Numerical control high-effective deep hole gun drill

A technology of deep hole gun and drilling machine, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc. It can solve the problems of not overcoming, damaging the tool, and damaging the whole machine, etc., and achieves improved recycling. The effect of reducing the number of times, reducing manufacturing costs, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

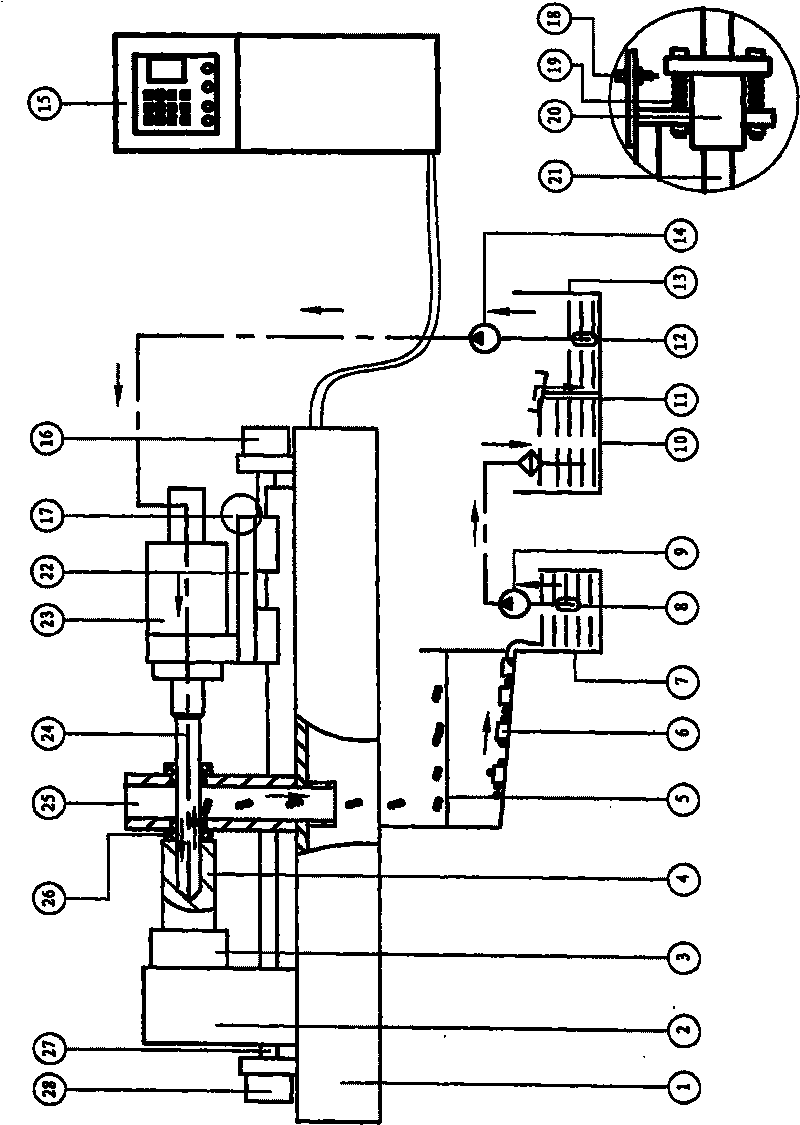

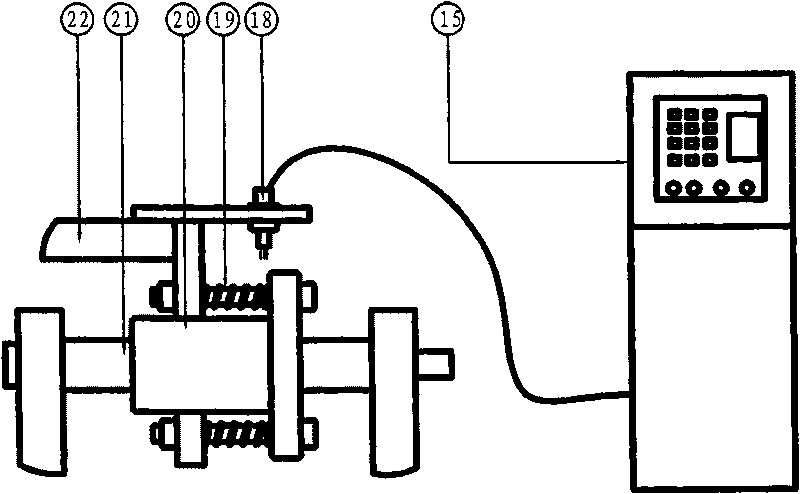

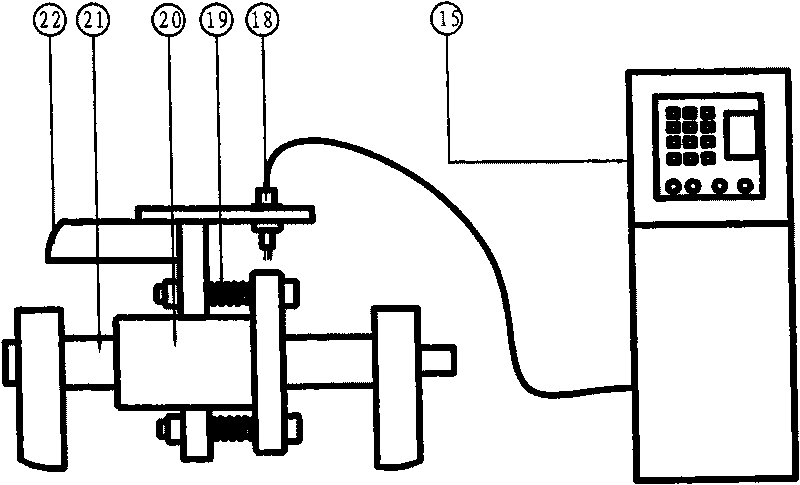

[0015] see Figure 1-Figure 3 , a CNC high-efficiency deep hole gun drilling machine, which includes a bed 1, a power distribution / control system 15, a spindle box 2, a feed device and a tool 24 assembled therein, a chip collection device 25, a front-end drive stepper motor 28 and a rear The end drive stepper motor 16, the spindle box 2, the chip collection device 25, and the feed device are installed on the bed 1, the front end drive stepper motor 28 and the back end drive stepper motor 16 are controlled by the power distribution / control system 15, and the The feeding device is driven by a stepping motor 16 at the rear end, and a sealing device 26 is installed outside the chip collecting device 25. At the front end of the bed 1, a three-jaw chuck 3 for clamping the workpiece 4 is installed on the headstock 2, and the magnetic grid filter device is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com