Four-tower mixed ion exchanger resin external separation regeneration method

A mixed ion and resin separation technology, applied in ion exchange regeneration, ion exchange, chemical instruments and methods, etc., can solve the problems of low content and harm, and achieve the automatic operation of saving acid consumption, avoiding resin residue and alkali consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

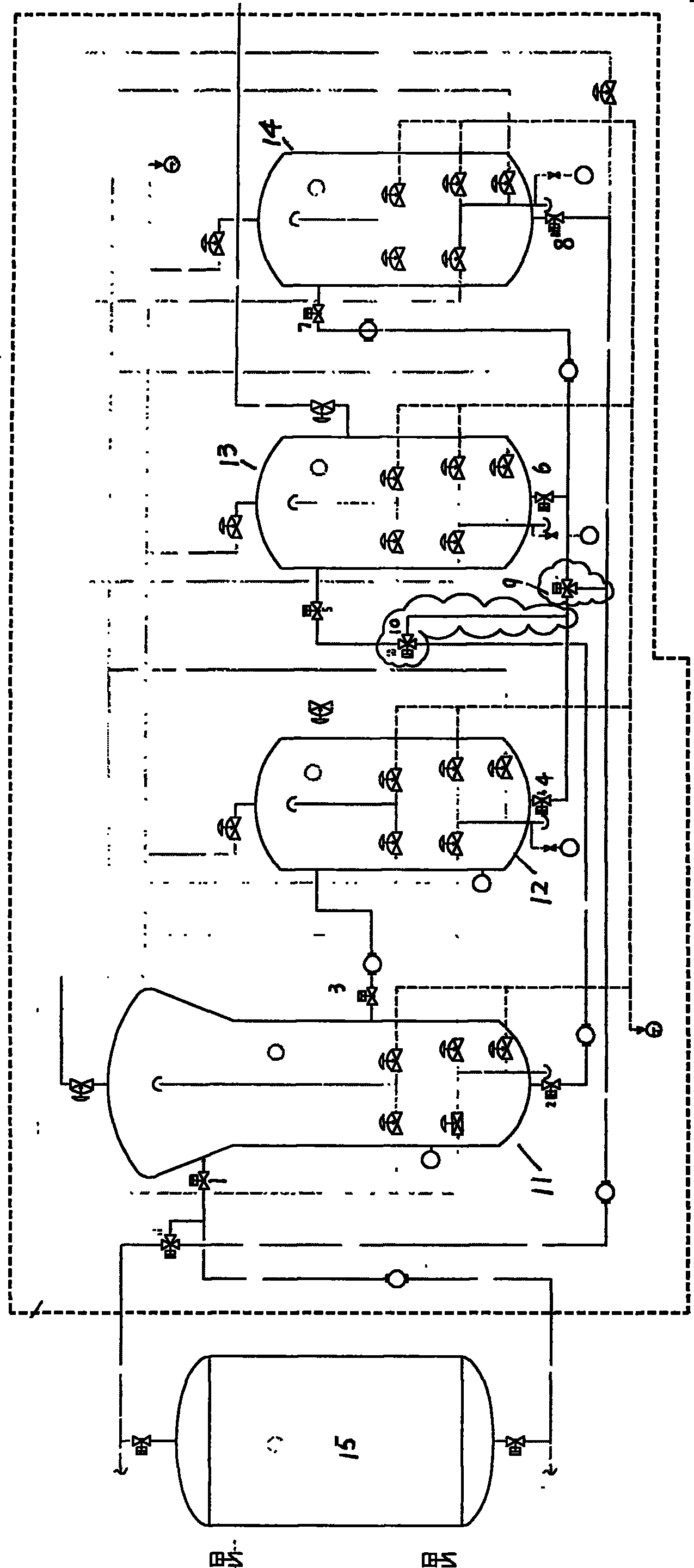

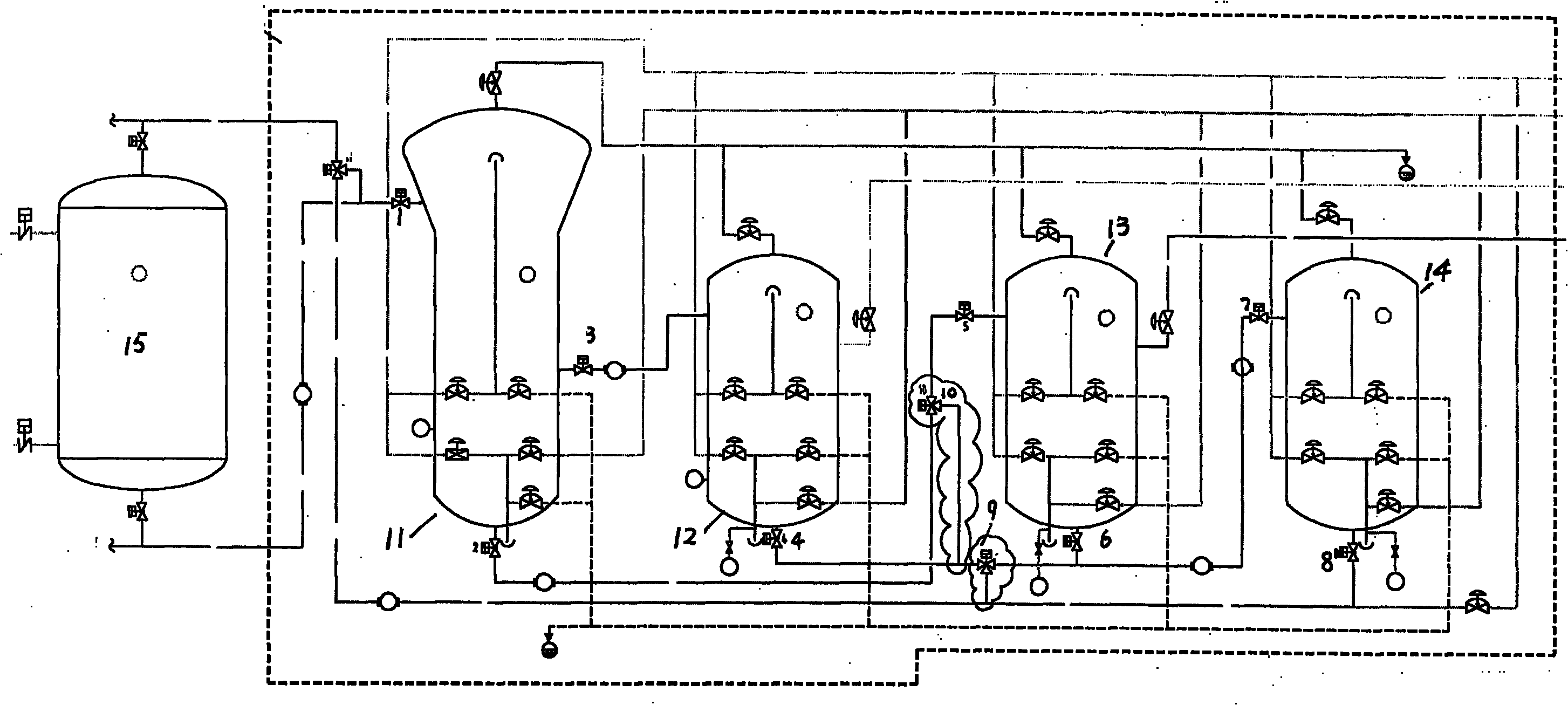

[0022] In conjunction with the accompanying drawings, the invention scheme is described as follows:

[0023]The spent resin in the mixed bed is connected from the bottom of the mixed bed 15 through the pipeline and the inlet valve 1 of the resin separation tank 11, and then transported to the resin separation tank 11 (the first tower, using the patent No. ZL 20052070245.8 equipment), scrubbing and separating with water and wind, The resin is layered, the upper part is anion resin, the lower part is a cation resin, the upper anion resin is connected to the anion resin regeneration tank 12 (second tower) through the valve 3 of the pipeline and the resin separation tank 11, and the lower part cation resin is passed through the pipeline, The lower valve 2 of the resin separation tank 11 and the cation resin regeneration valve 5 are sent to the cation resin regeneration tank 13 (the third tower), and the mixed resin layer with incomplete separation between the anion and yang resins ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com