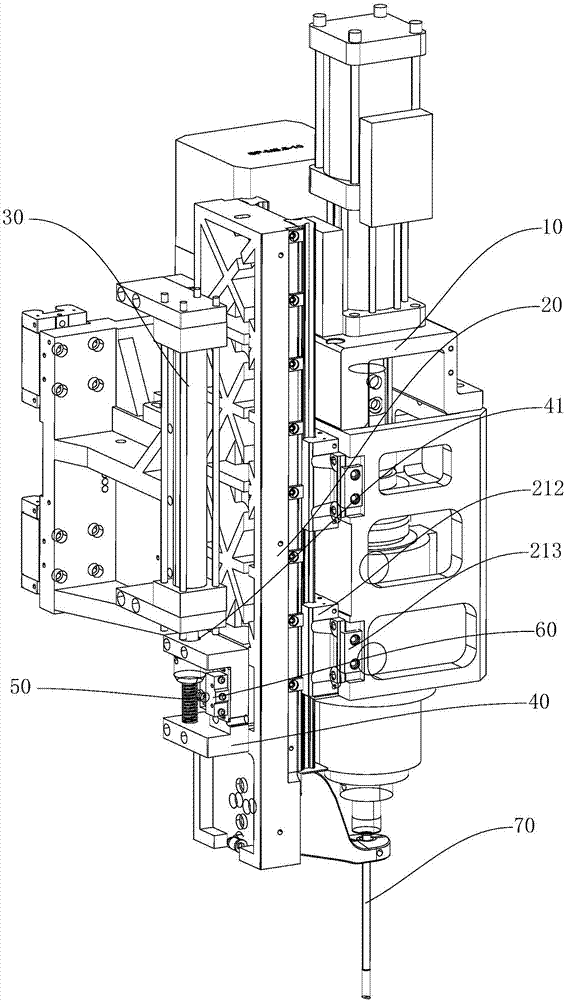

Automatic stress test drilling machine and working method thereof

ActiveCN105382295ARealize automatic driving functionCompact structureAutomatic control devicesFeeding apparatusWorking setDrilling machines

The invention discloses an automatic stress test drilling machine. The automatic stress test drilling machine comprises a base and a gun drill part, wherein the gun drill part is erected by the base and comprises a driving device and a gun drill driven by the driving device to move. The automatic stress test drilling machine and the working method thereof, provided by the invention have the advantages that the drilling machine is capable of realizing an automatic driving function in comparison with controlling drilling depth and accuracy manually, and is compact in structure and more convenient and accurate in operation. The gun drill part swings at a certain angle around a pin roll, so that an angle between the gun drill part and a to-be-measured sample surface can be finely adjusted to adapt to stress test drill holes at various positions with complex structures. The drilling machine provided by the invention can realize the adjustment on arranging angle and height of the base through stand bars arranged at the bottom part of a rack plate to ensure the stability of work. The gun drill provided by the invention is fixed by adopting a collet chuck manner, so the high-precision positioning accuracy of the gun drill is much facilitated. According to the automatic stress test drilling machine and the working method thereof, a longitudinal frame and a horizontal frame are used to realize the quick positioning of the gun drill part in all sides in a plane.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

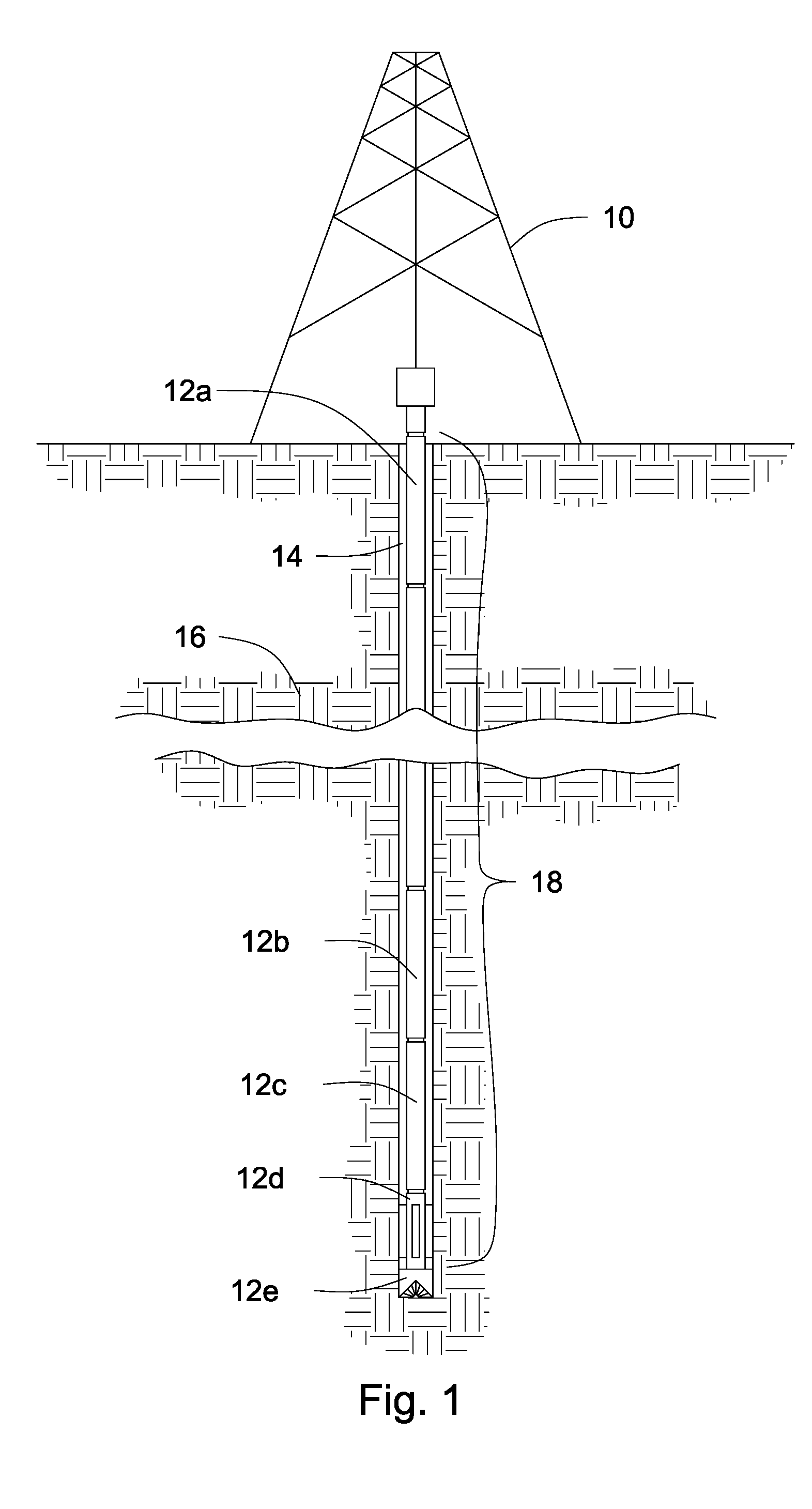

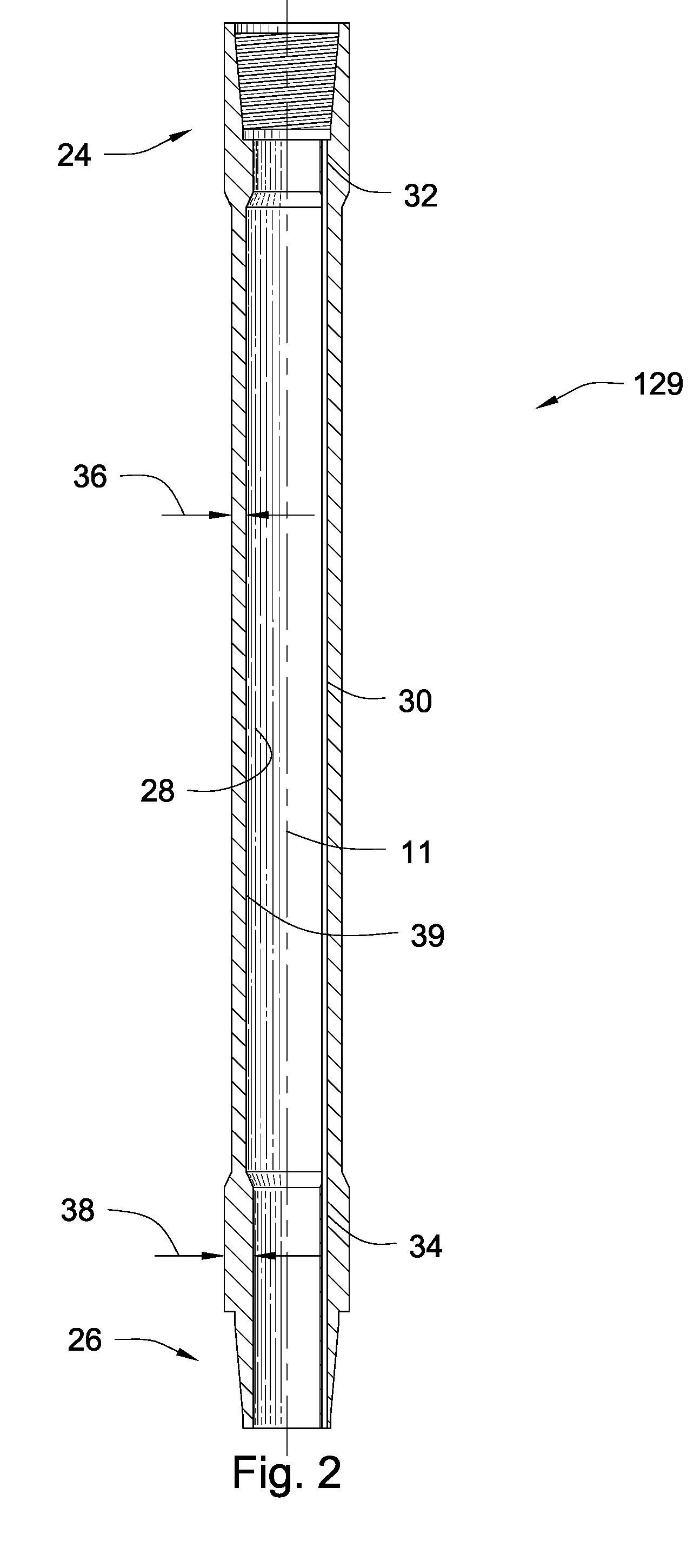

Apparatus and method for routing a transmission line through a downhole tool

ActiveUS7069999B2Prevent kinkingEfficient drillingDrilling rodsFluid removalEngineeringMechanical engineering

A method for routing a transmission line through a tool joint having a primary and secondary shoulder, a central bore, and a longitudinal axis, includes drilling a straight channel, at a positive, nominal angle with respect to the longitudinal axis, through the tool joint from the secondary shoulder to a point proximate the inside wall of the centtral bore. The method further includes milling back, from within the central bore, a second channel to merge with the straight channel, thereby forming a continuous channel from the secondary shoulder to the central bore. In selected embodiments, drilling is accomplished by gun-drilling the straight channel. In other embodiments, the method includes tilting the tool joint before drilling to produce the positive, nominal angle. In selected embodiments, the positive, nominal angle is less than or equal to 15 degrees.

Owner:INTELLISERV LLC

Gundrill

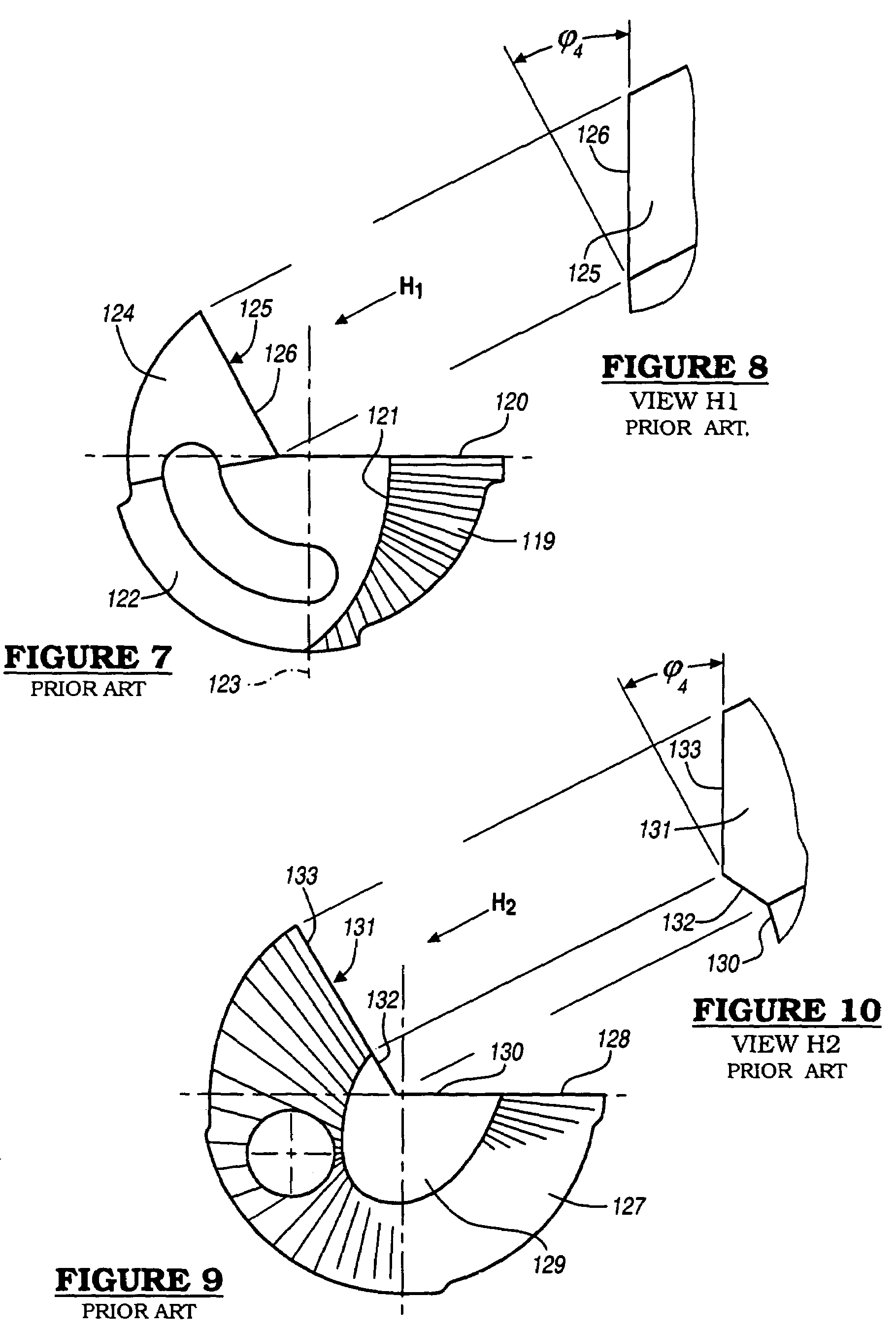

A method of forming deep holes and a gundrill therefore is disclosed. The gundrill has an elongate tubular shank and a cutting tip, each provided with a tubular central region supplying pressurized drilling fluid and a non-circular fluid cross-section defining a drilling fluid return path in conjunction with the hole being formed. The cutting tip flute defines a primary rake surface terminating in an offset point, and a secondary flank surface for forming an outlet with the hole being drilled, sized to maintain fluid pressure in the bottom end space to cool the cutting surfaces and to effectively remove chips as they are formed. The drilling fluid exiting an orifice of the cutting tip, forms a maximum angle β relative to the hole axis when viewed radially, which is greater than sixty-six degrees in order to minimize drilling fluid stagnation in an elongate fluid return path.

Owner:FORD GLOBAL TECH LLC

Device and method for machining metal beryllium single-blade outer chip removal deep hole

InactiveCN103658737AImprove processing yieldSolve chip breakingBoring/drilling machinesAttachable boring/drilling devicesEngineeringAlloy

The invention relates to a device and method for machining a metal beryllium single-blade outer chip removal deep hole. According to the device, a mounting plate used for clamping a workpiece, a tool bar guiding and supporting sleeve sued for supporting a tool and a connecting structure used for being connected with an oil pressure system and the tool are arranged on a common lathe, the tool is a hard alloy deep hole gun drill and is clamped on a three-jaw chuck of the lathe, the mounting plate is arranged on a middle supporting plate of the lathe, and the tool bar guiding and supporting sleeve is arranged between the three-jaw chuck and the mounting plate. Compared with the prior art, the method for machining the metal beryllium single-blade outer chip removal deep hole solves the problems of chip breakage, chip discharge, cooling, lubrication, guidance, drilling deviation and the like existing in the existing metal beryllium deep hole machining process, and therefore the machining finished product rate of beryllium is effectively improved, the deep hole with a draw ratio of 50-150 and an aperture phi smaller than or equal to 20mm of metal beryllium materials is machined successfully, hole machining precision can reach IT8, and surface smoothness can reach Ra0.8.

Owner:西北稀有金属材料研究院宁夏有限公司

Gun drill

InactiveCN101036950AExtend your lifeImprove securityToothed gearingsPortable drilling machinesElectric machineOutput device

A pistol drill includes a casing (20), a switch (19), a drill bit (1), a drill shaft (2) and an electric machine having a rotor and a stator, the rotor of the electric machine includes a rotor casing (18), a main shaft (17), also provided is an output device for adjusting rotating speed of the rotor, which includes a governor gear, a planetary gear mechanism and a clutch mechanism. The invention makes the pistol drill output three different speeds using the output device for adjusting rotating speed of the rotor, and achieves purpose of cutting drill based on the requirement of the big and small cutting drill, increases intensity of the drill, improves useful life of the drill and safety of operator.

Owner:陆昱森

Electrified fastening device for bolt of transformer device

ActiveCN102684084AIncrease the safety distanceReduce labor intensityPortable power-driven toolsPower driven toolsTransformerEngineering

The invention discloses an electrified fastening device for a bolt of a transformer device, which solves the problem that the power-cut processing must be carried out when the bolt of the traditional electrified device is loosened. The electrified fastening device for the bolt of the transformer device comprises an axial operating rod, a radial operating rod, a sleeve and a gun drill, wherein the axial operating rod comprises a sleeve plug which is fixedly arranged at the top part of a rotating insulation rod and is used for inserting the sleeve and a drill sleeve which is fixedly arranged at the bottom part of the rotating insulation rod and is used for inserting the gun drill, and the outer part of the rotating insulation rod is also sleeved with a first insulation sleeve; and the radial operating rod comprises a second insulation sleeve, an L-shaped sleeve inserting frame is fixedly arranged at the top part of the second insulation sleeve, and two ends of the L-shaped sleeve inserting frame can be sleeved with the sleeve. The electrified fastening device for the bolt of the transformer device, disclosed by the invention, has the advantages that the structure is simple, the operation is convenient, the electrified device can be maintained under the condition without cutting off the power of the electrified device, the maintenance procedure is simplified, the labor intensity is reduced, the working efficiency is increased, and the economic loss and the social impact due to the power failure are avoided as well.

Owner:山西省电力公司阳泉供电公司 +1

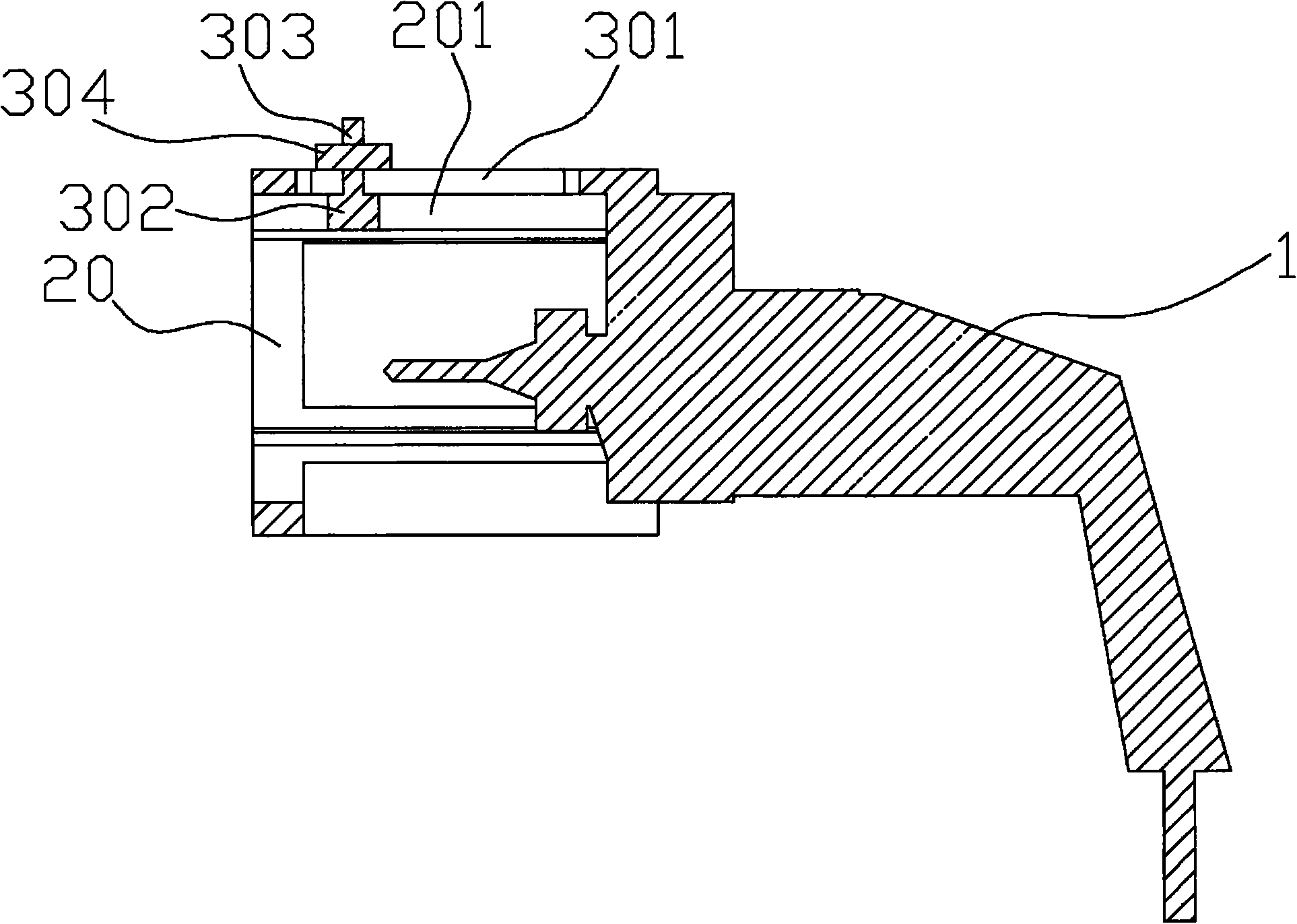

Pistol drill perpendicularity guiding device

InactiveCN103406570AImprove verticalityGuarantee the safety of lifePortable drilling machinesEngineeringGun drill

The invention provides a pistol drill perpendicularity guiding device which is an auxiliary device for guiding a pistol drill to be perpendicular to a to-be-processed part for drilling. The pistol drill perpendicularity guiding device comprises a slider connected with the pistol drill and a slide seat slidably connected with the slider, the slide seat is shaped in a sleeve and is sleeved outside the pistol drill, and the end portion of the slide seat is a plane perpendicular to an axis of the same. By the aid of the pistol drill perpendicularity guiding device, perpendicularity of holes drilled by the pistol drill is effectively improved, accident rate caused by deflection of the pistol drill is lowered, personal safety of operators is guaranteed, cost is saved, and production efficiency is improved.

Owner:苏州市合昌电器有限公司

Method for machining high-position-precision deep hole in connection rod of diesel engine

ActiveCN105728772AThe principle of the method is simpleImprove surface propertiesSurface roughnessEngineering

The invention provides a method for machining a high-position-precision deep hole in a connection rod of a diesel engine. Bolt holes are firstly machined by adopting a gun drill so that position precision between the holes is guaranteed; and the bolt holes are machined to technically required sizes by utilizing a reamer and the surface roughness of the holes is guaranteed, so that the quality and machining efficiency of products are guaranteed. With the adoption of the method provided by the invention, manual polishing does not need to be carried out again, so that procedures and labor cost are saved and the working efficiency is extremely improved; and the method has a very high practical value.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Machining process technique for aluminum alloy control plane

The invention provides a machining process technique for an aluminum alloy control plane. The machining process technique comprises the following steps of preparation before machining, pre-stretching on aluminum alloy plates, finish milling on the thickness and the appearance of a chuck, machining on deep holes by using a gun drill, high-speed finish milling on profiles and chuck removal by linear cutting machining. The plates are pre-stretched, the original inner stress generated in a raw material forming process is reduced, and deformation of parts in the followed-up machining process is reduced; a boring procedure is replaced by using an outward chip removal deep hole gun drill, the machining time is effectively reduced, and deep holes of which the depth-diameter ratio is greater than the gun drill by 10 times can be machined; machining stress caused by cutting force in a milling machining process and deformation caused by cutting heat can be reduced by high-speed milling machining, and cost and time on heat treatment production are avoided; and a chuck is removed by linear cutting instead of milling machining, the machining stress is further reduced, and the deformation of the parts is controlled. The problems that the machining efficiency in the existing machining technology is low, and the quality of parts is difficult to guarantee are solved. High-quality, high-efficiency and low-cost machining on control planes and parts such as missile wings can be realized.

Owner:BEIJING HANGTIAN XINFENG MECHANICAL EQUIP

High-precision deep hole processing machine

InactiveCN102009204AImprove protectionQuick protectionBoring/drilling componentsMaintainance and safety accessoriesBatch processingSmall footprint

The invention discloses a high-precision deep hole processing machine, which comprises a workbench, a power mechanism and a gun drill, wherein the power mechanism is connected with a main shaft, the main shaft is connected with the gun drill, and the main shaft and the gun drill are provided with a shaft cavity and a drill cavity which are mutually communicated respectively; the main shaft is connected with a high-pressure water inlet pipe communicated with the shaft cavity; a metal ring, a sealing ring and a high-speed radial bearing are sleeved on the main shaft positioned on at least one side of the high-pressure water inlet pipe; and the workbench is provided with an outer cooling pipe, and the workbench is erected on a guide rail and is in transmission connection with the power device. The high-precision deep hole processing machine has high drilling speed, high efficiency and high drilling depth, well protects workpieces, and does not need to retract a cutter midway; the drilling depth can reach 100 times diameter of a drill bit; and the processing machine has small floor area and low cost, is easy to maintain, and can be used for automatic batch processing.

Owner:广东垠星科技发展有限公司

Gun drill guide and gun drill guide assembly

ActiveUS7207751B2Easy to operateIncreased wear and durabilityDrilling/boring measurement devicesThread cutting feeding devicesDrill guideFlange

A gun drill guide is disclosed comprising a cylinder body member of a resilient polymer material having a central opening extending therethrough, a radially extending flange means at one end thereof to engage the end face of a bearing assembly and an annular groove near the opposite end thereof defined by second and third radially extending flanges for engaging the opposite end face of the bearing assembly. A locking member, a chip deflector assembly, a stabilizer assembly or other guide attachment are disclosed which may be attached to the drill guide.

Owner:F J FEDDERSEN

Method for processing slant oil hole in middle-speed machine crankshaft

ActiveCN101462180AGuarantee product qualityIncrease productivityBoring/drilling machinesCold airDiameter ratio

The invention relates to a method for processing an oblique oil hole of a crankshaft of a medium speed machine. A gun drill with length-diameter ratio of 30:1 is adopted for drilling and cutting; the drilling and cutting process of the gun drill comprises the drilling and cutting of a guide hole and an oil hole; the diameter of the guide hole is larger than that of the gun drill by 0.01 to 0.02 mm; the depth of the hole is double of the diameter of the gun drill; in the process of drilling and cutting the guide hole, high-pressure mixed cold air is used to spray and cool temperature; chips are discharged; the oil hole is drilled and cut by stages; a short gun drill drills first and machines the oil hole to the depth of between 300 and 310 mm; after the gun drill passes through a crossed hole, a long gun drill replaces the short gun drill and drills and machines the oil hole to the depth of 709 mm to the crossed hole; a plug is used to plug the processed oblique oil hole; the plug is fixed by screw threads; the gap part of the crossed hole is sealed; and the guide hole is drilled and cut by stages. A phi 20 oblique oil hole of a 6PC crankshaft is machined according to the method, not only can ensure the quality of a product, but also greatly improve production efficiency.

Owner:武汉重工铸锻有限责任公司

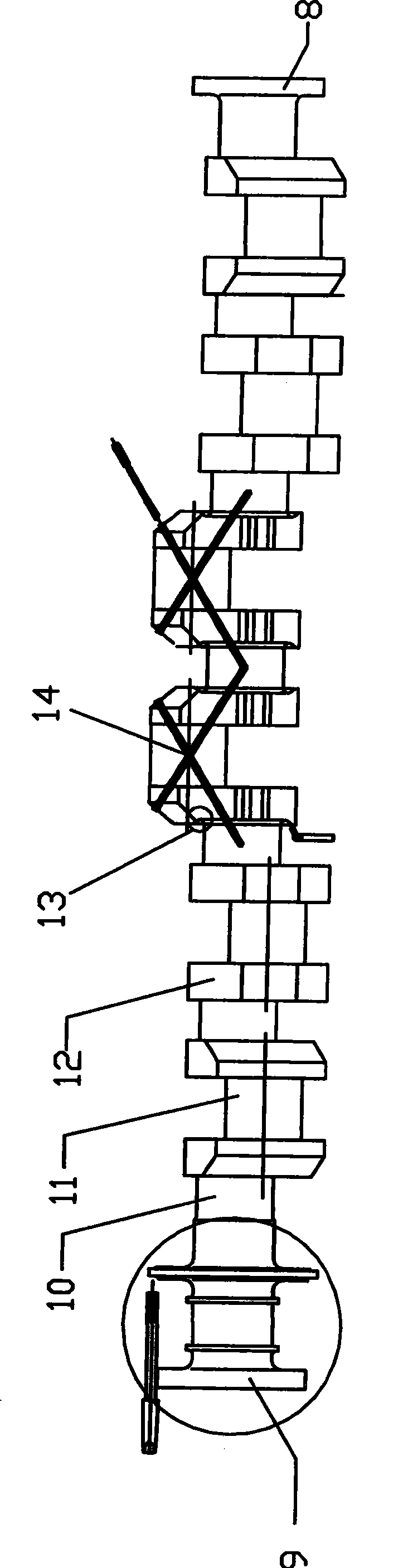

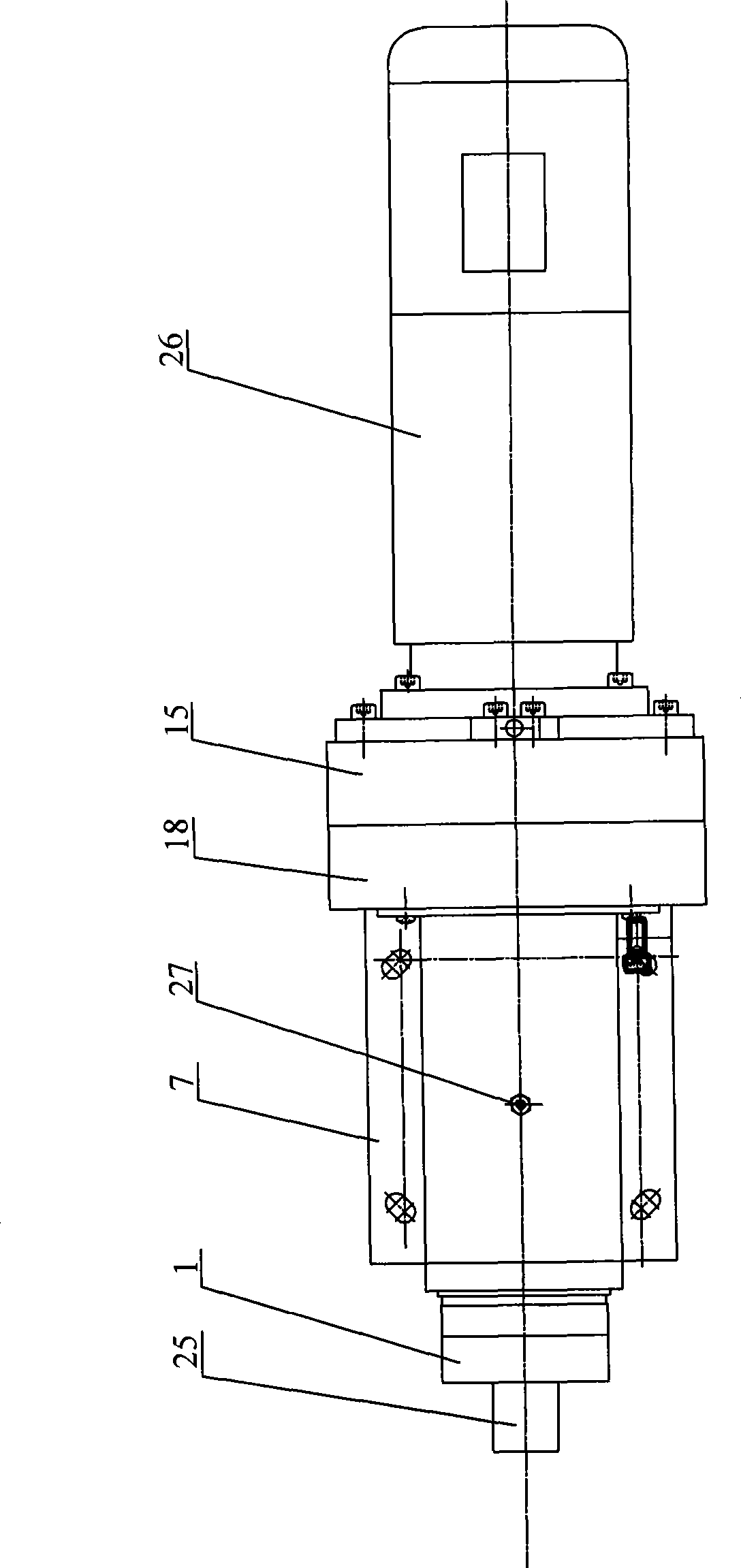

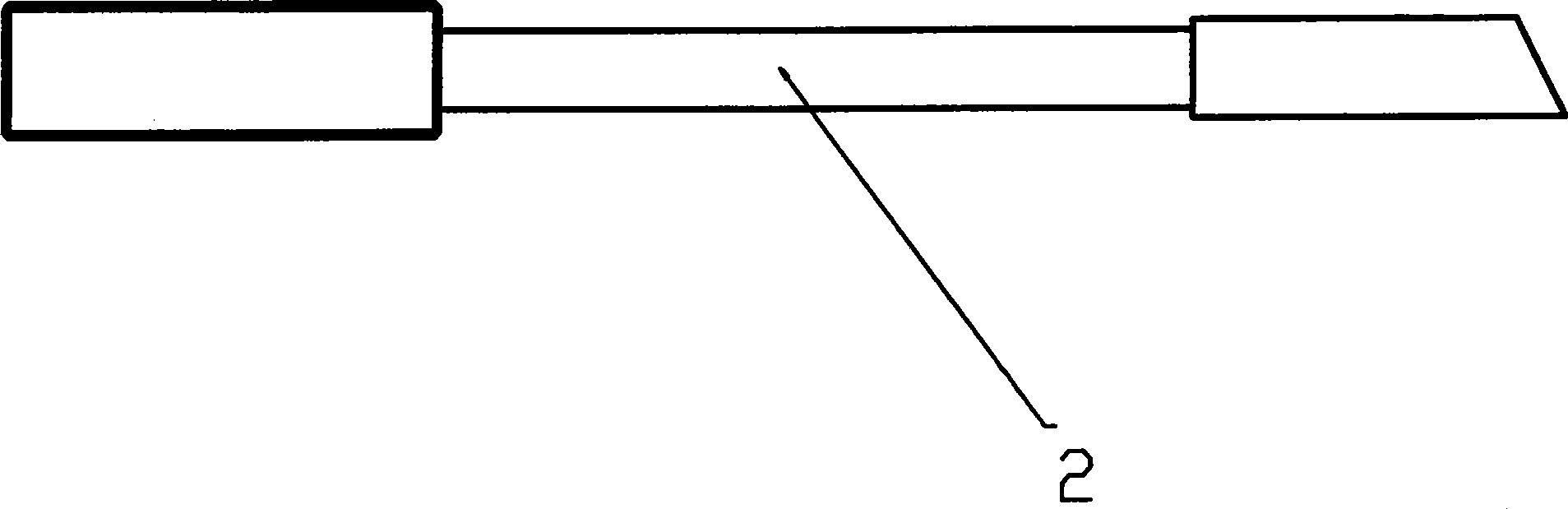

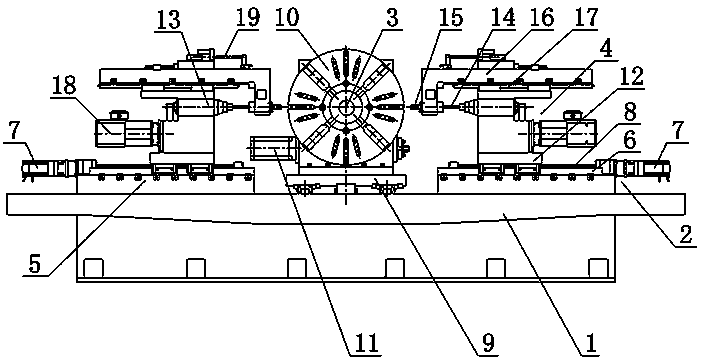

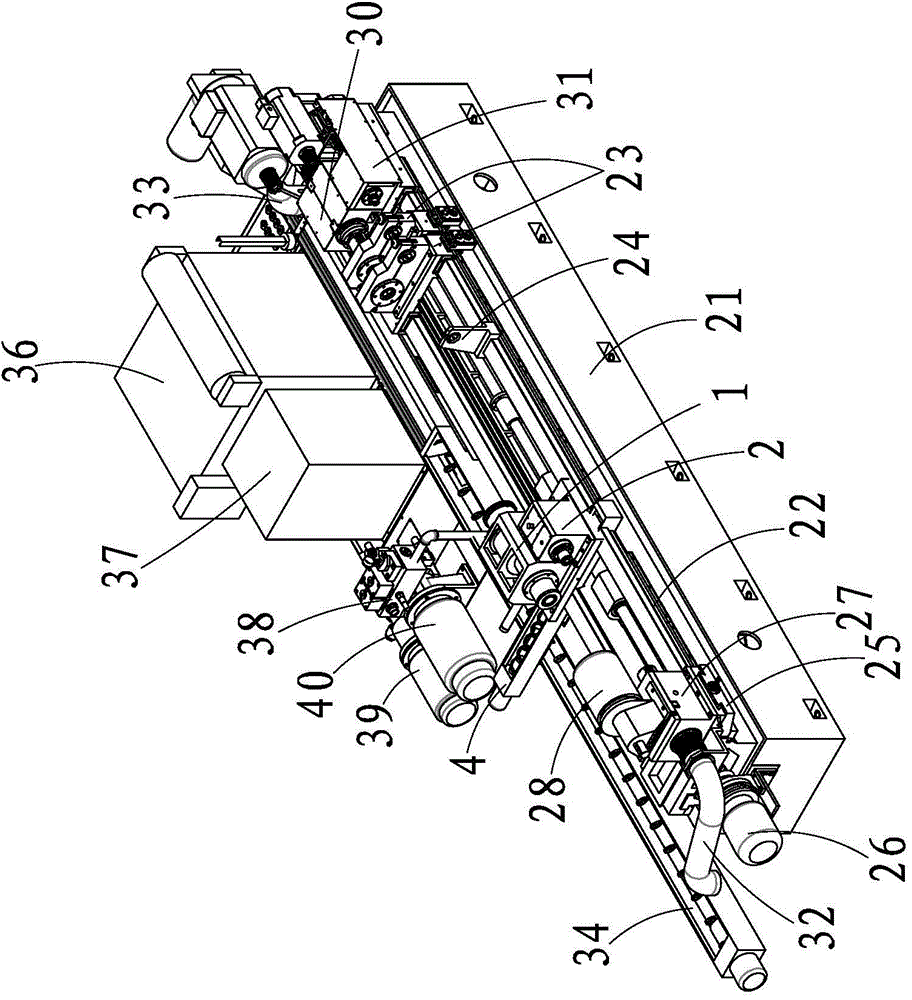

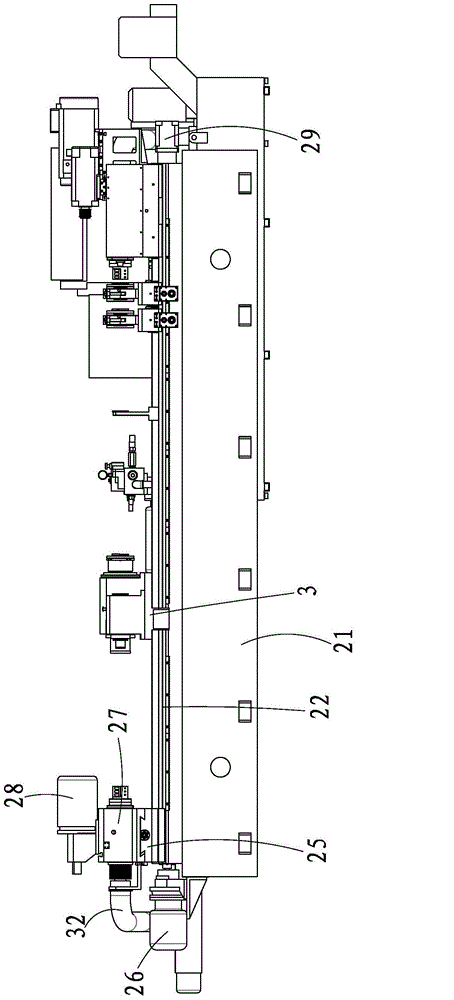

Machine tool for ring mold gun drill

InactiveCN103418812AImprove processing efficiencySmooth feedingDrilling/boring measurement devicesBoring/drilling machinesNumerical controlEngineering

The invention relates to a machine tool for a ring mold gun drill. The machine tool for the ring mold gun drill comprises a machine tool body (1), two sets of feeding sliding tables (2), a numerical control rotary table (3), a gun drill drilling power mechanism (4), a high-pressure cutting oil system and an electric control system, the two sets of feeding sliding tables (2) are transversely fixed on the two sides of the upper portion of the machine tool body (1) respectively, the numerical control rotary table (3) is arranged above the middle position of the machine tool body (1), and the gun drill drilling power mechanism (4) is arranged on the feeding sliding tables (2); the gun drill drilling power mechanism (4) comprises a drilling head support base (12), a drilling main shaft (13), a tool rod (14) and a main shaft motor (18); the electric control system is respectively connected with a servo motor (7), a transmission motor (11) and the main shaft motor (18). The machine tool for the ring mold gun drill has the advantages of being capable of achieving efficient drilling machining of the ring mold, low in surface roughness of a machined mold hole, reducing labor intensity and low in oil spray escaping, according with environmental-protection hygienic requirements, being low in overall machine energy cost, and saving electric power.

Owner:SICHUAN XUNLEIWEI MACHINERY MFG

Positioning and supporting auxiliary tool for precise drilling in aircraft

PendingCN109692987AEasy to adjustHigh precisionWork benchesPortable drilling machinesEngineeringMechanical engineering

The invention relates to a positioning and supporting auxiliary tool for precise drilling in an aircraft. The positioning and supporting auxiliary tool comprises a sliding rail, a sliding block, two electric telescopic rods, a connecting shaft, a longitudinal sliding rail I, a longitudinal sliding rail II, a sliding support and a gun drill clamping mechanism, wherein the longitudinal sliding railI and the longitudinal sliding rail II are horizontally arranged in the front-back direction. The gun drill clamping device is used for clamping and fixing a gun drill at a position matched with the height direction of a drilling position. The sliding support slides left and right to enable the longitudinal sliding rail I to slide along the connecting shaft through a linear bearing, so that the longitudinal sliding rail II slides along a guide rail groove I of the sliding rail through the sliding block, the gun drill can be conveniently adjusted to a to-be-drilled position in the left-right direction, the gun drill can be pushed to enable the sliding support to slide towards the inner side along the longitudinal sliding rail I and the longitudinal sliding rail II, and drilling or reaming operation can be carried out by the gun drill in the direction perpendicular to a drilling plane. The drilling efficiency and the drilling precision are improved. An operator only needs to hold the gundrill by hand and move the gun drill towards the inner side to complete drilling. The convenience of operation in a narrow space of a front storage cabinet is improved.

Owner:SHANDONG TAIKOO AIRCRAFT ENG

Composite deep hole machine tool

InactiveCN104400060AReduce biasExtended drilling rangeDrilling/boring measurement devicesPositioning apparatusThermodynamicsMachine

The invention relates to a composite deep hole machine tool. The composite deep hole machine tool comprises a machine body, a drilling tool, a driving mechanism which is arranged on the machine body and used for driving the drilling tool to drill a hole, a guiding mechanism, a chippings recovery mechanism which is arranged on the machine body and a cooling filtering mechanism, wherein the drilling tool comprises a BTA drilling rod and a gun drill, which are arranged in parallel, the guiding mechanism comprises a pre-tightening device, oil feeding devices and a guiding frame, the pre-tightening device is arranged on the front part of the machine body in a way of sliding in the longitudinal direction and used for pre-tightening a workpiece, the oil feeding devices are arranged side by side on the machine tool in the lateral direction, the front part of the BTA drilling rod is arranged in the oil feeding device in a penetrating manner, the rear end of the BTA drilling rod is installed on the driving mechanism, the front part of the gun drill is arranged in the guiding frame in a penetrating manner, and the rear end part of the gun drill is installed on the driving mechanism. The BTA drilling rod and the gun drill are arranged on one machine body, so that a machining way of coexistence of the BTA and gun drill is realized, and the drilling range is enlarged; the pre-tightening device is used for pre-tightening the workpiece, so that the deviation of the oil feeding device when in movement can be reduced.

Owner:SUZHOU XINNENG PRECISE MACHINERY

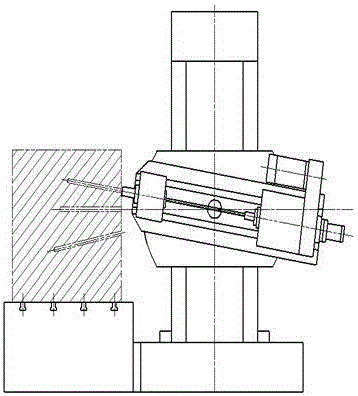

Tilt deep hole processing device and operation method

The invention relates to a device for mechanically processing deep holes, in particular to a tilt deep hole processing device and an operation method. The tilt deep hole processing device comprises a working table and a base which are assembled with each other and are separable, and is characterized by further comprising a stand column, a support plate, a rotating shaft, a sliding table, a drill rod box and a cutter, wherein the stand column is fixed on the base, the support plate is movably connected with the stand column and moves up and down along the vertical direction of the stand column, the rotating shaft is fixed on the support plate, the sliding table rotates around the rotating shaft by taking the rotating shaft as a center of rotation, the drill rod box is fixed on the sliding table and moves left and right along the direction of the sliding table, and the cutter is installed on the drill rod box and is driven to rotate by the drill rod box; an inner hole is formed in the drill rod box. When the tilt deep hole is processed by using a gun drill processing way, the rotating shaft is used for adjusting the angle of a gun drill so as to enable the angle of the gun rill to be consistent with that of the tilt hole, and a linear moving shaft is used for adjusting the position of the gun drill so as to enable the gun drill to reach a proper drilling position; the processing of deep holes, with different tilt angles, of a workpiece can be completed only by adjusting the angle and the position of the cutter; by combination of the rotating shaft and the linear moving shaft, the method is novel, and time and labor are saved.

Owner:德州德隆(集团)机床有限责任公司

Guide mechanism of gun drill of vertical numerical control drilling machine

ActiveCN107414146AGuaranteed accuracyIncrease stiffnessDrilling/boring measurement devicesNumerical controlStructural engineering

Owner:广东利工设备有限公司

Gun drill

InactiveUS7901163B2Inhibit wearHigh hardnessDrilling/boring measurement devicesThread cutting machinesEngineeringAlloy

A gun drill having excellent cutting efficiency, having high deep-hole drilling efficiency, and having a prolonged blade service life has a cutter head having a coolant discharge port communicating with a coolant supplying path at the distal end face at the distal end of a hollow shank portion having a cutting chip discharge groove, whose section along the lengthwise direction is V-shaped, on the outer surface and having the interior thereof made into a coolant supplying path, wherein a blade portion of the cutter head is made of cemented carbide alloy, and at the same time, the guide pads and that are brought into sliding contact with the inner circumference of a cutting bore are composed of a dissimilar material having higher hardness than the cemented carbide alloy.

Owner:YUNITAKKU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com